Siemens SITRANS F FST030 Operating Instructions Manual

SITRANS F

Ultrasonic Flowmeters

FST030 (HART)

Operating Instructions

Edition

Answers for industry.

08/2017

SITRANS F

Ultrasonic flowmeters

SITRANS F Ultrasonic flowmeters

FST030 (HART)

Operating Instructions

These Operating Instructions apply to Siemens

SITRANS FST030 transmitters for use in flow meter

systems with order codes commencing 7ME372

08/2017

A5E35971532

Introduction

1

Safety notes

2

Description

3

Installing/Mounting

4

Connecting

5

Commissioning

6

Operating

7

Service and maintenance

8

Diagnosing and

troubleshooting

9

Technical data

10

Dimension drawings

11

Certificates and support

A

SIMATIC PDM

B

-AC

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E35971532

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

may

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

08/2017 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Safety notes .......................................................................................................................................... 13

3 Description ............................................................................................................................................ 21

4 Installing/Mounting ................................................................................................................................ 31

1.1 Product compatibility ................................................................................................................. 7

1.2 Document history ...................................................................................................................... 8

1.3 Device documentation package ................................................................................................ 8

1.4 Items supplied ........................................................................................................................... 9

1.5 Checking the consignment ....................................................................................................... 9

1.6 Security information ................................................................................................................ 10

1.7 Transportation and storage ..................................................................................................... 11

1.8 Notes on warranty ................................................................................................................... 11

2.1 Preconditions for safe use ...................................................................................................... 13

2.1.1 Improper device modifications ................................................................................................ 13

2.2 Laws and directives ................................................................................................................ 13

2.2.1 FCC Conformity ...................................................................................................................... 14

2.2.2 Conformity with European directives ...................................................................................... 14

2.3 Requirements for special applications .................................................................................... 15

2.4 Use in hazardous areas .......................................................................................................... 15

2.4.1 Use in hazardous areas .......................................................................................................... 16

2.4.2 Loss of safety of device with type of protection "Intrinsic safety Ex i" .................................... 16

2.4.3 Dust layers above 5 mm ......................................................................................................... 17

2.5 Installation in hazardous areas ............................................................................................... 18

3.1 Design ..................................................................................................................................... 21

3.1.1 Transmitter .............................................................................................................................. 21

3.2 Features .................................................................................................................................. 21

3.3 Applications ............................................................................................................................. 24

3.4 Approvals ................................................................................................................................ 24

3.5 HART communication ............................................................................................................. 25

3.5.1 Universal commands .............................................................................................................. 28

3.5.2 Common practice commands ................................................................................................. 29

4.1 Installation location requirements ........................................................................................... 31

4.2 Installation instructions............................................................................................................ 32

4.2.1 Wall mount enclosure transmitter ........................................................................................... 32

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

3

Table of contents

5 Connecting ........................................................................................................................................... 35

6 Commissioning ..................................................................................................................................... 51

7 Operating .............................................................................................................................................. 69

5.1 Basic safety notes .................................................................................................................. 35

5.1.1 Missing PE/ground connection .............................................................................................. 35

5.1.2 Unsuitable cables, cable glands and/or plugs ....................................................................... 36

5.1.3 Lack of equipotential bonding ................................................................................................ 36

5.1.4 Unprotected cable ends ......................................................................................................... 36

5.1.5 Improper laying of shielded cables ........................................................................................ 37

5.1.6 Insufficient isolation of intrinsically safe and non-intrinsically safe circuits ............................ 37

5.1.7 Incorrect conduit system ........................................................................................................ 37

5.1.8 Energized devices .................................................................................................................. 38

5.2 Disconnecting device ............................................................................................................. 38

5.3 Device nameplates ................................................................................................................ 38

5.4 Transmitter power supply, communications and I/Os connection ......................................... 40

5.4.1 Sensor connections reference ............................................................................................... 40

5.4.2 Preparing for the connections ................................................................................................ 41

5.4.3 Terminal layout....................................................................................................................... 42

5.4.4 Connecting channel 1 ............................................................................................................ 43

5.4.5 Connecting channels 2 to 4 ................................................................................................... 44

5.4.5.1 Input/output configuration ...................................................................................................... 46

5.4.6 Connecting channels 5 and 6 ................................................................................................ 47

5.4.7 Connecting the power supply ................................................................................................. 48

5.5 Finishing the transmitter connection ...................................................................................... 49

6.1 Basic safety notes .................................................................................................................. 51

6.1.1 Opening device in energized state......................................................................................... 51

6.2 General requirements ............................................................................................................ 52

6.3 Power-up ................................................................................................................................ 52

6.4 Local display .......................................................................................................................... 52

6.5 Initial startup ........................................................................................................................... 53

6.6 Commissioning via local display ............................................................................................ 54

6.6.1 Wizards .................................................................................................................................. 54

6.6.1.1 Wizard overview ..................................................................................................................... 54

6.6.1.2 Quick commissioning wizard .................................................................................................. 55

6.6.1.3 Sensor settings wizard ........................................................................................................... 56

6.6.1.4 Process values wizard ........................................................................................................... 60

6.6.1.5 Inputs and outputs wizard ...................................................................................................... 62

6.6.2 Navigating the menu structure ............................................................................................... 67

6.6.2.1 Navigation view ...................................................................................................................... 67

7.1 Operating via the local display ............................................................................................... 69

7.1.1 Display views ......................................................................................................................... 69

7.1.2 Access control ........................................................................................................................ 69

7.2 Operating the FST030 ........................................................................................................... 70

7.2.1 Fixed display texts ................................................................................................................. 70

7.2.2 Reading the process values ................................................................................................... 72

SITRANS F Ultrasonic flowmeters FST030 (HART)

4 Operating Instructions, 08/2017, A5E35971532-AC

Table of contents

8 Service and maintenance ...................................................................................................................... 81

9 Diagnosing and troubleshooting ............................................................................................................ 85

10 Technical data .................................................................................................................................... 113

11 Dimension drawings ............................................................................................................................ 121

A Certificates and support ...................................................................................................................... 123

7.2.3 Operating the totalizers ........................................................................................................... 74

7.2.4 Handling alarms ...................................................................................................................... 75

7.2.5 Reading the diagnostic values ................................................................................................ 76

7.3 Reading / changing parameters .............................................................................................. 76

7.3.1 Alphanumeric parameters ....................................................................................................... 76

7.3.1.1 Changing the resolution .......................................................................................................... 78

7.3.2 Parameter lists ........................................................................................................................ 78

8.1 Basic safety notes ................................................................................................................... 81

8.1.1 Impermissible repair of explosion protected devices .............................................................. 81

8.2 Recalibration ........................................................................................................................... 81

8.3 Cleaning .................................................................................................................................. 82

8.4 Electrostatic charge ................................................................................................................ 82

8.5 Maintenance and repair work ................................................................................................. 82

8.5.1 Service and maintenance information .................................................................................... 82

8.6 Return procedure .................................................................................................................... 83

8.7 Disposal .................................................................................................................................. 84

9.1 Unexpected behavior .............................................................................................................. 85

9.2 Application questionnaire ........................................................................................................ 87

9.3 Device status icons ................................................................................................................. 88

9.4 Fault codes and corrective actions ......................................................................................... 90

10.1 Power .................................................................................................................................... 113

10.2 HART interface ..................................................................................................................... 113

10.3 Inputs .................................................................................................................................... 114

10.4 Outputs ................................................................................................................................. 115

10.5 Construction .......................................................................................................................... 117

10.6 Operating conditions ............................................................................................................. 118

10.7 Approvals .............................................................................................................................. 119

10.8 SensorFlash .......................................................................................................................... 120

11.1 Transmitter ............................................................................................................................ 121

A.1 Certificates ............................................................................................................................ 123

A.2 Technical support .................................................................................................................. 123

A.3 QR code label ....................................................................................................................... 124

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

5

Table of contents

B SIMATIC PDM ..................................................................................................................................... 125

Index ................................................................................................................................................... 137

B.1 Commissioning with SIMATIC PDM .................................................................................... 125

B.1.1 Operating via SIMATIC PDM ............................................................................................... 125

B.1.2 Functions in SIMATIC PDM ................................................................................................. 125

B.1.3 Supported SIMATIC PDM versions ..................................................................................... 125

B.1.4 Initial setup ........................................................................................................................... 126

B.1.5 Integrating the EDD ............................................................................................................. 126

B.1.6 Integrating a HART device in a HART modem network ...................................................... 127

B.1.7 Configuring a new device ..................................................................................................... 130

B.1.8 Wizard - Quick Start via PDM .............................................................................................. 130

B.1.9 Wizard - Clamp-On Configuration ........................................................................................ 131

B.1.10 Wizard - Zero point adjustment ............................................................................................ 132

B.1.11 Changing parameter settings using SIMATIC PDM ............................................................ 132

B.1.12 Parameters accessed via drop-down menus ....................................................................... 133

B.1.13 Process variables ................................................................................................................. 135

B.2 Diagnosing with PDM ........................................................................................................... 136

SITRANS F Ultrasonic flowmeters FST030 (HART)

6 Operating Instructions, 08/2017, A5E35971532-AC

1

Note

This manual applies to the SITRANS FST030 transmitter HART version only. HART

registered trademark of the HART Communication Foundation.

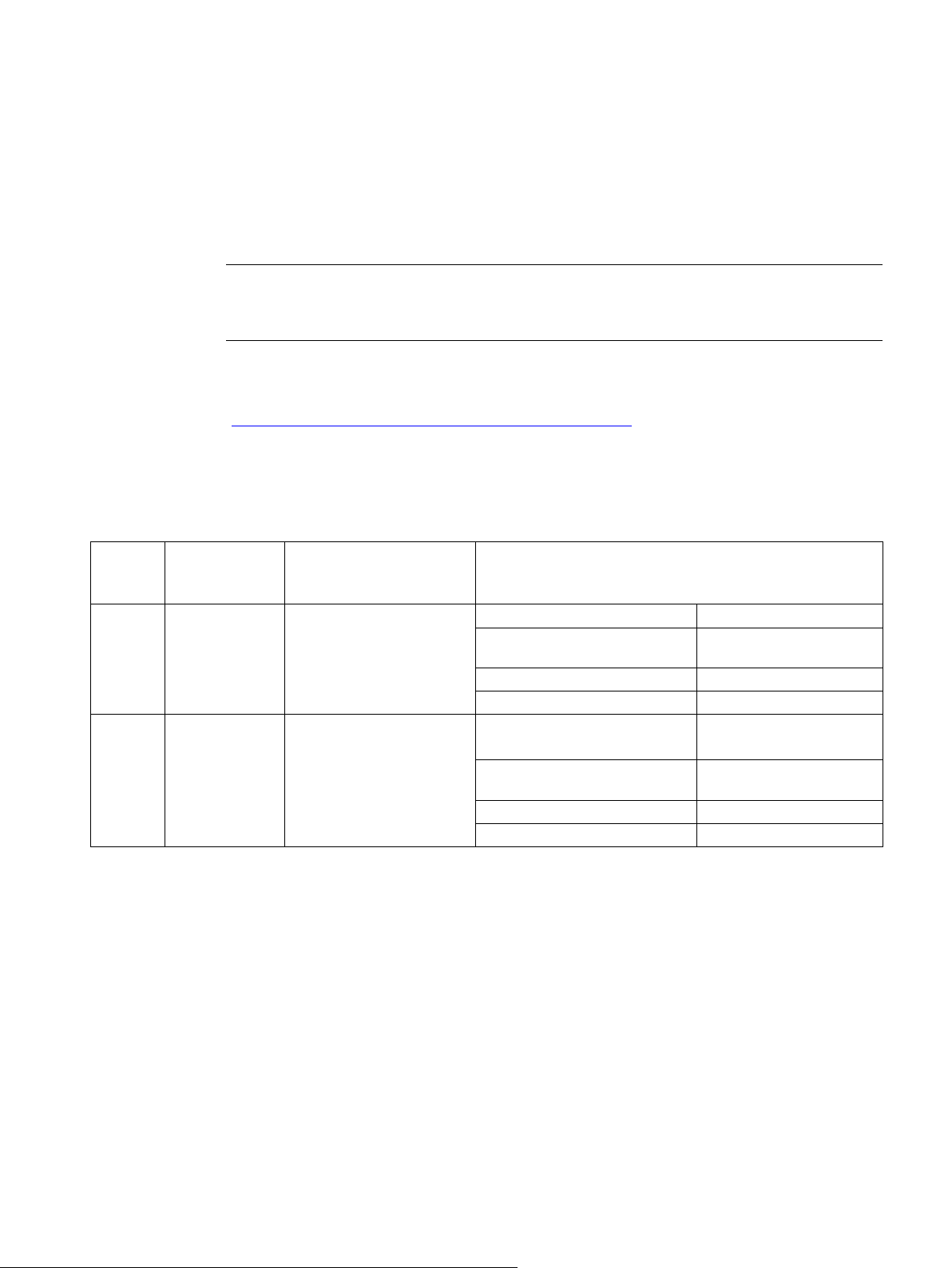

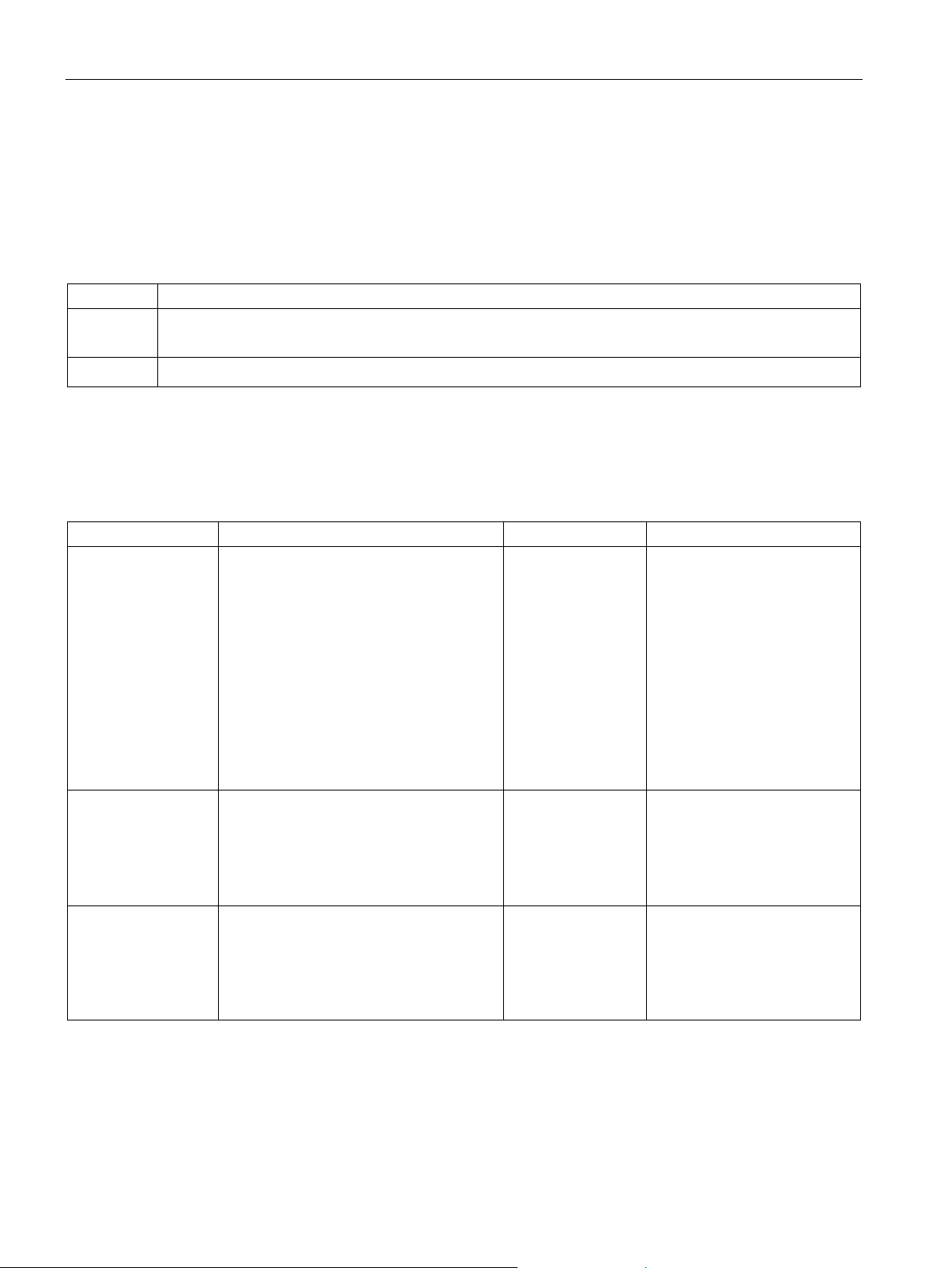

1.1

Product compatibility

Document

edition

Remarks

Device revision

Compatible version of device integration package

SIMATIC PDM V8.2 or later

EDD: 1.00.00 or later

later

Field communicator V3.8

EDD: 1.00.00 or later

later

SITRANS DTM V4.1

EDD: 1.00.00 or later

Field communicator V3.8

EDD: 1.00.00 or later

®

is a

In order to operate an ultrasonic flow meter, you need both the transmitter Operating

Instructions and the sensor Installation Manual, see Flow documentation

(https://support.industry.siemens.com/cs/ww/en/ps/17317

).

08/2017 New document

edition

02/2017 First edition HART

HART

FW: 1.00.00

HW: 02

Device revision 1 or later

FW:1.00.00

HW: 02

Device revision 1 or later

AMS Device Manager 12.0 or

SITRANS DTM V4.1 EDD: 1.00.00 or later

SIMATIC PDM V8.2 or later

AMS Device Manager 12.0 or

EDD: 1.00.00 or later

EDD: 1.00.00 or later

EDD: 1.00.00 or later

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

7

Introduction

1.2

Document history

Edition

Note

Chapter: Safety notes. Use in hazardous areas. Special conditions for safe use. Added: Must be installed

1.3

Device documentation package

Document

Purpose

Intended users

Availability

1.2 Document history

The following table shows major changes in the documentation compared to the previous

edition.

The most important changes in the documentation when compared with the respective

previous edition are given in the following table.

08/2017

02/2017

•

in accordance with Siemens control drawing A5E32778336A.

• First edition

The user documentation package for this product includes the following documents

Operating Instructions

Compact Operating

Instructions - Ex

Functions Manual Contains

Contains all information needed to

• check and identify the delivered pack-

age

• install and electrically connect the

product

• commission the product, (setting pa-

rameters via HMI menu)

• operate and maintain the device on a

daily basis

• troubleshoot and remedy minor opera-

tion interruptions

Contains all information needed to

• satisfy the Special conditions for instal-

lation of Ex-certified products

• descriptions of all functions that can be

accessed via the local display (HMI)

• guide to setting parameters to obtain

optimum operation of the device

Instrument technicians, plant operators

Instrument technicians, plant operators with special

training in systems

for hazardous areas.

Instrument technicians, plant operators

• Available for download from

homepage

• Hardcopy can be purchased

via PIA Life Cycle Portal

(only English and German

versions)

• On documentation disk

• Available for download from

homepage

• Hardcopy can be ordered

via PIA Life Cycle Portal

• Available for download from

homepage

SITRANS F Ultrasonic flowmeters FST030 (HART)

8 Operating Instructions, 08/2017, A5E35971532-AC

Introduction

1.4

Items supplied

Wall mount enclosure

With internal DSL (Digital Sensor Link)

•

•

Note

Supplementary information

Supplementary product and production specific certificates are included on the SensorFlash®

SD card in the transmitter socket.

Note

Scope of delivery may vary, depending on version and add

delivery and the information on the nameplate correspond to your order and the delivery

note.

Note

The SD

sold or imported in the United States. Products having enabled SD

functionality are intended to be used solely outside the United States and should not be

imported into the United States by the user. SIEMENS expressly

using, importing, or buying products with the SD

United States or performing any acts to enable the SD

products sold by SIEMENS with this feature disabled.

1.5

Checking the consignment

1.4 Items supplied

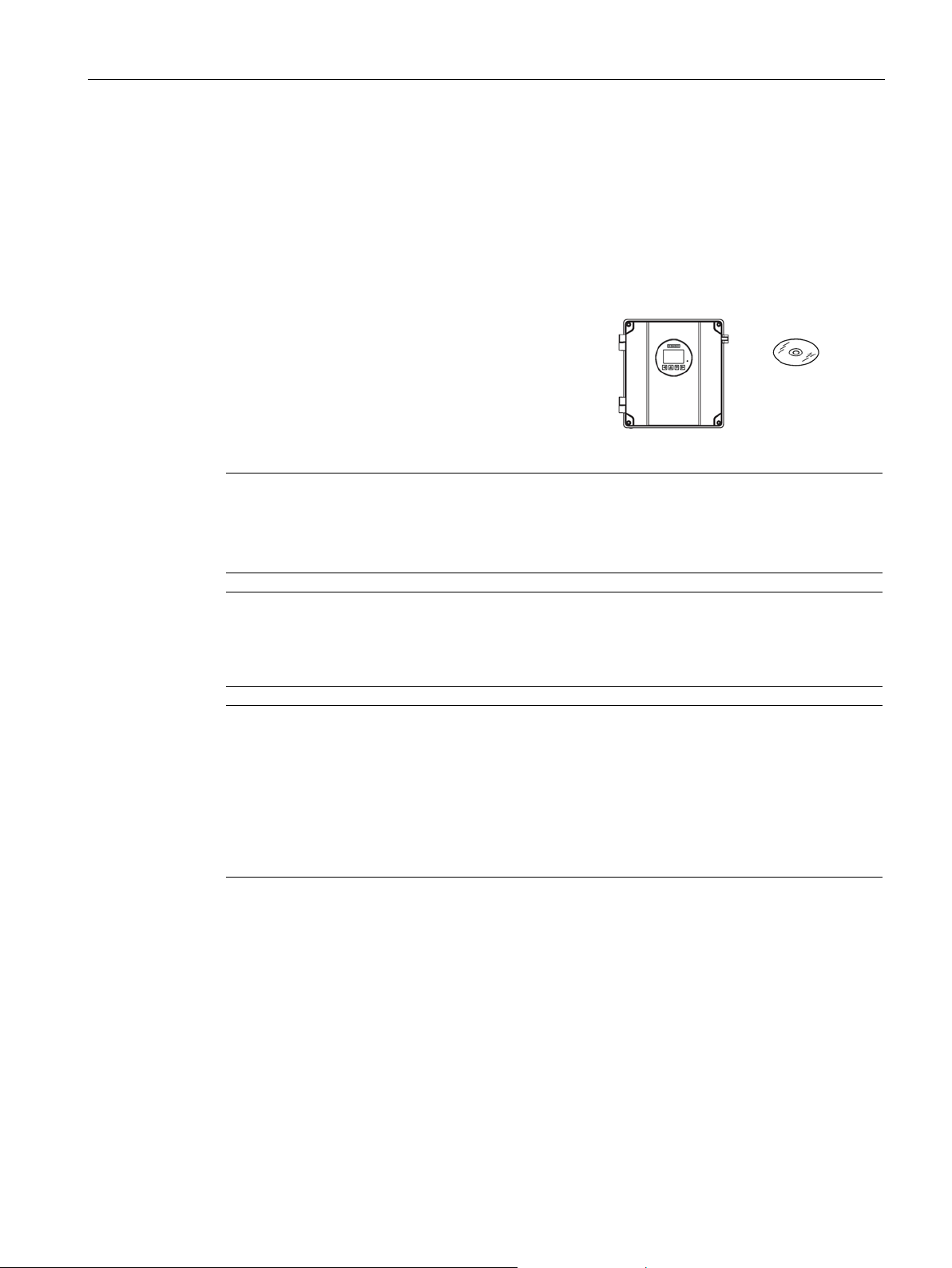

The device is delivered as:

SITRANS FST030 wall mount enclosure

transmitter with internal DSL

Siemens Process Instrumentation

documentation disk containing certificates,

and manuals for ATEX approved devices

-ons. Make sure the scope of

-Card Mass Storage functionality has been disabled by SIEMENS on all products

-Card Mass storage

prohibits customers from

-Card Mass Storage functionality in the

-Card Mass Storage functionality on

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

9

Introduction

WARNING

Using a damaged or incomplete device

1.6

Security information

1.6 Security information

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Risk of explosion in hazardous areas. May cause death or serious injury.

• Do not use damaged or incomplete devices.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

http://www.siemens.com/industrialsecurity.

SITRANS F Ultrasonic flowmeters FST030 (HART)

10 Operating Instructions, 08/2017, A5E35971532-AC

Introduction

1.7

Transportation and storage

NOTICE

Insufficient protection during storage

CAUTION

1.8

Notes on warranty

1.7 Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data

(Page 113).

Protection of transmitter parts

The styrofoam parts in the transmitter are NOT packaging material.

• Do not remove styrofoam parts.

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

11

Introduction

1.8 Notes on warranty

SITRANS F Ultrasonic flowmeters FST030 (HART)

12 Operating Instructions, 08/2017, A5E35971532-AC

2

2.1

Preconditions for safe use

Symbol

Explanation

2.1.1

Improper device modifications

WARNING

Improper device modifications

2.2

Laws and directives

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Risk of explosion in hazardous areas. May cause death or serious injury.

Risk to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

Observe the safety rules, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

13

Safety notes

2.2.1

FCC Conformity

US Installations only: Federal Communications Commission (FCC) rules

Note

•

•

2.2.2

Conformity with European directives

Electromagnetic

compatibility EMC

2014/30/EU

Directive of the European Parliament and of the Council on the harm

nisation of

compatibility

Low voltage d

rect

2014/35/EU

Directive of the European Parliament and of the Council on the harm

nisation of the laws of the Member States relating to the making avai

b

voltage limits

Atmosphère expl

sible ATEX

2014/34/EU

Directive of the European Parliament and the Council on the harmonisation of the laws of the Member States relating to equipment and pr

tive systems intended for use in potentially explosive atmospheres

The applicable directives can be fo

vice.

RoHS directive

2011/65/EU

Directive of the European Parliament and the Council on the restriction

of the use of certain hazardous substances in electrical and electronic

equipment.

2.2 Laws and directives

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the operating instructions, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference to radio communications, in which case the user will

be required to correct the interference at his own expense.

The CE marking on the device symbolizes the conformity with the following European

directives:

o-

the laws of the Member States relating to electromagnetic

i-

ive LVD

le on the market of electrical equipment designed for use within certain

o-

und in the EC conformity declaration of the specific de-

SITRANS F Ultrasonic flowmeters FST030 (HART)

14 Operating Instructions, 08/2017, A5E35971532-AC

ola-

otec-

Safety notes

Note

CE declaration

The CE declaration certificate is available on the SensorFlash SD card delivered with the

device.

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department b

encountered in nuclear power plants or when the device is used for research and

development purposes.

2.4

Use in hazardous areas

Qualified personnel for hazardous area applications

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

efore you operate the device under special ambient conditions as can be

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

15

Safety notes

2.4.1

Use in hazardous areas

WARNING

Use in hazardous areas

2.4.2

Loss of safety of device with type of protection "Intrinsic safety Ex i"

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

Special conditions for safe use

2.4 Use in hazardous areas

Risk of explosion. May cause death or serious injury.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

Risk of explosion May cause death or serious injury.

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a risk of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and/or in Technical

data (Page 113).

In general, it is required that:

● The terminal space may be opened when an explosive gas or dust atmosphere may be

present at any time. Access power terminals by lifting the cover only when de-energized.

● Appropriate cable connectors are used.

● Substitution of components may impair Intrinsic Safety.

● Sensor and transmitter are connected to the potential equalization throughout the

hazardous area.

● EN/IEC 60079-14 is considered for installation in hazardous areas.

Must be installed in accordance with Siemens control drawing A5E32778336A

SITRANS F Ultrasonic flowmeters FST030 (HART)

16 Operating Instructions, 08/2017, A5E35971532-AC

Safety notes

WARNING

Laying of cables

WARNING

Field wiring installation

2.4.3

Dust layers above 5 mm

WARNING

Dust layers above 5 mm

2.4 Use in hazardous areas

Further information and instructions including approval-specific special conditions for safe

use in Ex applications can be found in the certificates on the accompanying documentation

disk and at Certificates (Page 123).

Risk of explosion in hazardous areas. May cause death or serious injury.

Cable for use in hazardous areas must satisfy the requirements for having a proof voltage

of at least 500 V AC applied between the conductor/ground, conductor/shield and

shield/ground.

Connect the devices that are operated in hazardous areas as per the stipulations applicable

in the country of operation.

Risk of explosion in hazardous areas. May cause death or serious injury.

Ensure that the national requirements of the country in which the devices are installed are

met.

Risk of explosion in hazardous areas. May cause death or serious injury.

Device may overheat due to dust build up.

• Remove dust layers in excess of 5 mm.

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

17

Safety notes

2.5

Installation in hazardous areas

WARNING

Equipment used in hazardous areas

Hazardous area approvals

Device

Gas

Dust

FST030 transmitter

Zone 2

Zone 22

FSS200 sensor

Zone 0

Zone 20/21

FM approval

Transmitter

Sensor

Note

Control drawing

* See Control drawing A5E32778336A.

2.5 Installation in hazardous areas

Risk of explosion. May cause death or serious injury.

Equipment used in hazardous areas must be Ex-approved for the region of installation and

marked accordingly. It is required that the special conditions for safe use provided in the

manual and in the Ex certificate are followed!

The device is approved for use in hazardous area according to the lists below. Special

conditions for safe installation and operation specified by each approval authority are

included in the relevant certificate.

Table 2- 1 ATEX approval

Class I Division 2 Groups A,B,C,D T*

Class II Division 2 Groups E,F,G

Class III Division 1

Class I Zone 2 and Zone 22

Class I+II+III Division 1 Groups A, B, C, D, E, F, G.

Class I Zone 0, Zone 20/21

SITRANS F Ultrasonic flowmeters FST030 (HART)

18 Operating Instructions, 08/2017, A5E35971532-AC

Safety notes

Installation variations

Note

Requirements for safe installation

•

2.5 Installation in hazardous areas

The sensors can be installed in Zone 0, Div. 1 as Intrinsically Safe.

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

19

Safety notes

2.5 Installation in hazardous areas

SITRANS F Ultrasonic flowmeters FST030 (HART)

20 Operating Instructions, 08/2017, A5E35971532-AC

3

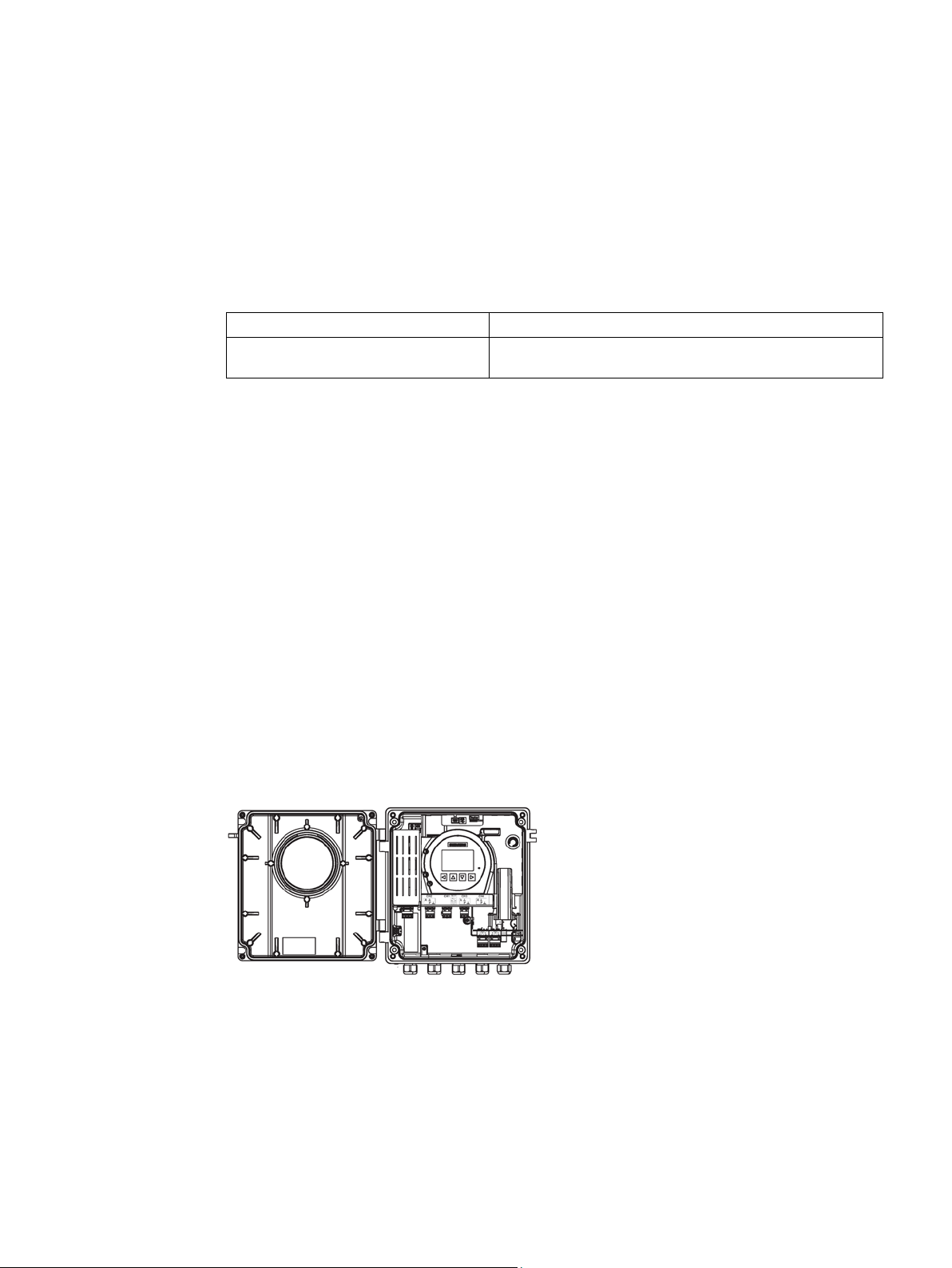

Transmitter

Sensor type

DN 15 to DN 9000 (0.5" to 360")

3.1

Design

3.1.1

Transmitter

Wall mount enclosure with internal DSL

3.2

Features

SITRANS F US ultrasonic flow meter systems consist of a transmitter and a sensor. The

following table lists the available combinations of transmitters and sensors.

FST030 FSS200

The transmitter reads the measured process values from the sensor and calculates derived

values. It provides up to five configurable I/Os, HART communication, USB service channel,

and a local display. It also adds functionalities such as totalizers, access control, diagnostics,

and configuration. The local user interface consists of a display and four buttons for user

interaction.

The transmitter has a modular design with discrete, replaceable electronic modules and

connection boards to maintain separation between functions and facilitate field service. All

modules are fully traceable and their provenance is included in the transmitter setup.

The SITRANS FST030 is available as:

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

● The flowmeter can be used as HART slave in operation on SIEMENS SIMATIC S7/PCS7

or third party automation systems

● Available as wall mount enclosure

21

Description

3.2 Features

● Full graphical local display

● SensorFlash (SD card) for memory backup and documentation storage (certificates etc.)

● USB service interface

● One current output

– Channel 1: Current output with HART

● Up to five input/output channels:

– Channel 2: Signal output; can be parameterized for:

Current output (0/4 to 20 mA)

Pulse output

Frequency output

Alarm, status

– Channels 3 and 4: Signal output

Current output (0/4 to 20 mA)

Pulse output

Frequency output

Alarm, status

Pulse or frequency redundancy mode (only channel 3)

– Channels 3 and 4: Relay output; can be parameterized as:

Alarm, status

– Channels 3 and 4: Signal input; can be parameterized as:

Current input (4 to 20 mA)

Totalizer control (resetting of totalizers)

Zero adjustment

Freezing of process values

Forcing of outputs

– Channels 5 and 6:

Temperature input (RTD)

● Current, frequency, and pulse outputs with configurable fail safe mode

● HART communication interface (HART 7.5)

● High immunity against process noise

● Fast response to step changes in flow

● High update rate (100 Hz) on all process values

SITRANS F Ultrasonic flowmeters FST030 (HART)

22 Operating Instructions, 08/2017, A5E35971532-AC

Description

3.2 Features

● Measurement of:

– Volume flow

– Mass flow

– Flow velocity

– Sound velocity

– LiquIdent (hydrocarbon variant only)

– Liquid identifier (hydrocarbon variant only)

– Medium temperature

– Standard density

– Standard kinematic viscosity

– API gravity (hydrocarbon variant only)

– Standard API gravity (hydrocarbon variant only)

– Specific gravity (hydrocarbon variant only)

– Standard specific gravity (hydrocarbon variant only)

● Measurement with external equipment connected to the transmitter via input channels 3

and 4

– Medium temperature

– Pressure

– Kinematic viscosity

– Density

● Configurable upper and lower alarms and warning limits for nearly all process values

● Independent low flow cut-off settings for volume flow and mass flow

● Zero-point adjustment (initiated by host system)

● Process noise damping using digital signal processing (DSP)

● Three totalizers for summation of flow process values

● Simulation of process values

● Simulation of all outputs

● Simulation of alarms

● Enabling alarms for visibility on all outputs (HMI, status and communication)

● Comprehensive diagnostics (NAMUR or Siemens standard) for troubleshooting and

sensor checking

● Firmware update

● Use in hazardous areas according to specification

● USB mass storage* (not available in the USA)

● Data logging in SensorFlash

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

23

Description

3.3

Applications

3.4

Approvals

Note

For further details see

3.3 Applications

● Peak indicators

● Alarm delay

* The SD-Card Mass storage function is not available for use in the USA. This option is not

available for ordering or shall not be ordered where end user may be located within USA.

● Water industry

● Wastewater industry

● HVAC industry

● Petrochemical industry

● Irrigation systems

● Plants transporting non-conductive liquids

● Power industry

● Processing industry

Approvals (Page 119).

The device is available with approvals for general purpose and for hazardous areas. In all

cases, check the nameplate on your device, and confirm the approval rating.

SITRANS F Ultrasonic flowmeters FST030 (HART)

24 Operating Instructions, 08/2017, A5E35971532-AC

Description

3.5

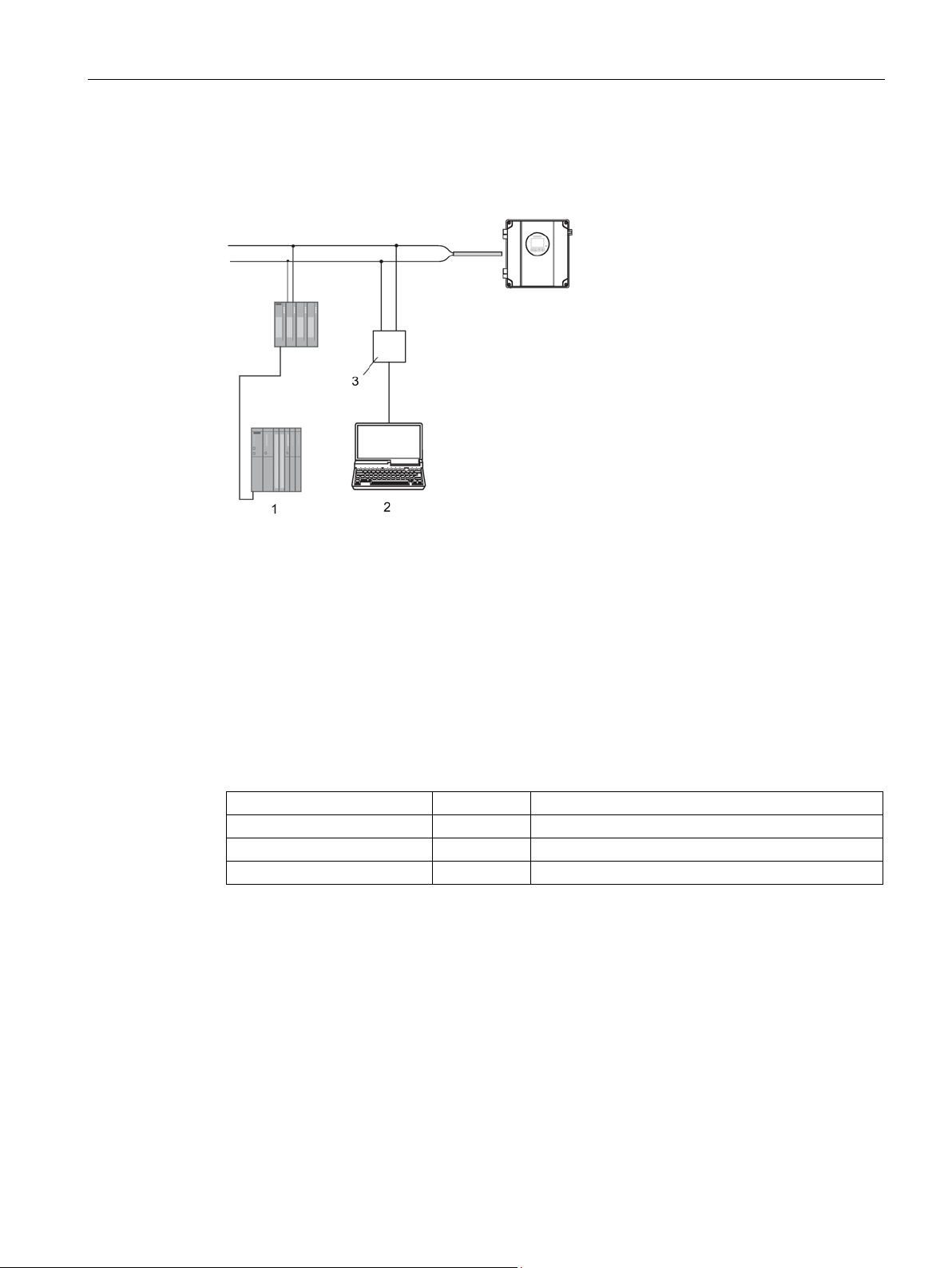

HART communication

①

SIMATIC PLC system with HART interface

②

PC with SIMATIC PDM or similar application

③

HART modem

System communication

Manufacturer ID

42 (2A Hex)

Manufacturer ID parameter

Device type

34 (22 Hex)

Device type parameter

HART protocol revision

7.5

HART protocol revision parameter

Device revision

2

Device revision parameter

Device description files

3.5 HART communication

Communication is via the HART protocol, using:

Figure 3-1 System integration example

The flowmeter can be used in a number of system configurations to enable simple, secure,

and reliable data transmission over long distances.

Table 3- 1 HART protocol identification data

Note: Version numbers and other references shown above are typical or example values.

Available EDD drivers:

● SIMATIC PDM

● FDT/DTM

● AMS suite

● 375 Field Communicator

The drivers can be downloaded here:

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

25

Description

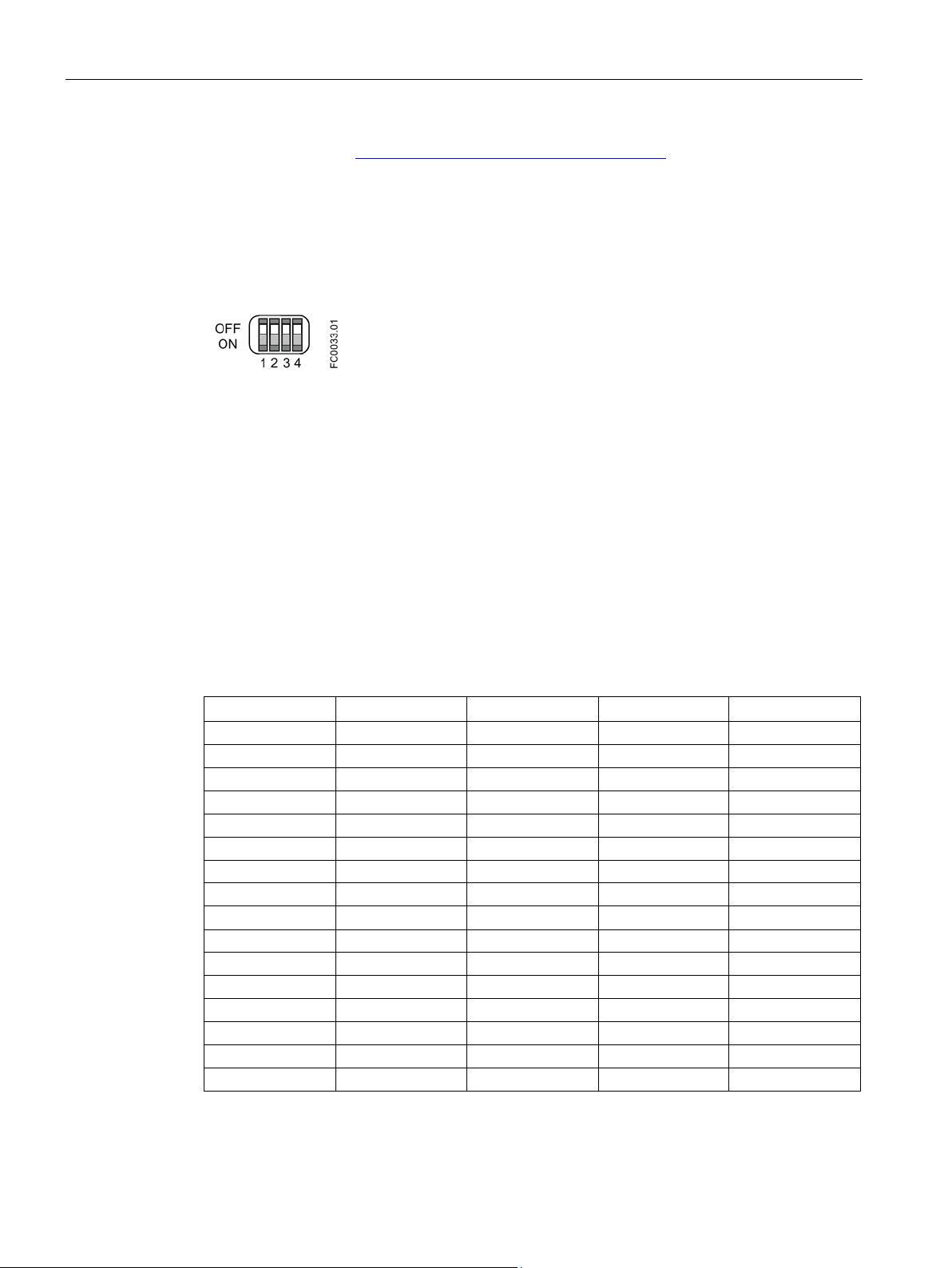

Configuration of the HART polling address

DIP switch configuration

Address

Switch 1

Switch 2

Switch 3

Switch 4

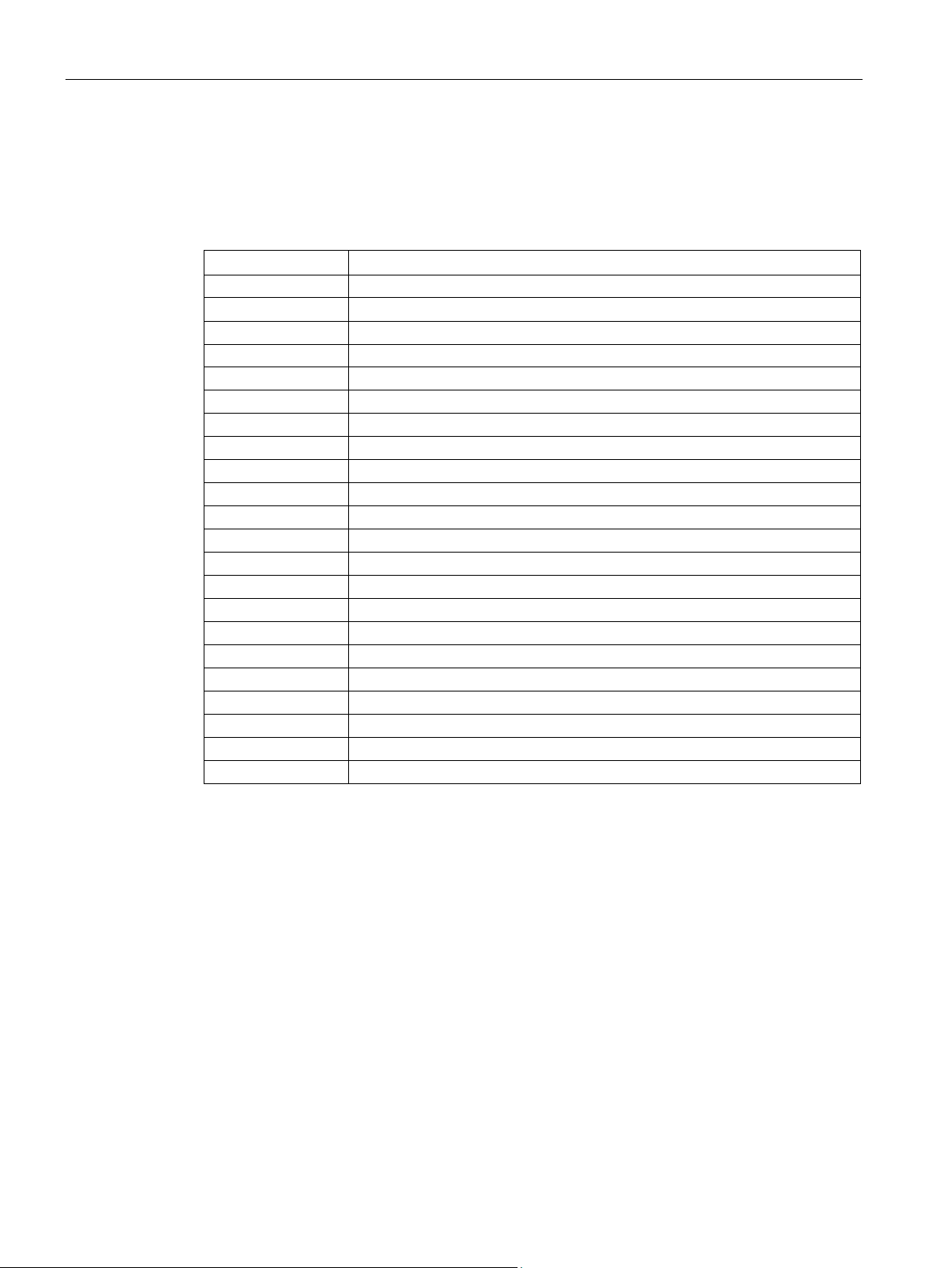

0 0 0 0 0

1 1 0 0 0

2 0 1 0 0 3 1 1 0

0

4 0 0 1 0

5 1 0 1 0

6 0 1 1 0 7 1 1 1

0

9 1 0 0 1

11 1 1 0 1

12 0 0 1 1

13 1 0 1 1

14 0 1 1 1

15 1 1 1 1

0: OFF; 1: ON

3.5 HART communication

Download EDD files (http://www.siemens.com/flowdocumentation)

The HART address can be set either via hardware (DIP switch) or via software (local display

or SIMATIC PDM).

The DIP switch is located on the transmitter cassette.

Figure 3-2 HART slave address switch

● Configuration via DIP switch (HW polling address)

Set 1 to 15 on the DIP switch if you wish to set a fixed (hardware-defined) HART polling

address (SW polling address will be ignored). The configured HW polling address can be

read via HMI in menu item 4.2.

● Configuration via the local display or SIMATIC PDM (SW polling address)

Disable the HW polling address by setting all switches to "OFF" on the HART DIP switch.

The device starts up with default slave address = 0. The SW polling address can be

changed to a value between 0 and 63 via HMI (menu item 4.1) or SIMATIC PDM

Table 3- 2 HW polling address

8 0 0 0 1

10 0 1 0 1

SITRANS F Ultrasonic flowmeters FST030 (HART)

26 Operating Instructions, 08/2017, A5E35971532-AC

Description

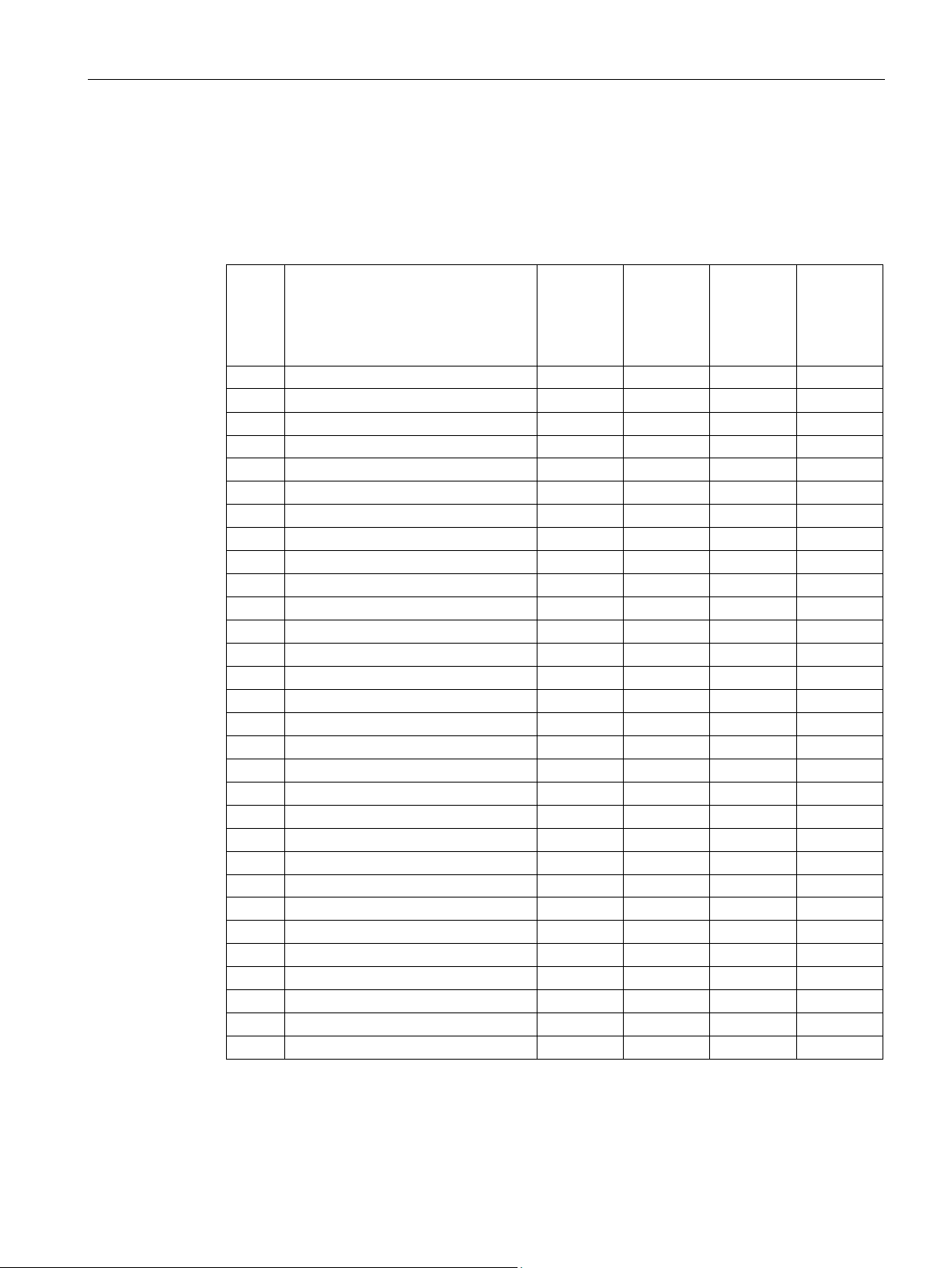

Mapping of measured process variables

The following table shows the possible and default mappings.

Device

Variable

Number

Device Variable Name

SV TV QV

0

Volume flow

D X X

X

2

Sound Velocity

X X D

X

4

Process Density

X X X

X

5

Process Temperature

X X X X 6

Process Pressure

X X X

X

7

Process Viscosity

X X X

X

8

Temperature 1

X X X X 9

Temperature 2

X X X

X

10

Concentration

X X X

X

11

Current in (Channel 5)

X X X

X

12

Current in (Channel 6)

X X X X 13

Standard Volume Flow

X X X

X

14

Standardizing Factor

X X X

X

15

Standard Viscosity

X X X

X

16

Standard Density

X X X X 17

LiquIdent

X X X

X

18

API Gravity

X X X

X

19

Standard API Gravity

X X X

X

21

Standard Specific Gravity

X X X

X

22

Rate of Change

X X X

X

23

Energy Flow

X X X

X

24

Delta Temperature

X X X X 25

Energy Efficiency Rating

X X X

X

27

Totalized Value 1

X X X 28

Totalized Value 2

X X

X

29

Totalized Value 3

X X

X

3.5 HART communication

The device supports all four dynamic variables (PV, SV, TV and QV). Except for PV, they

can be freely mapped to all device variables.

PV

1 Mass flow X D X X

3 Flow Velocity X X X D

SITRANS F Ultrasonic flowmeters FST030 (HART)

Operating Instructions, 08/2017, A5E35971532-AC

20 Specific Gravity X X X X

26 Coefficient of Performance X X X X

"D" marking denotes default mapping.

27

Description

3.5.1

Universal commands

Command number

Function

0

Read Unique Identifier

2

Read Loop Current And Percent Of Range

3

Read Dynamic Variables And Loop Current

6

Write Polling Address

7

Read Loop Configuration

8

Read Dynamic Variable Classifications

9

Read Device Variables With Status

11

Read Unique Identifier Associated With Tag

12

Read Message

13

Read Tag, Descriptor, Date

14

Read Primary Variable Transducer Information

15

Read Device Information

16

Read Final Assembly Number

17

Write Message

18

Write Tag, Descriptor, Date

19

Write Final Assembly Number

20

Read Long Tag

21

Read Unique Identifier Associated With Long Tag

22

Write Long Tag

48

Read Additional Device Status

3.5 HART communication

The device supports the following universal commands:

Table 3- 3 Universal commands

1 Read Primary Variable

38 Reset Configuration Changed Flag

SITRANS F Ultrasonic flowmeters FST030 (HART)

28 Operating Instructions, 08/2017, A5E35971532-AC

Loading...

Loading...