Siemens SITRANS F MAG 6000 I, SITRANS F MAG 6000 EX DE Operating Instructions Manual

SITRANS F

Electromagnetic Flowmeters

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions

04/2016Edition

Answers for industry.

SITRANS F

Electromagnetic Flowmeters

MAG 6000 I / MAG 6000 I Ex de

transmitter

Operating Instructions

Electromagnetic flow transmitter designed for use with

flow sensor types

MAG 1100/1100 HT/1100 F/5100 W/

3100 P/3100/3100 HT

Compact and remote installation

04/2016

A5E02083319

Introduction

1

Safety notes

2

Description

3

Installing/Mounting

4

Connecting

5

Commissioning

6

Functions

7

Alarm, error, and system

messages

8

Service and maintenance

9

Troubleshooting/FAQs

10

Technical data

11

Spare parts/Accessories

12

Menu diagrams

A

Factory settings

B

Control drawing

C

-AG

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E02083319

Ⓟ

Copyright © Siemens AG 2012 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

may

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

04/2016 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Safety notes .......................................................................................................................................... 11

3 Description ............................................................................................................................................ 19

4 Installing/Mounting ................................................................................................................................ 23

5 Connecting ........................................................................................................................................... 29

1.1 Preface ...................................................................................................................................... 7

1.2 Items supplied ........................................................................................................................... 7

1.3 History ....................................................................................................................................... 7

1.4 Device identification .................................................................................................................. 8

1.5 Further Information ................................................................................................................... 9

2.1 General safety instructions ..................................................................................................... 11

2.2 Laws and directives ................................................................................................................ 11

2.3 Installation in hazardous area ................................................................................................. 12

2.3.1 ATEX 2 GD approval .............................................................................................................. 13

2.3.2 FM/CSA Class I, Zone 1 approval .......................................................................................... 17

2.3.3 FM Class I, II, III, Div 1 approval ............................................................................................. 18

2.4 Certificates .............................................................................................................................. 18

3.1 Applications ............................................................................................................................. 19

3.2 System components ............................................................................................................... 19

3.3 Design ..................................................................................................................................... 20

3.4 Features .................................................................................................................................. 21

3.5 Theory of operation ................................................................................................................. 22

4.1 Installation safety precautions ................................................................................................ 23

4.2 Installation conditions.............................................................................................................. 23

4.3 Compact installation ................................................................................................................ 24

4.4 Remote installation ................................................................................................................. 25

4.4.1 Wall mounting using standard mounting plate ........................................................................ 27

4.4.2 Pipe or wall mounting with assembly bracket ......................................................................... 27

5.1 Safety precautions .................................................................................................................. 30

5.2 Electrical connection ............................................................................................................... 31

5.3 Connection of sensor and transmitter in remote version ........................................................ 33

5.4 Wiring in hazardous area ........................................................................................................ 36

5.5 Connection of bus communication add-on modules ............................................................... 37

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

3

Table of contents

6 Commissioning ..................................................................................................................................... 39

7 Functions .............................................................................................................................................. 47

8 Alarm, error, and system messages ...................................................................................................... 51

9 Service and maintenance ...................................................................................................................... 55

10 Troubleshooting/FAQs .......................................................................................................................... 59

11 Technical data ...................................................................................................................................... 61

12 Spare parts/Accessories ....................................................................................................................... 71

5.6 Reassembling the device ....................................................................................................... 37

6.1 Local user interface ................................................................................................................ 39

6.2 Menu structure ....................................................................................................................... 41

6.3 Changing password ............................................................................................................... 42

6.4 Changing basic settings ......................................................................................................... 42

6.5 Changing operator menu setup ............................................................................................. 45

6.6 Changing language ................................................................................................................ 46

7.1 Introduction ............................................................................................................................ 47

7.2 Output settings ....................................................................................................................... 47

7.3 External input ......................................................................................................................... 48

7.4 Sensor characteristics ............................................................................................................ 49

7.5 Reset mode ............................................................................................................................ 49

7.6 Service mode ......................................................................................................................... 49

8.1 Diagnostics ............................................................................................................................. 51

8.2 List of error numbers .............................................................................................................. 53

9.1 Maintenance ........................................................................................................................... 55

9.2 Unit repair ............................................................................................................................... 55

9.3 Technical support ................................................................................................................... 55

9.4 Return procedures ................................................................................................................. 56

10.1 Troubleshooting guide ........................................................................................................... 59

10.2 Transmitter check list ............................................................................................................. 60

11.1 Technical specifications ......................................................................................................... 61

11.2 Dimensions and weight .......................................................................................................... 63

11.3 Accuracy ................................................................................................................................ 64

11.4 Output characteristics ............................................................................................................ 65

11.5 Cable data .............................................................................................................................. 67

11.6 Cable requirements ................................................................................................................ 68

12.1 Ordering ................................................................................................................................. 71

MAG 6000 I / MAG 6000 I Ex de transmitter

4 Operating Instructions, 04/2016, A5E02083319-AG

Table of contents

A Menu diagrams ..................................................................................................................................... 73

B Factory settings .................................................................................................................................... 89

C Control drawing ..................................................................................................................................... 99

Index................................................................................................................................................... 103

12.2 Accessories ............................................................................................................................. 71

12.3 Spare parts ............................................................................................................................. 72

A.1 Transmitter menu overview .................................................................................................... 73

A.2 Basic settings .......................................................................................................................... 75

A.3 Current output ......................................................................................................................... 76

A.4 Digital output - pulse ............................................................................................................... 77

A.5 Digital output - frequency ........................................................................................................ 77

A.6 Error level ................................................................................................................................ 77

A.7 Error number ........................................................................................................................... 78

A.8 Direction/limit .......................................................................................................................... 78

A.9 Batch ....................................................................................................................................... 79

A.10 External input .......................................................................................................................... 80

A.11 Sensor characteristics............................................................................................................. 81

A.12 Reset mode ............................................................................................................................. 82

A.13 Service mode .......................................................................................................................... 83

A.14 Operator menu setup .............................................................................................................. 84

A.15 Product identity ....................................................................................................................... 86

A.16 Add-on communication module .............................................................................................. 87

B.1 Transmitter factory settings .................................................................................................... 89

B.2 50 Hz Dimension dependent Qmax ........................................................................................ 91

B.3 60 Hz Dimension dependent .................................................................................................. 92

B.4 50 Hz Dimension dependent batch and pulse output settings ............................................... 94

B.5 60 Hz Dimension dependent batch and pulse output settings ............................................... 96

C.1 Control drawing ....................................................................................................................... 99

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

5

Table of contents

MAG 6000 I / MAG 6000 I Ex de transmitter

6 Operating Instructions, 04/2016, A5E02083319-AG

1

1.1

Preface

Note

It is the responsibility of the

operating instructions are read, understood, and followed by the relevant personnel before

installing the device.

1.2

Items supplied

•

•

•

•

1.3

History

These instructions contain all the information you need for using the device.

The instructions are aimed at persons mechanically installing the device, connecting it

electrically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

customer that the instructions and directions provided in the

SITRANS F M MAG 6000 I or MAG 6000 I

Ex de transmitter

Wall mounting bracket (remote version)

SITRANS F M literature CD containing

software, certificates and device manuals

Quick start guide

The contents of these instructions are reviewed regularly and any corrections included in

subsequent editions. We welcome all suggestions for improvement.

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

7

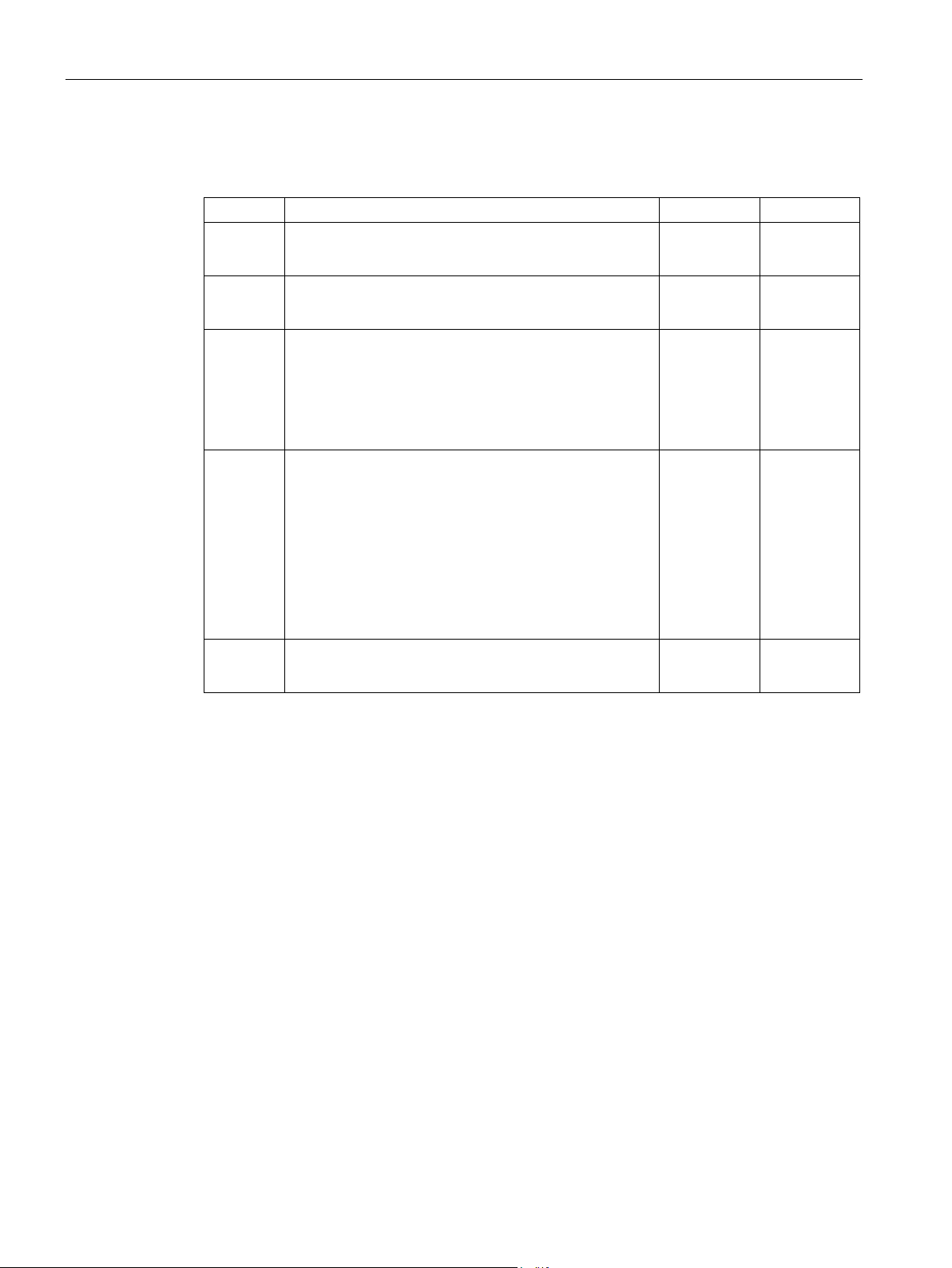

Introduction

Edition

Remarks

HW version

SW version

1.4

Device identification

Inspection

1.4 Device identification

The following table lists the most important changes made to the documentation in the

current and previous editions.

03/2011

12/2011

09/2012

01/2015

04/2016

• First edition

• Transmitter upgrade information included

• Updated ATEX approval

• General update

• Enhanced current output function

• Updated menu functions; possibility of showing user

defined units in display

• Updated ATEX approval

• General update

• Graphics, technical data and factory settings

changed to comprise:

– "BBL42" is displayed as the default setting in

customer unit instead of "?". The unit can still be

changed.

– Improved minimum supply voltage for current

output to 12 V.

• Document revision identification changed according

to new SIEMENS standard

• Various technical specifications updated

• Control drawing updated

3.04

4.04

4.06 X06 4.08 X06

4.06 X06 4.06 X06

08

09

4.06 X06

4.07 X06

4.04

1. Check for mechanical damage due to possible improper handling during shipment. All

claims for damage are to be made promptly to the carrier.

2. Make sure the scope of delivery, and the information on the namelate corresponds to the

ordering information

MAG 6000 I / MAG 6000 I Ex de transmitter

8 Operating Instructions, 04/2016, A5E02083319-AG

Introduction

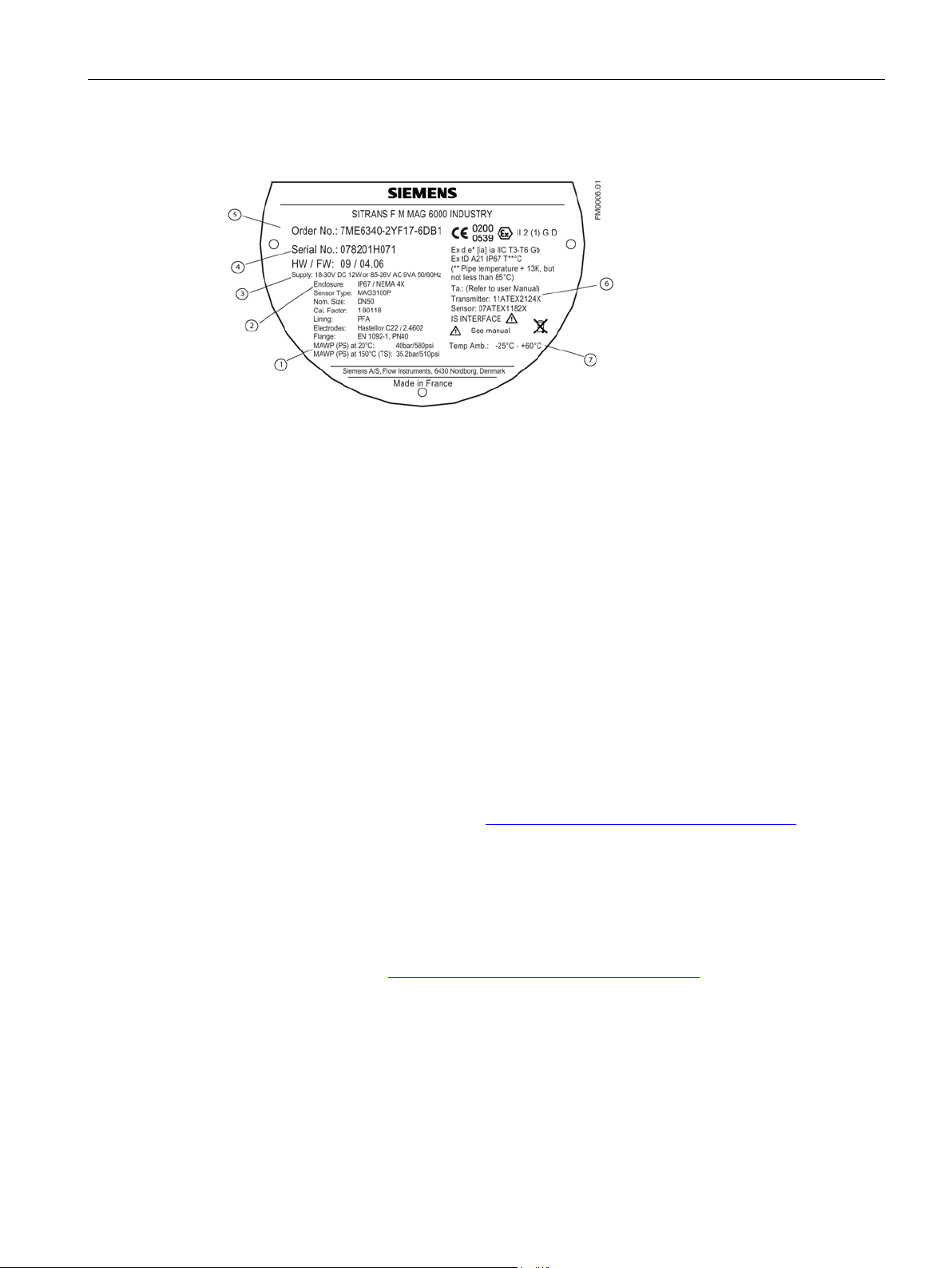

Identification

①

MAWP (Maximum Allowable Working Pressure) at defined temperature, e.g. 20°C

②

Enclosure rating

③

Power supply

④

Serial number

⑤

Code number

⑥

Approvals

⑦

Ambient temperature

1.5

Further Information

Product information on the Internet

Worldwide contact person

1.5 Further Information

Image 1-1 Example of MAG 6000 I Ex nameplate

The Operating Instructions are available on the CD-ROM shipped with the device, and

on the Internet on the Siemens homepage, where further information on the range of

SITRANS F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flowdocumentation

If you need more information or have particular problems not covered sufficiently by these

Operating Instructions, get in touch with your contact person. You can find contact

information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner

)

)

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

9

Introduction

1.5 Further Information

MAG 6000 I / MAG 6000 I Ex de transmitter

10 Operating Instructions, 04/2016, A5E02083319-AG

2

2.1

General safety instructions

CAUTION

Note

Alterations to the product, including opening or improper modifications of the product, are not

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2.2

Laws and directives

General requirements

Instrument safety standards

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance. Only qualified personnel should

install or operate this instrument.

Installation of the equipment must comply with national regulations. For example EN 6007914 for the European Community.

The device has been tested at the factory, based on the safety requirements. In order to

maintain this condition over the expected life of the device, the requirements described in

these Operating Instructions must be observed.

Environmental conditions according to IEC61010-1:

● Indoor/Outdoor use

● Altitude up to 2000 m

● Maximum relative humidity 80% for temperatures up to 31°C (88 °F) decreasing linearly

up to 50% relative humidity from 40 °C (104 °F)

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

11

Safety notes

NOTICE

Material compatibility

CE marked equipment

2.3

Installation in hazardous area

WARNING

WARNING

WARNING

"Flameproof enclosure" type of protection

2.3 Installation in hazardous area

● Overvoltage category II

● Pollution degree 2

Siemens Flow Instruments can provide assistance with the selection of wetted sensor

parts. However, the full responsibility for the selection rests with the customer and

Siemens Flow Instruments can take no responsibility for any failure due to material

incompatibility.

The CE-mark symbolizes the compliance of the device with the following directives:

● EMC-directive 2004/108/EC

● Low voltage directive 2006/95/EC

● Pressure equipment directive (PED/DGRL) 97/23/EC

● ATEX Directive 94/9/EG

Equipment used in hazardous areas must be Ex-approved and marked accordingly. It is

required that the special conditions for safe use provided in the manual and in the Ex

certificate are followed!

Make sure the hazardous area approval is suitable for the environment in which the device

will be installed.

Only open devices with type of protection "Flameproof enclosure" in hazardous areas when

the power to the device is turned off, otherwise there is a risk of explosion.

MAG 6000 I / MAG 6000 I Ex de transmitter

12 Operating Instructions, 04/2016, A5E02083319-AG

Safety notes

WARNING

Laying of cables

WARNING

2.3.1

ATEX 2 GD approval

Remote transmitter version:

Note

Markings for remote version only

These markings are for the Remote version only;

versions depend upon their construction. See the latest issues of certificates Sira

07ATEX3181X, Sira 07ATEX1182X and Sira 03ATEX3339X.

2.3 Installation in hazardous area

Cable for use in Zone 1 and 2 or 21 and 22 must satisfy the requirements for having a proof

voltage > 500 V AC applied between the conductor/ground, conductor/shield and

shield/ground.

Connect the devices that are operated in hazardous areas as per the stipulations applicable

in the country of operation, e.g. for Ex "d" and "nA", permanent cables must be laid

With intrinsically safe circuits, use only certified meters appropriate for the transmitter.

If a non-conforming supply unit is used, the "fail-safe" type of protection will no longer be

effective and the approval certification will be invalid.

The device is approved for use in hazardous area and has certificate Sira 11ATEX2124X.

II 2(1) GD

EX d e [ia] ia IIC T6 Gb

Ex tD A21 IP67 T85 °C

Ta -25 °C to 60 °C

the marking applicable to the Compact

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

13

Safety notes

Compact transmitter version:

Safety parameters associated with the remote transmitter version

Sensor electrode input (Terminals 0, 81, 82, 83, 84 - "ia circuits")

IIB

IIC

UO

30 V DC

30 V DC

IO

6.1 mA

6.1 mA

CO

560 nF

66 nF

LO

1 H

0.96 H

PO

45.5 mW

45.5 mW

Sensor coil terminals

Terminal type

85 and 86

"e"

Power supply:

Parameter

MAG 6000 I Ex de

Supply

115 to 230 VAC or 18 to 30 VDC

ATEX certificate)

Enclosure

IP67 / NEMA 4X

2.3 Installation in hazardous area

● Ex d e [ia] ia IIC T3-T6 Gb

Ex tD A21 IP67 T** °C (** pipe temperature +5K, but not less than T85 °C

(MAG 3100 / MAG 3100 P)

● Ex d e [ia] ia IIB T3-T6 Gb

Ex tD A21 IP67 T** °C (** pipe temperature +18K, but not less than T85 °C

(MAG 1100 / MAG 1100 F)

For sensors:

Refer to sensor certificates:

MAG 3100 / MAG 3100 P: Sira 07ATEX1182X (DN 15-DN300); Sira 03ATEX3339X (DN350DN2000)

MAG 1100 / MAG 1100 F: Sira 07ATEX3181X

Table 2- 1 Intrinsically safe data

Max. allowable supply voltage Um (according to

Ambient temperature -20 to +60 °C (-4 to 140 °F)

MAG 6000 I / MAG 6000 I Ex de transmitter

14 Operating Instructions, 04/2016, A5E02083319-AG

264 V

Safety notes

WARNING

Fail-safe protection

User I/O interface

Passive current

(31, 32)

Active current

(31, 32)

Relay

(44, 45, 46)

Frequency/pulse

(56, 57)

Profi (FISCO)

(95, 96)

Digital input

(77, 78)

IIC IIB

IIC IIC IIC IIC IIC

Ui

28 V DC

UO

30 V DC

30 V DC

Ui

30 V DC

Ui

28 V DC

Ui

17.5 V DC

Ui

30 V DC

II

100 mA

IO

87.8 mA

87.8 mA

II

200 mA

II

100 mA

II

380 mA

II CI

19.7 nF

CO

557 nF

63 nF

CI

3.3 nF

CI

14.2 nF

CI

0 nF

CI

0 nF

LI

36 µH

LO

18.4 mH

4.6 mH

LI

0 µH

LI

36 µH

LI

0 µH

LI

0 µH

PI

0.7 W

PO

0.66 W

0.61 W

PI

1.2 W

PI

1.2 W

PI

5.32 W

PI

1.2 W

2.3 Installation in hazardous area

With intrinsically safe circuits, use only certified meters appropriate for the transmitter.

If a non-conforming suuply unit is used, the "fail-safe" type of protection wil no longer be

effective and the approval certification will be invalid.

Remote MAG 6000 I: Model 7ME693-2BA4/5

Compact:

MAG 6000 I with MAG 3100 series: Model 7ME63x0-xxxxx-xD/E

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

15

Safety notes

Special conditions for ATEX 2 GD

2.3 Installation in hazardous area

It is required that:

● the equipment is supplied with its current output (terminals 31 and 32) in "Passive mode

only.

● the external connections to terminals 85 and 86 shall comply with the following:

– The wire conductors shall have a cross-sectional area between 0.5 mm

– No more than one single or multiple strand wire conductor shall normally be

connected to each of the terminals. If multiple conductors are required, these shall be

joined in a suitable manner, e.g. two conductors into a single insulated crimped boot

lace ferrule.

– The insulation on the wire conductors shall extend to within 1 mm of the metal of the

terminal throat.

– The terminal screws shall be tightened down with a torque between 0.4 Nm and 0.45 Nm.

– The equipment shall not be opened when an explosive gas or dust atmosphere may

be present.

– The equipment internal circuits at the following terminals are not capable of

withstanding a 500 V r.m.s. a.c. test to earth as required by clause 6.3.12 of

EN 60079-11-2007. This must be taken into account in any equipment installation:

2

and 2.5 mm2.

Terminals 77 and 78 – Digital input.

Terminals 95 and 96 – Foundation Fieldbus/Profibus (FISCO). (Not applicable to

Model 7ME693-2BA6)

Terminals 0, 81, 82, 83 and 84 – Sensor electrode input (Remote Version only).

● electrical connections are in accordance with national requirements for installation of

electrical systems in hazardous areas, e.g. EN60079-14 in Europe.

● the protective cover for the power terminals is properly installed.

When the device is de-energized, the power supply terminal room may be opened

because the non-intrinsically safe power terminals are separately covered. Only remove

protective cover when device is de-energized.

● sensor and transmitter are connected to the potential equalizing conductor.

● when protective earth (PE) is connected, no potential difference between the protective

earth (PE) and the potential equalization (PA) can exist, even during a fault condition.

MAG 6000 I / MAG 6000 I Ex de transmitter

16 Operating Instructions, 04/2016, A5E02083319-AG

Safety notes

2.3.2

FM/CSA Class I, Zone 1 approval

Compact and remote versions

User I/O interface

Passive current

(31, 32)

Active current

(31, 32)

Relay

(44, 45, 46)

Frequency/pulse

(56, 57)

Profi (FISCO)

(95, 96)

Digital input

(77, 78)

IIB/IIC

IIB

IIC IIB/IIC

IIB/IIC

IIB/IIC

IIB/IIC

Ui

28 V DC

UO

30 V DC

30 V DC

Ui

30 V DC

Ui

28 V DC

Ui

17.5 V DC

Ui

30 V DC

II

100 mA

IO

87.8 mA

87.8 mA

II

200 mA

II

100 mA

II

380 mA

II

CI

19.7 nF

CO

557 nF

63 nF

CI

7.5 nF

CI

14.2 nF

CI

0 nF

CI

0 nF

LI

36 µH

LO

18.4 mH

4.6 mH

LI

0 µH

LI

36 µH

LI

0 µH

LI

0 µH

PI

0.7 W

PO

0.66 W

0.61 W

PI

1.2 W

PI

1.2 W

PI

5.32 W

PI

1.2 W

2.3 Installation in hazardous area

FM: Class I, Zone 1 IIC

CSA: Class I, Zone 1 IIC, Zone 21

Remote MAG 6000 I: Model 7ME693-2BA4/5

Compact:

MAG 6000 I with MAG 1100: Model 7ME6110-xxx2x-xD/E

MAG 6000 I with MAG 1100 F: Model 7ME6140-xxx2x-xD/E

MAG 6000 I with MAG 3100 series: Model 7ME63x0-xxxxx-xD/E

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

17

Safety notes

2.3.3

FM Class I, II, III, Div 1 approval

Compact version for MAG 3100/3100 P sensors DN 15 to 300 (½" to 12")

User I/O interface

Passive current

(31, 32)

Active current

(31, 32)

Relay

(44, 45, 46)

Frequency/pulse

(56, 57)

Profi (FISCO)

(95, 96)

Digital input

(77, 78)

ABCD

CD

AB ABCD

ABCD

ABCD

ABCD

Ui

28 V DC

UO

30 V DC

30 V DC

Ui

30 V DC

Ui

28 V DC

Ui

17.5 V DC

Ui

30 V DC

II

100 mA

IO

87.8 mA

86.8 mA

II

200 mA

II

100 mA

II

380 mA

II CI

19.7 nF

CO

557 nF

63 nF

CI

3.3 nF

CI

14.2 nF

CI

0 nF

CI

0 nF

LI

36 µH

LO

18.4 mH

4.6 mH

LI

0 µH

LI

36 µH

LI

0 µH

LI

0 µH

PI

0.7 W

PO

0.66 W

0.66 W

PI

1.2 W

PI

1.2 W

PI

5.32 W

PI

1.2 W

Notes from control drawing

See also

2.4

Certificates

2.4 Certificates

Hazardous area

Class I, Div. 1, Group A, B, C, D

1. The non-intrinsically safe terminals (power rail) must not be connected to a device which

uses or generates more than 250/30 Vrms or DC.

2. The installation must meet the requirements of the National Electrical Code/Canadian

Electrical Code.

3. Conduit seal is required within 460 mm (18") from MAG 6000 I in hazardous areas

(Class I, Div. 1).

The control drawings are found on the CD-ROM shipped with the device and on the Siemens

homepage at http://www.siemens.com/flowdocumentation.

Control drawing (Page 99)

MAG 6000 I / MAG 6000 I Ex de transmitter

18 Operating Instructions, 04/2016, A5E02083319-AG

Certificates are posted on the Internet and on the documentation CD-ROM shipped with the

device.

3

3.1

Applications

3.2

System components

Communication solutions

Standard transmitter:

Ex-transmitter:

The pulsed DC-powered magnetic flowmeters are suitable for measuring the flow of almost

all electrically conductive liquids, pastes, and slurries with max. 40% solids.

The main applications can be found in the following sectors:

● Water and waste water

● Chemical and pharmaceutical industries

● Food & beverage industry

● Mining and cements industries

● Pulp and paper industry

● Steel industry

● Power generation; utility and chilled water industry

The SITRANS F M flowmeter system includes:

● Transmitter (types: standard transmitter MAG 6000 I or Ex transmitter MAG 6000 I Ex de

in compact or remote version)

● Sensor (types: SITRANS F M MAG 1100/1100 HT/1100F, MAG 5100 W, MAG 3100 P/

3100 or 3100 HT)

● Communication module (optional) (types: HART, PROFIBUS PA/DP, MODBUS RTU RS485,

Foundation Fieldbus H1, Devicenet)

The SITRANS F M platform enables fitting of add-on bus modules without loss of analog,

pulse and relay outputs, and all modules can be fitted as true Plug & Play.

● HART

● PROFIBUS PA and DP

● Foundation Fieldbus H1

● MODBUS RTU RS485

● Devicenet

● HART

● PROFIBUS PA

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

19

Description

3.3

Design

Compact version

Remote version

3.3 Design

The SITRANS F M MAG 6000 I/MAG 6000 I Ex de transmitter is designed for demands in

the process industry. The robust cast aluminum housing provides superb protection, even in

the most harsh industrial environments. Full input and output functionality is given even in

the Ex version.

The transmitter is designed for either compact or remote installation in non-hazardous or

hazardous areas.

Functions:

● Flow rate measurement

● 2 measuring ranges

● Display with 2 totalizers and keypad

● Low flow cut-off

● Analog, pulse/frequence and relay outputs

● Optional: additional digital communication modules

● Error and error log system

● Uni-/bidirectional flow

● Limit switches

● Integrated batch control

MAG 6000 I / MAG 6000 I Ex de transmitter

20 Operating Instructions, 04/2016, A5E02083319-AG

Description

3.4

Features

3.4 Features

● SENSORPROM® memory unit

– All SITRANS F M electromagnetic flowmeters feature a unique SENSORPROM

®

memory unit which stores sensor calibration data as well as transmitter settings for the

lifetime of the product.

– At commissioning the flowmeter commences measurement without any initial

programming.

®

– The factory settings matching the sensor are stored in the SENSORPROM

customer- specified settings are downloaded to the SENSORPROM

®

unit. Also

unit. Should the

transmitter be replaced, the new transmitter will upload all previous settings and

resume measurement without any need for re-programming.

● USM II "Plug & Play" add-on communication modules

USM II - the Universal Signal Module with "Plug & Play" simplicity makes it easy to

access and integrate the flow measurement with almost any control system. It ensures

the flowmeter will be easy to upgrade to new communication platforms in the future, too.

● CAN communication

The transmitter operates internally via an internal CAN communication bus. Signals are

transferred through a signal conditioner to the display module and to/from

internal/external option modules and the dialog module.

● Dialog module

The display unit consists of a 3-line display and a 6-key keypad. The display shows a flow

rate or a totalizer value as a primary reading and can be changed from the factory-set

English to ten other languages. In the Operator menu setup it is possible to configure the

display to show various different menus.

● Output module

The output module converts flow data to analog, digital and relay outputs. The outputs

are galvanically isolated and can be individually set to suit a particular application.

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

21

Description

3.5

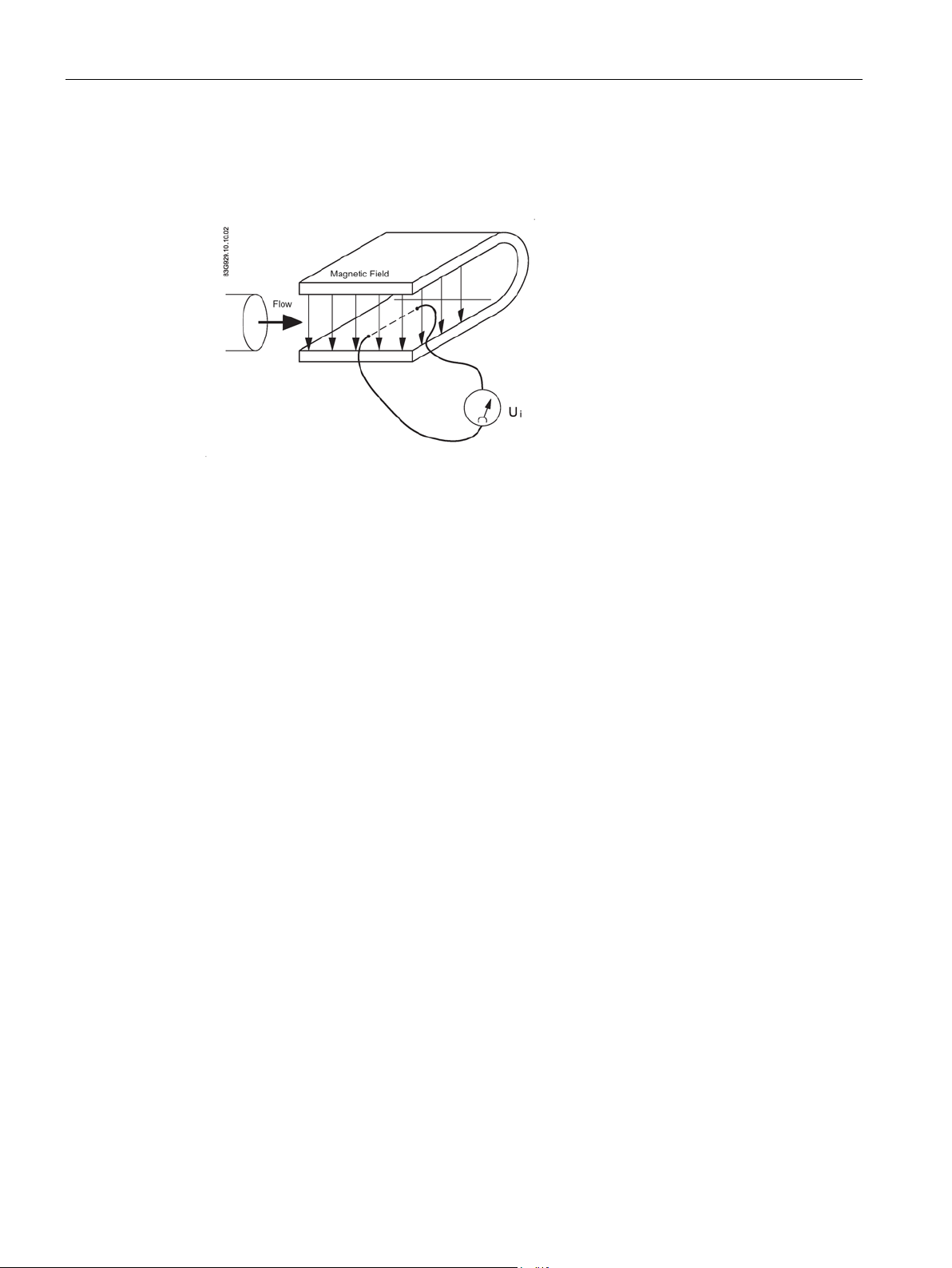

Theory of operation

Ui = L x B x v

Ui = k x v, the electrode signal is directly proportional to the fluid velocity

3.5 Theory of operation

The flow measuring principle is based on Faraday’s law of electromagnetic induction.

Ui = When an electrical conductor of length L is moved at velocity v, perpendicular to the

lines of flux through a magnetic field of strength B, the voltage Ui is induced at the ends of

the conductor

● Ui = Induced voltage

● L = Conductor length = Inner pipe diameter = k

● B = Magnetic field strength = k

2

1

● v = Velocity of conductor (media)

● k = k

x k2

1

Coil current module generates a pulsating magnetizing current that drives the coils in the

sensor. The current is permanently monitored and corrected. Errors or cable faults are

registered by the self-monitoring circuit.

Input circuit amplifies the flow-proportional induced signal from the electrodes. The input

14

impedance is extremely high: >10

Ω which allows flow measurements on fluids with

conductivities as low as 5 μS/cm. Measuring errors due to cable capacitance are eliminated

due to active cable screening.

Digital signal processor converts the analog flow signal to a digital signal and suppresses

electrode noise through a digital filter. Inaccuracies in the transmitter as a result of long-term

drift and temperature drift are monitored and continuously compensated for via the selfmonitoring circuit. The analog to digital conversion takes place in an ultra low noise ASIC

with 23 bit signal resolution. This has eliminated the need for range switching. The dynamic

range of the transmitter is therefore unsurpassed with a turn down ratio of minimum 3000:1.

MAG 6000 I / MAG 6000 I Ex de transmitter

22 Operating Instructions, 04/2016, A5E02083319-AG

4

4.1

Installation safety precautions

WARNING

High pressure hazard

4.2

Installation conditions

This chapter describes how to install the flowmeter in the compact version as well as in the

remote version.

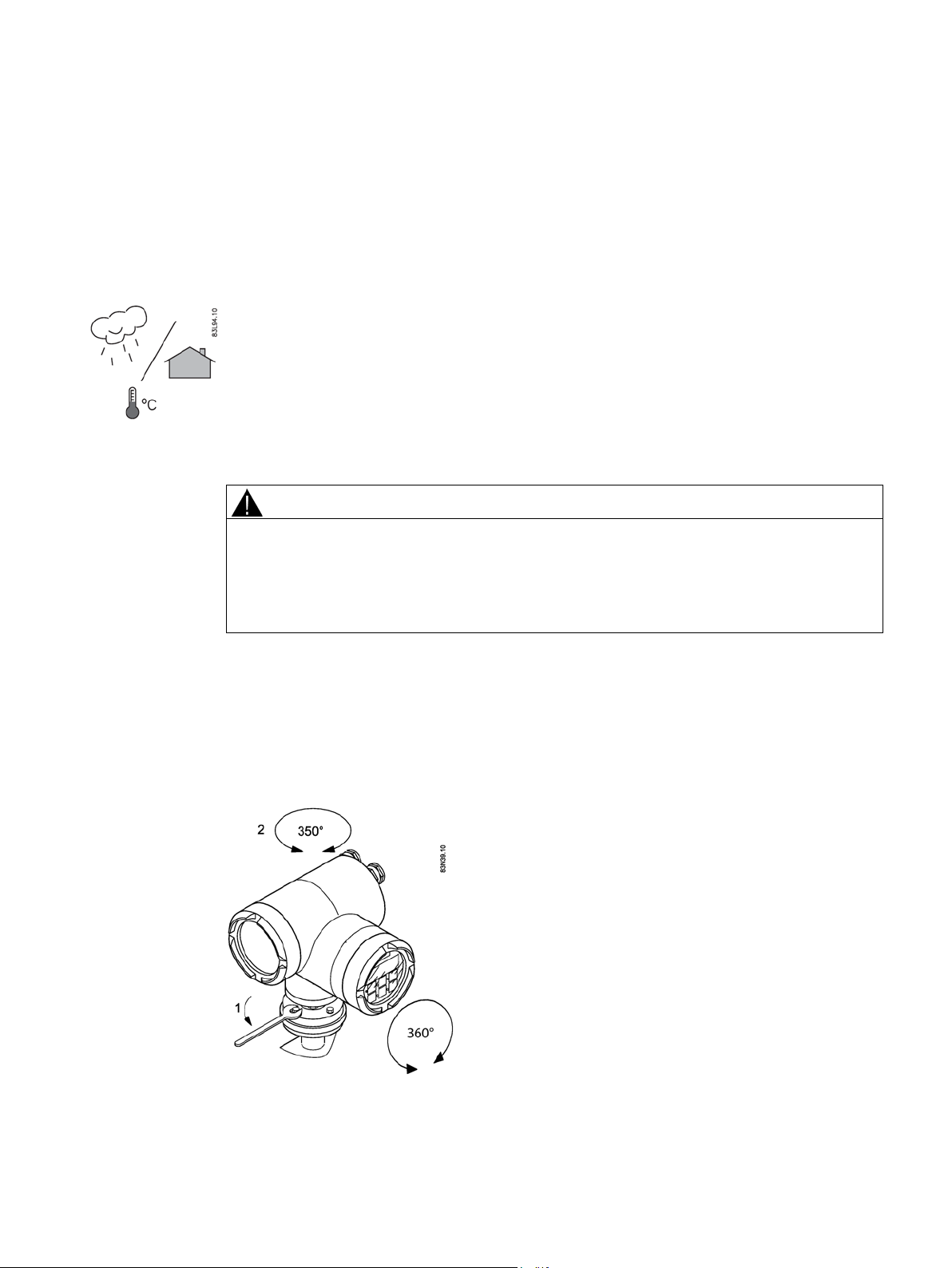

SITRANS F flowmeters with minimum IP67/NEMA 4X enclosure rating are suitable for indoor

and outdoor installations.

All sensors have an associated SENSORPROM

®

containing all necessary sensor data.

In applications with working pressures/media that can be dangerous to people,

surroundings, equipment or others in case of pipe fracture, we recommend that special

precautions such as special placement, shielding or installation of a pressure guard or a

safety valve are taken when the sensor is mounted.

As the transmitter housing and the display can be oriented in all directions, reading and

operating the flowmeter is possible under almost any installation conditions.

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

23

Installing/Mounting

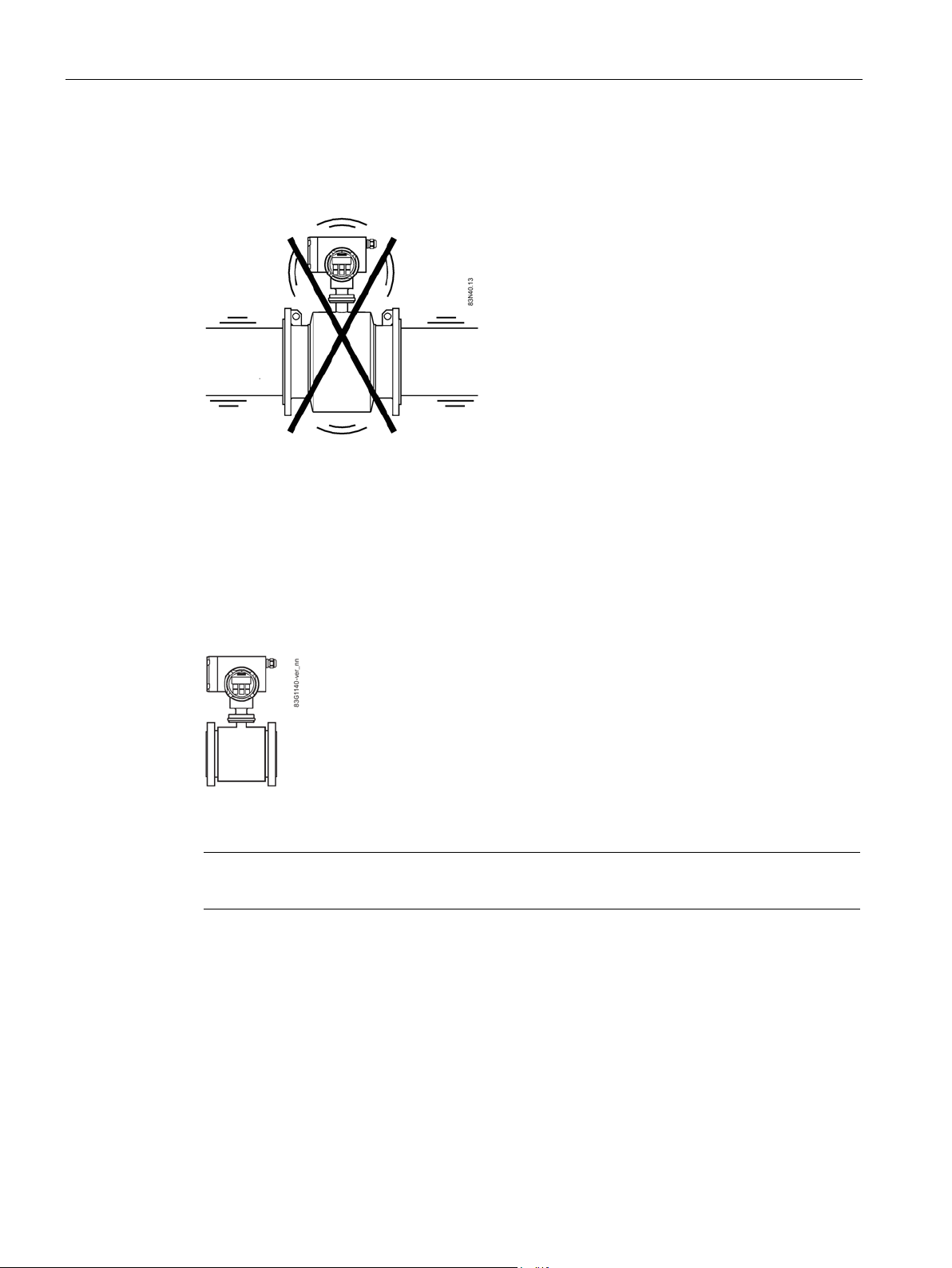

Vibrations

4.3

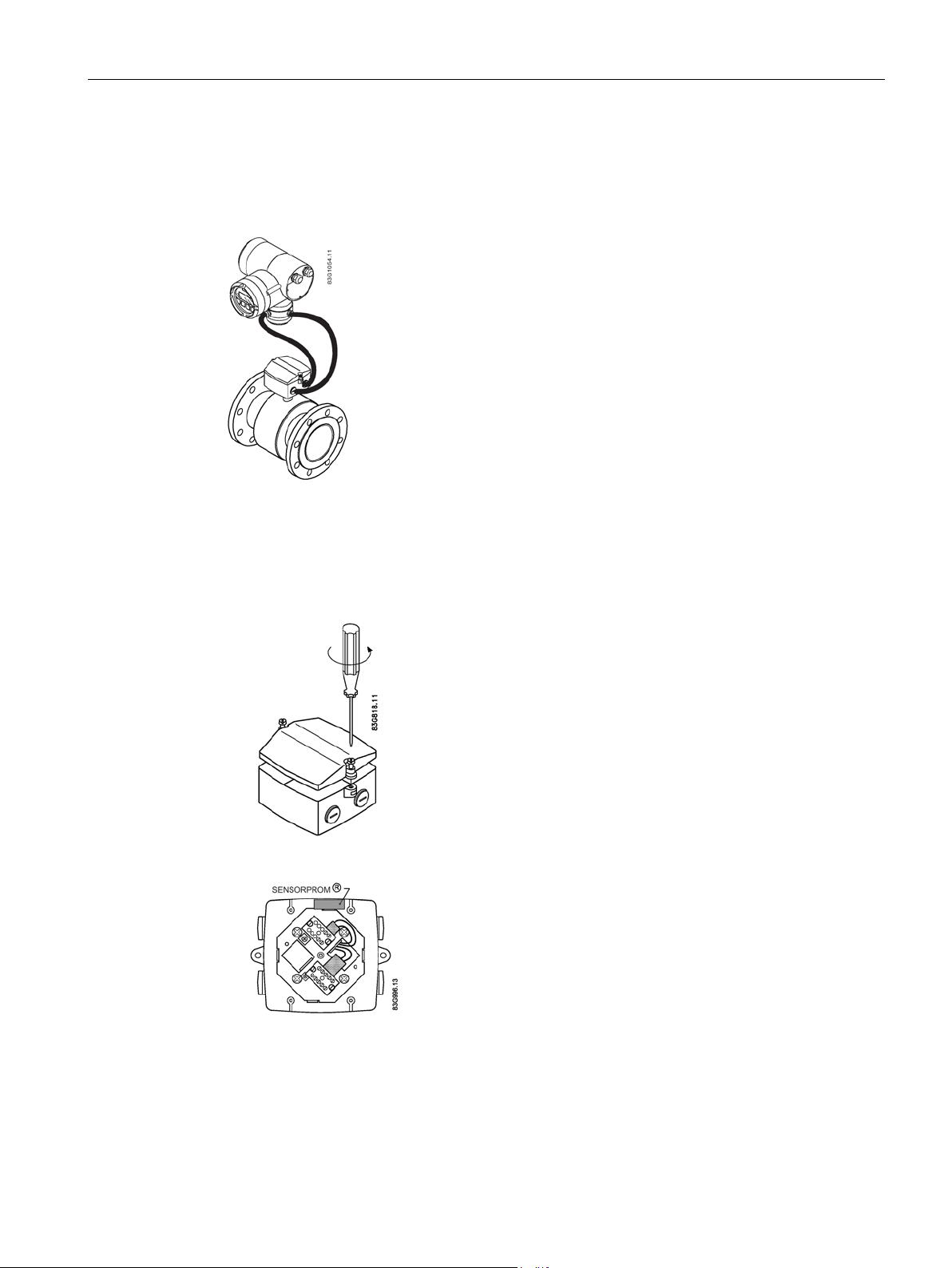

Compact installation

Note

To avoid too high tension on small sizes MAG 1100 sensors, transmitter must be supported.

4.3 Compact installation

To ensure optimum flow measurement, attention should be paid to the following:

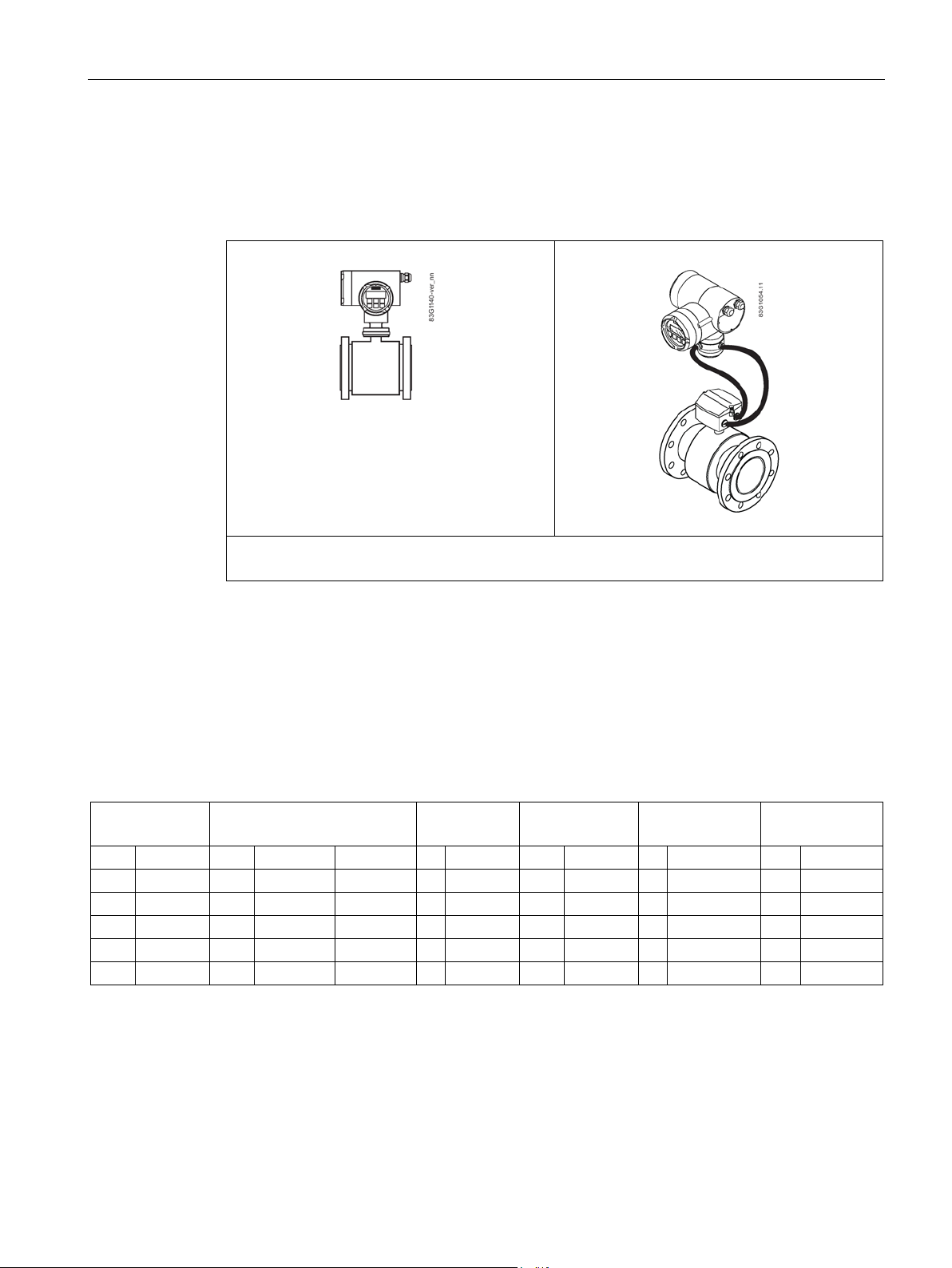

Image 4-1 Avoid strong vibrations

In installation with strong vibrations remote installation of the transmitter is recommended.

The flowmeter is delivered with default factory settings and start measuring the flow rate

®

after power-up. The SENSORPROM

Image 4-2 Compact installation

is factory-mounted in the transmitter.

MAG 6000 I / MAG 6000 I Ex de transmitter

24 Operating Instructions, 04/2016, A5E02083319-AG

Installing/Mounting

4.4

Remote installation

4.4 Remote installation

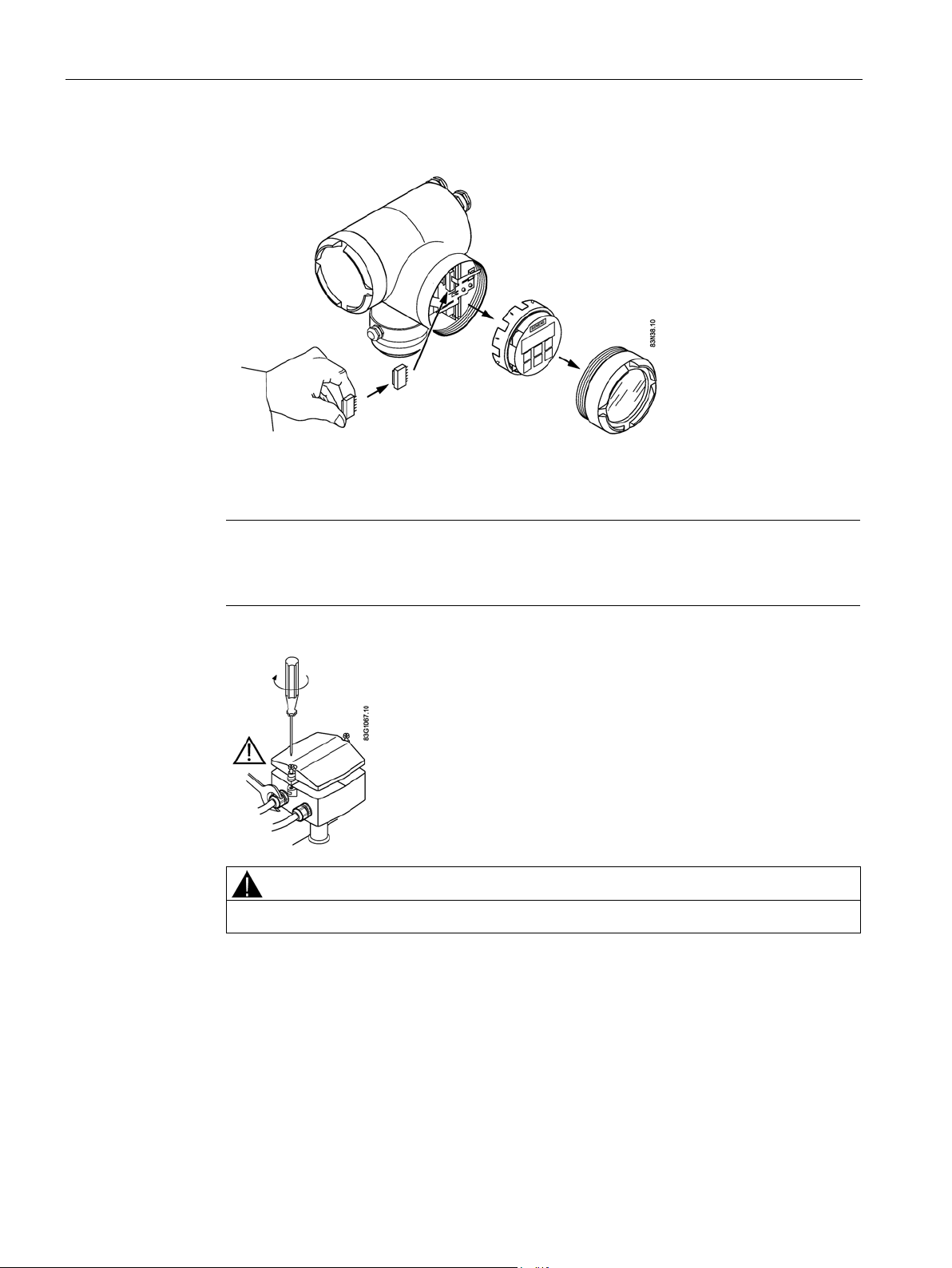

For remote versions the SENSORPROM® has to be removed from the sensor terminal box

and mounted in the remote transmitter.

Image 4-3 Remote installation

Cable length and type (as described in Cable requirements (Page 68)) must be used.

For installation conditions for sensors, see respective sensor operating instructions.

1. Remove sensor terminal box lid.

2. Remove SENSORPROM

®

unit from sensor terminal box.

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

25

Installing/Mounting

Note

Unscreened cable ends must be kept as short as possible.

Electrode cable and coil cable must be kept separate to prevent interference.

WARNING

4.4 Remote installation

3. Mount SENSORPROM

®

in remote transmitter.

4. Fit M20 or ½" NPT cable glands on sensor terminal box.

5. Fit and connect electrode and coil cables as described in Connecting (Page 31).

6. Tighten cable glands and lid screws well to obtain optimum sealing.

Mount terminal box lid before power up.

MAG 6000 I / MAG 6000 I Ex de transmitter

26 Operating Instructions, 04/2016, A5E02083319-AG

Installing/Mounting

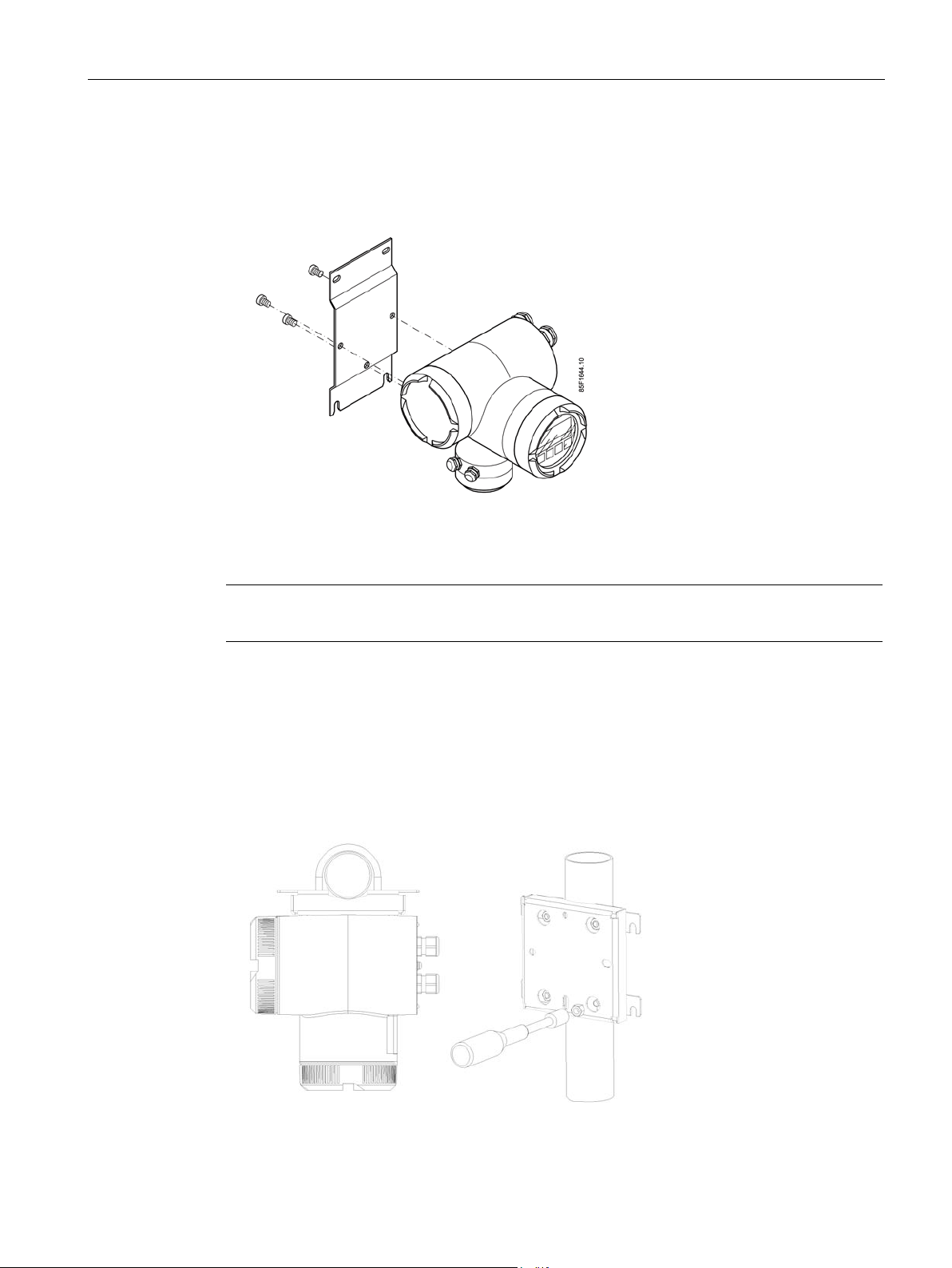

4.4.1

Wall mounting using standard mounting plate

Note

The standard mounting plate is only suitable for wall mounting.

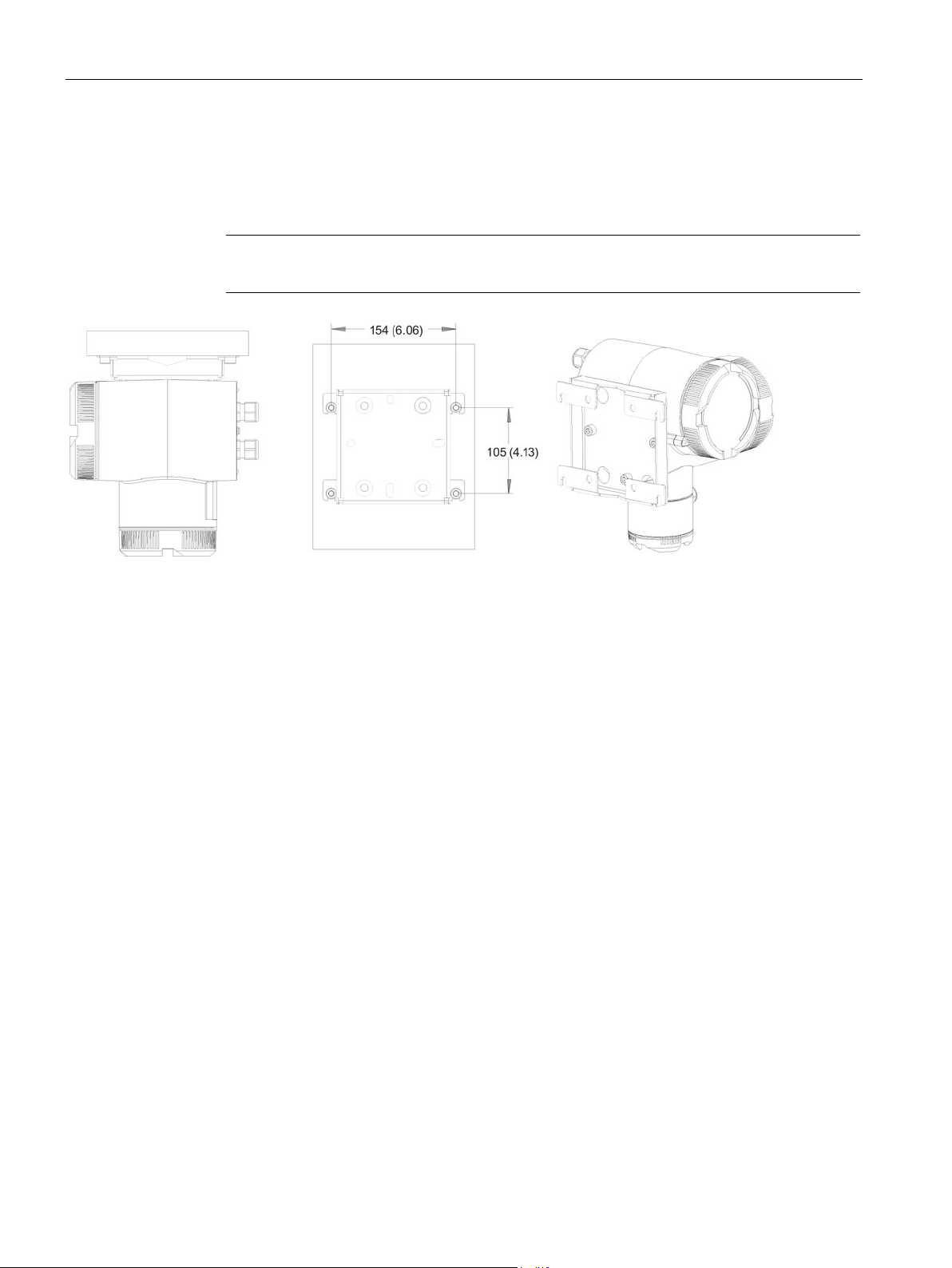

4.4.2

Pipe or wall mounting with assembly bracket

Pipe mounting

4.4 Remote installation

1. Fit the mounting plate on the transmitter using the mounting material provided

2. Mount transmitter with mounting plate on the wall.

Image 4-4 Standard mounting plate

For details on mounting plate, see Dimensions and weight (Page 63).

1. Mount the assembly bracket on the pipe using the fastening brackets

2. Fasten the transmitter with the two screws provided.

Pipe mounting with assembly bracket

MAG 6000 I / MAG 6000 I Ex de transmitter

Operating Instructions, 04/2016, A5E02083319-AG

27

Installing/Mounting

Wall mounting

Note

The fastening brackets and nuts are not needed for wall mounting.

4.4 Remote installation

1. Fasten the assembly bracket to the back of the transmitter

2. Fasten the transmitter and assembly bracket to the wall

Wall mounting with assembly bracket. Dimensions in mm (inch).

MAG 6000 I / MAG 6000 I Ex de transmitter

28 Operating Instructions, 04/2016, A5E02083319-AG

Loading...

Loading...