Page 1

Page 2

Page 3

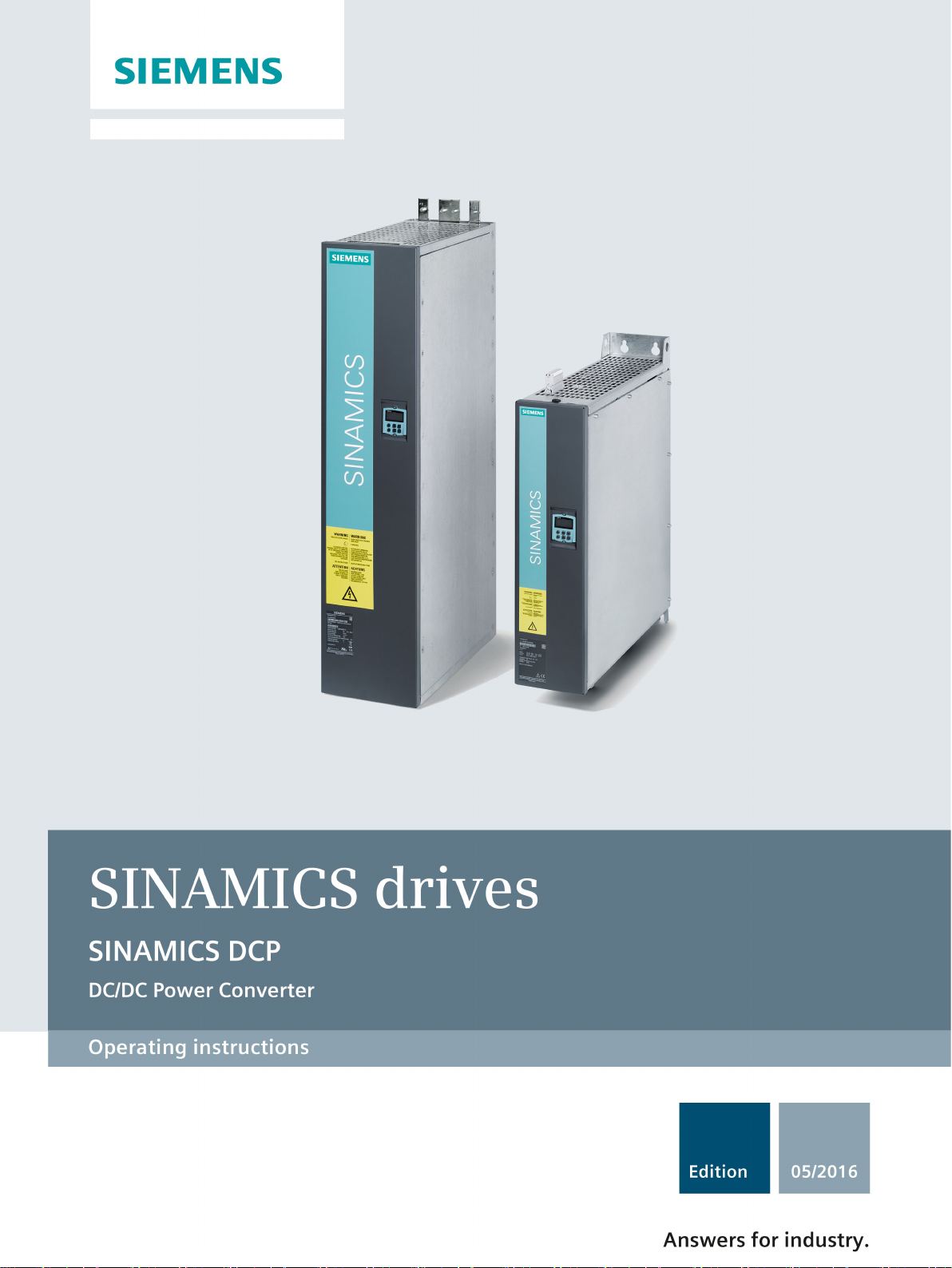

SINAMICS

SINAMICS DCP

Operating Instructions

05/2016

A5E34382853K

Preface

Introduction

1

Safety notes

2

Description

3

Preparations for use

4

Mounting

5

Electrical connection

6

Commissioning

7

Operation

8

Servicing

9

Spare parts

10

Disposal

11

Service and Support

A

Technical data

B

Quality documents

C

Additional documents

D

Checklists and forms

E

Assembly documents

F

Index

G

Page 4

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E34382853K

Ⓟ

Copyright © Siemens AG 2014 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

may

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

05/2016 Subject to change

Page 5

Preface

Device software version

Older software versions

Newer software versions

SINAMICS DCP documentation available

SINAMICS DCP Operating Instructions

Contains all information on

ordering, installation, connecting, commissioning, maintaining, description of functions,

and service

SINAMICS DCP List Manual

Contains

parameter list, function diagrams, list of faults and alarms

SINAMICS Free Function Blocks, Commissioning Manual

Contains a general description, the list of parameters, the function diagrams as well as

the list of faults and alarms.

SINAMICS DCP DVD Documentation

Contains, among others:

•

•

When these Operating Instructions went to print, SINAMICS DCP units were being supplied

from the factory with the software release specified on Page 3. However, these Operating

Instructions can, in principle, also apply to other software versions.

●

It is possible that not all of the functions described here may be available.

●

It is possible that the SINAMICS DCP may feature additional functions that are not

described in these Operating Instructions. Do not change any parameters that you cannot

find in the List Manual from their factory setting, and do not give parameters any values

that are not specified in the List Manual.

The software release is displayed using r50060[6].

Example:

01010203 displayed on the BOP20 means 01.01.02.03 → Version 1.1, Service Pack 2,

Hotfix 3

Downloading the latest software version

(https://support.industry.siemens.com/cs/ww/en/view/109474935

All the manuals mentioned above in all the available languages

The function diagrams in VISIO format

)

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

5

Page 6

Preface

Manuals in the Internet

Further Internet links

The manuals are also available in the Internet:

Manuals (https://support.industry.siemens.com/cs/ww/en/ps/13302

The list of general conditions available there include current supplements to the manuals.

The notes included in the general condition lists have a higher priority than the statements

made in the manuals.

)

Generic station description file (GSD) for

PROFIBUS (https://support.industry.siemens.com/cs/ww/en/view/98206128

PROFINET (https://support.industry.siemens.com/cs/at/en/view/98207877)

)

SINAMICS DCP

6 Operating Instructions, 05/2016, A5E34382853K

Page 7

Table of contents

Preface ................................................................................................................................................... 5

1 Introduction ........................................................................................................................................... 13

2 Safety notes .......................................................................................................................................... 15

3 Description ............................................................................................................................................ 23

4 Preparations for use .............................................................................................................................. 25

5 Mounting ............................................................................................................................................... 31

6 Electrical connection ............................................................................................................................. 35

7 Commissioning ..................................................................................................................................... 71

2.1 Safety concept ........................................................................................................................ 17

2.2 Notes on operator protection .................................................................................................. 18

2.2.1 Information about electromagnetic fields ................................................................................ 20

2.3 Notes on plant safety .............................................................................................................. 21

2.4 ESD-sensitive components ..................................................................................................... 22

4.1 Device order numbers............................................................................................................. 25

4.2 Rating plate ............................................................................................................................. 26

4.3 Ordering information for options and accessories .................................................................. 28

6.1 EMC-compliant installation ..................................................................................................... 36

6.1.1 Basic information about EMC ................................................................................................. 36

6.1.2 EMC-compliant installation of SINAMICS DCP (installation instructions) .............................. 38

6.2 Block diagram with connection suggestion ............................................................................. 40

6.3 Components ............................................................................................................................ 43

6.4 Terminals and connectors ...................................................................................................... 45

6.5 Additional system components ............................................................................................... 57

6.5.1 Option Board: Communication Board EtherNet CBE20 ......................................................... 57

6.5.1.1 Description .............................................................................................................................. 57

6.5.1.2 Safety instructions ................................................................................................................... 57

6.5.1.3 Interface description ................................................................................................................ 58

6.5.1.4 Meaning of the LEDs .............................................................................................................. 59

6.5.1.5 Assembling the 30 kW device ................................................................................................. 62

6.5.1.6 Assembling the 120 kW device ............................................................................................... 64

6.5.1.7 Technical data ......................................................................................................................... 65

6.5.2 Terminal Module Cabinet TMC (option G63) .......................................................................... 65

7.1 Switching on ............................................................................................................................ 73

7.1.1 BOP20 status display during ramp-up .................................................................................... 73

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

7

Page 8

Table of contents

8 Operation ............................................................................................................................................. 107

7.2 Commissioning using the BOP20 operator panel .................................................................. 75

7.2.1 Requirements ......................................................................................................................... 75

7.2.2 Commissioning steps ............................................................................................................. 75

7.3 Commissioning with the STARTER commissioning tool ....................................................... 78

7.3.1 STARTER commissioning tool ............................................................................................... 78

7.3.1.1 Description ............................................................................................................................. 78

7.3.1.2 Installing the STARTER commissioning tool ......................................................................... 78

7.3.1.3 Layout of the STARTER user interface ................................................................................. 79

7.3.2 Procedure for commissioning with STARTER ....................................................................... 79

7.3.2.1 Basic procedure when using STARTER ................................................................................ 79

7.3.2.2 Creating the project ................................................................................................................ 80

7.3.2.3 The STARTER project wizard ................................................................................................ 81

7.3.2.4 Configuring a drive unit .......................................................................................................... 88

7.3.2.5 Starting the drive project ........................................................................................................ 95

7.3.2.6 Connection through a serial interface .................................................................................... 99

7.4 Activating function modules ................................................................................................. 102

7.4.1 Activating offline via STARTER ........................................................................................... 102

7.4.2 Activating online via parameters

.......................................................................................... 103

8.1 Operation ............................................................................................................................. 107

8.1.1 Basics ................................................................................................................................... 107

8.1.1.1 Parameters ........................................................................................................................... 107

8.1.1.2 Data sets .............................................................................................................................. 110

8.1.1.3 Drive objects ........................................................................................................................ 111

8.1.1.4 Memory card functions ......................................................................................................... 113

8.1.1.5 BICO technology: Interconnecting signals ........................................................................... 118

8.1.2 Parameter assignment via the BOP20 (Basic Operator Panel 20) ...................................... 122

8.1.2.1 General information on the BOP20 ...................................................................................... 122

8.1.2.2 Display and operation with the BOP20 ................................................................................ 126

8.1.2.3 Displaying faults and alarms ................................................................................................ 131

8.1.2.4 Controlling the drive using the BOP20 ................................................................................. 132

8.2 Inputs/outputs....................................................................................................................... 133

8.2.1 Overview of the inputs/outputs ............................................................................................. 133

8.2.2 Digital inputs/outputs ............................................................................................................ 133

8.2.3 Analog inputs ....................................................................................................................... 133

8.2.4 Analog outputs ..................................................................................................................... 134

8.3 Communication, IT security .................................................................................................

135

8.4 Communication according to PROFIdrive ........................................................................... 136

8.4.1 General Information ............................................................................................................. 136

8.4.2 Application classes .............................................................................................................. 138

8.4.3 Cyclic communication .......................................................................................................... 139

8.4.3.1 Telegrams and process data ............................................................................................... 139

8.4.3.2 Description of the control word ............................................................................................ 142

8.4.3.3 Description of the status word .............................................................................................. 143

8.4.3.4 Diagnostics channels for cyclic communication ................................................................... 144

8.4.4 Parallel operation of communication interfaces ................................................................... 145

SINAMICS DCP

8 Operating Instructions, 05/2016, A5E34382853K

Page 9

Table of contents

8.4.5 Acyclic communication.......................................................................................................... 148

8.4.5.1 General information about acyclic communication ............................................................... 148

8.4.5.2 Structure of requests and responses .................................................................................... 150

8.4.5.3 Determining the drive object numbers .................................................................................. 155

8.4.5.4 Example 1: Read parameter ................................................................................................. 156

8.4.5.5 Example 2: Writing parameters (multi-parameter request)................................................... 158

8.5 Communication via PROFIBUS DP ...................................................................................... 162

8.5.1 PROFIBUS connection ......................................................................................................... 162

8.5.2 General information about PROFIBUS ................................................................................. 164

8.5.2.1 General information about PROFIBUS for SINAMICS ......................................................... 164

8.5.2.2 Example of a telegram structure for acyclic data acquisition ............................................... 166

8.5.3 Commissioning PROFIBUS .................................................................................................. 168

8.5.3.1 Setting the PROFIBUS interface .......................................................................................... 168

8.5.3.2 PROFIBUS interface in operation ......................................................................................... 169

8.5.3.3 Commissioning PROFIBUS .................................................................................................. 170

8.5.3.4 Diagnostics options ............................................................................................................... 171

8.5.3.5 SIMATIC HMI addressing ..................................................................................................... 171

8.5.3.6

Monitoring telegram failure ................................................................................................... 172

8.5.4 Direct data exchange ............................................................................................................ 174

8.5.4.1 Direct data exchange ............................................................................................................ 174

8.5.4.2 Setpoint assignment in the subscriber .................................................................................. 176

8.5.4.3 Activating/parameterizing direct data exchange ................................................................... 176

8.5.4.4 Commissioning the PROFIBUS direct data exchange ......................................................... 178

8.5.4.5 GSD during operation ........................................................................................................... 190

8.5.4.6 Diagnosing the PROFIBUS slave-to-slave communication in STARTER ............................ 191

8.5.5 Messages via diagnostics channels ..................................................................................... 191

8.6 Communication via PROFINET IO ....................................................................................... 194

8.6.1 Establishing online operation: STARTER via PROFINET IO ............................................... 194

8.6.2 General information about PROFINET IO ............................................................................ 200

8.6.2.1 Real-time (RT) and isochronous real-time (IRT) communication ......................................... 201

8.6.2.2 Addresses ............................................................................................................................. 202

8.6.2.3 Data transfer ......................................................................................................................... 204

8.6.2.4 Communication channels for PROFINET ............................................................................. 205

8.6.3 Drive control with PROFINET ............................................................................................... 205

8.6.3.1 Media redundancy ................................................................................................................ 207

8.6.4 RT classes for PROFINET IO ............................................................................................... 208

8.6.5 PROFINET GSDML .............................................................................................................. 214

8.6.6 Communication with CBE20 ................................................................................................. 214

8.6.7 Messages via diagnostics channels ..................................................................................... 215

8.7 EtherNet/IP ........................................................................................................................... 218

8.7.1 Connection of SINAMICS DCP with EtherNet/IP to EtherNet networks ............................... 218

8.7.1.1 Connection of SINAMICS DCP with EtherNet/IP to EtherNet networks ............................... 218

8.7.2 Configuration of SINAMICS DCP for EtherNet/IP ................................................................ 218

8.7.2.1 Setting the IP address and activating the EtherNet/IP protocol ........................................... 218

8.7.3 Configuration of a Rockwell controller with SINAMICS DCP ................................................ 225

8.7.4 Writing and reading parameters with Class 4xx ................................................................... 228

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

9

Page 10

Table of contents

9 Servicing .............................................................................................................................................. 271

10 Spare parts .......................................................................................................................................... 279

11 Disposal ............................................................................................................................................... 281

A Service and Support ............................................................................................................................ 283

B Technical data ..................................................................................................................................... 285

8.8 Switch on, switch off, enable ................................................................................................ 230

8.8.1 Switch on / switch off (ON/OFF1) - control word bit 0 .......................................................... 230

8.8.2 OFF2 (disconnection) - control word bit 1 ............................................................................ 230

8.8.3 OFF3 (quick stop) - control word bit 2.................................................................................. 231

8.8.4 Operation enable (enable) - control word bit 3 .................................................................... 231

8.9 Closed-loop control .............................................................................................................. 232

8.10 Precharging of the DC links ................................................................................................. 240

8.11 Device fan ............................................................................................................................ 243

8.12 Derating ................................................................................................................................ 244

8.13 Runtime (operating hours counter) ...................................................................................... 246

8.14 Diagnostics ........................................................................................................................... 247

8.14.1 Diagnostic memory .............................................................................................................. 247

8.14.2 Description of the LEDs on the CUD ................................................................................... 247

8.14.3 Faults and alarms................................................................................................................. 251

8.14.3.1 General information ............................................................................................................. 251

8.14.3.2 Buffer for faults and alarms .................................................................................................. 252

8.14.3.3 Configuring messages .........................................................................................................

255

8.14.3.4 Parameters and function diagrams for faults and alarms .................................................... 257

8.14.3.5 Forwarding faults and alarms ............................................................................................... 258

8.15 Drive Control Chart (DCC) for SINAMICS DCP ................................................................... 259

8.16 Technological functions ....................................................................................................... 264

8.16.1 MPP Tracker ........................................................................................................................ 264

8.16.2 Battery charging characteristic ............................................................................................. 268

8.17 Parallel connection of multiple SINAMICS DCPs ................................................................ 269

9.1 Upgrading software releases ............................................................................................... 272

9.1.1 Upgrading the device software ............................................................................................ 273

9.1.1.1 Backup the configuration ..................................................................................................... 273

9.1.1.2 Update the SINAMICS DCP software .................................................................................. 273

9.1.1.3 Update the STARTER project .............................................................................................. 274

9.1.1.4 Download to target system, RAM to ROM ........................................................................... 274

9.2 Replacing the fans ............................................................................................................... 275

9.2.1 Replacing the fan of a 30 kW device ................................................................................... 276

9.2.2 Replacing the fans for the 120 kW device ........................................................................... 277

11.1 Environmental compatibility ................................................................................................. 281

B.1 Ambient conditions ............................................................................................................... 285

B.2 Device data .......................................................................................................................... 287

B.3 Standards and certifications ................................................................................................. 290

SINAMICS DCP

10 Operating Instructions, 05/2016, A5E34382853K

Page 11

Table of contents

C Quality documents .............................................................................................................................. 291

D Additional documents .......................................................................................................................... 293

E Checklists and forms ........................................................................................................................... 301

F Assembly documents .......................................................................................................................... 303

G Index................................................................................................................................................... 305

Index................................................................................................................................................... 307

D.1 List of abbreviations .............................................................................................................. 293

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

11

Page 12

Table of contents

SINAMICS DCP

12 Operating Instructions, 05/2016, A5E34382853K

Page 13

1

Note

SINAMICS DCP is a member of the Sin

mainly comprises components for electric drives. This is the reason that in these operating

instructions in chapters which are applicable for several SINAMICS components (for

example PROFIBUS), the terms "Dri

system" are used. In these operating instructions, "drive", "drive unit" or "drive system"

always refers to the SINAMICS DCP.

The objective of these Operating Instructions is to convey know-how necessary to enable

instructed persons to operate the system professionally and safely.

Knowledge of the Operating Instructions and descriptions of the associated components is

required for all work on the various components. In case of doubt, request support from the

Siemens Customer Support.

Only appropriately trained and instructed personnel is permitted to operate the system.

These Operating Instructions are intended to inform and instruct defined target groups,

safeguard the manufacturer against liability, observe the product, provide traceability and

reproducibility, as well as the long-term or legally required archiving of the relevant

information content.

The individual sections of the Operating Instructions provide information about the product

itself, the handling of the product, and the actions of users.

This document includes safety information and the most important technical details of the

SINAMICS DCP.

amics family of devices. This series of devices

ve", "Master/leading drive", "Drive device" or "Drive

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

13

Page 14

Introduction

SINAMICS DCP

14 Operating Instructions, 05/2016, A5E34382853K

Page 15

2

Note

In the interests of cla

information for all product types and cannot take into account every possible aspect of

installation, operation, or maintenance.

Should further information be desired or should particul

covered sufficiently in the Operating Instructions for the purchaser’s purposes, please

contact your local SIEMENS office.

We also draw your attention to the fact that the contents of these Operating Instructions are

not par

relationship. The Purchase Agreement contains the complete and exclusive obligations of

Siemens, including the warranty provisions. Any statements contained in these Operating

Ins

WARNING

Note the safety instructions

WARNING

Qualified personnel

Note

In addition

manuals for the individual devices are also observed and followed at all times when working

with different components.

rity, these Operating Instructions do not contain full details of all

ar problems arise which are not

t of and do not modify any prior or existing agreement, commitment, or legal

tructions neither expand nor restrict the scope of these contractual warranty conditions.

Operating, servicing, maintaining or installing the SINAMICS DCP may result in property

damage, serious injury, and even death if the safety instructions are not observed.

You must strictly comply with all notes regarding intended use. Different operating modes,

overloads, load cycles, and differing ambient conditions are permitted only after special

arrangement with the manufacturer.

The system is at a hazardous voltage. Failure to comply with these Operating Instructions

can lead to death, serious injury and material damage.

Only qualified personnel are permitted to work on this system. Such personnel must be

thoroughly acquainted with all the warnings and maintenance procedures referred to in

these Operating Instructions.

Perfect, safe and reliable operation of the system assumes that it has been professionally

transported, stored, mounted and installed as well as correct operation and servicing.

to the safety instructions stated here, make sure that the safety instructions in the

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

15

Page 16

Safety notes

DANGER

Grounding the SINAMICS DCP

High voltages that could cause death or serious injury may be still present in the SINAMICS

DCP even after the system has been shut down.

Work on the power units is only permitted when steps have been taken to ensure proper

grounding.

SINAMICS DCP

16 Operating Instructions, 05/2016, A5E34382853K

Page 17

Safety notes

2.1

Safety concept

Safety components for personnel protection

External components for the safety concept

Enclosure

Protection and monitoring functions of internal components

2.1 Safety concept

The SINAMICS DCP is subject to a comprehensive safety concept which, when properly

implemented, ensures safe installation, operation, servicing, and maintenance.

The safety concept encompasses safety components and functions to protect the device and

operators.

●

Power contactors and fuses

●

The touch protection is ensured according to EN 61800-5-1

● Current converter protection by means of monitoring systems:

– Current monitoring

– Voltage monitoring

– Temperature monitoring of the heat sink

– Monitoring of the surrounding air temperature in the fan block

● Shutdown at a communication failure between the SINAMICS DCP and the higher-level

controller

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

17

Page 18

Safety notes

2.2

Notes on operator protection

Note

Qualified personnel

All work associated with the transport, installation, commissioning, operation or maintenance

must be performed by qualified specialist personnel (skilled electricians according to EN

50110

For the purpose of these basic safety instructions, "skilled technical personnel" means

people who are familiar

product. They must be properly qualified for the tasks with which they are charged.

The personnel must also be thoroughly familiar with all safety

measures in thi

Safety-relevant instructions for work on SINAMICS DCP devices

The five safety rules:

Operation of electrical installations according to the low-voltage directive 2006/95/EC

WARNING

Dangerous parts

2.2 Notes on operator protection

-1 "Operation of electrical installations").

with the installation, mounting, commissioning and operation of the

-related instructions and

s documentation.

Read the following information about personal protection.

This standard applies to the operation of and all work on, with or in the vicinity of electrical

installations.

Observe the five safety rules when performing any work

1. Disconnect the system

2. Protect against reconnection

3. Make sure that the equipment is in a no voltage condition

4. Ground and short-circuit

5. Cover or fence off adjacent components that are still live

The SINAMICS DCP may have live parts during operation.

Unauthorized removal of required covers, improper use, or incorrect installation or

operation may lead to death and serious injury or property damage.

Always take the appropriate precautions before touching any components.

SINAMICS DCP

18 Operating Instructions, 05/2016, A5E34382853K

Page 19

Safety notes

WARNING

Dangerous voltages

DANGER

Capacitor discharge / dangerous voltages

CAUTION

Hot surfaces

2.2 Notes on operator protection

High voltages can cause death or serious injury if the safety rules are not observed or if the

equipment is handled improperly.

As soon as the DC link or the battery is connected, dangerous DC voltages are present.

When the SINAMICS DCP is in operation, high voltages occur, and can remain present for

a longer period after the equipment is switched off.

Make sure that work is only carried out by qualified personnel under strict observance of

the five safety rules, the warning notices in this documentation, and the safety-relevant

instructions.

After disconnection of the supply voltage, voltages are still present in the SINAMICS DCP

devices that could result in death or serious injury.

After you have switched off the power supply, strictly observe the discharge time of the DC

link capacitors of 5 minute before you perform any maintenance work or repair work and do

not touch the device during this period.

Measure the voltage once the discharge time has elapsed.

During operation, the temperature of some components increases significantly; for

example, heat sinks, reactors, semiconductor modules etc.

These components can remain very hot for some time after operation. Serious injury

(scalding) may occur if you come into contact with these components.

Do not touch hot components even after you have switched off the SINAMICS DCP.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

19

Page 20

Safety notes

2.2.1

Information about electromagnetic fields

WARNING

Electromagnetic radiation during operation of the plant

2.2 Notes on operator protection

Electromagnetic fields are generated during operation of electrical power engineering

equipment, such as transformers, converters, and motors.

Electromagnetic fields can interfere with electronic devices, which could cause them to

malfunction.

For example, the operation of heart pacemakers can be impaired, potentially leading to

damage to a person's health or even death. Steps must be taken, therefore, to ensure that

persons with heart pacemakers cannot enter these areas.

The plant operator is responsible for taking appropriate measures (labels and hazard

warnings) to adequately protect operating personnel and others against any possible risk.

● Observe the relevant nationally applicable health and safety regulations or the applicable

national regulations in the country of installation.

● Display adequate hazard warning notices on the installation.

● Place barriers around hazardous areas.

● Take measures, e.g. using shields, to reduce electromagnetic fields at their source.

● Make sure that personnel are wearing the appropriate protective gear.

SINAMICS DCP

20 Operating Instructions, 05/2016, A5E34382853K

Page 21

Safety notes

2.3

Notes on plant safety

Requirements

2.3 Notes on plant safety

The operating company is responsible for the plant safety.

Ensure that:

● Basic planning activities and all work associated with transport, assembly, installation,

commissioning, maintenance and repair are performed exclusively by qualified personnel

or by experts assigned responsibility.

● The entire product documentation must always be available for all of the work that is

performed.

● The technical data and specifications regarding the permissible installation, connection,

environmental and operating conditions are always consequentially observed.

● The setup and safety regulations specific to this machine are observed and personal

safety precautions taken.

● It is prohibited for unqualified persons to work on these devices or in their vicinity.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

21

Page 22

Safety notes

2.4

ESD-sensitive components

NOTICE

Electrostatic discharge

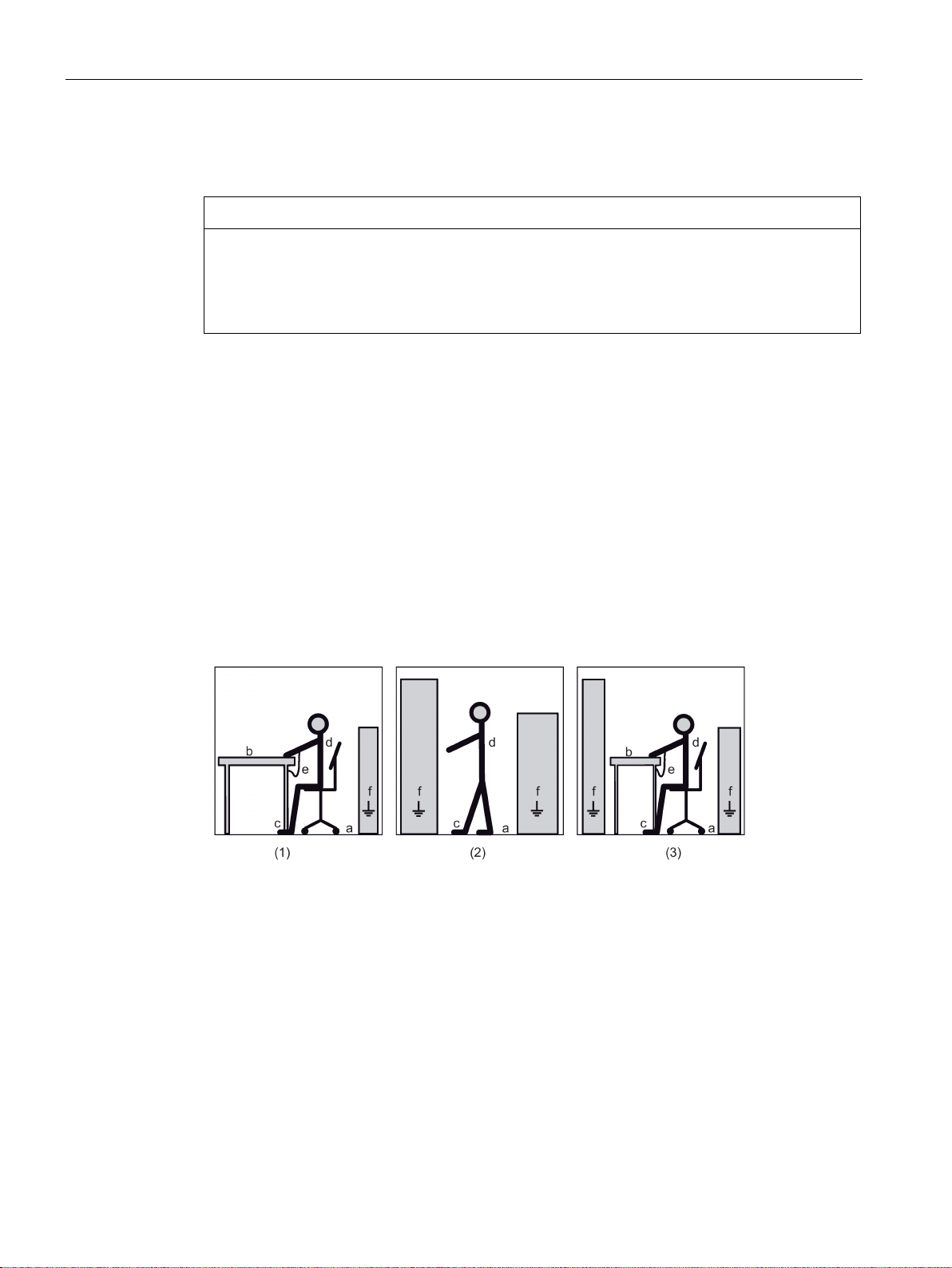

(1) = sitting

(2) = standing

(3) = standing/sitting

ESD protective measures

a = conductive floor surface

b = ESD table

c = ESD shoes

d = ESD overall

e = ESD wristband

f = cabinet ground connection

2.4 ESD-sensitive components

Electronic modules contain components that can be destroyed by electrostatic discharge.

These modules can be easily destroyed if they are not handled properly.

To protect your equipment against damage, follow the instructions given below.

● Never touch electronic modules unless absolutely necessary in the course of

maintenance and repair procedures.

● If the modules have to be touched, the body of the person concerned must be

electrostatically discharged immediately beforehand and be grounded.

● Electronic modules should not be brought into contact with electrically insulating materials

such as plastic foil, plastic parts, insulating table supports or clothing made of synthetic

fibers.

● Always place electrostatic sensitive devices on conductive bases.

● Always store and transport electronic modules or components in conductive packaging

(e.g. metallized plastic or metal containers).

The necessary ESD protective measures for electrostatically sensitive devices are illustrated

once again in the following drawings:

Image 2-1 ESD protective measures

SINAMICS DCP

22 Operating Instructions, 05/2016, A5E34382853K

Page 23

3

Area of application

Design

A SINAMICS DCP is used to control the electrical power flow between two direct current

systems. The device can be operated with current control or voltage control.

The main application of the SINAMICS DCP is to control the electrical power flow:

● from a DC link (the input side, terminals P1 and N1) into a stationary battery (the output

● from a battery (the output side, terminals P2 and N2) back to the DC link (the input side,

The power flow in both directions (from the DC link to the battery and from the battery to the

DC link) is called bidirectional.

side, terminals P2 and N2).

terminals P1 and N1).

The voltages in the two DC circuits are independent of one another.

The electrical power flow, controlled by a signed current setpoint specification, is possible

irrespective of the voltages in the two DC circuits (in the nominal range).

The integration of a SINAMICS DCP in a complete technical system is illustrated in Chapter

Block diagram with connection suggestion (Page 40).

The SINAMICS DCP are compact devices and contain power units and open-loop/closedloop control electronics.

The open-loop/closed-loop control electronics comprise several modules.

The module visible when the front plate is removed is called CUD (Control Unit DC).

LEDs are fitted on the CUD and other modules. They are not visible externally. They are not

relevant for the user, they are only used for diagnostics by SIEMENS experts.

The power units are made up of semiconductor switches; the heat sink is grounded.

The devices are forced-ventilated, the air flow is from the bottom to the top.

The minus cable is led from the input to the output, the current is controlled in the plus

branch.

The devices are only approved for cabinet mounting, vertical installation.

Communication with the devices is via fieldbus (PROFIBUS or PROFINET) during normal

operation and STARTER for the parameter assignment and diagnostics.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

23

Page 24

Description

Additional components

CBE20 additional module

PROFINET

Memory card

For communication between two Control Units via DRIVE-CLiQ

●

– The CBE20 additional module is inserted in the option module slot of the CUD. It

enables the SINAMICS DCP to participate in a

●

– The memory card enables the functions described in Chapter Memory card functions

(Page 113).

●

seeOALINK Function Manual:

https://support.industry.siemens.com/cs/ww/en/view/109477831)

(

network as a slave.

,

SINAMICS DCP

24 Operating Instructions, 05/2016, A5E34382853K

Page 25

4

4.1

Device order numbers

Rated output

Rated direct current

Rated DC voltage

Order number

MLFB

120 kW

200 A

600 V

6RP0010-1AA32-0AA0

30 kW 50 A 600 V 6RP0000-0AA25-0AA0

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

25

Page 26

Preparations for use

4.2

Rating plate

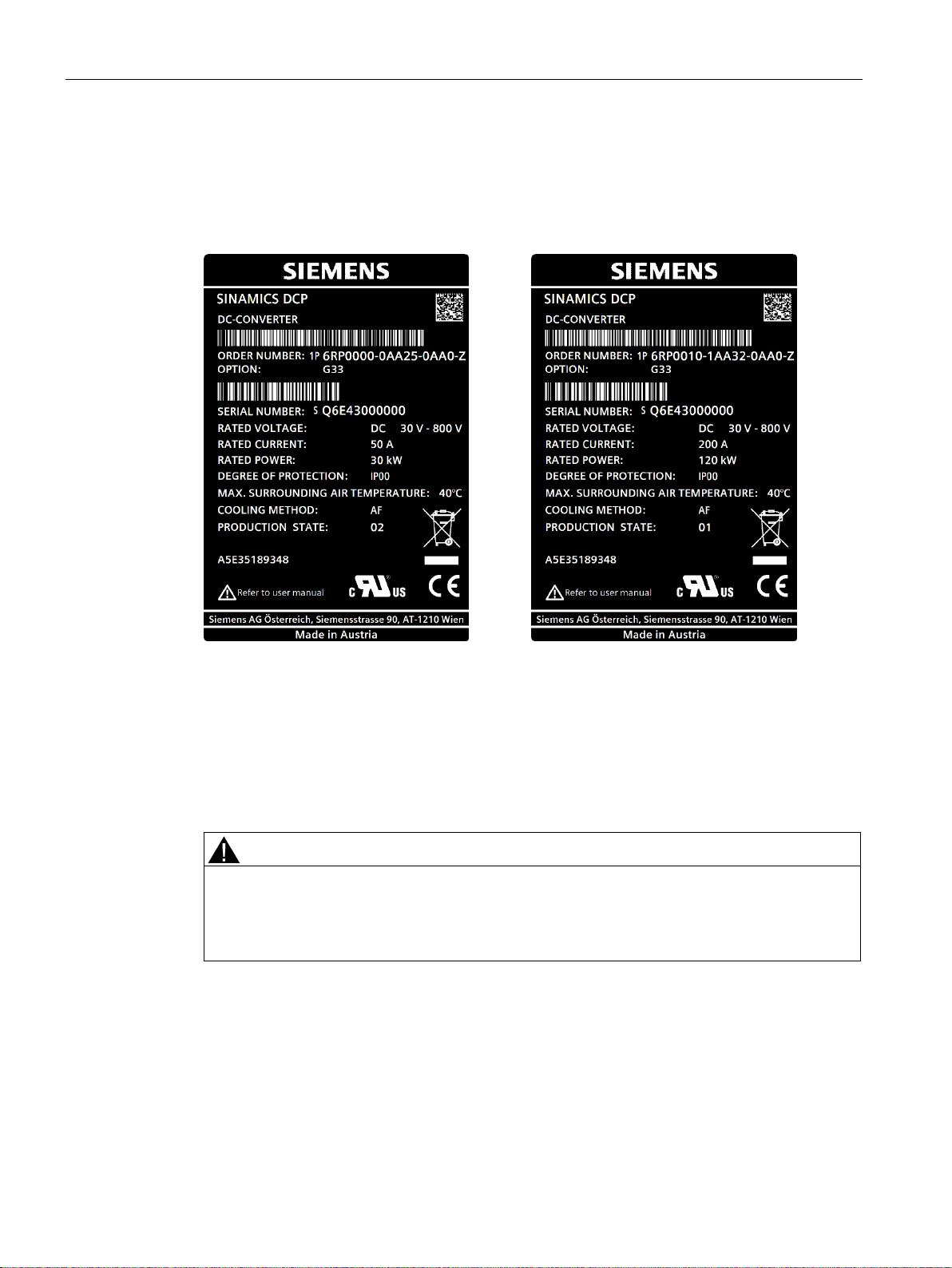

Symbolic illustration of a rating plate for

a 30 kW device

Symbolic illustration of a rating plate for

a 120 kW device

Explanation:

WARNING

Hazardous Voltage

4.2 Rating plate

The rating plate contains the most important technical data and the serial number.

It is attached to the front cover.

(1P) ... Article number

(S) ... Serial number

A5E ... SIEMENS-internal article number

There is a warning notice below the rating plate on the front cover about the hazardous

voltage present for up to 5 minute at the device after it has been disconnected from the

power supply.

SINAMICS DCP

26 Operating Instructions, 05/2016, A5E34382853K

Page 27

Preparations for use

4.2 Rating plate

Image 4-1 Symbolic illustration of the warning label

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

27

Page 28

Preparations for use

4.3

Ordering information for options and accessories

Option

Order codes

directly on the CUD.

CBE20 PROFINET

G33

Memory card

S03

Option

Order codes

Coated modules

Relative/absolute humidity 5% to 95% / 1 to 29 g/m3 for ambient or coolant temperature ≤

(2 years) after being delivered

(2½ years) after being delivered

(3 years) after being delivered

(3½ years) after being delivered

(4 years) after being delivered

(5 years) after being delivered

Power connections from below

M792)

1)

2)

Can only be ordered for the 120 kW device.

4.3 Ordering information for options and accessories

Ordering information for options with order codes

Table 4- 1 Control Unit CUD options

Terminal Module Cabinet (TMC) can be snapped onto a 35 mm mounting rail. Enables the

simple connection of the CUD standard signals (X177) via spring-loaded terminals in an easily accessible area of the control cabinet. The CUD is equipped with an adapter board. Terminal Module Cabinet and connecting cable (3 m) are supplied as separate items.

Note:

In the device version with option G63, the X177 terminal connections are no longer available

Table 4- 2 Further options

Coated modules increase the robustness against climate influences:

•

30° C.

• ≤ 60% when SO2 and H2S is present and/or for ambient or coolant temperature 30° C to

40° C.

• Oil mist, salt mist, ice formation, condensation, dripping water, spraying water, splashing

water and water jets are not permitted.

Extension of the warranty conditions by 12 months to a total of 24 months

G63

M08

Q80

*1)

Extension of the warranty conditions by 18 months to a total of 30 months

Extension of the warranty conditions by 24 months to a total of 36 months

Extension of the warranty conditions by 30 months to a total of 42 months

Extension of the warranty conditions by 36 months to a total of 48 months

Extension of the warranty conditions by 48 months to a total of 60 months

Can be ordered as an option for 30 kW devices, included in the standard scope of delivery for 120 kW devices.

SINAMICS DCP

28 Operating Instructions, 05/2016, A5E34382853K

Q81

Q82

Q83

Q84

Q85

Page 29

Preparations for use

Ordering information for accessories

Item

Order number

CBE20 PROFINET

6SL3055-0AA00-2EB0

STARTER commissioning tool

6SL3072-0AA00-0AG0

4.3 Ordering information for options and accessories

Table 4- 3 Order numbers for accessories

Memory card (corresponds to spare part for option S03) 6RX1800-0AS50

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

29

Page 30

Preparations for use

4.3 Ordering information for options and accessories

SINAMICS DCP

30 Operating Instructions, 05/2016, A5E34382853K

Page 31

5

The SINAMICS DCP is only designed for cabinet mounting. It must be mounted vertically.

The mandatory cooling clearances are indicated by the dotted line. The arrangement of the

fixing positions is shown in the following:

Image 5-1 Dimensions and fixing positions for 30 kW device (from product version 02)

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

31

Page 32

Mounting

Image 5-2 Dimensions and fixing positions for 120 kW device

The area below the device must be unobstructed and allow sufficient supply air.

The area above the device must allow the air outlet and the air outlet openings of the device

must be unobstructed.

For the 30 kW device, the lateral clearance to other components (also for the attachment of

further SINAMICS DCPs) must be at least 20 mm. This is not required for the 120 kW

device.

SINAMICS DCP

32 Operating Instructions, 05/2016, A5E34382853K

Page 33

Mounting

Note

For cabinet

if the power rating is fully utilized. This fan must be designed for the "fan air flow" (seeDevice

data

The customer must ensure that power cables are clamped nor further than 300 mm from

their termination.

designs with degree of protection greater than IP20, an additional fan is required

(Page 287)) of the device in question.

Image 5-3 120 kW device with mounted transport aid

The 120 kW device is delivered with 3 metal brackets, which are used as a transport aid (in

figure 5-3, shown in red). These have to be removed before mounting and disposed of as

scrap metal.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

33

Page 34

Mounting

SINAMICS DCP

34 Operating Instructions, 05/2016, A5E34382853K

Page 35

6

WARNING

DANGER

The devices are operated with hazardous voltages.

All connection work must be carried out while the cabinet is de-energized.

Only qualified personnel who are familiar with all the safety instructions in these Operating

Instructions, as well as the assembly, installation, operating, and maintenance instructions,

should carry out work on these units.

Failure to observe this warning information can result in death, serious injury, or extensive

material damage.

Connecting the unit incorrectly can lead to it being damaged or destroyed.

When handling the unit while it is open, remember that live parts are exposed. The unit

must only be operated with the front covers provided by the factory fitted. When required,

additional covers should be provided in the control cabinet.

This product can cause a direct current in the protective ground conductor. When a residual

current device (RCD) or a residual current monitor (RCM) is used for protection in the event

of direct or indirect contact, only an RCD or RCM of type B is permissible on the power

supply side of this product.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

35

Page 36

Electrical connection

6.1

EMC-compliant installation

6.1.1

Basic information about EMC

What is EMC?

Interference emissions and interference immunity

Product standard EN 61800-3

first environment

second environment

6.1 EMC-compliant installation

EMC stands for "electromagnetic compatibility" and describes "the capability of a device to

function satisfactorily in an electromagnetic environment without itself causing interference

unacceptable for other devices in the environment". Therefore, the various units used should

not cause interference to one another.

Within the context of the EMC Directive, the SINAMICS DCP units described in this

document are not "units" at all, but are instead "components" that are intended to be

installed in an overall system or overall plant. For reasons of clarity, however, the generic

term "units" is used in many cases.

EMC is dependent upon two properties demonstrated by the units involved in the system:

interference emissions and interference immunity. Electrical units may be sources of

interference (senders) and/or potentially susceptible equipment (receivers). Electromagnetic

compatibility is ensured when the existing sources of interference do not impair the function

of potentially susceptible equipment.

A unit may even be a source of interference and potentially susceptible equipment at the

same time: For example, the power unit of a converter should be viewed as a source of

interference and the control unit as potentially susceptible equipment.

EN 61800-3 defines different limits depending on the installation site of the system, referred

to as the first and second environments.

Residential buildings or locations at which the system is directly connected to a public lowvoltage network without an intermediate transformer are defined as the

The term

basically industrial areas which are powered from the medium-voltage network via their own

transformers.

refers to all locations outside residential areas. These are

.

SINAMICS DCP

36 Operating Instructions, 05/2016, A5E34382853K

Page 37

Electrical connection

Category C1:

Systems for rated voltages < 1000 V for unlimited use in the first enviro

ment

Category

Stationary systems for rated voltages < 1000 V for use in the second env

ronment. Use in the first environment is possible if the system is operated

and installed by qualified personnel. The warning information and install

tion instructions supplied by the manufacturer must be observed.

Category C3:

Systems for rated voltages < 1000

ronment

Category C4:

Systems for rated voltages

complex systems in the second environment

6.1 EMC-compliant installation

Image 6-1 Definition of the first and second environments

Four different categories are defined in EN 61800-3 depending on the location and the

power:

C2:

≥ 1000 V or for rated currents ≥ 400 A for use in

V for exclusive use in the second envi-

The figure below shows how the four categories are assigned to the first and second

environments:

Image 6-2 Definition of categories C1 to C4

n-

i-

a-

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

37

Page 38

Electrical connection

EN 61800-3

EN 61000-6-2

EN 61000-6-4

WARNING

6.1.2

EMC-compliant installation of SINAMICS DCP (installation instructions)

General information

Grounding of the DC link

not

Rules for EMC-compliant installation

1 Interconnect all metallic parts of the control cabinet highly conductively and with a large

contact area. (not paint on paint!). Use contact or scratch washers if necessary. The

cabinet door must be connected to the cabinet using the shortest possible ground strips

(at the top, center, and bottom).

2 Contactors, relays, solenoid valves, electromechanical operating hours counters, etc.,

in the cabinet and

quenching combinations such as RC elements, varistors, and diodes. These must be

connected directly at the appropriate coil.

3

Whenever possible, lead signal cables

into the cabinet at one level only.

4 Unshielded cables in the same circuit (supply/return conductors) must be twisted where

possible, or the area between them must be minimized, to avoid creating loop antennas

unnecessarily.

5 Connect spare wires to the cabinet ground

shielding effect.

6 Avoid unnecessary cable lengths in order to keep coupling capacities and inductances

low.

7 Crosstalk is generally reduced if the cables are laid close to the control cabinet ground.

Therefore, do not route cables freely around the cab

sible to the cabinet enclosure / mounting plates. This also applies to spare cables.

6.1 EMC-compliant installation

SINAMICS DCP devices satisfy the requirements for interference emission and interference

immunity defined in

generic standards

for the second environment (Category C3) and those in the

and

.

In a residential environment, this product can cause high-frequency disturbances, which

may make interference suppression measures necessary.

In order to ensure electromagnetic compatibility (EMC) in rugged electrical environments and

adhere to the standards required by the relevant legislating body, the EMC rules listed below

should be followed during the construction and installation stages.

The DC link does

have to be grounded. (for a 30 kW device from product version 02).

- where applicable - in neighboring cabinets - must be provided with

1)

2)

at both ends. This achieves an additional

SINAMICS DCP

38 Operating Instructions, 05/2016, A5E34382853K

inet, but lay them as close as pos-

Page 39

Electrical connection

8 Signal and power cables must be physically separated (to prevent coupling paths).

Minimum clearance: 20 cm should be aimed at. If it i

rate the signal cable and electric power cable, the signal cable must be decoupled e

ther using a partition or by routing it in a metal conduit. The partition or metal conduit

must be grounded at several points. If it is no

cables crossing, make sure that they cross at right angles only.

9 Ground the shields of digital signal cables at both ends (source and destination), ensu

ing maximum contact area and good conductivity. In the event

bonding between the shield connections, run an additional equalizing conductor with a

cross

shield current. Generally speaking, the shields may also be

enclosure (ground)

even outside the control cabinet. Foil shields should be avoided, as they are are at

least 5 times less effective than braided shields.

10 Shields

tial bonding is good (this must be done over a large area with good conductivity). It can

be assumed that equipotential bonding is good if all metal parts are well interconnected

and the electronics components are supplied from a single source.

Footnotes

1)

Signal cables are defined as:

Digital signal cables, e.g. cables for incremental encoders

Analog signal cables, e.g. ±10 V setpoint cable

Serial interfaces, e.g. PROFIBUS and PROFINET

2)

Generally speaking, "ground" refers to all metallic conductive parts that can be co

nected to a protective conductor, such as the cabinet enclosure, motor enclosure, or

foundation ground.

6.1 EMC-compliant installation

s not possible to physically sepa-

i-

t possible to prevent signal and power

r-

of poor equipotential

-section of at least 10 mm² parallel to the shield for the purpose of reducing the

connected to the cabinet

2)

at several points. The shields can be connected several times

for analog signal cables may be connected to ground at both ends if equipoten-

n-

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

39

Page 40

Electrical connection

6.2

Block diagram with connection suggestion

6.2 Block diagram with connection suggestion

Image 6-3 Block diagram with connection suggestion

SINAMICS DCP

40 Operating Instructions, 05/2016, A5E34382853K

Page 41

Electrical connection

6.2 Block diagram with connection suggestion

The block diagram above shows a (maximum) configuration for the SINAMICS DCP together

with possible interfaces to a higher level controller.

● Fuses: See Chapter Components (Page 43)

● Precharging (precharging interface: precharging resistors and fuses): See Chapter

Precharging of the DC links (Page 240)

● Main contactors: See Chapter Components (Page 43)

● The connections "from the previous DCP" and "to the next DCP" are only required if

multiple SINAMICS DCPs are switched in parallel: See Chapter Parallel connection of

multiple SINAMICS DCPs (Page 269)

To prevent coupling of external interference into the cabinet, the shields for the cables used

must be grounded extensively as close as possible to the point of entry into the cabinet.

Suitable shield buses or comb bars can be used here.

These busbars must be connected conductively and extensively to the cabinet housing.

Image 6-4 Shield connection for an electric power cable (e.g. connection to DC link, to the battery, or to a PV field) at

point of entry into the cabinet

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

41

Page 42

Electrical connection

6.2 Block diagram with connection suggestion

Image 6-5 Shield connection for the signal cables in the cabinet

The following rules apply for the connection cables:

● All cables that leave the cabinet system must be "shielded".

● Cables inside the cabinet do not have to be "shielded".

SINAMICS DCP

42 Operating Instructions, 05/2016, A5E34382853K

Page 43

Electrical connection

6.3

Components

Fuses

Suggested type

Line contactors

Recommended type

Precharging resistors

Recommended type

Note

Using this precharging resistor will result in the follow

30 kW device: 65 ms

120 kW device: 600

This must be taken into account in the parameterization (p55355).

6.3 Components

The device must be protected by DC fuses on the input side and output side.

For the 30 kW device:

Siemens PV fuse 63 A with designation 3NE1218-4

Fuse holder: Siemens 3NH7262-4KK01

Alternative fuse (with UL certification): Ferraz Shawmut/Mersen: A150X60-4

For the 120 kW device:

Siemens PV fuse 250 A with designation 3NE1227-4D

Fuse holder: Siemens 3NH7260-4

Alternative fuse (with UL certification): Ferraz Shawmut/Mersen: A150X250-4

Relevant to the 30 kW device:

Gigavac HX21 C A (with UL certification)

This type is only a single-pole contactor, which means that, to switch two poles, 2 contactors

are required for each current path.

The power contactors must be able to handle 1000 V and 50 A.

Relevant to the 120 kW device:

Gigavac HX21 C A (with UL certification)

This type is only a single-pole contactor, which means that, to switch two poles, 2 contactors

are required for each current path.

The power contactors must be able to handle 1000 V and 200 A.

CAV 150 C 100R 800, manufacturer: Danotherm company

ing precharging times:

ms

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

43

Page 44

Electrical connection

Precharging contactors

Recommended type

Note

With the recommended series resistor, the max. contact load of 10 A is not exceeded.

Pre-charge circuit fuse

6.3 Components

High-voltage relay H-507

Type code H00-04507/11-001128-002/005.00

Coil voltage 24 V

Manufacturer: Hengstler company

or

High-voltage relay RL 42

Coil voltage 24 V

Manufacturer: SPS Electronic Company

Alternatively, a UL-recognized type can be used

Gigavac P115 C D A

. This type is only implemented as single pole configuration. This means that 2 contactors

are required for each circuit if you wish to switch two poles.

Cylindrical fuse-links operating class gPV

10 x 38 4 A 1000 V 1.4 B 3NW6 004-4

Cylindrical fuse holder without signal detector

1P 25 10 x 38 1 B 3NW7 013-4

SINAMICS DCP

44 Operating Instructions, 05/2016, A5E34382853K

Page 45

Electrical connection

6.4

Terminals and connectors

Power connections for 30 kW device

6.4 Terminals and connectors

● The DC input power connection is on the bottom left of the device

● The DC output power connection is on the bottom right of the device

● The ground connection is on the bottom left of the device

Image 6-6 Connection area for power connections for the 30 kW device

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

45

Page 46

Electrical connection

Power connections for the 120 kW device

6.4 Terminals and connectors

● The DC input and DC output power unit connections are on top on the device, or on the

bottom for the M 79 option.

● The ground connection is located at the top and bottom of the device

Image 6-7 Connection area for power connections for the 120 kW device

SINAMICS DCP

46 Operating Instructions, 05/2016, A5E34382853K

Page 47

Electrical connection

Power connections

P1

Input circuit: Plus cable

N1

Input circuit: Minus cable

N2

Output circuit: Minus cable

NOTICE

Connection cables

30 kW device

Note

The sheaf diameter of the cable must not be greater than 10 mm.

Recommended connection cable:

RADOX® solar cable

6.4 Terminals and connectors

P2 Output circuit: Plus cable

Remark: On the 120 kW device, connections N1 and N2 are combined to form a busbar with

designation N.

Tightening torque of the nuts for the power connections: 13 Nm.

For reasons of safety, multiple use of the power connections is not permitted. In other

words, you must not place several cable lugs on top of each other and screw them

together. If it is necessary to loop through the power connections (for example, when

connecting several SINAMICS DCPs in parallel), you must use suitable distribution

terminals, which you mount in the cabinet.

The cable used must satisfy the requirements of the recommended connection cable.

●

Cross section: 10 mm

Order no.: 12537897

2

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

47

Page 48

Electrical connection

120 kW device

Recommended connection cable:

Cable with shield:

SIENOPYR(90) (N)HXSGAFCHXÖ 1.8/3 kV

Cable without shield:

SIENOPYR(90) (N)HXSGAFHXÖ 1.8/3 kV

Ground connection

6.4 Terminals and connectors

●

Cross section: 50 mm2

Order no.: 5DF9 660

●

Cross-section:

Order no.: 5DF8 153

50 mm2

The device must be grounded. The device has a ground connection, identified by a

grounding symbol.

30 kW device: Tightening torque of the screw for the protective conductor: 6 Nm.

120 kW device: Tightening torque of the screw nut for the protective conductor: 13 Nm.

SINAMICS DCP

48 Operating Instructions, 05/2016, A5E34382853K

Page 49

Electrical connection

Terminal block for the 24 V DC power supply and switching contacts

6.4 Terminals and connectors

There is a terminal block with 10 terminals either on or in the device (see following figures).

Image 6-8 Connection area for 24 V supply and switching contacts for 30 kW device

For the 120 kW device, the terminal block for the power supply and switching contacts is

only accessible after first removing the front panel.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

49

Page 50

Electrical connection

Terminal arrangement

1

P24 V ext

External power supply

24 VDC plus cable

2

M ext

External power supply

24 VDC minus cable

3

VLSE1

NO contact for contactor control:

Precharging contactor input

4

VLSE2

NO contact for contactor control:

Precharging contactor input

5

HLSE1

NO contact for contactor control:

Line contactor input

6

HLSE2

NO contact for contactor control:

Line contactor input

7

VLSA1

NO contact for contactor control:

Precharging contactor output

8

VLSA2

NO contact for contactor control:

Precharging contactor output

6.4 Terminals and connectors

Image 6-9 Connection area for 24 V supply and switching contacts for 120 kW device

SINAMICS DCP

50 Operating Instructions, 05/2016, A5E34382853K

Page 51

Electrical connection

9

HLSA1

NO contact for contactor control:

Line contactor output

10

HLSA2

NO contact for contactor control:

Line contactor output

Communication connections

①

PROFIBUS cable

6.4 Terminals and connectors

Terminal type: Spring-loaded terminal

● Type: PELV 24 V circuit

● Voltage tolerance of the P24 V ext: 18 V to 30 V for 30 kW devices, In = 5 A

for 120 kW devices, In = 20 A

● Conductor cross-sections: 1.5 to 2.5 mm

2.

For 120 kW devices, for connections P24 V ext and M ext, a cross-section of 2.5 mm2

must be used.

Contact rating of the "NO contact for the contactor control": 2 A at 30 VAC/DC resistive.

The cables for PROFIBUS or PROFINET must be connected inside the device. The front

cover must be removed for this.

● The PROFIBUS connector X126 is on the CUD module. The cable can be led out at the

bottom through the intended aperture.

● The PROFINET connector X1400 is on the CBE20 module. The cable can be brought out

at the top through the opening provided for this purpose.

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

Image 6-10 PROFIBUS connection for the 30 kW device or 120 kW device

51

Page 52

Electrical connection

①

PROFINET cable

Terminals on the CUD

-X178, -X179:

Flexible with end sleeve with/without plastic sleeve: 0.25 - 1.5 / 0.25 - 0.75 mm2

Stripping length

10 mm

-XR1,- XS1, -XT1:

Type

MSTB 2.5 / CIF plug-in terminal

end sleeve with/without plastic sleeve: 0.25 - 2.5 / 0.25 - 2.5 mm2

Stripping length

7 mm

Tightening torque

0.5 - 0.6 Nm

-X126:

Type

Submin D, 9-pin

6.4 Terminals and connectors

Image 6-11 PROFINET connection for the 30 kW device or 120 kW device

The CUD terminals are usually not required for the operation of the SINAMICS DCP.

Table 6- 1 Terminal type

Type FMC 1.5 plug-in terminal

Conductor size Rigid/flexible/conductor sizes (mm2/mm2/AWG): 0.2 - 1.5 / 0.2 - 1.5 / 24 - 16

Conductor size Rigid/flexible/conductor sizes (mm2/mm2/AWG): 0.2 - 2.5 / 0.2 - 2.5 / 24 - 12 flexible with

SINAMICS DCP

52 Operating Instructions, 05/2016, A5E34382853K

Page 53

Electrical connection

-X100, -X101:

Type

Modular jack 8/4 (RJ45)

6.4 Terminals and connectors

SINAMICS DCP

Operating Instructions, 05/2016, A5E34382853K

53

Page 54

Electrical connection

Terminals on the connector board

Analog inputs (assignable inputs)

2

4

6

8

Digital inputs (assignable inputs)

internal supply in relation to internal ground

11

DI 0

Digital input 0

12

DI 1

Digital input 1

13

DI 2

Digital input 2

14

DI 3

Digital input 3

Digital inputs/outputs (assignable inputs/outputs)

/output 4

If overload occurs: Alarm A60018

/output 5

/output 6

19

DO 0

Digital output 0

If overload occurs: Alarm A60018

20

DO 1

Digital output 1

21

DO 2

Digital output 2

22

DO 3

Digital output 3

Analog inputs, setpoint inputs (assignable inputs)

6.4 Terminals and connectors

See also Table 8-8 Overview of inputs and outputs (Page 133).

Table 6- 2 Assignment, terminal -X177

Terminal

-X177

1

3

5

7

9

10

15 DI/DO 4 Digital input

16 DI/DO 5 Digital input

17 DI/DO 6 Digital input

18 DI/DO 7 Digital input

Function Technical specifications

AI 3 +

AI 3 -

AI 4 +

AI 4 -

AI 5 +

AI 5 -

AI 6 +

AI 6 -

DC

24 V

Analog input 3 Input type (signal type): Differential input ±10 V; 150 kΩ resolution

Analog input 4

Analog input 5

Analog input 6

24 V supply (output) 24 VDC, short-circuit proof

/output 7

approx. 5.4 mV (±11 bits) common-mode controllability: ±15 V

Max. load 200 mA (terminals 9 and 10 combined),

H signal: +15 V to +30 V

L signal: – 30 V to +5 V or terminal open circuit

8.5 mA at 24 V

Type, parameterizable input/output

Input characteristics:

H signal: +15 V to +30 V

L signal: 0 V to +5 V or terminal open

8.5 mA at 24 V

Output characteristics:

H signal: +20 V to +26 V

L signal: 0 to +2 V

short-circuit proof; max. current carrying capacity: 100 mA per DO;

max. total load of all DO (CUD left -X177:15-22 + CUD

right -X177:15-22): 800 mA

Internal protection circuit (free-wheeling diode)

23 ... 24 M Ground, digital

SINAMICS DCP

54 Operating Instructions, 05/2016, A5E34382853K

H signal: +20 V to +26 V

L signal: 0 to +2 V

short-circuit proof; max. current carrying capacity: 100 mA per DO;

max. total load of all DO (CUD left -X177:15-22 + CUD

right -X177:15-22): 800 mA

Internal protection circuit (free-wheeling diode)

Page 55

Electrical connection

Common-mode controllability: ±15 V

Common mode controllability ±15 V

Reference voltage

32

N10

33, 34

M

Ground, analog

Terminals not used

35, 36

M

Ground, digital

37 Not used

38 Not used

39 Not used

40 Not used

Terminals not used

41

Supply

42

Ground

44

Not used

46

Not used