Siemens SIPROTEC 7SJ62, SIPROTEC 7SA6, SIPROTEC 7SJ61, SIPROTEC 7SJ63, SIPROTEC 7SJ64 User Manual

...

SIPROTEC

Preface

Table of contents

PROFIBUS Communication modules 1

Parameters and properties 2

Protection devices

7SA522, 7SA6

7SD5, 7SD610

7SJ61...7SJ64

7ST622, 7ST61, 7ST63

7UM61, 7UM62

7UT612, 7UT613, 7UT63

7VE61, 7VE63

7VK61

Input/Output unit

6MD63

Data type definitions 3

PROFIBUS-DP - Parameterization in DIGSI 4

Technical data 5

Index

Bay control unit

6MD663/6MD664

Communication module

PROFIBUS-DP

Communication profile

Revision 4.2

Edition: April 2005

C53000-L1840-B001-03

Liability statement

We have checked the contents of this manual against the

hardware and software described. Exclusions and deviations cannot be ruled out; we accept no liability for lack of

total agreement.

The information in this manual is checked periodically,

and necessary corrections will be included in future

editions.

We appreciate any suggested improvements.

We reserve the right to make technical improvements

without notice.

Siemens Aktiengesellschaft

C53000-L1840-B001-03

Copyright

Copyright © Siemens AG 2005. All rights reserved.

Dissemination or reproduction of this document, or evaluation and communication of its contents, is not authorized except where expressly permitted.

Violations are liable for damages. All rights reserved, particularly for the

purposes of patent application or trademark registration.

Registered trademarks

SIPROTEC

are registered trademarks of Siemens AG.

Other designations in this manual may be trademarks that if used by third

parties for their own purposes may violate the rights of the owner.

®

, SIMATIC®, SIMATIC NET ®, SINAUT ®, SICAM® and DIGSI®

Preface

Purpose of this

manual

SIPROTEC4

System Manual

Bus mapping

documentation

The manual describes the functions, bus specific parameters, DIGSI parameterization

and the hardware interface of the PROFIBUS-DP slave of the SIPROTEC devices and

is divided into the following topics:

• PROFIBUS Communication modules → Chapter 1;

• Parameters and properties → Chapter 2;

• Data type definitions → Chapter 3;

• PROFIBUS-DP - Parameterization in DIGSI → Chapter 4;

• Technical data → Chapter 5.

General details about the function, operation, assembly and commissioning of the

SIPROTEC devices you find in the

• SIPROTEC4 System Manual, order no. E50417–H1176–C151.

The following additional manuals inform you about the data in the PROFIBUS-DP

messages of the SIPROTEC devices:

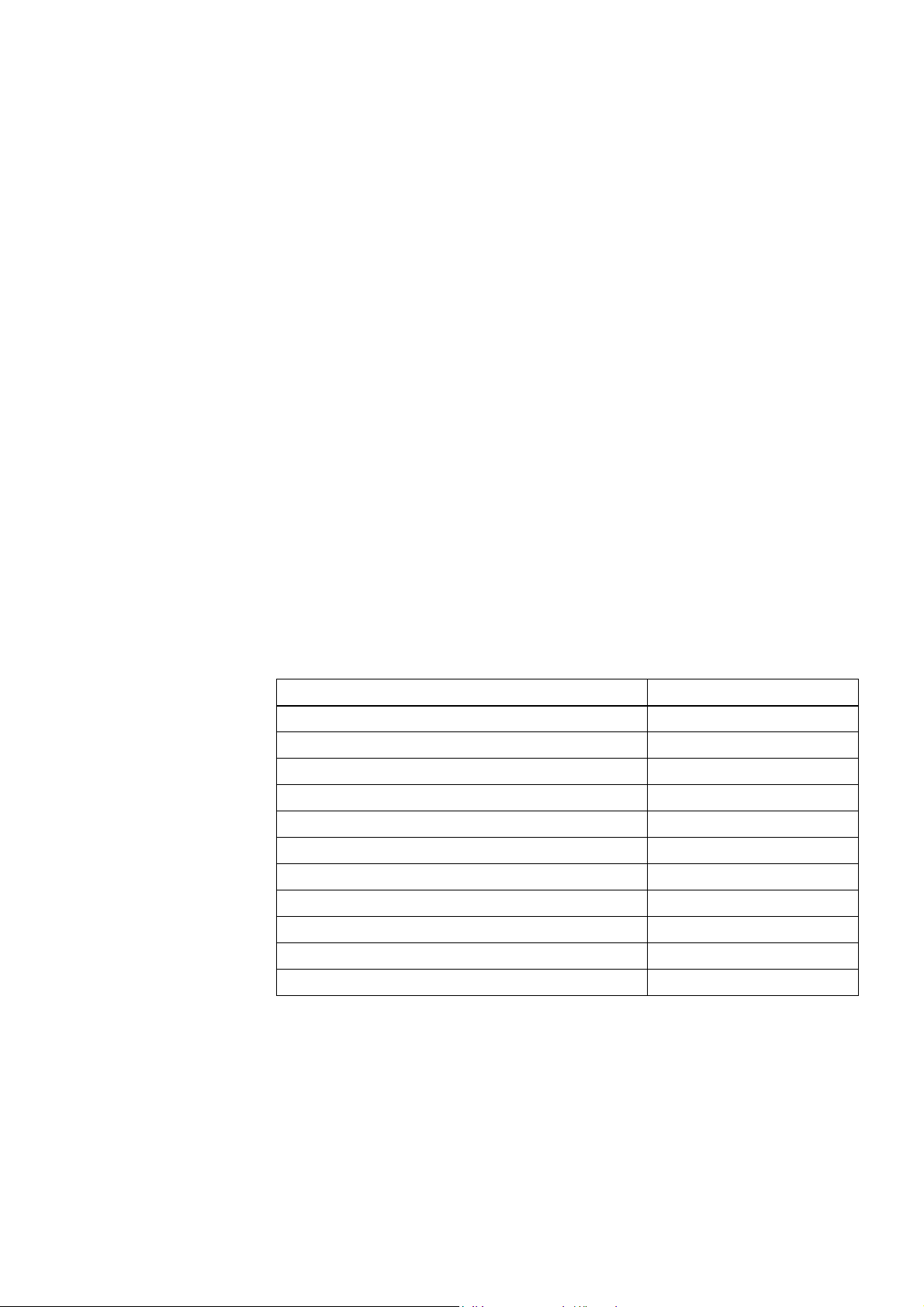

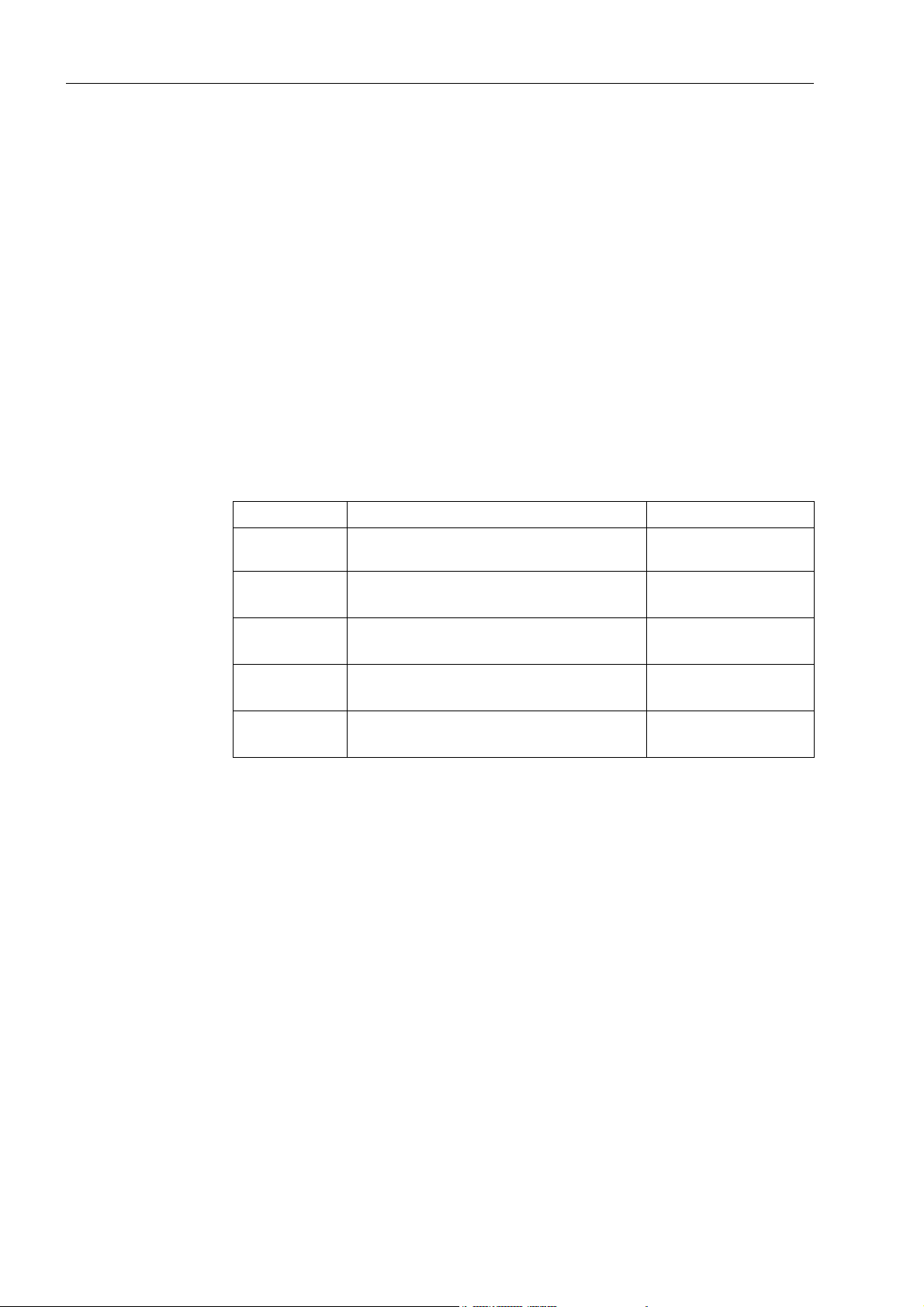

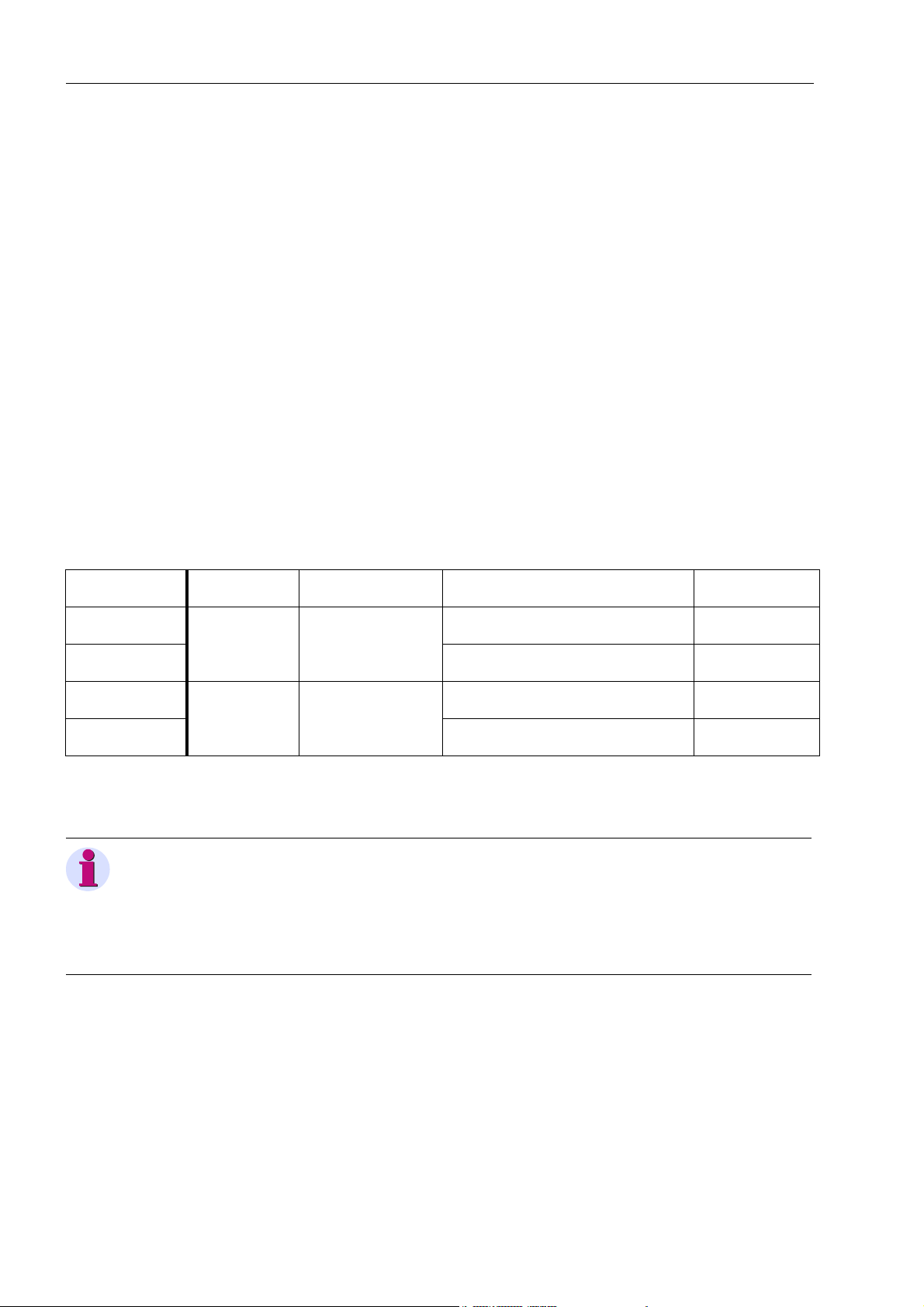

Manual Order number

PROFIBUS-DP - Bus mapping 7UM61 C53000-L1840-B005-03

PROFIBUS-DP - Bus mapping 7SJ61...7SJ64, 6MD63 C53000-L1840-B006-03

PROFIBUS-DP - Bus mapping 7SA522, 7SA6 C53000-L1840-B007-03

PROFIBUS-DP - Bus mapping 7UM62 C53000-L1840-B009-03

PROFIBUS-DP - Bus mapping 7UT612 C53000-L1840-B010-03

PROFIBUS-DP - Bus mapping 6MD663/6MD664 C53000-L1840-B011-03

PROFIBUS-DP - Bus mapping 7VK61 C53000-L1840-B013-03

PROFIBUS-DP - Bus mapping 7SD5, 7SD610 C53000-L1840-B014-03

PROFIBUS-DP - Bus mapping 7UT613, 7UT63 C53000-L1840-B015-03

PROFIBUS-DP - Bus mapping 7ST61, 7ST63 C53000-L1840-B016-03

PROFIBUS-DP - Bus mapping 7VE61, 7VE63 C53000-L1840-B017-03

You can download these manuals

from Internet http://www.siprotec.com

or please contact your Siemens representative.

C53000-L1840-B001-03

3SIPROTEC PROFIBUS-DP - Communication profile

Preview

PROFIBUS-DP

specification

The PROFIBUS-DP specification and the structure of the PROFIBUS-DP messages

are defined in the European Standard EN 50170:

PROFIBUS Specification

Normative Parts of PROFIBUS-FMS, -DP, -PA

According to the European Standard

EN 50170, Volume 2

PROFIBUS Nutzerorganisation e.V.

Validity This manual is valid for the SIPROTEC devices:

• 6MD63 (firmware version 4.40 or higher),

• 6MD663/6MD664 (firmware version 4.20 or higher),

• 7SA522, 7SA6 (firmware version 4.20 or higher),

• 7SD5, 7SD610 (firmware version 4.20 or higher),

• 7SJ61...7SJ64 (firmware version 4.40 or higher),

• 7ST61, 7ST63 (firmware version 4.00 or higher),

• 7ST622 (firmware version 4.00 or higher),

• 7UM61 (firmware version 4.10 or higher),

• 7UM62 (firmware version 4.00 or higher),

• 7UT612 (firmware version 4.00 or higher),

• 7UT613, 7UT63 (firmware version 4.00 or higher),

• 7VE61, 7VE63 (firmware version 4.00 or higher),

• 7VK61 (firmware version 4.00 or higher),

with PROFIBUS communication module up to HW revision 3 and

• PROFIBUS-DP firmware version 02.00.05,

• PROFIBUS-DP firmware version 03.00.03 or higher at use of

• Transformer tap change commands/Transformer tap position indications

(ref. to chap 3.7 and 3.8),

• Event list via PROFIBUS-DP (Sequence of events, ref. to chap. 2.5),

• PROFIBUS-DP firmware version 03.01.03 or higher at use of

• Time synchronization via PROFIBUS-DP with time intervals between time

synchronization messages of less than 1 minute (ref. to chap. 4.4),

• PROFIBUS-DP firmware version 03.04.01 or higher at use of

• PROFIBUS time synchronization messages with local time correction value

(ref. to chap. 4.4.2),

4

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

with PROFIBUS communication module from HW revision 4 and

• PROFIBUS-DP firmware version 04.00.06 or higher at use of

• Display of module specific information (ref. to chap. 1.2),

• OLM V3 mode of the PROFIBUS-DP module (ref. to chap. 2.1.2),

• PROFIBUS-DP firmware version 04.01.01 or higher at use of

• PROFIBUS time synchronization messages with local time correction value

(ref. to chap. 4.4.2).

For device parameterization have to be used:

• DIGSI 4.21 considering the preconditions explained in chapter 4.1.3,

• DIGSI 4.30 or higher,

• DIGSI 4.40 or higher at use of

• Transformer tap change commands/Transformer tap position indications

(ref. to chap 3.7 and 3.8),

• PROFIBUS-DP standard mappings 3-1 to 3-n

(n = device type dependent number of standard mappings).

Preview

Additional Support For questions regarding SIPROTEC4 devices, please contact your Siemens repre-

sentative.

Training courses Individual course offerings may be found in our Training Catalog and questions can be

directed to our Training Centre. Please contact your Siemens representative.

Target audience Protection engineers, commissioning engineers, personnel concerned with adjust-

ment, checking and service of selective protective equipment, automatic and control

facilities and personnel of electrical facilities and power plants.

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

5

Preview

Warning!

Hazardous voltages are present in this electrical equipment during operation.

Non-observance of the safety rules can result in severe personal injury or property

damage.

Only qualified personnel shall work on and around this equipment after becoming

thoroughly familiar with all warnings and safety notices of this and the associated

manuals as well as with the applicable safety regulations.

The successful and safe operation of this device is dependent on proper transport and

storage, proper handling, installation, operation, and maintenance by qualified personnel under observance of all warnings and hints contained in this and the associated manuals.

In particular the general erection and safety regulations (e.g. IEC, EN, DIN, VDE, or

other national and international standards) regarding the correct use of high-voltage

installations must observed. Non-observance can result in death, personal injury or

substantial property damage.

Typographic and

graphical conventions

QUALIFIED PERSONNEL

For the purpose of this manual and product labels, a qualified person is one who is

familiar with the installation, construction and operation of the equipment and the

hazards involved. In addition, he has the following qualifications:

• Is trained and authorized to energize, de-energize, clear, ground and tag circuits

and equipment in accordance with established safety practices.

• Is trained in the proper care and use of protective equipment in accordance with

established safety practices.

• Is trained in rendering first aid.

The following text formats are used to identify concepts giving device information described by the text flow:

Parameter names, or identifiers for configuration or function parameters that appear

in the device display or on the screen of a PC (with DIGSI) are shown in mono-script

(same point size) bold text. This also applies to header bars for selection menus.

Parameter conditions, or possible settings of parameters that appear in the device display or on the screen of a PC (with DIGSI), are additionally shown in italic style.

This also applies to selection items for selection menus.

„Annunciations“, or identifiers for information produced by the device or required

by other devices or from the switchgear is shown in mono-script (same point size) and

placed into quotation marks.

For diagrams in which the identifier type results from the representation itself, text conventions may differ from the above-mentioned.

6

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

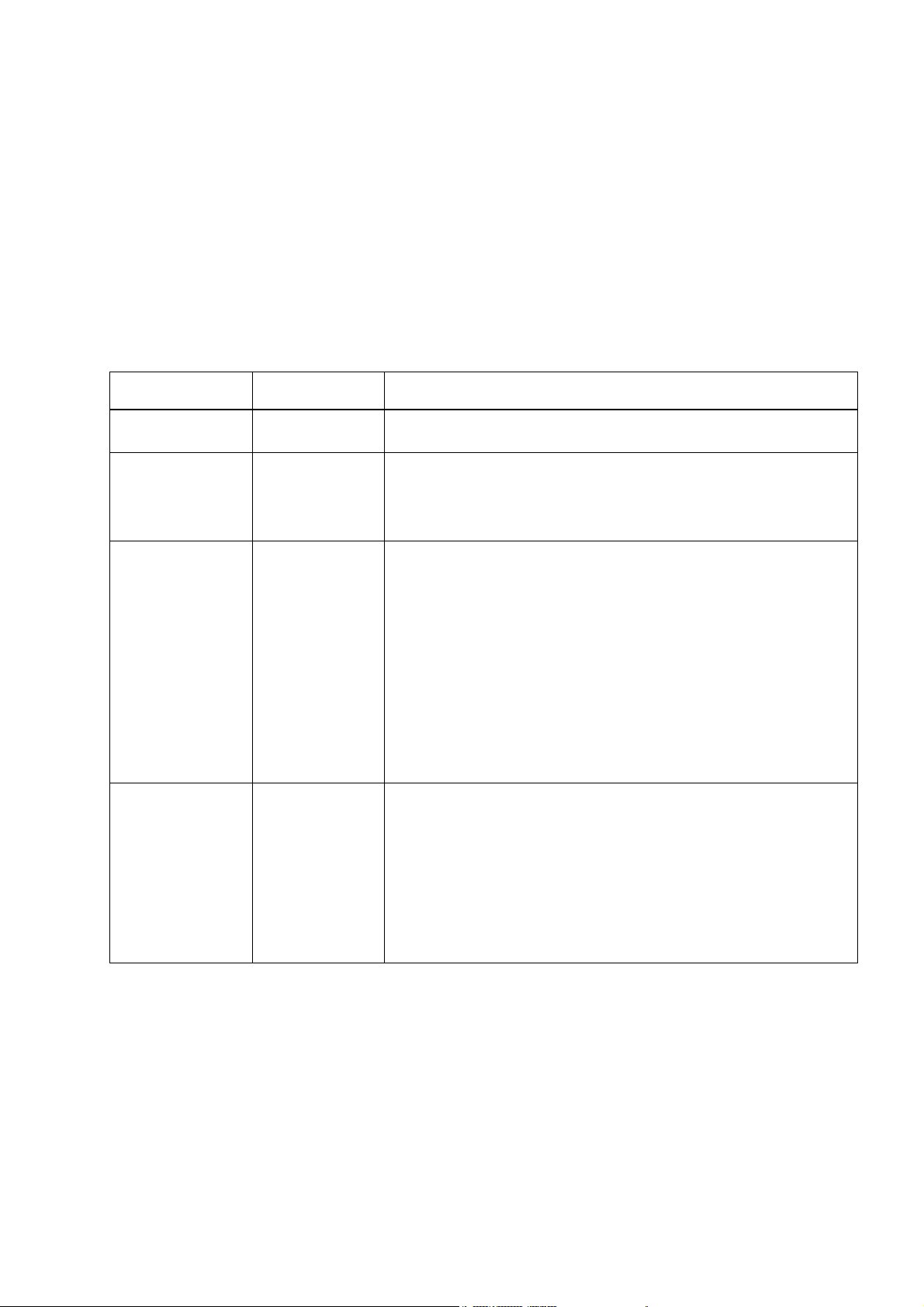

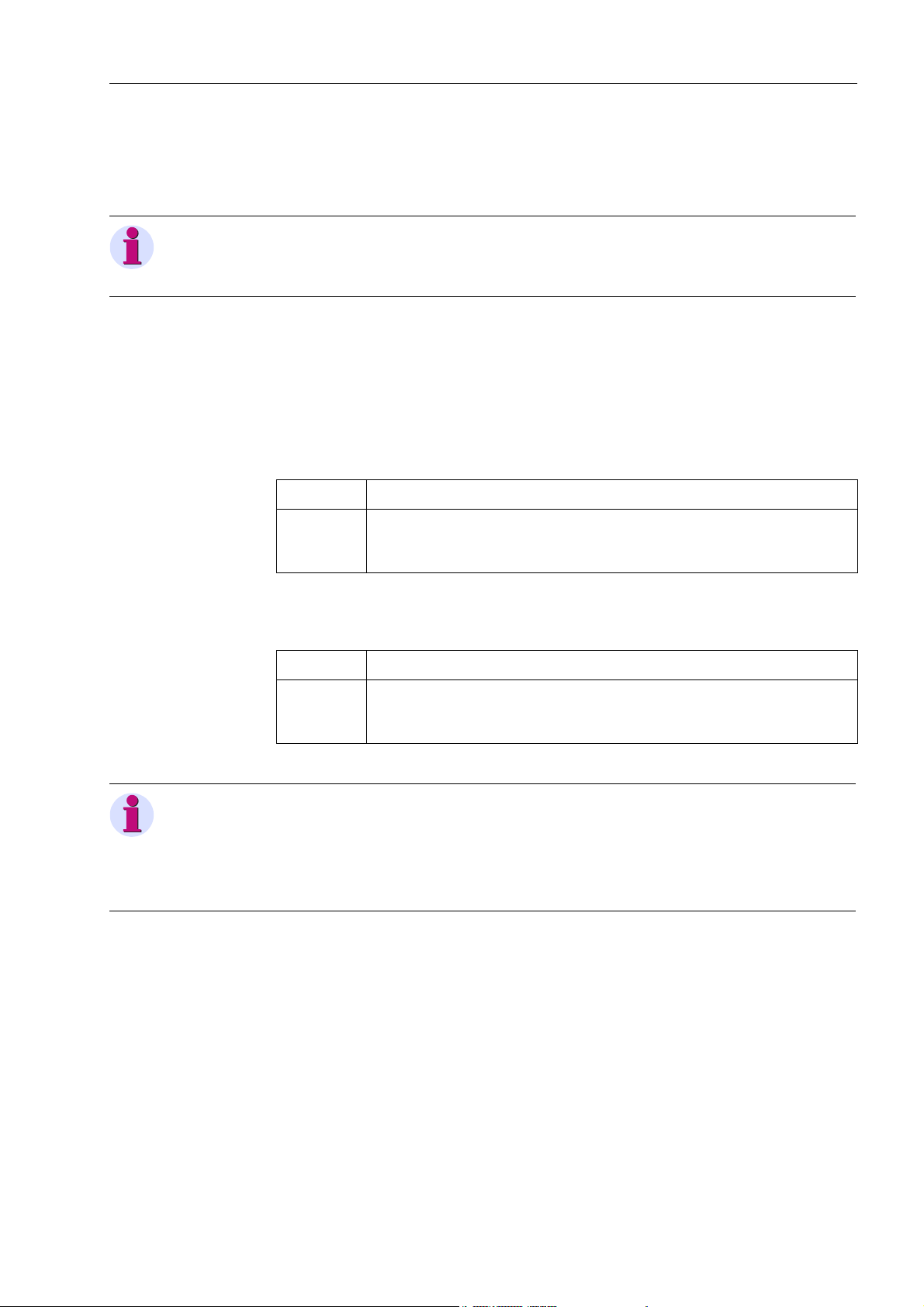

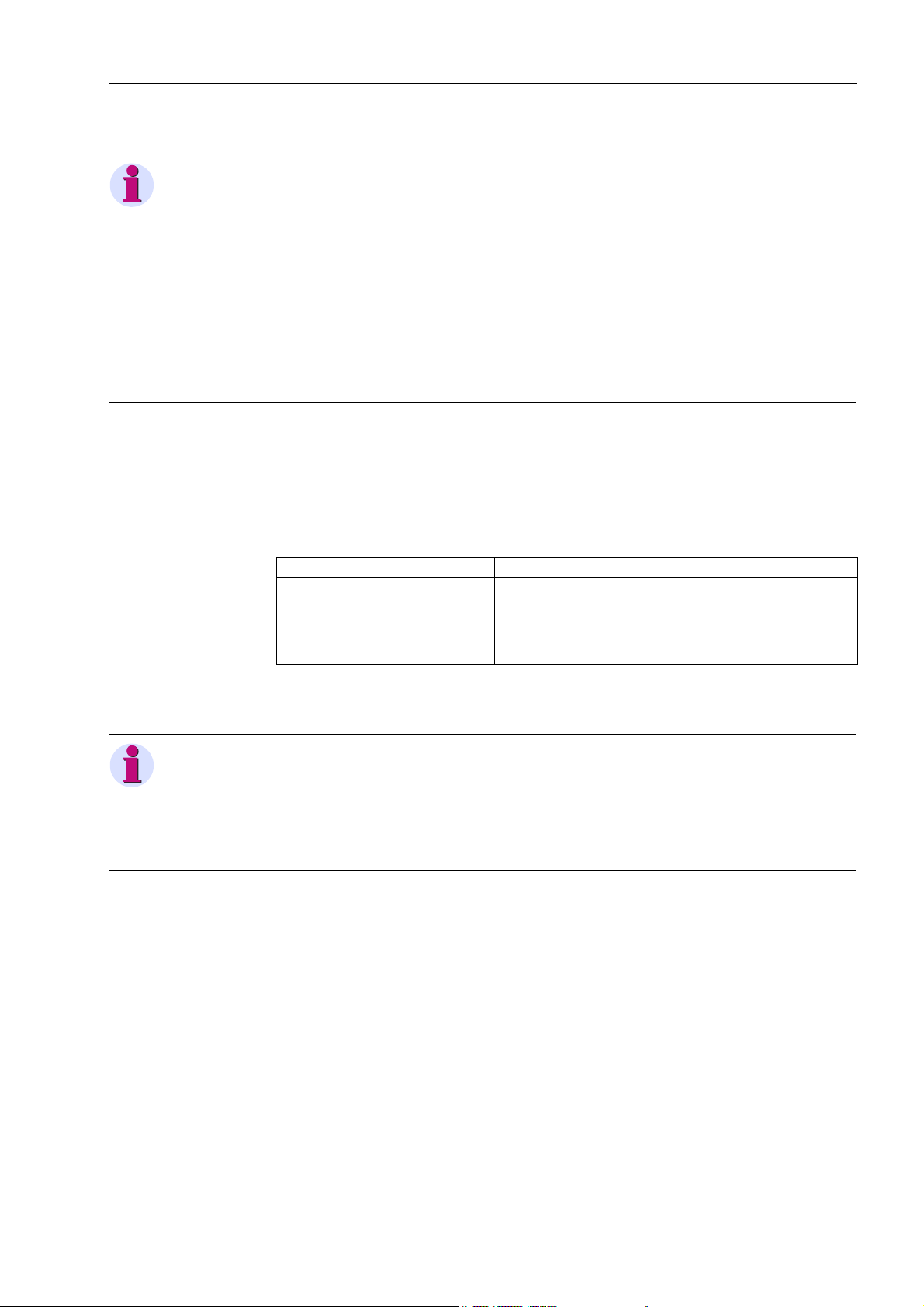

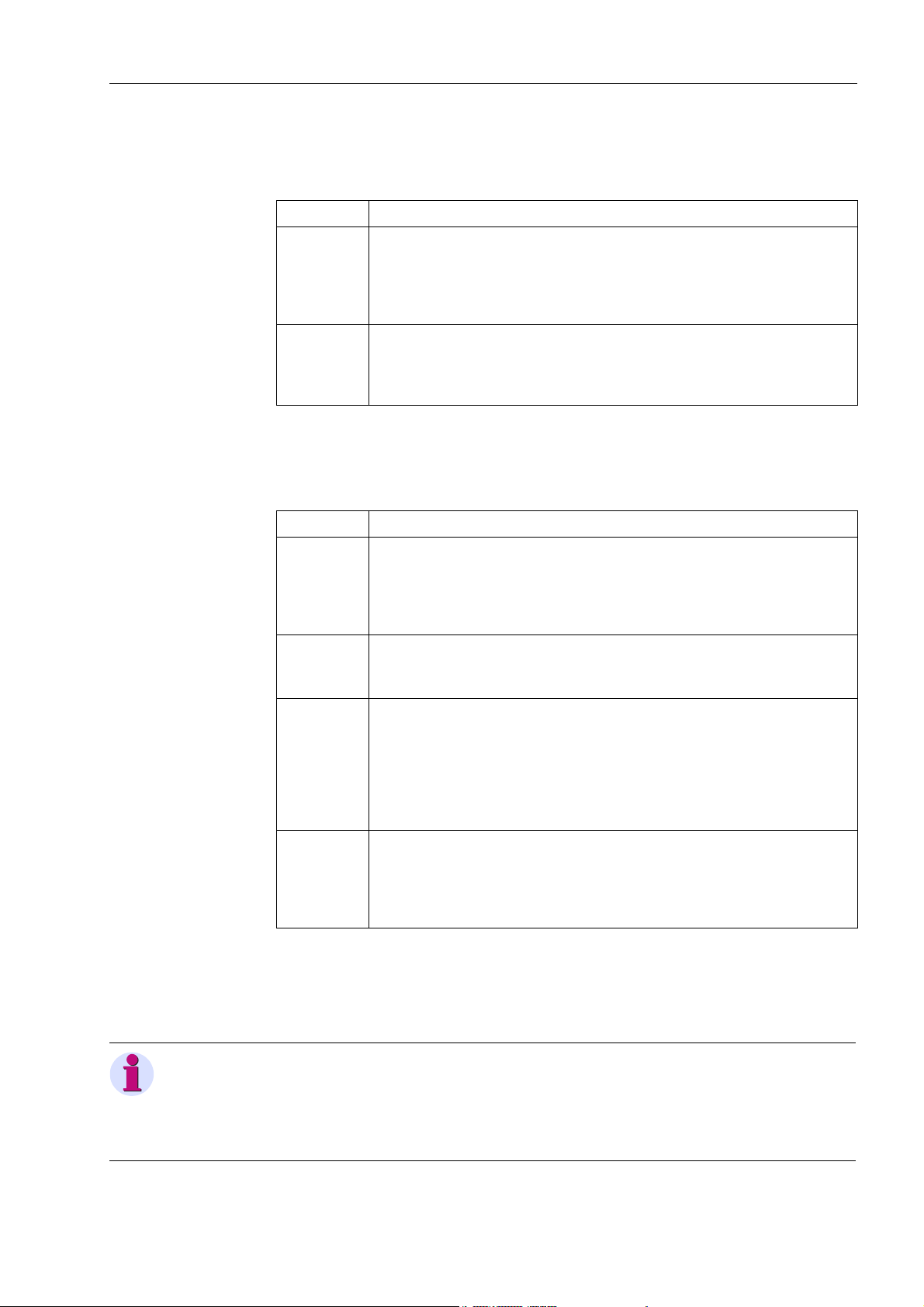

Revision index

Listing of the changes between the editions of this manual:

Modified chapters /

pages

general

Chap. 3.1.4

Chap. 3.3.3

Chap. 2.7 - 2.9

Chap 1.1.3

Chap. 1.3.1

Chap. 1.2.2

Chap. 1.5

Chap. 3.2

Chap. 4.2

general

Chap. 3.4.1

general

Chap. 1.1.2

Chap. 3.4.1

Chap. 4.2

Edition Reasons of modification

1.0 First edition, Doc.-No.: C53000-L1840-B001-03

Sept. 17

2.0

3.0

3.1

• Manual is also valid for 6MD63 an 7SJ61...7SJ64 devices

• New chapter “Interface selection and mapping selection in DIGSI 4.3 or

• Description of Scaling indices 7 to 9 added

Jan. 14

• new data type definitions for “Transformer tap change command”, “Trans-

• new chapter “Event list settings”

• Note for setting of tagging “SysIntErr” added

• new chapter “Transformer tap change commands”

• new chapter “Event list via PROFIBUS-DP”

• Type TxTap can be routed to “Destination system interface”

• max. line length for redundant optical rings an baud rates >= 500 kB/s

• Note to parameters “Retry limit” and “Slot time” added

• Manual is also valid for 7UM61 devices with firmware from V4.1

• Time interval for time synchronization of SIPROTEC devices via PROFI-

Sept. 18

• Manual is also valid for 7SD5, 7SD610 devices with firmware from V4.2,

• Notes for fibre-optical settings, Network size: S3 at the OLM/G12 has to

• Time intervals of less than 1 minute for time synchronization of SIPRO-

• Value for “Optical receiver sensitivity” added

Feb. 28

th

, 2001

higher”

th

, 2002

former tap position indication” and “Message block for event list”

corrected

BUS-DP has to be 1 minute

th

, 2002

7UT613, 7UT63 devices with firmware from V4.0 and 7VK61 devices with

firmware from V4.0

be set inversely to the value DP_OLM_NetworkSize

TEC devices are available with PROFIBUS-DP communication module

firmware from V03.01.03

th

, 2003

C53000-L1840-B001-03

7SIPROTEC PROFIBUS-DP - Communication profile

Revision index

Modified chapters /

pages

general

Chap. 1

Chap. 2.1.1

Chap. 2.1.2

Chap. 2.3.2

Chap. 4.4

Chap. 4.5

Chap. 5.2

general

Chap. 1.2.1

Chap. 3.3

Chap. 4.4.2

Chap. 4.4.2 4.2

Edition Reasons of modification

4.0

• Manual is also valid for 7ST61, 7ST63 devices with firmware from V4.0

and 7VE61, 7VE63 devices with firmware from V4.0

• Chap. “PROFIBUS communication modules” added (new HW revision 4),

the following chapter numbers moved up

• Assignment of PNO identification numbers for modules form HW rev. 4;

note to bus silent time after baud rate change added

• Setting of OLM V3 compatible modes for fibre-optical modules from HW

revision 4

• Example for routing of the OLM status indications in DIGSI added

• Precondition for time synchronization: only one master station may send

time messages in the PROFIBUS net

• new Chap. “Using SFC14 and SFC15 in STEP7”

• notes completed with OLM V3 mode and HW revisions and example for

correct parameterization with “Number of OLM” in the DP master added

th

, 2004

4.1

Feb. 5

• Page numbering in the manual now continuous, not chapter-related any

more

• Explanation of the display of the correction values from time synchroniza-

tion messages added

• Meaning of values 0 and 3 for DP, depending on the type, added

• New value ’2’ for GlobalSection.DP_TimeSyncEnable

th

Dec. 8

• New value ’3’ for GlobalSection.DP_TimeSyncEnable

Apr. 14

, 2004

th

, 2005

8

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

Table of contents

Preface.................................................................................................................................................. 3

Revision index ..................................................................................................................................... 7

1 PROFIBUS Communication modules .............................................................................................. 11

1.1 Communication module types and hardware revisions........................................................ 12

1.1.1 Communication module types .............................................................................................. 12

1.1.2 Hardware revisions............................................................................................................... 12

1.1.3 Compatibility of the communication module hardware with PROFIBUS-DP firmware versions

and mapping files ................................................................................................................. 13

1.2 Display of module-specific information at the SIPROTEC device ........................................ 15

1.2.1 Block 1: Status and parameters of the PROFIBUS-DP slave .............................................. 17

1.2.2 Block 2: Firmware versions and mapping file ....................................................................... 19

1.2.3 Block 3: Module hardware information and boot firmware version....................................... 20

1.2.4 Block 4: OLM information ..................................................................................................... 21

1.2.5 Block 5: Status of the event list via PROFIBUS-DP ............................................................. 24

2 Parameters and properties ............................................................................................................... 25

2.1 Bus specific parameters ....................................................................................................... 26

2.1.1 PROFIBUS-DP settings........................................................................................................ 26

2.1.2 Configuration of the fibre-optical interface............................................................................ 28

2.1.3 Event list settings ................................................................................................................. 31

2.1.4 PROFIBUS-DP Configuration data....................................................................................... 31

2.2 Execution of switching operations via PROFIBUS-DP ......................................................... 32

2.2.1 Command output modes ...................................................................................................... 32

2.2.2 Transformer tap change commands..................................................................................... 33

2.2.3 Behaviour under special operating conditions...................................................................... 33

2.3 Response in the event of disturbed communication to the PROFIBUS-DP master ............. 34

2.3.1 Communication interruption.................................................................................................. 34

2.3.2 Signalling of line-breaks in a redundant fibre-optical ring..................................................... 35

2.4 Annunciations to the PROFIBUS-DP master ....................................................................... 37

2.5 Event list via PROFIBUS-DP (Sequence of events recorder) .............................................. 38

2.5.1 Properties of the event list.................................................................................................... 39

C53000-L1840-B001-03

9SIPROTEC PROFIBUS-DP - Communication profile

Table of contents

2.5.2 Structure of a PROFIBUS-DP telegram with event list ......................................................... 40

2.5.2.1 Telegram in input direction ................................................................................................... 40

2.5.2.2 Telegram in output direction ................................................................................................. 42

2.5.3 Handshake mechanism ........................................................................................................43

3 Data type definitions.......................................................................................................................... 45

3.1 Single-point indication (SP, Input) ........................................................................................ 46

3.2 Single command (SC, Output).............................................................................................. 47

3.3 Double-point indication (DP, Input) / Double command (DC, Output) .................................. 48

3.4 Measured value (signed integer) .......................................................................................... 49

3.5 Measured value (float) .......................................................................................................... 50

3.6 Metered measurand (unsigned long).................................................................................... 51

3.7 Transformer tap change command (TC) .............................................................................. 52

3.8 Transformer tap position indication (TM).............................................................................. 53

3.9 Message block for event list via PROFIBUS-DP .................................................................. 54

4 PROFIBUS-DP - Parameterization in DIGSI ..................................................................................... 57

4.1 Interface selection and mapping files ................................................................................... 58

4.1.1 Standard mappings 3-1 to 3-n .............................................................................................. 58

4.1.2 Compatibility with standard mappings of previous versions ................................................. 59

4.1.3 Interface selection and mapping selection in DIGSI 4.21 ..................................................... 59

4.1.4 Interface selection and mapping selection in DIGSI 4.3 or higher........................................ 63

4.2 Customization of the allocations ........................................................................................... 66

4.3 Scaling of measured values.................................................................................................. 70

4.3.1 Measurement conversion .....................................................................................................70

4.3.2 Number representation depending on the parameterization ................................................ 71

4.3.3 Parameterization in DIGSI .................................................................................................... 73

4.4 Time synchronization............................................................................................................ 75

4.4.1 PROFIBUS-DP master .........................................................................................................75

4.4.2 Parameterization in DIGSI .................................................................................................... 77

4.5 Using SFC14 and SFC15 in STEP7 ..................................................................................... 79

5 Technical data .................................................................................................................................... 83

5.1 Connection via the PSE module ........................................................................................... 84

5.2 Connection via the PSO module........................................................................................... 86

Glossary.............................................................................................................................................. 89

Index.................................................................................................................................................... 91

10

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

PROFIBUS Communication modules 1

This chapter shows the hardware and software necessary for PROFIBUS-DP communication with SIPROTEC devices and describes the display of module-specific information at the device.

1.1 Communication module types and hardware revisions 12

1.2 Display of module-specific information at the SIPROTEC device 15

C53000-L1840-B001-03

11SIPROTEC PROFIBUS-DP - Communication profile

PROFIBUS Communication modules

1.1 Communication module types and hardware revisions

1.1.1 Communication module types

Two communication modules are available for the connection of PROFIBUS-DP to the

SIPROTEC devices:

RS485

bus interface

Fibre-optical

bus interface

Technical data The technical data of the above-mentioned PROFIBUS communication modules are

PROFIBUS module with isolated RS485 interface.

This module also is called PSE module (Communication module PROFIBUS slave

electrical) subsequently.

PROFIBUS module with fibre-optical interface.

An OLM (Optical link module) for electrical to optical conversion of PROFIBUS signals

is integrated on this communication module and two optical channels (each with Send

and Receive) are utilizable.

It is possible to build up PROFIBUS nets in a redundant optical ring topology with that.

This module also is called PSO module (Communication module PROFIBUS slave

fibre-optical) subsequently.

summarized in chap. 5.

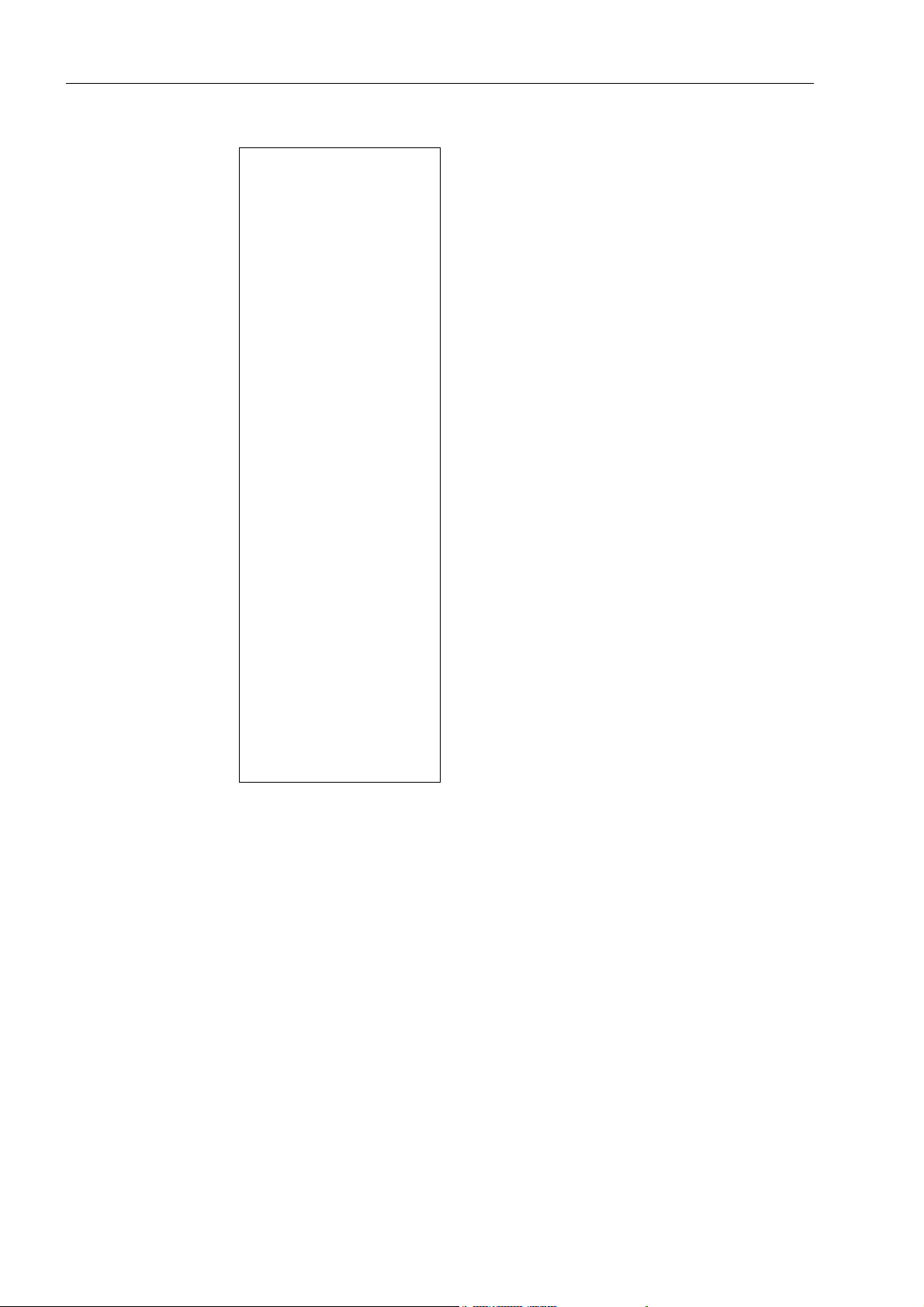

1.1.2 Hardware revisions

There exist two different hardware revisions for PROFIBUS communication modules:

• up to HW revision 3:

delivery up to the beginning of year 2004

12

• from HW revision 4:

replacement for modules up to HW revision 3, delivery from beginning of 2004

The communication modules from HW revision 4 are function compatible to the modules up to HW revision 3.

Please note the dependency of the PROFIBUS-DP firmware versions with the HW

revisions described in chap. 1.1.3.

The hardware revision of the PROFIBUS communication modules is also recognizable in build-in condition at the rear of the SIPROTEC device at the labelling of the

communication module mounting bracket:

• up to HW revision 3: identification “P-Slave”

• from HW revision 4: identification “Profibus”

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

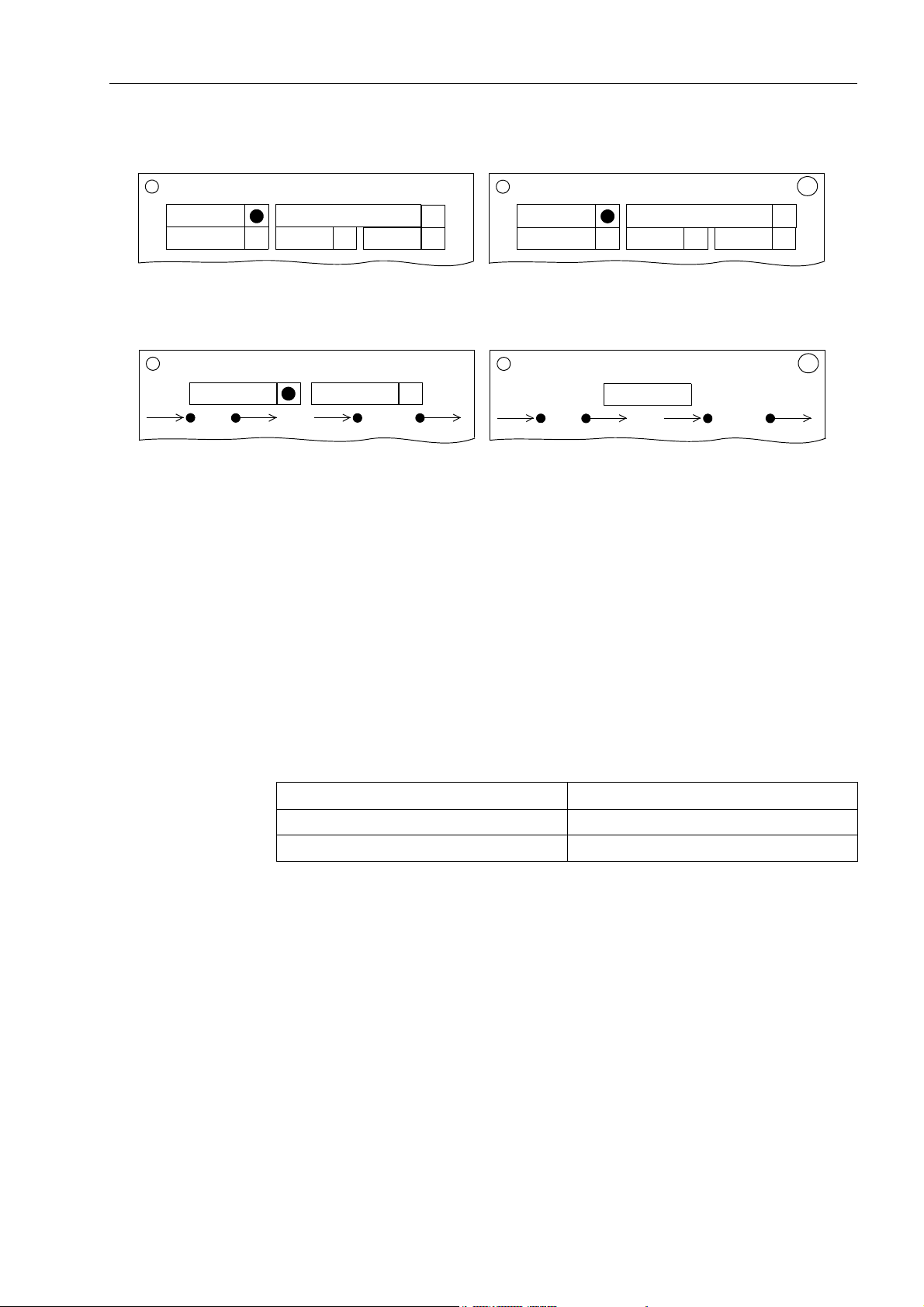

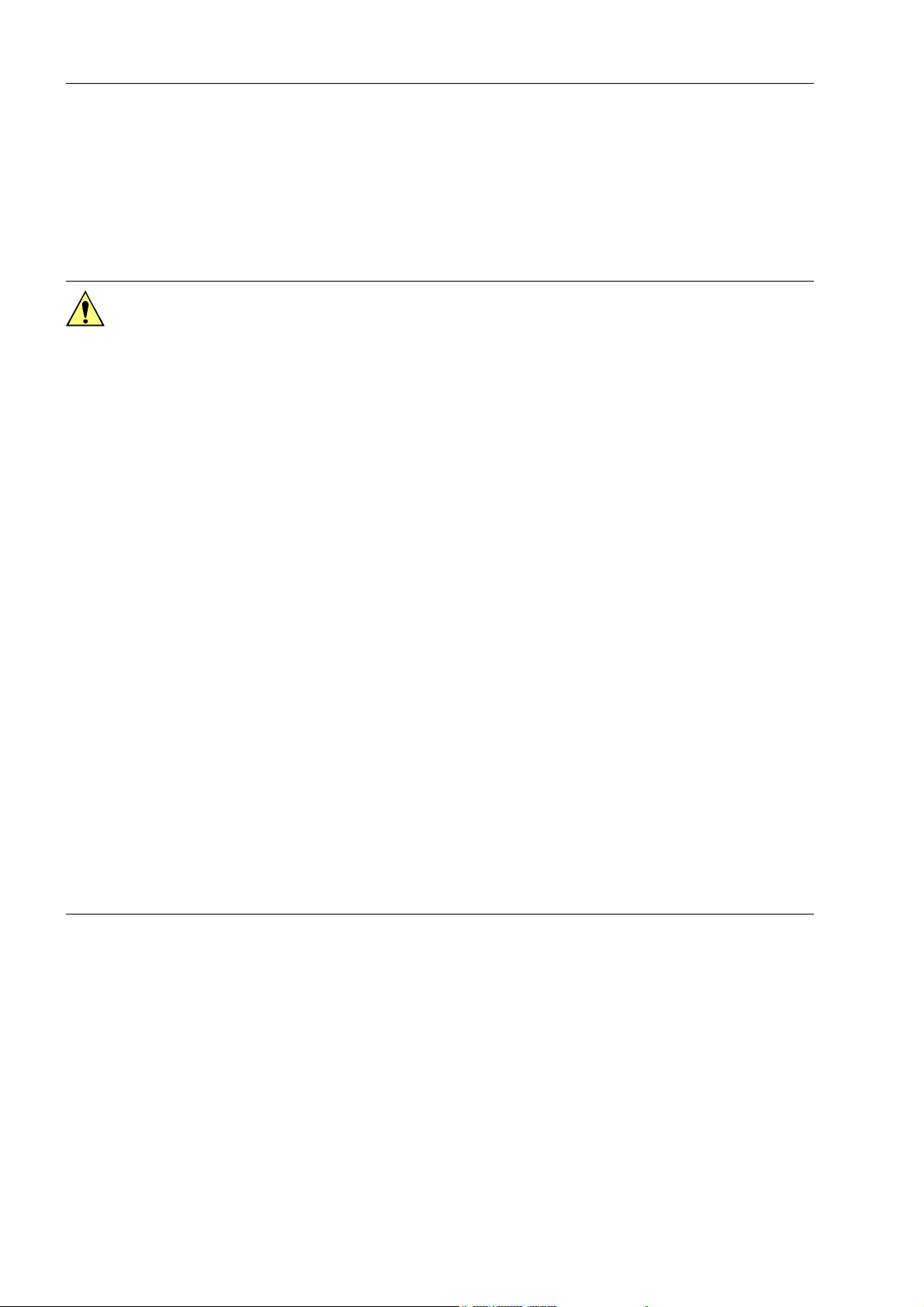

PROFIBUS RS485 (PSE module)

PROFIBUS Communication modules

P-Slave

AME

up to HW revision 3

RS232-LWL

RS232 RS485

Profibus

AME

from HW revision 4

RS232-LWL

RS232 RS485

PROFIBUS fibre-optical, double loop (PSO module)

Ch1

up to HW revision 3

Figure 1-1 HW revisions of the communication modules, labelling of the mounting brackets

P-Slave

P-Master

General details about the assembly of communication modules as well as the setting

of the terminating resistors on the PSE modules you find in the SIPROTEC4 System

Manual (ref. to page 3).

Ch2

Ch1

from HW revision 4

Profibus

Ch2

1.1.3 Compatibility of the communication module hardware with PROFIBUS-DP

firmware versions and mapping files

Hardware and

firmware

Please note the following listed compatibility between the hardware revisions of the

communication modules and the PROFIBUS-DP firmware versions:

Hardware revision Firmware version to be used

up to HW revision 3 up to PROFIBUS-DP firmware V03

from HW revision 4 from PROFIBUS-DP firmware V04

Table 1-1 Hardware revisions and firmware versions

The PROFIBUS-DP firmware for communication modules from HW revision 4 is:

• function compatible with firmware versions for modules up to HW revision 3

(i.e. contains all there contained functionalities),

• offers additional functionalities, e.g.:

• display of module-specific information at the device (ref. to chap. 1.2),

• OLM V3 compatibility mode with fibre-optical modules (ref to chap. 2.1.2).

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

13

PROFIBUS Communication modules

Note:

If, during loading of the PROFIBUS-DP firmware on the communication module, a

non-compatible hardware revision is recognized, then the firmware update is cancelled.

Please, in case of an abort of loading the PROFIBUS-DP communication firmware,

check first the dependencies indicated in Table 1-1.

After attempting to load a PROFIBUS-DP firmware version on a non-compatible hardware revision, the SIPROTEC device remains in the loader mode (display = empty,

LED 5 = ON, LED 6 flashing) and loading of a correct firmware version or an initial

reset is expected.

If no firmware shall be loaded in this situation, then the device has to be switched off

an (after at least 3 sec.) switched on again.

The previous firmware configuration is then used furthermore.

Hardware and

mapping files

There is no compatibility reduction between PROFIBUS-DP mapping files of the

SIPROTEC devices and the hardware revision of the communication modules, i.e.:

• the known PROFIBUS-DP mapping files for SIPROTEC devices, offered in DIGSI

and used so far, are used for parameterization furthermore,

• existing parameterizations can be used further, even if a communication module up

to HW revision 3 is replaced by a communication module from HW revision 4 (considering the firmware compatibility in Table 1-1).

14

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

PROFIBUS Communication modules

1.2 Display of module-specific information at the SIPROTEC device

Note:

The following prerequisites are necessary for using the functionality “Display of

module-specific information at the SIPROTEC device”:

• PROFIBUS communication module from HW revision 4 with PROFIBUS-DP firm-

ware from V04.00,

• SIPROTEC device firmware which supports this function, e.g.:

• 7SJ61...7SJ64, 6MD63 device firmware from V4.50,

• 6MD663/6MD664 device firmware from V4.50,

• 7SA522, 7SA6 device firmware from V4.50.

Changing parameters for the PROFIBUS-DP slave of the SIPROTEC device is exclusively possible using the DIGSI parameterization system.

If the display of module-specific information is not supported by the firmware of the

used SIPROTEC device then the below-mentioned menu items are not offered for

selection.

If a PROFIBUS communication module up to HW revision 3 is used, then in a SIPROTEC device with above-mentioned firmware V4.50 the following text is displayed in

case of selecting the menu item for display of module-specific information:

**** LIST EMPTY ****

The values in the display of module-specific information are actualized every 500 ms.

It is therefore possible that short-time changes of information are not displayed.

The display of module-specific information is accessible with the following menu items

or buttons:

• MENU

• Test/Diagnosis → 5

• Modulinfo → 5

• Port B → 1

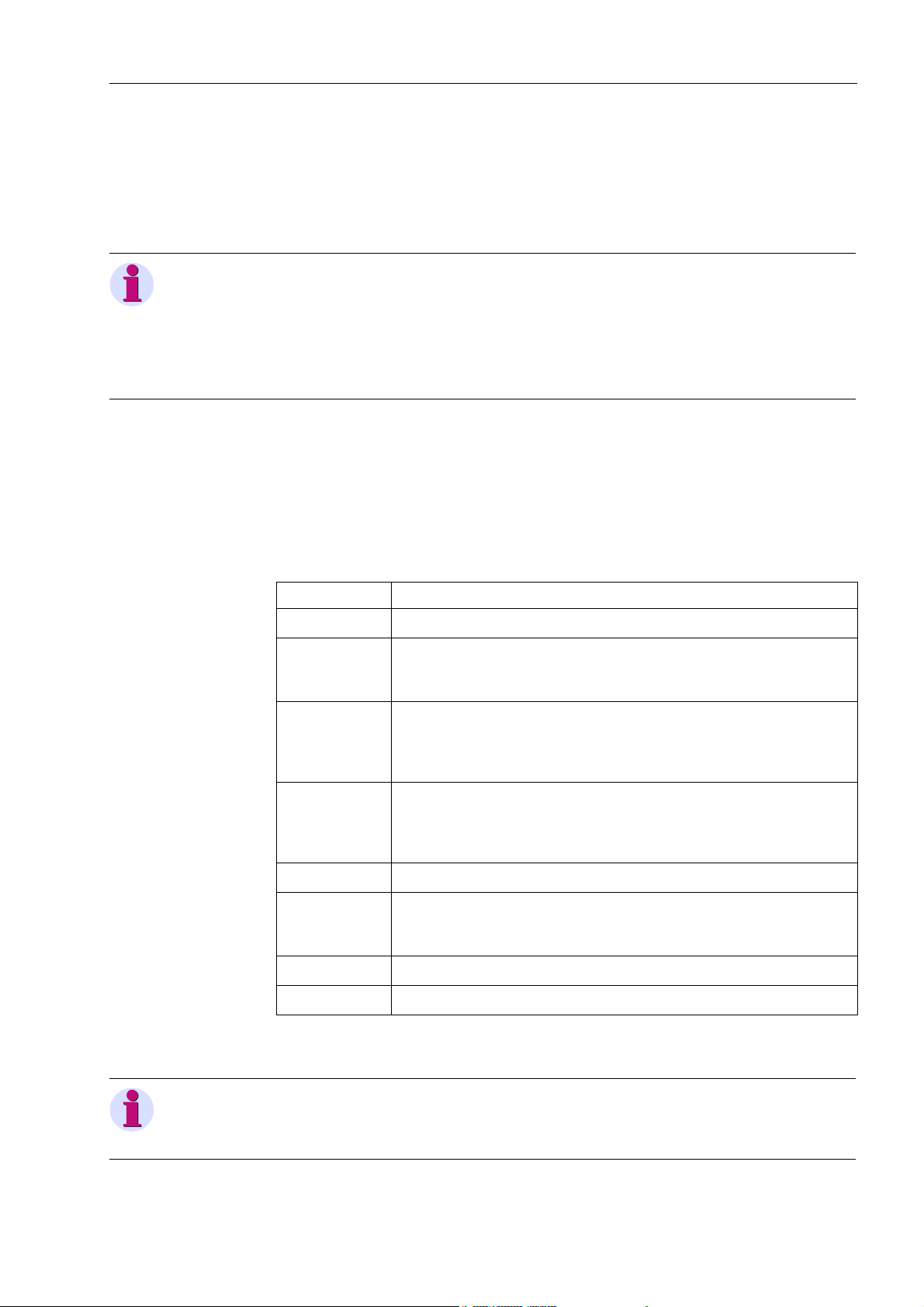

The maximum number of displayed information, separated in five blocks, is shown in

Figure 1-2.

Depending on the used communication module type and the selected mapping file

(and the resultant functional range) the blocks 4 and 5 are not existing.

The data in the individual information blocks are explained in the following chap. 1.2.1

to 1.2.5.

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

15

PROFIBUS Communication modules

PORT B

---------------------

PROFIBUS-DP

Slave : 2

Status: DATA_EXCHG

PNO-Id: 80BChex

Master: 1

Baudr.: 1.5 MB/s

SlvWDT: 70 ms

TimeSy: C355F7A6hex

function

Block 1:

Status and parameters of the PROFIBUS-DP slave.

DP_SW : V04.00.06

MapNo.: 3-1

MapRev: V01.00.05

Module: PSO2-GEN

HWCode: 0Chex

HWRev.: 04

Block 2:

PROFIBUS-DP firmware version as well as number and

version of the selected mapping file.

Block 3:

Module hardware information and version number of

the boot firmware.

BF-No.: 0310042351

Ld_Jmp: V01.00.05

OLMStA: OK

OLMStB: Error

OLMLed: G Y R

OLMCmp: V2, OLM/S4

Block 4:

OLM information

Block 4 is only available for fibre-optical PROFIBUS

modules.

OLMMod: Redundancy

OLMNWS: Standard

EvSize: 500

EvEntr: 0/0

EvCtrl: 00h-00h T-R

Block 5:

Status of the “Event list via PROFIBUS-DP”.

Block 5 is only available if the selected mapping file supports an “Event list via PROFIBUS-DP” (ref to chap. 2.5).

******* END ********

Figure 1-2 Display of module-specific information at the device

16

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

PROFIBUS Communication modules

1.2.1 Block 1: Status and parameters of the PROFIBUS-DP slave

Block 1 of the module-specific information shows parameterization data of the PROFIBUS-DP slave of the SIPROTEC device and the communication status with the

PROFIBUS-DP master.

Note:

If no PROFIBUS-DP mapping file was selected during parameterization in DIGSI then

all entries of Block 1 are marked with the sign ’-’:

Slave : Status: ...

Slave Display of the slave address which was entered during parameterization in DIGSI for

GlobalSection.DP_Addr (ref. to chap. 2.1.1).

Status Display of the communication status between the PROFIBUS-DP slave and the

PROFIBUS-DP master.

The following status indications are signaled:

Status Explanation

BAUD_SEARCH no connection to the PROFIBUS-DP master (line faulty or the like)

BAUD_FOUND the PROFIBUS-DP slave is connected to the bus but it is not addressed by

the PROFIBUS-DP master (and it was never addressed since the last connection break)

PRM_OK the PROFIBUS-DP slave is addressed by the PROFIBUS-DP master, the

Set Prm message was received and is OK, the Chk Cfg message from the

PROFIBUS-DP master is expected (this status often is not displayed because immediate transition to DATA_EXCHG)

PRM_REQ the PROFIBUS-DP slave was addressed by the master before but is now

no more addressed (parameter change at the master without connection

break or PROFIBUS-DP master software is disabled but lower PROFIBUS

layer is still active)

PRM_FAULT error in Set Prm message (e.g. wrong PNO identification number)

CFG_FAULT error in Chk Cfg message (different number of input/output bytes parame-

terized in the PROFIBUS-DP master compared with the number according

to the selected mapping file in the SIPROTEC device)

CLEAR_DATA PROFIBUS-DP master sends Global Control command CLEAR_DATA

DATA_EXCHG PROFIBUS-DP master and slave are in DATA_EXCHANGE mode

Table 1-2 Communication status indications

Note:

The tagging “SysIntErr” (ref. to chap. 2.3.1) also indicates the status DATA_EXCHG (tagging is set) and can be evaluated in the SIPROTEC device.

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

17

PROFIBUS Communication modules

PNO-Id Display of the PNO identification number which was entered during parameterization

in DIGSI for GlobalSection.DP_IdentNo (ref. to chap. 2.1.1).

Master Address of the PROFIBUS-DP master which sent the Set Prm and Chk Cfg messages

for the PROFIBUS-DP slave (and which is still in DATA_EXCHANGE mode with the

PROFIBUS-DP slave).

If the PROFIBUS-DP slave is not in status DATA_EXCHG then the displayed address

indicates the master which sent the Set Prm and Chk Cfg messages for the slave last.

A ’l’ (lower case character ’L’) in the last column is added in this situation, e.g.:

Master: 100 l

If the PROFIBUS-DP slave has not received the Set Prm and Chk Cfg messages yet,

then this is shown with:

Master: -

Baudr. Display of the baud rate determined by automatic baud rate recognition.

If a communication break occurs during the data exchange between the PROFIBUSDP master and slave then the baud rate recognized last is shown furthermore.

A ’l’ (lower case character ’L’) in the last column is added in this situation, e.g.:

Baudr.: 1.5 MB/s l

If (after switching on the device) no baud rate was recognized yet, then this is shown

with:

Baudr.: -

SlvWDT Watchdog time in milliseconds which was submitted by the PROFIBUS-DP master

with the Set Prm message to the PROFIBUS-DP slave for response monitoring.

If response monitoring is deactivated for this slave in the PROFIBUS-DP master then

this is indicated with:

SlvWDT: OFF

Note:

Response monitoring has to be activated for the slave in the PROFIBUS-DP master

if the tagging “SysIntErr” (ref. to chap. 2.3.1) shall be evaluated in the SIPROTEC device in case of communication break.

If the PROFIBUS-DP slave is not in status DATA_EXCHG then the last received

watchdog time is displayed.

A ’l’ (lower case character ’L’) in the last column is added in this situation, e.g.:

SlvWDT: 70 ms l

18

If the PROFIBUS-DP slave has not received the Set Prm and Chk Cfg messages yet,

then this is shown with:

SlvWDT: -

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

PROFIBUS Communication modules

TimeSy Reception of time synchronization messages via PROFIBUS (ref. to chap. 4.4).

The received value in seconds since 01-01-1900, 00:00 hours is displayed in hexadecimal representation, e.g.:

TimeSy: C355F7A6hex

This value has to be unequal 00000000hex and has to be changed about every minute

if time synchronization messages are received via PROFIBUS.

If the reception of time synchronization messages is deactivated in DIGSI with the

parameter GlobalSection.DP_TimeSyncEnable (ref. to chap. 2.1.1) then this is

indicated with:

TimeSy: OFF

In case of a communication break the seconds value received last is shown furthermore for one minute.

If no time synchronization message was received for a time interval of more than one

minute then it is shown in the display with:

TimeSy: Diff. >1min

With PROFIBUS-DP firmware V04.01.01 or higher also local time correction values

can be evaluated.

These correction values are contained e.g. in time synchronization messages of

SIMATIC PLC S7 CPU 412-2DP...CPU 416-2DP, CPU 414-3DP, CPU 416-3DP (from

firmware version 3.0 respectively) or of the Communication Processor Module CP

443-5 Extended (from firmware version 6.0).

The parameter GlobalSection.DP_TimeSyncEnable has to be set to the values

described in chap. 4.4.2 for this.

If the PROFIBUS-DP slave of the SIPROTEC device receives time synchronization

messages with a local time correction value then this is signaled with the additional

display of these correction value, e.g.:

TimeSy: C355F7A6+04

The first value (in hexadecimal representation) shows the seconds since 01-01-1900,

00:00 hours, the second value (in decimal representation) shows the signed correction

value in number of

1

/2 hours.

In the example given above the correction value is plus two hours.

1.2.2 Block 2: Firmware versions and mapping file

Block 2 of the module-specific information shows the PROFIBUS-DP firmware version

as well as the number and version of the selected mapping file.

Note:

If no PROFIBUS-DP mapping file was selected during parameterization in DIGSI then

all entries of Block 2 are marked with the text ’not loaded’:

MapNo.: not loaded

MapRev: not loaded

DP_SW PROFIBUS-DP firmware version loaded on the communication module.

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

19

PROFIBUS Communication modules

MapNo. Number of the selected standard mapping.

The mapping file determines the data size which is available via PROFIBUS-DP for

the SIPROTEC device.

Depending on the device type, several standard mappings are offered for parameterization in DIGSI (ref. to page 3, “Bus mapping documentation” for the individual

SIPROTEC devices).

MapRev. Version of the selected standard mapping with the number MapNo. (see above).

1.2.3 Block 3: Module hardware information and boot firmware version

Block 3 of the module-specific information contains hardware information for the builtin communication module.

Module Hardware type of the communication module built-in in the SIPROTEC device:

Module Explanation Note

PSE_GEN PROFIBUS module RS485 OK

PSO2_GEN

PSO1_GEN

AME_GEN Asynchronous module RS485

AMO-GEN Asynchronous module fibre-optical

Table 1-3 Communication module hardware types

PROFIBUS module fibre-optical, double loop

(with two fibre-optical channels)

PROFIBUS module fibre-optical, single loop

(with one fibre-optical channel)

OK

not for PROFIBUS-DP,

please replace

not for PROFIBUS-DP,

please replace

not for PROFIBUS-DP,

please replace

HWCode A hardware designation, coded on the module, in hexadecimal representation.

HWRev. Hardware revision of the communication module.

BF-No. Serial number (production number) of the communication module.

Ld_Jmp Version of the separate boot firmware part for start-up and with loader functions.

20

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

1.2.4 Block 4: OLM information

Block 4 with OLM information is only available for fibre-optical PROFIBUS modules.

Note:

All Optical Link Modules in the interconnected devices has to be configured identical

(ref. to chap 2.1.2, “Configuration of the fibre-optical interface”).

PROFIBUS Communication modules

OLMStA

OLMStB

Line status to the respective PROFIBUS-DP stations connected via optical channel A

(Ch1) and optical channel B (Ch2).

The interpretation of this status for communication modules from HW revision 4

depends on the selected operating mode of the Optical Link Module (ref. to chap.

2.1.2).

OLM V2 mode or OLM V3 mode without optical fibre link monitoring:

OK valid PROFIBUS messages are received via the optical channel

ERROR no valid PROFIBUS messages are received via the optical channel

(break in a fibre line or receive and transmit fibre line interchanged or no active

PROFIBUS station on the bus)

OLM V3 mode with optical fibre link monitoring

(Line/Star topology with optical fibre link monitoring or redundant optical ring):

OK the fibre-optical line to the partner station is OK

ERROR a break in the fibre line to the partner station is detected (line break or receive

and transmit fibre line interchanged) or the baud rate was not recognized yet

because no active PROFIBUS station is connected to the bus

Note:

• The status of the optical channels is also indicated with the optional routable tag-

gings “Line-break Channel A” and “Line-break Channel B” and can be

evaluated in the SIPROTEC device (ref. to chap. 2.3.2).

• Additionally, the tagging “SysIntErr” should be used (ref. to chap. 2.3.1).

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

21

PROFIBUS Communication modules

OLMLed Display of the LED indicators for System an the individual Channels how it is also

available at the OLM devices SINEC L2 OLM/S4 and SIMATIC NET PROFIBUS OLM/

G12.

Through this, further fault diagnoses with the LED indicators and with the following

listed manuals of the OLM devices are possible.

Manual Order number

SINEC L2 Optical Link Module OLM/S4 6ZB5530-1AF01-0BA0

SIMATIC NET PROFIBUS OLM/G12 6ZB5530-3AD00-0BA0

The status of the LED indicators is displayed with characters:

• G = green

• R = red

• Y = yellow

• - = LED is off

Assignment of the order of the three characters to the LED indicators:

st

• 1

character: System LED

nd

• 2

character: LED opt. channel A (Ch1 at the PROFIBUS communication module)

rd

• 3

character: LED opt. channel B (Ch2 at the PROFIBUS communication module)

As an example, the following display

OLMLed: G Y R

is to interpret as:

• System LED = green

• LED channel A = yellow

• LED channel B = red

The two LED indicators additional at the OLM devices OLM/S4 and OLM/G12 to the

indication of the status of the RS485 channels are not shown.

OLMCmp OLM compatibility mode which is parameterized for the fibre-optical communication

module (ref. to chap. 2.1.2).

Display for OLM V2 mode:

OLMCmp: V2, OLM/S4

Display for OLM V3 mode:

OLMCmp: V3, OLM/G12

22

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

PROFIBUS Communication modules

OLMMod OLM operating mode which is parameterized for the fibre-optical communication mod-

ule (ref. to chap. 2.1.2).

Redundant optical ring:

OLMMod: Redundancy

Line or Star topology with optical fibre link monitoring

OLMMod: L/S w Supv.

Line or Star topology without optical fibre link monitoring

OLMMod: Line/Star

OLMNWS Optical network size which is parameterized for the fibre-optical communication mod-

ule (ref. to chap. 2.1.2).

This parameter only is relevant if OLM V2 mode is selected:

OLMNWS: Standard

or

OLMNWS: Extended

In OLM V3 mode it is always displayed:

OLMNWS: -

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

23

PROFIBUS Communication modules

1.2.5 Block 5: Status of the event list via PROFIBUS-DP

Block 5 is only available if the selected mapping file supports an event list via PROFIBUS-DP (ref. to chap. 2.5) and contains information about the status of transmission

of indications using the event list mechanism.

EvSize Number of the parameterized (at most possible) entries in the event list on the PROFI-

BUS communication module (see GlobalSection.DP_EvtLst_ListSize).

EvEntr Number of entries which are stored in the event list and number of entries which are

offered to the master in the message blocks of the PROFIBUS-DP telegram, e.g.:

EvEntr: 12/3

Twelve entries are currently contained in the event recorder and additionally three

entries are currently offered to the PROFIBUS-DP master in the message blocks of

the PROFIBUS-DP telegram.

The receipt of the evaluation of these three entries in the message blocks is expected

from the PROFIBUS-DP master.

A buffer overflow is also shown in this line for the duration of signaling of this indication

to the PROFIBUS-DP master, e.g. (with EvSize equal 100):

EvEntr: 100/3, Ovfl.

EvCtrl Current contents of the handshake bytes “Control_I” (sent to the PROFIBUS-DP mas-

ter, ref. to chap. 2.5.2.1) and “Control_O” (received last from the PROFIBUS-DP master, ref. to chap. 2.5.2.2).

The display

EvCtrl: 40h-30h T-R

means e.g., that message blocks are offered to the master with message block number 4 but no receipt was received for this because the last received message block

number is 3.

The text T-R indicates the data direction for the two values of the handshake bytes

from view of the SIPROTEC device (T = Tx, to the master; R = Rx, from master).

24

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

Parameters and properties 2

This chapter describes the properties and functions of the PROFIBUS-DP slave and

the bus specific parameters which have to be defined during parameterization of the

SIPROTEC devices for PROFIBUS-DP communication.

2.1 Bus specific parameters 26

2.2 Execution of switching operations via PROFIBUS-DP 32

2.3 Response in the event of disturbed communication to the PROFIBUS-DP

master 34

2.4 Annunciations to the PROFIBUS-DP master 37

2.5 Event list via PROFIBUS-DP (Sequence of events recorder) 38

C53000-L1840-B001-03

25SIPROTEC PROFIBUS-DP - Communication profile

Parameters and properties

2.1 Bus specific parameters

The following settings for the serial communication between the PROFIBUS-DP master and the PROFIBUS-DP slave have to be defined during parameterization of the

SIPROTEC device.

Names written in MonoScriptText are the associated designations of the bus

specific parameters in the DIGSI parameterization software (ref. to chap. 4.1).

2.1.1 PROFIBUS-DP settings

Slave address GlobalSection.DP_Addr

Permissible PROFIBUS slave addresses for the SIPROTEC devices are in the range

between 1 and 126.

PNO identification

number

GlobalSection.DP_IdentNo

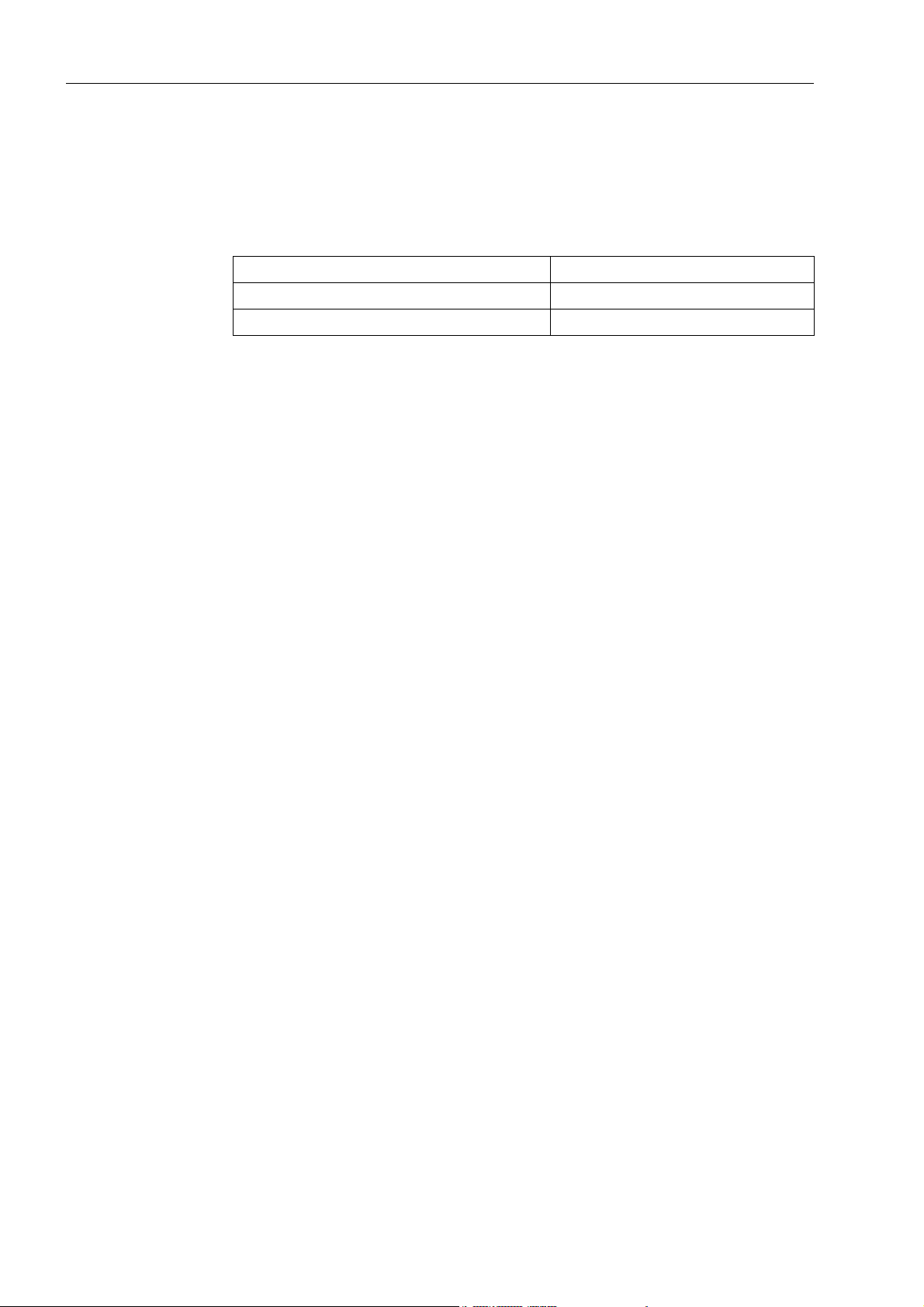

Depending on the chosen connection of the PROFIBUS net to the SIPROTEC device

(ref. to chap. 1.1 and 5) the PNO identification number of the communication module

has to be seleceted:

Communication

module

PSE,

up to HW-Rev. 3

PSE,

from HW-Rev. 4

PSO,

up to HW-Rev. 3

PSO,

from HW-Rev. 4

Table 2-1 PROFIBUS communication modules for SIPROTEC devices:

PNO identifi-

cation number

0x80A1

0x80BC

PNO identification numbers, device names and DDB files/GSD files

Connection Device name

Isolated RS485

interface

Fibre-optical

interface

"SIPROTEC4 - DP Modul" "siem80a1.gsd”

"SIPROTEC4 - DP Modul_HWRev4" "si1_80a1.gsd”

"SIPROTEC4 - DP Fibre" "siem80bc.gsd"

"SIPROTEC4 - DP Fibre_HWRev4" "si1_80bc.gsd"

Note:

You can continue to work also with the GSD file of the modules up to HW revision 3 if

a PROFIBUS communication module up to HW revision 3 is replaced with a PROFIBUS communication module from HW revision 4 (ref. to chap. 1.1) in an existing

installation

A changing of the PROFIBUS-DP master parameterization is not needed.

DDB file /

GSD file

26

The DDB file/GSD file (corresponding to the PNO identification number) is necessary

for parameterization of the des PROFIBUS-DP master and describes the technical

characteristics of the PROFIBUS-DP slave device.

After importing the DDB file/GSD file in the parameterization system of the PROFIBUS-DP master the SIPROTEC modules with their device names are inserted in the

slave family

“Other field controller - SIPROTEC”.

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

Parameters and properties

Note:

The DDB files/GSD files of the PROFIBUS-DP communication modules of the

SIPROTEC devices are enclosed within the parameterization system DIGSI:

DDB files/GSD files in the directory:

• “...\SIEMENS\DIGSI4\MANAGER\S7DATA\GSD” or

• “...\SIEMENS\STEP7\S7DATA\GSD” at installation of DIGSI and STEP7.

Associated Bitmap files:

• “...\SIEMENS\DIGSI4\MANAGER\S7DATA\NSBMP” or

• “...\SIEMENS\STEP7\S7DATA\NSBMP” at installation of DIGSI and STEP7.

Baud rate The PROFIBUS-DP slave of the SIPROTEC devices supports automatic baud rate

recognition. There are no settings necessary concerning the baud rate during the

parameterization of the SIPROTEC devices.

The baud rate is provided by the PROFIBUS-DP master.

Time

synchronization

The following baud rates are supported by the PROFIBUS communication modules:

Connection Supported baud rates

Isolated RS485 interface

(PSE module)

Fibre-optical interface

(PSO module)

Table 2-2 PROFIBUS communication moduls for SIPROTEC devices:

Supported baud rates

9.6; 19.2; 93.75; 187.5; 500; 1500; 3000; 6000 kB/s

9.6; 19.2; 93.75; 187.5; 500; 1500 kB/s

Note:

After baud rate change at the PROFIBUS-DP master a silent time of at least 2 seconds is necessary on the bus so that the PROFIBUS-DP slave of the SIPROTEC

device can recognize the baud rate change and start the automatic baud rate recognition again (short-time break of the bus connection at the PROFIBUS-DP master or

the like).

GlobalSection.DP_TimeSyncEnable

If the time stamp mechanism of PROFIBUS System Management Service is used for

time synchronization of the SIPROTEC devices then the evaluation of time synchronization messages from PROFIBUS has to be enabled on the communication module.

Ref. to chap. 4.4 for further information about parameter settings of time synchronization via PROFIBUS.

Status bit for

metered

measurands

GlobalSection.DP_CountersWithStatus

Counters (metered measurands) are transferred via PROFIBUS-DP as unsigned long

values.

The meaning of the status bit (most significant bit of the unsigned long value) can be

defined with this paramter (ref. to chap. 3.6).

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

27

Parameters and properties

2.1.2 Configuration of the fibre-optical interface

The following settings for "Operating mode / Monitor mode", "Redundancy function"

und "Network size" are only necessary at connection of PROFIBUS-DP via fibre-optical interface (PSO module).

Attention!

• Fibre-optical communication modules up to HW revision 3 are compatible with OLM

V2 (SINEC L2) devices (e.g. OLM/S3 and OLM/S4).

Fibre-optical communication modules from HW revision 4 offer in addition the OLM

V3 settings of the SIMATIC NET devices OLM/G11 and OLM/G12.

For this reason, the value of the three parameters, described in this chapter, has to

be selected depending on the hardware revision of the used communication modules (ref. to chap. 1.1).

If fibre-optical communication moduls up to HW revision 3 and from HW revision 4 are used together at the same PROFIBUS segment then all optical

devices (including external OLMs) have to be switched in the OLM V2 mode.

• After device reset or device start-up the optical channels of the communication

modules from HW revision 4 are switched to the optical net first after completion of

the parameter setting of the module (device-dependently approx. 15 seconds after

device start-up).

• The OLM configuration settings have to be identical for all Optical Link Modules

(OLM/S4, OLM/G12) and all fibre-optical PROFIBUS-DP communication modules

of the SIPROTEC devices which are interconnected.

Please ref. to chap. 5.2 for additional notes regarding the connection of PROFIBUSDP to SIPROTEC devices with fibre-optical interface.

• The help texts in the mapping files delivered so far for communication modules up

to HW revision 3 exclusively refer to setting for OLM V2 mode.

These mapping files can also be used for PROFIBUS-DP parameterization with

communication modules from HW revision 4.

The possibilities of the settings for OLM V3 mode listed below are valid despite of

the reductions in the help texts of the mapping files for OLM V2 mode.

The following OLM parameters are the default settings after selection of a mapping file

(independent of the HW revision of the used PROFIBUS communication module):

• “Operating mode / Monitor mode” = 0

28

• “Redundancy function” = 1

• “Network size” = 0

i.e.: OLM V2 mode and redundant optical ring topology.

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

Parameters and properties

Operation mode /

Monitor mode

GlobalSection.DP_OLM_MonitorMode

Devices with communication module up to HW revision 3

Oper. mode Meaning

Mode 0 / Transmit echo: (default setting)

The fibre-optical line is constantly checked for breaks in the line-connection.

0

1

An indication in the case of a line-break can be evaluated in the SIPROTEC

device (ref. to chap. 2.3).

For “Redundancy function” = 1, “Operating mode” always has to be set to 0.

Mode 1:

Select Mode 1 if PROFIBUS devices are conneted to the bus which do not

transmit, expect or accept an echo for line-break supervision (no fibre-optical

cable monitoring, ring topologies are not possible in Mode 1).

The parameter corresponds to DIL switch S1 at the OLM/S4 or OLM/G12 (in compatibility mode).

Devices with communication module from HW revision 4

Oper. mode Meaning

OLM V2 compatible, Mode 0 / Transmit echo: (default setting)

The fibre-optical line is constantly checked for breaks in the line-connection.

0

An indication in the case of a line-break can be evaluated in the SIPROTEC

device (ref. to chap. 2.3).

For “Redundancy function” = 1, “Operating mode” always has to be set to 0.

OLM V2 compatible, Mode 1:

1

10

11

Select Mode 1 if PROFIBUS devices are conneted to the bus which do not

transmit, expect or accept an echo for line-break supervision.

OLM V3 compatible: Mode depends on parameter “Redundancy function”

“Redundancy function” = 0

Line or Star topology with optical fibre link monitoring

“Redundancy function” = 1

Redundant optical ring

An indication in the case of a line-break can be evaluated in the SIPROTEC

device (ref. to chap. 2.3).

OLM V3 Modus: Mode depends on parameter “Redundancy function”

“Redundancy function” = 0

Line or Star topology without optical fibre link monitoring

“Redundancy function” = 1

Redundant optical ring

The parameter corresponds for Operating modes 0 an 1 to DIL switch S1 at the OLM/

S4 or OLM/G12 (in compatibility mode).

The parameter corresponds for Operating modes 10 an 11 to settings of DIL switches

S1 to S4 at the OLM/G12.

Note:

Both optical channels are always adjusted identically in the OLM V3 mode at the

SIPROTEC communication module unlike the possible settings at the SIMATIC NET

OLM/G12 for operating mode “Line” (i.e. both channels with or both channels without

line-break monitoring).

SIPROTEC PROFIBUS-DP - Communication profile

C53000-L1840-B001-03

29

Loading...

Loading...