Siemens SITRANS FC330 Operating Instructions Manual

SITRANS F

Coriolis Flowmeters

SITRANS FC330

7ME4633 (SITRANS FC330)

Introduction

1

Operating Instructions

Safety notes

Description

Installing/mounting

Connecting

Commissioning

Operating

Parameter assignment

2

3

4

5

6

7

8

Service and maintenance

Diagnostics and

troubleshooting

Technical data

Dimension drawings

Technical reference

HART communication

HMI menu structure

9

10

11

12

A

B

C

01/2019

A5E44030648-AB

Zero point adjustment

Certificates and support

D

E

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E44030648

Ⓟ 02/2019 Subject to change

Copyright © Siemens AG 2019.

All rights reserved

Table of contents

1 Introduction...................................................................................................................................................9

1.1 Purpose of this documentation.................................................................................................9

1.2 Document history .....................................................................................................................9

1.3 Product compatibility ..............................................................................................................10

1.4 Items supplied ........................................................................................................................10

1.5 Checking the consignment.....................................................................................................12

1.6 Security information ...............................................................................................................12

1.7 Transportation and storage ....................................................................................................13

1.8 Notes on warranty ..................................................................................................................13

2 Safety notes................................................................................................................................................15

2.1 Preconditions for use .............................................................................................................15

2.2 Laws and directives................................................................................................................15

2.2.1 FCC Conformity .....................................................................................................................16

2.2.2 Conformity with European directives......................................................................................16

2.3 Requirements for special applications ...................................................................................17

2.4 Use in hazardous areas .........................................................................................................17

2.4.1 Installation in hazardous areas ..............................................................................................19

2.4.2 Maximum temperature specifications for use in hazardous areas .........................................20

3 Description..................................................................................................................................................21

3.1 Overview ................................................................................................................................21

3.2 Design ....................................................................................................................................22

3.2.1 Versions .................................................................................................................................22

3.2.2 Sensor design ........................................................................................................................23

3.2.3 Transmitter design .................................................................................................................24

3.2.4 Wall mount housing transmitter exploded view......................................................................26

3.3 Device identification ...............................................................................................................27

3.4 Approvals ...............................................................................................................................32

3.5 Features .................................................................................................................................33

3.6 Applications............................................................................................................................35

4 Installing/mounting......................................................................................................................................37

4.1 Basic safety notes ..................................................................................................................37

4.1.1 Installation location requirements...........................................................................................39

4.1.2 Proper mounting.....................................................................................................................40

4.2 Installation instructions...........................................................................................................41

4.2.1 Transmitter installation ...........................................................................................................41

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 3

Table of contents

4.2.1.1 Remote field mount ................................................................................................................41

4.2.1.2 Wall mount housing................................................................................................................42

4.2.1.3 Turning the transmitter (compact version) .............................................................................45

4.2.1.4 Turning the transmitter (remote version)................................................................................46

4.2.1.5 Turning the local display ........................................................................................................48

4.2.2 Sensor installation..................................................................................................................49

4.2.2.1 Determining a location ..........................................................................................................49

4.2.2.2 Orientation of the sensor........................................................................................................50

4.2.2.3 Installation in a drop line ........................................................................................................52

4.2.2.4 Mounting the sensor...............................................................................................................52

4.2.2.5 Hydrostatic testing..................................................................................................................54

4.2.2.6 Installing with insulation .........................................................................................................54

4.3 Disassembly...........................................................................................................................55

5 Connecting .................................................................................................................................................57

5.1 Basic safety notes ..................................................................................................................57

5.2 Connecting FC330 .................................................................................................................60

5.2.1 Cable requirements................................................................................................................61

5.2.2 Transmitter power supply and I/Os connection......................................................................62

5.2.2.1 Connecting the DSL and the transmitter ................................................................................62

5.2.2.2 Preparing for the transmitter connections ..............................................................................65

5.2.2.3 Connecting the Current HART, CH1 ......................................................................................67

5.2.2.4 Connecting the Modbus (CH1)...............................................................................................69

5.2.2.5 Connecting the Profibus (CH1) ..............................................................................................71

5.2.2.6 Connecting channels 2 to 4....................................................................................................72

5.2.2.7 Input/output configuration.......................................................................................................74

5.2.2.8 Connecting the power supply - Field mount...........................................................................75

5.2.2.9 Connecting the power supply - Wall mount............................................................................77

5.2.2.10 Finishing the transmitter connection ......................................................................................78

5.3 Instructions specific to hazardous area installations ..............................................................79

5.3.1 Wiring in hazardous areas .....................................................................................................79

6 Commissioning ...........................................................................................................................................81

6.1 Basic safety notes ..................................................................................................................81

6.1.1 Warnings ................................................................................................................................83

6.2 General requirements ............................................................................................................84

6.3 Local commissioning via HMI.................................................................................................84

6.3.1 Local display ..........................................................................................................................84

6.3.2 Wizard introduction ................................................................................................................85

6.3.3 Initial startup...........................................................................................................................85

6.3.4 Zero point adjustment ............................................................................................................86

6.3.5 Wizards ..................................................................................................................................88

6.3.5.1 Quick commissioning wizard (menu item 1.1)........................................................................88

6.3.5.2 Zero point adjustment wizard (menu item 1.2).......................................................................90

6.3.5.3 Process values wizard (menu item 1.3) .................................................................................92

6.3.5.4 Inputs and outputs wizard (menu item 1.4) ............................................................................94

6.3.5.5 Gas application wizard (menu item 1.5).................................................................................99

6.3.5.6 Pulsating flow wizard (menu item 1.6) .................................................................................100

6.3.5.7 Dosing application wizard (menu item 1.7) ..........................................................................101

SITRANS FC330

4 Operating Instructions, 01/2019, A5E44030648-AB

Table of contents

6.4 Remote commissioning with PDM .......................................................................................102

7 Operating..................................................................................................................................................103

7.1 Local operation (HMI)...........................................................................................................103

7.1.1 Display view structure ..........................................................................................................104

7.1.2 Access control......................................................................................................................109

7.1.3 Operation view .....................................................................................................................110

7.1.4 Measurement views .............................................................................................................111

7.1.5 Operating views ...................................................................................................................114

7.1.6 Alarm views..........................................................................................................................115

7.1.7 Diagnostic views ..................................................................................................................117

7.1.8 Navigation view ....................................................................................................................117

7.1.9 Parameter view ....................................................................................................................119

7.2 Remote operation.................................................................................................................123

7.2.1 Overview of device configuration software...........................................................................123

7.2.2 SIMATIC PDM......................................................................................................................123

8 Parameter assignment .............................................................................................................................127

8.1 Upper scaling settings..........................................................................................................127

8.2 Functions..............................................................................................................................127

8.2.1 Process values.....................................................................................................................127

8.2.2 Zero point adjustment ..........................................................................................................131

8.2.3 Low flow cut-off ....................................................................................................................132

8.2.4 Empty tube monitoring .........................................................................................................132

8.2.5 Process noise damping........................................................................................................133

8.2.6 Inputs and outputs................................................................................................................134

8.2.6.1 Current output ......................................................................................................................135

8.2.6.2 Pulse output .........................................................................................................................140

8.2.6.3 Frequency output .................................................................................................................141

8.2.6.4 Redundancy mode (frequency)............................................................................................142

8.2.6.5 Digital output ........................................................................................................................144

8.2.6.6 Input .....................................................................................................................................144

8.2.7 Totalizers..............................................................................................................................145

8.2.8 Dosing ..................................................................................................................................145

8.2.8.1 Dosing control configuration.................................................................................................147

8.2.8.2 Valve control configuration...................................................................................................148

8.2.8.3 Dosing operation ..................................................................................................................153

8.2.8.4 Fault handling.......................................................................................................................153

8.2.9 Audit trail logging..................................................................................................................154

8.2.10 Diagnostic log.......................................................................................................................154

8.2.11 Custom unit ..........................................................................................................................155

8.2.12 SensorFlash .........................................................................................................................155

8.2.13 Datalogging on SensorFlash................................................................................................156

8.2.14 Process peak values on SensorFlash..................................................................................156

8.2.15 Simulation ............................................................................................................................156

8.2.16 Maintenance.........................................................................................................................157

9 Service and maintenance .........................................................................................................................159

9.1 Basic safety notes ................................................................................................................159

9.2 Recalibration ........................................................................................................................160

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 5

Table of contents

9.3 Cleaning ...............................................................................................................................160

9.4 Maintenance and repair work...............................................................................................161

9.4.1 Service information ..............................................................................................................164

9.5 Replacing the device............................................................................................................165

9.6 Ordering of spare parts ........................................................................................................165

9.7 Return procedure .................................................................................................................165

9.8 Disposal ...............................................................................................................................166

9.9 Ex-approved products ..........................................................................................................166

10 Diagnostics and troubleshooting ..............................................................................................................167

10.1 Device status symbols .........................................................................................................167

10.2 Fault codes and corrective actions.......................................................................................171

10.2.1 Sensor diagnostics...............................................................................................................171

10.2.2 Transmitter diagnostics ........................................................................................................176

10.3 Operation troubleshooting....................................................................................................189

10.3.1 Copying the application setup from one device to another ..................................................189

10.3.2 Updating the firmware ..........................................................................................................189

10.3.3 Troubleshooting sensor-related problems............................................................................190

11 Technical data ..........................................................................................................................................195

11.1 Power ...................................................................................................................................195

11.2 Performance.........................................................................................................................195

11.3 Interface ...............................................................................................................................197

11.3.1 Modbus interface..................................................................................................................197

11.3.2 HART interface.....................................................................................................................197

11.4 Inputs ...................................................................................................................................198

11.5 Outputs.................................................................................................................................198

11.6 Construction .........................................................................................................................200

11.6.1 Sensor design ......................................................................................................................201

11.6.2 Sensor cable specifications HART.......................................................................................202

11.7 Operating conditions ............................................................................................................204

11.8 Process variables.................................................................................................................205

11.9 Bus communication..............................................................................................................205

11.10 Certificates and approvals....................................................................................................206

11.11 SensorFlash .........................................................................................................................206

11.12 PED......................................................................................................................................207

11.13 Pressure - temperature ratings ............................................................................................211

11.13.1 Pressure - temperature ratings (stainless steel sensors) .....................................................212

11.13.2 Pressure - temperature ratings (nickel alloy sensors) ..........................................................214

12 Dimension drawings .................................................................................................................................217

12.1 Sensor dimensions...............................................................................................................217

SITRANS FC330

6 Operating Instructions, 01/2019, A5E44030648-AB

Table of contents

12.2 316L stainless steel - standard ............................................................................................218

12.3 316L stainless steel polished - hygienic versions ................................................................219

12.4 Nickel alloy ...........................................................................................................................220

12.5 Transmitter dimensions........................................................................................................221

12.6 Wall mount enclosure dimensions .......................................................................................222

12.7 Mounting bracket dimensions ..............................................................................................223

A Technical reference ..................................................................................................................................225

A.1 Theory of operation ..............................................................................................................225

A.2 Sensor dimension dependent default settings .....................................................................226

A.2.1 Mass flow: Sensor dimension dependent default settings (Process values) .......................226

A.2.2 Standard volume flow: Sensor dimension dependent default settings (Process values).....228

A.2.3 Volume flow: Sensor dimension dependent default settings (Process values)....................229

A.2.4 Fraction: Sensor dimension dependent default settings (Process values) ..........................231

A.2.5 Zero point adjustment: Sensor dimension dependent default settings (Process values).....233

B HART communication...............................................................................................................................235

B.1 Mode of operation HART function........................................................................................235

C HMI menu structure ..................................................................................................................................237

C.1 Main menu ...........................................................................................................................237

C.2 Menu item 2.1: Sensor.........................................................................................................239

C.3 Menu item 2.2: Process values............................................................................................239

C.4 Menu item 2.3: Totalizers.....................................................................................................243

C.5 Menu item 2.4: Inputs and outputs.......................................................................................244

C.6 Menu item 2.5: Dosing .........................................................................................................251

C.7 Menu item 2.7: Date and time..............................................................................................256

C.8 Menu item 2.8: Local display................................................................................................257

C.9 Menu item 3.1: Identification ................................................................................................259

C.10 Menu item 3.2: Diagnostic events ........................................................................................260

C.11 Menu item 3.3: Maintenance................................................................................................261

C.12 Menu item 3.4: Diagnostics..................................................................................................261

C.13 Menu item 3.5: Peak values.................................................................................................263

C.14 Menu item 3.6: Characteristics.............................................................................................263

C.15 Menu item 3.7: SensorFlash ................................................................................................264

C.16 Menu item 3.8: Simulation....................................................................................................265

C.17 Menu item 3.9: Audit trail .....................................................................................................266

C.18 Menu item 3.10: Self test .....................................................................................................266

C.19 Menu item 3.11: Resets .......................................................................................................267

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 7

Table of contents

C.20 Menu item 3.12: Firmware update .......................................................................................267

C.21 Menu item 4: Communication ..............................................................................................267

C.22 Menu item 5: Security ..........................................................................................................270

D Zero point adjustment ...............................................................................................................................271

E Certificates and support............................................................................................................................275

E.1 Certificates ...........................................................................................................................275

E.2 QR code label ......................................................................................................................275

E.3 Technical support.................................................................................................................275

Index.........................................................................................................................................................277

SITRANS FC330

8 Operating Instructions, 01/2019, A5E44030648-AB

Introduction

This document is delivered as standard in electronic media with the device. The latest version

can be downloaded at www.siemens.com (www.siemens.com).

1.1 Purpose of this documentation

These instructions contain all information required to commission and use the device. Read the

instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

See also

Certificates (Page 275)

Technical support (Page 275)

QR code label (Page 275)

1

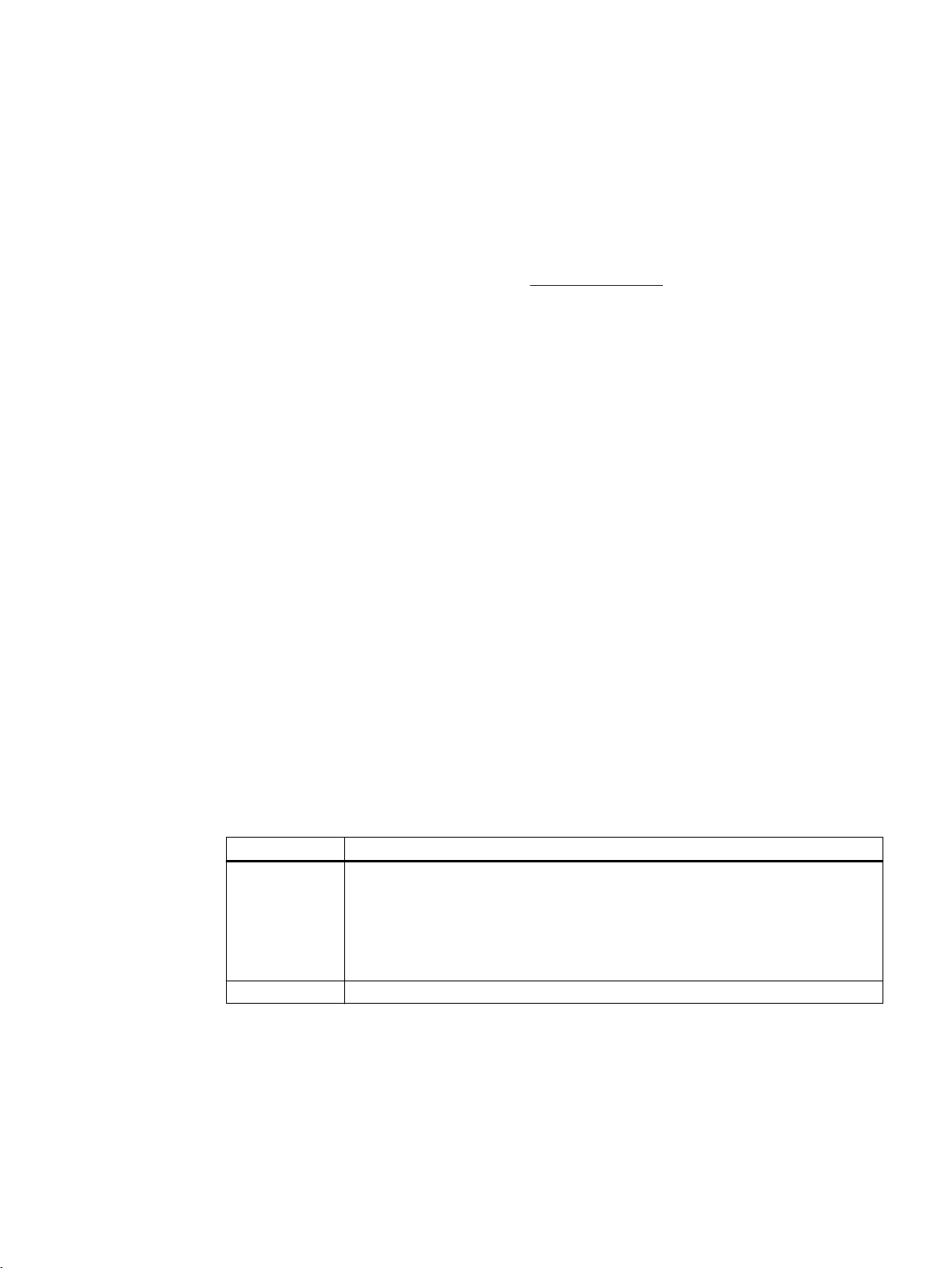

1.2 Document history

The following table shows major changes in the documentation compared to the previous

edition.

The most important changes in the documentation when compared with the respective

previous edition are given in the following table.

Edition Note

01/2019 Second edition

● Chapter Technical data (Page 195) updated

● Chapter Diagnostics and troubleshooting (Page 167) updated

● Appendix HMI menu structure (Page 237) updated

● Overall revision of chapters and contents

06/2018 First edition

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 9

Introduction

1.4 Items supplied

NOTICE

Use in a domestic environment

This Class A Group 1 equipment is intended for use in industrial areas.

In a domestic environment this device may cause radio interference.

1.3 Product compatibility

Edition Remarks Product compatibility Compatibility of device integration package

01/2019 Manual con‐

tent updated

06/2018 New hardware

New sensor

sizes

HW revision 03

Compact FW revision 4.xx.xx-xx

Remote FW revision 4.xx.xx-xx

HW revision 03

Compact FW revision 4.xx.xx-xx

Remote FW revision 4.xx.xx-xx

Service channel: SIMATIC

V8.2 Service Pack 1 or later

Modbus: SIMATIC V8.2 Serv‐

ice Pack 1 or later

HART: SIMATIC V8.2 Serv‐

ice Pack 1 or later

HART: SITRANS DTM V4.1 5.00.xx-xx

HART: AMS Device manager

V12

PROFIBUS: SIMATIC V8.2

Service Pack 1 or later

PROFIBUS: AMS Device

manager V12

PROFIBUS : SITRANS DTM

V4.1

Service channel: SIMATIC

V8.2 Service Pack 1 or later

Modbus: SIMATIC V8.2 Serv‐

ice Pack 1 or later

HART: SIMATIC V8.2 Serv‐

ice Pack 1 or later

HART: SITRANS DTM V4.1 5.00.xx-xx

HART: AMS Device manager

V12

PROFIBUS: SIMATIC V8.2

Service Pack 1 or later

PROFIBUS: AMS Device

manager V12

PROFIBUS : SITRANS DTM

V4.1

5.00.xx-xx

5.00.xx-xx

5.00.xx-xx

5.00.xx-xx

1.00.xx-xx

1.00.xx-xx

1.00.xx-xx

5.00.xx-xx

5.00.xx-xx

5.00.xx-xx

5.00.xx-xx

1.00.xx-xx

1.00.xx-xx

1.00.xx-xx

1.4 Items supplied

The device can be delivered as either a compact or a remote system.

SITRANS FC330

10 Operating Instructions, 01/2019, A5E44030648-AB

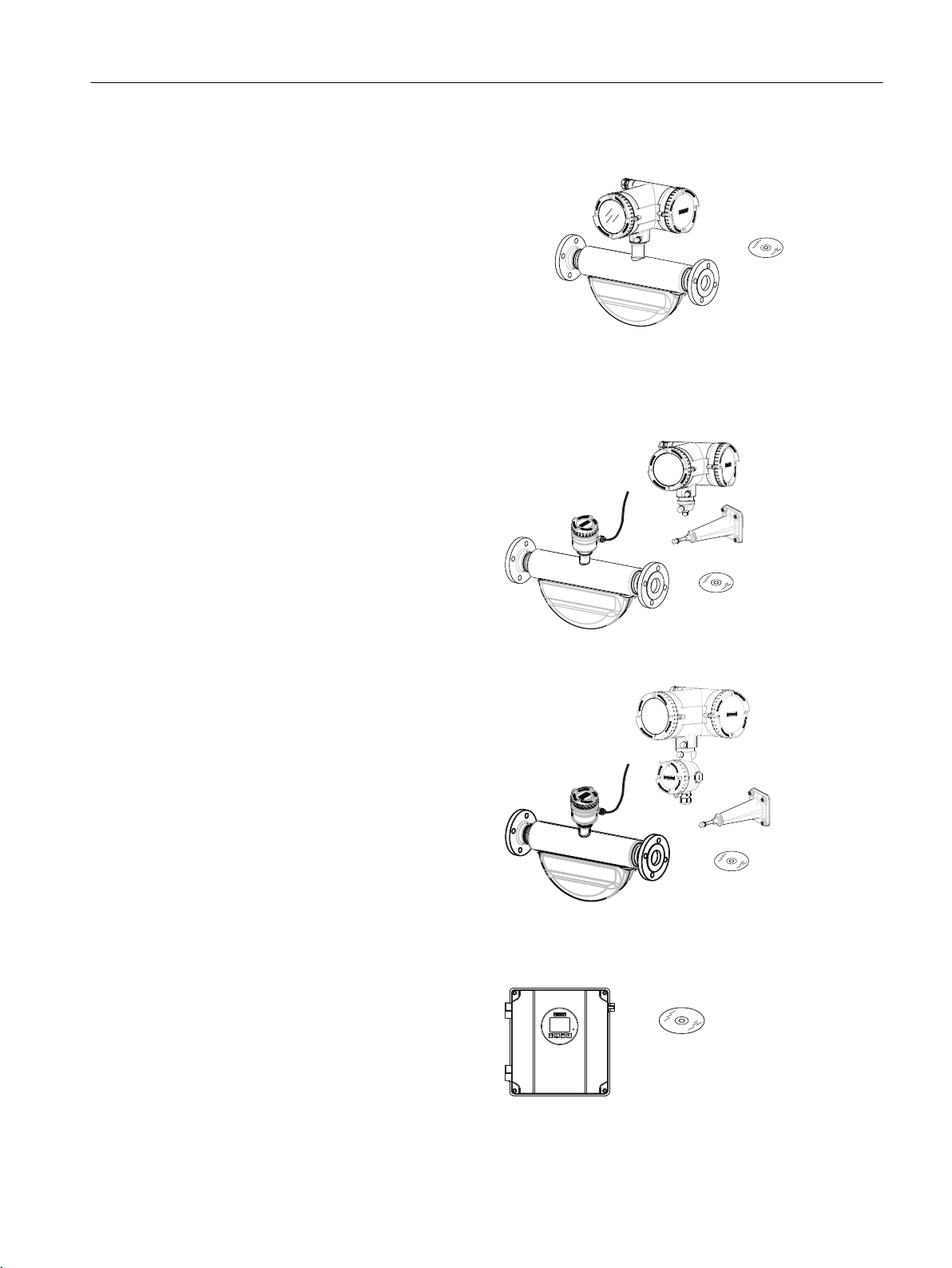

Compact system

● SITRANS FC330 sensor and compact

● DVD containing software, certificates and

Field mount system

Remote with M12 plug connection

● SITRANS FCS300 sensor

● SITRANS FCT030 transmitter with

● Mounting bracket and cushion pad

● Sensor cable

● DVD containing software,

Introduction

1.4 Items supplied

mounted transmitter

device manuals

M12 socket assembled

certificates and device manuals

Remote with sensor terminal housing

● SITRANS FCS300 sensor

● SITRANS FCT030 transmitter with

terminal housing assembled

● Mounting bracket and cushion pad

● Sensor cable

● DVD containing software,

certificates and device manuals

Wall mount housing transmitter

● SITRANS FCT030 wall mount

housing transmitter

● DVD containing software,

certificates and device manuals

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 11

Introduction

1.6 Security information

Note

Supplementary information

Supplementary product and production specific certificates are included on the SensorFlash®

SD card in the transmitter socket.

Note

Scope of delivery may vary, depending on version and add-ons. Make sure the scope of

delivery and the information on the nameplate correspond to your order and the delivery note.

1.5 Checking the consignment

1. Check the packaging and the delivered items for visible damages.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

WARNING

Using a damaged or incomplete device

Risk of explosion in hazardous areas.

● Do not use damaged or incomplete devices.

1.6 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be connected

to an enterprise network or the internet if and to the extent such a connection is necessary and

only when appropriate security measures (e.g. firewalls and/or network segmentation) are in

place.

For additional information on industrial security measures that may be implemented, please

visit

https://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they are available

and that the latest product versions are used. Use of product versions that are no longer

SITRANS FC330

12 Operating Instructions, 01/2019, A5E44030648-AB

supported, and failure to apply the latest updates may increase customer’s exposure to cyber

threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

https://www.siemens.com/industrialsecurity.

1.7 Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume liability

for any costs associated with transportation damages.

NOTICE

Insufficient protection during storage

Introduction

1.8 Notes on warranty

The packaging only provides limited protection against moisture and infiltration.

● Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data

(Page 195).

1.8 Notes on warranty

The contents of this manual shall not become part of or modify any prior or existing agreement,

commitment or legal relationship. The sales contract contains all obligations on the part of

Siemens as well as the complete and solely applicable warranty conditions. Any statements

regarding device versions described in the manual do not create new warranties or modify the

existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 13

Introduction

1.8 Notes on warranty

SITRANS FC330

14 Operating Instructions, 01/2019, A5E44030648-AB

Safety notes

2.1 Preconditions for use

Symbol Explanation

Consult operating instructions

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or symbols

from the device. Always keep the information and symbols in a completely legible state.

Use the device only for flow measurement in accordance with this operating instructions and

observe the technical data (Page 195).

WARNING

2

Improper device modifications

Risk to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

● Only carry out modifications that are described in the instructions for the device. Failure to

observe this requirement cancels the manufacturer's warranty and the product approvals.

2.2 Laws and directives

Observe the safety rules, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EU)

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 15

$

Safety notes

2.2 Laws and directives

2.2.1 FCC Conformity

US Installations only: Federal Communications Commission (FCC) rules

Note

● This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

● This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the operating instructions, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference to radio communications, in which case the user will be required to

correct the interference at his own expense.

Observe the test certification, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EU)

● For Korea only:

2.2.2 Conformity with European directives

The CE marking on the device symbolizes the conformity with the following European

directives:

Electromagnetic

compatibility EMC

2014/30/EU

Low voltage direc‐

tive LVD

2014/35/EU

Atmosphère explosi‐

ble ATEX

2014/34/EU

Directive of the European Parliament and of the Council on the harmoni‐

sation of the laws of the Member States relating to electromagnetic com‐

patibility

Directive of the European Parliament and of the Council on the harmoni‐

sation of the laws of the Member States relating to the making available

on the market of electrical equipment designed for use within certain volt‐

age limits

Directive of the European Parliament and the Council on the harmonisa‐

tion of the laws of the Member States relating to equipment and protective

systems intended for use in potentially explosive atmospheres

SITRANS FC330

16 Operating Instructions, 01/2019, A5E44030648-AB

Safety notes

2.4 Use in hazardous areas

Pressure equipment

directive PED

2014/68/EU

2011/65/EU RoHS Directive of the European Parliament and the Council on the restriction of

The applicable directives can be found in the EC conformity declaration of the specific device.

Note

CE declaration

The CE declaration certificate is available on the SensorFlash SD card delivered with the

device.

Directive of the European Parliament and of the Council on the approxi‐

mation of the laws of the Member States concerning pressure equipment

the use of certain hazardous substances in electrical and electronic

equipment

See also

Certificates (http://www.siemens.com/processinstrumentation/certificates)

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device versions

for each possible scenario during commissioning, operation, maintenance or operation in

systems cannot be considered in the instructions. If you need additional information not

covered by these instructions, contact your local Siemens office or company representative.

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special ambient conditions as can be

encountered in nuclear power plants or when the device is used for research and development

purposes.

2.4 Use in hazardous areas

Special conditions for safe use

In general, it is required that:

● EN/IEC 60079-14 is considered for installation in hazardous areas.

● Appropriate cable connectors are used.

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 17

Safety notes

2.4 Use in hazardous areas

● Sensor is connected to the potential equalization throughout the hazardous area.

● The device is not opened when energized and when an explosive gas or dust atmosphere

may be present.

Further information and instructions including approval-specific special conditions for safe use

in Ex applications can be found in the certificates on the documentation disk and at the product

web page (www.siemens.com/FC330).

WARNING

Substitution of components

Substitution of components may impair Intrinsic Safety.

WARNING

Laying of cables

Risk of explosion in hazardous areas.

Cable for use in hazardous areas must satisfy the requirements for having a proof voltage of

at least 500 V AC applied between the conductor/ground, conductor/shield and shield/ground.

Connect the devices that are operated in hazardous areas as per the stipulations applicable

in the country of operation.

WARNING

Field wiring installation

Ensure that the national requirements of the country in which the devices are installed are met.

Qualified personnel for hazardous area applications

Persons who install, connect, commission, operate, and service the device in a hazardous area

must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and systems

according to the safety regulations for electrical circuits, high pressures, aggressive, and

hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

SITRANS FC330

18 Operating Instructions, 01/2019, A5E44030648-AB

See also

Safety notes

2.4 Use in hazardous areas

WARNING

Use in hazardous area

Risk of explosion.

● Only use equipment that is approved for use in the intended hazardous area and labeled

accordingly.

● Do not use devices that have been operated outside the conditions specified for hazardous

areas. If you have used the device outside the conditions for hazardous areas, make all Ex

markings unrecognizable on the nameplate.

Technical data (Page 195)

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

If the device or its components have already been operated in non-intrinsically safe circuits or

the electrical specifications have not been observed, the safety of the device is no longer

ensured for use in hazardous areas. There is a risk of explosion.

● Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

● Observe the specifications for the electrical data on the certificate and/or in Technical data

(Page 195).

WARNING

Signal wiring

Input/output connections to the transmitter are required to be protected by intrinsic safe

barriers at all times.

2.4.1 Installation in hazardous areas

Hazardous area approvals

The device is approved for use in hazardous areas and has the approvals listed in Certificates

and approvals. (Page 206) Special conditions for safe installation and operation specified by

each approval authority are included in the relevant certificate.

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 19

Safety notes

2.4 Use in hazardous areas

Installation variations

Note

Requirements for safe installation

● Remote sensor FCS300 can be installed in Zone 1, Div. 1 as Intrinsically Safe or

Flameproof.

● Standard remote installation with FCT030 because the connection is certified Intrinsically

Safe. Flameproof seals and conduit (for IS cable) can be used.

● Requirement for IS circuit is that the maximum input voltage Vi to DSL is 20 VDC, Ii is

maximum 484 mA, Pi < 2.3 W

2.4.2 Maximum temperature specifications for use in hazardous areas

Temperature classification is related to the process temperature and ambient temperature as

listed below.

The maximum allowable process fluid temperatures with respect to temperature class for the

device when used with potentially explosive gases in a maximum ambient temperature of

+60°C are:

FCS300 Sensor and Pedestal Adapter:

● T4 at process temperature ≤ 100°C and Ta ≤ 53°C

● T3 at process temperature ≤ 150°C and Ta ≤ 33°C

● Temperature classes T6 and T5 are not applicable

FCT030 remote transmitter

Temperature classification with and without dust is as follows:

● Potentially explosive gases: T6 (85°C surface temperature)

● Dust environment (Zone 21): T85°C

The maximum dust layer shall be no greater than 5 mm (T5 85 °C).

If Tprocess ≤ 85°C, maximum surface temperature = 85°C

If Tprocess > 85°C, maximum surface temperature = process temperature

SITRANS FC330

20 Operating Instructions, 01/2019, A5E44030648-AB

Description

3.1 Overview

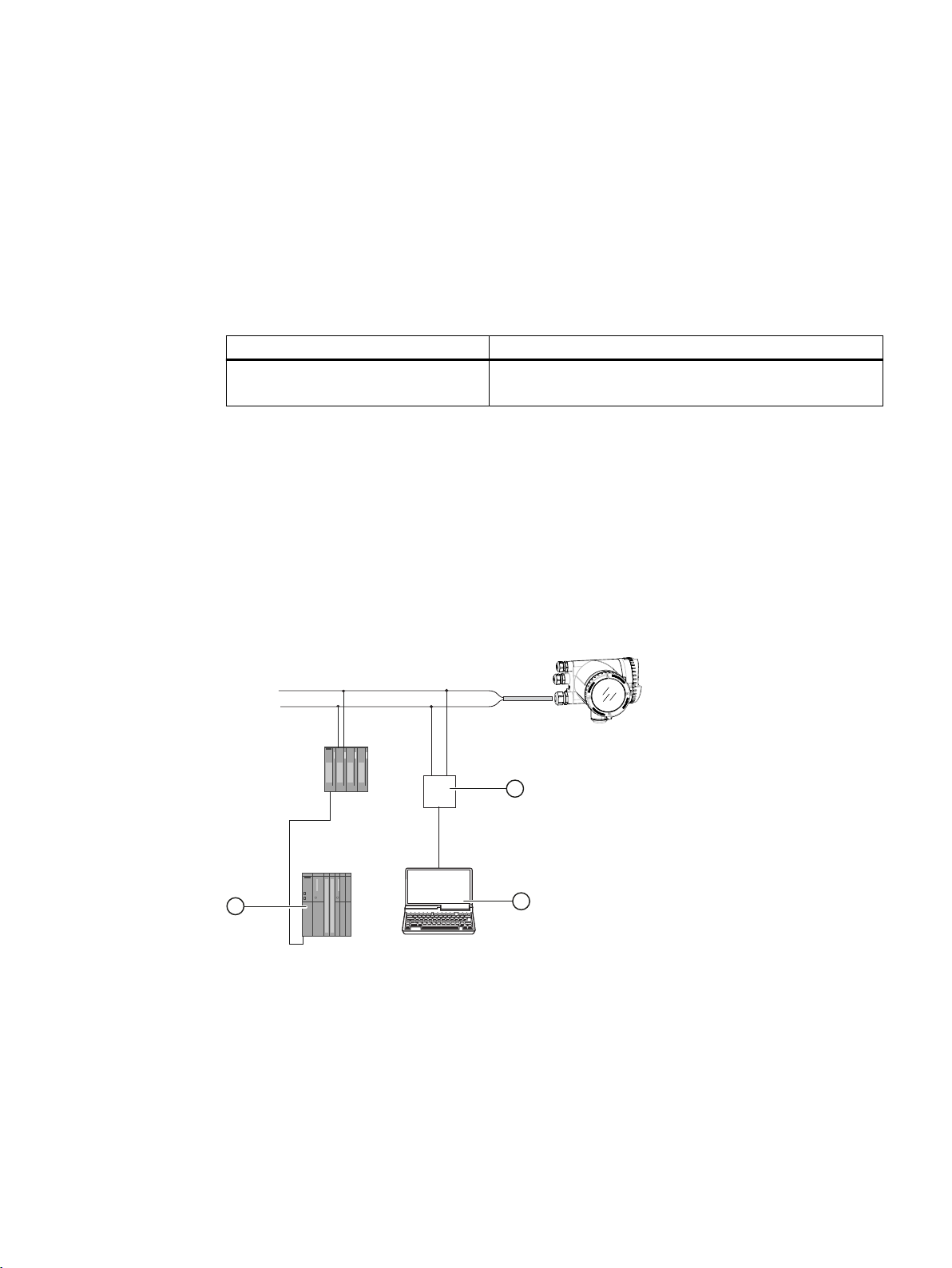

SITRANS Coriolis flowmeter systems consist of a transmitter and a sensor. The following table

lists the available combinations of transmitters and sensors.

Transmitter Sensor type

FCT030 FCS300

You can use the flowmeter for the following measuring tasks:

● Mass flow

● Volume flow

● Standard volume flow

● Density

● Medium temperature

● depending on product variants: fraction, including industry-specific fractions

Operate the device according to the specifications in section Technical data (Page 195).

3

DN 15 to DN 150 (0.5" to 6")

① Communication modem

② PC with SIMATIC PDM or similar application

③ SIMATIC PLC system with HART interface

The Coriolis flowmeter can be used in a number of system configurations:

● as a field mounted transmitter supplied with various optional inputs and outputs

● as part of a system environment, for example SIMATIC S7

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 21

Description

3.2 Design

3.2 Design

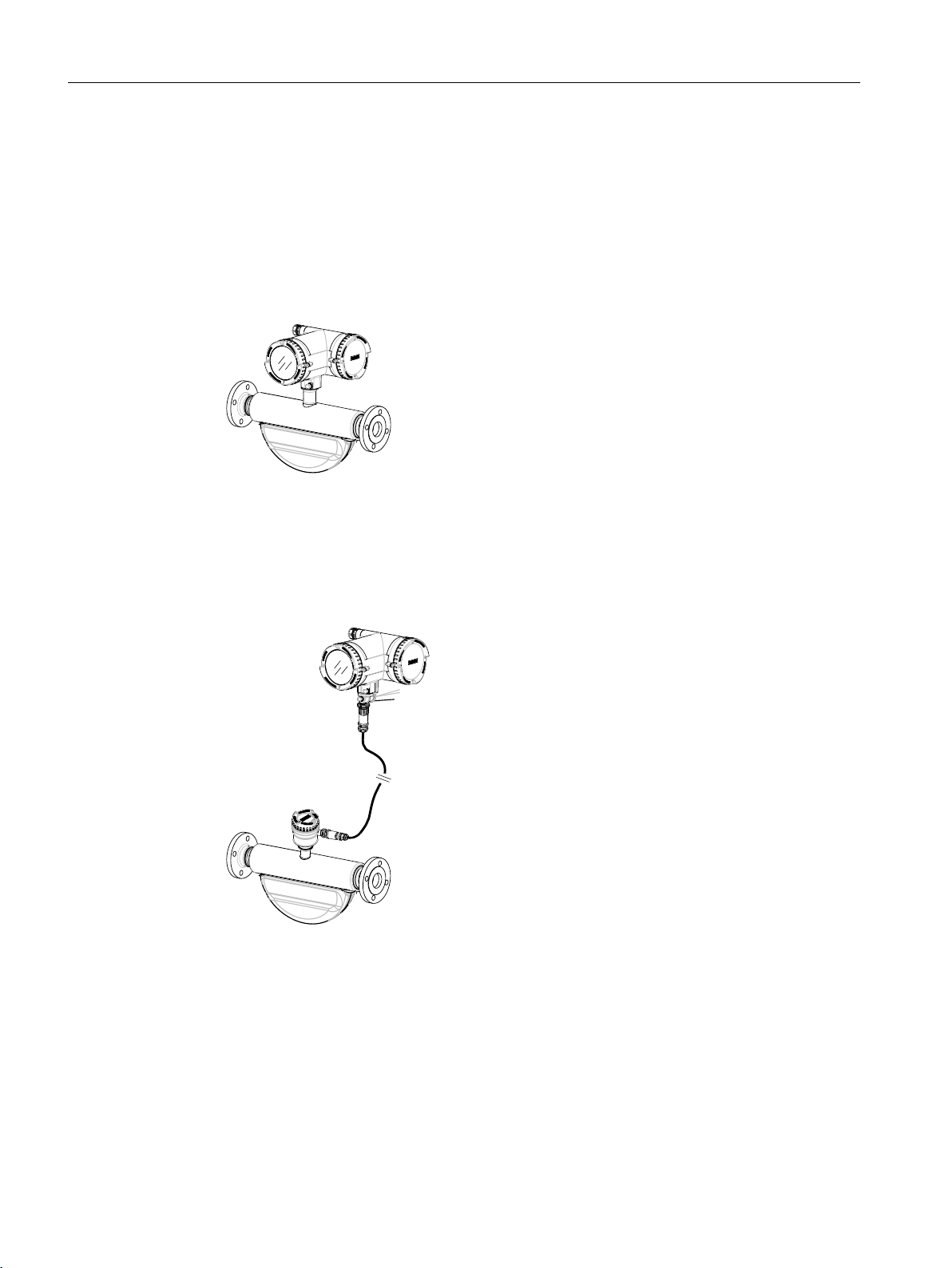

3.2.1 Versions

The flowmeter is available in a compact and a remote version.

● Compact version: The SITRANS FC330 is a single mechanical unit where the transmitter is

directly mounted on the sensor.

Figure 3-1 Compact version

● Remote version: The SITRANS FCS300 sensor unit is remotely connected to a SITRANS

FCT030 transmitter. Directly mounted on the sensor, its Digital Sensor Link (DSL) performs

the signal processing of all measured signals in the sensor. The 4-wire connection between

the transmitter and the sensor provides power and high-integrity digital communication

between the DSL and the transmitter.

Figure 3-2 Remote version - M12 connection

SITRANS FC330

22 Operating Instructions, 01/2019, A5E44030648-AB

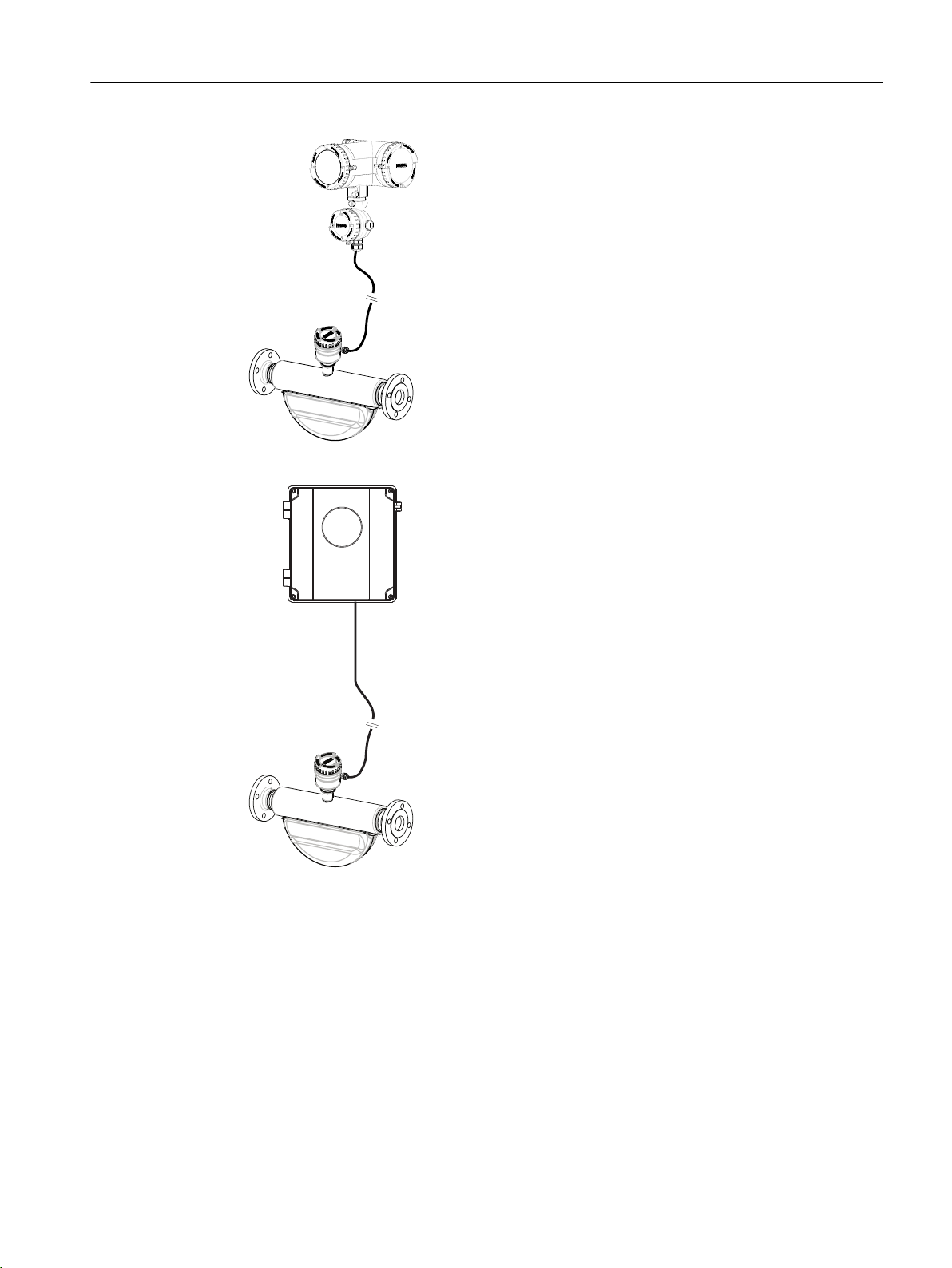

Figure 3-3 Remote version - terminated cable

Description

3.2 Design

Figure 3-4 Remote version with wallmount housing transmitter

3.2.2 Sensor design

All primary process measurements of mass flow, volume flow, density and process

temperature are made in the DSL.

The sensor comprises two parallel bent tubes welded directly to the process connections at

each end via a manifold. The sensor is available in an intrinsically safe (IS) design for

hazardous area installations.

The sensors are available in AISI 316L stainless steel and C4 (2.4610) nickel alloy or C22

(2.4602) nickel alloy. The enclosure is made of Stainless steel 1.4404 (AISI 316L), 1.4301 (AISI

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 23

Description

3.2 Design

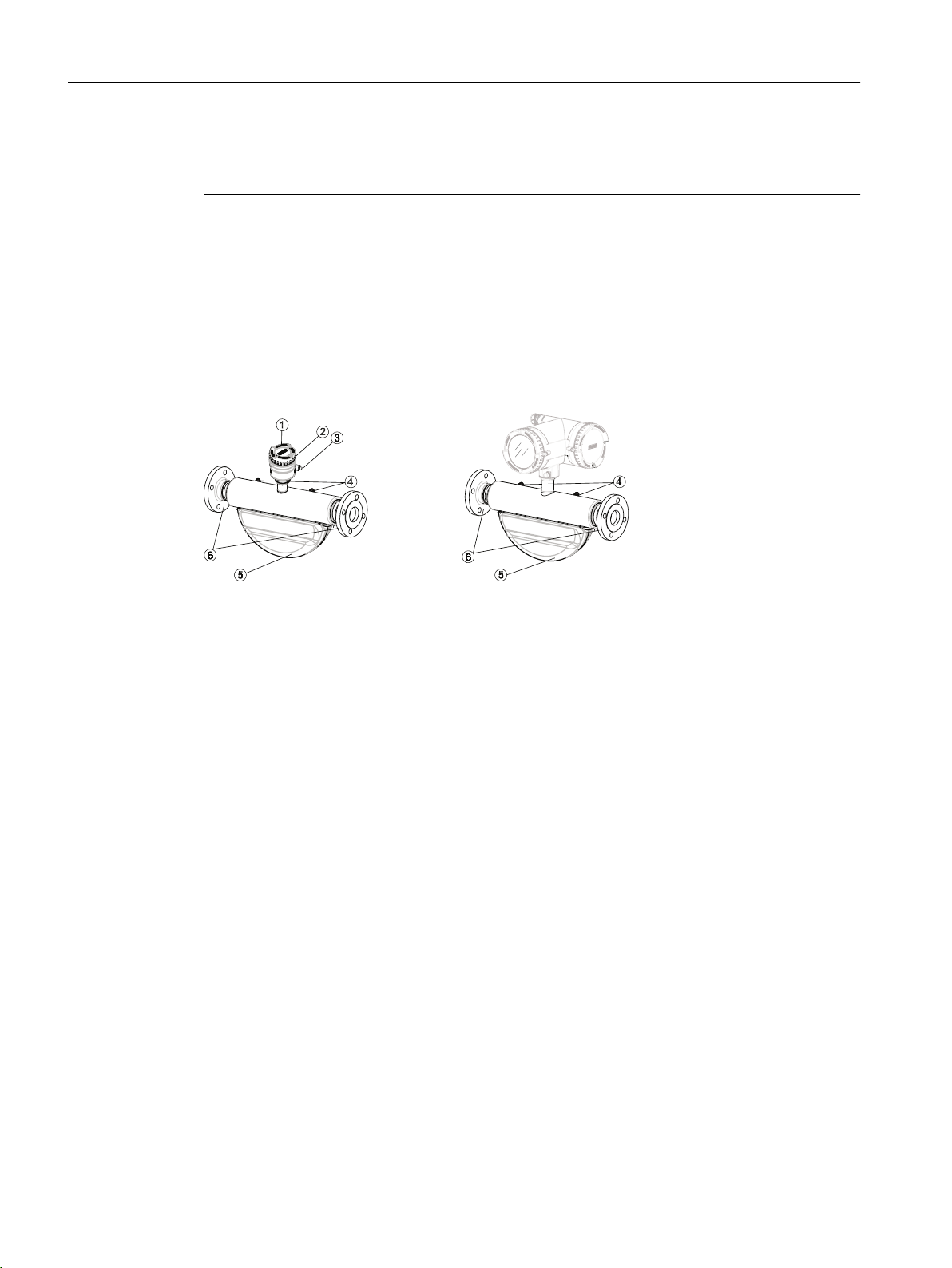

Sensor overview

304), 1.4308 (ASTM CF8). The maximum permissible operating pressure is determined by the

respective process connection, considering the process temperature.

Note

Ex certification requires that the threaded ports always remain closed.

In the remote version, the DSL is available in a painted aluminum with an ingress protection

grade of IP67/NEMA 4X. For communication and supply voltage a 4-wire connection can be

made via M12 plug and socket or cable gland/conduit entry for cable termination.

① DSL (remote version only)

② Lid-lock

③ Cable feed-through (M12 socket or gland)

④ Plug and threaded port for e.g. pressure guard

⑤ Sensor enclosure

⑥ Process connections

Figure 3-5 Overview remote and compact configuration

3.2.3 Transmitter design

The transmitter reads the primary values from the sensor and calculates derived values. It

provides up to four configurable I/Os. On channel 1, HART communication, PROFIBUS DP,

PROFIBUS PA or Modbus RTU RS-485 is possible. On channel 2, 3, 4 each I/O can be

individually configured. A local display (human machine interface - HMI) is available, which

consists of a display and four buttons for user interaction. The transmitter adds functionalities

such as Standard volume flow, fractions, totalizers, dosing, access control, diagnostics,

configuration and logging.

The transmitter has a modular design with discrete, replaceable electronic modules and

connection boards to maintain separation between functions and facilitate field service. All

modules are fully traceable and their provenance is included in the transmitter setup.

SITRANS FC330

24 Operating Instructions, 01/2019, A5E44030648-AB

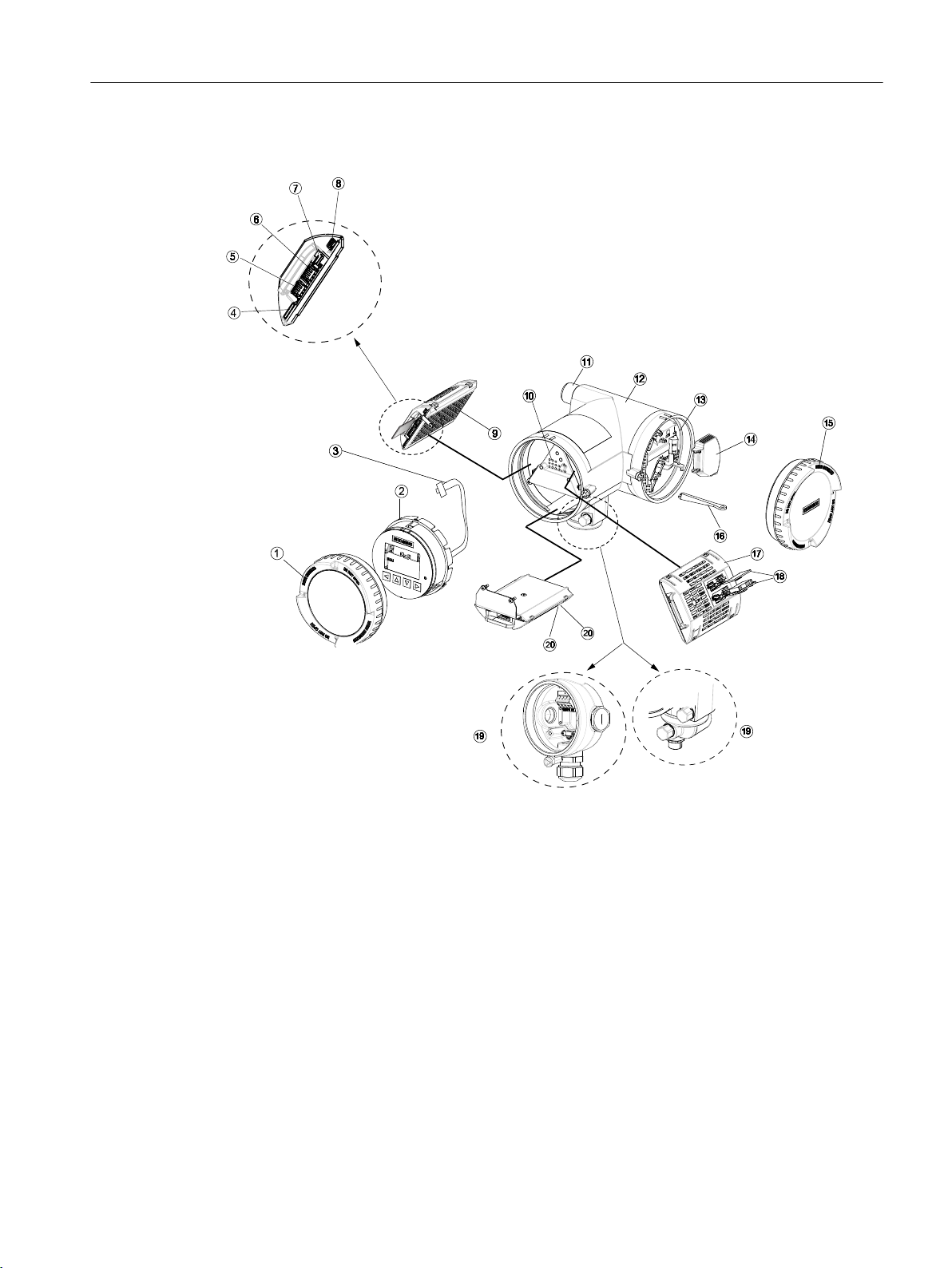

Transmitter exploded view

D

E

D

E

Description

3.2 Design

① Display cover ⑫ Transmitter housing

② Local display (HMI) ⑬ Terminal compartment

③ Connector for HMI ⑭ Power supply terminal protection cover

④ SD card (SensorFlash) ⑮ Lid for terminal compartment

⑤ DIP switch (for custody transfer) ⑯ Wiring tool

⑥ DIP switch (for HART and Modbus) ⑰ I/O cassette (optional)

⑦ HMI port ⑱ I/O configuration keys (optional)

⑧ USB service port ⑲a M12 socket

⑨ Transmitter cassette ⑲b Terminal housing

⑩ Heatsink cover for power supply module ⑳a Sensor module (compact version)

⑪ Cable entry ⑳b Barrier module (remote version)

Figure 3-6 Transmitter exploded view

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 25

Description

3.2 Design

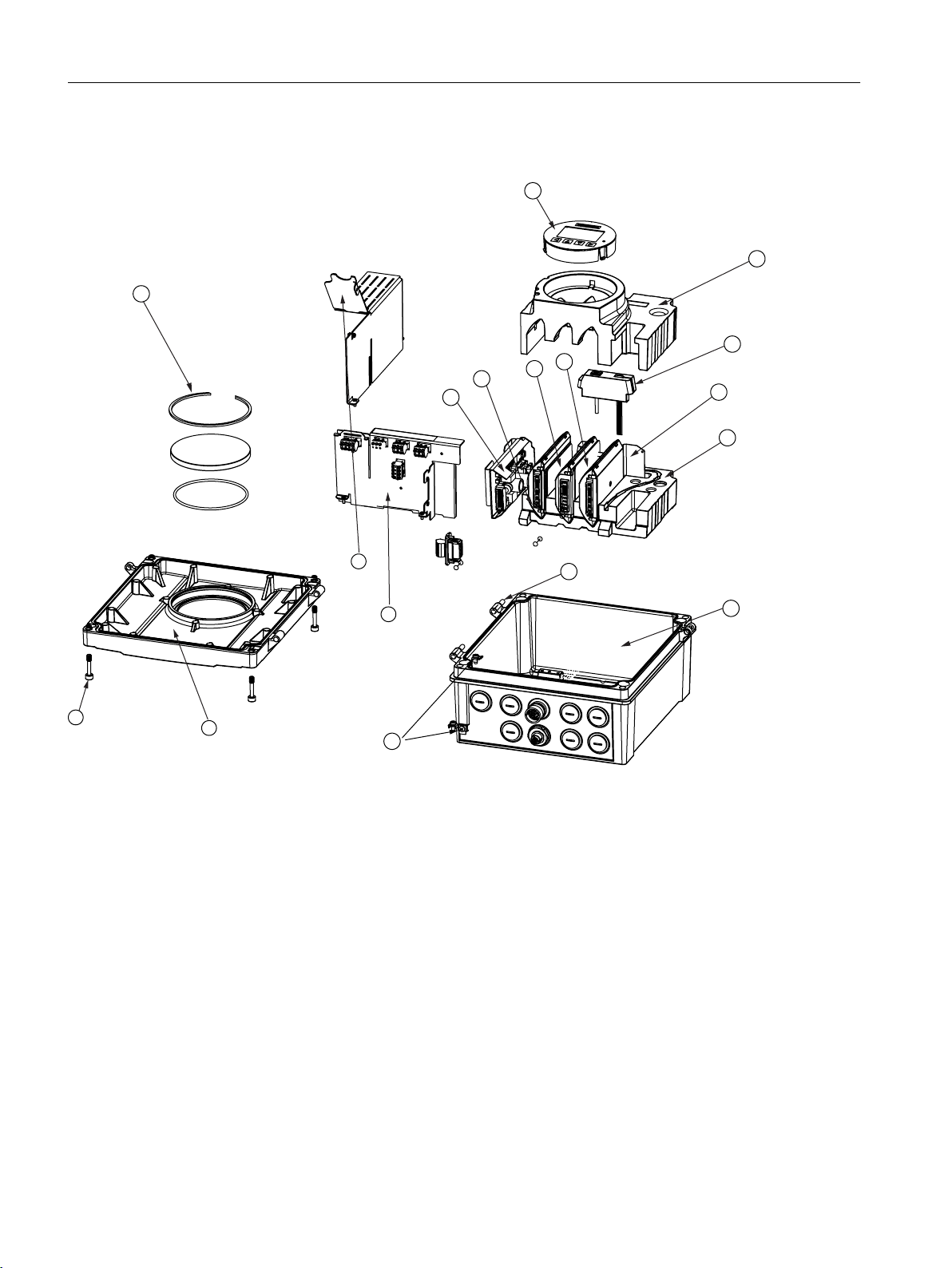

3.2.4 Wall mount housing transmitter exploded view

① Display glass with retaining ring ⑩ Foam bottom

② Power supply module (complete) ⑪ Hinge pin

③ SensorFlash (SD card) ⑫ Housing

④ Transmitter cassette ⑬ Ground connect set

⑤ IO cassette ⑭ Backplane module

⑥ HMI module ⑮ Power supply connector cover

⑦ Foam top ⑯ Front cover enclosure

⑧ Foam plugs ⑰ Front cover mounting screws

⑨ Sensor module (analog version)

Barrier module (digital version)

Figure 3-7 Wall mount housing transmitter exploded view

SITRANS FC330

26 Operating Instructions, 01/2019, A5E44030648-AB

3.3 Device identification

6\VWHPRUGHUQR0(/$*&=

$%()&/

7UDQVPRUGHUQR0(/$1&=

$%()&/

3RZHUVXSSO\9$&WR+]9$RU9'&:

0DWHULDO9HUVLRQ$OXPLQLXP5HPRWH

&RQGXLW&DEOHHQWULHV[0[0[

6HULDOQR1.;;;;;;;

6\VWHPUHYLVLRQV

):+:

<HDURIPDQXIDFWXUH

(QFORVXUH,37\SH;

7DPEr&r)WRr&r)

6,75$16)&7

SIEMENS

6LHPHQV$*'(.DUOVUXKH

0DGHLQ*HUPDQ\DVVHPEOHGLQ)UDQFH

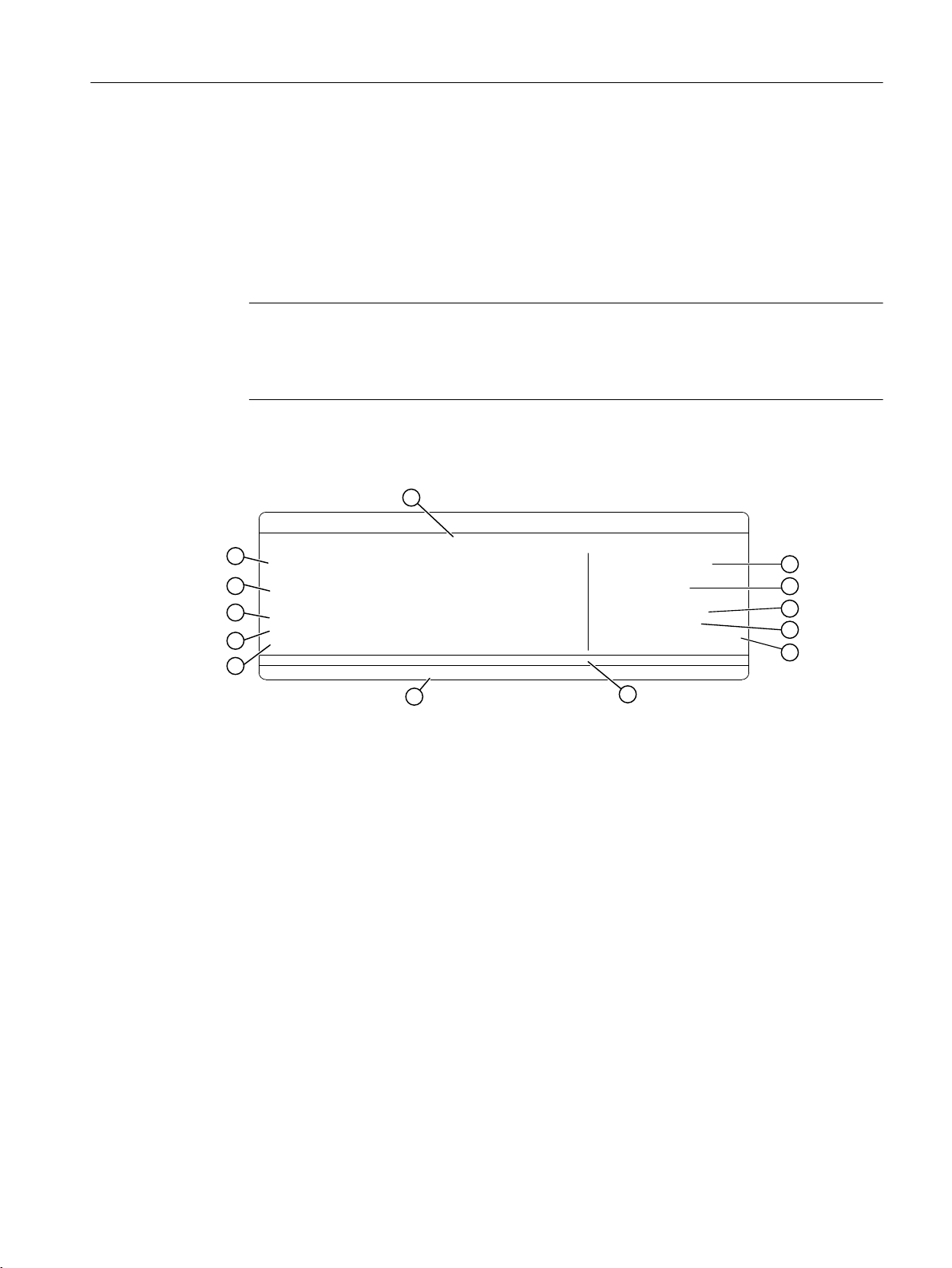

Each part of the FC330 Coriolis flowmeter has 3 nameplate types which show the following

information:

● product identification

● product specifications

● certificates and approvals

Note

Identification

Identify your device by comparing your ordering data with the information on the product and

specification nameplates.

Transmitter identification nameplate example

Description

3.3 Device identification

① SITRANS FCT030

② Serial no. Serial number

③ System revisions System revision numbers firmware (FW) and hardware (HW)

④ Year of manufacture Manufacturing year

⑤ Enclosure Degree of protection

⑥ Tamb. Range of ambient temperature

⑦ Manufacturer Manufacturer name and location

⑧ Country Manufacturing country

⑨ Conduit / Cable entries Type of conduit / cable entries

⑩ Material / Version Transmitter housing material and version (compact/remote)

⑪ Power supply Power supply

⑫ Transm. order no. Device-specific transmitter order number

⑬ System order no. Device-specific system order number (transmitter and sensor)

1)

With compact versions, the transmitter and sensor product identifications are both given as 'SITRANS

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 27

FC330'.

With remote versions, the transmitter is identified as 'SITRANS FCT030' and the sensor as 'SITRANS

FCS300'.

1)

Product name

6LHPHQV$*'(.DUOVUXKH

0DGHLQ*HUPDQ\DVVHPEOHGLQ)UDQFH

SIEMENS

6HULDOQR1.;;;;;;;

6HQ56

6L]H'1

6\VWHPRUGHUQR0(/$*&=

$%()&/

6HQVRURUGHUQR0(/$1&=

$%()&/

6,75$16)&6

Description

3.3 Device identification

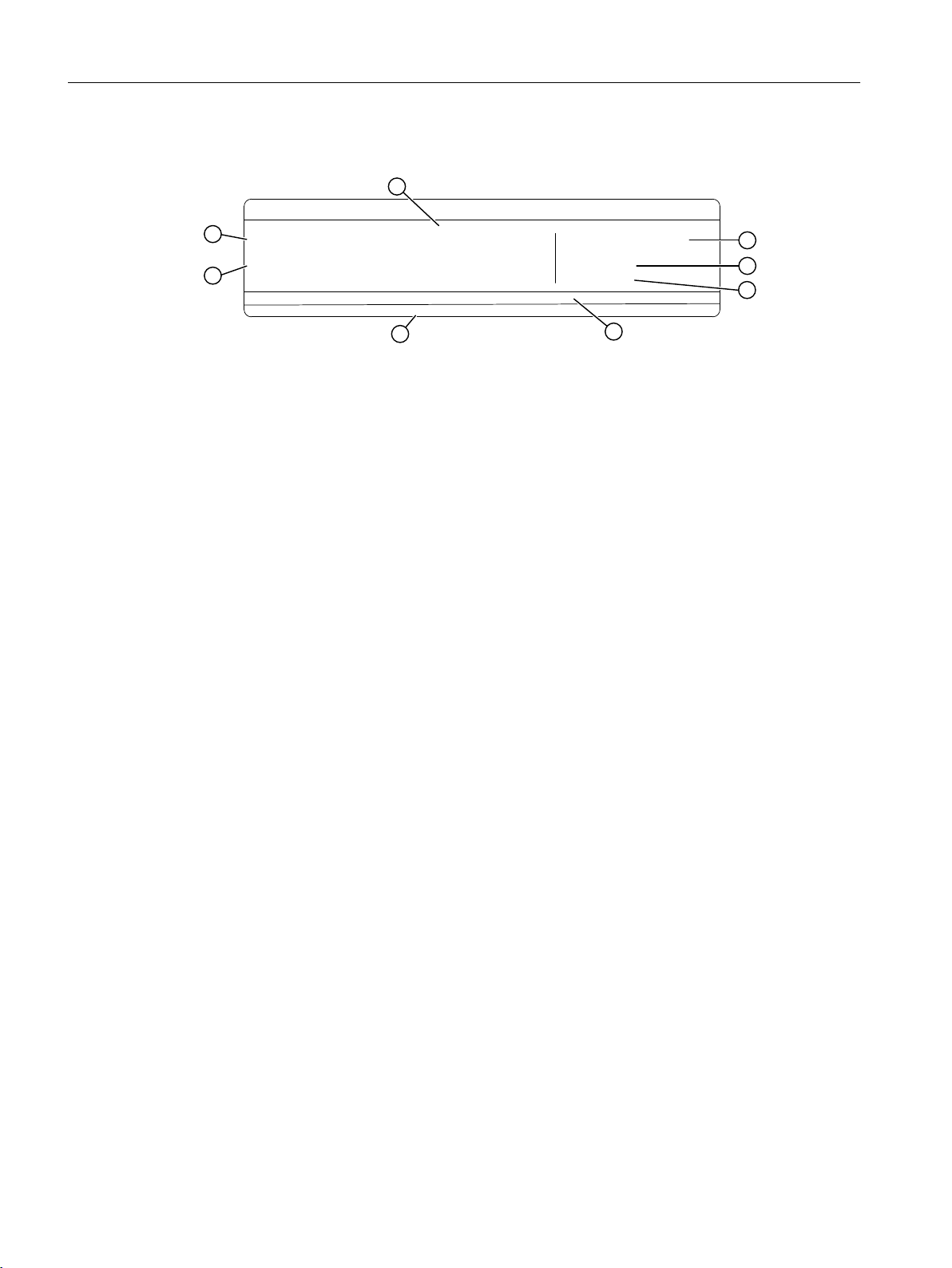

Sensor identification nameplate example

① SITRANS

FCS300

1)

② Serial no. Serial number

③ Sen. RS Mechanical sensor version number

④ Size DN Size

⑤ Manufacturer Manufacturer name and location

⑥ Country Manufacturing country

⑦ Sensor order no. Sensor replacement order number

⑧ System order no. Flowmeter system order number (transmitter and sensor)

1)

With compact versions, the transmitter and sensor product identifications are both given as 'SITRANS

FC330'.

With remote versions, the transmitter is identified as 'SITRANS FCT030' and the sensor as 'SITRANS

FCS300'.

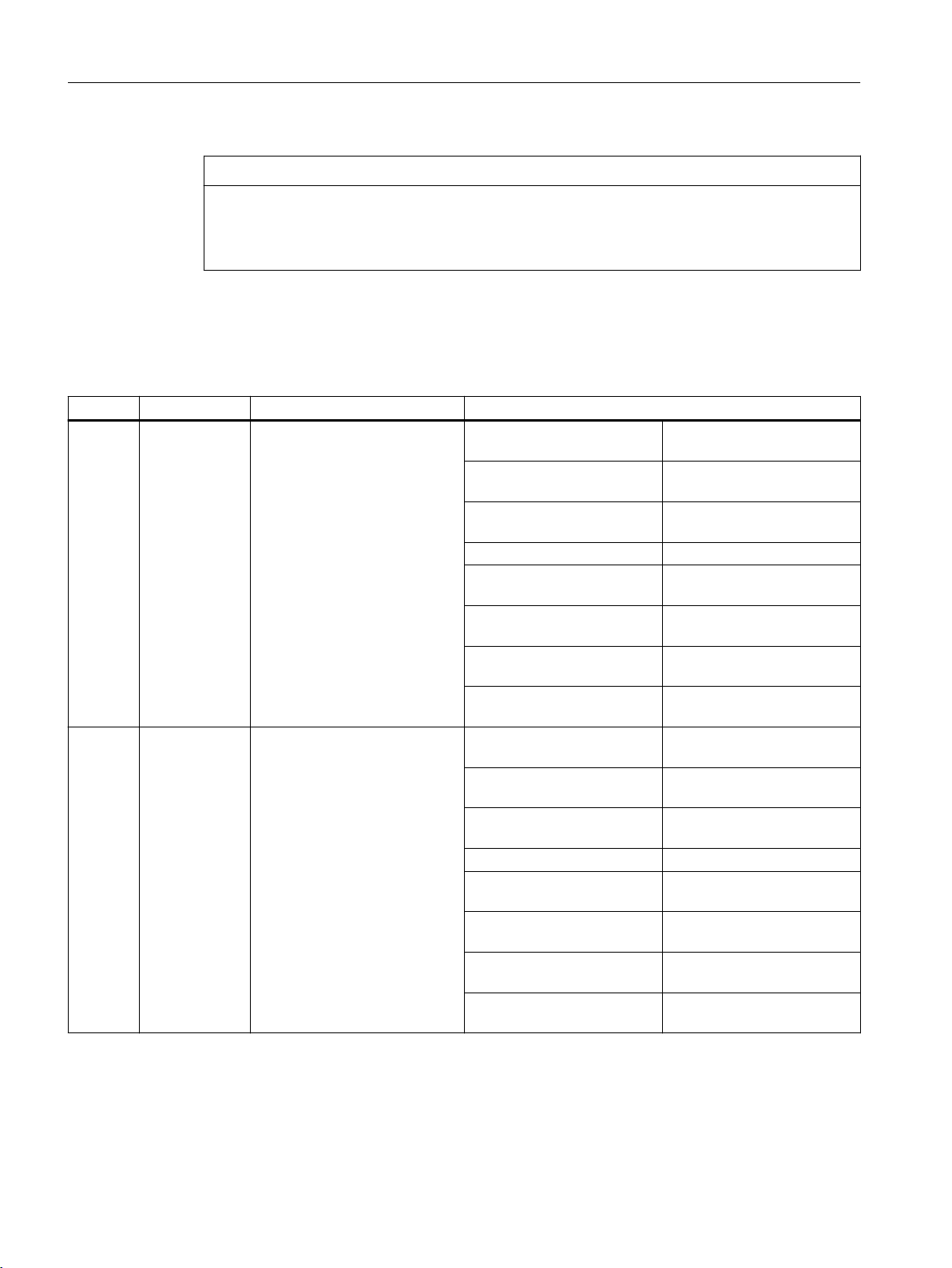

Flowmeter serial number construction

The flowmeter serial number consists of the following:

PPYMDDXXXX

where

PP = Production factory (Siemens Flow Instruments: N1)

Y = Production year (for encryption, see below)

M = Production month (for encryption, see below)

DD = Production day (for encryption, see below)

XXXX = Sequential number

Product name

28 Operating Instructions, 01/2019, A5E44030648-AB

Encryption:

Calendar year (Y) Code

1950, 1970, 1990, 2010 A

1951, 1971, 1991, 2011 B

1952, 1972, 1992, 2012 C

1953, 1973, 1993, 2013 D

1954, 1974, 1994, 2014 E

1955, 1975, 1995, 2015 F

1956, 1976, 1996, 2016 H (G)

1957, 1977, 1997, 2017 J

SITRANS FC330

Description

3.3 Device identification

1958, 1978, 1998, 2018 K

1959, 1979, 1999, 2019 L

1960, 1980, 2000, 2020 M

1961, 1981, 2001, 2021 N

1962, 1982, 2002, 2022 P

1963, 1983, 2003, 2023 R

1964, 1984, 2004, 2024 S

1965, 1985, 2005, 2025 T

1966, 1986, 2006, 2026 U

1967, 1987, 2007, 2027 V

1968, 1988, 2008, 2028 W

1969, 1989, 2009, 2029 X

Month (M) Code

January 1

February 2

March 3

April 4

May 5

June 6

July 7

August 8

September 9

October O

November N

December D

Day (DD) Code

Day 01 to 31 01 to 31 (corresponding to the actual date)

SITRANS FC330

Operating Instructions, 01/2019, A5E44030648-AB 29

4

5

2 31

)RU&DQ

([GEHELD>LD*D@,,&,,%77*E

)RU86

&O,'LY*URXSV$%&'

&ODVV,=RQH

$([GEHELD>LD*D@,,&,,%77*E

([LD

(;GEHELD>LD*D@,,&7*D*E

6LUD$7(;;

,(&([6,5;

7D r&WRr&

7&ODVV XSSHU7DPE

5HIHUWRXVHULQVWUXFWLRQV

,,*

Description

3.3 Device identification

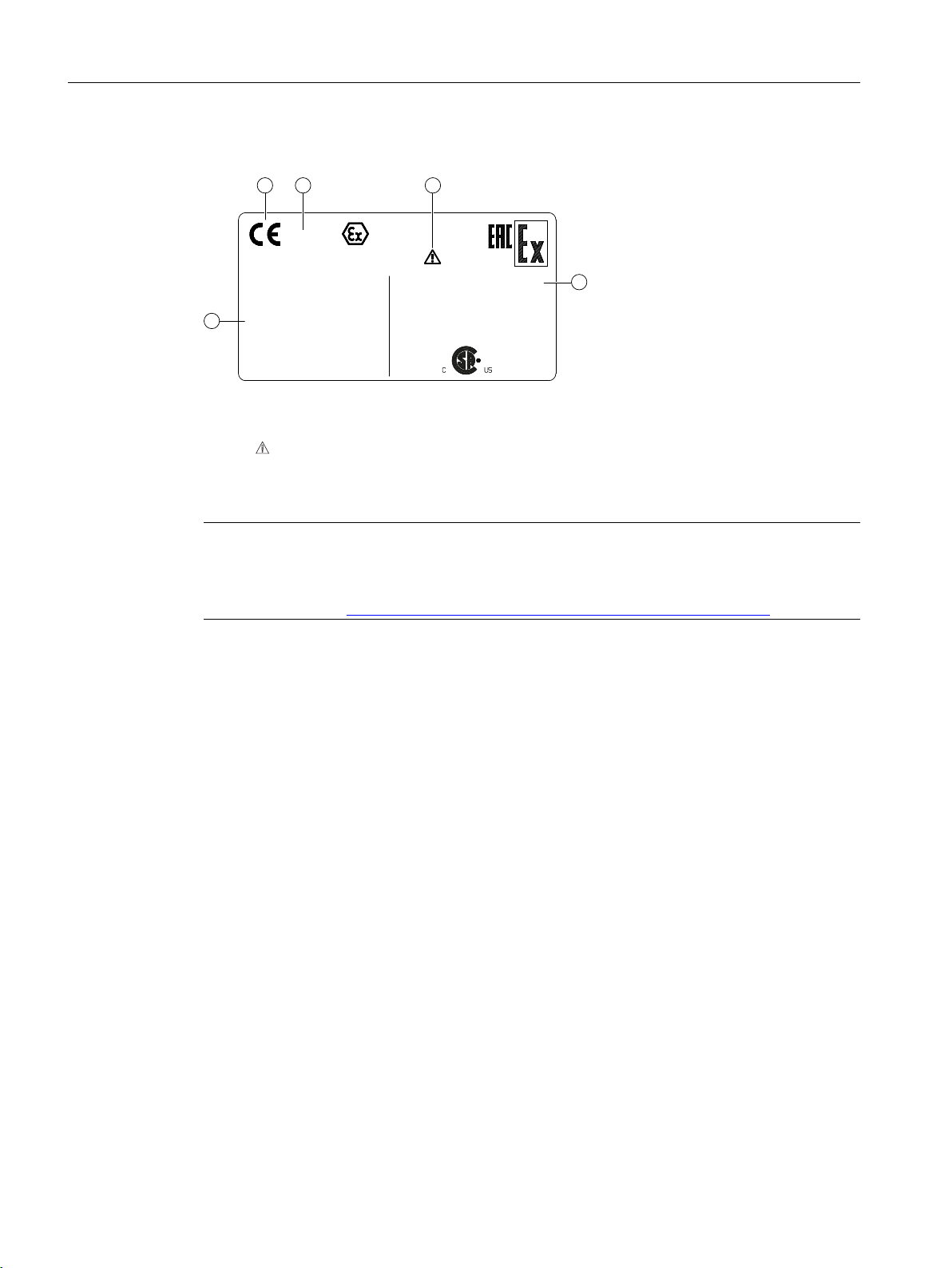

FCT030 transmitter specification nameplate example

① CE CE mark

② 0518 Notified Body ID (ATEX example)

③ Consult the operating instructions

④ For Can / For US Country-specific restrictions

⑤ Ex approvals Classification for hazardous locations

Note

Approvals and identifications

Approval certificates and notified body identifications are available for download at

www.siemens.com (http://www.siemens.com/processinstrumentation/certificates).

30 Operating Instructions, 01/2019, A5E44030648-AB

SITRANS FC330

Loading...

Loading...