Page 1

s

INSTRUCTIONS

SITRANS F M

Electromagnetic flowmeter

type MAG 1100, DN 2 - DN 100 1/12" - 4"

ENGLISH

DEUTSCH

FRANÇAIS

DANSK

Introduction

083R9017

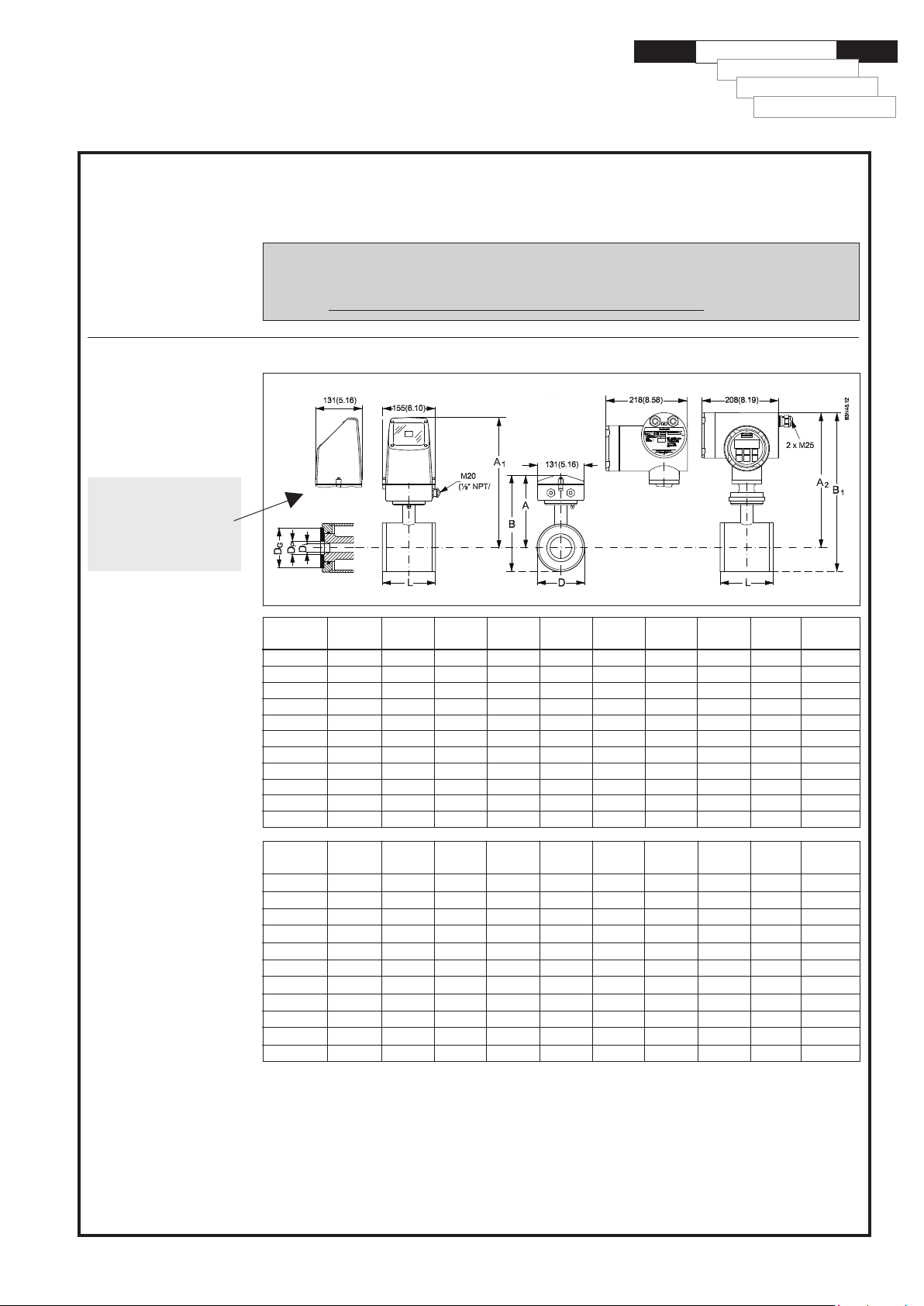

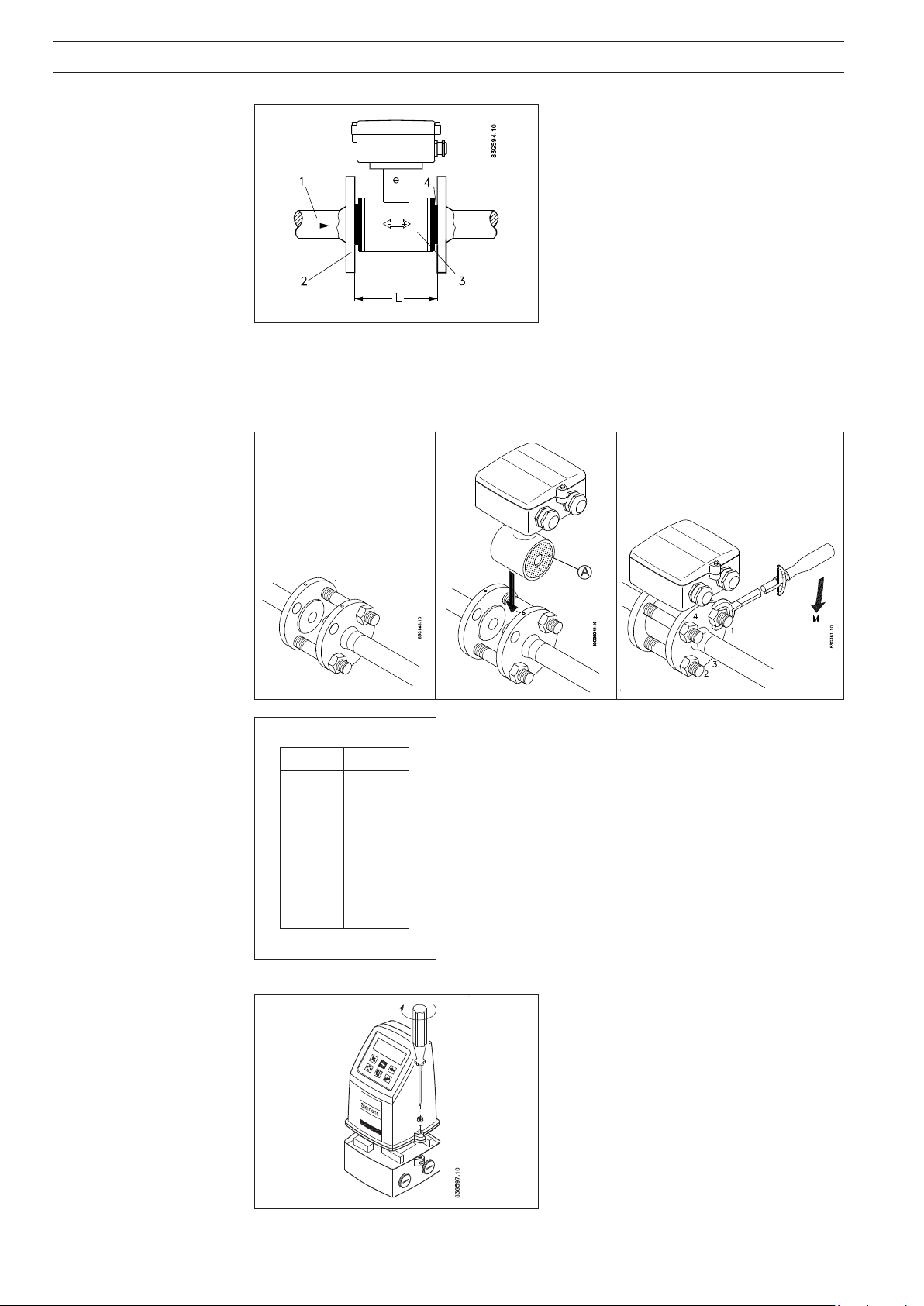

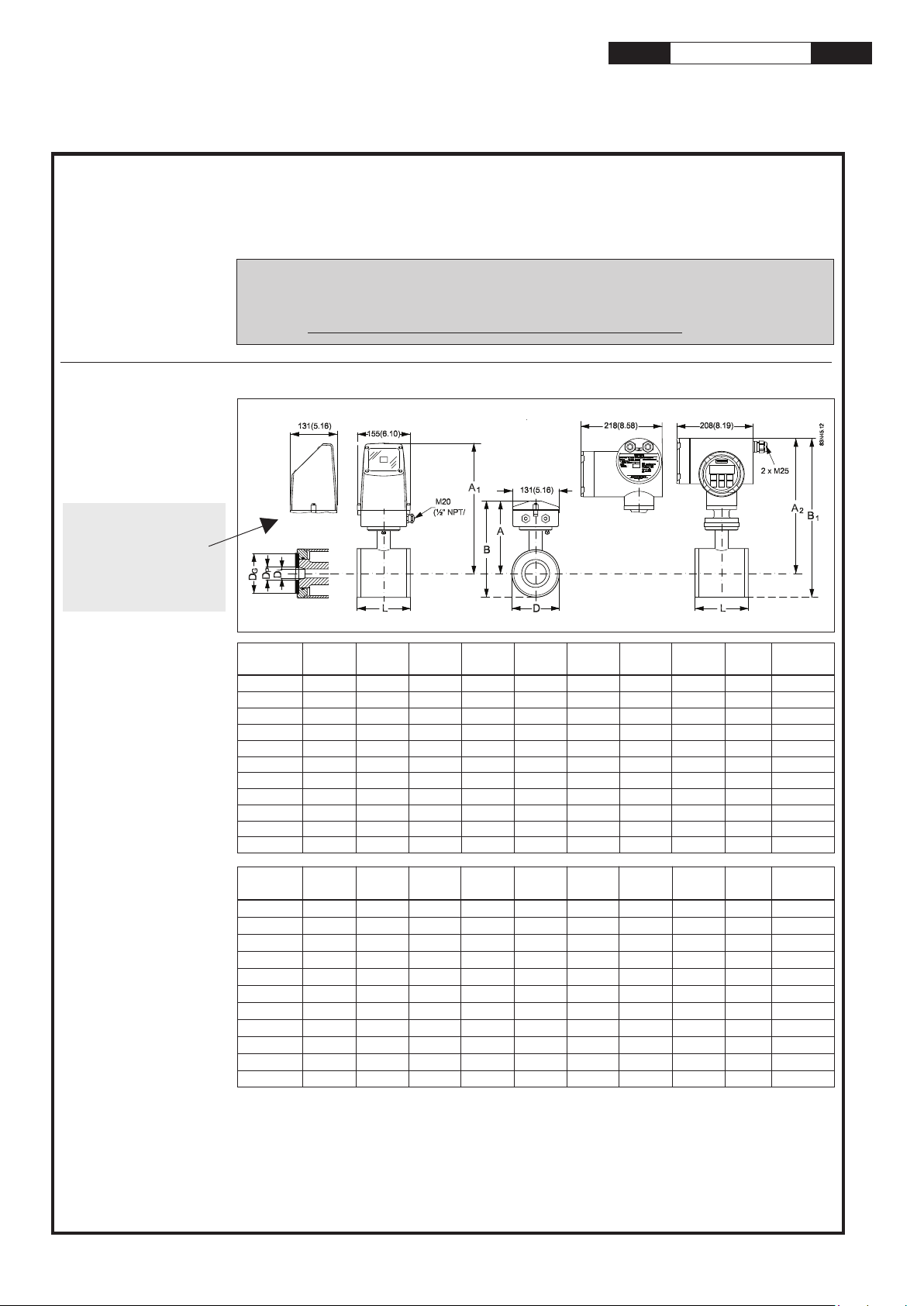

Dimensions and

weight

Important note!

for compact installations

with the MAG 6000I,

transmitter to be supported to avoid tension

on sensor part.

Siemens Flow Instruments SITRANS F M electromagnetic flowmeters consist of a sensor and a

transmitter. These instructions only describe the sensor installation. For further information on the

transmitter installation, please refer to the SITRANS F M handbook.

Technical Documentation (handbooks, instructions, manuals etc.) on the complete product

range SITRANS F can be found on the internet/intranet on the following links:

English:

http://www4.ad.siemens.de/WW/view/en/10806951/133300

MAG 1100/6000, MAG 1100/5000 and MAG 1100/6000I, compact/separate

DN A1)B1)A2/A

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

2 161 186 315 340 48.7 2 17.3 34 2.2

3 161 186 315 340 48.7 3 17.3 34 2.2

6 161 186 315 340 48.7 6 17.3 34 2.2

10 161 186 315 340 48.7 10 10 13.6 34 2.2

15 161 186 315 340 48.7 15 16 17.3 40 2.2

25 169 201 323 354 63.5 25 26 28.5 56 2.7

40 179 221 333 375 84.0 40 38 43.4 75 3.4

50 188 239 342 393 101.6 50 50 54.5 90 4.2

65 198 258 351 412 120.9 65 66 68.0 112 5.5

80 204 270 357 424 133.0 80 81 82.5 124 7.0

100 217 296 370 450 159.0 100 100 107.1 145 10.0

4

)B1DD

2

2

)Di (PFA) D

i

p

DGWeight3)

083R9017

Size A1)B1)A2/A

1

1

1

3

1

1½ 7.05 8.70 13.11 14.76 3.31 1.57 1.50 1.71 2.95 7.5

2½ 7.80 10.16 13.82 16.22 4.76 2.56 2.60 2.68 4.41 12

1

) 14.5 mm/0.57" shorter when the AISI terminal box is used. (high temperature 200°C (390°F)).

2

) DN 2-3 Zirconium (Zr02), DN 6-100/1/4"-4" Ceramic (Al2O3).

3

) With transmitter MAG 5000 or MAG 6000 installed, weight is increased by approximately 0.8 kg (1.8 lb).

4

)A2 is 3 mm(0.12") shorter than A1.

[inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch] [lbs]

/

12

/

/

/

/

1 6.66 7.92 12.72 13.94 2.50 0.98 1.02 1.12 2.20 4.9

2 7.40 9.41 13.47 15.47 4.00 1.97 1.97 2.15 3.54 9.2

3 8.03 10.63 14.06 16.70 5.24 3.15 3.19 3.25 4.88 15

4 8.54 11.65 14.57 17.72 6.26 3.94 3.94 4.22 5.91 22

6.34 7.33 12.40 13.39 1.92 0.08 0.68 1.34 4.8

6.34 7.33 12.40 13.39 1.92 0.12 0.68 1.34 4.8

8

6.34 7.33 12.40 13.39 1.92 0.24 0.68 1.34 4.8

4

6.34 7.33 12.40 13.39 1.92 0.39 0.39 0.53 1.34 4.8

8

6.34 7.33 12.40 13.39 1.92 0.59 0.63 0.68 1.57 4.8

2

4

)B1DD

2

2

)Di(PFA) D

i

p

DGWeight3)

SFIDK.PI.027.G7.52Order no.: FDK-521H0928

Page 2

SITRANS F M Electromagnetic flowmeter type MAG 1100, DN 2 - DN 100, 1/12" - 4"

Dimensions and weight

(continued)

The total build-in length "L" [mm/[inch]] depends on the gasket selected.

Size EPDM Graphite PTFE (Teflon) Without gasket Earthing ring

DN Inch [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]

1

2

2 ...10

/

64 2.52 66 2.60 70 2.75 64 2.52 77 3.03

12

1)

1

/

...3/864 2.52 66 2.60 70 2.75 64 2.52 77 3.03

12

15 ½ 65 2.56 66 2.60 70 2.75 64 2.52 77 3.03

25 1 80 3.15 81 3.19 85 3.35 79 3.10 92 3.62

40 1½ 95 3.74 96 3.78 100 3.94 94 3.70 107 4.21

50 2 105 4.13 106 4.17 110 4.33 104 4.05 117 4.61

65 2½ 130 5.12 131 5.15 135 5.31 129 5.05 142 5.60

80 3 155 6.10 156 6.14 160 6.30 154 6.00 167 6.57

100 4 185 7.28 186 7.31 190 7.48 184 7.20 197 7.76

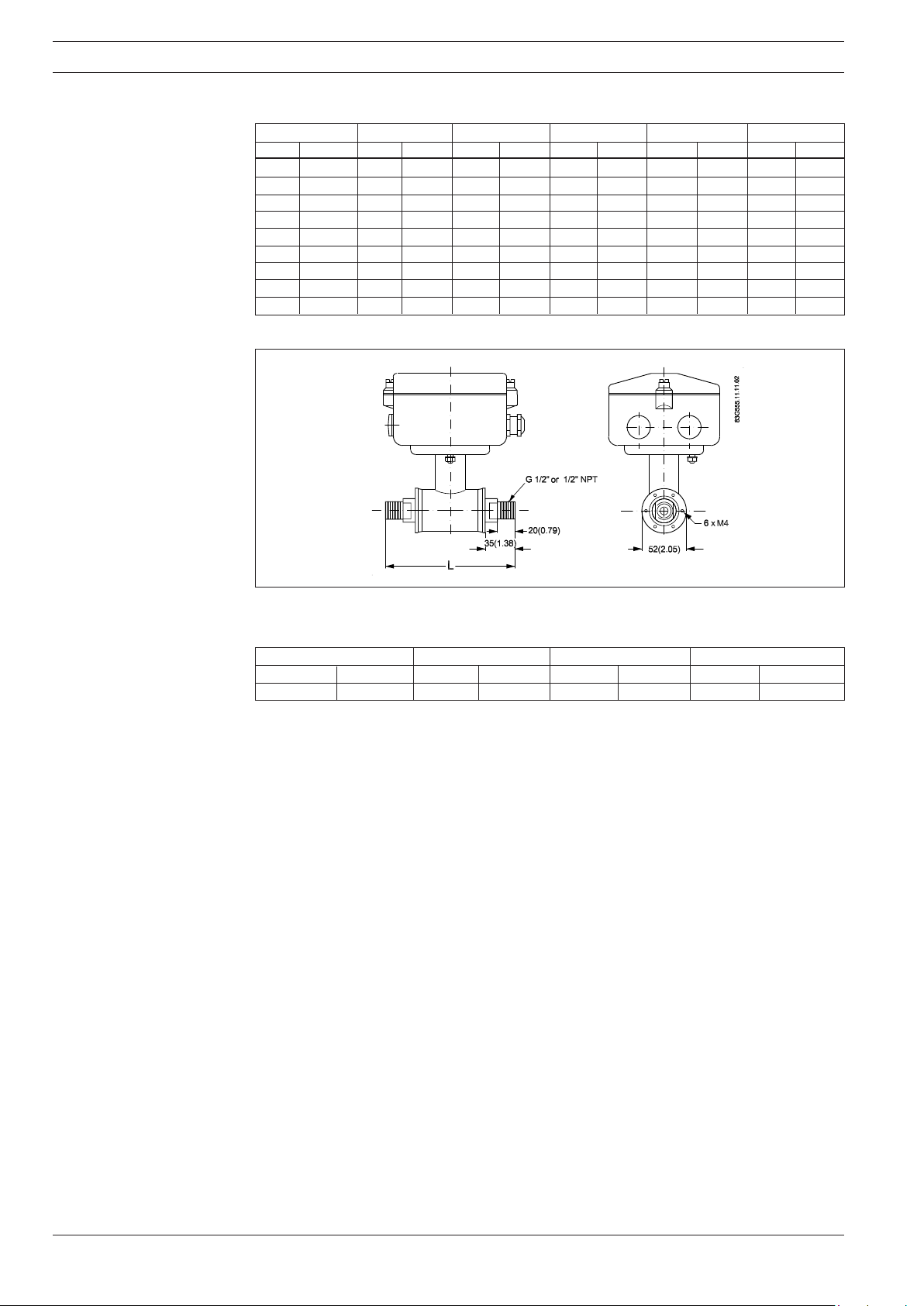

Sensor MAG 1100 DN2...10 (1/12”...3/8") with adaptors

The MAG 1100 DN 2, 3, 6 and DN 10 are prepared for G ½" (ISO) or ½" NPT pipe connection.

The length "L" varies dependent on the gasket choice.

Without gasket EPDM Graphite Teflon

[mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]

150 5.9 150 5.9 152 6.0 156 6.1

Important note:

For compact installation with the MAG 6000 I, transmitter to be supported to avoid tension on sensor

part.

2

Page 3

SITRANS F M Electromagnetic flowmeter type MAG 1100, DN 2 - DN 100, 1/12" - 4"

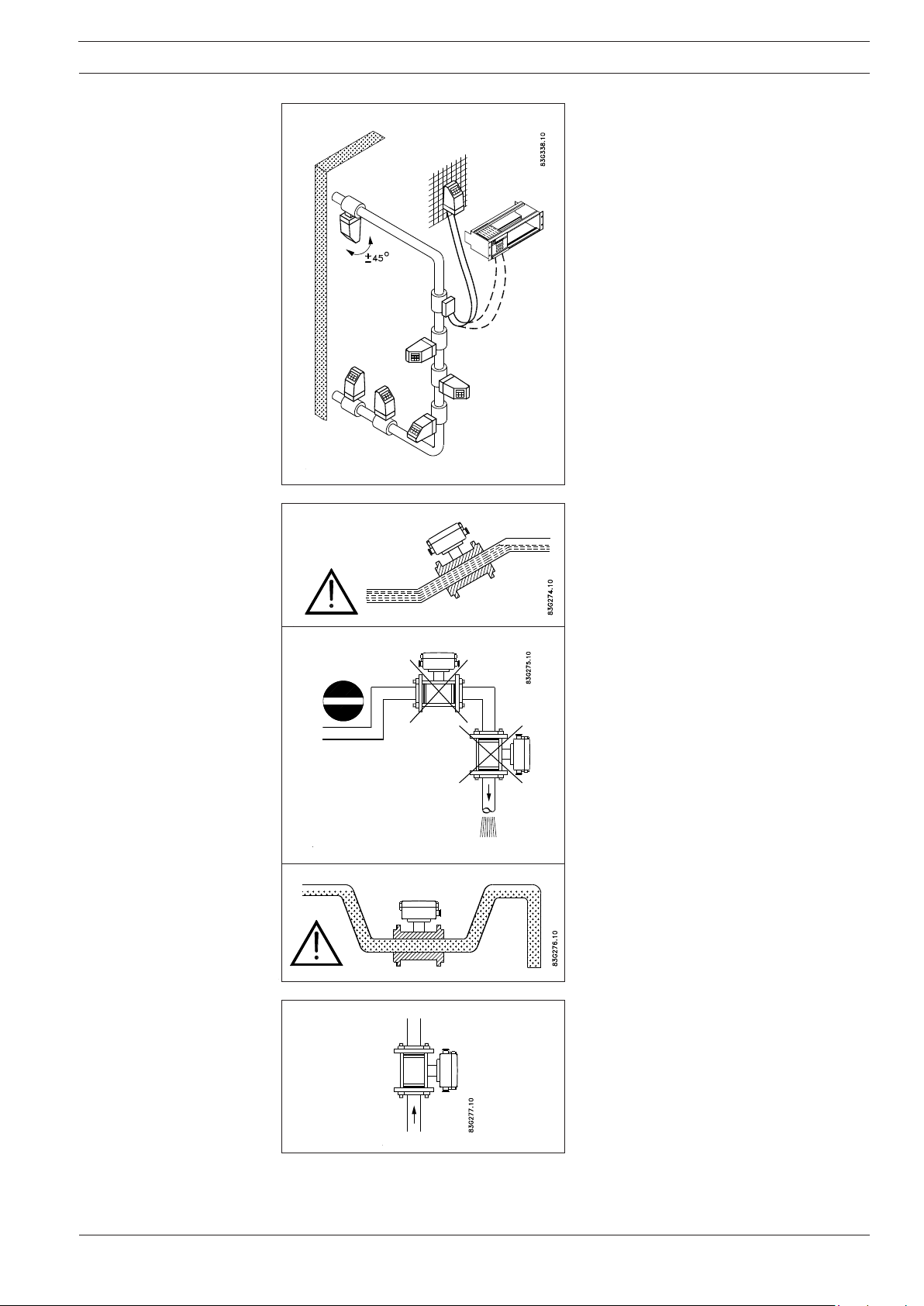

Installation, general

Reading and operating the flowmeter is possible under almost any installation conditions

because the display can be oriented in relation

to the sensor. To ensure optimum flow measurement attention should be paid to the following:

The sensor must always be completely full

with liquid.

Therefore avoid:

• Installation at the highest point in the pipe

system

• Installation in vertical pipes with free outlet

For partially filled pipes or pipes with downward flow and free outlet the flowmeter should

be located in a U-tube.

Installation in vertical pipes

Recommended flow direction: upwards. This

minimizes the effect on the measurement of

any gas/air bubbles in the liquid.

3

Page 4

SITRANS F M Electromagnetic flowmeter type MAG 1100, DN 2 - DN 100, 1/12" - 4"

Installation, general

(continued)

Installation in horizontal pipes

The sensor must be mounted as shown in the

upper figure. Do not mount the sensor as

shown in the lower figure. This will position the

electrodes at the top where there is possibility

for air bubbles and at the bottom where there

is possibility for mud, sludge, sand etc.

If using empty pipe detection the sensor can be

tilted 45°, as shown in the upper figure.

Measuring abrasive liquids and liquids containing particles

Recommended installation is in a vertical/

inclined pipe to minimize the wear and deposits in the sensor.

Avoid vibrations!

Inlet and outlet conditions

To achieve accurate flow measurement it is

essential to have straight lengths of inlet and

outlet pipes and a certain distance between

pumps and valves.

It is also important to centre the flowmeter in

relation to pipe flanges and gaskets.

Installation in large pipes

The flowmeter can be installed between two

reducers (e.g. DIN 28545). Assuming that at 8°

the following pressure drop curve applies. The

curves are applicable to water.

Example:

A flow velocity of 3 m/s (V) in a sensor with a

diameter reduction from DN 100 to DN 80

= 0.8) gives a pressure drop of 2.9 mbar.

(d

1/d2

4

Page 5

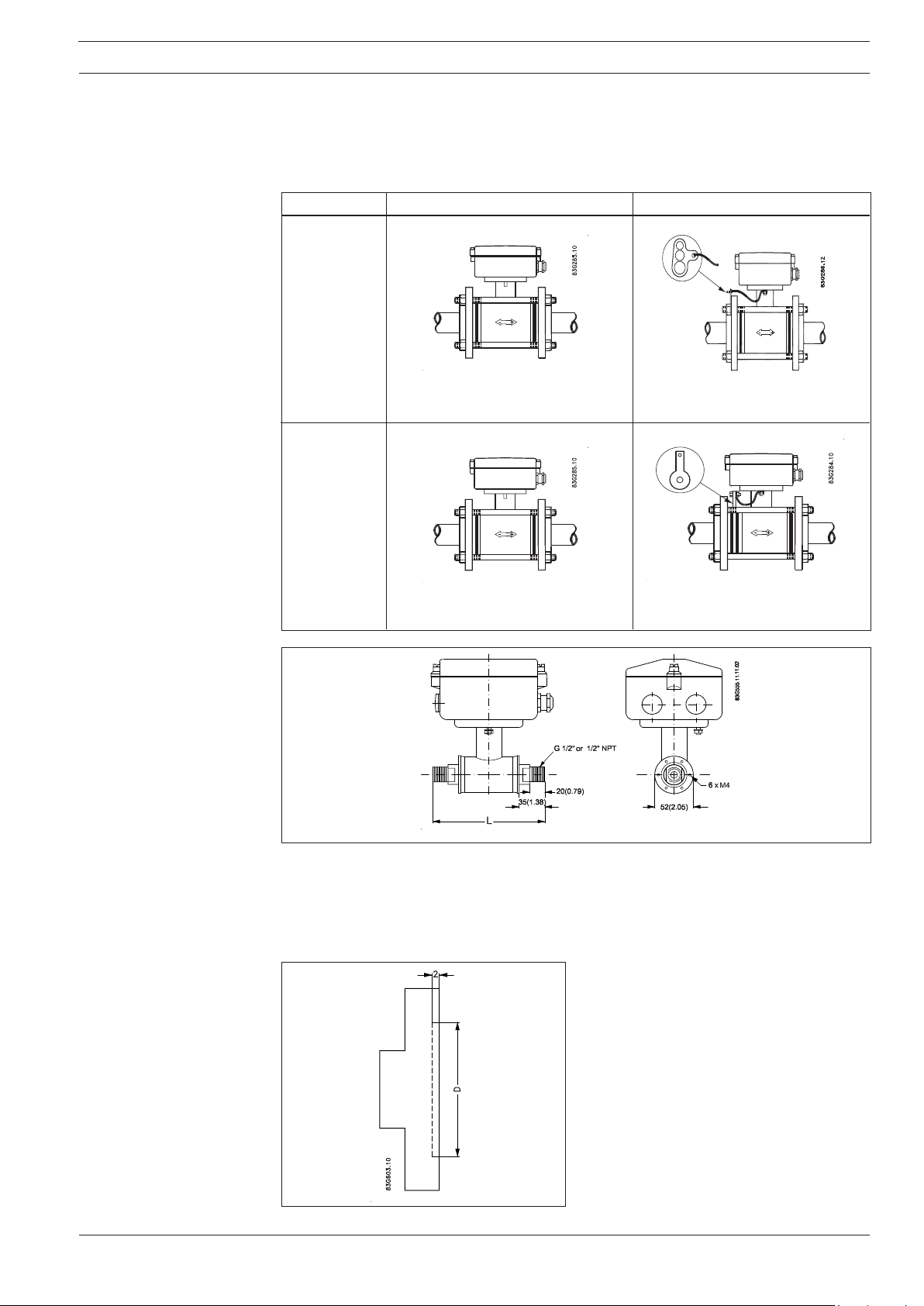

SITRANS F M Electromagnetic flowmeter type MAG 1100, DN 2 - DN 100, 1/12" - 4"

Installation, general

(continued)

Potential equalization

To obtain optimum results from the measuring system the sensor’s chassis point/housing must

have the same electrical potential as the liquid being measured.

Depending on the type of gasket selected (graphite, EPDM or PTFE) and application, this can

be achieved as follows:

Graphite gaskets EPDM or PTFE gaskets

Electrically

conductive

piping

A: Potential equalization with electri-

cally conductive graphite gaskets

Electrically

non-conductive

piping

B: Potential equalization using earth

strap supplied.

C: Potential equalization with electri-

cally conductive graphite gaskets

D: Potential equalization using sepa-

rate potential equalization ring

The sensors DN 2, 3, 6 and DN 10 can also be mounted between two adapter flanges. In this

way the potential equalization with the liquid occurs automatically.

NOTE:

Special attention must be paid to piping systems with cathodic protection.

See SITRANS F M handbook.

For applications where high accuracy is

required, it will be advantageous to use

recessed flanges as shown in the drawing.

NB

To obtain optimum measuring accuracy and

the necessary tightness, it is important that the

sensor gaskets and the flange centre lines are

merging and that the connection flanges have

been mounted at right angles to the pipe.

The connection flanges must be parallel.

5

Page 6

SITRANS F M Electromagnetic flowmeter type MAG 1100, DN 2 - DN 100, 1/12" - 4"

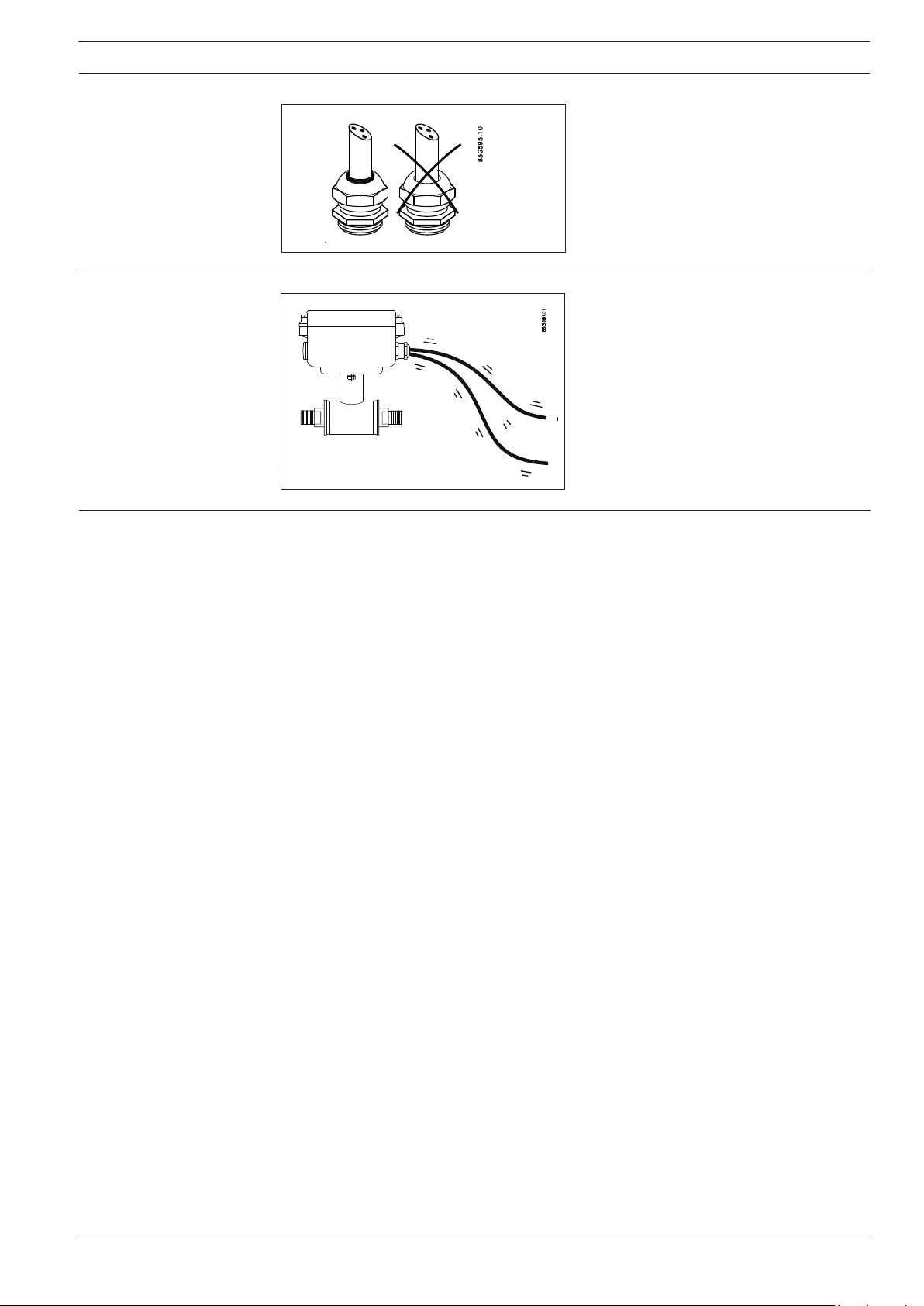

Installation

Tightening

The design of the sensor MAG 1100 allows for

bi-directional flow. Dimension L is given in the

previous table.

The arrow at the sensor indicates recommended

flow direction (the meter has been calibrated

with flow in arrow direction "+").

1. Existing pipe

2. Flange

3. Sensor

4. Gaskets

L. Sensor length incl. gaskets

First place three stay-bolts to locate the sensor, see a. These should be tightened gently, making

sure that each gasket fits exactly into its recess at either end of the sensor, see b.

The remaining flange bolts can now be inserted and tightened using about 25% of the actual

tightening torque, see table d.

ac

b

Installation of the cover or

transmitter on the terminal box

d

DN MA [Nm]

2

3

6

10

15

25

40

50

65

80

100

10 Nm ~ 1 kpm

13

13

13

13

16

30

54

90

90

90

115

The bolts must be tightened using up to 50% of the max.

tightening torque for the pipe dimensions stated. The max.

tightening torque for different size pipes is given in the table d.

The bolts must now be cross-tightened in the sequence shown

in c, using up to 100% torque.

1. Mount the cover or the transmitter on the

terminal box.

2. It is important that the screws are firmly

tightened (4 Nm). Use a large screwdriver

fitting into the screw slot.

6

Page 7

SITRANS F M Electromagnetic flowmeter type MAG 1100, DN 2 - DN 100, 1/12" - 4"

Installation, cable Tighten the cable glands and the cable entries

Installation, low conductivity and high vibration

levels of cables, MAG

1100 DN 2+3

Manufacturer’s design

and safety statement

1. Responsibility for the choice of lining and electrode materials with regard to their abrasion

and corrosion resistance lies with the purchaser; the effect of any change in process medium

during the operating life of the flowmeter should be taken into account. Incorrect selection

of lining and/or electrode materials could lead to a failure of the flowmeter.

2. It is the responsibility of the user to ensure that stresses and loading caused by earthquakes,

traffic, high winds and fire damage are taken into account during installation, when appropriate. These forces are not taken into account during flowmeter design.

3. It is the responsibility of the user to ensure that the flowmeter is installed such that it does not

act as a focus for pipeline stresses. External loadings are not taken into account during

flowmeter design.

4. During operation do not exceed the pressure and/or temperature ratings indicated on the data

label or in the installation instructions.

5. It is the responsibility of the user to ensure that all installations include over pressure protection,

means for draining/venting, and that adequate protection is provided to minimise

any risk of contact with hot surfaces.

6. Under the Pressure Equipment Directive this product is a pressure accessory, and not

approved for use as a safety accessory, as defined by the Pressure Equipment Directive.

7. Removal of the terminal box except by Siemens Flow Instruments or their approved agents

will invalidate the PED conformity of the product.

In accordance with the Pressure Equipment Directive (97/23/EC)

to obtain optimum sealing. The cable entry

gasket must obtain firm contact with the cable.

For sensors DN 2+3 in applications with low

conductivity and high vibration level of cables

use low noise coax electrode cable.

7

Page 8

s

INSTRUCTIONS

DEUTSCH

SITRANS F M

Magnetisch induktiver Durchflussmesser

Typ MAG 1100, DN 2 - DN 100 1/12" - 4"

Einführung

083R9017

Abmessungen und

Gewichte

Wichtiger Hinweis:

Bei Kompakteinbau mit

dem MAG 6000 I ist der

Messumformer abzustützen, um Zugspannung

auf den Messaufnehmer

zu vermeiden.

Siemens Flow Instruments SITRANS F M magnetisch-induktive Durchflussmesser bestehen aus

einem Messaufnehmer und einem Messumformer. Diese Instruktion beschreibt nur die Montage

des Messaufnehmers. Für weitere Informationen über die Montage des Messumformers, siehe

bitte das SITRANS F M Produkthandbuch.

Technische Unterlagen (Handbücher, Instruktionen, Betriebsanleitung usw.) des

kompletten Warenangebotes von SITRANS F sind auf dem Internet/Intranet unter folgenden

Links verfügbar

Deutsch:

http://www4.ad.siemens.de/WW/view/de/10806951/133300

MAG 1100/6000, MAG 1100/5000 und MAG 1100/6000I, kompakte/getrennte Montage

083R9017

DN A1)B1)A2/A

10 161 186 315 340 48,7 10 10 13,6 34 2,2

15 161 186 315 340 48,7 15 16 17,3 40 2,2

25 169 201 323 354 63,5 25 26 28,5 56 2,7

40 179 221 333 375 84,0 40 38 43,4 75 3,4

50 188 239 342 393 101,6 50 50 54,5 90 4,2

65 198 258 351 412 120,9 65 66 68,0 112 5,5

80 204 270 357 424 133,0 80 81 82,5 124 7,0

100 217 296 370 450 159,0 100 100 107,1 145 10,0

Size A1)B1)A2/A

1

/

1

1

3

1

1½ 7,05 8,70 13,11 14,76 3,31 1,57 1,50 1,71 2,95 7,5

2½ 7,80 10,16 13,82 16,22 4,76 2,56 2,60 2,68 4,41 12

1

) 13 mm kürzer bei Gebrauch des AISI-Klemmkastens (Hochtemperatur 200°C).

2

) DN 2-3 Zirkonium (Zr02), DN 6-100 Keramik (Al2O3).

3

) Bei eingebautem Messumformer MAG 5000 oder MAG 6000 erhöht sich das Gewicht um ca. 0,8 kg.

4

)A2 ist 3 mm(0.12") kürzer als A1.

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

2 161 186 315 340 48,7 2 17,3 34 2,2

3 161 186 315 340 48,7 3 17,3 34 2,2

6 161 186 315 340 48,7 6 17,3 34 2,2

[inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch] [lbs]

12

/

/

/

/

1 6,66 7,92 12,72 13,94 2,50 0,98 1,02 1,12 2,20 4,9

2 7,40 9,41 13,47 15,47 4,00 1,97 1,97 2,15 3,54 9,2

3 8,03 10,63 14,06 16,70 5,24 3,15 3,19 3,25 4,88 15

4 8,54 11,65 14,57 17,72 6,26 3,94 3,94 4,22 5,91 22

6,34 7,33 12,40 13,39 1,92 0,08 0,68 1,34 4,8

6,34 7,33 12,40 13,39 1,92 0,12 0,68 1,34 4,8

8

6,34 7,33 12,40 13,39 1,92 0,24 0,68 1,34 4,8

4

6,34 7,33 12,40 13,39 1,92 0,39 0,39 0,53 1,34 4,8

8

6,34 7,33 12,40 13,39 1,92 0,59 0,63 0,68 1,57 4,8

2

4

)B1DD

2

4

)B1DD

2

2

)Di (PFA) D

i

2

)Di(PFA) D

i

DGGewicht3)

p

DGGewicht3)

p

SFIDK.PI.027.G7.52

Page 9

SITRANS F M Magnetisch induktiver Durchflussmesser Typ MAG 1100, DN 2 - DN 100, 1/12" - 4"

Abmessungen und

Gewichte

(Fortsetzung)

Die Gesamteinbaulänge "L" [mm/[inch]] hängt von der Wahl der Dichtung ab.

Size EPDM Graphit PTFE (Teflon) Ohne Dichtung Erdungsflansch

DN Inch [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]

1

2

2 ,,10

/

64 2,52 66 2,60 70 2,75 64 2,52 77 3,03

12

1)

1

/

,,3/864 2,52 66 2,60 70 2,75 64 2,52 77 3,03

12

15 ½ 65 2,56 66 2,60 70 2,75 64 2,52 77 3,03

25 1 80 3,15 81 3,19 85 3,35 79 3,10 92 3,62

40 1½ 95 3,74 96 3,78 100 3,94 94 3,70 107 4,21

50 2 105 4,13 106 4,17 110 4,33 104 4,05 117 4,61

65 2½ 130 5,12 131 5,15 135 5,31 129 5,05 142 5,60

80 3 155 6,10 156 6,14 160 6,30 154 6,00 167 6,57

100 4 185 7,28 186 7,31 190 7,48 184 7,20 197 7,76

Sensor MAG 1100 DN2...10 (1/12”...3/8") mit Adaptern

MAG 1100 DN 2, 3, 6 und DN 10 sind für den Anschluss an G ½" (ISO) oder ½" NPT-Rohrleitungen

vorbereitet.

Die Gesamteinbaulänge "L" [mm] hängt von der Wahl der Dichtung ab.

Ohne Dichtung EPDM Graphit Teflon

[mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]

150 5.9 150 5.9 152 6.0 156 6.1

Wichtiger Hinweis:

Bei Kompakteinbau mit dem MAG 6000 I ist der Messumformer abzustützen, um Zugspannung

auf den Messaufnehmer zu vermeiden.

9

Page 10

SITRANS F M Magnetisch induktiver Durchflussmesser Typ MAG 1100, DN 2 - DN 100, 1/12" - 4"

Einbau, allgemein

Der Durchflussmesser kann in jeder Einbaulage abgelesen werden, da die Anzeige drehbar ist und in jeder beliebigen Position im

Verhältnis zum Messaufnehmer eingebaut

werden kann. Die endgültige Position sollte

vor der Montage festgelegt werden. Um optimale Messergebnisse zu sichern, sind folgende Hinweise zu beachten:

Der Messaufnehmer muss immer vollständig

gefüllt sein.

Vermeiden Sie:

• Einbau an höchster Stelle des Rohrsystems

• Einbau in einer senkrechten Rohrleitung mit

freiem Ablauf.

Ist eine nur teilweise gefüllte Rohrleitung oder

der freie Ablauf nicht zu vermeiden, sollte der

Durchflussmesser gedükert werden.

Einbau in einer senkrechten Rohrleitung

Empfohlene Strömungsrichtung: von unten

nach oben. Dadurch werden ungenaue

Messergebnisse, verursacht durch Gas- bzw.

Luftblasen im Medium, vermieden.

10

Page 11

SITRANS F M Magnetisch induktiver Durchflussmesser Typ MAG 1100, DN 2 - DN 100, 1/12" - 4"

Einbau, allgemein

(Fortsetzung)

Einbau in einer waagerechten Rohrleitung

Der Messaufnehmer ist wie nebenstehend in

der oberen Abbildung gezeigt zu montieren.

Wegen der Lage der Elektroden oben (hier

können Luftblasen entstehen) und unten (eventuelle Ansammlung von Schlamm, Sand usw.)

darf die Montage nicht wie in der unteren

Abbildung gezeigt erfolgen. Wird die Leerlaufüberwachung aktiviert, um einen leeren Messaufnehmer zu melden, dürfen Messaufnehmer

und Mess-umformer nicht mehr als 45 bis 60°

gedreht werden, siehe obere Abbildung.

Messen von verunreinigten bzw. abrasiven

Medien

In diesem Fall wird der Einbau in einer senkrechten bzw. schrägen Rohrleitung empfohlen, um Verschleiß bzw. Ablagerungen so weit

wie möglich zu vermeiden.

Vermeiden Sie Vibrationen!

Ein- und Auslauf

Genaue Messwerte können nur dann erzielt

werden, wenn ausreichend große gerade Einund Auslaufstrecken sowie genügender Abstand nach Pumpen, Ventilen o. ä. eingehalten

werden.

Außerdem muss der Durchflussmesser mittig

zu den Flanschen und Dichtungen des Rohrsystems eingebaut werden.

Einbau in einer Rohrleitung mit großem

Durchmesser

Falls notwendig, kann der Durchflussmesser

auch zwischen zwei Reduzierstücken, z. B.

nach DIN 28545 eingebaut werden. Unter der

Voraussetzung, dass α

< 8° gilt nebenstehen-

des Druckverlustdiagramm (Medium: Wasser).

Beispiel:

Eine Durchflussgeschwindigkeit von V = 3 m/

s in einem Messaufnehmer mit einer Durchmesserreduktion von DN 100 auf DN 80 (d

= 0,8) verursacht einen Druckabfall von 2,9

1/d2

mbar.

11

Page 12

SITRANS F M Magnetisch induktiver Durchflussmesser Typ MAG 1100, DN 2 - DN 100, 1/12" - 4"

Einbau, allgemein

(Fortsetzung)

Potentialausgleich

Optimale Messergebnisse lassen sich nur dann erzielen, wenn das Messaufnehmergehäuse

und das zu messende Medium das gleiche elektrische Potential haben.

Abhängig von der gewählten Dichtung (Graphit, EPDM oder Teflon) und der Anwendung wird dies

wie folgt erreicht:

Graphitdichtung EPDM- oder Teflondichtung

Elektrisch

leitendes

Rohrsystem

A: Potentialausgleich über elektrisch

leitende Graphitdichtungen

Elektrisch nicht

leitendes

Rohrsystem

B: Potentialausgleich über den

mitgelieferten Hilfserder

C: Potentialausgleich über elektrisch

leitende Graphitdichtungen

D: Potentialausgleich über den

zusätzlich zu bestellenden Potentialausgleichsflansch

Die Messaufnehmer DN 2, 3, 6 und DN 10 können auch zwischen zwei Prozessanschlüssen

montiert werden. Der Potentialausgleich mit dem Medium erfolgt dann automatisch über diese

Prozessanschlüsse und das angrenzende Rohr.

Hinweis:

Bei Rohrsystemen mit Kathodenschutz gelten folgende besondere Regeln:

Siehe SITRANS F M Produkthandbuch.

Für Anwendungen bei denen hohe Genauigkeit gefordert wird, ist es vorteilhaft Gegenflansche wie abgebildet einzusetzen.

12

NB

Zur Erreichung der optimalen Messgenauigket

und Stabilität ist es wichtig, dass die Dichtungen sowie die Flanschschnittlinie übereinstimmen.

Die Verbindungsflansche müssen im rechten

Winkel zum Messrohr und parallel zueinander

angebracht werden.

Page 13

SITRANS F M Magnetisch induktiver Durchflussmesser Typ MAG 1100, DN 2 - DN 100, 1/12" - 4"

Installation

Anziehen

Die Einbaurichtung des Messaufnehmers kann

beliebig gewählt werden.

Die Einbaulänge L der Messaufnehmers ist aus

der umstehende Tabelle ersichtlich.

Der Pfeil am Messaufnehmer zeigt die empfohlene Durchflussrichtung an (Das Gerät wurde in

Pfeilrichtung "+" kalibriert).

1. Rohrleitung

2. Flansch

3. Messaufnehmer

4. Dichtung

L. Einbaulänge mit Dichtungen

Drei Dehnbolzen in die Bohrungen der Flanschen einsetzen und mit den Sechskantmuttern

befestigen (Abb. a). Den Messaufnehmer nun zwischen die Dichtungen einpassen, wobei darauf

zu achten ist, dass die Dichtungen in den Dichtflächen des Messaufnehmers anliegen (Abb. b).

Die restlichen Dehnbolzen einsetzen. Danach die Sechskantmuttern mit einem Drehmomentschlüssel in der in Abb. c gezeigten Reihenfolge anziehen.

ac

b

Montage von Deckel oder

Messumformer auf den

Klemmenkasten

d

DN MA [Nm]

2

3

6

10

15

25

40

50

65

80

100

10 Nm ~ 1 kpm

13

13

13

13

16

30

54

90

90

90

115

Die Tabelle d zeigt die maximalen Anzugsmomente für die

entsprechenden Nennweiten. Die Muttern sollten zunächst mit

50%, danach mit 75% und schließlich mit 100% des max.

Momentes angezogen werden.

1. Ausschließend den Deckel oder den Messumformer auf den Klemmenkasten montieren.

2. Darauf achten, dass die Schrauben gut

festgezogen werden (min. 4 Nm).

13

Page 14

SITRANS F M Magnetisch induktiver Durchflussmesser Typ MAG 1100, DN 2 - DN 100, 1/12" - 4"

Montage, Kabel

IInstallation, geringe

Leitfähigkeit und hohe

Schwingungspegel von

Kabeln, MAG 1100 DN 2+3

Stellungnahme des

Herstellers hinsichtlich

Aufbau und Sicherheit

Die Kabelverschraubungen fest anziehen, um

optimale Dichtheit zu gewährleisten. Die

Dichtungen in der Kableverschraubung sollen

deutlich um das Kabel klemmen.

Für Messaufnehmer DN 2+3 in Applikationen

mit geringer Leitfähigkeit und hohen

Schwingungspegeln verwenden Sie rauscharmes Koaxkabel.

1.

Die Verantwortung für die Wahl der Auskleidungs- und Elektrodenwerkstoffe hinsichtich ihrer

Abrieb- und Korrosionsfestigkeit trägt der Käufer; die Auswirkung jeglicher Änderung im

Prozessmedium während der Betriebs-Lebensdauer des Durchflussmessers sollte man

berücksichtigen. Unsachgemäße Wahl der Auskleidungs- und/oder Elektrodenwerkstoffe

könnte zu einem Ausfall des Durchflussmessers führen.

2. Es liegt in der Verantwortung des Benutzers dafür zu sorgen, dass Anspannungen und

Belastungen durch Erdbeben, Verkehr, starke Winde und Brandschäden beim Einbau

gegebenenfalls berücksichtigt werden. Diese Kräfte werden bei der Auslegung des

Durchflussmessers nicht berücksichtigt.

3. Es liegt in der Verantwortung des Benutzers, den Durchflussmesser so einzubauen, dass er

nicht im Zentrum von Rohrleitungs-Verformungen steht. Externe Belastungen werden bei der

Auslegung des Durchflussmessers nicht berücksichtigt.

4. Während des Betriebs nicht die Druck- und/oder Temperaturwerte überschreiten, die auf dem

Typenschild oder in den Einbauanweisungen angegeben sind.

5. Es liegt in der Verantwortung des Benutzers dafür zu sorgen, dass alle Installationen einen

Überdruckschutz, Vorrichtungen zum Entleeren/Entlüften und einen geeigneten Schutz zur

Minimierung der Berührungsgefahr mit heißen Oberflächen enthalten.

6. Unter der Druckbehälter-Richtlinie ist dieses Produkt ein Druckzubehör und nicht zur

Verwendung als Sicherheitszubehör zugelassen, wie in der Druckbehälter-Richtlinie festgelegt.

7. Der Abbau der Anschlussdose, außer durch Siemens Flow Instruments oder deren zugelassene

Vertreter, macht die PED-Konformität des Produkts ungültig.

Gemäß der Druckbehälter-Richtlinie (97/23/EG).

14

Page 15

s

INSTRUCTIONS

FRANÇAIS

SITRANS F M

Débitmètre à induction magnétique

type MAG 1100, DN 2 - DN 100 1/12" - 4"

Présentation

083R9017

Dimensions et poids

Remarque importante :

Pour éviter d'exercer une

tension excessive sur la

tête de mesure, prévoir

un support adapté pour

le MAG 6000 I, montage

compact.

Siemens Flow Instruments SITRANS F M débitmètres à induction magnétique consistent d'une tête

de mesure et d'un convertisseur de signaux. Cette instruction seulement concerne le montage de

la tête de mesure. Pour plus d'informations sur le montage du convertisseur de signaux, voir le

Manuel.

Les Documentations techniques (manuels, instructions, etc...) de la gamme de produits

SITRANS F peuvent être trouvées sur internet/intranet avec le lien suivant :

Francais:

http://www4.ad.siemens.de/WW/view/fr/10806951/133300

MAG 1100/6000 et MAG 1100/5000, montage compact/séparé

DN A1)B1)A2/A

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

2 161 186 315 340 48,7 2 17,3 34 2,2

3 161 186 315 340 48,7 3 17,3 34 2,2

6 161 186 315 340 48,7 6 17,3 34 2,2

10 161 186 315 340 48,7 10 10 13,6 34 2,2

15 161 186 315 340 48,7 15 16 17,3 40 2,2

25 169 201 323 354 63,5 25 26 28,5 56 2,7

40 179 221 333 375 84,0 40 38 43,4 75 3,4

50 188 239 342 393 101,6 50 50 54,5 90 4,2

65 198 258 351 412 120,9 65 66 68,0 112 5,5

80 204 270 357 424 133,0 80 81 82,5 124 7,0

100 217 296 370 450 159,0 100 100 107,1 145 10,0

4

)B1DD

2

2

)Di (PFA) D

i

p

DGPoids3)

083R9017

Size A1)B1)A2/A

1

1

1

3

1

1½ 7,05 8,70 13,11 14,76 3,31 1,57 1,50 1,71 2,95 7,5

2½ 7,80 10,16 13,82 16,22 4,76 2,56 2,60 2,68 4,41 12

1

) 13 mm plus court si utilisation d’une boîte de connexions AISI (haute température 200°C).

2

) DN 2-3 Zirconium (Zr02), DN 6-100 céramique (Al2O3).

3

) Avec convertisseur de signaux MAG 5000 ou MAG 6000 intégré, le poids augmente d’environ 0,8 kg.

4

)A2 est 3 mm(0.12") plus court que A1.

[inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch] [inch] [lbs]

/

12

/

/

/

/

1 6,66 7,92 12,72 13,94 2,50 0,98 1,02 1,12 2,20 4,9

2 7,40 9,41 13,47 15,47 4,00 1,97 1,97 2,15 3,54 9,2

3 8,03 10,63 14,06 16,70 5,24 3,15 3,19 3,25 4,88 15

4 8,54 11,65 14,57 17,72 6,26 3,94 3,94 4,22 5,91 22

6,34 7,33 12,40 13,39 1,92 0,08 0,68 1,34 4,8

6,34 7,33 12,40 13,39 1,92 0,12 0,68 1,34 4,8

8

6,34 7,33 12,40 13,39 1,92 0,24 0,68 1,34 4,8

4

6,34 7,33 12,40 13,39 1,92 0,39 0,39 0,53 1,34 4,8

8

6,34 7,33 12,40 13,39 1,92 0,59 0,63 0,68 1,57 4,8

2

4

)B1DD

2

2

)Di(PFA) D

i

p

DGPoids3)

SFIDK.PI.027.G7.52

Page 16

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

Dimensions et poids

(suite)

La longueur totale avant montage "L" [mm/[inch]] dépend du joint sélectionné.

Size EPDM Graphite PTFE (téflon) Sans joint Bride de terre

DN Inch [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]

1

2

2 ,,10

/

64 2,52 66 2,60 70 2,75 64 2,52 77 3,03

12

1)

1

/

,,3/864 2,52 66 2,60 70 2,75 64 2,52 77 3,03

12

15 ½ 65 2,56 66 2,60 70 2,75 64 2,52 77 3,03

25 1 80 3,15 81 3,19 85 3,35 79 3,10 92 3,62

40 1½ 95 3,74 96 3,78 100 3,94 94 3,70 107 4,21

50 2 105 4,13 106 4,17 110 4,33 104 4,05 117 4,61

65 2½ 130 5,12 131 5,15 135 5,31 129 5,05 142 5,60

80 3 155 6,10 156 6,14 160 6,30 154 6,00 167 6,57

100 4 185 7,28 186 7,31 190 7,48 184 7,20 197 7,76

Tête de mesure MAG 1100 DN2...10 (1/12”...3/8") avec adaptateurs

Le MAG 1100 DN 2, 3, 6 et DN 10 sont préparés pour montage avec le raccord de tuyauterie

G ½" (ISO) ou ½" NPT.

La longueur "L" dépend du joint sélectionné:

Sans joint EPDM Graphite Téflon

[mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]

150 5,9 150 5,9 152 6,0 156 6,1

Remarque importante :

Pour éviter d'exercer une tension excessive sur la tête de mesure, prévoir un support adapté pour

le MAG 6000 I, montage compact.

16

Page 17

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

Installation générales Il est possible de lire et d’utiliser le débitmètre

dans la plupart des conditions d’installation

l’afficheur pouvant être orienté par rapport à la

tête de mesure. Pour obtenir des mesures de

débit optimales, respecter les recommandations suivantes:

La tête de mesure doit toujours être totalement remplie de liquide.

Pour cela, éviter:

• le montage au point le plus haut de la

tuyauterie,

• le montage sur tubes verticaux à sortie libre.

Dans le cas de tubes en partie vides ou à

écoulement vers le bas et sortie libre, le

débitmètre doit être installé dans un tube en U.

Installation sur conduites verticales

Sens d'écoulement recommandé: vers le haut,

afin de minimiser l'effet des bulles d'air ou de

gaz pouvant se trouver dans le liquide sur la

précision de mesure.

17

Page 18

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

Installation générales

(suite)

Montage sur conduites horizontales

La tête de mesure doit être montée conformément à la figure du haut. Eviter le montage de

la figure du bas les électrodes étant situées

dans la partie supérieure, où des bulles d’air

peuvent se former, et dans la partie inférieure,

où peuvent se trouver de la boue, du sable, etc.

Pour une surveillance optimale des conduites

vides, la tête de mesure doit être orientée selon

un angle de 45°, comme indiqué par la figure

du haut.

Mesure de fluides abrasifs ou contenant des

particules en suspension

Dans ce cas, nous recommandons un montage sur conduites verticales/inclinées pour

réduire l'usure et les dépôts dans la tête de

mesure.

Tenir à l’écart des vibrations!

Conditions amont et aval

Pour garantir la précision des mesures débits,

prévoir des sections droites en amont et en aval

de la tête de mesure et maintenir une distance

suffisante entre les pompes et les vannes.

Il est également important de centrer le

débitmètre par rapport aux brides et aux joints

de la tuyauterie.

Installation sur conduites de grand diamètre

Le débitmètre peut aussi être installé entre

deux raccords réducteurs (par ex. DIN 28545).

On suppose que, à 8°, on obtient la courbe de

perte de charge ci-dessous. Ces courbes sont

valables pour l'eau.

Exemple:

Pour une vitesse d'écoulement de 3 m/s (V)

dans la tête de mesure et une réduction de

diamètre de DN 100 à DN 80 (d

obtient une perte de charge de 2,9 mbar.

= 0,8), on

1/d2

18

Page 19

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

Installation générales

(suite)

Egalisation de potentiel

Pour une précision optimale du système de mesure, le châssis/boîtier de la tête de mesure doit

présenter le même potentiel électrique que le fluide mesuré.

Selon le type de joint utilisé (graphite, EPDM ou PTFE) et l'application, l'égalisation de potentiel

peut être effectuée de la manière suivante:

Joints en graphite Joints en EPDM ou PTFE

Tuyauterie

conductrice

A: Egalisation de potentiel à l'aide de

joints en graphite conducteurs

Tuyauterie non

conductrice

B: Egalisation de potentiel à l'aide de

la bride de terre fournie

C: Egalisation de potentiel à l'aide de

joints en graphite conducteurs

D: Egalisation de potentiel à l'aide de

brides d'égalisation particulières

La tête de mesure DN 2, DN 3, DN 6 et DN 10 peut aussi être installée entre deux raccords. Ces

raccords et le tube voisin permettent une égalisation de potentiel automatique avec le fluide.

NOTE:

Les tuyauteries à protection cathodique font l'objet de dispositions particulières.

Voir le Manuel SITRANS F M .

Dans les applications où une précision optimale est requise, il est préférable d'utiliser

des brides à emboîtement simple (voir le

schéma).

NB

Pour obtenir une précision optimale et un

montage correct, il est important que les joints

du capteur soient bien centrés sur les brides

de la tuyauterie et que ces dernières soient

montées avec le bon angle sur la conduite.

Les brides de la tuyaterie doivent être

parallèles.

19

Page 20

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

Installation

Serrage

La conception de la tête de mesure type MAG

1100 permet de mesurer le fluide quel que soit

le sens d’écoulement.

Voir le tableau précédent (L) pour la longueur

totale d'intégration.

La flèche sur le capteur indique le sens positif

recommandé pour le débit (le capteur a été

étalonné avec le débit dans le sens "+").

1. Tuyau existant

2. Bride

3. Tête de mesure

4. Joints

L. Longueur totale joint compris

Glisser deux ou trois tirants dans leurs logements respectifs et les serrer légèrement, voir a. Veiller

à ce que les joints s’insèrent correctement dans les logements de chaque côté de la tête de mesure,

voir b. Mettre en place tous les tirants et les serrer légèrement (à environ 25% du couple de serrage

définitif).

ac

b

Installation du couvercle

ou du convertisseur de

signaux sur la boîte à

bornes

d

DN MA [Nm]

2

3

6

10

15

25

40

50

65

80

100

10 Nm ~ 1 kpm

13

13

13

13

16

30

54

90

90

90

115

Commencer par serrer les boulons à 50% du couple de serrage

requis pour le diamètre concerné (voir tableau d).

Serrer ensuite, toujours en procédant par diagonales (voir c),

à 75% et finalement à 100% du couple de serrage requis.

1. Monter le couvercle ou le convertisseur de

signaux sur la boîte à bornes.

2. Veiller au serrage correct des vis (4 Nm).

Employer pour cela un tournevis de grande

taille adapté à la tête de vis.

20

Page 21

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

Installation de la tête

de mesure

Installation de câbles

MAG 1100 DN 2+3 en

présence de basse

conductivité et de vibrations importantes

Déclaration du fabricant

à l’égard de la construction

et de la sécurité

Ne pas soumettre le transmetteur à de fortes

vibrations. En présence de fortes vibrations, il

est préférable de prévoir le montage séparé

des transmetteurs MAG 6000 I et MAG 6000 I

Ex d.

L'installation de capteurs DN 2+3 en présence

de basse conductivité et de vibrations

importantes des câbles requiert l'utilisation de

câble coaxial faible bruit.

1.

L’acheteur est responsable pour le choix des matériaux de revêtement et d‘électrode à l’égard

de leur résistance à l’usure et à la corrosion; il faut tenir compte de l’effet de tout changement

dans le fluide de procès pendant la durée de service du débitmètre. Le choix inopportun des

matériaux de revêtement et/ou d‘électrode pourrait causer une défaillance du débitmètre.

2. Lors de l’installation l’utilisateur doit prendre en compte les pressions et les charges

susceptibles d’être provoquées par les tremblements de terre, le traffic, les vents forts et les

incendies. Ces forces extérieures ne sont pas prises en compte lors de la conception du

débitmètre.

3. L’utilisateur doit veiller à ce que le débitmètre soit installé de sorte qu’il ne soit pas une cible

pour les tensions exercées sur les conduites. Ces charges extérieures ne sont pas prises en

compte lors de la conception du débitmètre.

4. Pendant le fonctionnement, ne pas dépasser les valeurs de pression et/ou de température,

indiquées sur la plaque d’identification ou dans les instructions d‘installation.

5. L’utilisateur doit s’assurer que toutes les installations comportent une protection adéquate

des sur-pressions, ainsi que des dispositifs de vidange/ventilation, et qu’une protection

adéquate est assurée pour minimiser tout contact avec des surfaces chaudes.

6. Sous la Directive Équipements de Pression, ce produit est un accessoire de pression et ne

pas agréé pour l’utilisation comme accessoire de sécurité, comme fixé dans la Directive

Équipements de Pression.

7. Le démontage de la boîte de connexion, sauf si effectué par Siemens Flow Instruments ou

leurs représentants autorisés, annule la conformité PED du produit.

Selon la Directive Équipements de Pression (97/23/CE).

21

Page 22

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

22

Page 23

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

23

Page 24

SITRANS F M Débitmètre à induction magnétique type MAG 1100, DN 2 - DN 100 1/12" - 4"

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement

are always welcomed.

Technical data subject to change without prior notice.

Siemens Flow Instruments A/S

24

Nordborgvej 81

DK-6430 Nordborg

The reproduction, transmission or use of this document or its contents is not permitted without

express written authority.

Offenders will be liable for damages. All rights, including rights created by patent grant or

registration of a utility model or design, are reserved.

Copyright © Siemens AG 06.2009 All Rights Reserved

Order no.: FDK: 083R9017

Printed in: Denmark

Loading...

Loading...