Siemens SINAMICS DCM User Manual

SINAMICS DCM

DC Converter

Application document for functional

safety STO, SS1 (ISO 13849-1)

Compact User Manual

09/2016

A5E34871844AM

Introduction

1

Principle of the dual channel

architecture

2

STO stop Category 0 with

one switching device

3

SS1 stop Category 1 with

one switching device

4

STO, two switching devices

in series

5

SS1, two switching devices

connected in series

6

STO stop Category 0,

several power units

7

SS1 stop Category 1 for

several power units

8

Evaluating the safety

functions according to EN

ISO 13849 when using one

switching device

9

Evaluating the safety

functions according to EN

ISO 13849 when using two

switching devices

10

Evaluation of the safety

function according to EN

62061

11

Standards

12

Recommended safety relays

13

Connection circuit diagrams

for the switching devices

14

Recommended circuit

breakers and power

contactors

15

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E34871844AM

Ⓟ

09/2016 Subject to change

Copyright © Siemens AG .

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

5

Table of contents

1 Introduction................................................................................................................................. 11

1.1 Important note ................................................................................................................... 11

1.2 Preliminary remarks........................................................................................................... 11

1.2.1 Safe Torque Off (STO) ...................................................................................................... 12

1.2.2 Safe Stop 1 (SS1, time-controlled) ..................................................................................... 12

1.2.3 Using EMERGENCY STOP ............................................................................................... 13

1.3 Application overview .......................................................................................................... 13

1.4 Armature circuit with one switching device ......................................................................... 14

1.5 Armature circuit with two switching devices ........................................................................ 14

1.6 Field circuit description ...................................................................................................... 15

1.7 Safety shutdown (E-STOP)................................................................................................ 16

1.8 Parameterizing the digital outputs ...................................................................................... 17

1.9 Parameterizing the digital input for SS1 OFF3 ................................................................... 18

1.10 Abbreviations and circuit diagram symbols ........................................................................ 19

2 Principle of the dual channel architecture ....................................................................................... 21

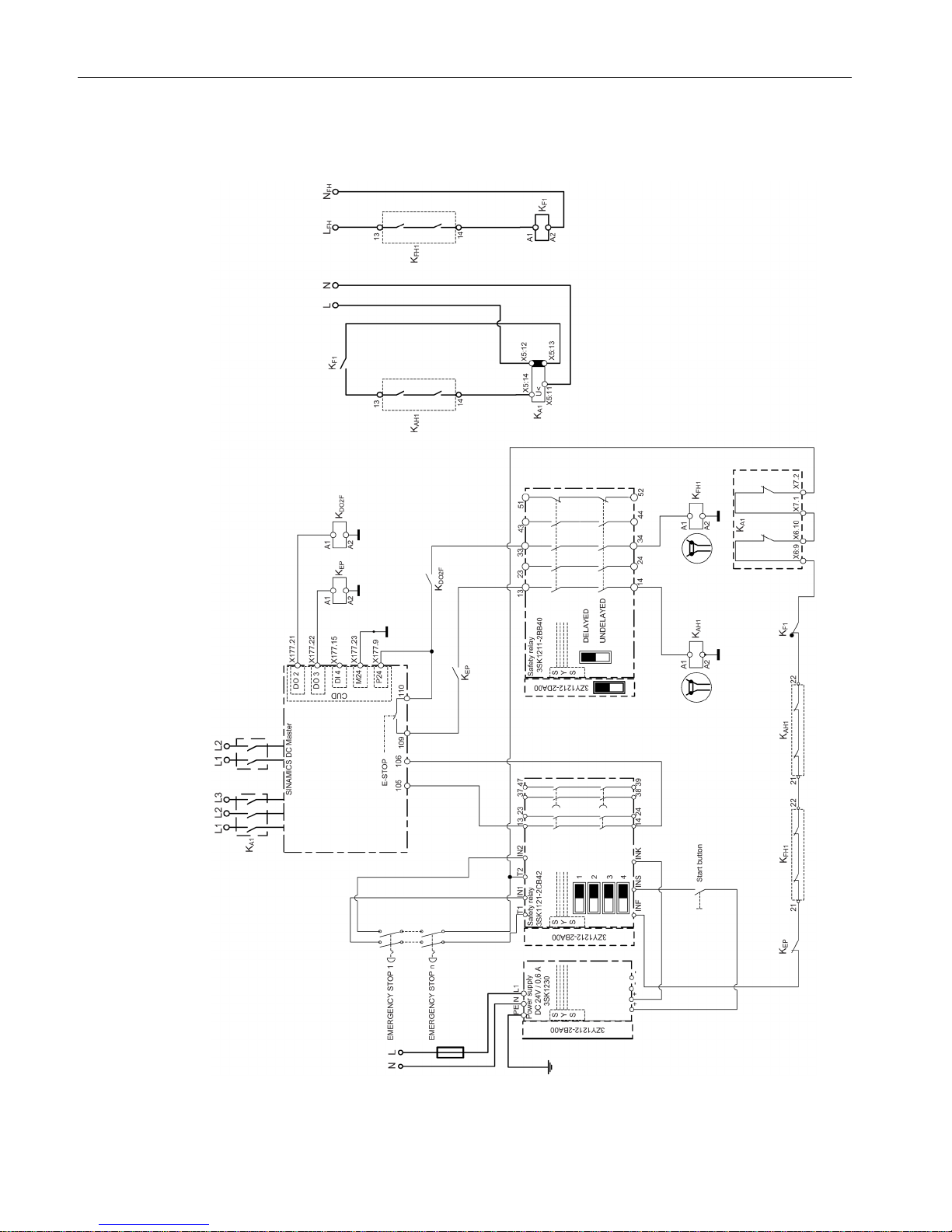

3 STO stop Category 0 with one switching device .............................................................................. 23

3.1 Description ........................................................................................................................ 23

3.2 STO circuit example with one 3WL circuit breaker ............................................................. 24

3.3 STO circuit example with one power contactor................................................................... 25

4 SS1 stop Category 1 with one switching device ............................................................................... 27

4.1 Description ........................................................................................................................ 27

4.2 SS1 circuit example with one 3WL circuit breaker .............................................................. 28

4.3 SS1 circuit example with one power contactor ................................................................... 29

5 STO, two switching devices in series ............................................................................................. 31

5.1 Description ........................................................................................................................ 31

5.2 STO circuit example with two 3WL circuit breakers connected in series ............................. 32

5.3 STO circuit example with two power contactors connected in series .................................. 33

6 SS1, two switching devices connected in series .............................................................................. 35

6.1 Description ........................................................................................................................ 35

6.2 SS1 circuit example with two 3WL circuit breakers connected in series .............................. 36

6.3 SS1 circuit example with two power contactors connected in series ................................... 37

Table of contents

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

6 Compact User Manual, 09/2016, A5E34871844AM

7 STO stop Category 0, several power units ..................................................................................... 39

7.1 Description .........................................................................................................................39

7.2 STO circuit example with two power units and circuit breakers............................................40

7.3 STO circuit example with two power units and power contactors .........................................41

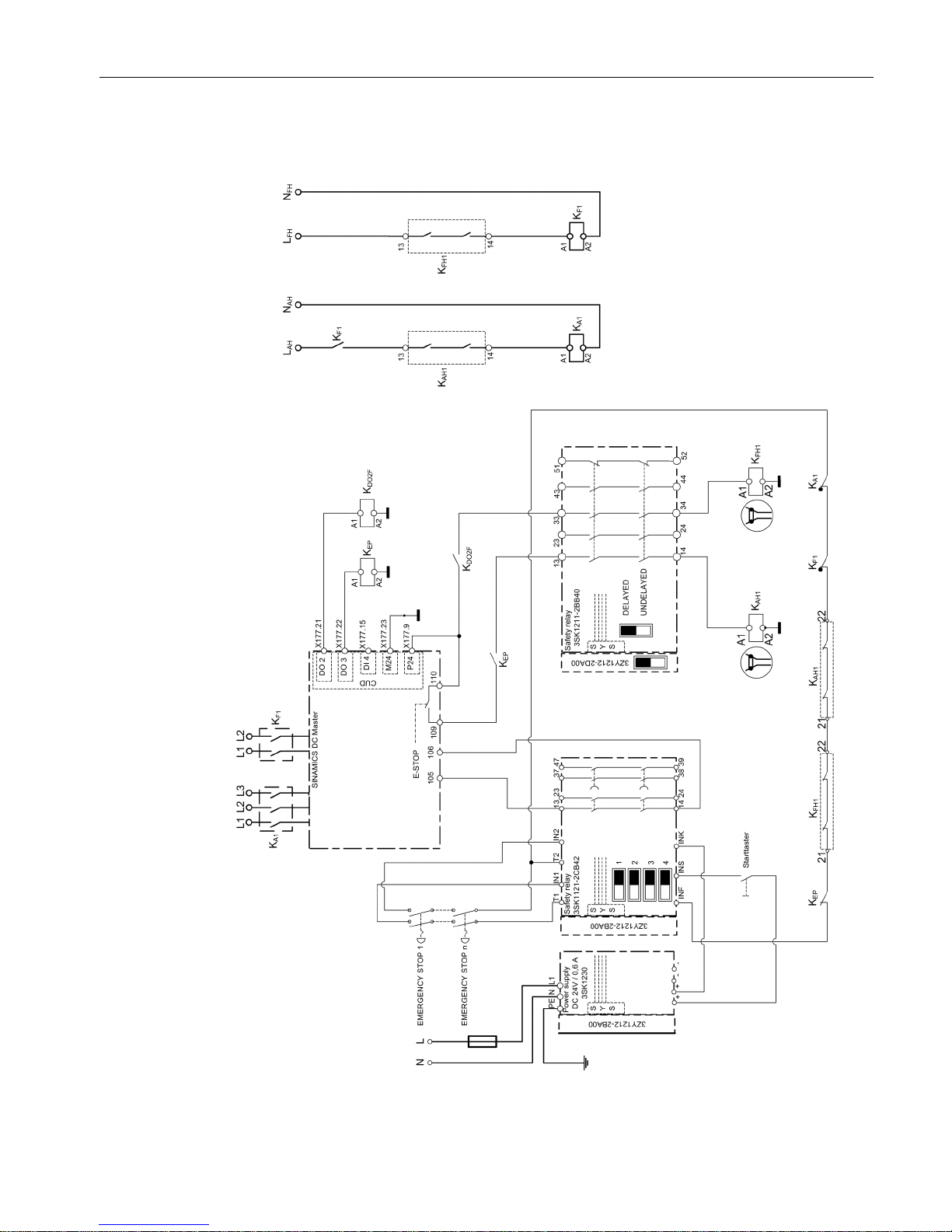

8 SS1 stop Category 1 for several power units .................................................................................. 43

8.1 Description .........................................................................................................................43

8.2 SS1 circuit example with two power units and circuit breakers ............................................45

8.3 SS1 circuit example with two power units and circuit breakers ............................................46

9 Evaluating the safety functions according to EN ISO 13849 when using one switching device .............. 47

9.1 Evaluation of "Detect" .........................................................................................................48

9.2 Evaluation of "Evaluate" .....................................................................................................49

9.3 Evaluation of "Respond" .....................................................................................................50

9.3.1 Evaluation of "Respond" with one power switching device ..................................................50

9.3.1.1 Evaluation of an 3WL circuit breaker...................................................................................50

9.3.1.2 Evaluation of a power contactor ..........................................................................................52

9.4 Result when using a 3WL circuit breaker ............................................................................53

9.5 Result when using a power contactor .................................................................................53

10 Evaluating the safety functions according to EN ISO 13849 when using two switching devices............. 55

10.1 Evaluation of "Detect" .........................................................................................................56

10.2 Evaluation of "Evaluate" .....................................................................................................57

10.3 Evaluation of "Respond" .....................................................................................................58

10.3.1 Evaluation of "Respond" with two power switching devices .................................................58

10.3.1.1 Evaluation of two 3WL circuit breakers connected in series ................................................58

10.3.1.2 Evaluation of two power contactors connected in series......................................................59

10.3.2 Result of "Respond" with two 3WL circuit breakers .............................................................60

10.3.3 Result of "Respond" with two power contactors ..................................................................60

10.4 Result when using two 3WL circuit breakers .......................................................................60

10.5 Result when using two power contactors ............................................................................61

11 Evaluation of the safety function according to EN 62061 .................................................................. 63

11.1 Evaluation of "Detect" .........................................................................................................64

11.2 Evaluation of "Evaluate" .....................................................................................................65

11.3 Evaluation of "Respond" .....................................................................................................66

11.3.1 Evaluation of "Respond" with two power switching devices .................................................66

11.3.1.1 Evaluation of two 3WL circuit breakers ...............................................................................66

11.3.1.2 Evaluation of two power contactors ....................................................................................67

11.3.2 Result "Respond" when using two 3WL circuit breakers ......................................................67

11.3.3 Result "Respond" when using two power contactors ...........................................................68

11.4 Result when using two 3WL circuit breakers .......................................................................68

11.5 Result when using two power contactors ............................................................................69

Table of contents

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

7

12 Standards ................................................................................................................................... 71

13 Recommended safety relays ......................................................................................................... 73

14 Connection circuit diagrams for the switching devices ...................................................................... 75

15 Recommended circuit breakers and power contactors ..................................................................... 81

Table of contents

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

8 Compact User Manual, 09/2016, A5E34871844AM

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

9

Supplement to liability exclusion

We accept no liability for any damage or loss caused by use of the safety functional

examples, information, programs, planning data or performance data described in this

document, irrespective of the legal basis for claims arising from such damage or loss, unless

liability is mandatory, for example, according to the product liability law, in cases of

malfeasance, gross negligence, due to endangerment of life, the body or health, due to

assumption of a guarantee for a product's characteristics of state, due to malicious

concealment of a defect or due to violation of basic contractual obligations. The damages for

a breach of a substantial contractual obligation are, however, limited to the foreseeable

damage, typical for the type of contract, except in the event of intent or gross negligence or

injury to life, body or health. Any change to the burden of proof to your disadvantage is not

covered hereby.

Copyright

Copyright © 2016 Siemens AG. Reproduction or transmissions of these safety function

examples or extracts thereof are forbidden without the express written authority of Siemens

AG.

Manuals and application notes on the Internet

The manuals and application documents are available in the Internet:

Manuals (https://support.industry.siemens.com/cs/ww/en/ps/13298)

The list of general conditions available there include current supplements to the manuals.

The notes included in the general condition lists have a higher priority than the statements

made in the manuals.

Introduction

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

10 Compact User Manual, 09/2016, A5E34871844AM

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

11

Introduction

1

1.1

Important note

The safety functional examples are non-binding and do not claim to be complete in respect

of configuration, equipment or practical eventualities. The safety functional examples are not

customer-specific solutions but are only intended to facilitate the performance of typical

tasks. You are responsible for ensuring that the products described are used correctly.

These safety functional examples do not relieve you of the obligation to use the products

safely during application, installation, operation and maintenance. By using these safety

functional examples, you acknowledge the fact that Siemens cannot be held liable for any

claims or damages above and beyond the liability described above. We reserve the right to

make changes to these safety function examples at any time without prior notice. In the case

of any differences between the suggestions made in these safety function examples and

other publications from Siemens, such as catalogs, the contents of the other documentation

have priority.

1.2

Preliminary remarks

In DIN EN 60204-1: 2007 a distinction is made between three stop categories to stop

machines: Stop categories 0, 1 and 2

The stop category to be used must be defined based on the risk assessment of the

particular machine.

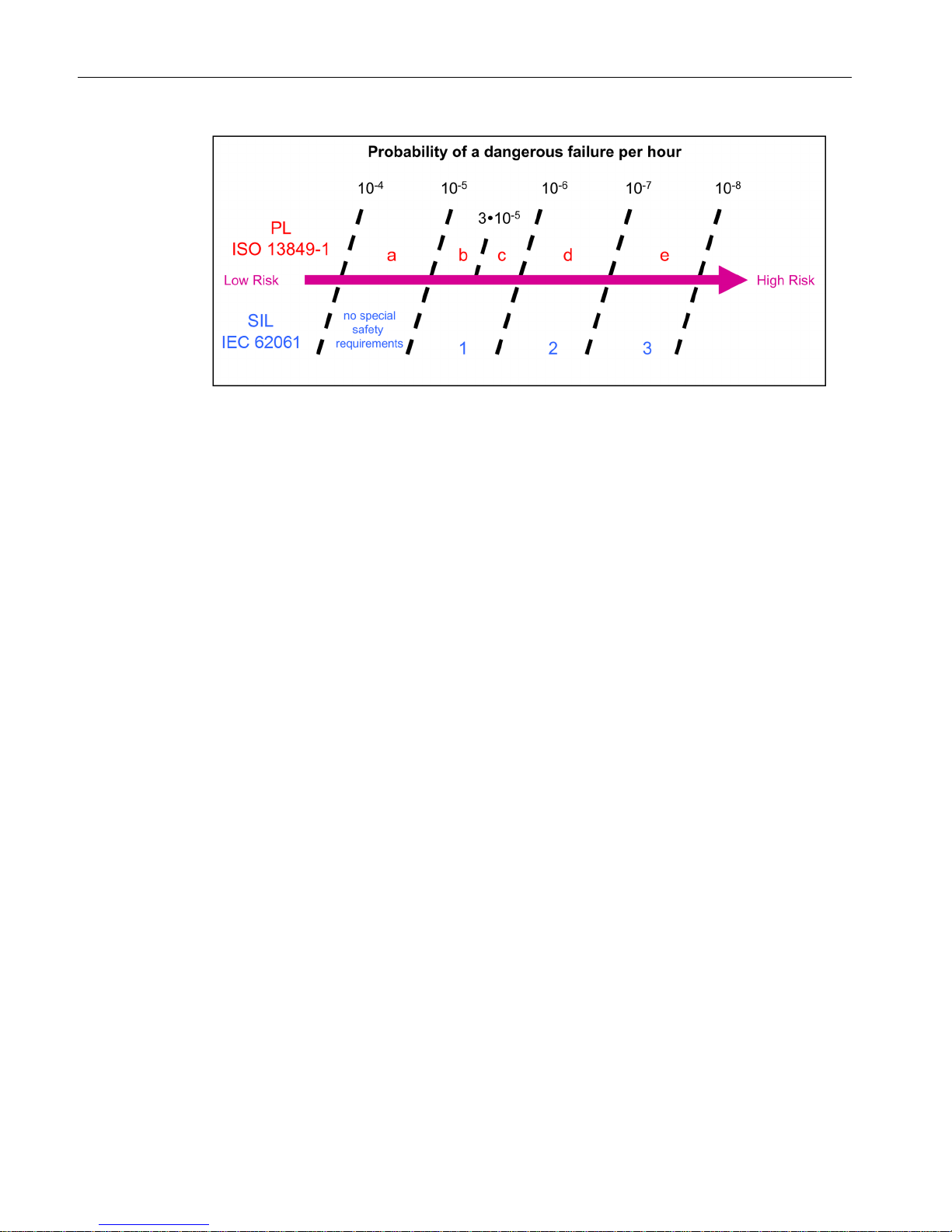

The safety functions listed here are in conformance with:

● Safety Integrity Level (SIL) 2 according to DIN EN 61508

● Category 3 according to DIN EN ISO 13849-1

● Safety of machinery - functional safety according to EN 62061

● Performance Level (PL) d according to DIN EN ISO 13849-1

The safety functions correspond to the functions according to DIN EN 61800-5-2.

This application document explains stop categories 0 and 1.

Introduction

1.2 Preliminary remarks

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

12 Compact User Manual, 09/2016, A5E34871844AM

1.2.1

Safe Torque Off (STO)

Safe Torque Off is a safety function to avoid unexpected starting in accordance with

EN 60204-1. STO prevents the supply of energy to the motor, which can generate a torque

and corresponds to Stop Category 0. The motor is stopped in an uncontrolled fashion.

Notes

● When a large DC smoothing reactor is used in the armature circuit the current decay time

of 0.05s before switching the firing pulses off may possibly not be sufficient for STO / stop

category

0. If the armature current at this instant is not pulsating, inverter shoot-through

can occur. As a consequence, in this particular case we recommend that the output e

x-

pansion of the safety relay is shut down with a short delay of 0.5 s. Setting the output e

x-

pansion, see circuit example SS1.

● When the 2Q field

option that does not contain any free-wheeling diode for the field cur-

rent is used, the use of SS1 / stop category

1 is recommended to protect the field contac-

tor. This is necessary because the braking voltage of the opening contacts of a field

contactor (

line side) does not suffice to activate the free-wheeling function of the 2Q thyri

s-

tor bridge.

1.2.2

Safe Stop 1 (SS1, time-controlled)

Safe Stop 1 is based on the "Safe Torque Off" function. This means that a Category 1 stop

according to EN 60204-1 can be implemented. The drive is actively braked to a standstill.

The energy feed is safely shut down after a time, which can be adjusted at the safety relay,

after the motor should safely remain stationary (STO).

Introduction

1.3 Application overview

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

13

1.2.3

Using EMERGENCY STOP

STO and SS1 are suitable for the EMERGENCY STOP function when the following

preconditions are carefully taken into consideration:

The user must evaluate as to whether an immediate shutdown of the energy feed for STO

does not result in dangerous states (uncontrolled stopping - STOP category 0 according to

EN ISO 13850).

When using SS1, if the line supply fails, the drive can no longer be actively braked - and it

must be taken into consideration that the drive only comes to an absolute standstill at a later

point in time.

Although actuating the EMERGENCY STOP switch disconnects the energy feed to the drive,

for a permanently excited DC motor that is still rotating, a voltage is still present at the

armature terminals corresponding to the speed.

With an EMERGENCY OFF function the system is brought into a no voltage condition after

switching off in an emergency according to IEC 60204-1. The motor must then come to a

complete standstill and the field supply must have been switched off.

EMERGENCY STOP function according to EN ISO 13850:

The function of the EMERGENCY STOP equipment must be designed so that after actuating

the EMERGENCY STOP device, hazardous motion and operation of the machine are

stopped in a suitable fashion without resulting in any additional risks and dangers.

1.3

Application overview

The following recommendations are described in this document:

Stop Category 0 (STO = Safe Torque OFF)

Stop Category 1 (SS1 = Safe Stop 1)

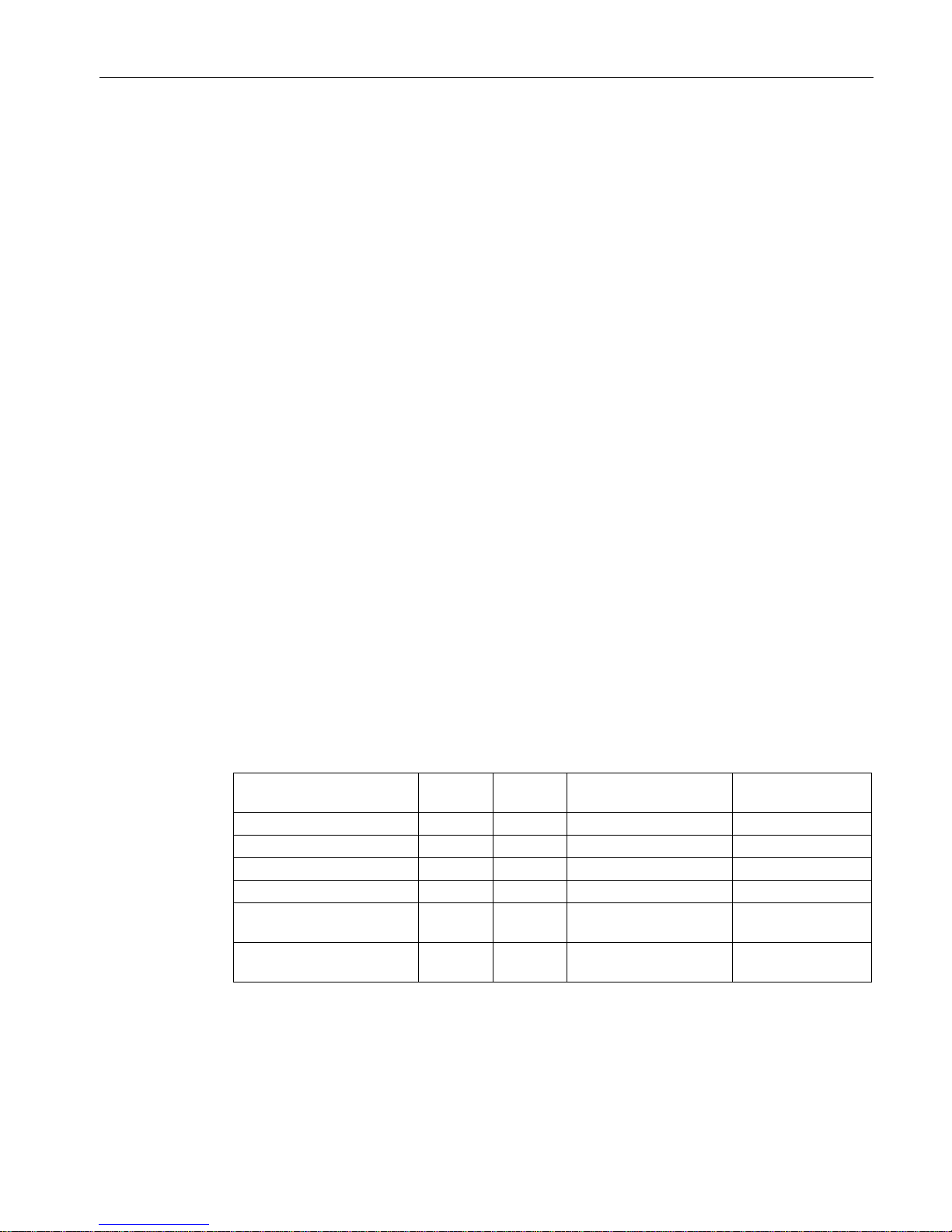

Overview of the various configurations

Switching device STO SS1 Achievable Performance

Level (PL)

Achievable Safety

Integrity Level (SIL)

1 3WL circuit breaker

Sec. 3.2

Sec. 4.2

d

X

1 power contactor Sec. 3.3 Sec. 4.3 d X

2x 3WL circuit breakers

Sec. 5.2

Sec. 6.2

d

2

2s power contactors Sec. 5.3 Sec. 6.3 e 3

2x power units with

3WL circuit breaker

Sec. 7.2 Sec. 8.2 d X

2x power units with

power contactor

Sec. 7.3 Sec. 8.3 d X

The safety relays used are listed in Recommended safety relays (Page 73).

Introduction

1.4 Armature circuit with one switching device

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

14 Compact User Manual, 09/2016, A5E34871844AM

The power contactors and circuit breakers that have been tested are listed in Recommended

circuit breakers and power contactors (Page 81).

Note

Circuit breakers

are, according to EN ISO 13849-2: 2013-02 considered as proven

components. As a consequence, two NC contacts of each circuit breaker are connected in

series to provide a feedback signal, which must be integrated in the feedback circuit of the

safety relay

.

Note

Power contactors

must have mirror contacts or positively-driven contacts to be considered

as proven component in compliance with EN

ISO 13849-2: 2013-02; these contacts must be

integrated in the feedback circuit of the safety relay.

1.4

Armature circuit with one switching device

The armature circuit power supply is realized with only one circuit breaker or one power

contactor. The E-Stop for the power unit is controlled in parallel.

After STO has been selected, the E-Stop function of the drive is activated using the safety

relay (supply at terminal 105 is disconnected). When setting p51616=0, using Alpha-W

pulses, the SINAMICS DCM reduces the armature current - and then inhibits the firing

pulses and also interrupts the main contactor control (terminals 109-110). The active E-Stop

state is integrated in the feedback circuit of the safety relay using digital output (DO3) via a

relay.

Via the expansion device, independent of the SINAMICS DCM state, a safety-related

coupling relay is switched, which immediately opens the circuit breaker with the undervoltage

coil - or for a power contactor, disconnects the solenoid.

If STO is not selected, then the circuit breaker or power contactor is switched with a

positively-driven interface relay from the SINAMICS DCM.

1.5

Armature circuit with two switching devices

The armature circuit power supply is realized with two circuit breakers or power contactors

connected in series. The E-Stop for the power unit is also controlled.

This solution essentially differs as a second switching device is installed in the amateur

circuit.

After STO has been selected, the E-Stop function of the drive is activated using the safety

relay (supply at terminal 105 is disconnected). When setting p51616=0, using Alpha-W

pulses, the SINAMICS DCM reduces the armature current - and then inhibits the firing

pulses and also interrupts the main contactor control (terminals 109-110). The active E-Stop

state is integrated in the feedback circuit of the safety relay using digital output (DO3) via a

relay.

Introduction

1.6 Field circuit description

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

15

Via the expansion device, independent of the SINAMICS DCM state, a safety-related

coupling relay is switched, which immediately opens the circuit breaker with the undervoltage

coil - or for a power contactor, disconnects the solenoid.

If STO is not selected, then the circuit breakers or power contactors are switched with a

positively-driven interface relay from the SINAMICS DCM.

Two switching devices are required to achieve SIL2 according to EN62061 and PL d

according to DIN EN ISO 13849-1.

1.6

Field circuit description

If a power contactor is used in the field circuit, then this can be optionally switched with the

safety function. If the field contactor is to be integrated in the safety function, then the field

contactor must be opened and closed with the output expansion of the safety relay using a

safety-related interface relay. The positively-driven NC contact of the coupling relay - as well

as the mirror contact of the field contactor - must be integrated in the feedback circuit of the

safety relay. This version is shown in the circuit examples.

Introduction

1.7 Safety shutdown (E-STOP)

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

16 Compact User Manual, 09/2016, A5E34871844AM

1.7

Safety shutdown (E-STOP)

Note

The

E-STOP function alone does not represent a safety function.

The E-STOP function forces the "line contactor closed" relay to drop out, activating the relay

contact (terminals XR1-109 and -110) for the main contactor control within approximately 20

ms, independent of the semiconductor components and Control Unit (CUD) functions. If the

CUD is operating correctly, entering I = 0 via the control ensures that the main contactor

switches in a no-current condition. The drive coasts down once E-STOP has been entered.

The E-STOP function is initiated when the switch between terminals XS1-105 and XS1-106

is opened.

The E-STOP function causes the drive to go into the "Switching on inhibited" operating state.

This must be acknowledged by activating the "shutdown" function e.g. by opening terminal

X177.12.

Sequence when initiating an E-STOP:

1.

The ramp-function generator, n controller, and I controller are disabled.

2.

The armature current is reduced to zero

3. a) p51616 = 0: E-STOP acts like OFF2 (firing pulses are inhibited as soon as I = 0).

b) p51616 = 1: E-STOP immediately stops firing pulses from being output (without waiting for I = 0).

4.

The "Close operating brake" signal is output (r53210.0 = 1, for p50080 = 2).

5.

Operating state o10.0 or higher is reached.

6. The field current is maintained at a fixed level

(i.e. there is no increase in the field current, even on exiting the field-weakening range).

7. The "Close line contactor" relay (terminals XR1-109 and -110) drops out.

8

The drive coasts down (or is decelerated by the operational brake).

9

The wait time (to be set at p50258) elapses.

10.

The field is reduced to a parameterizable value (p50257).

11.

Once n < nmin (p50370, p50371), the "Close holding brake" signal is output (r53210.0 = 1, for p50080 = 1).

Note

20 ms after an E-STOP has been initiated (even if point 7 in this sequence has not yet been

reached), the "Close line contactor" relay (terminal XR1-109 and XR1-110) is opened (drops

out), initiated by the hardware.

Introduction

1.8 Parameterizing the digital outputs

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

17

1.8

Parameterizing the digital outputs

In order to signal to the safety relay that the drive E-STOP function has been activated, the

following parameters must be set at the SINAMICS DC MASTER:

Digital output DO3 at connector X177.22 controls relay K

EP

. This serves as feedback signal

contact for the E-STOP path.

The function of DO3 (connector X177.22) is defined using parameter p50774:

p50774 = (63) r53100.0

Digital output DO2 at connector X177.21 controls, via relay K

DO2F

, the field contactor.

The function of DO2 (connector X177.21) is defined using parameter p50773.

The setting of p50773 is dependent on the setting of parameter p50082:

p50082 = 0

(no field)

p50773 = 0

p50082 = 1

(field is also switched with the armature contactor)

p50773 = (63) r53082.0

p50082 = 2

(standstill field at ≥ o7.0)

p50773 = 1

p50082 = 3

(field is permanently switched on)

p50773 = 1

p50082 = 4

(field is also switched with the auxiliaries ON si

g-

nal)

p50773 = (63) r53

210.2

p50082 = 21

(external field power unit, otherwise, as for setting

1)

p50773 = (63) r53082.0

p50082 = 22

(external field power unit, otherwise, as for setting

3)

p50773 = 1

p50082 = 23

(external field power unit, otherwise, as for setting

3)

p50773

= 1

p50082 = 24

(external field power unit, otherwise, as for setting

4)

p50773 = (63) r53210.2

Note

(63) signifies: "from own drive object"

r53100.0 is E

-Stop state (1 = no E-Stop, 0 = E-Stop)

r53082.0 is CLOSE armature contactor

r53210.2 is

auxiliaries ON

Note

The maximum 100 mA current rating of the digital outputs must be carefully observed.

Introduction

1.9 Parameterizing the digital input for SS1 OFF3

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

18 Compact User Manual, 09/2016, A5E34871844AM

1.9

Parameterizing the digital input for SS1 OFF3

Digital input DI/DO 4 (terminal X177.15 on the CUD electronics module) of the SINAMICS

DC MASTER must be used for the SS1 function. This digital input must be parameterized so

that signal OFF3 (fast stop) is controlled in all of the command data sets (CDS) used

Setting p849 (OFF3) p53010[8] (DI/DO 4)

Setting p50296 (OFF3 down ramp) e.g. 5 seconds

Note

For setting p50269=0 (OFF3 ramp down time), the drive brakes at the current limit. The

actual ramp

-down time is influenced by the driving forces of the mechanical system. The

safety relay delay should be set longer than the actual ramp

-down time

.

Introduction

1.10 Abbreviations and circuit diagram symbols

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

19

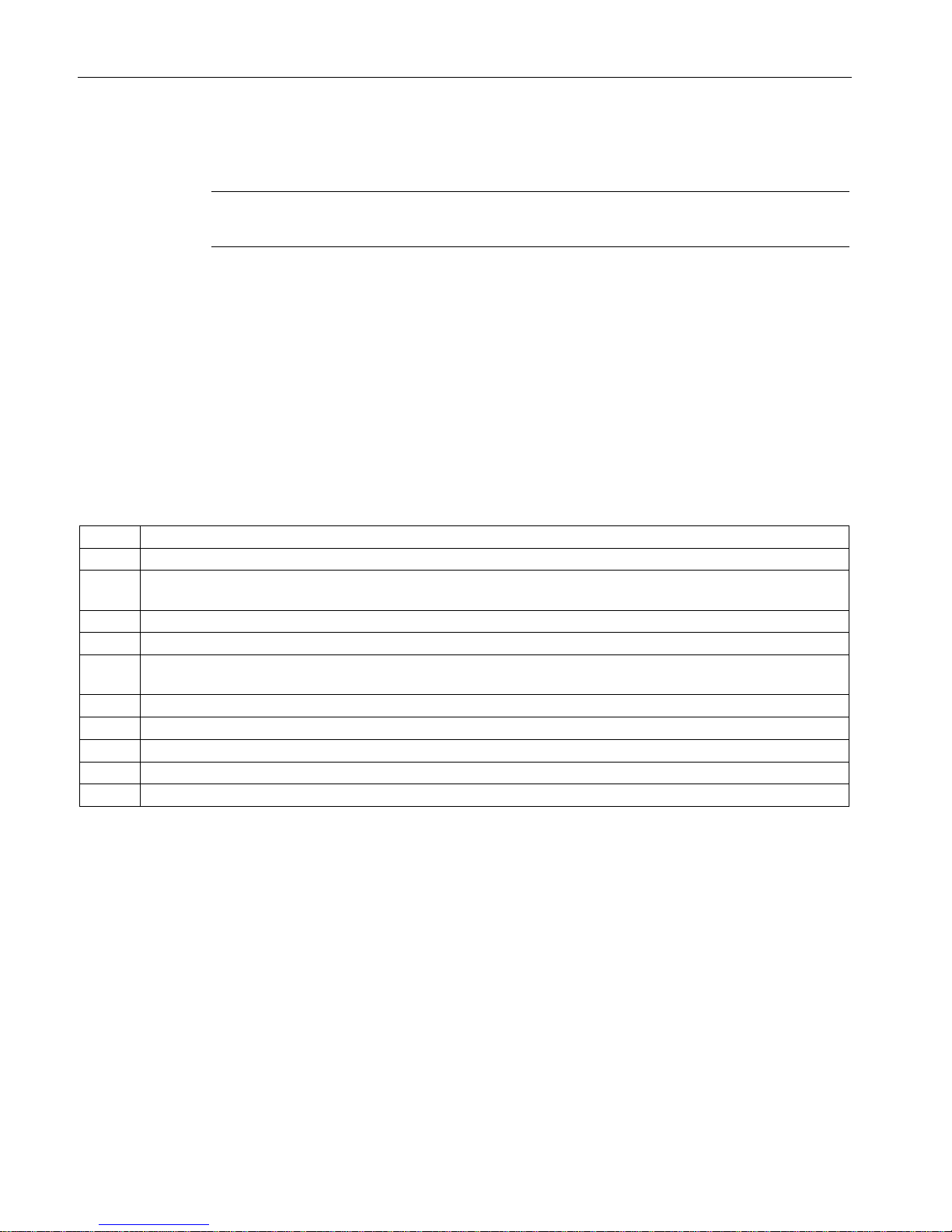

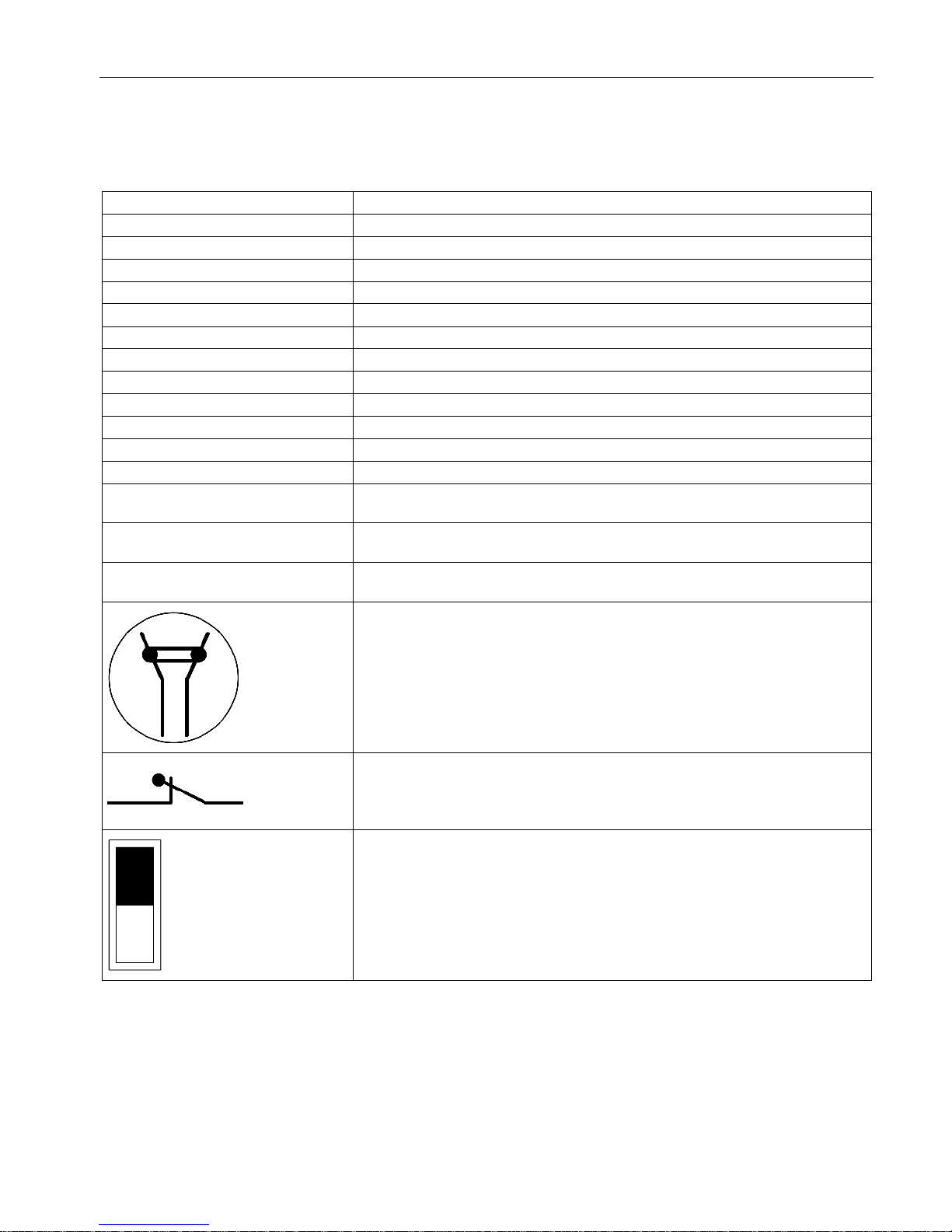

1.10

Abbreviations and circuit diagram symbols

K

A[n]

Armature contactor

KF

Field contactor

K

AH[n]

Safety-related interface relay to control the armature contactor

K

FH1

Safety-related interface relay to control the field contactor

K

EP[n]

Relay, feedback signal E-Stop

DO2

Programmable digital output 2 2 = X177.21 (field contactor control)

DO3

Programmable digital output 3 = X177.22 (feedback signal E-Stop active)

DI/DO4

Programmable digital input 4, X177.15 (to select OFF3 = fast stop)

K

FH1 KAH1 KAH[n]

Phoenix Contact, PSR-SPP-24DC/FSP/1X1/1X2 - 2981981

K

DOKop

; K

EP[n]

Phoenix Contact, PR1-RSC3-LDP-24DC/2X21AU - 2834520

P24

24 V supply via X177.9 or X177.10

M24

24 V ground via X177.23 or X177.24

L, N

Maximum supply voltage, 250 VAC

L

AH1

, N

AH1

Maximum armature contactor supply voltage 250V AC/DC 5A

Observe the load curve and derating of the K

AH

LFH, NFH Maximum field contactor supply voltage 250V AC/DC 5A

Observe the load curve and derating of the KFH

L

AH[n]

, N

AH[n]

Maximum armature contactor supply voltage 250V AC/DC 5A

Observe the load curve and derating of the K

AH[n]

Positively-driven contacts = combination of NO and NC contacts is designed so

that they can never be simultaneously closed

Mirror contact = auxiliary NC contact that cannot be closed simultaneously with a

main NO contact.

Switch position = black

Introduction

1.10 Abbreviations and circuit diagram symbols

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

20 Compact User Manual, 09/2016, A5E34871844AM

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

21

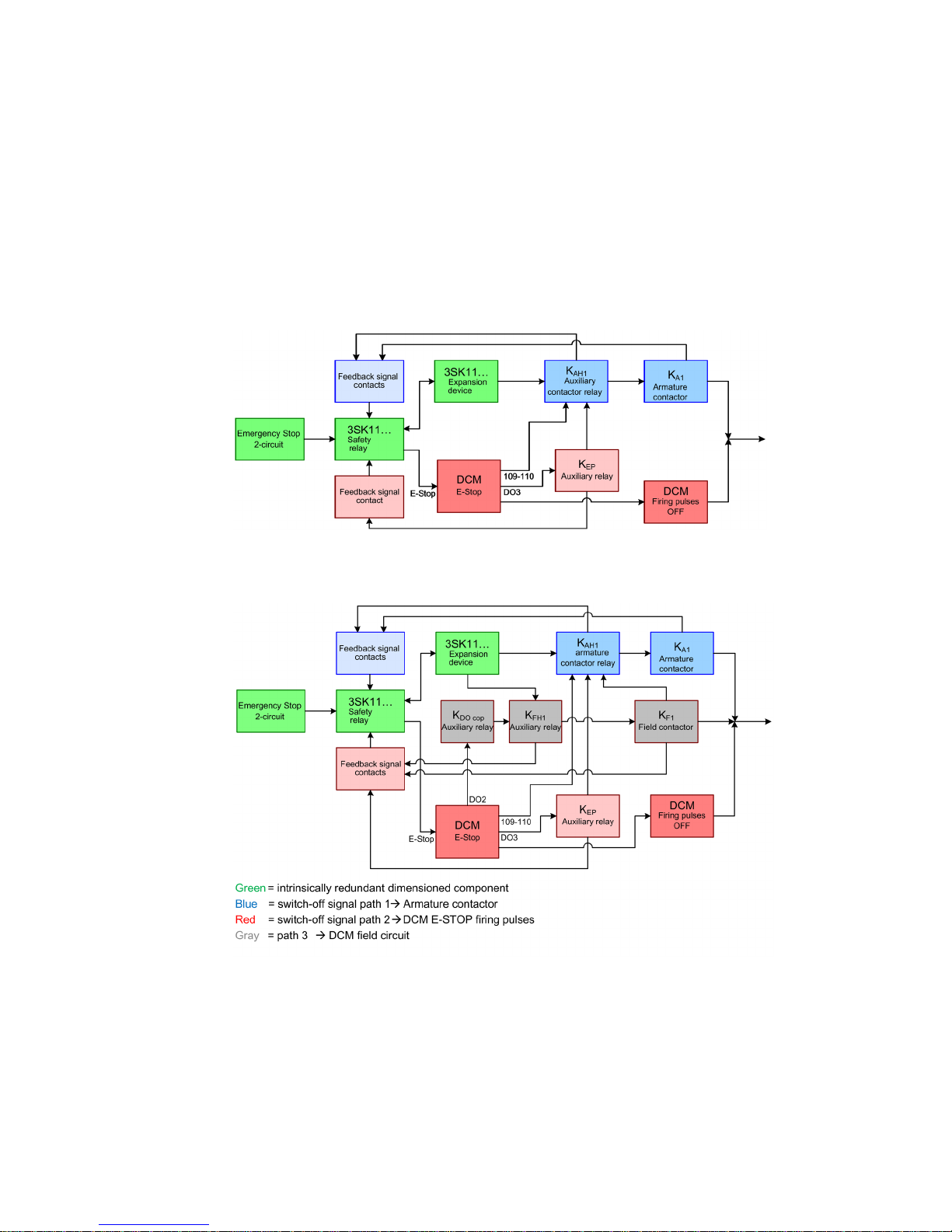

2

The following two block diagrams show the two-channel architecture of the safety system, so

that after the first two faults – each in one of the two channels – the system can fail.

Safety block diagram of a drive without field excitation

Safety block diagram of a drive with field excitation

Path 3 is not considered to be a safety-related switch-off signal path as the field remanence

of the DC motor – for a high armature current – can result in the motor developing a torque.

On the following page, as in 4.2, the function blocks are colored the same as in the previous

block diagram as example.

Principle of the dual channel architecture

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

22 Compact User Manual, 09/2016, A5E34871844AM

Dual channel architecture, color-coded using the application of SS1 as example

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

23

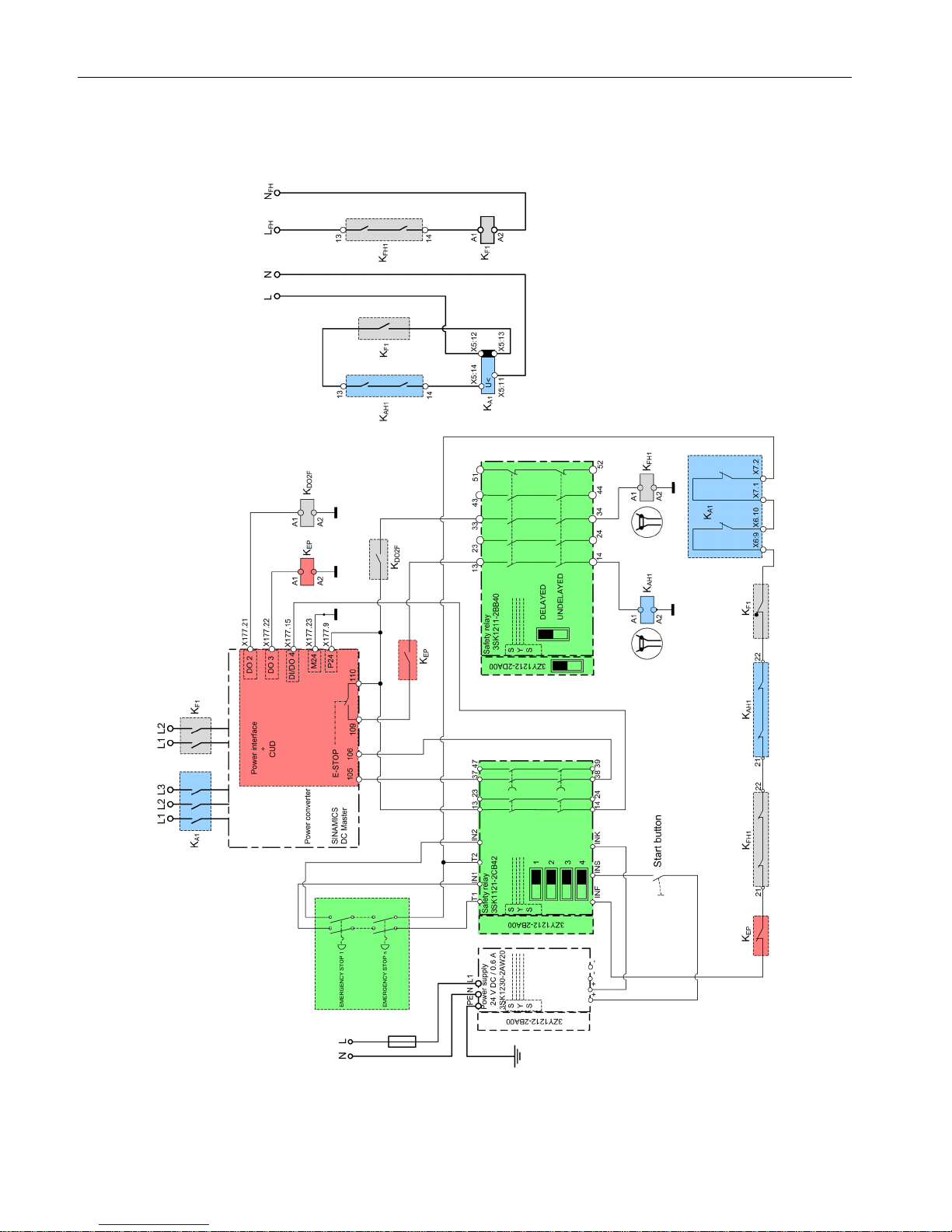

3

3.1

Description

When selecting the safety function (actuating the Emergency Stop pushbutton), the

instantaneous NO contacts are immediately opened in the 3SK1122-2CB41 safety relay. As

a consequence, the E-Stop function is initiated at the SINAMICS DCM. The SINAMICS DCM

reduces the armature current, inhibits the firing pulses and opens the armature contactor.

The "E-Stop active" signal must be integrated in the feedback circuit of the safety relay via a

coupling relay at digital output DO3 (X177.22).

At the same time when the NO contacts of the safety relay open, the safety-related output

expansion 3SK1211-2BB40 is shut down via the internal communication of the 3SK safety

relay; as a consequence, the safety-related coupling relays to control the armature and field

circuits are opened.

The motor current therefore goes to zero and in turn, the motor torque also goes to zero.

The motor coasts down.

In the circuit examples, the energy feed to the field power units as well as to the armature

circuit is interrupted. Controlling the field contactor is optional. However, in this case, the

motor cannot be considered to be in a no-voltage condition.

STO stop Category 0 with one switching device

3.2 STO circuit example with one 3WL circuit breaker

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

24 Compact User Manual, 09/2016, A5E34871844AM

3.2

STO circuit example with one 3WL circuit breaker

STO stop Category 0 with one switching device

3.3 STO circuit example with one power contactor

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

Compact User Manual, 09/2016, A5E34871844AM

25

3.3

STO circuit example with one power contactor

STO stop Category 0 with one switching device

3.3 STO circuit example with one power contactor

Application doc ument for functional safety STO, SS1 (ISO 13849-1)

26 Compact User Manual, 09/2016, A5E34871844AM

Loading...

Loading...