Page 1

SIPROTEC

Preface

Contents

Introduction 1

Functions 2

Line Differential Protection

7SD80

V4.6

Manual

Mounting and Commissioning 3

Technical Data 4

Appendix A

Literature

Glossary

Index

E50417-G1140-C474-A1

Page 2

Note

For safety purposes, please note instructions and warnings in the Preface.

Disclaimer of Liability

We have checked the contents of this manual against the hardware

and software described. However, deviations from the description

cannot be completely ruled out, so that no liability can be accepted

for any errors or omissions contained in the information given.

The information given in this document is reviewed regularly and

any necessary corrections will be included in subsequent editions.

Copyright

Copyright © Siemens AG 2011. All rights reserved.

Dissemination or reproduction of this document, or evaluation and

communication of its contents, is not authorized except where expressly permitted. Violations are liable for damages. All rights reserved, particularly for the purposes of patent application or trademark registration.

We appreciate any suggested improvements.

We reserve the right to make technical improvements without

notice.

Document version V04.00.03

Release date 09.2011

Registered Trademarks

SIPROTEC, SINAUT , SICAM and DIGSI are registered trademarks

of Siemens AG. Other designations in this manual might be trademarks whose use by third parties for their own purposes would infringe the rights of the owner.

Siemens Aktiengesellschaft Order no.: E50417-G1140-C474-A1

Page 3

Preface

Purpose of this Manual

This manual describes the functions, operation, installation, and placing into service of device 7SD80. In particular:

• Information regarding the configuration of the scope of the device and a description of the device functions

and settings → Chapter 2;

• Instructions for Installation and Commissioning → Chapter 3;

• Compilation of the Technical Data → Chapter 4;

• As well as a compilation of the most significant data for advanced users → Appendix A.

General information with regard to design, configuration, and operation of SIPROTEC 4 devices are set out in

the SIPROTEC 4 System Description /1/.

T arget Audience

Protection engineers, commissioning engineers, personnel concerned with adjustment, checking, and service

of selective protective equipment, automatic and control facilities, and personnel of electrical facilities and

power plants.

Applicability of this Manual

This manual applies to: SIPROTEC 4 Line Differential Protection 7SD80; firmware version V4.6.

Indication of Conformity

This product complies with the directive of the Council of the European Communities on the

approximation of the laws of the Member States relating to electromagnetic compatibility (EMC

Council Directive 2004/108/EC) and concerning electrical equipment for use within specified

voltage limits (Low-voltage Directive 2006/95 EC).

This conformity is proved by tests conducted by Siemens AG in accordance with the Council

Directive in agreement with the generic standards EN 61000-6-2 and EN 61000-6-4 for EMC

directive, and with the standard EN 60255-27 for the low-voltage directive.

The device has been designed and produced for industrial use.

The product conforms with the international standards of the series IEC 60255 and the German

standard VDE 0435.

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

3

Page 4

Preface

Additional St andards IEEE C37.90 (see Chapter 4 "Technical Data")

This product is UL certified according to the Technical Data.

file E194016

UL certification according to standard UL 508 for the devices 7SD803x and 7SD807x has

been applied for.

Additional Support

Should further information on the System SIPROTEC 4 be desired or should particular problems arise which

are not covered sufficiently for the purchaser's purpose, the matter should be referred to the local Siemens representative.

Our Customer Support Center provides a 24-hour service.

Telephone: +49 (180) 524-7000

Fax: +49 (180) 524-2471

e-mail: support.energy@siemens.com

Training Courses

Inquiries regarding individual training courses should be addressed to our Training Center:

Siemens AG

Siemens Power Academy

Humboldt Street 59

90459 Nuremberg

Telefon: +49 (911) 433-7415

Fax: +49 (911) 433-7929

Internet: www.siemens.com/energy/power-academy

e-mail: power-academy.energy@siemens.com

4

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 5

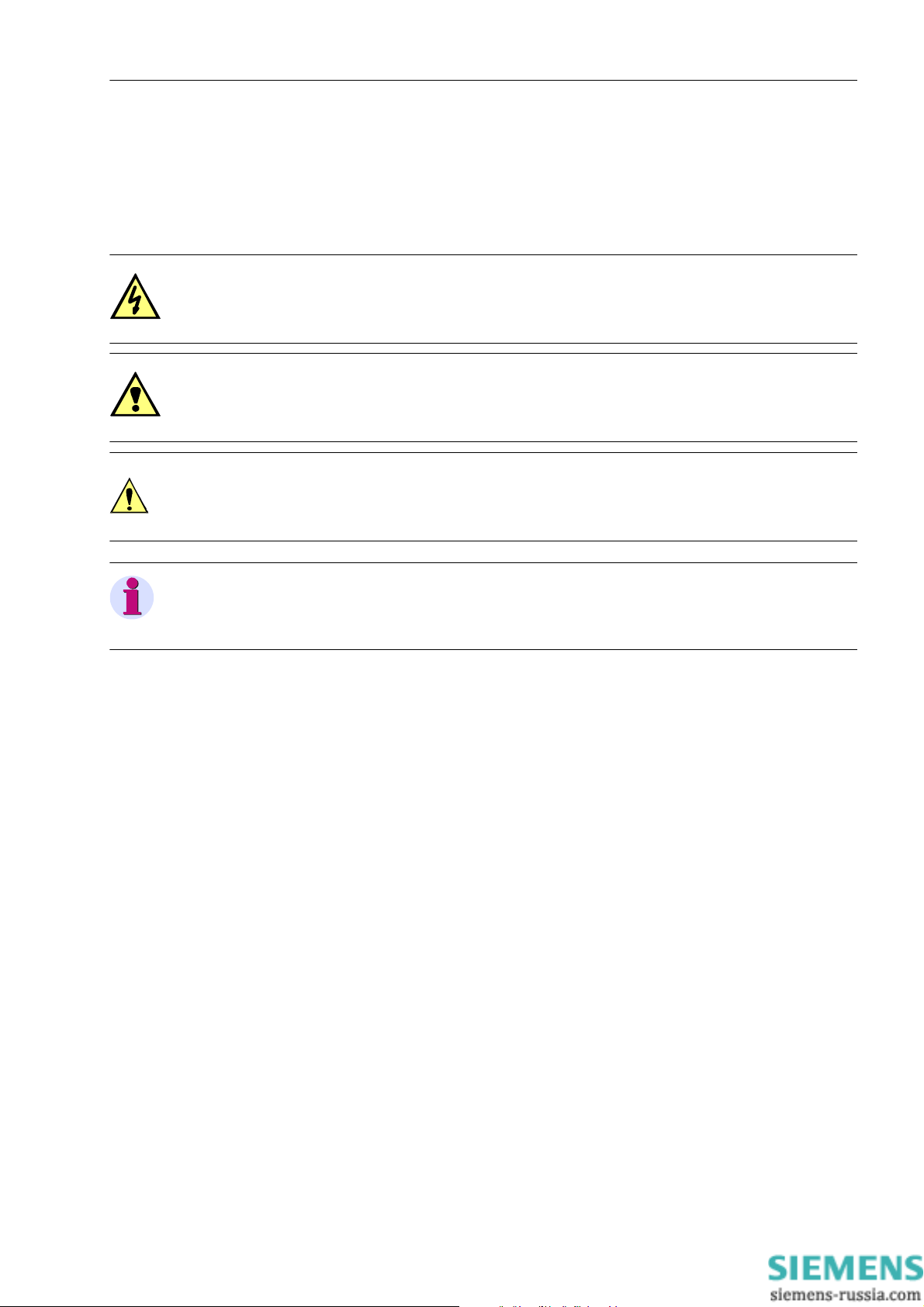

Safety Information

This manual does not constitute a complete index of all required safety measures for operation of the equipment (module, device), as special operational conditions may require additional measures. However, it comprises important information that should be noted for purposes of personal safety as well as avoiding material

damage. Information that is highlighted by means of a warning triangle and according to the degree of danger,

is illustrated as follows.

DANGER!

Danger indicates that death, severe personal injury or substantial material damage will result if proper precautions are not taken.

WARNING!

indicates that death, severe personal injury or substantial property damage may result if proper precautions are

not taken.

Caution!

indicates that minor personal injury or property damage may result if proper precautions are not taken. This

particularly applies to damage to or within the device itself and consequential damage thereof.

Preface

Note

indicates information on the device, handling of the device, or the respective part of the instruction manual

which is important to be noted.

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

5

Page 6

Preface

WARNING!

Qualified Personnel

Commissioning and operation of the equipment (module, device) as set out in this manual may only be carried

out by qualified personnel. Qualified personnel in terms of the technical safety information as set out in this

manual are persons who are authorized to commission, activate, to ground and to designate devices, systems

and electrical circuits in accordance with the safety standards.

Use as prescribed

The operational equipment (device, module) may only be used for such applications as set out in the catalog

and the technical description, and only in combination with third-party equipment recommended or approved

by Siemens.

The successful and safe operation of the device is dependent on proper handling, storage, installation, operation, and maintenance.

When operating an electrical equipment, certain parts of the device are inevitably subject to dangerous voltage.

Severe personal injury or property damage may result if the device is not handled properly.

Before any connections are made, the device must be grounded to the ground terminal.

All circuit components connected to the voltage supply may be subject to dangerous voltage.

Dangerous voltage may be present in the device even after the power supply voltage has been removed (ca-

pacitors can still be charged).

Operational equipment with exposed current transformer circuits may not be operated.

The limit values as specified in this manual or in the operating instructions may not be exceeded. This aspect

must also be observed during testing and commissioning.

6

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 7

T ypographic and Symbol Conventions

The following text formats are used when literal information from the device or to the device appear in the text

flow:

Parameter Names

Designators of configuration or function parameters which may appear word-for-word in the display of the

device or on the screen of a personal computer (with operation software DIGSI), are marked in bold letters in

monospace type style. The same goes for the titles of menus.

1234A

Parameter addresses have the same character style as parameter names. Parameter addresses contain the

suffix A in the overview tables if the parameter can only be set in DIGSI via the option Display additional set-

tings.

Parameter Options

Possible settings of text parameters, which may appear word-for-word in the display of the device or on the

screen of a personal computer (with operation software DIGSI), are additionally written in italics. This also

applies to header bars for selection menus.

„Messages“

Designators for information, which may be output by the relay or required from other devices or from the switch

gear, are marked in a monospace type style in quotation marks.

Preface

Deviations may be permitted in drawings and tables when the type of designator can be obviously derived from

the illustration.

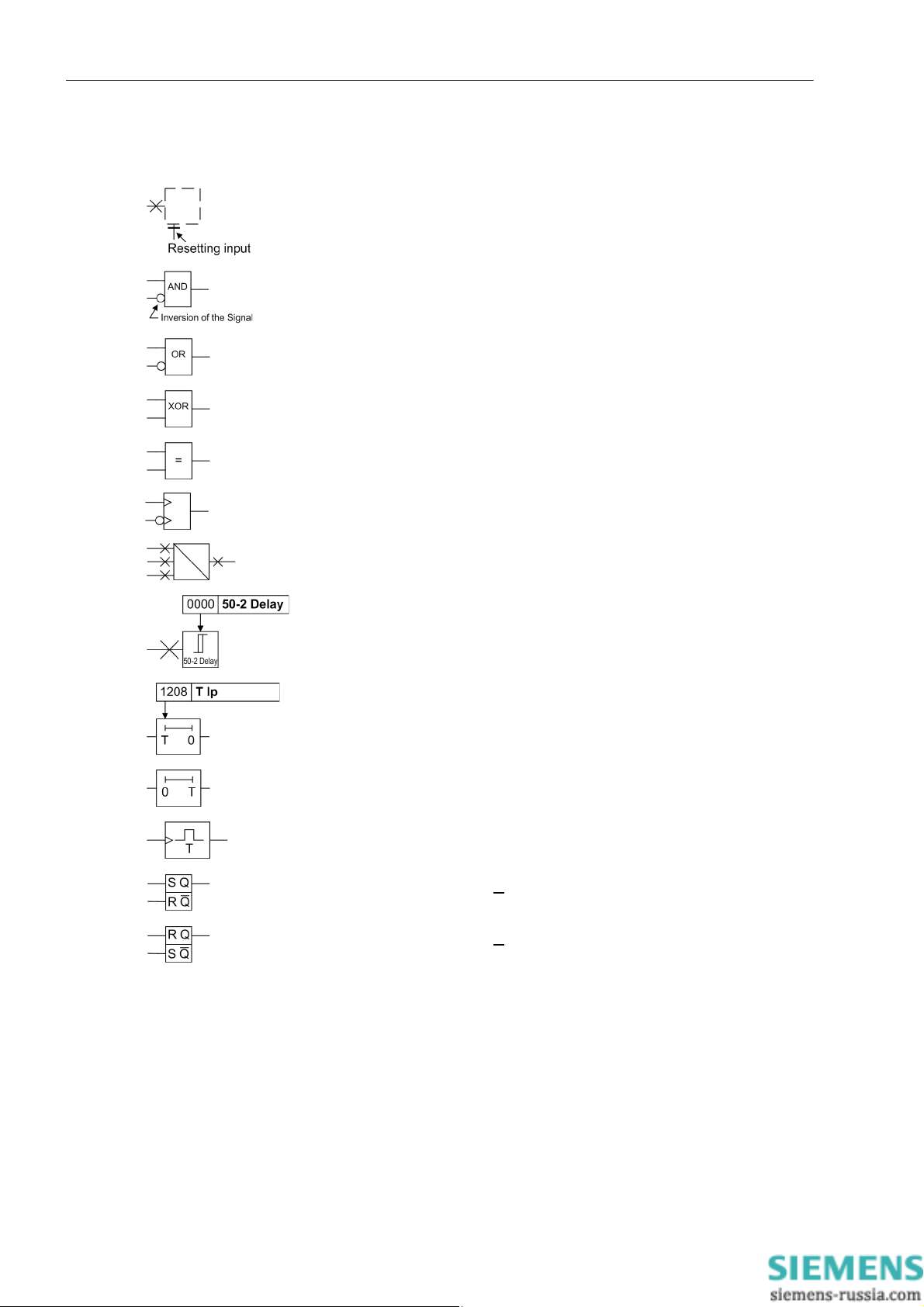

The following symbols are used in drawings:

Device-internal logical input signal

Device-internal logical output signal

Internal input signal of an analog quantity

External binary input signal with number (binary input,

input indication)

External binary input signal with number

(example of a value indication)

External binary output signal with number (device indication) used as

input signal

Example of a parameter switch designated FUNCTION with address

1234 and the possible settings ON and OFF

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

7

Page 8

Preface

Besides these, graphical symbols are used according to IEC 60617-12 and IEC 60617-13 or symbols derived

from these standards. Some of the most frequently used are listed below:

Analog input variable

AND operation of input variables

OR operation of input variables

Exclusive OR (antivalence): output is active if only one of the inputs is

active

Coincidence: output is active if both inputs are active or inactive at the

same time

Dynamic input signals (edge-triggered) above with positive, below with

negative edge

Formation of one analog output signal from a number of analog input

signals

Threshold element with setting address and parameter names

Timer (pickup delay T adjustable) with setting address and parameter

names

Timer (dropout delay T not adjustable)

Edge-triggered time element with action time T

Static memory (SR flipflop) with setting input (S), resetting input (R),

output (Q) and inverted output (Q

), setting input dominant

Static memory (RS-flipflop) with resetting input (R) setting input (S),

output (Q) and inverted output (Q

), resetting input dominant

■

8

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 9

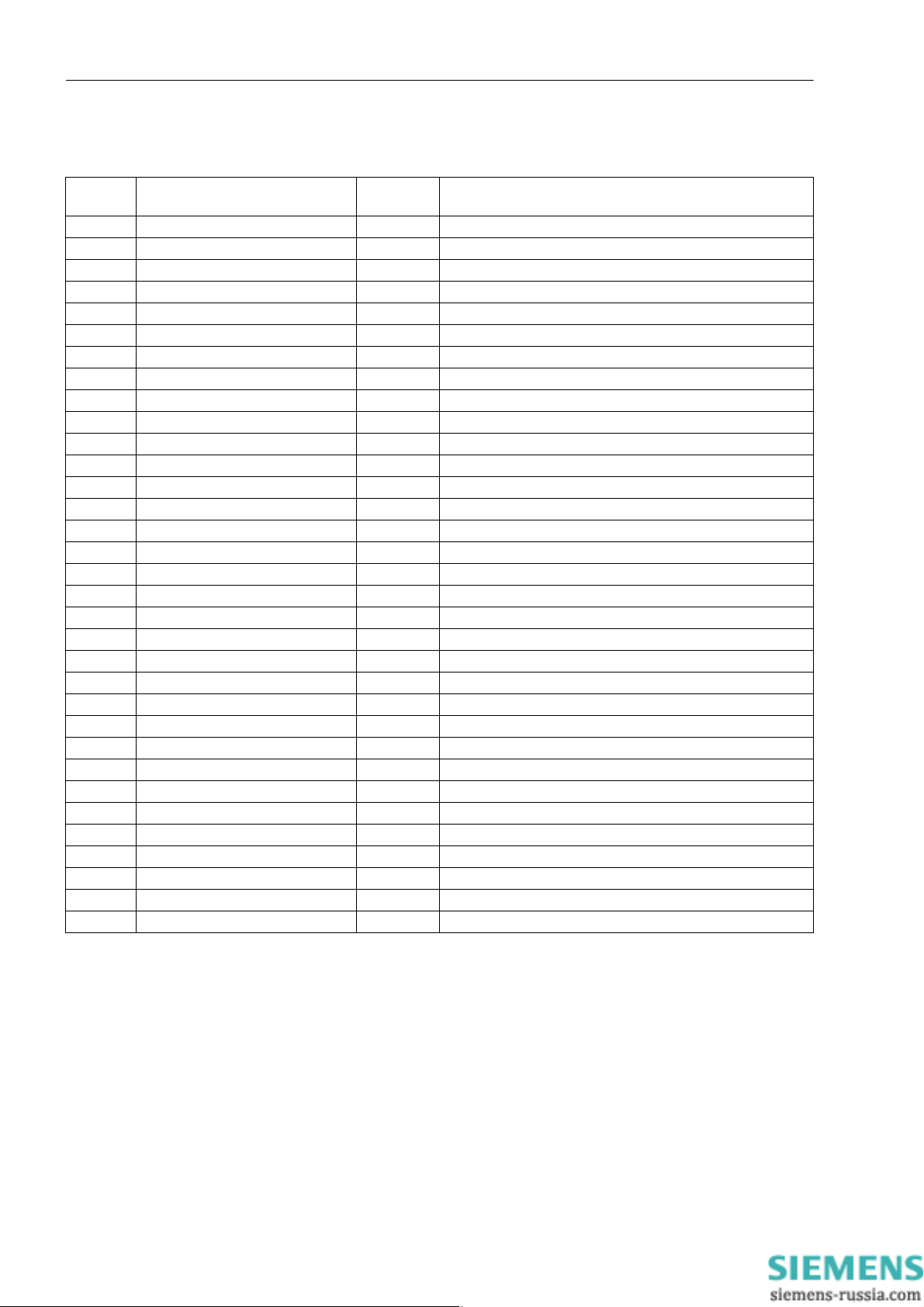

Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1.1 Overall Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

1.2 Application Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1.3 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1 Functional Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.1.1.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2.1.1.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2.1.2 Device, General Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.1.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.1.2.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1.2.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1.2.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.1.3 General Power System Data (Power System Data 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2.1.3.1 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2.1.3.2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2.1.4 Oscillographic Fault Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2.1.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2.1.4.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2.1.4.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2

2.1.4.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

2.1.5 Change Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

2.1.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

2.1.5.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

2.1.5.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

2.1.5.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2.1.6 General Protection Data (Power System Data 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2.1.6.1 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2.1.6.2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 7

2.1.6.3 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

2.1.7 EN100-Modul 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.7.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.8 Protection Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.8.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

2.1.8.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

2.1.8.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 1

2.1.8.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

9

Page 10

Contents

2.2 Phase Comparison Protection and Ground Differential Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.2.1 Differential Topol ogy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.2.1.1 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.2.1.2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.2.1.3 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2.2.2 Phase Comparison Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2.2.2.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2.2.2.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

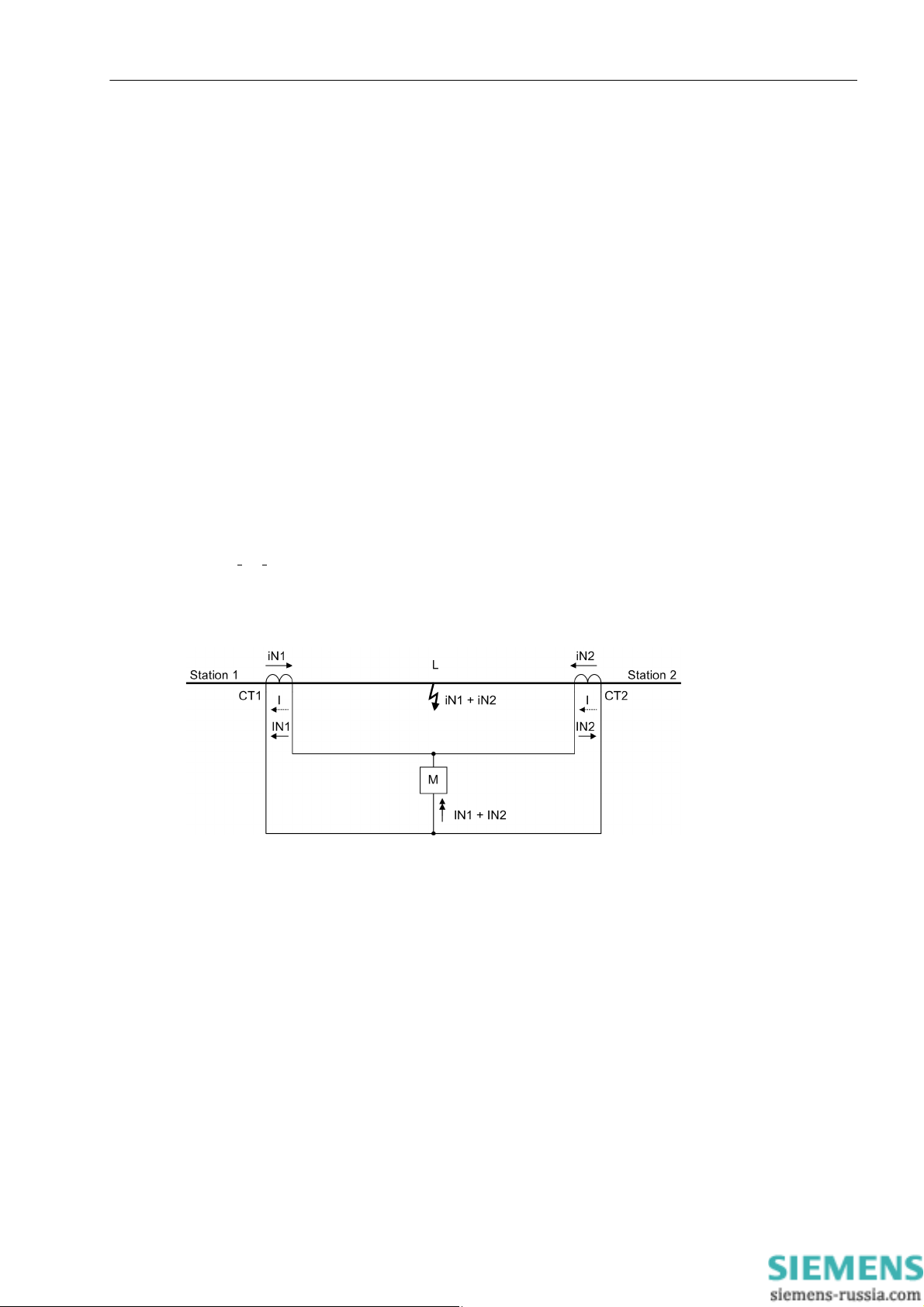

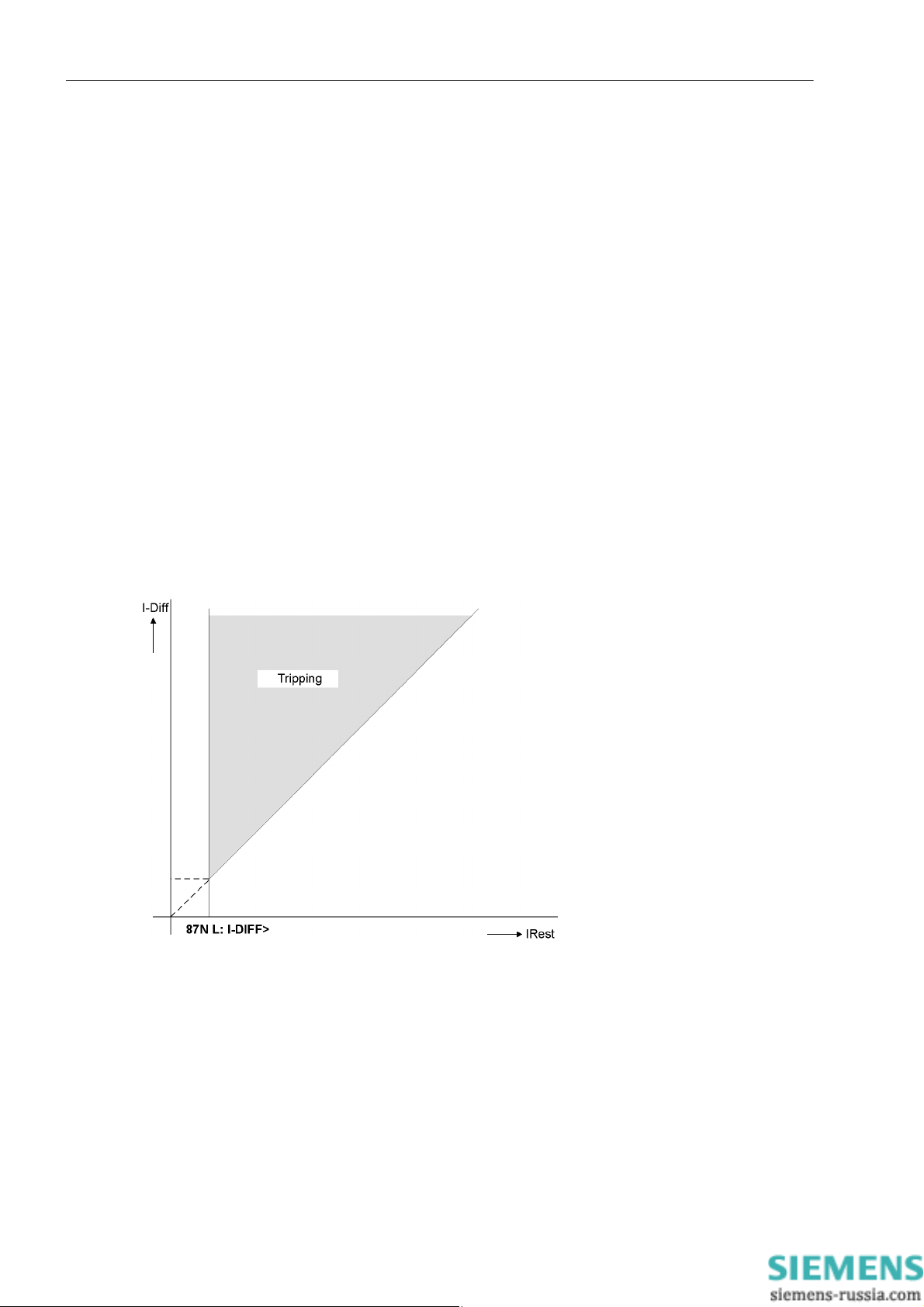

2.2.3 Ground Current Differential Protection in Grounded Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.2.3.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

2.2.3.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2.2.4 Ground Fault Differential Protection in Resonant-grounded/Isolated Systems. . . . . . . . . . . . . . . .63

2.2.4.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

2.2.4.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

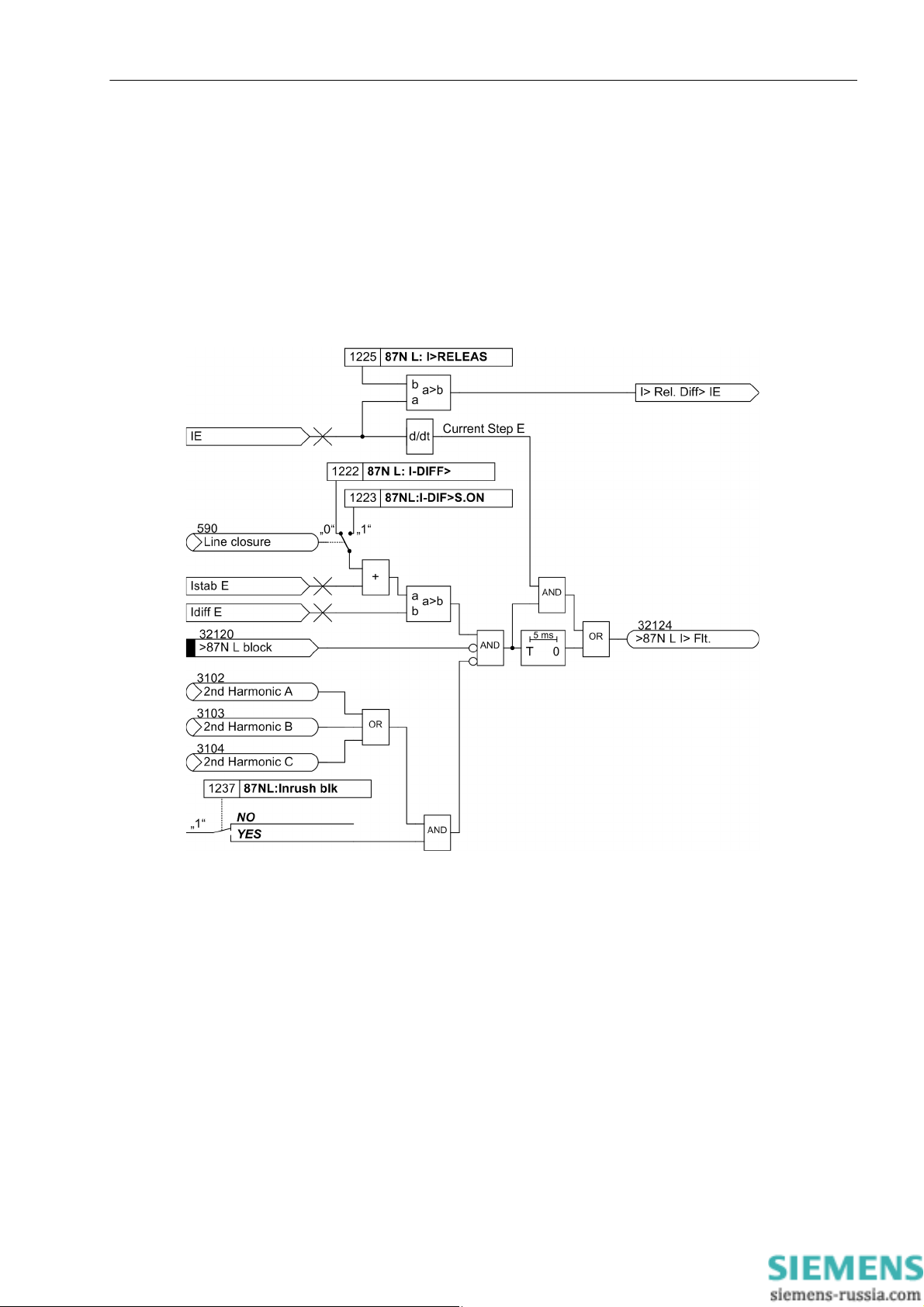

2.2.5 Differential Protection Pickup Logic and Tripping Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

2.2.5.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

2.2.6 87 Differential Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

2.2.6.1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

2.2.6.2 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

2.2.7 Differential Protection Test and Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

2.2.7.1 Differential Protection Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

2.2.7.2 Differential Protection Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

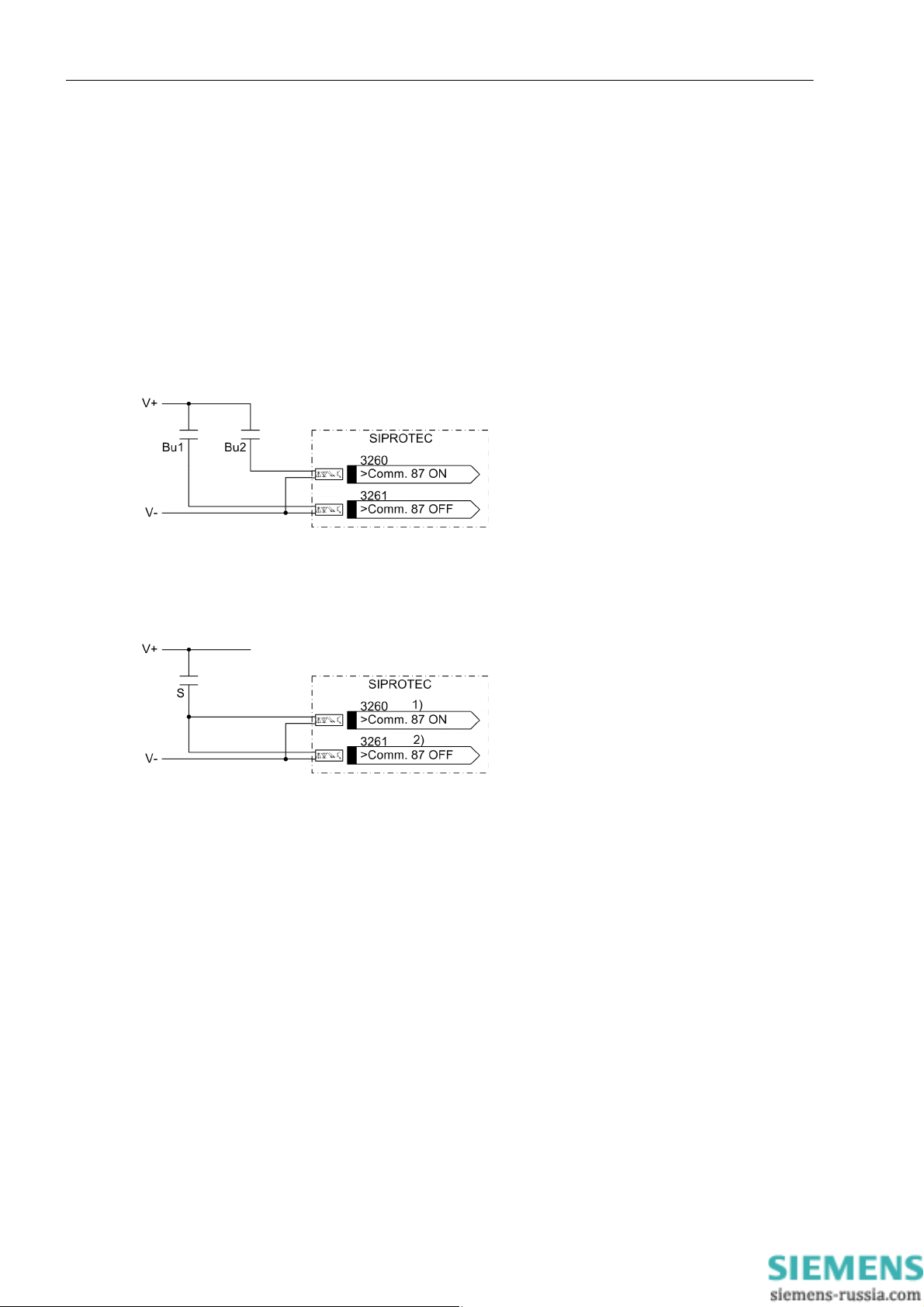

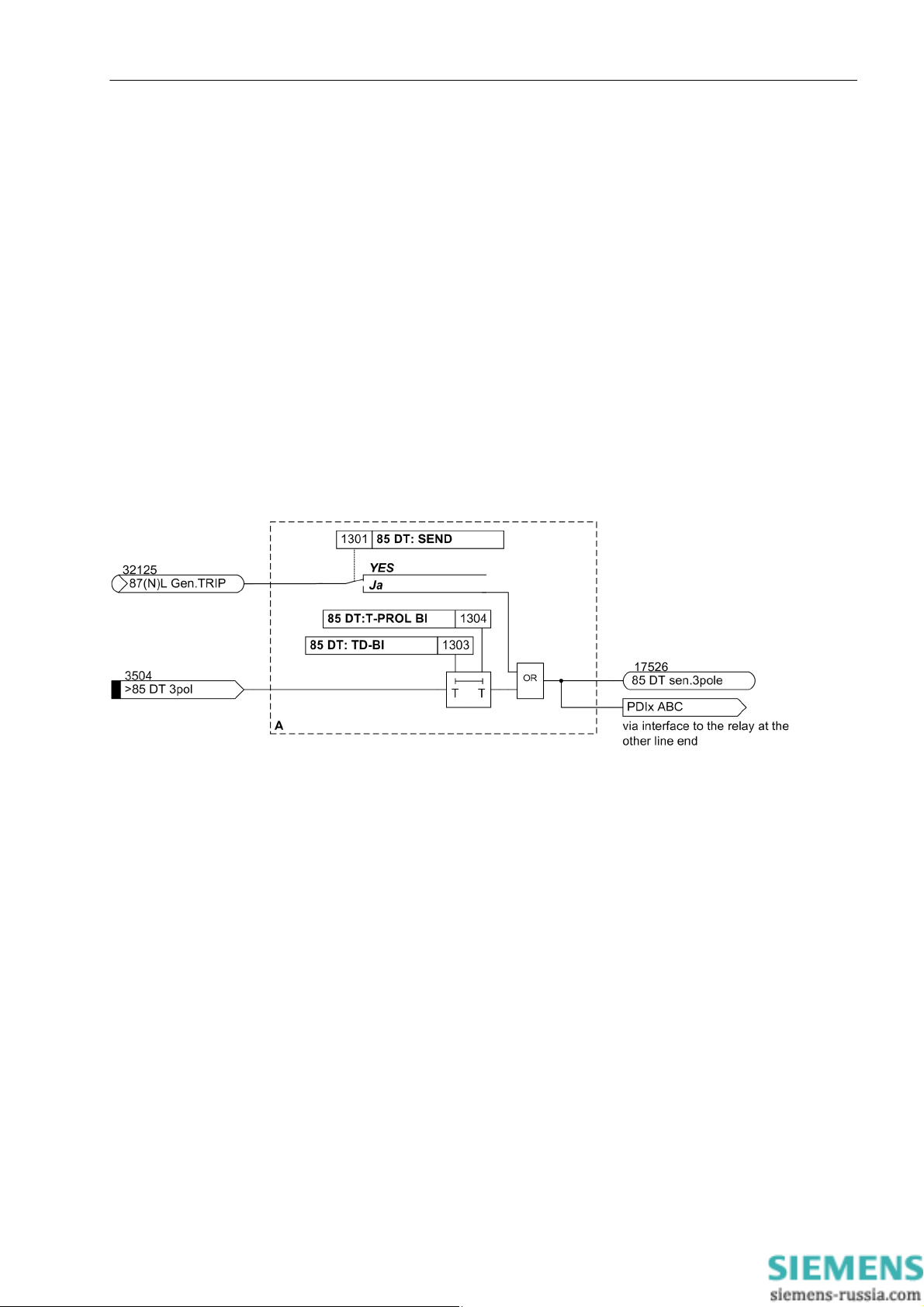

2.3 Breaker Intertrip and Remote Tripping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

2.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

2.3.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

2.3.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

2.3.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

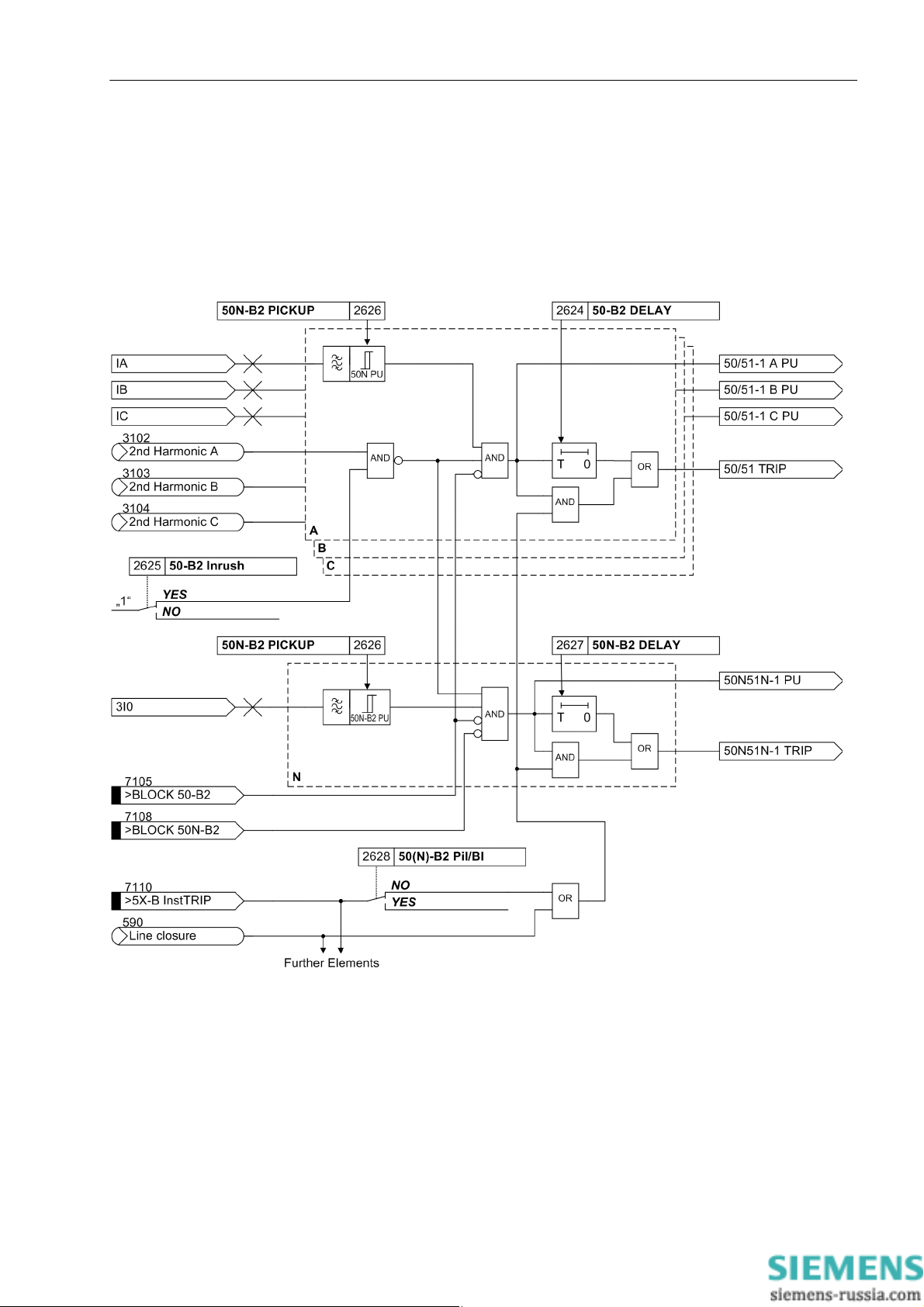

2.4 Backup Overcurrent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

2.4.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

2.4.2 Non-directional Overcurrent Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

2.4.3 Directional Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

2.4.4 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

2.4.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

2.4.6 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

2.5 Inrush Restraint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

2.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

2.5.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

2.5.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

2.5.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

2.6 Circuit-Breaker Failure Protection 50BF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

2.6.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

2.6.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

2.6.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.6.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 11

Contents

2.7 Thermal Overload Protection 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

2.7.1 Method of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

2.7.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

2.7.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

2.7.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

2.8 Undervoltage and Overvoltage Protection 27/59 (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

2.8.1 Overvoltage Protection (ANSI 59) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

2.8.2 Undervoltage Protection (ANSI 27) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

2.8.3 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

2.8.4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

2.8.5 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

2.9 Frequency Protection 81 (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

2.9.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

2.9.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

2.9.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

2.9.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

2.10 Direct Local Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

2.10.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

2.10.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

2.10.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

2.10.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

2.11 Automatic Reclosure Function 79 (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

2.11.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

2.11.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

2.11.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

2.11.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

2.12 Circuit-Breaker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

2.12.1 CB Close Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

2.12.2 Circuit-Breaker Position Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

2.12.3 Circuit-Breaker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

2.12.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

2.13 Direct Remote Trip and Transmission of Binary Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

2.13.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

2.13.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

11

Page 12

Contents

2.14 Monitoring Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

2.14.1 Measurement Supervision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

2.14.1.1 Hardware Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

2.14.1.2 Software Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

2.14.1.3 External Transformer Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

2.14.1.4 Fault Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

2.14.1.5 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

2.14.1.6 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

2.14.1.7 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

2.14.2 74TC Trip Circuit Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

2.14.2.1 Method of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

2.14.2.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

2.14.2.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

2.14.2.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

2.15 Flexible Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

2.15.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

2.15.2 Setting Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

2.15.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

2.15.4 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

2.16 Function Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

2.16.1 Pickup Logic for the Entire Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

2.16.2 Overall Tripping Logic of the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

12

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 13

Contents

2.17 Additional Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

2.17.1 Indications Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

2.17.1.1 LEDs and Binary Outputs (Output Relays). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

2.17.1.2 Information via Display Fi e ld or PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

2.17.1.3 Information to a Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

2.17.2 Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

2.17.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

2.17.2.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

2.17.3 Measurement During Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

2.17.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

2.17.3.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

2.17.4 Differential Protection Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

2.17.4.1 Measured Values of the Differential Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

2.17.4.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

2.17.5 Constellation Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

2.17.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

2.17.6 Min/Max Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

2.17.6.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

2.17.6.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

2.17.6.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

2.17.6.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

2.17.7 Demand Measurement Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

2.17.7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

2.17.7.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

2.17.7.3 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

2.17.7.4 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

2.17.8 Set Points (Measured Values) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

2.17.8.1 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

2.17.8.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

2.17.9 Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

2.17.9.1 Energy Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

2.17.9.2 Setting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

2.17.9.3 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

2.18 Breaker Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

2.18.1 Control Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

2.18.1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

2.18.1.2 Information List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

2.18.2 Command Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

2.18.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .216

2.18.3 Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

2.18.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

2.18.4 Switchgear Interlocking Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

2.18.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

2.18.5 Command Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

2.18.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

2.19 Notes on Device Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

2.19.1 Different operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

13

Page 14

Contents

3 Mounting and Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

3.1 Mounting and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

3.1.1 Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

3.1.2 Hardware Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

3.1.2.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

3.1.2.2 Connections of the Current Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

3.1.2.3 Connections of the Voltage Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

3.1.2.4 Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

3.1.2.5 Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .247

3.1.3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

3.1.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

3.1.3.2 Panel Flush Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

3.1.3.3 Cubicle Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

3.1.3.4 Panel Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

3.2 Checking Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

3.2.1 Checking the Data Connections of the Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

3.2.2 Checking the Protection Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

3.2.3 Checking the System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

3.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

3.3.1 Test Mode and Transmission Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

3.3.2 Checking Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

3.3.3 Testing the System Interface (at Port B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

3.3.4 Configuring Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

3.3.5 Checking the Status of Binary Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

3.3.6 Checking the Protection Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

3.3.7 Tests for Circuit-Breaker Failure Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

3.3.8 Checking the Instrument Transformer Connections of One Line End. . . . . . . . . . . . . . . . . . . . . .272

3.3.9 Checking the Instrument Transformer Connections of Two Line Ends . . . . . . . . . . . . . . . . . . . . . 277

3.3.10 Checking the Pilot Protection for Internal and External Remote Tripping . . . . . . . . . . . . . . . . . . .277

3.3.11 Testing User-defined Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

3.3.12 Trip and Close Test with the Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

3.3.13 Switching Check for the Configured Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .278

3.3.14 Triggering Oscillographic Recording for Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

3.4 Final Preparation of the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

4.1 General Device Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

4.1.1 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

4.1.2 Auxiliary Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

4.1.3 Binary Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 84

4.1.4 Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

4.1.5 Electrical Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .288

4.1.6 Mechanical Stress Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .290

4.1.7 Climatic Stress Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

4.1.8 Service Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .291

4.1.9 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .291

4.1.10 UL certification conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .292

14

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 15

Contents

4.2 Protection interfaces and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .293

4.3 87 Differential Protection Phase Comparison Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .296

4.4 Ground Fault Differential Protection in Grounded Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .299

4.5 Ground Fault Differential Protection in Resonant-grounded / Isolated Systems . . . . . . . . . . . . . . . . .300

4.6 Breaker Intertrip and Remote Tripping- Direct Local Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .301

4.7 Time Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

4.8 Inrush Current Restraint Breaker Intertrip and Remote Tripping. . . . . . . . . . . . . . . . . . . . . . . . . . . . .309

4.9 Circuit-Breaker Failure Protection (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .310

4.10 Thermal Overload Protection 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

4.11 Voltage Protection (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .313

4.12 Frequency Protection (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .316

4.13 Automatic Reclosing (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .317

4.14 Transmission of Binary Information and Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .318

4.15 Monitoring Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .319

4.16 Flexible Protection Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .321

4.17 User-defined Functions (CFC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .324

4.18 Additional Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .328

4.19 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .330

4.19.1 Panel Flush Mounting and Cabinet Flush Mounting (H ousing Size 1/6) . . . . . . . . . . . . . . . . . . . .330

4.19.2 Panel Surface Mounting (Housing Size 1/6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .331

4.19.3 Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .332

A Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

A.1 Ordering Information and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

A.1.1 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

A.1.1.1 7SD80 V4.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .334

A.1.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .337

A.2 Terminal Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .339

A.2.1 7SD80 — Housing for Panel Flush Mounting and Cabinet Flush Mounting and

for Panel Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .339

A.3 Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .345

A.4 Current Transformer Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .348

A.4.1 Current Transformer Ratio: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .348

A.4.2 Overcurrent Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .348

A.4.3 Class Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

A.4.4 Core Balance Current Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

Class Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .350

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

15

Page 16

Contents

A.5 Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .351

A.5.1 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .351

A.5.2 Binary Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .351

A.5.3 Binary Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .352

A.5.4 Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .352

A.5.5 Default Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

A.5.6 Pre-defined CFC Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

A.6 Protocol-dependent Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

A.7 Functional Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .358

A.8 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .360

A.9 Information List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .371

A.10 Group Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

A.11 Measured Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .394

Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .399

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .401

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

16

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 17

Introduction 1

This chapter introduces the SIPROTEC 4 7SD80 and gives an overview of the device's application, properties

and functions.

1.1 Overall Operation 18

1.2 Application Scope 21

1.3 Characteristics 23

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

17

Page 18

Introduction

1.1 Overall Operation

1.1 Overall Operation

The digital SIPROTEC 7SD80 overcurrent protection is equipped with a powerful microprocessor. It allows all

tasks to be processed digitally, from the acquisition of measured quantities to sending commands to circuit

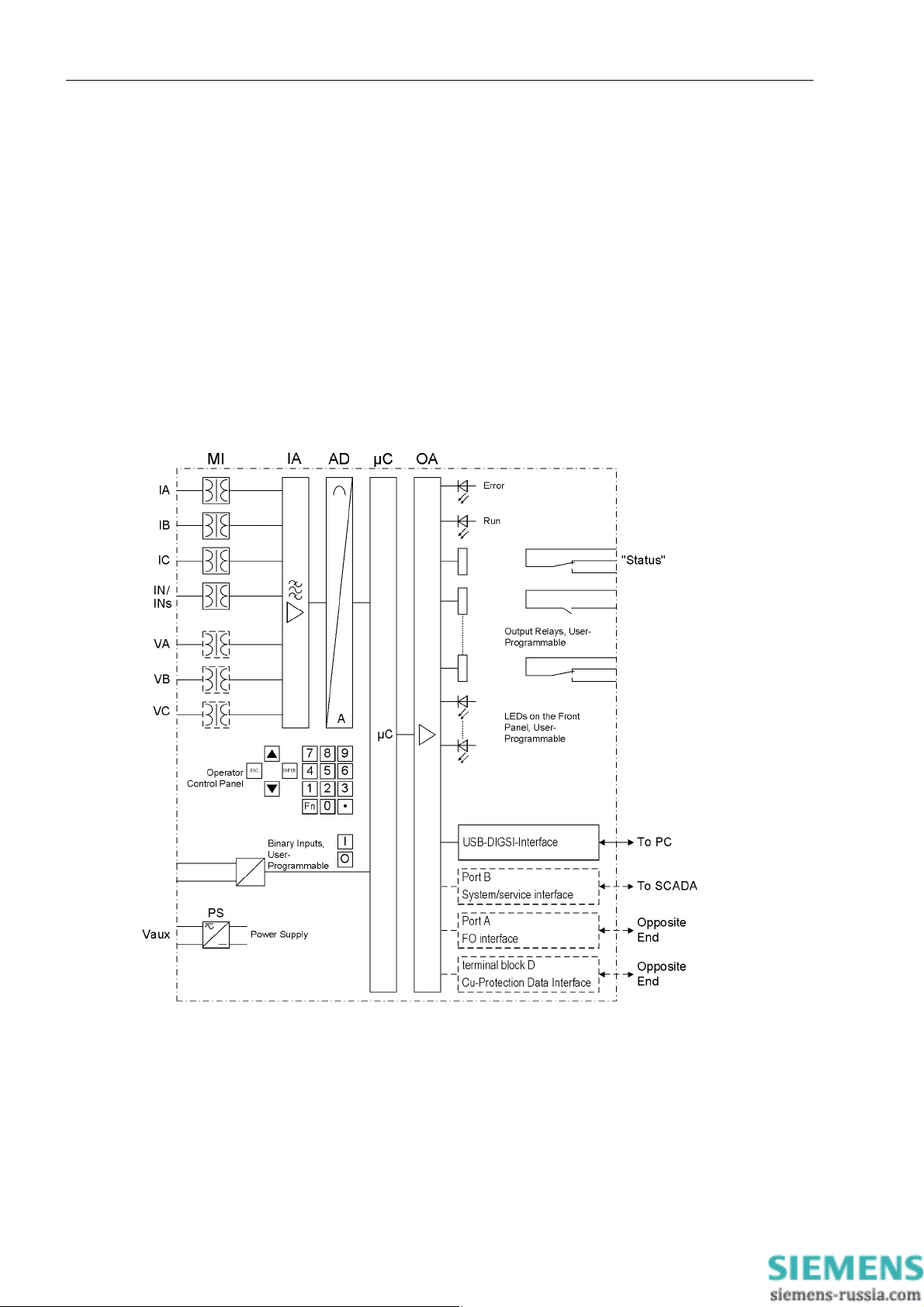

breakers. Figure 1-1 shows the basic structure of the 7SD80 device.

Analog Inputs

The measuring inputs (MI) convert the currents and voltages coming from the instrument transformers and

adapt them to the level appropriate for the internal processing of the device. The device provides 4 current

transformers and - depending on the model - additionally 3 voltage transformers. Three current inputs serve for

the input of the phase currents, another current input (I

I

(current transformer starpoint) or for a separate ground current transformer (for sensitive ground fault detec-

N

tion I

and directional determination of ground faults) - depending on the model.

Ns

) may be used for measuring the ground fault current

N

18

Figure 1-1 Hardware structure of the 7SD80 differential protection

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 19

There is one voltage input available for each phase-to-ground voltage. The differential protection does not need

measuring voltages due to its functional principle. Directional overcurrent protection, however, requires the

phase-to-ground voltage V

displaying voltages and power values and also measuring the line voltage for automatic reclosing. The analog

quantities are forwarded to the input amplifier group (IA).

The input amplifier group IA provides high-resistance termination for the analog input quantities. It consists of

filters that are optimized for measured value processing with regard to bandwidth and processing speed.

The analog-to-digital (AD) element consists of an analog-to-digital (A/D) converter and memory components

for data transmission to the microcomputer system.

Microcomputer System

Apart from processing the measured values, the microcomputer system µC also executes the actual protection

and control functions. They especially consist of:

• Filtering and preparation of the measured quantities

• Continuous monitoring of the measured quantities

• Monitoring of the pickup conditions for the individual protection functions

• Interrogation of limit values and time sequences

• Control of signals for the logic functions

• Decision on trip and close commands

• Recording of messages, fault data and fault values for analysis

• Administration of the operating system and its functions, e.g. data storage, realtime clock, communication,

interfaces, etc.

• Formation of the local differential protection values (phasor analysis and charge current computation) and

creation of the transmission protocol

• Decoding the received transmission protocol, synchronization of differential protection values and totaling

the differential currents and charge currents

• Monitoring the communication with the device of the remote en d

Introduction

1.1 Overall Operation

, VB and VC to be connected. Additionally, voltages can be connected that allow

A

The information is provided via output amplifier OA.

Binary Inputs and Outputs

Binary inputs and outputs to and from the computer system are relayed via the input/output modules. The computer system obtains information from the system (e.g. remote resetting) or from other devices (e.g. blocking

commands). Outputs are, in particular, commands to the switchgear units and annunciations for remote signaling of important events and statuses.

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

19

Page 20

Introduction

1.1 Overall Operation

Front Elements

Information such as messages related to events, states, measured values and the functional status of the

device are visualized by light-emitting diodes (LEDs) and a display screen (LCD) on the front panel.

Integrated control and numeric keys in conjunction with the LCD enable communication with the remote device.

These elements enable the user to retrieve all device information such as configuration and setting parameters,

operational indications and fault indications or measured values and to edit setting parameters.

In addition, control of circuit breakers and other equipment is possible from the front panel of the device.

Interfaces

Communication with a PC can be implemented via the USB DIGSI interface using the DIGSI software allowing

the user to conveniently handle all device functions.

Port A can be used as protection interface to communicate with another 7SD80 device via an optical fiber

cable.

If you are using a copper link to create a connection to the other 7SD80 device, use the voltage terminals D1

and D2 as protection interface.

The protection data interfaces are used to transfer the data of the measured quantities from each end of the

protected zone to the opposite end. Further information such as closing of the local circuit breaker or other externally injected trip commands can be transmitted to the opposite end via the protection interface.

In addition to the device communication via DIGSI, port B can also be used to transmit all device data to a

central evaluator or a control center. This interface may be provided with various protocols and physical transmission schemes to suit the particular application.

Power Supply

The functional units described are supplied by a power supply (PS) with the adequate power in the different

voltage levels. Transient voltage dips may occur if the auxiliary voltage supply system becomes short-circuited.

Usually, they are bridged by a capacitor storage (see also the Section 4, Technical Data).

A buffer battery is located behind the lower front cover.

20

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 21

1.2 Application Scope

The digital Line Differential Protection SIPROTEC 4 7SD80 is a selective short-circuit protection for overhead

lines and cables with single- and multi-ended infeeds in radial, ring or any type of meshed systems of any transmission level. The measured data are compared separately for each phase.

A major advantage of the differential protection principle is the instantaneous tripping in the event of a short

circuit at any point within the entire protected zone. The current transformers limit the protected zone at the

ends towards the remaining system. This rigid delimitation is the reason why the differential protection scheme

shows such an ideal selectivity.

The differential protection system requires a 7SD80 device as well as a set of current transformers at either

end of the protected zone. Voltage transformers are not required for the differential protection functions in the

7SD80; they are, however, available to record and display measured values (voltages, power, power factor) or

when using a directional overcurrent protection element.

The devices located at the ends of the protected zone exchange measuring information via protection interfaces using communication links (usually optical fiber or copper cables).

Since fault-free data transmission is the prerequisite for the proper operation of the protection, it is continuously

monitored internally.

Introduction

1.2 Application Scope

Protection Functions

The device's basic function is to detect short-circuits or ground faults in the protected zone – even weak-current

or high-resistance short-circuits. Even complex multiphase faults are detected correctly, as the measured

values are evaluated separately for each phase. The protection is restraint against inrush currents of power

transformers. When switching a line onto a fault, it is possible to send an instantaneous trip signal. The 7SD80

line differential protection includes the differential protection functions of phase comparison protection and

ground fault differential protection. Both differential protection functions operate independently of each other.

In the event of a communication failure, the devices can automatically switch to emergency operation using an

integrated overcurrent protection until communication is restored. The overcurrent protection comprises two

definite time-overcurrent protection elements and one inverse time-overcurrent protection element. Both elements operate directional or non-directional. Additionally, the device features a third definite time-overcurrent

protection element that always operates non-directionally.

For inverse time overcurrent protection, several characteristic curves of different standards are available.

Alternatively, the time overcurrent protection can be used as a backup time overcurrent protection, i.e. it oper-

ates independent of and parallel to the differential protection at either end.

The communication link can be used for transmitting further information. Besides measured values, it is possi-

ble to transmit binary information.

All protection functions in the 7SD80 always trip 3-pole. They can work together with an integrated automatic

reclose function (optional). The automatic reclose functions enables 3-pole automatic reclosing with two

reclose attempts.

The thermal overload protection protects cables and power transformers from inadmissible heating due to overload.

Additionally, a two-element overvoltage and undervoltage protection and a four-element frequency protection

can be used. A circuit-breaker failure protection monitors the response of the circuit breaker following a trip

command.

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

21

Page 22

Introduction

1.2 Application Scope

Control Functions

The device provides a control function which can be accomplished for activating and deactivating switchgear

via operator buttons, port B, binary inputs and - using a PC and the DIGSI software - via the front interface.

The switch positions are fed back to the device via auxiliary contacts of the circuit breakers and binary inputs.

The current switch positions can be read out at the device and used for plausibility monitoring and interlockings.

The number of the devices to be switched is limited by the binary inputs and outputs available in the device or

the binary inputs and outputs allocated for the switch position feedbacks. Depending on the equipment, one

binary input (single point indication) or two binary inputs (double point indication) can be used. The release to

switch can be restricted by appropriate settings for the switching authority (remote or local), and by the operating mode (interlocked/non-interlocked, with or without password validation). Interlocking conditions for

switching (e.g. switchgear interlocking) can be defined with the help of integrated user-configurable logic functions.

Messages and Measured Values; Recording of Event and Fault Data

The operational indications provide information about conditions in the power system and the device. Measurement quantities and values that are calculated can be displayed locally and communicated via the serial interfaces.

Device messages can be assigned to a number of LEDs on the front cover (allocatable), can be externally processed via output contacts (allocatable), linked with user-definable logic functions and/or issued via serial interfaces.

During a fault (system fault) important events and changes in conditions are saved in fault protocols (Event Log

or Trip Log). Instantaneous fault values are also saved in the device and may be analyzed subsequently.

Communication

The following interfaces are available for communication with external operating, control and memory systems.

The USB DIGSI interface on the front cover serves for local communication with a PC. With the SIPROTEC 4

operating software DIGSI, all operation and evaluation tasks can be executed using this operator interface, for

instance specifying and editing configuration parameters and settings, configuring user-specific logic functions,

retrieving operational messages and measured values, inquiring device conditions and measured values,

issuing control commands.

Port A is located on the bottom side of the device. This protection data interface connects the device to its

partner device at the remote end of the protected object.

Alternatively, you can implement the communication link using the voltage terminals D-1 and D-2.

Port B serves for central communication between the device and a control center. It can be operated via data

lines or optical fiber cables. For the data transfer, standardized protocols according IEC 60870-5-103 are available. The integration of the devices into the SINAUT LSA and SICAM automation systems can also be implemented with this profile.

Alternatively, there are additional connection options available in connection with PROFIBUS DP and the

DNP3.0 and MODBUS protocols. If an EN100 module is available, it is also possible to use the IEC61850 protocol.

You can also use port B to connect a time synchronization device such as DCF77 or IRIG-B.

22

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 23

1.3 Characteristics

General Properties

• Powerful 32-bit microprocessor system

• Complete digital processing of measured values and control, from the sampling of the analog input values,

the processing and organization of the communication between devices up to the closing and tripping commands to the circuit breakers.

• Total galvani c and fail-safe separation of the internal processing circuits from the measuring, control and

supply circuits of the system via measuring transformers, binary input and output modules and DC or AC

converters

• Suited for lines with two ends, even with transformers in the protected zone

• Easy device operation using the integrated operator panel or from a connected personal computer running

DIGSI

• Storage of fault indications as well as instantaneous values for fault recording

• Digital protection data transmission; communication of the device through optical fiber cables

• Communication is possible via a single copper wire pair (typically 8 km (4.97 miles), max. 20 km

(12.43 miles), depending on the used cable type, see Section 4, Technical Data).

Introduction

1.3 Characteristics

• Permanent supervision of the protection data transmission for disturbance, failure or transfer time variations

Phase Comparison Protection

• Differential protection for two ends with digital protection data transmission

• Protection for all types of short-circuits in systems with any starpoint conditioning

• Reliable distinction between load and short-circuit conditions using adaptive measureme nt methods, also

for high-resistance faults with small fault currents

• High sensitivity in light load operation, highest stability against load steps and power fluctuations

• Due to phase segregated measurement, the pickup sensitivity is independent of the fault type

• Suited for feeder transformers in the protected zone

• Detection of high-resistance, weak-current faults due to high sensitivity of the protection functions

• Fast tripping also on weak or zero infeed ends (breaker intertrip)

• No frequency dependency

Ground Fault Differential Protection for Grounded Systems

• Short command time

• High sensitivity for short circuits to ground

• High stability against external ground faults by stabilizing the through-flowing ground current

Ground Fault Differential Protection for Isolated / Grounded Systems

• Short command time

• High sensitivity for short circuits to ground

• High stability against external short-circuits to ground using the magnitude and phase relationship of the

ground current flowing through for stabilization

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

23

Page 24

Introduction

1.3 Characteristics

External Direct and Remote T ripping

• Tripping of the local end by an external device via binary input

• Tripping of the opposite end by local protection functions or by an external device via binary input

Time Overcurrent Protection

• Optionally selectable as emergency function during protection data communication failure or as backup

function or both

• A maximum of 3 definite time elements and one inverse time element, each for phase currents and ground

current

• A maximum of 2 directional definite time elements and one directional inverse time element, each for phase

currents and ground current

• For inverse time overcurrent protection, selection from various characteristics of different standards possible

• Blocking options e.g. for reverse interlocking with any element

• Instantaneous tripping when closing onto a short circuit possible with any element

Inrush Current Restraint

• Insensitive to inrush currents, even in the case of feeder transformers in the protected zone, and against

higher-frequency transients

• High stability also for different current transformer saturation

Circuit-Breaker Failure Protection

• With independent current elements for the monitoring of the current flow through each pole of the circuit

breaker

• Separate pickup thresholds for phase and ground currents

• Monitoring time element for tripping

• Initiation by the trip command of each integrated protection function

• Initiation by external trip functions possible

• Single-element or two-element

• No dropout and seal-in times

Thermal Overload Protection

• Thermal replica of the current heat losses of the protected object

• RMS measurement for all three phase currents

• Adjustable thermal and current-dependent warning elements

24

E50417-G1140-C474-A1, Release date 09.2011

SIPROTEC, 7SD80, Manual

Page 25

Vo ltage Protection

• Overvoltage and undervoltage detection with different elements

• Two overvoltage elements for the phase-to-ground voltages

• Two overvoltage elements for the phase-to-phase voltages

• Two overvoltage elements for the positive sequence voltage

• Two overvoltage elements for the negative sequence system of the voltages

• Two overvoltage elements for the zero system of the voltages or for any other single-phase voltage

• Adjustable dropout conditions

• Two undervoltage elements for the phase-to-ground voltages

• Two undervoltage elements for the phase-to-phase voltages

• Two undervoltage elements for the positive sequence system of the voltages

• Adjustable current criterion for undervoltage protection functions

Frequency Protection 81 (Optional)

• Monitoring of falling below (f<) and/or exceeding (f>) with 4 frequency limits and time delays that are independently adjustable

Introduction

1.3 Characteristics

• Particularly insensitive to harmonics and abrupt phase angle changes

• Wide frequency range (approx. 25 Hz to 70 Hz)

Automatic Reclose Function (Optional)

• For reclosing after 3-pole open condition

• Two recl o si n g attempts

• With separate action times for each reclosing attempt, optionally without action times

• With separate dead times

• Optionally controlled by protection element pickup with separate dead times after 1-pole, 2-pole or 3-pole

pickup

Monitoring Functions

• Reliability of the device is greatly increased because of self-monitoring of the internal measurement circuits,

the auxiliary power supply as well as the hardware and software

• Monitoring of the current transformer and voltage transformer secondary circuits using summation and symmetry check techniques

• Monitoring of communication with statistics showing the availability of transmission telegrams

• Check of the consistency of protection settings at both line ends: no processor system start-up with inconsistent settings which could lead to a malfunction of the differential protection system

• Trip circuit monitoring possible

• Check of local and remote measured values and comparison of both

• Broken wire supervision for the secondary CT circuits with fast phase segregated blocking of the differential

protection system in order to avoid malfunction

• Supervision of measuring voltage failure using "Fuse Failure Monitor"

SIPROTEC, 7SD80, Manual

E50417-G1140-C474-A1, Release date 09.2011

25

Page 26

Introduction

1.3 Characteristics

Flexible Protection Functions

• Up to 20 customizable protection functi ons with 3-phase or 1-phase operation

• Any calculated or directly measured variable can theoretically be evaluated

• Standard protection logic with a constant (i.e. definite time) characteristic curve

• Internal and configurable pickup and dropout delay

• Editable indication texts

User-defined Logic Functions (CFC)

• Internal and external signals can be logically combined to realize user-defined logic functions

• All common logic functions

• Time delays and limit value interrogations

Command Processing

• Switching devices can be opened and closed manually using control keys, programmable function keys, via

port B (e.g. of SICAM or SCADA), or via the user interface (using a personal computer and the DIGSI operating software)

• Feedback of the circuit-breaker states via the breaker auxiliary contacts (for commands with feedback)

• Plausibility monitoring of the circuit-breaker positions and interlocking conditions.

Commissioning; Operation; Maintena nce

• Indication of the local and remote measured values according to magnitude and phase angle

• Indication of the calculated differential and restraint currents

• Indication of the measured values of the communication connection, as runtime and availability

Additional Functions

• Battery-buffered clock which can be synchronized via a synchronization signal (DCF77, IRIGB via satellite

receiver), binary input or system interface