Siemens SITRANS F C MASS 6000 IP67 Technical Data Manual

3

■

Overview

MASS 6000 is based on digital signal processing technology –

engineered for high performance, fast flow step response, fast

batching applications, high immunity against process noise,

easy to install, commission and maintain.

The MASS 6000 transmitter delivers true multiparameter measurements i.e. mass flow, volume flow, density, temperature and

fraction.

The MASS 6000 IP67 transmitter can be compact mounted on all

sensors of type MASS 2100 DI 3 to DI 15, and can be used in

remote version for all types of MASS 2100 and FC300 sensors.

Note

nd

Due to RoHs directives active from July 22

transmitters of any model and variants are not for sale within EU,

EU candidate countries, Norway, Switzerland, Iceland, Croatia,

and Turkey.

Replacement products: 7ME461.-..., 7ME462.-..., 7ME471.-...

and 7ME481.-...

Repair parts for MASS 6000 (all models and variants) are available. See spare part list.

■

Benefits

• Dedicated mass flow chip with the latest ASIC technology

• Fast batching and flow step response with an update rate of

true 30 Hz

• Superior noise immunity due to a DFT (Discrete

Fourier Transformation) algorithm.

• Front end resolution better than 0.35 ns improves zero point

stability and enhances dynamic turn-down ratio on flow and

density accuracy.

• Advanced diagnosis and service menu enhances troubleshooting and meter verification.

• Built-in batch controller with compensation and monitoring

comprising 2 built-in totalizers

• Multi-parameter outputs, individual configurable for mass

flow, volume flow, density, temperature or fraction flow such as

Brix or Plato

• Digital input for batch control, remote zero adjust or forced

output mode

• All outputs can be forced to preset value for simulation, verification or calibration purposes.

• User-configurable operation menu with password protection

- 3 lines, 20 characters display in 11 languages

- Self-explaining error handling/log in text format

- Keypad can be used for controlling batch as

start/stop/hold/reset

2017, MASS 6000

© Siemens AG 2018

• SENSORPROM technology automatically configures transmitter at start-up providing:

- Factory pre-programming with calibration data, pipe size,

sensor type, output settings

- Any values or settings changed by users are stored

automatically

- Automatically re-programming any new transmitter without

loss of accuracy

- Transmitter replacement in less than 5 minutes.

- True "plug & play"

• 4-wire Pt1000 temperature measurement ensures optimum

accuracy on mass flow, density and fraction flow.

• Fraction flow computation based on a 3rd-order algorithm

matching all applications.

•USM II platform enables fitting of add-on bus modules without

loss of functionality.

- All modules can be fitted through true "plug & play"

- Module and transmitter are automatically configured through

the SENSORPROM.

• Installation of the transmitter to the sensor is simple "plug &

play" via the sensor pedestal.

■

Application

SITRANS F C mass flowmeters are suitable for all applications

within the entire process industry, where there is a demand for

accurate flow measurement. The meter is capable of measuring

both liquid and gas flow.

The main applications for the MASS 6000 IP67 transmitter can

be found in:

• Food and beverage industries

• Pharmaceutical industries

• Automotive industry

• Oil and gas industry

• Power generation and utility industry

• Water and waste water industry

■

Design

The transmitter is designed in an IP67/NEMA 6 compact

polyamide enclosure which can be compact mounted on the

MASS 2100 sensor range DI 3 to DI 15 (1/8" to ½") and remote

mounted for the entire sensor series.

The MASS 6000 IP67 is available as standard with 1 current,

1 frequency/pulse and 1 relay output and can be fitted with addon modules for bus communication.

■

Function

The following functions are available:

• Mass flow rate, volume flow rate, density, temperature, fraction flow

• 1 current output, 1 frequency/pulse output, 1 relay output,

1 digital input

• All outputs can be individually configured with mass, volume,

density etc.

• 2 built-in totalizers which can count positive, negative or net

• Low flow cut-off

• Density cut-off or empty pipe cut-off, adjustable

• Flow direction adjustable

• Error system consisting of error-log, error pending menu

• Display of operating time

• Uni/bidirectional flow measurement

• Limit switches with 1 or 2 limits, programmable for flow, density or temperature

• Noise filter setting for optimization of measurement performance under non-ideal application conditions

• Full batch controller

• Automatic zero adjustment menu, with zero point evaluation

feed back

• Full service menu for effective and straight forward application

and meter troubleshooting

Flow Measurement

SITRANS F C

Transmitter MASS 6000 IP67 compact/remote

Update 08/2018

Siemens FI 01 · 2018

3/205

Flow Measurement

3

SITRANS F C

Transmitter MASS 6000 IP67 compact/remote

■

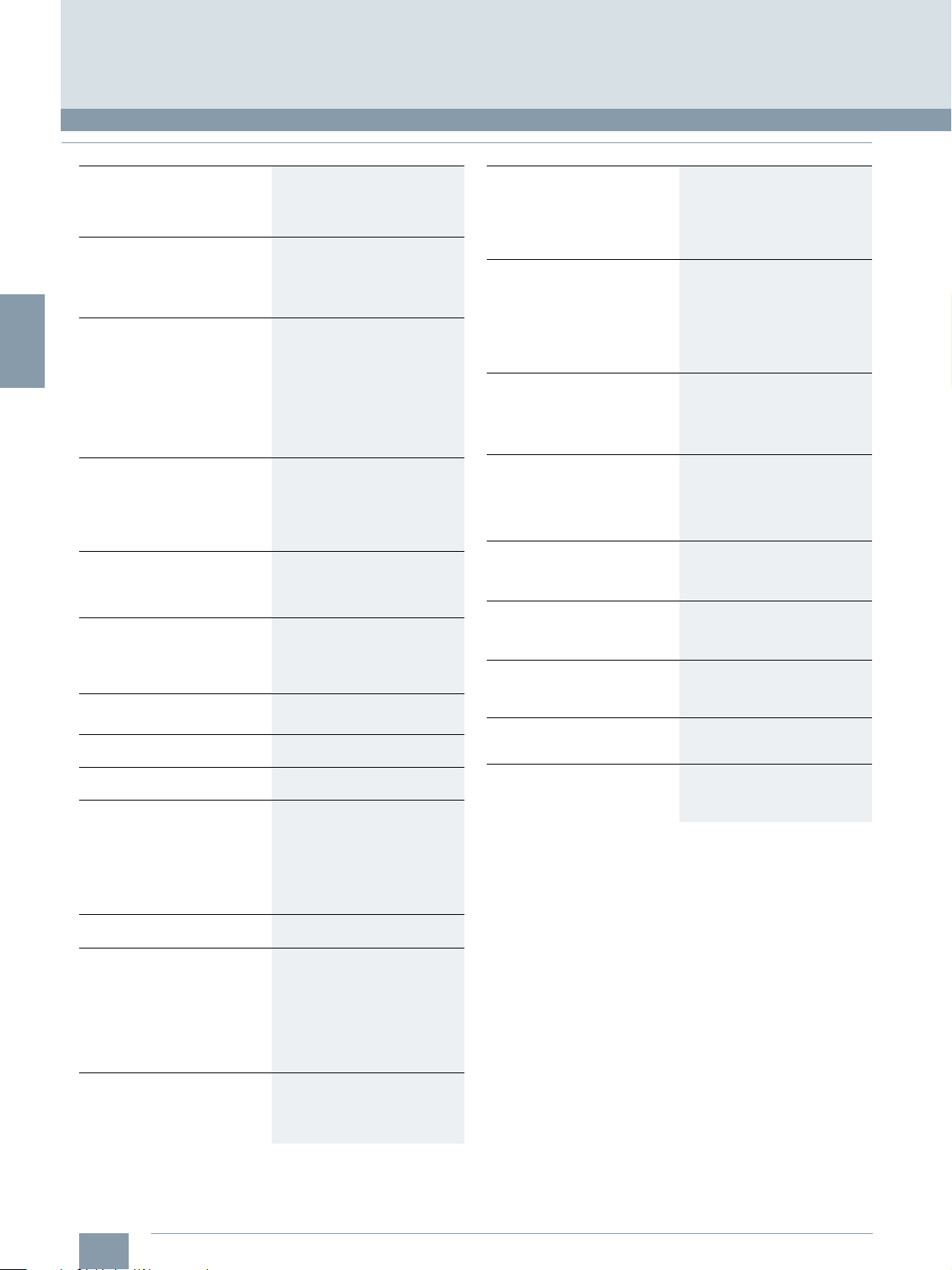

Technical specifications

Measurement of Mass flow [kg/s (lb/min)],

Current output

Current 0 ... 20 mA or 4 ... 20 mA

Load < 800 Ω

Time constant

Digital output

Frequency 0 ... 10 kHz, 50 % duty cycle

Time constant

Active 24 V DC, 30 mA,

Passive

Relay

Type Change-over relay

Load

Functions

Digital input 11 ... 30 V DC (Ri = 13.6 kΩ)

Functionality Start/hold/continue batch, zero

Galvanic isolation

Cut-off

Low-flow 0 ... 9.9 % of maximum flow

Limit function Mass flow, volume flow, fraction,

Tot al iz er Two eight-digit counters for for-

Display • Background illumination with

Zero point adjustment Via keypad or remote via digital

Ambient temperature

Operation -20 ... +50 °C (-4 ... +122 °F),

Storage -40 ... +70 °C (-40 ... +158 °F)

Communication Add-on modules: HART,

volume flow [l/s (gpm)],

fraction [%],

°Brix, density [kg/m3, (lb/ft3)],

temperature [°C (°F)]

0 ... 99.9 s adjustable

0 ... 99.9 s adjustable

1 KΩ ≤ R

short-circuit-protected

3 ... 30 V DC, max. 110 mA,

250 Ω ≤ R

42 V/2 A peak

Error level, error number, limit,

flow direction

point adjust, reset totalizer 1/2,

force output, freeze output

All inputs and outputs are galvanically isolated.

Isolation voltage:

• 500 V to supply

• 50 V between outputs

density, sensor temperature

ward, net or reverse flow

alphanumerical text, 3 × 20

characters to indicate flow rate,

totalized values, settings and

faults. Time constant as current

output 1

• Reverse flow indicated by negative sign

input

max. rel. humidity 80 % at 31 °C

(87.8 °F) decreasing to 50 % at

40 °C (104 °F) according to

IEC/EN/UL 61010-1

(Humidity max. 95 %)

PROFIBUS PA and DP,

Modbus RTU RS 485,

DeviceNet,

FOUNDATION Fieldbus H1

≤ 10 KΩ,

load

≤ 10 KΩ

load

© Siemens AG 2018

Enclosure

Material Fibre glass reinforced polyamide

Rating

Mechanical load

Supply voltage

24 V version

•Supply 18 ... 30 V DC

230 V version

•Supply 87 ... 253 V AC, 50 ... 60 Hz

Power consumption

24 V DC 6 W

24 V AC 10 VA

230 V AC

Fuse

230 V version T 400 mA, T 250 V (IEC 127) - not

24 V version T 1 A, T 250 V (IEC 127) - not

EMC performance

Emission EN 55011/CISPR-11 (Class A)

Immunity EN/IEC 61326-1 (Industry)

NAMUR

Environment

Environmental conditions acc. to

IEC/EN/UL 61010-1:

Maintenance The flowmeter has a built-in error

Cable glands Two types of cable gland are

Note

Due to RoHs directives active from July 22

transmitters of any model and variants are not for sale within EU,

EU candidate countries, Norway, Switzerland, Iceland, Croatia,

and Turkey.

Replacement products: 7ME461.-..., 7ME462.-..., 7ME471.-...

and 7ME481.-...

Repair parts for MASS 6000 (all models and variants) are available. See spare part list.

IP67/NEMA 6

18 ... 1000 Hz random,

3.17 g RMS, in all directions

20 ... 30 V AC

9 VA

replaceable by operator

replaceable by operator

Within the value limits according

to "General requirements“ with

error criteria A in accordance with

NE 21

• Altitude up to 2000 m

• POLLUTION DEGREE 2

log/pending menu which should

be inspected on a regular basis.

available in polyamide in the following dimensions:

M20 or ½“ NPT

nd

2017, MASS 6000

3/206

Siemens FI 01 · 2018

Update 08/2018

Loading...

Loading...