Page 1

Preface

www . ElectricalPartManuals . com

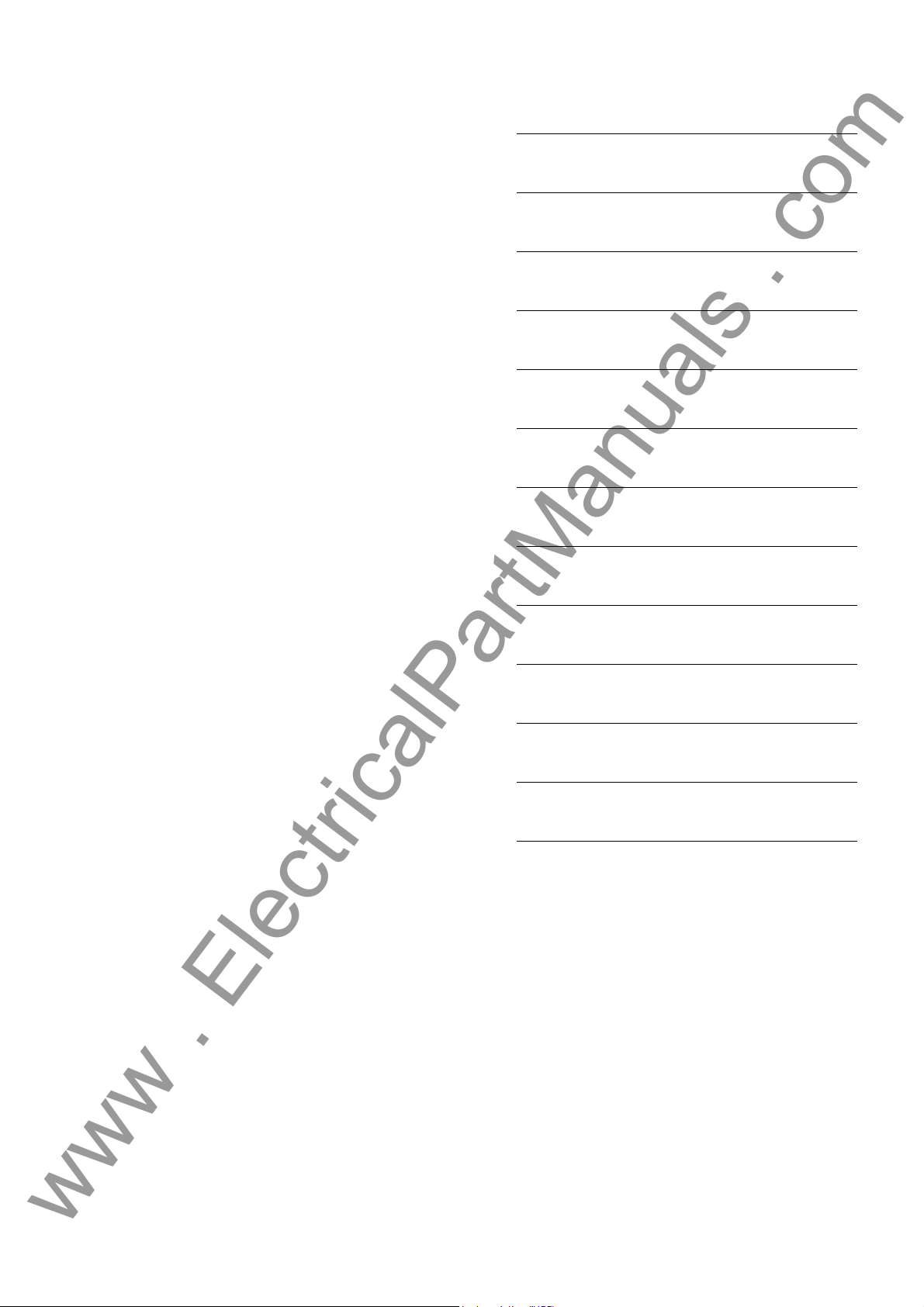

Table of Contents

Introduction 1

SIPROTEC

Distributed Busbar/ Breaker

Failure Protection

7SS522 V4.6

7SS523 V3.3

7SS525 V3.3

Manual

Design and Connection System 2

Getting Started 3

Configuration 4

Functions 5

Control During Operation 6

Installation and Commissioning 7

Maintenance and Repair 8

Technical Data 9

C53000-G1176-C182-3

Appendix A

References

Index

Page 2

Exclusion of Liability

-

-

www . ElectricalPartManuals . com

We have checked the contents of this publication and every effort has been

made to ensure that the descriptions of both hardware and software are as

accurate as possible. However, deviations from the description cannot be

completely ruled out, so that no liability can be accepted for any errors or

omissions contained in the information given.

The data in this manual are checked regularly and the necessary corrections

are included in subsequent editions. We are grateful for any improvements

that you care to suggest.

Subject to technical modifications.

Document Release 4.62.00

Edition 09.2007

Copyright

Copyright © Siemens AG 2007 All Rights Reserved

Dissemination or reproduction of this document, or evaluation and communication of its contents, is not authorized except wh ere expr essly p ermitted .

Violations are liable for damages. All rights reserved, parti cularly for the pur

poses of patent application or trademark registration.

Registered Trademarks

®

is a registered trademark of SIEMENS AG. Other designations in

DIGSI

this manual may be trademarks that if used by third parties for their own pur

poses may violate the rights of the owner.

Siemens AG Order-No. C53000-G1176-C182-3

Page 3

Preface

www . ElectricalPartManuals . com

Aim of this Manual This manual describes the functions, operation, installation, and commissioning of the

complete SIPROTEC 7SS52 V4 distributed busbar and breaker failure protection system. In particular, you will find:

• Information on configuration of the system → Chapter 4, page 45

• Description of the system functions and their setting op tions → Chapter 5, page 91

• Information on control during operation → Chapter 6, page 209

• Information on installation and commission in g → Chapter 7, page 255

• Overview of technical data → Chapter 9, page 311

• and a compilation of the most important information for the exper ienced user

→ Chapter A.1, page 336

The SIPROTEC 4 System Description /1/ deals in a general way with the management, configuration, parameterization, operation, installation and commissioning of a

SIPROTEC 4 system.

Target audience Protection engineers, commissioners, persons who are involved in setting, testing and

maintenance of protection, automation, and control devices, as well as operation personnel in electrical plants and power stations.

Scope of validity of

this manual

This manual is valid for the complete SIPROTEC 7SS52 V4 distributed busbar and

breaker failure protection system, firmware version 4.6. The system comprises the

central unit 7SS522 V4.6 and the bay units 7SS523 V3.3 and 7SS525 V3.3. The complete system will be referred to in the manual as 7SS52 V4.

Indication of Conformity

This product complies with the directive of the Council of the Eur opean Comm unities

on the approximation of the laws of the Member States relating to electromagnetic

compatibility (EMC Council Directive 89/336/EEC) and concerning electrical equipment for use within specified voltage limits (Low-voltage directive 73/23 EEC).

This conformity has been proved by tests performed according to Article 10 of the

Council Directive in agreement with the generic standards EN 61000-6-2 and EN

61000-6-4 (for EMC directive) and with the standard EN 60255-6 (for Low Voltage Directive) by Siemens AG.

The device is designed and manufactured for application in industrial environment.

The product conforms with the international standar ds of IEC 60255 and the Ger man

standard VDE 0435.

iii7SS52 V4 Manual

C53000-G1176-C182-3

Page 4

Preface

www . ElectricalPartManuals . com

Additional support For any questions concerning your SIPROTEC system, please contact your Siemens

representative.

Training courses Individual course offers may be found in our T raining Cat alog, or questions can b e di-

rected to our training center in Nuremberg.

Instructions and

Warnings

The warnings and notes contained in this manual serve for your own safety and for an

appropriate lifetime of the device. Please obser ve the m!

The following terms and definitions are used:

DANGER

indicates that death, severe personal injury or substantial property damage will result

if proper precautions are not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result

if proper precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken. This is especially valid for damage on or in the device itself and

consequential damage thereof.

Note

indicates information about the device or respective part of the instruction manual

which is essential to highlight.

Warning!

Hazardous voltages are present in this electrical equipment during operation. Non–

observance of the safety rules can result in severe personal injury or property damage.

Only qualified personnel shall work on and around this equipment afte r becoming thoroughly familiar with all warnings and safety notices of this manual as well as with the

applicable safety regulations.

The successful and safe operation of this device is dependent on proper handlin g, installation, operation, and maintenance by qualified personnel under observance of all

warnings and hints contained in this manual.

In particular the general erection and safety regulations (e.g. IEC, DIN, VDE, EN or

other national and international standards) regarding the corr ect u se of hoisting gear

must be observed. Non–observance can r esult in death, personal injury or substantial

property damage.

iv

7SS52 V4 Manual

C53000-G1176-C182-3

Page 5

Preface

www . ElectricalPartManuals . com

QUALIFIED PERSONNEL

For the purpose of this instruction manual and product labels, a qualified person is one

who is familiar with the installation, construction and operation of the equipment and

the hazards involved. In addition, he or she has the following qualifications:

• Is trained and authorized to energize, de-energize, clear, ground and tag circuits

and equipment in accordance with established safety practices.

• Is trained in the proper care and use of protective equipment in accordance with established safety practices.

• Is trained in rendering first aid.

Typographic

and symbol

conventions

The following text formats are used when literal information from the device or to the

device appear in the text flow:

Parameter names, i.e. designators of configuration or function parameters, which

may appear word-for-word in the display of the device or on the screen of a personal

computer (with DIGSI), are marked in bold letters of a monospace type style.

Parameter options, i.e. possible settings of text parameters, which may appear

word-for-word in the display of the device or on the screen of a personal computer

(with DIGSI), are written in italic style, additionally. This applies also for options in

menus.

“Annunciations”, i.e. designators for information, which may be output by the relay

or required from other devices or from the switch gear, are marked in a monospace

type style in quotes.

Deviations may be permitted in drawings when the type of designator can be o bviously

derived from the illustration.

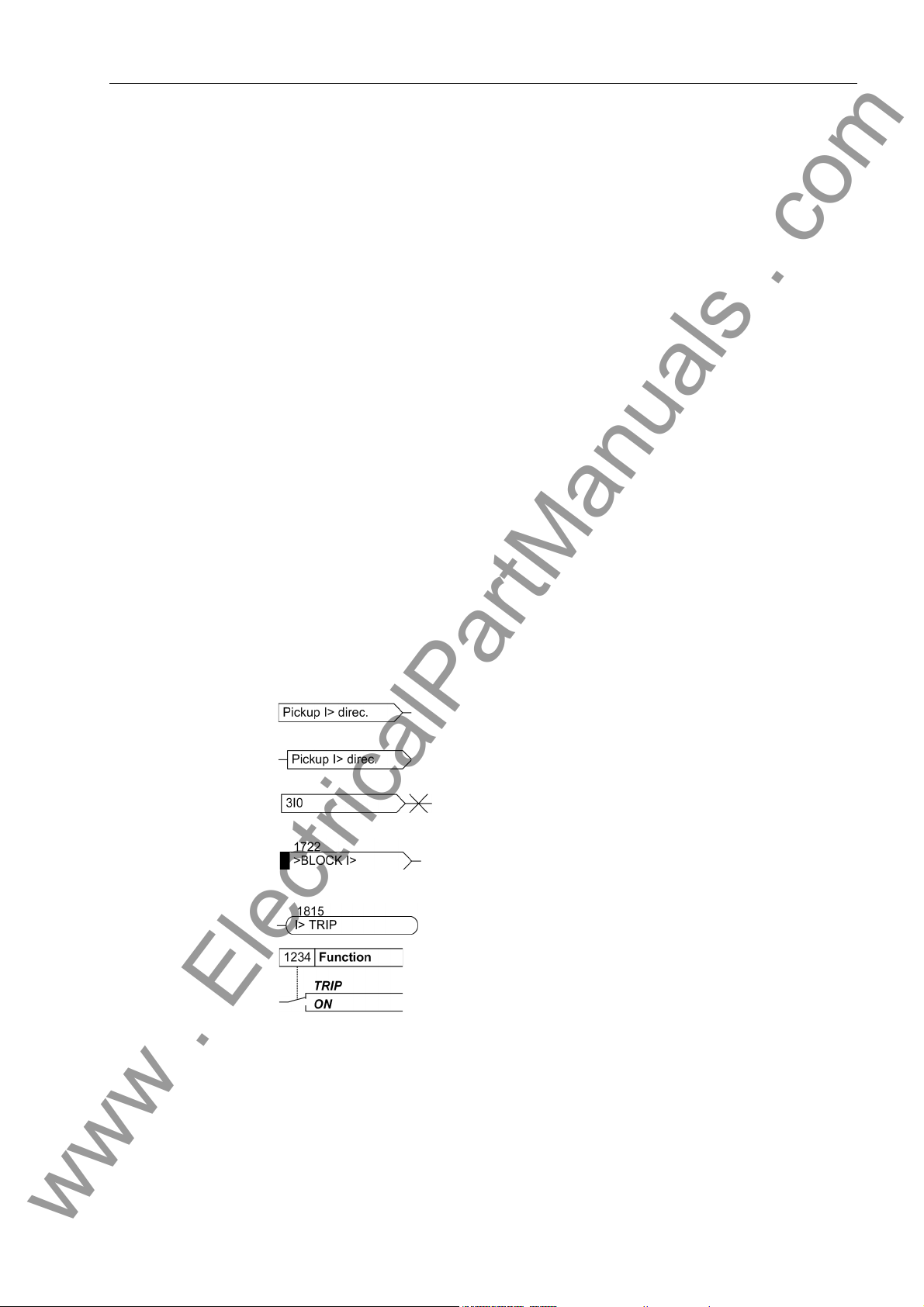

The following symbols are used in drawings:

Device-internal logical input signal

Device-internal logical output signal

Internal input signal of an analog quantity

External binary input signal with number (binary input,

input indication)

External binary output signal with number (device indication)

Example of a parameter switch designated with the

address and the possible settings

7SS52 V4 Manual

C53000-G1176-C182-3

v

Page 6

Preface

www . ElectricalPartManuals . com

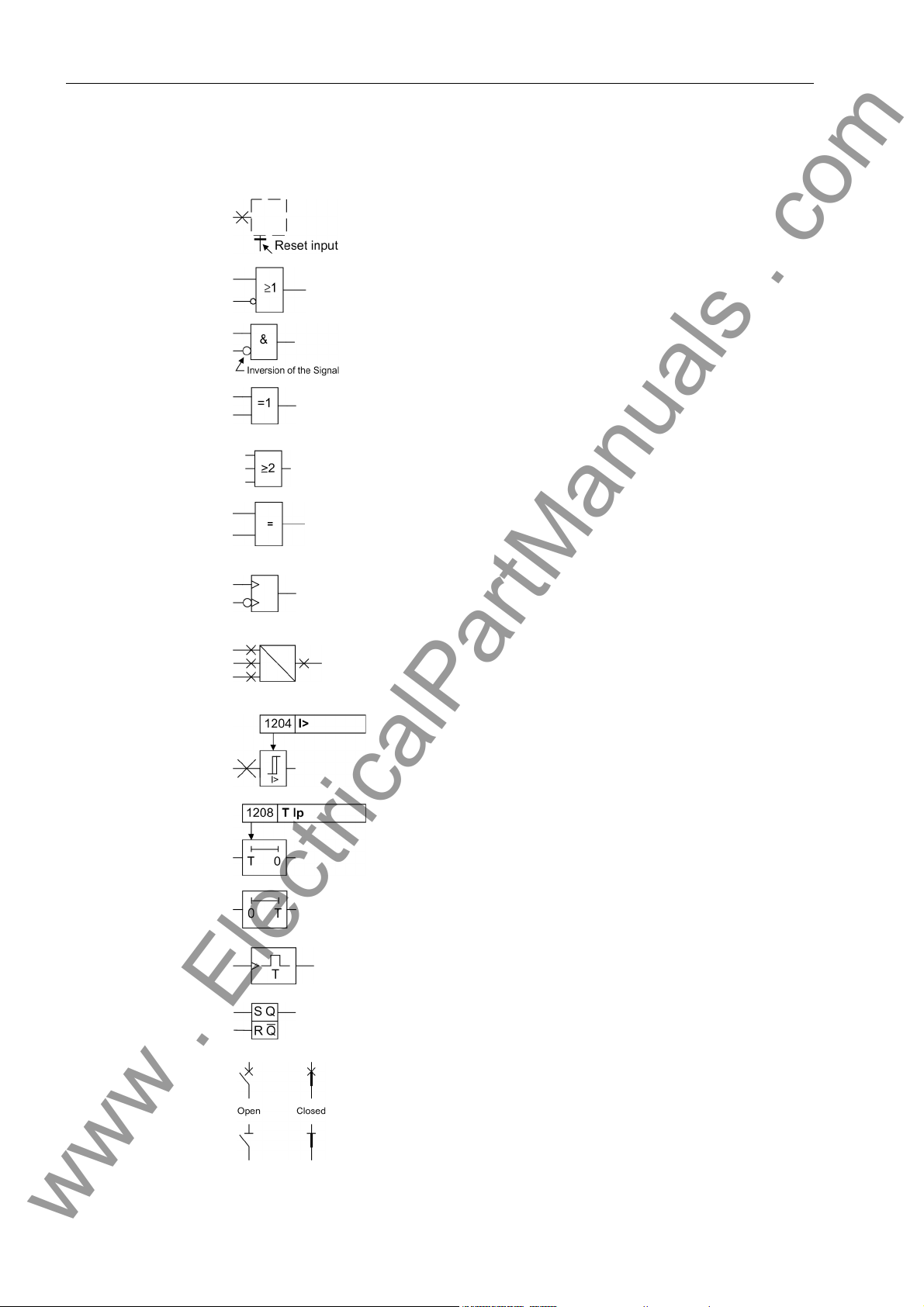

Besides these, graphical symbols are used according to IEC 60 617–12 and

IEC 60 617–13 or symbols derived from these standards. The most frequen t symbols

are the following:

Input signal of an analogue quantity

OR-combination of input values

AND-combination of input values

Exclusive–OR gate: output is active, if only one of the

inputs is active

2-of-3-combination of input values

Coincidence: output is active if both inputs are active

or inactive at the same time

Dynamic input signals (edge–triggered) above with

positive, below with negative edge

Formation of one analogue output signal from a

number of analogue input signals

Limit value stage with parameter addr ess and parameter name

Timer (pickup delay T adjustable) with parameter

address and parameter name

Timer (dropout delay T, non-adjustable)

Edge-controlled time stage with effective time T

Static memory (RS-flipflop) with setting input (S),

resetting input (R), output (Q) and inverted output (Q)

Circuit breaker (open and closed)

Isolator (open and closed)

vi

7SS52 V4 Manual

C53000-G1176-C182-3

Page 7

Table of Contents

www . ElectricalPartManuals . com

1 Introduction.......................................................................................................................................... 1

1.1 Overall Operation ................................................................................................................... 2

1.2 Applications............................................................................................................................ 4

1.3 Features ................................................................................................................................. 5

2 Design and Connection System....................................................................................................... 13

2.0 General................................................................................................................................. 14

2.1 Central Unit .......................................................................................................................... 15

2.1.1 Front View ............................................................................................................................ 15

2.1.2 Modules and Submodules.................................................................................................... 16

2.1.3 Design .................................................................................................................................. 17

2.2 Bay Unit................................................................................................................................ 18

2.2.1 Front View ............................................................................................................................ 18

2.2.2 Modules and Submodules.................................................................................................... 19

2.2.3 Design .................................................................................................................................. 21

2.2.3.1 Panel Surface Mounting....................................................................................................... 21

2.2.3.2 Panel Flush Mounting or Cubicle Mounting.......................................................................... 21

2.3 Connection Method .............................................................................................................. 22

2.3.1 Location of Device Connections........................................................................................... 22

2.3.2 Device Connections.............................................................................................................. 25

2.3.2.1 Screw-Type Terminals.......................................................................................................... 26

2.3.2.2 Double Leaf-Spring-Crimp Contacts..................................................................................... 26

2.3.2.3 D-SUB Female Connectors........... ... .... ... ... ... .... ... ... ... .... ... ... ... ....... ... ... ... .... ... ... ... ... .... ... ... .. .27

2.3.2.4 Fiber-Optic Cable Connections ............................................................................................27

2.3.2.5 EN100 module Ethernet (IEC 61850)................................................................................... 28

3 Getting Started...................... ... ... ... .... ...................................... .... ...................................................... 29

3.1 Unpacking and Repacking.................................................................................................... 30

3.2 Checking the Rated Data ........................................ ... .... ... ... ... ... ....................................... ... 30

3.3 Matching the Control Voltage for the Binary Inputs and

Inserting the Buffer Battery................................................................................................... 31

3.4 Electrical Checks.................................................................................................................. 38

3.5 Setting up the Communication between the Central Unit

vii7SS52 V4 Manual

C53000-G1176-C182-3

Page 8

Table of Contents

www . ElectricalPartManuals . com

and the Bay Unit............................. ... ....................................... ... ......................................... 39

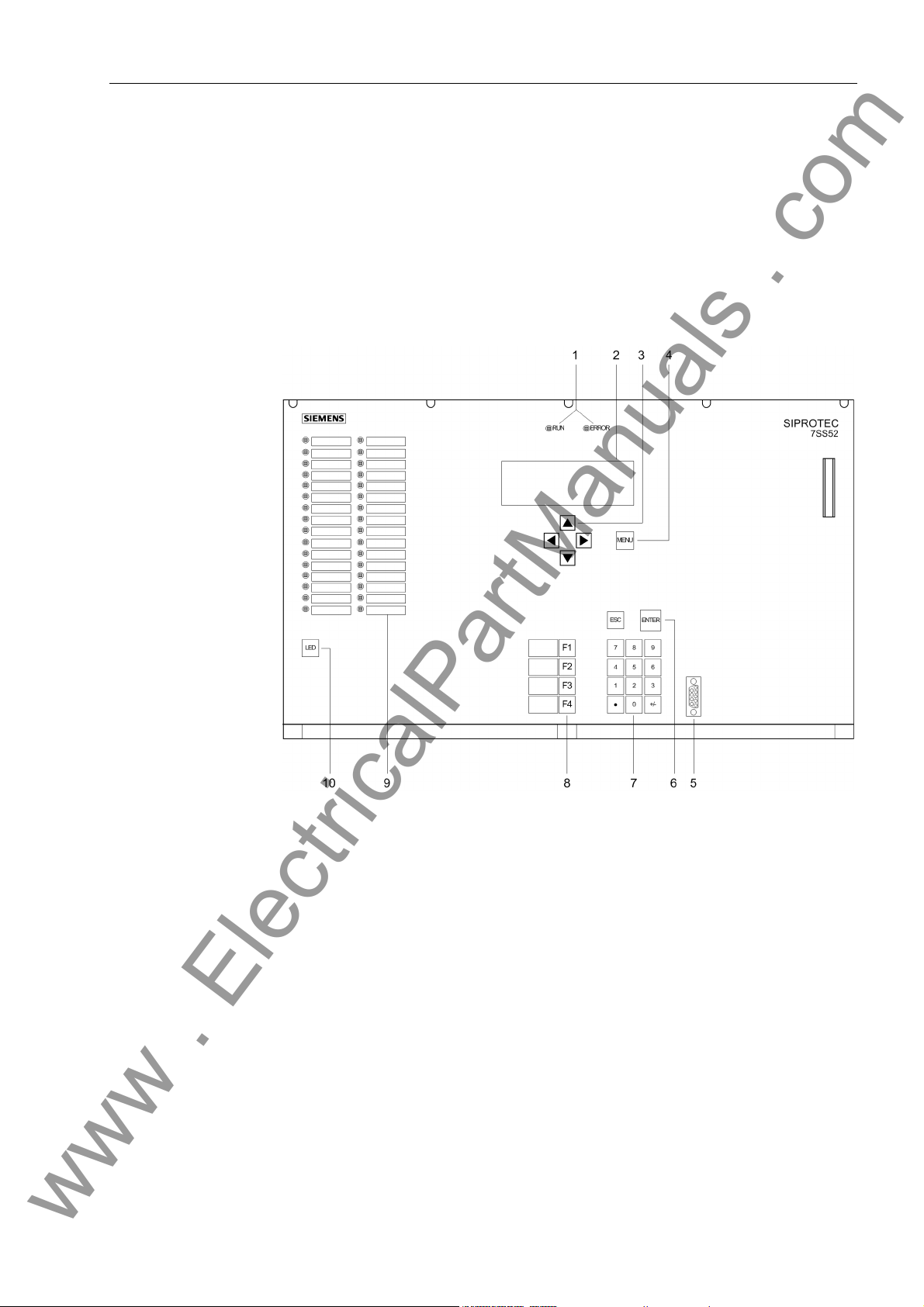

3.6 Operation of SIPROTEC Devices from the Operator Panel ................................................. 40

3.6.1 User Interface....................... ... ... .... ... ....................................... ... ......................................... 40

3.6.2 Navigating the Operating Tree of the Display....................................................................... 40

3.6.3 Setting Addresses in the Bay Unit ........................................................................................ 41

3.6.4 Adjusting the Display Contrast.............................................................................................. 43

3.7 Storage................................................................................................................................. 44

4 Configuration ..................................................................................................................................... 45

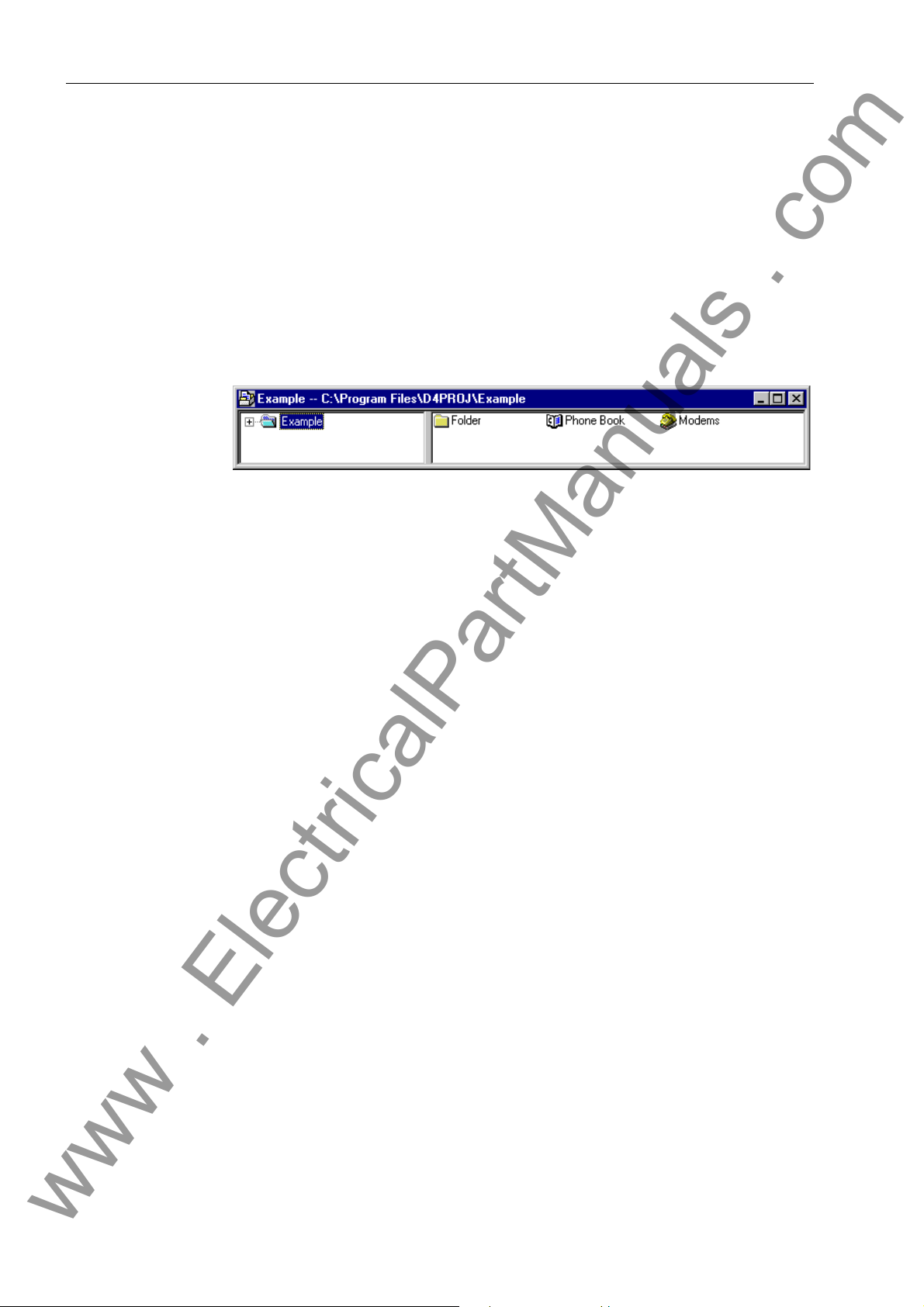

4.1 Creating a Project................................................................................................................. 46

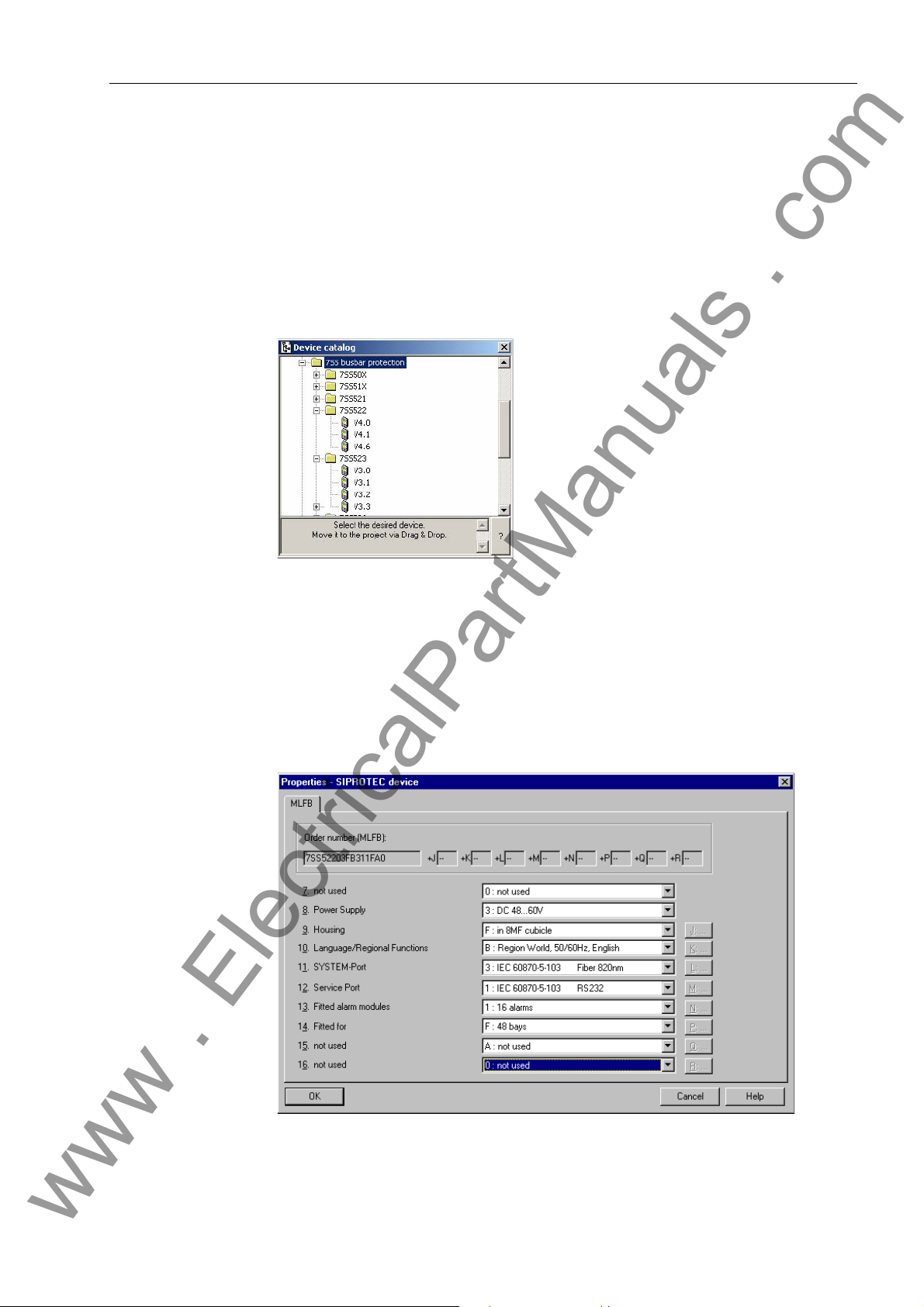

4.2 Inserting Central Unit / Bay Units.......................................................................................... 47

4.3 Plant Configuration............................ ... ....................................... ... ...................................... 49

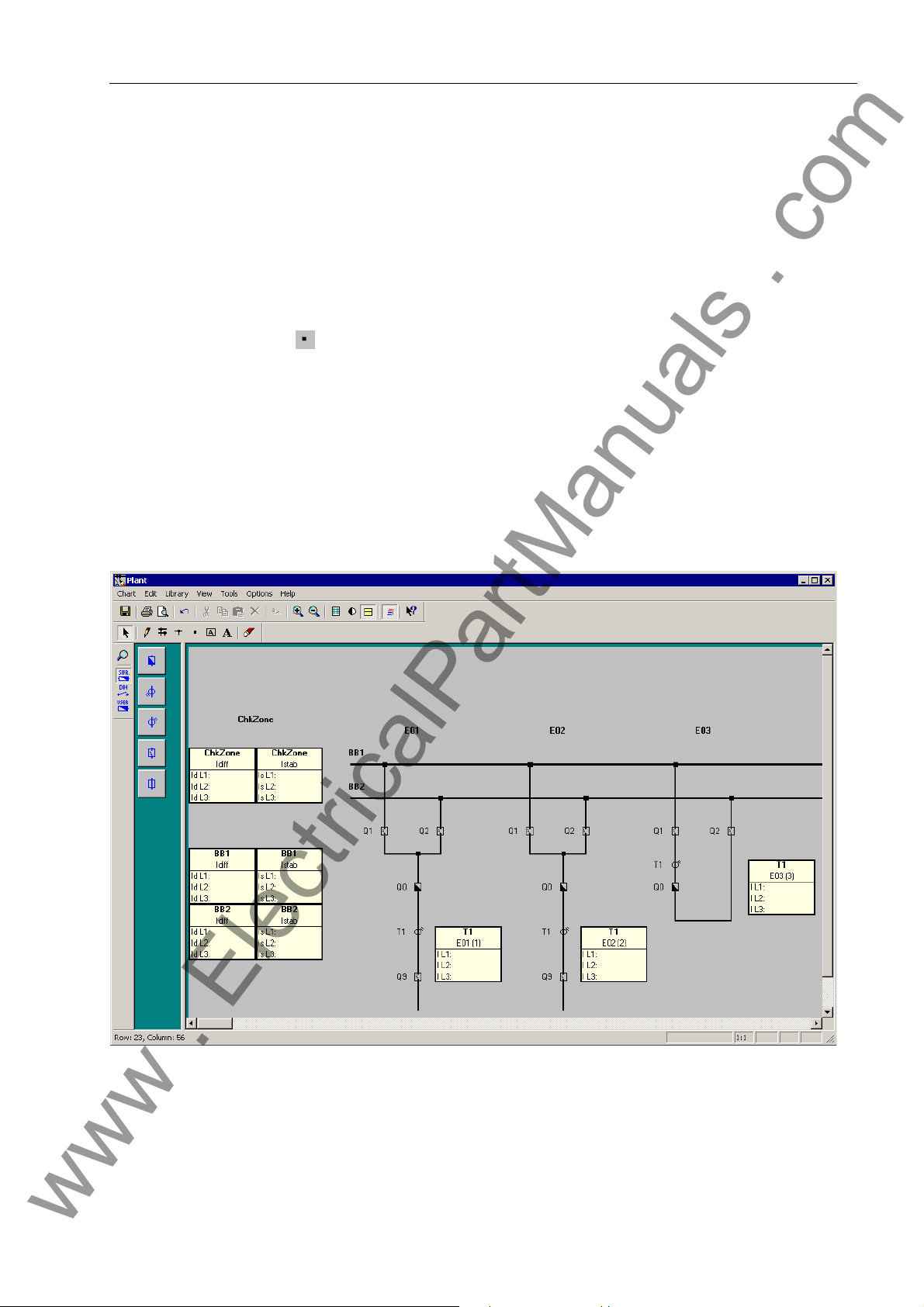

4.3.1 How to Proceed.................................................................................................................... 49

4.3.2 Starting the Plant Configuration .. .... ... ... ... ... .... ...................................... ................................ 50

4.3.3 Drawing Busbars .................................... ... .... ... ... ... .... ...................................... ................... 52

4.3.4 Defining Bays........................................................................................................................ 54

4.3.5 Inserting Dynamic Elements....... ....................................... ....................................... ... .........56

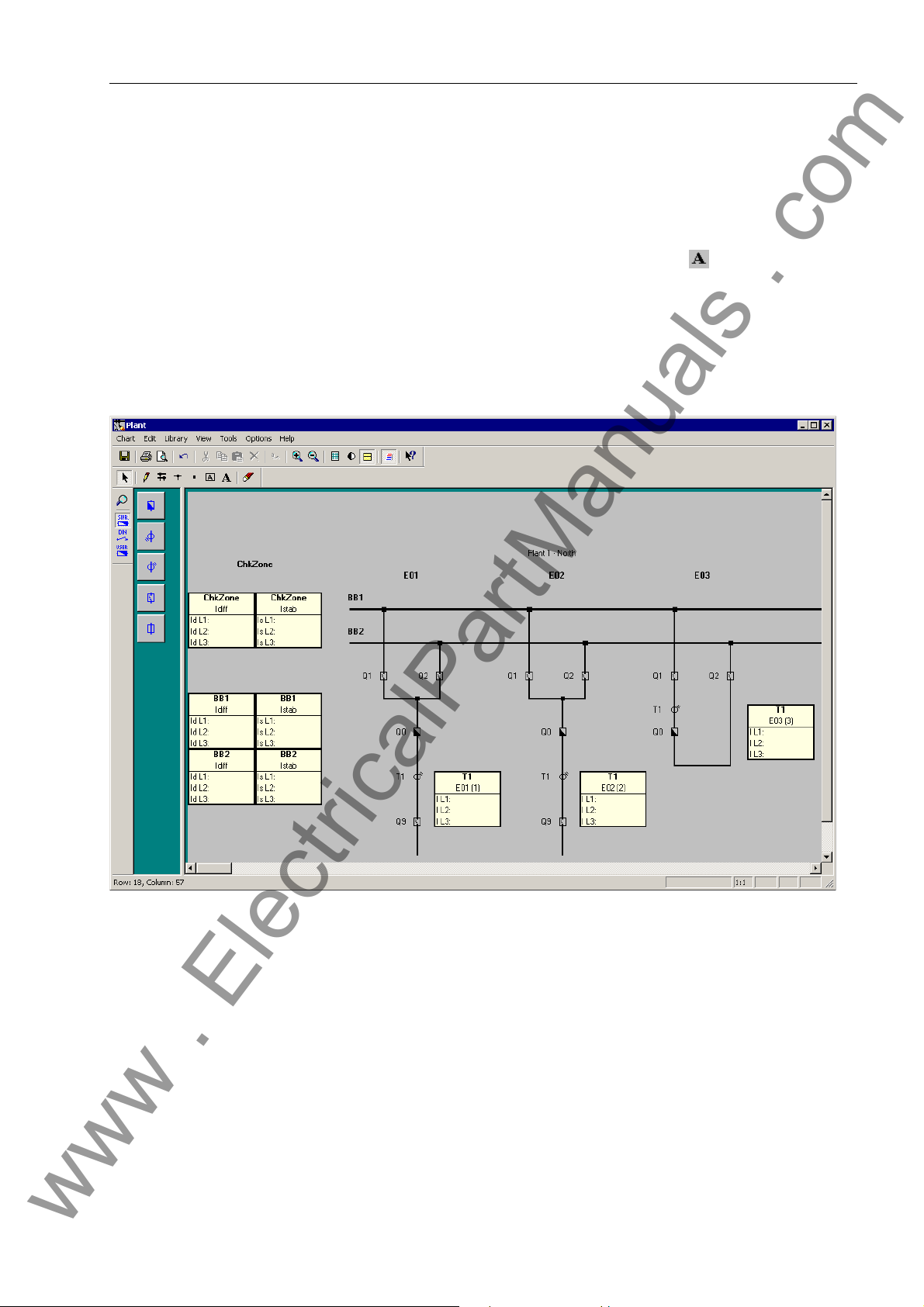

4.3.6 Connecting Dynamic Elements to the Busbars .................................................................... 58

4.3.6.1 Inserting Lines ......................................... ....................................... ...................................... 58

4.3.6.2 Inserting a Connection................................ .... ... ... ....................................... ......................... 59

4.3.7 Normalized Current...............................................................................................................60

4.3.8 Inserting Static Text....... .... ...................................... .... ...................................... ................... 61

4.3.9 Creating and Inserting Typicals...................... ... ... ... .... ...................................... .... ...............62

4.3.10 Saving the Substation Chart................................................................................................. 62

4.4 Configuration Notes....... ....................................... ....................................... ... ...................... 63

4.5 Assigning Bay Units.............................................................................................................. 71

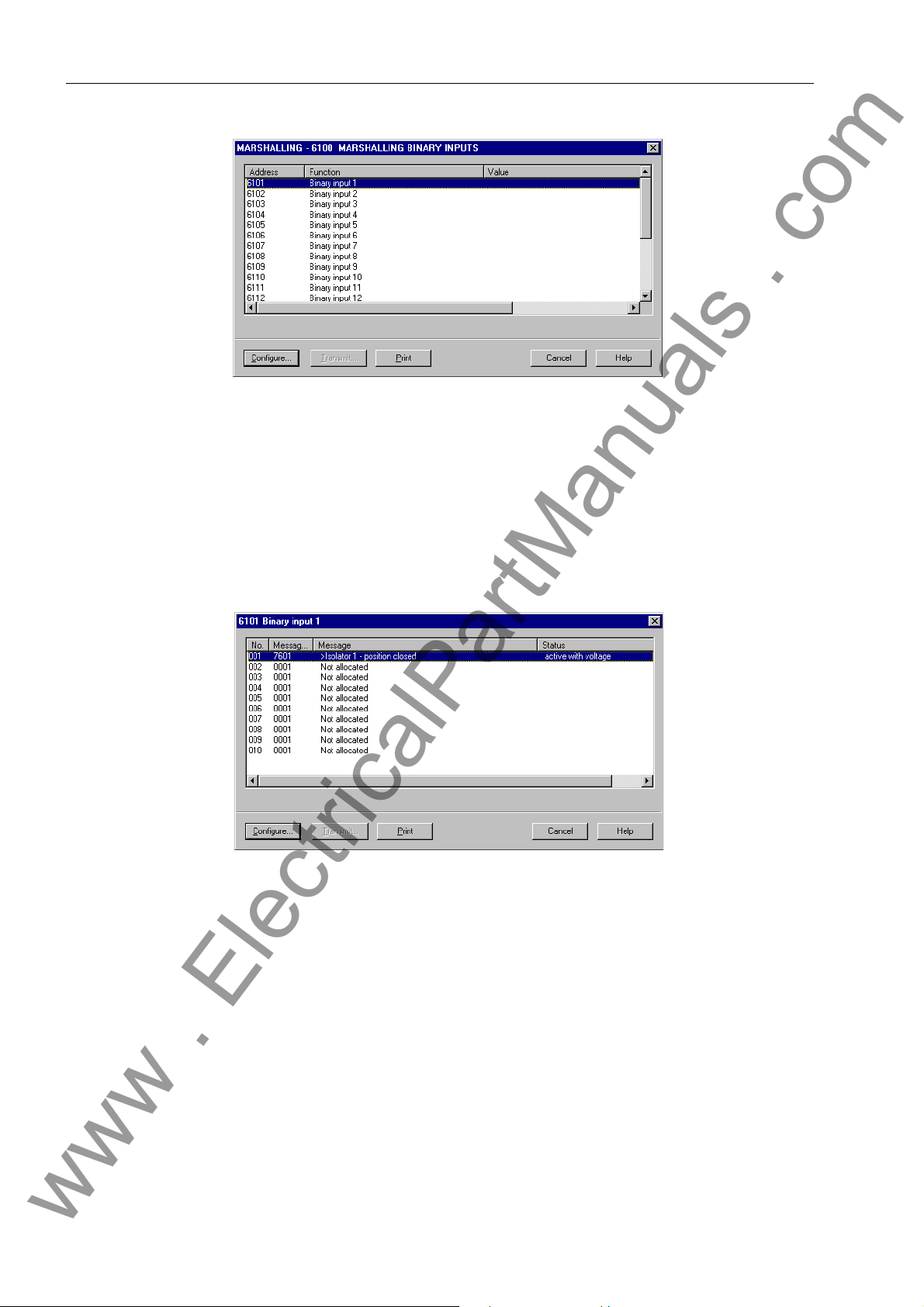

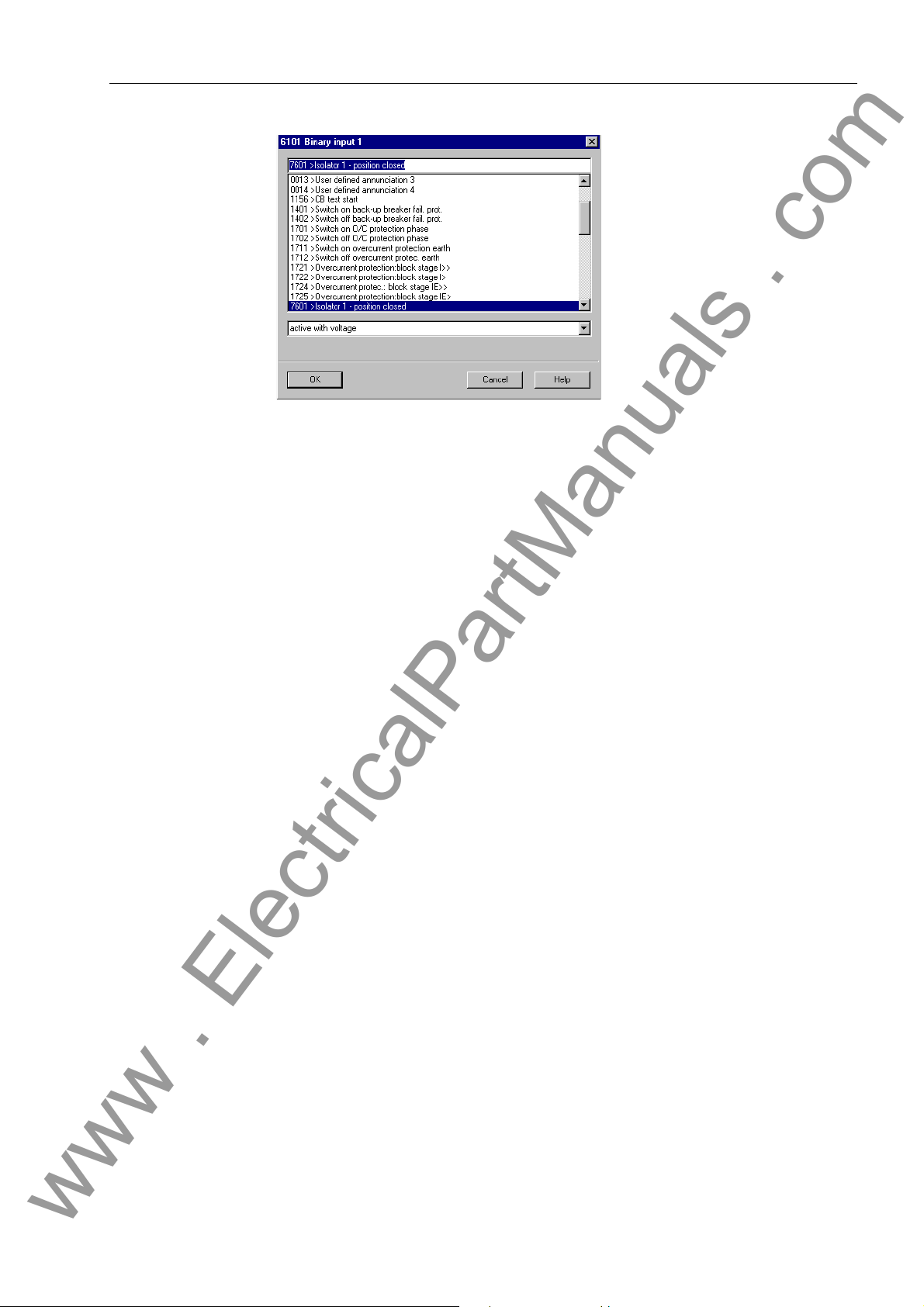

4.6 Marshalling ........................................................................................................................... 73

4.6.1 Marshalling Information Items of the Central Unit................................................................. 73

4.6.1.1 Allocable Information............ ... ....................................... ... ....................................... ............ 73

4.6.1.2 Marshalling ........................................................................................................................... 74

4.6.2 Marshalling Bay Unit Information.......................................................................................... 76

4.6.2.1 Allocable Information............ ... ....................................... ... ....................................... ............ 76

4.6.2.2 Marshalling ........................................................................................................................... 77

4.7 Settings................................................................................................................................. 80

4.7.1 Serial Ports.................... .... ... ... ... .... ... ... ....................................... ......................................... 81

4.7.2 Date/Clock Management......................................................................................................85

4.8 Concluding the Configuration ............................................................................................... 89

viii

7SS52 V4 Manual

C53000-G1176-C182-3

Page 9

Table of Contents

www . ElectricalPartManuals . com

5 Functions............................................................................................................................................ 91

5.1 Busbar Protection................................................................................................................. 92

5.1.1 Mode of operation ................................................................................................................ 92

5.1.1.1 Basic Principle............ ....................................... ...................................... .... ......................... 92

5.1.1.2 Algorithm with Instantaneous Values ................................................................................... 94

5.1.1.3 Separate Evaluation of Half-Cycles...................................................................................... 96

5.1.1.4 Evaluation of the Initial Values ............................................................................................. 99

5.1.1.5 Algorithm with Filtered Values............................................................................................ 100

5.1.1.6 Summary of the Measuring Method ................................................................................... 100

5.1.2 Isolator Replica. ... .... ... ....................................... ...................................... .... ....................... 101

5.1.3 Bus Coupler Variants.......................................................................................................... 103

5.1.3.1 Bus Couplers with One Current Transformer..................................................................... 103

5.1.3.2 Bus Couplers with Two Current Transformers ................................................................... 104

5.1.3.3 Bus Couplers without Circuit Breaker................................................................................. 104

5.1.3.4 Bus Couplers with more than 5 Isolators............................................................................ 104

5.1.3.5 Combi-Coupler ................................................................................................................... 104

5.1.3.6 Transfer Busbars..... ... ... ... .... ... ... ....................................... ...................................... ........... 105

5.1.3.7 Transfer Busbar With Inside Transformers................................. ....... ... ... .... ... ... ... ... .... ... ... . 107

5.1.3.8 Special Cases of Transfer Busbar Operation.......... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... . 107

5.1.4 Setting Notes...................................................................................................................... 108

5.1.5 Settings for the Central Unit ............................................................................................... 111

5.2 Check Zone........................................................................................................................ 112

5.2.1 Mode of operation .............................................................................................................. 112

5.2.2 Setting Notes...................................................................................................................... 113

5.2.3 Settings for the Central Unit ............................................................................................... 113

5.3 Circuit Breaker Failure Protection....................................................................................... 114

5.3.1 Characteristics for the Circuit Breaker Failure Protection.................................. ...... .... ... ... . 114

5.3.2 Setting Notes...................................................................................................................... 115

5.3.3 Settings for the Central Unit ............................................................................................... 116

5.3.4 List of Information from the Central Unit..... ... .... ... ... ... .... ...................................... .............. 116

5.3.5 Bay-Specific Functions (BU)............................................................................................... 117

5.3.5.1 Triggering and Releasing the Breaker Failure Protection................................................... 117

5.3.5.2 Circuit Breaker Failure Protection during a Feeder Short-Circuit...... ... ... .... ...... ... ... .... ... ... . 119

5.3.5.3 Circuit Breaker Failure Protection for Busbar Faults.......................................................... 126

5.3.5.4 Failure of the Bus Coupler Circuit Breaker......................................................................... 127

5.3.5.5 Circuit Breaker Not Ready.................................................................................................. 127

5.3.6 Setting Notes...................................................................................................................... 128

5.3.7 Settings for the Central Unit ............................................................................................... 132

5.3.8 List of Information from the Central Unit..... ... .... ... ... ... .... ...................................... .............. 133

5.3.9 List of Information from the Bay Unit................................. ...................................... ........... 134

7SS52 V4 Manual

C53000-G1176-C182-3

ix

Page 10

Table of Contents

www . ElectricalPartManuals . com

5.4 End Fault Protection........................................................................................................... 135

5.4.1 End Fault Protection in the Feeder..................................................................................... 135

5.4.2 Protection with fault in the ”Dead Zone” of the Bus Coupler........................... .................... 137

5.4.2.1 Without detection of the circuit-breaker position................................................................. 137

5.4.2.2 With detection of the circuit-breaker position, circuit breaker closed.................................. 137

5.4.2.3 With detection of the circuit-breaker position, circuit breaker open .................................... 138

5.4.2.4 CLOSE Command of the Bus Coupler Circuit Breaker ...................................................... 138

5.4.3 Setting Notes...................................................................................................................... 139

5.4.4 Settings for the Central Unit................................................................................................139

5.4.5 List of Information from the Central Unit............................................................................. 139

5.4.6 List of Information from the Bay Unit ..................................................................................139

5.5 Supervisory Functions .......................................................................................................140

5.5.1 Functional Description........................................................................................................140

5.5.1.1 Zone-Selective Blocking..................................................................................................... 140

5.5.1.2 Auxiliary and Reference Voltages....................................................................................... 142

5.5.1.3 Measured Value Supervision.......................... ... ... ... .... ...................................... .... ............. 142

5.5.1.4 Output Trip Supervision...................................................................................................... 143

5.5.1.5 Battery Monitoring....................... .... ... ... ... ... .... ...................................... .............................. 143

5.5.1.6 Supervision in Maintenance Mode...................................................................................... 143

5.5.1.7 Cyclic Test.......................................................................................................................... 144

5.5.1.8 Supervision of External Current Transformer Circuits ........................................................ 144

5.5.1.9 Isolator Status Supervision................................................................................................. 146

5.5.1.10 Supervisory of Circuit Breaker................. ... ....................................... ... .............................. 151

5.5.1.11 Overview of the Supervisory Functions..............................................................................152

5.5.2 Setting Notes...................................................................................................................... 154

5.5.3 Settings for the Central Unit................................................................................................157

5.5.4 List of Information from the Central Unit............................................................................. 158

5.5.5 List of Information from the Bay Unit ..................................................................................159

5.6 Oscillographic Fault Recording........................................................................................... 160

5.6.1 Mode of operation.... ... ... .... ...................................... ....................................... ... ................. 160

5.6.2 Setting Notes...................................................................................................................... 161

5.6.3 Settings for the Central Unit................................................................................................162

5.6.4 Settings of the Bay Unit......................................................................................................162

5.6.5 List of Information from the Central Unit............................................................................. 162

5.7 Device................................................................................................................................. 163

5.7.1 Mode of operation.... ... ... .... ...................................... ....................................... ... ................. 163

5.7.2 Setting notes....................................................................................................................... 163

5.7.3 Annunciations.....................................................................................................................163

5.7.4 Settings for the Central Unit................................................................................................165

5.7.5 List of Information from the Central Unit............................................................................. 165

5.8 Power System Data............................................................................................................166

5.8.1 Mode of operation.... ... ... .... ...................................... ....................................... ... ................. 166

5.8.2 Setting Notes...................................................................................................................... 166

5.8.3 Settings for the Central Unit................................................................................................166

5.8.4 Settings of the Bay Unit......................................................................................................166

x

7SS52 V4 Manual

C53000-G1176-C182-3

Page 11

Table of Contents

www . ElectricalPartManuals . com

5.9 Protection General ............................................................................................................. 167

5.9.1 Current-Controlled TRIP Reset .......................................................................................... 167

5.9.2 Local Control of the Bay Unit..............................................................................................167

5.9.3 Operating States "Bay Out of Service", "Maintenance Mode"............................................ 168

5.9.4 Overcurrent-Controlled TRIP command............................................................................. 169

5.9.5 Feeder-Selective Trip Release........................................................................................... 170

5.9.6 Testing the Tripping Circuits and the Circuit Breakers ....................................................... 170

5.9.7 Busbar Tripping via an External Signal .............................................................................. 171

5.9.8 Setting Notes...................................................................................................................... 172

5.9.9 Settings for the Central Unit ............................................................................................... 174

5.9.10 List of Information from the Central Unit.................. ... .... ... ... ... ....................................... .... 175

5.9.11 Settings for the Bay Unit..................................................................................................... 175

5.9.12 List of Information from the Bay Unit.................................................................................. 176

5.10 Bay Unit.............................................................................................................................. 177

5.10.1 Functional Description...... .... ... ... ... ....................................... ... ........................................... 177

5.10.2 Setting Notes...................................................................................................................... 177

5.11 Integrated Operation of the Bay Unit.................................................................................. 178

5.11.1 Functional Description...... .... ... ... ... ....................................... ... ........................................... 178

5.11.2 Setting Notes...................................................................................................................... 178

5.11.3 Settings of the Bay Unit...................................................................................................... 179

5.12 PC Port of the Bay Unit .............................. ....................................... ................................. 180

5.12.1 Functional Description...... .... ... ... ... ....................................... ... ........................................... 180

5.12.2 Setting Notes...................................................................................................................... 180

5.12.3 Settings of the Bay Unit...................................................................................................... 181

5.13 Fault Recording in the Bay Unit (”Local Fault Recording”)................................................. 182

5.13.1 Functional Description...... .... ... ... ... ....................................... ... ........................................... 182

5.13.2 Setting Notes...................................................................................................................... 182

5.13.3 Settings of the Bay Unit...................................................................................................... 183

5.14 Scope of Protective Functions in the Bay Unit ................................................................... 184

5.14.1 Functional Description...... .... ... ... ... ....................................... ... ........................................... 184

5.14.2 Setting Notes...................................................................................................................... 184

5.14.3 Settings of the Central Unit................................................................................................. 185

5.14.4 Settings of the Bay Unit...................................................................................................... 185

5.15 Power System Data of the Bay Unit..... ... ... ... ....................................... .............................. 186

5.15.1 Functional Description...... .... ... ... ... ....................................... ... ........................................... 186

5.15.2 Setting Notes...................................................................................................................... 186

5.15.3 Settings of the Central Unit................................................................................................. 187

5.15.4 Settings of the Bay Unit...................................................................................................... 187

7SS52 V4 Manual

C53000-G1176-C182-3

xi

Page 12

Table of Contents

www . ElectricalPartManuals . com

5.16 Overcurrent Protection in the Bay Unit ............................................................................... 188

5.16.1 Functional Description........................................................................................................188

5.16.2 Setting Notes...................................................................................................................... 190

5.16.3 Settings of the Bay Unit......................................................................................................195

5.16.4 List of Information from the Bay Unit .................................................................................. 196

5.17 User-Defined Annunciations............................................................................................... 197

5.17.1 Functional Description........................................................................................................197

5.17.2 Setting Notes...................................................................................................................... 199

5.17.3 Settings of the Bay Unit......................................................................................................200

5.17.4 List of Information from the Bay Unit .................................................................................. 201

5.18 Backup Breaker Failure Protection in the Bay Unit...... ... ... ... .... ... ...................................... . 202

5.18.1 Functional Description........................................................................................................202

5.18.2 Setting Notes...................................................................................................................... 206

5.18.3 Settings of the Central Unit................................................................................................. 207

5.18.4 List of Information from the Central Unit............................................................................. 207

5.18.5 Settings of the Bay Unit......................................................................................................207

5.18.6 List of Information from the Bay Unit .................................................................................. 208

6 Control During Operation................................................................................................................ 209

6.1 Overview.............................................................................................................................210

6.2 Reading Out Information..................................................................................................... 212

6.2.1 Annunciations.....................................................................................................................212

6.2.1.1 Operational Annunciations.................................................................................................. 214

6.2.1.2 Fault events........................................................................................................................ 216

6.2.1.3 Alarm List............................................................................................................................ 217

6.2.1.4 General Interrogation.......................................................................................................... 218

6.2.1.5 Spontaneous Annunciation................................... ....................................... .......................218

6.2.1.6 Statistics ............................................................................................................................. 219

6.2.2 Reading Out Measured Values........................................................................................... 219

6.2.3 Reading Out Fault Data......................................................................................................221

6.3 Controlling Device Functions.............................................................................................. 225

6.3.1 Creating an Oscillographic Record..................................................................................... 225

6.3.2 Blocking.............................................................................................................................. 226

6.3.2.1 Blocking the TRIP Command ............................................................................................. 226

6.3.2.2 Blocking the Breaker Failure Protection ............................................................................. 230

6.3.2.3 Blocking of Individual Busbar Sections........................... ... ....................................... ... .......232

6.3.3 Saving and Deleting Annunciations.................................................................................... 233

6.3.3.1 Saving Annunciations......................................................................................................... 233

6.3.3.2 Deleting Annunciations....................................................................................................... 234

6.3.4 Circuit Breaker Test............................................................................................................ 235

6.3.5 Reset Blocking.................................................................................................................... 237

6.3.5.1 Reset Blocking of Differential Current Supervision............................................................. 237

6.3.5.2 Reset Blocking of Isolator Fault.......................................................................................... 238

6.3.6 Trigger Initial Start and Restart ... .... ... ... ... ... ....................................... ................................. 238

6.3.7 Read and Set Date / Time.................................................................................................. 239

xii

7SS52 V4 Manual

C53000-G1176-C182-3

Page 13

Table of Contents

www . ElectricalPartManuals . com

6.4 Feeder Shutdown and Commissioning............................................................................... 244

6.5 Maintenance Mode.............................................................................................................247

6.6 Plant Visualization.............................................................................................................. 249

7 Installation and Commissioning .................................................................................................... 255

7.1 Installation and Commissioning.......................................................................................... 256

7.1.1 Central Unit ........................................................................................................................ 256

7.1.2 Bay Unit.............................................................................................................................. 257

7.1.3 General Information on the 2-Bay Bus Coupler.................................................................. 258

7.1.3.1 General............................................................................................................................... 258

7.1.3.2 2-Bay Bus Coupler With 2 Current Transformers............................................................... 259

7.1.3.3 2-Bay Bus Coupler With one Current Transformer............................................................. 259

7.1.3.4 Connection ......................................................................................................................... 260

7.2 Checking the Connections................................. ... ... ... .... ... ... ... ....................................... .... 261

7.3 Commissioning ................................ ................................................................. ................. 262

7.3.1 How to Proceed.......... ... ....................................... ... ....................................... .................... 263

7.3.2 Web Monitor....................................................................................................................... 264

7.3.2.1 General............................................................................................................................... 264

7.3.2.2 Functions............................................................................................................................ 265

7.3.3 Checking the Switching States of the binary Inputs/Outputs.............................................. 268

7.3.3.1 Central Unit ........................................................................................................................ 268

7.3.3.2 Bay Unit.............................................................................................................................. 271

7.3.4 Testing the System Port..................................................................................................... 273

7.3.5 Control of the Isolator Replica............................................................................................275

7.3.6 Switching the Test Mode and the Transmission Block On and OFF.................................. 277

7.4 Checks With Secondary Values......................................................................................... 278

7.4.1 General............................................................................................................................... 278

7.4.2 Trip Characteristic of the Busbar Protection....................................................................... 279

7.4.2.1 busbar-selective Protection................................................................................................ 279

7.4.2.2 Check Zone........................................................................................................................ 281

7.4.3 Differential Current Monitoring............................................................................................283

7.4.3.1 busbar-selective Protection................................................................................................ 283

7.4.3.2 Check Zone........................................................................................................................ 284

7.4.3.3 Time Delay ........................................... ... ... ... ....................................... .............................. 284

7.4.4 Overcurrent Threshold Tripping...................................... ... ... ... ....... ... ... ... .... ... ... ... ... .... ... ... . 285

7.4.5 Breaker Failure Protection.... ... ... ... ... .... ... ....................................... .................................... 285

7.4.5.1 Trip Characteristic for Operating Mode “Unbalancing”....................................................... 285

7.4.5.2 Delay Time at Operating Mode “Unbalancing” and “I>Query”............................................ 286

7.4.6 Finishing the Tests with Secondary Values........................................................................ 286

7.5 Checks With Primary Values.............................................................................................. 287

7.5.1 Transformer Polarity........................................................................................................... 287

7.6 Final Check of the Protection ............................................................................................. 288

7SS52 V4 Manual

C53000-G1176-C182-3

xiii

Page 14

Table of Contents

www . ElectricalPartManuals . com

8 Maintenance and Repair.................................................................................................................. 289

8.1 Maintenance .....................................................................................................................290

8.2 Fault Analysis ..................................................................................................................... 292

8.2.1 Evaluation of Operational Events ....................................................................................... 292

8.2.2 Checking the Auxiliary Voltage Supply...............................................................................293

8.2.3 Checking the LEDs on the Modules ...................................................................................293

8.2.4 Analysis of Internal Communication Failures...................................................................... 295

8.3 Troubleshooting..................................................................................................................299

8.4 Repair................................................................................................................................. 302

8.4.1 Replacing the Buffer Battery...............................................................................................303

8.4.2 Replacing the Fine-Wire Fuse............................................................................................306

8.4.3 Startup with a Defective Bay Unit / Defective Fiber-Optic Cable........................................ 309

9 Technical Data............. ... .... ... ... ... .... ...................................... ....................................... .................... 311

9.1 General Data ......................................................................................................................312

9.2 General Device Data ..........................................................................................................313

9.2.1 Analog Inputs and Outputs.................................................................................................313

9.2.2 Rated Auxiliary Voltage ...................................................................................................... 313

9.2.3 Binary Inputs....................................................................................................................... 314

9.2.4 Alarm Contacts................................................................................................................... 314

9.2.5 Trip Contacts ..................................... ... ... ... ....................................... ................................. 315

9.2.6 Light Emitting Diodes.......................................................................................................... 315

9.2.7 Operation, Displays ........................................ ...................................... .............................. 315

9.2.8 Serial Ports.................... .... ... ... ... .... ... ... ....................................... ....................................... 316

9.2.9 Busbar Protection.................... ... ....................................... ... ....................................... ....... 317

9.2.10 Circuit Breaker Failure Protection....................................................................................... 318

9.2.11 Overcurrent Protection in the Bay Unit............................................................................... 319

9.2.12 Auxiliary Functions..............................................................................................................321

9.2.13 User-Configurable Functions (CFC)...................................................................................322

9.2.14 Electrical Tests .................................. ... ... ... .... ...................................... .... .......................... 323

9.2.15 Mechanical Tests................................................................................................................ 325

9.2.16 Climatic Stress Tests.......................................................................................................... 326

9.2.17 Service Conditions.............................................................................................................. 327

9.2.18 Design Versions.................................................................................................................. 327

9.2.19 MCBs for Device 7SS52x...................................................................................................328

9.3 Dimensions......................................................................................................................... 329

9.3.1 Central Unit. ... ... .... ... ... ... .... ...................................... ....................................... ... .................329

9.3.2 Bay Unit.............................................................................................................................. 331

xiv

7SS52 V4 Manual

C53000-G1176-C182-3

Page 15

Table of Contents

www . ElectricalPartManuals . com

A Appendix .......................................................................................................................................... 335

A.1 Data for Selection and Ordering......................................................................................... 336

A.1.1 Central Unit ........................................................................................................................ 336

A.1.2 Bay Units............................................................................................................................ 337

A.1.3 Accessories........................................................................................................................ 338

A.2 Basis for Selection of the Stabilization Factor k ................................................................. 341

A.3 Connection Diagrams......................................................................................................... 342

A.4 Settings − Central Unit........................................................................................................ 348

A.4.1 Settings of the ZPS Modules.............................................................................................. 348

A.4.2 Settings of the EAZ Module................................................................................................ 352

A.4.3 Jumper Settings of the D-CPU Module .............................................................................. 354

A.5 Jumper Settings − Bay Unit............................... ... ... ... .... ...................................... ... ........... 356

A.5.1 Settings of the PFE Module................................................................................................ 356

A.5.2 Settings of the SVW Module............................................................................................... 357

A.5.3 Settings of the SAF Module................................................................................................ 358

A.5.4 Settings of the AFE Module................................................................................................ 359

A.5.5 Settings of the EFE Module................................................................................................ 360

A.5.6 Settings of the EFE_10 Module.......................................................................................... 362

A.6 Protocol-Dependent Functions................................ ... .... ... ... ... ... .... ...... ... .... ... ... ... ... .... ... ... . 364

A.7 Parameter Listing - Central Unit......................................................................................... 365

A.8 Parameter Listing - Bay Unit............................................................................................... 367

A.9 List of information - Central Unit........................... ... ... ....................................... ... .............. 373

A.10 List of Information - Bay Unit..............................................................................................383

A.11 Group Alarms - Central Unit............................................................................................... 389

A.12 Group Alarms - Bay Unit.....................................................................................................392

A.13 Measured Value List - Central Unit................................................. ... ... ... ....... ... ... ... .... ... ... . 393

A.14 Measured Value List - Bay Unit.......................................................................................... 394

A.15 Marshalling - Central Unit................................................................................................... 395

A.16 Marshalling - Bay Unit 7SS523........................................................................................... 398

A.17 Marshalling - Bay Unit 7SS525........................................................................................... 401

A.18 Navigation Tree - Central Unit............................................................................................ 403

A.19 Navigation Tree of the Bay Unit.......................................................................................... 413

A.20 Abbreviations...................................................................................................................... 414

A.21 References......................................................................................................................... 415

7SS52 V4 Manual

C53000-G1176-C182-3

xv

Page 16

Table of Contents

www . ElectricalPartManuals . com

xvi

7SS52 V4 Manual

C53000-G1176-C182-3

Page 17

Introduction 1

www . ElectricalPartManuals . com

This chapter introduces the SIPROTEC 7SS52 V4 distributed busbar and breaker failure protection. An overview of the device is presented in its application, characteristics, and scope of functions.

1.1 Overall Operation 2

1.2 Applications 4

1.3 Features 5

17SS52 V4 Manual

C53000-G1176-C182-3

Page 18

Introduction

www . ElectricalPartManuals . com

1.1 Overall Operation

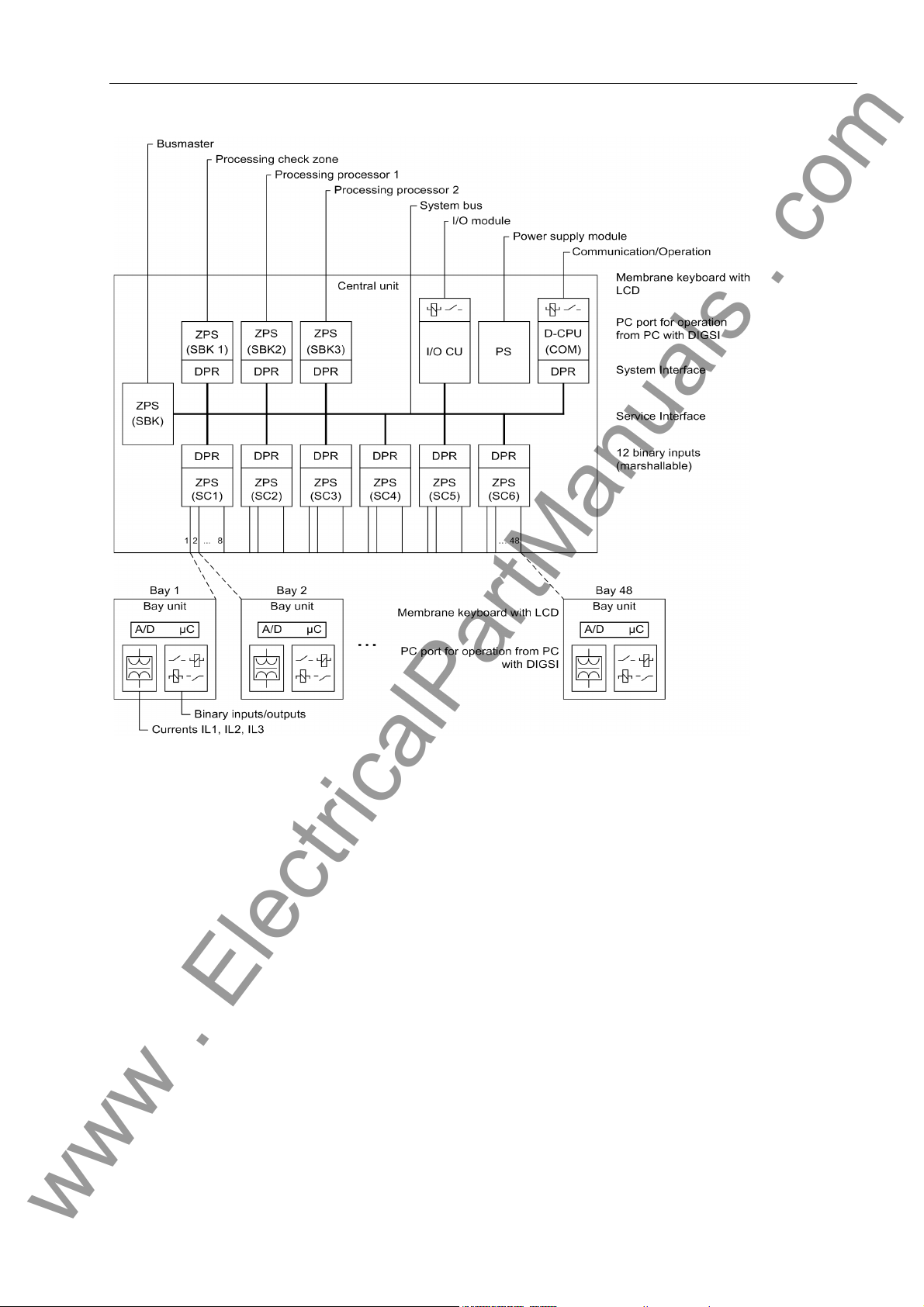

The SIPROTEC 7SS52 V4 distributed busbar and breaker failure protection consists

of compact bay units which are connected to the central unit by fiber-optic cables. Figure 1-1, page 3 shows the basic structure of the protection system.

All tasks from acquisition of the measured values up to the commands to the circuit

breakers are exclusively processed in a digital manner.

In the bay units the feeder or coupler currents are measured time-synchronized, digitalized, preprocessed and transmitted to the central unit via the fast serial port. The

input nominal current can be 1 or 5 A depending on the main current transformer design. A full galvanic and low-capacitive isolation of the measuring inputs is provided

by transducers. Suppression of disturbances is achieved by filters which are optimized

for the measured value processing with regard to bandwidth and processing speed.

Bay units The bay units can be parameterized and operated either directly or from the central

unit. Chapter 6.1, page 210 summarizes the operator options during operation.

The bay units capture the isolator positions and bay-related binary signals, process

functions of the breaker failure protection and fulfil auto diagnosis tasks.

Heavy-duty command relays take the protec ti on system's trip commands directly to

the circuit breakers. Marshallable alarm relays and indicators (LEDs, LC display,

DIGSI communication software) allow event indication. In addition operational measured values are displayed.

For the marshalling of isolator positions, command relays, alarm relays and allocatable binary inputs the DIGSI communication software is used.

Optionally, the bay units can be equipped with a backup protection function (definitetime, inverse-time) including breaker failure protection.

Central unit The central unit reads in time-synchronized measured currents from the connected

bay units and processes them together with binary information from the protection

functions (differential protection, breaker failure protection). The central unit transmits

the results of the calculations cyclically to the bay units, which perform logical combinations of the results.

Freely marshallable alarm relays and LED displays are provided for signalling. They

are marshalled with the DIGSI communication software.

The central unit manages all configuration and setting data for the bu sbar and breaker

failure protection functions. Communication is possible via the serial port by mean s of

a PC utilizing a current version of the DIGSI communication software. With DIGSI V4.6

the central unit - but not the bay unit - can also be operated via IEC 61850 with the

optional EN100 module. Indications, parameters and measured values are visualized

in the display or in DIGSI. In addition the pro gram can read ou t fault data from the protection device and analyze it.

The central unit and bay units contain power supply modules for a reliable powe r supply on different voltage ranges.

2

7SS52 V4 Manual

C53000-G1176-C182-3

Page 19

Overall Operation

www . ElectricalPartManuals . com

SBK: Protection processing SC: Serial coupling

DPR: Dual port RAM PS: Power supply

I/O CU: Input/output central unit ZPS: Central processor protection

SBK: Bus master

Figure 1-1 General view of the configuratio n of the protection system

7SS52 V4 Manual

C53000-G1176-C182-3

3

Page 20

Introduction

www . ElectricalPartManuals . com

1.2 Applications

Application The SIPROTEC 7SS52 V4 distributed busbar and breaker failure protection is a se-

lective, reliable and fast protection for busbar short-circuits and circuit-b reaker failures

in medium-voltage, high-voltage and extra high-voltage switching stations. It is suitable for almost all busbar configurations.

The busbar protection uses a phase-selective measuring principle.

The protection system consists of a central unit (CU) and up to 48 bay units (BU) con-

nected by fiber-optic (FO) cables. The latter can be located in the vicinity of the bays

(distributed) but also together with the CU in cubicles (centralized).

Use and scope of

functions

The protection can be used with all types of switchgear with either conventional or linearized CTs.

The modular design facilitates extensions or modifications of the protection system in

conformity with the switchgear design.

The 7SS52 V4 is designed for 12 selective bus zones and 12 bus coupler (auxiliary

bus) sections. These are sections which serve exclusively for coupling of the bus

zones. They do not have any feeders. The busbar co nfigura tion can includ e up to 24

sectionalizing isolators and 16 bus couplers with one bay unit or 8 bus couplers with

two bay units.

By virtue of the universal isolator replica, the SIPROTEC 7SS52 V4 distributed busbar

and breaker failure protection can be matched with differ ent b usbar configu ra tions in

the design phase.

Compensation of different current transformer ratios is achieved by parameter setting.

Interposing current transformers are thus no more required.

A busbar short-circuit is detected by evaluating the differential current and the stabilizing current. Appropriate measures ensure corr ect performance even for extreme CT

saturation (requested current transmission time ≥ 2 ms for stability in the case of external faults and ≥ 3 ms for tripping).

The integrated circuit breaker failure protec tion (CBF) can be operated in five modes,

selectable per bay (see Chapter 5.3.5.2, page 119):

• I> query (1-stage CBF)

• TRIP repetition with overcurrent detection I> (2-stage CBF)

• Unbalancing (1-stage CBF)

• TRIP repetition with following unbalancing (2-stage CBF)

• Single-pole or three-pole start by external CBF and tripping via the isolator replica

In addition, the integrated circuit breaker failure protection provides two operating

modes that can be set in parallel to the other five modes (see Chapter 5.3.5.2, page

119):

• Low-current operating mode without/with TRIP repetition

• Pulse mode

4

7SS52 V4 Manual

C53000-G1176-C182-3

Page 21

1.3 Features

www . ElectricalPartManuals . com

Features

The overcurrent-time protection is a back-up protection function of the bay unit an d includes the following functions (see Chapter 5.16, page 188):

• Phase-selective high-set stage (I>>)

• High-set stage for the earth current (IE>>)

• Phase-selective overcurrent stage with definite time or inverse time characteristic

(I> / Ip)

• Overcurrent stage for the earth curren t with definite time or inverse time character-

istic (IE> / IEp)

Back-up protection function, can work without the central unit

Separate circuit breaker failure protectio n

• Powerful multiprocessor system

• Completely digital measured value processing and co ntrol, from the acquisition and

digitizing of measured values, recognition of the isolator status and processing of

the CB failure protection signals up to the trip decisions for the circuit-breaker

• Graphical station planning with the DIGSI communication software

• Easy station configuration with the DIGSI communication software

• Easy centralized operation of bay units from the central unit using DIGSI, or local

menu-guided operation via integrated keypad and display panel

• Battery-buffered storage of fault events as well as instantaneous values for fault recording

• Complete galvanic and disturbance-free isolation betwe en the internal processing

circuits of central unit and bay units and the measuring and auxiliary supply circuits

of the station by virtue of screened measuring transducers, binary input and output

modules and DC converters

• Disturbance-free and fast data transmission from and to the bay units by fiber-optic

links

• Complete scope of functions for the selective protection of multiple busbar systems

• Central administration of the isolator states

• Continuous monitoring of measured values as well as of hardware an d software of

the unit

• Comprehensive self-monitoring provides for fast signaling of unit failures

• Communication via electrical or optical interfaces and use of the DIGSI communi-

cation software for planning, parameterization and for indication and fault record

analysis

• Communication check via Web browser

• IEC 61850

• Control center link of the central unit as per IEC 60870-5-103 and IEC 61850

7SS52 V4 Manual

C53000-G1176-C182-3

5

Page 22

Introduction

www . ElectricalPartManuals . com

• Output of indications to

− Control center

− LEDs

− Binary outputs of the central unit

• Commissioning support by measuring and display functions, and output of indica-

tions to a control center as well as to LEDs and outputs of the central unit.

Busbar

protection

The digital busbar protection contains the following functions:

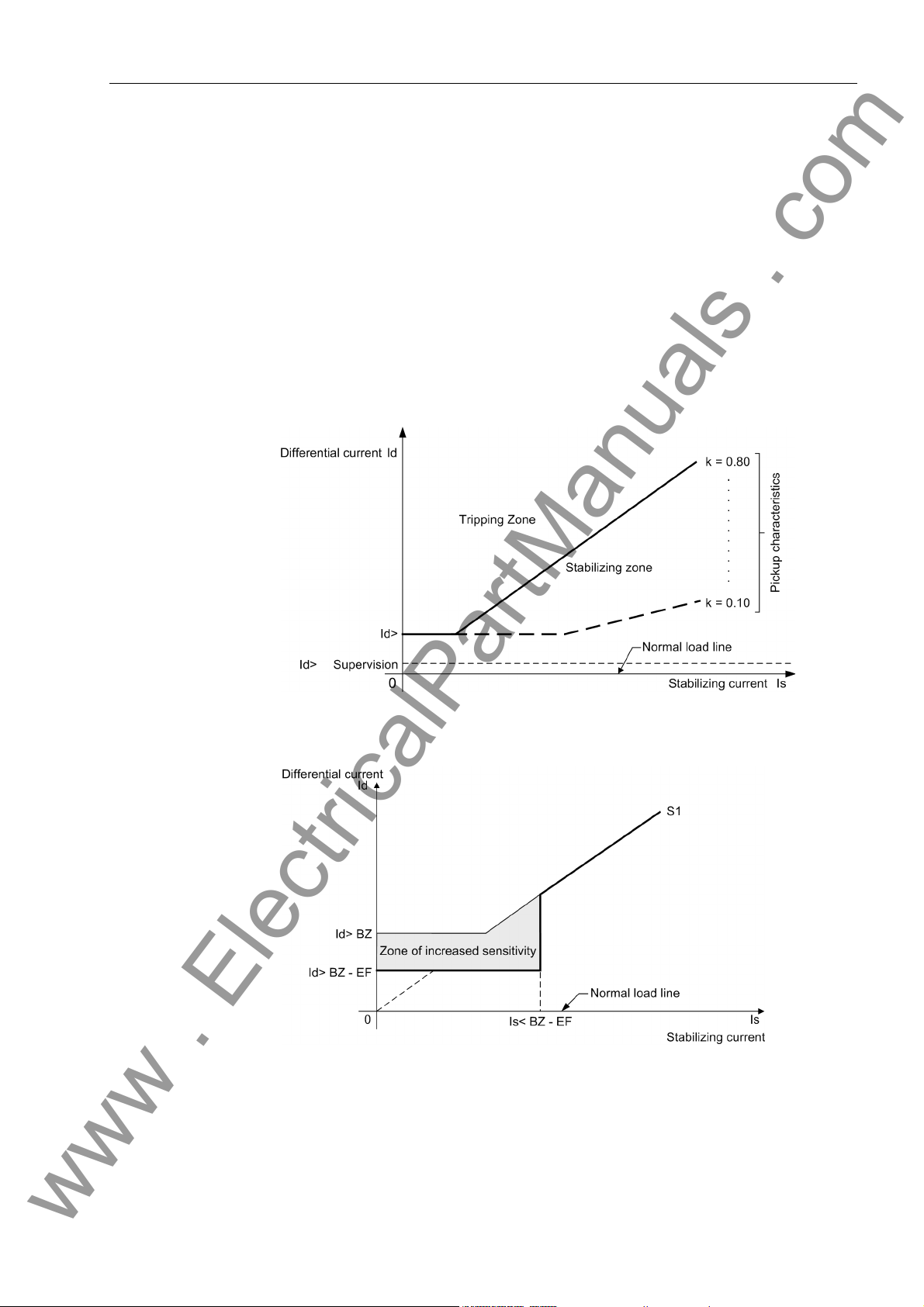

• Evaluation of the differential current in conjunction with through-current stabilization

(Figure 1-2, page 7)

• Trip decision based on 3 independent measurements. 2 mea surements are based

on busbar configuration, and the third measurement considers all busbar sections

independent of the isolator replica (check zone).

• Fast tripping (typical trip time 15 ms)

• Busbar protection with up to 12 bus zones (BZ), 12 bus coupler (auxiliary bus) sec-

tions (AB) and up to 48 bay units

• Protection of systems with up to quintuple busbars (including transfe r busbars)

• Stabilization against spurious tripping in case of external faults and CT saturation

• Zone-selective and phase-selective blocking of the busbar protection by the differ-

ential current monitor

• Selective blocking of the bus section in case of

− Isolator faults

− Bay faults (bay unit, FO cable)

− Measured value error

− Response of the zero crossing supervision

• Characteristics for check zone and bus-selective zones can be set independently

from each other

− Normal pick-up characteristic (Figure 1-2, page 7)

− Earth fault characteristic (Figure 1-3, page 7)

• Matching to different CT ratios without interposing matching transformers

• Selective clearance of short-circuits even on the bypass bus with signal transmis-

sion to the remote end

• Detection and disconnection of short-circuits in the coupler bay betwee n current

transformers and circuit-breaker based on current measurement and selective unbalance

• Detection and disconnection of short-circuits between current transformers and circuit-breaker of a line by end fault protection

6

7SS52 V4 Manual

C53000-G1176-C182-3

Page 23

Features

www . ElectricalPartManuals . com

• Circuit breaker failure protection (CBF), selectable per bay, for low-current faults in

the variants

− I> query (1-stage CBF)

− TRIP repetition with overcurrent detection I> (2-stage CBF)

− Unbalancing (1-stage CBF)

− TRIP repetition with following unbalancing (2-stage CBF)

− Single-pole or three-pole start by external breaker failure pro tection and tripping

via the isolator replica

• Direct operation of the circuit breaker by the ba y un it

• Direct tripping of busbar sections via binary inputs of the central unit

Figure 1-2 Pick-up characteristics of the busbar and breaker failure protection (unbalancing)

Figure 1-3 Earth fault characteristic

7SS52 V4 Manual

C53000-G1176-C182-3

7

Page 24

Introduction

www . ElectricalPartManuals . com

Breaker failure

protection

The integrated circuit breaker failure protection (CBF) contains th e following functions:

• In case of a busbar short-circuit, a breaker failure is detected by co mparison of current thresholds.

• In all operating modes of the circuit breaker failure protection, a bay-selective command is output by the bay units to trip the circuit breaker at the remote end (transfer

trip command).

• The external breaker failure protection can be started for one phase or for three

phases.

• The breaker failure protection can be started on 1 channel or, for extra reliability, on

2 channels. Both settings can be combined with a monitoring feature.

• Reduced response times in case of a circuit breaker malfunction

• Query of the circuit breaker position in case of low-current faults

• The circuit breaker failure protection function can be deactivated fo r te st purp oses.

The following modes are available for the circuit breaker failure protection:

• I> query:

After initiation by a TRIP command from the feeder protection, the 7SS52 V4

checks the feeder current. If the measured current stays above the set threshold after a set time has elapsed, the 7SS52 V4 issues zone- selective TRIP commands in

the bays considering the isolator replica.

• TRIP repetition with subsequent I> query:

When initiated by a TRIP command from the feeder protection, the 7SS52 V4 issues a second TRIP command to the circuit breaker of the initiating feeder after a

set time delay. In case this second TRIP command is also unsuccessful, tripping as

per mode I>query is effected.

• Unbalancing:

After initiation by a TRIP command from the feeder protection, the

7SS52 V4 system checks the feeder current. If the measured current stays above

the set threshold after a set time has elapsed, the polarity of the current in this feeder is inverted by the 7SS52 V4 (unbalancing).

• TRIP repetition with subsequent unbalancing:

When initiated by a TRIP command from the feeder protection, the 7SS52 V4 issues a second TRIP command to the circuit breaker of the initiating feeder after a

set time delay. In case this second TRIP command is also unsuccessful, tripping as

per mode Unbalancing is effected.

• TRIP by external CBF:

Where a separate circuit breaker failure protection is provided, the 7SS52 V4 can

generate zone-selective feeder trip commands utilizing the integrated isolator replica.

• TRIP repetition with subsequent unbalancing with pulse trigger or I>query:

This mode should be used when the CBF is triggered by the remote station. The

function is triggered by a trip command from the feeder protection at the remote

feeder terminal. The further proceeding is described in the modes TRIP repetition

with subsequent unbalancing and I>query.

• Low-current CBF:

This mode outputs a TRIP command even in the case of low-cur rent faults (e.g. tripping by Buchholz protection). After a settable time the circuit breaker position is

queried. A TRIP repetition also takes place with a low-current oper ating mode.

8

7SS52 V4 Manual

C53000-G1176-C182-3

Page 25

Features

www . ElectricalPartManuals . com

End fault protection This mode detects short-circuits between the current transformers and the circuit

breaker and generates the necessary commands to disconnect the faulted line.

Overcurrent

protection

Isolator

replica

The overcurrent protection of the bay unit is independent of the busbar protection

function and of the central unit. The overcurrent protection comprises the following

functions (Chapter 5.16, page 188):

• High-set stage I>> with separate fault detection in each phase

• High-set stage IE>>

• Definite time overcurrent stage I> with separate fault detection in each phase OR

• Inverse time overcurrent stage Ip with separate fault detection in each phase

• Definite time earth current stage IE> OR

• Inverse time earth current stage IEP

• Setting of different current/time characteristics for phase and earth currents is pos-

sible.

• With inverse time O/C protection: three standardized characteristics are selecta ble

for phase currents and earth currents.

• The CBF function remains active even in case of central unit failure or with the bay

unit out of service.

The isolator replica is common for the busbar protection and the circuit-brea ker failure

protection function. The isolator replica comprises the following functions:

• Management of up to 48 bay units, 12 bus zones and 12 bus coupler sections:

The protection system is suitable for configurations up to quintuple busbars. Combibus operation is possible. Up to 16 couplers can be configured with one bay unit,

and up to 8 couplers with 2 bay units. These can be bus couplers or/and sectionalizing isolators.

Trip output / Trip reset

• Isolator running time supervision

• Integrated storage of isolator status on loss of DC supply:

The isolator replica allows to allocate to the isolators their positions prior to the DC

supply failure. It is also possible to allocate to all isolators of this feeder the position

CLOSED. The allocation of NOT OPEN = CLOSED eliminates the necessity of calibrated isolator auxiliary contacts. Also, it ensures stable functioning of the protection even in case of a wire break.

• Graphical planning of the station configuration with the DIGSI communication software

• Visualization of isolator positions by LEDs on the bay units

The signal processing is distinguished by the following characteristics:

• Feeder-selective TRIP command by the bay units

• Feeder-selective selectable overcurrent release of the TRIP command

• Extension of busbar TRIP signal for set time

• Current-controlled reset of TRIP signal

7SS52 V4 Manual

C53000-G1176-C182-3

9

Page 26

Introduction

www . ElectricalPartManuals . com

Fault recording During a fault event, the instantaneous values of the measured values are stored at

intervals of 1 ms at 50 Hz and 0.83 ms at 60 Hz respectively in a buffer of the central

unit or of the bay units. The central unit calculates from the instantaneous valu es the