Siemens SIRIUS 3RT User Manual

Manual

Industrial Controls

Switching Devices

SIRIUS - SIRIUS 3RT Contactors /

Contactor assemblies

Edition

09/2017

siemens.com

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

Industrial Controls

Switching devices

SIRIUS - SIRIUS 3RT

Contactors/Contactor assemblies

Manual

09/2017

A5E03656507120A/RS

Introduction

1

Standards

2

Safety instructions

3

Product description

4

Product combinations

5

Configuration

6

Mounting

7

Connection

8

Accessories

9

Technical data

10

Circuit diagrams

11

Types of coordination

A

References

B

Dimension drawings

(dimensions in mm)

C

-AE/006

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

3ZX1012-0RT20-5AC1

Ⓟ

Copyright © Siemens AG 2011.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

09/2017 Subject to change

Table of contents

1 Introduction ........................................................................................................................................... 13

2 Standards ............................................................................................................................................. 21

3 Safety instructions ................................................................................................................................. 29

4 Product description ............................................................................................................................... 31

1.1 Responsibility of the user for system configuration and functionality ..................................... 13

1.2 Purpose of the manual ............................................................................................................ 14

1.3 Advantages through energy efficiency .................................................................................... 15

1.4 Required basic knowledge ...................................................................................................... 15

1.5 Scope of the manual ............................................................................................................... 15

1.6 Siemens Industry Online Support ........................................................................................... 16

1.7 Further documentation ............................................................................................................ 17

1.8 DataMatrix code ...................................................................................................................... 18

1.9 Siemens Industry Online Support app .................................................................................... 18

1.10 Recycling and disposal ........................................................................................................... 19

1.11 Technical Assistance .............................................................................................................. 19

2.1 Standards and product approvals ........................................................................................... 21

2.2 Protective separation .............................................................................................................. 23

2.3 Positively driven contact elements/Mirror contacts ................................................................. 24

2.4 Used for stop category 0 / 1 .................................................................................................... 25

2.5 IE3 / IE4 ready ........................................................................................................................ 26

2.6 Applications ............................................................................................................................. 27

3.1 General safety notes ............................................................................................................... 29

3.2 Intended use ........................................................................................................................... 30

3.3 Current information about operational safety ......................................................................... 30

4.1 Overview of the contactor range ............................................................................................. 31

4.2 Device versions ....................................................................................................................... 35

4.2.1 3RT2 power contactors ........................................................................................................... 36

4.2.2 3RT10 / 3RT14 power contactors and 3RT12 vacuum contactors ........................................ 41

4.2.3 3RH2 contactor relays ............................................................................................................ 47

4.2.4 3RT26 capacitor contactors .................................................................................................... 50

4.2.5 3RA23 reversing contactor assemblies .................................................................................. 56

4.2.6 3RA24 contactor assemblies for star-delta (wye-delta) start .................................................. 59

4.2.7 Drive options ........................................................................................................................... 63

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

5

Table of contents

5 Product combinations............................................................................................................................ 65

6 Configuration ........................................................................................................................................ 67

4.3 Reference ............................................................................................................................... 63

6.1 Overview of applications for contactors and contactor assemblies ....................................... 67

6.2 SIRIUS system configurator ................................................................................................... 68

6.3 Operating mechanism system / coil selection 3RT contactors and 3RH2 contactor

relays ...................................................................................................................................... 69

6.3.1 Operating mechanism system / coil selection 3RT2 contactors and 3RH2 contactor

relays ...................................................................................................................................... 69

6.3.2 Operating mechanism system / coil selection 3RT1 contactors ............................................ 70

6.3.2.1 Conventional operating mechanism....................................................................................... 72

6.3.2.2 Solid-state operating mechanism for standard contactors .................................................... 73

6.3.2.3 Solid-state operating mechanism for standard contactors with remaining lifetime signal

RLT ........................................................................................................................................ 77

6.3.2.4 Solid-state operating mechanism for contactors with extended operating range and rail

applications ............................................................................................................................ 83

6.3.2.5 Solid-state operating mechanism for contactors with fail-safe control input .......................... 85

6.3.2.6 Typical circuit diagrams (standard contactors) ...................................................................... 87

6.4 Application environment ......................................................................................................... 89

6.4.1 3RH2 contactor relays ........................................................................................................... 89

6.4.2 3RT power contactors ............................................................................................................ 90

6.4.3 Contactors for railway applications ........................................................................................ 93

6.4.4 Installation altitude ................................................................................................................. 94

6.5 Switching motorized loads ..................................................................................................... 95

6.6 Switching resistive loads ...................................................................................................... 100

6.7 Changing the polarity of hoisting gear motors ..................................................................... 103

6.8 Switching in the auxiliary circuit ........................................................................................... 105

6.9 Switching of capacitive loads ............................................................................................... 106

6.10 Contactors with extended operating range .......................................................................... 114

6.10.1 Contactors for rail applications according to IEC 60077-2 .................................................. 114

6.10.2 Coupling relays .................................................................................................................... 116

6.10.2.1 Technical background information ....................................................................................... 117

6.11 Contactors in safety applications ......................................................................................... 118

6.11.1 Safety notes ......................................................................................................................... 118

6.11.1.1 General safety notes ............................................................................................................ 118

6.11.1.2 Intended use ........................................................................................................................ 119

6.11.1.3 Current information about operational safety ....................................................................... 121

6.11.1.4 Security information ............................................................................................................. 121

6.11.2 Examples/applications ......................................................................................................... 122

6.11.2.1 User responsibility for system design and function .............................................................. 122

6.11.2.2 Safety information ................................................................................................................ 123

6.11.2.3 Layout of application examples ............................................................................................ 124

6.11.2.4 P-switching fail-safe outputs ................................................................................................ 125

6.11.2.5

PM-switching fail-safe outputs ............................................................................................. 132

6.12 Operation of a motor in two directions of rotation (reversing contactor assembly) ............. 140

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

6 Manual, 09/2017, A5E03656507120A/RS-AE/006

Table of contents

7 Mounting ............................................................................................................................................. 179

8 Connection ......................................................................................................................................... 227

9 Accessories ........................................................................................................................................ 243

6.12.1 Reference ............................................................................................................................. 146

6.13 Starting three-phase motors with reduced starting current peaks (contactor assembly

for star-delta (wye-delta) start) .............................................................................................. 147

6.13.1 Reference ............................................................................................................................. 152

6.13.2 Technical background information ........................................................................................ 153

6.14 Using long control cables ...................................................................................................... 158

6.15 Configuration information for use downstream of frequency converters .............................. 164

6.16 Contact service life of auxiliary and main contacts ............................................................... 166

6.16.1 3RT2 power contactors (sizes S00 to S3) ............................................................................ 166

6.16.1.1 Contact service life of auxiliary and main contacts (sizes S00 and S0) ............................... 166

6.16.1.2 Contact service life of auxiliary and main contacts (size S2)................................................ 169

6.16.1.3 Contact service life of auxiliary and main contacts (size S3)................................................ 171

6.16.2 3RT26 capacitor contactors (sizes S00 to S3) ..................................................................... 173

6.16.2.1 Contact service life of auxiliary and main contacts ............................................................... 173

6.16.3 3RT10 power contactors and 3RT12 vacuum contactors (sizes S6 to S12) ........................ 175

6.16.3.1 Mechanical endurance .......................................................................................................... 175

6.16.3.2 Electrical endurance ............................................................................................................. 175

7.1 Warning notice ...................................................................................................................... 179

7.2 Mounting ............................................................................................................................... 179

7.2.1 Mounting options ................................................................................................................... 179

7.2.2 Mounting position .................................................................................................................. 180

7.2.3 Mounting on mounting plate / wall mounting ........................................................................ 181

7.2.4 Snapping onto DIN rail (snap-on mounting) ......................................................................... 185

7.3 Replacing solenoid coils ....................................................................................................... 188

7.3.1 Replacing solenoid coils for size S0 ..................................................................................... 188

7.3.2 Replacing solenoid coils for size S2 ..................................................................................... 191

7.3.3 Replacing solenoid coils for size S3 ..................................................................................... 196

7.3.4 Replacing solenoid coils for sizes S6-S12 ............................................................................ 202

7.4 Contact piece replacement (sizes S2 to S12) ...................................................................... 205

7.4.1 Contact piece replacement (size S2) .................................................................................... 205

7.4.2 Contact piece replacement (size S3) .................................................................................... 211

7.4.3 Contact piece replacement (size S6) .................................................................................... 217

7.4.4 Contact piece replacement (size S10 and S12) ................................................................... 219

7.5 Replacing the vacuum interrupters (sizes S10 and S12) ..................................................... 222

8.1 Warning notice ...................................................................................................................... 227

8.2 Conductor cross-sections ..................................................................................................... 230

8.2.1 Conductor cross-sections for screw-type connection systems ............................................. 230

8.2.2 Conductor cross-sections for spring-loaded connection systems ........................................ 238

8.2.3 Conductor cross-sections for ring cable lug connection system .......................................... 240

9.1 Overview of accessories for 3RT2 contactors ...................................................................... 243

9.1.1 Overview of accessories for 3RT2 contactors ...................................................................... 243

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

7

Table of contents

9.2 Overview of accessories for 3RT1 contactors ..................................................................... 253

9.2.1 Overview of accessories for 3RT1 contactors ..................................................................... 253

9.3 Auxiliary switch blocks ......................................................................................................... 255

9.3.1 Auxiliary switch block for 3RT2 power contactors and 3RH2 contactor relays ................... 255

9.3.1.1 Description ........................................................................................................................... 255

9.3.1.2 Configuration ........................................................................................................................ 258

9.3.1.3 Selection guide for mountable auxiliary switch blocks for power contactors and

contactor relays .................................................................................................................... 264

9.3.1.4 Mounting/Disassembly ......................................................................................................... 284

9.3.2 Auxiliary switch blocks for 3RT1 power contactors .............................................................. 287

9.3.2.1 Description ........................................................................................................................... 287

9.3.2.2 Configuration ........................................................................................................................ 290

9.3.2.3 Terminal designations and identification numbers for auxiliary contacts............................. 292

9.3.2.4 Mounting/Disassembly ......................................................................................................... 293

9.4 Surge suppressor ................................................................................................................. 296

9.4.1 Description ........................................................................................................................... 296

9.4.2 Configuration ........................................................................................................................ 300

9.4.3 Mounting .............................................................................................................................. 308

9.5 EMC suppression module .................................................................................................... 315

9.5.1 Description ........................................................................................................................... 315

9.5.2 Configuration ........................................................................................................................ 317

9.5.3 Mounting .............................................................................................................................. 319

9.6 OFF-delay device ................................................................................................................. 320

9.6.1 Description ........................................................................................................................... 320

9.6.2 Configuration ........................................................................................................................ 320

9.6.3 Mounting .............................................................................................................................. 321

9.7 Mechanical latch .................................................................................................................. 323

9.7.1 Description ........................................................................................................................... 323

9.7.2 Mounting/Disassembly ......................................................................................................... 324

9.7.3 Operation ............................................................................................................................. 326

9.8 Additional load module ......................................................................................................... 327

9.8.1 Description ........................................................................................................................... 327

9.8.2 Mounting .............................................................................................................................. 327

9.9 Control kit for manual operation of contactor contacts ........................................................ 328

9.9.1 Description ........................................................................................................................... 328

9.9.2 Mounting .............................................................................................................................. 329

9.10 Coupling link for PLC

........................................................................................................... 331

9.10.1 Description ........................................................................................................................... 331

9.10.2 Mounting the 3RH2924-1GP11 coupling link ....................................................................... 334

9.10.3 Mounting and disassembling the 3RH2926-1AP1 coupling module.................................... 335

9.11 LED display indicator module .............................................................................................. 338

9.11.1 Description ........................................................................................................................... 338

9.11.2 Mounting .............................................................................................................................. 339

9.12 Solder pin adapter ................................................................................................................ 340

9.12.1 Description ........................................................................................................................... 340

9.12.2 Mounting .............................................................................................................................. 341

9.13 Coil terminal module ............................................................................................................ 343

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

8 Manual, 09/2017, A5E03656507120A/RS-AE/006

Table of contents

9.13.1 Description ............................................................................................................................ 343

9.13.2 Mounting ............................................................................................................................... 344

9.14 Cover for ring cable lug ......................................................................................................... 346

9.14.1 Description ............................................................................................................................ 346

9.15 Sealable cover ...................................................................................................................... 347

9.15.1 Description ............................................................................................................................ 347

9.15.2 Mounting ............................................................................................................................... 347

9.16 3-phase infeed terminal ........................................................................................................ 348

9.16.1 Description ............................................................................................................................ 348

9.16.2 Mounting ............................................................................................................................... 348

9.17 1-phase infeed terminal ........................................................................................................ 349

9.17.1 Description ............................................................................................................................ 349

9.17.2 Mounting ............................................................................................................................... 349

9.18 Parallel switching connectors ............................................................................................... 350

9.18.1 Description ............................................................................................................................ 350

9.18.2 Configuration ......................................................................................................................... 351

9.18.3 Mounting ............................................................................................................................... 353

9.19 Link module for two contactors in series ............................................................................... 354

9.19.1 Description ............................................................................................................................ 354

9.19.2 Mounting ............................................................................................................................... 354

9.20 Link module for motor starter protector ................................................................................. 356

9.20.1 Description ............................................................................................................................ 356

9.21 Pneumatically delayed auxiliary switch................................................................................. 357

9.21.1 Description ............................................................................................................................ 357

9.21.2 Mounting/Disassembly .......................................................................................................... 358

9.21.3 Operation .............................................................................................................................. 359

9.22 Insulating stop ....................................................................................................................... 360

9.22.1 Description ............................................................................................................................ 360

9.23 Terminal module for contactors with screw connections ...................................................... 361

9.23.1 Description ............................................................................................................................ 361

9.23.2 Mounting ............................................................................................................................... 362

9.24 3RA27 function modules for connection to the automation level (AS-Interface or IO-

Link) ...................................................................................................................................... 363

9.24.1 Description ............................................................................................................................ 363

9.25 3RA28 function modules for mounting on 3RT2 contactors ................................................. 364

9.25.1 Description

............................................................................................................................ 364

9.26 Assembly kit for reversing contactor assemblies (sizes S00 to S3) ..................................... 366

9.26.1 Description ............................................................................................................................ 366

9.26.2 Mounting size S00 ................................................................................................................ 368

9.26.3 Mounting size S0 .................................................................................................................. 371

9.26.4 Mounting size S2 .................................................................................................................. 376

9.26.5 Mounting size S3 .................................................................................................................. 380

9.27 Wiring kit for reversing contactor assemblies (sizes S6 to S12) .......................................... 385

9.27.1 Description ............................................................................................................................ 385

9.27.2 Mounting size S6 .................................................................................................................. 386

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

9

Table of contents

10 Technical data ..................................................................................................................................... 461

11 Circuit diagrams ................................................................................................................................... 463

A Types of coordination ........................................................................................................................... 493

B References .......................................................................................................................................... 495

9.27.3 Mounting sizes S10 and S12 ............................................................................................... 389

9.28 Assembly kit for contactor assemblies for star-delta (wye-delta) start (sizes S00 to S3) .... 391

9.28.1 Description ........................................................................................................................... 391

9.28.2 Mounting size S00 ............................................................................................................... 395

9.28.3 Mounting size S0.................................................................................................................. 399

9.28.4 Mounting size S2.................................................................................................................. 404

9.28.5 Mounting size S3.................................................................................................................. 415

9.29 Wiring kit for contactor assemblies for star-delta (wye-delta) start (sizes S6 to S12). ........ 427

9.29.1 Description ........................................................................................................................... 427

9.29.2 Mounting size S6.................................................................................................................. 429

9.29.3 Mounting sizes S10 and S12 ............................................................................................... 435

9.30 Terminal cover for cable lug connection and busbar connection ........................................ 439

9.30.1 Description ........................................................................................................................... 439

9.30.2 Mounting .............................................................................................................................. 441

9.31 Terminal covers for box terminal block ................................................................................ 450

9.31.1 Description ........................................................................................................................... 450

9.31.2 Mounting .............................................................................................................................. 450

9.32 Main current path surge attenuation module for vacuum contactors ................................... 451

9.32.1 Description ........................................................................................................................... 451

9.32.2 Mounting .............................................................................................................................. 452

9.33 Box terminal block (size S6 to S12) ..................................................................................... 454

9.33.1 Description ........................................................................................................................... 454

9.33.2 Mounting .............................................................................................................................. 455

9.34 Solid-state time-delay auxiliary switch blocks (size S6 to S12) ........................................... 456

9.34.1 Description ........................................................................................................................... 456

9.34.2 Configuration ........................................................................................................................ 459

9.34.3 Mounting/Disassembly ......................................................................................................... 459

10.1 Technical data in Siemens Industry Online Support ............................................................ 461

10.2 Overview tables.................................................................................................................... 461

11.1 CAx data .............................................................................................................................. 463

11.2 Contactors and contactor accessories ................................................................................. 464

11.3 Capacitor contactors (S00 /S0 / S2 / S3) ............................................................................. 480

11.4 Reversing contactor assemblies (S00 / S0 / S2 / S3) .......................................................... 484

11.5 Reversing contactor assemblies (S6 / S10 / S12) ............................................................... 485

11.6 Contactor assemblies for star-delta (wye-delta) start (S00 / S0 / S2 / S3) .......................... 487

11.7 Contactor assemblies for star-delta (wye-delta) start (S6 / S10 / S12) ............................... 490

B.1 References ........................................................................................................................... 495

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

10 Manual, 09/2017, A5E03656507120A/RS-AE/006

Table of contents

C Dimension drawings (dimensions in mm) ............................................................................................ 501

Index................................................................................................................................................... 547

B.2 Manuals - SIRIUS Modular System ...................................................................................... 497

B.3 More information ................................................................................................................... 499

C.1 CAx data ............................................................................................................................... 501

C.2 3RT2.1 contactors and 3RH2 contactor relays (size S00) ................................................... 502

C.3 3RT2.2 contactors (size S0) ................................................................................................. 508

C.4 3RT2.3 contactors (size S2) ................................................................................................. 514

C.5 3RT2.4 contactors (size S3) ................................................................................................. 518

C.6 3RT1.5 contactors (size S6) ................................................................................................. 522

C.7 3RT1.6 contactors (size S10) ............................................................................................... 523

C.8 3RT1.7 contactors (size S12) ............................................................................................... 524

C.9 3RT26 capacitor contactors .................................................................................................. 525

C.9.1 3RT261 capacitor contactors (size S00)............................................................................... 525

C.9.2 3RT262 capacitor contactors (size S0) ................................................................................. 526

C.9.3 3RT263 capacitor contactors (size S2) ................................................................................. 529

C.9.4 3RT264 capacitor contactors (size S3) ................................................................................. 530

C.10 3RA23 reversing contactor assemblies ................................................................................ 531

C.10.1 3RA231 reversing contactor assemblies (size S00) ............................................................. 531

C.10.2 3RA232 reversing contactor assemblies (size S0) ............................................................... 533

C.10.3 3RA233 reversing contactor assemblies (size S2) ............................................................... 537

C.10.4 3RA234 reversing contactor assemblies (size S3) ............................................................... 538

C.10.4.1 3RA234.-8X.30-1 reversing contactor assemblies (size S3) ................................................ 538

C.10.4.2 Drilling diagram for 3RA234.-8X.30-1 reversing contactor assemblies (size S3)................. 538

C.11 3RA24 contactor assemblies for star-delta (wye-delta) start ................................................ 539

C.11.1 3RA241 contactor assemblies for star-delta (wye-delta) start (size S00) ............................ 539

C.11.2 3RA242 contactor assemblies for star-delta (wye-delta) start (size S0) .............................. 541

C.11.2.1 3RA242.-8X.3.-1 contactor assemblies for star-delta (wye-delta) start (size S0, screw-

type connection system) ....................................................................................................... 541

C.11.2.2 Drilling diagram for 3RA242.-8X.3.-1 contactor assemblies for star-delta (wye-delta)

start (size S0, screw-type connection system) ..................................................................... 541

C.11.2.3 3RA242.-8X.3.-2 contactor assemblies for star-delta (wye-delta) start (size S0, spring-

loaded connection system) ................................................................................................... 542

C.11.2.4 Drilling diagram for 3RA242.-8X.3.-2 contactor assemblies for star-delta (wye-delta)

start (size S0, spring-loaded connection system) ................................................................. 542

C.11.3 3RA243 contactor assemblies for star-delta (wye-delta) start (size S2) .............................. 543

C.11.4 3RA244 contactor assemblies for star-delta (wye-delta) start (size S3) .............................. 545

C.11.4.1 3RA244.-8X.32-1 contactor assemblies for star-delta (wye-delta) start (size S3) ............... 545

C.11.4.2 Drilling diagram for 3RA244.-8X.32-1 contactor assemblies for star-delta (wye-delta)

start (size S3) ........................................................................................................................ 546

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

11

Table of contents

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

12 Manual, 09/2017, A5E03656507120A/RS-AE/006

1

1.1

Responsibility of the user for system configuration and functionality

Note

When designing a system, comply with all valid national installation specifications and

standards.

The SIRIUS modular system offers various switching devices for the safe and functional

switching of electrical loads. 3RT2 contactors are available in sizes S00 to S3.

3RT1 contactors are available in sizes S6 to S12.

● 3RT.0 power contactors and 3RT12 vacuum contactors for switching motorized loads

● 4-pole 3RT23 contactors for switching resistive loads

● 3-pole 3RT24 / 3RT14 contactors for switching resistive loads

● 4-pole 3RT25 contactors for changing the polarity of hoisting gear motors

● 3RH2 contactor relays for switching in the control circuit

● 3RT26 capacitor contactors for switching capacitive loads (AC-6b)

● 3RT1 / 3RT2 / 3RH2 contactors with extended operating range

– 3RT10 / 3RT20 / 3RH21 contactors for rail applications

– 3RT20 / 3RH21 coupling relays for system-compliant interaction with electronic

controllers

● 3RT1...-.S.36 contactors with fail-safe control inputs for safety-related applications

● Operation of a motor in two directions of rotation (reversing contactor assembly)

● Starting three-phase motors with reduced starting current peaks (contactor assemblies for

star-delta (wye-delta) start)

Siemens AG, its regional offices, and associated companies (hereinafter referred to as

"Siemens") cannot guarantee all the properties of an overall installation or machine that has

not been designed by Siemens.

Nor can Siemens assume liability for recommendations that appear or are implied in the

following description. No new guarantee, warranty, or liability claims beyond the scope of the

Siemens general terms of supply are to be derived or inferred from the following description.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

13

Introduction

1.2

Purpose of the manual

1.2 Purpose of the manual

This manual describes 3RT2 contactors (up to 55 kW), 3RT1 contactors (from 55 kW),

3RH21 contactor relays, reversing contactor assemblies, and contactor assemblies for stardelta (wye-delta) start, and it supplies the following information:

● Information about integrating the contactors and contactor assemblies into the system

environment.

● Information on necessary hardware components.

● Information about installing and connecting the contactors.

● Technical information such as dimension drawings and unit wiring diagrams.

The information in this manual enables you to configure and commission the contactors.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

14 Manual, 09/2017, A5E03656507120A/RS-AE/006

Introduction

1.3

Advantages through energy efficiency

1.4

Required basic knowledge

1.5

Scope of the manual

1.3 Advantages through energy efficiency

Siemens offers you a unique portfolio for efficient energy management in industry – a

process that serves to optimally shape your energy requirement. Operational energy

management is subdivided into three phases:

● Identification

● Evaluation

● Realization

Siemens supports you with suitable hardware and software solutions in every phase of a

project.

More information can be found on the Internet

(http://www.automation.siemens.com/mcms/industrial-controls/en/energy-efficiency).

3RT contactors make the following contribution to energy efficiency in the overall plant:

● AC/DC coils with electrical control to reduce the closing power and holding power

● Smaller power supplies in the control circuit through low holding power at 24 V DC

● Reduced energy requirements of the contactors thanks to increased switching capacity in

each size from S00 to S3

Figure 1-1 Overview of the energy management process

To understand these operating instructions you should have a general knowledge of

automation engineering and low-voltage switchgear.

The manual is valid for these contactors and contactor assemblies. It contains a description

of the devices that is valid at the time of publication.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

15

Introduction

1.6

Siemens Industry Online Support

Information and Service

Link:

Product support

FAQs

Manuals/operating instructions

Certificates

Characteristic curves

Product announcements

Downloads

Application examples

Technical data

Link:

1.6 Siemens Industry Online Support

In Siemens Industry Online Support, you can obtain up-to-date information from our global

support database quickly and simply. To accompany our products and systems, we offer a

wealth of information and services that provide support in every phase of the lifecycle of your

machine or plant – from planning and implementation, through commissioning, up to

maintenance and modernization:

● Product support

● Application examples

● Services

● Forum

● mySupport

Siemens Industry Online Support (https://support.industry.siemens.com/cs/ww/en)

You will find here all the information and comprehensive know-how covering all aspects of

your product:

●

Our answers to frequently asked questions.

●

Read online or download, available as PDF or individually configurable.

●

Clearly sorted according to approving authority, type and country.

●

For support in planning and configuring your system.

●

The latest information and news concerning our products.

●

You can find here updates, service packs, HSPs and much more for your product.

●

Function blocks, background and system descriptions, performance statements,

demonstration systems, and application examples, clearly explained and represented.

●

Technical product data for support in planning and implementing your project.

Product support (https://support.industry.siemens.com/cs/ww/en/ps)

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

16 Manual, 09/2017, A5E03656507120A/RS-AE/006

Introduction

mySupport

Personal messages

Inquiries

Notifications

Filters

Favorites / Tags

Entries last viewed

Documentation

Personal data

CAx data

1.7

Further documentation

1.7 Further documentation

With "mySupport", your personal workspace, you get the very best out of your Industry

Online Support. Everything to enable you to find the right information every time.

The following functions are now available:

●

Your personal mailbox for exchanging information and managing your contacts

●

Use our online form for specific solution suggestions, or send your technical inquiry

directly to a specialist in Technical Support

●

Make sure you always have the latest information - individually tailored to your needs

●

Simple management and re-use of your filter settings from Product Support and the

Technical Forum

●

Create your own knowledge database by assigning "Favorites" and "Tags" to documents

– simply and efficiently

●

Clear presentation of your last viewed entries

●

Configure your individual documentation from different manuals – quickly and without

complications

●

Change personal data and contact information here

●

Simple access to thousands of items of CAx data such as 3D models, 2D dimension

drawings, EPLAN macros and much more

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

To install and connect the contactors and contactor assemblies, you require the operating

instructions of the contactors and contactor assemblies used.

You can find a list of operating instructions and an overview of the manuals pertaining to the

SIRIUS modular system in the Appendix "References (Page 495)".

17

Introduction

1.8

DataMatrix code

1P Article

number

+ S Loc

/ Date

Serial numbe

Data

identifier

User content

Separ

User content

Separ

User content

User content

Note

The information content is displayed without spaces.

1.9

Siemens Industry Online Support app

Siemens Industry Online Support app

Link for Android

Link for iOS

Link for Windows Phone

1.8 DataMatrix code

A Data Matrix code has been lasered onto the contactors and contactor assembly

enclosures.

The Data Matrix codes are standardized in ISO/IEC 16022. The Data Matrix codes on

Siemens devices use ECC200 coding for powerful error correction.

The following information is stored in the Data Matrix code:

ation

ator

ator

r

This machine-readable information simplifies and accelerates handling of the respective

devices.

As well as fast access to the serial numbers of the respective devices for unique

identification, the Data Matrix codes simplify communication with Siemens Technical

Support.

You can use the Siemens Industry Online Support app to access all the device-specific

information available on the Siemens Industry Online Support portal for a particular article

number, including operating instructions, manuals, datasheets, FAQs etc.

The Siemens Industry Online Support app is available for iOS, Android or Windows Phone

devices. You can download the app from the following links:

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

18 Manual, 09/2017, A5E03656507120A/RS-AE/006

Introduction

1.10

Recycling and disposal

1.11

Technical Assistance

Up-to-the-minute information

Technical Assistance:

or on the Internet at:

1.10 Recycling and disposal

These devices can be recycled thanks to their low pollutant content. For environmentallyfriendly recycling and disposal of your electronic waste, please contact a company certified

for the disposal of electronic waste.

You can obtain further assistance by calling the following numbers:

Telephone: +49 (911) 895-5900 (8 a.m. to 5 p.m. CET)

Fax: +49 (911) 895-5907

E-mail: (mailto:technical-assistance@siemens.com)

Internet: (http://www.siemens.com/sirius/technical-assistance)

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

19

Introduction

1.11 Technical Assistance

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

20 Manual, 09/2017, A5E03656507120A/RS-AE/006

2

2.1

Standards and product approvals

Applicable regulations, standards, and approvals

Note

Depending on meaning, some standards and approvals are applied only to specific product

variants and are restricted to these. For example, the IEC

account only for contactors for rail applications but not for standard contactors.

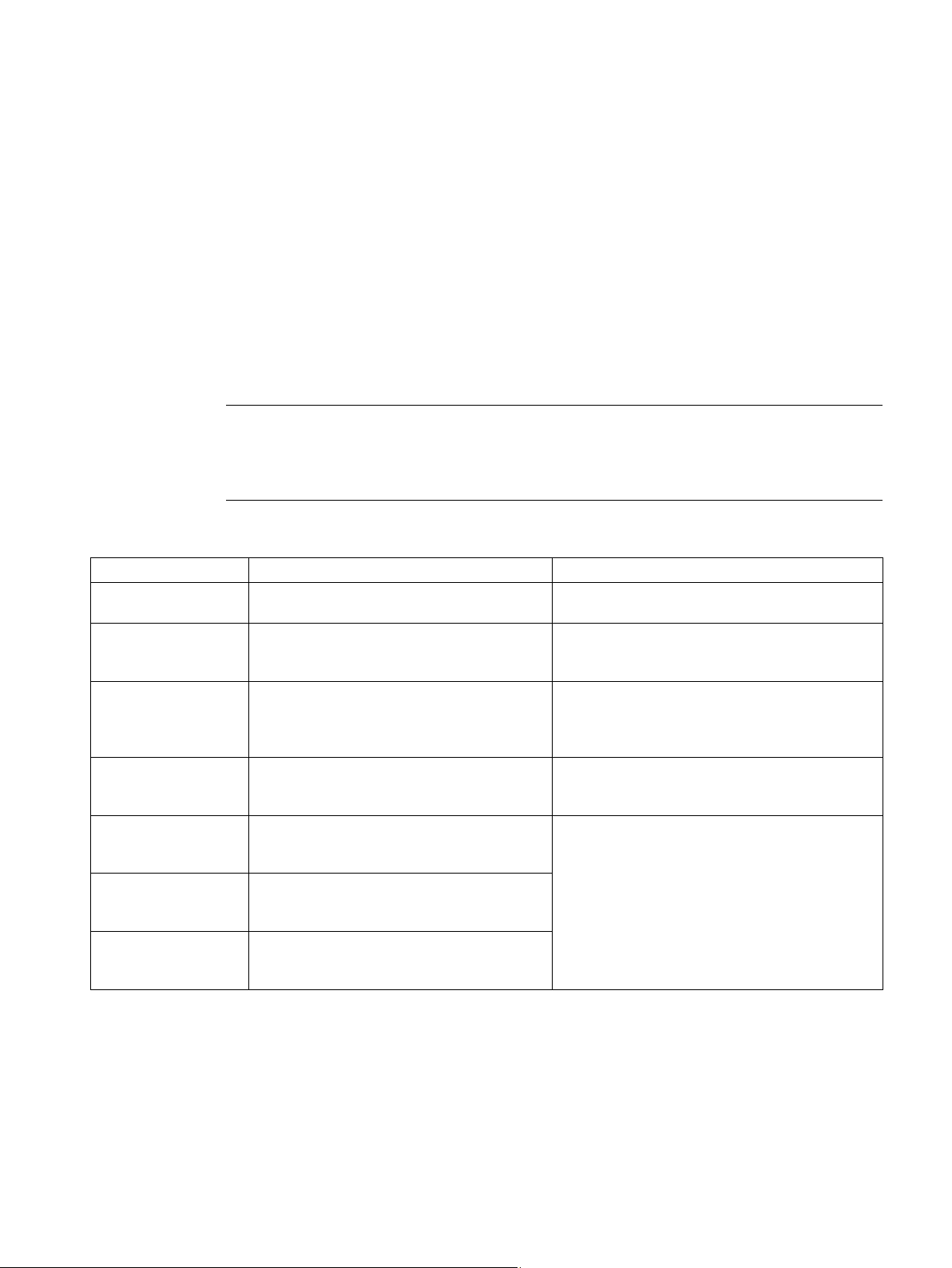

Standard / approvals

Description

Note

General rules

starters

devices

components - General rules

for design

safety-related systems

programmable electronic control systems

Below is a list of extracts from the most important standards and approvals of the 3RT and

3RH contactors.

60077-2 standard is taken into

IEC 60947-1 Low-voltage switchgear and controlgear -

IEC 60947-4-1 Low-voltage switchgear and controlgear Part

4-1: Electromechanical contactors and motor-

IEC 60947-5-1 Low-voltage switchgear and controlgear Part

5-1: Control circuit devices and switching

elements - Electromechanical control circuit

IEC 60077-2 Railway applications - Electric equipment for

rolling stock - Part 2: Electrotechnical

EN ISO 13849-1 Safety of machinery – safety-related parts of

control systems - Part 1: General principles

IEC 61508 Functional safety of

electrical/electronic/programmable electronic

IEC 62061 Safety of machinery - Functional safety of

safety-related electrical, electronic and

Main approval for IEC-orientated international

markets

Relevant for auxiliary circuits and 3RH contactor

relays

Additional approval for railroad applications

Approvals for use in safety-related applications

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

21

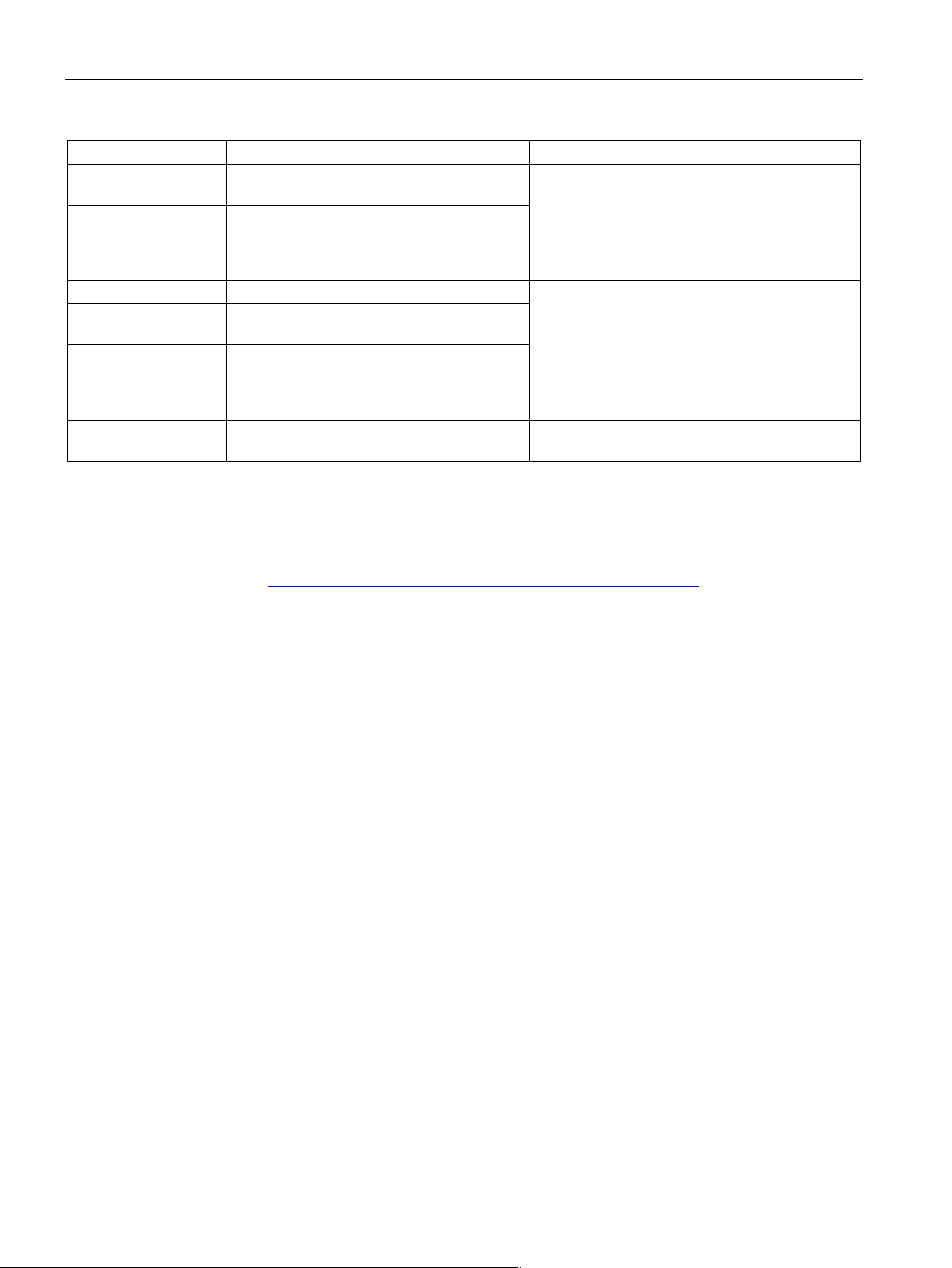

Standards

Standard / approvals

Description

Note

Part 1: General rules

starters

CSA-C22.2 No. 14-13

Industrial Control Equipment

No 60947-1-13

Part 1: General rules

starters

Certification

Reference

Reference

2.1 Standards and product approvals

UL 60947-1 Low-Voltage Switchgear and Control gear -

UL 60947-4-1 Low-Voltage Switchgear and Control gear -

Part 4-1: Contactors and motor-starters Electromechanical contactors and motor-

CAN/CSA-C22.2

CAN/CSA-C22.2

No 60947-4-1-14

CCC Certificate for China Compulsory Product

Low-Voltage Switchgear and Control gear -

Low-Voltage Switchgear and Control gear Part 4-1: Contactors and motor-starters Electromechanical contactors and motor-

SIRIUS components have been approved by a whole range of bodies for various sectors

(shipbuilding, etc.). More information and certificates for download are available on the

Internet (https://support.industry.siemens.com/cs/ww/en/ps/16131/cert).

Approvals for the UL market, predominantly the

USA

Approvals specifically for the Canadian market

Approval specifically for the Chinese market

You can find all the technical data and other information regarding the products in the

Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/ps/16132/td).

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

22 Manual, 09/2017, A5E03656507120A/RS-AE/006

Standards

2.2

Protective separation

Definition

Protective separation for 3RT10, 3RT20 and 3RH2 contactor relays

Regulations

2.2 Protective separation

In order for the "protective separation" of circuits to be achieved, an individual fault must not

be able to trigger a voltage overspill from one circuit into another. The kinds of fault to be

taken into account include twisted or loose conductive parts, twisted solder pins, broken

winding wires, missing screws, or broken barriers within a device.

The term "protective separation" is used in relation to safety extra low voltage (SELV/PELV)

and functional extra low voltage (FELV). Protective separation reliably prevents a dangerous

contact voltage from spilling over to the voltage which has been protectively separated

(e.g. to a safety extra low voltage which is present or switched in the same device). If the

current paths of a contactor are operated at different voltages, "protective separation"

requirements must be met. With 3RT1 and 3RT2 contactors, and 3RH2 contactor relays,

"protective separation" is ensured up to a certain voltage.

"Protective separation" between circuits within equipment is achieved by complying with the

basic requirements contained in the IEC 60947-1 standard.

Basic requirements include, for example:

● Double or reinforced insulation

● Electrically protective shielding

● Combination of double or reinforced insulation and electrically protective shielding

The insulation must be resistant to aging for the duration of the expected service life.

Circuits without a safety extra low voltage or a functional extra low voltage do not require

protective separation.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

23

Standards

2.3

Positively driven contact elements/Mirror contacts

Positively driven contacts for contactor relays according to IEC 60947-5-1

Mirror contact for power contactors to IEC 60947-4-1

Note

Both contact characteristics, the

well as the mirror contact in the power contactor, meet the same technical requirements.

2.3 Positively driven contact elements/Mirror contacts

Positively-driven contact elements according to IEC 60947-5-1 are a combination of "n" NO

contacts and "m" NC contacts which are designed in such a way that they cannot be closed

simultaneously. "Positively driven operation" may only apply to auxiliary switch elements

which are contained in switching devices and whose actuating forces are generated

internally. An example of such elements are the SIRIUS 3RH2 contactor relays.

All SIRIUS 3RH2 contactor relays (with at least 1 NC contact) are tested to IEC 60947-5-1,

and ever since the product was launched, they have featured positively driven contact

elements in the basic device, or in the basic device in conjunction with auxiliary switches.

Figure 2-1 Symbol for positively driven contact elements in a switching device

A mirror contact according to IEC 60947-4-1 is an auxiliary NC contact that cannot be closed

simultaneously with an NO main contact.

Figure 2-2 Symbol for mirror contacts in a switching device

All SIRIUS 3RT1 / 3RT2 motor contactors (with at least 1 NC auxiliary contact) are tested to

IEC 60947-4-1 and have featured mirror contact characteristics in conjunction with auxiliary

switches ever since the product was launched.

positively driven contact element in the contactor relay as

The 3RT1 / 3RT2 / 3RH2 contactors are suitable for applications in the safety circuit. For

contactor relays, this applies on account of the positively driven operation of the contacts.

For motor contactors, it applies on account of the mirror contact properties of the auxiliary

contacts.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

24 Manual, 09/2017, A5E03656507120A/RS-AE/006

Standards

Employer's Liability Insurance Association / SUVA

Note

The SUVA certificate is required if products or systems are operated in Switzerland.

2.4

Used for stop category 0 / 1

Used for stop category 0 / stop category 1

2.4 Used for stop category 0 / 1

In addition to the standards IEC 60947-4-1 and IEC 60947-5-1, the requirements of the

German Employer's Liability Insurance Associations or the Swiss Accident Insurance

Institute (SUVA) also apply in the case of safety circuits for the protection of personnel.

These requirements set stricter conditions for devices with mirror contacts or positively

driven contact elements. The basic SUVA requirement is that all auxiliary switches must be

mounted on the basic device at the factory in such a way that they cannot be removed.

Manual actuation of the contactor must not be possible.

A SUVAPro type-examination certificate confirms that the switching device meets the basic

health and safety requirements and that this requirement agreement has been assessed by

an accredited European Notified Body.

All SIRIUS 3RH2 contactor relays (with at least 1 NC auxiliary contact) are tested according

to IEC 60947-5-1 and have possessed the SUVA type-examination certificate since product

launch.

All SIRIUS 3RT2 motor contactors (with at least 1 NC contact) are tested according to

IEC 60947-4-1 and can be supplied in accordance with SUVA requirements.

Thanks to use of a double bridge for the contacts, all 3RT2 motor contactors and

3RH2 contactor relays feature contact redundancy and optimization of the contact surface.

This crucially enhances the contactors' contact reliability.

The 3RT1 contactors are also available with non-removable lateral auxiliary switches.

All SIRIUS 3RT1, 3RT2 and 3RH2 contactors with mirror contacts / positively driven contacts

are generally suitable for use in safety circuits according to stop category 0 / stop category 1.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

25

Standards

2.5

IE3 / IE4 ready

Note

Using 3RT contactors with IE3 / IE4 motors

For the use of 3RT contactors in conjunction with highly energy

please observe the information on dimensioning and configuring in the "Application Manual

SIRIUS Controls with IE3

(

2.5 IE3 / IE4 ready

Ambitious climate protection goals in Europe call for increasingly energy-efficient

components.

With this in mind, the energy efficiency class IE3 / IE4 has been mandatory since January

2015 (with exceptions) for three-phase asynchronous motors, and this will have an effect on

motors, low-voltage power distribution systems, and industrial controls.

This applies:

● Since January 1, 2015 for motors from 7.5 kW to 375 kW

● From January 1, 2017 for motors from 0.75 kW to 375 kW

You will be optimally equipped for the current motor generation with the SIRIUS modular

system components and 3VA molded case circuit breakers.

You will find information on IE3 / IE4 at:

Information IE3 (http://www.siemens.com/IE3ready)

-efficient IE3 / IE4 motors,

-

/ IE4 Motors

https://support.industry.siemens.com/cs/ww/en/view/94770820)".

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

26 Manual, 09/2017, A5E03656507120A/RS-AE/006

Standards

2.6

Applications

Use and application areas

2.6 Applications

Various different switching devices are available for switching electrical loads. When

frequent switching is necessary, the contactor is the ideal device.

Contactors are the most commonly used switching devices in industry, mechanical

engineering and switchgear construction. The progressive automation of production plants

has increased the significance of contactors, but this is also associated with higher and

sometimes different requirements.

An automatic production system is significantly more sensitive to operating faults than

manually operated systems. Every fault on an electrical device means a standstill,

production downtime, and often substantial costs for recommissioning.

For this reason, value was placed on high operational reliability in the development of the

SIRIUS contactor series. High service life, high contact reliability, and the option of using the

contactors in the control cabinet at higher ambient temperatures are among the factors

contributing to this. The contactors can be used at up to 60 °C and without derating even

with side-by-side mounting.

Due to the diverse range application options, the range of contactors also encompasses

versions for special applications such as switching resistive loads or switching capacitors, as

well as the main 3RT20 and 3RT10 series for switching motorized loads. Besides the

contactor versions for various load types, there are also special versions for specific areas of

application with extended operating range and special additional approvals for rail

applications or for fail-safe control in safety applications.

The different contactor series with their possible application areas are explained in the

following subsections.

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

27

Standards

Utilization categories

Utilization categories

AC

Main circuit contacts: Utilization category for AC voltages

AC-2

Slip-ring motors: starting, switching off

AC-3

Squirrel-cage motors: starting, switching-off motors during running

AC-4

Squirrel-cage motors: starting, plugging, inching

AC-5a

Switching of discharge lamp controls

AC-5b

Switching of incandescent lamps

AC-6a

Switching of transformers

AC-6b

Switching of capacitive loads

DC

Main circuit contacts: Utilization category for DC voltages

DC-1

Non-inductive or slightly inductive loads, resistance furnaces

DC-3

Shunt-wound motors: Starting, plugging, reversing, inching, dynamic braking

DC-5

Series-wound motors: Starting, plugging, reversing, inching, dynamic braking

AC

Auxiliary circuit contacts: Utilization category for AC voltages

AC-12

Control of resistive loads and solid-state loads with isolation by opto couplers

AC-14

Control of small electromagnetic loads (max. 72 VA)

AC-15

Control of electromagnetic loads (over 72 VA)

DC Auxiliary circuit contacts: Utilization category for DC voltages

DC-12

Control of resistive loads and solid-state loads with isolation by opto couplers

DC-13

Control of electromagnets

2.6 Applications

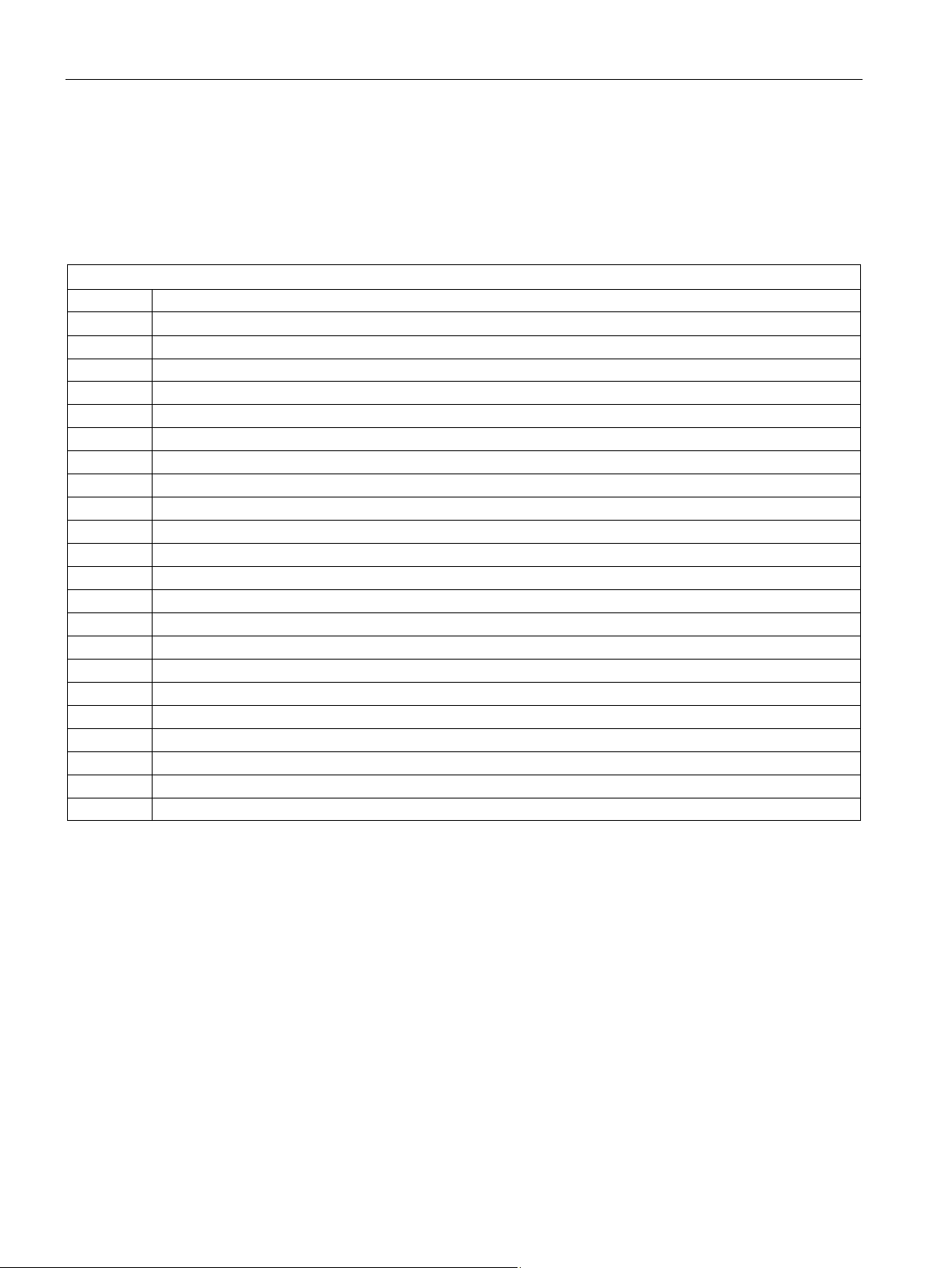

According to IEC 60947-4-1, the application area of and the load applied to power contactors

can be identified by looking at the specified utilization category in conjunction with the

specified rated operational current or the motor power and the rated voltage. The table below

lists the most important utilization categories for contactors.

AC-1 Non-inductive or slightly inductive loads, resistance furnaces

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

28 Manual, 09/2017, A5E03656507120A/RS-AE/006

3

3.1

General safety notes

DANGER

Hazardous voltage.

Will cause death or serious injury.

Electromagnetic compatibility (EMC)

Note

EMC Environment A

The 3RT / 3RH cont

Environment

Use of these products in Environment

in which case the user may be required to take adequate mitigation measures.

Turn off and lock out all power supplying this device before working on this device.

The 3RT / 3RH contactors with electronic operating mechanism have been designed for

Environment A according to IEC 60947-1, IEC 60947-4-1 and Class A according to

CISPR 11, EN 55011.

A.

actors with electronic operating mechanism have been designed for

B may cause unwanted electromagnetic disturbances

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

Manual, 09/2017, A5E03656507120A/RS-AE/006

29

Safety instructions

3.2

Intended use

WARNING

Hazardous Voltage

Can Cause Death or Serious Injury.

Use of hardware products for intended purpose

3.3

Current information about operational safety

Important note for maintaining operational safety of your system

3.2 Intended use

This equipment is only allowed to be used for the applications described in the catalog and

in the technical description, and only in conjunction with non-Siemens equipment and

components recommended by Siemens.

Correct transport, storage, installation and assembly, as well as careful operation and

maintenance, are required to ensure that the product operates safely and without faults.

Before you run any sample programs or programs you have written yourself, make sure

that running the plant cannot cause injury to anyone else or damage to the machine itself.

EU note regarding machine safety: Start-up/commissioning is absolutely prohibited until it

has been ensured that the machine in which the component described here is to be

installed fulfills the regulations/specifications of Directive 2006/42/EC.

Please take note of our latest information.

Systems with safety-related characteristics are subject to special operational safety

requirements on the part of the operator. The supplier is also obliged to comply with special

product monitoring measures. For this reason, we publish a special newsletter containing

information on product developments and features that are (or could be) relevant to

operation of safety-related systems. By subscribing to the appropriate newsletter, you will

ensure that you are always up-to-date and able to make changes to your system, when

necessary:

SIEMENS newsletter (http://www.industry.siemens.com/newsletter)

Sign on to the following newsletter under "Products & Solutions":

● Industrial Controls - SIRIUS News (en)

SIRIUS - SIRIUS 3RT Contactors/Contactor assemblies

30 Manual, 09/2017, A5E03656507120A/RS-AE/006

Loading...

Loading...