Siemens SIPROTEC 7SJ80, SIPROTEC 7SK80 Product Information

SIPROTEC

7SJ80 / 7SK80

V4.6

Product Information

E50417-K1150-C342-A6

Caution

Please observe Notes and Warnings for your own safety in Chapter 2.

Note

This Product Information contains important information about the

SIPROTEC 7SJ80 / 7SK80.

It is part of the product supplied, and the information in it should be

considered more up-to-date than any other information if uncertainties

arise.

Subject to change without prior notice.

Document Release V04.05.01

Edition 07.2010

Siemens Aktiengesellschaft Order No.: E50417-K1150-C342-A6

Table of Contents

1 General 4

2 Notes on Safety 5

3 Statement of Conformity 7

4 Unpacking and Re-packing 8

5 Storage and Transport 9

6 Dimensions 10

7 Installation Notes 13

8 Connection Notes 14

9 Limit Values of Inputs and Outputs 26

10 General Diagrams 29

11 Operating Pre-conditions 39

E50417-K1150-C342-A6, Edition 07.2010

3SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

1 General

Disclaimer of Liability

Although we have carefully checked the contents of this publication for

conformity with the hardware and software described, we cannot guarantee complete conformity since errors cannot be excluded.

The information provided in this Product Information is checked at regular

intervals and any corrections that might become necessary are included

in the next releases. Any suggestions for improvement are welcome.

Subject to change without prior notice.

Copyright

Copyright © Siemens AG 2010

The reproduction, transmission or use of this document or its contents is

not permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

Registered Trademarks

SIMATIC®, SIMATIC NET®, SIPROTEC®, DIGSI®, SIMEAS® , SICAM®

and SINAUT® are registered trademarks of SIEMENS AG. All other product and brand names in this manual might be trademarks, the use of

which by third persons for their purposes might infringe the rights of their

respective owners.

Note:

For further information see

SIPROTEC 7SJ80 V4.60, Manual E50417-G1140-C343,

SIPROTEC 7SK80 V4.60, Manual E50417-G1140-C344,

SIPROTEC System Description E50417-H1176-C151,

ReadMe-USB.pdf for DIGSI V4.82 (www.siprotec.com).

4 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

2 Notes on Safety

This manual does not constitute a complete catalog of all safety measures

required for operating the equipment (module, device) in question

because special operating conditions might require additional measures.

However, it does contain notes that must be adhered to for your own personal safety and to avoid damage to property. These notes are highlighted

with a warning triangle and different keywords indicating different degrees

of danger:

Danger

means that death, severe injury, or substantial damage to property will

occur if the appropriate safety measures are not taken.

Warning

means that death, severe injury, or substantial damage to property can

occur if the appropriate safety measures are not taken.

Caution

means that minor injury or damage to property can occur if the appropriate

safety measures are not taken.

Caution

means that damage to property can occur if the appropriate safety measures are not taken.

Note

is important information about the project, handling the product, or the part

of the documentation in question, to which special attention must be paid.

E50417-K1150-C342-A6, Edition 07.2010

5SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

Qualified Personnel

Commissioning and operation of the equipment (module, device) described in this manual must be performed by qualified personnel only. As

used in the safety notes contained in this manual, qualified personnel are

those persons who are authorized to commission, release, ground, and

tag devices, systems, and electrical circuits in accordance with safety

standards.

Use as Prescribed

The equipment (device, module) must not be used for any other purposes

than those described in the Catalog and the Technical Description. If it is

used together with third-party devices and components, these must be

recommended or approved by Siemens.

Correct and safe operation of the product requires adequate transportation, storage, installation, and mounting as well as appropriate use and

maintenance.

During operation of electrical equipment, it is unavoidable that certain

parts of this equipment will carry dangerous voltages. Severe injury or

damage to property can occur if the appropriate measures are not taken:

• Before making any connections at all, ground the equipment at the PE

terminal.

• Hazardous voltages can be present on all switching components con-

nected to the power supply.

• Even after the supply voltage has been disconnected, hazardous vol-

tages can still be present in the equipment (capacitor storage).

• The secondary circles of the current transformer in the system must not

be operated while open.

• The limit values indicated in the manual or the operating instructions

must not be exceeded; that also applies to testing and commissioning.

6 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

3 Statement of Conformity

This product complies with the directive of the Council of the European

Communities on the approximation of the laws of the Member States

relating to electromagnetic compatibility (EMC Council Directive 2004/

108/EC) and concerning electrical equipment for use within specified

voltage limits (Low-voltage Directive 2006/95/EC).

This conformity has been established by means of tests conducted by

Siemens AG in accordance of the Council Directive in agreement with

the generic standards EN 61000-6-2 and EN 61000-6-4 for the EMC

directives, and with the standard EN 60255-27 for the low-voltage directive.

The device has been designed and produced for industrial use.

The product is conforming to the international standards of the series

IEC 60255 and the German regulation of VDE 0435.

Further

IEEE Std C37.90

This product is UL-certfied with the values as stated in the Technical Data.

file E194016

NOTE concerning battery disposal

The batteries must only be replaced with the same type or a another type

recommended by the manufacturer. Improper replacement involves

explosion hazard. For disposing the batteries it is necessary to observe

the local national / international directives.

E50417-K1150-C342-A6, Edition 07.2010

7SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

UL-certification conditions

Servicing of the circuitry involving the batteries and replacement of the

lithium batteries shall be done by a trained technician.

Replace Battery with VARTA or Panasonic Cat. Nos. CR 1/2 AA or BR 1/

2 AA only. Use of another Battery may present a risk of fire or explosion.

See manual for safety instructions.

Caution: The battery used in this device may present a fire or chemical

burn hazard if mistreated. Do not recharge, disassemble, heat above

100 °C (212 °F) or incinerate.

Dispose of used battery promptly. Keep away from children.

4 Unpacking and Re-packing

When dispatched from the factory, the equipment is packed in accordance with the guidelines laid down in IEC 60255–21 which specify the

impact resistance of packaging.

This packing shall be removed with care, without force and without the use

of inappropriate tools. The equipment should be visually checked to

ensure that there are no external traces of damage.

Please observe absolutely all notes and hints which may be enclosed in

the packaging.

Before initial energization with supply voltage, or after storage, the relay

shall be situated in the operating area for at least two hours in order to

ensure temperature equalization and to avoid humidity influences and

condensation.

8 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

5 Storage and Transport

SIPROTEC® relays should be stored in dry and clean rooms. The limit

temperature range for storage of the relays or associated spare parts is

−25 °C to +55 °C, corresponding to −13 °F to 131 °F.

The relative humidity must be within limits such that neither condensation

nor ice forms.

It is recommended to reduce the storage temperature to the range

+10 °C to +35 °C (50 °F to 95 °F); this prevents early ageing of the

electrolytic capacitors which are contained in the power supply.

For very long storage periods, it is recommended to connect the relay to

the auxiliary voltage source for one or two days every other year, in order

to regenerate the electrolytic capacitors. The same is valid before the

relay is finally installed.

For further transport, the transport packing can be re-used when applied

in the same way. The storage packing of the individual relays is not suited

for transport. If alternative packing is used, this must also provide the

same degree of protection against mechanical shock and vibration as laid

down in IEC 60255–21–1 class 1 and IEC 60255–21–2 class 1.

The Lithium-batteries in our equipment are subject to Special Provision

188 of the UN Recommendations on the Transport of Dangerous Goods

Model Regulations and Special Provision A45 of the IATA Dangerous

Goods Regulation and the ICAO Technical Instructions. This is only valid

for the original battery or original spare batteries.

E50417-K1150-C342-A6, Edition 07.2010

9SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

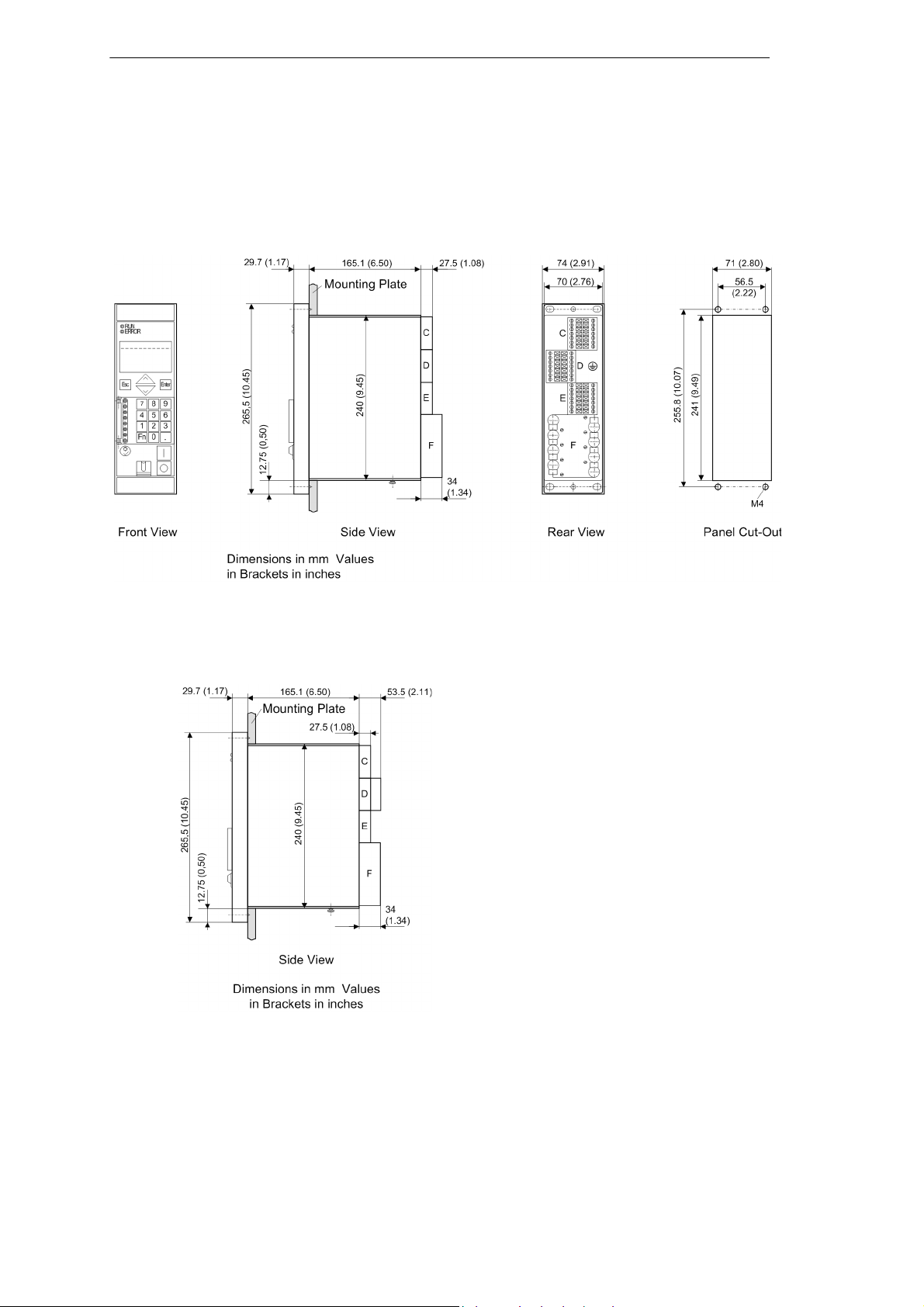

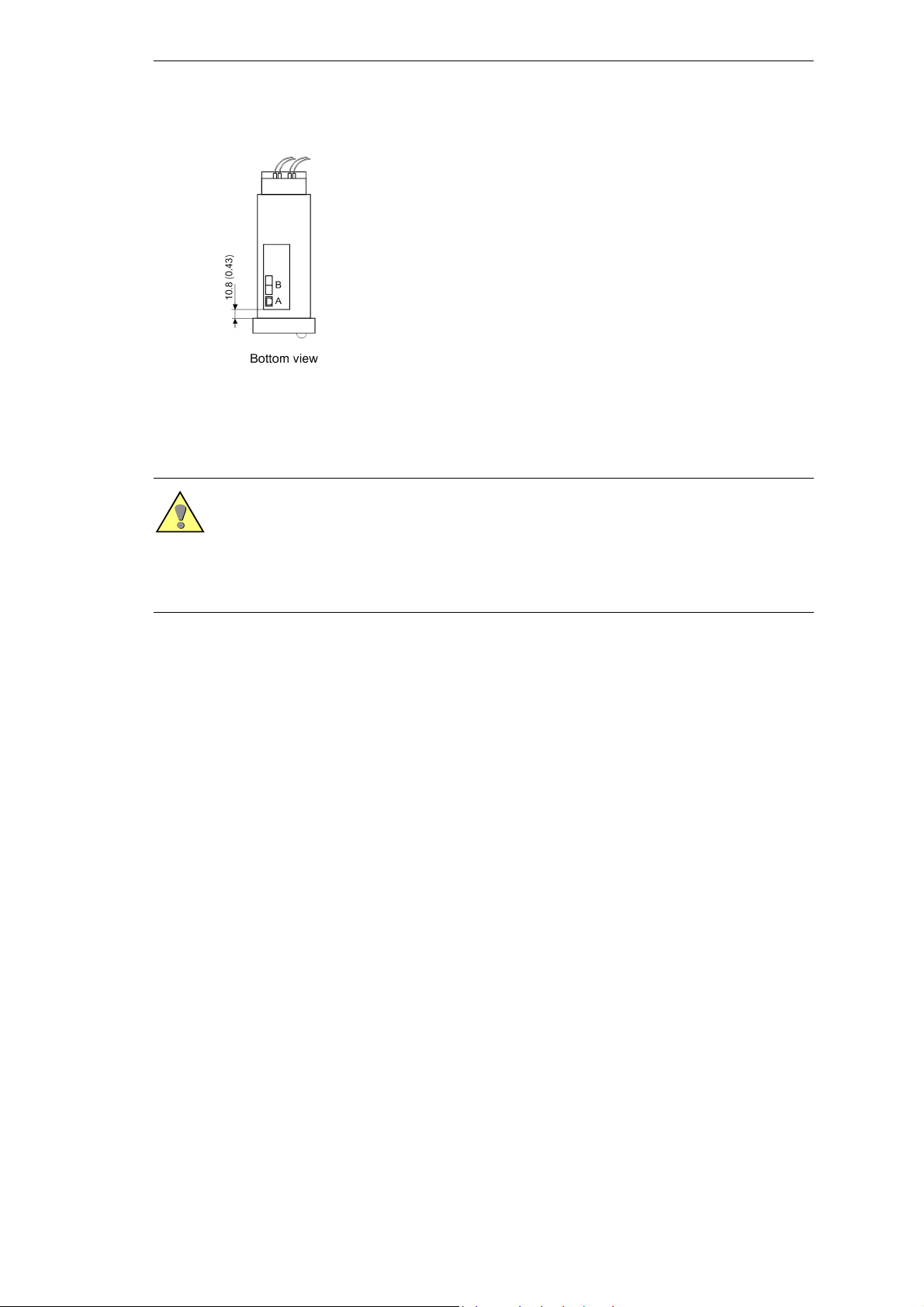

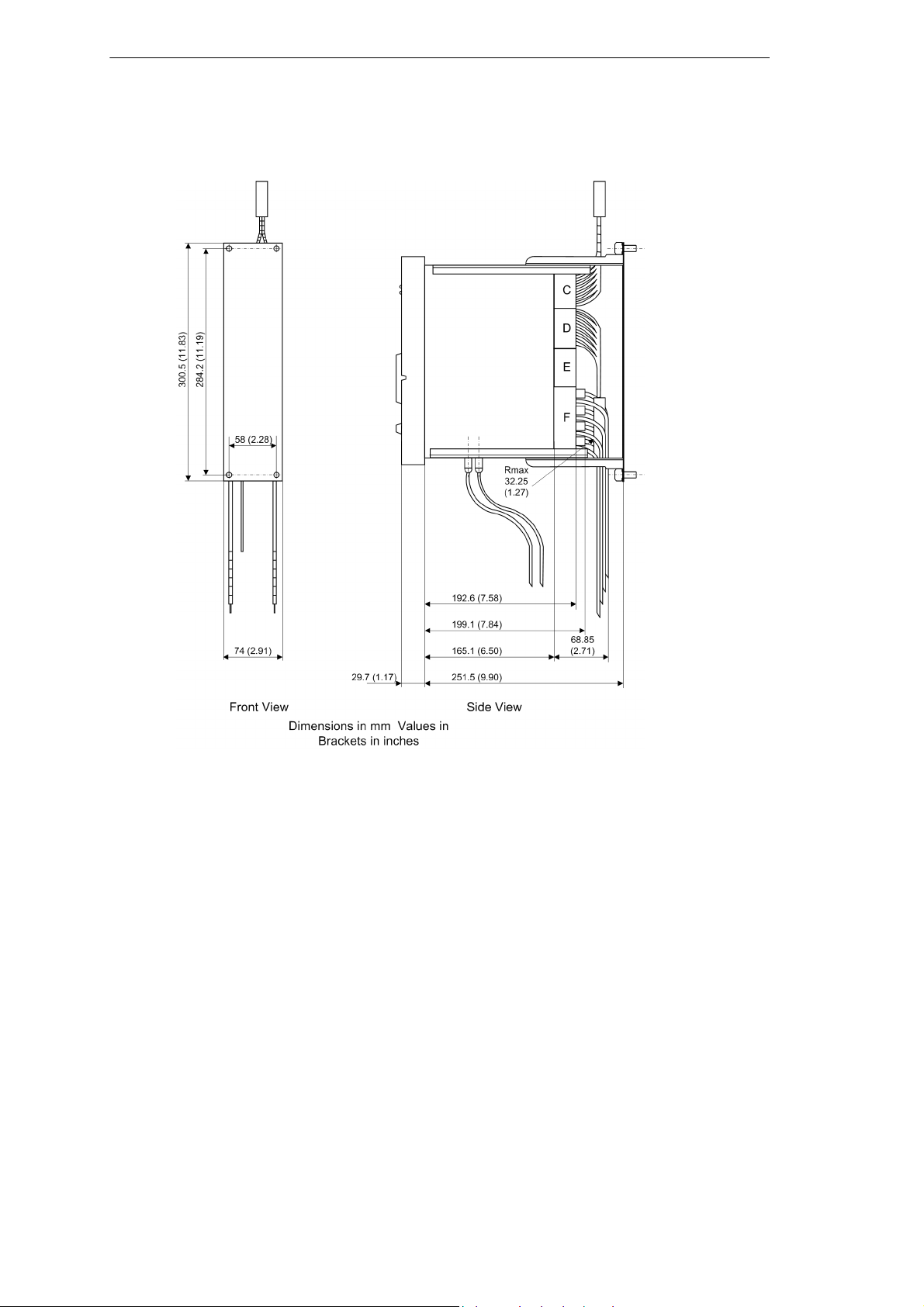

6 Dimensions

Figure 1 Dimensional drawing of a 7Sx80 for panel flush or cubicle

mounting (housing size 1/6)

Figure 2 Dimensional drawing of a 7SK80 (Terminalblock "D" with cap)

10 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

Figure 3 Bottom view of a 7Sx80 (housing size 1/6)

Caution

An angle strip set (contains upper and lower mounting brackets) (OrderNo. C73165-A63-D200-1) is necessary to install the device in a rack.

Using the Ethernet interface it might be necessary to rework the lower

mounting bracket.

E50417-K1150-C342-A6, Edition 07.2010

11SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

Figure 4 Dimensional drawing of a 7Sx80 for panel flush mounting

(housing size 1/6)

12 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

7 Installation Notes

Housing for installation in panels, racks, or cubicles

Remove the 2 covers at the top and bottom of the front cover. Thus, 4

elongated holes are revealed in the mounting bracket and can be

accessed.

Insert the device into the panel cut-out and fasten it with four screws.

Mount the 2 covers again.

Connect a solid low-ohmic protective and operational ground to the

grounding terminal of the device. The cross-section of the cable used

must correspond to the maximum connected cross-section but must be at

least 2.5 mm2.

Caution

The printed circuit boards of digital equipment contain CMOS circuits.

These shall not be withdrawn or inserted under live conditions! The modules must be so handled that any possibility of damage due to static electrical charges is excluded. During any necessary handling of individual

modules or printed circuit boards the recommendations relating to the

handling of electro-statically endangered components (EEC) must be

observed. In installed conditions, the modules are in no danger.

UL-certification conditions

Field Wires of Control Circuits shall be separated from other circuits with

respect to the end use requirements!

E50417-K1150-C342-A6, Edition 07.2010

13SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

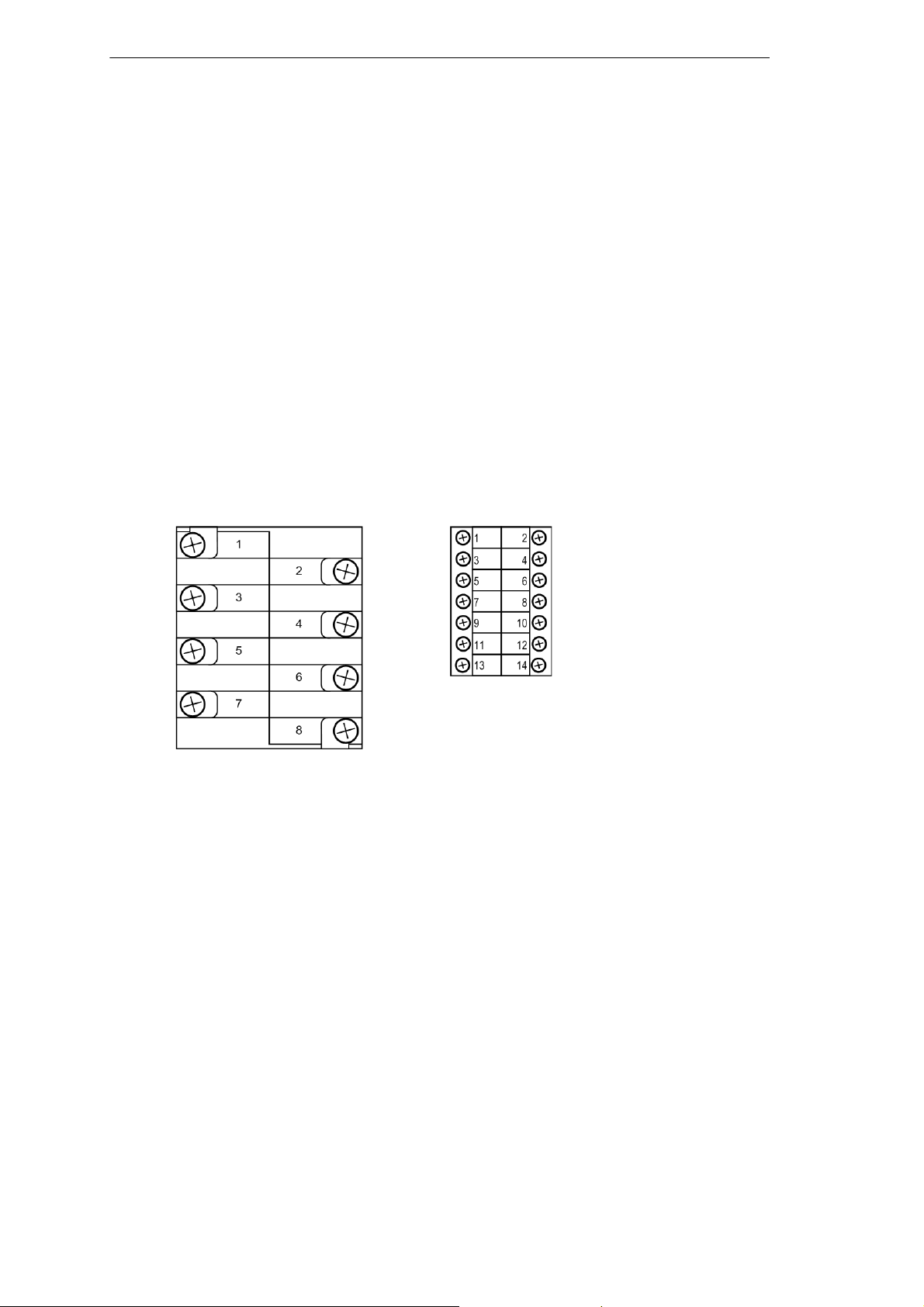

8 Connection Notes

The device provides screw terminals for field wiring. Additionally, serial

interfaces may be present which are to be connected by wires or by optical fiber.

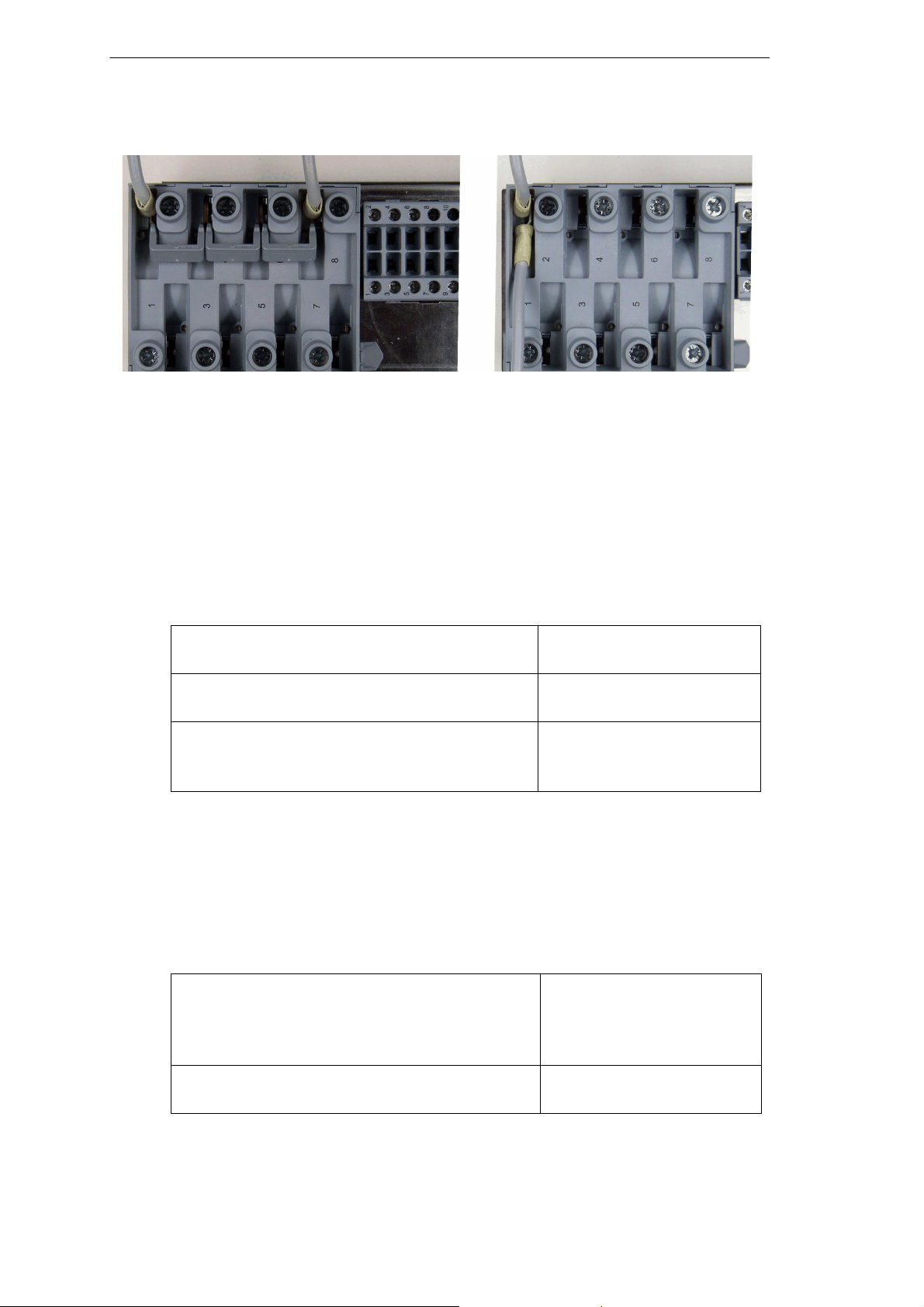

Screw-type terminals on connection modules

The following connectors may exist:

Connection modules for currents, 8-pole,

Connection modules for voltages, 14-pole,

Figure 5 Current and voltage terminal

14 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

Connections of the Current Terminals

Fixing Elements

The fixing elements for the transformer connection are part of the current

terminal (housing side). The head shape of the terminal screw allows for

using a flat screwdriver (5.5 mm x 1.0 mm / 0.21 in x 0.039 in) or a crosstip

screwdriver (PZ2). PZ2 is recommended.

Cable lugs and Wire Cross-sections

There are two connection options: the connection of single wires and the

connection with a ring lug. Only copper wires may be used.

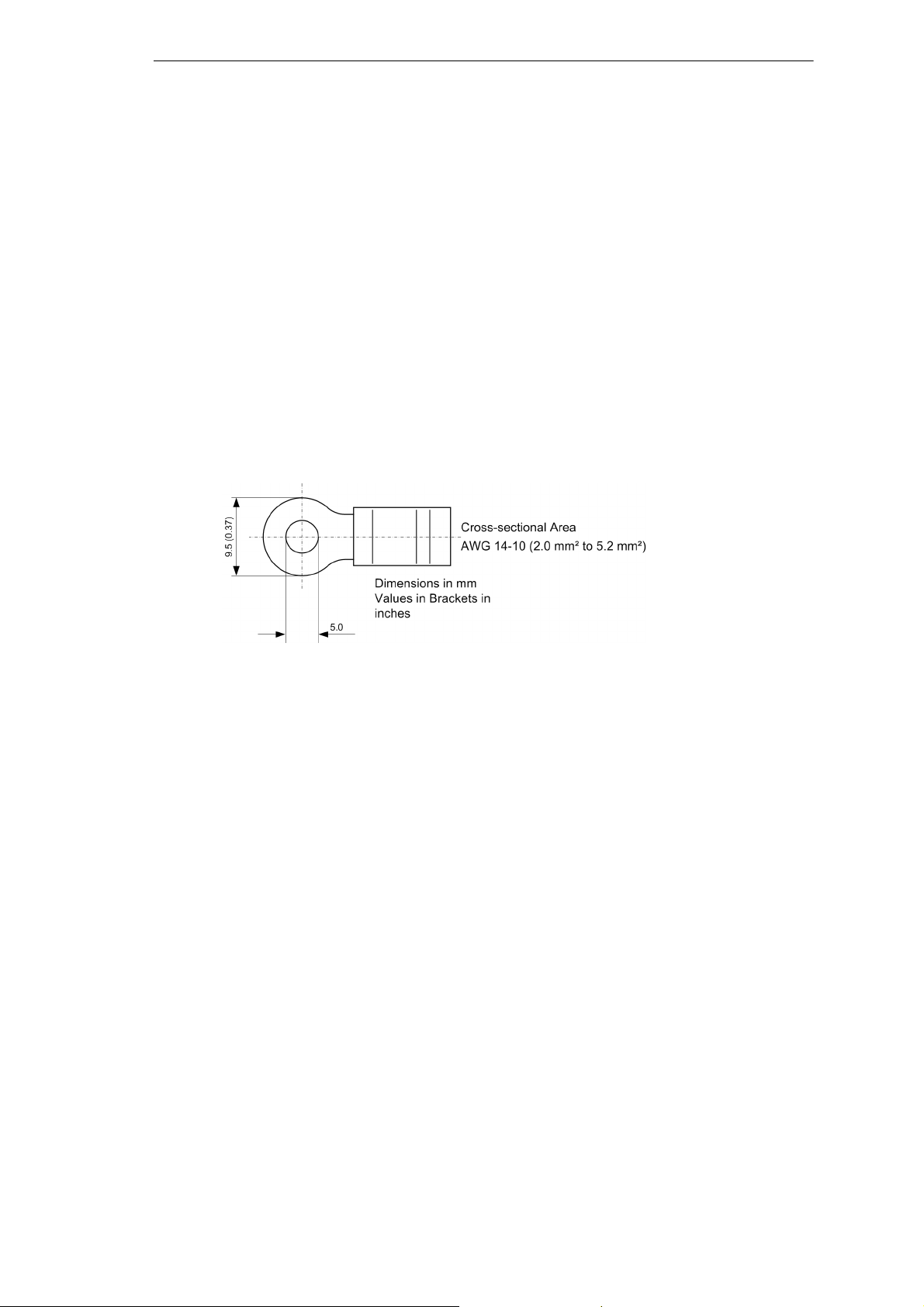

We recommend ring lugs with the following dimensions:

Figure 6 Ring lug

For complying with the required insulation clearances, insulated ring lugs

have to be used. Otherwise, the crimp zone has to be insulated with corresponding means (e.g. by pulling a shrink-on sleeve over).

We recommend ring lugs of the PIDG range from Tyco Electronics.

Two ring lugs can be mounted per connection.

E50417-K1150-C342-A6, Edition 07.2010

15SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

Figure 7 Current transformer connection

As single wires, solid conductors as well as stranded conductors with conductor sleeves can be used. Up to two single wires with identical crosssections can be used per connection.

Alternatively, short circuit links (Order no. C53207-A406-D193-1) can be

used for vertically arranged terminal points. If short circuit links are used,

only ring lugs are permitted.

When connecting single wires, the following cross-sections are allowed::

Wire cross-section: AWG 14-10

Conductor sleeve with plastic sleeve L = 10 mm (0.39 in) or

Stripping length:

(when used without conductor sleeve)

Mechanical Requirements

The fixing elements and the connected components are designed for the

following mechanical requirements:

(2.0 mm2 to 5.2 mm2)

L = 12 mm (0.47 in)

15 mm (0.59 in)

Only solid copper wires

may be used.

Permissible tightening torque at the terminal

screw

2.7 Nm (23.9 lb.in.)

With solid conductors the

allowed maximum tightening torque is 2 Nm.

Permissible traction per connected conductor

16 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

80 N based on IEC 609471 (VDE 660, Part 100)

E50417-K1150-C342-A6, Edition 07.2010

Connections of the Voltage Terminals

Fixing Elements

The fixing elements for the voltage transformer connection are part of the

voltage terminal (housing side). They have a stress-crack- and corrosionresistant alloy. The head shape of the terminal screw allows for using a

flat screwdriver (4.0 mm x 0.8 mm / 0.16 in x 0.031 in) or a crosstip screwdriver (PZ1). PZ1 is recommended.

Cable lugs and Wire Cross-sections

The connection mode available is the connection as single wire. As single

wires, solid conductors as well as stranded conductors with or without

conductor sleeves can be used. For the connection of two single wires we

recommend to use twin connector sleeves. We recommend twin connector sleeves of the PN 966 144 range from Tyco Electronics.

When connecting single wires, the following cross-sections are allowed:

Wire cross-sections: AWG 20-14

Conductor sleeve with plastic sleeve L = 10 mm (0.39 in) or

(0.5 mm2 to 2.0 mm2)

L = 12 mm (0.47 in)

Stripping length:

(when used without conductor sleeve)

With vertically arranged terminal points, single conductors and short circuit links (order no. C53207-A406-D194-1) can be connected together.

Make sure that the short circuit links are connected in alternate sides.

Mechanical Requirements

The fixing elements and the connected components are designed for the

following mechanical requirements:

Permissible tightening torque at the terminal

screw

Permissible traction per connected conductor

12 mm (0.47 in)

Only copper wires may be

used.

1.0 Nm (8.85 lb.in.)

50 N based on IEC 609471 (VDE 660, Part 100)

E50417-K1150-C342-A6, Edition 07.2010

17SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

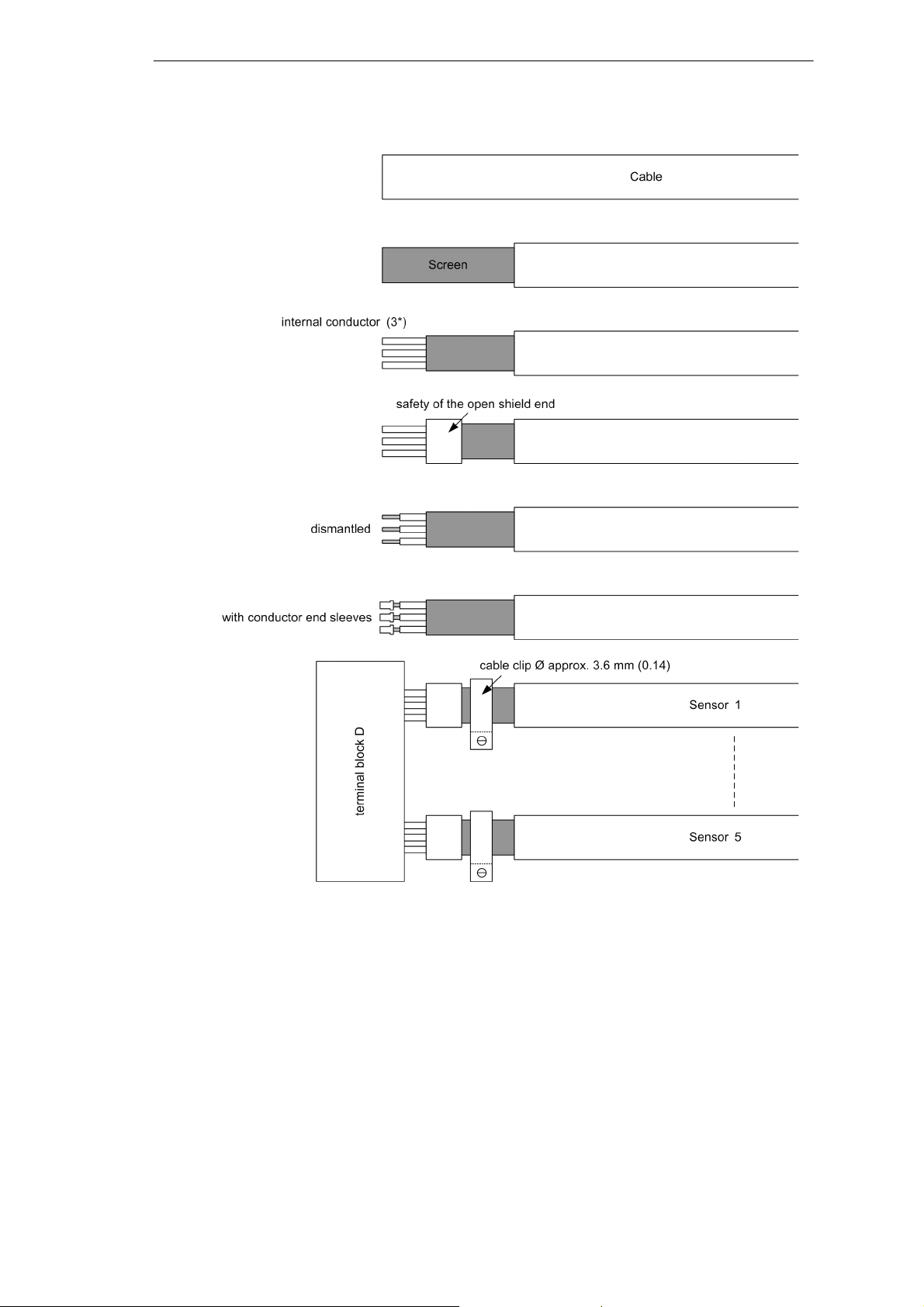

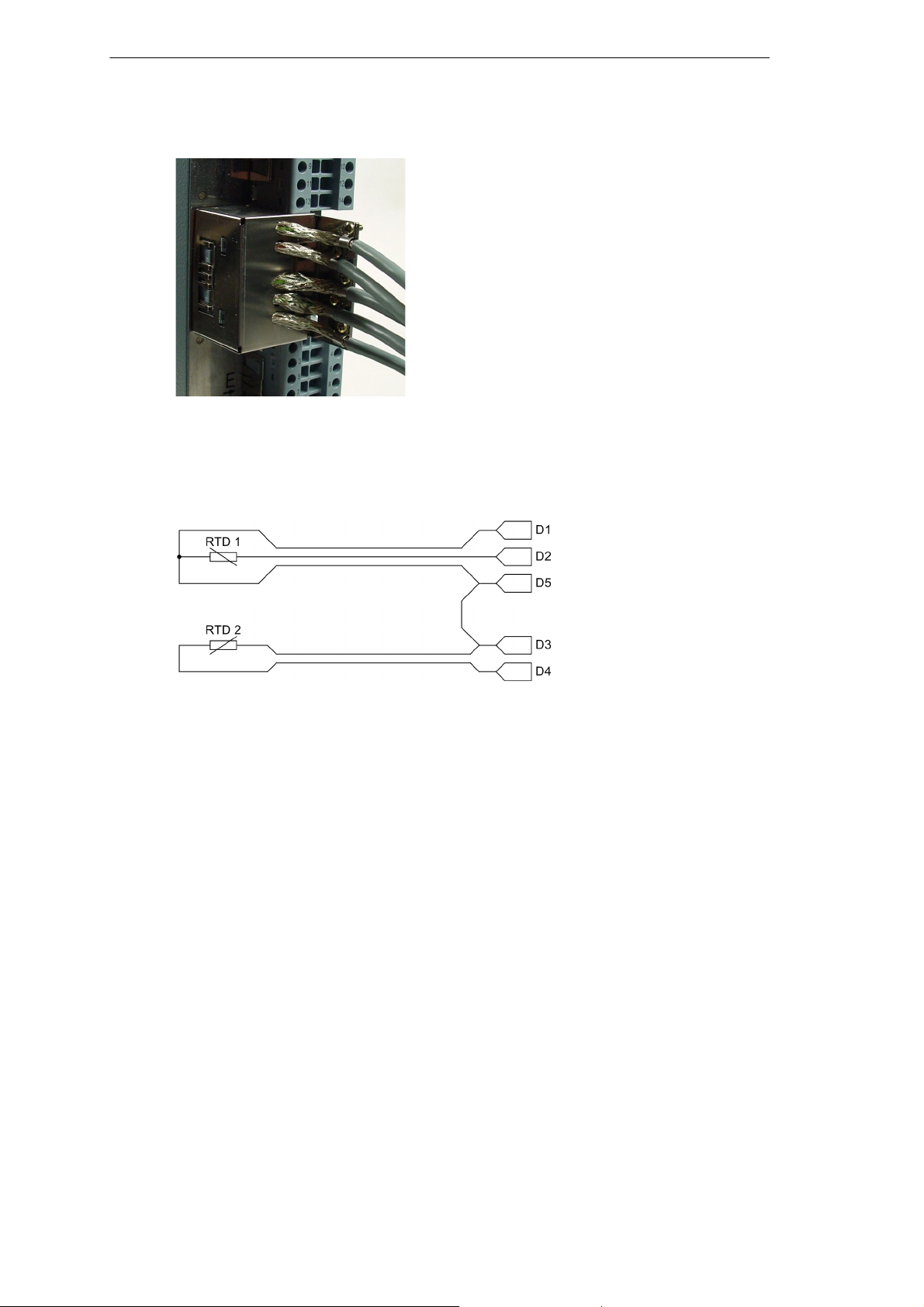

Connection of the temperature sensors

Remove the external insulation from the shielded cable over a length of

approx. 7 cm (2.8 in).

Cut the cable shielding to approx. 4 cm in length and protect the open end

by means of a shrink tube, insulating tape or a similar material. Make sure

that the approx. 1 cm (0.39 in) of the shielding remains open for the

grounding.

Remove the internal insulation of the signaling leads over a length of

approx. 1 cm (0.39 in).

Crimp appropriate conductor sleeves onto the ends of the inner conductors.

Guide the cables through the openings of the shield cap and then connect

the inner conductors as shown in the wiring diagram.

Plug the cap onto the voltage terminals.

Clamp the free part of the cable shielding underneath the cable clamp

next to the connector on the shield cap.

Next, plug the complete clamp into the retaining clips on the rear panel.

18 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

Figure 8 Connection of the cables

E50417-K1150-C342-A6, Edition 07.2010

19SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

Figure 9 Terminal block “D” with cap

Figure 10 Example: connection of temperature sensor RTD 1 (3-wire

connection) and RTD 2 (2-wire connection) to clip D1 to D5

When using 2-wire connections, short circuit links must be used e.g. for

RTD 2 between D3 and D5.

20 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

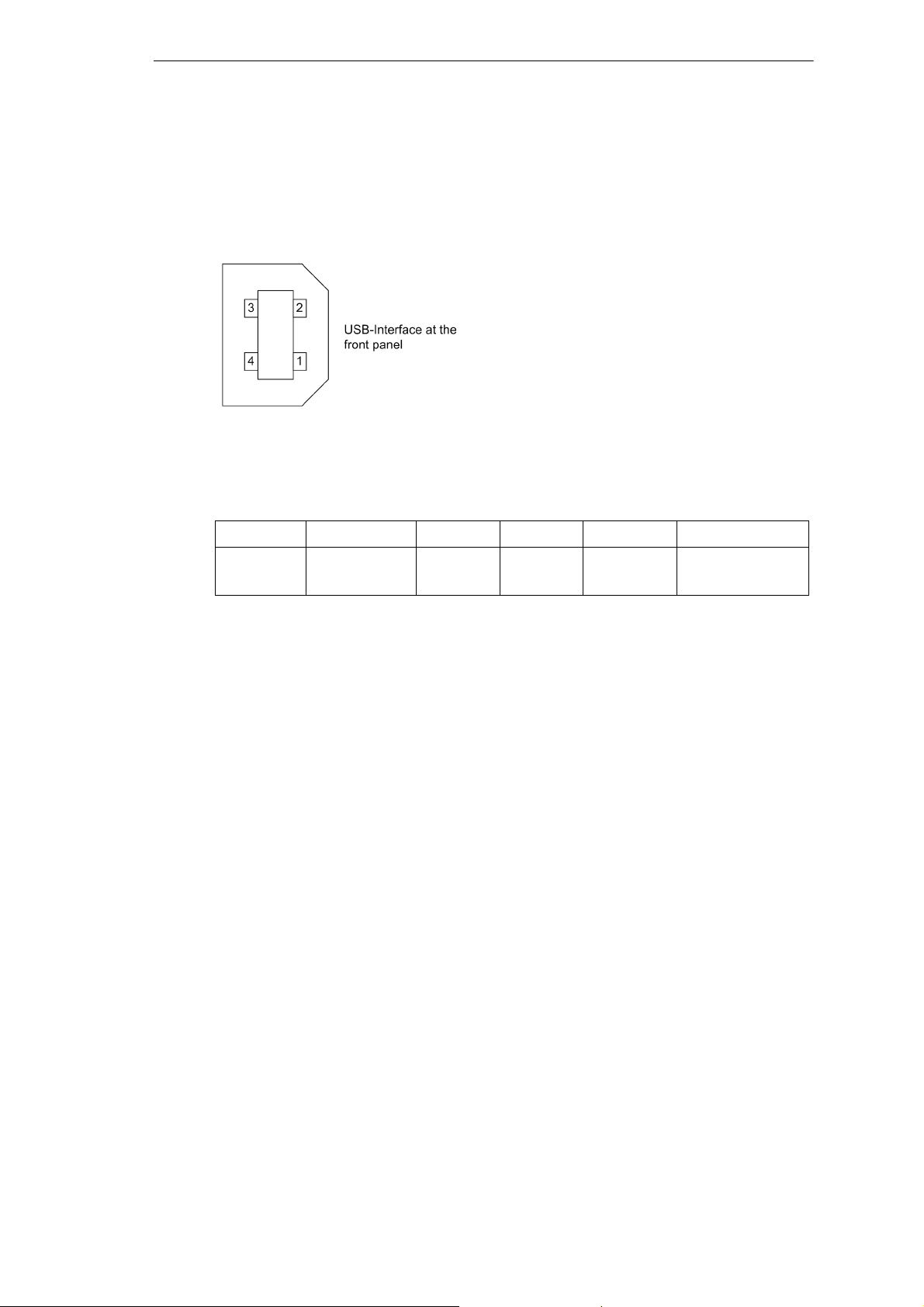

Front USB-interface

USB-interface for the connection between the protection device and the

PC.

Figure 11 USB-interface

Assignment of the USB socket

Pin-No. 1 2 3 4 Housing

USB VBUS

(unused)

D- D+ GND Shield

E50417-K1150-C342-A6, Edition 07.2010

21SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

D-Subminiature Sockets (only at optional port B)

9-pin D-subminiature sockets are provided for all electrical communication interfaces Standard 9-pin D-subminiature plug connectors per MIL–

C–24308 and DIN 41652 can be used.

The necessary communication cables are dependent on the interface:

RS232: Three-wire or five-wire, twisted and shielded, e.g. interface

cable 7XV5100–4.

RS 485: Three-wire, twisted and shielded.

Profibus: Two-wire or four-wire, twisted and shielded:

Wire type A according EN 50170/vol. 2 and DIN 19245/part 2,

Wire Resistance: 135 Ω to 165 Ω (f > 100 kHz),

Capacitance: < 48 nF/mile or < 30 nF/km,

Circuit Resistance: < 177 Ω/mile or < 110 Ω/km,

Conductor Diameter: > 0.64 mm,

Conductor Cross-sectional Area: > 0.34 mm2,

e.g. SINEC L2 Industrial Twisted Pair installation wire,

(see catalogue IK 10 “SIMATIC NET, Industrial Communication Networks”).

Figure 12 Nine-pin D-subminiature Connector

22 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

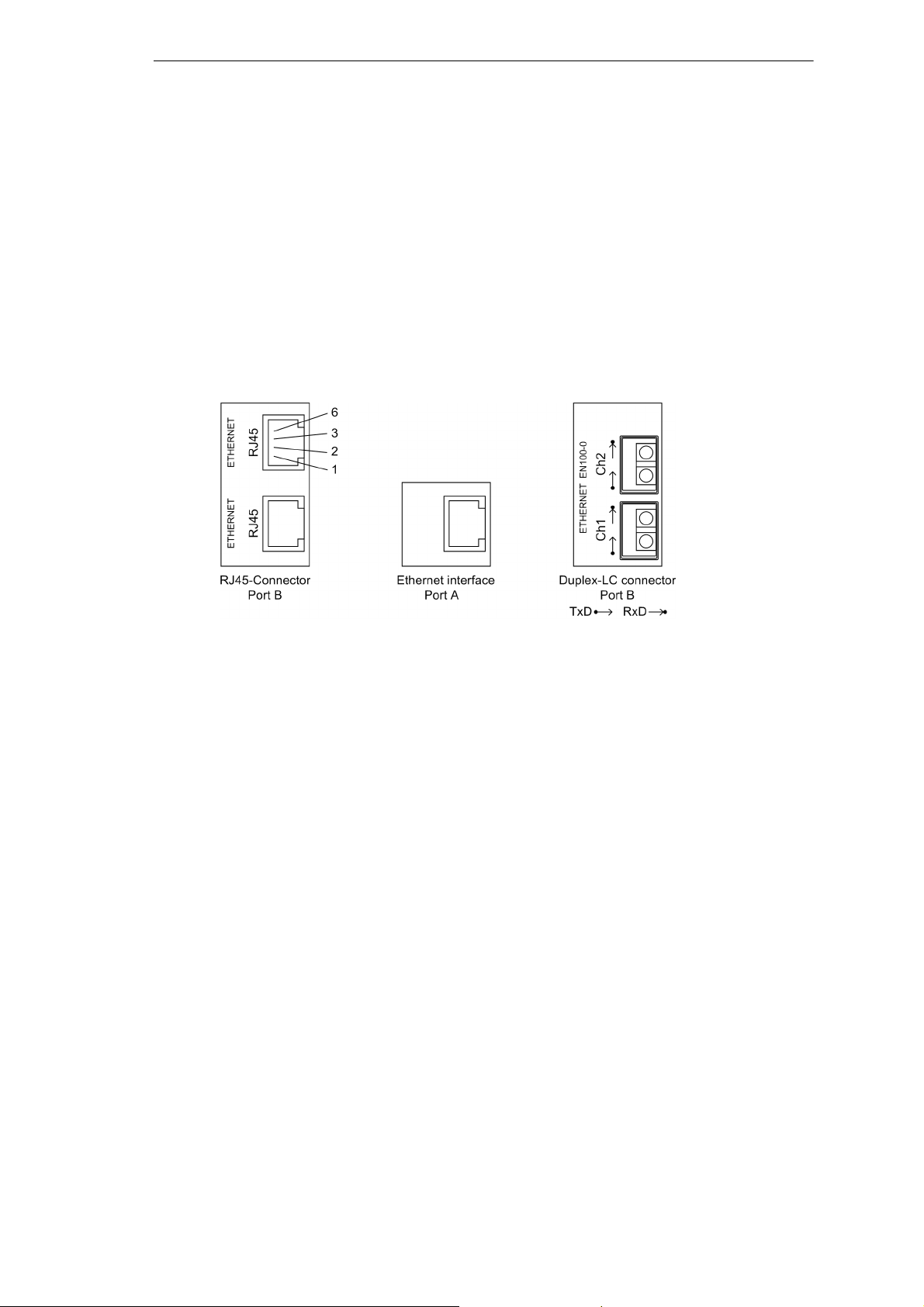

Connections to Ethernet

Two different connection modes per IEEE 802.3 are available:

100Base-T (10/100 TX)

Electrical: RJ45 socket connector

100Base-FL

Optical:Duplex-LC with optical connectors

Select only one of these facilities, you cannot use both at the same time.

The Ethernet interface on port A is only available in the version RJ45.

Figure 13 Ethernet connection – examples

For 100Base-T

Connector Type: RJ45 plug connector as per IEEE 802.3

Cables: CAT 5 (shielded twisted-pair)

For 100Base-FL

Fibre-optic plug type: Duplex-LC

Applicable fibre-type: multimode

G50 µm/125 µm

G62.5µm/125µm

Wave length: λ = approx. 1300 nm

Permissible bending radius: for indoor cables r

for outdoor cables r

= 5 cm (2.0 in)

min

= 20 cm (8.0 in)

min

E50417-K1150-C342-A6, Edition 07.2010

23SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

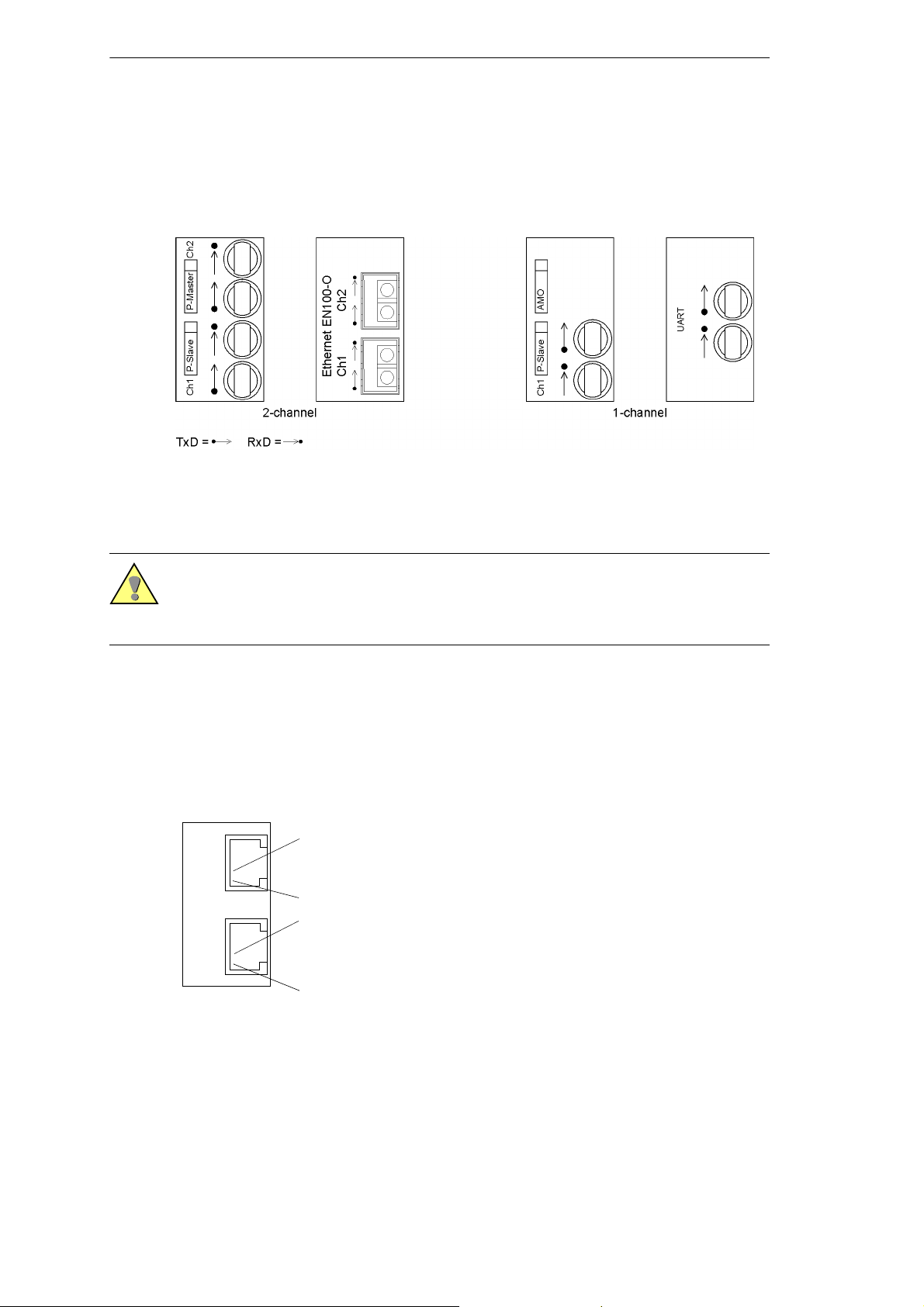

Optical Fiber

The optical fiber communication interfaces are provided with caps to

protect the optical components against dust or other contaminants.

Figure 14 Optical Communication Interfaces

Warning!

Laser Radiation! Class 1

Do not look into the fiber–optic elements! .

Connections to IEC 60870-5-103 redundant

8-pin RJ45 socket connectors are provided for electrical communication

interface T103 redundant..

2

1

2

Ch1 Ch2

T103 - redundant

RJ45 socket

1

Figure 15 Interface T103 redundant

24 SIPROTEC 7SJ80 / 7SK80 V4.60, Product Information

E50417-K1150-C342-A6, Edition 07.2010

Loading...

Loading...