Siemens SITRANS F, SITRANS 1010AERWDP Operating Instructions Manual

12/2014Edition

Answers for industry.

Operating Instructions

Ultrasonic Flowmeters

SITRANS 1010AERWDP Portable Flowmeter

SITRANS F

IMPORTANT NOTICE

Controlotron is now part of:

Siemens Industry, Inc.

Industry Automation Division

CoC Ultrasonic Flow

Hauppauge, NY 11788 USA

1010AERWDP

UNIFLOW UNIVERSAL

PORTABLE FLOWMETER

This equipment contains components that are

susceptible to electrostatic discharge (ESD).

Please observe ESD control measures during

the handling and connection process.

Field Manual A5E02617285 Rev AB

December 2014

For use with Operating System

Software Version 3.01.06F or later

Copyright©2014 Siemens Industry, Inc. All Rights Reserved Made in the USA

Manual Changes

NOTE: For the latest updates and revisions to this field manual go to:

http://support.automation.siemens.com/ and check the Product Manual listing.

MANUAL

ADDENDUM

1010FMA-56

Operating System Software

Version Update

Manual Addendum

September 2008

Copyright © 2008 Siemens Industry, Inc. All rights reserved Made in the USA

Manual Addendum

1010FMA-56

Operating System Software Version Update

INTRODUCTION

The following software operating system version update is for Version 3 flowmeters. Please refer to

this addendum when using this technical manual with Version 3 operating system software and

flowmeters that have been updated to Version 5.

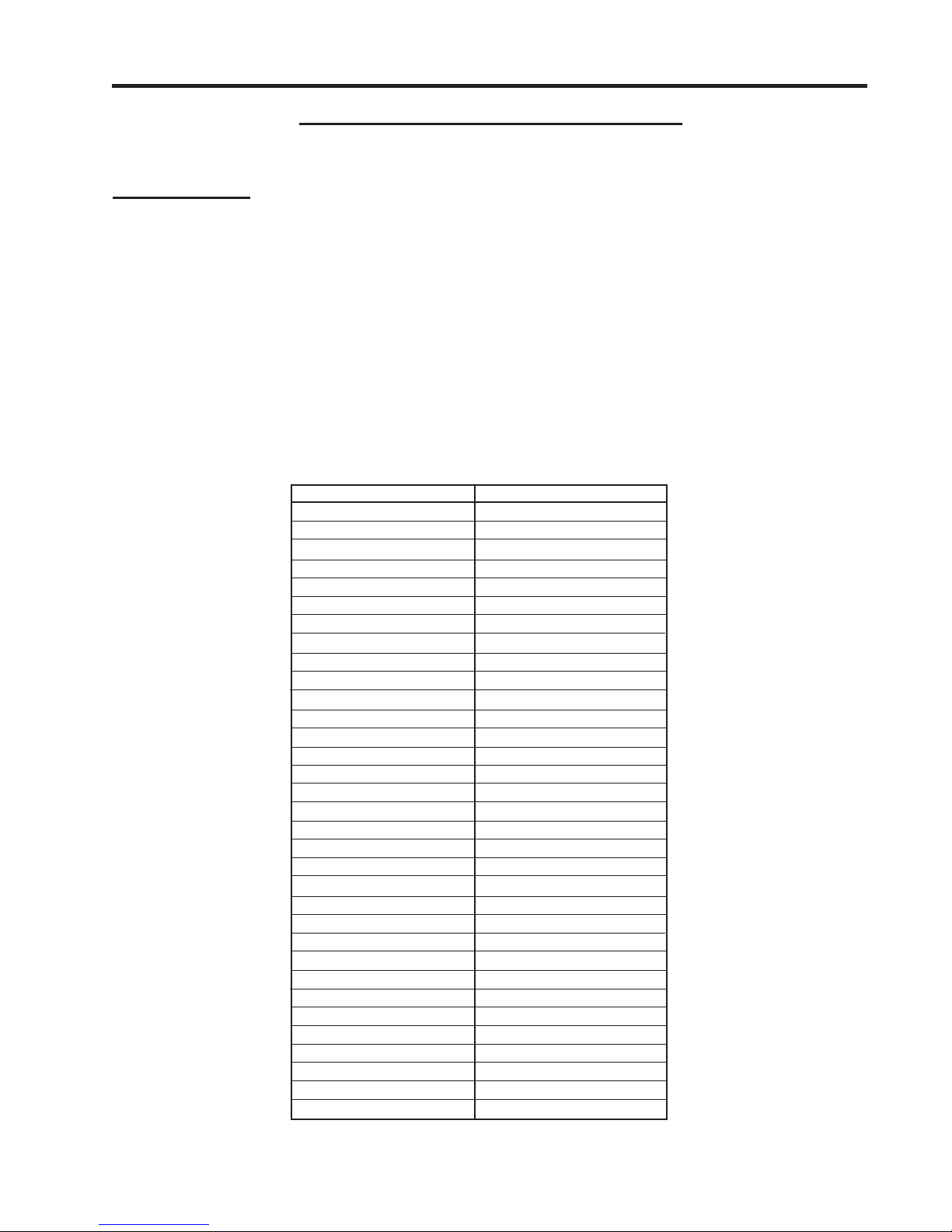

Operating System Software Changes

The [Meter T ype Menu] includes a [Language] menu item that allows the selection of multiple flowmeter

1.

menu foreign languages.

ersion 3 and Version 5 Operating System Dif ferences

2. V

The following table lists the differences between Version 3 and Version 5 operating system menu

items and menu hint lines.

Version 3 Version 5

Select Pipe Class Pick Pipe Class

Pick/Install Xdcr Install Xdcr

Data/Sp an/Set/Ca Span/Set/Cal

Strip Chart Setup Display Setup

Dual Channel Flow 2 Channel Flow

Dual Beam Flow Dual Path Flow

Datalogger Setup Logger Setup

T emperature Range Temp Range

Pipe Configuration Pipe Config

Datalogger Setup Logger Setup

Datalogger Mode Logger Mode

Datalogger Data Logger Data

Log Time Interval Logger Interval

Display Datalogger Display Logger

Recall Site Setup Recall Site

Delete Site Setup Delete Site

Install Completed? Install Complete

Estimated Vs m/s Estimated Vs M/S

Channel /Path Setup Channel Setup

Reflexor Zero Fault/Set Zero Fault/Set

Memory Delay (sec) Memory Delay s)

Flow Volume Units Flow Vol. Units

Flow Display Range Flow Disp. Range

Flow Display Scale Flow Disp. Scale

T otal V olume Units Total Vol. Units

Batch/Sample T otal Batch/Sample Tot

Calibrate Flowrate Calib. Flowrate

Analog Input Setup Analog Inp Setup

Flow Vel F/S Velocity F/S

Vs m/s Vs M/S

Valc % Valc

V aer % Vaer

Vs Max m/s Vs Max M/S

(continued )

A-1

Manual Addendum

Version 3 Version 5

Vs Min m/s Vs Min M/S

Channel/Path Setup Chan/Path Setup

Vfmax GAL/MIN Vfmax

Date Site Created: Site Created:

Empty % Empty

Analog Output Trim Analog Out Trim

Pick flowtube size and type Select flowtube

and start operation

Empty Flowtube Set Empty Pipe Set

1010FMA-56

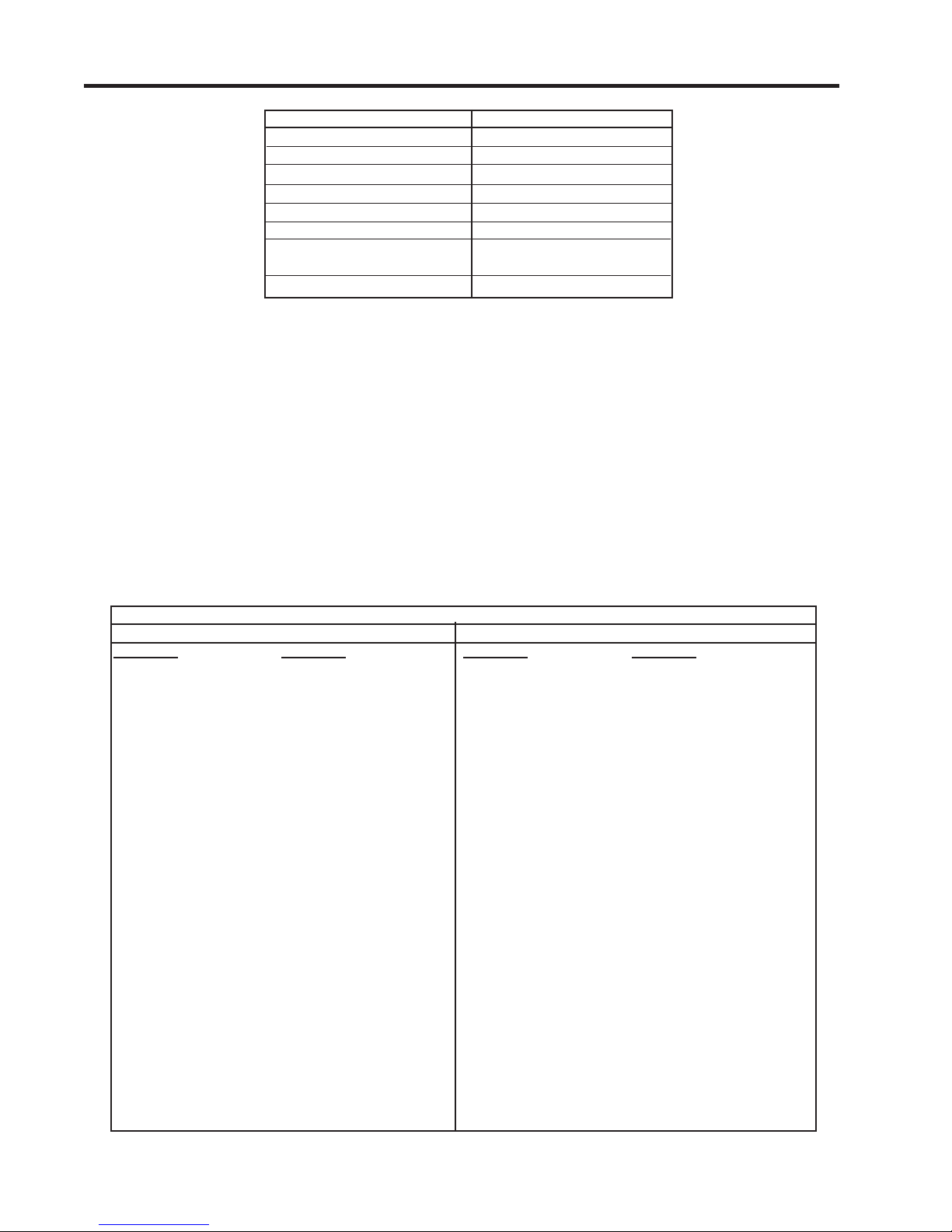

Gas Flowmeter Flow and VoS Unit Changes

1. Flowmeter Types

Flowmeter configurations included with this change include all SITRANS F Gas Flowmeters (7ME361*).

2. Flow Units

The table below describes the translation from the current gas flow units to the new gas flow units,

where only Cubic Feet and Cubic Meter volume units are affected. Also note that M = thousands and

MM = millions. Mass units and V elocity units remain unchanged.

Note: The flow legend changes depending upon the selection of Standard Volume enabled or

disabled.

FLOW UNITS

For STD VOLUME disabled For STD VOLUME enabled

Version 3 Version 5 Version 3 Version 5

CU FT/SEC ACFS CU FT/SEC SCFS

CU FT/MIN ACFM CU FT/MIN SCFM

CU FT/HR ACFH CU FT/HR SCFH

CU FT/DAY ACFD CU FT/DAY SCFD

KCU FT/SEC MACFS KCU FT/SEC MSCFS

KCU FT/MIN MACFM KCU FT/MIN MSCFM

KCU FT/HR MACFH KCU FT/HR MSCFH

KCU FT/DA Y MACFD KCU FT/DAY MSCFD

MCU FT/SEC MMACFS MCU FT/SEC MMSCFS

MCU FT/MIN MMACFM MCU FT/MIN MMSCFM

MCU FT/HR MMACFH MCU FT/HR MMSCFH

MCU FT/DA Y MMACFD MCU FT/DAY MMSCFD

CU M/SEC M3/sec M/SEC NM3/sec

CU M/MIN M3/min CU M/MIN NM3/min

CU M/HR M3/hr CU M/HR NM3/hr

CU M/DA Y M3/day CU M/DAY NM3/day

KCU M/SEC E3 M3/sec KCU M/SEC E3 NM3/sec

KCU M/MIN E3 M3/min KCU M/MIN E3 NM3/min

KCU M/HR E3 M3/hr KCU M/HR E3 NM3/hr

KCU M/DA Y E3 M3/day KCU M/DAY E3 NM3/day

MCU M/SEC E6 M3/sec MCU M/SEC E6 NM3/sec

MCU M/MIN E6 M3/min MCU M/MIN E6 NM3/min

MCU M/HR E6 M3/hr MCU M/HR E6 NM3/hr

MCU M/DA Y E6 M3/day MCU M/DA Y E6 NM3/day

A-2

Manual Addendum

3. Total Units

Total units are similar to flow units.

For STD VOLUME disabled

Version 3 Version 5

CU FT ACF

KCU FT MACF

MCU FT MMACF

CUM M3

KCU M E3 M3

MCU M E6 M3

For STD VOLUME enabled

Version 3 Version 5

CU FT SCF

KCU FT MSCF

MCU FT MMSCF

CUM NM3

KCU M E3 NM3

MCU M E6 NM3

1010FMA-56

TOTALIZE UNITS

TOTALIZE UNITS

4. Sound Velocity Units

Sound velocity will continue to be reported in units of meters/sec for metric units but will change to

Feet/sec for English unit selection. The flowmeter will display M/S and F/S to represent these two

variations.

Note: The units for Sound Velocity will be based on the [Preferred Units] menu item found in

the [Meter Facilities] menu and can not be changed unless a new site is created.

5. Transducer Model Menu Name

The following table lists the operating system menu item differences between Version 3 Hi Precision

and Version 5 Hi Precision transducer model names that appear on the [Inst all Xdcr] menu. Note that

T1, T2 and T3 indicate the dif ferent temperature ranges of the transducer.

Version 3 Transducers Version 5 Transducers

Hi Precision Hi Precision

101 1HG Hi Prec. 101 1HP-T1

101 1HP-T2

101 1HP-T3

A-3

MANUAL

ADDENDUM

1010FMA-58

Digital Damping

Procedure Update

For Gas & Liquid

Flowmeters

Manual Addendum

September 2008

Copyright © 2008 Siemens Industry, Inc. All rights reserved Made in the USA

Manual Addendum

1010FMA-58

Digital Damping Procedure Update for Gas & Liquid Flowmeters

INTRODUCTION

The following Digital Damping procedure updates are for SITRANS F gas and liquid clamp-on

flowmeters.Replace the Digital Damping Control: (Hot Key 1 and 2) procedure in the “Detection Modes”

section (sub-paragraph: Command Modes) in the appropriate gas and liquid STIRANS F flowmeter

manuals.

FUG1010 Gas Clamp-on Flowmeter Manuals

Digital Damping Control: (Hot Key 1 and 2)

The FUG1010 permits user modification of the digital averaging used by the signal processing routines.

In general, the default damping values selected by the FUG1010 will provide optimal performance over

a wide range of transit time applications. However, in extreme cases of unstable flow, pulsating flow,

low signal levels or high electronic noise it may be necessary to override these default settings to

permit uninterrupted and reliable flow measurement.

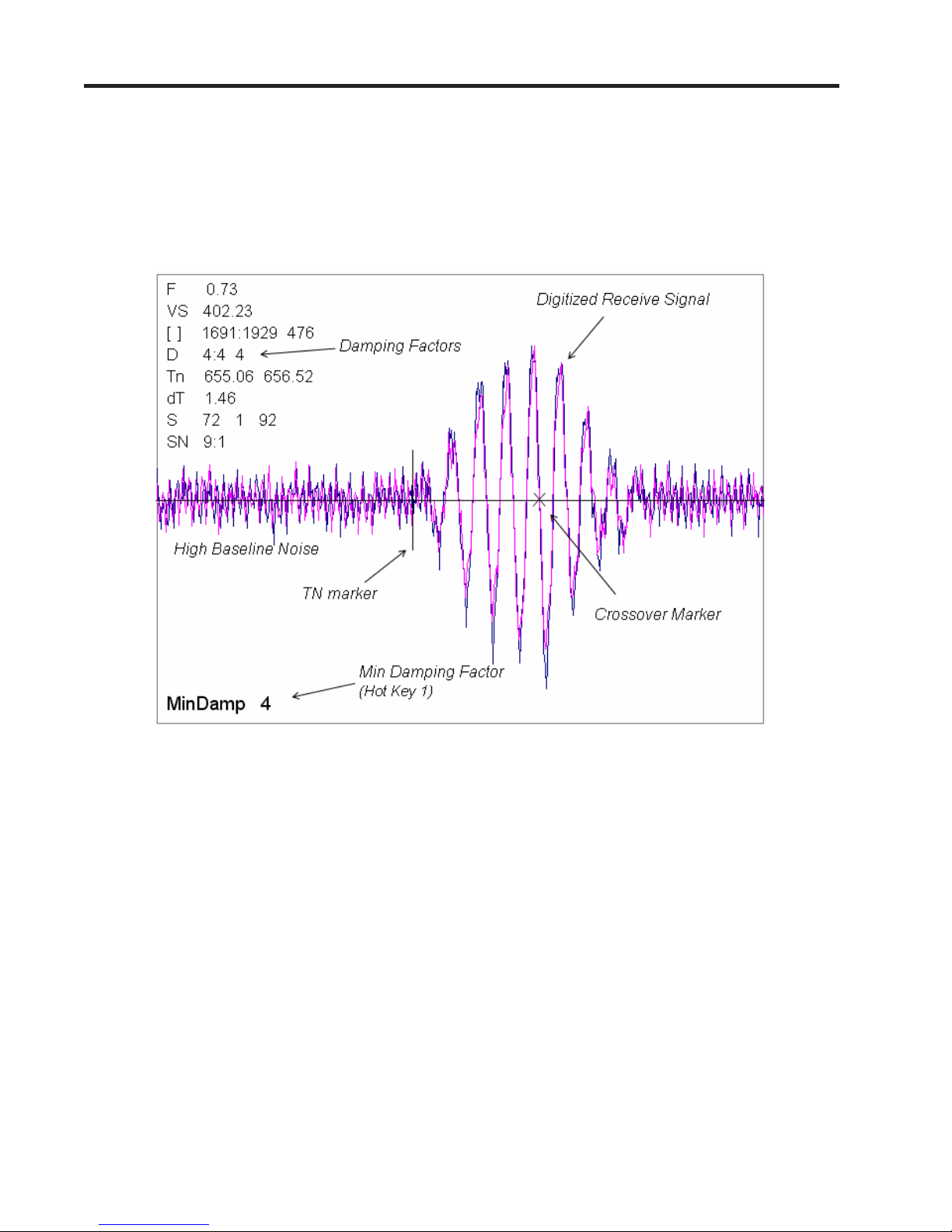

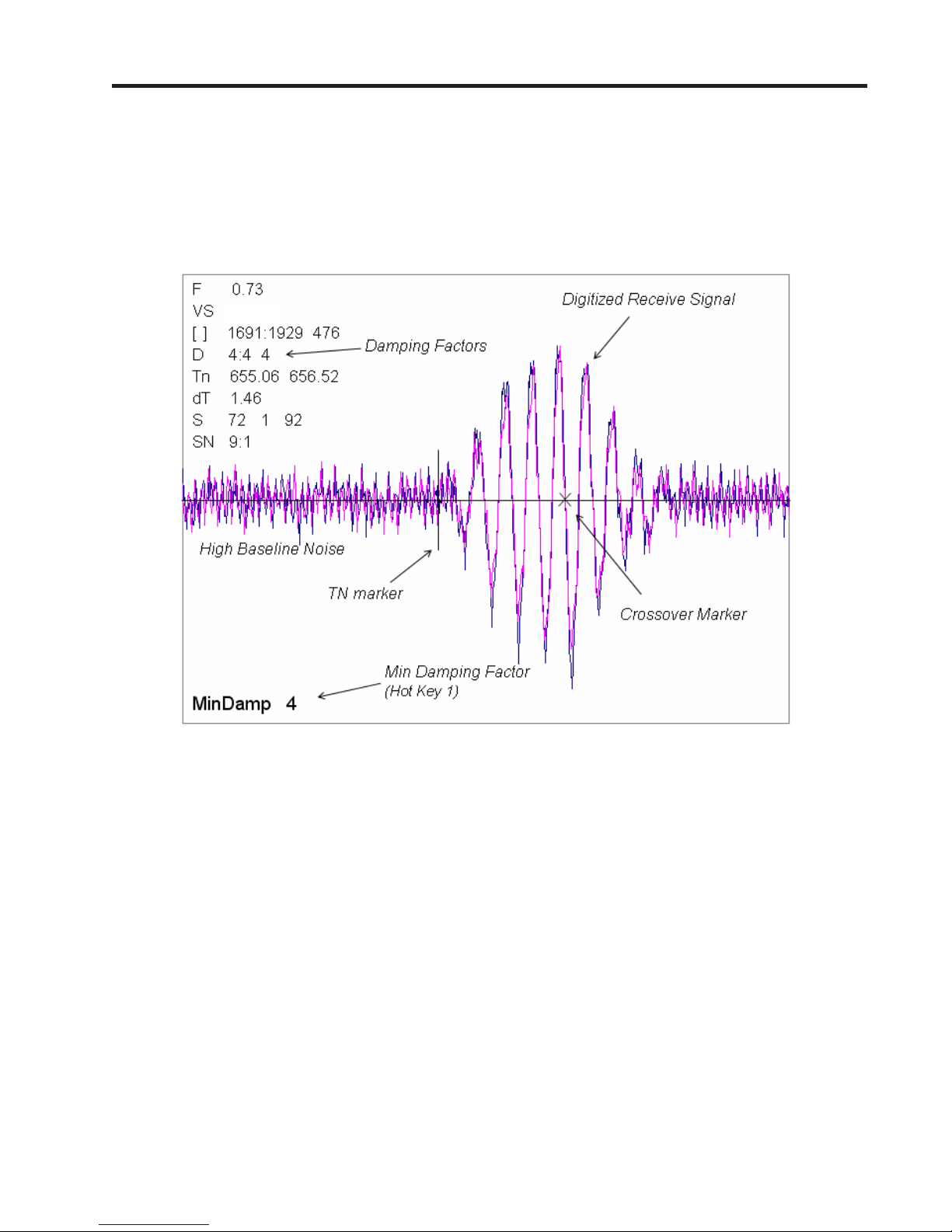

Test Facilities Graph Screen

The FUG1010 Graph Screen includes the capability to access a set of command codes, which enable

a user to override a number of default meter settings. The most important parameter is the digital

damping control, which can be accessed by pressing number <1> or <2> on the keypad while in the

Signal Graph Screen mode.

[MinDamp] Command

Pressing the <1> key will cause [MinDamp #] to appear on the command line at the lower left-hand

corner of the screen. The number listed to the right of the command code represents the exponent in

the FUG1010 exponential averaging routine, where the larger the number the greater the digital averaging.

Pressing the <+> key will increase the damping value. Likewise, pressing the <-> key will decrease

the damping value. To exit this mode, press the <0> key on the keypad.

[MaxDamp] Command

Pressing the <2> key will bring up the [MaxDamp] command. The function of this parameter is similar

to the [MinDamp] command described above; however, the two parameters interact in the following

manner . The MinDamp value must not exceed the MaxDamp value, therefore increasing the MinDamp

value above the previous MaxDamp value will set both parameters to the same value. In most cases,

it is preferred that both damping parameters be set to the same value, however , in cases where rapid

response to changes in gas sound velocity for flow rate is required, the two values may be set differently .

In this situation the meter will use the MaxDamp value when conditions are stable, but then switch to

a faster damping value (limited by MinDamp) when a significant change in sound velocity or flow rate

is perceived. To exit this mode, press the <0> key on the keypad.

A-1

Manual Addendum

1010FMA-58

To access the Digital Damping Control using the Test Facilities Graph Screen, proceed as follows:

1. To use the Test Facilities Graph Screen you must have a working site.

2. To activate the Test Facilities Graph Screen:

z In the main menu, scroll to the [Diagnostic Data] menu and select [Test Facilities].

z Scroll down to [Graph], press the <Right Arrow> and highlight [Yes]. Press <ENT> to select.

z The Test Facilities Graphic Screen will appear on the meter display as shown below.

Setting the Digital Damping Factor to a value HIGHER than the default value of 4 may be necessary

in cases where the signal to noise ratio (SN) is found to be unacceptably low (<15:1), but only if the

noise is determined to be asynchronous (i.e., not associated with the transmit or flowmeter timing

circuitry) as shown in the signal example above, where the baseline noise has a higher frequency

than the true gas signal.

The following application conditions may require a higher Digital Damping Factor:

z Close proximity to pressure control valves which may generate in-band acoustic noise

z Very low acoustic signal levels (ALC < 40%)

z High electronic noise from variable frequency drives or other external equipment.

A-2

Manual Addendum

1010FMA-58

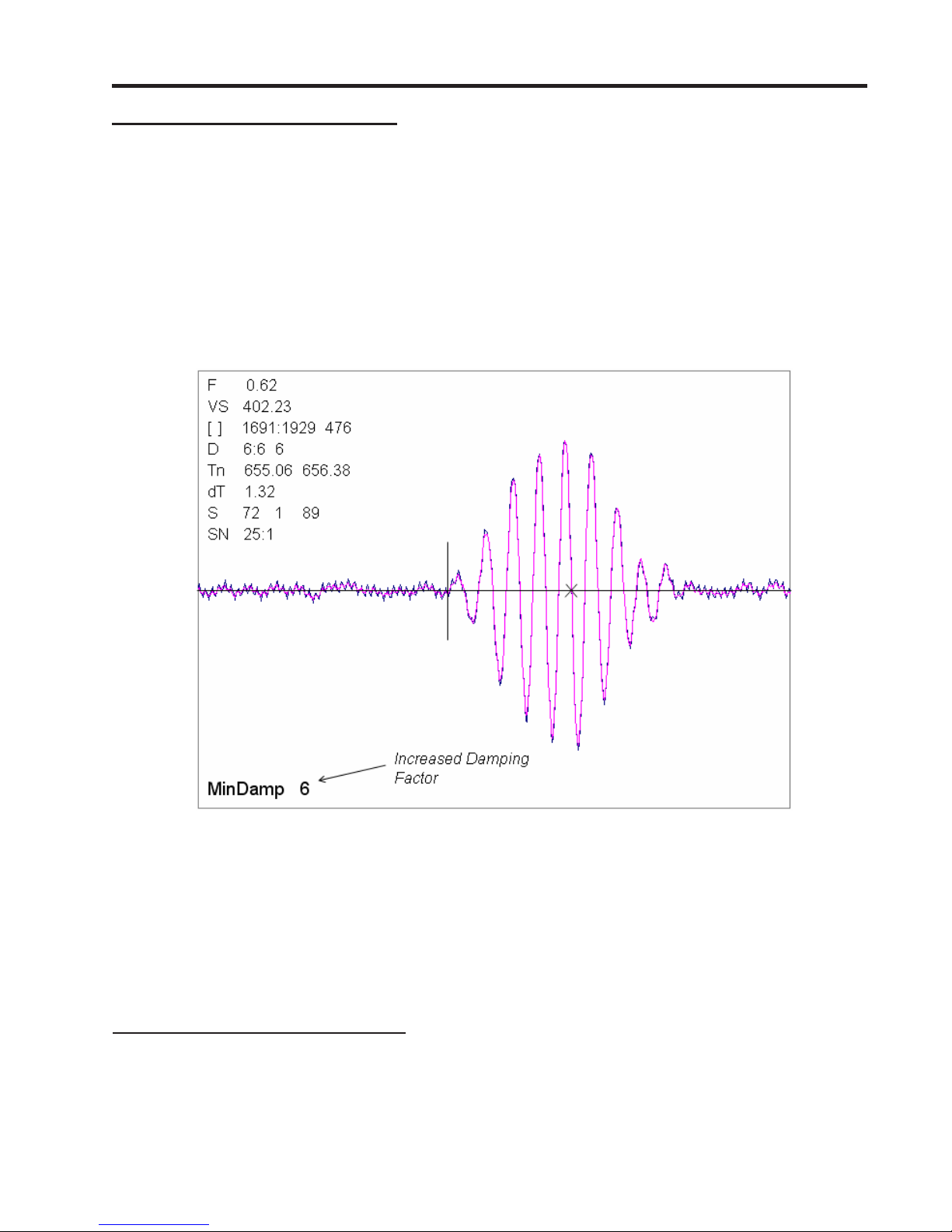

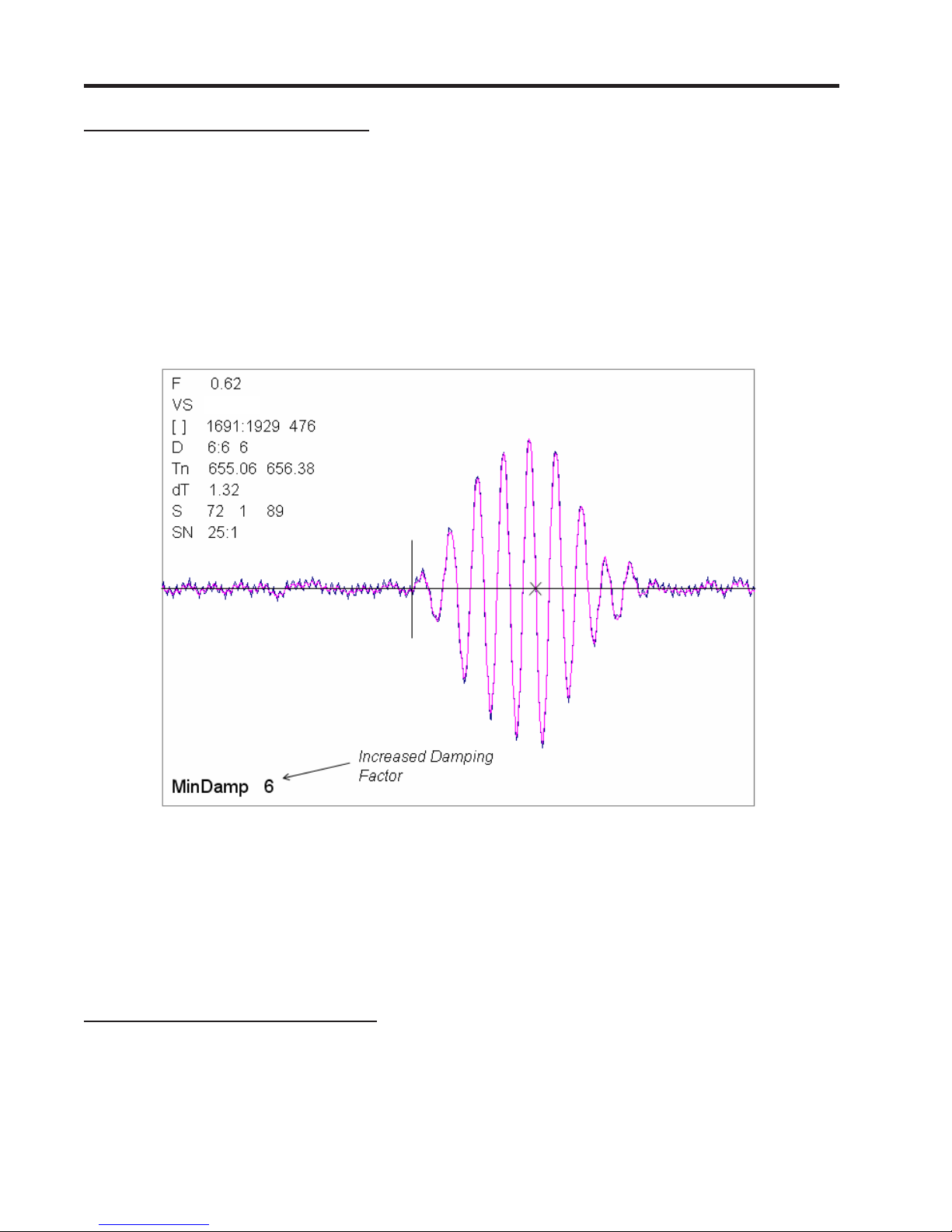

To INCREASE the Digital Damping:

1. Press the <1> key while viewing the Test Facilities Graph Screen as shown above. The damping

control [MinDamp #] should appear on the command line at the lower left-hand corner of the

screen.

Note: The number listed to the right of the command code on the screen represents the

exponent in the exponential averaging routine, where the larger the number represents

the greater the digital averaging. Setting this exponent higher than 7 is generally not

recommended.

2, Pressing the <+> key will increase the MinDamp Factor by one unit for each key press. To exit this

mode, press the <0> key on the keypad.

The above example shows that increasing the Digital Damping reduces asynchronous noise.

Setting the Digital Damping factor to a value LOWER than the default value of 4 may be justified in

cases where pulsating flow is present (such as from a reciprocating compressor) or for the purpose

of diagnosing transient signal behavior. A pulsating flow condition that generates more than +/- 45

degrees of phase jitter will generally cause signal correlation problems when any digital averaging is

used. In this case it may be necessary to completely eliminate the digital averaging by reducing the

Digital Damping Factor to 0. In such a case it may also be necessary to install a narrow band tuned

amplifier (Input Module) if too much asynchronous noise exists.

To DECREASE the Digital Damping:

1. Press the <2> key while viewing the T est Facilities Graph Screen. The damping control [MaxDamp

#] should appear on the command line at the lower left-hand corner of the screen.

2. Pressing the <-> key will decrease the MaxDamp Factor by one unit for each key press. T o exit this

mode, press the <0> key on the keypad.

A-3

Manual Addendum

1010FMA-58

Liquid Clamp-on Flowmeter Manuals

Replace the Digital Damping Control: (Hot Key 1 and 2) procedure in the “Detection Modes” section

(sub-paragraph: Command Modes) in the following flowmeter manuals:

FUS1010 IP 65 (NEMA 4X) Clamp-On Flowmeter manual (CQO:1010NFM-3)

FUE1010 IP 65 (NEMA 4X) Clamp-On Flowmeter manual (CQO:1010ENFM-3)

FUH1010 IP 65 (NEMA 4X) Clamp-On Flowmeter manual (CQO:1010DVNFM-3)

FUH1010 IP 65 (NEMA 4X) Clamp-On Flowmeter manual (CQO:1010PVNFM-3)

FUP1010 IP 40 (NEMA 1) Clamp-On Portable Flowmeter manual (CQO:1010PFM-3)

FUE1010 IP 40 (NEMA 1) Clamp-On Portable Flowmeter manual (CQO:1010EPFM-3)

Digital Damping Control: (Hot Key 1 and 2)

The meter permits user modification of the digital averaging used by the signal processing routines. In

general, the default damping values selected by the METER will provide optimal performance over a

wide range of transit time applications. However, in extreme cases of unstable flow , pulsating flow , low

signal levels or high electronic noise it may be necessary to override these default settings to permit

uninterrupted and reliable flow measurement.

Test Facilities Graph Screen

The Graph Screen includes the capability to access a set of command codes, which enable a user to

override a number of default meter settings. The most important parameter is the digital damping

control, which can be accessed by pressing number <1> or <2> on the keypad while in the Signal

Graph Screen mode.

[MinDamp] Command

Pressing the <1> key will cause [MinDamp #] to appear on the command line at the lower left-hand

corner of the screen. The number listed to the right of the command code represents the exponent in

the meter exponential averaging routine, where the larger the number the greater the digital averaging.

Pressing the <+> key will increase the damping value. Likewise, pressing the <-> key will decrease

the damping value. To exit this mode, press the <0> key on the keypad.

[MaxDamp] Command

Pressing the <2> key will bring up the [MaxDamp] command. The function of this parameter is similar

to the [MinDamp] command described above; however, the two parameters interact in the following

manner. The MinDamp value must not exceed the MaxDamp value, therefore increasing the MinDamp

value above the previous MaxDamp value will set both parameters to the same value. In most cases,

it is preferred that both damping parameters be set to the same value, however , in cases where rapid

response to changes in liquid sound velocity for flow rate is required, the two values may be set

differently . In this situation the meter will use the MaxDamp value when conditions are stable, but then

switch to a faster damping value (limited by MinDamp) when a significant change in sound velocity or

flow rate is perceived. To exit this mode, press the <0> key on the keypad.

A-4

Manual Addendum

1010FMA-58

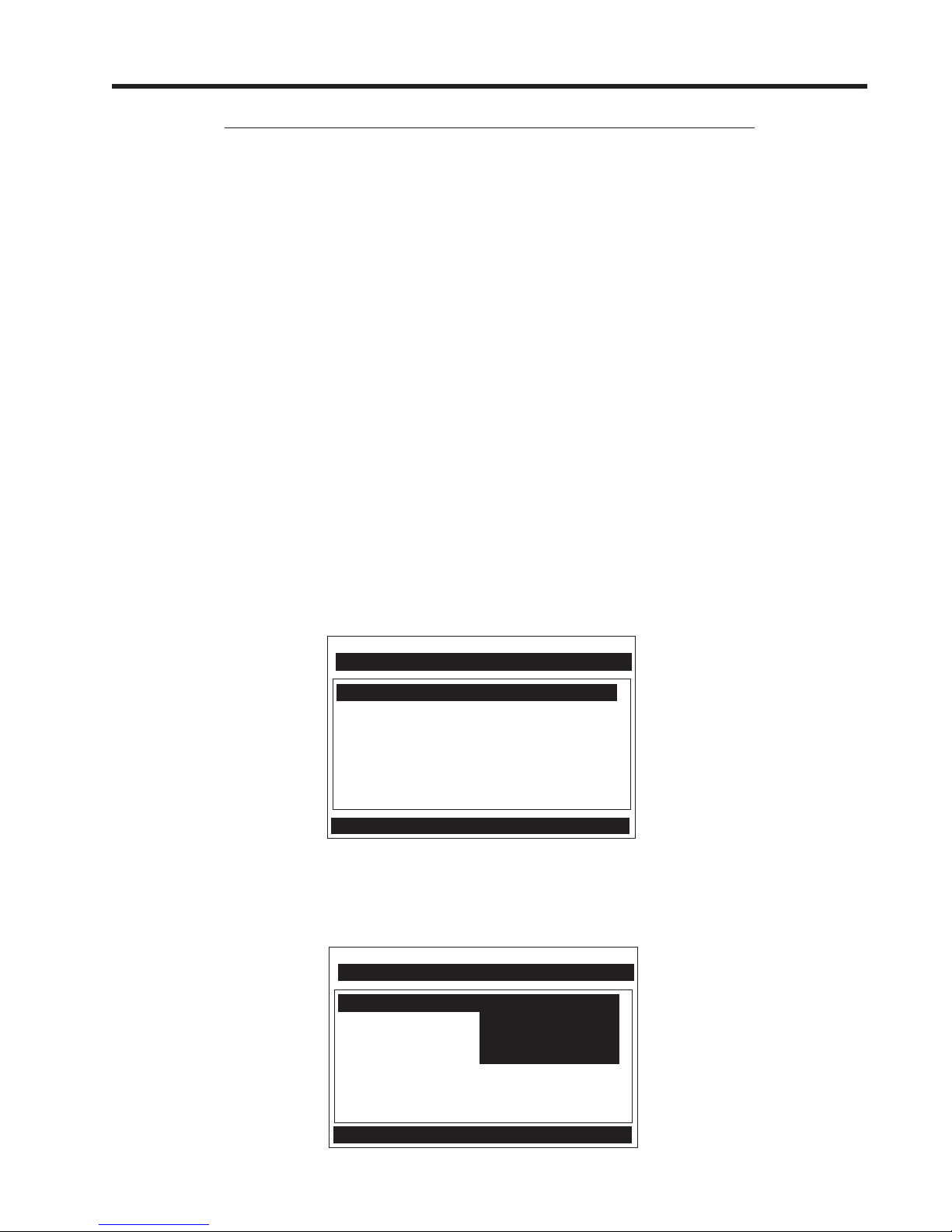

To access the Digital Damping Control using the Test Facilities Graph Screen, proceed as follows:

1. To use the Test Facilities Graph Screen you must have a working site.

2. To activate the Test Facilities Graph Screen:

z In the main menu, scroll to the [Diagnostic Data] menu and select [Test Facilities].

z Scroll down to [Graph], press the <Right Arrow> and highlight [Yes]. Press <ENT> to select.

z The Test Facilities Graphic Screen will appear on the meter display as shown below.

1482.1

Setting the Digital Damping Factor to a value HIGHER than the default value of 4 may be necessary in

cases where the signal to noise ratio (SN) is found to be unacceptably low (<15:1), but only if the noise

is determined to be asynchronous (i.e., not associated with the transmit or flowmeter timing circuitry)

as shown in the signal example above, where the baseline noise has a higher frequency than the true

liquid signal.

The following application conditions may require a higher Digital Damping Factor:

z Close proximity to pressure control valves which may generate in-band acoustic noise

z High un-dissolved gas solids content in liquid.

z High electronic noise from variable frequency drives or other external equipment.

A-5

Manual Addendum

1010FMA-58

To INCREASE the Digital Damping:

1. Press the <1> key while viewing the Test Facilities Graph Screen as shown above. The damping

control [MinDamp #] should appear on the command line at the lower left-hand corner of the

screen.

Note: The number listed to the right of the command code on the screen represents the

exponent in the exponential averaging routine, where the larger the number represents

the greater the digital averaging. Setting this exponent higher than 7 is generally not

recommended.

2. Pressing the <+> key will increase the MinDamp Factor by one unit for each key press. To exit this

mode, press the <0> key on the keypad.

1482.1

The above example shows that increasing the Digital Damping reduces asynchronous noise.

Setting the Digital Damping factor to a value LOWER than the default value of 4 may be justified in

cases where pulsating flow is present (such as from a reciprocating pump) or for the purpose of

diagnosing transient signal behavior. A pulsating flow condition that generates more than +/- 45 degrees

of phase jitter will generally cause signal correlation problems when any digital averaging is used. In

this case it may be necessary to completely eliminate the digital averaging by reducing the Digital

Damping Factor to 0.

To DECREASE the Digital Damping:

1. Press the <2> key while viewing the Test Facilities Graph Screen. The damping control [MaxDamp

#] should appear on the command line at the lower left-hand corner of the screen.

2. Pressing the <-> key will decrease the MaxDamp Factor by one unit for each key press. T o exit this

mode, press the <0> key on the keypad.

A-6

MANUAL

ADDENDUM

1010FMA-22

System 1010AP/AER

Ultrasonic Aerospace

Portable Flowmeter

Manual Addendum

1010FMA-22

March 2007

Copyright © 2007 Siemens Industry, Inc all Rights Reserved Made in the USA

1010AERWDP TRANSDUCER INSTALLATION

1. INTRODUCTION

The System 1010AERWDP flowmeters are part of Siemens extensive System FUS 1010 ClampOn Transit-Time Ultrasonic Flowmeter division. These meters have all the capabilities of the

FUS1010 Clamp-On Series flowmeters plus all the added features of the Aerospace line, which

is specifically designed to accurately and non-intrusively measure flow in steel, aluminum,

and titanium tubing typically used in aircraft hydraulic and fuel systems.

NOTE: If not installing aerospace transducers refer to the FUP1010 Portable Flow-

meter Field Manual instead.

2. FLOWMETER SETUP

NOTE: If flowmeter is already installed at the site disregard the following set up proce-

dure.

The following instructions require the use of the FUP1010 Flowmeter keypad and menus. The

installer should become familiar with them before proceeding further. Refer to Tables 1 and 2

as needed for menu setup data. In addition, refer to Section 2 - The Installation Menu in the

appropriate flowmeter field manual.

To set up the flowmeter with the Aerospace Transducer, proceed as follows:

Selecting Aerospace Transducer

z Switch the flowmeter on. Press the <MENU> key.

Siemens Site [1]

Select Meter Type

Meter Type >Dual Channel Flow

Meter Facilities

z Press <Right> arrow key to select “Dual Channel Flow” mode. To select, press <ENT>

key.

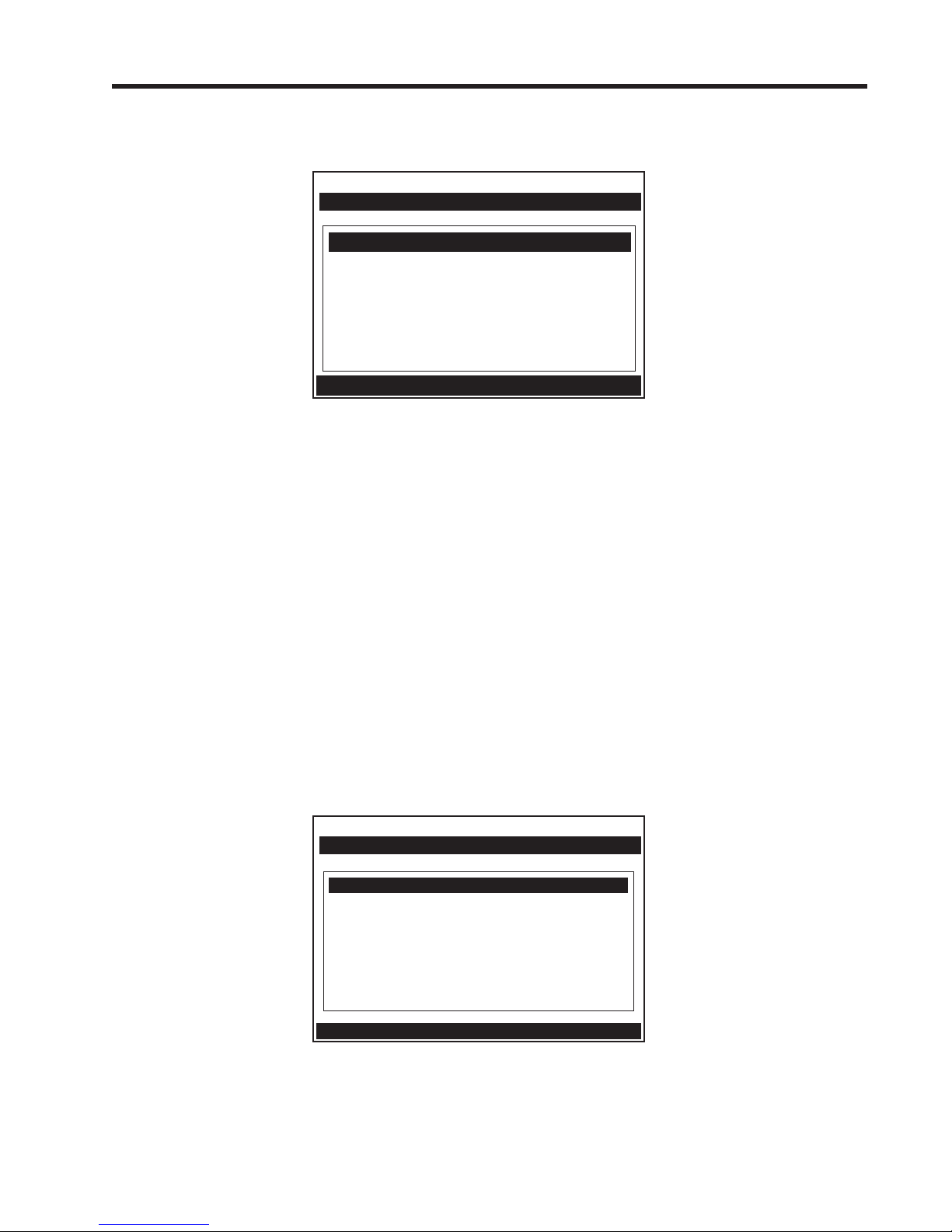

z Press <Right> arrow key and then the <Down> arrow key to select Aerospace, then

press the <ENT> key.

Siemens Site [1]

Dual Channel Flow Setup

Dual Channel Flow >Aerospace

Clamp-on

Flow Tube

Reflexor

Single Channel

1

Creating a New Site Setup (See also paragraph 2.1.3 in 1010P Field Manual)

This section provides an example of how to use the [Create/Rename Site] command to create a

new site setup. Always begin a new installation by issuing the [Create/Name Site] command.

Although you do not need to enter a site name to create a new site setup, you will have to provide

one to save the site setup or to identify the source of logged data. In this example, [SITE1] will be

used for the site name.

zz

z To access the [Channel Setup] menu press the <Right> arrow, then move the highlight

zz

down to [Create/Name Site].

Siemens Site [1]

Right Arrow & Enter Creates a new Site

Recall Site Setup No Sites

Channel Enable No

Create/Name Site

Site Security Off

Delete Site Security No Sites

Save/Rename Site

Channel Setup

z Press the <Right> arrow. Note that the cursor changes to a block that appears after a

question mark (?). This indicates that you have accessed the first character position of an

eight-character (maximum) alphanumeric entry field.

Siemens Site [1]

Right Arrow & Enter Creates a new Site

Recall Site Setup No Sites

Channel Enable No

Create/Name Site ?

Site Security Off

Delete Site Security No Sites

Save/Rename Site

Channel Setup

z You can create a site name (up to 8 characters) by scrolling through the list of available

This block cursor is

currently placed at the first

character position.

characters, using the <UP> or <Down> arrows or numeric keypad. Pressing the <Right>

arrow advances the cursor to the next character space.

z Once the desired site name is filled in, press the <ENT> key to register the selection.

z Press the <Left> arrow to exit this menu.

2

Selecting Pipe Data

z Press the <Down> arrow to select Pipe Data, then press the <Right> arrow.

Siemens Site [1] SITE1

Enter Pipe Outer Diameter manually

Pipe OD (in) 1.000

Pipe Material Steel

Wall Thickness 0.035

Liner Material None

Liner Thickness 0.000

Pipe Data

z To select Pipe OD (in), press the <Right> arrow. Use numeric keys to change pipe size.

Press the <ENT> key to register data.

z Press the <Down> arrow to select Pipe Material if it is not displayed, then press the

<Right> arrow to select option list.

z Use the <Up> and <Down> keys to scroll the option list for the desired pipe material.

Press the <ENT> key to register data.

z Press <Down> arrow to select Liner Material if it is not displayed, then press the <Right>

arrow to select option list.

z Use the <Up> and <Down> keys to scroll the option list for the desired liner material.

Press the <ENT> key to register data.

z Press the <Down> arrow to select Liner Thickness, then press <Right> arrow. Use nu-

meric keys to change pipe size. Press the <ENT> key to register data.

Liquid Data

z Press the <Down> arrow to select Liquid Data if it is not displayed, then press the <Right>

arrow.

Siemens Site [1] SITE1

Kinematic Viscosity of liquid

Viscosity <cS> 1.00

Density S.G. 1.000

Liquid Data

z Press the <Right> arrow and use numeric keys to change Viscosity <cS>. Press <ENT>

to register data.

z Press the <Right> arrow and use numeric keys to change Density SG. Press <ENT> to

register data.

3

Using the Pick/Install Xdcr Menu

z Press the <Down> arrow to select Pick/Install Xdcr if it is not displayed, then press the

<Right> arrow. The meter will display only the transducers that are suitable for the

entered tube diameter.

The prompt line will display the recommended transducer part number based on the

entered wall thickness as indicated in Table 2 on page 9 of this addendum.

Siemens Site [1] SITE1

Recommended Xdcr: 1011AP-16S2-B

Transducer P/N *1011AP-16S2-B

Install Completed? 1011AP-16S3-B

Empty Pipe Set 1010AP-16S4-B

Zero Flow Adjust Chan Not Setup

Pick/Install Xdcr

z Press the <Right> arrow and scroll to desired transducer P/N (e.g., P/N 1011AP-16S2-B).

z Press the <ENT> key to register your selection.

3. AEROSPACE TRANSDUCER INSTALLATION

Transducer Mounting Procedure

To install the Aerospace Transducer, refer to Installation Drawing 1011AP-8 in this addendum and proceed as follows:

z Apply a thin bead of Super Lube (CC128) to the active area of the transducer.

z Press the transducer onto the tube and snap it into place. Check to make sure that the

transducer makes positive contact with the tube.

Connecting Transducer Cables

NOTE: The 1010 Aerospace Transducer is a bi-directional device. The upstream and

downstream transducer cabling can be interchanged depending on which direction of flow is desired to be positive or negative.

z Connect one end of the BNC transducer cable to the upstream transducer connector

(UP).

z Connect the other end of the flow transducer cable to the UP connector on flowmeter.

z Connect one end of another BNC transducer cable to the downstream transducer connec-

tor (DN).

z Connect the other end of the flow transducer cable to the DN connector on flowmeter.

4

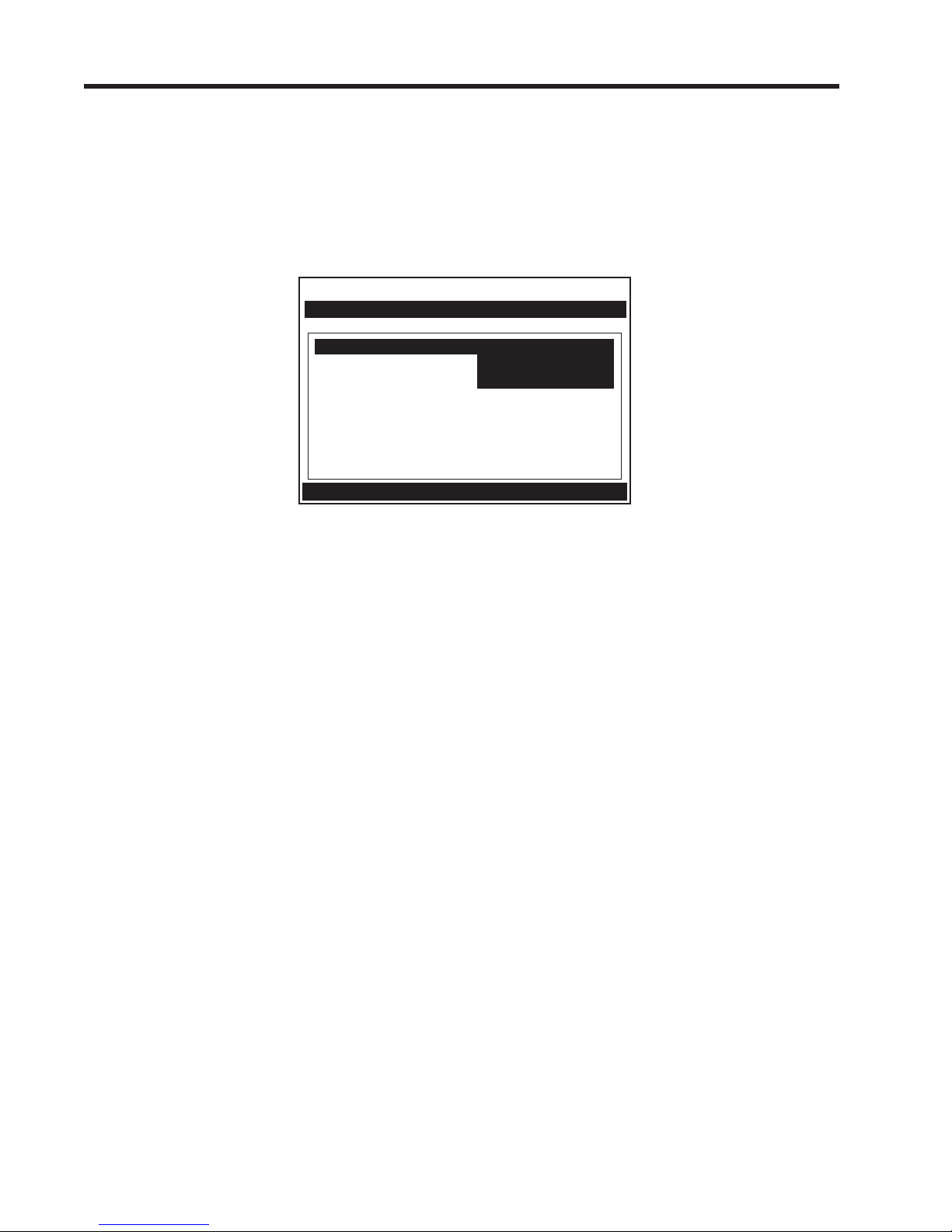

z Press the <Down> arrow to select Install Completed?, then press the <Right> arrow.

Siemens Site [1] SITE1

Key [Install] after mounting transducers

Transducer P/N 1011AP-16S2-B

Install Completed? No

*Install

Empty Pipe Set Chan Not Setup

Zero Flow Adjust Chan Not Setup

Pick/Install Xdcr

z Use the <UP> or <Down> arrows to move the cursor to Install.

z Press the <ENT> key to register selection. The meter will then perform an Initial Makeup,

which conditions its operation to the selected transducer, pipe, and liquid. It then automatically sets the empty pipe and zero flow levels. Be patient, this process may take

several minutes.

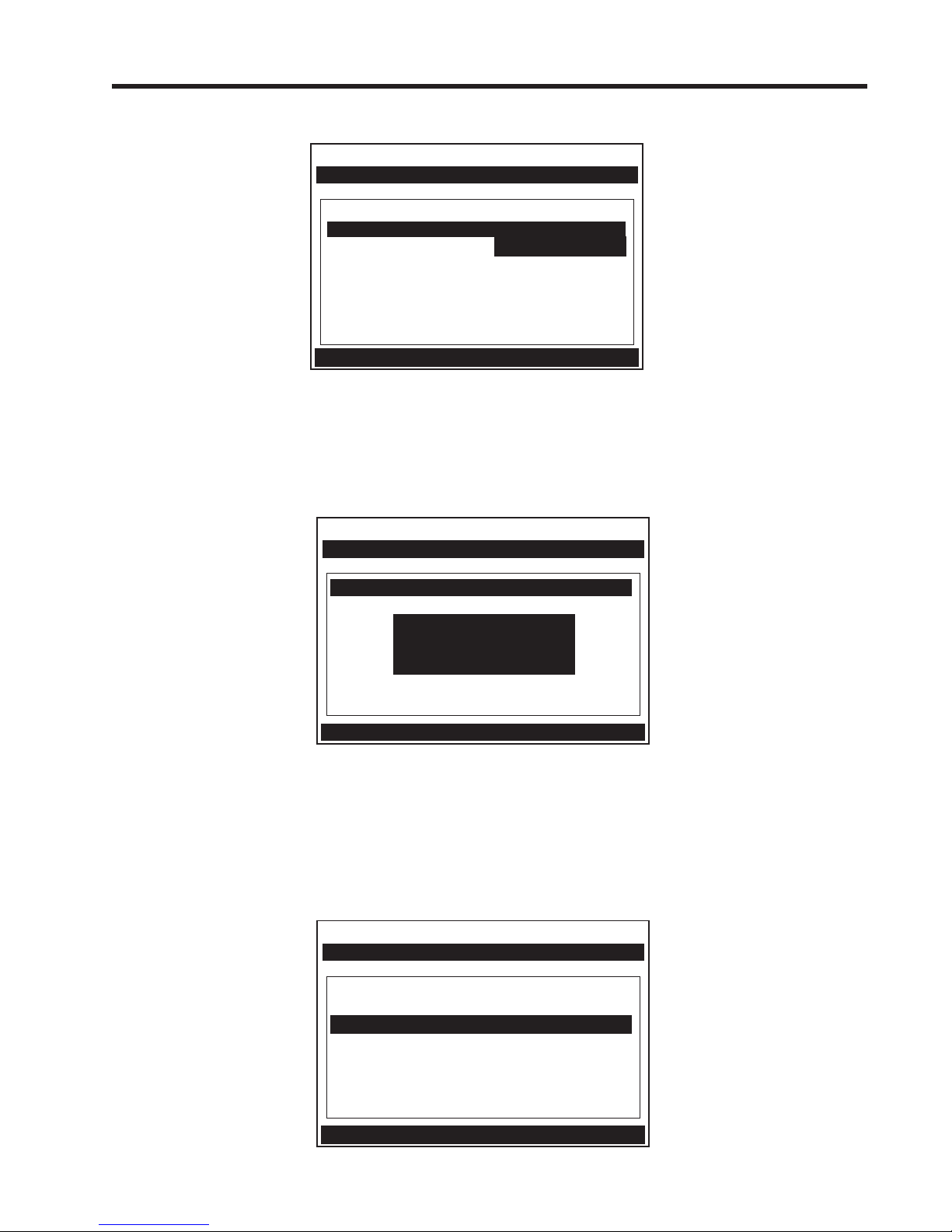

Siemens Site [1] SITE1

Drive 10 m 13 [6:----------:0]

Transducer P/N 1011AP-16S2-B

Install Completed? Install

Empty Pipe Set Chan Not Setup

Zero Flow Adjust Chan

Not Setup

Pick/Install Xdcr

z Upon completion the meter reports the measured liquid sonic velocity. To accept the

Measured Vs m/s

1490

Measured Vs, press the <Down> arrow.

NOTE: If you want to correct the reported sound velocity, press the <Right> arrow to

edit the indicated Vs value, then press <ENT> to continue.

NOTE: The meter will now perform an AutoZero operation where the meter measures

any zero flow offset, which is used to correct the flow reading.

Siemens Site [1] SITE1

Set Empty Pipe Detection Threshold

Transducer P/N 1011AP-16S2-B

Install Completed? Yes

Empty Pipe Set MTYmatic

Zero Flow Adjust Actual Zero

Pick/Install Xdcr

5

After the meter completes its Initial Makeup command, the [Installed Completed?] option

list changes to:

Install Completed? Yes

New Makeup

If you want to redo the Initial Makeup, move cursor to New Makeup, then press the <ENT> key.

This resets the option list. You can now repeat the install routine described previously.

z Refer to the FUP1010 Portable field manual for the Empty Pipe Set procedure.

z Refer to the FUP1010 Portable field manual for the Zero Flow Adjust procedure.

NOTE: For additional FUP1010 flowmeter functions refer to the FUP1010PFM-3 field

manual.

6

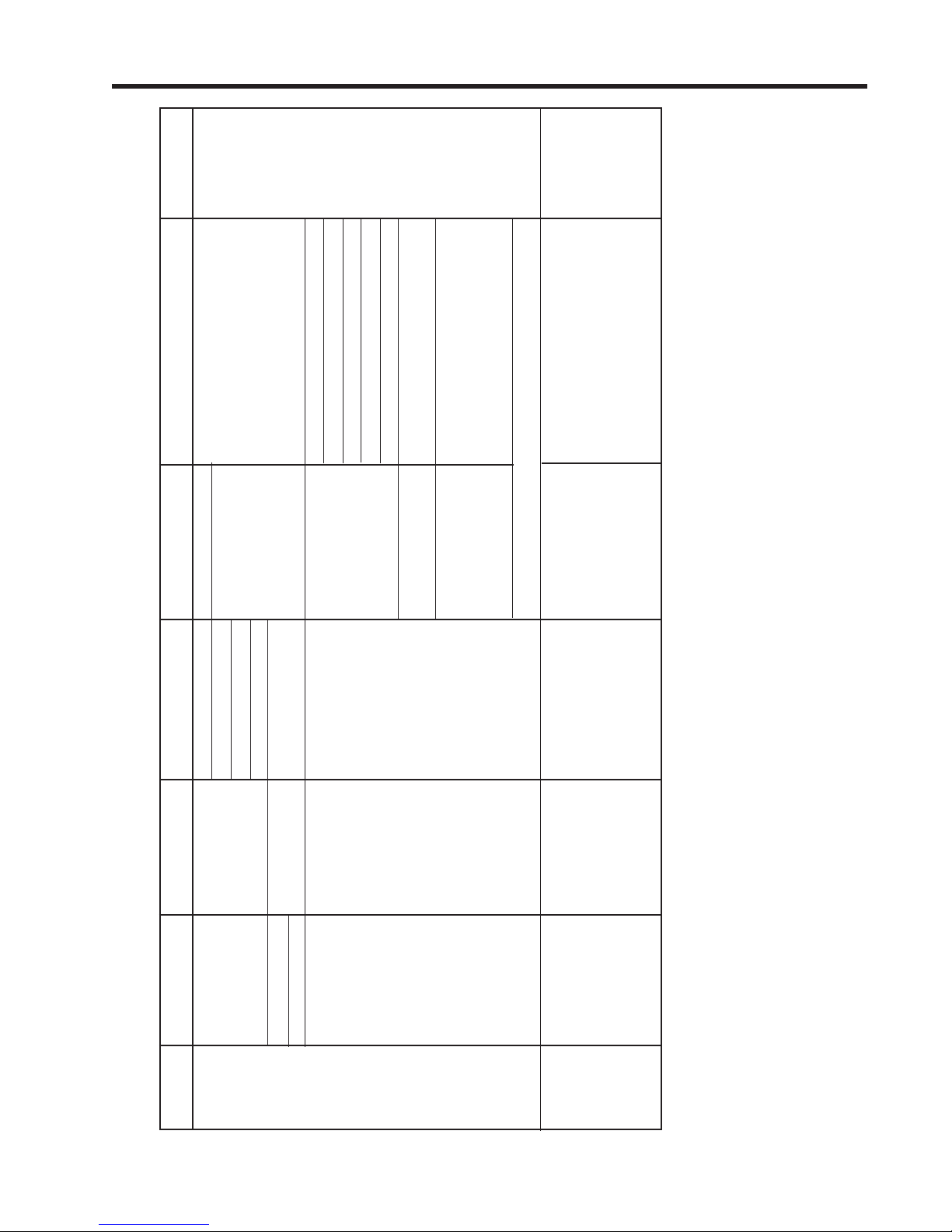

Pipe Material

Wall Thickness

Liner Material

Liner Thickness

(Select Xdcr)

Install Completed?

Empty Pipe Set

Density S.G.

Zero Flow Adjust

Meter Facilities

Menu does not

include “T able

Setups.” See

1010P manual.

FlowTube*

Clamp-on*

Reflexor*

Single Channel Channel 1 Aerospace Channel Setup

Thickness Gauge

Pipe Data Pipe OD (in)

Flaw Detector

Liquid Data Viscosity cS

Pick/Install Xdcr Transducer P/N

All other menu items are unchanged (see 1010P manual).

Table 1. System Menu

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 - Data/Entry Level Comments

Meter Type

Meter

Facilities

* For additional functions refer to the FUP1010 Portable field manual.

7

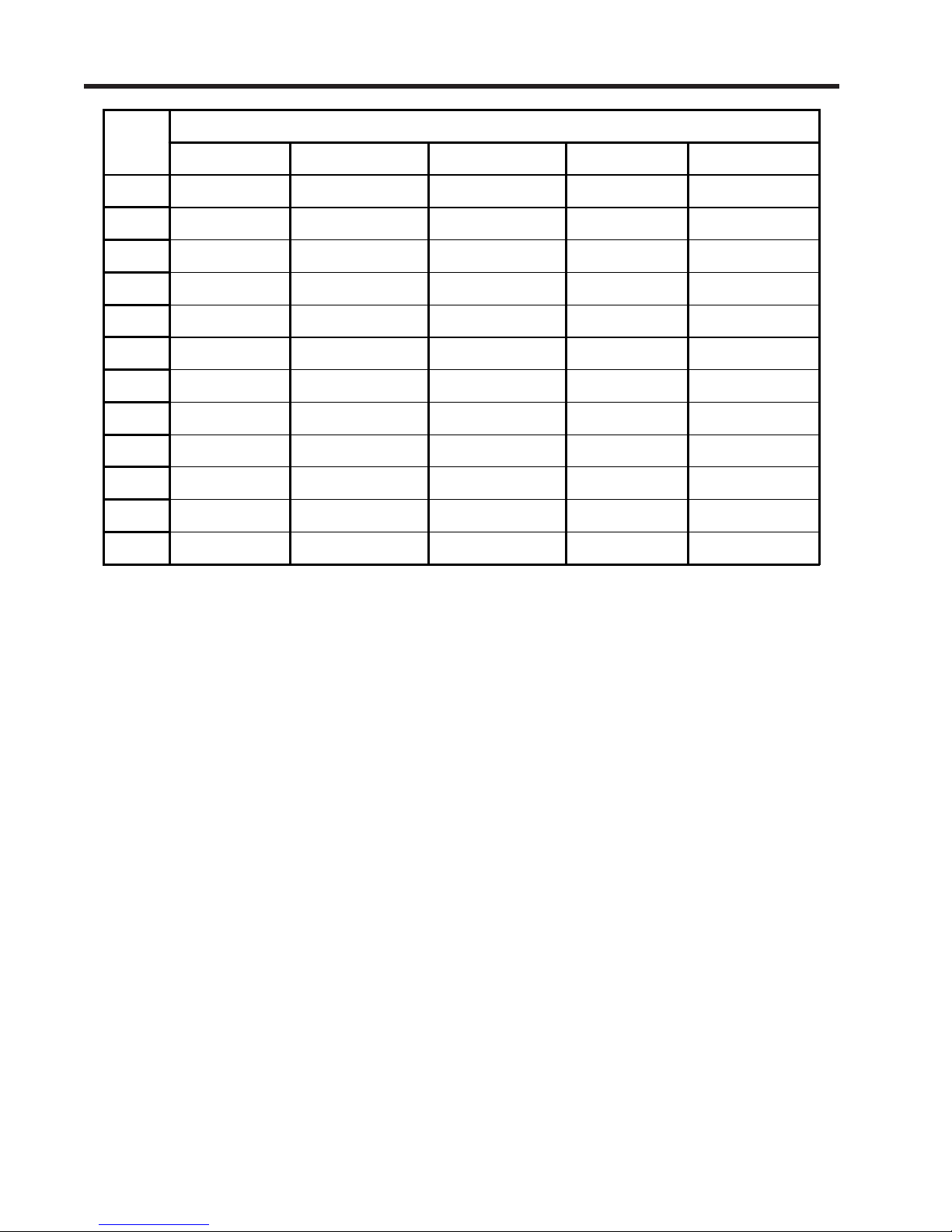

Wall Thickness Range (in)

OD (in)

1/4 1011AP-4S1-B

1/3 1011AP-5S1-B

3/8 1011AP-6S1-B

1/2 1011AP-8S1-B 1011AP-8S2-B

5/8 1011AP-10S2-B 1011AP-10S3-B

3/4 1011AP-12S2-B 1011AP-12S3-B 1011AP-12S4-B

7/8 1011AP-14S2-B 1011AP-14S3-B 1011AP-14S4-B

1 1011AP-16S2-B 1011AP-16S3-B 1011AP-16S4-B

1 1/8 1011AP-18S2-B 1011AP-18S3-B 1011AP-18S4-B 1011AP-18S5-B

1 1/4 1011AP-20S2-B 1011AP-20S3-B 1011AP-20S4-B 1011AP-20S5-B

1 1/2 1011AP-24S2-B 1011AP-24S3-B 1011AP-24S4-B 1011AP-24S5-B

2 1011AP-32S2-B 1011AP-32S3-B 1011AP-32S4-B 1011AP-32S5-B

0.015 to 0.042 0.015 to 0.042 0.043 to 0.061 0.062 to 0.084 0.085 to 0.116

Table 2. Pipe Outer Dimension and Wall Thickness Chart

NOTE: The 1011AP Aerospace Transducer part number designations are expressed in

1/16-inch increments (e.g., part number 1011AP-4S1-B indicates 4S = 1/4”).

8

Loading...

Loading...