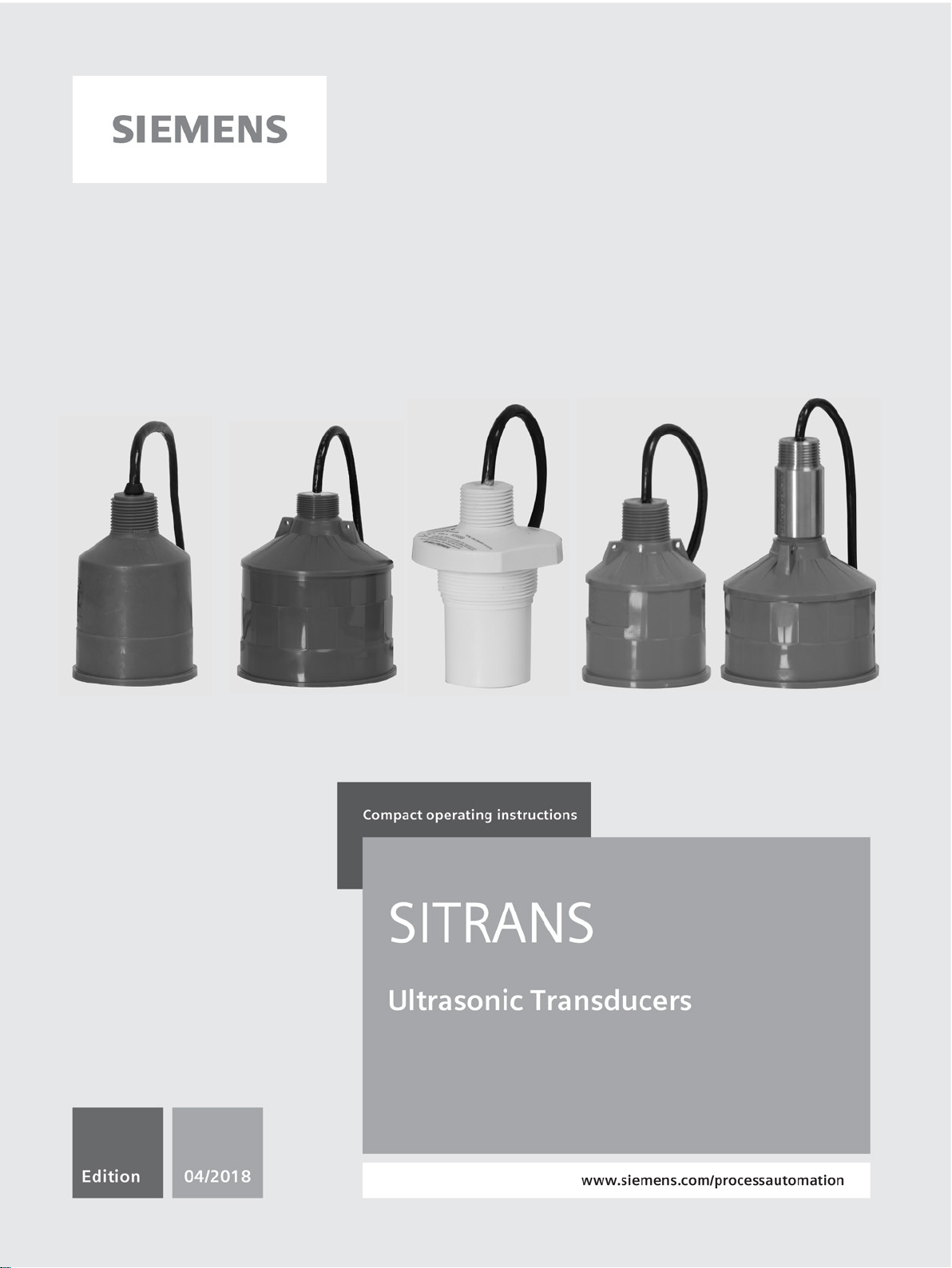

Siemens SITRANS 7ML1100, SITRANS 7ML1105, SITRANS 7ML1106, SITRANS 7ML1115, SITRANS 7ML1118 Compact Operating Instructions

...

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Ultrasonic transducers

Transducers

Compact Operating Instructions

01/2018

A5E43390688_AA

Introduction

1

Safety notes

2

Installing/mounting

3

Connecting

4

Technical data

5

Appendix A: Applications

A

Appendix B: Certificates

B

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E43390688

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

04/2018 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 5

2 Safety notes ............................................................................................................................................ 9

3 Installing/mounting ................................................................................................................................ 13

4 Connecting ........................................................................................................................................... 29

1.1 Purpose of this documentation ................................................................................................. 5

1.2 Checking the consignment ....................................................................................................... 5

1.3 Security information .................................................................................................................. 5

1.4 Transportation and storage ....................................................................................................... 6

1.5 Notes on warranty ..................................................................................................................... 6

1.6 About Siemens' Transducers .................................................................................................... 7

2.1 Preconditions for use ................................................................................................................ 9

2.1.1 Warning symbols on device ...................................................................................................... 9

2.1.2 Laws and directives .................................................................................................................. 9

2.1.3 Improper device modifications ................................................................................................ 10

2.1.4 Safety Precautions .................................................................................................................. 10

2.2 Use in hazardous areas .......................................................................................................... 11

2.3 Requirements for special applications .................................................................................... 12

3.1 Basic safety notes ................................................................................................................... 13

3.1.1 Installation location requirements ........................................................................................... 15

3.1.1.1 Insufficient air supply .............................................................................................................. 15

3.1.2 Proper mounting ..................................................................................................................... 16

3.2 Disassembly ............................................................................................................................ 16

3.3 Outline and Dimensions .......................................................................................................... 17

3.3.1 XPS Transducers .................................................................................................................... 17

3.3.2 XRS-5...................................................................................................................................... 18

3.3.3 ST-H ........................................................................................................................................ 19

3.4 Mounting ................................................................................................................................. 20

3.4.1 Solids applications .................................................................................................................. 20

3.4.2 Liquids applications ................................................................................................................. 21

3.4.2.1 XPS Transducers .................................................................................................................... 21

3.4.2.2 XRS-5...................................................................................................................................... 23

3.4.2.3 ST-H ........................................................................................................................................ 25

4.1 Basic safety notes ................................................................................................................... 29

4.1.1 Connecting device in energized state in hazardous areas ..................................................... 30

4.2 Connecting note ...................................................................................................................... 31

4.3 Direct connection .................................................................................................................... 32

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

3

Table of contents

5 Technical data ...................................................................................................................................... 37

A Appendix A: Applications ...................................................................................................................... 39

B Appendix B: Certificates ........................................................................................................................ 53

Index .................................................................................................................................................... 57

4.4 Coaxial connection ................................................................................................................. 33

4.5 2 Wire Extension .................................................................................................................... 34

4.6 3 Terminal .............................................................................................................................. 35

5.1 Specifications ......................................................................................................................... 37

A.1 Liquids applications ................................................................................................................ 40

A.1.1 Stilling well ............................................................................................................................. 40

A.1.2 Submergence ......................................................................................................................... 41

A.1.3 Standpipes ............................................................................................................................. 42

A.1.4 Volume ................................................................................................................................... 44

A.1.5 Water/wastewater .................................................................................................................. 46

A.2 Solids applications ................................................................................................................. 47

A.2.1 Typical .................................................................................................................................... 47

A.2.2 Special ................................................................................................................................... 50

B.1 Wiring setups for hazardous area installations ...................................................................... 53

B.2 Instructions specific to hazardous area installations .............................................................. 55

Transducers

4 Compact Operating Instructions, 01/2018, A5E43390688_AA

1

1.1

Purpose of this documentation

1.2

Checking the consignment

WARNING

Using a damaged or incomplete device

1.3

Security information

These instructions are a brief summary of important features, functions and safety

information, and contain all information required for safe use of the device. Read the

instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons who install and commission the device.

To realize optimum performance from the device, read the complete operating instructions.

1. Check the packaging and the delivered items for visible damages.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Risk of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http://www.siemens.com/industrialsecurity.

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

5

Introduction

1.4

Transportation and storage

NOTICE

Insufficient protection during storage

1.5

Notes on warranty

1.4 Transportation and storage

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

http://www.siemens.com/industrialsecurity.

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data

(Page 37).

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

Transducers

6 Compact Operating Instructions, 01/2018, A5E43390688_AA

Introduction

1.6

About Siemens' Transducers

Note

This product is intended for use in industrial areas. Operation of this equipment in a

residential area may cause interference to several frequency based communications.

1.6 About Siemens' Transducers

The transducers operate in association with Siemens' ultrasonic level monitoring products by

converting electrical pulses that are provided by the transceiver into ultrasonic pulses. When

transmitted, these ultrasonic pulses reflect from the material surface and echo back to the

transducer. The echo is converted back to an electrical signal, and is interpreted by the

Siemens transceiver using our proven Sonic Intelligence™ algorithms.

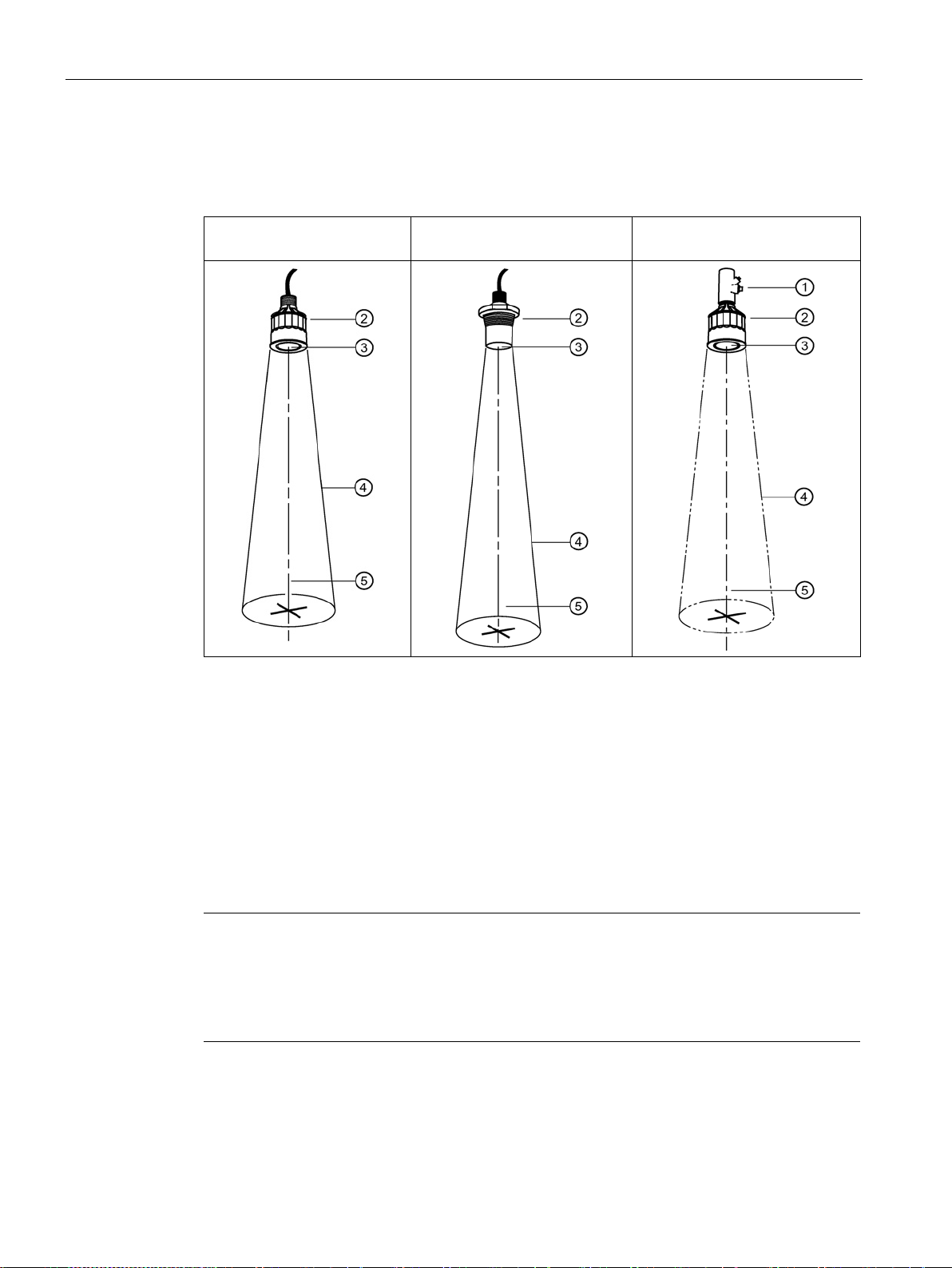

The effective acoustical energy is emitted from the transducer face and radiated outward,

decreasing in amplitude at a rate inversely proportional to the square of the distance.

Maximum power is radiated axially (perpendicular) from the transducer face in a line referred

to as the axis of transmission. Where power is reduced by half (– 3 dB), a conical boundary

defining the sound beam, centered about the axis of transmission, is established. The

diametric measurement of the cone in degrees defines the beam angle. Impedance

matching techniques are used to optimize the transfer of power from the transducer into air

and vice versa.

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

7

Introduction

XPS-10, XPS-15/15F,

XPS-30, XRS-5/5C

ST-H

Transducer with explosion proof

conduit seal

①

Explosion proof conduit seal

②

Transducer

③

Transducer face

④

3 db boundary

⑤

Axis of transmission

Note

Use in hazardous areas

The XPS

All other transducers need the optional explosion proof conduit seal for use in hazardous

areas.

1.6 About Siemens' Transducers

All transducers incorporate an integral temperature sensor that reports the air temperature at

the transducer to the transceiver. The connection is transparent, in that both the ultrasonic

and temperature components of the transducer use the same leads.

1)

1)

Optional

2)

Perpendicular to Transducer face

2)

-15F and XRS-5C already have a built-in explosion proof conduit seal.

Transducers

8 Compact Operating Instructions, 01/2018, A5E43390688_AA

2

2.1

Preconditions for use

2.1.1

Warning symbols on device

Symbol

Explanation

2.1.2

Laws and directives

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Observe the safety rules, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EU)

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

9

Safety notes

2.1.3

Improper device modifications

WARNING

Improper device modifications

2.1.4

Safety Precautions

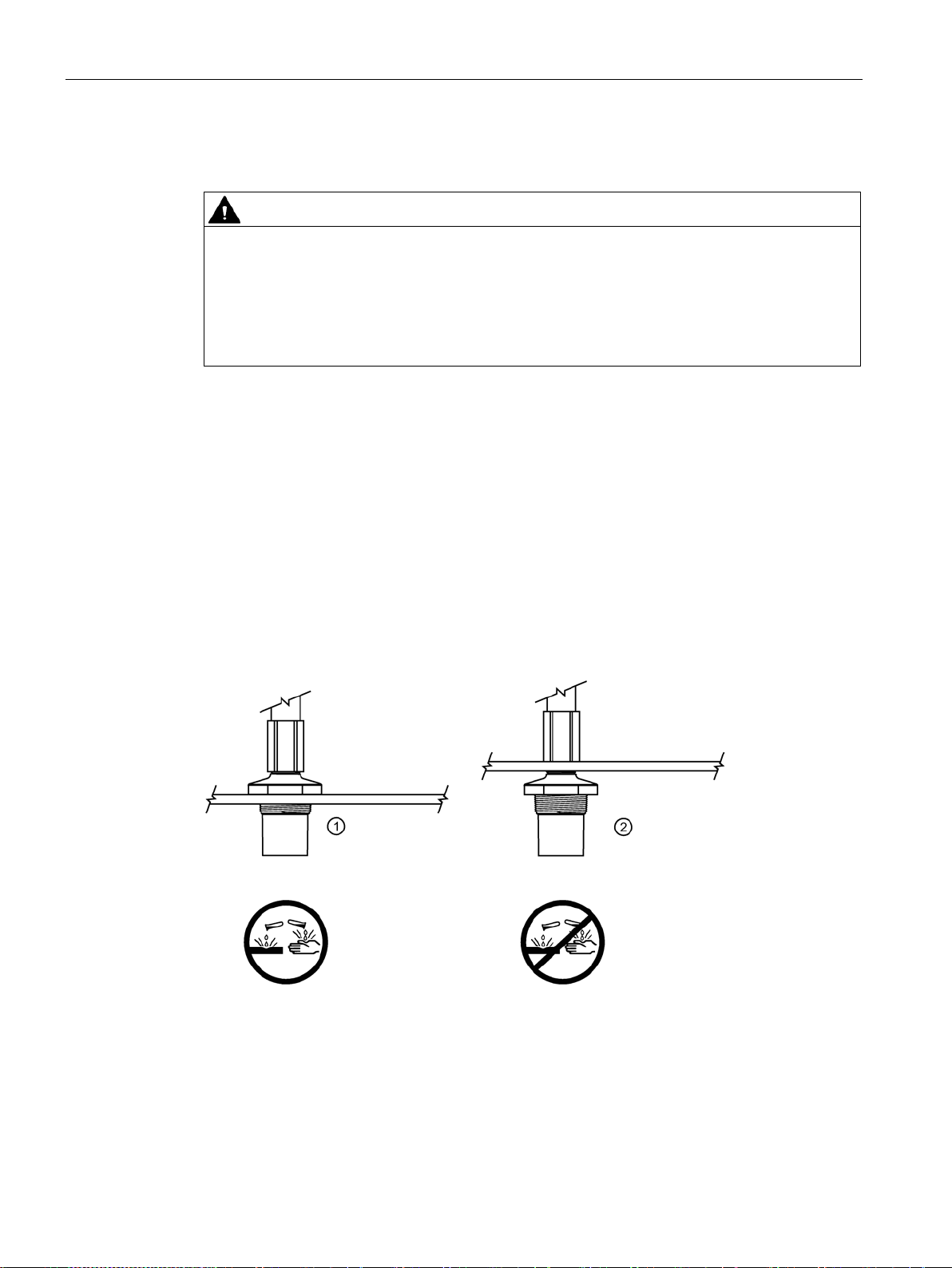

①

Suitable for use in a corrosive environment

②

Not suitable for use in a corrosive environment

2.1 Preconditions for use

Risk to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

The ST-H transducer body is a two part design molded in PVDF or ETFE with internal parts

potted in epoxy. The joint between the upper and lower sections is not a hermetic seal. The

structural integrity of the transducer will be compromised if the joint is exposed to an

environment that attacks epoxy. As a result, the top section will separate from the main body

of the transducer.

For environments that are compatible with PVDF or ETFE but may degrade epoxy, the

transducer must be mounted through a flange or stub mount using the 2" thread on the lower

section of the transducer. The joint between upper and lower sections of the transducer must

be isolated from the corrosive environment.

Transducers

10 Compact Operating Instructions, 01/2018, A5E43390688_AA

Safety notes

WARNING

Risk of explosion

2.2

Use in hazardous areas

Qualified personnel for hazardous area applications

WARNING

Use in hazardous area

2.2 Use in hazardous areas

If the top section separates from the main body of the transducer, live circuitry will be

exposed to the hazardous environment, increasing the risk of an explosion if volatile or

explosive dusts or gases are in sufficient concentration. A malfunction of the level system

may also occur, which may affect the process using the ultrasonic ranging system.

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

Risk of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

• Don't use devices that have been operated outside the conditions secified for hazardous

areas. If you have used the device outside the conditions for hazardous areas

permanently make all Ex markings unrecognizable on the nameplate.

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

11

Safety notes

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact

department before you operate the device under special ambient conditions as can be

encountered in nuclear power plants or when the device is used for research and

development purposes.

Note

Operation under special atmospheric conditions

Ultrasonic measurement requires that the sound wave travel through the atmosphere in a

consistent manner. Applications with atmospheric conditions different from air (including, but

not limited to, gas layer

properly assessed to ensure safe, reliable use in the event of measurement errors due to

sound wave velocity changes.

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

your Siemens representative or our application

stratification, very high methane or CO2 concentrations), should be

Transducers

12 Compact Operating Instructions, 01/2018, A5E43390688_AA

3

3.1

Basic safety notes

DANGER

Pressure applications

WARNING

Wetted parts unsuitable for the process media

Ensure that the material of the device parts wetted by the process medium is suitable for

Note

Material compatibility

Siemens can provide you with support concerning selection of sensor components wetted by

process media. However, you are responsible for the select

accepts no liability for faults or failures resulting from incompatible materials.

WARNING

Unsuitable connecting parts

Danger to personnel, system and environment will result from improper disassembly.

• Never attempt to loosen, remove, or disassemble process connection while vessel

contents are under pressure.

Risk of injury or damage to device.

Hot, toxic and corrosive media could be released if the process medium is unsuitable for

the wetted parts.

•

the medium. Refer to the information in Technical data (Page 37).

ion of components. Siemens

Risk of injury or poisoning.

In case of improper mounting, hot, toxic, and corrosive process media could be released at

the connections.

• Ensure that connecting parts (such as flange gaskets and bolts) are suitable for

connection and process media.

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

13

Installing/mounting

WARNING

Exceeded maximum permissible operating pressure

CAUTION

Hot surfaces resulting from hot process media

CAUTION

External stresses and loads

3.1 Basic safety notes

Risk of injury or poisoning.

The maximum permissible operating pressure depends on the device version, pressure

limit and temperature rating. The device can be damaged if the operating pressure is

exceeded. Hot, toxic and corrosive process media could be released.

Ensure that maximum permissible operating pressure of the device is not exceeded. Refer

to the information on the nameplate and/or in Technical data (Page 37).

Risk of burns resulting from surface temperatures above 65 °C (149 °F).

• Take appropriate protective measures, for example contact protection.

• Make sure that protective measures do not cause the maximum permissible ambient

temperature to be exceeded. Refer to the information in Technical data (Page 37).

Damage to device by severe external stresses and loads (e.g. thermal expansion or pipe

tension). Process media can be released.

• Prevent severe external stresses and loads from acting on the device.

Transducers

14 Compact Operating Instructions, 01/2018, A5E43390688_AA

Installing/mounting

3.1.1

Installation location requirements

3.1.1.1

Insufficient air supply

WARNING

Insufficient air supply

CAUTION

Aggressive atmospheres

CAUTION

Direct sunlight

NOTICE

Strong vibrations

3.1 Basic safety notes

The device may overheat if there is an insufficient supply of air.

• Install the device so that there is sufficient air supply in the room.

• Observe the maximum permissible ambient temperature. Refer to the information in the

section Technical data (Page 37).

Damage to device through penetration of aggressive vapors.

• Ensure that the device is suitable for the application.

Device damage.

The device can overheat or materials become brittle due to UV exposure.

• Protect the device from direct sunlight.

• Make sure that the maximum permissible ambient temperature is not exceeded. Refer

to the information in Technical data (Page 37).

Damage to device.

• In installations with strong vibrations, mount the transmitter in a low vibration

environment.

Transducers

Compact Operating Instructions, 01/2018, A5E43390688_AA

15

Installing/mounting

3.1.2

Proper mounting

CAUTION

Loss of type of protection

NOTICE

Incorrect mounting

3.2

Disassembly

WARNING

Incorrect disassembly

3.2 Disassembly

Damage to device if the enclosure is open or not properly closed. The type of protection

specified on the nameplate or in Technical data (Page 37) is no longer guaranteed.

• Make sure that the device is securely closed.

The device can be damaged, destroyed, or its functionality impaired through improper

mounting.

• Before installing ensure there is no visible damage to the device.

• Make sure that process connectors are clean, and suitable gaskets and glands are

used.

• Mount the device using suitable tools. Refer to the information in Technical data

(Page 37).

The following risks may result from incorrect disassembly:

- Injury through electric shock

- Risk through emerging media when connected to the process

- Risk of explosion in hazardous area

In order to disassemble correctly, observe the following:

• Before starting work, make sure that you have switched off all physical variables such

as pressure, temperature, electricity etc. or that they have a harmless value.

• If the device contains hazardous media, it must be emptied prior to disassembly. Make

sure that no environmentally hazardous media are released.

• Secure the remaining connections so that no damage can result if the process is started

unintentionally.

Transducers

16 Compact Operating Instructions, 01/2018, A5E43390688_AA

Loading...

Loading...