Siemens SIRIUS 3RW5 User Manual

Industrial Controls

Soft starters and solid-state

switching devices

SIRIUS 3RW5

EtherNet/IP communication module

Manual

05/2019

A5E45131885002A/RS

Siemens Industry Online

Support

1

Safety information

2

Description

3

Installing and removing

4

Connection

5

Configuring

6

Messages and diagnosis

7

Maintenance and service

8

Technical data

9

Dimension drawings

10

Circuit diagrams

11

Appendix

A

SIRIUS 3RW5

EtherNet/IP communication module

-AA/001

Siemens Industry Inc.

100 Technology Drive

Alpharetta, GA 30005

UNITED STATES

A5E45131885002A/RS-AA/001

Ⓟ

Copyright © Siemens AG 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

05/2019 Subject to change

Table of contents

1 Siemens Industry Online Support ............................................................................................................ 5

1.1 Support Request ....................................................................................................................... 9

1.2 Additional documentation ....................................................................................................... 10

2 Safety information ................................................................................................................................. 13

2.1 Security information ................................................................................................................ 13

2.2 ESD Guidelines ....................................................................................................................... 14

2.3 Data security in automation .................................................................................................... 16

2.4 Recycling and disposal ........................................................................................................... 18

3 Description ............................................................................................................................................ 19

3.1 Hardware configuration ........................................................................................................... 21

3.2 Functions of the 3RW5 EtherNet/IP communication module ................................................. 22

3.3 Interaction interfaces............................................................................................................... 23

3.4 Operating modes and master control function ........................................................................ 25

3.5 Bus connection cable and bus connector ............................................................................... 27

3.6 Accessories ............................................................................................................................. 28

3.6.1 SIRIUS Soft Starter ES (TIA Portal) ....................................................................................... 28

4 Installing and removing ......................................................................................................................... 29

4.1 Installing the 3RW5 communication module in the 3RW5 soft starter ................................... 29

4.1.1 Break out the cover of the slot ................................................................................................ 30

4.1.2 Mount the 3RW5 communication module in the slot of the 3RW5 Soft Starter ...................... 32

4.2 Removing the 3RW5 communication module in the 3RW5 soft starter ................................. 33

5 Connection ........................................................................................................................................... 35

5.1 Connecting the bus connector ................................................................................................ 35

5.2 Removing the bus connector .................................................................................................. 37

6 Configuring ........................................................................................................................................... 39

6.1 Configuring the 3RW5 soft starter in the EtherNet/IP system ................................................ 39

6.2 Configuring the 3RW5 soft starter .......................................................................................... 41

6.2.1 Configuring the 3RW5 soft starter in the EtherNet/IP system ................................................ 41

6.2.1.1 Configuring 3RW5 soft starters without 3RW5 HMI High Feature ......................................... 41

6.2.1.2 Configuring 3RW5 soft starters with the aid of a 3RW5 HMI High Feature ............................ 43

6.2.1.3 IP parameters ......................................................................................................................... 45

6.2.1.4 MAC address .......................................................................................................................... 46

6.2.1.5 BOOTP/DHCP server ............................................................................................................. 46

6.2.2 Integrating the 3RW5 soft starter with EDS file into the EtherNet/IP system ......................... 47

6.3 Operation on failure of the bus connection to the controller ................................................... 48

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

3

Table of contents

7 Messages and diagnosis ....................................................................................................................... 51

7.1 LED display ............................................................................................................................ 52

7.1.1 Device LEDs on the 3RW5 EtherNet/IP communication module .......................................... 52

7.1.2 Status and error displays ....................................................................................................... 53

7.2 Diagnostics via the Dataset Object ........................................................................................ 55

7.3 Errors and remedial measures on the 3RW5 communication module .................................. 56

7.4 Messages about the mode ..................................................................................................... 57

8 Maintenance and service ...................................................................................................................... 59

8.1 Firmware update .................................................................................................................... 59

8.1.1 Performing firmware update with micro SD card (3RW5 HMI High Feature) ........................ 61

8.2 Replacing the 3RW5 communication module ........................................................................ 62

8.3 Restoring factory setting ........................................................................................................ 63

9 Technical data ...................................................................................................................................... 65

9.1 Technical data in Siemens Industry Online Support .............................................................. 65

10 Dimension drawings .............................................................................................................................. 67

10.1 CAx data ................................................................................................................................ 67

11 Circuit diagrams .................................................................................................................................... 69

11.1 CAx data ................................................................................................................................ 69

A Appendix .............................................................................................................................................. 71

A.1 Data formats ........................................................................................................................... 71

A.1.1 Current values as percentages .............................................................................................. 71

A.1.2 Statistic data ........................................................................................................................... 72

A.2 Byte arrangement................................................................................................................... 73

A.3 Specifications ......................................................................................................................... 74

A.4 Supported objects .................................................................................................................. 75

A.5 Identity Object ........................................................................................................................ 76

A.6 Message Router Object ......................................................................................................... 77

A.7 Assembly Object .................................................................................................................... 78

A.8 Connection Manager Object .................................................................................................. 81

A.9 Dataset Object ....................................................................................................................... 83

A.9.1 Soft starter diagnostics .......................................................................................................... 84

A.9.2 Measured values .................................................................................................................... 90

A.9.3 Statistic data ........................................................................................................................... 91

A.9.4 Parameters ............................................................................................................................. 92

A.9.5 HMI parameters ................................................................................................................... 103

A.10 TCP/IP Interface Object ....................................................................................................... 104

A.11 Ethernet Link Object ............................................................................................................ 108

Glossary .............................................................................................................................................. 111

Index ................................................................................................................................................... 115

SIRIUS 3RW5 EtherNet/IP communication module

4 Manual, 05/2019, A5E45131885002A/RS-AA/001

1

Information and service

At Siemens Industry Online Support you can obtain up-to-date information from our global

support database quickly and simply. To accompany our products and systems, we offer a

wealth of information and services that provide support in every phase of the lifecycle of your

machine or plant – from planning and implementation and commissioning, right through to

maintenance and modernization:

● Product support

● Application examples

● Services

● Forum

● mySupport

Link: Siemens Industry Online Support (https://support.industry.siemens.com/cs/ww/en/)

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

5

Siemens Industry Online Support

Product support

Here you will find all the information and comprehensive know-how for your product:

● FAQs

Our replies to frequently asked questions.

● Manuals/operating instructions

Read online or download, available as PDF or individually configurable.

● Certificates

Clearly sorted according to approving authority, type and country.

● Characteristics

For support in planning and configuring your system.

● Product announcements

The latest information and news concerning our products.

● Downloads

Here you will find updates, service packs, HSPs and much more for your product.

● Application examples

Function blocks, background and system descriptions, performance statements,

demonstration systems, and application examples, clearly explained and represented.

● Technical data

Technical product data for support in planning and implementing your project.

Link: Product support (https://support.industry.siemens.com/cs/ww/en/ps)

SIRIUS 3RW5 EtherNet/IP communication module

6 Manual, 05/2019, A5E45131885002A/RS-AA/001

Siemens Industry Online Support

mySupport

With "mySupport", your personal work area, you get the very best out of your Industry Online

Support experience. Everything enables you to find the right information - every time.

The following functions are now available:

● Personal Messages

Your personal mailbox for exchanging information and managing your contacts

● Requests

Use our online form for specific solution suggestions, or send your technical inquiry

directly to a specialist in Technical Support

● Notifications

Make sure you always have the latest information - individually tailored to your needs

● Filter

Simple management and re-use of your filter settings from Product Support and the

Technical Forum

● Favorites / Tagging

Create your own knowledge database by assigning "Favorites" and "Tags" to documents

– simply and efficiently

● Entries last viewed

Clear presentation of your last viewed entries

● Documentation

Configure your individual documentation from different manuals – quickly and without

complications

● Personal data

Change personal data and contact information here

● CAx data

Simple access to thousands of items of CAx data such as 3D models, 2D dimension

drawings, EPLAN macros, and much more

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

7

Siemens Industry Online Support

Link for Android

Link for iOS

Link for Windows Phone

Siemens Industry Online Support app

You can use the Siemens Industry Online Support app to access all the device-specific

information available on the Siemens Industry Online Support portal for a particular article

number, including operating instructions, manuals, datasheets, FAQs etc.

The Siemens Industry Online Support app is available for iOS, Android or Windows Phone

devices. You can download the app from the following links:

SIRIUS 3RW5 EtherNet/IP communication module

8 Manual, 05/2019, A5E45131885002A/RS-AA/001

Siemens Industry Online Support

Support Request:

Internet (https://support.industry.siemens.com/My/ww/en/requests)

1.1 Support Request

1.1 Support Request

Using the Support Request form in Online Support you can send your query directly to our

Technical Assistance. After describing your query in a few guided steps, you will immediately

be provided with possible suggestions for solving the problem.

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

9

Siemens Industry Online Support

1.2 Additional documentation

1.2 Additional documentation

Manuals / online help

At this point, you will find further manuals and online helps that may be of interest to you for

your automation system. They are available to download from the Internet free of charge.

You can create your own individual system documentation in mySupport.

● 3RW5 topic page (https://support.industry.siemens.com/cs/ww/en/view/109747404

● Equipment Manual for the 3RW52 soft starter

(https://support.industry.siemens.com/cs/ww/en/view/109753751

● Equipment Manual for the 3RW55 soft starter

(https://support.industry.siemens.com/cs/ww/en/view/109753752

● Manuals for the 3RW5 soft starter

(https://support.industry.siemens.com/cs/ww/en/ps/16212/man

● Equipment Manual for the 3RW5 EtherNet/IP communication module

(https://support.industry.siemens.com/cs/ww/en/view/109758201

● Equipment Manual for the 3RW5 PROFINET communication modules

(https://support.industry.siemens.com/cs/ww/en/view/109753754

● Equipment Manual for the 3RW5 PROFIBUS communication module

(https://support.industry.siemens.com/cs/ww/en/view/109753753

● Equipment Manual for the 3RW5 Modbus communication modules

(https://support.industry.siemens.com/cs/ww/en/view/109753755

● "System Software for S7-300/400, System and Standard Functions" reference manual

(https://support.industry.siemens.com/cs/ww/en/view/1214574

● Online help for SIRIUS Soft Starter ES (TIA Portal)

● Online help for STEP 7

)

)

)

)

)

)

)

)

)

● The EMC Directive 2014/30/EU in practice (http://www.siemens.com/emc-guideline

● Industrial Control Panels and Electronic Equipment of Industrial Machinery for North

America (http://www.siemens.com/UL508A

● Control Panels compliant with IEC Standards and European Directives

(http://www.siemens.com/iec60204

SIRIUS 3RW5 EtherNet/IP communication module

10 Manual, 05/2019, A5E45131885002A/RS-AA/001

)

)

)

Siemens Industry Online Support

1.2 Additional documentation

Interesting links

● Manuals in Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/ps/man

● FAQs for 3RW5 soft starters

(https://support.industry.siemens.com/cs/ww/en/ps/16212/faq

● Downloads for 3RW5 soft starters

(https://support.industry.siemens.com/cs/ww/en/ps/16212/dl

● Product support for STEP 7 (TIA Portal)

(https://support.industry.siemens.com/cs/ww/en/ps/14672

● Premium Efficiency - Efficiency class IE3

http://w3.siemens.com/mcms/topics/en/application-

(

consulting/ie3ready/Pages/Default.aspx)

● ODVA technologies (https://www.odva.org)

)

)

)

)

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

11

Siemens Industry Online Support

1.2 Additional documentation

SIRIUS 3RW5 EtherNet/IP communication module

12 Manual, 05/2019, A5E45131885002A/RS-AA/001

2

2.1 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit

https://www.siemens.com/industrialsecurity

.

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer’s exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security

RSS Feed under

https://www.siemens.com/industrialsecurity

.

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

13

Safety information

NOTICE

Electrostatic discharge

2.2 ESD Guidelines

2.2 ESD Guidelines

ESD

All electronic devices are equipped with large-scale integrated ICs or components. Due to

their design, these electronic elements are highly sensitive to overvoltage, and thus to any

electrostatic discharge.

The acronym ESD has become the established designation for such electrostatic sensitive

components/devices. This is also the international abbreviation for such devices.

ESD devices are identified by the following symbol:

ESD devices can be destroyed by voltages well below the threshold of human perception.

These static voltages develop when you touch a component or electrical connection of a

device without having drained the static charges present on your body. The damage

caused to a device by overvoltage is usually not immediately evident and is only noticed

after an extended period of operation.

SIRIUS 3RW5 EtherNet/IP communication module

14 Manual, 05/2019, A5E45131885002A/RS-AA/001

Safety information

2.2 ESD Guidelines

Electrostatic charging

Anyone who is not connected to the electrical potential of their surroundings can be

electrostatically charged.

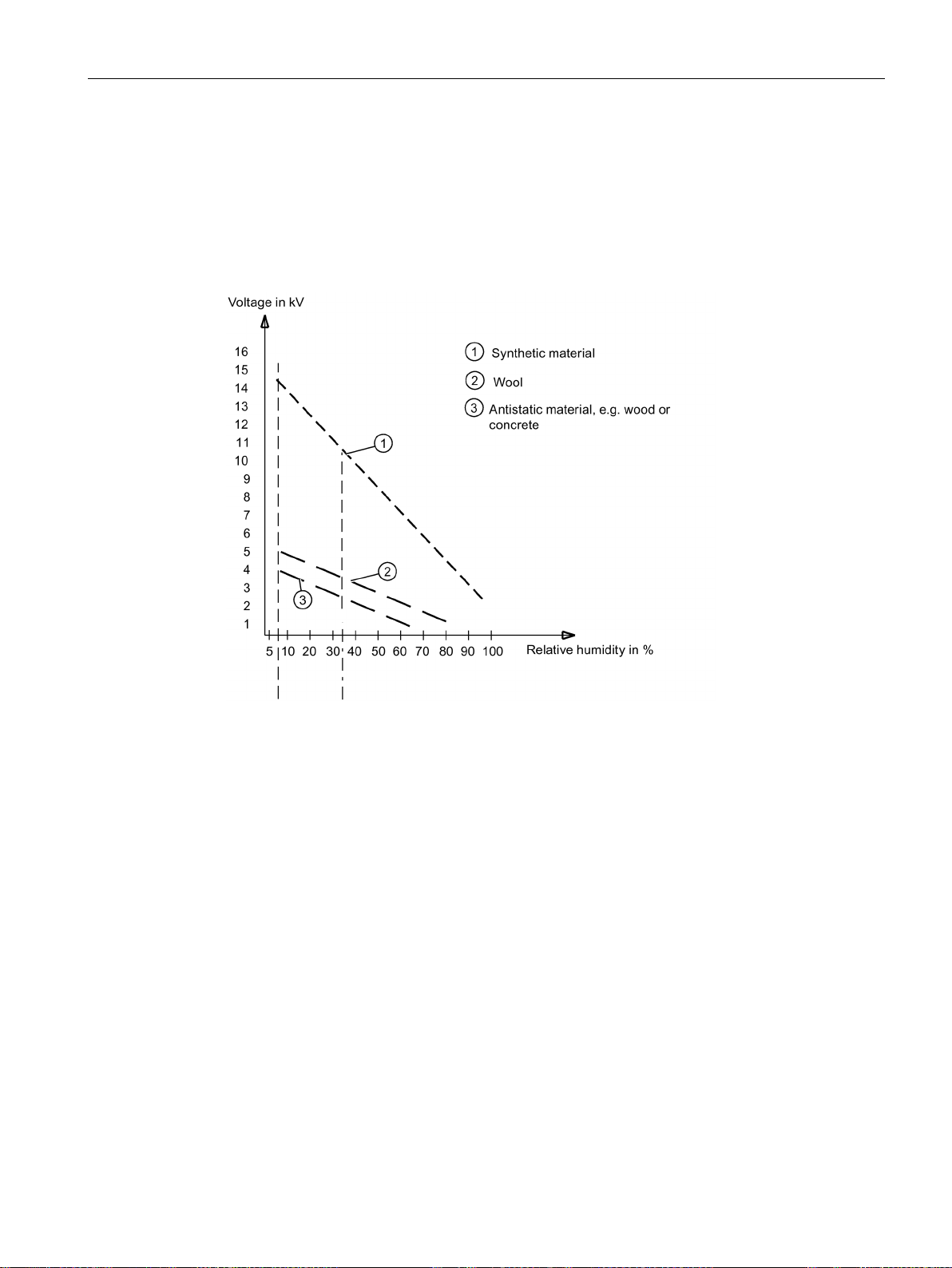

The diagram below shows the maximum electrostatic voltage which may build up on a

person coming into contact with the materials specified in the diagram. These values

correspond to IEC 801-2 specifications.

Basic protective measures against electrostatic discharge

● Make sure the grounding is good:

When handling electrostatic sensitive devices, ensure that your body, the workplace and

packaging are grounded. In this way, you can avoid becoming electrostatically charged.

● Avoid direct contact:

As a general rule, only touch electrostatic sensitive devices when this is unavoidable

(e.g. during maintenance work). Handle the devices without touching any chip pins or

PCB traces. In this way, the discharged energy cannot reach or damage sensitive

devices.

Discharge your body before taking any necessary measurements on a device. Do so by

touching grounded metallic parts. Use only grounded measuring instruments.

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

15

Safety information

2.3 Data security in automation

2.3 Data security in automation

The topic of data security and access protection (security) is becoming more and more

important in industrial environments. Increased networking of entire industrial plants, vertical

integration and networking of the levels within a company, and new technologies, such as

remote maintenance, are resulting in more increased requirements for protection of the

industrial plant. Security is the generic term for all protection measures:

● Loss of confidentiality due to unauthorized accessing of data

● Loss of integrity due to data manipulation

● Loss of availability due to destruction of data

To provide protection from manipulation in sensitive plant and production networks, it is not

enough to apply data security solutions for offices to industrial applications without any

adaptation.

Requirements

The special requirements of communication in an industrial environment (e.g.

communication in real time) result in additional requirements for security in industrial use:

Threats

● Protection against interaction between automated cells

● Protection of network segments

● Protection from unauthorized access

● Scalability of the security functionality

● No influence on the network structure.

Threats can arise from external and internal manipulation. Loss of data security is not always

caused by deliberate actions.

Internal threats arise due to:

● Technical faults

● Operating errors

● Errors in programs

This internal hazards are compounded by external threats. The external hazards do not differ

from the known threats in the office environment:

● Computer viruses and computer worms

● Trojan horses

● Unauthorized access

● Password phishing.

Password phishing means attempting to get a user to divulge access data and passwords by

masquerading as a different identity in an e-mail.

SIRIUS 3RW5 EtherNet/IP communication module

16 Manual, 05/2019, A5E45131885002A/RS-AA/001

Safety information

2.3 Data security in automation

Precautions

The most important precautions against manipulation and loss of data security in an

industrial environment are:

● Filtering and verification of data traffic through virtual private networks (VPN). A virtual

private network is used to exchange private data in a public network (e.g. the Internet).

The most common VPN technology is IPsec. IPsec is a collection of protocols based on

the IP protocol at the network layer.

● Segmentation into protected automation cells. The aim of this concept is to protect

devices in the network through security modules. A group of protected devices forms a

protected automation cell. Only security modules in the same group or the device

protected by you can be interchanged.

● Authentication (identification) of the networked devices. The security modules identify

themselves to each other via a secure (encrypted) channel using authentication

procedures. This prevents access to a protected segment by unauthorized persons from

outside.

● Encryption of the data traffic. The confidentiality of the data is ensured by encrypting the

data traffic. For this purpose, every security module is given a VPN certificate which

includes the encryption key.

VDI guidelines on information security in industrial automation

The VDI/VDE Association of German Engineers "Measurement and Automation" has

published a guideline for implementation of a security architecture in the industrial

environment in the VDI guideline "VDI/VDE 2182 Sheet 1, IT Security for Industrial

Automation - General Model". You will find the guideline under "VDI Standards" on the VDI

home page: VDI guidelines (http://www.vdi.de/43460.0.html

)

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

17

Safety information

2.4 Recycling and disposal

2.4 Recycling and disposal

For environmentally friendly recycling and disposal of your old device, please contact a

company certified for the disposal of old electrical and/or electronic devices and dispose of

the device in accordance with the regulations in your country.

SIRIUS 3RW5 EtherNet/IP communication module

18 Manual, 05/2019, A5E45131885002A/RS-AA/001

3

Note

3RW5 EtherNet/IP communication module

The 3RW5

3RW55

The 3RW5

from 3RW5

You can equip SIRIUS soft starters of the 3RW5 series with an optional

3RW5 communication module and therefore also with network functionality. Using the

3RW5 communication module, you integrate the 3RW5 soft starters into the associated

network environment with their complete functionality.

The 3RW5 soft starters have a slot for fitting the 3RW5 communication modules.

Preconditions for using the 3RW5 communication modules on the 3RW5 soft starter

EtherNet/IP communication module can be used on 3RW52 and

soft starters as from 3RW52 V2.0 and 3RW55 V2.0.

EtherNet/IP communication module is supported by 3RW5 HMI High Feature as

HMI High Feature V2.0.

When operating in an automation system:

● Programmable logic controller (PLC)

● PC / programming device with installed configuration software of controller

(e.g. Rockwell Studio 5000 with EDS file)

● Parameterization software (e.g. SIRIUS Soft Starter ES (TIA Portal), only possible via

local interface on the 3RW5 HMI High Feature) (optional)

Basic knowledge of the following areas:

● General electrical engineering

● Drive technology

● Automation technology

● Handling the automation system and the software used

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

19

Description

Note

Full functional scope

In order to be able to use 3RW5

of functions, ensure that you have the latest firmw

•

•

•

The latest downloads are available on the Internet

(

Note

Trademarks

This manual refers to technologies with names that are protected by the Open DeviceNet

Vendor Association (ODVA).

The OD

•

•

soft starters without any difficulties and with their full range

are and software updates:

3RW5 soft starter, 3RW5 communication module, 3RW5 HMI High Feature

EDS file

SIRIUS Soft Starter ES (TIA Portal)

https://support.industry.siemens.com/cs/ww/en/ps/16212/dl).

ODVA technologies

Target group

VA technologies referred to in this manual are as follows:

EtherNet/IP (EtherNet Industrial Protocol, often referred to as EIP) ™

CIP (Common Industrial Protocol) ™

Further information about ODVA and technologies protected by ODVA can be found on the

ODVA website (https://www.odva.org

).

The manual is intended for everyone involved in the following tasks:

● Planning and configuring systems

● Installation

● Commissioning

● Service and maintenance

SIRIUS 3RW5 EtherNet/IP communication module

20 Manual, 05/2019, A5E45131885002A/RS-AA/001

Description

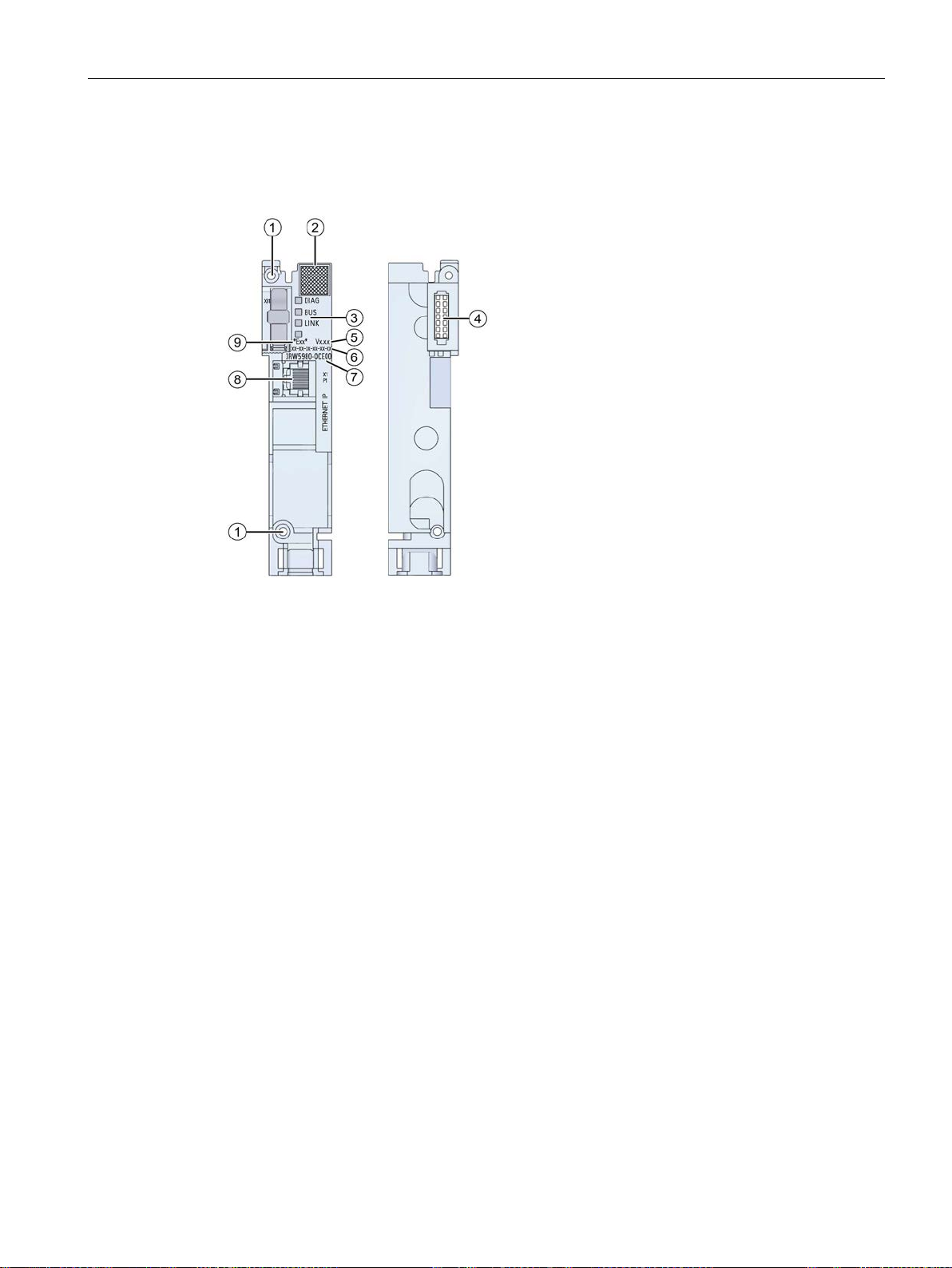

①

Mounting hole

②

Data Matrix Code

③

LED display

④

Plug-in connection to the basic unit

⑤

Firmware version of the 3RW5 communication module as delivered

⑥

MAC address

⑦

Article number

⑧

Fieldbus connection (RJ45 socket)

⑨

Product version

3.1 Hardware configuration

3.1 Hardware configuration

3RW5 EtherNet/IP communication module with the Article No. 3RW5980-0CE00:

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

21

Description

3.2 Functions of the 3RW5 EtherNet/IP communication module

3.2 Functions of the 3RW5 EtherNet/IP communication module

EtherNet/IP

The Ethernet Industrial Protocol (EIP) is a real-time Ethernet and an open standard for

industrial networks. This standard defines a non-manufacturer-specific communication,

automation, and engineering model.

Accessories for wiring the EtherNet/IP components are available in industrial quality.

Functionality of the 3RW5 communication module

The 3RW5 communication module supports the following EtherNet/IP functions:

● Supported Ethernet services: Ping, IGMP, TCP, UDP, DHCP, CIP, ENIP, ARP, IPV4,

Auto MDI-X, ACD and autonegotiation of speed and duplex

● Manual speed and duplex settings

● Minimum ENIP IO update time: 5 ms

● Resetting communication parameters to factory settings via EtherNet/IP

The 3RW5 communication module supports the following additional features:

● I&M identification data 0

SIRIUS 3RW5 EtherNet/IP communication module

22 Manual, 05/2019, A5E45131885002A/RS-AA/001

Description

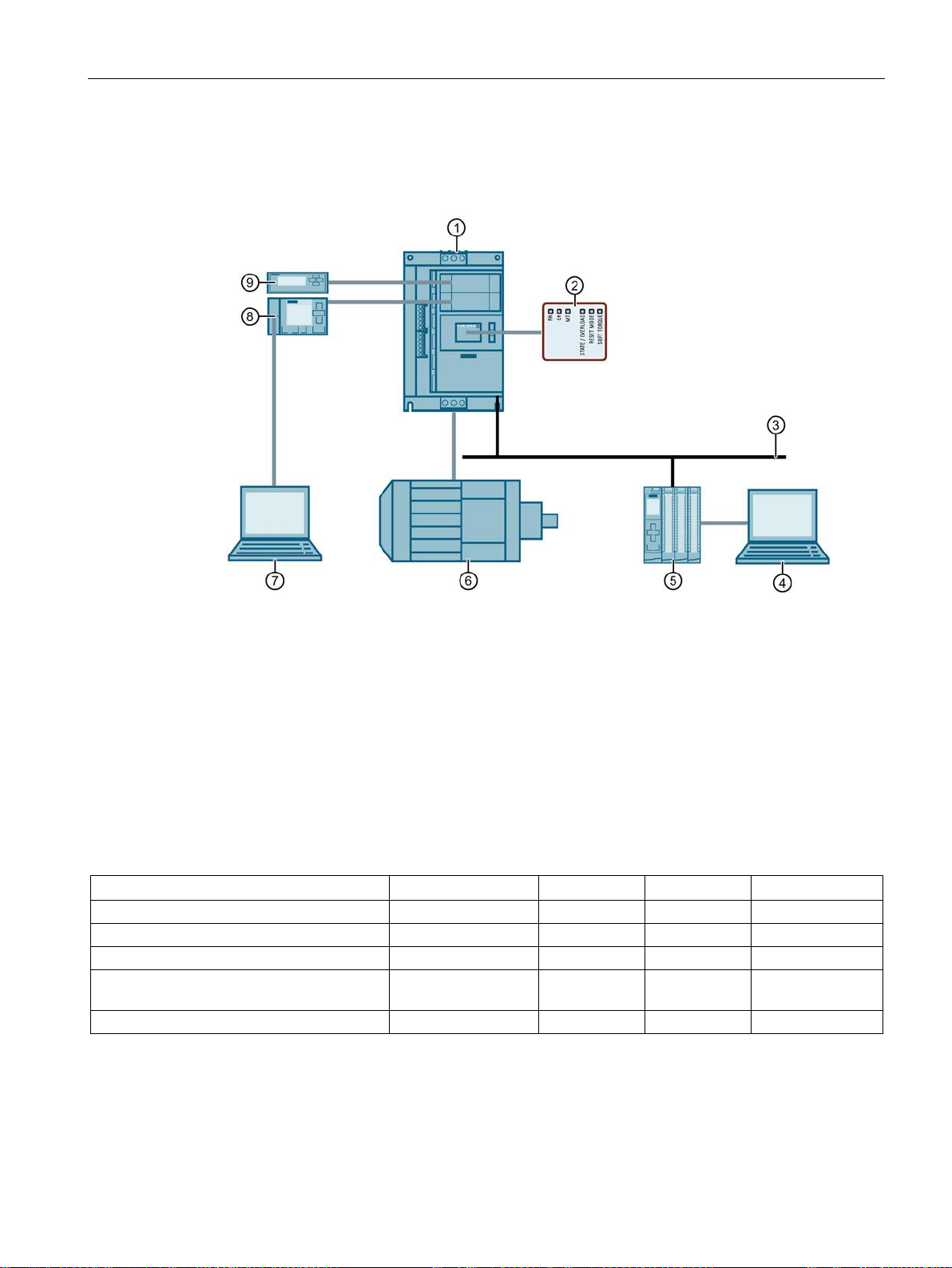

①

SIRIUS 3RW5 soft starter (illustration similar)

②

LED display on 3RW5 soft starter

③

EtherNet/IP (via 3RW5 EtherNet/IP communication module)

④

PC / programming device with configuration software of controller (e.g. Rockwell Studio 5000)

⑤

Programmable logic controller

⑥

Motor

⑦

PC with SIRIUS Soft Starter ES (TIA Portal) via local interface on 3RW5 HMI High Feature

⑧

3RW5 HMI High Feature (accessories depend on 3RW5 soft starter)

⑨

3RW5 HMI Standard (accessories depend on 3RW5 soft starter)

Monitoring

Diagnosis

Control

Parameterization

3RW5 HMI High Feature

✓

✓ ✓ (✓)2)

3RW5 HMI Standard

✓

✓ ✓ -

SIRIUS Soft Starter ES (TIA Portal)1)

✓

✓ ✓ (✓)2)

(via user program)

3RW5 soft starter

LEDs

LEDs

Via input IN

(✓)2)

1)

2)

Depends on the 3RW5 soft starter

3.3 Interaction interfaces

3.3 Interaction interfaces

Options for data transfer

Fieldbus via 3RW5 communication module ✓

✓ ✓ (✓)2)

Via local interface on the 3RW5 HMI High Feature

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

23

Description

Access path

Number of applications

Programmable logic controller

1

3.3 Interaction interfaces

Possible number of applications per access path

The following number of applications are simultaneously possible for each access path via

the 3RW5 EtherNet/IP communication module:

SIRIUS 3RW5 EtherNet/IP communication module

24 Manual, 05/2019, A5E45131885002A/RS-AA/001

Description

Operating mode

Control source

Control of the 3RW5 soft starter

Priority

Automatic

Fieldbus

PLC controlled

Lowest

parameter assignment)1)

Input controlled1)

Digital inputs

Input actions controlled

↓

PC controlled

Local interface

SIRIUS Soft Starter ES (TIA Portal) controlled

Highest

1)

Explanation for the lowest priority in the operating mode "Manual operation local" in the following text.

Note

Response of 3RW52 soft starter in the event of bus connection failure

To enable you to continue control

failure of the bus connection, you require a 3RW5

switch to "Manual operation local" mode.

Without 3RW5

been restored.

Alternatively, you can remove the

). Then restore the

3RW52

"Manual operation local

the factory setting on the device in the Equipment Manual of the 3RW52

3.4 Operating modes and master control function

3.4 Operating modes and master control function

The following modes are available (in ascending order of priority):

Manual

operation

local

- - Connection abort (depending on the 3RW5 soft starter and

3RW5 HMI controlled 3RW5 HMI 3RW5 HMI controlled ↓

-

If the connection to the control source is aborted, the control priority automatically switches

back to the lowest priority of the current mode.

Example: Control priority is with the 3RW5 HMI. If the connection to the 3RW5 HMI is

aborted, the control priority automatically switches back to "Manual operation local - Input

controlled" or "Manual operation local - Connection abort" (depending on the

3RW5 soft starter and the parameter assignment).

Depending on the 3RW5 soft starter and the parameter assignment, the lowest priority in

operating mode "Manual operation local" is "Input controlled" in the following cases:

● 3RW52 soft starter

● 3RW55 soft starter with one of the following parameter assignments:

– Input action "Manual operation local" is parameterized and switched on.

– A controlling input action (e.g. "Motor CW") is parameterized, but the input action

"Manual operation local" is not parameterized.

ling the 3RW52 soft starter in "Automatic" mode after

HMI (accessory) which enables you to

HMI, you cannot control the 3RW52 soft starter until the bus connection has

3RW5 communication module (Page 33

soft starter on the device to the factory setting, in order to switch to the

- Input controlled" mode. You will find more information on restoring

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

soft starter.

25

Description

3.4 Operating modes and master control function

Sets the operating mode

A higher-priority operating mode can actively take over as master control from a

lower-priority mode at any time; the reverse is not possible.

The master control function can only be returned to the operating mode with the lowest

priority. Control sources with higher priority must take the master control function from the

operating mode with the lowest priority.

An operating mode with lower priority can only take the master control function back while

the motor is switched off.

The operating mode with higher priority takes over or receives the master control function

from the current mode in the following ways:

● The operating mode with higher priority actively takes over the master control function:

– Digital inputs: By switching on the input action "Manual operation local", if this is

parameterized (depending on the 3RW5 soft starter).

– 3RW5 HMI: With the action "LOCAL / REMOTE"

– SIRIUS Soft Starter ES (TIA Portal)

● If the input action "Manual operation local" is not parameterized or available (depending

on the 3RW5 soft starter), the digital inputs obtain the master control function from an

operating mode of lower priority in one of the following ways:

– Via the "Manual operation local - input controlled" bit in the "process image output

(PIQ)" (Page 78).

The operating mode with the lowest priority receives or takes over the master control

function from the current mode in the following ways:

● The operating mode with higher priority actively returns the master control function:

– Digital inputs: By switching off the input action "Manual operation local", if this is

parameterized (depending on the 3RW5 soft starter).

– 3RW5 HMI: With the action "LOCAL / REMOTE"

– SIRIUS Soft Starter ES (TIA Portal)

● If the input action "Manual operation local" is not parameterized or available (depending

on the 3RW5 soft starter), the operating mode with the lowest priority can actively obtain

the master control function from the digital inputs or on connection abort:

– Via the "Manual operation local - input controlled" bit in the "process image output

(PIQ)" (Page 78).

Messages about the mode

You will find more information on messages in chapter Messages about the mode (Page 57).

SIRIUS 3RW5 EtherNet/IP communication module

26 Manual, 05/2019, A5E45131885002A/RS-AA/001

Description

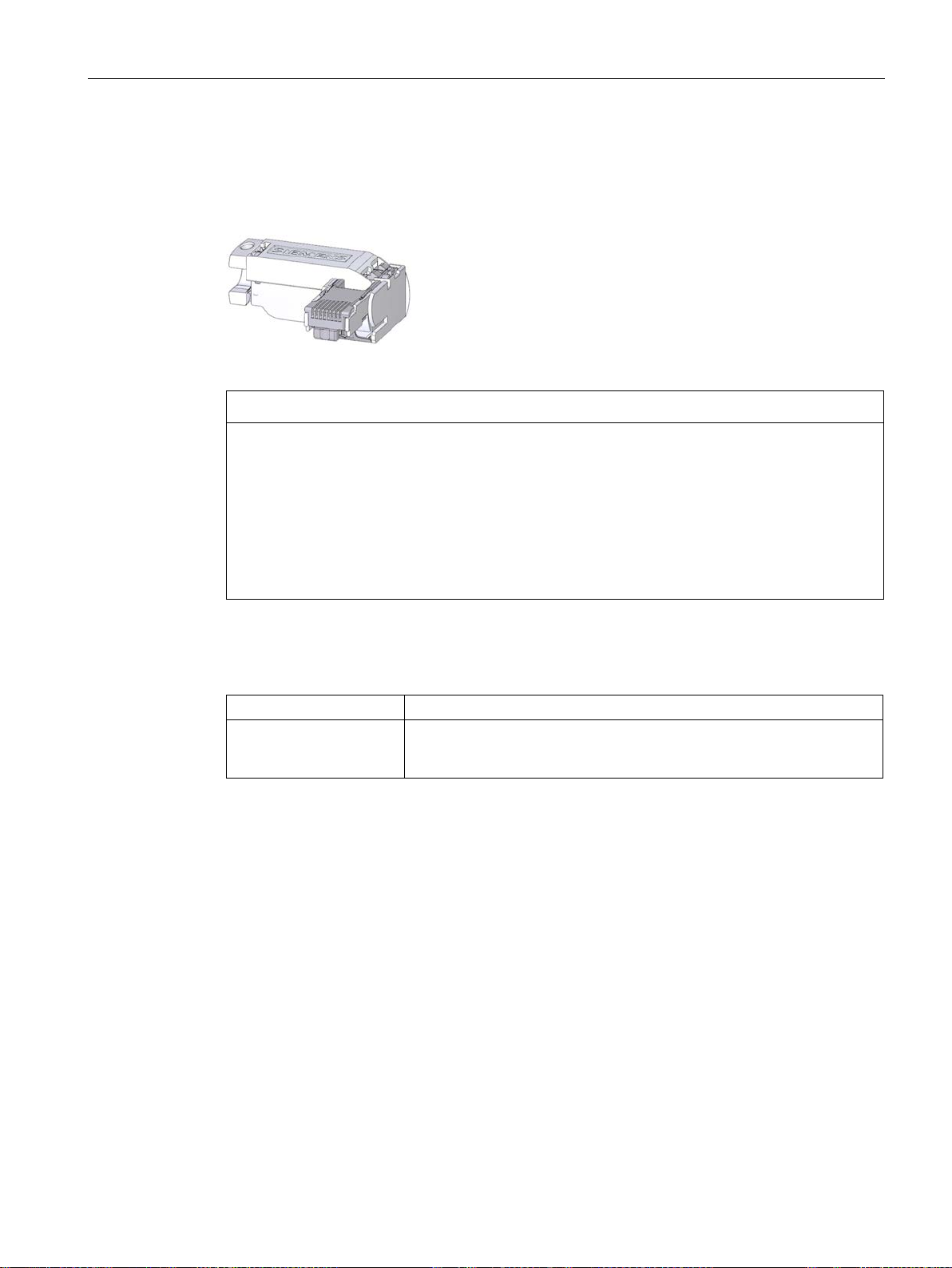

Illustration similar

NOTICE

Damage to the cable, bus connector and 3RW5 communication module

Article number

Description

for IE FC cable 2x 2; 90° cable outlet

3.5 Bus connection cable and bus connector

3.5 Bus connection cable and bus connector

For connection, use only angled industrial bus connectors with a RJ45 socket for Industrial

Ethernet.

If you use unsuitable bus connectors, the following can happen:

• The hinged cover of the 3RW5 soft starter does not close.

• The connecting cable is impermissibly bent.

• The bus connector or the 3RW5 communication module is damaged.

Use bus connectors with a right-angled cable outlet and dimensions that match the

recommended bus connector.

Recommended bus connector

6GK1901-1BB20-2AA0 Industrial Ethernet FastConnect RJ45 Plug 90 2x 2, RJ45 plug connector

(10/100 Mbit/s) with rugged metal housing and FC connecting method,

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

27

Description

3.6 Accessories

3.6 Accessories

3.6.1 SIRIUS Soft Starter ES (TIA Portal)

SIRIUS Soft Starter ES (TIA Portal) is the central software for configuration, commissioning,

operation, and diagnostics of 3RW5 soft starters.

You connect your PC / programming device to the 3RW5 soft starter via the local interface

on the optional 3RW5 HMI High Feature.

By displaying all operating data, service data and diagnostics data, SIRIUS Soft Starter ES

(TIA Portal) supplies reliable information, helping to avoid faults, or to quickly locate and

eliminate them if they occur.

SIRIUS Soft Starter ES (TIA Portal) can be downloaded from the Internet

(https://support.industry.siemens.com/cs/ww/en/ps/24231/dl

).

SIRIUS 3RW5 EtherNet/IP communication module

28 Manual, 05/2019, A5E45131885002A/RS-AA/001

4

NOTICE

Damage to property due to electrical voltage

4.1 Installing the 3RW5 communication module in the 3RW5 soft starter

Requirements

● 3RW5 soft starter

Switch off the power to the 3RW5 soft starter before starting work

(main and control supply voltage).

Procedure

Result

1. Break out the cover of the slot (Page 30).

2. Mount the 3RW5 communication module (Page 32).

You have mounted the 3RW5 communication module in the 3RW5 soft starter, which you

can connect to the fieldbus (Page 35) via the 3RW5 communication module.

SIRIUS 3RW5 EtherNet/IP communication module

Manual, 05/2019, A5E45131885002A/RS-AA/001

29

Installing and removing

CAUTION

Sharp edges.

NOTICE

Damage to property

4.1 Installing the 3RW5 communication module in the 3RW5 soft starter

4.1.1 Break out the cover of the slot

Requirements

● Sharp, robust knife or diagonal cutter

Procedure

Risk of injury from sharp edges or burrs.

Make sure that there are no sharp-edged burrs on the connecting webs and the preset

breaking points after knocking out. If necessary, deburr these spots professionally to avoid

injury.

Hold the cover tight so that it does not fall into the interior.

Ensure that no further foreign matter can get into the slot.

SIRIUS 3RW5 EtherNet/IP communication module

30 Manual, 05/2019, A5E45131885002A/RS-AA/001

Loading...

Loading...