Page 1

Page 2

: IMPRINT ::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of Siemens.

Subject to change without notice.

Copyright 2009 by Siemens

2

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 3

SITRANS FX300

CONTENTS

1 Safety instructions 6

1.1 Intended use ..................................................................................................................... 6

1.2 Certifications .................................................................................................................... 7

1.3 Safety instructions from the manufacturer ..................................................................... 8

1.3.1 Copyright and data protection ................................................................................................ 8

1.3.2 Disclaimer ............................................................................................................................... 8

1.3.3 Product liability and warranty ................................................................................................ 9

1.3.4 Information concerning the documentation........................................................................... 9

1.3.5 Warnings and symbols used................................................................................................. 10

1.4 Safety instructions for the operator............................................................................... 10

2 Device description 11

2.1 Scope of delivery............................................................................................................. 11

2.2 Instrument versions ....................................................................................................... 11

2.2.1 Devices with connection flange ............................................................................................ 12

2.2.2 Sandwich version .................................................................................................................. 12

2.2.3 Device description................................................................................................................. 13

2.2.4 Free air delivery measurement - FAD (optional) ................................................................. 13

2.2.5 Gross heat meter .................................................................................................................. 14

2.2.6 Dual seal ............................................................................................................................... 15

2.3 Nameplate ...................................................................................................................... 16

3 Installation 17

3.1 Notes on installation ......................................................................................................17

3.2 Storage ........................................................................................................................... 17

3.3 Transport ........................................................................................................................ 17

3.4 Installation condtitions...................................................................................................18

3.4.1 Measurement of liquids ........................................................................................................ 19

3.4.2 Measurement of vapours and gases .................................................................................... 21

3.4.3 Pipelines with control valve.................................................................................................. 22

3.4.4 Preferred mounting position ................................................................................................ 22

3.4.5 Turning the connection housing ...........................................................................................23

3.4.6 Turning the display ............................................................................................................... 24

3.4.7 Heat insulation ......................................................................................................................25

3.5 Inlet and outlet runs....................................................................................................... 26

3.5.1 Minimum inlet runs............................................................................................................... 26

3.5.2 Minimum outlet runs ............................................................................................................ 27

3.5.3 Flow straightener.................................................................................................................. 27

3.6 Installation...................................................................................................................... 28

3.6.1 General installation notes..................................................................................................... 28

3.6.2 Installing devices in flange design ....................................................................................... 29

3.6.3 Installing devices in sandwich design .................................................................................. 30

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

3

Page 4

CONTENTS

SITRANS FX300

4 Electrical connections 31

4.1 Safety instructions.......................................................................................................... 31

4.2 Connecting the signal converter .................................................................................... 32

4.3 Electrical connection of current and pulse output ........................................................ 33

4.3.1 Power supply......................................................................................................................... 34

4.3.2 Totalizer / pulse output......................................................................................................... 34

4.4 Grounding connections................................................................................................... 36

4.5 Protection category ........................................................................................................37

5 Start-up 38

5.1 Start ................................................................................................................................ 38

5.2 Start-up and control .......................................................................................................38

6 Operation 39

6.1 Display and operating elements .................................................................................... 39

6.2 Operating principles .......................................................................................................40

6.2.1 Functional description of the keys........................................................................................ 40

6.2.2 Switch from measuring mode to menu mode...................................................................... 40

6.2.3 Navigation within the menu structure.................................................................................. 41

6.2.4 Changing the settings in the menu....................................................................................... 41

6.2.5 Changing units ...................................................................................................................... 42

6.2.6 Measures in the event of faulty indications.......................................................................... 43

6.3 Overview of the most important functions and units..................................................... 44

6.4 Error messages.............................................................................................................. 46

6.5 Menu structure............................................................................................................... 47

6.5.1 Overview of firmware versions ............................................................................................. 47

6.5.2 Entering values in change mode .......................................................................................... 48

6.5.3 Character selection in change mode.................................................................................... 48

6.5.4 Menu item Quick Setup......................................................................................................... 49

6.5.5 Menu item Tests.................................................................................................................... 50

6.5.6 Menu item Setup (firmware version - basic) ........................................................................ 51

6.5.7 Menu item Setup (firmware version - steam) ...................................................................... 54

6.5.8 Menu item Setup (firmware version - gas)........................................................................... 58

7 Service 63

7.1 Replacing signal converter / LCD display...................................................................... 63

7.2 Spare parts availability...................................................................................................64

7.3 Availability of services .................................................................................................... 64

7.4 Returning the device to the manufacturer..................................................................... 64

7.4.1 General information.............................................................................................................. 64

7.4.2 Form (for copying) to accompany a returned device............................................................ 65

4

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 5

SITRANS FX300

CONTENTS

8 Technical data 66

8.1 Functional principle........................................................................................................ 66

8.2 Technical data................................................................................................................. 67

8.3 Dimensions and weights ................................................................................................ 70

8.3.1 Flange versions..................................................................................................................... 70

8.3.2 Sandwich version .................................................................................................................. 73

8.4 Flow tables ..................................................................................................................... 75

9 Notes 79

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

5

Page 6

1 SAFETY INSTRUCTIONS

1.1 Intended use

The vortex flowmeters are made to measure the flow of gases, steam and liquids.

The devices are particularly suitable for the measurement of:

• Clean liquids with low viscosity (< 10 cP)

• Hydrocarbons with low viscosity (< 10 cP)

• Water

• Chemicals with low corrosiveness

• Saturated steam

• Superheated steam, including CIP and SIP applications in the food industry

• Industrial gases

The devices are rated for the following flow velocities:

• Liquids: 0,3...7 m/s / 1.0...23 ft/s

• Gases and steam: 2.0...80 m/s / 6.6...262 ft/s

DN15: 3.0...45 m/s / 9.8...148 ft/s; DN25: 2.0...70 m/s / 6.6...230 ft/s

SITRANS FX300

If there is a risk of waterhammers in steam networks, appropriate condensate separators must

be installed.

Suitable measures must be taken to avoid water cavitation if it is a possible risk.

CAUTION!

The operator himself bears the sole responsibility for the intended use of the device regarding

the suitability and the corrosion resistance of the used materials against the measured fluid.

• The sensors are made from Stainless Steel 316 L (1.4404) or Hastelloy

• In your project planning, please observe the data given in the corrosion tables.

• The pressure-bearing parts have been designed and rated for stationary operation taking into

account the maximum pressure and temperature.

• External forces and moments, caused e.g. by pipe stresses, have not been taken into account.

Primarily, volumetric flow and temperature are measured, with pressure measurement as an

option. From these parameters the measuring device calculates the mass flow or standard

volumetric flow using pre-programmed density data and then exports the measured values via

various communication interfaces.

®

C22.

6

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 7

SITRANS FX300

1.2 Certifications

CE marking

The device fulfils the statutory requirements of the following EC directives:

• Pressure Equipment Directive 97/23/EC

• Low Voltage Directive 73/23/EEC

• EMC Directive 89/336/EC

as well as

• EN 61010

• EMC specification acc. to EN 61326/A1

• NAMUR recommendations NE 21 and NE 43

SAFETY INSTRUCTIONS 1

The manufacturer certifies successful testing of the product by applying the CE marking.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

7

Page 8

1 SAFETY INSTRUCTIONS

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to German copyright. Contributions from

third parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

SITRANS FX300

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect, incidental, punitive and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

8

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 9

SITRANS FX300

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

9

Page 10

1 SAFETY INSTRUCTIONS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SITRANS FX300

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

10

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 11

SITRANS FX300

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Measuring device in ordered version

2 Handbook

3 Certificates, calibration report and parameter datasheet

4 Bar magnet

2.2 Instrument versions

The devices come in the following versions:

• Converter with display

• Blind device

• Sensor in flanged design

• Sensor in sandwich design

The following designs are available as options:

• with pressure sensor

• with isolation valve for the pressure sensor

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

11

Page 12

2 DEVICE DESCRIPTION

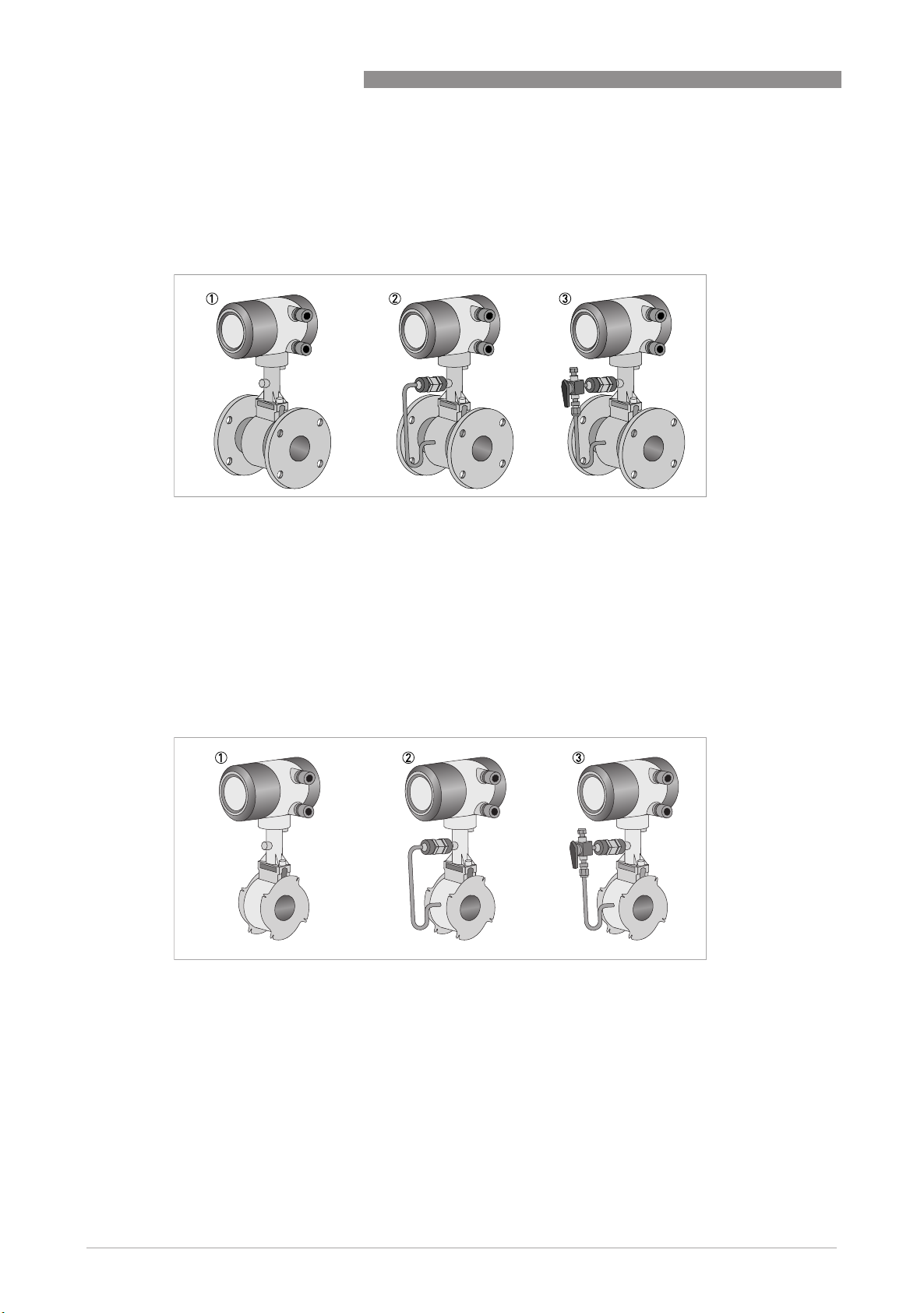

2.2.1 Devices with connection flange

The measuring system consists of a measuring sensor and a signal converter. These elements

form a permanent mechanical unit.

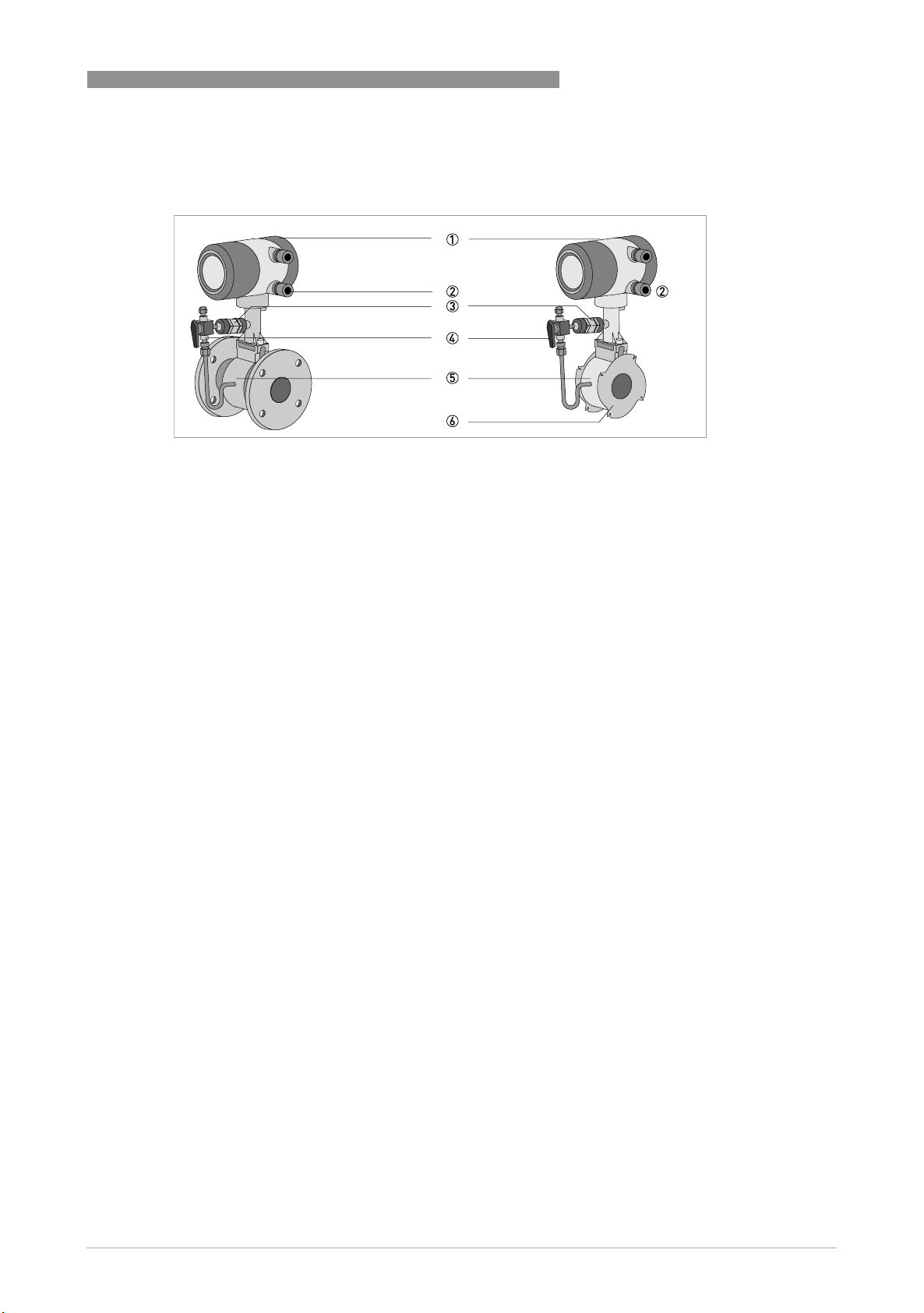

Figure 2-2: Flanged devices with display

1 Version with temperature sensor

2 Version with temperature sensor and optional pressure sensor

3 Version with temperature sensor, optional pressure sensor and shut-off valve

SITRANS FX300

2.2.2 Sandwich version

The sandwich version features 2 centring rings to aid with installation.

Figure 2-3: Sandwich versions with display

1 Version with temperature sensor

2 Version with temperature sensor and optional pressure sensor

3 Version with temperature sensor, optional pressure sensor and shut-off valve

12

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 13

SITRANS FX300

2.2.3 Device description

Figure 2-4: Device description

1 Signal converter

2 Cable feedthrough grey, standard version

3 Pressure sensor, optional

4 Shut-off valve, optional

5 Measuring sensor

6 Centering ring

DEVICE DESCRIPTION 2

2.2.4 Free air delivery measurement - FAD (optional)

A (air) compressor draws air from the ambient atmosphere, compresses it and delivers it at the

required pressure. Since the ambient atmosphere also contains water vapour, what the

compressor draws in is a mixture of air and water vapour. Free air delivery measurement is to

be understood under this condition. Most manufacturers specify free air delivery only at

standard intake conditions. What the user ultimately requires as process air must first be

determined before measuring can take place with an accuracy of ±1%.

The vortex flowmeter with the optional FAD function can measure the free air delivery online,

humidity and speed compensated, regardless of its function as standard flowmeter. The

integrated software evaluates the free air delivery automatically online.

The menu-driven, user-friendly software prompts the operator to enter the pressure, relative

humidity, the required as well as current discharge pressure.

The steam tables and compressibility tables are saved as standard. The measuring device is

optionally available with a pressure sensor which measures the discharge pressure online,

making manual input of the values unnecessary.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

13

Page 14

2 DEVICE DESCRIPTION

2.2.5 Gross heat meter

In almost all applications with saturated steam, the steam is used for heating. It is much more

interesting to know how great the heat flow volume is that is available to the process, than to

know how great the flow is in kg/h.

As the enthalpy of steam changes with the temperature, it cannot be assumed to be constant.

The vortex flowmeter has a special feature which calculates the flow of steam and water as

power. The enthalpy tables are permanently programmed into the memory of the device.

The online density-compensated mass flow is multiplied by the correct enthalpy to obtain the

flow as power output.

SITRANS FX300

Power {Q

] = mass flow [Qm] x enthalpy [H]

H

If the gross heat meter is activated, both the totalizer for the absolute steam consumption as

well as that for the energy run internally.

14

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 15

SITRANS FX300

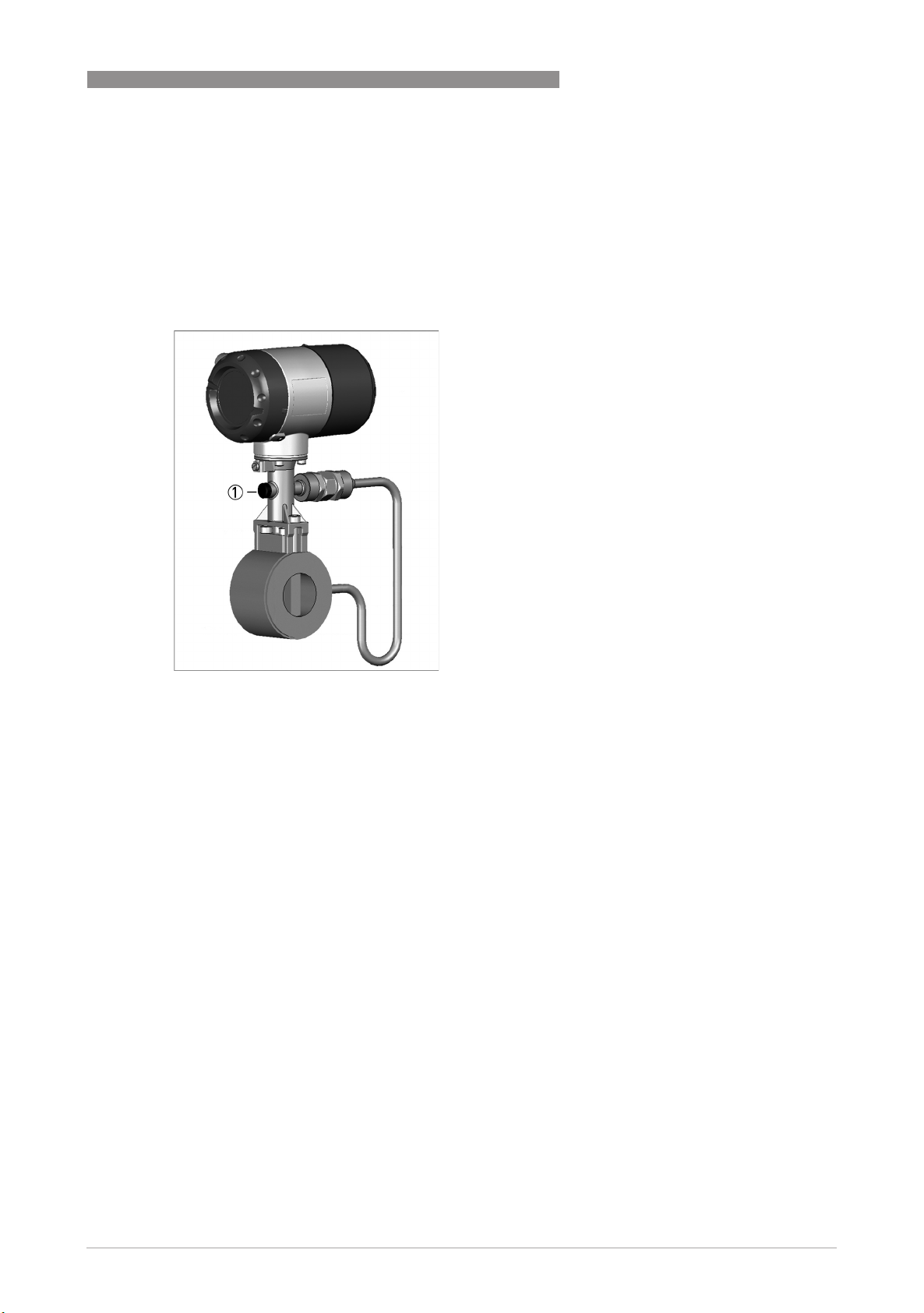

2.2.6 Dual seal

To cover the requirements of ANSI/ISA-12.27.01-2003 “Requirements for Process Sealing

Between Electrical Systems and Flammable or Combustible Process Fluid” Dual seal, a

membrane vent is integrated in the neck of the instrument. This vent works in the improbable

case of a leakage as an annunciation valve between the primary seal (Process) and secondary

seal (electronic compartment).

DEVICE DESCRIPTION 2

1 Annunciation valve (Membrane vent)

The sealing between the pick-up and the Flow tube is considered as the primary seal. Its

construction material is always the same as the Flow tube itself (e.g. Stainless steel 316L or

Hastelloy C22). Chemicals used for the process, going through the Flow tube, must be

compatible with the designated material.

By using the membrane vent as annunciation valve, all requirements for a dual seal device in

accordance to above mentioned standard, are fulfilled.

• It protects the electronic compartment against access by process media, due to possible

leakages.

• The leakage of the primary seal is visible.

Regular maintenance should be performed by the customer to ensure this Dual Seal notification

system is working properly or that there is no leak.

If a leakage is noticed:

Siemens customer service should be contacted for servicing or replacement of the meter.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

15

Page 16

2 DEVICE DESCRIPTION

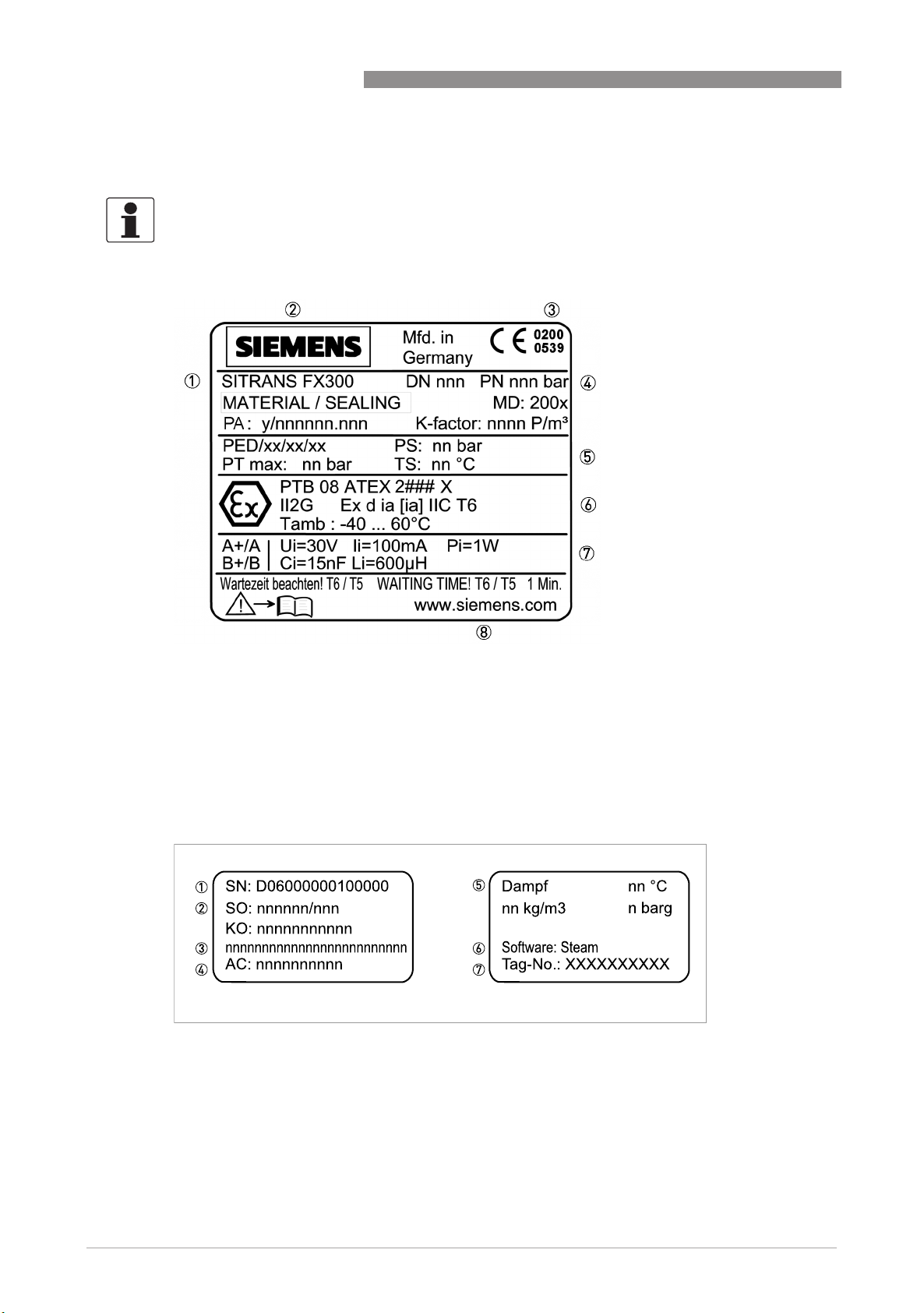

2.3 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

SITRANS FX300

Figure 2-5: Example for nameplate

1 Device type

2 Manufacturer

3 Notified ATEX & DGRL bodies (only available if this option was ordered)

4 Connection data: nominal diameter and pressure rating

5 PED data

6 Ex data (only available if this option was ordered)

7 Electrical connection data

8 Manufacturer's website

Figure 2-6: Example for nameplate

1 Serial number

2 Order number

3 Type code

4 Item number

5 Fluid data

6 Software variant

7 Tag number

16

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 17

SITRANS FX300

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry and dust-free location.

• Avoid extended direct exposure to the sun.

• Store the device in its original packing.

• The permissible storage temperature for standard devices is -40...+80°C / -40...+176°F.

INSTALLATION 3

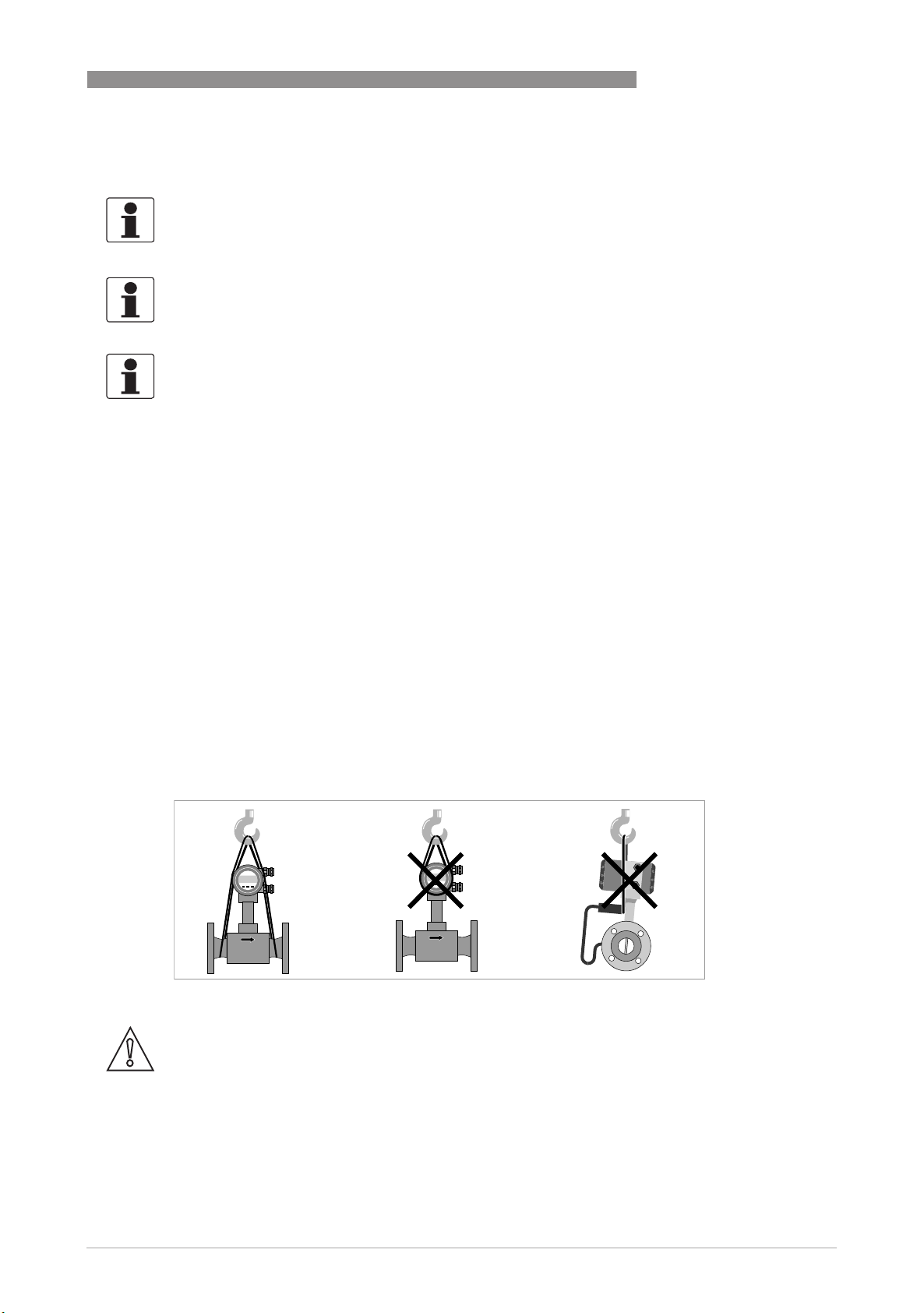

3.3 Transport

• Use lifting straps wrapped around both process connections for transport.

• Do not lift measuring devices by the signal converter housing for transport.

• Never lift the measuring device by the pressure sensor.

• Do not use lifting chains as they may damage the housing.

Figure 3-1: Transport instructions

CAUTION!

Non-secured devices can pose risk of injury. The centre of mass of the device is often higher

than the point at which the lifting straps are attached.

Prevent the measuring device from sliding or rotating accidentally.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

17

Page 18

3 INSTALLATION

3.4 Installation condtitions

INFORMATION!

For accurate volumetric flow measurement the measuring device needs a completely filled pipe

and a fully developed flow profile.

Please observe the instructions regarding inlet and outlet pipe runs as well as the installation

position.

In the event of vibrations

their lowest in a transverse direction to the flowmeter.

CAUTION!

When installing the device in the piping, the following points must be observed:

•

Nominal diameter of connection pipe flange = nominal flange diameter of pipe!

•

Use flanges with smooth holes, e.g. welding neck flanges.

•

Align carefully the holes of the connecting flange and the flowmeter flange.

•

Check the compatibility of the gasket material with the process product.

•

Make sure that the gaskets are arranged concentrically. The flange gaskets must not project

into the pipe cross-section.

•

The flanges have to be concentric.

•

There must not be any pipe bends, valves, flaps or other internals in the immediate inlet run.

•

Devices in sandwich version may only be installed using a centering ring.

•

Never install the device directly behind piston compressors or rotary piston meters.

•

Do not lay signal cables directly next to cables for the power supply.

vibrations on the piping, select the installation site so that the vibrations are at

vibrationsvibrations

SITRANS FX300

18

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 19

SITRANS FX300

3.4.1 Measurement of liquids

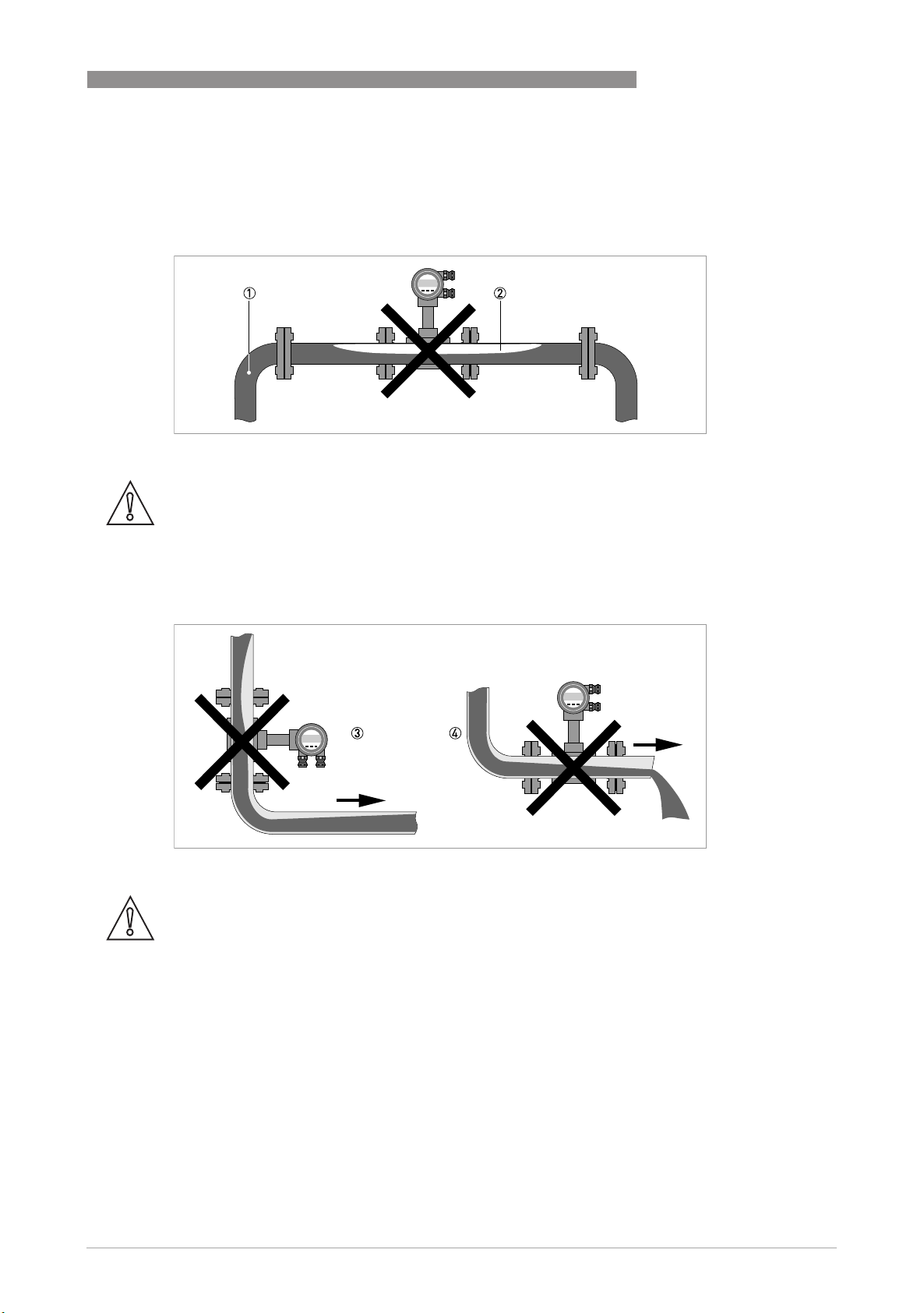

Prohibited installation

Prohibited installation

Prohibited installationProhibited installation

Figure 3-2: Upper pipe bend

CAUTION!

Prohibited: Installing the device in an upper pipe bend 1, because there is a risk of gas bubbles

2 forming. Gas bubbles can lead to pressure surges and inaccurate measurement.

INSTALLATION 3

Figure 3-3: Downpipe and outlet

CAUTION!

Prohibited: Installing the device in a downstream pipe 3 or upstream pipe of a outlet 4. There is

the risk of partially filled pipes.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

19

Page 20

3 INSTALLATION

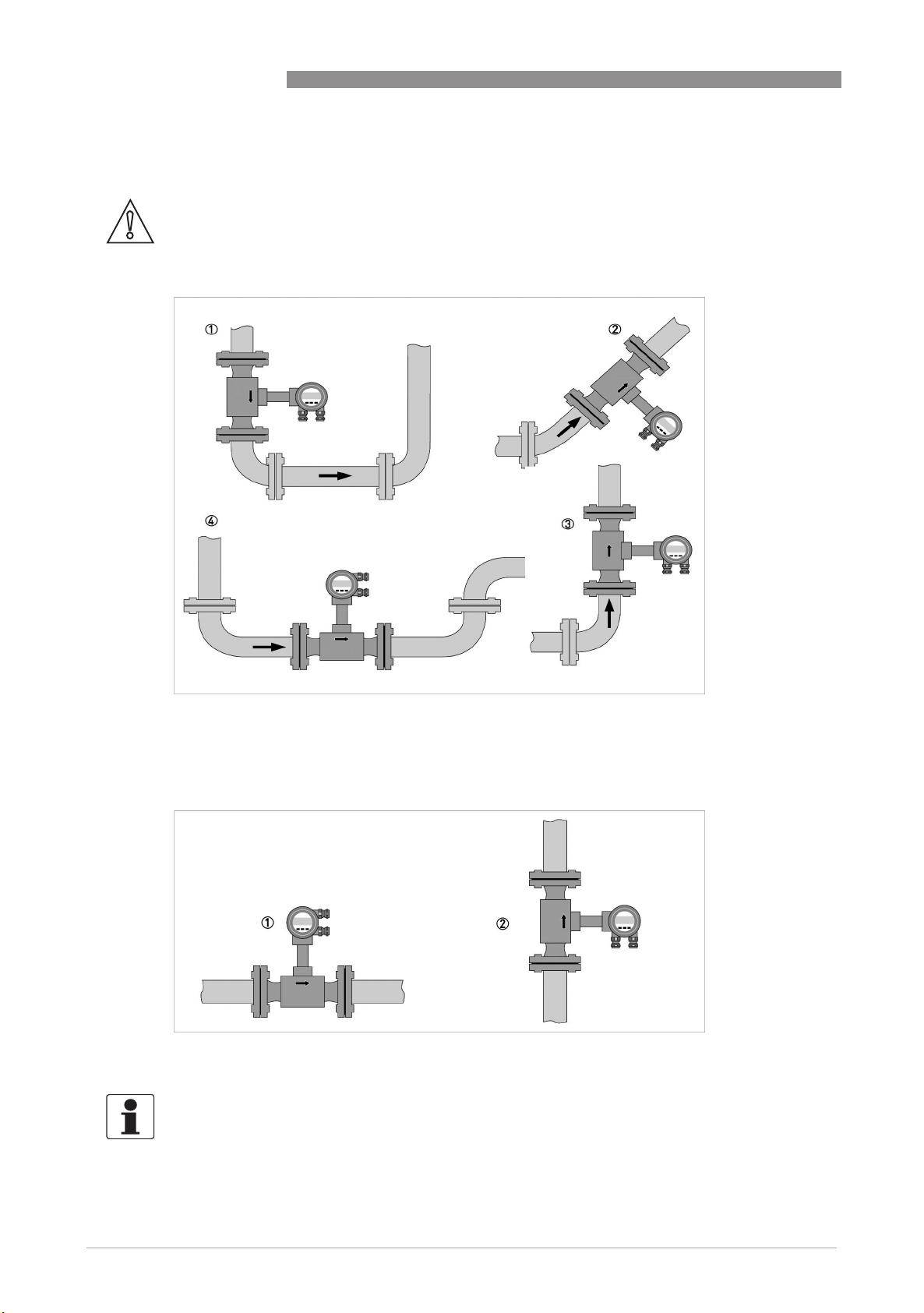

Recommended installations for measurement of liquids

Recommended installations for measurement of liquids

Recommended installations for measurement of liquidsRecommended installations for measurement of liquids

CAUTION!

It is absolutely necessary to comply with the required inlet and outlet runs.

SITRANS FX300

1 If the device is installed in a downpipe, a standpipe must be installed immediately after it.

2 Installing the device in an inclined standpipe.

3 Installing the device in a vertical standpipe.

4 Installing the device in the lower pipe bend.

1 Above a horizontal pipe

2 On a vertical pipe

INFORMATION!

Depending on the installation position, you may have to rotate the display and/or the connection

housing.

20

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 21

SITRANS FX300

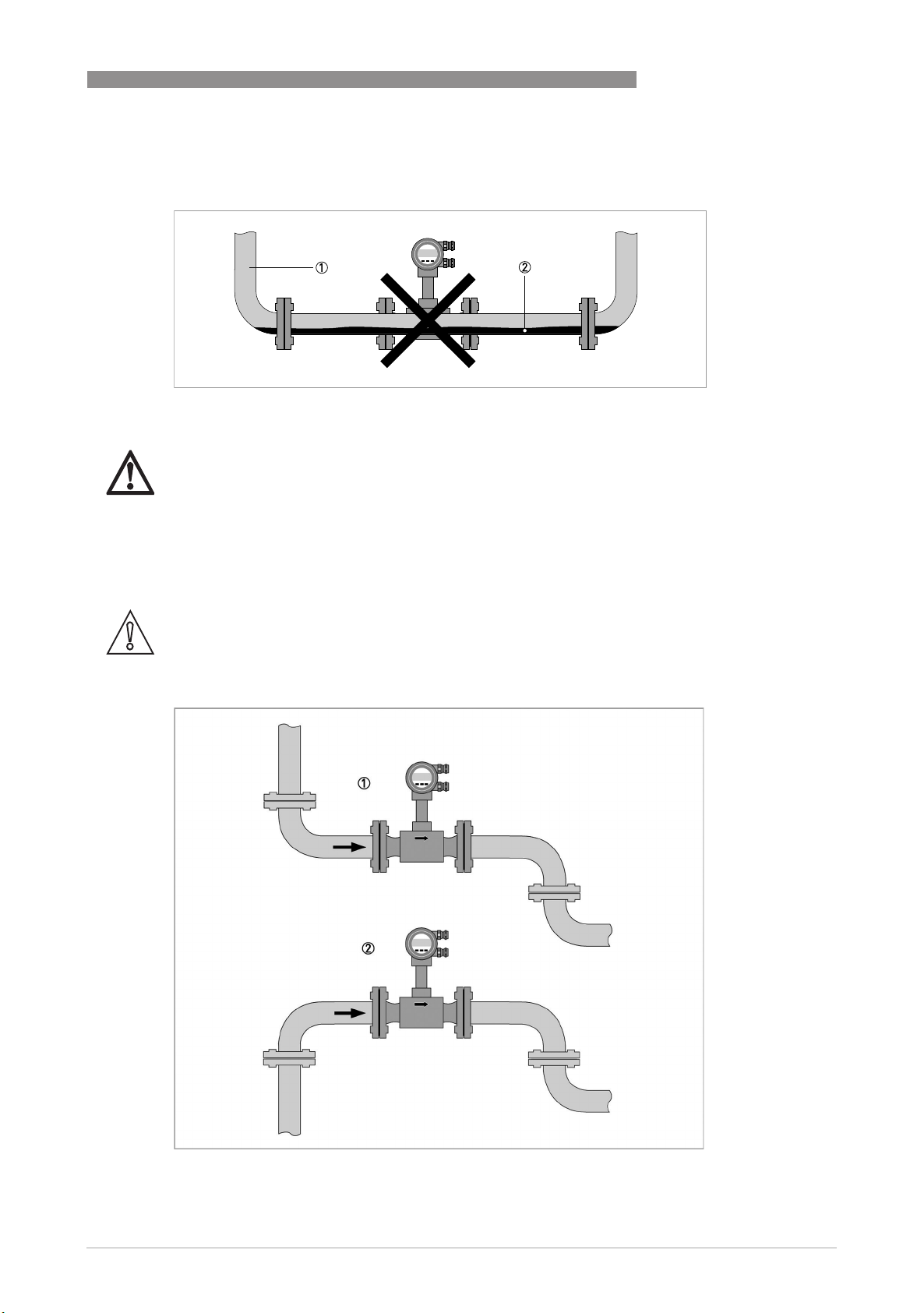

3.4.2 Measurement of vapours and gases

Prohibited installation

1 Lower pipe bends

2 Condensate

DANGER!

Prohibited: Installing the device in a lower pipe bend 1, because there is a risk of condensate

forming 2.

Condensate can lead to cavitation and inaccurate measurement. Under certain circumstances

the device can be destroyed and the measured product can leak.

INSTALLATION 3

Recommended installations

Recommended installations

Recommended installationsRecommended installations

CAUTION!

It is absolutely necessary to maintain the required inlet and outlet runs.

1 Inlet and outlet falling

2 Rising inlet - falling outlet

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

21

Page 22

3 INSTALLATION

3.4.3 Pipelines with control valve

INFORMATION!

To ensure smooth and correct measurement, the manufacturer recommends not installing the

measuring device downstream from a control valve. This would run the risk of vortex formation,

which would distort the measuring result.

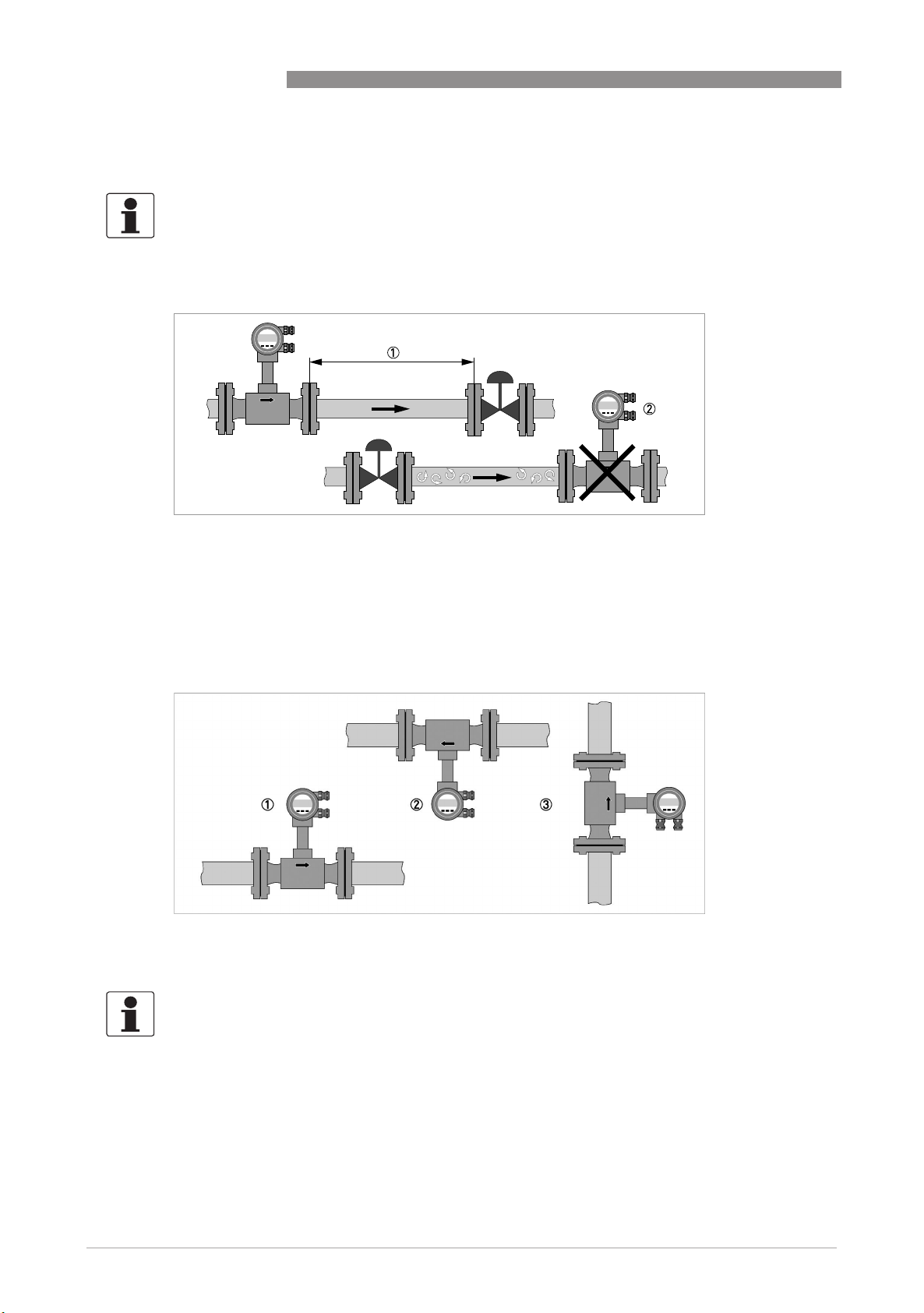

Figure 3-4: Pipeline with control valve

1 Recommended: installing the device upstream

2 Not recommended: Installing the flowmeter directly downstream

upstream from the control valve at a distance of ≥ 5 DN

upstreamupstream

directly downstream of control valves, due to vortex formation.

directly downstreamdirectly downstream

SITRANS FX300

3.4.4 Preferred mounting position

Preferred mounting position

1 Above a horizontal pipe

2 underneath a horizontal pipe (not permitted with lines at risk for condensate )

3 On a vertical pipe

INFORMATION!

Depending on the installation position, you may have to rotate the display and/or the connection

housing. For further information refer to Turning the display on page 24

.

22

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 23

SITRANS FX300

3.4.5 Turning the connection housing

DANGER!

All work on the device electrics may only be carried out by appropriately trained personnel. The

regional occupational health and safety directives must always be observed.

CAUTION!

Do not damage the electrical cable by overtwisting it.

Do not remove the electrical connector.

INSTALLATION 3

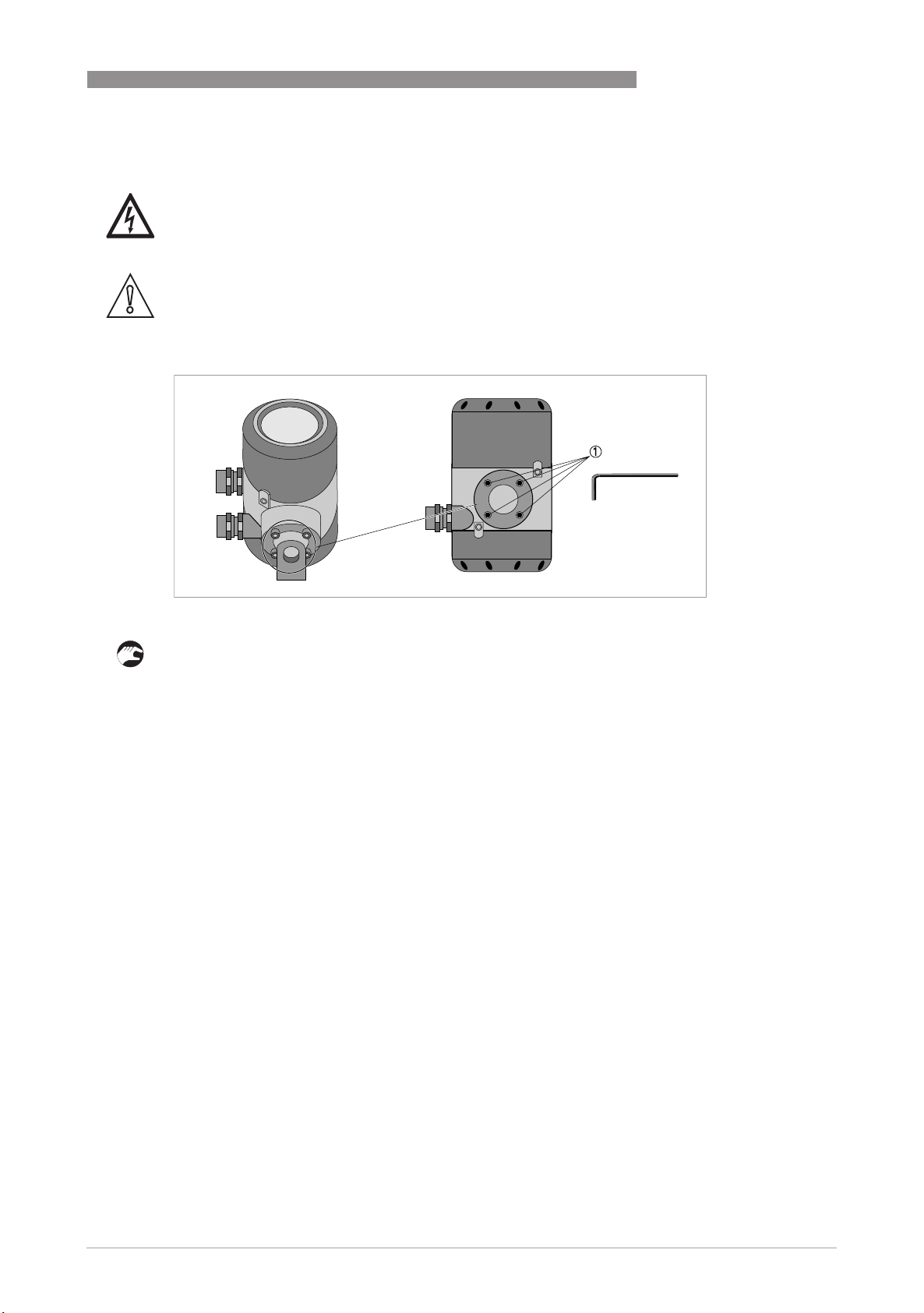

Figure 3-5: Allen screws on connection housing

• Disconnect the power supply from the measuring device.

• Loosen the four screws 1 on the rear side of the connection housing.

• Lift the connection housing and turn it to the required position in 90° steps.

• Screw the connection housing back on.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

23

Page 24

3 INSTALLATION

3.4.6 Turning the display

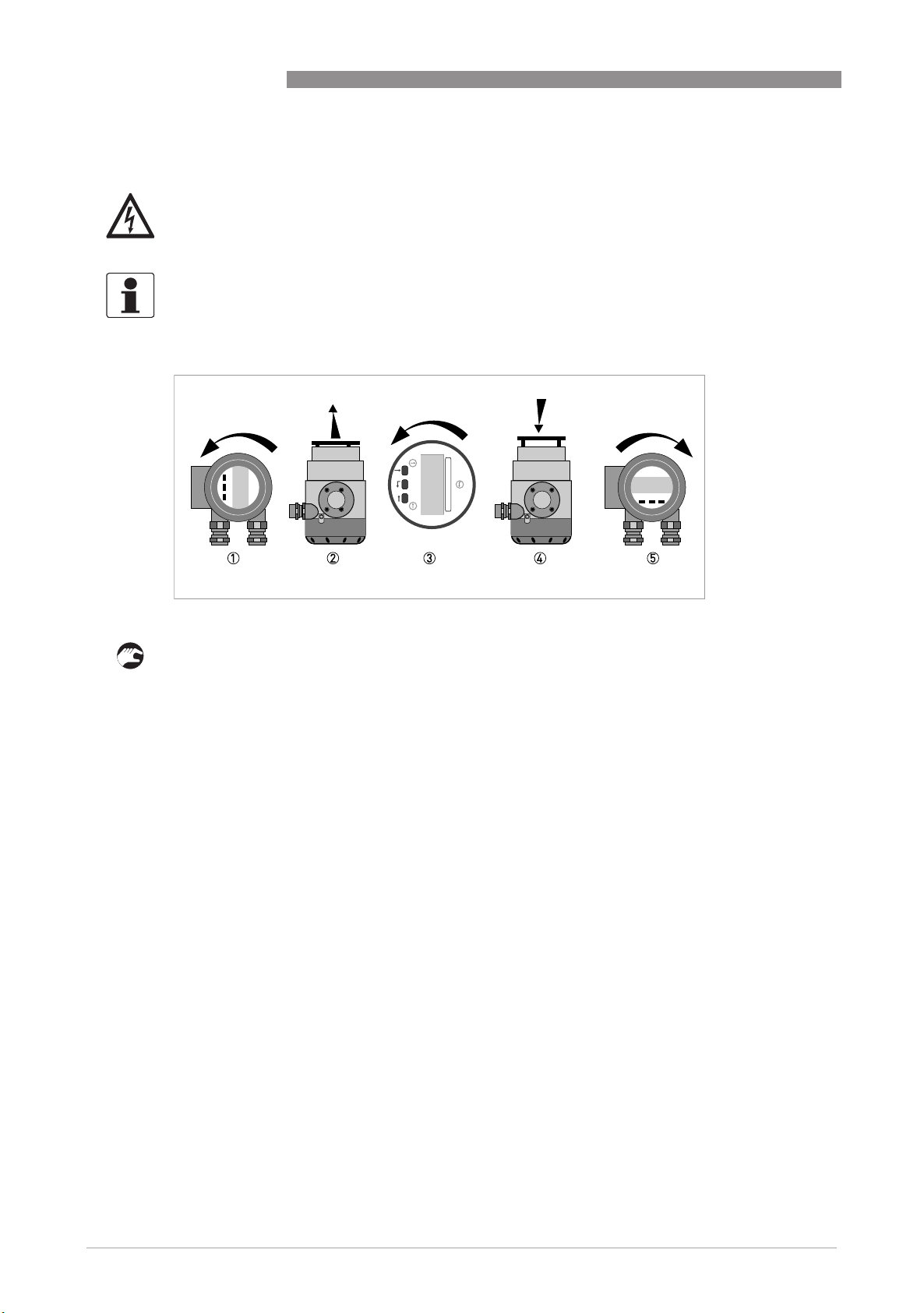

DANGER!

All work on the device electrics may only be carried out by appropriately trained personnel. The

regional occupational health and safety directives must always be observed.

INFORMATION!

If the measuring device is installed in a vertical pipe, you will have to turn the display by 90

installed below a pipe, turn 180

SITRANS FX300

°

; if

°

.

Figure 3-6: Turning the display

Turn the display as follows:

• Disconnect the power supply from the measuring device.

• Unscrew the cover in front of the display 1 from the connection housing.

• Pull the display 2 carefully a few centimetres out of the anchor fitting and turn it to the

required position 3.

• Press the display onto the spacer pins 4, until it clicks.

• Turn the cover with gasket 5 back onto the housing and tighten it by hand.

24

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 25

SITRANS FX300

3.4.7 Heat insulation

CAUTION!

The area above the converter support must not be heat-insulated.

The heat insulation 3 may only extend to the maximum height 1 shown below up to the

connecting screws of the measuring sensor.

INSTALLATION 3

Figure 3-7: Heat insulation on connection piece and signal cable

1 Max. height of insulation up to intermediate piece between measuring sensor and signal converter

2 Max. thickness of the insulation up to the bend of the pressure pipe

3 Insulation

CAUTION!

The heat insulation 3 may only extend as far as the bend of the pressure sensing line 2.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

25

Page 26

3 INSTALLATION

3.5 Inlet and outlet runs

3.5.1 Minimum inlet runs

SITRANS FX300

1 General inlet run without disturbing flow ≥ 20 DN

2 Behind a control valve ≥ 50 DN

3 After a pipe diameter reduction ≥ 20 DN

26

1 After a single bend 90° ≥ 20 DN

2 After a double bend 2x90° ≥ 30 DN

3 After a double three-dimensional bend 2x90° ≥ 40 DN

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 27

SITRANS FX300

3.5.2 Minimum outlet runs

INSTALLATION 3

Figure 3-8: Minimum outlet runs

1 Upstream of pipe expanders, pipe bends, control valves, etc. ≥ 5 DN

2 Upstream of metering points ≥ 5…6 DN

INFORMATION!

The interior of the pipe at the metering points must be free of burrs and other flow impediments.

The measuring device has an internal temperature sensor. External temperature sensor must

be located ≥ 5 DN behind the flow sensor outlet. Use sensors that are as short as possible to

avoid disturbing the flow profile.

3.5.3 Flow straightener

If, due to the type of installation, the required inlet runs are not available, the manufacturer

recommends using flow straighteners. Flow straighteners are installed between two flanges

upstream of the device and shorten the required inlet run.

Figure 3-9: Flow straightener

1 Straight inlet run upstream of straightener ≥ 2 DN

2 Flow straightener

3 Straight pipe run between flow straightener and device ≥ 8 DN

4 Minimum straight outlet run ≥ 5 DN

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

27

Page 28

3 INSTALLATION

3.6 Installation

3.6.1 General installation notes

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

The following procedures have to be carried out before installing the device:

• Remove all transportation safety devices and protective coverings from the device.

• Ensure that the gaskets have the same diameter as the pipelines.

• Note the correct flow direction for the device. This is indicated by an arrow on the housing of

the measuring sensor.

• On metering points with varying thermal loads, the flowmeters have to be mounted with stress

bolts (DIN 2510).

• Stress bolts or bolts and nuts are not included in the scope of delivery.

• Ensure that the measuring flange is concentrically fitted.

• Note the exact installation length of the measuring device when preparing the metering point.

SITRANS FX300

Figure 3-10: Preparing the metering point

1 Installation length of measuring device + thickness of gaskets.

CAUTION!

The internal diameter of the pipelines, the measuring sensor and the gaskets must match. The

gaskets may not protrude into the flow.

Figure 3-11: Internal diameter

1 Internal diameter connection pipe

2 Internal diameter flange and gasket

3 Internal diameter measuring sensor

28

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 29

SITRANS FX300

3.6.2 Installing devices in flange design

INSTALLATION 3

Figure 3-12: Installing devices in flange design

1 Gasket

2 Bolts with fixing nuts

• Use bolts and fastening nuts 2 to attach the measuring device to one side of the flange.

• While doing so, insert the gaskets 1 between measuring sensor and flange and align them.

• Check that the gasket is concentric and that it is not protruding into the pipe cross-section.

• Install the gasket, bolts and fastening nuts on the other side of the flange.

• Align the measuring device and the gaskets so they are concentric.

• Now tighten all nuts bit by bit alternately across the diagonal.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

29

Page 30

3 INSTALLATION

3.6.3 Installing devices in sandwich design

SITRANS FX300

Figure 3-13: Installation using centering ring

1 Measuring sensor

2 Centering ring

3 Bolts with fixing nuts

4 Hole

5 Hole

6 Gasket

• Push the first bolt 3 through the hole 5 of both flanges.

• Screw on the nuts and washers to both ends of the bolt 3 but do not tighten them.

• Install the second bolt through the holes 4.

• Place the measuring sensor 1 between the two flanges.

• Insert the gaskets 6 between measuring sensor 1 and flanges and align them.

• Check that the flange is concentric.

• Install the remaining bolts, washers and nuts. Do not yet tighten the nuts.

• Turn the centring ring 2 in a counter-clockwise direction and align the device.

• Check that the gaskets 6 are concentric; they must not protrude into the pipe cross-section.

• Now tighten all nuts bit by bit alternately across the diagonal.

30

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 31

SITRANS FX300

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

31

Page 32

4 ELECTRICAL CONNECTIONS

4.2 Connecting the signal converter

Figure 4-1: Signal converter housing with housing cover

1 Housing cover of the electrical terminal compartment

2 Electrical connection terminals with the housing cover open

3 Terminal A current output -

4 Terminal A+ current output +

5 Terminal B pulse output -

6 Terminal B+ Pulse output +

7 PE terminal in housing

8 PE terminal on connection piece between measuring sensor and signal converter.

SITRANS FX300

Both grounding terminals 7 and 8 are equally effective from a technical point of view.

The following procedures are to be performed:

• Unscrew the housing cover 1 of the electrical terminal compartment.

• Thread the connection cable through the leadthrough in the housing.

• Connect the cable for the current output and the cable for the optional pulse output as shown

in the cable terminal diagrams below. To facilitate installation the connection plug can be

removed from the device. The plug is configured in such a way as to prevent reverse polarity.

• Connect the grounding to terminal 7 alternatively use the PE terminal on the connection

piece between measuring sensor and signal converter 8.

• Tighten the cable glands.

• Hand-tight the housing cover with gasket.

32

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 33

SITRANS FX300

ELECTRICAL CONNECTIONS 4

4.3 Electrical connection of current and pulse output

• Current output:

Current output:

Current output:Current output:

In some cases, a shielded or twisted cable may be necessary. The cable shield may only be

earthed (grounded) at one place (on the power supply unit).

• Pulse output:

Pulse output:

Pulse output:Pulse output:

When using the pulse output, two separate signal circuits are necessary if the pulse output is

utilized together with analogue signals. Each signal circuit requires its own power supply.

The total resistance must be adapted so that the total current I

• Connection current output on terminals A, A+

Connection pulse output on terminals B, B+

does not exceed 100 mA.

tot

Figure 4-2: Electrical connection of current and pulse output

1 Power supply per signal circuit

2 Optional display unit

3 Load for HART

4 e.g. counter

®

≥ 250 Ω

The maximum load resistance is calculated as follows:

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

33

Page 34

4 ELECTRICAL CONNECTIONS

4.3.1 Power supply

INFORMATION!

The supply voltage has to be between 14 VDC and 36 VDC. This is based on the total resistance of

the measuring loop. To determine this, add up the resistances of each component in the

measuring loop (not including the measuring device).

The required supply voltage can be calculated using the formula below:

U

= RL * 22mA + 14V

ext.

where

= the minimum supply voltage and

U

ext.

= the total measuring loop resistance is.

R

L

INFORMATION!

The power supply has to be able to supply a minimum of 22 mA.

SITRANS FX300

4.3.2 Totalizer / pulse output

The basic units for the totalizer and the pulse output are mmmm

3333

norm.

norm. for standard volume and kg

mmmm

norm.norm.

The unit and the conversion factor can be changed in menu item 3.2.8 "Conf.Tot". User specific

units (User Def.) can also be entered but the conversion factor must always be entered based on

the base unit. For a sample calculation see chapter 6.2.5 "Change units".

The maximum frequency of the pulse output is 0.5 Hz.

Figure 4-3: Pulse output

≤ 0.5 Hz

1 f

max

2 closed

3 open

4 Pulse ≥ 250 ms

kg for mass.

kgkg

3333

for volume,

34

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 35

SITRANS FX300

The pulse output is a passive "open collector" output which is electrically separated from the

current interface and the measuring sensor. It can be configured as a high current output or

NAMUR output using a jumper on the amplifier board.

Jumper in NAMUR setting

Jumper in NAMUR setting

Jumper in NAMUR settingJumper in NAMUR setting

Ri = 900 Ω U

= 36 VDC

max

ELECTRICAL CONNECTIONS 4

The maximum frequency of the pulse output is f

Jumper in high current setting

Jumper in high current setting

Jumper in high current settingJumper in high current setting

Open: Maximum voltage U

Closed: Maximum current I

= 36 VDC Closed current IR < 1 mA

max

= 100 mA Voltage U < 2 VDC

max

The maximum frequency of the pulse output is f

max

max

= 0.5 Hz

= 0.5 Hz

Figure 4-4: Jumper settings pulse output

1 Electronic insert

2 Jumper on board

3 Jumper in high current setting

4 Jumper in NAMUR setting

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

35

Page 36

4 ELECTRICAL CONNECTIONS

4.4 Grounding connections

The grounding can be done either by connecting the PE terminal in the housing or the PE

terminal on the connection piece between measuring sensor and signal converter. Both of these

electrical connections are equally effective from a technical point of view.

SITRANS FX300

Figure 4-5: Grounding connection

1 Electrical grounding connection on connection piece between measuring sensor and signal converter.

2 Electrical grounding connection on housing

DANGER!

The measuring device has to be grounded properly to achieve accurate measurement. The

grounding wire may not transfer any interference voltage.

Do not use this grounding wire to ground any other items of electrical equipment.

36

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 37

SITRANS FX300

4.5 Protection category

The measuring device meets all requirements of protection category IP66/67.

DANGER!

After all servicing and maintenance work on the measuring device, the specified protection

category must be ensured again.

Figure 4-6: Cable feedthrough

ELECTRICAL CONNECTIONS 4

Therefore it is essential to observe the following points:

• Use only original gaskets. They must be clean and free of any damage. Defective gaskets must

be replaced.

• The electrical cables used must be undamaged and must comply with regulations.

• The cables must be laid with a loop 1 upstream of the measuring device to prevent water

from getting into the housing.

• The cable feedthroughs 2 must be tightened.

• Align the measuring device so that the cable feedthrough is never facing up 3.

• Close the unused cable feedthroughs using blind plugs 4.

• Do not remove the required cable bushing from the cable feedthrough.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

37

Page 38

5 START-UP

5.1 Start

After the device is switched on, the display shows the following in sequence

1. Testing...

2. Device type

Sofware Version - Revision

The device performs a self-test and switches to measurement mode. Here, all of the parameters

preset for the customer are analysed and checked for plausibility, and the current measured

value is displayed.

5.2 Start-up and control

INFORMATION!

The flowmeter is largely maintenance-free.

Observe the application limits in respect of temperature and medium. Additional information

refer to Technical data on page 67

SITRANS FX300

.

38

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 39

SITRANS FX300

6.1 Display and operating elements

With the cover open the device is operated by using the mechanical keys on the front; with the

cover closed a bar magnet is used.

CAUTION!

The switching point of the magnetic sensors is directly under the glass panel above the

appropriate symbol. Only touch the symbol vertically and from the front using the bar magnet.

Touching it from the side may cause a malfunction.

OPERATION 6

Figure 6-1: Display and operating elements

1 Enter button (bar magnet)

2 Right button (bar magnet)

3 Up button (bar magnet)

4 Up button (mechanical)

5 Enter button (mechanical)

6 Right button (mechanical)

7 Display

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

39

Page 40

6 OPERATION

The mechanical keys and keys for the bar magnet have the same functionality. In this

documentation the keys are represented as symbols to describe the operating functions:

Mechanical Bar magnet Symbol

Table 6-1: Description of keys

6.2 Operating principles

SITRANS FX300

→

↑

^

6.2.1 Functional description of the keys

→ Switch from measuring mode to menu mode

Switch to one menu level lower

Open menu item and activate change mode

In change mode:

In change mode: Move the input cursor one position to the right; after the last digit the

In change mode:In change mode:

input cursor jumps back to the beginning.

↑ In measuring mode:

^^^^ Switch to one menu level higher

Table 6-2: Description of the operating keys

In measuring mode: Switch between measured values and error messages

In measuring mode:In measuring mode:

Change between the menu items within a menu level

In change mode:

In change mode: Changing parameters and settings; running through the available

In change mode:In change mode:

characters; shifting the decimal point to the right.

Return to measuring mode with a query whether the data should be accepted

6.2.2 Switch from measuring mode to menu mode

Measuring mode Operation Menu mode

156.3

156.3

156.3156.3

kg/h

kg/h

kg/hkg/h

→ 1.1.1

1.1.1

1.1.11.1.1

Language

Language

LanguageLanguage

40

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 41

SITRANS FX300

6.2.3 Navigation within the menu structure

Navigation within the menu is by means of the and ^ buttons. Pressing button takes you one

menu level lower, ^ takes you one menu level higher.

If you are already located at the lowest level (function level), you can use the button to go in the

change mode, which can be used to set data and values.

If you are located at the first level (main menu), you can use the ^ key to exit the menu mode and

return to the measuring mode.

OPERATION 6

Measuring

mode

Table 6-3: Navigation menu structure

→ Main menu↑→ Sub-menu↑→ Function

^^^^ ^^^^ ^^^^ ^^^^

6.2.4 Changing the settings in the menu

• Use the and ↑ keys to navigate in the menu in which you want to change a setting or value.

Use the key to activate the change mode in the selected menu.

i The current values or settings are displayed.

• Use the and ↑ keys to change the value or setting.

Save the new value or setting using the ^ key.

Some menu items contain several setting options. They are displayed in sequence by pressing

the ^ key.

i Takes you back to the main menu.

• Press the ^ key to save the settings.

i The query "Save Yes" appears. Switch between "Yes" and "No" by pressing the ↑ key.

Switch between "YES" and "NO" by pressing the ↑ key.

↑

→ Edit

→

↑

^^^^

Save Yes ^^^^ Changes saved.

Save No ^^^^ Changes not saved.

An update is carried out and the display returns to measuring mode.

The display returns to measuring mode.

CAUTION!

Each time parameters or settings are changed, the measuring device carries out an internal

plausibility check.

If implausible inputs have been made, the display remains in the current menu, and the changes

are not saved.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

41

Page 42

6 OPERATION

Example: changing the default parameter from m3/h to l/min

Procedure Display Procedure Display

SITRANS FX300

1 3 x

2 3 x

3 →

4 3 x

3 x 1.1.1111

3 x 3 x

3 x ↑ 1.1.4444

3 x 3 x

3 x ↑ L/min

3 x 3 x

6.2.5 Changing units

When entering numbers and values in floating point format, the maximum possible accuracy is

0.003%. The accuracy depends on both the position of the decimal point and the length of the

number entered.

Numerical values and factors are displayed in the first line of the 10-digit display. Numerical

values are either displayed in floating point format (123.4567890) or are expressed in exponential

format (123456E002). The conversion factor of the totalizer and the pulse output is, however,

expressed in whole numbers.

Input values exponential format

107.2

3

/h

m

Language

Max. Flow

m3/h

Unit

Unit

5 ^^^^ 0000600.00

L/min

6 ^^^^ Display

Unit

7 ^^^^ 1111.1.4

Max. Flow

8 ^^^^ Save Yes

9 ^^^^ 1787.0000

L/min

Display position 1 2 3 4 5 6 7 8 9 10

Decimal point - • • • • - - - - -

Input values 0 ...

9

0 ...90 ...90 ...

9

0 ...90 ...9E -

or

0

0 ...30 ...

8

To select the exponential function, the decimal point must be located between the 2nd and 5th

decimal position.

Flow units

The base units are mmmm

measurement and kg/h

3333

/h for volume flow measurement, mmmm

kg/h for mass flow measurement.

kg/hkg/h

The flow units can be changed in menu item 1.1.4 "Max.Flow".

User defined units can be entered using "User Def."

The unit (text) as well as the conversion factor (number) can be entered here.

The conversion factor must always be entered based on the base unit.

3333

/h stand.

/h stand. for standard volumetric flow

/h stand./h stand.

Conversion

Formula New unit (User Def.)

Example: 1 litre / h = 0.001 *

(User Def.) ==== A1 Coeff.

(User Def.)(User Def.)

A1 Coeff. **** Base unit

A1 Coeff.A1 Coeff.

Base unit

Base unitBase unit

m3/h

Menu items

1.1.3 Maes.Inst Volume / Standard volume / Mass

1.1.4 Max. Flow Unit (User Def.) / Text / A1 Coeff.

Unit (User Def.) / Text / A1 Coeff. / Max. Flow / Flow Displ

Unit (User Def.) / Text / A1 Coeff.Unit (User Def.) / Text / A1 Coeff.

42

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 43

SITRANS FX300

Totalizer / pulse output

The base units for the totalizer and the pulse output are mmmm

3333

mmmm

The unit and the conversion factor can be changed in menu item 3.2.8 "Tot.Conf.". User defined

units (User Def.) can be selected and entered. The conversion factor of the unit must always be

entered based on the base unit.

The maximum pulse output frequency is 0.5 Hz. To ensure that the pulse output does not exceed

0.5 Hz, the conversion factor of the totalizer must be selected and set accordingly. The pulse

output represents an exact copy of the whole number value of the internal totalizer.

Max. pulses per hour

norm. for standard volume and kg

kg for mass.

kgkg

3333

for volume,

OPERATION 6

fmax. ≤ 0.5 Hz 1 pulse-break ≥ 2 seconds Max. pulses / hour = 1800

1800 pulses

18001800

Example

Flow Qmax. Factor A1 Coef. Pulses / litre Pulses / h Comment

5.6 m3/h

0.001 1 pulse / 1 litre 5600 not possible

0.01 1 pulse / 10 litres 560 560 < 1800 = ok.

Menu items

1.1.3 Maes.Inst Volume / Standard volume / Mass

1.1.4 Max. Flow Unit (User Def.) / Text / A1 Coeff. / Max. Flow

3.2.5 Function P Yes

3.2.7 Totalizer Tot. on

3.2.8 Tot. Conf. User def. / Unit Text / A1 Coeff.

Yes / No

YesYes

Tot. on / Tot. off

Tot. onTot. on

User def. / Unit Text / A1 Coeff. / Preset Value / Reset / Display

User def. / Unit Text / A1 Coeff.User def. / Unit Text / A1 Coeff.

Max. Flow / Flow Displ

Max. FlowMax. Flow

6.2.6 Measures in the event of faulty indications

If the indications on the display or the responses to keypad commands are faulty, you have to do

a hardware reset. Switch the power supply OFF and ON again.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

43

Page 44

6 OPERATION

6.3 Overview of the most important functions and units

INFORMATION!

A complete list of all functions and short descriptions is provided in the appendix. All default

parameters and settings are adapted for the specific customer.

Level Designation Explanation

1.1.1 Language Select the menu language

1.1.4 Max. Flow Maximum flow rate

1.1.5 Min. Flow Minimum flow rate

1.1.6 Timeconst. Time constant, damping value [s]

2.1.1 Test I Check current output

2.1.2 Test P Test pulse output

3.1.1 Error Msg. Error indicator

Table 6-4: The most important functions

The value set is represented by a 20 mA analogue current output. If the current

value exceeds the preset value, an alarm is indicated.

The set value does not

not represent the 4 mA value of the current output.

notnot

Yes: error messages are displayed

No: error messages are suppressed. A flashing cursor at the top left indicates

that error messages are present.

SITRANS FX300

Volume mass units

Volume mass units

Volume mass unitsVolume mass units

Volume Standard volume Mass

Liquids, steams, gases Air Gas Liquids, steams, gases

m3/h

3

/min

m

3

/s

m

L/h

L/min

L/s

3

/h

ft

3

/min

ft

3

/s

ft

gal/h

gal/min

gal/s

ImpGal/h

ImpGal/min

ImpGal/s

3

/h

cm

3

/min

cm

3

/s

cm

3

/h

dm

3

/s

dm

bbl/h

bbl/d

User Def.

Table 6-5: Flow measurements and units

FAD m3/h

3

FAD m

FAD m

/min

3

/s

FAD L/h

FAD L/min

FAD L/s

3

/h

FAD ft

3

/min

FAD ft

3

/s

FAD ft

User Def.

m3/h (norm)

3

/min (norm)

m

3

/s (norm)

m

L/h (norm)

L/min (norm)

L/s (norm)

3

/d (std.)

ft

3

/h (std.)

ft

3

/min (std.)

ft

3

/s (std.)

ft

User Def.

kg/h

kg/min

kg/s

t/h

t/min

t/s

lb/h

lb/min

lb/s

g/min

g/s

User Def.

44

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 45

SITRANS FX300

Unit totalizer

Unit totalizer

Unit totalizerUnit totalizer

Volume Standard volume Mass

Liquids, steams, gases Gas Liquids, steams, gases

m

L

3

ft

3

ft

gal

ImpGal

cm

dm

bbl

User Def.

Table 6-6: Totalizer units

Temperature - Pressure - Power - Energy - Density units

Temperature - Pressure - Power - Energy - Density units

Temperature - Pressure - Power - Energy - Density unitsTemperature - Pressure - Power - Energy - Density units

OPERATION 6

3

/h

m3 norm

L norm

3

std.

ft

User Def.

3

3

kg

t

lb

g

User Def.

Temp. Absolute

pressure

(over)

°C

°F

K

User Def.

Table 6-7: Additional units

Pa(g)

kPa(g)

MPa(g)

2

kg/ms

2

kp/cm

atm(g)

torr(g)

bar(g)

mbar(g)

psi(g)

2

(g)

lbf/ft

kgf/cm

inHg(g)

mmHg(g)

mmH2O(g)

User Def.

(g)

(g)

2

(g)

Power Energy Density

kJ/h

MJ/h

GJ/h

Btu/h th

kcal/h

User Def.

kW

MW

TR

kJ

MJ

GJ

Btu th

kcal

kWh

MWh

User Def.

3

kg/m

kg/L

g/L

h/mL

3

g/cm

3

g/ft

g/ImpGal

g/gal

kg/gal

Lb/gal

Lb/ImpGal

User Def.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

45

Page 46

6 OPERATION

6.4 Error messages

Error message Cause Measure

SITRANS FX300

No Signal No signal from vortex amplifier Check connector

In the event of measuring sensor

problems contact service.

Low freq Sample frequency too low Contact service.

High Freq Sample frequency too high Contact service.

Low Flow Flow rate less than the set minimum

flow rate q

min

Q too high Flow rate higher than the set maximum

flow rate q

max

Signal converter continues to display the

current flow rate but the accuracy of the

measurement may be affected.

Corrective measures depend on the

application!

If the flow rate exceeds the maximum

value, the measuring sensor may be

physically damaged.

Inv. Config. Invalid configuration data in FRAM

(permanent memory)

Check entire configuration!

Contact service if error message

persists.

Amp. Fail Error in the pre-amplifier stage Contact service.

Chk. Instal. Quality of the vortex signal too poor 1. Check q

min

2. Excessive pipe vibration and faulty

flow profile

Low Signal Amplitude of vortex signal is too low 1. q

2. If q

ok?

min

OK, contact service

min

Hi. Signal Amplitude of vortex signal is too high Occurs with media of high density

L.Temp.Phy Operating temperature lower than

specified

H.Temp.Phy Operating temperature higher than

specified

Hi.P.Phys Pressure higher than specified

1. Check q

2.If q

Take corrective measures within

process.

Take corrective measures within

process as quickly as possible,

otherwise both the measuring sensor

and the signal converter may be

max

OK, contact service

max

damaged.

Tsens Shrt. Temperature sensor short circuit Shows error at temperature sensor!

Tsens Open Open temperature sensor

Contact service.

P. Sen. Fail Faulty pressure sensor Displays error at pressure sensor!

Contact service.

Table 6-8: Error messages

46

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 47

SITRANS FX300

6.5 Menu structure

6.5.1 Overview of firmware versions

There are three firmware versions, each of which is tailored to a different use of the

measuring device:

• Basic:

Basic: liquids and gases without compensation, saturated steam with density compensation

Basic:Basic:

using the temperature

• Steam:

Steam: saturated and superheated steam with density compensation using pressure and

Steam:Steam:

temperature, gross heat meter

• Gas:

Gas: gas, gas mixture and wet gas with density compensation using pressure and

Gas:Gas:

temperature, FAD (free air delivery measurement)

The menu structures differ from one another depending on the firmware version.

The following table contains an overview of all menu items in the first menu level. For a

complete description of the menu, note the firmware version of your measuring device and

follow the relevant instructions in the table.

OPERATION 6

Menu items Firmware version

Basic

1. Quick setup refer to

2. Tests refer to

3. Setup refer to

Setup (firmware version

- basic)

5. Service The service menu is only accessible to service personnel and is not described.

Table 6-9: Overview of menu structure

Menu item Quick Setup

Menu item Tests

Menu item

on page 51

Firmware version

Steam

on page 49

on page 50

refer to

Setup (firmware version

- steam)

Menu item

on page 54

Firmware version

Gas

refer to

Setup (firmware version

- gas)

Menu item

on page 58

INFORMATION!

The measuring device has been preset at the factory in accordance with the customer order.

Therefore, subsequent configuration via the menu is only necessary if the intended use of the

measuring device changes.

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

47

Page 48

6 OPERATION

6.5.2 Entering values in change mode

→

Moves the insertion point one position to the right; after the last position, the insertion point

returns to the beginning.

↑

Cycles through available values and characters; moves the decimal point to the right.

^^^^

Accepting the entry.

6.5.3 Character selection in change mode

Depending on the menu function, you can choose from the following characters:

SITRANS FX300

Numbers

0 1 2 3 4 5 6 7 8 9

Lowercase letters

a b c d e f g h i j

k l m n o p q r s t

u v w x y z

Uppercase letters

A B C D E F G H I J

K L M N O P Q R S T

U V W X

Y

Z

Special characters

°

- . /

1 "blank"

2 3

" % & : < = >

1

48

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 49

SITRANS FX300

6.5.4 Menu item Quick Setup

Level Designation Selection / entry field Explanation

1.1.1 Language

→

German ↑... German language

French ↑… French language

English ↑...^ English language

1.1.2 Location

→

0000000000

Location↑…↑...↑...^

1.1.3 Maes.Inst

→

Volume ↑… Volume measurement

Norm. Vol. ↑… 1 Standard volume flow measurement

Mass ↑...^ Mass flow measurement

1.1.4 Max. Flow

→

2

m3/h

Unit ↑...^

888888888

Upp.Limit

00600.0000 or other value

3

/h ↑…↑...↑...^

m

Display Unit /

Display %Max Flow ↑...^

3

m3/h norm

Unit ↑...^

00600.0000 or other value

3

/h norm ↑…↑...↑...^

m

Display Unit /

Display %Max Flow ↑...^

4

kg/h

Unit

00600.0000 or other value

kg/h ↑…↑...↑...^

Display Unit /

Display %Max Flow ↑...^

1.1.5 Min. Flow

→

1.1.6 Timeconst.

→

1 only with gas

2 available if Maes.Inst = Volume (see menu item 1.1.3)

3 available if Maes.Inst = Norm. Vol. (see menu item 1.1.3)

4 available if Maes.Inst = Mass (see menu item 1.1.3)

001111111

00300.0000

3

/h ^

m

00002.0000

s ↑…↑...↑...^

Select menu language

Enter the name of the location (max.

10 characters)

Select type of flow measurement

Set maximum flow rate

Select unit for volume flow

measurement

Enter value for the maximum volume

flow

Display flow rate in units /

in % of maximum flow rate

Select unit for standard volume flow

measurement

Enter value for the maximum

standard volume flow rate

Display flow rate in units /

in % of maximum flow rate

Select unit for mass flow

measurement

Enter value for the maximum mass

flow rate

Display flow rate in units /

in % of maximum flow rate

The minimum flow rate value is

factory-set.

Enter the time constant for the

measured value output in seconds

(0–20s)

0: disabled

OPERATION 6

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

49

Page 50

6 OPERATION

6.5.5 Menu item Tests

Level Designation Selection / entry Explanation

SITRANS FX300

2.1.1 Test I

→

2.1.2 Test P

→

Table 6-10: Menu item Test

4 mA ^ Test current output

8 mA ^

12 mA ^

16 mA ^

20 mA ^

0.5003 Hz ^ Test pulse output

Every current value has to be confirmed with ^. Only after this is the current output

set to the respective value. The following is then displayed:

• "Contin. Yes":

"Contin. Yes": continue with the test of current output function

"Contin. Yes":"Contin. Yes":

• "Contin. No":

"Contin. No": back to menu

"Contin. No":"Contin. No":

The test current is maintained until the menu has been exited.

50

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 51

SITRANS FX300

6.5.6 Menu item Setup (firmware version - basic)

Level Designation Selection / entry Explanation

3.1 Set display

3.1.1 Error Msg.

→

3.1.2 Cycle.Disp.

→

3.1.3 Code 1

→

Yes ↑... Shows error messages in measuring mode in plain text

No ↑...^ Flashing cursor in the top left corner of the display

Yes ↑... Cyclically display measured values in measuring mode

No ↑...^ Do not display measured values cyclically

Yes ↑... Activate access code:

No ↑...^ Deactivate access code

Display error

alternating with the measured values

indicates errors.

Display measured values

(6 s intervals)

Set security query 1 (menu)

→→→↑↑↑^^^

OPERATION 6

3.2 I/O settings

3.2.1 4-20mA off

→

3.2.5 Function P

→

3.2.7 Totalizer

→

3.2.8 Tot. Conf.

→

(available if Maes.Inst =

Volume, see menu item

1.1.3)

(available if Maes.Inst =

Norm. Vol., see menu

item 1.1.3)

4-20mA ↑... Current output 4-20 mA

4-20/22E ↑... Current output 4-20 mA or error current 22 mA

4-20/3.55E ↑...^ Current output 4-20 mA or error current 3.55 mA

Yes ↑... Activate pulse output

No ↑...^ Deactivate pulse output

Tot. on ↑... Start totalizer

Tot. off ↑...^ Stop totalizer (value is held)

3

m

Unit ↑...^

0000000000

3

↑…↑...↑...^

m

Reset yes /

Reset no ↑...^

Disp. off /

Disp. on ↑...^

m3 norm

Unit ↑...^

0000000000

3

norm ↑…↑...↑...^

m

Reset yes /

Reset no ↑...^

Disp. off /

Disp. on ↑...^

Current output 4-20 mA and error current

Pulse output

Totalizer

Configure totalizer

Select totalizer unit for volume flow measurement

Enter preset totalizer value

Reset totalizer /

Do not reset totalizer/

Display totalizer /

Do not display totalizer

Select totalizer unit for standard volume flow

measurement

Enter preset totalizer value

Reset totalizer /

Do not reset totalizer/

Display totalizer /

Do not display totalizer

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

51

Page 52

6 OPERATION

Level Designation Selection / entry Explanation

SITRANS FX300

(available if Maes.Inst =

Mass, see menu item

1.1.3)

3.3 HART settings

3.3.1 Poll. Adr.

→

3.3.2 HART SV

→

3.3.3 HART TV

→

3.3.4 HART 4V

→

3.4 Set fluid and medium

3.4.1 Fluid 1

→

3.4.2 Medium

→

(available if Fluid = Gas or

Liquid, see menu item

3.4.1)

(available if Fluid = Steam,

see menu item 3.4.1)

1 Density check

3.5 Set pressure, temperature and density

3.5.1 T-sensor

→

3.5.3 Sat.P/T

→

(verfügbar wenn FLUID =

DAMPF, siehe Menüpunkt

3.4.1)

3.5.4 Temp. Opr.

→

kg

Unit ↑...^

0000000000

kg ↑…↑...↑...^

Reset yes /

Reset no ↑...^

Disp. off /

Disp. on ↑...^

000

0 – 15

↑…→↑...→↑...^

Total Flow ^ HART secondary variable

Temp. ^ HART tertiary variable

Density ^

Density ^ HART quaternary variable

Temp. ^

Gas ↑... Gas

Liquid. ↑... Liquid

Steam ↑...^ Steam

Custom ↑... Customer medium

Sat.Steam ↑...^ Saturated steam

Custom

No ↑... No temperature sensor available

Yes ↑...^ Temperature sensor available

Sat. T ^ Density calculation for saturated steam with the

°C

Unit ↑...^

0000000.0

°C ^

Disp. on /

Disp. off ↑...^

Select totalizer unit for mass flow measurement

Enter preset totalizer value

Reset totalizer /

Do not reset totalizer/

Display totalizer /

Do not display totalizer

Enter HART polling address for "Multidrop operation"

Set fluid type

Set medium

Internal temperature sensor

Density calculation for saturated steam

saturated temperature

Operating temperature

Set temperature unit

Operating temperature

Display temperature /

Do not display temperature

52

www.siemens.com/flow 06/2009 - SFIDK.PS.050.F2.02 A5E02100423

Page 53

SITRANS FX300

Level Designation Selection / entry Explanation

OPERATION 6

3.5.6 Dens. Opr.

3.5.9 Dens. Norm 2

3.6

3.6.1 Remote 0.000

3.6.2 Cable Coef 14.074

1 Disp. off

Disp. on

2 available if Maes.Inst = Norm.Vol.

→

→

kg/m

Unit ↑...^

00000.0000

kg/m

00000.0000

kg/m

length/m

Cable Coef

3

3

^ 1

3

↑…↑...↑...^

Density at operating pressure and operating

temperature

Set density unit

Operating density

Enter density for reference conditions (pressure and

temperature)

(max. = 30m)

www.siemens.com/flow06/2009 - SFIDK.PS.050.F2.02 A5E02100423

53

Page 54

6 OPERATION

6.5.7 Menu item Setup (firmware version - steam)

Level Designation Selection / entry Explanation

3.1 Set display

3.1.1 Error Msg.

→

3.1.2 Cycle.Disp.

→

3.1.3 Code 1

→

Yes ↑... Shows error messages in measuring mode in plain text

No ↑...^ Flashing cursor in the top left corner of the display

Yes ↑... Cyclically display measured values in measuring mode

No ↑...^ Do not display measured values cyclically

Yes ↑... Activate access code: