Siemens SITRANS F M MAG 5100 W,SITRANS F Series Operating Instructions Manual

Electromagnetic flowmeters

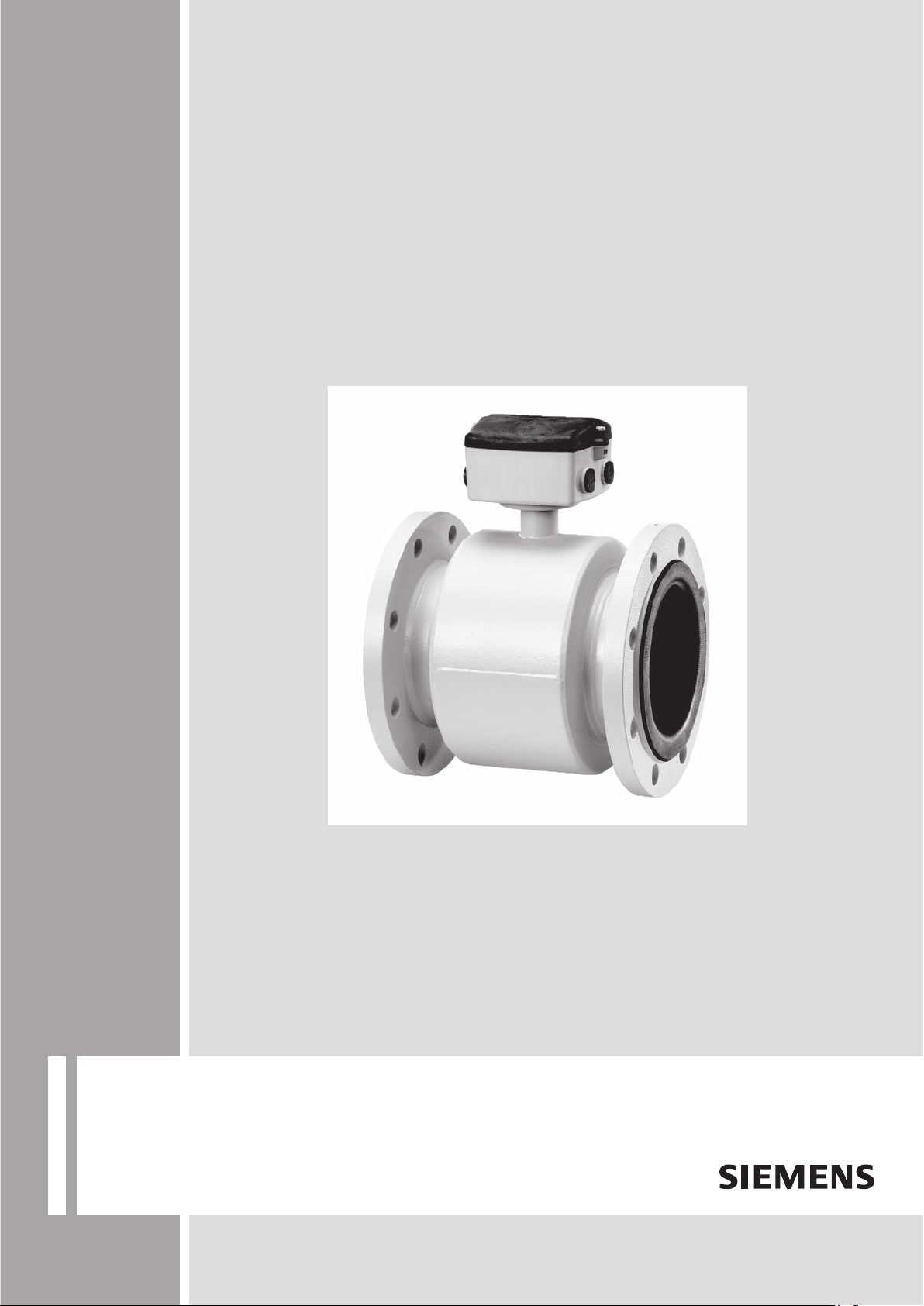

SITRANS F M MAG 5100 W

Operating Instructions • 11/2010

SITRANS F

SITRANS F

SITRANS F

Electromagnetic Flowmeters

SITRANS F M MAG 5100 W

Operating Instructions

Introduction

Safety notes

Description

Installing/Mounting

Connecting

Service and maintenance

Troubleshooting/FAQs

Technical data

Appendix

1

2

3

4

5

6

7

8

A

Electromagnetic sensor type SITRANS F M MAG

5100 W for use with transmitter types SITRANS F M

MAG 5000/6000/6000I

11/2010

A5E03063678-02

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG order number: A5E03063678 Copyright © Siemens AG 2010.

Industry Sector Ⓟ 11/2010 Technical data subject to change

Postfach 48 48

90026 NÜRNBERG

GERMANY

Table of contents

1 Introduction................................................................................................................................................ 5

1.1 Items supplied................................................................................................................................5

1.2 History............................................................................................................................................5

1.3 Further Information ........................................................................................................................6

2 Safety notes............................................................................................................................................... 7

2.1 Laws and directives .......................................................................................................................7

2.2 Installation in hazardous area........................................................................................................9

2.3 Certificates ...................................................................................................................................10

3 Description............................................................................................................................................... 11

3.1 System components ....................................................................................................................11

3.2 Theory of operation......................................................................................................................12

4 Installing/Mounting................................................................................................................................... 15

4.1 Installation safety precautions......................................................................................................15

4.2 Determining a location .................................................................................................................16

4.3 Orienting the sensor.....................................................................................................................18

4.4 Mounting ......................................................................................................................................19

4.5 Potential equalization...................................................................................................................21

5 Connecting .............................................................................................................................................. 23

5.1 Remote installation ......................................................................................................................24

5.2 Installation check .........................................................................................................................26

5.3 Potting..........................................................................................................................................26

5.4 Direct burial..................................................................................................................................28

6 Service and maintenance ........................................................................................................................ 29

6.1 Maintenance.................................................................................................................................29

6.2 Recalibration ................................................................................................................................29

6.3 Transportation/storage.................................................................................................................29

Unit repair.....................................................................................................................................30

6.4

6.5 Technical support.........................................................................................................................30

6.6 Return procedures .......................................................................................................................31

7 Troubleshooting/FAQs............................................................................................................................. 33

7.1 Sensor check ...............................................................................................................................33

7.2 Fluctuating process values ..........................................................................................................35

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

3

Table of contents

8 Technical data ......................................................................................................................................... 37

8.1 MAG 5100 W............................................................................................................................... 37

8.2 Cable data................................................................................................................................... 40

8.3 Effect of temperature on work

ing pres

sure................................................................................. 41

8.4 Process fluid conductivity............................................................................................................ 42

8.5 Liner selection ............................................................................................................................. 43

8.6 Electrode selection...................................................................................................................... 43

8.7 Sizing tables................................................................................................................................ 44

8.8 Dimensions and weight............................................................................................................... 46

A Appendix.................................................................................................................................................. 51

A.1 Flange mating dimensions (metric)............................................................................................. 51

A.2 Factory settings........................................................................................................................... 53

A.3 Coil resistance............................................................................................................................. 55

A.4 Ordering ...................................................................................................................................... 57

Glossary .................................................................................................................................................. 59

Index........................................................................................................................................................ 61

SITRANS F M MAG 5100 W

4 Operating Instructions, 11/2010, A5E03063678-02

Introduction

These instructions contain all the information you need for using the device.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it as well as service and

1.1 Items supplied

maintenance engineers.

Note

It is the responsibility of the customer that the instructions and directions provi

manual are read, understood and followed by the relevant personnel before installing the

device.

SITRANS F M MAG 5100 W

Calibration report

SITRANS F M literature CD

Quick Start guide

1

ded in the

1.2 History

The contents of these instructions are regularly reviewed and corrections are included in

subsequent editions. We welcome all suggestions for improvement.

The following table shows the most important changes in the documentation compared to

each previous edition.

Edition Remarks

11/2010 Minor updates

07/2010 First edition

Replaces MAG 5100 W part of SITRANS F M Handbook (A5E02435647) and MAG 5100

W instruction (A5E00718677)

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

5

Introduction

1.3 Further Information

1.3 Further Information

The contents of these Operating Instructions shall not become part of or modify any prior or

existing agreement, commitment or legal relationship. All obligations on the part of Siemens

AG are contained in the respective sales contract which also contains the complete and

solely applicable warranty conditions. Any statements contained herein do not create new

warranties or modify the existing warranty.

Product information on the Internet

The Operating Instructions are available on the CD-ROM shipped with the device, and on

the Internet on the Siemens homepage, where further information on the range of SITRANS

F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flowdocumentation

Worldwide contact person

If you need more information or have particular problems not covered sufficiently by the

operating instructions, please get in touch with your contact person. You can find contact

information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner

See also

Technical support (Page 30)

)

)

SITRANS F M MAG 5100 W

6 Operating Instructions, 11/2010, A5E03063678-02

Safety notes

2.1 Laws and directives

CAUTION

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance. Only qualified personnel should

install or operate this instrument.

Note

Alterations to the product, including opening or improper repairs of the product, are not

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2

General requirements

Installation of the equipment must comply with national regulations.

Instrument safety standards

The device has been tested at the factory, based on the safety requirements. In order to

maintain this condition over the expected life of the device the requirements described in

these Operating Instructions must be observed.

CAUTION

Material compatibility

Siemens Flow Instruments can provide assistance with the selection of wetted sensor

parts. However, the full responsibility for the selection rests with the customer and Siemens

Flow Instruments can take no responsibility for any failure due to material incompatibility.

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

7

Safety notes

2.1 Laws and directives

CE marked equipment

All meters carry either a CE mark or a CE mark followed by eg.200

● CE200: This indicates that the product conforms to:

– PED 97/23/EC

– LVD 2006/95/EC

– EMC 2004/108/EC

● CE: This indicates that the product conforms to:

– LVD 2006/95/EC

– EMC 2004/108/EC

Compliance with PED directive

"Pressure Equipment Directive" (PED) is mandatory for all pressure equipment sold within

the EU and EFTA.

Siemens Flow Instruments products confirms to PED by following the tables below.

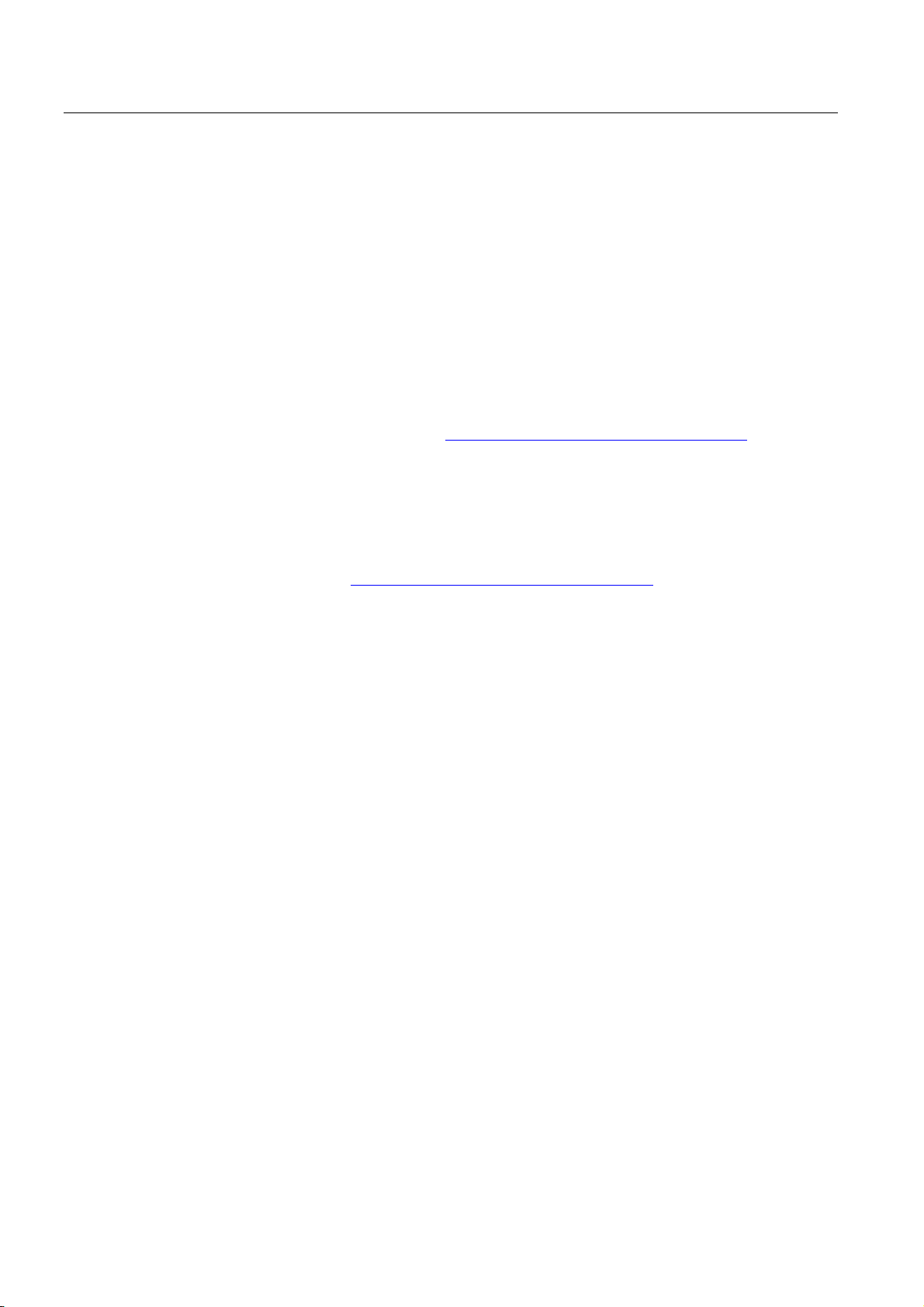

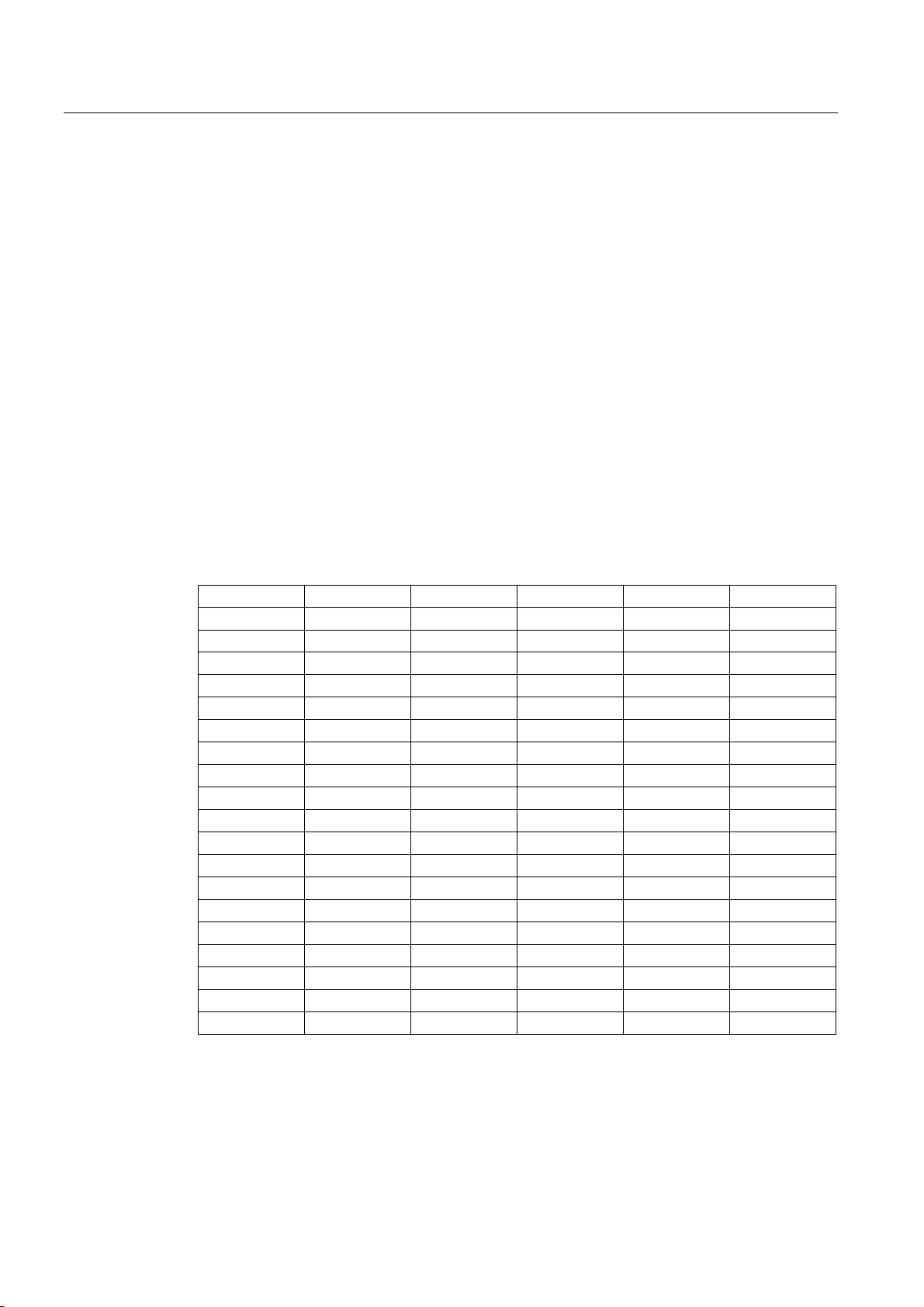

Table 2- 1 MAG 5100 W (7ME6580 only DN15 ... 600 (½" ... 24"))

Flange mm PN 10 PN 16 PN 40 150 lb 300 lb

15 N/A N/A SEP SEP N/A

25 N/A N/A SEP SEP N/A

40 N/A N/A SEP SEP N/A

50 N/A SEP N/A SEP N/A

65 N/A SEP N/A SEP N/A

80 N/A SEP N/A SEP N/A

100 SEP SEP N/A SEP N/A

125 N/A SEP N/A PED N/A

150 N/A PED N/A PED N/A

200 SEP PED N/A PED N/A

250 LVD PED N/A PED N/A

300 LVD PED N/A PED N/A

350 LVD PED N/A PED N/A

400 LVD PED N/A PED N/A

450 LVD PED N/A PED N/A

500 LVD PED N/A PED N/A

600 LVD PED N/A PED N/A

700 LVD PED* N/A N/A PED

750 N/A N/A N/A N/A PED

SITRANS F M MAG 5100 W

8 Operating Instructions, 11/2010, A5E03063678-02

Safety notes

2.2 Installation in hazardous area

800 LVD PED* N/A N/A PED

900 LVD PED* N/A N/A PED

1000 LVD PED* N/A N/A PED

1050 N/A N/A N/A N/A PED

1100 N/A N/A N/A N/A PED

1200 LVD PED* N/A N/A PED

The key to the tables is as follows:

PED Product covered by PED and only available as fully PED-conforming

PED* Product covered by PED but available as either conforming or non-conforming to

PED

SEP Excluded from PED under Sound Engineering Practice

LVD Excluded from PED under the Low Voltage Directive

2.2 Installation in hazardous area

WARNING

Equipment used in hazardous areas must be approved for use in hazardous area and

marked accordingly. It is required that the special conditions for safe use provided in the

manual and in the FM / CSA certificates are followed!

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

9

Safety notes

2.3 Certificates

Hazardous area approvals

The device is approved for use in hazardous area and has the following approvals:

● MAG 5100 W DN 15 ... 1200: FM / CSA Class I, Div. 2

WARNING

Make sure the hazardous area approval is suitable for the environment in which the

device will be installed.

WARNING

All approvals are based on non-flammable processes only!

WARNING

Potential equalization

In operation, the output is earthed through the conductive medium being measured and

therefore potential equalisation is necessary throughout the hazardous area.

The apparatus housing shall be connected to the potential equalising conductor in the

hazardous area.

WARNING

Laying of cables

Cables for use in hazardous area must satisfy the requirements for having a proof

voltage < AC 500 V applied between the conductor/ground, conductor/shield and

shield/ground.

Connect the devices that are operated in hazardous areas as per the stipulations

applicable in the country of operation.

2.3 Certificates

Certificates are posted on the Internet and on the documentation CD-ROM shipped with the

device.

See also

Technical data (Page 37)

Certificates on the Internet (http://www.siemens.com/processinstru

mentation/certificates)

SITRANS F M MAG 5100 W

10 Operating Instructions, 11/2010, A5E03063678-02

Description

The main applications of the SITRANS F M electromagnetic flow sensors can be found in the

following fields:

● Process industry

● Chemical industry

● Steel industry

● Mining

● Utility

● Power generation & distribution

● Oil & gas / HPI

● Water & waste water

● Pulp & paper

3.1 System components

3

The SITRANS F M USM II flowmeter system includes:

● Transmitter (types: SITRANS F M MAG 5000/6000 or MAG 6000 I)

● Sensor (types: SITRANS F M MAG 1100/1100F, MAG 3100/3100 P or MAG 5100 W)

● Communication module (optional) (types: HART, PROFIBUS PA/DP, MODBUS RTU RS

485, Foundation Fieldbus H1, Devicenet)

● SENSORPROM memory unit

Communication solutions

The SITRANS F USM II range of add on modules, presently including HART, Foundation

Fieldbus. MODBUS RTU RS 485, PROFIBUS PA / DP and Devicenet, are all applicable with

the SITRANS F M MAG 6000 transmitter.

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

11

Description

3.2 Theory of operation

The SITRANS F M MAG 5100 W sensor housing and flanges are designed in carbon steel

and terminal box in fibre glass reinforced polyamide. Measuring pipe is made of stainless

steel (AISI 304) and liners are available in NBR Hard Rubber, Ebonite Hard Rubber, or

EPDM, which makes the sensor highly resistant to a wide range of chemicals. Electrodes are

made of Hastelloy.

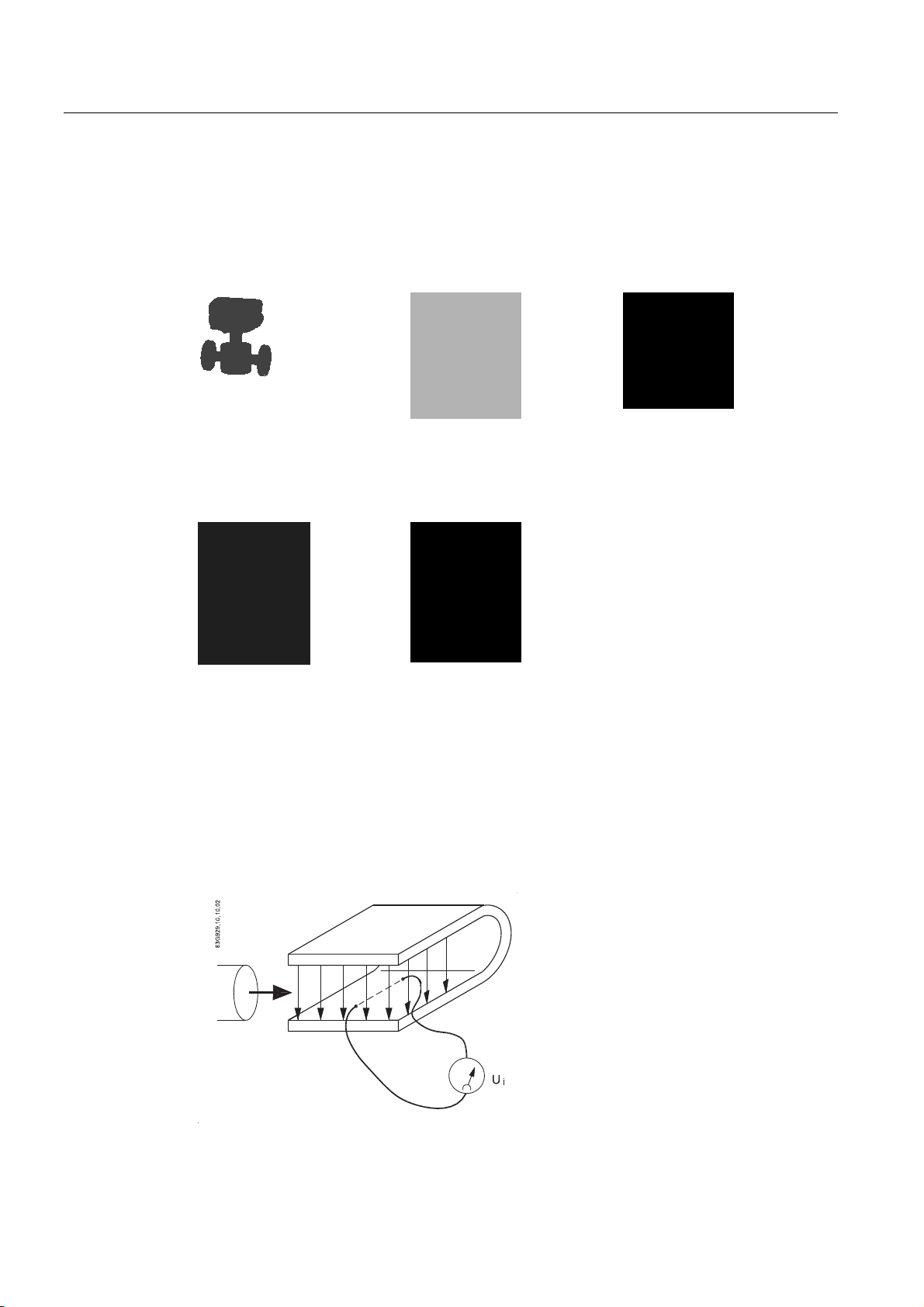

MAG 5100W DN15 ... 40 MAG 5100W DN50 ... 300 MAG 5100W

MAG 5100W compact

installation with MAG

5000/6000 IP67

The sensors carry a wide range of approvals, see Technical data (Page 37).

3.2 Theory of operation

MAG 5100W compact

installation with MAG 6000 I

DN350 ... 1200

(7ME6520)

MAG 5100W DN25 ... 2000

(7ME6580)

The flow measuring principle is based on Faraday’s law of electromagnetic induction.

0DJQHWLF)LHOG

)ORZ

SITRANS F M MAG 5100 W

12 Operating Instructions, 11/2010, A5E03063678-02

Description

3.2 Theory of operation

Ui = When an electrical conductor of length L is moved at velocity v, perpendicular to the

lines of flux through a magnetic field of strength B, the voltage Ui is induced at the ends of

the conductor

= L x B x v

U

i

● Ui = Induced voltage

● L = Conductor length = Inner pipe diameter = k

● B = Magnetic field strength = k

● v = Velocity of conductor (media)

● k = k

Ui = k x v, the electrode signal is directly proportional to the fluid velocity

Operating principle

The coil current module generates a pulsating magnetizing current that drives the coils in the

sensor. The current is permanently monitored and corrected. Errors or cable faults are

registered by the self-monitoring circuit.

Input circuit amplifies the flow-proportional induced voltage signal from the electrodes. The

input impedance is extremely high: >10

conductivities as low as 5 µS/cm. Measuring errors due to cable capacitance are eliminated

due to active cable screening.

Digital signal processor converts the analog flow signal to a digital signal and suppresses

electrode noise through a digital filter. Inaccuracies in the transmitter as a result of long-term

drift and temperature drift are monitored and continuously compensated for via the selfmonitoring circuit. The analog to digital conversion takes place in an ultra low noise ASIC

with 23 bit signal resolution. This has eliminated the need for range switching. The dynamic

range of the transmitter is therefore unsurpassed with a turn down ratio of minimum 3000:1.

x k2

1

1

2

14

Ω which allows flow measurements on fluids with

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

13

Description

3.2 Theory of operation

SITRANS F M MAG 5100 W

14 Operating Instructions, 11/2010, A5E03063678-02

Installing/Mounting

SITRANS F flowmeters with minimum IP67/NEMA 4X enclosure rating are suitable for inand outdoor installations.

● Make sure that pressure and temperature specifications indicated on the device

nameplate / label will not be exceeded.

4.1 Installation safety precautions

WARNING

Installation in hazardous location

Special requ

transmitter. See "Installation in hazardous area" (Page 9)

WARNING

In applications with working pressures/media that can be dangerous to people,

surroundings, equipment or others in case of pipe fracture, we recommend that special

precautions such as special placement, shielding or installation of a security guard or a

security valve are taken when the sensor is mounted.

irements apply to the location and interconnection of sensor and

4

● Ensure that stresses and loading caused by e.g. earthquakes, traffic, high winds and fire

damage if appropriate are taken into account during installation.

● Ensure that the flowmeter is installed such that it does not act as a focus for pipeline

stresses. External loadings are not taken into account in the flowmeter design.

● Provide adequate protection to minimise any risk of contact with hot surfaces.

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

WARNING

Prevent personal injuries by assuring that operation belo

place, if working with vacuum or fluids boiling readily.

w pressure guards cannot take

15

Installing/Mounting

4.2 Determining a location

4.2 Determining a location

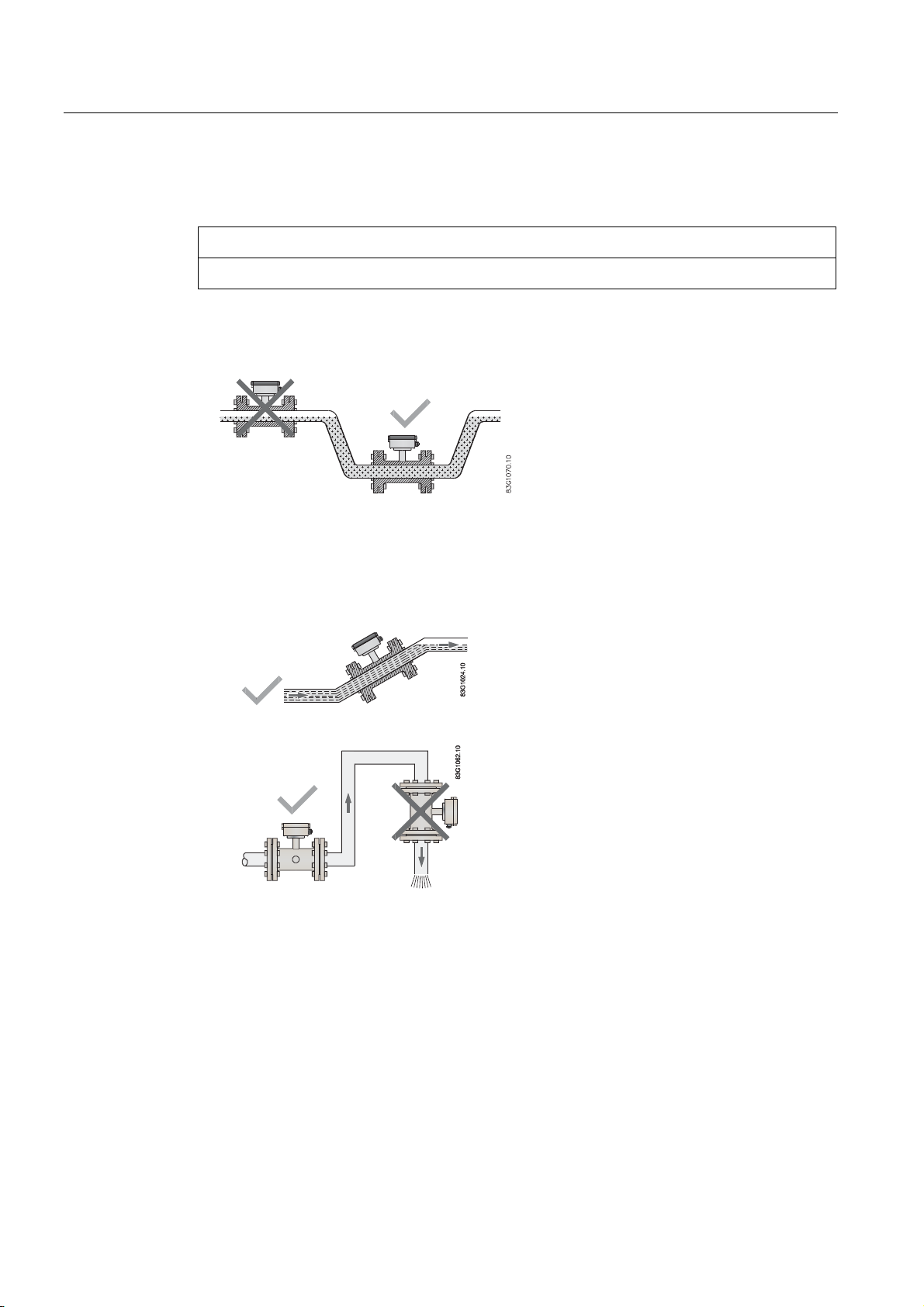

NOTICE

The sensor must always be completely filled with liquid.

● Locate the the flowmeter in u-shaped pipes if pipes are only partially filled or have free

outlet

Figure 4-1 Correct installation in U-tube

● Avoid the following installations

– Installation at the highest point in the pipe system

– Installation in vertical pipes with free outlet

Figure 4-2 Correct installation with filled pipes

Figure 4-3 Correct installation at low point in system before outlet

Inlet and outlet conditions

To achieve accurate flow measurement it is essential to have straight lengths of inlet and

outlet pipes and a certain distance to pumps and valves.

It is also important to centre the flowmeter in relation to pipe flanges and gaskets.

SITRANS F M MAG 5100 W

16 Operating Instructions, 11/2010, A5E03063678-02

Installing/Mounting

4.2 Determining a location

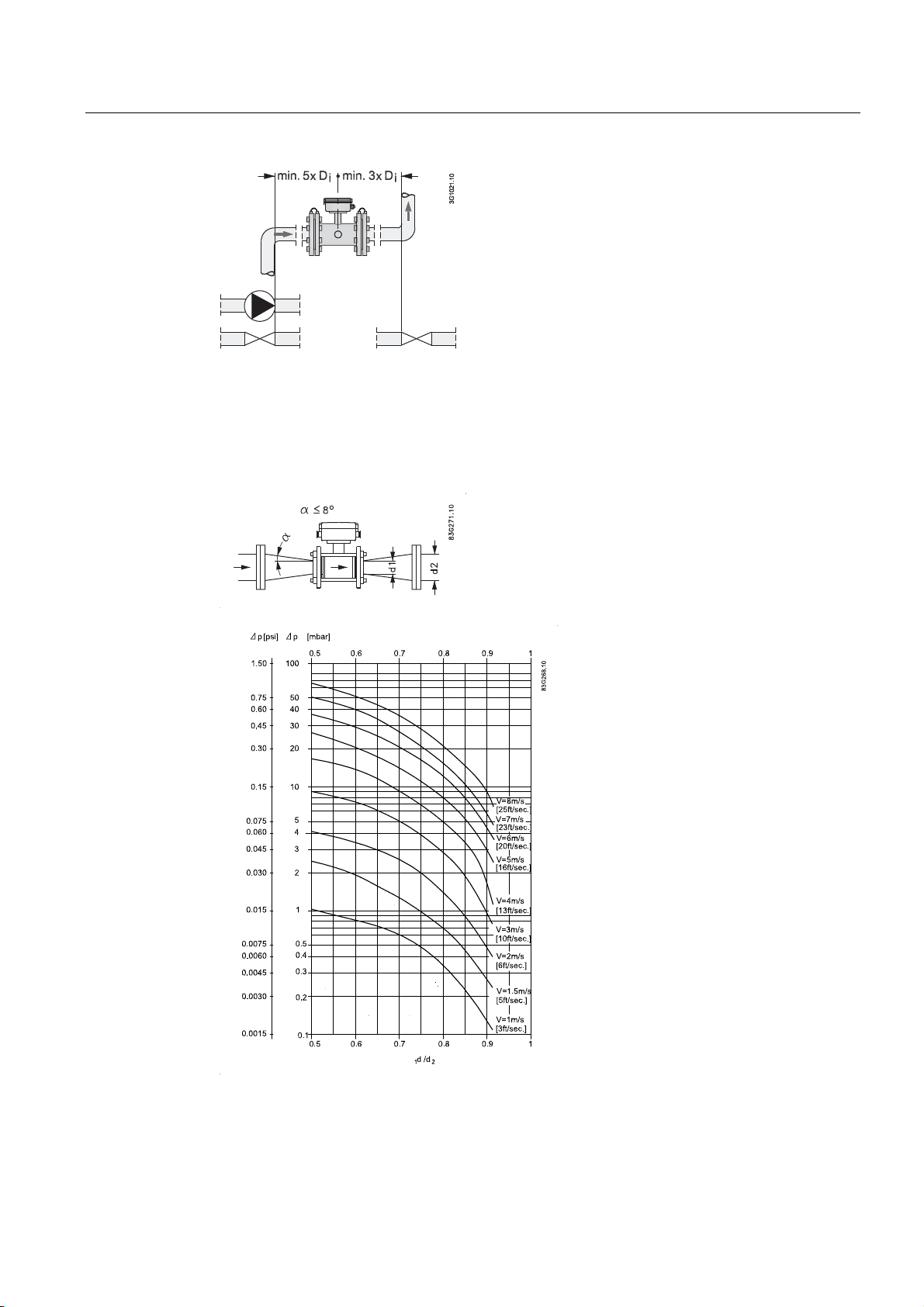

Figure 4-4 Inlet and outlet conditions

Installation in large pipes

The flowmeter can be installed between two reducers (e.g. DIN 28545). At 8° the following

pressure drop curves apply. The curves are applicable to water.

Example:

A flow of 3 m/s (V) in a sensor with a diameter reduction from DN 100 to DN 80 (d

gives a pressure drop of 2.9 mbar.

SITRANS F M MAG 5100 W

Operating Instructions, 11/2010, A5E03063678-02

= 0.8)

1/d2

17

Installing/Mounting

4.3 Orienting the sensor

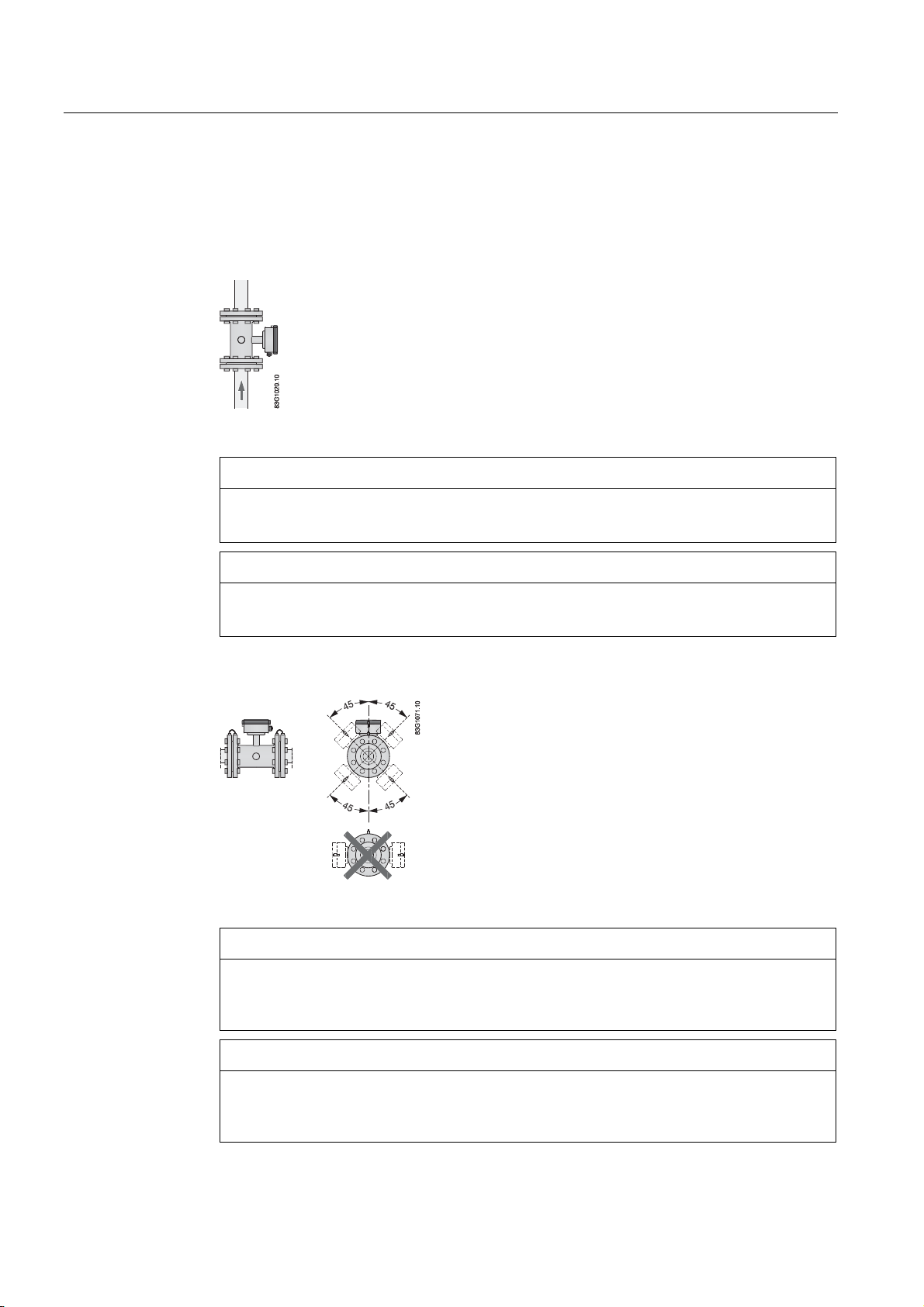

4.3 Orienting the sensor

The sensor operates in all orientations, but Siemens has the following recommendations:

● Vertical installation with an upwards flow

Figure 4-5 Vertical orientation, upwards flow

CAUTION

Abrasive liquids / liquids containing solid particles

A vertical installation minimizes wear and deposits in the sensor

NOTICE

Gas/air bubbles in the liquid

A vertical installation minimizes any negative effect of gas/air bubbles in the liquid

● Horizontal installation, terminal box upwards or downwards

Figure 4-6 Horizontal installation, various terminal box positions

CAUTION

Do NOT mount the sensor with the terminal box sideways

This will position the electrodes at the top where there is possibility for air bubbles and

at the bottom where there is possibility for mud, sludge, sand etc.

NOTICE

Empty pipe detection

For applications with empty pipe detection, the sensor can be tilted 45°, as shown

above.

SITRANS F M MAG 5100 W

18 Operating Instructions, 11/2010, A5E03063678-02

Loading...

Loading...