Siemens SITRANS F M MAG 5000 Blind, SITRANS F M MAG 5000 CT, SITRANS F M MAG 6000 Blind, SITRANS F M MAG 6000 CT, SITRANS F M MAG 5000 SV Operating Instructions Manual

...

Electromagnetic Flowmeters

SITRANS F M MAG 5000/6000

Operating Instructions • 01/2010

SITRANS F

SITRANS F

Flowmeters

SITRANS F M MAG 5000/6000

Operating Instructions

Introduction

Safety notes

Description

Installing/Mounting

Connecting

Commissioning

Service and maintenance

Functions

Alarm, error, and system

messages

Troubleshooting/FAQs

Technical data

Spare parts/Accessories

Menu diagrams

Appendix

1

2

3

4

5

6

7

8

9

10

11

12

A

B

Electromagnetic flow transmitter designed for use with

flow sensor types

MAG 1100/1100 F/3100/3100 P/5100 W

Compact and remote i

nstallation

01/2010

SFIDK.PS.026.G1.02

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG Ordernumber: A5E02338368 Copyright © Siemens AG 2010.

Industry Sector Ⓟ 01/2010 Technical data subject to change

Postfach 48 48

90026 NÜRNBERG

GERMANY

Table of contents

1 Introduction................................................................................................................................................ 7

1.1 Preface...........................................................................................................................................7

1.2 Items supplied................................................................................................................................7

1.3 History............................................................................................................................................8

1.4 Further Information ........................................................................................................................9

2 Safety notes............................................................................................................................................. 11

2.1 Laws and directives .....................................................................................................................11

2.2 Installation in hazardous location.................................................................................................12

3 Description............................................................................................................................................... 13

3.1 System components ....................................................................................................................13

3.2 Operating principle.......................................................................................................................13

3.3 Applications..................................................................................................................................13

3.4 Features.......................................................................................................................................14

3.5 MAG 5000/MAG 6000 versions ...................................................................................................15

4 Installing/Mounting................................................................................................................................... 17

4.1 Installation conditions...................................................................................................................18

4.2 MAG 5000/6000 compact ............................................................................................................20

4.3 Remote installation ......................................................................................................................22

4.4 MAG 5000/6000 CT.....................................................................................................................27

4.4.1 Installing hardware key ................................................................................................................27

4.4.2 Seal device...................................................................................................................................28

4.5 Turning transmitter/keypad ..........................................................................................................29

5 Connecting .............................................................................................................................................. 33

5.1 Electrical connection....................................................................................................................34

5.2 Connection of add-on modules....................................................................................................35

6 Commissioning ........................................................................................................................................ 37

MAG 5000/6000 Blind..................................................................................................................37

6.1

6.2 Local user interface......................................................................................................................38

6.3 Menu structure .............................................................................................................................39

6.4 Changing password .....................................................................................................................40

6.5 Changing basic settings...............................................................................................................40

6.6 Changing operator menu setup ...................................................................................................42

6.7 Changing language......................................................................................................................43

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

3

Table of contents

7 Service and maintenance ........................................................................................................................ 45

7.1 Transmitter check list .................................................................................................................. 45

7.2 Technical support........................................................................................................................ 46

7.3 Return procedures ...................................................................................................................... 48

7.4 Recalibration ............................................................................................................................... 48

8 Functions................................................................................................................................................. 49

8.1 Output settings ............................................................................................................................ 49

8.2 External input .............................................................................................................................. 50

8.3 Sensor characteristics................................................................................................................. 51

8.4 Reset mode................................................................................................................................. 52

8.5 Service mode .............................................................................................................................. 53

8.6 MAG 5000 CT and MAG 6000 CT settings................................................................................. 53

8.7 MAG 6000 SV ............................................................................................................................. 54

9 Alarm, error, and system messages ........................................................................................................ 55

9.1 Diagnostics.................................................................................................................................. 55

9.2 List of error numbers................................................................................................................... 57

10 Troubleshooting/FAQs............................................................................................................................. 59

11 Technical data ......................................................................................................................................... 61

11.1 Technical specifications .............................................................................................................. 61

11.2 Accuracy...................................................................................................................................... 64

11.3 Output characteristics ................................................................................................................. 66

11.4 Cable data................................................................................................................................... 68

11.5 Cable requirements..................................................................................................................... 68

12 Spare parts/Accessories.......................................................................................................................... 69

12.1 Ordering ...................................................................................................................................... 69

12.2 Accessories................................................................................................................................. 69

12.3 Spare parts

.................................................................................................................................. 70

12.4 Sun shield.................................................................................................................................... 71

A Menu diagrams........................................................................................................................................ 73

A.1 Overview MAG 5000/6000.......................................................................................................... 73

A.2 Overview MAG 5000/6000 CT.................................................................................................... 75

A.3 Change password ....................................................................................................................... 76

A.4 Basic settings.............................................................................................................................. 77

A.5 Operator menu setup .................................................................................................................. 78

A.6 Language mode .......................................................................................................................... 79

A.7 Current output ............................................................................................................................. 79

SITRANS F M MAG 5000/6000

4 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Table of contents

A.8 Digital output - pulse ....................................................................................................................79

A.9 Digital output - frequency.............................................................................................................80

A.10 Error level.....................................................................................................................................80

A.11 Error number................................................................................................................................80

A.12 Direction/limit................................................................................................................................81

A.13 Batch ............................................................................................................................................82

A.14 Cleaning .......................................................................................................................................82

A.15 External input ...............................................................................................................................83

A.16 Sensor characteristics..................................................................................................................84

A.17 Reset mode..................................................................................................................................85

A.18 Reset mode - MAG 6000 SV .......................................................................................................86

A.19 Service mode ...............................................................................................................................87

A.20 Product identity ............................................................................................................................88

A.21 HART module...............................................................................................................................89

B Appendix.................................................................................................................................................. 91

B.1 Factory settings............................................................................................................................91

B.2 Sensor dependent factory settings for M

AG 5000/6000 Blind.....................................................93

B.3 Approvals/certificates...................................................................................................................94

B.3.1 Certificates ...................................................................................................................................94

Index........................................................................................................................................................ 95

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

5

Table of contents

SITRANS F M MAG 5000/6000

6 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Introduction

1.1 Preface

These instructions contain all the information you need for using the device.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it as well as service and

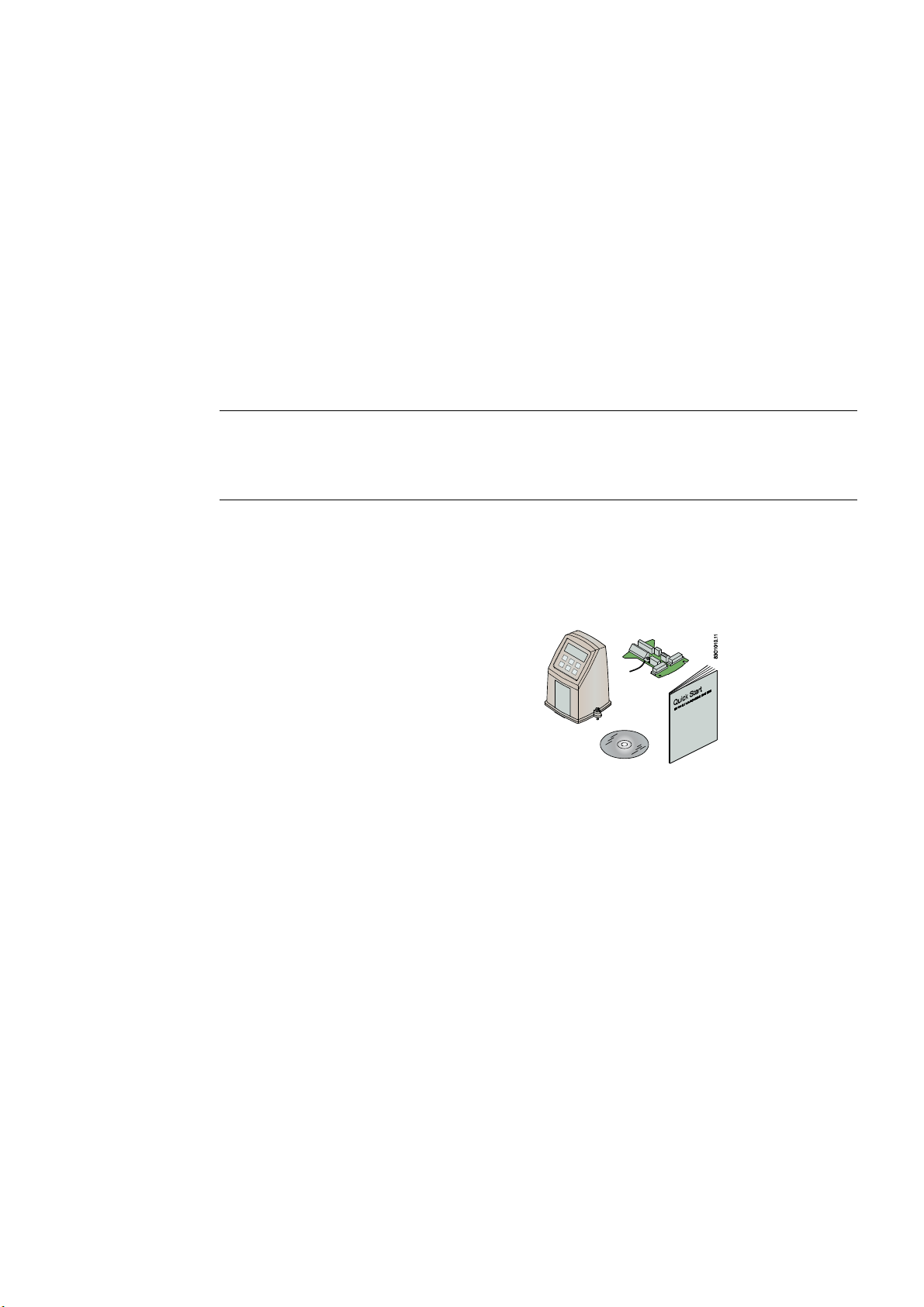

1.2 Items supplied

maintenance engineers.

Note

It is the responsibility of the customer that the instructions and directions provided in the

manual are read, understood and followed by the relevant personnel before installing the

device.

• SITRANS F M MAG 5000/6000

transmitter

• Calibration report

• SITRANS F literature CD

• Quick start guide

1

Inspection

1. Check for mechanical damage due to possible improper handling during shipment. All

claims for damage are to be made promptly to the shipper.

2. Make sure the scope of delivery, and the information on the type plate corresponds to the

ordering information

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

7

Introduction

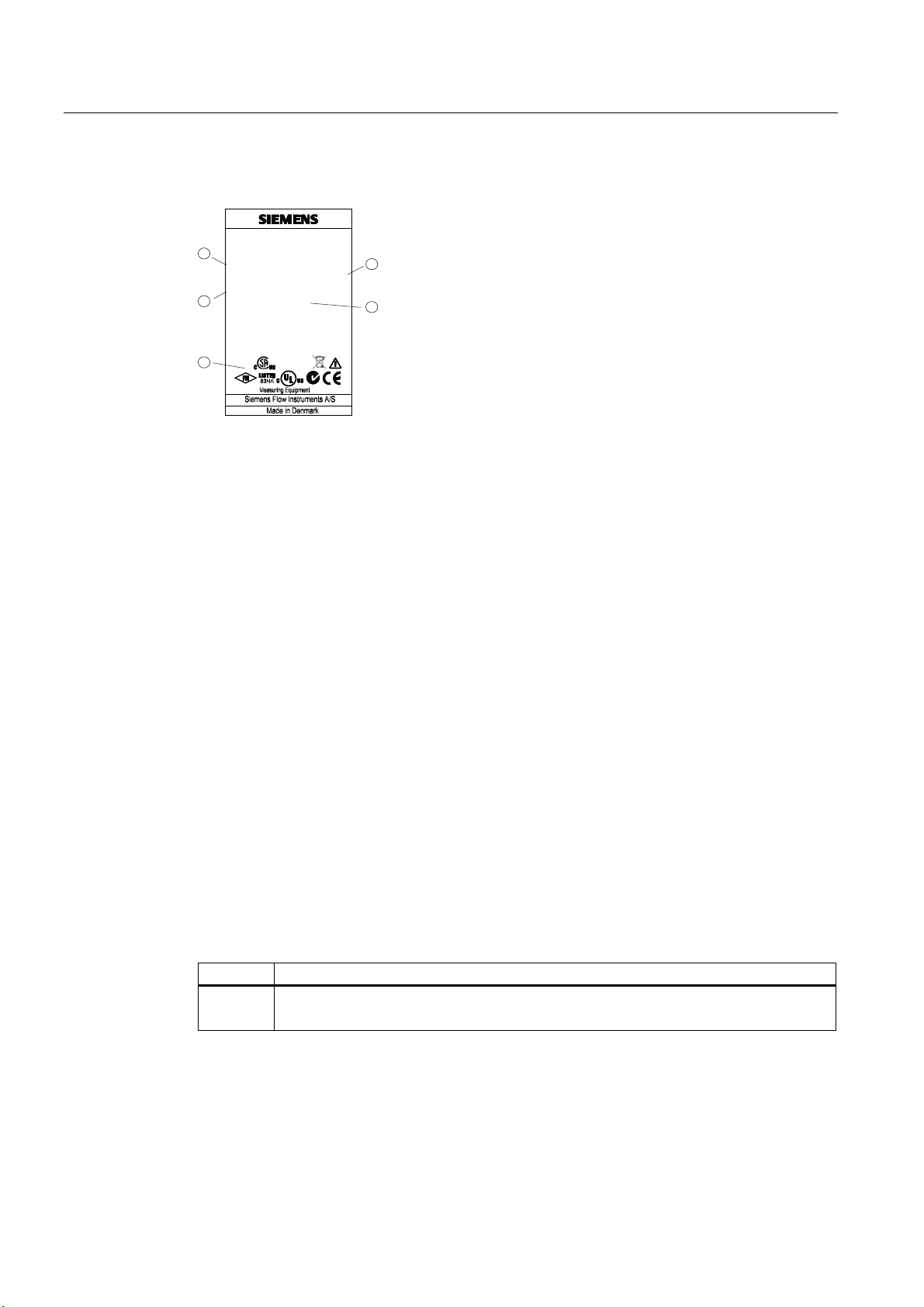

83G1121.10

SITRANS F M MAGFLO

MAG 6000

Maximum teghtening torque 4 ft-lb

No direct sunlight exposure

Class 1, Division 2, Group A, B, C, D

Code no.:

Supply:

IP:

Tamb.:

7ME6920-1AA10-1AA0

115/230V AC 50-60Hz 17VA

67 / NEMA 6

-20° to +60° C

1.3 History

Device identification

1

3

5

① Code number

② Power supply

③ Enclosure rating

④ Ambient temperature

⑤ Approvals

Figure 1-1 MAG 5000/6000 type plate

1.3 History

This document describes:

● SITRANS F MAG 5000 and MAG 6000 transmitters (standard version).

SITRANS F M MAGFLO

MAG 6000

Code no.:

7ME6920-1AA10-1AA0

Supply:

115/230V AC 50-60Hz 17VA

IP:

67 / NEMA 6

Tamb.:

-20° to +60° C

Maximum teghtening torque 4 ft-lb

No direct sunlight exposure

Class 1, Division 2, Group A, B, C, D

83G1121.10

2

4

● Optional versions:

– MAG 5000 Blind and MAG 6000 Blind

– MAG 5000 CT and MAG 6000 CT

– MAG 6000 SV

Documentation history

The contents of these instructions are regularly reviewed and corrections are included in

subsequent editions. We welcome all suggestions for improvement.

The following table shows the most important changes in the documentation compared to

each previous edition.

Edition Remarks

01

01/2010

SITRANS F M MAG 5000/6000

8 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

First edition

Introduction

1.4 Further Information

1.4 Further Information

The contents of these Operating Instructions shall not become part of or modify any prior or

existing agreement, commitment or legal relationship. All obligations on the part of Siemens

AG are contained in the respective sales contract which also contains the complete and

solely applicable warranty conditions. Any statements contained herein do not create new

warranties or modify the existing warranty.

Product information on the Internet

The Operating Instructions are available on the CD-ROM shipped with the device, and on

the Internet on the Siemens homepage, where further information on the range of SITRANS

F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flowdocumentation

Worldwide contact person

If you need more information or have particular problems not covered sufficiently by the

operating instructions, please get in touch with your contact person. You can find contact

information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner

)

)

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

9

Introduction

1.4 Further Information

SITRANS F M MAG 5000/6000

10 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Safety notes

2.1 Laws and directives

General requirements

CAUTION

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance. Only qualified personnel should

install or operate this instrument.

Note

Alterations to the product, including opening or improper repairs of the product, are not

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

Installation of the equipment must comply with national regulations. For example EN 6007914 for the European Community.

2

Instrument safety standards

The device has been tested at the factory, based on the safety requirements. In order to

maintain this condition over the expected life of the device the requirements described in

these Operating Instructions must be observed.

CE marked equipment

The CE-mark symbolizes the compliance of the device with the following guidelines:

● EMC-guideline 89/336/EEC

● Low voltage guideline 73/23/EWG

● ATEX Directive 94/9/EG

● CT: (MI-001) Directive 2004/22/EC

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

11

Safety notes

2.2 Installation in hazardous location

2.2 Installation in hazardous location

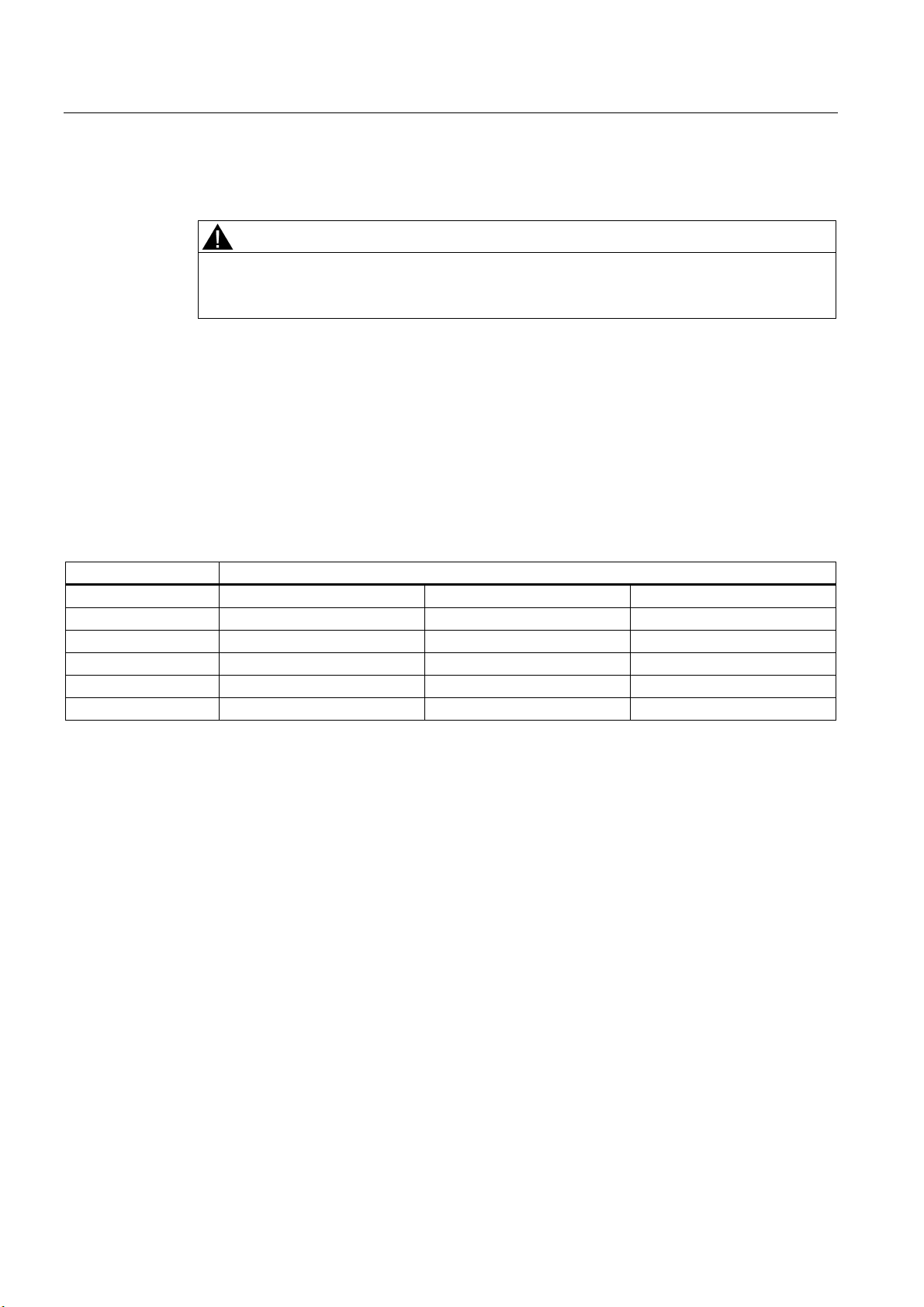

WARNING

Equipment used in hazardous areas must be Ex-approved and marked accordingly. It is

required that the special conditions for safe use provided in the manual and in the Ex

certificate are followed!

Ex approvals

CSA Class I, Division 2, Groups A, B, C and D. Code T5 for an ambient temperature of

+60ºC.

FM Class I, Division 2, Groups A, B, C and D and Class I, Zone 2, Group IIC indoor/outdoor

Type IP67 hazardous (classified) locations

Temperature specifications for Ex use

Temperature class Ambient temperature [°C]

-40...+40 -40...+50 -40...+60

T2 180 (process temperature) - T3 165 (process temperature) 140 (process temperature) T4 100 (process temperature) 100 (process temperature) 80 (process temperature)

T5 65 (process temperature) 65 (process temperature) 65 (process temperature)

T6 50 (process temperature) 50 (process temperature) 50 (process temperature)

EX requirements

It is required that:

● Electrical connections are in accordance with Elex V (VO in explosion hazardous areas)

and EN60079-14 (Installing Electrical Systems in Explosion Hazardous Areas).

● The protective cover over the power supply is properly installed. For intrinsically safe

circuits the connection area can be opened.

● Appropriate cable connectors are used for the output cicuits: intrinsically safe: blue, nonintrinsically safe: black

● Sensor and transmitter are connected to the potential equalization. For intrinsically safe

output circuits potential equalization must be maintained along the entire connection path.

● Sensor insulation thickness is max. 100mm (only insulated sensors).

● EN50281-1-2 is considered for installation in areas with combustible dust.

● When protective earth (PE) is connected, no potential difference between the protective

earth (PE) and the potential equalization (PA) can exist, even during a fault condition.

SITRANS F M MAG 5000/6000

12 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Description

3.1 System components

A SITRANS F M MAG 5000/6000 flowmeter system includes:

● Transmitter (type SITRANS F M MAG 5000/6000)

● Sensor (types: SITRANS F MAG 1100/1100F/3100/3100 P/5100 W)

● Communication module (optional) (types: HART, PROFIBUS PA/DP, MODBUS RTU RS

485, Foundation Fieldbus H1, Devicenet)

● SENSORPROM memory unit

Communication solutions

The SITRANS F USM II range of add on modules, presently including HART, Foundation

Fieldbus. MODBUS RTU RS 485, PROFIBUS PA / DP and Devicenet, are all applicable with

the SITRANS F M MAG 6000 transmitter.

3.2 Operating principle

3

The transmitters are microprocessor-based with a built-in alphanumeric display in several

languages. The flow measuring principle is based on Faraday's law of electromagnetic

induction. Magnet coils mounted diametrically on the measuring pipe generate a pulsed

electromagnetic field. The liquid flowing through this electromagnetic field induces a voltage.

The transmitters evaluate the signals from the associated electromagnetic sensors, convert

the signals into appropriate standard signals such as 4 ... 20 mA, and also fulfil the task of a

power supply unit providing the magnet coils with a constant current.

The transmitter consists of a number of function blocks which convert the sensor voltage into

flow readings.

3.3 Applications

The DC-powered magnetic flowmeters are suitable for measuring the flow of almost all

electrically conductive liquids, pastes, and slurries with max. 40% solids. The main

applications can be found in the following sectors:

● Water and waste water

● Chemical and pharmaceutical industries

● Food & beverage industry

● Mining, aggregates and cements industries

● Pulp and paper industry

● Steel industry

● Power generation; utility and chilled water industry

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

13

Description

3.4 Features

3.4 Features

Power supply

2 different types of power supply are available. A 12 ... 24 V AC/DC and a 115 ... 230 V AC

switch mode type.

Coil current module generates a pulsating magnetizing current that drives the coils in the

sensor. The current is permanently monitored and corrected. Errors or cable faults are

registered by the self-monitoring circuit.

Input circuit amplifies the flow-proportional signal from the electrodes. The input impedance

is extremely high: >10

low as 5 µS/cm. Measuring errors due to cable capacitance are eliminated due to active

cable screening.

Digital signal processor converts the analog flow signal to a digital signal and suppresses

electrode noise through a digital filter. Inaccuracies in the transmitter as a result of long-term

drift and temperature drift are monitored and continuously compensated for via the selfmonitoring circuit. The analog to digital conversion takes place in an ultra low noise ASIC

with 23 bit signal resolution. This has eliminated the need for range switching. The dynamic

range of the transmitter is therefore unsurpassed with a turn down ratio of minimum 3000:1.

CAN communication

The transmitter operates internally via an internal CAN communication bus. Signals are

transferred through a signal conditioner to the display module and to/from internal/external

option modules and the dialog module.

Dialog module

The display unit consists of a 3-line display and a 6-key keypad. The display shows a flow

rate or a totalizer value as a primary reading.

Output module

The output module converts flow data to analog, digital and relay outputs. The outputs are

galvanically isolated and can be individually set to suit a particular application.

14

Ω which allows flow measurements on fluids with conductivities as

SITRANS F M MAG 5000/6000

14 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Description

3.5 MAG 5000/MAG 6000 versions

3.5 MAG 5000/MAG 6000 versions

The transmitters are designed in various versions and offer high performance and easy

installation, commissioning and maintenance.

Standard version

The standard version is an IP67 version for compact or remote installation. Its robust design

ensures a long lifetime if installed outdoors.

Blind version

This version carries all the normal MAG 5000/6000 features, except those associated with

the display and keypad.

Both current and digital outputs are available.

Factory setting of current output in unit is switched off when delivered.

CT version

The MAG 5000/6000 CT version is a custody transfer-approved transmitter.

It is approved accordi

ng to:

● Cold water pattern approval (MAG 5000/6000 CT):

– PTB

– OIML R 49

● Cold water pattern approval (MAG 6000 CT only):

– MI-001

● Hot water pattern approval (MAG 6000 CT only):

– PTB

● Heat meter pattern approval (MAG 6000 CT only):

– OIML R 75

● Other media than water (MAG 6000 CT only):

– OIML R 117

SV version (MAG 6000 only)

This version is identical to the standard MAG 6000 transmitters except for the following

additional functions:

● Zero point adjustment

● Adjustable excitation frequency up to 44 Hz

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

15

Description

3.5 MAG 5000/MAG 6000 versions

SITRANS F M MAG 5000/6000

16 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Installing/Mounting

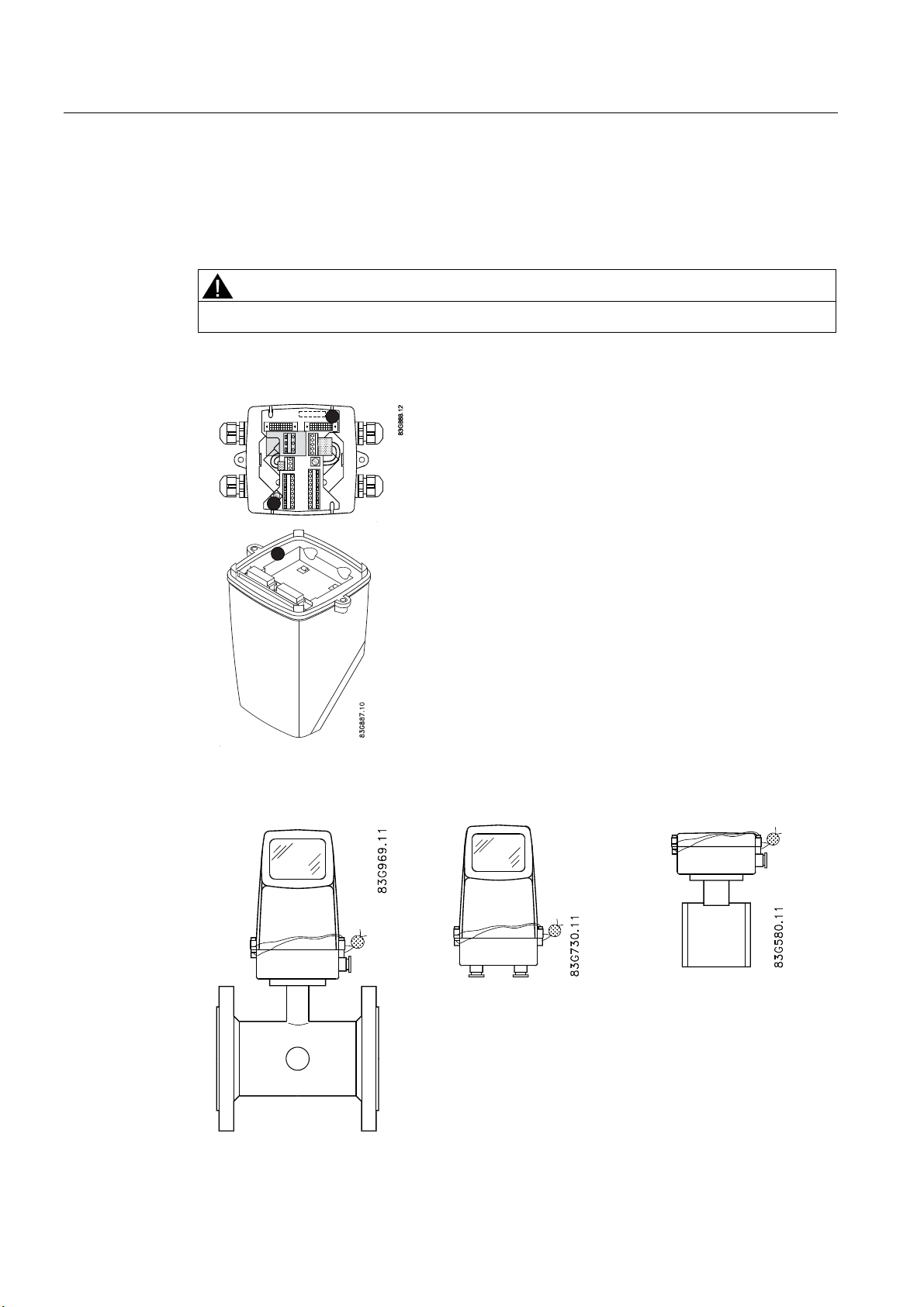

This chapter describes how to install the flowmeter in the compact version as well as in the

remote version.

The transmitter is delivered ready for mounting on the sensor. The transmitter is delivered

with a compression plate ready for mounting on the sensor. No further assembling is

necessary.

The transmitter can be installed either compact on the sensor or remote.

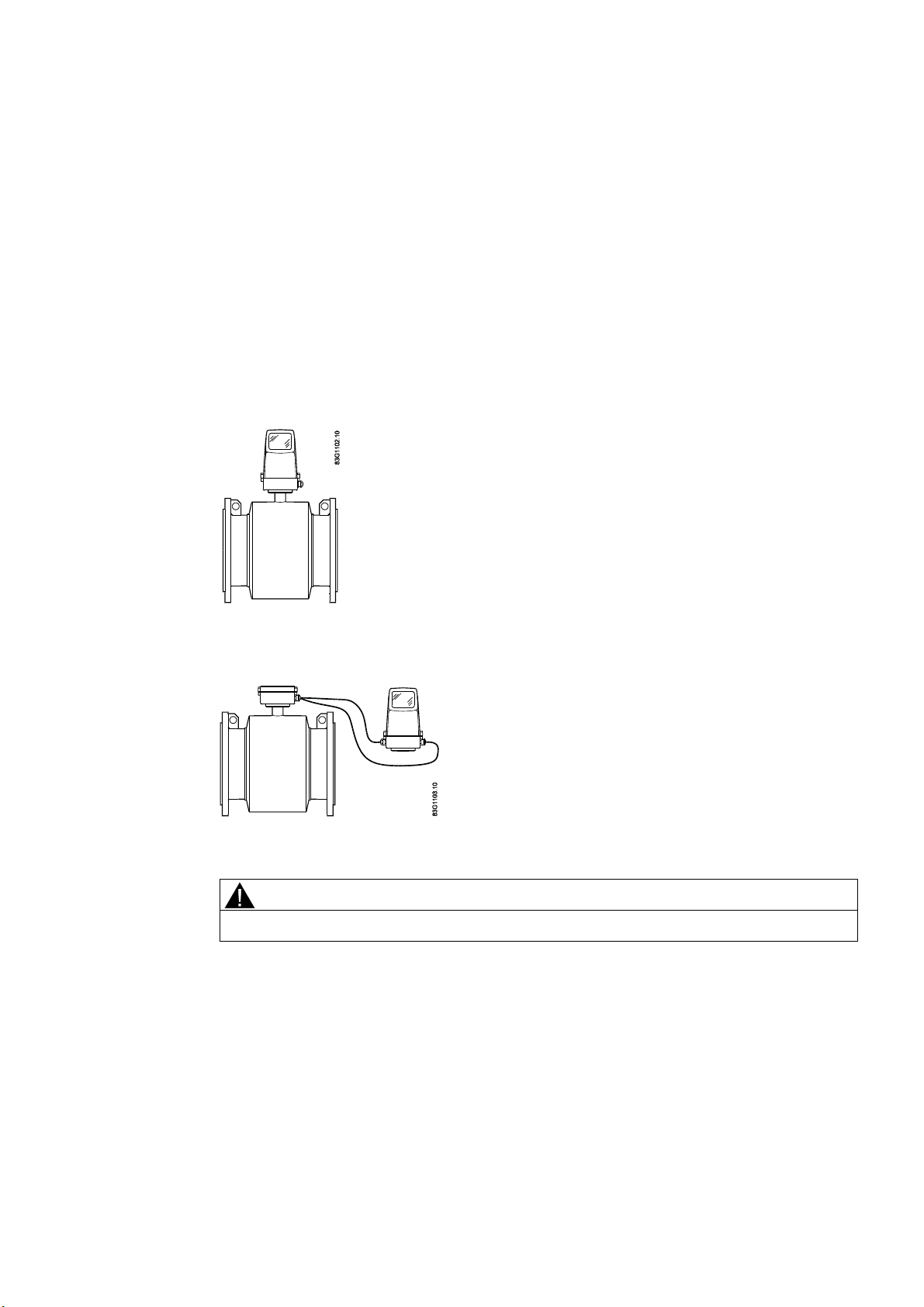

Figure 4-1 Compact installation

4

Figure 4-2 Remote installation

CAUTION

See Cable requirements (Page 68) before installing transmitter

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

17

Installing/Mounting

4.1 Installation conditions

4.1 Installation conditions

Reading and operating the flowmeter is possible under almost any installation conditions

because the display can be oriented in relation to the sensor. To ensure optimum flow

measurement, attention should be paid to the following:

Vibrations

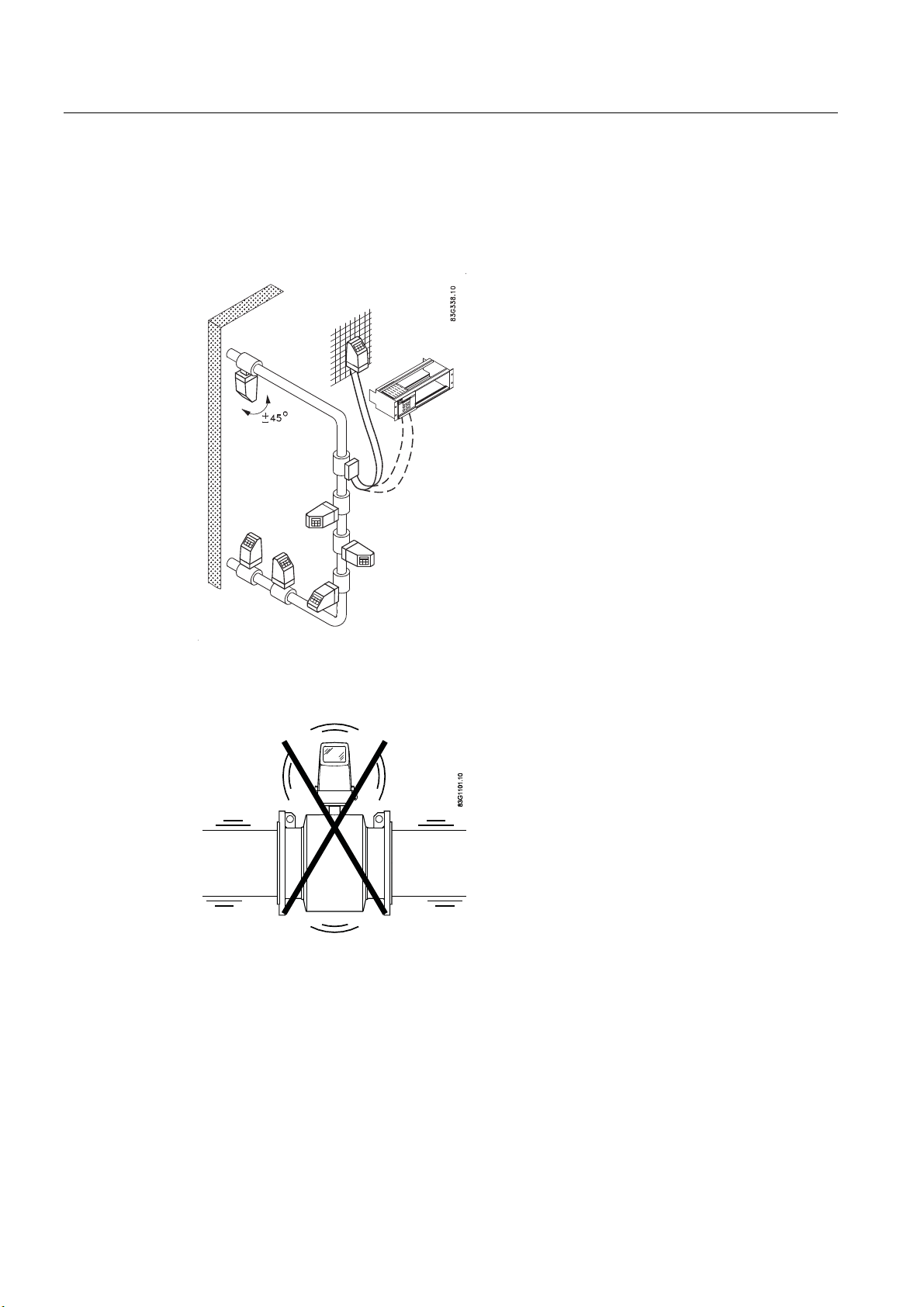

Figure 4-3 Avoid strong vibrations

SITRANS F M MAG 5000/6000

18 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Installing/Mounting

4.1 Installation conditions

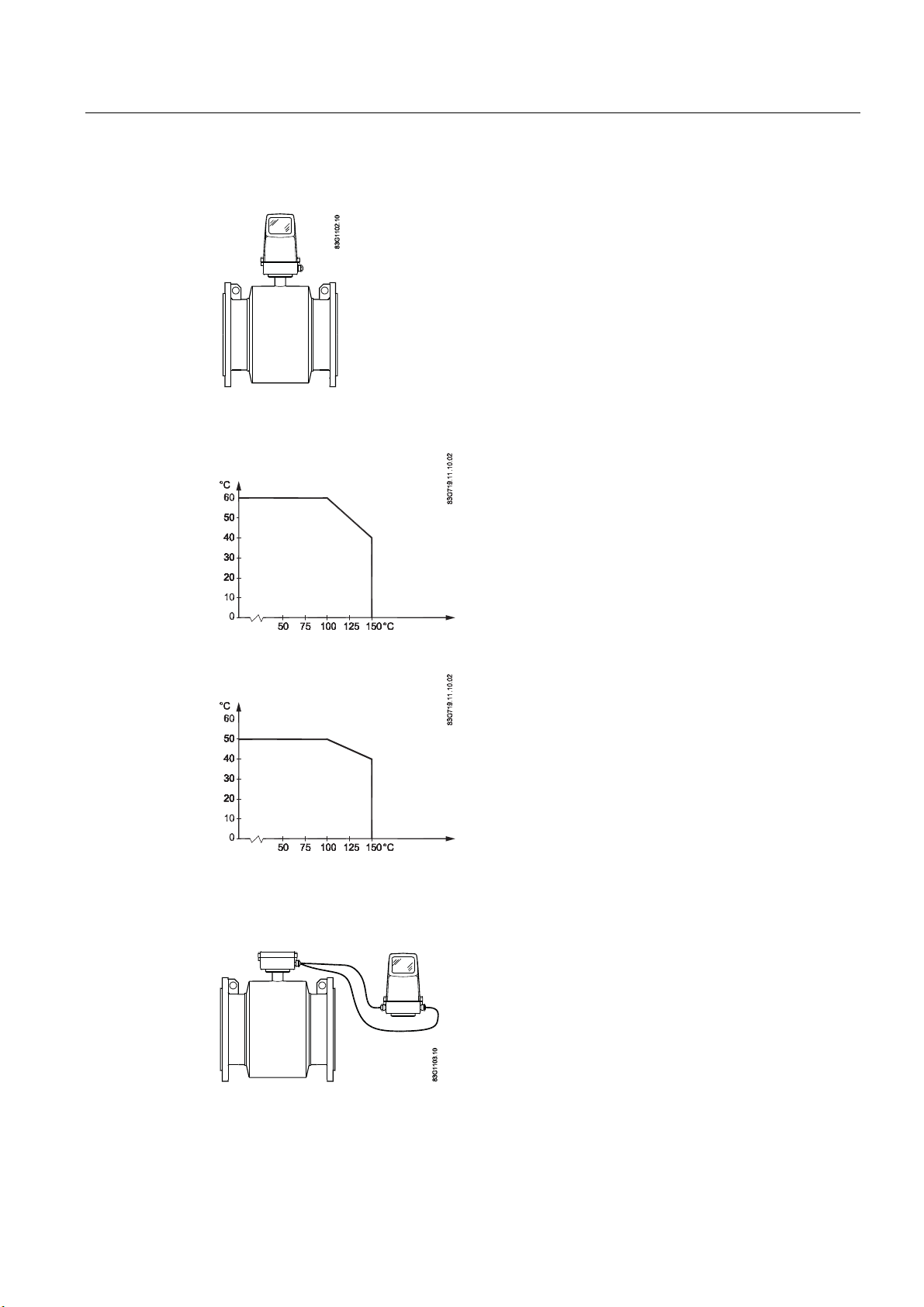

Compact installation

Medium temperature must be in accordance with the graphs showing max. ambient

temperature as a function of medium temperature.

$PELHQWWHPSHUDWXUH

Figure 4-4 Standard, blind and SV versions

$PELHQWWHPSHUDWXUH

Figure 4-5 CT version

Remote installation

0HGLXP

WHPSHUDWXUH

0HGLXP

WHPSHUDWXUH

Cable length and type (as described in Cable requirements) must be used.

For installation conditions for sensors, see respective sensor operating instructions.

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

19

Installing/Mounting

4.2 MAG 5000/6000 compact

4.2 MAG 5000/6000 compact

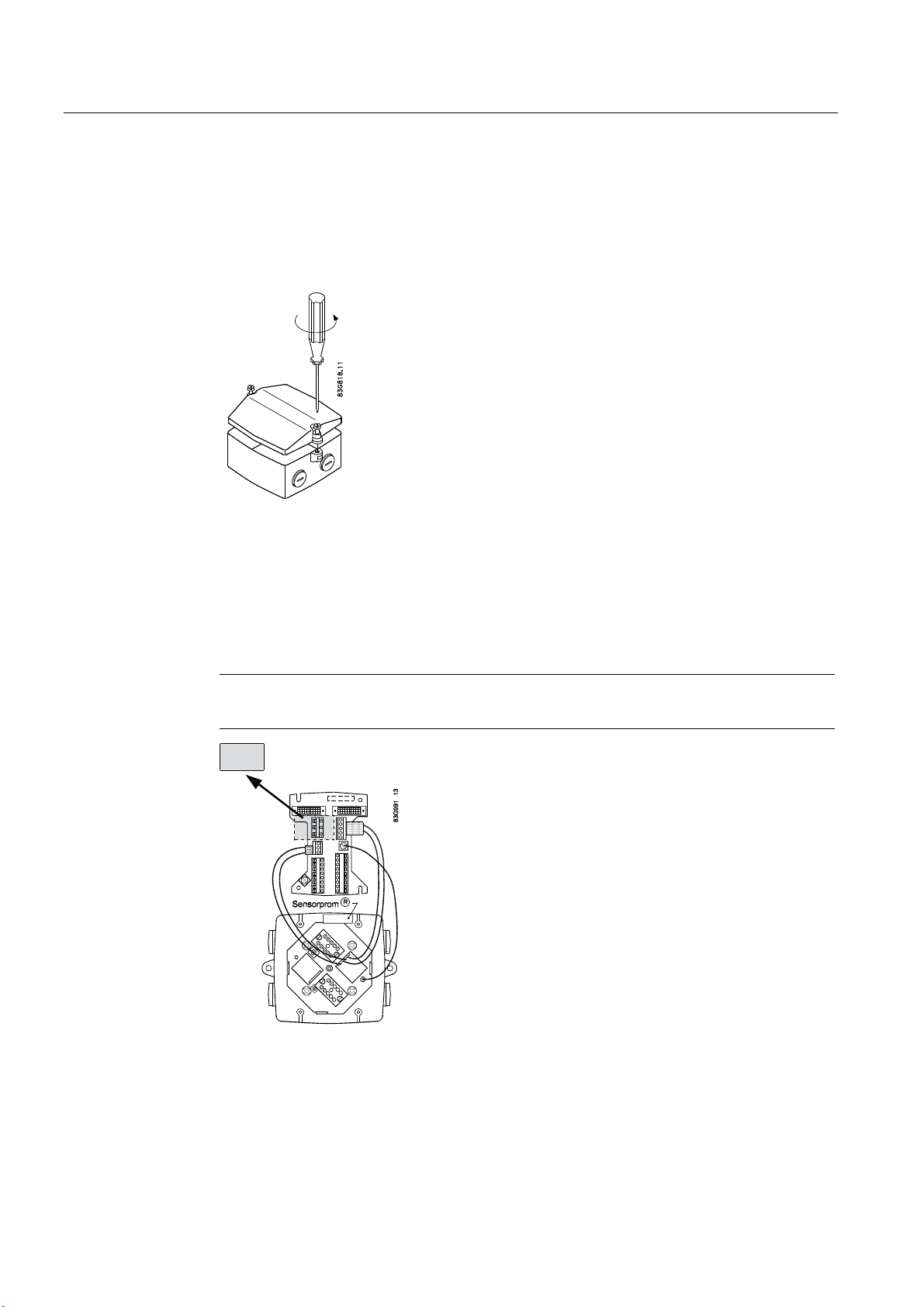

Install MAG 5000 / MAG 6000 compact version

1. Remove and discard terminal box lid of sensor.

2. Ensure SENSORPROM

3. Fit M20 or ½" NPT cable glands for supply and output cables.

®

memory unit is installed.

4. Unplug the two black plug assemblies for coil and electrode cables in terminal box.

5. Connect earth wire from connection board to bottom of terminal box.

6. Connect 2-pin connector and 3-pin connector as shown to their corresponding terminal

numbers on connection board as shown in Electrical connection (Page 34).

Note

System will not register flow if black plugs are not connected to connection board

A

7. Fit supply and output cables through cable glands and connect to connection plate as

shown in Electrical connection (Page 34).

SITRANS F M MAG 5000/6000

20 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Installing/Mounting

4.2 MAG 5000/6000 compact

8. Mount connection plate in terminal box.

Note

Check that your connection board lines up with SENSORPROM

®

SENSORPROM

unit to the other side of terminal box.

®

unit, if not, move

SENSORPROM® memory unit connections will be established automatically when

connection plate is mounted in terminal box.

B

9. Tighten cable glands to obtain optimum sealing.

10. Mount transmitter on terminal box.

11. Transmitter is ready to be powered up.

CAUTION

Exposing transmitter to direct sunlight may increase operating temperature above its

specified limit, and decrease display visibility.

A sunshield is available as accessory.

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

21

Installing/Mounting

4.3 Remote installation

4.3 Remote installation

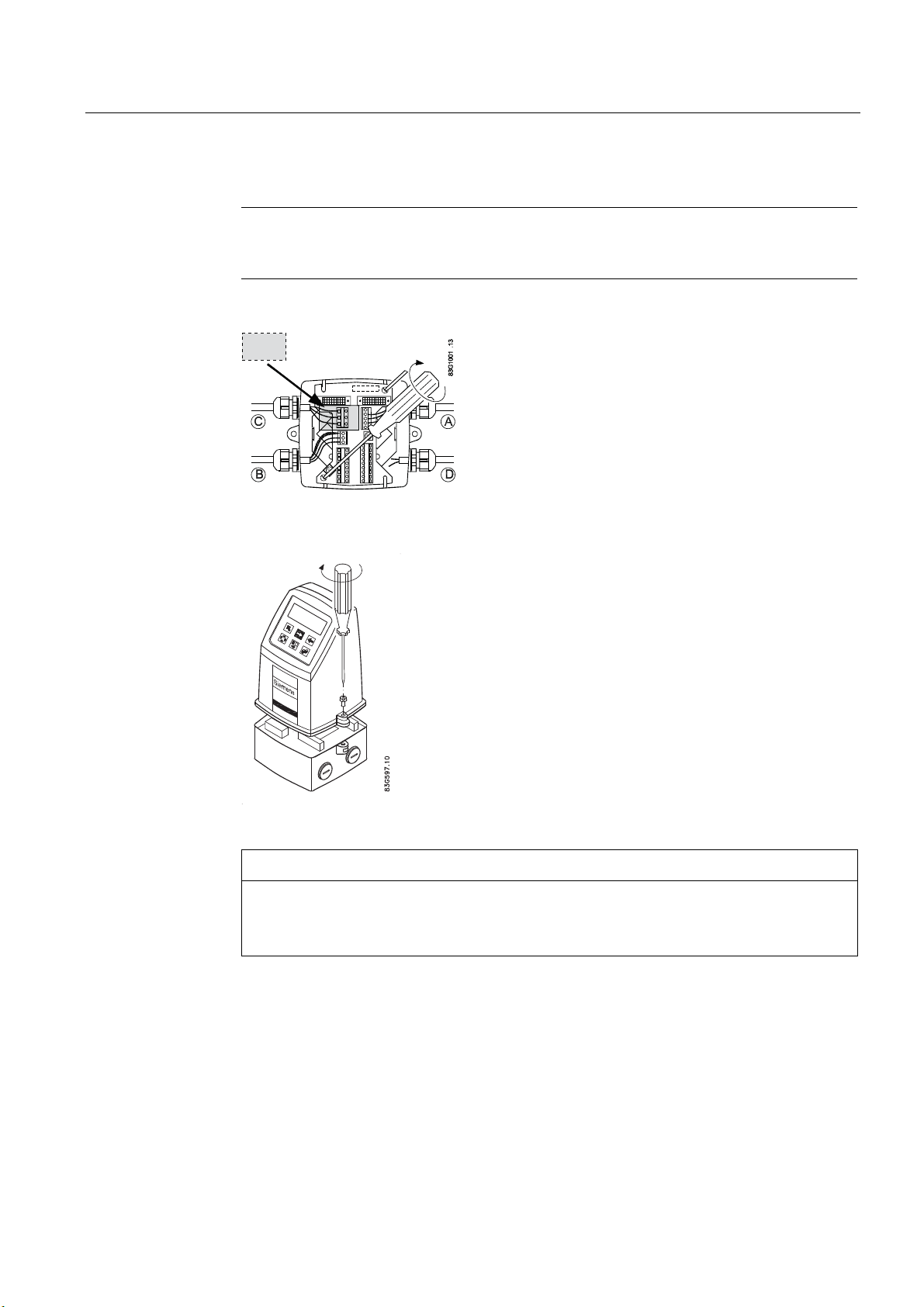

At sensor

1. Remove terminal box lid.

2. Remove SENSORPROM

wall mounting unit.

®

unit from sensor terminal box and mount it in terminal box of

3. Fit M20 or ½" NPT cable glands for cables.

SITRANS F M MAG 5000/6000

22 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Installing/Mounting

4.3 Remote installation

4. Fit and connect electrode (1) and coil (2) cables as shown in Electrical connection

(Page 34).

Note

Unscreened cable ends must be kept as short as possible.

Electrode cable and coil cable must be kept separate to prevent interference.

5. Tighten cable glands well to obtain optimum sealing.

WARNING

Mount terminal box lid before power up.

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

23

Installing/Mounting

4.3 Remote installation

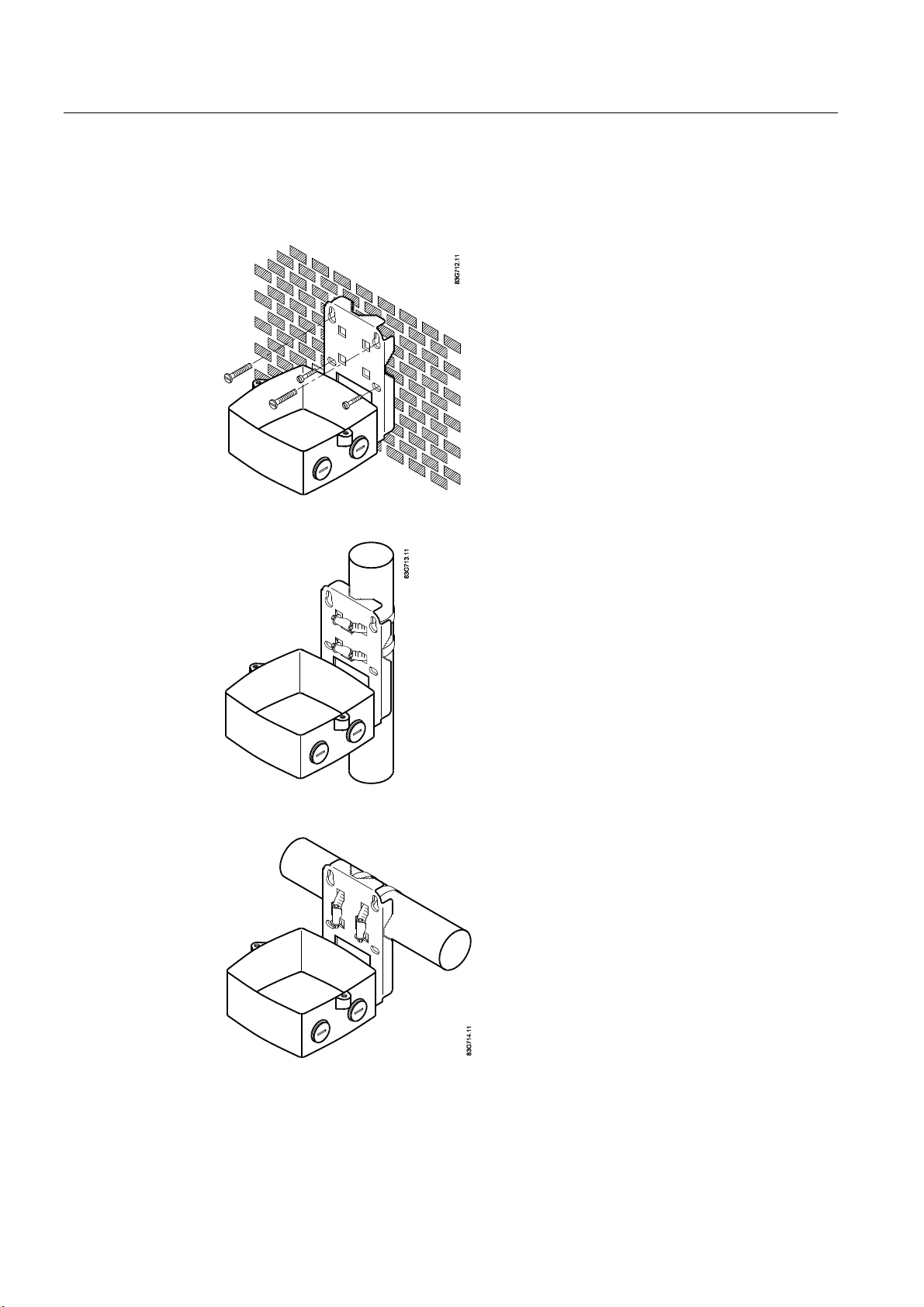

Wall mounting

1. Mount bracket on a wall or on a horizontal or a vertical pipe using ordinary hose clips or

duct straps.

Figure 4-6 Wall mounting

Figure 4-7 Pipe mounting - vertical

Figure 4-8 Pipe mounting - horizontal

2. Ensure that correct SENSORPROM® memory unit is mounted in wall/pipe mounting unit.

3. Fit M20 or ½" NPT cable glands for cables from bottom or sides of terminal box.

SITRANS F M MAG 5000/6000

24 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Installing/Mounting

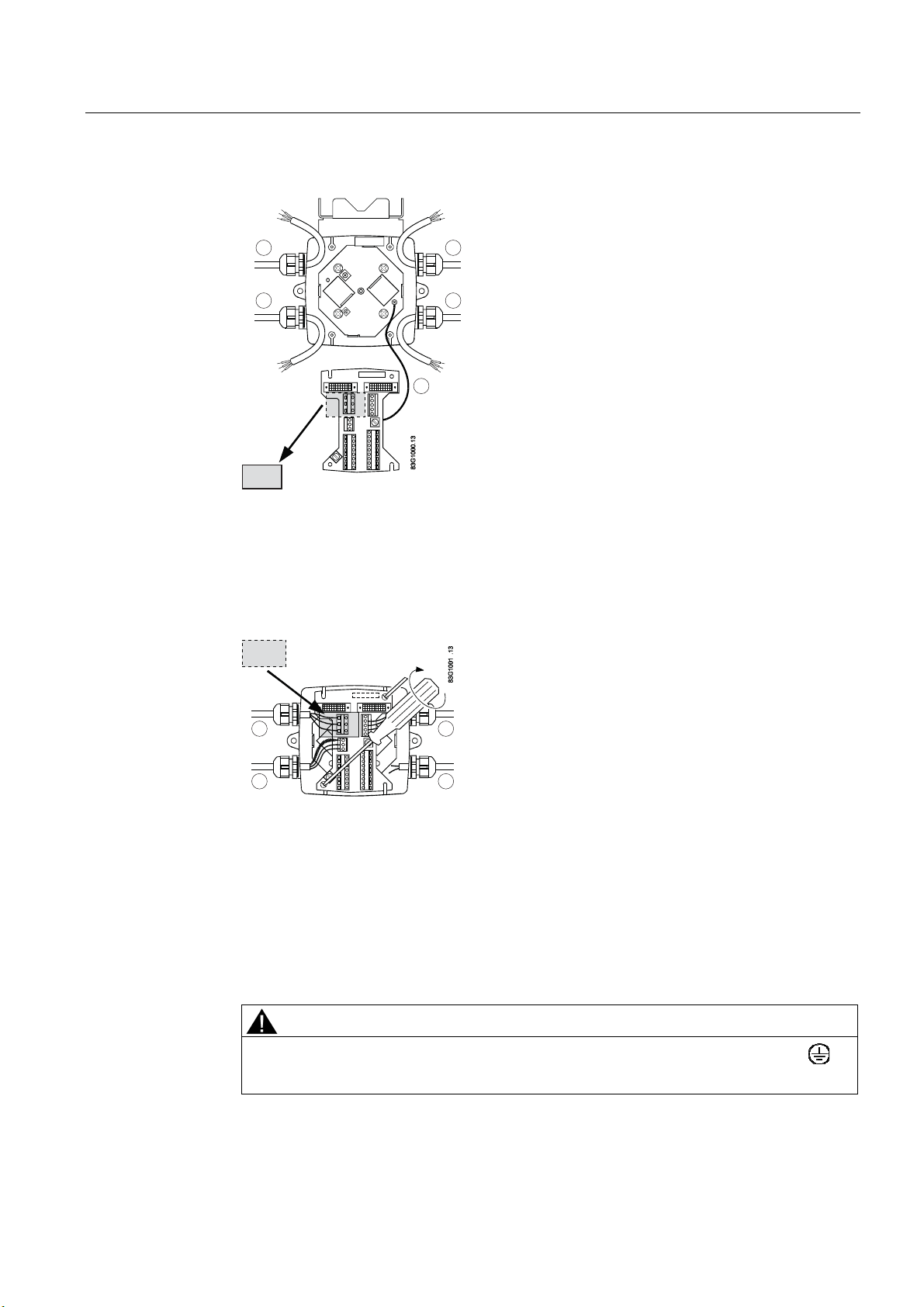

4.3 Remote installation

4. Mount earth wire in bottom of terminal box.

3

2

1

4

5

1 Connect electrode cable

2 Connect coil cable - keep separate from electrode cable

3 Connect power supply

4 Connect output cable

5 Connect PE (ground) wire

1. Mount connection plate in terminal box.

B

3

2

1

4

1 Electrode cable

2 Coil cable

3 Power supply

4 Output cable

1. Fit coil, electrode, supply and output cables through cable glands and connect to

connection plate as shown in Electrical connection (Page 34).

2. Fix conne

ction plate with the two diagonally opposite screws.

3. Tighten cable glands to obtain optimum sealing.

CAUTION

When remote mounted, power supply PE wire must be connected to PE terminal ( ).

Coil cable shield must be connected to SHIELD terminal.

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

25

Installing/Mounting

4.3 Remote installation

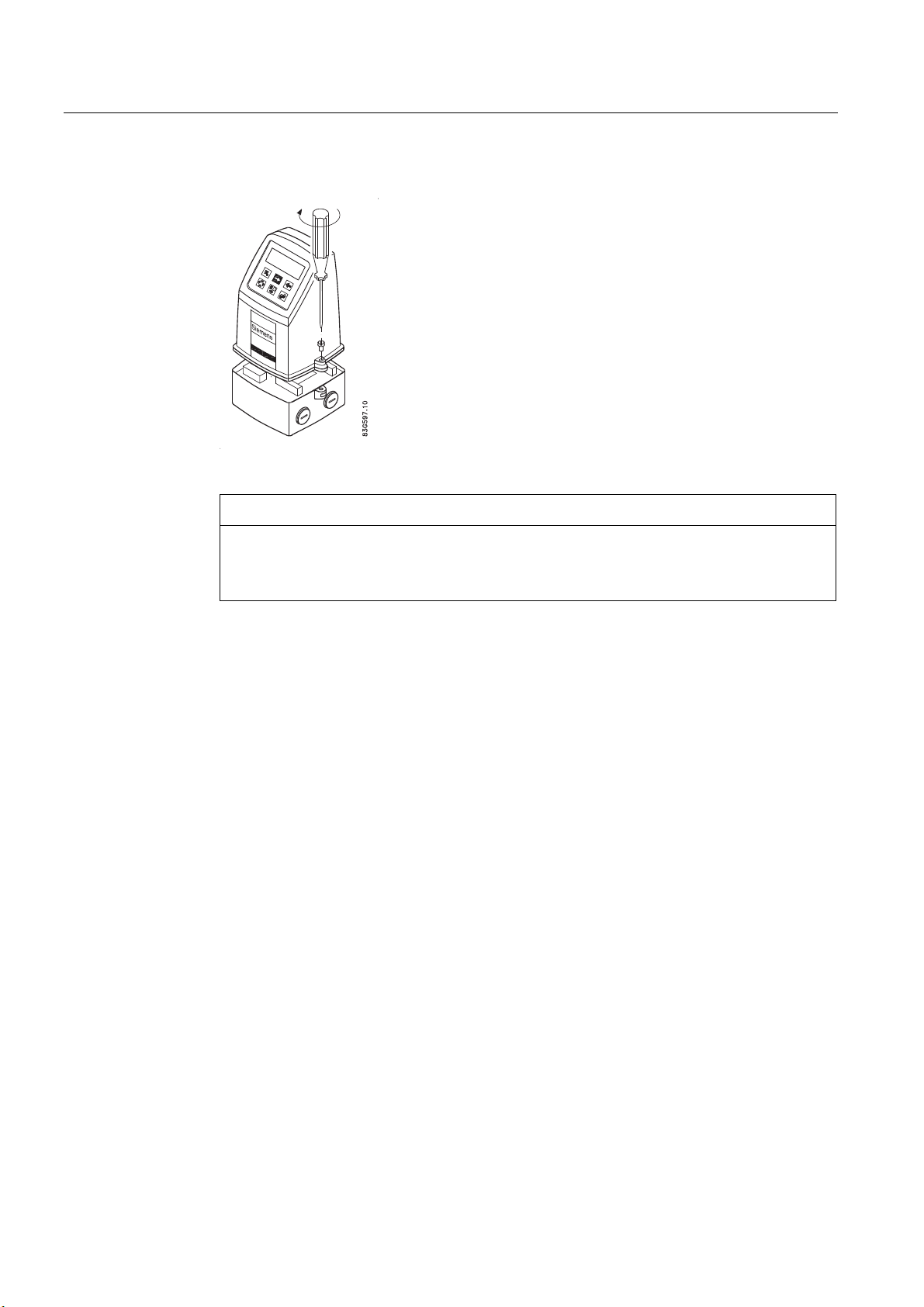

4. Mount transmitter on terminal box.

5. Transmitter is ready to be powered up.

CAUTION

Exposing the transmitter to direct sunlight may increase the operating temperature

above its specified limit, and decrease display visibility.

A sun shield is available as accessory.

SITRANS F M MAG 5000/6000

26 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Installing/Mounting

4.4 MAG 5000/6000 CT

4.4 MAG 5000/6000 CT

To ensure that the settings of this custody transfer-approved MAG 5000/6000 CT transmitter

are not changed, it is necessary to install a hardware key to lock the software functions and

to seal the device.

MAG 6000 CT is installed like a Standard MAG 6000 except for the final sealing.

Calibration sealing has been carried out at calibration.

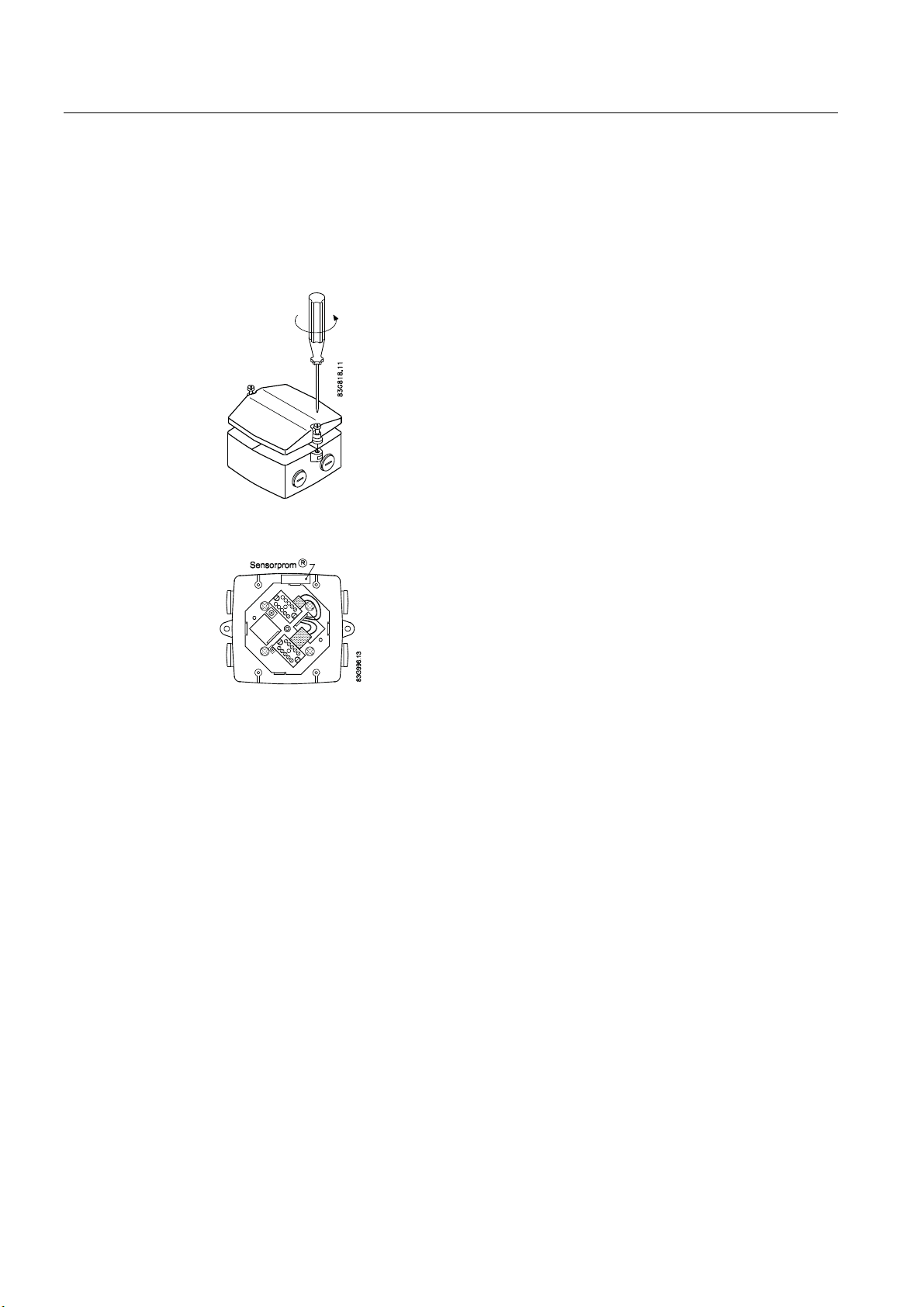

4.4.1 Installing hardware key

Use hardware key on non-verified transmitter

1. Mount hardware key on transmitter connection plate during setting of primary operating

parameters such as Q

commissioning or calibration. See setup menus in appendix menu diagrams (Page 73).

., low-flow cut-off, units, approvals, etc. in connection with

max

2. Remove hardware key after setting up and calibrating unit.

This locks the menu structure and the selected settings.

Note

Hardware key function

Setting of primary operating parameters is blocked during normal operation.

When key is mounted, access to all menu items is gained. When key is removed, primary

settings are blocked in accordance with requirements in authorisation.

SITRANS F M MAG 5000/6000

Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

27

Installing/Mounting

4.4 MAG 5000/6000 CT

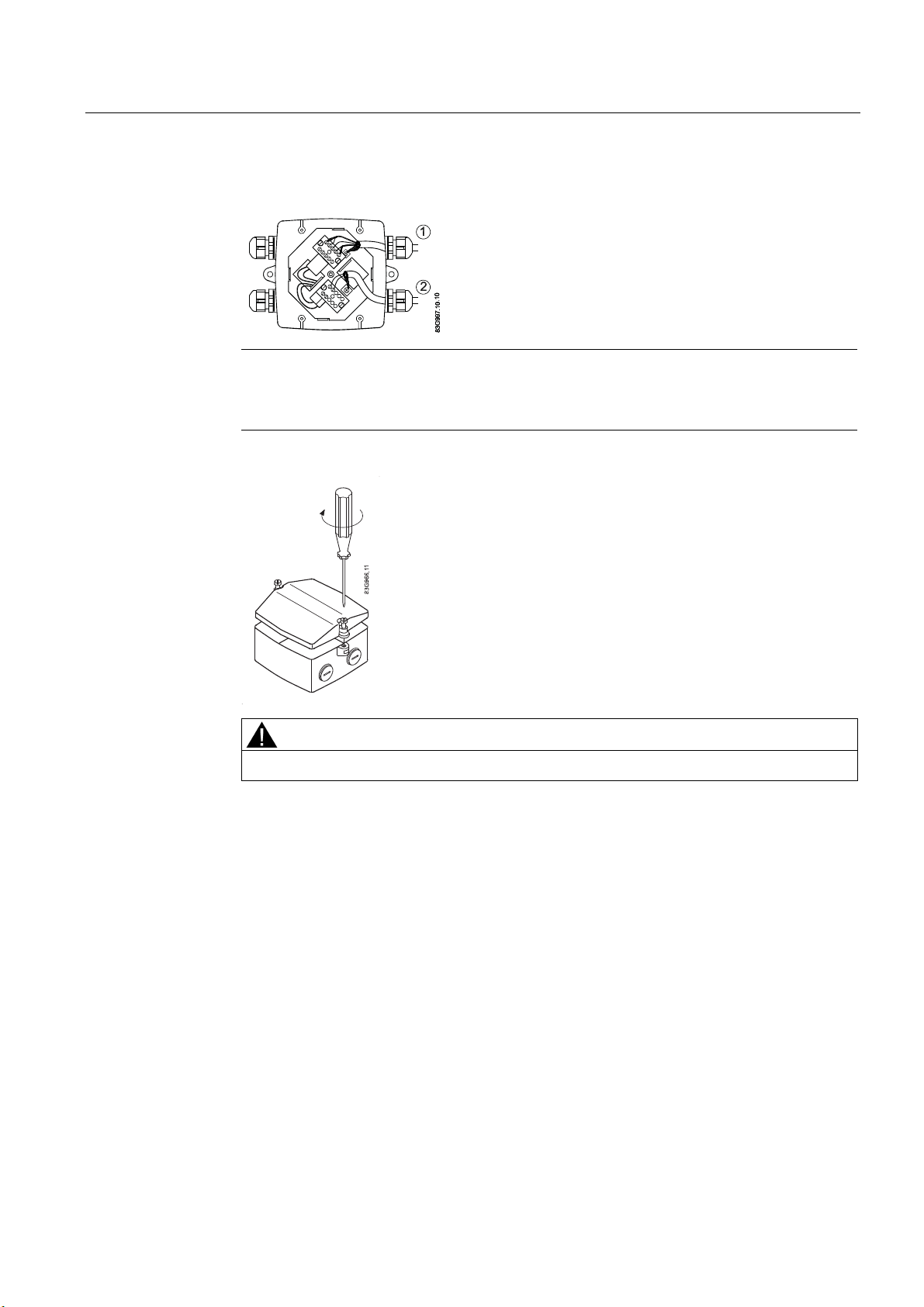

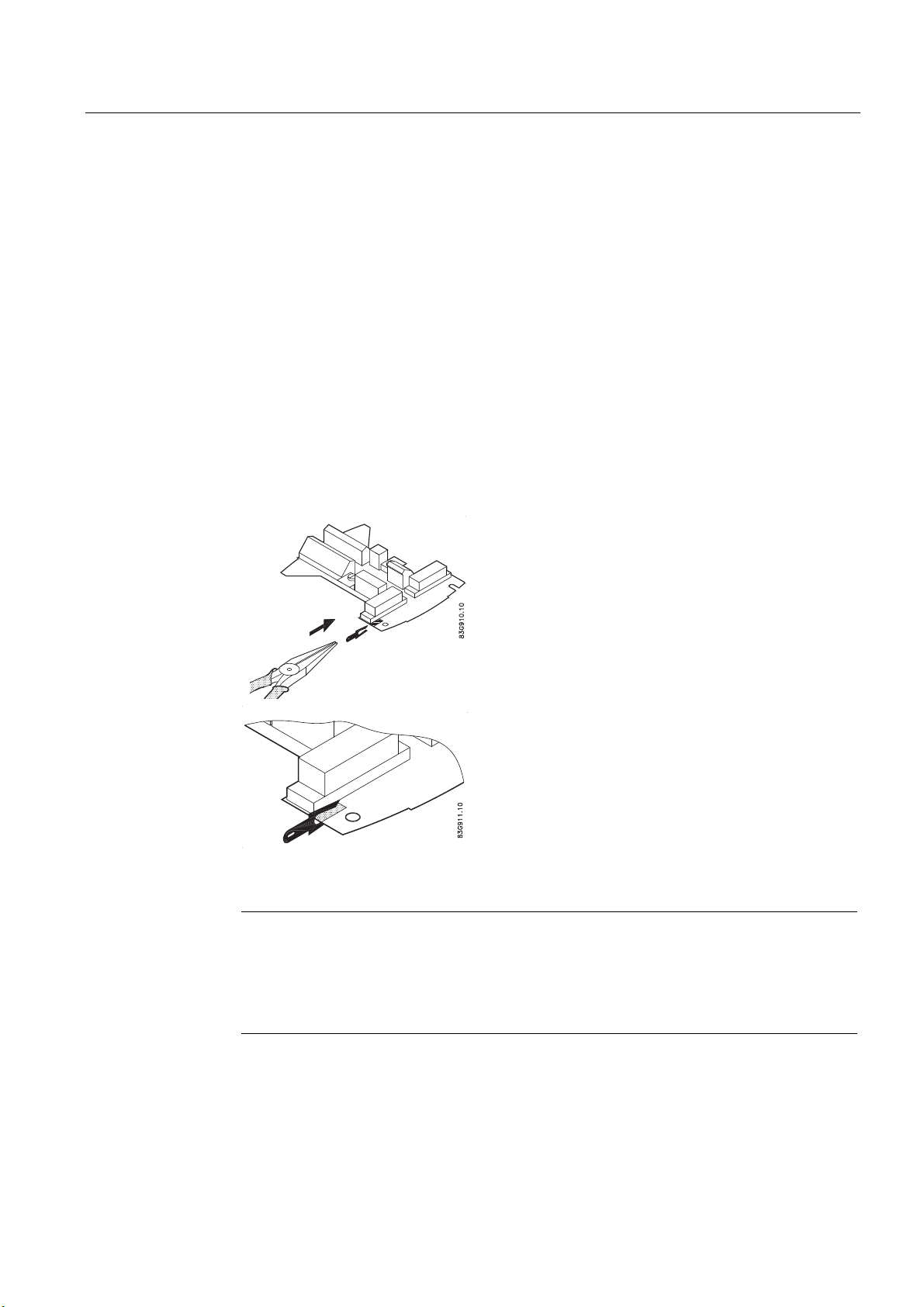

4.4.2 Seal device

Seal transmitter

CAUTION

Seal transmitter to prevent unauthorized access.

1. Seal connection plate to prevent access to SENSORPROM® memory unit as shown

below. 1 indicates sealing locations.

1

1

1

2. Drill through marked drilling holes in terminal box and transmitter/lid. Seal transmitter

externally as shown below.

SITRANS F M MAG 5000/6000

28 Operating Instructions, 01/2010, SFIDK.PS.026.G1.02

Loading...

Loading...