Siemens SITRANS F M MAGFLO MAG 3100 Instructions Manual

s

Introduction

ENGLISH

INSTRUCTIONS

®®

®

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 3100 with

®®

DEUTSCH

FRANÇAIS

DANSK

PTFE or PFA liner

®

Siemens Flow Instruments SITRANS F M MAGFLO

sensor and a transmitter. These instructions only describe the sensor installation. For further

information on the transmitter installation, please refer to the SITRANS F M MAGFLO

Technical Documentation (handbooks, instructions, manuals etc.) on the complete product

range SITRANS F can be found on the internet/intranet on the following links:

English: http://www4.ad.siemens.de/WW/view/en/10806951/133300

electromagnetic flowmeters consist of a

®

handbook.

A5E01019391

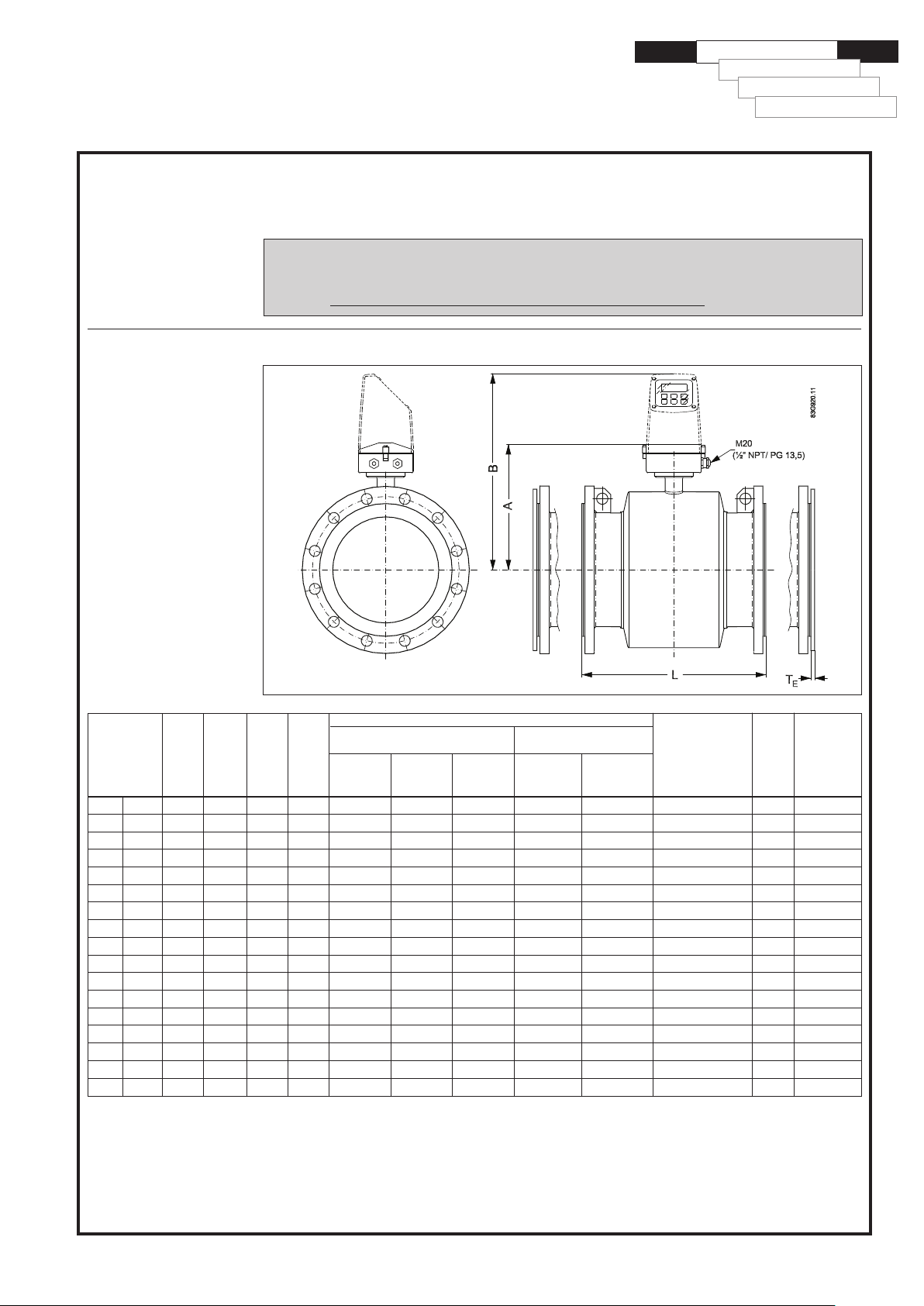

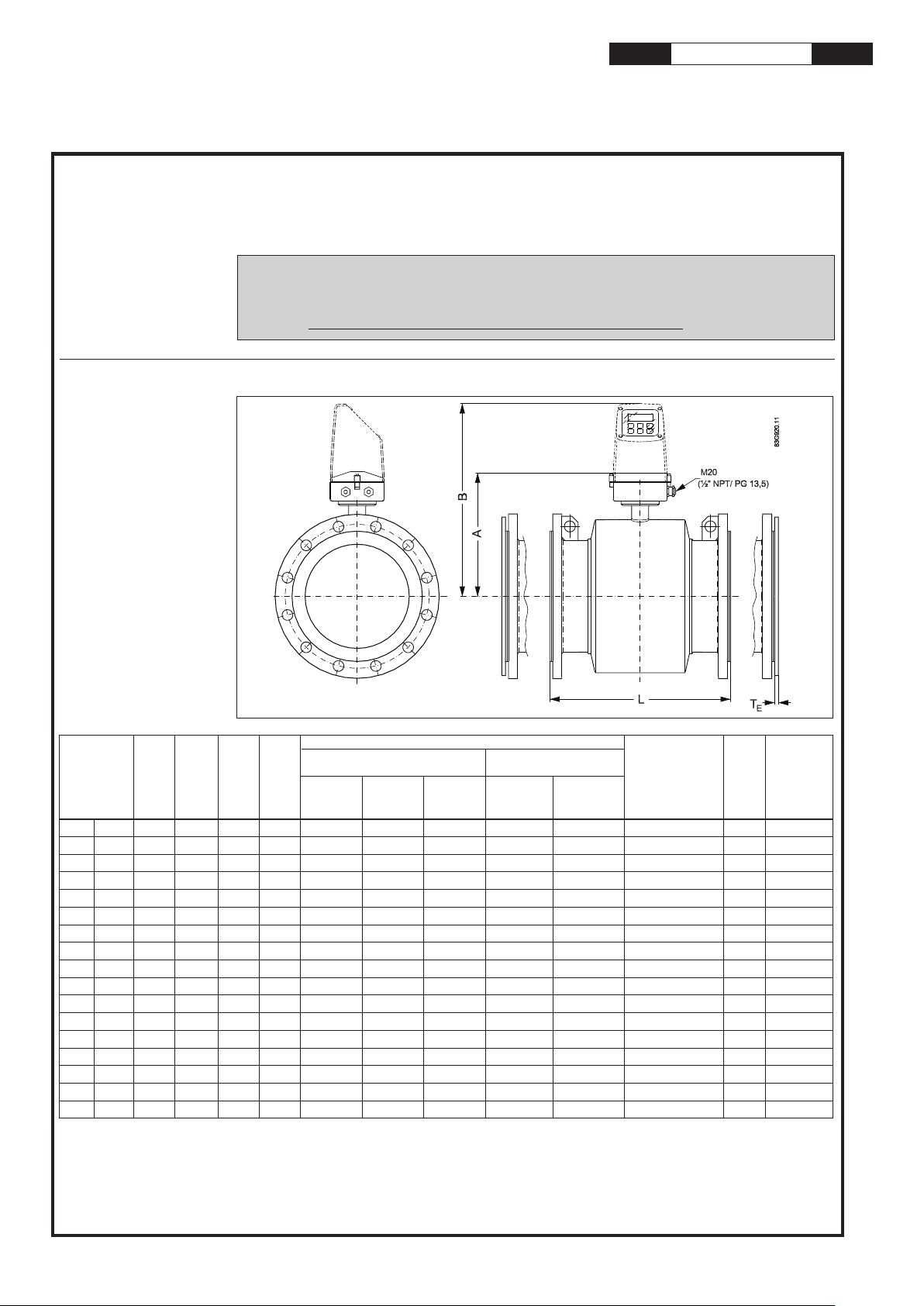

Dimensions and

MAG 3100 with PTFE or PFA liner

weight

Nominal

size

[mm] [inch] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

15 ½ 187 338 59 104 - - 200 200 200 200 6 4

25 1 187 338 59 104 - - 200 200 200 200 6 5

40 1½ 197 348 82 124 - - 200 200 200 200 6 8

50 2 205 356 72 139 - - 200 200 200 200 6 9

65 2½ 212 363 72 154 200 - 200 200 272 200 6 11

80 3 222 373 72 174 200 - 272 272 272 200

100 4 242 393 85 214 250 - 250 250 310 250 6 16

125 5 255 406 85 239 250 - 250 250 335 250 6 19

150 6 276 427 85 282 300 - 300 300 300 300 6 27

200 8 304 455 137 338 350 350 350 350 350 350 8 40

250 10 332 483 157 393 450 450 450 450 450 450 8 60

300 12 357 508 157 444 500 500 500 500 500 500 8 80

350 14 362 513 270 451 550 550 550 550 550 550 8 110

400 16 387 538 270 502 600 600 600 600 600 600 10 125

450 18 418 569 310 563 600 600 600 600 600 600 10 175

500 20 443 594 350 614 600 625 680 600 730 600

600 24 494 645 430 715 600 750 800 600 860 600

1

) When earthing flanges are used, the thickness of the earthing flange must be added to the built-in length

2

)TE = Type E grounding ring for PTFE only

3

) Weights are approx. and for PN 16 without transmitter

4

) PN 35 DN 500 = 680 mm

5

) PN 35 DN 600 = 750 mm

6

) PN 35 DN 80 = 272 mm

- Not available, D = Outside diameter of flange, see flange tables

A A1BD

1

EN 1092-1-2001

PN PN PN Class Class Class 21 (PN 21)

6, 10, 16 25 40 150 300 Class 35 (PN 35)

1)

L

BS 1560/ANSI 16.5

AS 2129 E T

AS 4087

Class 14 (PN 16)

6)

4)

5)

2)

Weight

E

612

10 200

10 287

3)

SFIDK.PI.024.E4.52

SITRANS F M MAGFLO

®®

®

®®

Electromagnetic flowmeter type MAG 3100 with PTFE or PFA liner

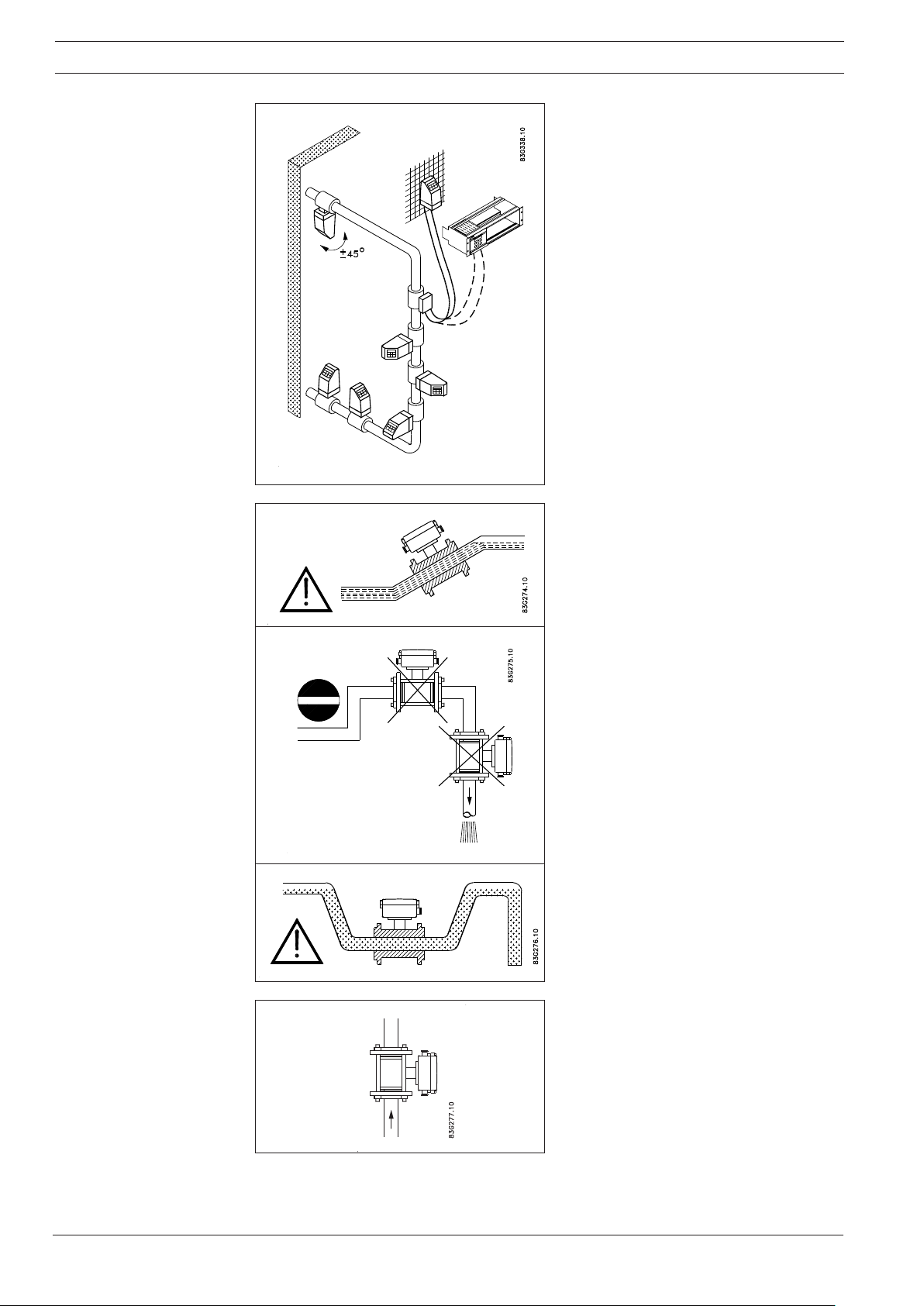

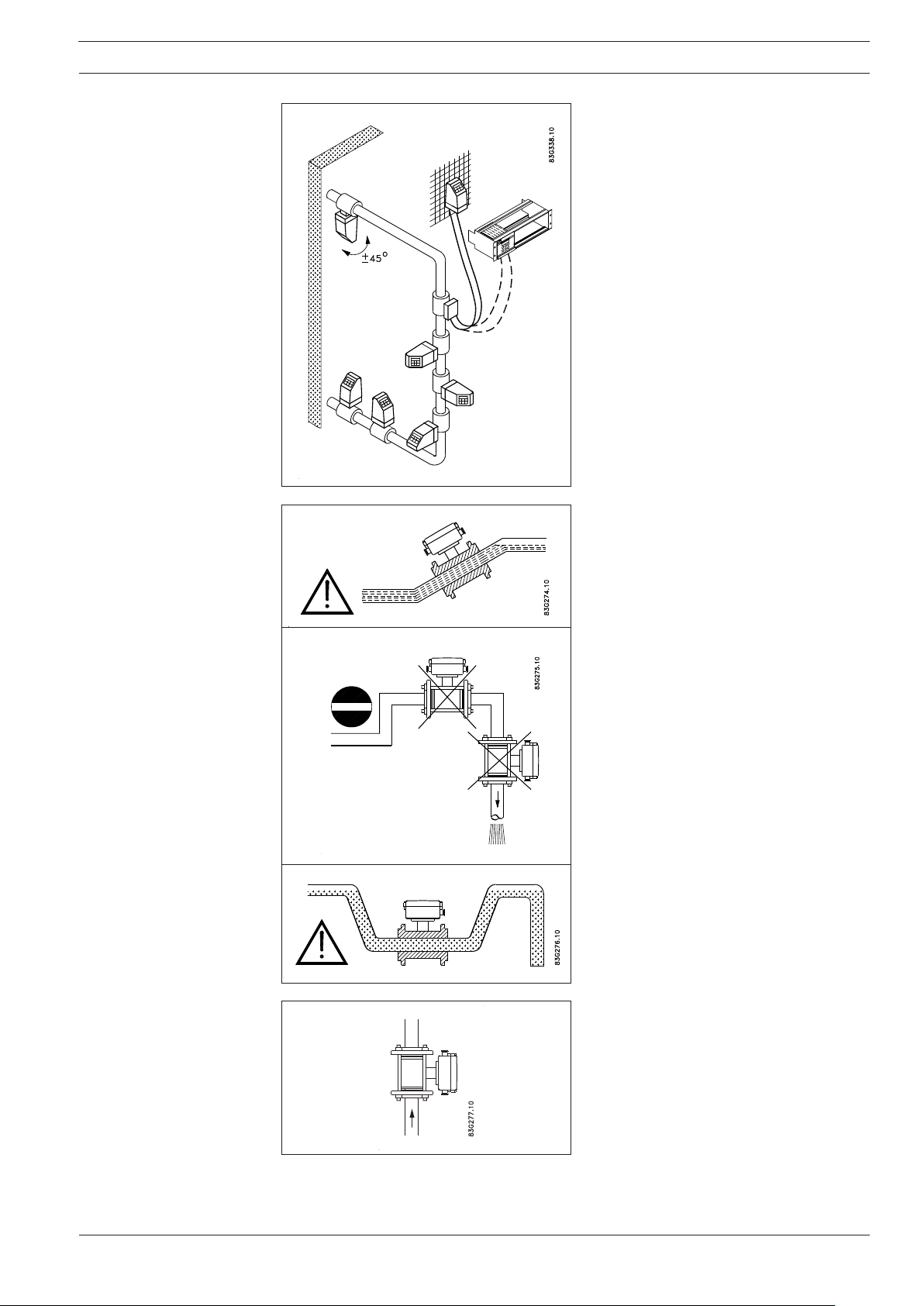

Installation, general

Reading and operating the flowmeter is possible under almost any installation conditions because the display can be oriented in

relation to the sensor. To ensure optimum

flow measurement attention should be paid

to the following:

The sensor must always be completely full

with liquid.

Therefore avoid:

• Installation at the highest point in the pipe

system.

• Installation in vertical pipes with free outlet.

For partially filled pipes or pipes with downward flow and free outlet the flowmeter should

be located in a U-tube.

Installation in vertical pipes

Recommended flow direction: upwards. This

minimizes the effect on the measurement of

any gas/air bubbles in the liquid.

2

SITRANS F M MAGFLO

®®

®

®®

Electromagnetic flowmeter type MAG 3100 with PTFE or PFA liner

Installation, general

(continued)

Installation in horizontal pipes

The sensor must be mounted as shown in

the upper figure. Do not mount the sensor as

shown in the lower figure. This will position

the electrodes at the top where there is

possibility for air bubbles and at the bottom

where there is possibility for mud, sludge,

sand etc.

If using empty pipe detection, the sensor can

be tilted 45° , as shown in the upper figure.

Measuring abrasive liquids and liquids

containing particles

Recommended installation is in a vertical/

inclined pipe to minimize the wear and deposits in the sensor.

Inlet and outlet conditions

To achieve accurate flow measurement it is

essential to have straight lengths of inlet and

outlet pipes and a certain distance between

pumps and valves.

It is also important to centre the flowmeter in

relation to pipe flanges and gaskets.

Pressure drop

The flowmeter can be installed between two

reducers (e.g. DIN 28545). At 8° the following pressure drop curve applies. The curves

are applicable to water.

Example:

A flow velocity of 3 m/s (V) in a sensor with a

diameter reduction from DN 100 to DN 80

= 0.8) gives a pressure drop of 2.9

(d

1/d2

mbar.

3

SITRANS F M MAGFLO

®®

®

®®

Electromagnetic flowmeter type MAG 3100 with PTFE or PFA liner

Installation, general

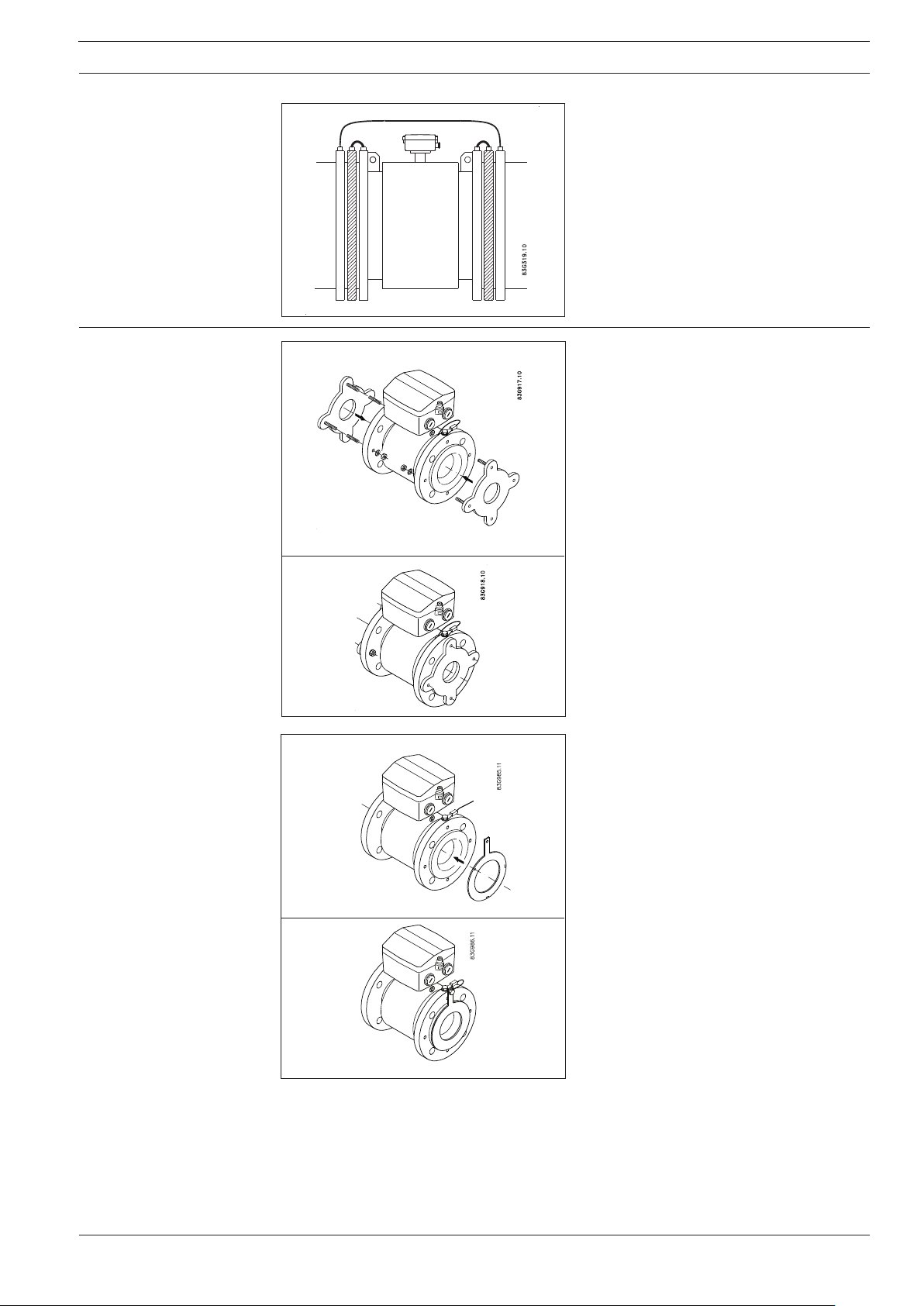

For PTFE liner

For PFA liner

The sensor is equipped with a liner of PTFE

teflon. At delivery the sensor is mounted with

wooden blanks to hold the liner in place during

transportation and storage. These blanks

should remain on the sensor until installation.

Without the blanks the liner will creep back

towards its original shape and installation will

be more difficult to carry out.

The sensor should max. be left a few hours

without the blanks.

Immediately before installation, remove the

blanks.

The sensor is equipped with a liner of PFA. At

delivery the sensor is mounted with blanks to

protect the liner during transportation and

storage. These blanks should remain on the

sensor until installation.

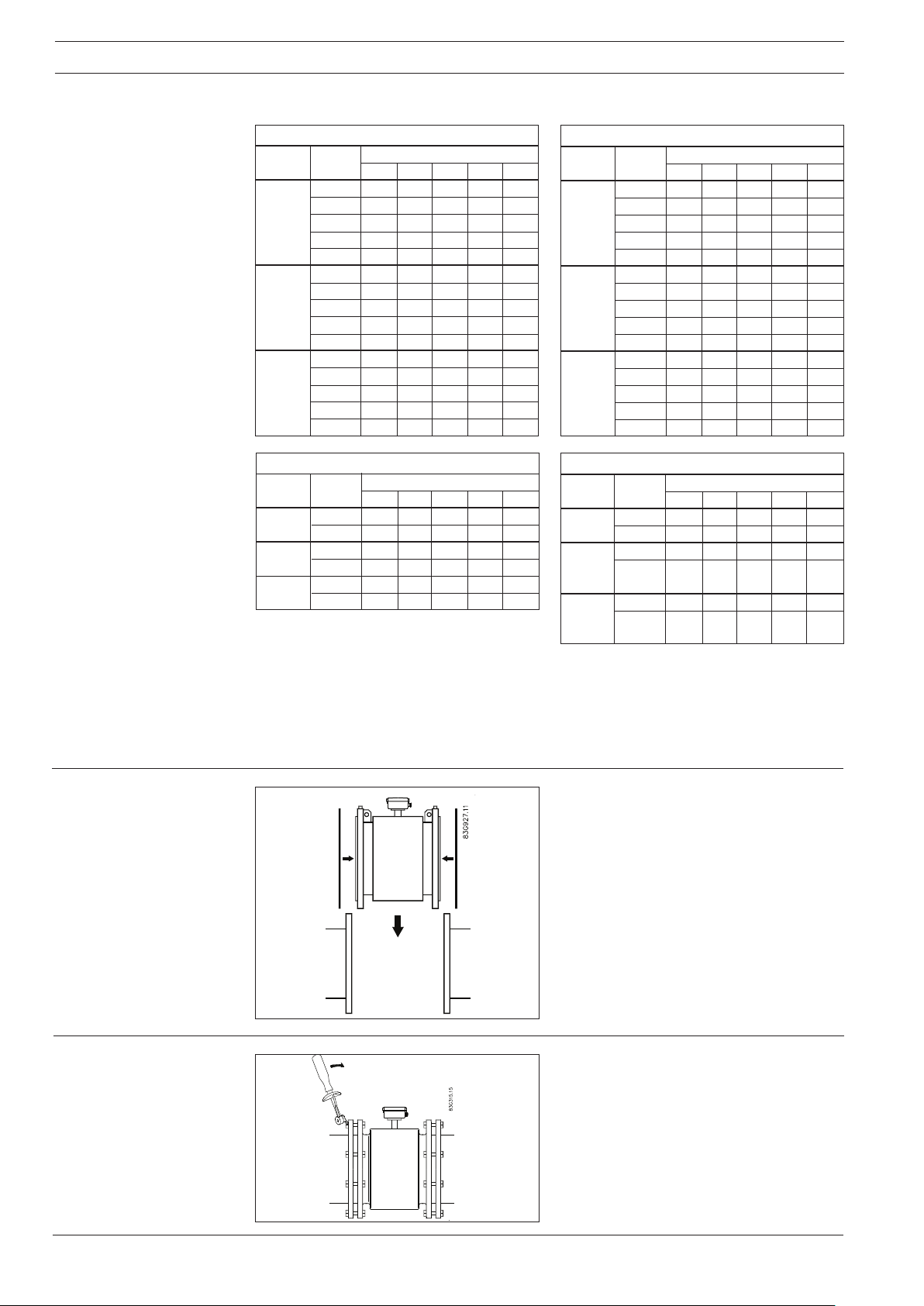

Potential equalization

Before installation, remove the blanks without

using sharp objects which can damage the

liner.

Electrically conductive piping

Potential equalization with an electrically conductive pipe.

Use an earth straps on one side.

Non-conductive piping

Here an earthing flange is used, placed between flowmeter and the adjacent pipe flange.

Earthing flange type E for PTFE.

For PFA flat rings must be used.

4

SITRANS F M MAGFLO

®®

®

®®

Electromagnetic flowmeter type MAG 3100 with PTFE or PFA liner

Cathodic protected piping

Earting flanges

For PTFE liner

Special attention must be given to systems

with cathodic protection.

By compact mounting:

The transmitter must be supplied through an

isolation transformer. The terminal "PE" must

never be connected.

By remote mounting:

The screen must only be connected at the

sensor end via a 1.5 μF condensator. The

screen must never be connected at both ends.

By isolated sensor:

If above mentioned connections are unacceptable, the sensor must be isolated from the

pipe work.

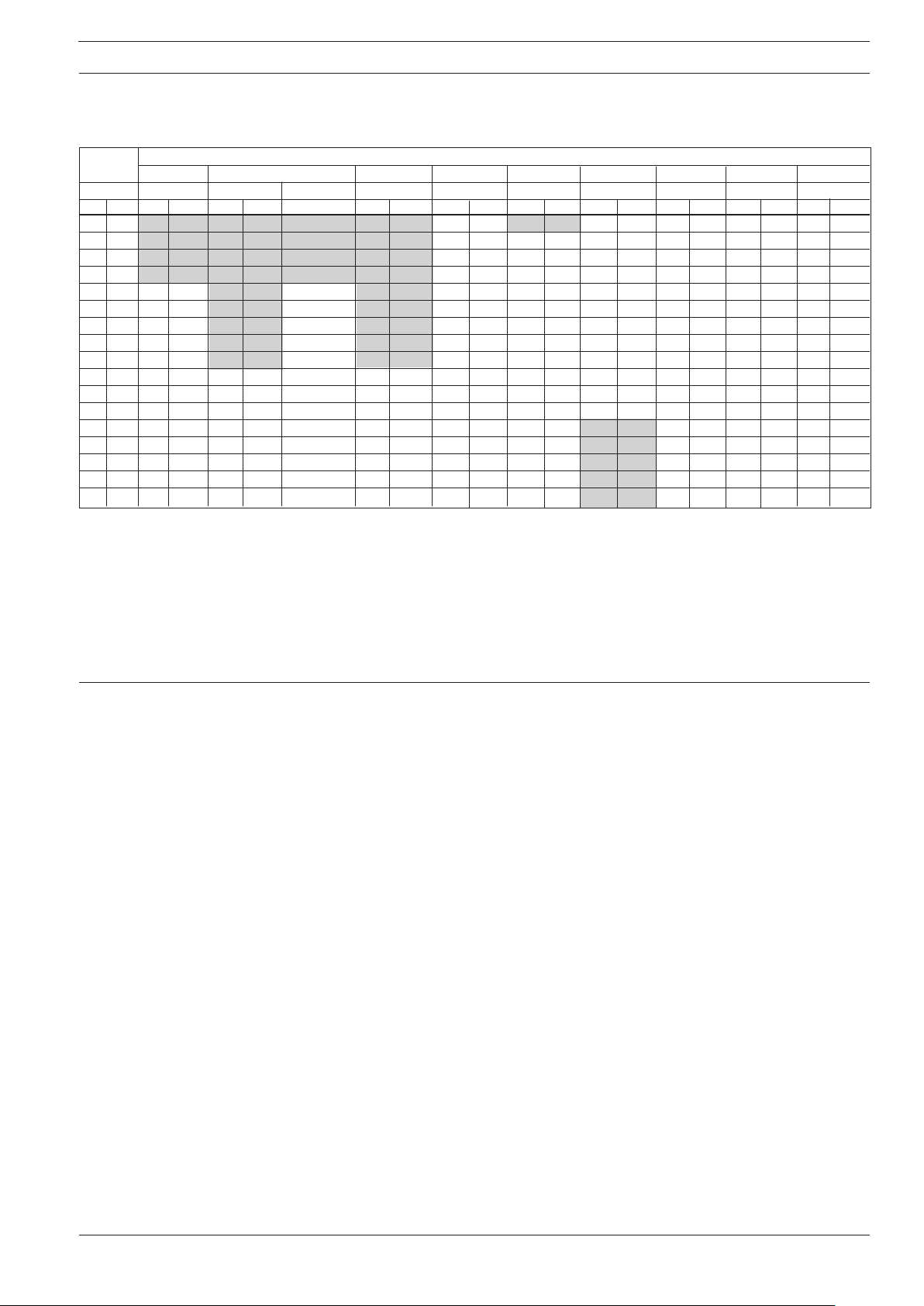

Where necessary on non conductive pipes,

mount earthing flanges type E.

For potential equalization one earthing flange

is sufficient even for bidirectional flow. With

unidirectional flow the earthing flange should

be mounted on the inlet side.

In special cases with abrasive flow the earthing

flanges will also work as inlet protection.

High temperature sensors are delivered with

two factory mounted earthing flanges. No further action need to be taken for potential equalisation.

For PFA liner

Earthing flanges must be connected to the

meter body with the enclosed earthing straps.

Where necessary on non conductive pipes,

mount flat earthing rings.

For potential equalization one earthing ring is

sufficient even for bidirectional flow. With unidirectional flow the earthing ring should be

mounted on the inlet side.

In special cases with abrasive flow the earthing

ring will also work as inlet protection.

Earthing rings must be connected to the meter

body with the enclosed earthing straps.

5

SITRANS F M MAGFLO

®®

®

®®

Electromagnetic flowmeter type MAG 3100 with PTFE or PFA liner

Effect of temperature and

material on working

pressure

Metric (Pressures in bar)

PN rated flanges

Material Flange Temperature

group rating −20 50 100 150 180

1C1 PN 6 6.0 6.0 6.0 5.8 5.6

(A105) PN10 10.0 10.0 10.0 9.7 9.4

PN16 16.0 16.0 16.0 15.6 15.1

PN 25 25.0 25.0 25.0 24.4 23.7

PN 40 40.0 40.0 40.0 39.1 37.9

2C1 PN 6 5.5 5.3 4.5 4.1 3.8

(304) PN 10 9.1 8.8 7.5 6.8 6.3

PN 16 14.7 14.2 12.1 11.0 10.2

PN 25 23.0 22.1 18.9 17.2 16.0

PN 40 36.8 35.4 30.3 27.5 25.5

2C2 PN 6 5.5 5.3 4.6 4.2 3.9

(316) PN 10 9.1 8.9 7.8 7.1 6.6

PN 16 14.7 14.3 12.5 11.4 10.6

PN 25 23.0 22.3 19.5 17.8 16.5

PN 40 36.8 35.6 31.3 28.5 26.4

ANSI flanges

Material Flange Temperature

group rating −20 38 93 149 180

1.1 Cl. 150 19.7 19.7 17.9 15.9 14.7

(A105) Cl. 300 51.0 51.0 46.6 45.2 44.4

2.1 Cl. 150 19.0 19.0 15.9 14.1 13.6

(F304) Cl. 300 49.7 49.7 41.4 37.2 35.5

2.2 Cl. 150 19.0 19.0 16.2 14.8 14.1

(F316) Cl. 300 49.7 49.7 42.8 38.6 36.9

°°

° C

°°

°°

° C

°°

Imperial (Pressures in Psi)

PN rated flanges

Material Flange Temperature

group rating −5 122 212 302 356

ASTM PN 6 87 87 87 84 81

A105 PN 10 145 145 145 141 136

PN 16 232 232 232 226 219

PN 25 363 363 363 354 344

PN 40 580 580 580 567 550

ASTM PN 6 80 77 65 59 55

A240 PN 10 132 128 109 99 91

304 PN 16 213 206 175 160 148

PN 25 334 320 274 249 232

PN 40 534 513 439 399 370

ASTM PN 6 80 77 67 61 57

A240 PN 10 132 129 113 103 96

316 PN 16 213 207 181 165 154

PN 25 334 323 283 258 239

PN 40 534 516 454 413 383

ANSI flanges

Material Flange Temperature

group rating −5 100 200 300 356

ASTM Cl. 150 285 285 260 230 213

A105 Cl. 300 740 740 675 655 644

ASTM Cl. 150 275 275 230 205 197

A240 Cl. 300 720 720 600 540 515

F304

ASTM Cl. 150 275 275 235 215 204

A240 Cl. 300 720 720 620 560 535

F316

°°

° F

°°

°°

° F

°°

The above tables show the effect that an increase of temperature or change of material have

on the maximum working pressure of the flange. The values are independent of nominal size.

For intermediate temperatures use value from nearest higher temperature.

Example

For a PN 16 flange in 2C2 (316) material at 80 degrees the maximum working pressure should

be taken as 12.5 bar.

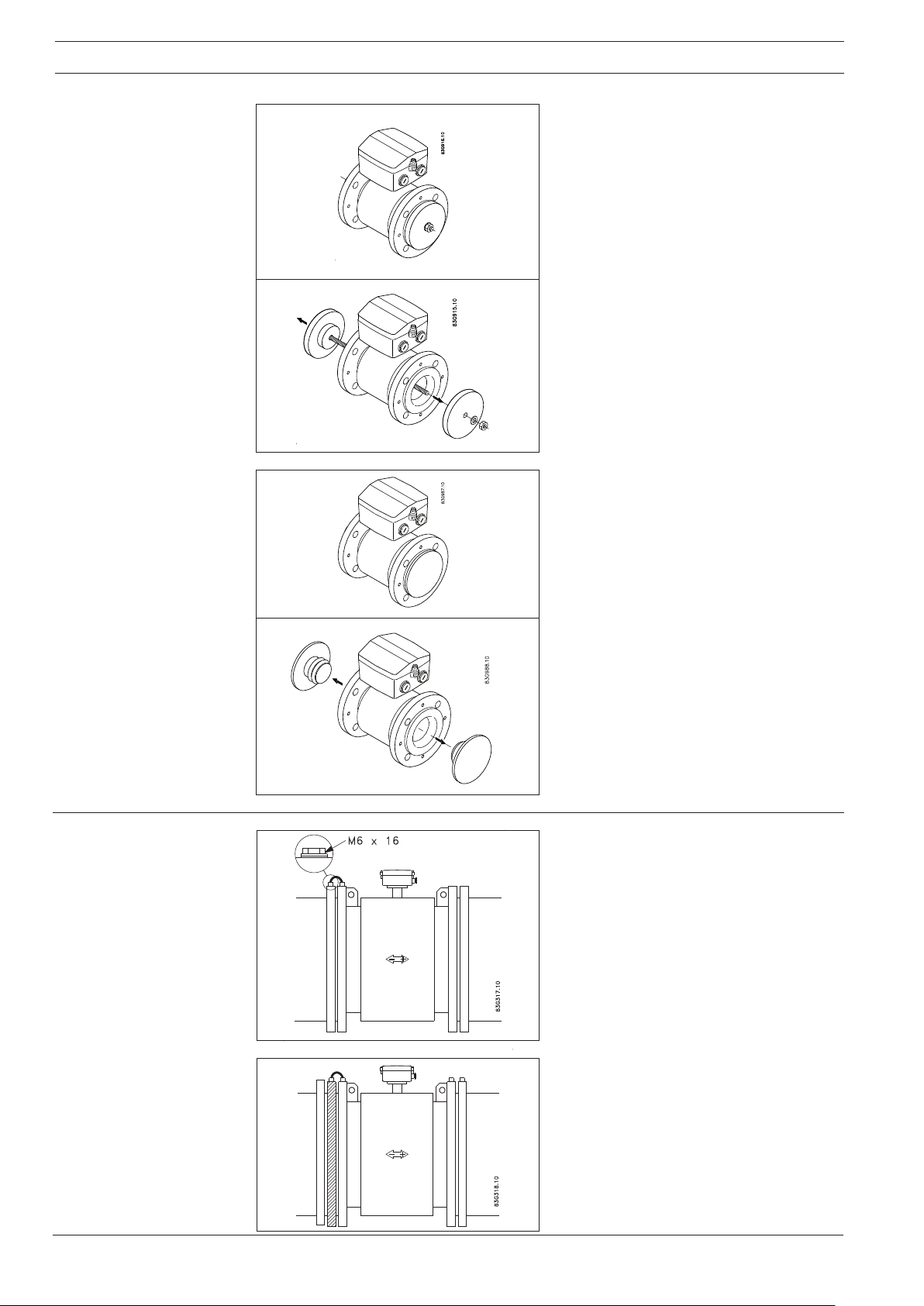

Installation

Tightening

The sensor must be mounted between two

flanges. Gaskets are only necessary when the

flowmeter is installed with earthing flanges as

the liner replaces gaskets.

Standard bolts must be well lubricated and

tightened evenly around the gasket. Leakage/

damage to the flowmeter or piping may arise if

bolts are overtightened.

6

®®

®

SITRANS F M MAGFLO

®®

Electromagnetic flowmeter type MAG 3100 with PTFE or PFA liner

Maximum allowable torques

(to meet PED)

Nominal Maximum torque

size EN 1092-1 EN 1092-1 EN 1092-1 EN 1092-1 EN 1092-1 ANSI B16.5 ANSI B16.5 AS 2129 JIS JIS

PN 6 PN 10 PN 16 PN 25 PN 40 Class 150 Class 300 Table E K10 K20

mm Inch Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs Nm F/Lbs

15½”N/AN/AN/AN/AN/AN/AN/AN/A107N/AN/A32648686

251"N/AN/AN/AN/AN/AN/AN/AN/A161275 759716121612

40 1½” N/A N/A N/A N/A N/A N/A N/A N/A 34 25 9 7 18 13 17 13 20 15 20 15

50 2" N/A N/A N/A N/A N/A N/A N/A N/A 46 34 20 14 11 8 20 15 27 20 13 10

65 2½” 10 7 N/A N/A 25 18 N/A N/A 34 25 25 18 16 12 21 16 36 27 18 13

80 3" 25 18 N/A N/A 25 18 N/A N/A 42 31 34 25 24 18 32 23 21 16 28 21

100 4" 25 18 N/A N/A 25 18 N/A N/A 72 53 26 19 34 25 24 18 26 19 37 27

125 5" 25 18 N/A N/A 32 24 N/A N/A 114 84 42 31 42 31 33 24 43 32 59 44

150 6" 25 18 N/A N/A 50 37 N/A N/A 144 106 57 42 35 26 40 30 76 56 40 30

200 8" 25 18 50 37 52 38 105 77 185 137 88 65 57 42 61 45 46 34 62 45

250 10" 25 18 50 37 88 65 160 118 300 221 99 73 57 42 62 46 72 53 113 83

300 12" 50 37 60 44 117 86 170 125 320 236 132 97 86 63 78 58 56 41 96 71

350 14" 50 37 60 44 120 89 240 177 450 332 225 166 N/A N/A 147 109 72 53 147 108

400 16" 50 37 88 65 170 125 330 244 650 480 210 155 N/A N/A 168 124 115 85 175 129

450 18" 56 41 92 68 170 125 320 236 570 421 220 162 N/A N/A 164 121 109 80 184 135

500 20" 53 39 103 76 230 170 390 288 740 546 200 148 N/A N/A 194 143 127 93 211 155

600 24" 81 60 161 119 350 258 560 413 1220 900 280 207 N/A N/A 306 225 150 111 255 188

Torque calculations

Manufacturer’s design

and safety statement

All values are theoretical and are calculated making the following assumptions:

1. All bolts are new and material selection is according to EN 1515-1 table 2.

2. The standard flange gasket material to be used between the flowmeter and mating flanges

should not exceed 75 shore A durometer.

3. All bolts are galvanized and adequately lubricated.

4. The values are calculated for use with carbon steel flanges.

5. Flowmeter and mating flanges are correctly aligned.

1. Responsibility for the choice of lining and electrode materials with regard to their abrasion

and corrosion resistance lies with the purchaser; the effect of any change in process

medium during the operating life of the flowmeter should be taken into account. Incorrect

selection

of lining and/or electrode materials could lead to a failure of the flowmeter.

2. It is the responsibility of the user to ensure that stresses and loading caused by earthquakes,

traffic, high winds and fire damage are taken into account during installation, when

appropriate. These forces are not taken into account during flowmeter design.

3. It is the responsibility of the user to ensure that the flowmeter is installed such that it does

not act as a focus for pipeline stresses. External loadings are not taken into account during

flowmeter design.

4. During operation do not exceed the pressure and/or temperature ratings indicated on the

data label or in the installation instructions.

5. It is the responsibility of the user to ensure that all installations include over pressure

protection, means for draining/venting, and that adequate protection is provided to

minimise any risk of contact with hot surfaces.

6. Under the Pressure Equipment Directive this product is a pressure accessory, and not

approved for use as a safety accessory, as defined by the Pressure Equipment Directive.

emoval of the terminal box except by Siemens Flow Instruments or their approved agents

7. R

will invalidate the PED conformity of the product.

In accordance with the Pressure Equipment Directive (97/23/EC)

7

s

INSTRUCTIONS

DEUTSCH

®®

®

SITRANS F M MAGFLO

Magnetisch induktiver Durchflussmesser Typ MAG 3100 mit

PTFE- oder PFA- Auskleidung

®®

Einführung

Abmessungen und

Gewichte

Siemens Flow Instruments SITRANS F M MAGFLO

®

magnetisch-induktive Durchflussmesser

bestehen aus einem Messaufnehmer und einem Messumformer. Diese Instruktion beschreibt nur

die Montage des Messaufnehmers. Für weitere Informationen über die Montage des Messumformers,

siehe bitte das SITRANS F M MAGFLO

®

Produkthandbuch.

Technische Unterlagen (Handbücher, Instruktionen, Betriebsanleitung usw.) des

kompletten Warenangebotes von SITRANS F sind auf dem Internet/Intranet unter folgenden

Links verfügbar

Deutsch:

http://www4.ad.siemens.de/WW/view/de/10806951/133300

MAG 3100 mit PTFE- oder PFA-Auskleidung

A5E01019391

Nominelle

Nennweite

[mm] [inch] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

15 ½ 187 338 59 104 - - 200 200 200 200 6 4

25 1 187 338 59 104 - - 200 200 200 200 6 5

40 1½ 197 348 82 124 - - 200 200 200 200 6 8

50 2 205 356 72 139 - - 200 200 200 200 6 9

65 2½ 212 363 72 154 200 - 200 200 272 200 6 11

80 3 222 373 72 174 200 - 272 272 272 2006)612

100 4 242 393 85 214 250 - 250 250 310 250 6 16

125 5 255 406 85 239 250 - 250 250 335 250 6 19

150 6 276 427 85 282 300 - 300 300 300 300 6 27

200 8 304 455 137 338 350 350 350 350 350 350 8 40

250 10 332 483 157 393 450 450 450 450 450 450 8 60

300 12 357 508 157 444 500 500 500 500 500 500 8 80

350 14 362 513 270 451 550 550 550 550 550 550 8 110

400 16 387 538 270 502 600 600 600 600 600 600 10 125

450 18 418 569 310 563 600 600 600 600 600 600 10 175

500 20 443 594 350 614 600 625 680 600 730 6004) 10 200

600 24 494 645 430 715 600 750 800 600 860 6005) 10 287

1

) Beim Ensatz von Erdungsflanschen muss die Wandstärke zur Gesamtlänge hinzugerechnet werden

2

)TE = Typ E Erdungsflansch

3

) Die Gewichtsangaben sind Näherungswerte und gelten für PN 16 Flanschausführungen ohne Messumformer

4

) PN 35 DN 500 = 680 mm

5

) PN 35 DN 600 = 750 mm

6

) PN 35 DN 80 = 272 mm

- Nicht verfügbar, D = Außendurchmesser des Flansches

A A1BD

1

EN 1092-1-2001

PN PN PN Class Class Class 21 (PN 21)

6, 10, 16 25 40 150 300 Class 35 (PN 35)

1)

L

BS 1560/ANSI 16.5

AS 2129 E T

AS 4087

Class 14 (PN 16)

E

2)

Gewicht

3)

SFIDK.PI.024.E4.52

SITRANS F M MAGFLO

®®

®

®®

Magnetisch induktiver Durchflussmesser Typ PTFE- oder PFA-Auskleidung

Einbau, allgemein

Der Durchflussmesser kann in jeder Einbaulage abgelesen werden, da die Anzeige

drehbar ist und in jeder beliebigen Position

im Verhältnis zum Messaufnehmer eingebaut werden kann. Die endgültige Position

sollte vor der Montage festgelegt werden.

Um optimale Messergebnisse zu sichern,

sind folgende Hinweise zu beachten:

Der Messaufnehmer muss immer vollständig gefüllt sein.

Vermeiden Sie:

• Einbau an höchster Stelle des Rohrsystems

• Einbau in einer senkrechten Rohrleitung

mit freiem Ablauf.

Ist eine nur teilweise gefüllte Rohrleitung

oder der freie Ablauf nicht zu vermeiden,

sollte der Durchflussmesser gedükert werden.

Einbau in einer senkrechten Rohrleitung

Empfohlene Strömungsrichtung: von unten

nach oben. Dadurch werden ungenaue

Messergebnisse, verursacht durch Gas- bzw.

Luftblasen im Medium, vermieden.

9

Loading...

Loading...