Siemens SIPROTEC 7SK80 User Manual

SIPROTEC

Preface

Contents

Introduction 1

Functions 2

Motor Protection

7SK80

V4.6

Manual

Mounting and Commissioning 3

Technical Data 4

Appendix A

Literature

Glossary

Index

E50417-G1140-C344-A4

Note

For safety purposes, please note instructions and warnings in the Preface.

Disclaimer of Liability

We have checked the contents of this manual against the hardware

and software described. However, deviations from the description

cannot be completely ruled out, so that no liability can be accepted

for any errors or omissions contained in the information given.

The information given in this document is reviewed regularly and

any necessary corrections will be included in subsequent editions.

Copyright

Copyright © Siemens AG 2010. All rights reserved.

Dissemination or reproduction of this document, or evaluation and

communication of its contents, is not authorized except where expressly permitted. Violations are liable for damages. All rights reserved, particularly for the purposes of patent application or trademark registration.

We appreciate any suggested improvements.

We reserve the right to make technical improvements without

notice.

Document version V04.03.01.

Release date 08.2010

Registered Trademarks

SIPROTEC, SINAUT, SICAM and DIGSI are registered trademarks

of Siemens AG. Other designations in this manual might be trademarks whose use by third parties for their own purposes would infringe the rights of the owner.

Siemens Aktiengesellschaft Order no.: E50417-G1140-C344-A4

Preface

Purpose of this Manual

This manual describes the functions, operation, installation, and commissioning of 7SK80 devices. In particular,

one will find:

• Information regarding the configuration of the scope of the device and a description of the device functions

and settings → Chapter 2;

• Instructions for Installation and Commissioning → Chapter 3;

• Compilation of the Technical Data → Chapter 4;

• As well as a compilation of the most significant data for advanced users → Appendix A.

General information with regard to design, configuration, and operation of SIPROTEC 4 devices are set out in

the SIPROTEC 4 System Description /1/.

T arget Audience

Protection engineers, commissioning engineers, personnel concerned with adjustment, checking, and service

of selective protective equipment, automatic and control facilities, and personnel of electrical facilities and

power plants.

Applicability of this Manual

This manual applies to: SIPROTEC 4 Multifunctional Protection Device with Motor Protection 7SK80; Firmware

Version V4.6

Indication of Conformity

This product complies with the directive of the Council of the European Communities on the

approximation of the laws of the Member States relating to electromagnetic compatibility (EMC

Council Directive 2004/108/EC) and concerning electrical equipment for use within specified

voltage limits (Low-voltage Directive 2006/95 EC).

This conformity is proved by tests conducted by Siemens AG in accordance with the Council

Directive in agreement with the generic standards EN 61000-6-2 and EN 61000-6-4 for EMC

directive, and with the standard EN 60255-27 for the low-voltage directive.

The device has been designed and produced for industrial use.

The product conforms with the international standards of the series IEC 60255 and the German

standard VDE 0435.

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

3

Preface

Additional St andards

Additional Support

Should further information on the System SIPROTEC 4 be desired or should particular problems arise which

are not covered sufficiently for the purchaser's purpose, the matter should be referred to the local Siemens representative.

Our Customer Support Center provides a 24-hour service.

Telephone: +49 (180) 524-7000

Fax: +49 (180) 524-2471

e-mail: support.energy@siemens.com

IEEE C37.90 (see Chapter 4 "Technical Data")

This product is UL-certfied with the values as stated in the Technical Data.

file E194016

Training Courses

Enquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy TD

Humboldt Street 59

90459 Nuremberg

Telephone: +49 (911) 433-7005

Fax: +49 (911) 433-7929

Internet: www.siemens.com/power-academy-td

4

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Safety Information

This manual does not constitute a complete index of all required safety measures for operation of the equipment (module, device), as special operational conditions may require additional measures. However, it comprises important information that should be noted for purposes of personal safety as well as avoiding material

damage. Information that is highlighted by means of a warning triangle and according to the degree of danger,

is illustrated as follows.

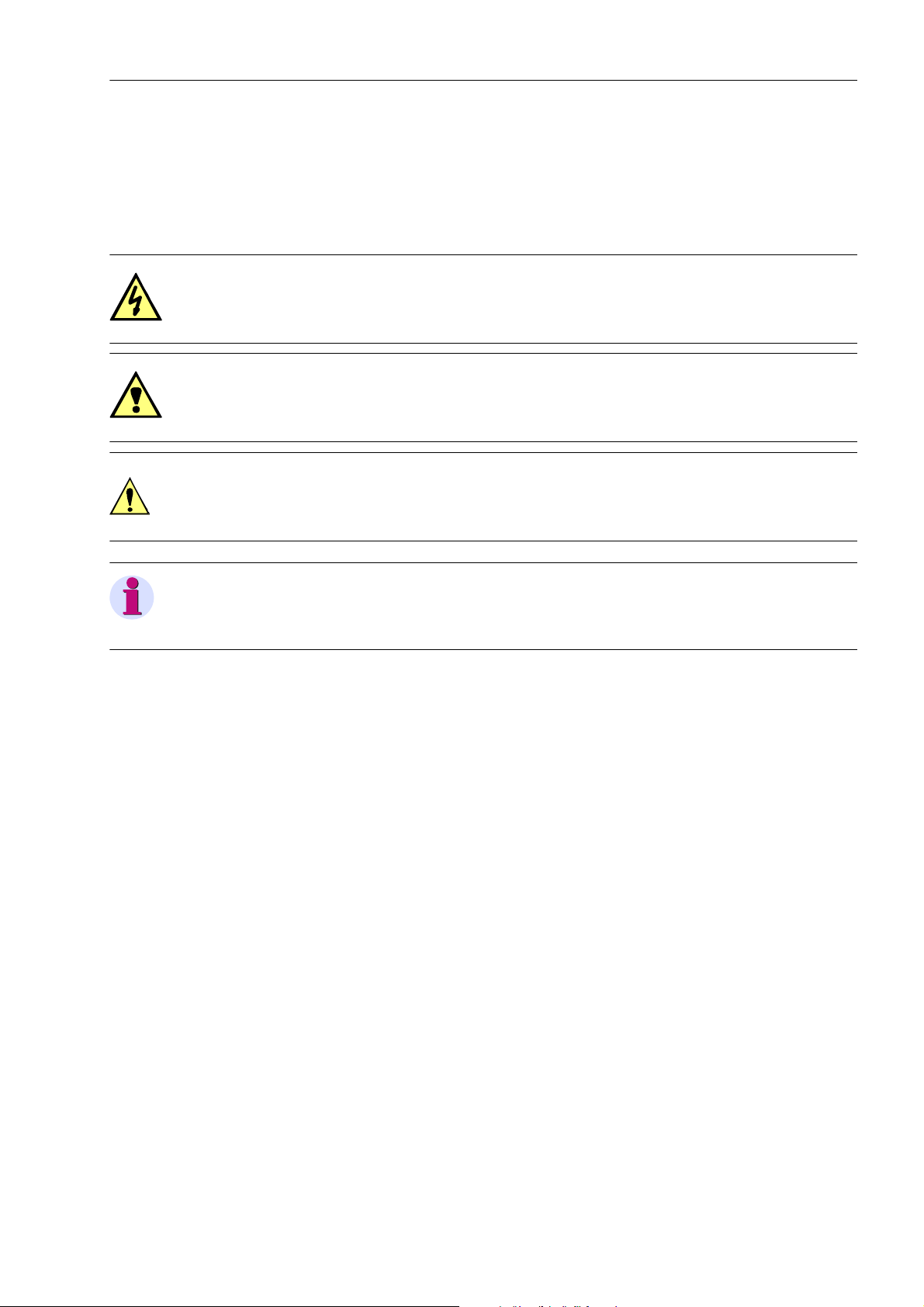

DANGER!

Danger indicates that death, severe personal injury or substantial material damage will result if proper precautions are not taken.

WARNING!

indicates that death, severe personal injury or substantial property damage may result if proper precautions are

not taken.

Caution!

indicates that minor personal injury or property damage may result if proper precautions are not taken. This

particularly applies to damage to or within the device itself and consequential damage thereof.

Preface

Note

indicates information on the device, handling of the device, or the respective part of the instruction manual

which is important to be noted.

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

5

Preface

WARNING!

Qualified Personnel

Commissioning and operation of the equipment (module, device) as set out in this manual may only be carried

out by qualified personnel. Qualified personnel in terms of the technical safety information as set out in this

manual are persons who are authorized to commission, activate, to ground and to designate devices, systems

and electrical circuits in accordance with the safety standards.

Use as prescribed

The operational equipment (device, module) may only be used for such applications as set out in the catalogue

and the technical description, and only in combination with third-party equipment recommended or approved

by Siemens.

The successful and safe operation of the device is dependent on proper handling, storage, installation, operation, and maintenance.

When operating an electrical equipment, certain parts of the device are inevitably subject to dangerous voltage.

Severe personal injury or property damage may result if the device is not handled properly.

Before any connections are made, the device must be grounded to the ground terminal.

All circuit components connected to the voltage supply may be subject to dangerous voltage.

Dangerous voltage may be present in the device even after the power supply voltage has been removed (capacitors can still be charged).

Operational equipment with exposed current transformer circuits may not be operated.

The limit values as specified in this manual or in the operating instructions may not be exceeded. This aspect

must also be observed during testing and commissioning.

6

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

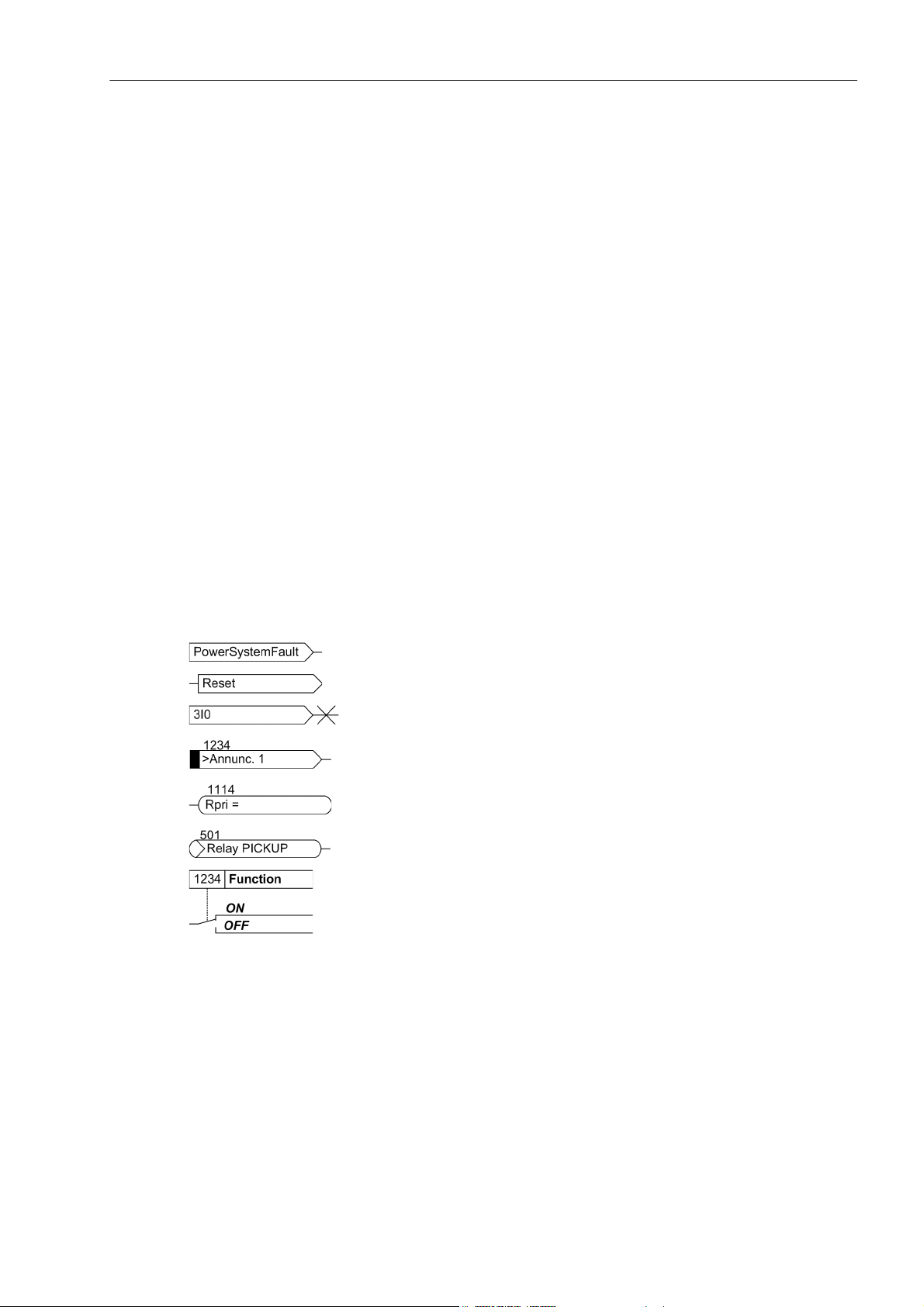

T ypographic and Symbol Conventions

The following text formats are used when literal information from the device or to the device appear in the text

flow:

Parameter Names

Designators of configuration or function parameters which may appear word-for-word in the display of the

device or on the screen of a personal computer (with operation software DIGSI), are marked in bold letters in

monospace type style. The same applies to the titles of menus.

1234A

Parameter addresses have the same character style as parameter names. Parameter addresses contain the

suffix A in the overview tables if the parameter can only be set in DIGSI via the option Display additional set-

tings.

Parameter Options

Possible settings of text parameters, which may appear word-for-word in the display of the device or on the

screen of a personal computer (with operation software DIGSI), are additionally written in italics. The same

applies to the options of the menus.

„Messages“

Designators for information, which may be output by the relay or required from other devices or from the switch

gear, are marked in a monospace type style in quotation marks.

Preface

Deviations may be permitted in drawings and tables when the type of designator can be obviously derived from

the illustration.

The following symbols are used in drawings:

Device-internal logical input signal

Device-internal logical output signal

Internal input signal of an analog quantity

External binary input signal with number (binary input,

input indication)

External binary input signal with number

(example of a value indication)

External binary output signal with number (device indication) used as

input signal

Example of a parameter switch designated FUNCTION with address

1234 and the possible settings ON and OFF

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

7

Preface

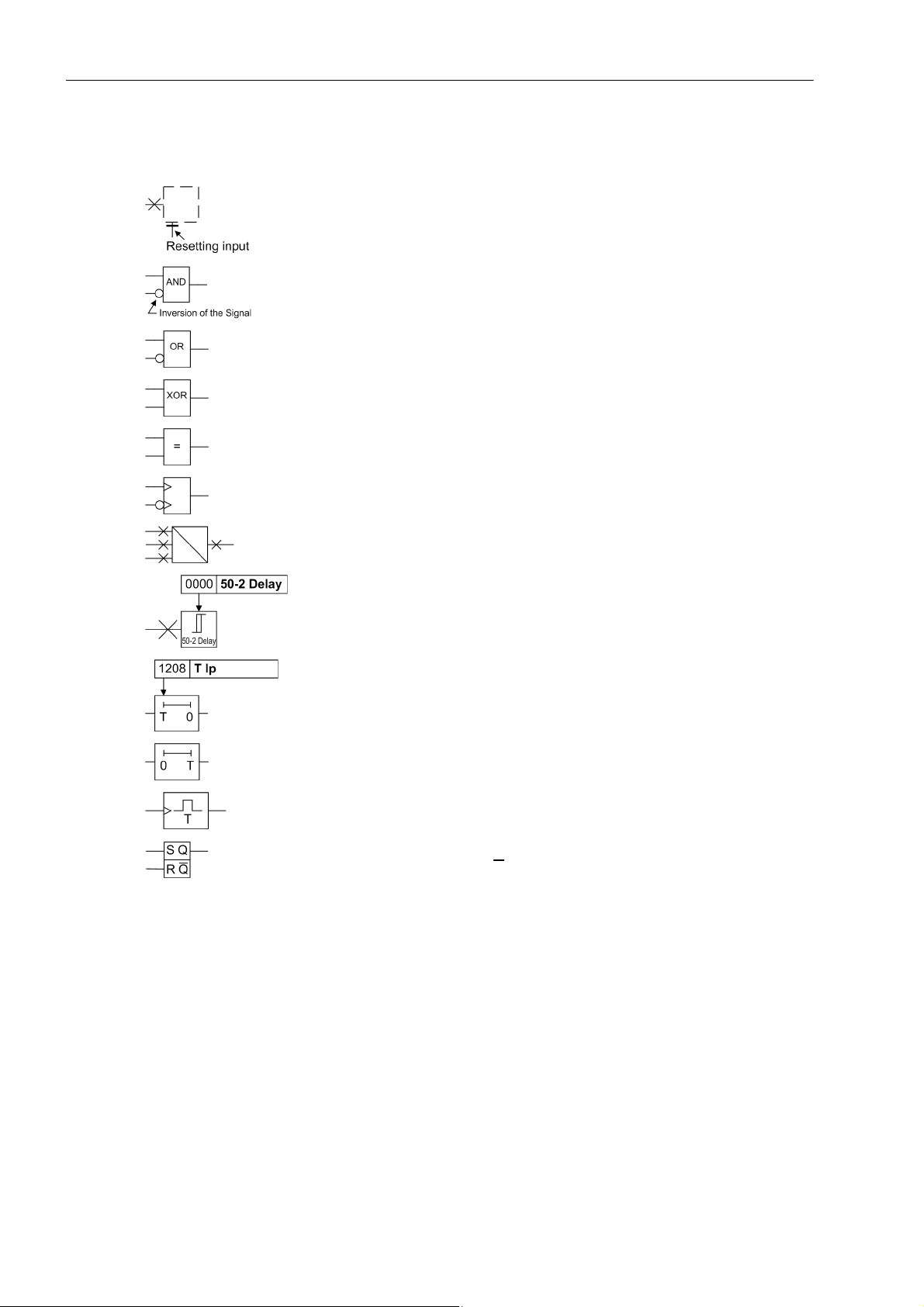

Besides these, graphical symbols are used in accordance with IEC 60617-12 and IEC 60617-13 or similar.

Some of the most frequently used are listed below:

Input signal of analog quantity

AND-gate operation of input values

OR-gate operation of input values

Exklusive OR-gate (antivalence): output is active, if only one of the

inputs is active

Coincidence gate (equivalence): output is active, if both inputs are

active or inactive at the same time

Dynamic inputs (edge-triggered) above with positive, below with negative edge

Formation of one analog output signal from a number of analog input

signals

Limit stage with setting address and parameter designator (name)

Timer (pickup delay T, example adjustable) with setting address and

parameter designator (name)

Timer (dropout delay T, example non-adjustable)

Dynamic triggered pulse timer T (monoflop)

Static memory (RS-flipflop) with setting input (S), resetting input (R),

output (Q) and inverted output (Q

)

■

8

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1.1 Overall Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1.2 Application Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1.3 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1 Functional Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2.1.2 Device, General Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2.1.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2.1.2.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.1.2.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.1.2.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1.3 Power System Data 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.1.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.1.3.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.1.3.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2.1.3.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

2.1.4 Oscillographic Fault Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.4.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

2.1.4.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

2.1.4.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

2.1.5 Settings Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.1.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.1.5.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.1.5.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.1.5.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.1.6 Power System Data 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.1.6.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.1.6.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.1.6.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2.1.6.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2.1.7 EN100-Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.1.7.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.1.7.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

9

Contents

2.2 Overcurrent Protection 50, 51, 50N, 51N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.2.2 Definite Time High-set Elements 50-3, 50-2, 50N-3, 50N-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.2.3 Definite Time Overcurrent Elements 50-1, 50N-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.2.4 Inverse Time Overcurrent Elements 51, 51N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2.2.5 Dynamic Cold Load Pickup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2.6 Inrush Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.2.7 Pickup Logic and Tripping Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.2.8 Two-phase Overcurrent Protection (Only Non-directional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.2.9 Fast Busbar Protection Using Reverse Interlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2.2.10 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.2.11 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.2.12 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2.3 Directional Ground Overcurrent Protection 67N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

2.3.2 Definite Time, Directional High-set Current Element 67N-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2.3.3 Definite Time, Directional Overcurrent Element 67N-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

2.3.4 Inverse Time, Directional Overcurrent Element 67N-TOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.3.5 Interaction with Fuse Failure Monitor (FFM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.3.6 Dynamic Cold Load Pickup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.3.7 Inrush Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2.3.8 Determination of Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2.3.9 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2.3.10 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2.3.11 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

2.4 Dynamic Cold Load Pickup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.4.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.4.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

2.4.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.5 Voltage Protection 27, 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.5.1 Measurement Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

2.5.2 Overvoltage Protection 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

2.5.3 Undervoltage Protection 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

2.5.4 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2.5.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.5.6 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

2.6 Negative Sequence Protection 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.6.1 Definite Time Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

2.6.2 Inverse Time Characteristic 46-TOC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.6.3 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

2.6.4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

2.6.5 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Contents

2.7 Motor Protection (Motor Starting Protection 48, Motor Restart Inhibit 66, Load Jam Protection) . . . .120

2.7.1 Motor Starting Protection 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

2.7.1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

2.7.1.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

2.7.2 Motor Restart Inhibit 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

2.7.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

2.7.2.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

2.7.3 Load Jam Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

2.7.3.1 Mode of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

2.7.3.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

2.7.4 Motor (Motor Starting Protection 48, Motor Restart Inhibit 66, Load Jam Protection) . . . . . . . . . .140

2.7.4.1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

2.7.4.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

2.8 Frequency Protection 81 O/U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

2.8.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

2.8.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

2.8.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

2.8.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

2.9 Thermal Overload Protection 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

2.9.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

2.9.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

2.9.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

2.9.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

2.10 Monitoring Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

2.10.1 Measurement Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

2.10.1.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

2.10.1.2 Hardware Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

2.10.1.3 Software Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

2.10.1.4 Monitoring of the Transformer Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

2.10.1.5 Measuring Voltage Failure Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

2.10.1.6 Broken Wire Monitoring of Voltage Transformer Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

2.10.1.7 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

2.10.1.8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

2.10.1.9 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

2.10.2 Trip Circuit Supervision 74TC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

2.10.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

2.10.2.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

2.10.2.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

2.10.2.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

2.10.3 Malfunction Responses of the Monitoring Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

2.10.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

2.11 Ground Fault Protection 64, 67N(s), 50N(s), 51N(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

2.11.1 Ground Fault Detection for cos-ϕ– / sin-ϕ Measurement (Standard Method) . . . . . . . . . . . . . . . .178

2.11.2 Ground Fault Detection for V0/I0-ϕ

Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

2.11.3 Ground Fault Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

2.11.4 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

2.11.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

2.11.6 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

11

Contents

2.12 Breaker Failure Protection 50BF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

2.12.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

2.12.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

2.12.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

2.12.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

2.13 Flexible Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

2.13.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

2.13.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

2.13.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

2.13.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

2.14 Reverse-Power Protection Application with Flexible Protection Function. . . . . . . . . . . . . . . . . . . . . . 219

2.14.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

2.14.2 Implementation of the Reverse Power Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

2.14.3 Configuring the Reverse Power Protection in DIGSI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

2.15 Temperature Detection via RTD Boxes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

2.15.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

2.15.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

2.15.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

2.15.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

2.16 Phase Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

2.16.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

2.16.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

2.17 Function Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

2.17.1 Pickup Logic of the Entire Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

2.17.2 Tripping Logic of the Entire Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

2.17.3 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

12

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Contents

2.18 Auxiliary Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

2.18.1 Message Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

2.18.1.1 LEDs and Binary Outputs (Output Relays). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

2.18.1.2 Information via Display Field or PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

2.18.1.3 Information to a Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

2.18.2 Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

2.18.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

2.18.2.2 Circuit Breaker Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

2.18.2.3 Motor Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

2.18.2.4 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

2.18.2.5 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

2.18.3 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

2.18.3.1 Display of Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

2.18.3.2 Transmitting Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

2.18.3.3 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

2.18.4 Average Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

2.18.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

2.18.4.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

2.18.4.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

2.18.4.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

2.18.5 Min/Max Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

2.18.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

2.18.5.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

2.18.5.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

2.18.5.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

2.18.6 Set Points for Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

2.18.6.1 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

2.18.7 Set Points for Statistic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

2.18.7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

2.18.7.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

2.18.7.3 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

2.18.8 Energy Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

2.18.8.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

2.18.8.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

2.18.8.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

2.18.8.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

2.18.9 Commissioning Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

2.18.9.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

2.19 Breaker Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

2.19.1 Control Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

2.19.1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

2.19.1.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

2.19.2 Command Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

2.19.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

2.19.3 Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

2.19.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

2.19.4 Interlocking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

2.19.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

2.19.5 Command Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

2.19.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

13

Contents

2.20 Notes on Device Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

2.20.1 Different operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

3 Mounting and Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

3.1 Mounting and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

3.1.1 Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

3.1.2 Hardware Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

3.1.2.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

3.1.2.2 Connections of the Current Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .293

3.1.2.3 Connections of the Voltage Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295

3.1.2.4 Connection of the temperature sensors to the I/O 2 extension module. . . . . . . . . . . . . . . . . . 295

3.1.2.5 Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

3.1.2.6 Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

3.1.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

3.1.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

3.1.3.2 Panel Flush Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

3.1.3.3 Cubicle Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

3.1.3.4 Panel Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

3.2 Checking Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

3.2.1 Checking the Data Connections of the Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

3.2.2 Checking the System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

3.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

3.3.1 Test Mode and Transmission Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

3.3.2 Testing the System Interface (at Port B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

3.3.3 Configuring Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .315

3.3.4 Checking the Status of Binary Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

3.3.5 Tests for Circuit Breaker Failure Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

3.3.6 Testing User-Defined Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

3.3.7 Current, Voltage, and Phase Rotation Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .323

3.3.8 Testing the Reverse Interlocking Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .324

3.3.9 Direction Check with Load Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

3.3.10 Polarity Check for Voltage Input V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

3

3.3.11 Ground Fault Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

3.3.12 Polarity Check for Current Input I

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

N

3.3.13 Checking the Temperature Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

3.3.14 Trip/Close Tests for the Configured Operating Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

3.3.15 Creating Oscillographic Recordings for Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

3.4 Final Preparation of the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

14

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Contents

4 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

4.1 General Device Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

4.1.1 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

4.1.2 Auxiliary Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335

4.1.3 Binary Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .336

4.1.4 Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .337

4.1.5 Electrical Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .339

4.1.6 Mechanical Stress Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .342

4.1.7 Climatic Stress Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .343

4.1.8 Service conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .343

4.1.9 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .344

4.1.10 UL-certification conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .344

4.2 Definite-Time Overcurrent Protection 50(N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .345

4.3 Inverse-Time Overcurrent Protection 51(N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .347

4.4 Directional Ground Overcurrent Protection 67N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .358

4.5 Inrush Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .359

4.6 Dynamic Cold Load Pickup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .360

4.7 Voltage Protection 27, 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .361

4.8 Negative Sequence Protection 46-1, 46-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .363

4.9 Negative Sequence Protection 46-TOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .364

4.10 Motor Starting Protection 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .370

4.11 Motor Restart Inhibit 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .371

4.12 Load Jam Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .372

4.13 Frequency Protection 81 O/U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .373

4.14 Thermal Overload Protection 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

4.15 Ground Fault Protection 64, 67N(s), 50N(s), 51N(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .376

4.16 Breaker Failure Protection 50BF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .379

4.17 Flexible Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .380

4.18 Temperature Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .383

4.19 User-defined Functions (CFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .385

4.20 Additional Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .390

4.21 Breaker Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .395

4.22 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .396

4.22.1 Panel Flush and Cubicle Mounting (Housing Size 1/6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .396

4.22.2 Panel Surface Mounting (Housing Size 1/6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .397

4.22.3 Bottom view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .398

A Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .399

A.1 Ordering Information and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400

A.1.1 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400

A.1.1.1 7SK80 V4.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400

A.1.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .403

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

15

Contents

A.2 Terminal Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 405

A.2.1 7SK80 — Housing for panel flush mounting and cubicle installation and for panel surface mounting

405

A.3 Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

A.3.1 Connection Examples for RTD Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

A.4 Current Transformer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

A.4.1 Accuracy limiting factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Effective and Rated Accuracy Limiting Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Calculation example according to IEC 60044–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

A.4.2 Class conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

A.4.3 Cable core balance current transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

Class accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 426

A.5 Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

A.5.1 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

A.5.2 Binary Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

A.5.3 Binary Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

A.5.4 Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 429

A.5.5 Default Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

A.6 Protocol-dependent Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

A.7 Functional Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

A.8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

A.9 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 451

A.10 Group Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

A.11 Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 469

Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .473

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .475

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

16

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Introduction 1

This chapter introduces the SIPROTEC 4 7SK80 and gives an overview of the device's application, properties

and functions.

1.1 Overall Operation 18

1.2 Application Scope 21

1.3 Characteristics 23

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

17

Introduction

1.1 Overall Operation

1.1 Overall Operation

The digital SIPROTEC 7SK80 motor protection is equipped with a powerful microprocessor. It allows all tasks

to be processed digitally, from the acquisition of measured quantities to sending commands to circuit breakers.

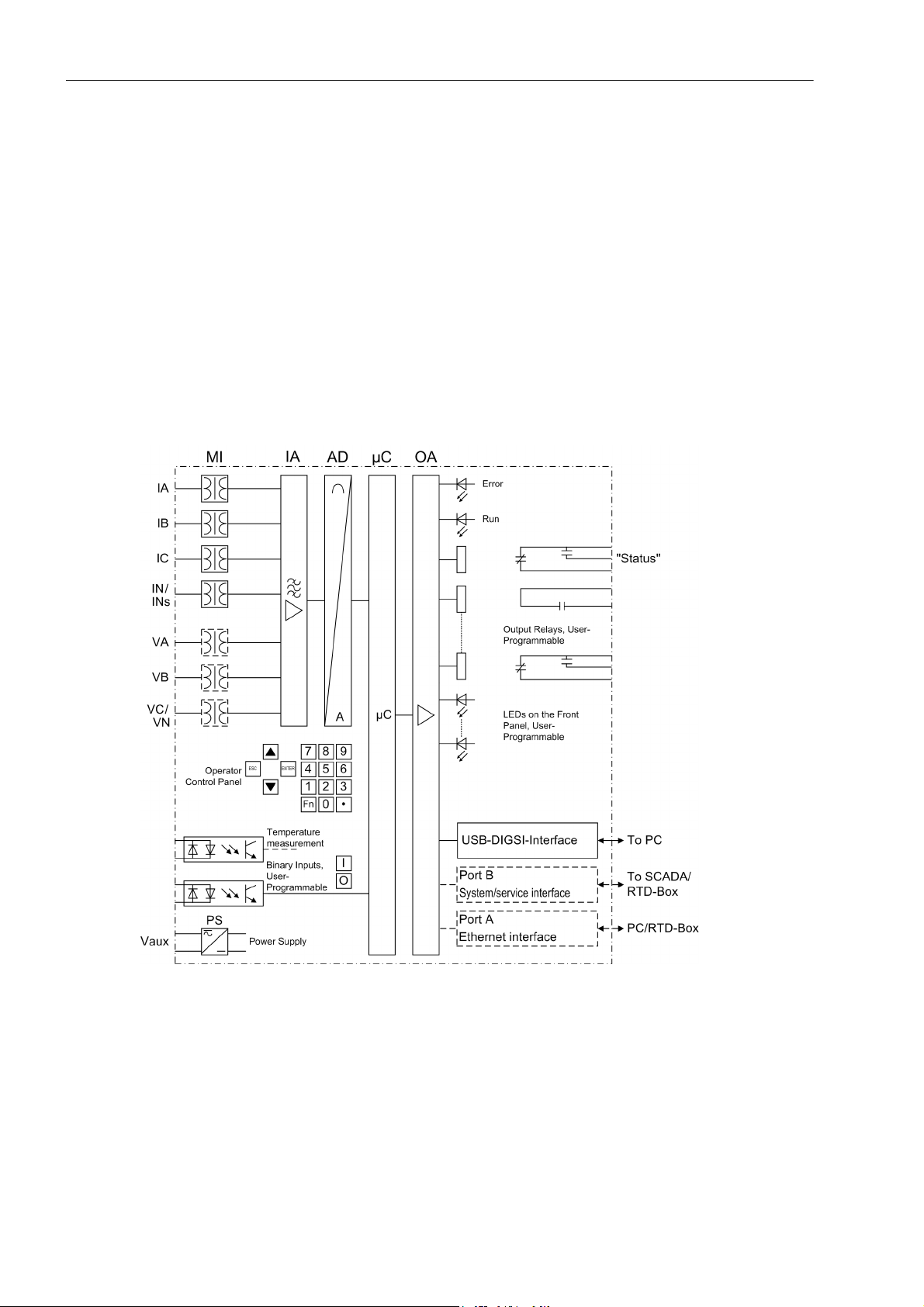

Figure 1-1 shows the basic structure of the 7SK80.

Analog Inputs

The measuring inputs (MI) convert the currents and voltages coming from the measuring transformers and

adapt them to the level appropriate for the internal processing of the device. The device provides 4 current

transformers and - depending on the model - additionally 3 voltage transformers. Three current inputs serve for

the input of the phase currents, another current input (I

I

(current transformer neutral point) or for a separate ground current transformer (for sensitive ground fault

N

detection I

and directional determination of ground faults ) - depending on the model.

Ns

) may be used for measuring the ground fault current

N

18

Figure 1-1 Hardware structure of the digital 7SK80 motor protection device

The optional voltage transformers can either be used to input 3 phase-to-Ground voltages or 2 phase-to-phase

voltages and the displacement voltage (open delta voltage) or any other voltages. It is also possible to connect

two phase-to-phase voltages in open delta connection.

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

The analog input quantities are passed on to the input amplifiers (IA). The input amplifier IA element provides

a high-resistance termination for the input quantities. It consists of filters that are optimized for measured-value

processing with regard to bandwidth and processing speed.

The analog-to-digital (AD) transformer group consists of a an analog-to-digital converter and memory components for the transmission of data to the microcomputer.

Microcomputer System

Apart from processing the measured values, the microcomputer system (μC) also executes the actual protection and control functions. They especially include:

• Filtering and preparation of the measured quantities

• Continuous monitoring of the measured quantities

• Monitoring of the pickup conditions for the individual protective functions

• Interrogation of limit values and sequences in time

• Control of signals for the logic functions

• Output of control commands for switching devices

• Recording of messages, fault data and fault values for analysis

• Management of the operating system and the associated functions such as data recording, real-time clock,

communication, interfaces, etc.

• The information is distributed via output amplifiers (OA).

Introduction

1.1 Overall Operation

Binary Inputs and Outputs

Binary inputs and outputs to and from the computer system are relayed via the input/output modules. The computer system obtains the information from the system (e.g. remote resetting) or the external equipment (e.g.

blocking commands). Outputs are, in particular, commands to the switchgear units and annunciations for

remote signalling of important events and statuses.

Front Elements

Information such as messages related to events, states, measured values and the functional status of the

device are visualized by light-emitting diodes (LEDs) and a display screen (LCD) on the front panel.

Integrated control and numeric keys in conjunction with the LCD enable interaction with the remote device.

These elements can be used to access the device for information such as configuration and setting parameters.

Similarly, setting parameters can be accessed and changed if needed.

In addition, control of circuit breakers and other equipment is possible from the front panel of the device.

Interfaces

Communication with a PC can be implemented via the USB DIGSI interface using the DIGSI software, allowing all device functions to be easily executed.

Communication with a PC is also possible via port A (Ethernet Interface) and port B (System Interface EN 100)

using DIGSI.

Port A or port B can be used for connecting a thermobox - via Ethernet - to enter external temperatures (e.g.

overload protection). Optionally, up to 5 temperature sensors can be connected directly to the device via the

I/O 2 extension module.

In addition to the device communication via DIGSI, port B can also be used to transmit all device data to a

central evaluator or a control center. This interface may be provided with various protocols and physical transmission schemes to suit the particular application.

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

19

Introduction

1.1 Overall Operation

Power Supply

A power supply unit (Vaux or PS) delivers power to the functional units using the different voltage levels. Voltage

dips may occur if the voltage supply system (substation battery) becomes short-circuited. Usually, they are

bridged by a capacitor (see also Technical Data).

A buffer battery is located under the flap at the lower end of the front cover.

20

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

1.2 Application Scope

The digital motor protection SIPROTEC 4 7SK80 is suitable as protection and monitoring unit for asynchronous

machines of any size. It can nevertheless also be used in busbar feeders or as line protection in networks with

grounded, low-resistance grounded, isolated or compensated star point structure. It is suited for networks that

are radial and supplied from a single source, open or closed looped networks and for lines with sources at both

ends.

The device includes the functions that are usually necessary for protection, monitoring of circuit breaker positions and control of circuit breakers; therefore, the device can be employed universally. The device provides

excellent backup facilities of differential protective schemes of any kind for lines, transformers, generators,

motors, and busbars of all electromotive series.

Protection Functions

The basic function is the motor protection with start-up time monitoring, restart inhibit and load step function.

Additionally, there is a non-directional overcurrent protection with three definite time elements each and one

inverse time Element for the phase currents and the ground current. For the inverse time Elements, several

characteristics of different standards are provided. Alternatively, a user-defined Curve can be used for the sensitive ground fault detection.

Introduction

1.2 Application Scope

Further protection functions included are the negative sequence protection, overload protection, circuit breaker

failure protection and ground fault protection.

Depending on the ordered variant, further protection functions are included, such as frequency protection, overvoltage and undervoltage protection, and ground fault protection for high-resistance ground faults (directional

or non-directional).

External detectors account for ambient temperatures or coolant temperatures (possibly also by means of an

external thermobox).

Control Functions

The device provides a control function which can be accomplished for activating and deactivating switchgear

via operator buttons, port B, binary inputs and - using a PC and the DIGSI software - via the front interface.

The status of the primary equipment can be transmitted to the device via auxiliary contacts connected to binary

inputs. The present status (or position) of the primary equipment can be displayed on the device, and used for

interlocking or alarm condition monitoring. The number of operating equipment to be switched is limited by the

binary inputs and outputs available in the device or the binary inputs and outputs allocated for the switch position indications. Depending on the primary equipment being controlled, one binary input (single point indication)

or two binary inputs (double point indication) may be used for this process.

The capability of switching primary equipment can be restricted by a setting associated with switching authority

(Remote or Local), and by the operating mode (interlocked/non-interlocked, with or without password request).

Processing of interlocking conditions for switching (e.g. switchgear interlocking) can be established with the aid

of integrated, user-configurable logic functions.

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

21

Introduction

1.2 Application Scope

Messages and Measured Values; Recording of Event and Fault Data

The operational indications provide information about conditions in the power system and the device. Measurement quantities and values that are calculated can be displayed locally and communicated via the serial interfaces.

Device messages can be assigned to a number of LEDs on the front cover (allocatable), can be externally processed via output contacts (allocatable), linked with user-definable logic functions and/or issued via serial interfaces.

During a fault (system fault) important events and changes in conditions are saved in fault protocols (Event Log

or Trip Log). Instantaneous fault values are also saved in the device and may be analized subsequently.

Communication

The following interfaces are available for communication with external operating, control and memory systems.

The USB DIGSI interface on the front cover serves for local communication with a PC. By means of the SIPRO-

®

TEC

4 operating software DIGSI

®

, all operational and evaluation tasks can be executed via this operator in-

terface, such as the specification and modification of configuration parameters and settings, configuration of

user-specific logic functions, read-out of operational and fault messages as well as measured values, read-out

and displaying of fault records, inquiry of device conditions and measured values, issuing of control commands.

Depending on the ordered variant, additional interfaces are located at the bottom of the device. They serve for

establishing extensive communication with other digital operating, control and memory components:

Port A serves for DIGSI communication directly on the device or via a network.

Furthermore, the connection of one or two thermoboxes for entering external temperatures can be provided via

port A (via Ethernet) or port B, e.g. via RS485.

Port B serves for central communication between the device and a control center. It can be operated via data

lines or fiber optic cables. For the data transfer, there are standard protocols in accordance with IEC 60870-5103 available. The integration of the devices into the SINAUT LSA and SICAM automation systems can also

be implemented with this profile.

Alternatively, there are further coupling options possible with PROFIBUS DP and the DNP3.0 and MODBUS

protocols. If an EN100 module is available, it is also possible to use the IEC61850 protocol.

22

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

1.3 Characteristics

General Characteristics

• Powerful 32-bit microprocessor system.

• Complete digital processing and control of measured values, from the sampling of the analog input quantities to the initiation of outputs, for example, tripping or closing circuit breakers or other switchgear devices.

• Total electrical separation between the internal processing stages of the device and the external transformer,

control, and DC supply circuits of the system because of the design of the binary inputs, outputs, and the

DC or AC converters.

• Complete set of functions necessary for the proper protection of lines, feeders, motors, and busbars.

• Easy device operation through an integrated operator panel or by means of a connected personal computer

running DIGSI.

• Continuous calculation and display of measured and metered values on the front of the device.

• Storage of min/max measured values (slave pointer function) and storage of long-term mean values.

• Recording of event and fault data for the last 8 system faults (fault in a network) with real-time information

as well as instantaneous values for fault recording for a maximum time range of 18 s.

Introduction

1.3 Characteristics

• Constant monitoring of the measured quantities, as well as continuous self-diagnostics covering the hardware and software.

• Communication with SCADA or substation controller equipment via serial interfaces through the choice of

data cable, modem, or optical fibers.

• Battery-buffered clock which can be synchronized via a synchronization signal at the binary input or via a

protocol.

• Switching statistics: Recording of the number of trip signals initiated by the device and logging of currents

switched off last by the device, as well as accumulated short circuit currents of each pole of the circuit breaker.

• Motor Statistics: Recording of the operational information and startup information such as the total number

of motor starts, motor operating hours, percentage of motor operating time, total megawatt hours, and the

startup information duration and currents for each motor startup.

• Operating Hours Counter: Tracking of operating hours of the equipment being protected.

• Commissioning aids such as connection and direction check, status indication of all binary inputs and outputs, easy testing of port B and influencing of information at port B during test operation.

Time Overcurrent Protection 50, 51, 50N, 51N

• Three definite time overcurrent protective Elements and one inverse time overcurrent protective element for

phase current and ground current I

• Allowence of a two-phase (IA, IC) time overcurrent protection;

or summation current 3I0;

N

• For inverse time overcurrent protection, selection from various characteristics of different standards possible.

• Blocking capability e.g. for reverse interlocking with any Element;

• Instantaneous tripping by any overcurrent Element upon switch onto fault is possible;

• In-rush restraint with second harmonic current quantities.

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

23

Introduction

1.3 Characteristics

Ground Fault Protection 50N, 51N

• Three definite time overcurrent protective Elements and one inverse time overcurrent protective element applicable for grounded or high-resistance grounded systems;

• For inverse time overcurrent protection, selection from various characteristics of different standards.

• In-rush restraint with second harmonic current quantities;

• Instantaneous tripping by any overcurrent Element during switch onto fault is possible;

Dynamic Cold Load Pick-up Function 50C, 50NC, 51C, 51NC, 67C, 67NC

• Dynamic changeover of time overcurrent protection settings, e.g. when cold load conditions are recognized;

• Detection of cold load condition via circuit breaker position or current threshold;

• Activation also possible via binary input.

Voltage Protection 27, 59

• Two-element undervoltage detection via system positive sequence voltages, phase-to-phase or phaseground voltages;

• Choice of current supervision for 27-1 and 27-2;

• Separate two-element overvoltage detection of the largest voltages applied or detection of the positive or

negative sequence component of the voltages.

• settable dropout ratio for all elements of the undervoltage and overvoltage protection.

Negative Sequence Protection 46

• Evaluation of negative sequence component of the currents;

• Two definite-time elements 46-1 and 46-2 and one inverse-time element 46-TOC; curves of common standards are available for 46-TOC.

Motor Starting Protection 48

• Inverse time tripping Curve based on an evaluation of the motor starting current;

• Definite time delay for blocked rotor.

Motor Restart Inhibit 66, 86

• Approximate replica of excessive rotor temperature;

• Startup is permitted only if the rotor has sufficient thermal reserves for a complete startup;

• Disabling of the start inhibit is possible if an emergency startup is required.

Load Step Function

24

• Detection of mechanical or thermal overload of the rotor.

E50417-G1140-C344-A4, Release date 08.2010

SIPROTEC, 7SK80, Manual

Frequency Protection 81 O/U

• Monitoring on underfrequency (f<) and/or overfrequency (f>) with 4 frequency limits and delay times that are

independently adjustable;

• Insensitive to harmonics and abrupt phase angle changes;

• Adjustable undervoltage threshold.

Thermal Overload Protection 49

• Thermal profile of energy losses (overload protection has total memory capability);

• True r.m.s. calculation;

• Adjustable thermal alarm level;

• Adjustable alarm level based on current magnitude;

• Additional time constant setting for motors to accommodate the motor at standstill;

• Integration of the ambient temperature or coolant temperature is possible via internal temperature detection

or an external thermobox.

Monitoring Functions

Introduction

1.3 Characteristics

• Reliability of the device is greatly increased because of self-monitoring of the internal measurement circuits

as well as the hardware and software.

• Fuse failure monitor with protection function blocking.

• Monitoring of the current transformer and voltage transformer secondary circuits using summation and symmetry monitoring with optional protection function blocking.

• Trip circuit monitoring;

• Phase rotation check.

Ground Fault Detection 50N(s), 51N(s), 67N(s), 59N/64

• Displacement voltage is measured or calculated from the three phase voltages;

• Determination of a faulty phase on ungrounded or grounded systems;

• Two-element Ground Fault Detection: High-set element 50Ns-2 and overcurrent element 50Ns-1.

• High sensitivity (as low as 1 mA);

• Overcurrent element with definite time or inverse time delay;

• For inverse time overcurrent protection, a user-defined characteristic is available.

• Direction determination with zero sequence quantities(I

tion;

• A sector characteristics can be set as directional characteristic.

, V0), wattmetric ground fault direction determina-

0

• Any Element can be set as directional or non-directional — forward sensing directional, or reverse sensing

directional;

• Optionally applicable as additional ground fault protection.

SIPROTEC, 7SK80, Manual

E50417-G1140-C344-A4, Release date 08.2010

25

Introduction

1.3 Characteristics

Breaker Failure Protection 50 BF

• Checking current flow and/or evaluation of the circuit breaker auxiliary contacts;

• Initiated by the tripping of any integrated protective element that trips the circuit breaker;

• Initiation possible via a binary input from an external protective device.

Flexible Protective Functions

• Up to 20 protection functions which can be set individually to operate in three-phase or single-phase mode;

• Any calculated or directly measured value can be evaluated on principle;