Page 1

SINAMICS G: Control of a G120 or G110M with an Allen-Bradley controller (Compact/ ControlLogix) via EtherNet/IP

SINAMICS G120, G110M

https://support.industry.siemens.com/cs/ww/en/view/82843076

Siemens

Industry

Online

Support

Page 2

Legal information

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

2

Siemens AG

2015 All rights reserved

Legal information

Use of application examples

Application examples illustrate the solution of automation tasks through an interaction of several

components in the form of text, graphics and/or software modules. The application examples are

a free service by Siemens AG and/or a subsidiary of Siemens AG (“Siemens”). They are nonbinding and make no claim to completeness or functionality regarding configuration and

equipment. The application examples merely offer help with typical tasks; they do not constitute

customer-specific solutions. You yourself are responsible for the proper and safe operation of the

products in accordance with applicable regulations and must also check the function of the

respective application example and customize it for your system.

Siemens grants you the non-exclusive, non-sublicensable and non-transferable right to have the

application examples used by technically trained personnel. Any change to the application

examples is your responsibility. Sharing the application examples with third parties or copying the

application examples or excerpts thereof is permitted only in combination with your own products.

The application examples are not required to undergo the customary tests and quality inspections

of a chargeable product; they may have functional and performance defects as well as errors. It is

your responsibility to use them in such a manner that any malfunctions that may occur do not

result in property damage or injury to persons.

Disclaimer of liability

Siemens shall not assume any liability, for any legal reason whatsoever, including, without

limitation, liability for the usability, availability, completeness and freedom from defects of the

application examples as well as for related information, configuration and performance data and

any damage caused thereby. This shall not apply in cases of mandatory liability, for example

under the German Product Liability Act, or in cases of intent, gross negligence, or culpable loss of

life, bodily injury or damage to health, non-compliance with a guarantee, fraudulent

non-disclosure of a defect, or culpable breach of material contractual obligations. Claims for

damages arising from a breach of material contractual obligations shall however be limited to the

foreseeable damage typical of the type of agreement, unless liability arises from intent or gross

negligence or is based on loss of life, bodily injury or damage to health. The foregoing provisions

do not imply any change in the burden of proof to your detriment. You shall indemnify Siemens

against existing or future claims of third parties in this connection except where Siemens is

mandatorily liable.

By using the application examples you acknowledge that Siemens cannot be held liable for any

damage beyond the liability provisions described.

Other information

Siemens reserves the right to make changes to the application examples at any time without

notice. In case of discrepancies between the suggestions in the application examples and other

Siemens publications such as catalogs, the content of the other documentation shall have

precedence.

The Siemens terms of use (https://support.industry.siemens.com) shall also apply.

Security information

Siemens provides products and solutions with industrial security functions that support the secure

operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is necessary

to implement – and continuously maintain – a holistic, state-of-the-art industrial security concept.

Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems, machines

and networks. Such systems, machines and components should only be connected to an

enterprise network or the Internet if and to the extent such a connection is necessary and only

when appropriate security measures (e.g. firewalls and/or network segmentation) are in place.

For additional information on industrial security measures that may be implemented, please visit

https://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they are available

and that the latest product versions are used. Use of product versions that are no longer

supported, and failure to apply the latest updates may increase customer’s exposure to cyber

threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS Feed

at: https://www.siemens.com/industrialsecurity.

Page 3

Table of contents

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

3

Siemens AG

2015 All rights reserved

Table of contents

Legal information ......................................................................................................... 2

1 Introduction ........................................................................................................ 5

1.1 EtherNet/IP Overview ........................................................................... 5

1.2 SINAMICS G series Connectivity to EtherNet/IP ................................. 5

2 Solution Overview ............................................................................................. 6

2.1 Solution Overview ................................................................................ 6

2.2 Used Components ................................................................................ 6

3 Programming Overview .................................................................................... 7

3.1 Configuration Choices .......................................................................... 7

3.2 AOI’s for SINAMICS G Series drives ................................................... 8

3.3 AOI Types ............................................................................................ 8

4 SINAMICS G120 Add-On Instructions ............................................................. 9

4.1 Function Description ............................................................................. 9

4.2 Telegram Descriptions ......................................................................... 9

4.2.1 Telegram Type 1 for Simple Speed ...................................................... 9

4.2.2 Telegram Type 352 for Simple Speed .................................................. 9

4.2.3 Telegram Type 111 for EPOS mode .................................................. 10

4.3 Basic Speed Control –Telegram 1 ..................................................... 11

4.3.1 Functionality ....................................................................................... 11

4.3.2 Schematic Ladder Representation ..................................................... 11

4.3.3 Input and Output Parameters ............................................................. 11

4.4 Speed Control –Telegram 352 ........................................................... 12

4.4.1 Functionality ....................................................................................... 12

4.4.2 Schematic Ladder Representation ..................................................... 13

4.4.3 Input and Output parameters ............................................................. 13

4.5 EPOS Control ..................................................................................... 15

4.5.1 Functionality ....................................................................................... 15

4.5.2 Schematic Ladder Representation ..................................................... 15

4.5.3 Input and Output parameters ............................................................. 16

4.6 UDTs .................................................................................................. 18

5 Drive Configuration ......................................................................................... 19

5.1 Configuring IP Address of CU ............................................................ 19

5.2 Using a Freely Configurable Telegram ............................................... 23

5.2.1 Example of "Free telegram" commissioning ...................................... 24

6 Configuring a Generic Ethernet Module........................................................ 25

6.1 Adding a new module in RSLogix ...................................................... 25

6.1.1 Inserting the module in an RSLogix project ....................................... 25

6.1.2 Configuring network parameters ........................................................ 26

6.1.3 Connection Parameters...................................................................... 27

6.1.4 Using IO Data ..................................................................................... 27

7 Using AIOs in a new application .................................................................... 28

7.1 Importing AIOs ................................................................................... 28

7.1.1 Installing L5K Files in RSLogix ........................................................... 28

7.2 Using the AOI ..................................................................................... 29

7.2.1 Adding AOI to an RSLogix Program .................................................. 29

7.2.2 I/O Interface ........................................................................................ 30

8 Drive Parameter Access.................................................................................. 31

8.1 Explicit Messaging .............................................................................. 31

Page 4

Table of contents

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

4

Siemens AG

2015 All rights reserved

8.2 Using the MSG Instruction ................................................................. 32

9 Troubleshooting .............................................................................................. 37

9.1 I can’t go online with the drive in Starter using the Ethernet

cable. .................................................................................................. 37

9.2 The drive and the PLC are not communicating .................................. 37

10 Glossary ........................................................................................................... 40

11 Appendix .......................................................................................................... 41

11.1 Service and support ........................................................................... 41

11.2 Change documentation ...................................................................... 42

Page 5

1 Introduction

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

5

Siemens AG

2015 All rights reserved

1 Introduction

1.1 EtherNet/IP Overview

Industrial Ethernet communication networks continue to gain global importance in

automation solutions. Industrial Ethernet connectivity down to device level

components (i.e. drives, I/O, etc.) is an end user requirement that demands

openness and flexibility. To capitalize on the flexibility to connect to different

Industrial Ethernet protocols the SINAMICS G120 can seamlessly be applied in

PROFINET and EtherNet/IP networks.

1.2 SINAMICS G series Connectivity to EtherNet/IP

The SINAMICS drive family offers both PROFINET and EtherNet/IP software

stacks for the SINAMICS G series which is easily selected via a parameter setting

in the standard SINAMICS firmware.

The network IP address of the SINAMICS G drive can be set through the

STARTER software. With STARTER software installed on your computer you can

connect to the SINAMICS drive through PROFINET or EtherNet/IP.

The SINAMICS drives operate on unicast telegrams which reduces network traffic.

SINAMICS G drives have been certified by ODVA for EtherNet/IP conformance

testing and participated in the EtherNet/IP PlugFest. Siemens is a member of

ODVA with Vendor ID # 1251.

Figure 1-1

Page 6

2 Solution Overview

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

6

Siemens AG

2015 All rights reserved

2 Solution Overview

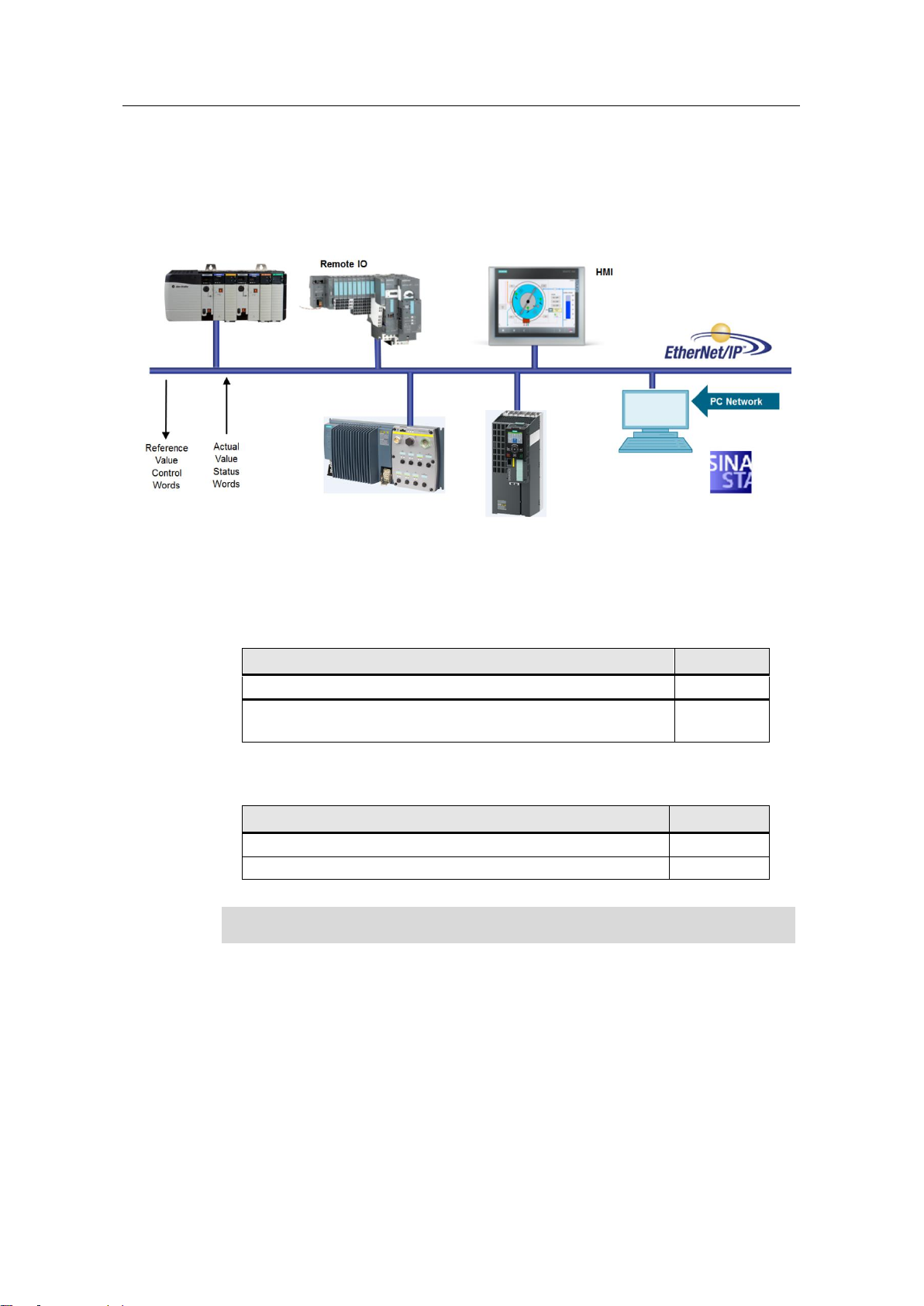

2.1 Solution Overview

Figure 2-1

2.2 Used Components

The application was generated with the following components:

Hardware Components

Component

No.

PROFINET versions of G120 with Firmware version 4.10.1

1

Rockwell Automation Logix family controller Firmware version

20

1

Software components

Component

No.

STARTER Version 5.1.1 or later

1

RS Logix 5000 Version 20 or later

1

NOTE

RSLogix 5000 Version 19 can be used when not using the EDS file

Page 7

3 Programming Overview

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

7

Siemens AG

2015 All rights reserved

3 Programming Overview

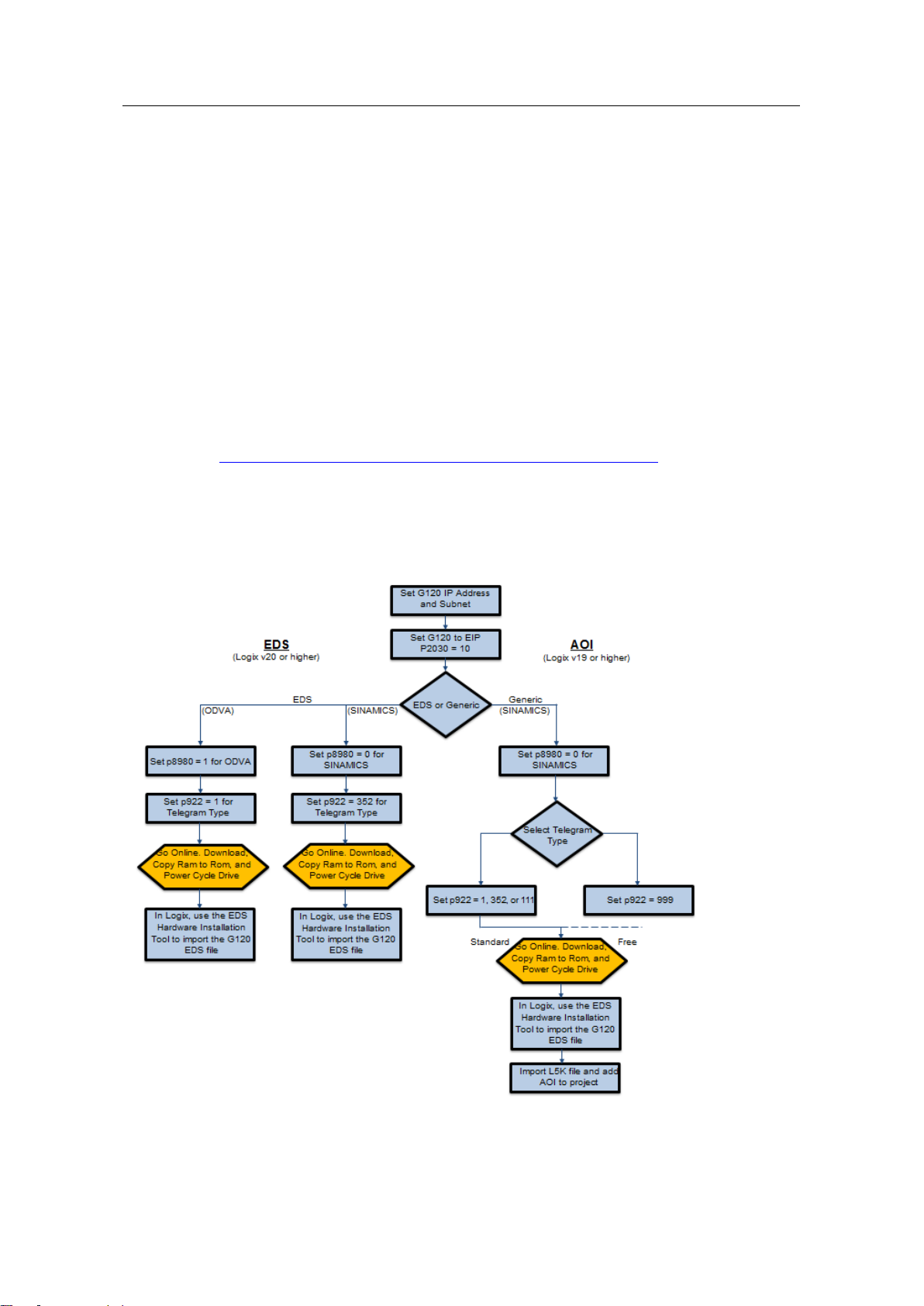

3.1 Configuration Choices

There are two main ways to configure a SINAMICS G drive to communicate over

EtherNet/IP. The approach described in this note uses Add On Instructions with a

Generic Ethernet Module. This approach requires version 19 or higher for RSLogix

5000.

Alternatively, the drive can be set up for ODVA type configuration. This allows the

user to import a ODVA G120 EDS file to use the drive as an ODVA AC drive

object. This approach requires version 20 or higher for RSLogix 5000. A newer

option is an EDS file that works with Telegram 352 and setting P8990 to 0

(SINAMICS). This EDS path is discussed in a separate application note.

https://support.industry.siemens.com/cs/ww/en/view/109761721

Refer to the diagram below for a general overview of the steps to configure

depending on method.

Figure 3-1

Page 8

3 Programming Overview

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

8

Siemens AG

2015 All rights reserved

3.2 AOI’s for SINAMICS G Series drives

Add On Instructions have been designed for the RSLogix programming that mimic

standard telegrams used in SINAMICS G configurations. For most standard

applications the use of the AOI’s can greatly reduce the engineering time needed

to configure a system. The SINAMICS G series drives can also be freely

configured using the free telegram structure, dependent on application needs.

Figure 3-2

3.3 AOI Types

There are presently three Add On Instruction blocks that can be used for standard

telegrams T1, T352, and T111.

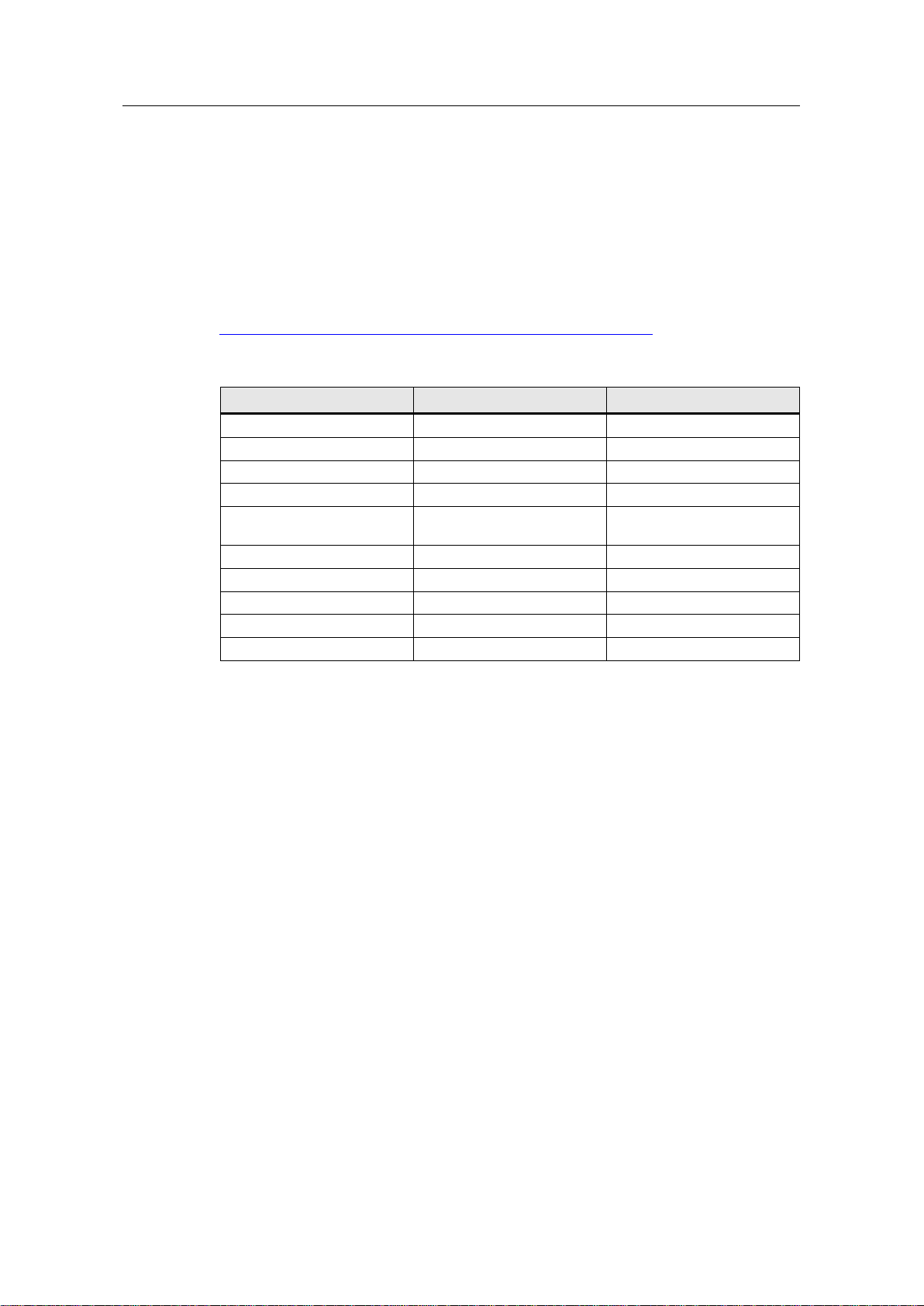

Table 3-1

Name

Standard Telegram #

Length

Simple Speed

Telegram 1

2 words in / 2 words out

Vector Speed

Telegram 352

6 words in / 6 words out

EPOS Control

Telegram 111

12 words in / 12 words out

Siemens AG Copyright 2015 All rights reserved

Page 9

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

9

Siemens AG

2015 All rights reserved

4 SINAMICS G120 Add-On Instructions

4.1 Function Description

The drive control function block (AOI) described in this section is intended to

provide SINAMICS G series drive users with a quick and effective way to integrate

into an automation system where a Logix family controller is the primary control.

The AOI can also be used as a starting point since the user is free to customize it

to fit their specific application. The canned AOIs in this application guide have been

designed to seamlessly integrate with the PROFIdrive telegrams T1, T352, and

T111, commonly used for controlling SINAMICS G drives.

4.2 Telegram Descriptions

4.2.1 Telegram Type 1 for Simple Speed

This telegram is a standard PROFIdrive telegram of 2 words in length. It will control

the state of the drive by selecting the appropriate bits in the control word and set

the running speed in the speed setpoint word. For additional information on this

telegram and the details of its function, refer to the SINAMICS G120 Operating

Instructions Manual and List Manual.

Table 4-1 Telegram 1

WORD

INPUT

OUTPUT

1

Control Word 1

Status Word 1

2

Speed Setpoint value

Actual Speed value

4.2.2 Telegram Type 352 for Simple Speed

This telegram is a standard PROFIdrive telegram of 6 words in length. It is similar

to Telegram1 but with added functionality. There are 4 freely configurable words

available for control of the drive. These could be a separate control word or analog

values such as torque limitation or additional speed setpoint. Status to the PLC

contains a standard Status word, Speed, Current, Torque, Fault or Warning

number. For additional information on this telegram refer to the SINAMICS G120

Operating Instructions and List Manual.

Table 4-2: Telegram 352

WORD

INPUT

OUTPUT

1

Control Word 1

Status Word 1

2

Speed Setpoint Value

Actual Speed Value

3

User-Defined

ABS_Current

4

User-Defined

Torque

5

User-Defined

Warn_Code

6

User-Defined

Fault_Code

Page 10

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

10

Siemens AG

2015 All rights reserved

4.2.3 Telegram Type 111 for EPOS mode

Telegram 111 is a standard PROFIdrive telegram for a positioning drive. It allows

sequence and control of the drive functions in addition to control of the positioning

function EPOS. 12 Words of data are exchanged with the drive where the 12th

word is reserved as a user selectable value. For detailed information on this

telegram refer to the SINAMICS List and Operating Instruction manuals for G120

CU250S-2 and CU250D-2. A license for EPOS is needed for CU250S-2; see the

link below for ordering an EPOS license.

https://support.industry.siemens.com/cs/ae/en/view/109755273

Table 4-3: SIEMENS telegram 111

WORD

Input

Output

1

Control Word 1

Status Word 1

2

Pos Control Word 1

Pos Status Word 1

3

Pos Control Word 2

Pos Status Word 2

4

Control Word 2

Status Word 2

5

Velocity Override

MELDW (Extended) Control

Word

6-7

MDI Position Setpoint

Position Actual Value

8-9

MDI Velocity Setpoint

Velocity Actual Value

10

MDI Percent Acceleration

Active Fault Number

11

MDI Percent Deceleration

Active Warning Number

12

User Selectable

User Selectable

Siemens AG Copyright 2015 All rights reserved

Page 11

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

11

Siemens AG

2015 All rights reserved

4.3 Basic Speed Control –Telegram 1

4.3.1 Functionality

The G120 Simple Speed Block provides an interface for basic speed control of a

SINAMICS drive via EtherNet/IP. The drive is configured for control using Standard

Telegram Type 1 which presets the drive speed reference and control word to be

sourced from the communication interface.

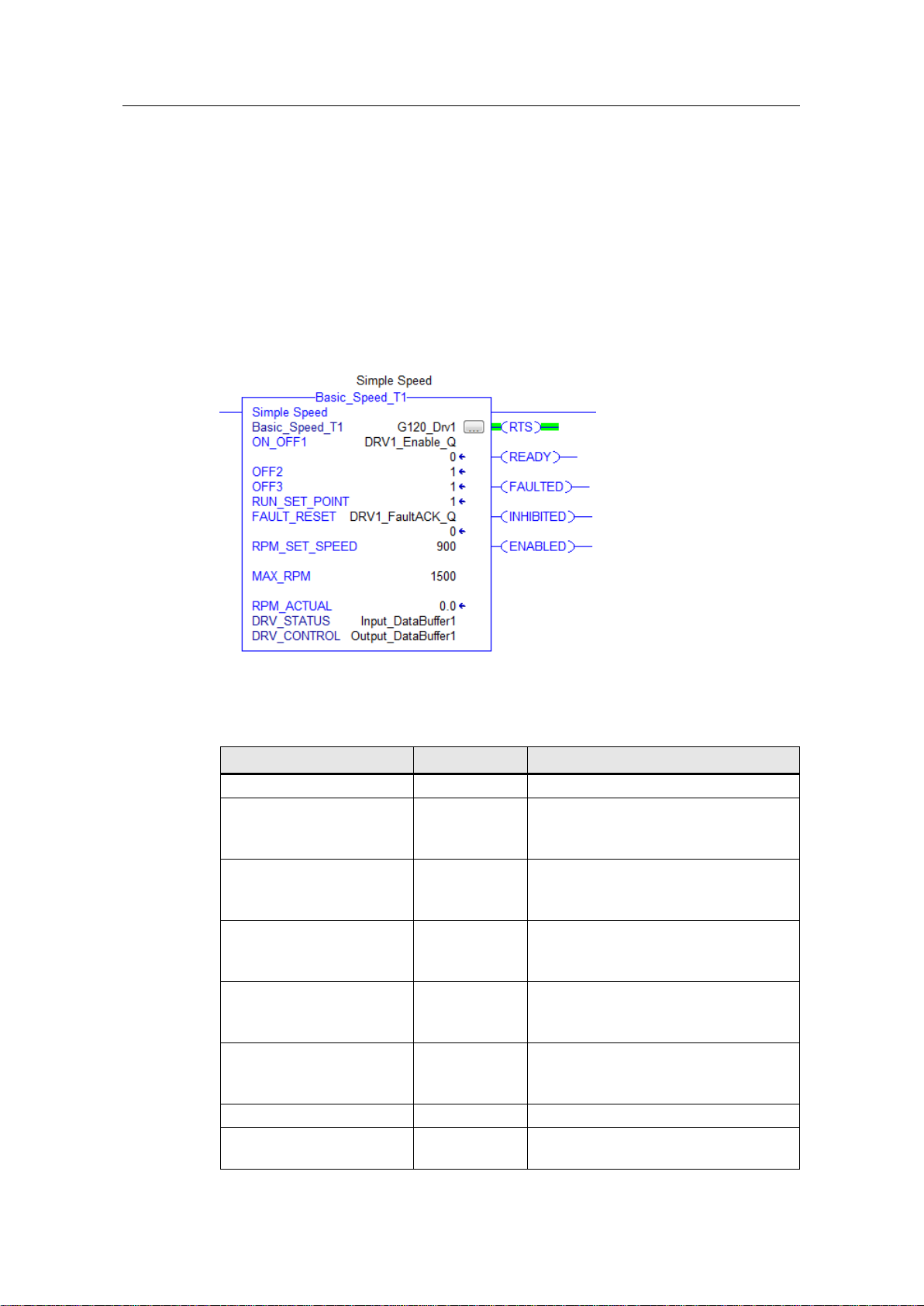

4.3.2 Schematic Ladder Representation

Figure 4-1 G120 Simple Speed Block

4.3.3 Input and Output Parameters

Table 4-4 Input parameters

Variable Name

Data Type

Description

G120_Speed_Block

Instance Data

ON_OFF1

BOOL

Drive Enable (ON/OFF1)

1 = Enable Drive

2 = Ramp down and disable drive

OFF2

BOOL

Coast Stop Command

0 = Off2 (Immediate disable)

1 = No OFF2 command

OFF3

BOOL

Fast Stop command

0 = OFF3 Fast ramp and disable drive

1 = No OFF3 command

RUN_SET_POINT

BOOL

Speed setpoint enable

0 = Setpoint disabled

1 = Setpoint enabled

FAULT_RESET

BOOL

Reset active drive faults

0 = No fault reset

1 = Reset fault(s) on rising edge

RPM_SET_SPEED

REAL

Speed setpoint in [rpm]

MAX_SPEED

REAL

Speed at 100% setpoint

Must be the same p2000 ( of the drive)

Page 12

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

12

Siemens AG

2015 All rights reserved

Table 4-5 In/Out parameters

Variable Name

Data Type

Description

DRV_CONTROL

ARRAY

Array of 2 integers referenced to the two

outputs words of the drive telegram.

DRV_STATUS

ARRAY

Array of 2 integers referenced to the two

input words of the drive telegram.

Table 4-6 Output parameters

Variable Name

Data Type

Description

RTS

BOOL

Ready to Start

RDY_OP

BOOL

Ready for Operation

FAULTED

BOOL

Fault is Active

ENABLED

BOOL

Pulses are Enabled

RPM_ACTUAL

REAL

Actual Speed in RPM

4.4 Speed Control –Telegram 352

4.4.1 Functionality

The Vector_Speed_352 Speed Block provides an interface for speed control via

EtherNet/IP. The Drive is configured for control using Standard Telegram Type 352

which presets the drive speed reference and control word to be sourced from the

communication interface. In addition there are four separate user defined control

words/setpoints available, as well as feedback for Current, Torque, Warning and

Fault values.

Page 13

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

13

Siemens AG

2015 All rights reserved

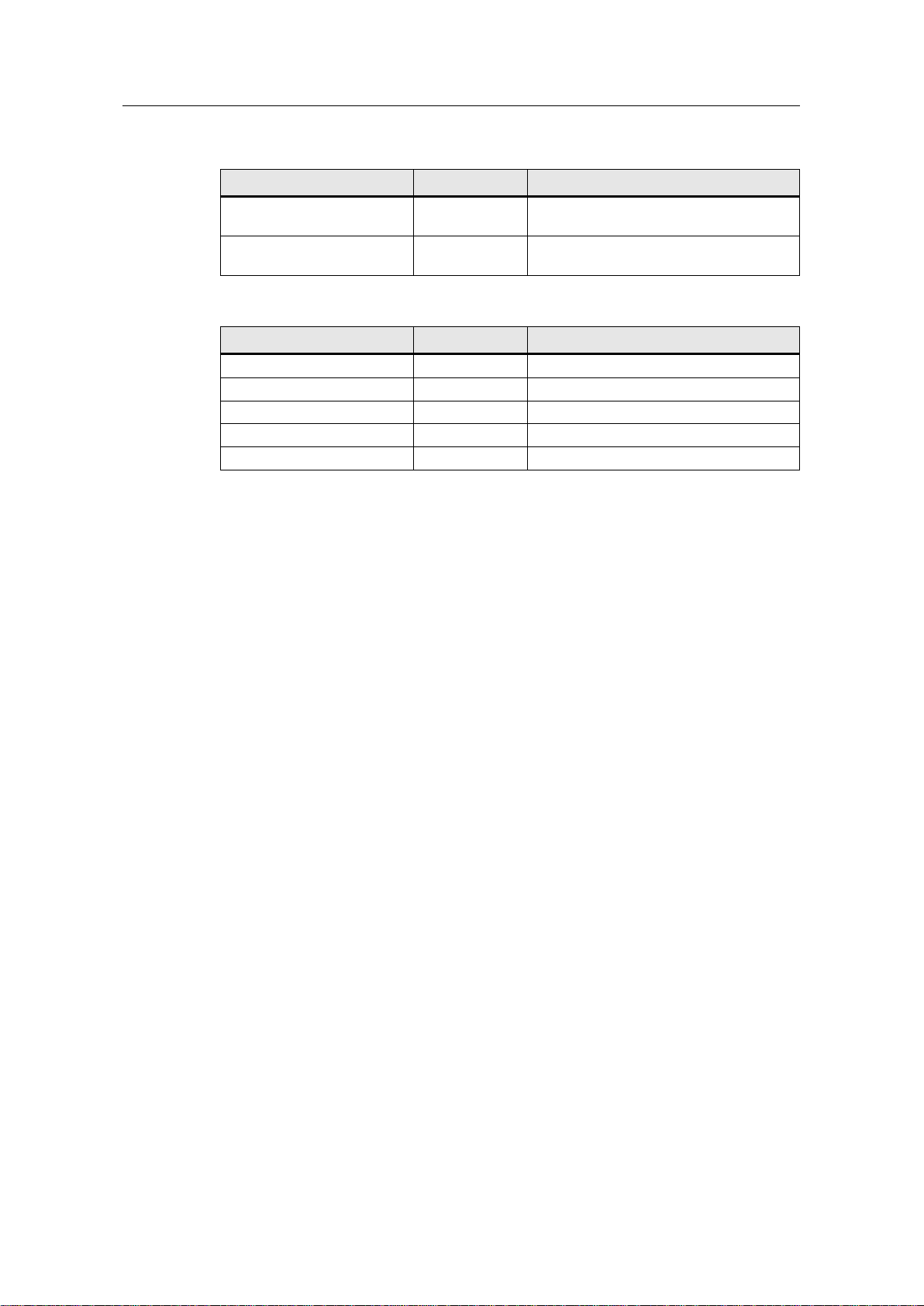

4.4.2 Schematic Ladder Representation

Figure 4-2 Vector Speed T352

4.4.3 Input and Output parameters

Table 4-7 Input parameters

Vector_Speed_T352

Instance Data

ON_OFF1

BOOL

Drive Enable (ON/OFF1)

1 = Enable Drive

2 = Ramp down and disable drive

OFF2

BOOL

Coast Stop Command

0 = Off2 (Immediate disable)

1 = No OFF2 command

OFF3

BOOL

Fast Stop command

0 = OFF3 Fast ramp and disable drive

1 = No OFF3 command

RUN_SET_POINT

BOOL

Speed setpoint enable

0 = Setpoint disabled

1 = Setpoint enabled

FAULT_RESET

BOOL

Reset active drive faults

0 = No fault reset

1 = Reset fault(s) on rising edge

RPM_SET_SPEED

REAL

Speed setpoint in [rpm]

Page 14

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

14

Siemens AG

2015 All rights reserved

MAX_RPM

REAL

Speed at 100% setpoint

Must be the same p2000 ( of the drive)

MAX_CURRENT

REAL

Current Feedback 100% value

Can be Scaled to P2002 or % (100.0)

MAX_TORQUE

REAL

Torque Feedback 100% value

Can be Scaled to P2003 or % (100.0)

USER_SETPOINT1

Integer

User Defined setpoint 0 to 16384

= 0 to 100% Value to Drive

USER_SETPOINT2

Integer

User Defined setpoint 0 to 16384

= 0 to 100% Value to Drive

USER_SETPOINT3

Integer

User Defined setpoint 0 to 16384

= 0 to 100% Value to Drive

USER_SETPOINT4

Integer

User Defined setpoint 0 to 16384

= 0 to 100% Value to Drive

Table 4-8 IN/OUT parameters

Variable Name

Data Type

Description

DRV_CONTROL

ARRAY

Array of 12 integers referenced to the

two outputs words of the drive telegram.

DRV_STATUS

ARRAY

Array of 12 integers referenced to the

two input words of the drive telegram.

Table 4-9 Output parameters

RTS

BOOL

Ready to Start

READY

BOOL

Ready for Operation

FAULTED

BOOL

Fault is Active

INHIBITED

BOOL

Power On Inhibited

ENABLED

BOOL

Pulses are Enabled

MTR_OVRTEMP_OK

BOOL

Motor Not Overtemp

PM_OVERTEMP_OK

BOOL

Power Module Overtemp

RPM_ACTUAL

REAL

Actual Speed in RPM

*Set Scale Value to 100 for Percentage

or set to P2000 Value

CURRENT_ACTUAL

REAL

Actual Current in AMP

*Set Scale Value to 100 for Percentage

or set to P2002 value

Page 15

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

15

Siemens AG

2015 All rights reserved

4.5 EPOS Control

4.5.1 Functionality

The EPOS block interfaces to the SINAMICS Basic Positioner via EtherNet/IP. The

EPOS Positioner is used for absolute and relative positioning of linear and rotary

axes. The CU250D-2 and CU250S-2 G120 controllers are capable of EPOS

control.

The AOI provides a direct interface to EPOS control. Note that the drive must be

referenced before absolute positioning is allowed. State control and sequencing is

not provided. Additional user logic is required to synchronize the state of the drive

with the positioning functions.

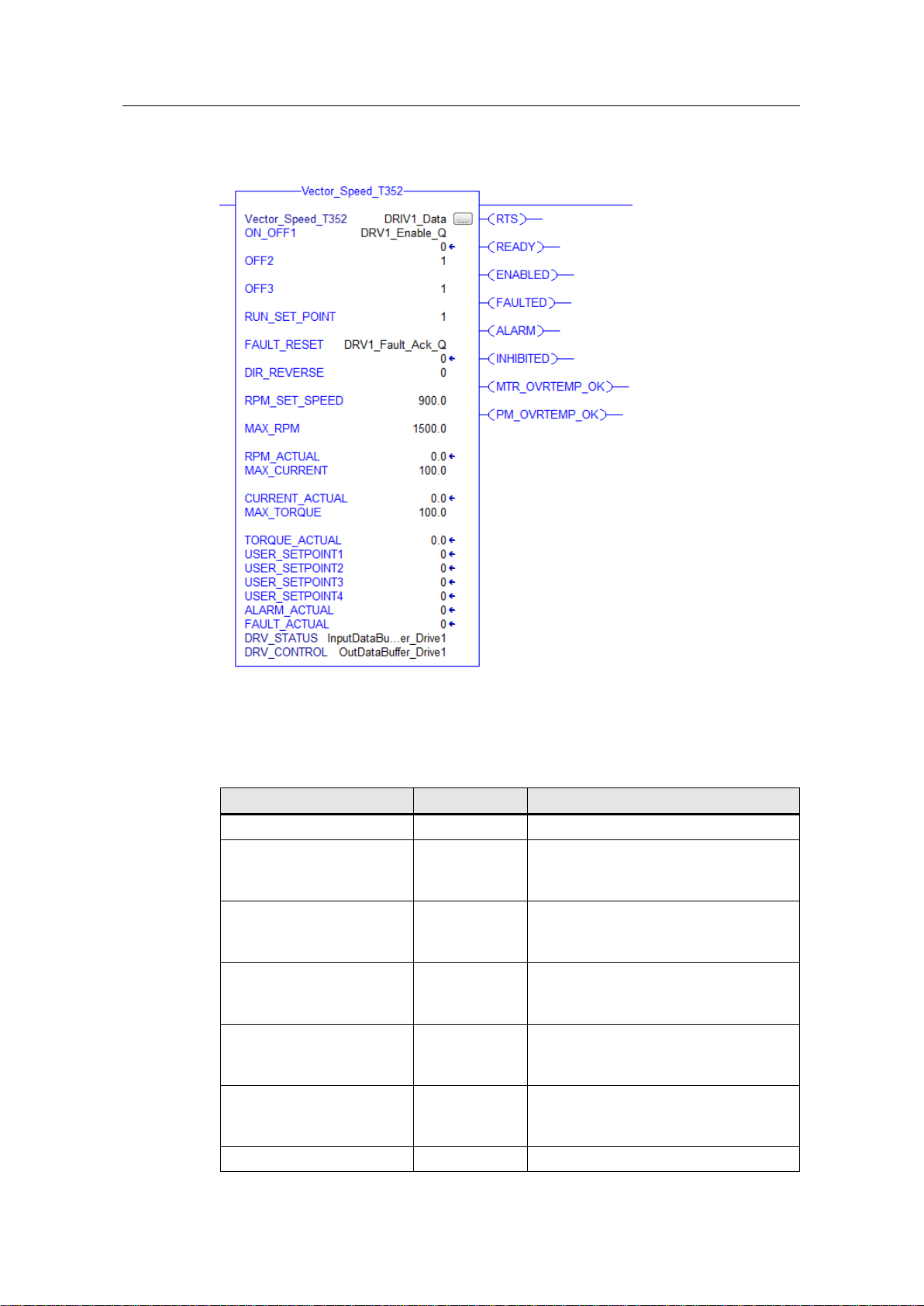

4.5.2 Schematic Ladder Representation

Figure 4-3 EPOS block

Page 16

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

16

Siemens AG

2015 All rights reserved

4.5.3 Input and Output parameters

Table 4-10 Input parameters

S120_EPOS_BLOCK

Instance Data

ON

BOOL

Drive Enable (ON/OFF1)

1 = Enable Drive

2 = Ramp down and disable drive

FAULT_RESET

BOOL

Reset Active Fault(s)

0 = No Fault Reset

1 = Reset Fault on Rising Edge

JOG_FWD

BOOL

0 = No Jog

1 = Jog Forward at speed in P2586

JOG_REV

BOOL

0 = No Jog

1 = Jog Reverse at speed in P2585

REF_START

BOOL

Referencing Start

0 = No Referencing

1 = Enable Referencing

MDI_START

BOOL

1 = Enable MDI Mode

0 = No MDI mode

Note: All motion should be

completed before disable to avoid

fault.

MDI_SETUP

BOOL

Enable MDI Setup Mode

0 = No Setup Mode

1 = Enable MDI Setup Mode

MDI_POS_TYPE

BOOL

Select MDI Positioning Type 0 =

Absolute Positioning

1 = Relative Positioning

MDI_FWD_DIR

BOOL

Enable Forward Direction

MDI_REV_DIR

BOOL

Enable Reverse Direction

Note: If Both MDI_FWD_DIR and

MDI_REV_DIR are True, shortest

path is selected for absolute

positioning

MDI_EDGE_TRIG

BOOL

Trigger Loading of Setpoints

Load executed on rising edge of

input transition

MDI_CONSTANT_TRIG

BOOL

Select Setpoint loading type

0 = The setpoint are accepted on

the rising edge of the

MDI_EDGE_TRIG input

1 = Setpoints are continuously

loaded. (Absolute Positioning only)

INTERMEDIATE_STOP

BOOL

Stop motion. The canceling the

motion command.

0 = Stop motion

1 = Allow motion

POSITION_SETPOINT

DINT

Position Setpoint in [LU]

ACCEL_RATE

REAL

% of Nominal Acceleration

DECEL_RATE

REAL

% of Nominal Deceleration

V_OVERRIDE

REAL

% of Override for Velocity

Page 17

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

17

Siemens AG

2015 All rights reserved

Table 4-11 IN/OUT parameters

Variable Name

Data Type

Description

DRV_CONTROL

ARRAY

Array of 12 integers referenced to

the two outputs words of the drive

telegram.

DRV_STATUS

ARRAY

Array of 12 integers referenced to

the two input words of the drive

telegram.

Table 4-12 Output parameters

RTS

BOOL

Ready to Start

RDY_OP

BOOL

Ready for Operation

ENABLED

BOOL

Pulses are Enabled at Motor Output

FAULTED

BOOL

Fault is Active

ALARM

BOOL

Alarm is Active

JOGGING

BOOL

Axis is Jogging

HOMING

BOOL

Referencing Mode Enabled

REFERENCED

BOOL

Axis is Referenced

MDI_POS

BOOL

MDI Mode is Active

MDI_SETUP_ON

BOOL

MDI Setup Mode is Active

TARGET_REACHED

BOOL

Position Actual is within the position

window set

FAULT_NUMBER

INT

Active Fault number; 0 if no Fault

ALARM_NUMBER

INT

Active Alarm Number; 0 if no Alarm

POSITION_ACTUAL

DINT

Position value in [LU]

SPEED_ACT_PCT

REAL

Speed in percent of P2000

TORQUE_ACTUAL

REAL

Torque value in percent of P2002

This value is mapped to word 12 of the

telegram status data. For the torque to

be displayed, Parameter 2051.11 must

be connected to r80.

Page 18

4 SINAMICS G120 Add-On Instructions

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

18

Siemens AG

2015 All rights reserved

4.6 UDTs

UDTs are provided as representing the typical control and status words used for

Telegrams implemented by the AOI provided. These cannot be utilized when using

the provided EDS file. The UDTs can also be used independently to map IO data

sent and received by the drive. The user application can directly control telegram

words and bits to accomplish control functions not included in the AOIs provided by

Siemens. This is the case when using user-defined telegrams (free telegram

configuration with BICO) to exchange data with the drives.

Page 19

5 Drive Configuration

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

19

Siemens AG

2015 All rights reserved

5 Drive Configuration

Commissioning of the G120 drives is not in the scope of this document. Refer to

the “Getting Started Manual” for your G120 model to assist in the commissioning of

the drive(s). See the link below for G120 Getting Started manuals.

https://support.industry.siemens.com

5.1 Configuring IP Address of CU

The IP address can be set from Starter. Make sure that your PC is in the same

Subnet as address desired for the G120 and AB PLC.

Figure 5-1 TCP/IPv4 Address for PC or PG

Figure 5-2 Use Accessible Nodes to Find CU250. Right click on Node to Open address

setting.

Page 20

5 Drive Configuration

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

20

Siemens AG

2015 All rights reserved

Figure 5-3 Set IP Address for the G120 as shown

Figure 5-4 Bring the Drive Unit into Project. Choose Select and then Accept.

Figure 5-5 The G120 controller is now in the Project Tree. Go online to upload Power

Module properties.

Page 21

5 Drive Configuration

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

21

Siemens AG

2015 All rights reserved

Figure 5-6 Load HW Configuration to PG.

Figure 5-7 Go offline with the G120 and Complete Commissioning.

Figure 5-8

Figure 5-9 Commission Drive Object(s) as needed.

Note the message frame in next section for the Example Dual Axis Demo program.

Refer to the documentation link in previous section if commissioning assistance is

needed.

8. Open the Communication folder. Set Telegram to desired telegram (352 in this

example) and set Protocol to 10 EtherNet/IP. Alternately this can be done in Expert

List via parameters P922 for telegram type and P2030 for protocol type.

Page 22

5 Drive Configuration

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

22

Siemens AG

2015 All rights reserved

Figure 5-10

Figure 5-11 . Highlight the Drive Unit, Go Online, and download to the G120.

Figure 5-12 Complete the Motor ID and Rotation Check.

Page 23

5 Drive Configuration

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

23

Siemens AG

2015 All rights reserved

Figure 5-13 Save RAM to ROM and Upload to PC

14. Power Cycle the G120; the Control Unit must be powered off to set the

communication protocol to EtherNet/IP. Wait sufficient time that the Control Unit

powers down. The CU will be ready for EtherNet/IP communication when power is

restored.

5.2 Using a Freely Configurable Telegram

Selectable Telegrams such as T352 offer easy parameter mapping for drive

control. Binectors or Connectors terminated by the telegram can be changed if the

telegram is changed to “Free Telegram” (P922 = 999).

It is possible to configure a custom telegram to fit a specific application

requirement. The custom configuration can be accomplished using one the

methods listed.

1. Using a standard telegram as a template and changing the configuration

manually.

2. Selecting the input and output data length and connecting the telegram words

in the communications window of the drive configuration.

3. Configuration by Script execution. A script can be written in Starter that

configures the telegram size and connections required. The script is then

executed in Starter, configuring the drive.

Parameter r2067 displays the number of PZDs the controller detected to be part of

the telegram. The Input and Output data length must match the values in r2067 of

the drive. For example, if telegram T352 was used as a basis for a free Telegram, it

would have 4 User Defined Words to the drive from the PLC. If these words are not

used for connections such as Added Speed Setpoint, Torque Setpoint, or Torque

Limits, then they must be terminated to unused Connector Input Parameters.

Figure 5-14

Page 24

5 Drive Configuration

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

24

Siemens AG

2015 All rights reserved

5.2.1 Example of "Free telegram" commissioning

1. Drive commissioned with T352 and change then parameter 922 Telegram Type

set to [999] for use with Free Telegram

Figure 5-15

2. Check r2067 in the Expert List. All words being sent to the drive from the PLC

and from the PLC to the drive must be accounted for. Vector Speed uses 6 words

IN / 6 words OUT. That message frame must agree with r2067 in the Expert List.

Figure 5-16 Example using T352 AOI for Free Telegram before terminating spare words

3. Words not being used must be terminated to “Dummy Parameters”. These

words could be used for more useful connections such as Added Speed Setpoint,

Torque Limits, or Torque Setpoints. This programming can be done via scripting,

Expert List, or the Starter GUI.

Figure 5-17 Example of spare word holder script using p20110 (free blocks multiplier)

Figure 5-18 The values in r2067 after terminating extra words and downloading

4. After downloading, cycle power to the drive.

NOTE

The Spare Words In or Out for a standard telegram can be freely used by the

user. It is only necessary to use a free telegram if changing the mapped value of

a Standard Telegram or making a User Defined Telegram.

Page 25

6 Configuring a Generic Ethernet Module

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

25

Siemens AG

2015 All rights reserved

6 Configuring a Generic Ethernet Module

6.1 Adding a new module in RSLogix

A Generic IO module is used to configure the cyclic data exchange between the

automation controller and the SINAMICS drive without an EDS file.

6.1.1 Inserting the module in an RSLogix project

Table 6-1 Inserting the Generic Ethernet Module

1.

Insert a module by rightclicking the network interface

in the IO configuration section

of the Project tree.

2.

In the “Select Module” dialog

box, use the “Find” function to

search for the term

“GENERIC”.

Select the “Generic Ethernet

Module” to be inserted

Page 26

6 Configuring a Generic Ethernet Module

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

26

Siemens AG

2015 All rights reserved

6.1.2 Configuring network parameters

Table 6-2 Configuring the Network Parameters

The module name should identify the

G120 to allow easy selection from

other modules configured in the

controller. It is also the name used for

the controller level tag that will hold

the data. Use the Description box to

describe the Drive objects contained

in the module.

The data exchange format should be

set to Integer (INT).

Enter the IP Address of the G120.

The Connection Parameters section

configures the IO Assemblies. The

Assembly Instances should always be

101 through 103 for the Input, Output

and Configuration Assembly

respectively. The size of the Input and

Output assemblies is the total number

of words. For Standard Telegram 1,

there are 2 words in and 2 words out.

For Telegram 352 there are 6 words

in and 6 words out.

In this example the speed block

telegram for T352 is shown.

Page 27

6 Configuring a Generic Ethernet Module

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

27

Siemens AG

2015 All rights reserved

6.1.3 Connection Parameters

Table 6-3 Setting the connection parameters

The Requested Packet Interval (RPI)

is the rate at which the controller will

exchange data with the drive. The

G120 can operate with a RPI set to a

minimum of 5 ms. In this application

we will use a value of 10 ms.

Unicast is selected as the exchange

method.

6.1.4 Using IO Data

The IO data is available as an array of integers in the controller tags section of the

project tree. They are included as a tag list with the L5K file.

Figure 6-1 Controller Tags for new module

Page 28

7 Using AIOs in a new application

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

28

Siemens AG

2015 All rights reserved

7 Using AIOs in a new application

7.1 Importing AIOs

The AOIs provided with the sample application can be easily integrated into a new

or existing user program by importing the instructions using L5K files.

7.1.1 Installing L5K Files in RSLogix

Table 7-1

Import the AOI into the Add-On

Instructions folder. Right click the AddOn Instructions folder in the project tree

and select the Import Add-On

Instruction option.

Select the required L5K file for the

desired Instruction and click Import.

Review the Import configuration and

click OK.

The Project should now show the

imported Instruction. Notice that UDTs

required for the instruction have also

been imported. These UDTs can also

be used to create additional variables

and aliases.

Page 29

7 Using AIOs in a new application

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

29

Siemens AG

2015 All rights reserved

7.2 Using the AOI

7.2.1 Adding AOI to an RSLogix Program

Table 7-2 Using the G120 Simple Speed Block

Add the AOI to a new rung by dragging

from the project tree.

Declare and assign the instance data

variable. The new tag can be created

as a local program tag with a name that

clearly identifies the drive data. Right

click the field next to

G120_Speed_Block and select New

Tag.

Give the tag a descriptive name and

select OK.

Page 30

7 Using AIOs in a new application

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

30

Siemens AG

2015 All rights reserved

7.2.2 I/O Interface

Connecting the instruction to the Controller IO tags is accomplished by moving the

IO data into the AOI Interface.

Figure 7-1 Configuring AOI Communication

The second rung holds the AOI. The local variables “InputDataBuffer” and

“OutputDataBuffer” are used as storage for the AOI to receive and send data to the

Controller IO tags.

The first rung copies the IO data for the drive to a local variable to be used by the

AOI as inputs in the “DRV_STATUS” parameters. “DRV_STATUS” and

“DRV_CONTROL” are declared as INOUT parameters and are therefore passed

by reference.

The third rung holds the copy command that moves the control data from the

working variable “OutputDataBuffer” to the controller IO tag.

All AOIs provided will use this method of data exchange with IO containing the

drive data. Additional access to the control data can be performed before the data

is copied to the IO Tag. This allows the user to utilize features already mapped in

the telegram that are not controlled by the AOI. In a similar manner the Status data

can be accessed by the user program

Page 31

8 Drive Parameter Access

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

31

Siemens AG

2015 All rights reserved

8 Drive Parameter Access

8.1 Explicit Messaging

In many applications it is necessary to read or write parameters in the drive. This

allows increased flexibility in implementation of the machine functionality.

To allow this occasional (acyclic) data exchange of drive and motor parameters,

the drive supports explicit messaging.

The MSG instruction can read from or write to a parameter by accessing the drive’s

communication object. When parameterizing the MSG instruction, below are some

important parameters:

Class = 401hex (for G120)

Instance = parameter number

p1027 = instance 1027

Attribute = parameter index number (hex) Index

Index 0 = attribute 0

Index 1 = attribute 1

…

Index 65535 = attribute FFFFh

Get attribute single = read a parameter

Set attribute single = write a parameter

Page 32

8 Drive Parameter Access

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

32

Siemens AG

2015 All rights reserved

8.2 Using the MSG Instruction

NOTE

It is a good idea to one-shot the message requests (e.g. with a flasher). If the

rung for the MSG instruction is always true, the communication board can get

overwhelmed and fault out.

Table 8-1

MSG Instruction:

Insert the MSG instruction.

Instruction Tag:

Create a controller scope tag for the

instruction in the Tag tab of the

message configuration dialog box.

This tag contains the working memory

area for the MSG instruction.

Message Type:

Select the CIP Generic message

type.

Page 33

8 Drive Parameter Access

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

33

Siemens AG

2015 All rights reserved

Service Type:

Select “Get Attribute Single” to read

the parameter or “Set Attribute

Single” to write to the parameter.

Class: 401 (hex)

Instance:

This is the parameter number of the

object, in Starter. E.g. DC Link

voltage (p26).

Page 34

8 Drive Parameter Access

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

34

Siemens AG

2015 All rights reserved

Attribute:

This is the parameter index. For

parameters without an index, use “0”.

Destination:

For reading a parameter select a

Controller scope tag where the

value will be written.

If writing a value to the parameter,

select a tag in the Source element

entry.

Source Length (writing only): When

writing to a parameter, make sure

the source length matches the

parameter that you are trying to

write to.

INT = 2 Bytes (16 bit)

REAL = 4 Bytes (32 bit)

Page 35

8 Drive Parameter Access

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

35

Siemens AG

2015 All rights reserved

Make sure the data type of the tag

(source/destination) matches the

data type of the parameter.

INT = 2 Bytes (16 bit)

REAL = 4 Bytes (32 bit)

To figure out the data type of the

parameter, search for the parameter

in the Starter help tool, or refer to the

List Manual.

Page 36

8 Drive Parameter Access

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

36

Siemens AG

2015 All rights reserved

Path:

In the communication tab enter the

name of the IO node for the G120.

Use the Browse option to find the

node in the Project Tree.

Page 37

9 Troubleshooting

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

37

Siemens AG

2015 All rights reserved

9 Troubleshooting

9.1 I can’t go online with the drive in Starter using the Ethernet cable.

Do you have firmware v4.7 or above on the drive unit? Communication from Starter

to the drive using Ethernet/IP is only support with firmware v4.7 or later on the

G120. If you are using v4.6, then you will need to use the USB cable to connect to

the drive with Starter.

9.2 The drive and the PLC are not communicating

Figure 9-1

Figure 9-2

1. Check the LED lights

a. PLC: Is the I/O light solid green?

b. G120: Is the Link1 light solid green?

c. This means that the drive is communicating and it is another issue

2. Is the drive set for EIP (G120: p2030 = 10)?

a. A power cycle is required after changing p2030.

Page 38

9 Troubleshooting

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

38

Siemens AG

2015 All rights reserved

3. Are there duplicate IP addresses on the network?

a. Verify IP addresses (accessible nodes, edit Ethernet nodes, etc.)

4. Did you parameterize the Generic Ethernet Module in RSLogix 5000 correctly?

Figure 9-3

a. Do you have the “Comm. Format” set to Data –INT, or accidentally set

to Data-DINT?

Figure 9-4

b. Do the Connection Parameters (addresses and length) match the drive

telegram?

Figure 9-5

5. Could it be a bad Ethernet cable?

Page 39

9 Troubleshooting

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

39

Siemens AG

2015 All rights reserved

6. Are there faults on the drive?

a. Check drive status LEDs

b. Check drive diagnostics for faults

7. Are all Drive Enables (OFF1/OFF2/OFF3) enabled?

Page 40

10 Glossary

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

40

Siemens AG

2015 All rights reserved

10 Glossary

AOI (Add On Instruction): Commonly used logic for a task that is encapsulated

into a block to be reused in RSLogix programs

BICO: BICO technology (Binector Connector Technology) allows the drive to be

adapted to a wide variety of requirements. Digital and analog signals which can be

connected freely by means of BICO parameters are identified by the prefix BI, BO,

CI or CO in their parameter name.

Control Word: Arrangement of two bytes used to command the drive sequence

control (referred to as STW1 in SINAMICS Documentation)

EDS File: Text files used by RSLogix network configuration tool to help identify

products and easily integrate them on a network. All available G120 EDS files can

be found here:

https://support.industry.siemens.com/cs/ww/en/view/78026217

Free Telegrams: Send and receive telegrams that can be configured as required

by using BICO technology to interconnect the send and receive process data.

L5K file: File type used for importing an AOI into RSLogix program

MDI (Motion Direct Input): Direct setpoint input function for positioning

ODVA: Open DeviceNet Vendors Association. Organization that supports network

technologies built on the Common Industrial Protocol (CIP™) — DeviceNet™,

EtherNet/IP™, CompoNet™, and ControlNet™

PN Interface: PROFINET interface

PROFIdrive: Device profile to provide standardization of drive telegram type thus

minimizing integration and commissioning time and effort.

Siemens Standard Telegrams: Structured in accordance with manufacturer

specification with the internal process data links automatically set up in accordance

with the telegram number setting.

Standard PROFIdrive Telegrams: Structured in accordance with PROFIdrive

profile with the internal process data links automatically set up in accordance with

the telegram number setting.

STARTER: Software for Siemens SINAMICS drives configuration and diagnostics

Status Word: Arrangement of two bytes used to report the current status of the

drive (referred to as ZSW1 in SINAMICS Documentation)

UDT: User Defined Type; holds data relevant to the device

Page 41

11 Appendix

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

41

Siemens AG

2015 All rights reserved

11 Appendix

11.1 Service and support

Industry Online Support

Do you have any questions or need assistance?

Siemens Industry Online Support offers round the clock access to our entire

service and support know-how and portfolio.

The Industry Online Support is the central address for information about our

products, solutions and services.

Product information, manuals, downloads, FAQs, application examples and videos

– all information is accessible with just a few mouse clicks:

https://support.industry.siemens.com/

Technical Support

The Technical Support of Siemens Industry provides you fast and competent

support regarding all technical queries with numerous tailor-made offers

– ranging from basic support to individual support contracts. Please send queries

to Technical Support via Web form:

https://www.siemens.com/industry/supportrequest

SITRAIN – Training for Industry

We support you with our globally available training courses for industry with

practical experience, innovative learning methods and a concept that’s tailored to

the customer’s specific needs.

For more information on our offered trainings and courses, as well as their

locations and dates, refer to our web page:

https://www.siemens.com/sitrain

Service offer

Our range of services includes the following:

• Plant data services

• Spare parts services

• Repair services

• On-site and maintenance services

• Retrofitting and modernization services

• Service programs and contracts

You can find detailed information on our range of services in the service catalog

web page:

https://support.industry.siemens.com/cs/sc

Industry Online Support app

You will receive optimum support wherever you are with the "Siemens Industry

Online Support" app. The app is available for Apple iOS, Android and Windows

Phone:

https://support.industry.siemens.com/cs/ww/en/sc/2067

Page 42

11 Appendix

SINAMICS G: Control of a G120 with an Allen-Bradley controller

(Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP

Entry-ID: 82843076, V4.0, 09/2018

42

Siemens AG

2015 All rights reserved

11.2 Change documentation

Table 11-1

Version

Date

Modifications

V1.0

05/2013

First version

V1.2b

10/2014

Draft for Revision

V2.0

03/2015

Add in explicit messaging Added in troubleshooting

V3.0

07/2015

Added in G130/G150 information

Removed references to USB

connection

Removed the appendix and added the “edit ethernet node”

to the main documentation

Updated T352 block Added in T111 block

V4.0

09/2018

Removed G130/ G150 information. This type information

/configuration in the S120 note for AB Controller. Upgraded

Setting Ethernet Address and other sections.

Loading...

Loading...