Siemens SITRANS F FUS380, SITRANS F FUE380 Operating Instructions Manual

SITRANS F

Ultrasonic Flowmeters

FUS380/FUE380

Introduction

1

Operating Instructions

Safety notes

Description

Installing/Mounting

Connecting

Commissioning

Functions

Service and maintenance

2

3

4

5

6

7

8

Troubleshooting/FAQs

Technical data

Parameter lists

Settings

9

10

A

B

09/2016

A5E00730100-AB

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E00730100

Ⓟ 09/2016 Subject to change

Copyright © Siemens AG 2016.

All rights reserved

Table of contents

1 Introduction...................................................................................................................................................7

1.1 Preface.....................................................................................................................................7

1.2 History......................................................................................................................................7

1.3 Items supplied..........................................................................................................................8

1.4 Checking the consignment.......................................................................................................9

1.5 Device identification.................................................................................................................9

1.6 Further Information.................................................................................................................12

2 Safety notes................................................................................................................................................13

2.1 General safety instructions.....................................................................................................13

2.2 Lithium batteries.....................................................................................................................13

2.3 Laws and directives................................................................................................................13

2.4 Installation in hazardous area................................................................................................14

2.5 Certificates.............................................................................................................................14

3 Description..................................................................................................................................................15

3.1 Overview................................................................................................................................15

3.2 System components...............................................................................................................15

3.3 Design....................................................................................................................................16

3.4 Features.................................................................................................................................16

3.5 Principle of operation.............................................................................................................18

4 Installing/Mounting......................................................................................................................................21

4.1 Flowmeter installation............................................................................................................21

4.2 Sensor installation..................................................................................................................21

4.2.1 Inlet/outlet conditions.............................................................................................................21

4.2.2 Reduction...............................................................................................................................26

4.2.3 Insulation................................................................................................................................26

4.3 Transmitter installation (compact/remote versions)...............................................................27

4.3.1 Installation wall mounting kit (remote transmitter)..................................................................28

4.3.2 Battery-powered transmitter...................................................................................................29

5 Connecting.................................................................................................................................................31

5.1 Mains-powered transmitter.....................................................................................................31

5.2 Compact system....................................................................................................................32

5.3 Remote system......................................................................................................................35

5.3.1 Sensor side............................................................................................................................35

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 3

Table of contents

5.3.2 Transmitter side.....................................................................................................................40

5.3.3 Wiring energy calculator.........................................................................................................43

5.4 Sealing of FUE380.................................................................................................................43

5.4.1 User sealing...........................................................................................................................43

5.4.2 Verification sealing.................................................................................................................44

6 Commissioning...........................................................................................................................................45

6.1 Operating the local display.....................................................................................................45

6.2 Navigating the menu structure...............................................................................................46

6.3 Start-up routine......................................................................................................................47

6.4 Commissioning via PDM........................................................................................................48

6.4.1 Installing and connecting the IrDA interface adapter.............................................................49

6.4.2 Installing the device driver......................................................................................................50

6.4.3 Adding the device to the network...........................................................................................52

6.4.4 Configuring the device...........................................................................................................53

6.4.5 Optimizing the system............................................................................................................54

6.4.6 Output A, terminals 56/57:.....................................................................................................56

6.4.7 Output B, terminals 66/67:.....................................................................................................57

6.4.8 Checking the operation readiness..........................................................................................57

7 Functions....................................................................................................................................................59

7.1 Unit selection..........................................................................................................................59

7.2 Number of decimal digits........................................................................................................60

7.3 Password-protected data.......................................................................................................60

7.4 Hardware key.........................................................................................................................60

8 Service and maintenance...........................................................................................................................63

8.1 Maintenance...........................................................................................................................63

8.2 Battery replacement...............................................................................................................63

8.3 Technical support...................................................................................................................66

8.4 Application-specific data - Qualification certificate.................................................................67

8.5 Return procedures.................................................................................................................71

8.6 Battery disposal......................................................................................................................72

9 Troubleshooting/FAQs................................................................................................................................73

9.1 Error codes.............................................................................................................................73

9.2 Diagnosing with PDM.............................................................................................................74

10 Technical data............................................................................................................................................79

10.1 FUS380 and FUE380 systems...............................................................................................79

10.2 Battery....................................................................................................................................80

10.3 Sensor for FUS380 and FUE380...........................................................................................81

10.4 Dimensional drawings for FUS380 and FUE380...................................................................82

10.5 Sensor dimensions for FUS380 and FUE 380.......................................................................82

FUS380/FUE380

4 Operating Instructions, 09/2016, A5E00730100-AB

Table of contents

A Parameter lists............................................................................................................................................85

A.1 Identification...........................................................................................................................85

A.2 Output....................................................................................................................................86

A.3 Diagnostic..............................................................................................................................88

A.4 Meter setup............................................................................................................................93

A.5 Human Interface.....................................................................................................................95

A.6 Unit conversion table..............................................................................................................96

B Settings.......................................................................................................................................................97

B.1 Factory settings......................................................................................................................97

B.2 Factory settings for Modbus communication..........................................................................98

B.3 Ordering of spare parts..........................................................................................................99

Index.........................................................................................................................................................101

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 5

Table of contents

FUS380/FUE380

6 Operating Instructions, 09/2016, A5E00730100-AB

Introduction

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

The contents of this manual shall not become part of or modify any prior or existing agreement,

commitment or legal relationship. The sales contract contains all obligations on the part of

Siemens as well as the complete and solely applicable warranty conditions. Any statements

regarding device versions described in the manual do not create new warranties or modify the

existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

1.1 Preface

These instructions contain all the information you need for using the device.

1

The instructions are aimed at persons mechanically installing the device, connecting it

electrically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

Note

It is the responsibility of the customer that the instructions and directions provided in the

operating instructions are read, understood, and followed by the relevant personnel before

installing the device.

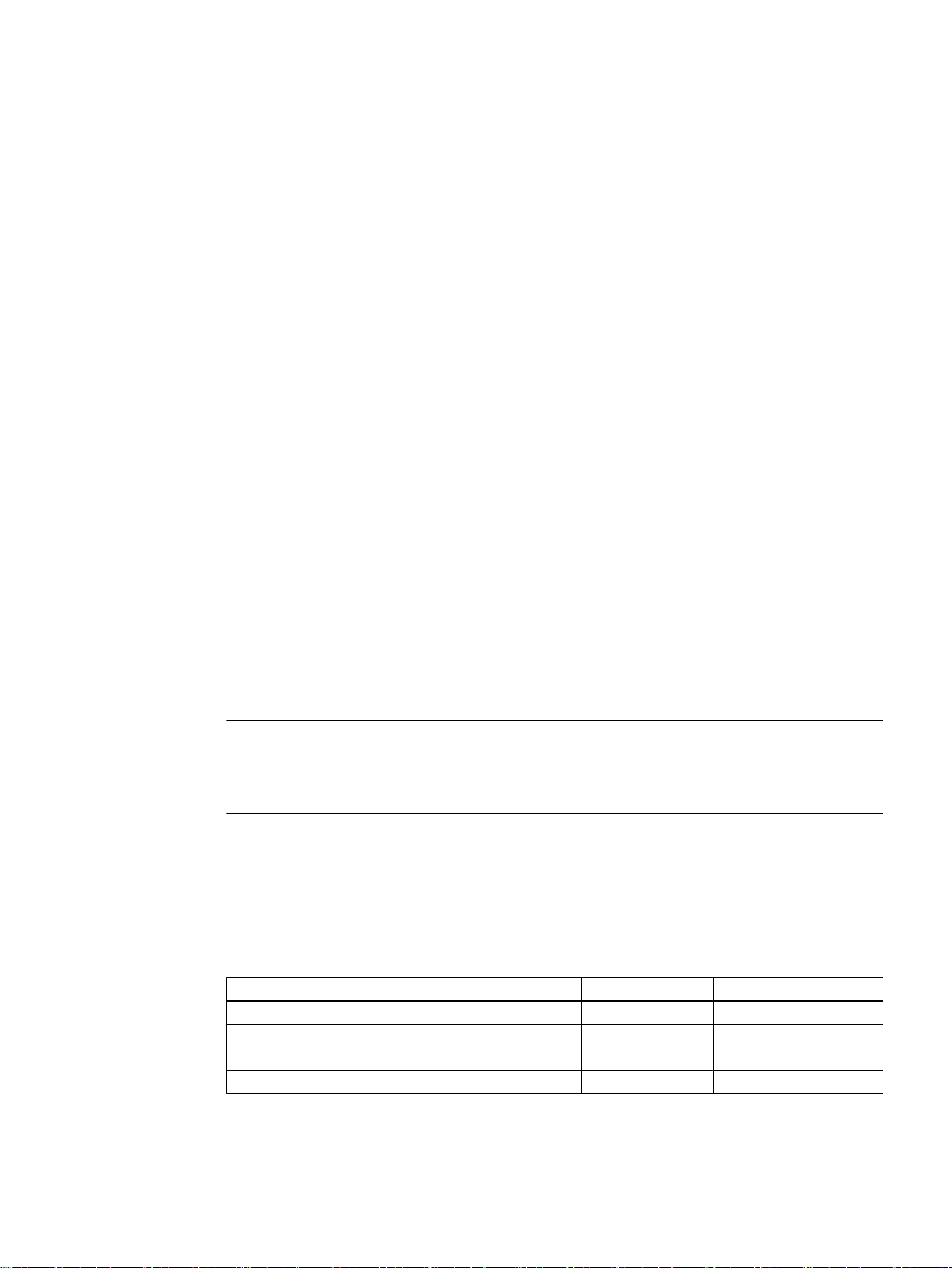

1.2 History

The following table shows the most important changes in the documentation compared to each

previous edition.

Edition Remarks FW version EDD version

2003 First edition with product release 1.02 1.01.04

12/2009 Update with FW 1.04 1.04 1.01.04

10/2010 Update with FW 1.05 1.05 1.01.04

09/2011 Update with FW 2.03 2.03 1.02.07

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 7

mnnmnmn

nmmnnmmnmnnmnmn

nmmn

nmmnmnnmnmn

mnmnnmnmn

nnmnmn

m

n

nmnmnn

mnn

mnmn

m

nn

m

n

m

n

n

m

n

m

n

n

m

nnmnn

Safety N

ote

C

al.

rep.

mnnmnmn

nmmnnmmnmnnmnmn

nmmn

nmmnmnnmnmn

mnmnnmnmn

mnn

m

nm

nn

mnn

m

nm

n

mnn

m

nm

nn

m

nmnn

mnnm

nn

nnmnmn

Safety N

ote

C

al.

rep.

Introduction

1.3 Items supplied

Edition Remarks FW version EDD version

09/2013

● Restructure this document

● Adding transmitter information

09/2016

● Restructure this document

● Updates for SIMATIC PDM 8.2

The FUS080 is configured in a combination of hardware (HW) and firmware (FW). For

communication and parametrization via SIMATIC PDM the correct version of the EDD driver

for FUS/FUE 380 is needed. The various relations are listed above.

These Operating Instructions describe FW version 2.03 and EDD version 1.02.08-01 (with min.

SIMATIC PDM V8.2).

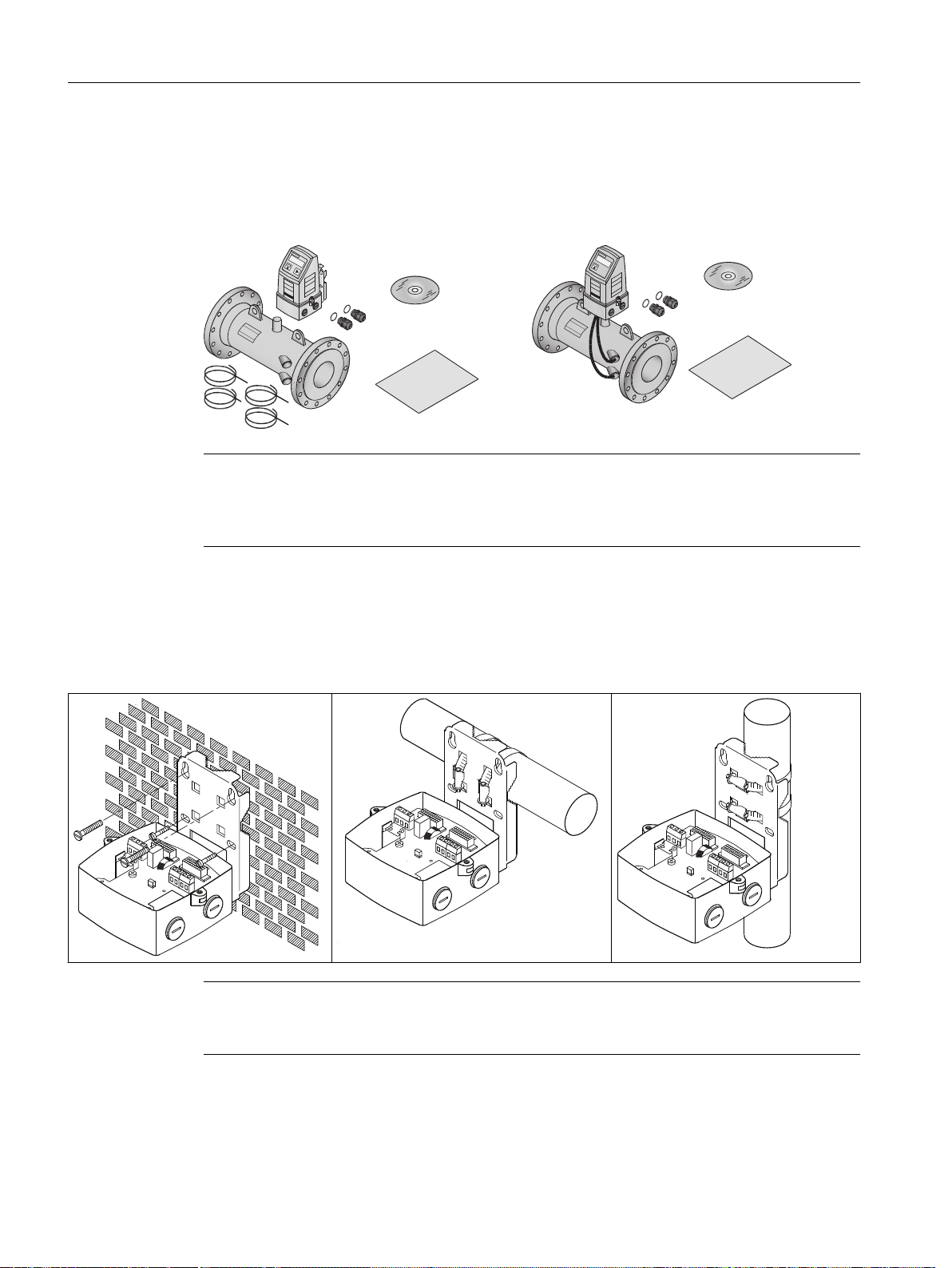

1.3 Items supplied

The device can be delivered as either a compact or a remote system.

Compact system

2.03 1.02.07

2.03 1.02.08-01

● Sensor SITRANS FUS300

● Transmitter SITRANS FUS080 or FUE080

● Siemens Process Instrumentation

documentation disk containing certificates,

and manuals

● Safety note

● Calibration report

Remote system

● Sensor SITRANS FUS300

● Transmitter SITRANS FUS080 or FUE080

● Siemens Process Instrumentation

documentation disk containing certificates,

and manuals

● Safety note

● Calibration report

● Wall/pipe mounting kit with bracket and

terminal box

● 4 Transducer coaxial cables

8 Operating Instructions, 09/2016, A5E00730100-AB

FUS380/FUE380

Note

Scope of delivery may vary, depending on version and add-ons. Make sure the scope of

delivery and the information on the nameplate correspond to your order and the delivery note.

1.4 Checking the consignment

1. Check the packaging and the device for visible damage caused by inappropriate handling

during shipping.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Introduction

1.5 Device identification

1.5 Device identification

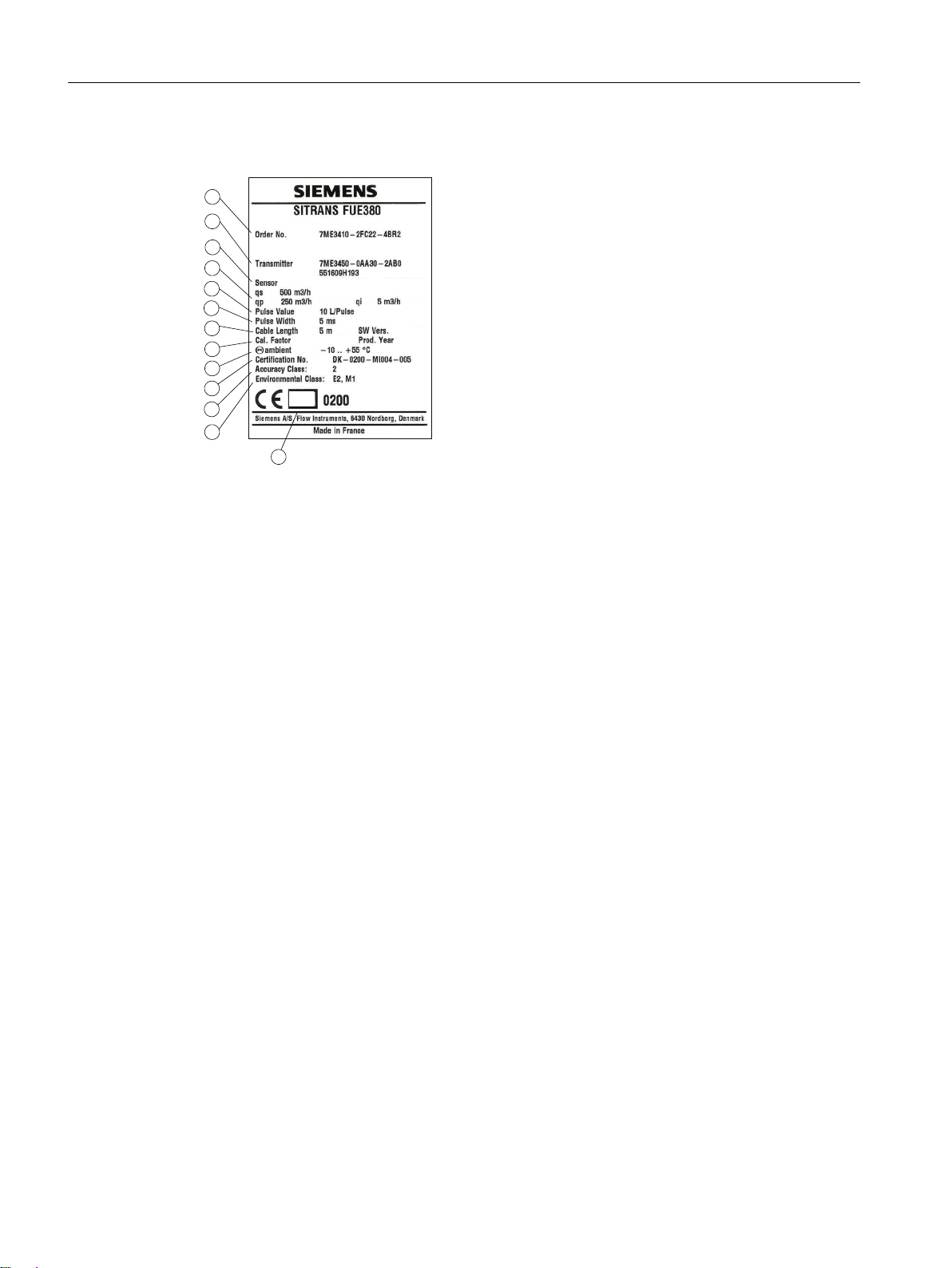

The FUS380 or FUE380 flowmeter is delivered with different labels (nameplates) on the

transmitter and sensor. The transmitter and sensor are matched paired.

The transmitter has two nameplates. One (silver) is placed on the front of the transmitter. The

transmitter system nameplate (white) is placed on the right side of the transmitter. Both provide

valuable information about the device and system. The sensor system nameplate (white) is

placed on middle of the sensor.

Note

Identification

Identify your device by comparing your ordering data with the information on the product and

specification nameplates.

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 9

1.000000

123412H123

123412H123

FDK:087H2503

2.03

2015

M15

Introduction

1.5 Device identification

Transmitter system nameplate

① System number (order code identifying selected options and system serial number)

② Transmitter production code and serial number

③ Sensor production code and serial number

④ Maximum flow value (qs), Nominal flow value (qp), Minimum flow value (qi)

⑤ Pulse value (output A)

⑥ Pulse width (output A)

⑦ Cable length (one transducer cable); Software version

⑧ Calibration factor; Production year

⑨ Ambient temperature range

⑩ Type approval number (shown on FUE380 versions only)

⑪ Accuracy class (shown on FUE380 versions only)

⑫ Environmental class (shown on FUE380 versions only)

⑬ Verification markings (shown on MID-verified FUE380 versions only)

Figure 1-1 Transmitter system nameplate, FUE380 example

10 Operating Instructions, 09/2016, A5E00730100-AB

FUS380/FUE380

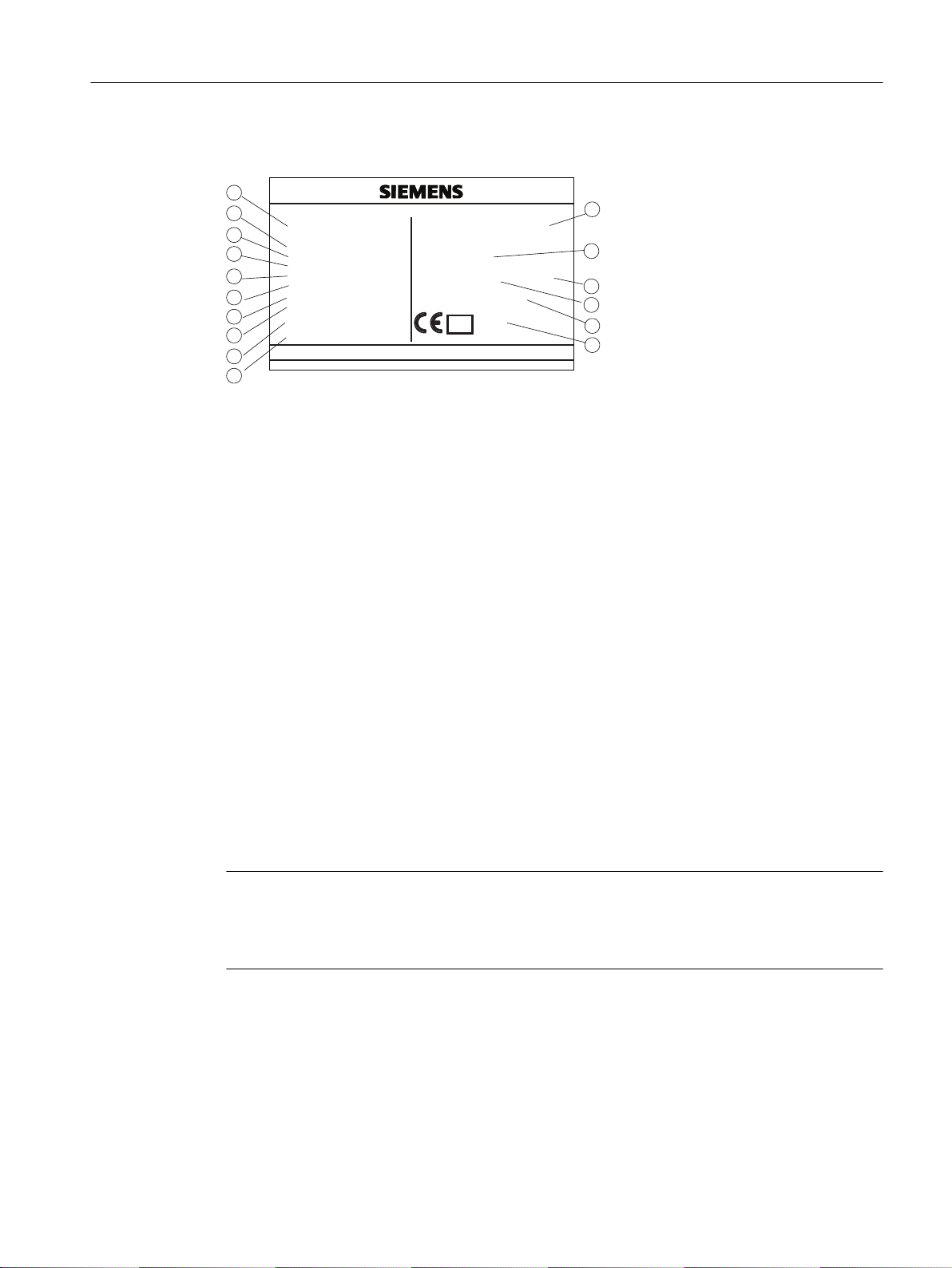

Sensor system nameplate

SITRANS FUE380

Sensor

Dimension

Process Con.

qs

qp / qi

Θmin − Θmax

Cal. Factor

T-amb.

(PS) at +15

°C

(PS) at +200

°C (TS)

Fluid group

FDK-087H2503

123412H123

DN 200

EN 1092-1, PN16

500 m3/h

250 / 5 m3/h

+15 °C ... +200 °C

1.000000

-10 to +55 °C

16 Bar

13.5 Bar

PED/G2

SYSTEM No.

Prod. Year

7ME3410-2FC22-4BR2

123412H123

2015

0200

0200

M15

Siemens A/S, Flow Instruments, 6430 Nordborg, Denmark

Made in France

Accuracy Class: 2

Certification No.: DK-0200-MI004-005

Environmental Class: E2, M1

① Sensor production code and serial number

② Dimension (nominal size ordered)

③ Process connections

④ Maximum flow value (qs)

⑤ Nominal flow value (qp), Minimum flow value (qi)

⑥ Water temperature range

⑦ Calibration factor

⑧ Ambient temperature range

⑨ Maximum allowable working pressures at 15 °C (59 °F) and 200°C (392 °F) (max. tempera‐

⑩ Fluid group

⑪ System number (order code identifying selected options and system serial number)

⑫ Production year

⑬ Certification number (shown on FUE380 versions only)

⑭ Accuracy class (shown on FUE380 versions only)

⑮ Environmental class (shown on FUE380 versions only)

⑯ Verification and PED markings (verification marking shown on MID-verified FUE380 versions

Introduction

1.5 Device identification

ture (TS))

only)

Figure 1-2 Sensor system nameplate, FUE380 example

Note

The matched paired transmitter and sensor shall be mounted together

At installation, please check that the system nameplates of transmitter and sensor have the

same system serial number.

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 11

Introduction

1.6 Further Information

1.6 Further Information

Product information on the Internet

The Operating Instructions are available on the documentation disk shipped with the device,

and on the Internet on the Siemens homepage, where further information on the range of

SITRANS F flowmeters may also be found:

Product information on the internet (

Worldwide contact person

If you need more information or have particular problems not covered sufficiently by these

Operating Instructions, get in touch with your contact person. You can find contact information

for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner)

http://www.siemens.com/flow)

FUS380/FUE380

12 Operating Instructions, 09/2016, A5E00730100-AB

Safety notes

2.1 General safety instructions

CAUTION

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Only qualified personnel should install or operate this instrument.

Note

Alterations to the product, including opening or improper modifications of the product are not

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2.2 Lithium batteries

2

Lithium batteries are primary power sources with high energy content designed to provide the

highest possible degree of safety.

WARNING

Potential hazard

Lithium batteries may present a potential hazard if they are abused electrically or

mechanically. Observe the following precautions when handling and using lithium batteries:

● Do not short-circuit, recharge or connect with false polarity.

● Do not expose to temperatures beyond the specified temperature range.

● Do not incinerate.

● Do not crush, puncture or open cells or disassemble.

● Do not weld or solder to the battery’s body.

● Do not expose contents to water.

2.3 Laws and directives

General requirements

Installation of the equipment must comply with national regulations. For example EN 60079-14

for the European Community.

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 13

Safety notes

2.5 Certificates

Instrument safety standards

The device has been tested at the factory, based on the safety requirements. In order to

maintain this condition over the expected life of the device the requirements described in these

Operating Instructions must be observed.

NOTICE

Material compatibility

Siemens Flow Instruments can provide assistance with the selection of wetted sensor parts.

However, the full responsibility for the selection rests with the customer and Siemens Flow

Instruments can take no responsibility for any failure due to material incompatibility.

CE-marked equipment

The CE mark symbolizes the compliance of the device with the following directives:

● EMC-directive 2004/108/EC

● Low voltage directive 2006/95/EC

● Pressure equipment directive (PED/DGRL) 93/23/EC

● ATEX Directive 94/9/EG

2.4 Installation in hazardous area

WARNING

NOT allowed for use in hazardous areas!

Equipment used in hazardous areas must be Ex-approved and marked accordingly!

This device is NOT approved for use in hazardous areas!

WARNING

500 V insulation test

The device is not capable of withstanding the 500 V insulation test required by Clause 6.3.12

of EN60079-11. This must be taken into account when installing the device.

2.5 Certificates

You can find certificates on the Internet at online support portal (http://www.siemens.com/

processinstrumentation/certificates) or on an included DVD.

FUS380/FUE380

14 Operating Instructions, 09/2016, A5E00730100-AB

Description

3.1 Overview

The SITRANS F US ultrasonic flowmeter systems consist of a sensor and a transmitter. This

system consists of sensor type FUS300 or SONOKIT and the transmitters type FUS080 or

FUE080. The transmitter type FUS080 is for the standard flowmeter series SITRANS FUS380

or SONOKIT series. The transmitter type FUE080 is for the type-approved flowmeter series

SITRANS FUE380 with the custody transfer approval for use in energy metering systems. The

transmitters are designed to measure flow in water applications.

The ultrasonic flowmeter transmitter comes as battery or mains-powered version.

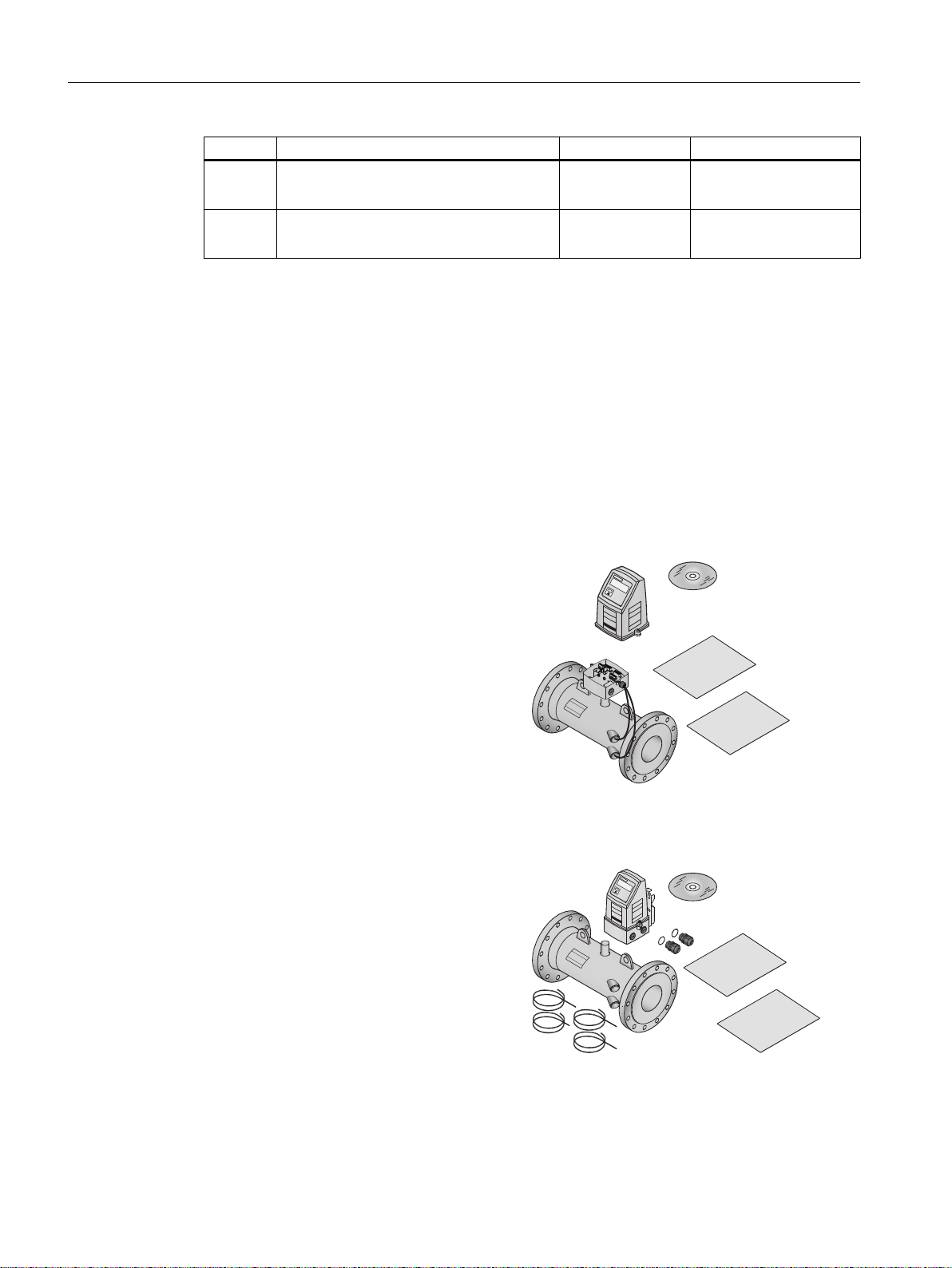

The following table shows the ultrasonic flowmeter systems with these transmitter types:

Sensor type Transmitter Flowmeter system

FUS300 (2-path)

DN 50 – DN 1200

FUS300 (2-path)

DN 50 – DN 1200 (with custody transfer approval

for use with heatmeters)

SONOKIT (1- or 2-path)

DN 100 – DN 1200

3

FUS080 FUS380

FUE080 FUE380

FUS080 SONOKIT (1-path / 2-path)

These Operating Instructions are only for the FUS380 and FUE380 flowmeter system. The

FUS080 for SONOKIT and the SONOKIT sensors have separate Operating Instructions.

3.2 System components

The flowmeter system includes:

● Battery or mains-powered transmitter (FUS080 or FUE080)

● Sensor FUS300 as 2-path sensor with flanges and inline transducers wet-calibrated from

factory together with the transmitter (DN 50 (2") to DN 1200 (48"))

or the retrofitting set SONOKIT (1-path for pipe diameters from DN 100 (4") up to DN 1200

(48") or for 2-path from DN 200 (8") up to DN 1200 (48")).

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 15

Description

3.4 Features

3.3 Design

The transmitter type SITRANS FUS080 is designed with fiberglass reinforced polyamide

enclosure for remote or compact installation in normal areas. The remote versions are available

with up to 30 meter distance from flowmeter to transmitter. When ordered as a compact version

in the series FUS380 and FUE380 the transducer cables are pre-mounted at the sensor.

The transmitter is available in an IP67/NEMA 4X/6 enclosure and is designed for use in the

flowmeters series:

● SONOKIT (1-path or 2-path)

● FUS380 (2-path)

● FUE380 (2-path)

For spare part cases the transmitter is always ordered as part of a complete flowmeter system,

it can be ordered preprogrammed with the given sensor data (system serial number).

3.4 Features

The following features are available:

● Battery or mains-powered transmitter

● Battery-powered with 3.6 V Lithium dual D-cell batteries

● Suitable for sensor pipe diameters from DN 50 (2") up to DN 1200 (48")

● IP67 (NEMA 4X/6) rated polyamid transmitter enclosure

● Factory preset to the nominal dimensions of pipe type and pipe size

SITRANS FUS080 transmitter

SITRANS FUS080 Display

● Programming via SIMATIC PDM

● Local control panel with single push button, 8-digit display and IrDA optical interface for

communication with SIMATIC PDM

● Display showing accumulated volume as well as instantaneous flow rate. The displayed

units are m3 and m3/h

● Two digital outputs for volume pulse or alarm

FUS380/FUE380

16 Operating Instructions, 09/2016, A5E00730100-AB

Applications

The main application for flowmeters type SITRANS FUS380 / SONOKIT and the typeapproved version FUE380 is measurement of water flow in district heating plants, local

networks, boiler stations, substations, chiller plants, irrigations plants, and other general water

applications.

Integration

The flowmeter pulse output is often used as input for an energy meter or as input for digital

systems for remote reading. The transmitter has two pulse outputs, with functions that can be

individually selected, and integrated IrDA (optical eye) communication interface (Modbus RTU).

The settings of the transmitter, for example flow and pulse output rate, are defined when

ordering the complete flowmeter. If the flowmeter forms part of an energy meter system for

custody transfer, no further approvals are needed, except eventually local approvals on the

flowmeter.

Transmitter communication solutions

The transmitter supports Modbus RTU communication via the optical IrDA interface at the

display, enabling the change of different transmitter settings using the SIMATIC PDM software

tool.

Description

3.4 Features

The FUS080 is configured in a combination of hardware (HW) and firmware (FW). For the

communication and parametrization via SIMATIC PDM a firmware-specific electronic device

description (EDD) is needed. The various relations are listed below:

FW version EDD version

1.02 to 1.05 1.01.04 (with SIMATIC PDM 6 versions)

2.03 1.02.07 (with SIMATIC PDM 6 versions)

2.03 1.02.08-01 (min. SIMATIC PDM 8 versions)

This operating instruction is about the FW 2.03 and related EDD 1.02.08-01 (with min. SIMATIC

PDM 8.2).

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 17

Description

3.5 Principle of operation

3.5 Principle of operation

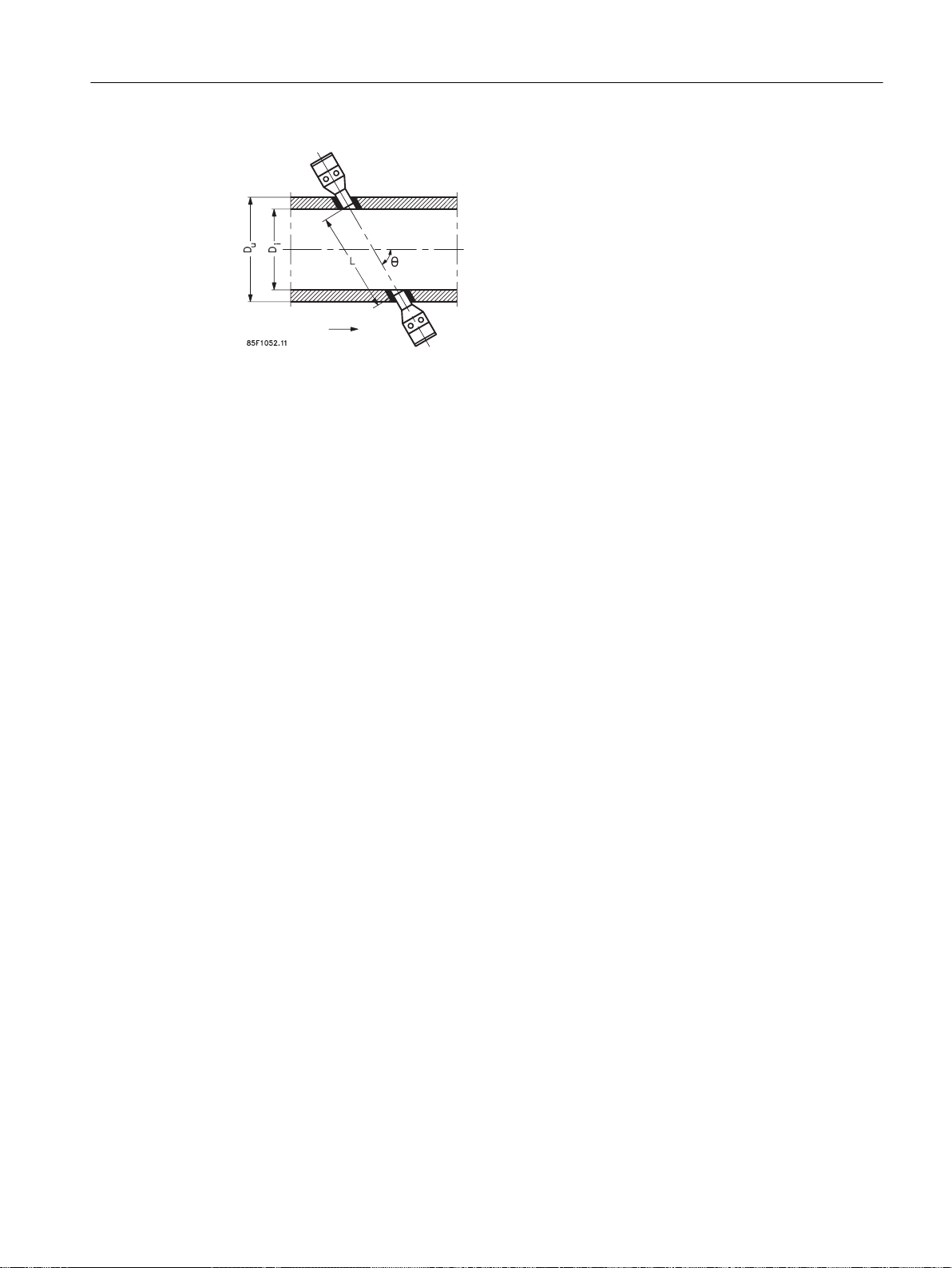

Physical principle

Figure 3-1 Velocity distribution along sound path

A sound wave travelling in the same direction as the liquid flow arrives at point B from point A

in a shorter time than the sound wave travelling against the flow direction (from point B to A).

The difference in sound transit time indicates the flow velocity in the pipe.

Since delay time is measured at short intervals both in and against flow direction, temperature

has no influence on measurement accuracy.

SITRANS F US flowmeters

In SITRANS F US flowmeters the ultrasonic transducers are placed at an angle θ in relation

to the pipe axis. The transducers function as transmitters and receivers of the ultrasonic

signals. Measurement is performed by determining the time the ultrasonic signal takes to travel

with and against the flow. The principle can be expressed as follows:

v = K × (t

where

v = Average flow velocity

t = Transit time

K = Proportional flow factor

This measuring principle offers the advantage that it is independent of variations in the actual

sound velocity of the liquid, i.e. independent of the temperature.

The mechanical/geometrical pipe data is transducer angle (θ), distance between sensors (L)

and pipe dimension (Di and Du) shown in the figure below.

B,A

– t

A,B

) / (t

A,B

× t

B,A

) = K × Δt/t²

FUS380/FUE380

18 Operating Instructions, 09/2016, A5E00730100-AB

1A

1B

Description

3.5 Principle of operation

Figure 3-2 Measuring principle

The ultrasonic signal is sent directly between the transducers. The advantage gained by

sending signals from point to point is an extremely good signal strength.

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 19

Description

3.5 Principle of operation

FUS380/FUE380

20 Operating Instructions, 09/2016, A5E00730100-AB

Installing/Mounting

4.1 Flowmeter installation

The flowmeter installation is done in two steps:

1. Sensor installation

2. Transmitter installation

Environment

SITRANS F flowmeters are suitable for indoor and outdoor installations.

● Make sure that temperature and ambient specifications indicated on the device type plate/

label are not exceeded.

CAUTION

Direct sunlight

Device damage.

The device can overheat or materials become brittle due to UV exposure.

Protect the device from direct sunlight.

4

Make sure that the maximum permissible ambient temperature is not exceeded.

Refer to the technical data in FUS380 and FUE380 systems (Page 79).

Ambient temperatures for FUS080:

● MID version: -10 to +55 °C (14 to 131 °F)

● Non-MID version: -10 to +60 °C (14 to 140 °F)

See also Insulation (Page 26).

The enclosure rating of the transmitter is IP67 (NEMA 4X/6) or better.

4.2 Sensor installation

4.2.1 Inlet/outlet conditions

Requirement for straight inlet before flowmeter

In order to maximize performance it is necessary to have straight inlet and outlet flow conditions

before and after the flowmeter.

Furthermore, a minimum distance between flowmeter and pumps and valves must be

respected.

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 21

Installing/Mounting

4.2 Sensor installation

It is also important to centre the flowmeter in relation to flanges and gaskets.

Make sure that the flowmeter is positioned as low as possible to prevent air from being trapped

in the flowmeter at the transducers.

Find a position on the pipeline where the inlet pipe tothe flowmeter has a straight length as

specified below.

Note

MID-approved FUE380 systems

Minimum straight inlet pipe: 1.5 m. See further recommendations below.

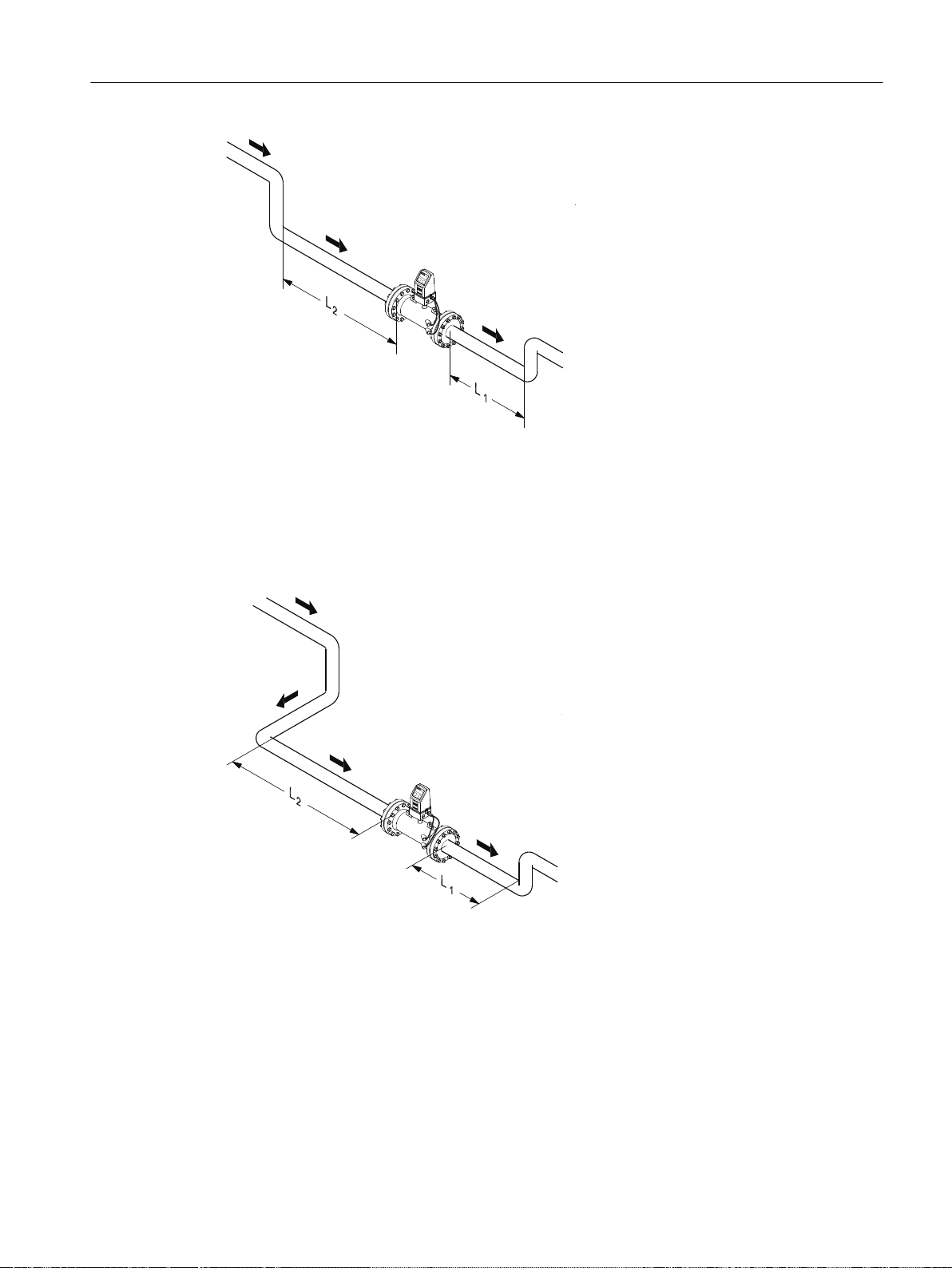

Single bend

1 x 90° bend

L2: Min. 10 x pipe diameter

L1: 3 x pipe diameter

Dual bend

2 x 90° bends in the same plane

L2: Min. 10 x pipe diameter

L1: 3 x pipe diameter

FUS380/FUE380

22 Operating Instructions, 09/2016, A5E00730100-AB

Triple bend

Installing/Mounting

4.2 Sensor installation

3 x 90° bends in two planes

Valves and pumps

L2: Min. 20 x pipe diameter

L1: 3 x pipe diameter

Valves

L2: Min. 10 x pipe diameter, fully open valve

L1: 3 x pipe diameter

Partially opened valves

L2: Min. 40 x pipe diameter, partially opened valves (or equal valves design)

Pumps

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 23

Installing/Mounting

4.2 Sensor installation

L2: Min. 20 x pipe diameter

L1: 3 x pipe diameter

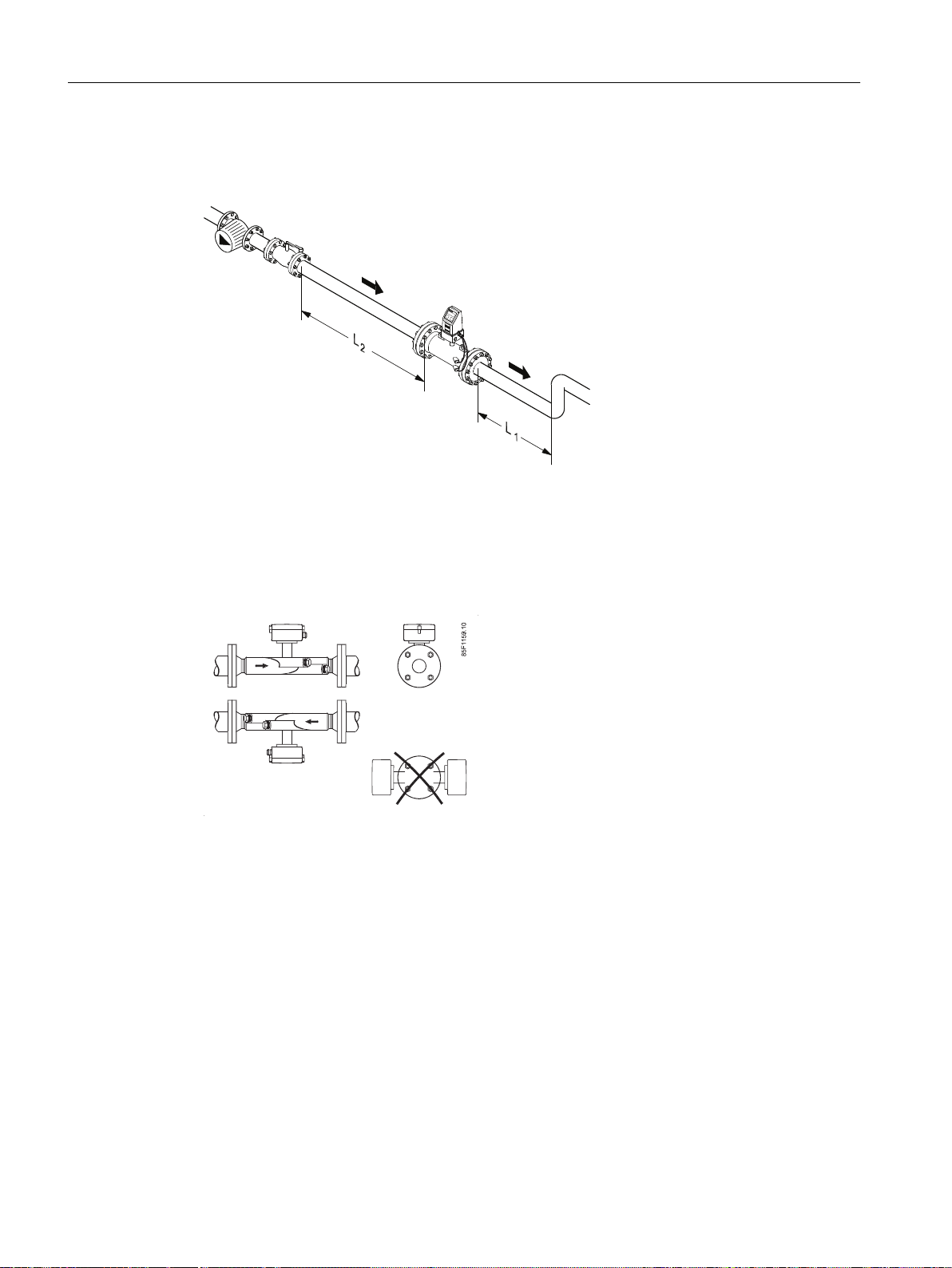

Orienting the sensor

Horizontal orientation: sensors with terminal box must be mounted with the terminal box in

upwards or downwards position. Sensor without terminal box (remote versions) must be

mounted with the transducers in the vertical plane.

In horizontal installation avoid any upward/downward position of the transducers.

FUS380/FUE380

24 Operating Instructions, 09/2016, A5E00730100-AB

Installing/Mounting

4.2 Sensor installation

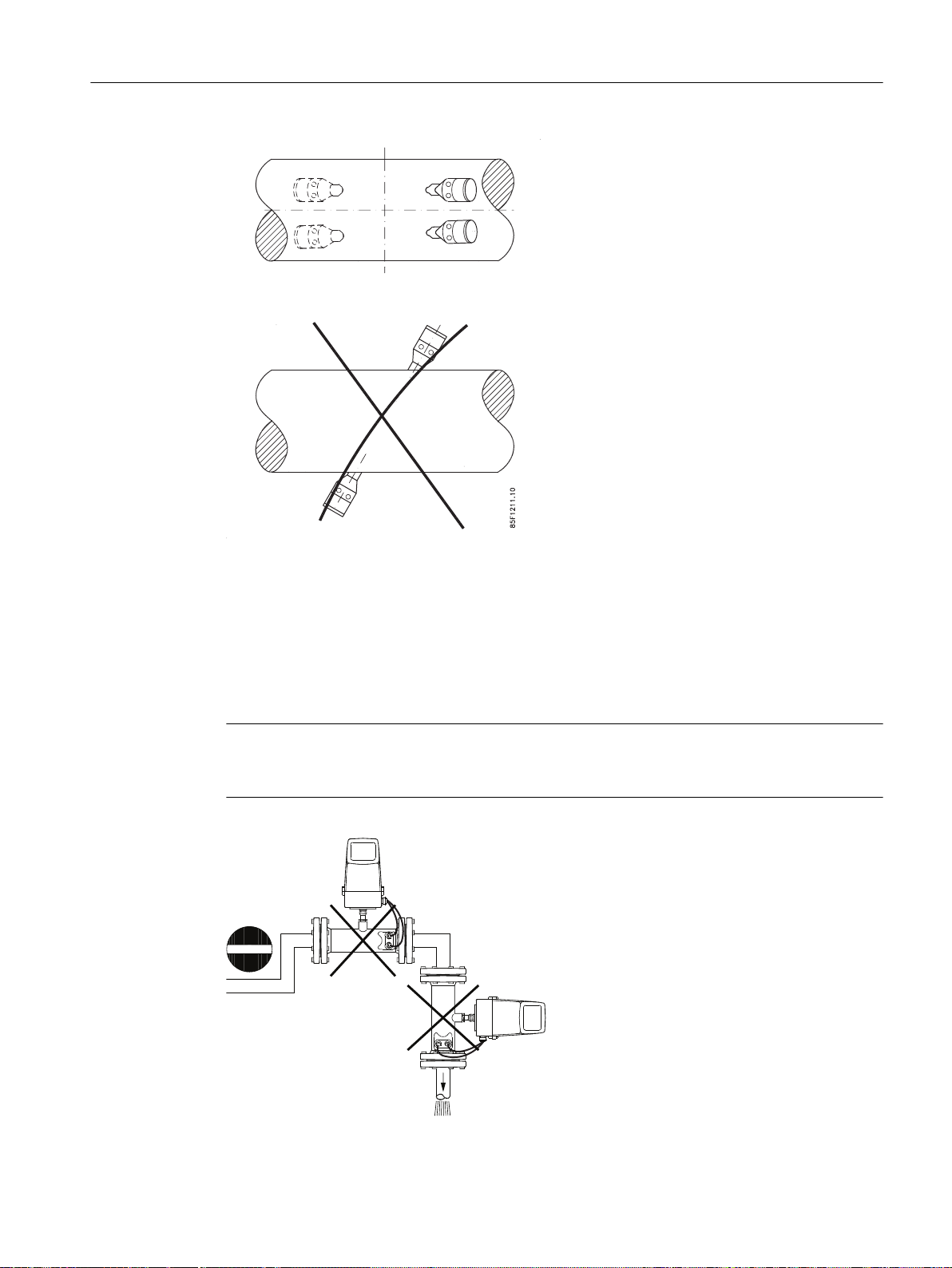

Precautions

Avoid installation at the highest point in the system because air bubbles will be trapped in the

flowmeter.

Avoid installation at a point where there is a free outlet after the flowmeter.

The flowmeter pipe section may be installed in either a horizontal or vertical position.

Note

To obtain maximum battery lifetime of the Lithium Thionyl Chloride battery pack, Siemens

recommends installing the flowmeter transmitter in an upright position.

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 25

Installing/Mounting

4.2 Sensor installation

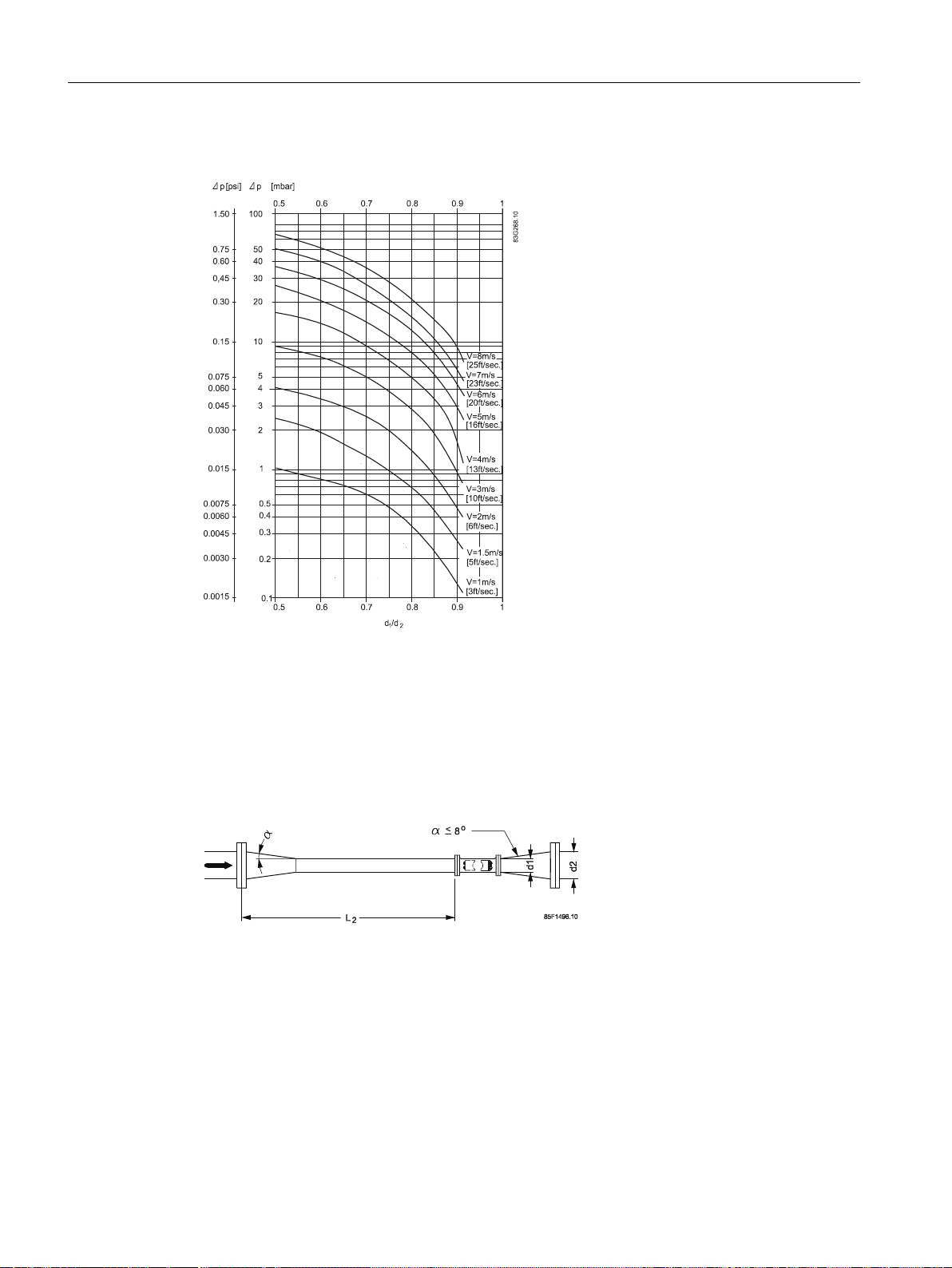

4.2.2 Reduction

Installation in large pipes

The flowmeter can be installed between two reducers as shown. At 8° reducing angles the

below pressure drop curve applies.

Delta-P example:

A water flow velocity of 3 m/s (V) in a sensor with a diameter reduction from DN 200 to DN

100 (D1/D2 = 0.5) gives a pressure drop of 9 mbar.

L2: Min. 10 x pipe diameter

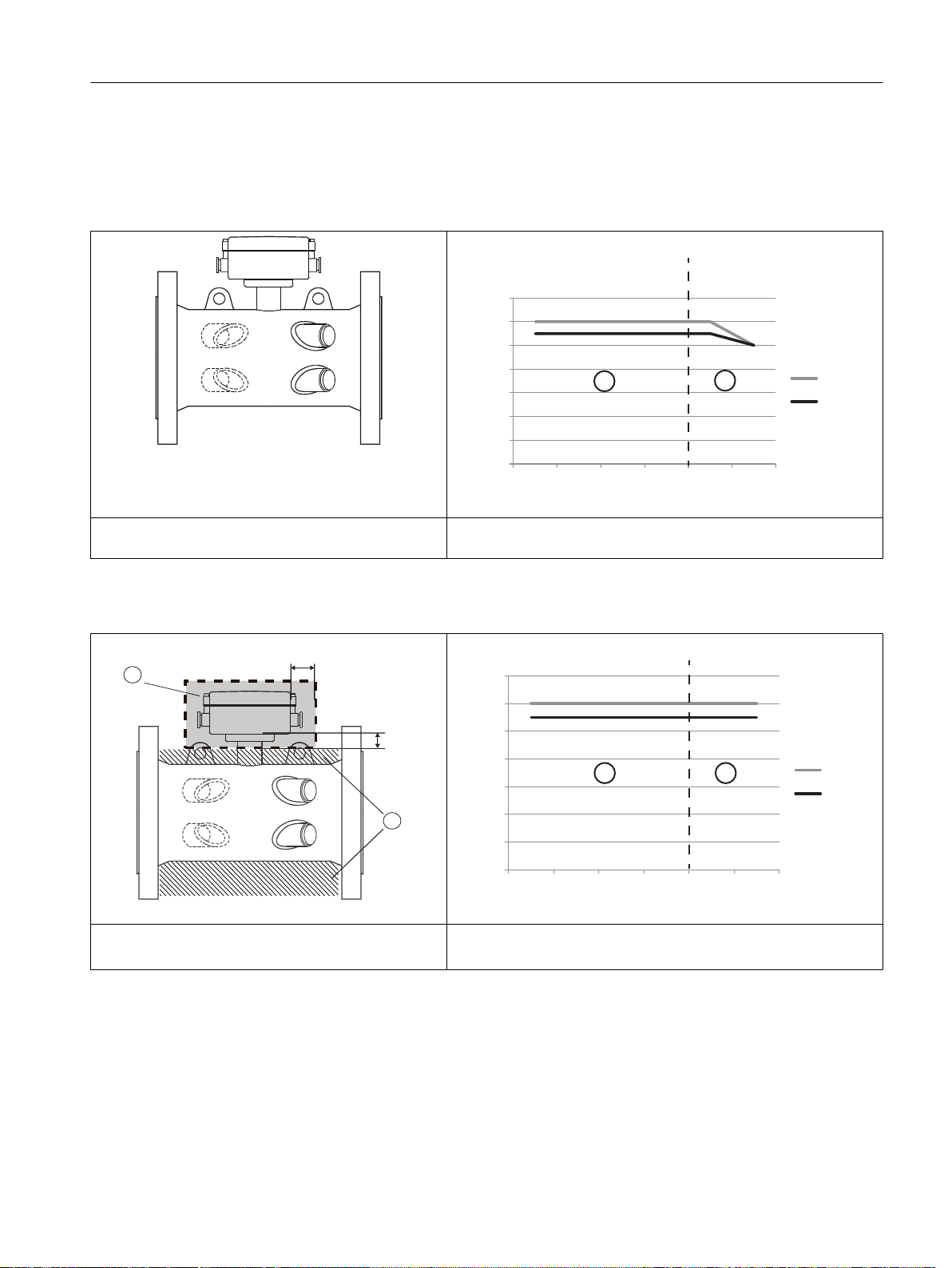

4.2.3 Insulation

Siemens always recommends insulation of the sensor in both the compact and the remote

versions. This recommendation applies to both battery-powered and mains-powered versions.

The insulation will prevent heat transfer to the transmitter (compact versions) or terminal box

(remote versions).

FUS380/FUE380

26 Operating Instructions, 09/2016, A5E00730100-AB

For media temperatures above 120 °C (248 °F) only remote installation is allowed.

0

10

20

30

40

50

60

70

10- 10 50 100 140 200

FUS 380

FUE 380

0HGLDWHPSHUDWXUHr&

$PELHQWWHPSHUDWXUHr&

0LQPP

0LQPP

2

0HGLDWHPSHUDWXUHr&

$PELHQWWHPSHUDWXUHr&

0

10

20

30

40

50

60

70

10- 10 50 100 140 200

FUS 380

FUE 380

Temperatur specifications for non-insulated sensors

① Compact and remote versions

Installing/Mounting

4.3 Transmitter installation (compact/remote versions)

② Remote versions only

Temperatur specifications for insulated sensors

① Keep terminal box free from insulation (gray area)

4.3 Transmitter installation (compact/remote versions)

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 27

① Compact and remote versions

② Insulation

The transmitter is packed separately - ready for plug-in into base part.

② Remote versions only

Safety N

ote

mnnmnmn

nmmnnmmnmnnmnmn

nmmn

nmmnmnnmnmn

mnmnnmnmn

mnn

m

nm

nn

mnn

m

nm

n

mnn

m

nm

nn

m

nmnn

mnnm

n

n

nnmnmn

mnnmnmn

nmmnnmmnmnnmnmn

nmmn

nmmnmnnmnmn

mnmnnmnmn

mnn

m

nm

nn

mnn

m

nm

n

mnn

m

nm

nn

m

nmnn

mnnm

nn

nnmnmn

Safety N

ote

Installing/Mounting

4.3 Transmitter installation (compact/remote versions)

There are two mounting versions of the transmitter (as shown in figures below):

● remote transmitter

● compact transmitter

Note

The matched paired transmitter and sensor shall be mounted together. At installation, please

check that the system nameplates of transmitter and sensor have the same system serial

number.

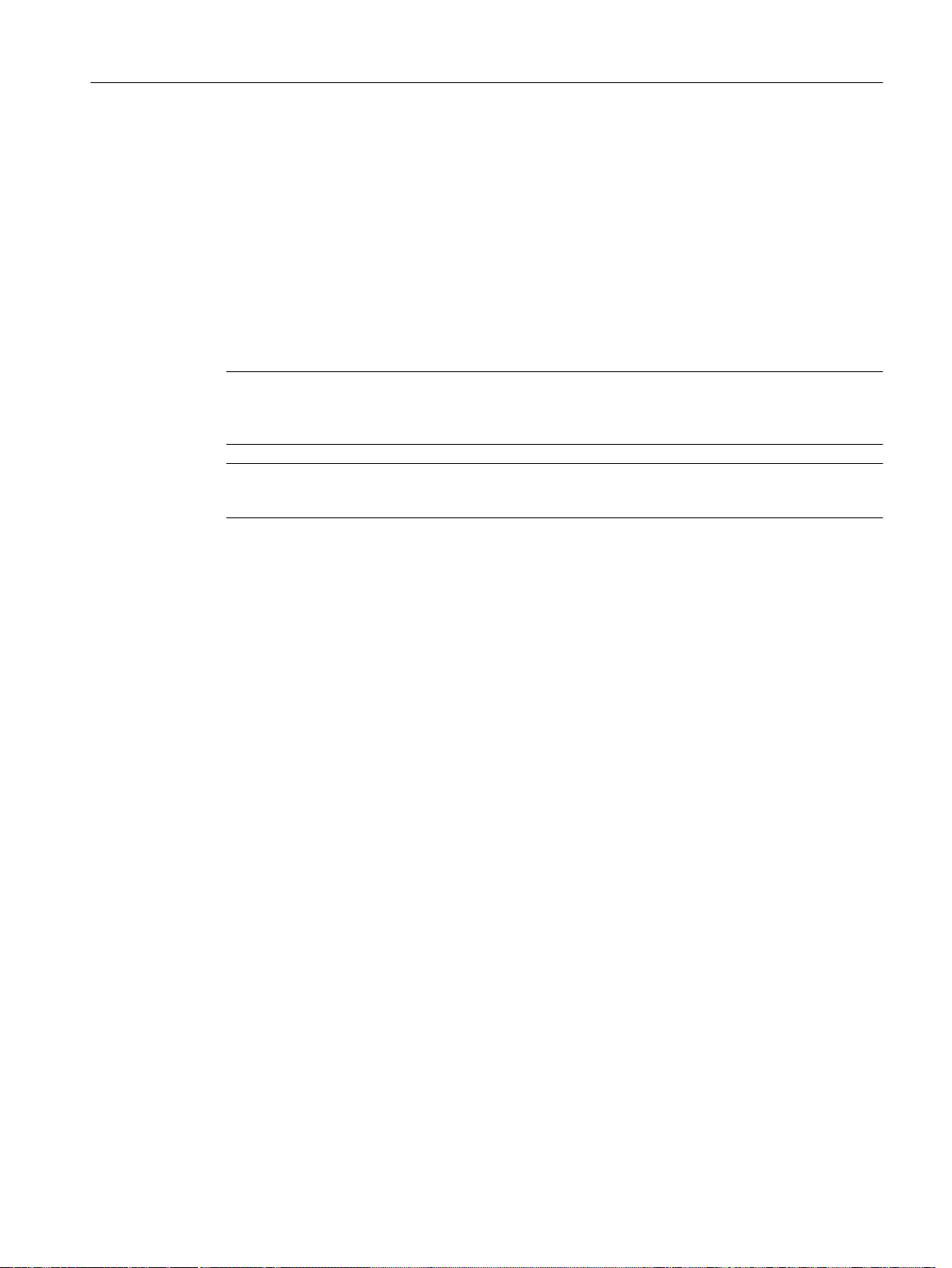

4.3.1 Installation wall mounting kit (remote transmitter)

Mount wall/pipe mounting bracket in an appropriate place.

Note

Take the connection cable length into consideration, and allow adequate space for the cable

inlets.

28 Operating Instructions, 09/2016, A5E00730100-AB

FUS380/FUE380

4.3.2 Battery-powered transmitter

The battery-powered transmitter is prepared for one battery pack of 2 lithium 3.6 V D-cell

batteries and a single backup battery. The battery lifetime depends on the use of the different

functions, for example the use of Modbus IrDA communication or higher pulse output frequency

will decrease the lifetime significantly. Under normal temperature and working conditions a

battery can have an operation lifetime of up to 6 years. The typical liftetime of a dual battery

pack with nominal working pulse output frequency of 20 Hz is approximately 4.2 years.

Siemens recommends replacing batteries after maximum 6 years. For the replacement, see

Battery replacement (Page 63) and Start-up routine (Page 47). Every time a battery plug is

reconnected, the unit runs a start-up routine, see Start-up routine (Page 47).

Note

The male battery plug is not connected upon delivery. This connection must be made to enable

the back-up battery power supply.

Note

Changing the battery does not influence the settings and accumulated values.

Installing/Mounting

4.3 Transmitter installation (compact/remote versions)

FUS380/FUE380

Operating Instructions, 09/2016, A5E00730100-AB 29

Installing/Mounting

4.3 Transmitter installation (compact/remote versions)

FUS380/FUE380

30 Operating Instructions, 09/2016, A5E00730100-AB

Loading...

Loading...