Page 1

Coriolis flowmeters

SITRANS F C MASS 2100 Di 3-40

Operating Instructions • 07/2010

SITRANS F

SITRANS F

Page 2

Page 3

SITRANS F

Coriolis Flowmeters

SITRANS F C MASS 2100 Di 3-40

Operating Instructions

Introduction

Safety notes

Description

Installing/Mounting

Connecting

Commissioning

Service and maintenance

Technical data

Appendix

1

2

3

4

5

6

7

8

A

Coriolis flow sensor type MASS 2100 Di 3, 6, 15, 25

or 40 designed for use with transmitter types

SITRANS F C MASS 6000 or SIFLOW FC070

07/2010

A5E02896535-01

Page 4

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation for the specific task, in particular its warning notices and

safety instructions. Qualified personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG order number: A5E02896535 Copyright © Siemens AG 2010.

Industry Sector Ⓟ 08/2010 Technical data subject to change

Postfach 48 48

90026 NÜRNBERG

GERMANY

Page 5

Table of contents

1 Introduction................................................................................................................................................ 5

1.1 Items supplied................................................................................................................................5

1.2 History............................................................................................................................................6

1.3 Further Information ........................................................................................................................6

2 Safety notes............................................................................................................................................... 9

2.1 Laws and directives .......................................................................................................................9

2.2 Installation in hazardous area......................................................................................................10

3 Description............................................................................................................................................... 13

3.1 Design..........................................................................................................................................13

3.2 Theory of operation......................................................................................................................15

4 Installing/Mounting................................................................................................................................... 17

4.1 Installation safety precautions......................................................................................................17

4.2 Determining a location .................................................................................................................18

4.3 Orienting the sensor.....................................................................................................................19

4.4 Mounting the sensor ....................................................................................................................21

4.5 Mounting a pressure guard..........................................................................................................22

5 Connecting .............................................................................................................................................. 23

5.1 Safety precautions .......................................................................................................................23

5.2 Wiring...........................................................................................................................................24

5.3 Turning the terminal box ..............................................................................................................25

6 Commissioning ........................................................................................................................................ 27

6.1 Zero point adjustment ..................................................................................................................27

7 Service and maintenance ........................................................................................................................ 29

7.1 Maintenance.................................................................................................................................29

7.2 Transportation/storage.................................................................................................................29

7.3 Recalibration ................................................................................................................................29

Unit repair.....................................................................................................................................30

7.4

7.5 Technical support.........................................................................................................................30

7.6 Return procedures .......................................................................................................................31

8 Technical data ......................................................................................................................................... 33

8.1 Technical specifications ...............................................................................................................33

8.2 Measurement range.....................................................................................................................34

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

3

Page 6

Table of contents

8.3 Accuracy specifications............................................................................................................... 35

8.4 Pressure drop.............................................................................................................................. 36

8.5 Pressure / temperature range ..................................................................................................... 38

8.6 Electrical connection schematics................................................................................................ 41

8.7 Dimensions and weight............................................................................................................... 42

A Appendix.................................................................................................................................................. 47

A.1 Ordering ...................................................................................................................................... 47

Glossary .................................................................................................................................................. 49

Index........................................................................................................................................................ 53

SITRANS F C MASS 2100 Di 3-40

4 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 7

Introduction

These instructions contain all the information you need for using the device.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it as well as service and

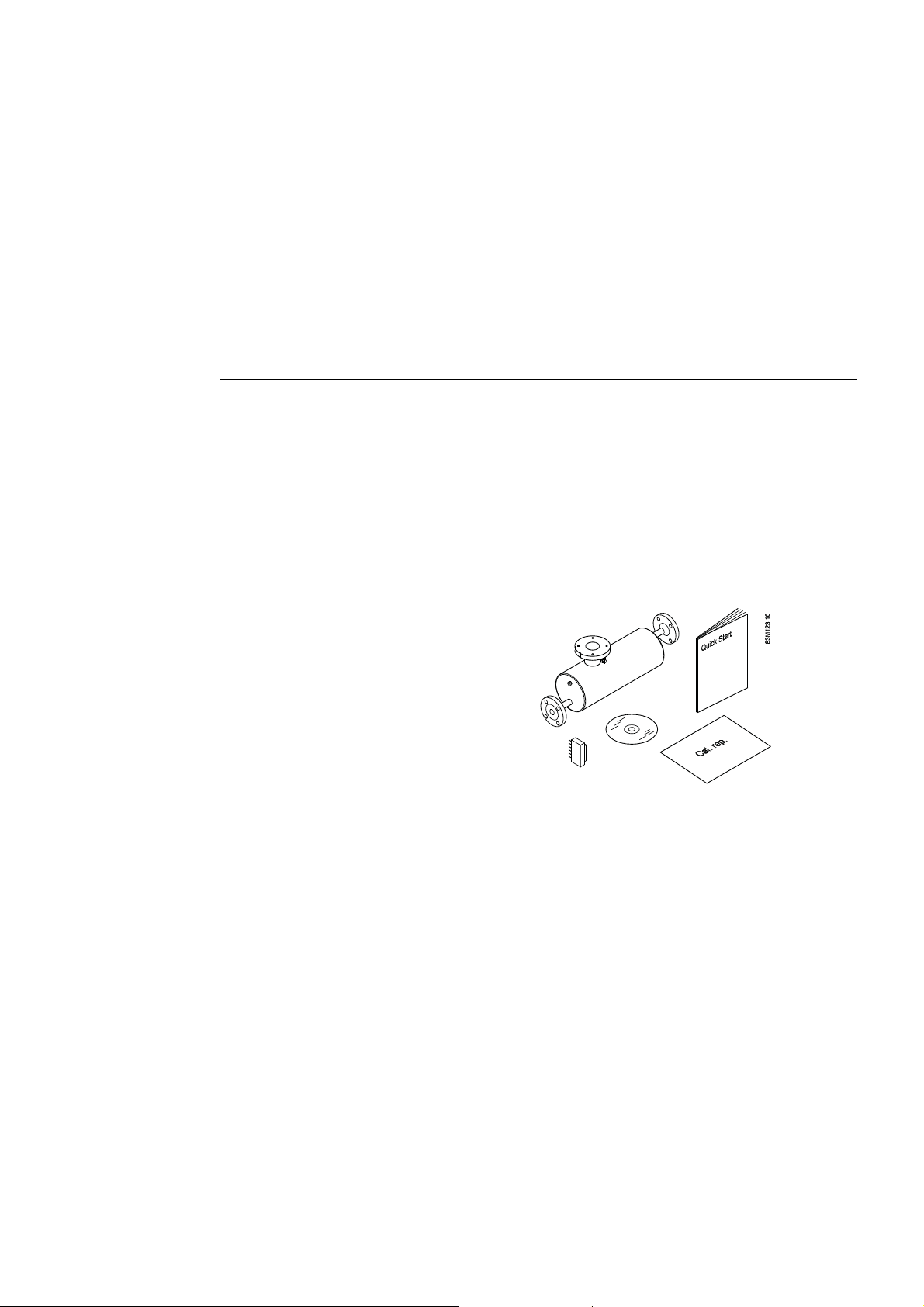

1.1 Items supplied

maintenance engineers.

Note

It is the responsibility of the customer that the instructions and directions provi

manual are read, understood and followed by the relevant personnel before installing the

device.

• MASS 2100 sensor

• Sensorprom

• Calibration report

• Quick Start

• SITRANS F technical literature CD-ROM

1

ded in the

Inspection

1. Check for visual mechanical damage due to possible improper handling during shipment.

All claims for damage are to be made promptly to the carrier.

2. Make sure the scope of delivery, and the information on the type plate corresponds to

your order and the delivery note.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

5

Page 8

Introduction

1.2 History

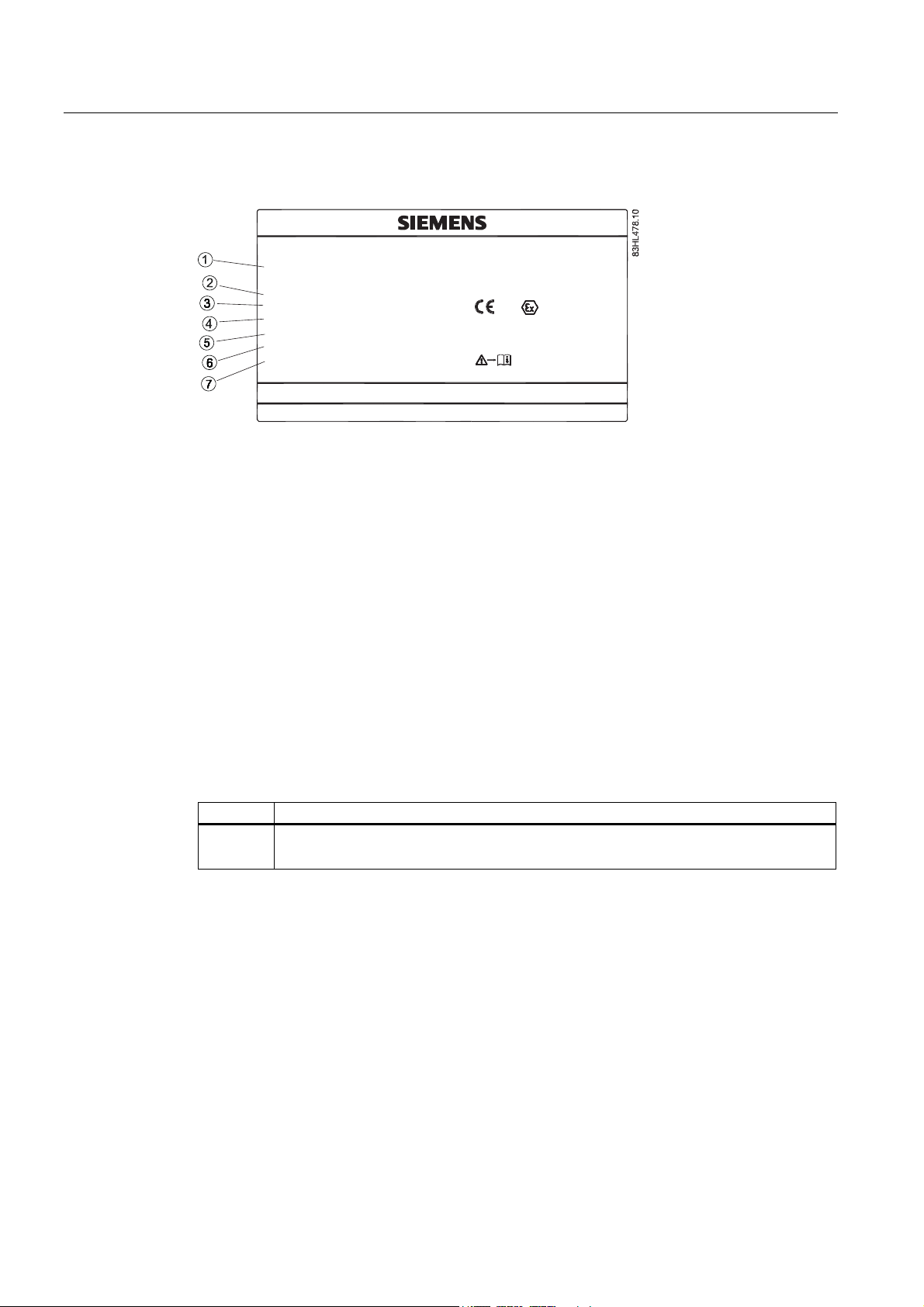

Identification

① Code number Device specific code number

② Serial number Device specific serial number

③ DN / PN Process connector nominal size / sensor pressure rating

④ PT / Year Test pressure and time stamp

⑤ Connection Process connector

⑥ Material Material of the pipe

⑦ Cal. factor Device specific calibration factor

Figure 1-1 MASS 2100 Type plate

1.2 History

&RGH1R

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

6HULDO1R

'131

37<HDU

&RQQHFWLRQ

0DWHULDO

&DO)DFWRU

7PHGLDrWRr&,3,3

;;;;;;;;;;;;;;;;

0(;;;;;;;;;1::<

;;;;;;;;;;;;

;;EDU;;

;;;;;;;;;;

;;;;;O

;;;;;;;;;;;

6LHPHQV$6)ORZ,QWUXPHQWV

0DGHLQ'HQPDUN1RUGERUJYHM1RUGERUJ

(1FDWHJRU\,,

,,*

'(0.2$7(;;

([LD,,&77

6HQVRUW,QWULQVLFVDIHW\VSHFLILFDWLRQ

6,75$16)&0$66

6((0$18$/55

7(&+1,&$/'$7$,17(5)$&('$7$

The contents of these instructions are regularly reviewed and corrections are included in

subsequent editions. We welcome all suggestions for improvement.

The following table shows the most important changes in the documentation compared to

each previous edition.

Edition Remarks

07/2010 First edition of Operating Instructions for SITRANS F C MASS 2100 DN 3-40.

The document replaces all previous Instructions for use.

1.3 Further Information

The contents of these Operating Instructions shall not become part of or modify any prior or

existing agreement, commitment or legal relationship. All obligations on the part of Siemens

AG are contained in the respective sales contract which also contains the complete and

solely applicable warranty conditions. Any statements contained herein do not create new

warranties or modify the existing warranty.

SITRANS F C MASS 2100 Di 3-40

6 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 9

Introduction

1.3 Further Information

Product information on the Internet

The Operating Instructions are available on the CD-ROM shipped with the device, and on

the Internet on the Siemens homepage, where further information on the range of SITRANS

F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flowdocumentation

Worldwide contact person

If you need more information or have particular problems not covered sufficiently by the

operating instructions, please get in touch with your contact person. You can find contact

information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner

See also

Technical support (Page 30)

)

)

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

7

Page 10

Introduction

1.3 Further Information

SITRANS F C MASS 2100 Di 3-40

8 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 11

Safety notes

2.1 Laws and directives

CAUTION

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance. Only qualified personnel should

install or operate this instrument.

Note

Alterations to the product, including opening or improper repairs

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2

of the product, are not

General requirements

Installation of the equipment must comply with national regulations. For example EN 6007914 for the European Community.

Instrument safety standards

The device has been tested at the factory, based on the safety requirements. In order to

maintain this condition over the expected life of the device the requirements described in

these Operating Instructions must be observed.

CAUTION

Material compatibility

Siemens Flow Instruments can provide assistance with the selection of wetted sensor

parts. However, the full responsibility for the selection rests with the customer and Siemens

Flow Instruments can take no responsibility for any failure due to material incompatibility.

CE marked equipment

The CE-mark symbolizes the compliance of the device with the following guidelines:

● EMC-directive 2004/108/EC

● Low voltage directive 2006/95/EC

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

9

Page 12

Safety notes

2.2 Installation in hazardous area

● Pressure equipment directive (PED/DGRL) 93/23/EC

● ATEX Directive 94/9/EC

2.2 Installation in hazardous area

WARNING

Equipment used in hazardous areas must be Ex-approved and marked accordingly.

It is required that the special conditions for safe use provided in the manual and in the Ex

certificate are followed!

Hazardous area approvals

The device is approved for use in hazardous area and has the following approval:

● II 1G EEx ia IIC T3-T6

WARNING

Make sure the hazardous area approval is suitable for the environment in whi

device is installed.

• SITRANS F C MASS 6000 Ex d is approved for use in hazardous area.

• SITRANS F C MASS 6000 19" Ex (IP65) is approved for Class I Div 2 and Zone 2.

• SIFLOW FC070 Ex is approved for use in Zone 2.

Intrinsically safe data

ch the

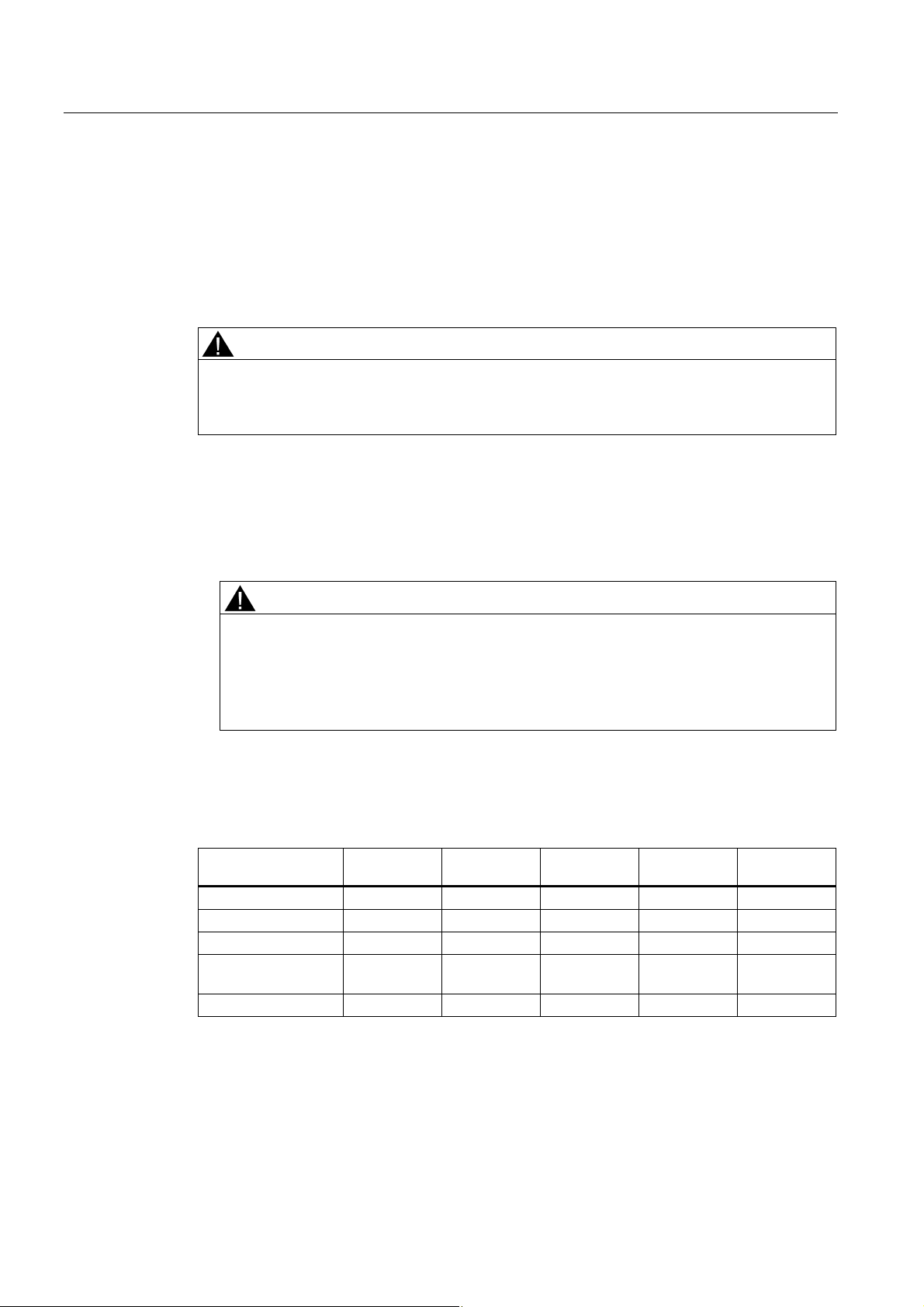

Table 2- 1 Sensor circuit

Sensor circuit

(Terminal 1-2)

Ui 16V 16V 16V 16V 16V

Ii 0.132A 0.132A 0.132A 0.132A 0.132A

Pi 0.75W 0.75W 0.75W 0.75W 0.75W

Li or Li/Ri 0.5mH or

Ci 50pF 50pF 50pF 50pF 50pF

SITRANS F C MASS 2100 Di 3-40

Di3 Di6 Di15 Di25 Di40

80[μH/Ω]

1.5mH or

40[μH/Ω]

30[μH/Ω] 1mH or

10[μH/Ω]

15[μH/Ω]

10 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 13

Safety notes

2.2 Installation in hazardous area

Table 2- 2 Temperature sensor circuit

Temperature sensor (Terminals 3,4 & 9)

Ui 15V

Ii 8mA

Pi 0.03W

Li Insignificant

Ci 50pF

Table 2- 3 Pickup driver circuit

Pickup driver (Terminals 5-6 & 7-8)

Ui 15V

Ii 15mA

Pi 0.056W

Li 0.5mH

Ci 50pF

WARNING

With intrinsically safe circuits, use only certified transmitters appropriate for the sensor.

If a non-conforming supply unit is used, the "fail-safe" type of protection will no longer be

effective and the approval certification will be invalid.

Temperature specifications for Ex use

Temperature class Ambient temperature [°C] Process media temperature [°C]

T3 -20 ... +50 -50 ... +180

T4 -20 ... +50 -50 ... +125

T5 -20 ... +50 -50 ... +90

T6 -20 ... +50 -50 ... +60

For ambient temperatures below -10°C and above +60°C use field wiring suitable for both minimum

and maximum ambient temperature.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

11

Page 14

Safety notes

2.2 Installation in hazardous area

Hazardous area safety requirements

It is required that:

● Electrical connections are in accordance with national directives such as IEC/EN6007914 (Installing Electrical Systems in Explosion Hazardous Areas).

● Sensor and transmitter are connected to the potential equalization.

WARNING

Laying of cables

Cable for use

in zone 1 and 2 or 21 and 22 must satisfy the requirements for having a

proof voltage AC 500 V applied between the conductor/ground, conductor/shield and

shield/ground.

SITRANS F C MASS 2100 Di 3-40

12 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 15

Description

Measurement of liquids and gases

SITRANS F C Coriolis mass flow meters are designed for measurement of a variety of

liquids and gases. The meters are multi parameter devices offering accurate measurement

of mass flow, volume flow, density, fraction, Brix/Plato, and temperature.

Main applications

The main applications of the Coriolis flow meter can be found in all industries, such as:

● Chemical & Pharma: Detergents, bulk chemicals, pharmaceuticals, acids, alkalis

● Food & Beverage: Dairy products, beer, wine, softdrinks, plato/brix, fruit juices and pulps,

bottling, CO

● Automotive: Fuel injection, nozzle & pump testing, filling of AC units, engine consumption,

paint robots

● Oil & Gas: Filling of gas bottles, furnace control, CNG-dispensers, test separators

● Water & Waste Water: Dosing of chemicals for water treatment

dosing, CIP/SIP-liquids

2

3

3.1 Design

Versions

MASS 2100 DI 3-40, remote

versio

The MASS 2100 Di3–40 is designed for use with the whole range of SITRANS F C

transmitters presently including MASS 6000 IP67, MASS 6000 19", MASS 6000 Ex d and

Siflow FC070.

All transmitters are suitable for remote installation and the MASS 6000 IP67 and MASS 6000

Ex d transmitters are also applicable for compact installations (mounted directly on the

sensor). Regardless of transmitter version, the accuracy specification remains valid.

n

MASS 2100 compact mounted

with MASS 6000 IP67

MASS 2100 compact mounted

with MASS 6000 Ex d

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

13

Page 16

Description

3.1 Design

Description

① Transmitter connection

② Threaded hole for e.g. pressure guard

③ Nipple

④ Process connector

⑤ Mounting bracket

⑥ Type plate

⑦ Earth terminal

Figure 3-1 Product description

Design

The MASS 2100 sensor design is based on a single bent tube welded directly to the process

connections at each end. The tube has a large internal diameter which reduces pressure

loss and improves overall flow capacity. All Mass 2100 sensors come with an intrinsically

safe Ex design.

The sensors are available in two material configurations (W1.4435, AISI 316L or W2.4602,

Hastelloy C22). The enclosure is made of stainless steel W1.4301, AISI 316L with an

encapsulation grade of IP67/NEMA 4.

Maximum immunity towards process noise is among many things obtained through the

center block.

The sensors can be equipped with a pressure guard or flushed at the corresponding holes at

the end of the sensor.

SITRANS F C MASS 2100 Di 3-40

14 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 17

Description

3.2 Theory of operation

Heating Jacket

MASS 2100, DI 3 to DI 40 can optionally be ordered with an integral heating coil to avoid

solidification of sensitive fluids as e.g. chocolate or bitumen during down-time or periods

between discontinuing processes. This feature gives the freedom to let e.g. hot water,

superheated steam or hot oil maintain a constant temperature inside the sensor.

Figure 3-2 MASS 2100 heating jacket version cut-off

① integral heating connector

② Process connector

Figure 3-3 MASS 2100 heating jacket version

3.2 Theory of operation

The flow measuring principle is based on Coriolis law of movement.

The Sitrans F C sensors are energized by an electromechanical driver circuit which

oscillates the pipe at its resonant frequency. Two pick-ups, 1 and 2 are placed symmetrically

on both sides of the driver. When the media flows through the sensor, Coriolis force will act

on the measuring tube and cause a tube deflection which can be measured as a phase shift

between pick-up 1 and pick up 2.

The phase shift is proportional to the mass flow rate. The amplitude of the driver is

automatically regulated via a "phase locked loop", to ensure a stable output from the 2

pickups in the region of 80 to 120 mV. The temperature of the sensor is measured by a

Pt1000, in a 4-wire configuration.

The flow proportional signal from the 2 pick-ups, the temperature measurement and the

driver frequency are fed into the transmitter for calculations of mass, density, volume,

fraction, Brix/Plato, and temperature.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

15

Page 18

Description

3.2 Theory of operation

SENSORPROM

All SITRANS F C Coriolis flow meters feature a SENSORPROM® memory unit which stores

sensor specific calibration data and transmitter settings for the lifetime of the product. The

factory settings matching the sensor are stored in the SENSORPROM® unit. At

commissioning the flow meter commences measurement without any initial programming.

Also customer specified settings are downloaded to the SENSORPROM® unit.

Figure 3-4 Sensorprom memory unit

SITRANS F C MASS 2100 Di 3-40

16 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 19

Installing/Mounting

SITRANS F flowmete

● Make sure that pressure and temperature specifications indicated on the device type

plate / label will not be exceeded.

WARNING

Installation in hazardous location

Special requ

transmitter. See "Installation in hazardous area" (Page 10)

rs are

suitabl

irements apply to the location and interconnection of sensor and

4.1 Installation safety precautions

WARNING

In applications with working pressures/media that can be dangerous to people,

surroundings, equipment or others in case of pipe fracture, we recommend that special

precautions such as special placement, shielding or installation of a security guard or a

security valve are taken when the sensor is mounted.

e for in- and outdoor installations.

4

● Ensure that stresses and loading caused by e.g. earthquakes, traffic, high winds and fire

damage if appropriate are taken into account during installation.

● Ensure that the flowmeter is installed such that it does not act as a focus for pipeline

stresses. External loadings are not taken into account in the flowmeter design.

● Provide adequate protection to minimise any risk of contact with hot surfaces.

WARNING

Prevent personal injuries by assuring that operation belo

place.

WARNING

The sensor enclosure is not rated for pressure containment.

w pressure guards cannot take

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

17

Page 20

Installing/Mounting

4.2 Determining a location

4.2 Determining a location

CAUTION

Do not install the sensor in the vicinity of strong electromagnetic fields, e.g. near motors,

pumps, transformers etc.

Upstream / downstream

● No pipe run requirements, i.e. straight inlet/outlet sections are not necessary.

● Avoid long drop lines downstream from the flow meter to prevent the meter tube from

draining (min. back pressure: 0.2 Bar).

● Avoid installing the sensor immediately upstream of a free discharge in a drop line.

Location in the system

The optimum location in the system depends on the application:

● Liquid applications

For liquid applications the presence of gas or air bubbles in the fluid may result in

erroneous measurements, particularly in the density measurement. Therefore do not

install the flow meter at the highest point in the system, where gas / air bubbles will be

trapped. For liquids it is advantageous to install the flow meter in low pipeline sections, at

the bottom of a U-section in the pipeline.

Figure 4-1 Liquid applications

● Gas applications

For gas applications the presence of oil may result in erroneous measurements.

Therefore do not install the flow meter at the lowest point of the system, or install a filter.

Figure 4-2 Gas applications

SITRANS F C MASS 2100 Di 3-40

18 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 21

Installing/Mounting

4.3 Orienting the sensor

4.3 Orienting the sensor

Flow direction

The flow direction is indicated by the arrow on the sensor. Flow in this direction will be

indicated as positive.

The sensor must always be completely filled with process fluid in order to measure

accurately.

Orienting the sensor

MASS 2100 Di 3-40 operates in any orientation, but Siemens Flow Instruments recommends

orienting the sensor according to application type:

1. Horizontal installation (optimum orientation)

2. Vertical installation with an upwards flow (only liquid applications).

Liquid applications

CAUTION

Especially suited for low flow applications: Solid particles will not be deposited in the tube

and the sensor can easily be degassed.

NOTICE

Self drainage

The flowmete

r is self-draining if installed horizontally

Horizontal installation, c

Vertical installation, correct

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

orrect

Horizontal installation, wro

Vertical installation, wrong

ng

19

Page 22

Installing/Mounting

4.3 Orienting the sensor

Gas applications

Horizontal installation

Vertical installation (not recommended)

Installation in a drop line

Installation in a dropline is only possible if a pipeline reduction or orifice with a smaller crosssection can be installed to prevent the sensor from being partially drained during the

measurements.

① Orifice Pipe

② Valve

Figure 4-3 Installation in drop line

SITRANS F C MASS 2100 Di 3-40

20 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 23

Installing/Mounting

4.4 Mounting the sensor

4.4 Mounting the sensor

● Install the sensor in rigid pipelines in order to support the weight of the meter.

● Center the connecting pipelines axially in order to assure a stress-free installation.

● Install two supports or hangers symmetrically and stress free in close proximity to the

process connections.

Siemens Flow Instruments recommends installing the supports / hangers between sensor

enclosure and process connections.

Avoid vibrations

Use flexible hoses, if vibrations exist in the pipeline. The hoses must be installed outside the

supported flow meter section and outside the section between the shut off devices. The

direct connection of flexible elements to the sensor should be avoided.

Avoid crosstalk

Mount the sensors on separate steel frames, keep distance between the sensors, or

decouple the pipelines, if operating more than one meter in one or multiple interconnected

pipelines. This will prevent cross talk.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

21

Page 24

Installing/Mounting

4.5 Mounting a pressure guard

4.5 Mounting a pressure guard

The sensor enclosure is supplied with two 1/8" nipples. These holes can be used for e.g. a

pressure guard, which can be connected to an automatic shut off valve which will stop the

flow in case of sensor pipe fracture.

Mounting of pressure guard

See also

CAUTION

Avoid moisture, liquids or particles getting into the sensor enclosure

All sensors are filled with argon to avoid condensation. Penetration of humidity, liquids or

particles into the sensor may influence the measurement and in worst case affect the

measuring function.

Install a pressure guard as follows:

1. Place the sensor in a dry, clean place and leave it to acclimatize until it reaches ambient

temperature, preferred 20°C (68°F).

2. Carefully disconnect the nipple and mount the pressure guard. Use the enclosed spare

part sealing ring for proper sealing.

3. Make sure that the pressure guard does NOT touch any of the parts inside the sensor.

4. Check that the pressure guard has been correctively mounted and thoroughly tightened.

After dismantling the sealing ring must be replaced with a new sealing ring.

Pressure guards are not supplied with the sensor. For more information, please refer to

www.siemens.com/sitransp (http://www.siemens.com/sitransp

)

SITRANS F C MASS 2100 Di 3-40

22 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 25

Connecting

The following contains a short description of how to connect a remote mounted sensor to the

transmitter SITRANS F C MASS 6000 / SIFLOW FC070. For more information, including

information about compact versions, refer to the Operating Instructions for the respective

Before connecting

transmitters.

Only qualified personnel may carry out work on the electrical connections.

● Check that serial numbers on sensor and SENSORPROM® unit are identical.

WARNING

WARNING

Use in hazardous locations

Before connecting check

• No explosion hazard exists

• A fire department permission certificate has been issued

• All connection leads are potential free

that:

5

Special requirements apply to the location and interconnection of sensor and

transmitter. See "Installation in hazardous area" (Page 10)

5.1 Safety precautions

WARNING

Mains supply from building installation Class II

A switch or circuit breaker (Max. 15 A) must be installed in close proximity to the equipment

and within easy reach of the operator. It must be marked as the disconnecting device for

the equipment.

WARNING

Field wiring installation

Ensure that the National Installation Code of the country in which the devices are installed

is met.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

23

Page 26

Connecting

5.2 Wiring

5.2 Wiring

1. Connect transmitter and sensor using the screw connector on the blue cable supplied

with the sensor.

Figure 5-1 Sensor and transmitter connection

2. Connect grounding terminal ① to protective earth (PE).

See also

Figure 5-2 Grounding terminal

NOTICE

Cable screen

Cable screen is

WARNING

connected to earth.

Only commission the device after the device has been properly connected and, if

required, closed.

Electrical connection schematics (Page 41)

SITRANS F C MASS 2100 Di 3-40

24 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 27

Connecting

5.3 Turning the terminal box

5.3 Turning the terminal box

For remote versions, the adapter can optionally be oriented in four directions.

1. Loosen the four screws by use of an allen key and turn the adaptor.

2. Tighten the screws and mount the multiple plug.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

25

Page 28

Connecting

5.3 Turning the terminal box

SITRANS F C MASS 2100 Di 3-40

26 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 29

Commissioning

Before commissioning it must be checked that:

● The device has been installed and connected in accordance with the guidelines provided

in chapter 4 "Installing / Mounting (Page 17)" and 5 "Connecting (Page 23)"

● Device installed in ha

hazard

s location (Page 10)"

ou

6.1 Zero point adjustment

Performing a zero point adjustment establishes the reference point of the flowmeter at zero

flow. All Coriolis sensors from Siemens are calibrated before they are sent out to customers.

However, Coriolis sensors are very sensitive, and several factors might move the zero point,

e.g. installation, pressure, temperature and even very small vibrations coming from the

process. All these factors are customer specific and cannot be simulated at the factory.

Therefore Siemens recommends carrying out a zero point adjustment before use to obtain

optimum accuracy.

In the following it is described how to zero point adjust the device. For setting application

specific parameters, please refer to the Operating Instructions of the relevant transmitter.

zardous location meets the requirements described in "Installation in

6

Before zero point adjusting

● Install shut off devices in the pipeline, optimally both up- and downstream of the sensor,

otherwise at the sensor outlet

Horizontal

Vertical

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

27

Page 30

Commissioning

6.1 Zero point adjustment

CAUTION

In order to avoid damaging the pump and interrupting the process it is recommended to

install a bypass line

Auto zero point adjustment

● Power up the device and acclimate the transmitter (min. 30 min).

● Pump liquid at max. flow through the sensor (min. 2 min or until the driver signal and

driver frequency are stable) in order to avoid air in the liquid.

● Stop the flow while pumping by shutting off the outlet valve and then the inlet valve. Wait

min. 1 minute. In this way the liquid remain pressurized and any degassing is avoided.

Note

The flow must be completely stopped and the sensor completely filled with liquid.

● Perform an auto zero point adjustment:

MASS 6000 SIFLOW FC070

Choose menu entry "Reset mode"

-> Zero adjust

-> Zero adjust auto

Choose the SIMATIC PDM menu

-> Device

-> zero adjust

For further information on performing an auto zero point adjustment please refer to the

relevant transmitter Operating Instructions.

● After count down (30 s.), the actual zero point is displayed and the meter ready for

operation.

SITRANS F C MASS 2100 Di 3-40

28 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 31

Service and maintenance

7.1 Maintenance

The device is maintenance-free, however, a periodic inspection according pertinent

directives and regulations must be carried out.

An inspection can include check of:

● Ambient conditions

● Seal integrity of the process connections, cable entries, and cover screws

● Reliability of power supply, lightning protection, and grounds

7.2 Transportation/storage

The sensor is a fragile piece of equipment. Impact and shock can

cause measuring inaccuracy. Therefore during transportation it must

be placed in the transportation box delivered by Siemens Flow

Instruments. If this is not possible, the alternative sensor packaging

must be able to withstand the hazards from transportation.

7

7.3 Recalibration

Siemens Flow Instruments offers to recalibrate the sensor. The following calibrations are

offered as standard according to configuration (standard, density, brix/plato, fraction):

● Standard calibration

● Customer specified calibration (up to 10 points)

● Accredited calibration

● Matched pair calibration

See also

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Note

For recalibration the SENSORPROM memory unit must always be returned with the

sensor

Return procedures (Page 31)

29

Page 32

Service and maintenance

7.4 Unit repair

7.4 Unit repair

CAUTION

Repair and service must be carried out by Siemens authorized personnel only.

Note

Siemens Flow Instruments defines sensors as non-repairable products.

7.5 Technical support

If you have any technical questions about the device described in these Operating

Instructions and do not find the right answers, you can contact Technical Support:

● Via the Internet using the Support Request:

Support request (http://www.siemens.com/automation/support-request

● Phone: +49 (0)911 895 7222

Further information about our technical support is available in the Internet at

Technical support (http://support.automation.siemens.com/WW/vi

Service & Support on the Internet

In addition to our documentation, we offer a comprehensive knowledge base online on the

Internet at:

)

ew/en/16604318

)

Service and support (http://www.siemens.com/automation/servi

There you will find:

● The latest product information, FAQs, downloads, tips and tricks.

● Our newsletter, providing you with the latest information about your products.

● A Knowledge Manager to find the right documents for you.

● Our bulletin board, where users and specialists share their knowledge worldwide.

● You can find your local contact partner for Industry Automation and Drives Technologies

● Information about field service, repairs, spare parts and lots more under "Services."

Additional Support

Please contact your local Siemens representative and offices if you have additional

questions about the device

Find your contact partner at:

Local contact person (http://www.automation.siemens.com/partner

ce&support)

in our partner database.

)

SITRANS F C MASS 2100 Di 3-40

30 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 33

Service and maintenance

7.6 Return procedures

7.6 Return procedures

Enclose the delivery note, the cover note for return delivery together with the declaration of

decontamination form on the outside of the package in a well-fastened clear document

pouch.

Required forms

● Delivery Note

● Cover Note for Return Delivery with the following information

Decontamination declaration

(http://pia.khe.siemens.com/efiles/feldg/files

pdf)

– product (ordering number)

– number of devices or spare parts returned

– reason for the return

● Declaration of Decontamination

ice/declaration_of_decontamination_en.

/Serv

Return delivery form (http://support.automation.siemens.com/WW/view/en/16604370

With this declaration you certify

carefully cleaned and are free from any residues.

that the returned products/spare parts have been

)

If the device has been operated together with toxic, caustic, flammable or waterdamaging products, clean the device before return by rinsing or neutralizing. Ensure that

all cavities are free from dangerous substances. Then, double-check the device to ensure

the cleaning is completed.

We shall not service a device or spare part unless the declaration of decontamination

confirms proper decontamination of the device or spare part. Shipments without a

declaration of decontamination shall be cleaned professionally at your expense before

further proceeding.

You can find the forms on the Internet and on the CD delivered with the device.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

31

Page 34

Service and maintenance

7.6 Return procedures

SITRANS F C MASS 2100 Di 3-40

32 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 35

Technical data

8

8.1 Technical specifications

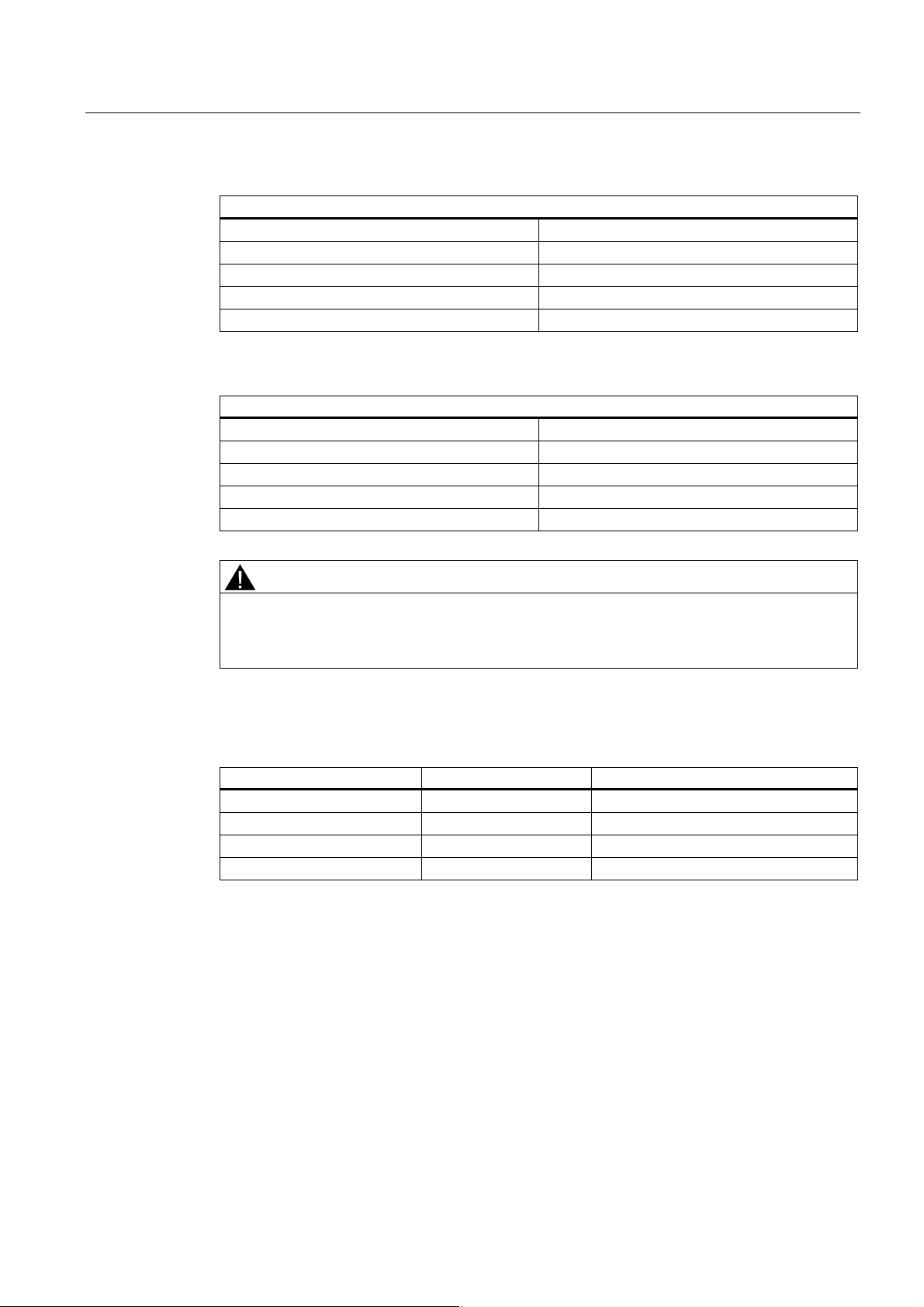

Table 8- 1 Technical data, MASS 2100, Di 3,6,15,25 and 40.

Versions mm (inch) DI 3 (1/8) DI 6 (¼) DI 15 (5/8) DI 25 (1) DI 40 (1½)

Inside pipe diamter (sensor

consists of one pipe)

Pipe wall thickness mm (inch) 0.5 (0.02) 1.0 (0.04) 1.0 (0.04) 2,0 (0.08) 2,6 (0.10)

Massflow measuring range kg/h (lb/inch3) 0 ... 250

Density g/cm3 0 ... 2.9 (0 ... 0.10)

Fraction, e.g. °Brix 0 ... 100

Temperature °C (°F) -50 ... +180 (-58 ... +356)

Pressure of liquid in

measuring pipe1)

Stainless steel bar (psi) 230 (3336) 265 (3844) 130 (1885) 110 (1595) 105 (1523)

Hastelloy C-22 bar (psi) 350 (5076) 410 (5946) 200 (2900) 185 (2683) Materials (Measuring pipe,

flange and thread

connection)

Enclosure and enclosure

material

Cable connection Multiple connector to sensors 5 x 2 x 0.35 mm

EX-version2) EEx ia IIC T3-T6

Weight, approx. (Sensor

only)

1) Max. at 20°C, DIN 2413, DIN 17457

2) Intrinsic safety certification CENELEC and ASEV

mm (inch) 3.0 (0.12) 6.0 (0.24) 14.0 (0.55) 29.7 (1.17) 43,1(1.70)

0 ... 1000

(0 ... 500)

• 1.4435/1.4404 (AISI 316L) (stainless steel)

• 2.4602 (Hastelloy C-22) (only Di 3, 6 ,15 and 25)

• IP 65 (NEMA 4)

• W 1.4404 AISI 316L) (stainless steel)

Note: Sensor enclosure not rated for pressure containment

12 mm

kg (lb) 4 (8.8) 8 (17.6) 12 (26.5) 48 (105.8) 70 (154.5)

(0 ... 2200)

0 ... 5600

(0 ... 12345)

2,

twisted and shielded pairs, external diameter

0 ... 25000

(0 ... 55100)

0 ... 52000

(0 ... 114600)

Table 8- 2 Process connections

Versions mm (inch) DI 3 (1/8) DI 6 (¼) DI 15 (5/8) DI 25 (1) DI 40 (1½)

Flange

EN 1092-1 PN40 DN 10 DN 10 DN 15 DN 25 DN 40

ANSI B16,5, Class 150 1/2" 1/2" 1/2" 1" 1 1/2"

ANSI B16,5 Class 600 (Class 300) 1/2" 1/2" 1/2" 1" 1 1/2"

Dairy screwed connection (PN 16/25/40)1)

DIN 11851 DN 10 DN 10 DN 15 DN 25 DN 40

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

33

Page 36

Technical data

8.2 Measurement range

Versions mm (inch) DI 3 (1/8) DI 6 (¼) DI 15 (5/8) DI 25 (1) DI 40 (1½)

ISO 2853/BS 4825 Part 4 (SS3351) 25 mm 25 mm 25 mm 38 mm 51 mm

1)

Dairy clamp connection (PN 16)

ISO 2852/BS 4825 Part 3 (SMS3016) 25 mm 25 mm 25 mm 38 mm 51 mm

Thread

ISO 228/1, PN 100 G1/4" female G1/4" male G1/2" male G1" male G2" male

ANSI/ASME B1.20.1, PN 100 1/4" NPT

female

1/4" NPT

male

1/2" NPT

male

male 2" NPT

1" NPT

male

1) Material, 1.4401 or corresponding

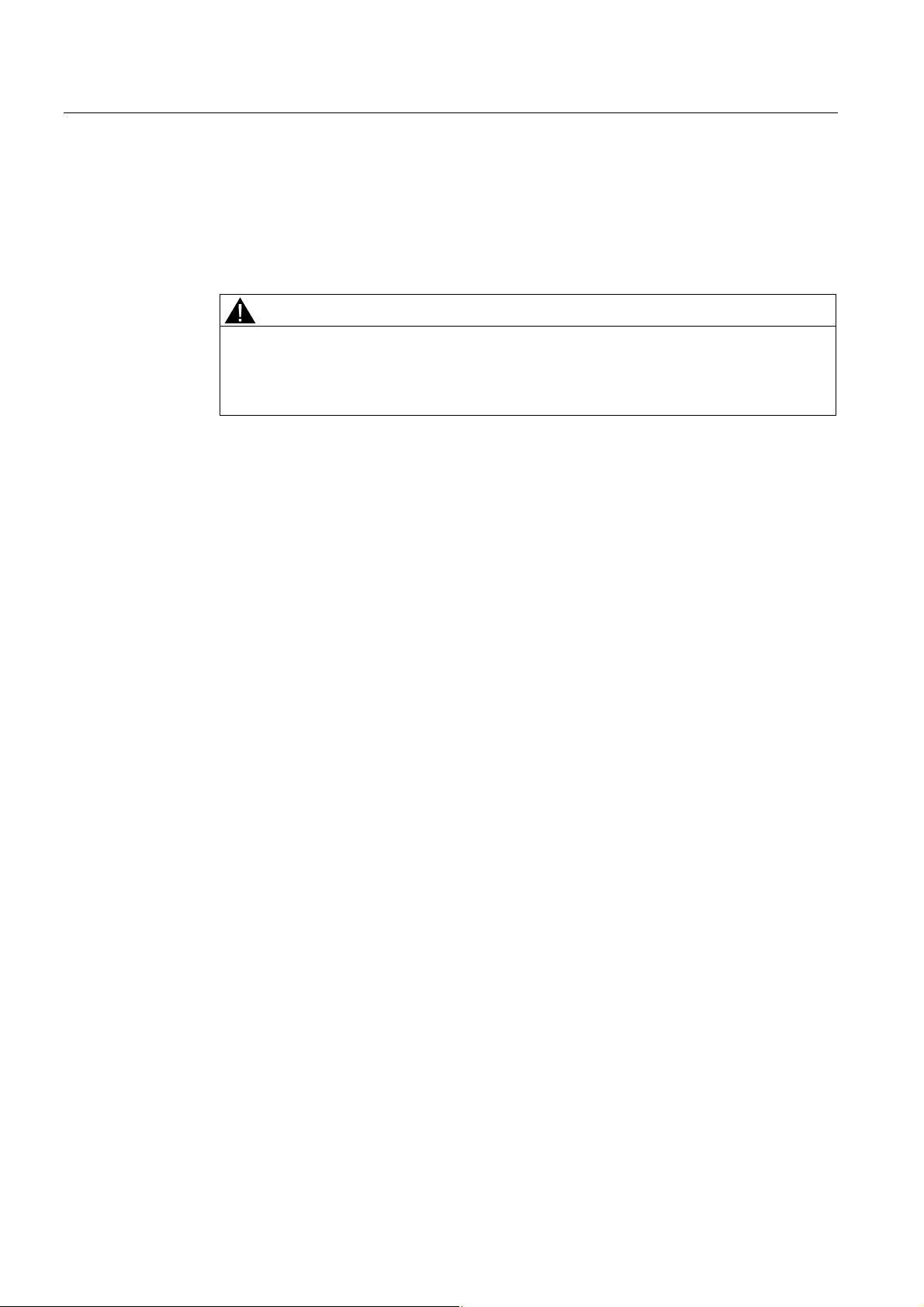

8.2 Measurement range

Measuring accuracy of frequency and pulse outputs

(UURULQRI

DFWXDOPDVVIORZUDWHZLWKFRQILGHQFHSUREDELOLW\

$FWXDO

PDVVIORZUDWH

VHQVRUV

PD[IORZUDWH

Figure 8-1 Measuring accuracy

Table 8- 3 Measurement range

Sensor size Max. flow of sensor at

5 % 5

DI 3 kg/h 12.5 125 250

DI 6 kg/h 50 500 1000

DI 15 kg/h 280 2800 5600

DI 25 kg/h 1250 12500 25000

DI 40 kg/h 2600 26000 52000

0 % 100 %

● At a flow > 5 % of the max. measurement range, you can directly read the error on the

curve.

● At a flow < 5 % of the max. measurement range, use the equation to calculate the error.

The error curve is calculated using the formula:

SITRANS F C MASS 2100 Di 3-40

34 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 37

Technical data

8.3 Accuracy specifications

E error [%]

Z zero point error [kg/h]

Qm mass flow [kg/h]

Figure 8-2 Equation for error curve

Example Di3

● Max zero point error Z = 0.01 kg/h

● Measured mass flow Qm = 12 kg/h

● Error E = ±0.13%

8.3 Accuracy specifications

Table 8- 4 Measuring type errors

Sensor size DI 3 DI 6 DI 15 DI 25 DI 40

Number of measuring tubes

Massflow

Linearity error % 0.10

Repeatability error % 0.05

Max. zero point error kg/h 0.01 0.05 0.2 1.5 6.0

Density

Density error g/cm3 0.0015 0.0015 0.0005 0.0005 0.0005

Repeatability error g/cm3 0.0002 0.0002 0.0001 0.0001 0.0001

Temperature error °C 0.5

Brix error °Brix 0.3 0.3 0.1 0.1 0.1

1

Reference conditions (ISO 9104 and DIN / EN 29104)

Table 8- 5 Reference conditions

Flow conditions Fully developed flow profile

Temperature of the medium 20 °C ± 2 K

Ambient temperature 20 °C ± 2 K

Liquid pressure 2 ± 1 bar

Density 0.997 g / cm3

Brix 40 ° Brix

Supply voltage Un ± 1 %

Warming-up time 30 min

Cable length 5 m between transmitter and sensor

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

35

Page 38

Technical data

8.4 Pressure drop

Additional error on deviation from reference conditions

Current output As pulse output (± 0.1% of actual flow +0.05%

FSO)

Effect of ambient temperature Display/Frequency/pulse output:

• < ±0.003 % / K measured value

Current output:

• < ± 0.005% / K act.

Effect of supply voltage < 0.005% of measuring value on 1% alteration

8.4 Pressure drop

The pressure drop through the instrument is a function of the properties of the fluid viscosity

and the flow rate.

In the following charts, the pressure drop for the various sensor sizes is available (Reference

density is 1000 kg/m

3

). The charts are used for correct sensor dimensioning with regard to

capacity, pressure loss and accuracy.

Figure 8-3 MASS 2100 DI3

SITRANS F C MASS 2100 Di 3-40

36 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 39

Technical data

8.4 Pressure drop

Figure 8-4 MASS 2100 DI6

Figure 8-5 MASS 2100 DI15

Figure 8-6 MASS 2100 DI25

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

37

Page 40

Technical data

33

52

82

31

79

50

8.5 Pressure / temperature range

Figure 8-7 MASS 2100 DI40

8.5 Pressure / temperature range

The pressure - temperature ratings depend on type of process connection.

110

100

90

80

70

60

50

40

352&(6635(6685(EDU

30

-50 30 80 130 180

352&(667(03(5$785(r&

Figure 8-8 Flange EN1092.1 W1.4404 /4435

110

100

90

80

70

60

50

40

352&(6635(6685(EDU

30

-50 30 80 130 180

352&(667(03(5$785(r&

Figure 8-9 Flange EN1092.1, W2.4602

31

31

31

31

31

31

SITRANS F C MASS 2100 Di 3-40

38 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 41

Technical data

12

30

60

10

20

30

40

50

60

70

80

90

15

49

98

10

20

30

40

50

60

70

80

90

100

110

-50 30 80 130 180

71

164

188

92

145

275

287

157

322

8.5 Pressure / temperature range

&/$66

&/$66

352&(6635(6685(EDU

-50 30 80 130 180

352&(667(03(5$785(r&

&/$66

Figure 8-10 Flange ASME B16.5, W1.4404 / 4435

&/$66

&/$66

352&(6635(6685(EDU

352&(667(03(5$785(r&

&/$66

Figure 8-11 Flange ASME B16.5, W2.4602

260

210

160

110

352&(6635(6685(EDU

60

-50 30 80 130 180

352&(667(03(5$785(r&

31

31

31

31

Figure 8-12 Flange ISO228, Pipe thread, W1.4404 / 4435

420

370

320

270

220

170

352&(6635(6685(EDU

120

-50 30 80 130 180

Figure 8-13 Flange ISO228, Pipe thread, W2.4602

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

352&(667(03(5$785(r&

31

31

31

31

31

39

Page 42

Technical data

25

40

10

15

20

25

30

35

40

45

-50 0 20 40 60 80 100 120 140

16

25

10

5

10

15

20

25

30

-50 5 25 45 65 85 105 125 145

8.5 Pressure / temperature range

31'1

31'1

352&(6635(6685(EDU

352&(667(03(5$785(r&

Figure 8-14 Flange DIN 11851, W1.4404

352&(6635(6685(EDU

352&(667(03(5$785(r&

Figure 8-15 Flange DIN 32676, W1.4404

31'1

31

31

31

SITRANS F C MASS 2100 Di 3-40

40 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 43

Technical data

8.6 Electrical connection schematics

8.6 Electrical connection schematics

Electrical connection, MASS 2100 with MASS 6000 (remote mounted)

① Driver

② PT 1000 (IN)

③ PT 1000 (OUT)

④ Pick up 2

⑤ Pick up 1

Figure 8-16 MASS 2100 / MASS 6000 Connection

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

41

Page 44

Technical data

8.7 Dimensions and weight

8.7 Dimensions and weight

Remote versions

)ODQJH(1

$16,%

'DLU\VFUHZHG

FRQQHFWLRQ

',1VFUHZHG

Table 8- 6 Dimensions and weight, remote versions

Sensor

Connection L1 L2 L3 H1 B1 D1 D2 D3 D4 D5

size

DI

(Inch)

Type

(size)

Pipe

thread ISO

228/1 -

Pressure

mm (inch)

rating

PN 100 400

(15.75)

280

(11.02)

75.5

(2.97)

G¼ (¼")

Pipe

thread

ANSI/ASM

PN 100 400

(15.75)

280

(11.02)

75.5 60

(2.97) (2.36) 0 (0)

E B 1.20.1

- ¼" NPT

(¼")

60

(2.36) 0 (0)

6FUHZHGFRQQHFWRUIRU

'L,62*~

DQG$16,$60(

%~137

21.3

(0.84)

21.3

(0.84)

104

(4.09)

104

(4.09)

- - - 3 (1/8")

- - -

SITRANS F C MASS 2100 Di 3-40

42 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 45

Technical data

8.7 Dimensions and weight

size

DI

(Inch)

6 (¼")

15 (½")

25(1")

Connection L1 L2 L3 H1 B1 D1 D2

Type

(size)

Flange EN

1092-1

(DN 10)

Flange

ANSI

B16.5 (½")

Screwed

connection

DIN 11851

(DN10)

Clamp

ISO 2852

(25 mm)

Flange EN

1092-1

(DN15)

Flange

ANSI

B16.5 (½")

Screwed

connection

DIN 11851

(DN15)

Clamp

ISO 2852

(25 mm)

Flange EN

1092-1

(DN25)

Flange

ANSI

B16.5 (1")

Screwed

connection

DIN 11851

(DN32)

Pressure

rating

PN 100 580

PN 40 560

Class 150 624

Class 600 608

PN 40 532

PN 16 570

PN 100 634

PN 40 620

Class 150 639

Class 600 660

PN 40 586

PN 16 624

PN 100 970

PN 40 934

Class 150 967

Class 600 992

PN 40 922

mm (inch)

(22.83)

(22.05)

(24.57)

(23.94)

(20.94)

(22.44)

(24.96)

(24.41)

(25.16)

(25.98)

(23.07)

(24.57)

(38.19)

(36.77)

(38.07)

(39.06)

(36.30)

390

(15.35)

390

(15.35)

390

(15.35)

390

(15.35)

390

(15.35)

390

(15.35)

444

(17.48)

444

(17.48)

444

(17.48)

444

(17.48)

444

(17.48)

444

(17.48)

700

(27.56)

700

(27.56)

700

(27.56)

700

(27.56)

700

(27.56)

62.0

(2.44)

62.0

(2.44)

62.0

(2.44)

62.0

(2.44)

62.0

(2.44)

62.0

(2.44)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

75.5

(2.97)

40

(1.57)

40

(1.57)

40

(1.57)

40

(1.57)

40

(1.57)

40

(1.57)

44

(1.73)

44

(1.73)

44

(1.73)

44

(1.73)

44

(1.73)

44

(1.73)

126

(4.96)

126

(4.96)

126

(4.96)

126

(4.96)

126

(4.96)

12

(0.47)

12

(0.47)

12

(0.47)

12

(0.47)

12

(0.47)

12

(0.47)

20

(0.79)

20

(0.79)

20

(0.79)

20

(0.79)

20

(0.79)

20

(0.79)

25

(0.98)

25

(0.98)

25

(0.98)

25

(0.98)

25

(0.98)

17.0

(0.67)

17.0

(0.67)

17.0

(0.67)

17.0

(0.67)

17.0

(0.67)

17.0

(0.67)

21.3

(0.84)

21.3

(0.84)

21.3

(0.84)

21.3

(0.84)

21.3

(0.84)

21.3

(0.84)

33.7

(1.33)

33.7

(1.33)

33.7

(1.33)

33.7

(1.33)

33.7

(1.33)

104

(4.09)

104

(4.09)

104

(4.09)

104

(4.09)

104

(4.09)

104

(4.09)

129

(5.08)

129

(5.08)

129

(5.08)

129

(5.08)

129

(5.08)

129

(5.08)

219

(8.62)

219

(8.62)

219

(8.62)

219

(8.62)

219

(8.62)

D3 D4 D5 Sensor

100

(3.94)

90.0

(3.54)

88.9

(3.5)

95.3

(3.75)

- - -

105

(2.95)

95.0

(3.74)

88.9

(3.5)

95.3

(3.75)

- - -

- - -

140.0

(3.94)

115.0

(4.53)

108.0

(4.25)

124.0

(4.88)

- - -

70.0

(2.76)

60.0

(2.36)

60.5

(2.38)

66.5

(2.62)

-

75.0

(4.13)

65.0

(2.56)

60.5

(2.38)

66.5

(2.62)

100.0

(5.51)

85.0

(3.35)

79.2

(3.12)

88.9

(3.50)

14.0

(0.55)

14.0

(0.55)

15.7

(0.62)

15.7

(0.62)

-

14.0

(0.55)

14.0

(0.55)

15.7

(0.62)

15.7

(0.62)

18.0

(0.71)

14.0

(0.55)

15.7

(0.62)

19.1

(0.75)

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

43

Page 46

Technical data

8.7 Dimensions and weight

size

DI

(Inch)

40

(1½")

Connection L1 L2 L3 H1 B1 D1 D2

Type

(size)

Clamp

ISO 2852

(38 mm)

Flange EN

1092-1

Flange

ANSI

B16.5

(1½")

Screwed

connection

DIN 11851

(DN 50)

Clamp

ISO 2852

(51 mm)

Pressure

rating

PN 16 940

PN 100 1100

PN 40 1063

Class 150 1100

Class 600 1128

PN 25 1090

PN 25 1062

mm (inch)

(37.01)

(43.31)

(41.85)

(43.31)

(44.41)

(42.91)

(41.81)

700

(27.56)

850

(33.46)

850

(33.46)

850

(33.46)

850

(33.46)

850

(33.46)

850

(33.46)

74.5 126

(2.93) (4.96)

71.5

(2.81)

71.5 180

(2.81) (7.09) 0 (0)

71.5 180

(2.81) (7.09) 0 (0)

71.5 180

(2.81) (7.09) 0 (0)

71.5 180

(2.81) (7.09) 0 (0)

71.5 180

(2.81) (7.09) 0 (0)

180

(7.09) 0 (0)

25

(0.98)

33.7

(1.33)

48.3

(1.9)

48.3

(1.9)

48.3

(1.9)

48.3

(1.9)

48.3

(1.9)

48.3

(1.9)

219

(8.62)

273

(10.75)

850

(10.75)

850

(10.75)

850

(10.75)

850

10.75

()

850

(10.75)

D3 D4 D5 Sensor

- - -

170.0

(4.92)

150.0

(5.91)

127.0

(5.91)

155.4

(6.12)

- - -

- - -

125.0

(6.69)

110.0

(4.33)

98.6

(4.33)

114.3

(4.50)

22.0

(0.87)

18.0

(0.71)

15.7

(0.71)

22.4

(0.88)

Compact versions

Figure 8-17 MASS 2100 compact mounted with MASS 6000 Ex d

SITRANS F C MASS 2100 Di 3-40

44 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 47

Technical data

8.7 Dimensions and weight

Table 8- 7 MASS 2100 compact mounted with MASS 6000 Ex d

Sensor size

[DI (inch)]

3 (1/8) 75 (2.95) 82 (3.23) 247 (9.72) 329 (12.95)

6 (¼) 62 (2.44) 72 (2.83) 257 (10.12) 329 (12.95)

15 (½) 75 (2.95) 87 (3.43) 267 (10.51) 354 (13.94)

25 (1) 75 (2.95) 173 (6.81) 271 (10.67) 444 (17.48)

40 (1½) 75 (2.95) 227 (8.94) 271 (10.67) 498 (19.61)

L3

mm (inch)

H5 H6 H5+H6

mm (inch) mm (inch) mm (inch)

Figure 8-18 MASS 2100 compact mounted with MASS 6000 IP67

Table 8- 8 MASS 2100 compact mounted with MASS 6000 IP67

Sensor size

[DI (inch)]

3 (1/8) 75 (2.95) 82 (3.23) 306 (12.04) 388 (15.28)

6 (¼) 62 (2.44) 72 (2.83) 316 (12.44) 388 (15.28)

15 (½) 75 (2.95) 87 (3.43) 326 (12.83) 413 (16.26)

25 (1) 75 (2.95) 173 (6.81) 330 (13.00) 503 (19.80)

40 (1½) 75 (2.95) 227 (8.94) 330 (13.00) 557 (21.93)

L3

mm (inch)

H5 H6 H5+H6

mm (inch) mm (inch) mm (inch)

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

45

Page 48

Technical data

8.7 Dimensions and weight

Heating Jacket versions

Figure 8-19 Dimensions, MASS 2100 with heating jacket

Table 8- 9 Dimensions, MASS 2100 with heating jacket

Sensor

size

DI (inch) Type (Size) Pressure

DI 3

(1/8")

ANSI B16.5

DI 6 (¼") EN 1092-1

ANSI B16.5

DI 15

(½")

ANSI B16.5

DI 25 (1") EN 1092-1

ANSI B16.5

DI 40

(1½")

ANSI B16.5

Connections L5 H3 B2 D6 D7 D8

rating

EN 1092-1

(DN 15)

(½")

(DN 15)

(½")

EN 1092-1

(DN 15)

(½")

(DN 15)

(½")

EN 1092-1

(DN 15)

(½")

PN 40 234 (9.21) 122 (4.8) 22 (0.87) 95 (3.74) 65.0 (2.56) 14.0 (0.55)

Class 150 234 (9.21) 131.6

PN 40 234 (9.21) 112 (4.41) 22.7 (0.89) 95 (3.74) 65.0 (2.56) 14.0 (0.55)

Class 150 234 (9.21) 121.6

PN 40 234 (9.21) 126.5

Class 150 234 (9.21) 136.1

PN 40 420 (16.54) 213.6

Class 150 420 (16.54) 223.2

PN 40 500 (19.68) 267.5

Class 150 500 (19.68) 277.1

mm (inch)

22 (0.87) 88.9 (3.5) 60.5 (2.38) 15.7 (0.62)

(5.18)

22.7 (0.89) 88.9 (3.5) 60.5 (2.38) 15.7 (0.62)

(4.79)

31.5 (1.24) 95 (3.74) 65.0 (2.56) 14.0 (0.55)

(4.98)

31.5 (1.24) 88.9 (3.5) 60.5 (2.38) 15.7 (0.62)

(5.36)

60 (2.36) 95 (3.74) 65.0 (2.56) 14.0 (0.55)

(8.41)

60 (2.36) 88.9 (3.5) 60.5 (2.38) 15.7 (0.62)

(8.79)

43 (1.69) 95 (3.74) 65.0 (2.56) 14.0 (0.55)

(10.53)

43 (1.69) 88.9 (3.5) 60.5 (2.38) 15.7 (0.62)

(10.91)

SITRANS F C MASS 2100 Di 3-40

46 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 49

Appendix

Certificates are posted on the Internet and on the manual collection shipped with the device.

See also

Certificates on the Internet

(http://support.automation.siemens.com/

UL control drawings on the internet (http://www.automation.siemens.com/w1/automation-

technology-process-instrumentation-18092.htm#lb-61,related-installationdrawings)

A.1 Ordering

In order to ensure that the ordering data you are using is not outdated, the latest ordering

data is always available on the Internet: Process instrumentation catalog

(http://www.siemens.com/processinstrumentation/catalogs

A

WW/view/en/10806951/134200)

)

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

47

Page 50

Appendix

A.1 Ordering

SITRANS F C MASS 2100 Di 3-40

48 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 51

Glossary

ASIC

BRIX

CAN

Application-Specific Integrated Circuit is an integrated circuit (IC) customized for a particular

use, rather than intended for general-purpose use.

Degrees Brix (symbol °Bx) is a measurement of the mass ratio of dissolved sugar to water in

a liquid. A 25 °Bx solution is 25% (w/w), with 25 grams of sugar per 100 grams of solution.

Controller Area Network. CAN is the leading serial bus system for embedded control. CAN is

a mainstream network and was internationally standardized (ISO 11898–1) in 1993.

Coriolis

DFT

EMC

The Coriolis effect is an apparent deflection of moving objects from a straight path when they

are viewed from a rotating frame of reference. The effect is named after Gaspard-Gustave

Coriolis, a French scientist who described it in 1835. The Coriolis effect is caused by the

Coriolis force, which appears in the equation of motion of an object in a rotating frame of

reference.

The discrete Fourier transform (DFT) is one of the specific forms of Fourier analysis. As

such, it transforms one function into another, which is called the frequency domain

representation, or simply the DFT, of the original function (which is often a function in the

time domain). The DFT evaluates enough frequency components to reconstruct the finite

segment that was analyzed. The DFT is thus a transform for Fourier analysis of finite-domain

discrete-time functions.

Electromagnetic compatibility (EMC) is the branch of electrical sciences which studies the

unintentional generation, propagation and reception of electromagnetic energy with

reference to the unwanted effects (Electromagnetic Interference, or EMI) that such energy

may induce. The goal of EMC is the correct operation, in the same electromagnetic

environment, of different equipment which use electromagnetic phenomena, and the

avoidance of any interference effects.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

49

Page 52

Glossary

Fraction

Fraction designates a proportional relation between an object part and the object whole. For

example, the fraction 3⁄4 represents three equal parts of a whole object, divided into four

equal parts.

HART

HART Communication is a bi-directional industrial field communication protocol used to

communicate between intelligent field instruments and host systems. HART is the global

standard for smart process instrumentation and the majority of smart field devices installed in

plants worldwide are HART-enabled. HART technology is easy to use and very reliable

IP

An IP (Ingress Protection) number is used to specify the environmental protection of

enclosures around electronic equipment. These ratings are determined by specific tests. The

IP number is composed of two numbers, the first referring to the protection against solid

objects and the second against liquids. The higher the number, the better the protection. For

example, in IP67 the first Number (6) means that the device is totally protected against dust,

and the second (7) that it is protected against the effect of immersion between 15cm and 1m

MODBUS

NAMUR

PED

Plato

MODBUS is a serial communications protocol intended for use with programmable logic

controllers (PLCs). MODBUS allows for communication between many devices connected to

the same network, for example a system that measures temperature and humidity and

communicates the results to a computer. MODBUS is often used to connect a supervisory

computer with a remote terminal unit (RTU) in supervisory control and data acquisition

systems.

Normenarbeitsgemeinschaft für Meß- und Regeltechnik in der Chemischen Industrie

(NAMUR). NAMUR is a group representing the interests of the chemical industry which

create standards for instrumentation and electrical devices used in industrial plants.

The Pressure Equipment Directive (97/23/EC) is the legislative framework on European level

for equipment subject to a pressure hazard. It was adopted by the European Parliament and

the European Council in May 1997 and has been obligatory throughout the European Union

since May 2002.

Plato is a measure of the weight of the solids dissolved in water. It is expressed in %.

SITRANS F C MASS 2100 Di 3-40

50 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 53

Glossary

PROFIBUS

PROFIBUS (Process Field Bus) is a vendor-independent, open bus system standardized in

the German DIN 19 245. It is a standard for field bus communication in automation

technology and should not be confused with the PROFINET standard for industrial Ethernet.

PROFIBUS-PA (Process Automation) is one of three PROFIBUS variants that are

compatible with each other. PROFIBUS-DP (Decentralized Periphery)

SENSORPROM

All sensor related settings/data saved on an EPROM. SENSORPROM technology

automatically configures the transmitter at start up providing calibration data, pipe size,

sensor type, and output settings. The SENSORPROM automatically stores values or

settings changed by users, and automatically re-programs any new transmitter without loss

of accuracy.

Turndown ratio

'Turndown ratio' is a flow measurement term indicating the range a specific flow meter, or

meter type, is able to measure with specific accuracy. It is also known as rangeability. If a

gas flow to be measured is expected to vary between 100,000 m³ per day and 1,000,000 m³

per day, the specific application has a turndown ratio of at 10:1. Therefore the meter requires

a turndown ratio of at least 10:1.

USM

USM II is a Communication Platform. The Siemens USM II concept enables fitting of add-on

bus modules without loss of functionality:

1. All modules can be fitted as true "plug & play"

2. Module and transmitter are automatically configured through the SENSORPROM

Zero point adjustment

In order to measure accurately with a measuring instrument it is important that zero and gain

have been calibrated. All Coriolis sensors are calibrated before they are sent out to

customers. However, Coriolis sensors are very sensitive, and several factors might move the

zero point, e.g installation, pressure, temperature and even very small vibrations coming

from the process. All these factors are customer specific and can’t be simulated at the

factory. Therefore Siemens recommends to carry out a zero point adjustment before use.

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

51

Page 54

Glossary

SITRANS F C MASS 2100 Di 3-40

52 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 55

Index

A

Accuracy, 38

Accuracy specifications, 39

Temperature specifications, 13

Hazardous area

Approvals, 12

Safety requirements, 13

Heating Jacket, 17

Hotline, 34

C

Commissioning

Zero point adjustment, (See Zero point adjustment)

Compliance, 11

Connection

Electrical, (See Electrical connection)

Contact person, 9

Coriolis

Applications, 15

Measurement principle, 17

Crosstalk, 24

Customer Support Hotline, 34

D

Decontamination, 35

Design, 16

Device

Identification, 8

Inspection, 7

Dimensions

Compact versions, 49

Heating Jacket version, 50

Remote versions, 46

Document history, 8

I

Installation

Drop line, 22

Gas, 20

Indoor/outdoor, 19

Inlet / Outlet conditions, 20

Liquid, 20

Location in the system, 20

Mounting of sensor, 23

Pressure guard, 24

Safety instructions, 19

Sensor orientation, 21

Upstream / Downstream, 20

Internet

Contact person, 9, 34

Flowdocumentation, 9

Support, 34

Intrinsically safe data, 12

Introduction, 7

Items supplied, 7

L

Laws and directives, 11

E

Electrical connection, 45

Basic requirements, 27

F

Flow direction, 21

H

Hazadous area

SITRANS F C MASS 2100 Di 3-40

Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

M

Mains supply, 27

Maintenance, 33

Material compatibility, 11

Measurement range, 38

Mounting, (See Installation)

P

Pickup driver circuit, 13

Pressure

Safety instructions, 19

53

Page 56

Index

Pressure / temperature ratings, 42

Pressure drop, 40

R

Recalibration, 33

Reference conditions, 39

Repair, 34

Return procedures, 35

S

Safety

Instrument safety standards, 11

Safety instructions

Installation, 19

Safety notes, 11

Sensor circuit, 12

Sensor orientation, (See Installation)

SENSORPROM, 18

Service, 34

Support, 34

T

Technical data, 37

Temperature sensor circuit, 12

Temperature specifications, 13

Theory of operation, 17

Type plate, 8

V

Versions, 15

Vibrations, 23

Z

Zero point adjustment, 32

basic requirements, 31

SITRANS F C MASS 2100 Di 3-40

54 Operating Instructions, 07/2010, SFIDK.PS.028.Z1.02

Page 57

Page 58

For more information

www.siemens.com/flow

Siemens A/S

Flow Instruments

DK-6430 Nordborg

DENMARK

www.siemens.com/processautomation

Subject to change without prior notice

Order No.: A5E02896535

Literature No.: A5E02896535-01

SFIDK.PS.028.Z1.02

Copyright Siemens A/S 07/2010

All rights reserved

*A5E02896535*

Loading...

Loading...