City of Decatur Implements

Siemens SITRANS store IQ for

Operational Transparency

Digitalization Application Case Study

Customer Operational Challenges

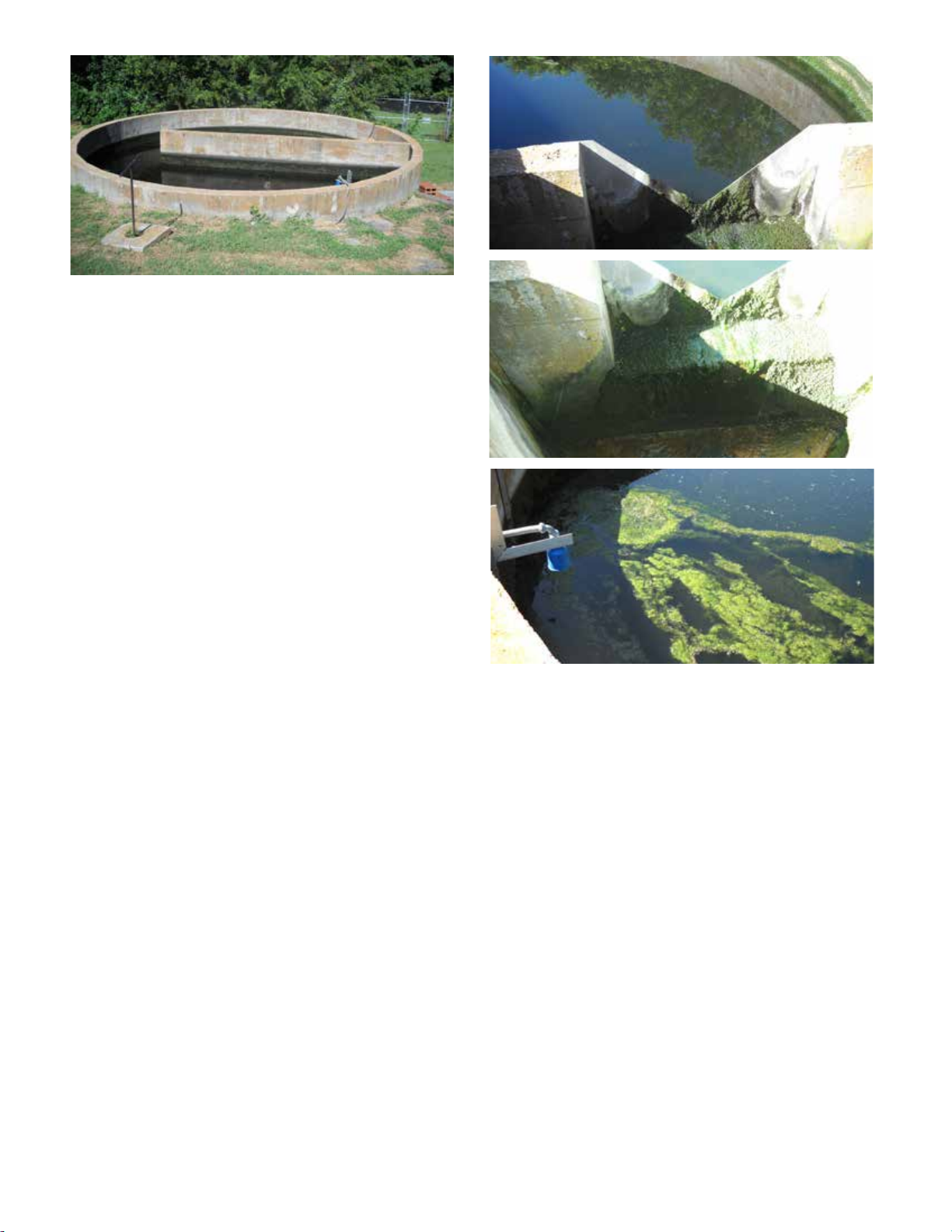

The City of Decatur Wastewater Treatment plant in Texas includes a polishing pond and effluent discharge basin, both of which can be overcome with

algae growth depending on weather and environmental conditions

throughout the year. At times, the algae overgrowth would plug areas of

these systems and restrict or block the flow from the polishing pond and

effluent basin, which sit approximately 300 yards from each other. The

12-inch diameter line from the polishing pond to the effluent basin is

buried and not easily accessible. This and the effluent basin’s discharge

V-notch weir are both subject to this plugging. The line also includes a

shutoff valve, which is another point of clogging that may cause the polishing pond to back-up and potentially overflow. This valve is also used for

testing and to ensure proper zero level during annual inspection and calibration of instrumentation per TCEQ (Texas Commission on Environmental

Quality) requirements.

Figure 1. Pump truck clearing the discharge line from

the Polishing Pond to the Effluent Discharge Basin

usa.siemens.com/monitoring-apps

Figure 2. Effluent discharge basin and inlet underground valve

handle located in line from the polishing pond

The City of Decatur was already using a HydroRanger 200 with

Echomax transducer to monitor the effluent flow from the

wastewater treatment plant and record the effluent basin

level. The HydroRanger data was recorded so the staff would

be aware of any changes that could indicate the potential of a

blockage or loss of flow. It’s also worth noting that the HydroRanger 200 was not connected to any SCADA and, as such,

required a physical visit to manually read the totalizer and

other process information from this instrument. These values

were read daily for reporting purposes.

If the effluent flow head measured by the HydroRanger 200

dropped below 5 inches, the staff would typically review the

system for the potential of algae blockage in the line from the

polishing basin to the effluent discharge basin. Over time,

reduction of normal flow from the polishing pond to the

effluent basin typically causes the polishing pond to back up,

potentially leading to a spill within the confines of the treatment plant. The head level in the effluent basin was monitored as well, and if the HydroRanger 200 indicated a high

level, the staff would check the V-notch weir for blockage.

High levels in the effluent discharge basin could also cause

spills into the environment.

The challenge to the City of Decatur’s operation included the fact

that the plant does not have 24-hr manned coverage. If either of

these issues arise whether the facililty is manned or unmanned,

the possible spills from either the polishing pond or the effluent

basin can damage equipment. In addition, there are possible fines

from the TCEQ governing body if spills are not found and responded to quickly.

Siemens Digital Solution – SITRANS store IQ

Siemens presented the possible benefits that could be achieved if

a digital application such as SITRANS store IQ was implemented for

continuous remote monitoring. SITRANS store IQ works with any

manufacturer’s instrumentation and allows operators to monitor

key data that normally requires physical visits by personnel. Siemens offered a system that could connect, monitor and transmit

data to enable more efficient operations. In this case it would

automate the manual data gathering process, which included

taking readings from the HydroRanger 200 every day at 8:00AM.

This information is critical as it is reported to the regulatory agency

each month.

So, rather than continue with this manual data collection process,

Siemens’ local account manager worked with the customer and

the Siemens Engineered Instrumentation Solutions (EIS) team to

Figure 3.a.b.c. Effluent discharge basin V-notch weir for discharge

flow measurement and Echomax transducer for level measurement.

Note the algae buildup.

deploy SITRANS store IQ. Deploying this digital application included the development of a comprehensive solution to provide

remote monitoring of the instruments and equipment at the

customer’s site and in accordance with their specific needs. The

customer had located the HydroRanger 200 20 to 30 yards from

the effluent treatment basin, and this included the availability of

120Vac. The mounting position of the Hydroranger 200 was

perfect for the installation of the SITRANS store IQ solution.

A new hardware system developed by Siemens EIS utilized the

HydroRanger 200 RS485 MODBUS RTU port and transmitted

the data via the Siemens MindSphere cloud platform to the

web-enabled Siemens SITRANS store IQ App. The application

was configured to extract specific holding registers and meet

the remote monitoring requirements of the customer. The

entire system included the following items.

• Siemens SITRANS store IQ Enclosure (16”x12”x8”)

• Siemens 24 VDC Power Supply

• SIMATIC S7-1200 Controller

• RS485 MODBUS Communication Module

• Siemens IOT2040 MindConnect Gateway

• Siemens SCALANCE M876-4 Mobile Wireless Router

• AT&T Sim Package Data Plan

Figure 4.a.b HydroRanger 200 mounting stand and StoreIQ remote

monitoring solution.

The addition of the Siemens SITRANS store IQ hardware

solution and app allows the City of Decatur immediate access

to the flow rate, totalizer and head measurement on their

smart phone, tablet or from their computer. Alarms alert the

customer when the head value falls below a specified alarm

level, warning them if there is a problem upstream of the

effluent basin and providing high-level alarms if the head

value rises above a specified alarm level. This provides peace

of mind that the plant is monitored, and personnel can respond to emergencies when they happen , even if they are

not at the plant.

Customer Feedback on SITRANS store IQ

In addition to SITRANS store IQ’s ability to remotely monitor, it offers the added resiliency of a parallel data stream.

“On October 20, 2019, we received very heavy thunderstorms in the Decatur area. There were direct lightning

strikes all around the city and one or two happened at the

WWTP. One of the strikes knocked out our in-office chart

recorders for both the influent and effluent flows. However,

due to us being set up on the SITRANS store IQ monitoring

system in conjunction with the HydroRanger, we were able

to still monitor our flows for the effluent for permit purposes. It has been a real help for us to remain connected to the

trends and flow totals.” -Mr. Roddy Boston, WWTP Superintendent, City of Decatur.

about my flows. It has alarmed every time we have backwashed and have received both text and email updates on all

instances.” -Mr. Roddy Boston, WWTP Superintendent, City of

Decatur.

“I will be taking a look at the stored flow data this week. We

have started talks of a possible expansion of the plant facilities

and I will see if the info will give us what the engineers need

in order to help facilitate this process.” -Mr. Roddy Boston,

WWTP Superintendent, City of Decatur.

Summary

The addition, of the Siemens SITRANS store IQ hardware solution and app allows the City of Decatur immediate access to the

flow rate, totalizer and head measurement on their smart

phone, tablet or from their computer. It has taken a formerly

manual process and allowed the information and alerts in case

of upset conditions to be provided immediately to operators

regardless of their location.

In addition, it serves as a backup record-keeping methodology

to allow continued gathering of critical information that is

required for local governing bodies.

For more information please email: Engineered Instrument

Solutions at eis.solutions.us@siemens.com

This added benefit of the SITRANS store IQ solution allows

easy capture of required data to report to the regulatory

authority (TCEQ) monthly. The new solution will take the

place of a manual process and allow for a more consistent and

accurate report.

Another benefit of SITRANS store IQ is its flexibility and the

ability to customize the application. It is highly scalable,

allowing deployment to other equipment and instruments as

needed.

“I really like the fact that I can formulate the alarms to give me

gallons instead of inches of head. That tells me so much more

Siemens Industry, Inc.

Process Industries and Drives

100 Technology Drive

Alpharetta, GA 30005

1-800-365-8766

Subject to change without prior notice

All rights reserved

Order No.: PICS-00160-0720

© 2020 Siemens Industry, Inc.

Loading...

Loading...