Siemens SITRANS FC430 Operating Instructions Manual

SITRANS F

Coriolis flowmeters

SITRANS FC430 with HART

Operating Instructions

05/2015Edition

Answers for industry.

SITRANS F

Coriolis Flowmeters

FC430 with HART

Operating Instructions

These Operating Instructions apply to Siemens

products SITRANS FC430 with order codes

comm

05/2015

A5E03361511

Introduction

1

Safety notes

2

Description

3

Installing/mounting

4

Connecting

5

Commissioning

6

Operating

7

Functions

8

Custody Transfer

9

Alarms and system

messages

10

Service and maintenance

11

Troubleshooting/FAQs

12

Technical data

13

Spare parts/Accessories

14

Dimensions and weight

15

HMI menu structure

A

HART commands

B

Default settings

C

Zero point adjustment

D

encing 7ME4613, 7ME4623 and 7ME4713

-AF

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E03361511

Ⓟ

Copyright © Siemens AG 2011 - 2015.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

may

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

05/2015 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 9

2 Safety notes .......................................................................................................................................... 21

3 Description ............................................................................................................................................ 29

4 Installing/mounting ................................................................................................................................ 41

5 Connecting ........................................................................................................................................... 55

1.1 History ....................................................................................................................................... 9

1.2 Compatibility ........................................................................................................................... 10

1.3 Items supplied ......................................................................................................................... 11

1.4 Checking the consignment ..................................................................................................... 12

1.5 Device identification ................................................................................................................ 12

1.6 Further Information ................................................................................................................. 19

2.1 Laws and directives ................................................................................................................ 21

2.2 Installation in hazardous locations .......................................................................................... 23

2.3 Certificates .............................................................................................................................. 28

3.1 Applications ............................................................................................................................. 29

3.2 System configuration .............................................................................................................. 30

3.3 Design ..................................................................................................................................... 31

3.4 Features .................................................................................................................................. 35

3.5 HART Communication Interface ............................................................................................. 37

3.6 Theory of operation ................................................................................................................. 40

4.1 Introduction ............................................................................................................................. 41

4.2 Strong vibrations ..................................................................................................................... 41

4.3 Transmitter installation ............................................................................................................ 41

4.3.1 Wall mounting ......................................................................................................................... 42

4.3.2 Pipe mounting ......................................................................................................................... 42

4.3.3 Mounting the transmitter ......................................................................................................... 43

4.3.4 Turning the transmitter ............................................................................................................ 43

4.3.5 Turning the local display ......................................................................................................... 45

4.4 Sensor installation ................................................................................................................... 46

4.4.1 Installation safety precautions ................................................................................................ 46

4.4.2 Determining a location ............................................................................................................ 47

4.4.3 Orientation of the sensor ........................................................................................................ 48

4.4.4 Mounting the sensor ............................................................................................................... 51

4.4.5 Hydrostatic testing .................................................................................................................. 53

4.4.6 Mounting a pressure guard ..................................................................................................... 53

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

3

Table of contents

6 Commissioning ..................................................................................................................................... 73

7 Operating ............................................................................................................................................. 109

5.1 General safety requirements .................................................................................................. 55

5.2 Wiring in hazardous locations ................................................................................................ 56

5.3 Cable requirements ................................................................................................................ 56

5.4 Safety notes for connecting ................................................................................................... 57

5.5 Step 1: Connecting the DSL and the transmitter ................................................................... 57

5.6 Lack of equipotential bonding ................................................................................................ 61

5.7 Step 2: Preparing for the transmitter connections ................................................................. 61

5.8 Step 3: Connecting the power supply .................................................................................... 66

5.9 Step 4a: Connecting the current output HART (channel 1) ................................................... 68

5.10 Step 4b: Connecting the inputs and outputs (channels 2 to 4) .............................................. 69

5.11 Step 5: Finishing the transmitter connection .......................................................................... 72

6.1 General requirements ............................................................................................................ 73

6.2 Warnings ................................................................................................................................ 73

6.3 Commissioning via HMI ......................................................................................................... 74

6.3.1 Wizard introduction ................................................................................................................ 74

6.3.2 Quick Commissioning wizard (menu item 1.1) ...................................................................... 75

6.3.3 Zero point adjustment ............................................................................................................ 76

6.3.4 Zero Point Adjustment wizard (menu item 1.2) ...................................................................... 77

6.3.5 Wizards .................................................................................................................................. 78

6.3.5.1 Process Values wizard (menu item 1.3) ................................................................................ 80

6.3.5.2 Inputs/Outputs wizard (menu item 1.4) .................................................................................. 81

6.3.5.3 Gas Application wizard (menu item 1.5) ................................................................................ 85

6.3.5.4 Pulsating Flow wizard (menu item 1.6) .................................................................................. 86

6.3.5.5 Dosing Application wizard (menu item 1.7) ........................................................................... 87

6.4 Commissioning with PDM ...................................................................................................... 88

6.4.1 Operating via SIMATIC PDM ................................................................................................. 88

6.4.2 Functions in SIMATIC PDM ................................................................................................... 88

6.4.3 Initial setup ............................................................................................................................. 89

6.4.4 Adding device to communication network .............................................................................

6.

4.5 Configuring a new device ....................................................................................................... 92

91

6.4.6 Wizard - Quick Start via PDM ................................................................................................ 92

6.4.7 Wizard - Zero Point adjustment ........................................................................................... 100

6.4.8 Changing parameter settings using SIMATIC PDM ............................................................ 102

6.4.9 Parameters accessed via drop-down menus ....................................................................... 103

6.4.10 Zero point adjustment .......................................................................................................... 105

6.4.11 Process variables ................................................................................................................. 107

7.1 Local display (HMI) .............................................................................................................. 109

7.1.1 Display view structure .......................................................................................................... 110

7.1.2 Access control ...................................................................................................................... 115

7.1.3 Operation view ..................................................................................................................... 116

7.1.4 Navigation view .................................................................................................................... 125

7.1.5 Parameter view .................................................................................................................... 127

FC430 with HART

4 Operating Instructions, 05/2015, A5E03361511-AF

Table of contents

8 Functions ............................................................................................................................................ 131

9 Custody Transfer ................................................................................................................................ 161

10 Alarms and system messages ............................................................................................................. 171

11 Service and maintenance .................................................................................................................... 181

8.1 Process values ...................................................................................................................... 131

8.2 Zero point adjustment ........................................................................................................... 134

8.3 Low flow cut-off ..................................................................................................................... 135

8.4 Empty tube monitoring .......................................................................................................... 135

8.5 Process noise damping......................................................................................................... 136

8.6 Inputs and outputs ................................................................................................................ 138

8.6.1 Current output ....................................................................................................................... 139

8.6.2 Pulse output .......................................................................................................................... 144

8.6.3 Frequency output .................................................................................................................. 145

8.6.4 Redundancy mode ................................................................................................................ 146

8.6.5 Status output ......................................................................................................................... 147

8.6.6 Input ...................................................................................................................................... 147

8.7 Totalizers .............................................................................................................................. 148

8.8 Dosing ................................................................................................................................... 149

8.8.1 Dosing control configuration ................................................................................................. 150

8.8.2 Valve control configuration ................................................................................................... 151

8.8.3 Dosing operation ................................................................................................................... 156

8.8.4 F

ault handling ....................................................................................................................... 157

8.9 Audit trail ............................................................................................................................... 157

8.10 Alarm acknowledgement ...................................................................................................... 157

8.11 Custom unit ........................................................................................................................... 158

8.12 SensorFlash .......................................................................................................................... 158

8.13 Simulation ............................................................................................................................. 158

8.14 Maintenance ......................................................................................................................... 160

9.1 Operating conditions ............................................................................................................. 161

9.2 Verification ............................................................................................................................ 161

9.3 Setting up custody transfer mode ......................................................................................... 163

9.4 Parameter protection in custody transfer mode .................................................................... 166

9.5 Disabling custody transfer mode .......................................................................................... 170

10.1 Overview of messages and symbols .................................................................................... 171

10.2 Alarm messages ................................................................................................................... 172

11.1 Maintenance ......................................................................................................................... 181

11.2 Service information ............................................................................................................... 181

11.3 Recalibration ......................................................................................................................... 182

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

5

Table of contents

12 Troubleshooting/FAQs ......................................................................................................................... 187

13 Technical data ..................................................................................................................................... 193

14 Spare parts/Accessories ...................................................................................................................... 217

15 Dimensions and weight ........................................................................................................................ 223

11.4 Technical support ................................................................................................................. 183

11.5 Transportation and storage .................................................................................................. 184

11.6 Cleaning ............................................................................................................................... 184

11.7 Repair ................................................................................................................................... 184

11.8 Return and disposal ............................................................................................................. 185

12.1 Diagnosing with PDM ........................................................................................................... 187

12.2 Troubleshooting sensor-related problems ........................................................................... 187

12.3 How do I copy application setup from one device to another? ............................................ 192

12.4 How do I update the firmware? ............................................................................................ 192

13.1 Function and system design ................................................................................................ 193

13.2 SensorFlash ......................................................................................................................... 193

13.3 Process variables ................................................................................................................. 194

13.4 Bus communication .............................................................................................................. 195

13.5 Performance ......................................................................................................................... 195

13.6 Rated operating conditions .................................................................................................. 196

13.7 Pressure drop curves ........................................................................................................... 197

13.8 Pressure - temperature ratings ............................................................................................ 198

13.9 Design .................................................................................................................................. 201

13.10 Inputs and outputs ............................................................................................................... 203

13.11 Local display (HMI) .............................................................................................................. 205

13.12 Power supply ........................................................................................................................ 205

13.13 Cables and cable entries ..................................................................................................... 205

13.14 Installation torques ............................................................................................................... 207

13.15 Certificates and approvals HART......................................................................................... 209

13.16 PED ...................................................................................................................................... 211

14.1 Ordering ............................................................................................................................... 217

14.2 Ex approved products .......................................................................................................... 217

14.3 Replaceable components .................................................................................................... 218

15.1 Sensor dimensions .............................................................................................................. 223

15.2 Lengths matrix...................................................................................................................... 224

15.3 Transmitter dimensions ........................................................................................................ 229

FC430 with HART

6 Operating Instructions, 05/2015, A5E03361511-AF

Table of contents

A HMI menu structure............................................................................................................................. 231

B HART commands ................................................................................................................................ 257

C Default settings ................................................................................................................................... 259

15.4 Mounting bracket .................................................................................................................. 230

A.1 Main menu ............................................................................................................................ 231

A.2 Menu item 2.1: Basic Settings .............................................................................................. 232

A.3 Menu item 2.2: Process Values ............................................................................................ 233

A.4 Menu item 2.3: Totalizer ....................................................................................................... 235

A.5 Menu item 2.4: Inputs/Outputs .............................................................................................. 236

A.6 Menu item 2.5: Dosing .......................................................................................................... 241

A.7 Menu item 2.6: Zero Point Adjustment ................................................................................. 245

A.8 Menu item 2.7: Safe Operation ............................................................................................. 245

A.9 Menu item 2.8: Display ......................................................................................................... 246

A.10 Menu item 3.1: Identification ................................................................................................. 248

A.11 Menu item 3.2: Alarms .......................................................................................................... 249

A.12 Menu item 3.3: Maintenance ................................................................................................ 250

A.13 Menu item 3.4: Diagnostics .................................................................................................. 251

A.14 Menu item 3.5: Characteristics ............................................................................................. 251

A.15 Menu item 3.6: SensorFlash ................................................................................................. 252

A.16 Menu item 3.7: Simulate ....................................................................................................... 252

A.17 Menu item 3.8: Audit Trail ..................................................................................................... 254

A.18 Menu item 3.9: Aerated Flow ................................................................................................

19 Menu item 3.10: Self Test ..................................................................................................... 255

A.

254

A.20 Menu item 4.6: Mapping of Variables ................................................................................... 255

A.21 Menu item 4.7: HART units ................................................................................................... 255

A.22 Menu item 5.1: Access Management ................................................................................... 256

B.1 Universal commands ............................................................................................................ 257

B.2 Common practice commands ............................................................................................... 257

C.1 Basic Settings ....................................................................................................................... 259

C.2 Process Values ..................................................................................................................... 260

C.3 Totalizer ................................................................................................................................ 270

C.4 Inputs/Outputs ....................................................................................................................... 276

C.5 Dosing ................................................................................................................................... 307

C.6 Zero Point Adjustment .......................................................................................................... 329

C.7 Safe Operation ...................................................................................................................... 330

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

7

Table of contents

D Zero point adjustment .......................................................................................................................... 379

Glossary .............................................................................................................................................. 383

Index ................................................................................................................................................... 385

C.8 Display ................................................................................................................................. 331

C.9 Maintenance & Diagnostics ................................................................................................. 356

C.10 Communication .................................................................................................................... 367

C.11 Security ................................................................................................................................ 372

C.12 Language ............................................................................................................................. 373

C.13 Sensor dimension dependent default settings ..................................................................... 373

FC430 with HART

8 Operating Instructions, 05/2015, A5E03361511-AF

1

1.1

History

Edition

Remarks

EDD version

FW revision

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

03/2012

06/2012

12/2013

The following table shows major changes in the documentation compared to the previous

edition.

• First edition • SIMATIC PDM driver 1.00.00

• CT chapter included • SIMATIC PDM driver 1.00.00 • Standard version:

• Various LUI functions, for

example wizards

• Various transmitter func-

tionalities

• SIMATIC PDM driver 2.00.00-**

• AMS Device Manager 2.00.00-**

• SITRANS DTM 2.00.00-**

• 375 Field Communicator 2.00.00-**

– Compact: 3.00.00-10

– Remote: 2.00.00-30

• CT version:

– Compact: 3.00.00-11

– Remote: 2.00.00-31

• Compact version: 3.02.0*-**

• Remote version: 2.02.0*-**

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

9

Introduction

Edition

Remarks

EDD version

FW revision

1.2

Compatibility

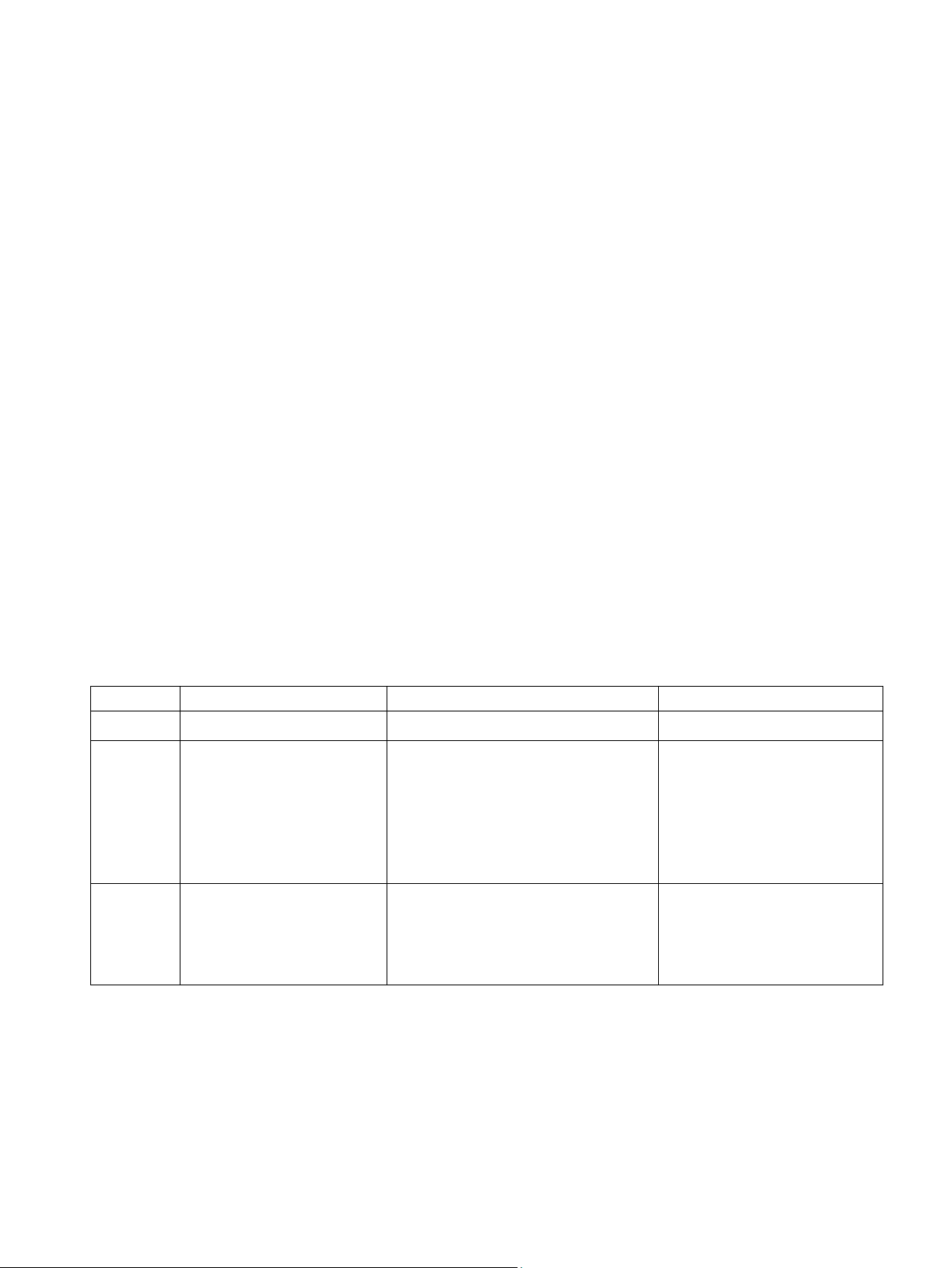

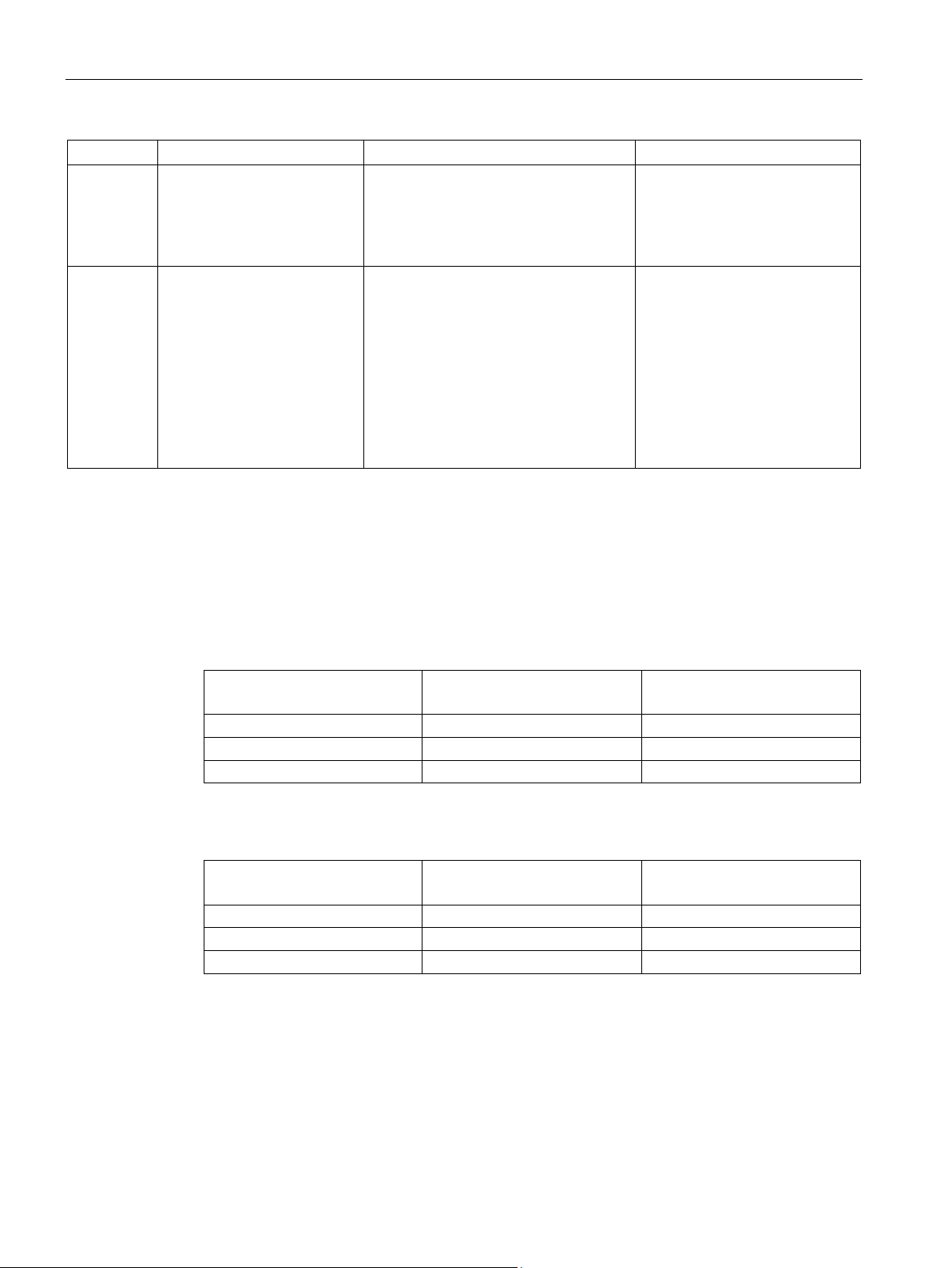

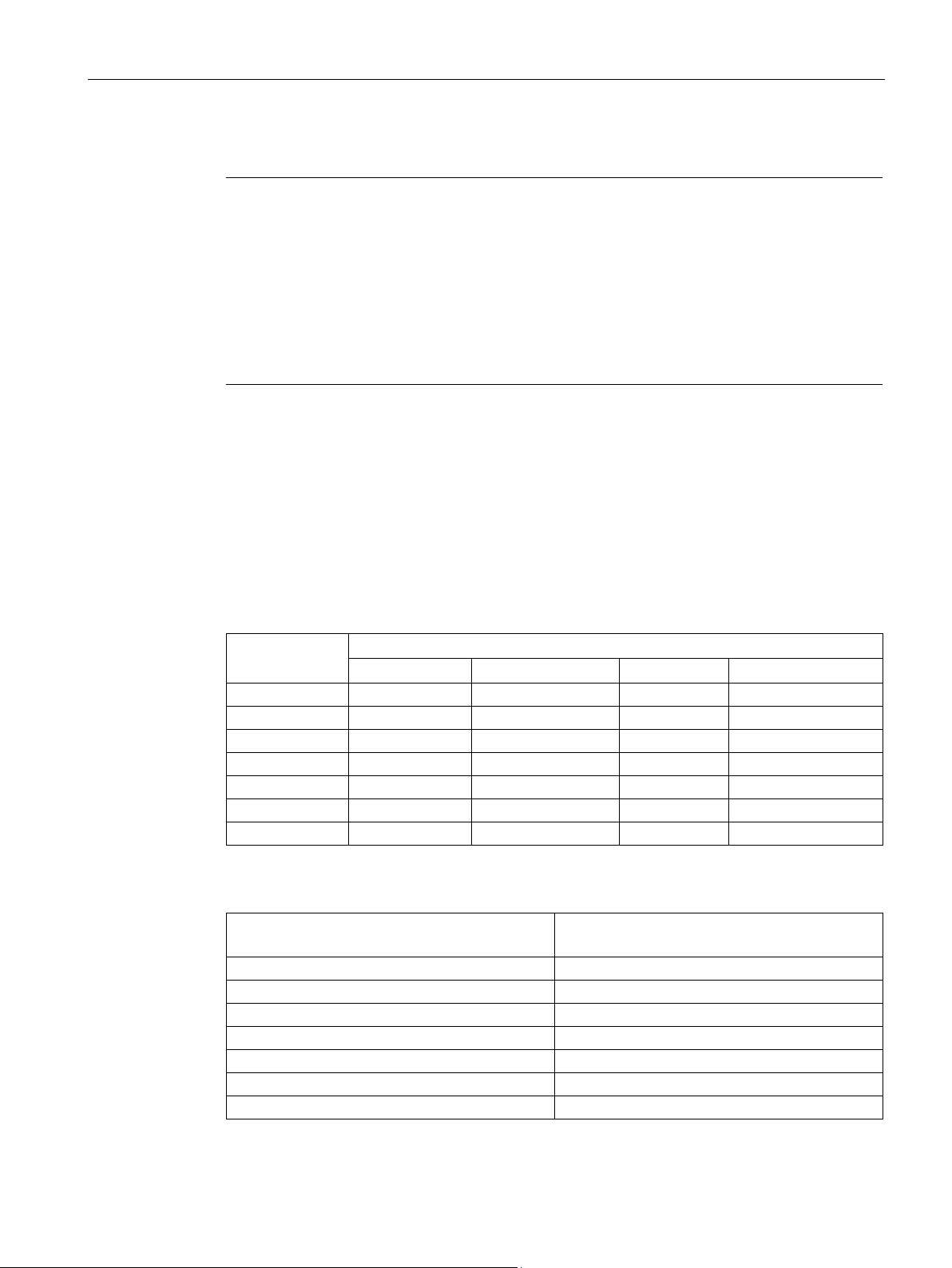

FW/HW revisions and EDD versions compatibility

FW revision

HW revision

HART EDDs

(PDM/AMS/DTM/HCF)

2.00.0x-xx

01

V 1.00.00-xx, Revision 1

2.02.02-xx

02

V 4.00.00-xx, Revision 3

FW revision

HW revision

HART EDDs

(PDM/AMS/DTM/HCF)

3.00.0x-xx

01

V 1.00.00-xx, Revision 1

3.02.00-xx

02

V 2.00.00-xx, Revision 2

02

V 4.00.00-xx, Revision 3

1.2 Compatibility

05/2014

05/2015

• Description of new param-

eters for spare part replacement

• Aerated Flow parameters

added

• SIMATIC PDM driver 3.00.00-**

• AMS Device Manager 3.00.00-**

• SITRANS DTM 3.00.00-**

• 375 Field Communicator 3.00.00-**

• SIMATIC PDM driver HART EDD:

4.00.00-00 **

• SIMATIC PDM driver MODBUS:

4.00.00-00 **

• AMS Device driver HART: 4.00.00-

02 **

• SITRANS DTM HART: 4.00.00-00 **

• 375 Field Communicator HART:

4.00.00-02 **

• Compact version: 3.02.01-**

• Remote version: 2.02.01-**

• Compact version: 3.02.02-01

**

• Remote version: 2.02.02-01

**

Table 1- 1 Remote version

2.02.00-xx 02 V 2.00.00-xx, Revision 2

Table 1- 2 Compact version

3.02.02-xx

FC430 with HART

10 Operating Instructions, 05/2015, A5E03361511-AF

Introduction

1.3

Items supplied

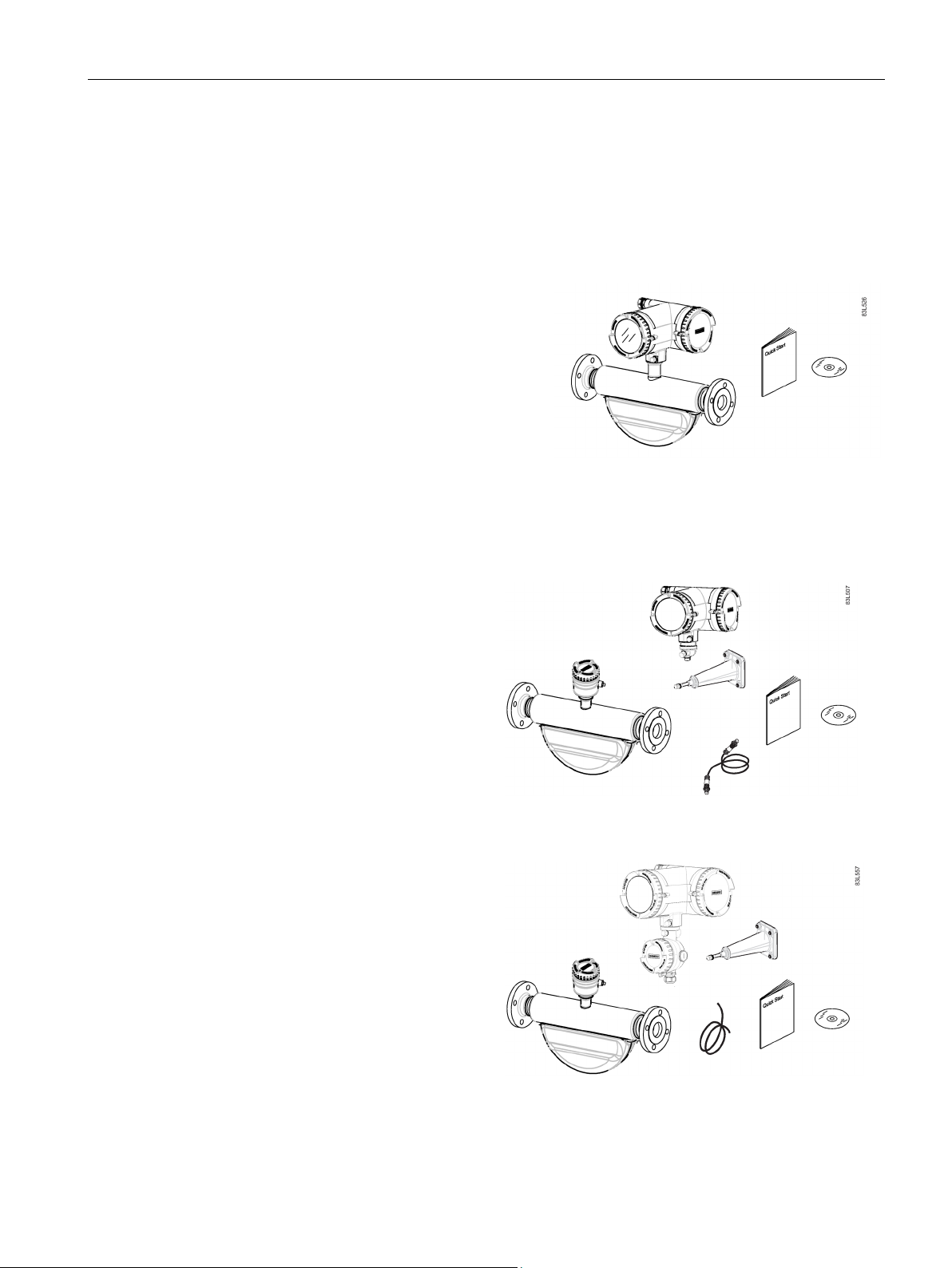

Compact system

•

•

•

•

Remote system

Remote with M12 plug connection

•

•

•

•

•

•

•

Remote with sensor terminal housing

•

•

•

•

•

•

•

1.3 Items supplied

The device can be delivered as either a compact or a remote system.

SITRANS FC430 sensor and compact

mounted transmitter

Packet of cable glands

Quick Start guide

CD containing software, certificates and

device manuals

SITRANS FCS400 sensor

SITRANS FCT030 transmitter with

M12 socket assembled

Mounting bracket and cushion pad

Sensor cable with M12 connector

Packet of cable glands

Quick Start guide

CD containing software, certificates

and device manuals

SITRANS FCS400 sensor

SITRANS FCT030 transmitter with

terminal housing assembled

Mounting bracket and cushion pad

Sensor cable

Packet of cable glands

Quick Start guide

CD containing software, certificates

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

and device manuals

11

Introduction

Note

Supplementary information

Supplementary prod

®

SD card in the transmitter socket.

Note

Scope of delivery may vary, depending on version and add

delivery and the information on the nameplate corres

note.

1.4

Checking the consignment

WARNING

Using a damaged or incomplete device

1.5

Device identification

Note

Identification

Identify your device by comparing your ordering data with the inform

and specification nameplates.

1.4 Checking the consignment

uct and production specific certificates are included on the SensorFlash

-ons. Make sure the scope of

pond to your order and the delivery

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Danger of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

Each part of the FC430 Coriolis flowmeter has three nameplate types showing the following

information:

● product identification

● product specifications

● certificates and approvals

FC430 with HART

12 Operating Instructions, 05/2015, A5E03361511-AF

ation on the product

Introduction

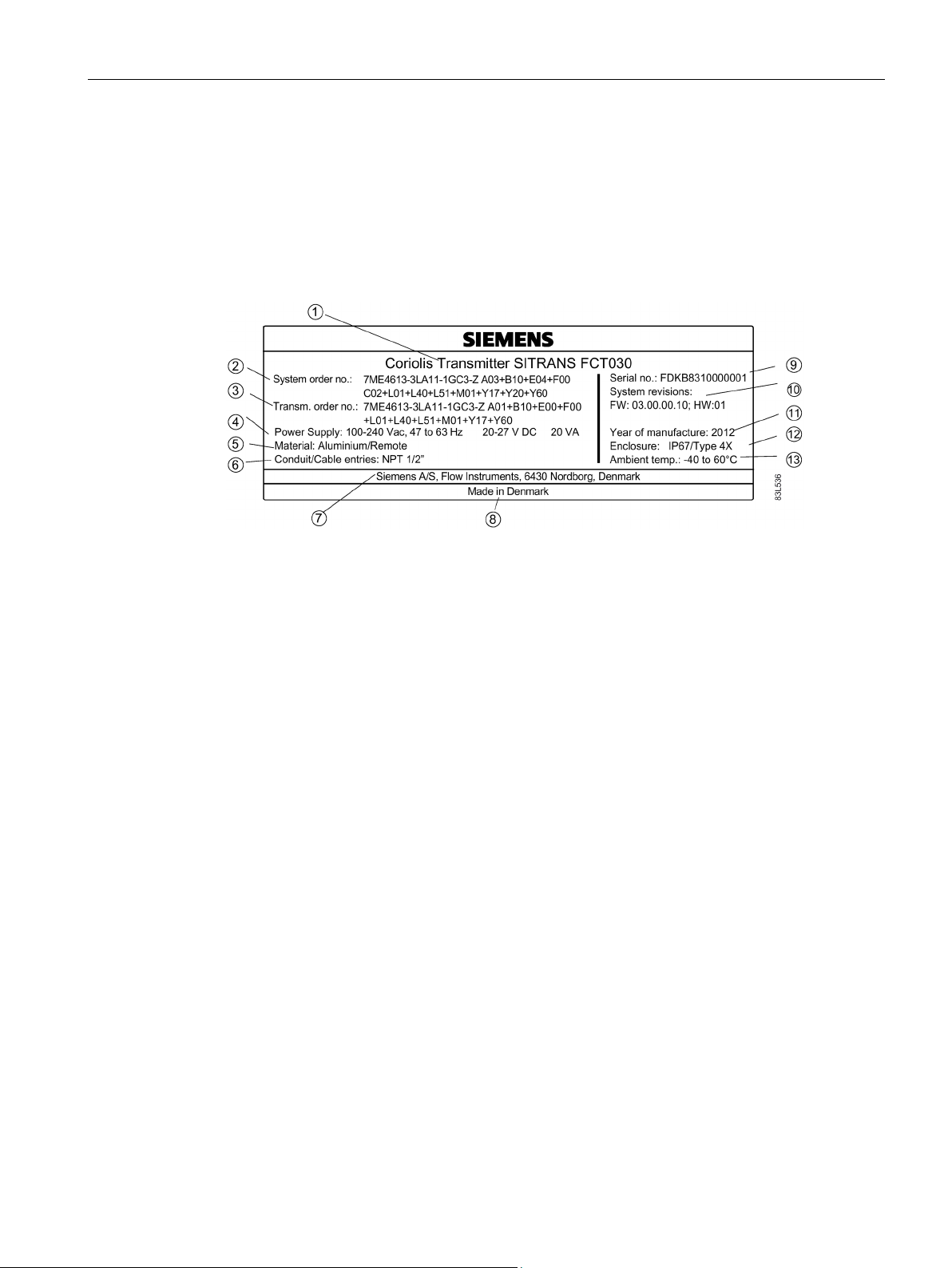

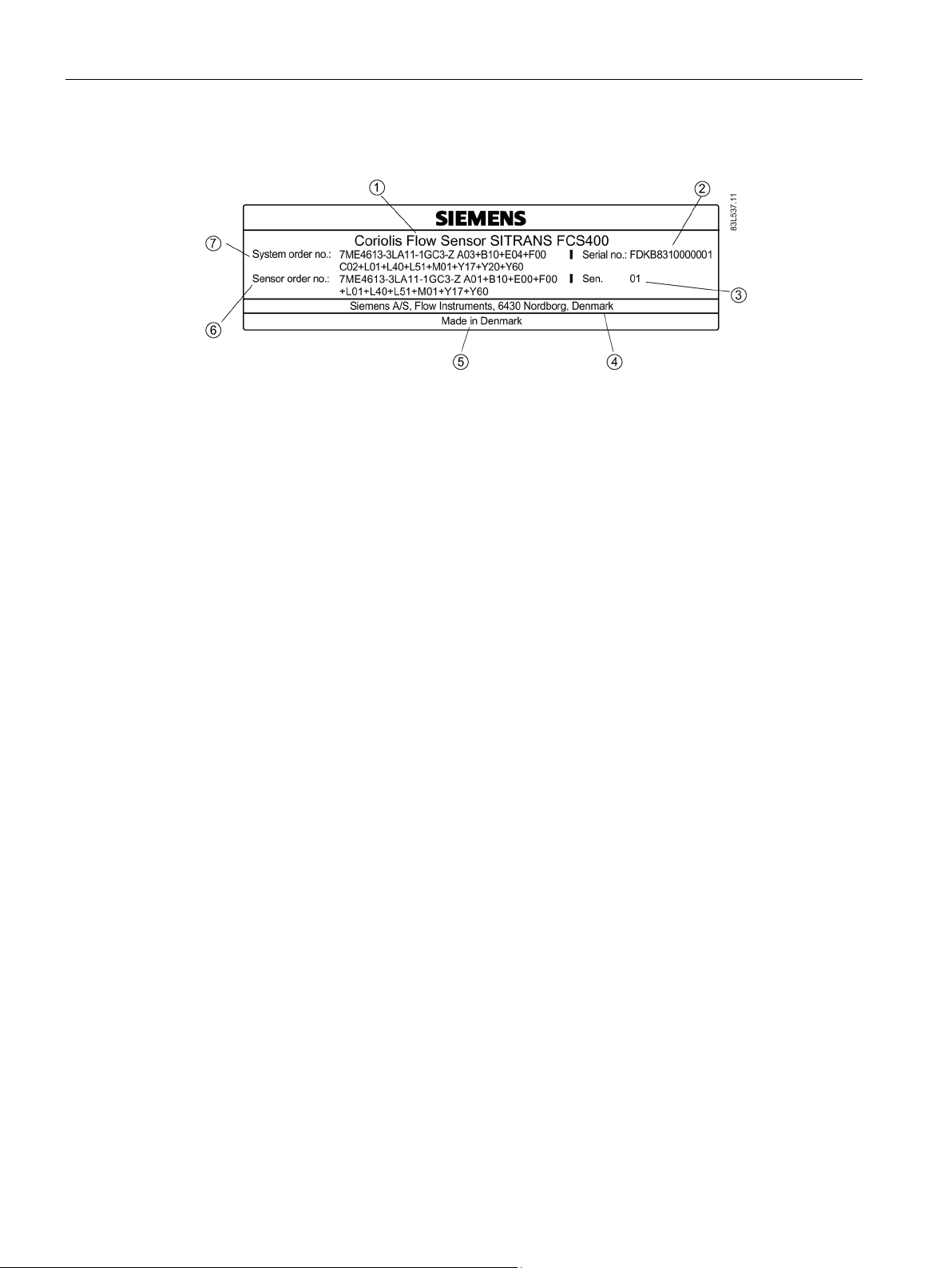

FCT030 transmitter identification nameplate

①

Product name

Transmitter product name

②

System order no.

Device-specific system order number (transmitter and sensor)

③

Transm. order no.

Transmitter replacement order number

④

Power Supply

Power supply

⑤

Material

Transmitter housing material and style (compact/remote)

⑥

Conduit / cable entries

Type of conduit / cable entries

⑦

Manufacturer

Manufacturer name and location

⑧

Country

Manufacturing country

⑨

Serial no.

Transmitter serial number

⑩

System revisions

System revision numbers; firmware (FW) and hardware (HW)

⑪

serial number (see sensor identification nameplate above)

⑫

Enclosure IP

Degree of protection

⑬

Ambient temp.

Ambient temperature

1.5 Device identification

With compact versions, the transmitter and sensor product identifications are both given as

'Coriolis flowmeter SITRANS FC430'.

With remote versions, the transmitter is identified as 'Coriolis transmitter SITRANS FCT030'

and the sensor as 'Coriolis sensor SITRANS FCS400'.

Year of Manufacture Manufacturing year

Figure 1-1 FCT030 identification nameplate example

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

More detailed manufacturing date information is given in the

13

Introduction

FCS400 sensor identification nameplate

①

Product name

Sensor product name

②

Serial no.

Sensor serial number

③

Sen.

Mechanical sensor version number

④

Manufacturer

Manufacturer name and location

⑤

Country

Manufacturing country

⑥

Sensor order no.

Sensor replacement order number

⑦

System order no.

Flowmeter system order number (transmitter and sensor)

Flowmeter serial number construction

Calendar year (Y)

Code

1950, 1970, 1990, 2010

A

1951, 1971, 1991, 2011

B

1952, 1972, 1992, 2012

C

1953, 1973, 1993, 2013

D

1954, 1974, 1994, 2014

E

1955, 1975, 1995, 2015

F

1956, 1976, 1996, 2016

H (G)

1957, 1977, 1997, 2017

J

1958, 1978, 1998, 2018

K

1959, 1979, 1999, 2019

L

1960, 1980, 2000, 2020

M

1.5 Device identification

Figure 1-2 FCS400 identification nameplate example

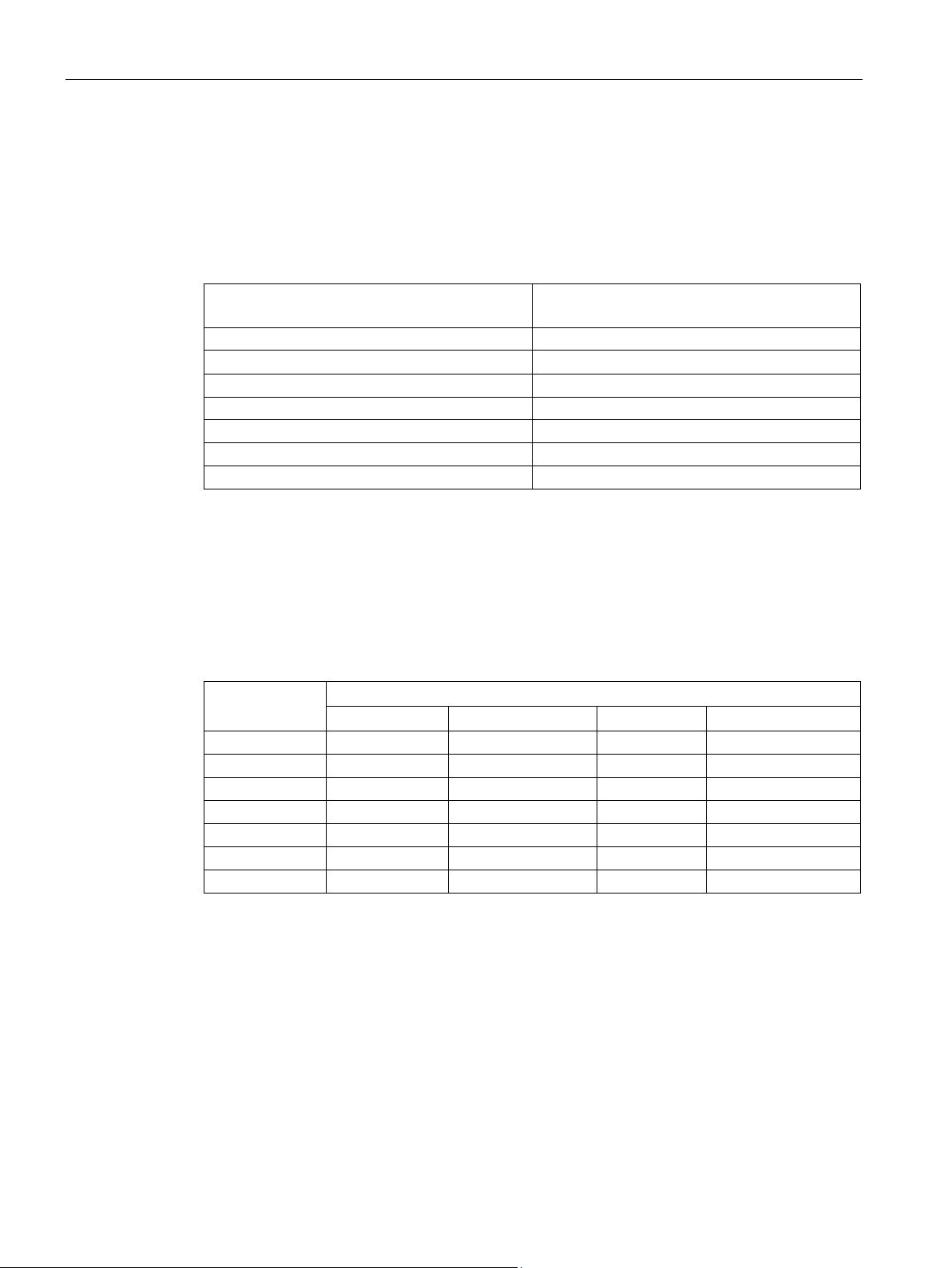

The flowmeter serial number is constructed as follows:

PPPYMDDxxxxxx

where

PPP = Production factory (Siemens Flow Instruments: FDK)

Y = Production year (for encryption, see below)

M = Production month (for encryption, see below)

DD = Production date (for encryption, see below)

xxxxxx = Sequential number

Encryption:

FC430 with HART

14 Operating Instructions, 05/2015, A5E03361511-AF

Introduction

1961, 1981, 2001, 2021

N

1962, 1982, 2002, 2022

P

1963, 1983, 2003, 2023

R

1964, 1984, 2004, 2024

S

1965, 1985, 2005, 2025

T

1966, 1986, 2006, 2026

U

1967, 1987, 2007, 2027

V

1968, 1988, 2008, 2028

W

1969, 1989, 2009, 2029

X

Month (M)

Code

January

1

February

2

March

3

April

4

May

5

June

6

July

7

August

8

September

9

October

O

November

N

December

D

Date (DD)

Code

Day 1 to 31

01 to 31 (corresponding to the actual date)

1.5 Device identification

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

15

Introduction

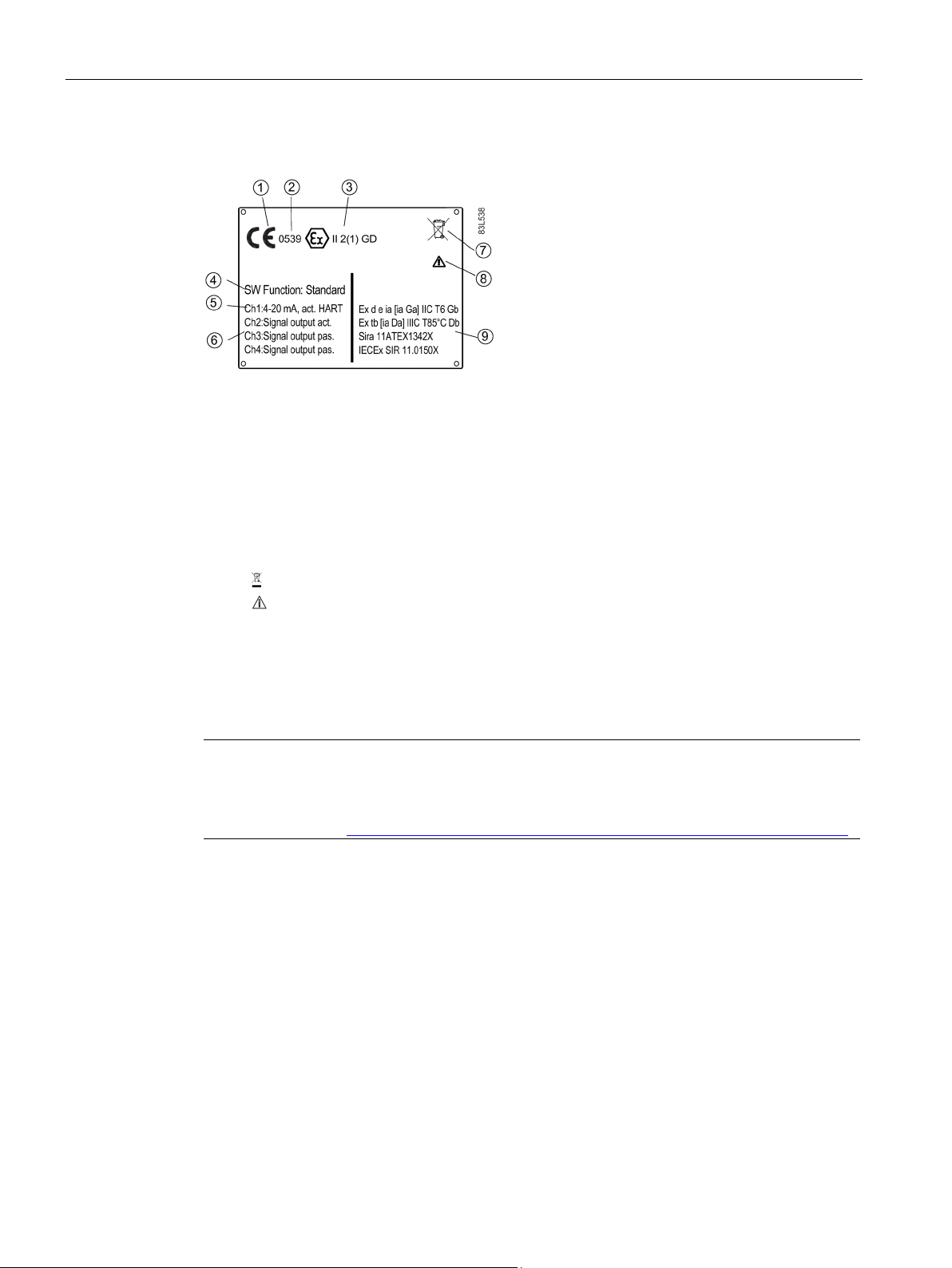

FCT030 transmitter specification nameplate

①

CE

CE mark

②

0539

ATEX Notified Body ID (UL-DEMKO)

③

Ex

Ex mark Installation in hazardous locations (Page 23)

④

SW Function

Software function ("Standard" or "CT standard")

⑤

HART, active or passive)

⑥

Ch4

⑦

WEEE symbol, see Return and disposal (Page 185)

⑧

Consult the operating instructions

⑨

Ex approval specifications for the transmitter (ATEX example; for

(Page 209))

Note

Approval identifications

Approval certificates and notified body identifications are available for download at

www.siemens.com (

1.5 Device identification

Ch1 Communication interface on channel 1 (always 4-20 mA with

Ch2

Ch3

Ex approvals

Figure 1-3 FCT030 specification nameplate example

Input/output setup of channels 2 to 4, if ordered

details on all approvals refer to Certificates and approvals HART

http://support.automation.siemens.com/WW/view/en/60666565/134200).

FC430 with HART

16 Operating Instructions, 05/2015, A5E03361511-AF

Introduction

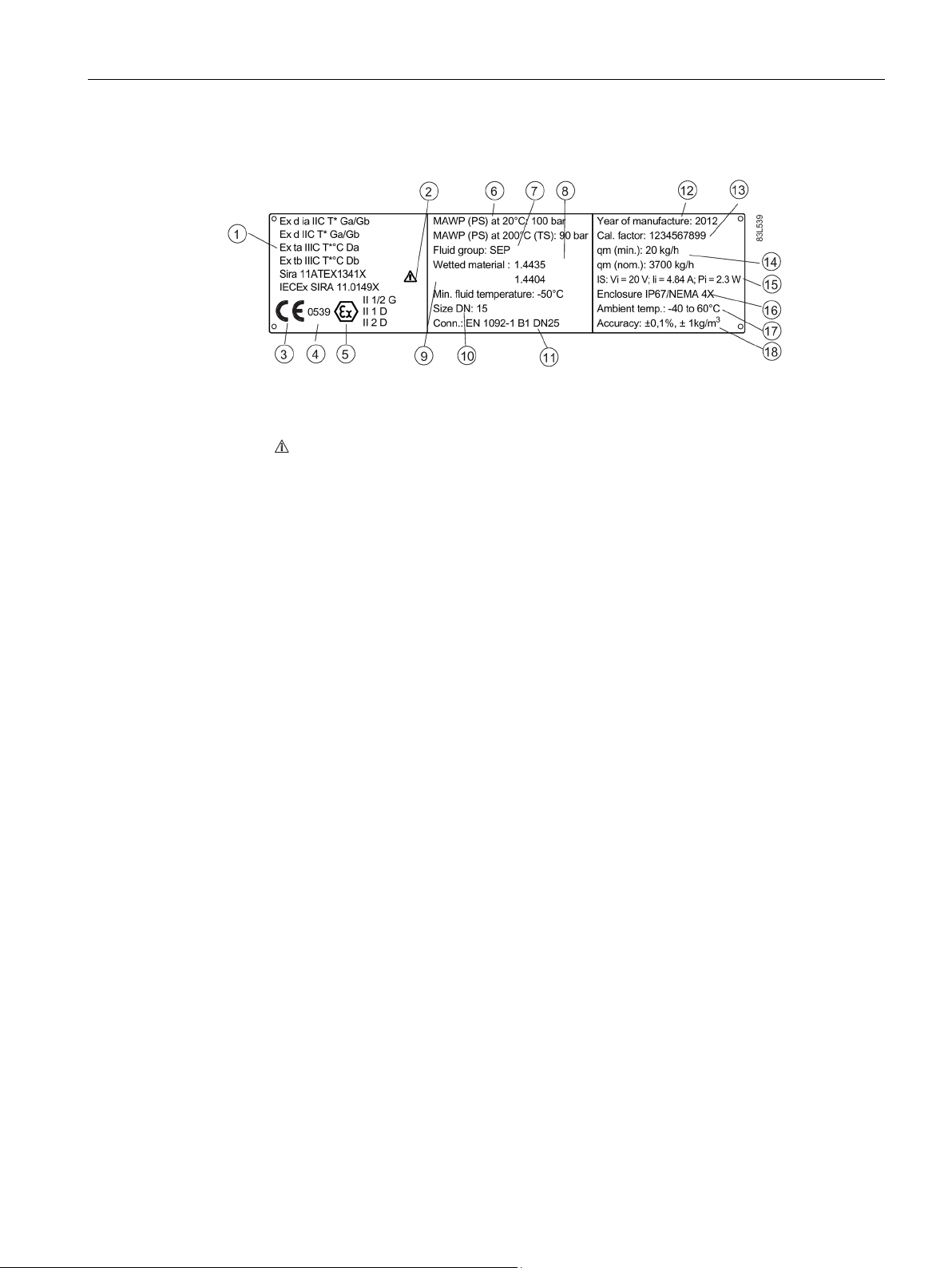

FCS400 sensor specification nameplate

①

(Page 209))

②

Consult the operating instructions

③

CE

CE mark

④

0539

Notified Body ID (ATEX example)

⑤

Ex

Ex mark, Installation in hazardous locations (Page 23)

⑥

°C (392 °F) (max. temperature (TS))

⑦

Fluid group

Fluid group statement required by PED

⑧

Wetted material

Measuring tube/process connection materials

⑨

Min. fluid temperature

Minimum fluid temperature

⑩

Size DN

Nominal size

⑪

Conn.

Process connection type and size

⑫

serial number found on the identification nameplate

⑬

Cal. Factor

Calibration factor

⑭

Qm (nom)

⑮

internal)

⑯

Enclosure IP

Degree of protection

⑰

Ambient Temp.

Ambient temperature range

⑱

Accuracy

Massflow, density calibration accuracy

1.5 Device identification

Ex approvals Ex approval specifications for the sensor (ATEX example; for

details on all approvals refer to Certificates and approvals HART

MAWP Maximum allowable working pressures at 20 °C (68 °F) and 200

Year of Manufacture Manufacturing year

More detailed manufacturing date information is given in the

Qm (min)

Power Supply Power supply (not given on the compact variant because it is

Figure 1-4 FCS400 specification nameplate example

Minimum and nominal massflows with water at 20 °C (68 °F)

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

17

Introduction

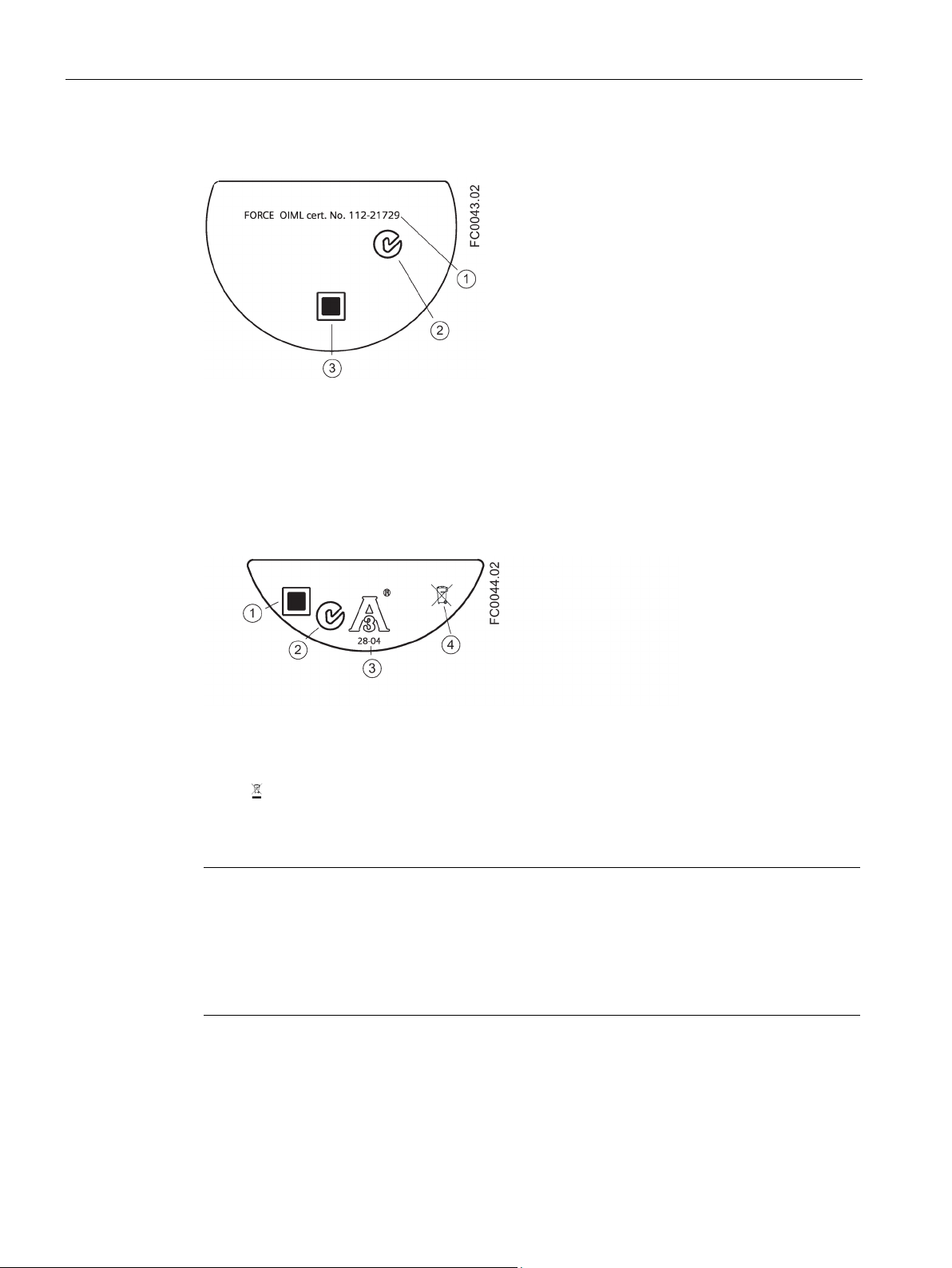

FCT030 transmitter approval nameplate

①

FORCE OIML

Custody Transfer evaluation certificate number

②

C✓

C-tick logo

③

QR code

Product-specific QR code

FCS400 sensor approval nameplate

①

QR code

Product-specific QR code

②

C✓

C-tick logo

③

3A

3A logo

④

WEEE symbol, see Return and disposal (Page 185)

Note

Logos and warnings

Logos and warnings are only shown on the product where applicable. The combination

shown in the example above is relevant for a hygienic sensor installed in hazardous location

in Canada.

The Australian C

1.5 Device identification

Figure 1-5 FCT030 approval nameplate example

Figure 1-6 FCS400 approval nameplate example

-tick mark is mandatory on all products.

FC430 with HART

18 Operating Instructions, 05/2015, A5E03361511-AF

Introduction

FCS400 EHEDG nameplate

Other label

1.6

Further Information

Product information on the Internet

Worldwide contact person

1.6 Further Information

Figure 1-7 EHEDG nameplate

This nameplate appears on all Hygienic sensors 7ME462.

Figure 1-8 How to install

The QR code provides direct internet connection to

● The product support portal, which includes access to the "How to Install" YouTube video.

(This example provides that function.)

● Product and production-specific documentation maintained in the production database.

The Operating Instructions are available on the documentation disk shipped with the device,

and on the Internet on the Siemens homepage, where further information on the range of

SITRANS F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flow

)

If you need more information or have particular problems not covered sufficiently by these

Operating Instructions, get in touch with your contact person. You can find contact

information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

)

19

Introduction

1.6 Further Information

FC430 with HART

20 Operating Instructions, 05/2015, A5E03361511-AF

2

Symbol

Explanation

Note

Functional safety applications (SIL)

In case the device is used in a functional safety application, refer to the functional safety

manual.

2.1

Laws and directives

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Observe the test certification, provisions and laws applicable in your country during

connection, assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

21

Safety notes

Conformity with European directives

Electromagnetic compatibi

ity EMC

2004/108/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC.

Low voltage directive LVD

2006/95/EC

Directive of the European Parliament and of the Council on the

harmonisation of the laws of Member States relating to electr

cal equipment designed for use within certain voltage limits.

Atmosphère explosible

ATEX

94/9/EC

Directive of the European Parliament and the Council on the

approximation of the laws of the Member States concerning

equipment and protective systems intended for use in potentia

ly explosive atmospheres.

Pressure equipment d

rective PED

97/23/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States concerning

pressure equipment.

WARNING

Improper device modifications

Note

CE declaration

The CE declaration certificate is required to be included with each flowmeter. The certificate

is therefore available on the SensorFlash SD card delivered with the device.

2.1 Laws and directives

The CE marking on the device symbolizes the conformity with the following European

directives:

l-

i-

The applicable directives can be found in the EC conformity declaration of the specific

device. Further country or region-specific code conformity information is available on

request.

i-

l-

Danger to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

FC430 with HART

22 Operating Instructions, 05/2015, A5E03361511-AF

Safety notes

2.2

Installation in hazardous locations

WARNING

Equipment used in hazardous locations

Hazardous area approvals

ATEX:

2.2 Installation in hazardous locations

Equipment used in hazardous locations must be Ex-approved for the region of installation

and marked accordingly. It is required that the special conditions for safe use provided in

the manual and in the Ex certificate are followed!

The device is approved for use in hazardous area and has the approvals listed below.

Special conditions for safe installation and operation specified by each approval authority are

included in the relevant certificate.

FCT030 transmitter (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: SIRA 11ATEX1342X

II 2(1) GD

Ex d e [ia Ga] IIC T6 Gb Ta = -40°C to +60°C

Ex tb [ia Da] IIIC T85°C Db

FCS400 sensor + DSL (can be installed in Zone 1 for gas and Zone 20/21 for dust):

Certificate: SIRA 11ATEX1341X

II 1/2 G

1D

2D

For gas:

Ex d ia IIC T* Ga/Gb

Ex d IIC T* Ga/Gb

(Ga/Gb: Zone 20 in pipe and Zone 21 in environment)

For dust:

Ex ta IIIC T* °C Da

Ex tb IIIC T* °C Db

(Zone 20 ("ta") process and ambient temperature limited in comparison with Zone 21 ("tb")

Ta = -40°C to +60°C

* Temperature class (dependent on the process temperature and the ambient temperature")

FC430 compact system (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: SIRA 12ATEX1102X

II 1/2 (1) G

II 2 D

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

23

Safety notes

IECEx:

FM:

Note

Control drawing

*

2.2 Installation in hazardous locations

Ex d e ia [ia GA] IIC T* Ga/Gb Ta = -40°C to ** °C

Ex tb [ia Da] IIIC T**°C Db

(Ga/Gb: Zone 20 in pipe and Zone 21 in environment)

* Temperature class (dependent on the "Maximum Process Temperature")

** Upper ambient temperature (dependent on the "Maximum Process Temperature")

FCT030 transmitter (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: IECEx SIR 11.0150X

Ex d e ia [ia Ga] IIC T6 Gb Ta = -40°C to +60°C.

Ex tb [ia Da] IIIC T85°C Db

FCS400 sensor + DSL (can be installed in Zone 1 for gas and Zone 20/21 for dust):

Certificate: IECEx SIR 11.0149X

For gas:

Ex d ia IIC T* Ga/Gb

Ex d IIC T* Ga/Gb

(Ga/Gb: Zone 20 in pipe and Zone 21 in environment)

For dust:

Ex ta IIIC T* °C Da

Ex tb IIIC T* °C Db

(Zone 20 ("ta") process and ambient temperature limited in comparison with Zone 21 ("tb")

Ta = -40°C to +60°C

* Temperature class (dependent on the process temperature and the ambient temperature")

FC430 compact system (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: IECEx SIR 12.0040X

Ex d e ia [ia Da] IIC Ga/Gb Ta= -40 to ** °C

Ex tb [ia Da] IIIC T ** °C Db

* Temperature class (dependent on the "Maximum Process Temperature")

** Upper ambient temperature (dependent on the "Maximum Process Temperature")

Transmitter (FCT030), Sensor with DSL (FCS400) and Compact (FC430):

Class I Division 1 Groups A,B,C,D T* (XP, IS)

Class II Division 1 Groups E,F,G

Class III Division 1 Group H (granulates)

Class I Zone 1 and Zone 21

Class 1 Zone 1 and Zone 20 (FCS400 remote)

FC430 with HART

24 Operating Instructions, 05/2015, A5E03361511-AF

See Control drawing: A5E31205486A

Safety notes

Installation variations

Note

Requirements for safe installation

•

•

•

•

Maximum temperature specifications for Ex use

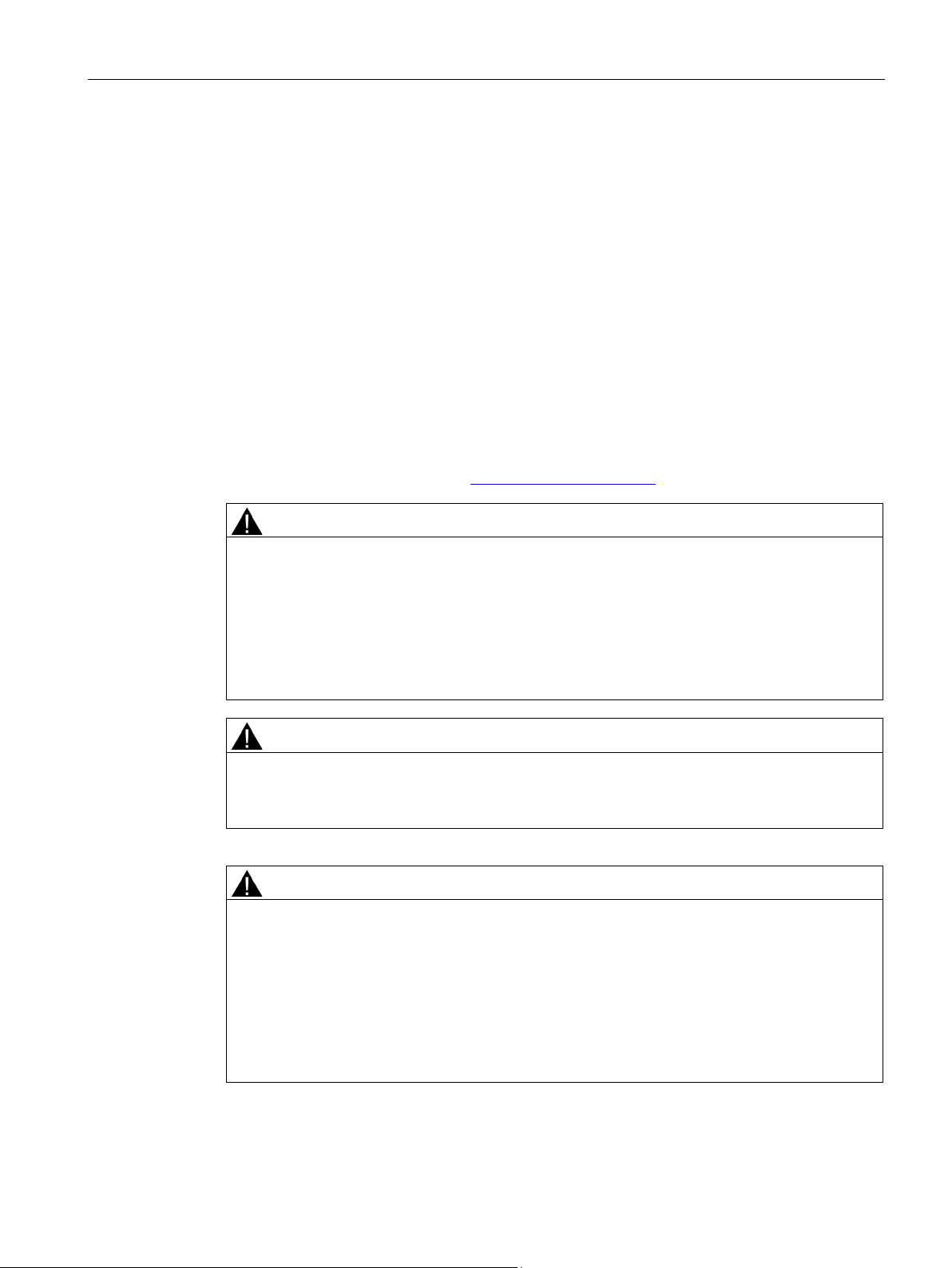

FCS400 remote sensor with DSL

Ta (°C)

Maximum Process Temperature per Temperature Class (°C)

T6

T5

T4

T3

60

70

70

70

70

55

85

100

100

100

50

85

100

130

130

45

85

100

135

160

40

85

100

135

190

35

85

100

135

200

30

85

100

135

200

Ta (°C)

Maximum Process Temperature per Temperature

Class (°C)

60

70

55

100

50

130

45

160

40

190

30

200

2.2 Installation in hazardous locations

Remote sensor FCS400 can be installed in Zone 1, Div. 1 as Intrinsically Safe or

Flameproof.

Standard remote installation with FCT030 because the connection is certified Intrinsically

Safe. however flameproof seals and conduit (for IS cable) can be used.

Requirement for IS circuit is that the maximum input voltage Vi to DSL is 20 VDC, Ii is

maximum 484 mA, Pi < 2.3 W

In Ex d installation Um is 24 VDC

Temperature classification with and without dust is related to the process temperature and

ambient temperature as listed below.

The maximum allowable process fluid temperatures with respect to temperature class for the

device when used with potentially explosive gases in a maximum ambient temperature of

+60°C are:

If the equipment is placed in a "tb" environment (Zone 21), the maximum process

temperatures shall be as follows:

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

35 200

25

Safety notes

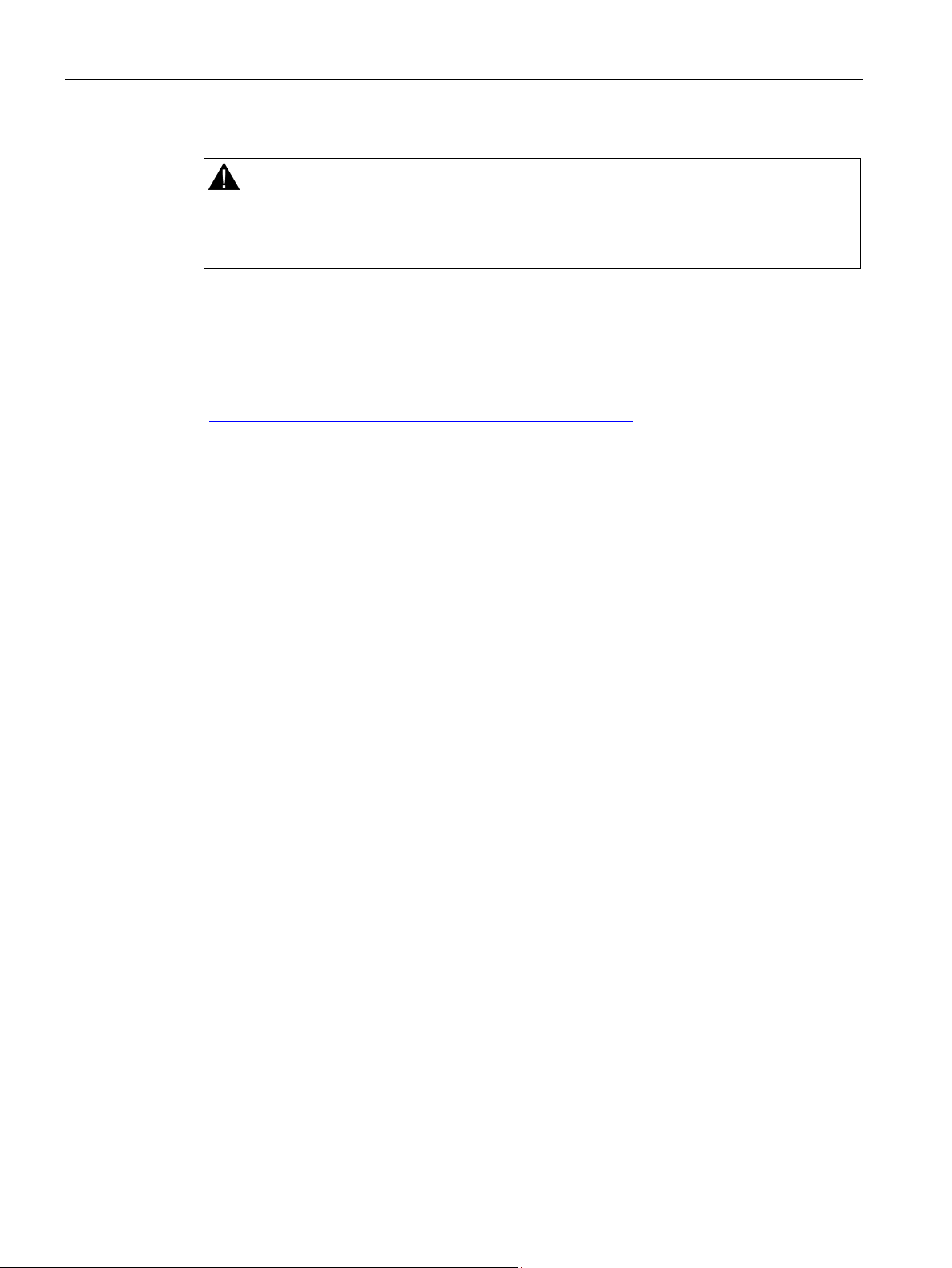

Ta (°C)

Maximum Process Temperature per Temperature

Class (°C)

60

-40

50

20

45

50

40

80

35

110

30

140

FC430 compact flowmeter

Ta (°C)

Maximum Process Temperature per Temperature Class (°C)

T6

T5

T4

T3

60

80

80

80

80

55

85

100

110

110

50

85

100

135

140

45

85

100

135

170

40

85

100

135

200

35

85

100

135

200

30

85

100

135

200

FCT030 remote transmitter

2.2 Installation in hazardous locations

Additionally, the maximum surface temperature of the overall device shall be:

● If Tprocess ≤ 85°C, maximum surface temperature = 85°C.

● If Tprocess > 85°C, maximum surface temperature = process temperature.

If the equipment is placed in a "ta" environment (Zone 20), the maximum process

temperature shall be as follows:

55 -10

Additionally, the maximum surface temperature of the overall device shall be:

● If Tprocess ≤ 85°C, maximum surface temperature = 85°C.

● If Tprocess > 85°C, maximum surface temperature = Tprocess.

Temperature classification with and without dust is related to the process temperature and

ambient temperature as listed below:

In case the equipment is placed in a "tb" environment (Zone 21), the following must be

observed:

● If Tprocess ≤ 85°C, maximum surface temperature = 85°C.

● If Tprocess > 85°C, maximum surface temperature = process temperature.

Temperature classification with and without dust is as follows:

● Potentially explosive gases: T6 (85°C surface temperature)

● Dust environment (Zone 21): T85°C

FC430 with HART

26 Operating Instructions, 05/2015, A5E03361511-AF

Safety notes

Special conditions for safe use

WARNING

Laying of cables

Explosion hazard

WARNING

Field wiring installation

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

2.2 Installation in hazardous locations

In general, it is required that:

● The transmitter electronic space shall not be opened when energized and when an

explosive gas or dust atmosphere may be present.

● The terminal space may be opened when an explosive gas or dust atmosphere may be

present at any time. Access power terminals by lifting the cover only when de-energized.

● Appropriate cable connectors are used.

● Substitution of components may impair Intrinsic Safety.

● Sensor and transmitter are connected to the potential equalization throughout the

hazardous area.

● EN/IEC 60079-14 is considered for installation in hazardous areas.

Further information and instructions including approval-specific special conditions for safe

use in Ex applications can be found in the certificates on the accompanying literature CD

and at www.siemens.com/FC430 (www.siemens.com/FC430

).

Cable for use in hazardous locations must satisfy the requirements for having a proof

voltage of at least 500 V AC applied between the conductor/ground, conductor/shield and

shield/ground.

Connect the devices that are operated in hazardous areas as per the stipulations applicable

in the country of operation.

Ensure that the national requirements of the country in which the devices are installed are

met.

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a danger of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and/or in Chapter

"Technical data (Page 193)".

FC430 with HART

Operating Instructions, 05/2015, A5E03361511-AF

27

Safety notes

WARNING

Signal wiring

2.3

Certificates

2.3 Certificates

Input/output connections to the transmitter are required to be protected by intrinsic safe

barriers at all times.

Certificates are posted on the online support portal

(http://www.siemens.com/processinstrumentation/certificates

documentation disk shipped with the device.

Certification documents including calibration report are supplied with each sensor included

on the SensorFlash. Material, pressure test, and factory conformance certificates are

optional at ordering.

) and can also be found on the

FC430 with HART

28 Operating Instructions, 05/2015, A5E03361511-AF

Loading...

Loading...