Siemens SITRANS F M MAGFLO Operating Manual

Order no.: FDK:521H1184

SFIDK.PS.026.C2.02

SITRANS F M MA GFLO

®®

®®

®

Electromagnetic flowmeters

Transmitter type MAG 6000 19" &

safety barrier [EEx ia/ib] IIB

sensor type MAG 1100 Ex & MAG 3100 Ex

[]

*083R9171*

Operating Manual

s

SITRAN S F M MAGFLO

®®

®®

®

2

SFIDK.PS.026.C2.02

ENGLISH

Contents

1. Introduction...................................................................................................................... 3

2. Installation ....................................................................................................................... 4

2.1 Installation of transmitter MAG 6000 ............................................................................... 4

2.2 Installation of sensor .......................................................................................................4

2.3.1 Remote installation - At the sensor ................................................................................. 6

2.3.2 Remote installation - Transmitter in 19" inser t ................................................................ 6

2.4 Ex survey according to Directive 94/9/EC (ATEX) .......................................................... 7

2.5 Overview and intrinsically safe data ............................................................................... 8

2.6 Device identification........................................................................................................8

2.7 Approvals ........................................................................................................................ 9

2.8 Special conditions for safe use ..................................................................................... 10

3. Electrical connection .....................................................................................................11

3.1.1 19” IP 20 version EEx (ia/ib) DN ≤ 300 ......................................................................... 11

3.1.2 19” IP 20 version EEx e (ib) DN ≥ 350 .......................................................................... 11

3.1.3 19” IP 66 version EEx (ia/ib) DN ≤ 300 ......................................................................... 11

3.1.4 19” IP 66 version EEx e (ib) DN ≥ 350 .......................................................................... 11

3.2 Transmitter MAG 6000.................................................................................................. 1 2

4. Technical data ............................................................................................................... 13

4.1.1 Dimensions and weight MAG 1100 Ex ......................................................................... 13

4.1.2 Sensor MAG 1100 Ex .................................................................................................... 1 4

4.2.1 Dimensions and weight MAG 3100 Ex ......................................................................... 15

4.2.2 Sensor MAG 3100 Ex .................................................................................................... 1 6

4.3 Transmitter MAG 6000 .................................................................................................. 1 7

4.4.1 Safety barrier (ia/ib) DN ≤ 300 ...................................................................................... 1 8

4.4.2 Safety barrier (ia) DN ≥ 350 .......................................................................................... 18

4.4.3 IS data sensor ............................................................................................................... 18

4.5 Output characteristics MAG 6000 ................................................................................. 19

5. Commissioning ............................................................................................................. 20

5.1 Keypad and display layout ............................................................................................ 20

5.2.1 Basic settings ................................................................................................................21

5.2.2 Outputs ..........................................................................................................................22

5.2.3 External input ................................................................................................................ 22

5.2.4 Sensor characteristics................................................................................................... 23

5.2.5 Language mode ............................................................................................................ 23

5.2.6 Service mode ................................................................................................................ 24

6. Service .......................................................................................................................... 25

6.1 Transmitter check list..................................................................................................... 25

6.2 Trouble shooting MAG transmitter ................................................................................ 2 6

7. Ordering ........................................................................................................................ 27

8. Certificates .................................................................................................................... 28

8.1 EC-declaration of conformity ......................................................................................... 28

8.2 EC type examination certificate .................................................................................... 29

SITRAN S F M MAGFLO

®®

®®

®

3

SFIDK.PS.026.C2.02

ENGLISH

1. Introduction

For safety reasons it is important that the following points, especially the points marked with

a warning sign, are read and understood before the system is being installed:

• Installation, connection, commissioning and service must be carried out by personnel

who are qualified and authorized to do so.

• It is very important that the same people have read and understand the instructions and

directions provided in this manual and that they follow the instructions and directions

before taking the equipment into use!

• People who are authorized and trained by the owner of the equipment may operate the

equipment.

• The installation must ensure that the measuring system is correctly connected and is

in accordance with the connection diagram. The transmitter has to be earthed unless

the power supply is galvanically isolated.

• In applications with working pressures/media that can be dangerous to people,

surroundings, equipment or others in case of pipe fracture, we recommend that special

precautions such as special placement, shielding or installation of a security guard or

a security valve should be made when the sensor is being installed.

• Siemens Flow Instruments want to assist by estimating the chemical resistance of the

sensor parts that are in connection with the media, but it is at any time the customer’s

responsibility, which materials are chosen and Siemens Flow Instruments takes no

responsibility if the sensor corrodes!

• Equipment used in hazardous areas must be Ex-approved and marked for Europe

and UL for USA.

It is required that the special directions provided in the manual and in the Ex certificate

must be followed!

• Installation of the equipment must comply with national regulations.

Example EN 60079-14 for Denmark.

• Repair and service can be done by approved Siemens Flow Instruments personnel

only.

1. Introduction

SITRAN S F M MAGFLO

®®

®®

®

4

SFIDK.PS.026.C2.02

ENGLISH

2. Installation

2. Installation

Category 2 equipment

Sensors may be installed in zone 1 and zone 2.

2.2 Installation of sensor

Transmitter MAG 6000 can be installed in the

safe area only!

2.1 Installation of

transmitter MAG

6000

Safe area only!

Hazardous area

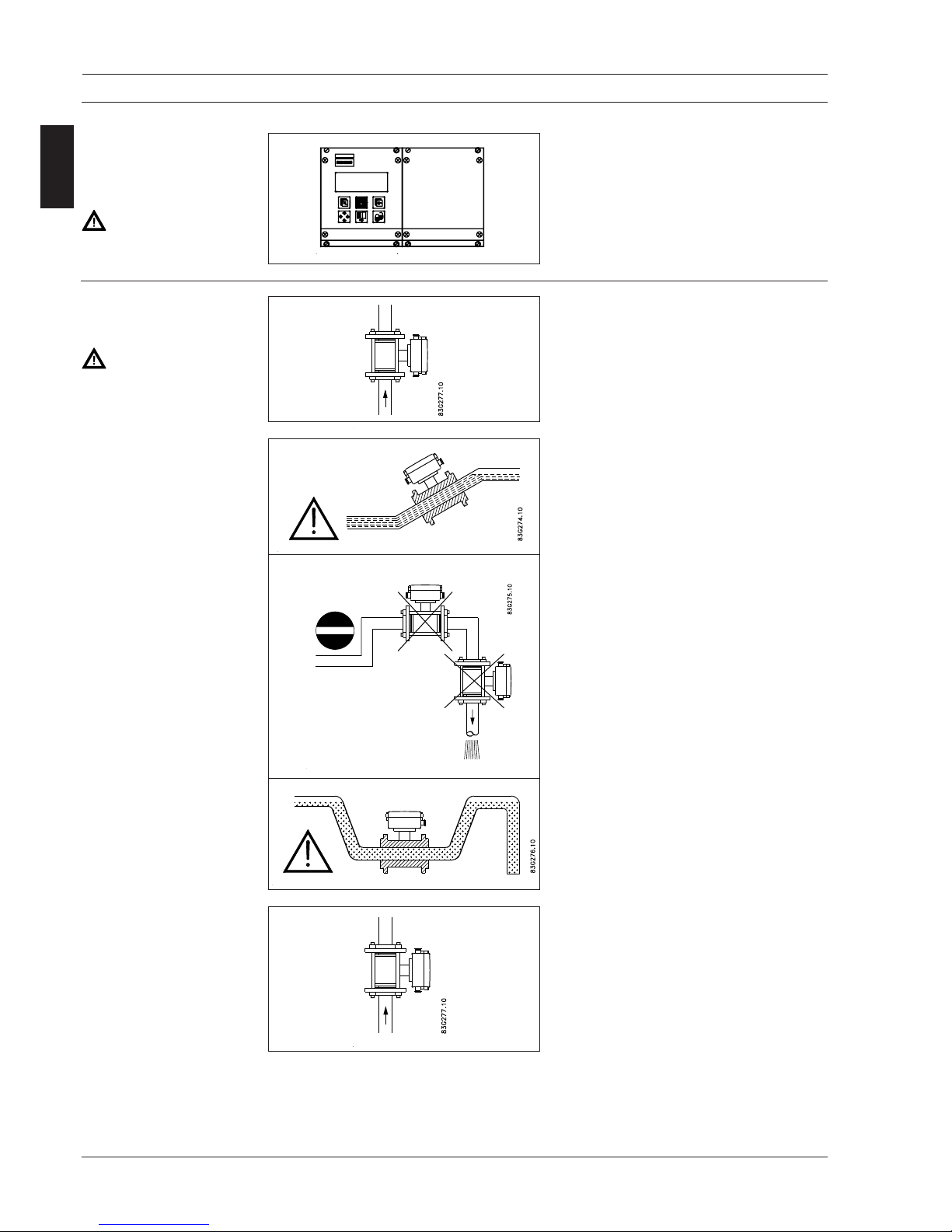

The sensor must always be completely full with

liquid.

Therefore avoid:

• Installation at the highest point in the pipe

system

• Installation in vertical pipes with free outlet

For partially filled pipes or pipes with downward flow and free outlet the flowmeter should

be located in a U-tube.

Installation in vertical pipes

Recommended flow direction: upwards. This

minimizes the effect on the measurement of

any gas/air bubbles in the liquid.

SITRAN S F M MAGFLO

®®

®®

®

5

SFIDK.PS.026.C2.02

ENGLISH

Installation in horizontal pipes

The sensor must be mounted as shown in the

upper figure. Do not mount the sensor as shown

in the lower figure. This will position the electrodes at the top where there is possibility for air

bubbles and at the bottom where there is possibility for mud, sludge, sand etc.

If using empty pipe detection the sensor can be

tilted 45°, as shown in the upper figure.

Measuring abrasive liquids and liquids containing particles

Recommended installation is in a vertical/inclined pipe to minimize the wear and deposits

in the sensor.

Inlet and outlet conditions

To achieve accurate flow measurement it is

essential to have straight lengths of inlet and

outlet pipes and a certain distance between

pumps and valves.

It is also important to centre the flowmeter in

relation to pipe flanges and gaskets.

2.2 Installation of sensor

(continued)

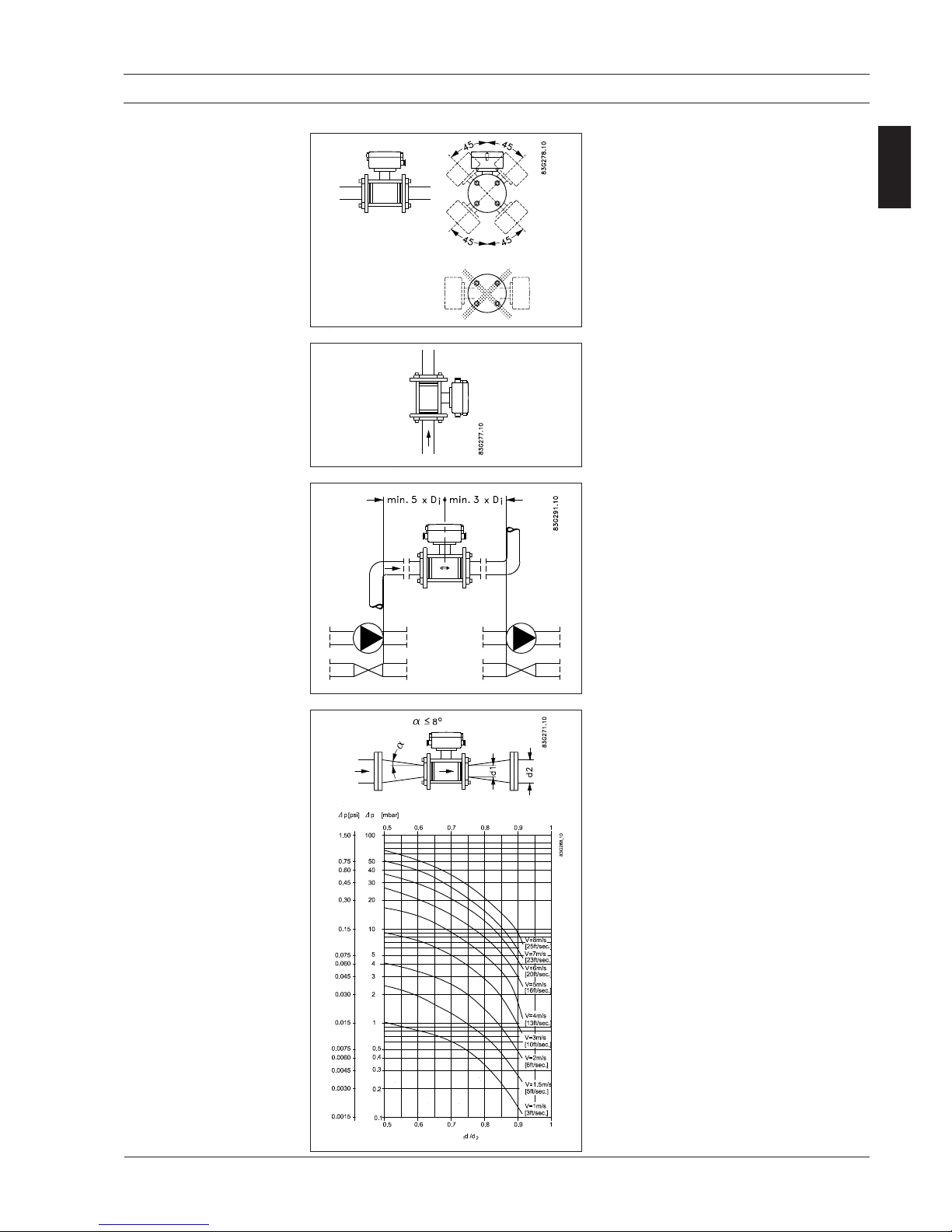

Installation in large pipes

The flowmeter can be installed between two

reducers (e.g. DIN 28545). Assuming that at 8°

the following pressure drop curve applies. The

curves are applicable to water.

Example:

A flow velocity of 3 m/s (V) in a sensor with a

diameter reduction from DN 100 to DN 80

(d

1/d2

= 0.8) gives a pressure drop of 2.9 mbar.

2. Installation

SITRAN S F M MAGFLO

®®

®®

®

6

SFIDK.PS.026.C2.02

ENGLISH

2. Installation

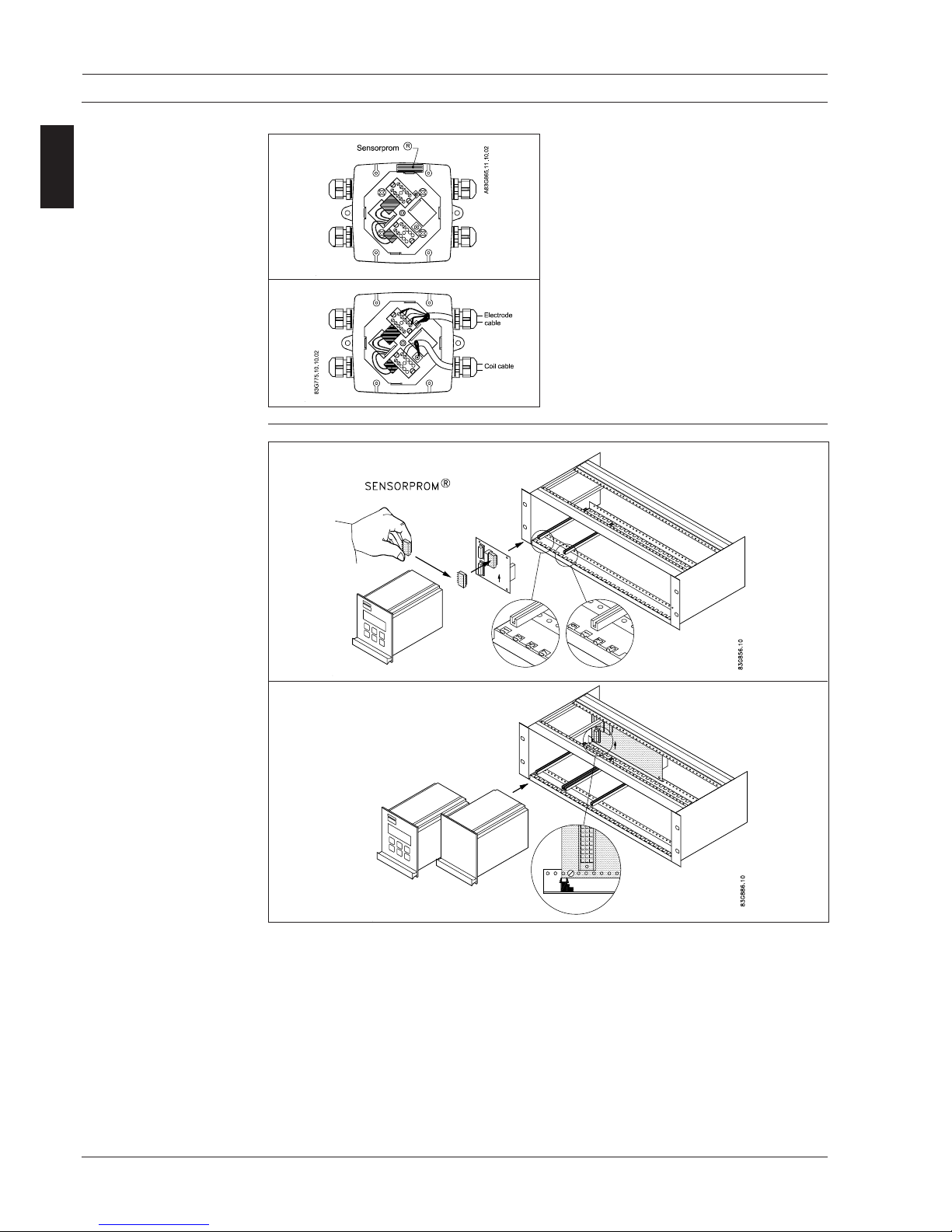

2.3.1 Remote installation -

At the sensor

Fit and connect the electrode and coil cables

as shown in chapter 7 “Electrical connections”

in the handbook.

The unscreened cable ends must be kept as

short as possible.

The electrode cable and the coil cable must be

kept separate to prevent interference.

Tighten the cable glands well to obtain optimum sealing.

Remove the SENSORPROM® unit from the

sensor and mount it on the connection plate in

the transmitter.

2.3.2 Remote installation -

Transmitter in 19"

insert

1. Fit the SENSORPROM® memory unit on the connection board supplied with the transmitter.

The SENSORPROM® unit is supplied with the sensor in the terminal box.

2. Mount the guide rails into the rack system as shown. Distance between guide rails is 20 TE.

Guide rails are supplied with the rack system and not with the transmitter.

3. Mount the connection board as shown.

4. Connect the cables as shown under "Electrical connection", chapter 7 in the handbook.

5. Insert the transmitter into the rack system.

SITRAN S F M MAGFLO

®®

®®

®

7

SFIDK.PS.026.C2.02

ENGLISH

2. Installation

2.4 Ex survey according

to Directive 94/9/EC

(ATEX)

Applies to instruments used in underground mining

operations, as well as their above ground

operations, which can be endangered by mine gas

and/or flammable dusts.

Instrument groups

Applies to instruments used in the remaining areas

which can be endangered by a potentially explosive

atmosphere.

Instruments of this category are for use in

areas where ignitable atmospheres, caused by

a mixture of air and gasses, vapours or mists or

by dust/air mixtures, can exist all of the time or

for long periods of time or else frequently.

Instruments of this category are for use in

areas where ignitable atmospheres caused, by

a mixture of air and gasses, vapours or mists or

by dust/air mixtures, can exist some of the time.

Instruments of this category are for use in

areas where ignitable atmospheres, caused by

a mixture of air and gasses, vapours or mists or

by dust/air mixtures, are not likely to exist.

However, if they do occur then in all probability,

only seldom or for short periods of time.

Instrument category

(The figures in brackets refer to IEC)

Built according to European norm = E

Explosion protected electrial equipment = Ex

Ex protection labelling in square brackets refers to "Associated electrical equipment"

as an example

:

II 2G E Ex ia IIB T3-T6

Type of protection

o Oil encapsulated i Intrinsic safety (ia, ib)

p Pressurized apparatus n Non-incentive equipment

q Powder filling m Encapsulation

d Flameproof enclosure s Special protection

e Increased safety

Explosion groups

Gases and vapours Minimum EN/

(examples) ignition IEC

energy [mJ]

• Ammonia - IIA

• Acetone, aircraft fuel, benzine,

crude oil, diesel oil, ethane, ethanoic

acid, ether, gasolines, heating oil,

hexane, methane, propane 0.18 IIA

• Ethylene, isoprene, town gas 0.06 IIB

• Acetylene, carbon disulphide,

hydrogen 0.02 IIC

Ignition temperature

Maximum surface temperature EN / IEC

450°C 842°FT1

300°C 572°FT2

200°C 392°FT3

135°C 275°FT4

100°C 212°FT5

85°C 185°FT6

I

II

EN 50014 Directive 94/9/EC (ATEX)

Definition

1G

(0)

Labelling

with gases

Labelling

with dusts

1D

(20)

2G

(1)

2D

(21)

3G

(2)

3D

(22)

SITRAN S F M MAGFLO

®®

®®

®

8

SFIDK.PS.026.C2.02

ENGLISH

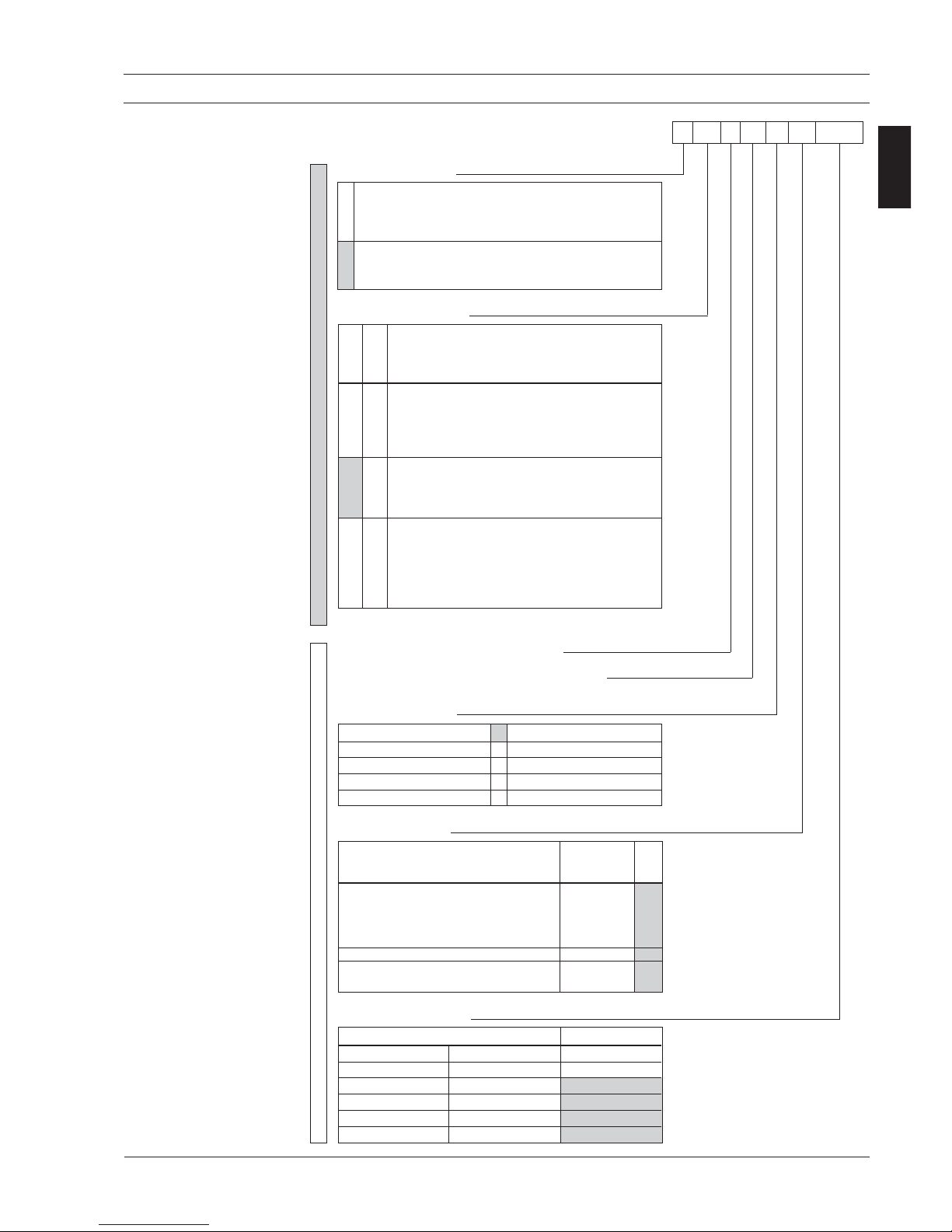

2.6 Device identification

Sensor MAG 1100 Ex or

MAG 3100 Ex label

2. Installation

Can

only

be installed in safe area!

All MAG 1100 Ex and MAG 3100 Ex sensors

have the following ratings and input parameters:

2.5 Overview and

intrinsically safe data

MAG 6000 19" IP 20

& I P 6 5 [EEx ia] IIB

Category 2 equipment

Sensors may be installed in zone 1 and zone 2.

Sensors intrinsically safe data

See table below.

MAG 1100 & MAG 3100

EEx ia IIB T3...T6

Terminals 85-86 82-83

MAG barriers ib coil ia electrode

U

o

28 V 9.3 V

I

o

138 mA 40 mA

P

o

0.4 W

L

o

4 mH 23 mH

C

o

100 nF 500 nF

Terminals 85-86 82-83

MAG sensor coil electrode

U

i

28 V 10 V

I

i

140 mA 50 mA

P

i

2 W 0.5 W

L

i

2 mH 20 mH

C

i

50 nF 50 nF

MAG 1100 DN 6 - 100

MAG 3100 DN 15 - 300 Ex ib

Terminals 85-86 82-83

MAG sensor coil electrode

U

i

- 10 V

I

i

- 50 mA

P

i

- 0.5 W

L

i

- 20 mH

C

i

- 50 nF

MAG 3100 DN 350 - 2000 Ex e ia

IS data transmitter

IS data sensor

Specifications:

Supply: 115-230 V or 24 V

Ambient temperature: −20 to 50°C

Enclosure: IP 20 or IP 65

SITRAN S F M MAGFLO

®®

®®

®

9

SFIDK.PS.026.C2.02

ENGLISH

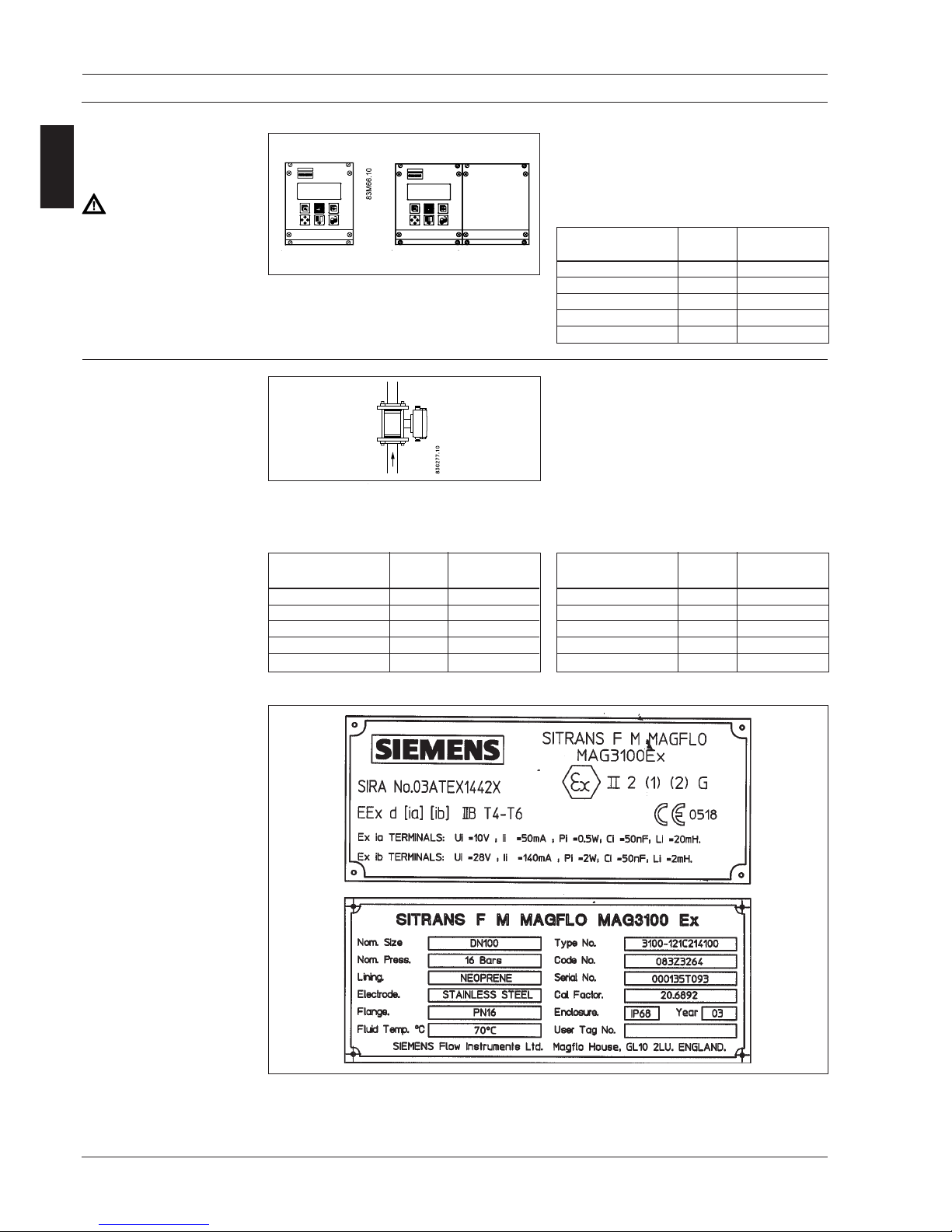

SITRANS F M MAGFLO® sensors carry the following approvals

MAG 1100 Ex for mounting in Ex areas

DN 6 - DN 100

EEx [ia] [ib] IIB T4...T6, II 2 (1)(2)

SIRA 03 ATEX 1423X CE 0518

Temperature ratings are as follows:

T4 (max. surface < 135°C) for liquid temperatures lower than 100°C

T5 (max. surface < 100°C) for liquid temperatures lower than 82°C

T6 (max. surface < 85°C) for liquid temperatures lower than 67°C

For an ambient temperature of –20°C to + 50°C

MAG 3100 Ex for mounting in Ex areas

DN 15 - DN 300

EEx-d [ia] [ib] IIB T4...T6, II 2 (1)(2)

SIRA 03 ATEX 1442X CE 0518

Temperature ratings are as follows*):

T4 (max. surface < 135°C) for liquid temperatures lower than 100°C

T5 (max. surface < 100°C) for liquid temperatures lower than 87°C

T6 (max. surface < 85°C) for liquid temperatures lower than 72°C

For an ambient temperature of –20°C to +50°C

DN 350 - DN 2000

EEx e ia IIC T3…T6, II 2 GD IP 65 T(**)

O

C

SIRA 03 ATEX 3339X CE 0518

where (**) represents the pipeline temperature + 5K for the purposes of the dust approval

Temperature ratings are as follows*):

T3 (max. surface < 200°C) for liquid temperatures lower than 190°C

T4 (max. surface < 135°C) for liquid temperatures lower than 125°C

T5 (max. surface < 100°C) for liquid temperatures lower than 90°C

T6 (max. surface < 85°C) for liquid temperatures lower than 75°C

For an ambient temperature of –20°C to +40°C

MAG 6000 & safety barriers carry the following approvals

For use with MAG 1100 Ex (all sizes) and MAG 3100 Ex sizes DN 15 - DN 300 for mounting in

the safe area

[EEx ia ib] IIB, II 2 G

DEMKO 03 ATEX 135255X CE539

For use with MAG 3100 Ex sizes DN 350 - DN 2000, for mounting in the safe area

[EEx ia] IIC, II 2 G

DEMKO 03 ATEX 135254X CE539

*) Note

Temperature ratings may be limited by the lining selected, see section 4.2.2.

2.7 Approvals

2. Installation

Transmitter

MAG 6000 19" IP 20 and

IP 65 label

SITRAN S F M MAGFLO

®®

®®

®

10

SFIDK.PS.026.C2.02

ENGLISH

2.8 Special conditions for

safe use

MAG 3100 Ex DN 40 - DN 300

The relation between assigned temperature ambient temperature and media temperature:

Temperature class Ambient temperature range Media temperature range

T6 −20 °C to +50 °C −20 °C to +60 °C

T5 −20 °C to +50 °C −20 °C to +75 °C

T4 −20 °C to +50 °C −20 °C to +100 °C

This electrode circuit "ia" is connected to the media inside the sensor. The screen for the "ib" circuit

is connected to chassis and the installations shall therefore take that into account.

2. Installation

Safety Barrier type FDK:083F50_ _ for MAG sensors

Special conditions for safe use:

• The ambient temperature range is −20 °C to +50 °C.

• The safety barrier shall be connected to the PE earth (light blue) according to local installation

equipments. IEC 60079-14 can be used as guideline.

• The PE earth shall be connected to the PE at the sensor according to local installation

equipments. IEC 60079-14 can be used as guideline.

• The intrinsic safety wiring shall be separated from non intrinsic safety wiring according to local

installation equipments.

• The apparatus must be installed in plastic enclosure code FDK:083F5038 with an Ingress

Protection suitable for the environment. The plastic box FDK:083F5038 has been evaluated

for IP 65 according to EN 60529: 1989.

SITRAN S F M MAGFLO

®®

®®

®

11

SFIDK.PS.026.C2.02

ENGLISH

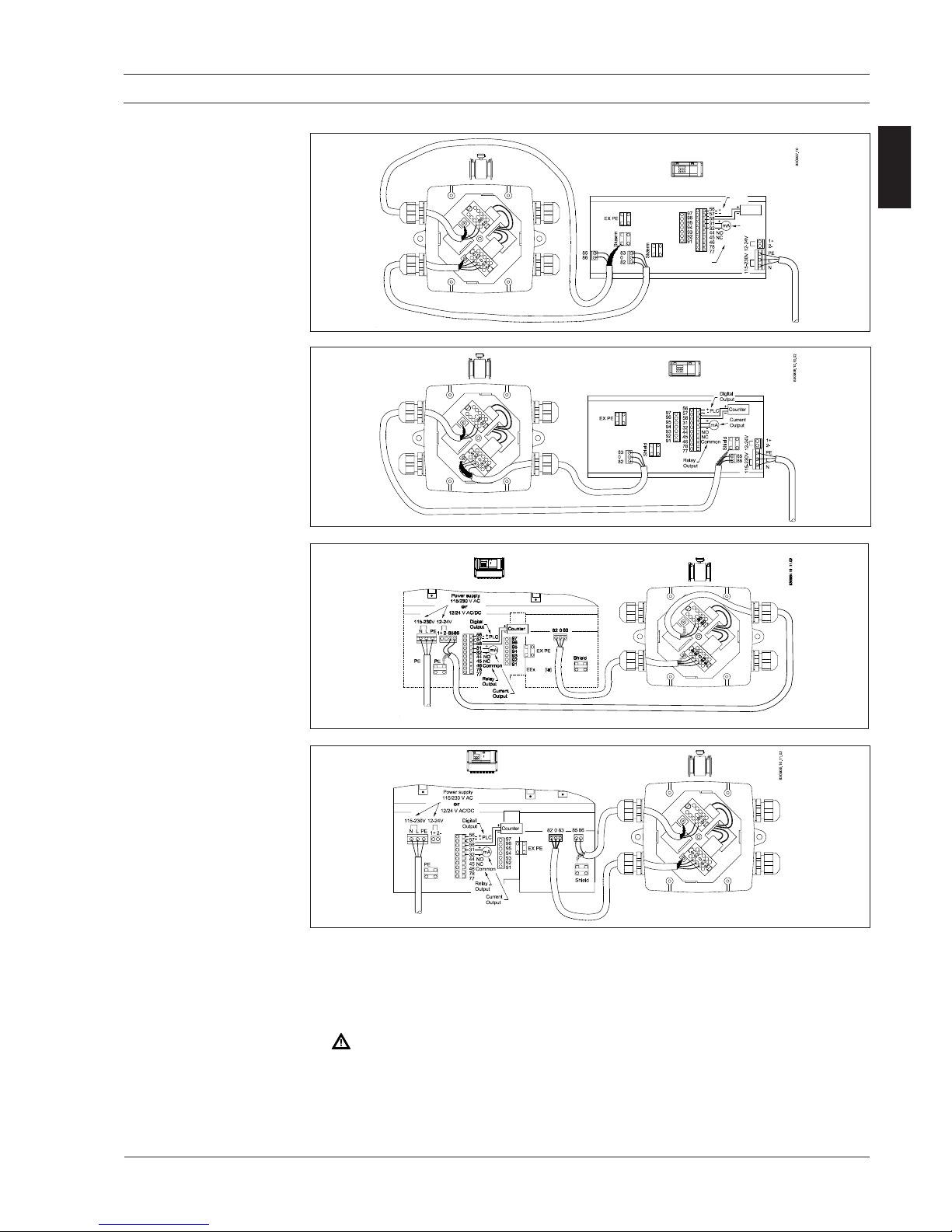

It is an absolute requirement that the wires/terminals of the intrinsically safe circuits cannot get

into contact with the wires of the other cables. The distance between cables/wires therefore must

be at least 50 mm.

It is recommended to fasten the cables/wires in a way that they, even in case of an error, cannot

get into contact with each other. Make the wire ends as short as possible.

1. Connection terminals to:

• Power supply

• In- and output

2. Connection terminals to:

Sensors

Intrinsically safe terminals!

3. Electrical connection

3. Electrical connection

3.1.1 19” IP 20 version

EEx (ia/ib) DN

≤≤

≤≤

≤ 300

3.1.3 19” IP 66 version

EEx (ia/ib) DN

≤ ≤

≤ ≤

≤ 300

3.1.4 19” IP 66 version

EEx e (ib) DN

≥≥

≥≥

≥ 350

3.1.2 19” IP 20 version

EEx e (ib) DN

≥≥

≥≥

≥ 350

Loading...

Loading...