Siemens SITOP PSU6200 User Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SITOP power supply

SITOP PSU6200 1ph

Manual

SITOP PSU6200 12 V/7 A

6EP3323

SITOP PSU6200 12 V/12 A

6EP3324

SITOP PSU6200 24 V/3.7 A

6EP3333

SITOP PSU6200 24 V/5 A

6EP3333

SITOP PSU6200 24 V

6EP3334

SITOP PSU6200 24 V/20 A

6EP3336

03.2019

A5E44623264

Overview

Notes on safety

1

Description, device design,

dimension drawing

2

Mounting/removal

3

Mounting position, mounting

clearances

4

Installation

5

Technical data

6

Safety, approvals, EMC

7

Ambient conditions

8

Applications

9

Environment

10

Service & Support

11

-7SB00-0AX0

-7SB00-3AX0

-7LB00-0AX0

-7SB00-0AX0

/10 A

-7SB00-3AX0

-7SB00-3AX0

-1-76

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E44623264-1-76

Ⓟ

Copyright © Siemens AG 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

03/2019 Subject to change

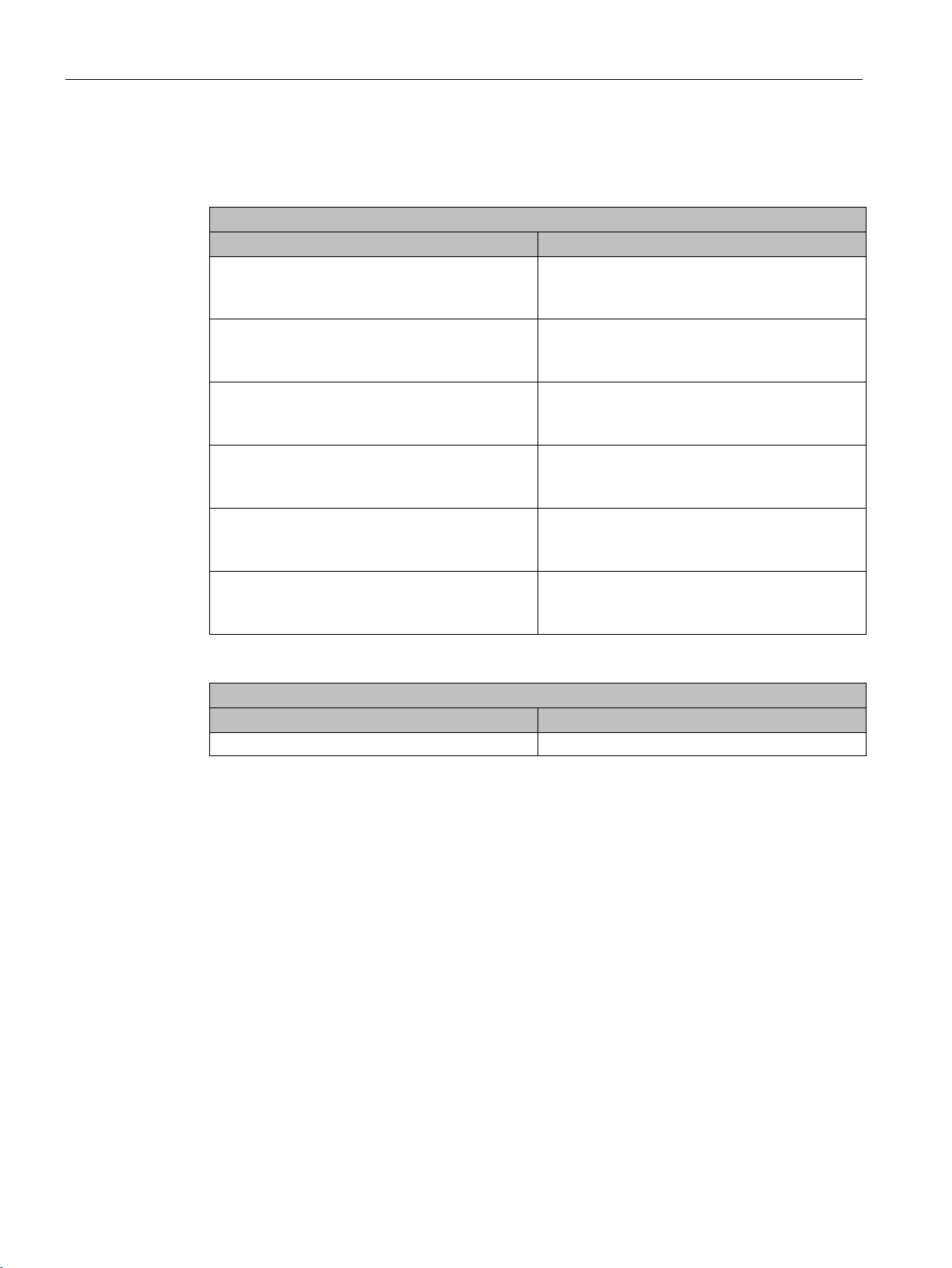

Overview

Figure 1 View of devices

The 1-phase SITOP PSU6200 from the product line is a powerful, regulated standard power

supply for automated machines and systems. In addition to a high efficiency, these lowprofile power supply units have an outstanding overload behavior.

The key benefits of the product include:

● Wide-range input that allows it to be connected to almost any 1-phase line supply around

the world – or to a DC power source

● The output voltage can be set in the range 12 V - 15.5 V or 24 V - 28 V

● Brief overload capability of 150% for 5 s/min (extra power)

● Continuous overload capability of 120% up to an ambient temperature of 45 °C

● Integrated signaling contact for "12 V O.K." or "24 V O.K."

● Push-in connections facilitate fast wiring

● Diagnostic monitor with utilization and service life display using LEDs

● Diagnostics interface to connect to the automation system via only one digital PLC input

● Ambient temperature -25 °C ... 70 °C

● To increase the system availability, these reliable power supplies can be expanded using

SITOP supplementary modules (redundancy module, selectivity module, buffer module),

as well as SITOP DC-UPS modules.

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

3

Overview

Regulated SITOP PSU6200S power supply

Type

Order number

Output 12 V DC/7 A

Output 12 V DC/12 A

Output 24 V DC/3.7 A

Output 24 V DC/5 A

24 V/10 A DC output

24 V/20 A DC output

Accessories

Type

Order number

Reference labeling plate (160 plates)

6ES7193-6LF30-0AW0

Ordering data

The following device options are available:

Input 1 AC 120/230 V,

110 - 240 V DC

Input 1 AC 120/230 V,

110 - 240 V DC

Input 1 AC 120/230 V,

120 - 240 V DC

Input 1 AC 120/230 V,

120 - 240 V DC

Input 1 AC 120/230 V,

120 - 240 V DC

Input 1 AC 120/230 V,

120 - 240 V DC

6EP3323-7SB00-0AX0

6EP3324-7SB00-3AX0

6EP3333-7LB00-0AX0

6EP3333-7SB00-0AX0

6EP3334-7SB00-3AX0

6EP3336-7SB00-3AX0

SITOP PSU6200 1ph

4 Manual, 03.2019, A5E44623264-1-76

Table of contents

Overview .................................................................................................................................................... 3

1 Notes on safety .......................................................................................................................................... 7

2 Description, device design, dimension drawing ......................................................................................... 9

2.1 Device description ..................................................................................................................... 9

2.2 Connections and terminal designation.................................................................................... 10

2.3 Potentiometer .......................................................................................................................... 11

2.4 Status displays and signaling ................................................................................................. 12

2.5 Operating mode ...................................................................................................................... 15

2.6 Block diagram ......................................................................................................................... 16

2.7 Dimensions and weight ........................................................................................................... 18

3 Mounting/removal .................................................................................................................................... 21

4 Mounting position, mounting clearances .................................................................................................. 23

4.1 Standard mounting position .................................................................................................... 23

4.2 Other mounting positions ........................................................................................................ 26

4.2.1 6EP3323-7SB00-0AX0 ........................................................................................................... 26

4.2.2 6EP3324-7SB00-3AX0 ........................................................................................................... 28

4.2.3 6EP3333-7LB00-0AX0 ........................................................................................................... 30

4.2.4 6EP3333-7SB00-0AX0 ........................................................................................................... 32

4.2.5 6EP3334-7SB00-3AX0 ........................................................................................................... 34

4.2.6 6EP3336-7SB00-3AX0 ........................................................................................................... 36

5 Installation ............................................................................................................................................... 39

5.1 Line-side connection ............................................................................................................... 39

5.2 Output-side connection ........................................................................................................... 41

6 Technical data ......................................................................................................................................... 43

6.1 Input ........................................................................................................................................ 43

6.2 Output ..................................................................................................................................... 46

6.3 Efficiency ................................................................................................................................. 52

6.4 Closed-loop control ................................................................................................................. 56

6.5 Protection and monitoring ....................................................................................................... 57

6.6 MTBF ...................................................................................................................................... 58

6.7 Mechanical system ................................................................................................................. 59

6.8 Dimension drawing ................................................................................................................. 60

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

5

Table of contents

7 Safety, approvals, EMC ........................................................................................................................... 61

7.1 Safety ..................................................................................................................................... 61

7.2 Test voltage ............................................................................................................................ 62

7.3 Approvals ............................................................................................................................... 63

7.4 EMC ....................................................................................................................................... 64

8 Ambient conditions .................................................................................................................................. 65

9 Applications ............................................................................................................................................. 67

9.1 Parallel connection to increase the power rating ................................................................... 67

9.2 Overload protection in the 24 V output circuit ........................................................................ 69

9.3 Protection against short-time voltage dips ............................................................................. 70

9.4 Protecting against longer power failures ................................................................................ 71

10 Environment ............................................................................................................................................ 73

11 Service & Support .................................................................................................................................... 75

SITOP PSU6200 1ph

6 Manual, 03.2019, A5E44623264-1-76

1

WARNING

Correct handling of the devices

When operating electrical devices, it is inevitable that certain components will carry

dangerous voltages.

Therefore, failure to handle the units properly can result in death or serious physical injury

as well as extensive property damage.

Only appropriately qualified personnel may work on or in the vicinity of this equipment.

Perfect, safe, and reliable operation of this equipment is dependent on proper

transportation, storage, installation and mounting.

Before installation or maintenance work can begin, the system's main switch must be

switched off and measures taken to prevent it being switched on again.

If this instruction is not observed, touching live parts can result in death or serious injury.

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

7

Notes on safety

SITOP PSU6200 1ph

8 Manual, 03.2019, A5E44623264-1-76

2

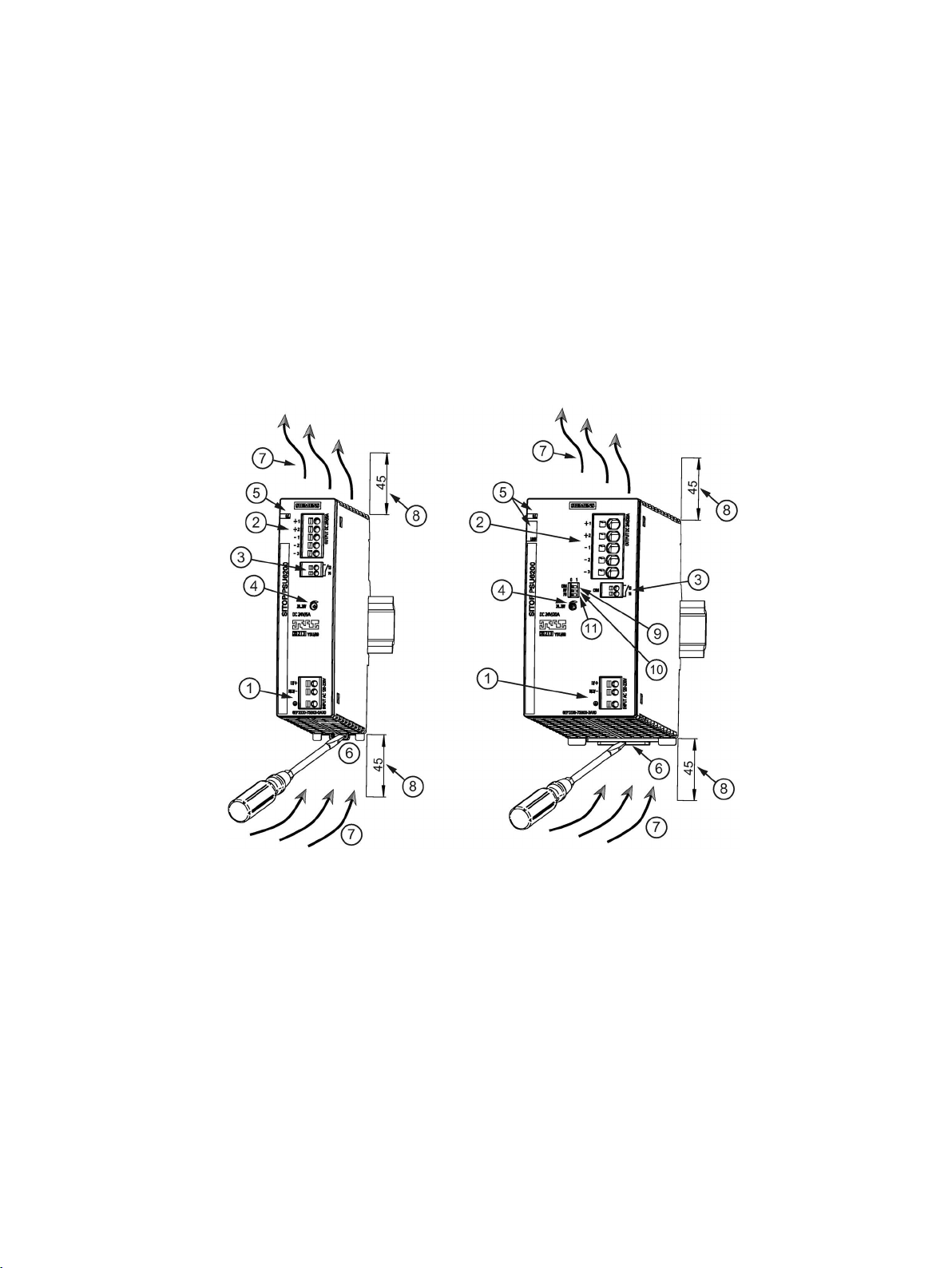

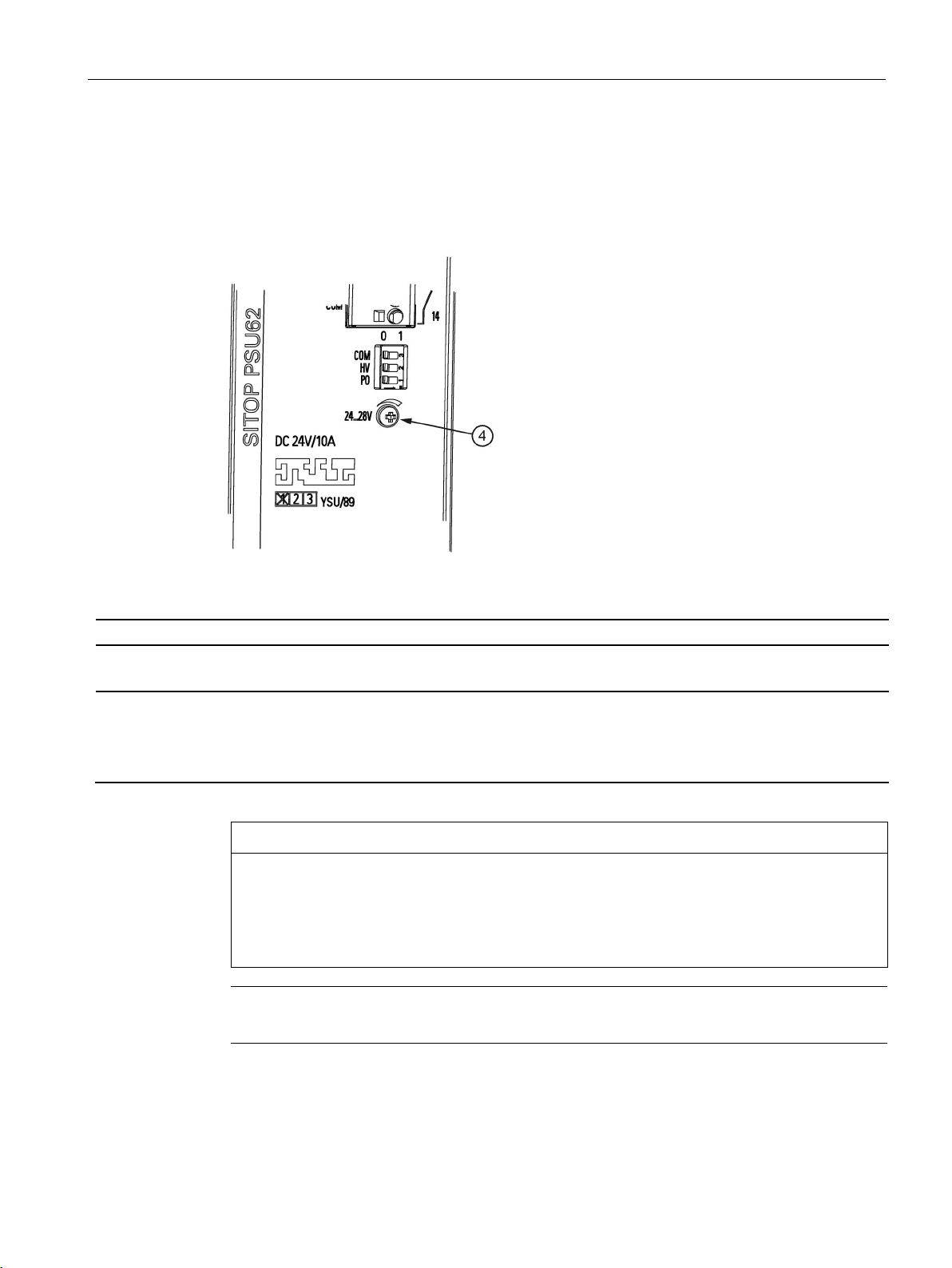

①

AC/DC input

②

DC output

③

Signaling contact (13, 14)

④

Potentiometer, 12 V - 15.5 V or 24 V - 28 V

⑤

Indicator light, diagnostics monitor (O.K., LOAD)

⑥

DIN rail slider

⑦

Convection

⑧

Clearance above/below

⑨

Diagnostics interface (COM)

⑩

DC voltage level increase (HV)

⑪

Parallel operation (PO)

2.1 Device description

SITOP PSU6200 is a primary-clocked power supply for connection to a 1-phase AC line

supply and a DC supply. An electronically regulated DC voltage that can be set via a

potentiometer is available at the output of the device. The output of the device is isolated,

no-load proof and short-circuit proof. The LED display indicates the operating status. The

operating state of the device can be processed via the signaling contact.

Figure 2-1 Design

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

9

Description, device design, dimension drawing

Connections and terminal designations

①

②

②

③

Do not subject the end stop to higher loads

Do not subject the end stop to higher loads

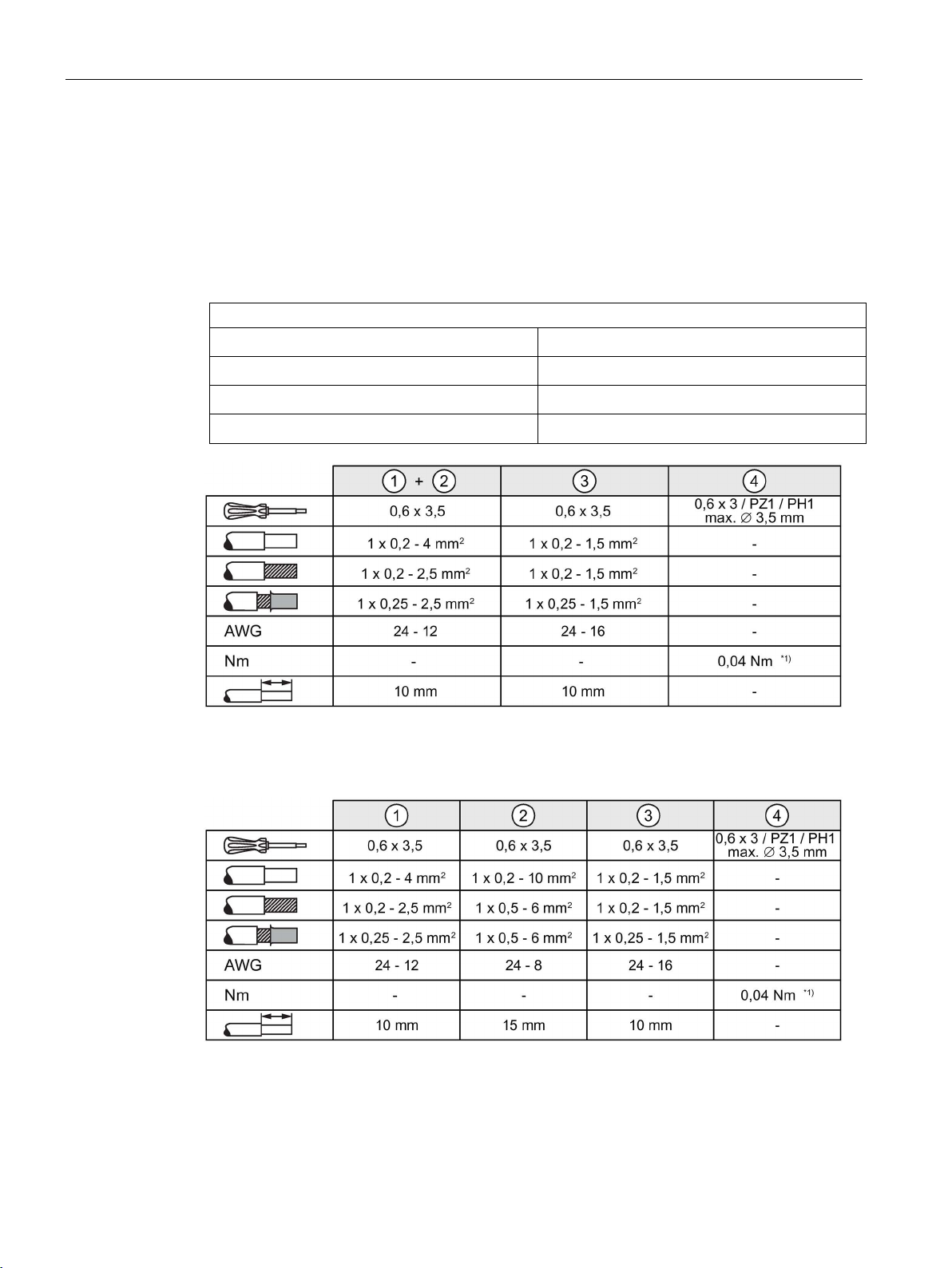

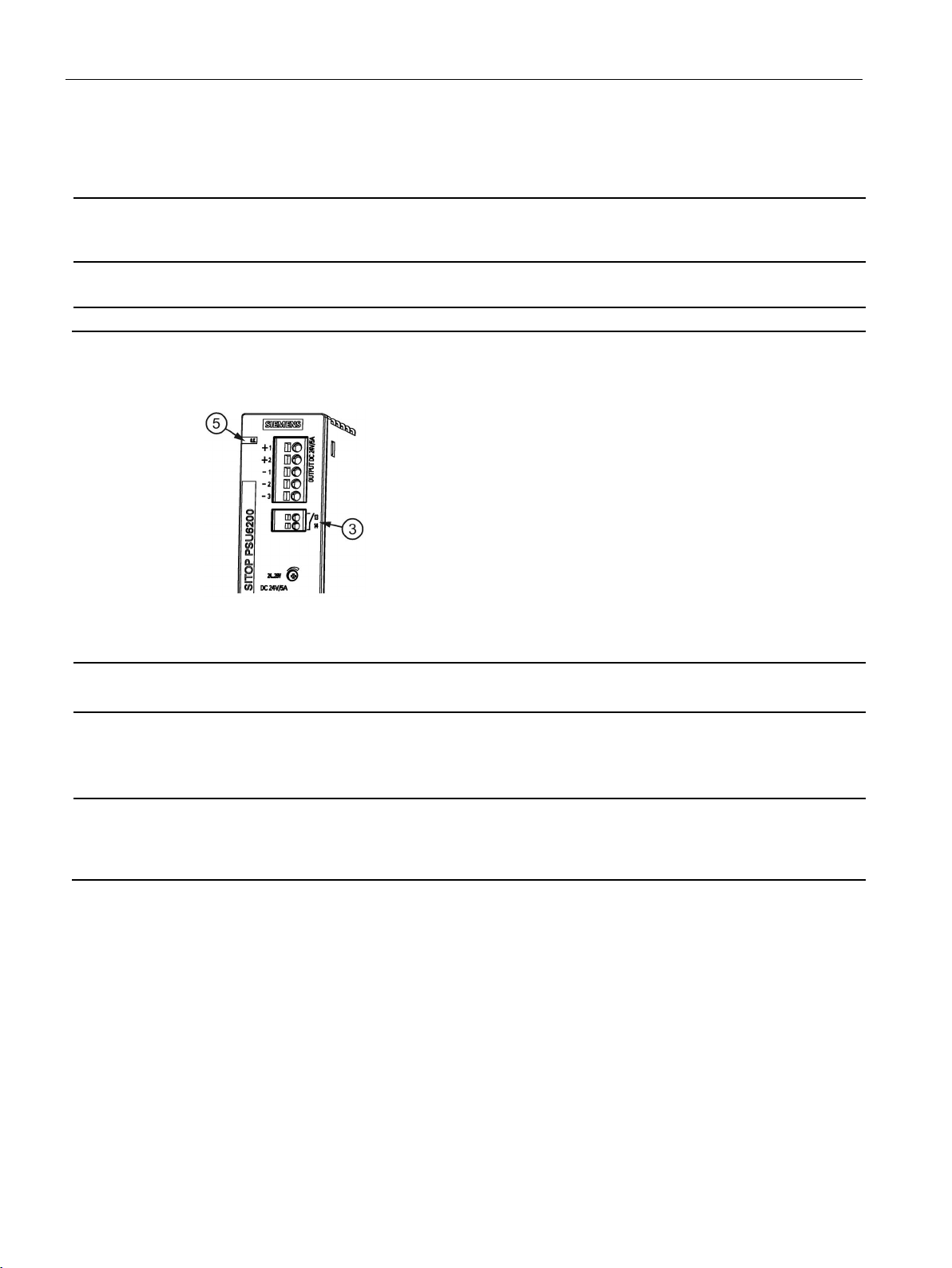

2.2 Connections and terminal designation

2.2 Connections and terminal designation

The line input terminals ① can be used to establish the connection to supply voltage. The

output terminals

Installation (Page 39)).

② are used to connect to the loads to be supplied (see also Section

The operating state of the device can be processed via the signaling contact

and contact rating, see Chapter Status displays and signaling (Page 12)).

Line input L1, N (L2), PE

Output +

Output –

Signaling contact 13, 14

*1)

one spring-loaded terminal each

2 spring-loaded terminals

3 spring-loaded terminals

one spring-loaded terminal each

③ (function

Figure 2-2 Terminal data for 6EP3323-7SB00-0AX0, 6EP3324-7SB00-3AX0, 6EP3333-7LB00-

0AX0, 6EP3333-7SB00-0AX0 and 6EP3334-7SB00-3AX0

*1)

Figure 2-3 Terminal data for 6EP3336-7SB00-3AX0

SITOP PSU6200 1ph

10 Manual, 03.2019, A5E44623264-1-76

Description, device design, dimension drawing

Type

Factory setting

Adjustment range

6EP3324-7SB00-3AX0

6EP3336-7SB00-3AX0

NOTICE

Thermal overload possible

Note

It is only permissible to use an insulated screwdriver when actuating the potentiometer.

2.3 Potentiometer

2.3 Potentiometer

The potentiometer ④ on the front of the device is used to adjust the output voltage. The

output voltage is set to the rated value at the factory and can be set within certain limits; for

example, to compensate voltage drops across long supply lines to the connected load.

6EP3323-7SB00-0AX0

6EP3333-7LB00-0AX0

6EP3333-7SB00-0AX0

6EP3334-7SB00-3AX0

Figure 2-4 Potentiometer

12 V 12 V - 15.5 V

24 V 24 V - 28 V

When adjusting the output voltage to greater than the rated voltage, the output current must

be derated by 4 %/V (for devices with a rated output voltage of 24 V) and 8 %/V (for

devices with a rated output voltage of 12 V) – or the permissible ambient temperature must

be taken into account with 3 °C/V.

For information on actuating the potentiometer (screwdriver, torque), see Connections and

terminal designation (Page 10).

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

11

Description, device design, dimension drawing

6EP3323-7SB00-0AX0 (12 V/7 A), 6EP3324-7SB00-3AX0 (12 V/12 A),

6EP3333-7LB00-0AX0 (24 V/3,7 A), 6EP3333-7SB00-0AX0 (24 V/5 A),

6EP3334-7SB00-3AX0 (24 V/10 A), 6EP3336-7SB00-3AX0 (24 V/20 A)

Yellow LED

Signaling contact (13, 14)

Relay contact (NO contact, contact rating (isolated) 24 V AC/0.1 A; 30 V DC/0.1 A

Signaling

Signaling contact

6EP3323-7SB00-0AX0 (12 V/7 A)

6EP3333-7LB00-0AX0 (24 V/3.7 A)

6EP3333-7SB00-0AX0 (24 V/5 A)

LED "O.K.":

green flashing (0.5 Hz):

shutdown as a result of thermal overload

shutdown as a result of thermal overload

Signaling contact (13, 14)

NOTICE:

ing contact is connected on the primary side!

NOTICE:

ing contact is connected on the primary side!

2.4 Status displays and signaling

2.4 Status displays and signaling

Status display LED green for 12 V O.K. or 24 V O.K.

Device without diagnostics monitor

green:

closed:

Figure 2-5 Signaling, signaling contact

Output voltage U

U

> 11.8 V

out

Output voltage U

> 10 V or

out

> 10 V

out

contact rating: 24 V AC/0.1 A; 30 V DC/0.1 A

It is not permissible that the signal-

Output voltage U

U

> 23 V

out

Output voltage U

> 20 V or

out

> 20 V

out

contact rating 24 V AC/0.1 A; 30 V DC/0.1 A

It is not permissible that the signal-

SITOP PSU6200 1ph

12 Manual, 03.2019, A5E44623264-1-76

Description, device design, dimension drawing

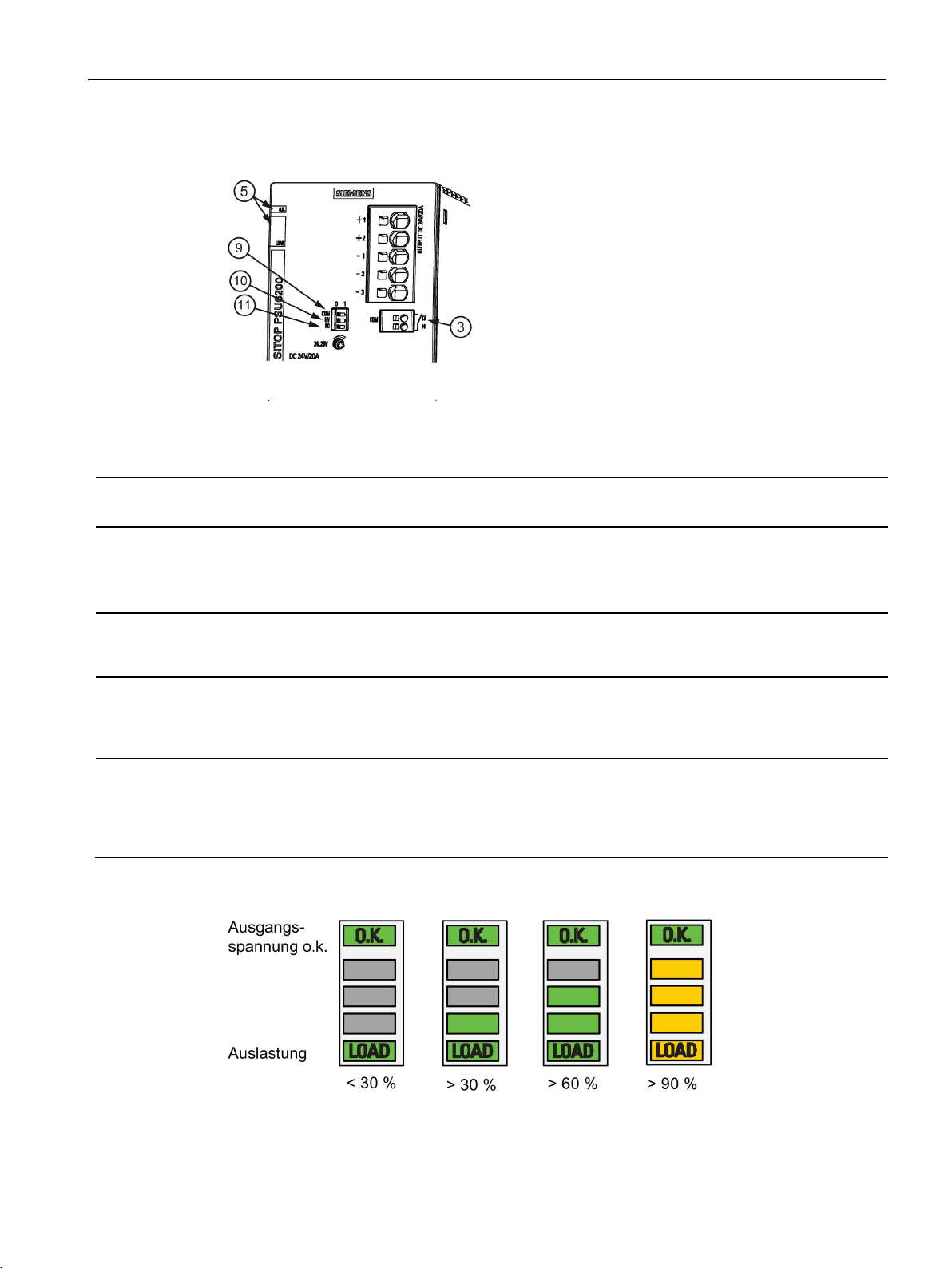

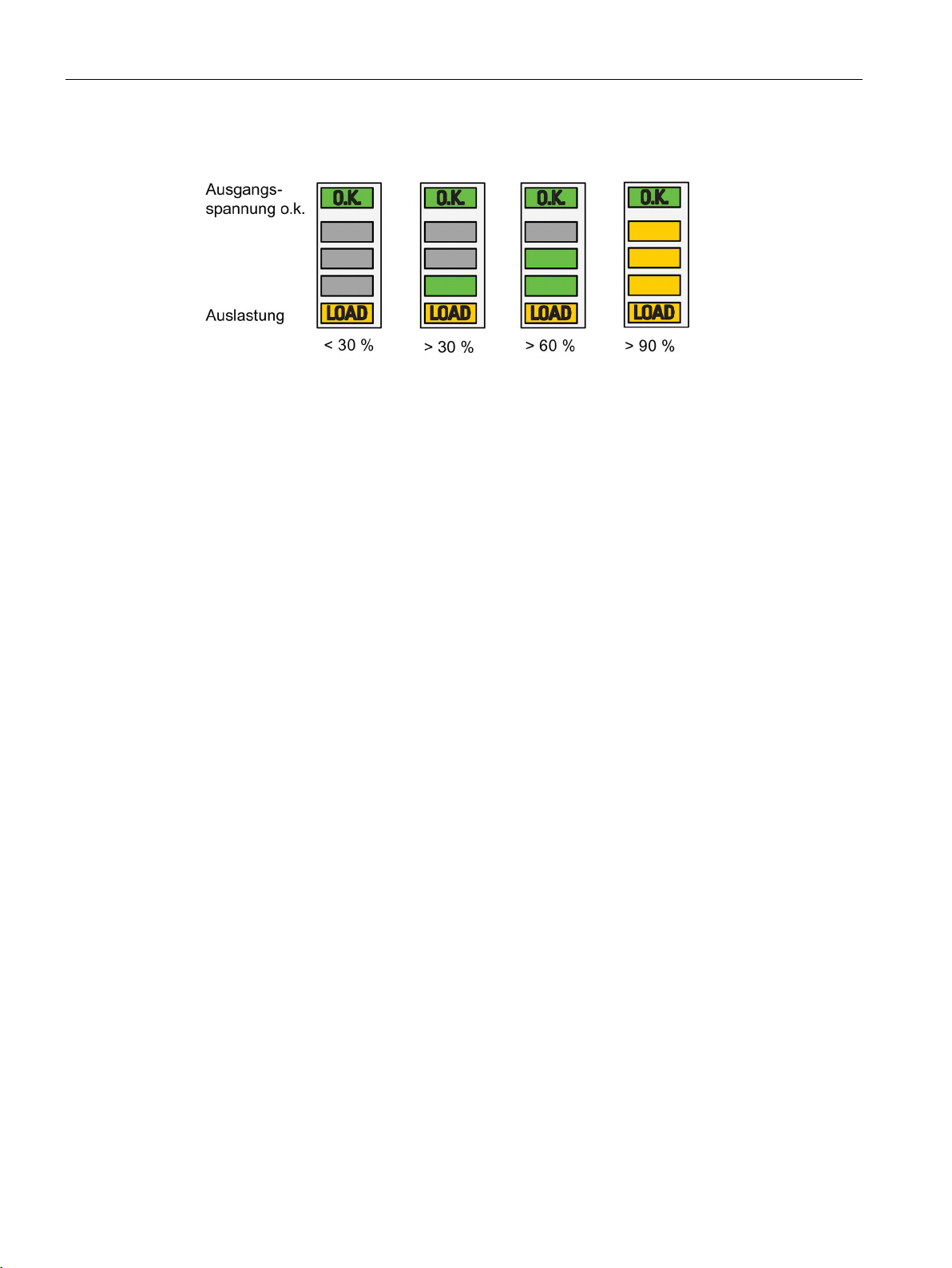

Signaling contact

6EP3324-7SB00-3AX0 (12 V/12 A)

6EP3334-7SB00-3AX0 (24 V/10 A)

6EP3336-7SB00-3AX0 (24 V/20 A)

LED "O.K.":

green flashing (0.5 Hz):

shutdown as a result of thermal overload

shutdown as a result of thermal overload

LED "LOAD":

yellow:

reached service life ≥ 90 %; I

out rated

≥ 90 %

reached service life ≥ 90 %; I

out rated

≥ 90 %

LEDs above LED "LOAD":

LEDs 5.1+5.2+5.3 yellow:

I

out rated

> 90 %

I

out rated

> 90 %

Contact ''COM'' (13, 14):

NOTICE:

tact is connected on the primary side!

NOTICE:

tact is connected on the primary side!

2.4 Status displays and signaling

Device with diagnostics monitor

Figure 2-6 Signaling, signaling contact

green:

green:

LED 5.1 green:

LEDs 5.1+5.2 green:

closed:

(for DIP switch COM = 0)

Diagnostic monitor display:

Output voltage U

U

> 11.8 V

out

reached service life < 90 %

I

30 - 60 %

out rated

I

60 - 90 %

out rated

Output voltage U

or U

> 11.8 V; data transfer contact rating

out

24 V AC/0.1 A; 30 V DC/0.1 A

It is not permissible that the con-

> 10 V or

out

> 10 V

out

Output voltage U

U

> 23 V

out

> 20 V or

out

reached service life < 90 %

I

30 - 60 %

out rated

I

60 - 90 %

out rated

Output voltage U

or U

> 23 V; data transfer contact rating

out

> 20 V

out

24 V AC/0.1 A; 30 V DC/0.1 A

It is not permissible that the con-

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

13

Description, device design, dimension drawing

2.4 Status displays and signaling

Service life < 10 %

SITOP PSU6200 1ph

14 Manual, 03.2019, A5E44623264-1-76

Description, device design, dimension drawing

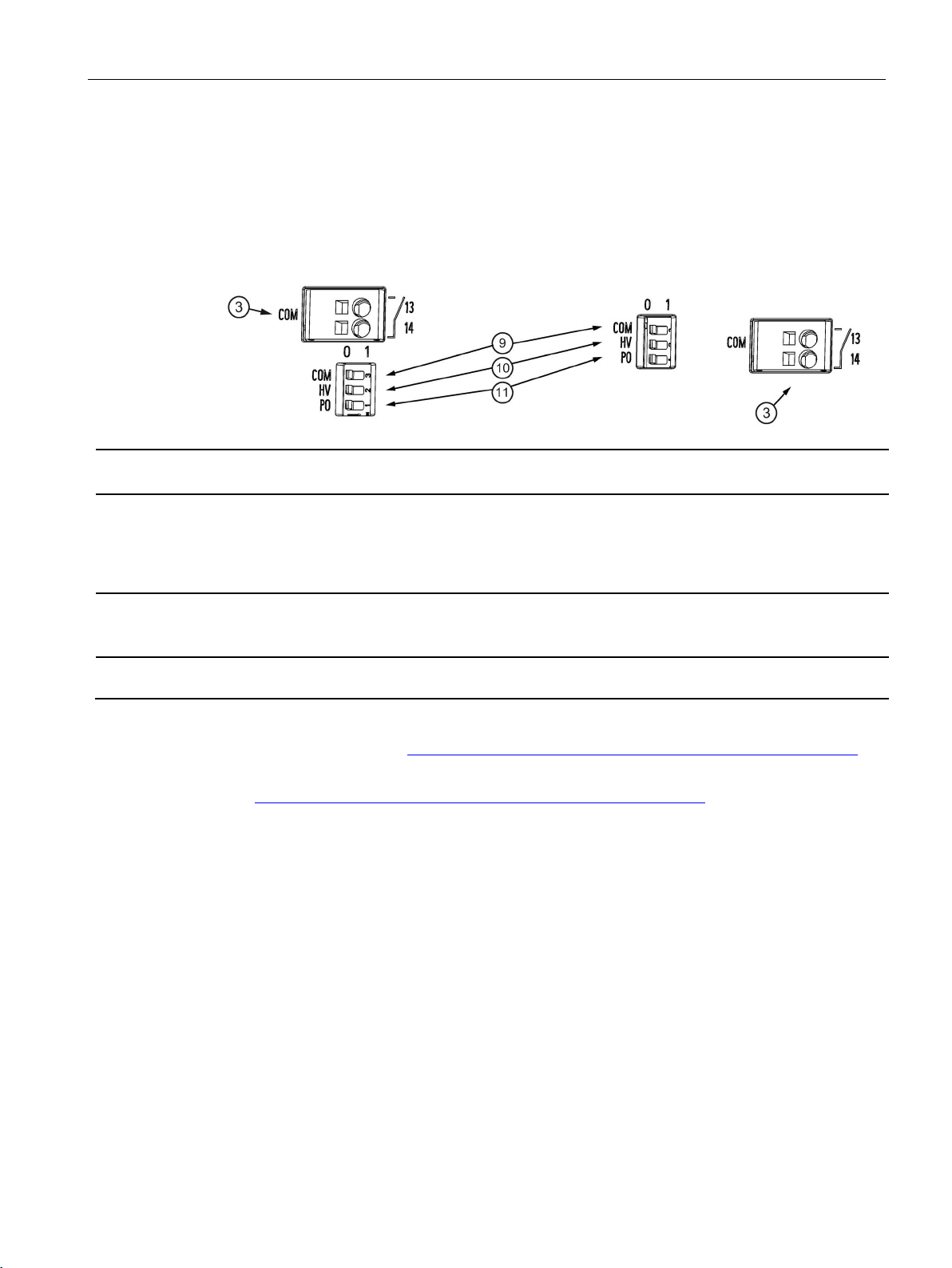

DIP switch

6EP3324-7SB00-3AX0 (12 V/12 A)

6EP3334-7SB00-3AX0 (24 V/10 A)

6EP3336-7SB00-3AX0 (24 V/20 A)

COM ⑨:

CAUTION:

Contact rating: 24 V AC/0.1 A; 30 V DC/0.1 A

HV ⑩:

1: > 11.8 V

PO ⑪:

pendent output voltage "parallel operation"

2.5 Operating mode

2.5 Operating mode

The selection is made using individual DIP switches (when supplied, these are in the 0

position).

It is only permissible to connect two identical devices in parallel to increase the power by

changing over the output characteristic by switching selector switch PO

⑪ to 1

Selector switch to toggle between the U

0: Display of the output voltage status

1: Internal device parameters are transferred via signaling contact (13, 14) (diagnostics interface)

It is not permissible that the signaling contact is connected on the primary side!

Setting, above which value, the "O.K." LED is lit.

0: > 10 V

Switching over output characteristic 0: Constant output voltage "single operation" 1: Load-de-

status display and the communication

out

Setting, above which the "O.K." LED is lit

0: > 20 V

1: > 23 V

Additional information can be found in the documents:

● Diagnostics interface (https://support.industry.siemens.com/cs/ww/en/view/109763467)

● Faceplates and communication blocks

(https://support.industry.siemens.com/cs/ww/en/view/109760217

)

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

15

Description, device design, dimension drawing

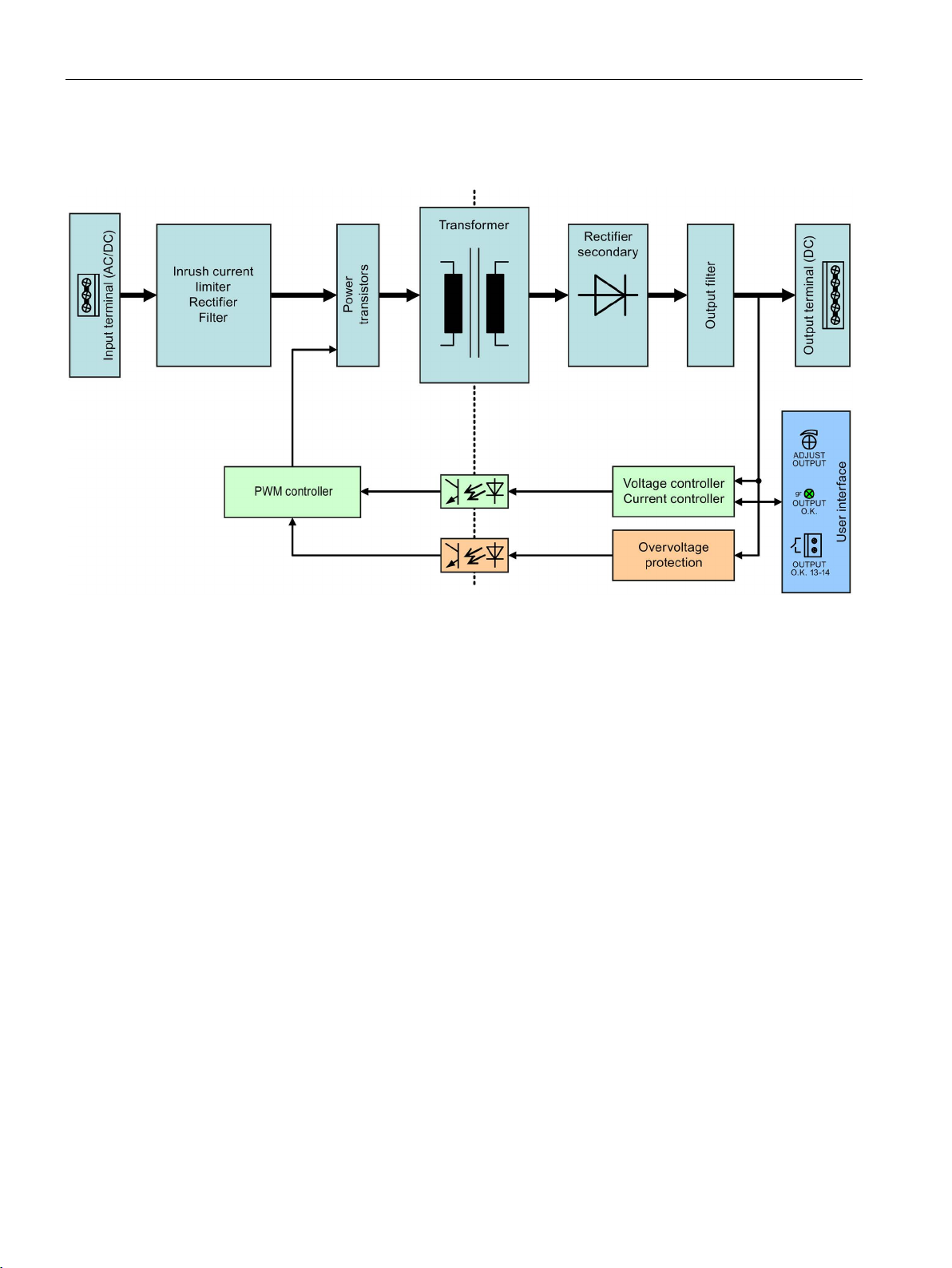

2.6 Block diagram

2.6 Block diagram

Figure 2-7 Block diagram 3.7/5/7 A

SITOP PSU6200 1ph

16 Manual, 03.2019, A5E44623264-1-76

Description, device design, dimension drawing

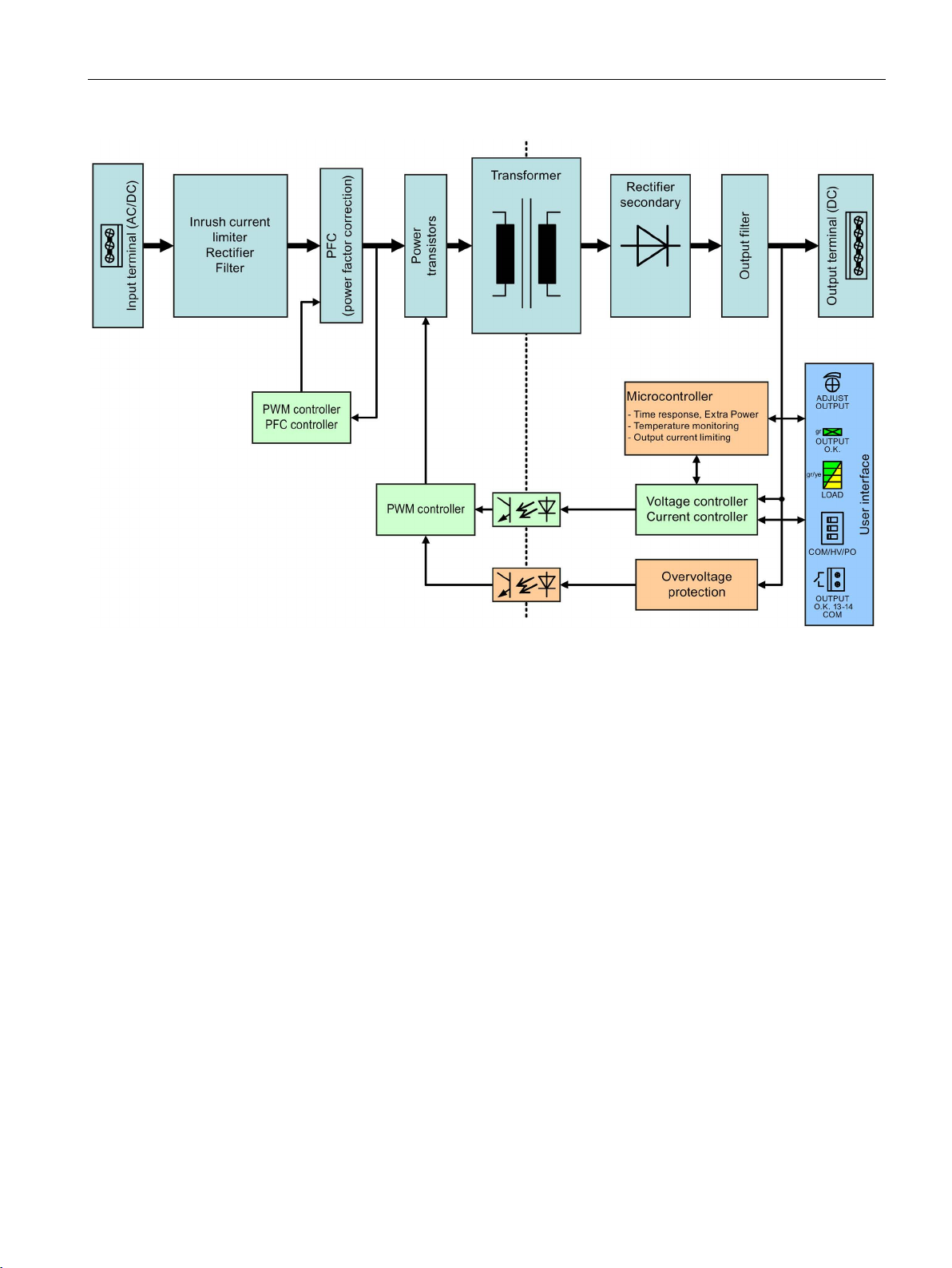

2.6 Block diagram

Figure 2-8 Block diagram 10/12/20 A

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

17

Description, device design, dimension drawing

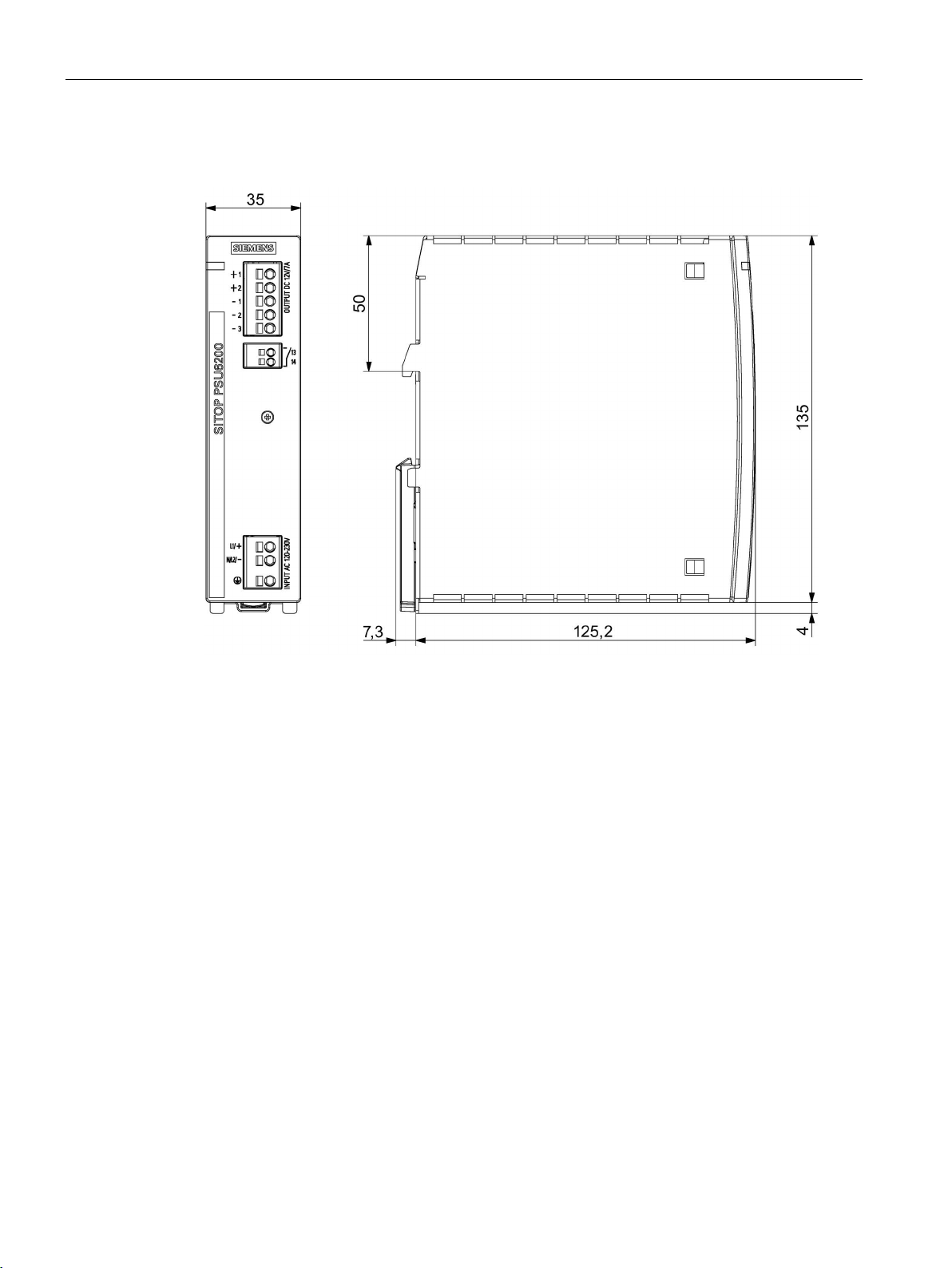

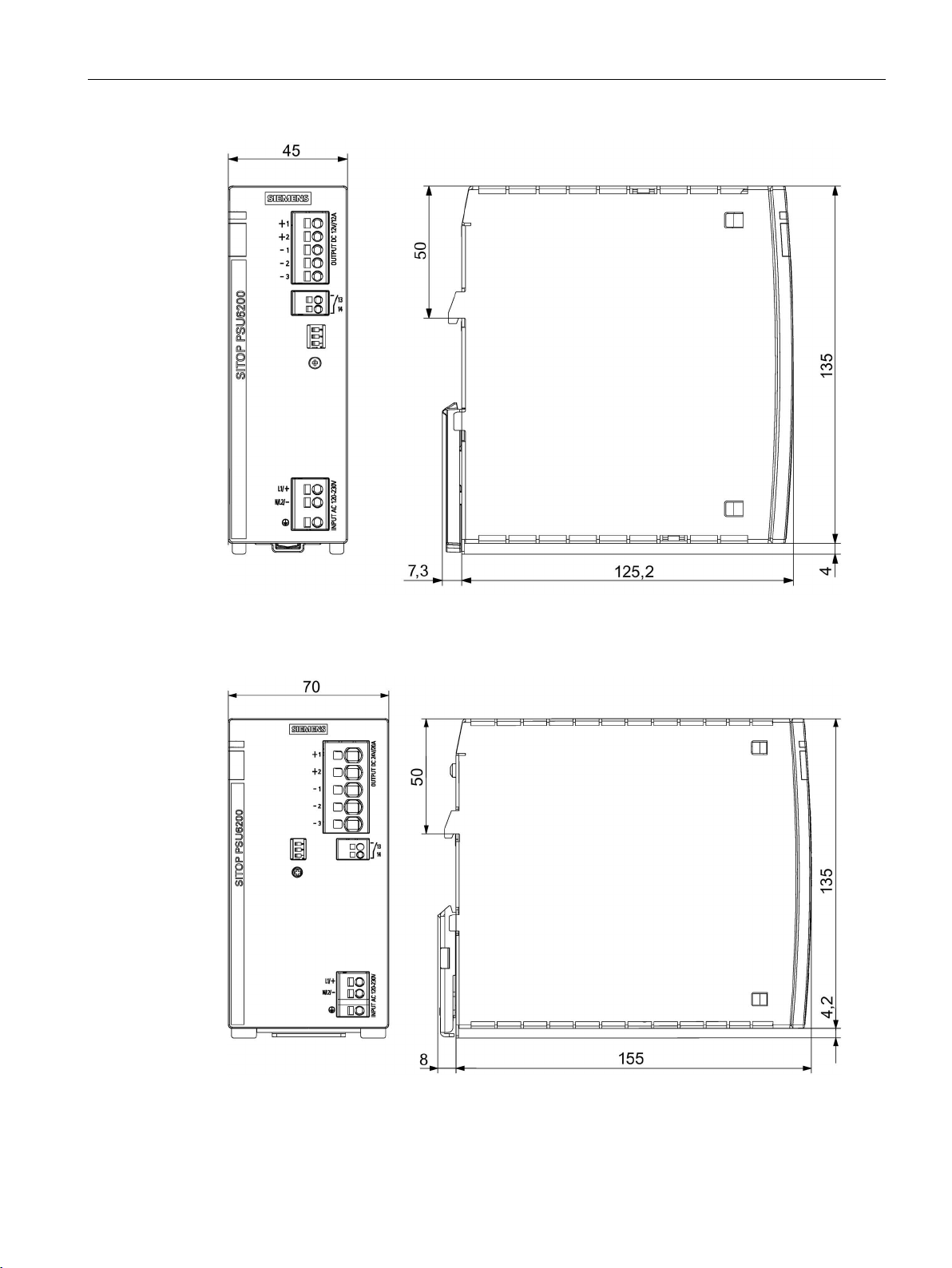

2.7 Dimensions and weight

2.7 Dimensions and weight

Figure 2-9 Dimension drawing

6EP3323-7SB00-0AX0

6EP3333-7LB00-0AX0

6EP3333-7SB00-0AX0

SITOP PSU6200 1ph

18 Manual, 03.2019, A5E44623264-1-76

Description, device design, dimension drawing

2.7 Dimensions and weight

Figure 2-10 Dimension drawing

6EP3324-7SB00-3AX0

6EP3334-7SB00-3AX0

Figure 2-11 Dimension drawing 6EP3336-7SB00-3AX0

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

19

Description, device design, dimension drawing

6EP3323-7SB00-0AX0

(12 V/7 A)

6EP3333-7LB00-0AX0

(24 V/3.7 A)

6EP3333-7SB00-0AX0

(24 V/5 A)

6EP3324-7SB00-3AX0

(12 V/12 A)

6EP3334-7SB00-3AX0

(24 V/10 A)

6EP3336-7SB00-3AX0

(24 V/20 A)

(W × H × D) in mm

Weight

Approx. 0.7 kg

Approx. 0.9 kg

Approx. 1.5 kg

2.7 Dimensions and weight

Dimensions

35 × 135 × 125 45 × 135 × 125 70 × 135 × 155

SITOP PSU6200 1ph

20 Manual, 03.2019, A5E44623264-1-76

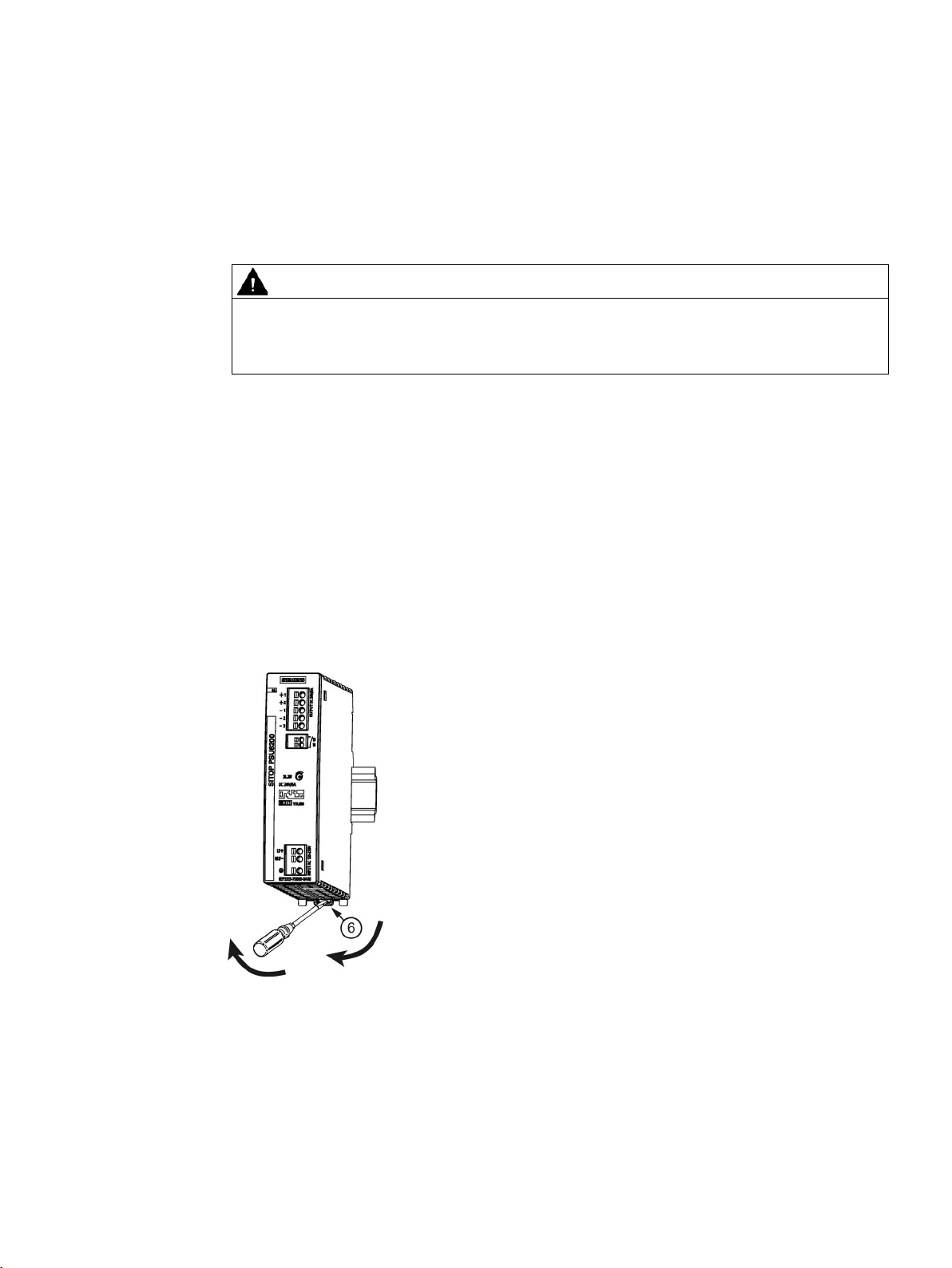

3

WARNING

Installing the device in a housing or a control cabinet

devices. They must be installed in a housing or

SITOP PSU6200 power supplies are built-in

control cabinet where only qualified personnel have access.

The device can be mounted in a control cabinet on standard mounting rails according to

TH35-15/7,5 (EN 60715).

Mounting

The device must be mounted in such a way that the input terminals are at the bottom and the

output terminals at the top. A clearance of at least 45 mm must be maintained above and

below the device (max. cable duct depth 50 mm).

Removal

To remove, pull up the slider ⑥ using a screwdriver and disengage the device at the bottom

edge of the standard mounting rail (see Removal diagram). Then you can remove the device

from the upper edge of the standard mounting rail.

Figure 3-1 Mounting/removal

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

21

Mounting/removal

SITOP PSU6200 1ph

22 Manual, 03.2019, A5E44623264-1-76

4

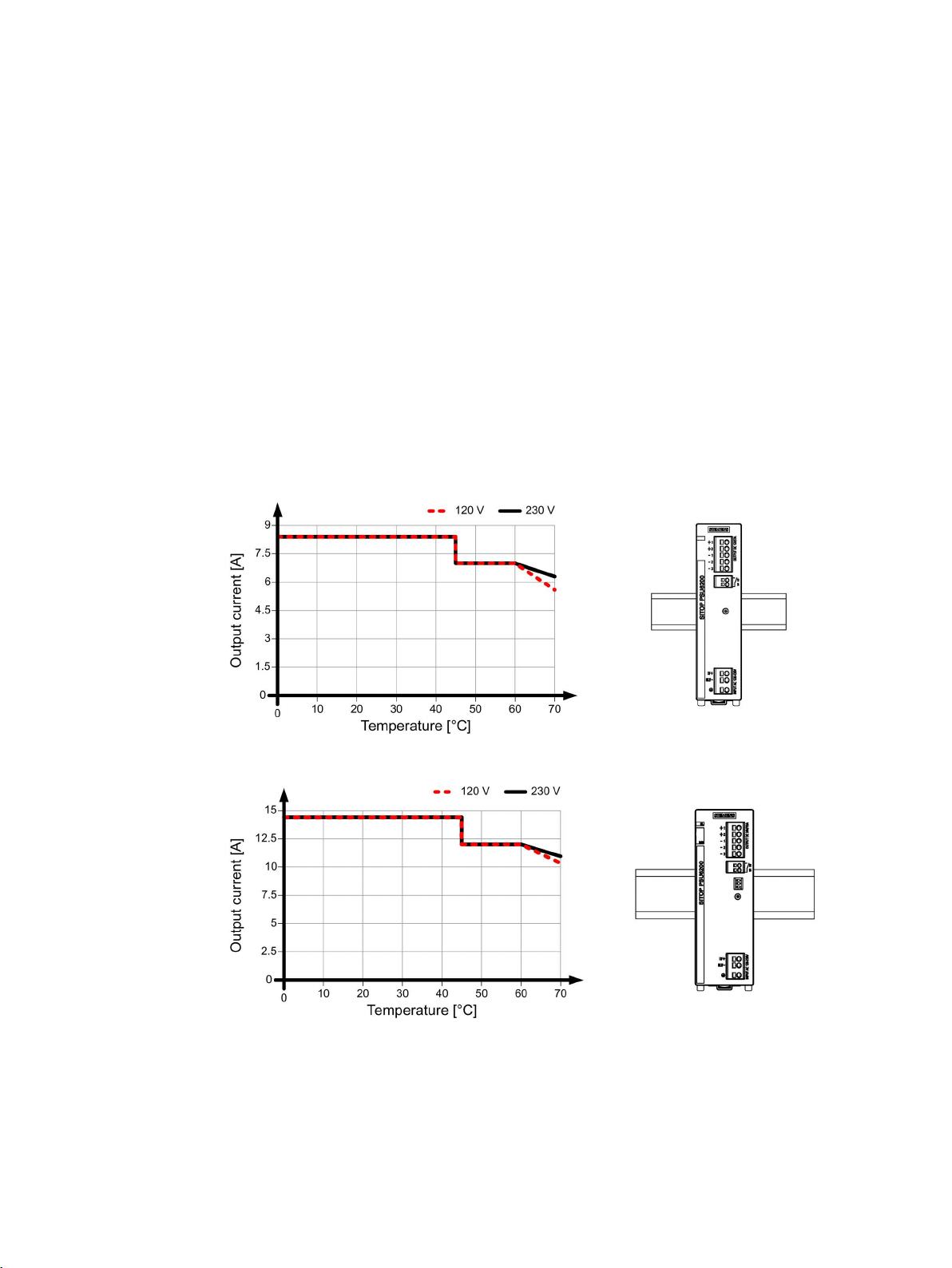

4.1 Standard mounting position

The device is mounted on standard mounting rails according to EN 60715 35x7,5/15. The

device must be mounted vertically in such a way that the input terminals are at the bottom

and the output terminals are at the top to ensure correct cooling.

A clearance of at least 45 mm must always be maintained above and below the device (max.

cable channel depth, 50 mm).

Lateral clearances do not have to be maintained.

Output current as a function of the ambient temperature and mounting height

Figure 4-1 6EP3323-7SB00-0AX0 output current in the standard mounting position

Figure 4-2 6EP3324-7SB00-3AX0 output current in the standard mounting position

SITOP PSU6200 1ph

Manual, 03.2019, A5E44623264-1-76

23

Loading...

Loading...