Siemens Sinamics Connect Series Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS CONNECT

Operating Instructions

Software 1.0.0

10/2018

A5E45421408

Preface

Safety instructions

1

Overview

2

Mounting

3

Connecting

4

Configuring the device

5

Getting connected to

MindSphere

6

Maintaining and repairing the

device

7

Technical specifications

8

Appendix

A

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E45421408

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

for the specific

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

11/2018 Subject to change

Preface

Basic knowledge requirements

Scope of this documentation

Conventions

Figures

Reference

Product maintenance

These operating instructions contain all the information you need for commissioning and

operation of the SINAMICS CONNECT.

It is intended both for commissioning and testing personnel who commission and operate the

device and connect it with converters, as well as for service and maintenance personnel who

carry out fault/error analyses.

Knowledge of personal computers and operating systems is required to understand this

manual. General knowledge in the field automation control engineering is recommended.

The device documentation comprises:

● SINAMICS CONNECT Operating Instructions

● SINAMICS CONNECT Quick Install Guide

The term "device" refers to a SINAMICS CONNECT unit.

This manual contains figures of the described devices. The supplied devices may differ in

some details from the figures. Within some of the figures, one device is used to represent all

devices.

You can find the overview of documentation and links to download documents as well as to

use documentation online at:

More information (https://support.industry.siemens.com/cs/ww/en/ps/25436/man).

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

The components are subject to continuous further development within the scope of product

maintenance (improvements to robustness, discontinuations of components, etc).

These further developments are "spare parts-compatible" and do not change the article

number.

3

Preface

Use of third-party products

Compliance with the General Data Protection Regulation

In the scope of such spare parts-compatible further developments, connector positions are

sometimes changed slightly. This does not cause any problems with proper use of the

components. Please take this fact into consideration in special installation situations (e.g.

allow sufficient clearance for the cable length).

This document contains recommendations relating to third-party products. Siemens accepts

the fundamental suitability of these third-party products.

You can use equivalent products from other manufacturers.

Siemens does not accept any warranty for the properties of third-party products.

Siemens respects the principles of data protection, in particular the data minimization rules

(privacy by design).

For this product, this means:

The product does not process neither store any person-related data, only technical function

data (e.g. time stamps). If the user links these data with other data (e.g. shift plans) or if he

stores person-related data on the same data medium (e.g. hard disk), thus personalizing

these data, he has to ensure compliance with the applicable data protection stipulations.

SINAMICS CONNECT

4 Operating Instructions, 10/2018, A5E45421408

Table of contents

Preface ...................................................................................................................................................... 3

1 Safety instructions ..................................................................................................................................... 8

2 Overview .................................................................................................................................................. 18

3 Mounting .................................................................................................................................................. 23

4 Connecting .............................................................................................................................................. 29

5 Configuring the device ............................................................................................................................. 37

1.1 Fundamental safety instructions ............................................................................................... 8

1.1.1 General safety instructions ....................................................................................................... 8

1.1.2 Equipment damage due to electric fields or electrostatic discharge ...................................... 13

1.1.3 Warranty and liability for application examples ...................................................................... 13

1.1.4 Industrial security .................................................................................................................... 14

1.1.5 Residual risks of power drive systems .................................................................................... 15

1.2 Additional safety instructions .................................................................................................. 16

1.2.1 General safety instructions ..................................................................................................... 16

1.2.2 Notes on use ........................................................................................................................... 17

2.1 Product description ................................................................................................................. 18

2.2 Structure of the device ............................................................................................................ 19

2.3 Scope of delivery .................................................................................................................... 20

2.4 Accessories ............................................................................................................................. 22

3.1 Preparing for installation ......................................................................................................... 23

3.1.1 Checking the delivery.............................................................................................................. 23

3.1.2 Permitted mounting orientation and mounting types .............................................................. 24

3.2 Mounting the device ................................................................................................................ 25

3.2.1 Mounting instructions .............................................................................................................. 26

3.2.2 Mounting on DIN rails ............................................................................................................. 27

3.2.3 Wall mounting ......................................................................................................................... 27

4.1 Connecting the device ............................................................................................................ 29

4.1.1 Notes on connecting ............................................................................................................... 29

4.1.2 Connecting the power supply ................................................................................................. 30

4.1.3 Connecting the device to MindSphere network ...................................................................... 32

4.1.4 Connecting the device to a PC ............................................................................................... 32

4.1.5 Securing the cables ................................................................................................................ 33

4.2 Connecting the converter to the device .................................................................................. 33

4.2.1 Connecting the converter ........................................................................................................ 33

4.2.2 Identifying the converter (optional) ......................................................................................... 36

5.1 Accessing the Web pages ...................................................................................................... 37

5.2 Standard Web pages .............................................................................................................. 38

5.2.1 First login ................................................................................................................................ 38

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

5

Table of contents

6 Getting connected to MindSphere ........................................................................................................... 61

7 Maintaining and repairing the device ....................................................................................................... 78

8 Technical specifications ........................................................................................................................... 81

5.2.1.1 Logging in ............................................................................................................................... 38

5.2.1.2 Changing the default password ............................................................................................. 39

5.2.1.3 Setting security questions ...................................................................................................... 40

5.2.2 Normal login ........................................................................................................................... 41

5.2.2.1 Logging in ............................................................................................................................... 41

5.2.2.2 Retrieving the password ........................................................................................................ 42

5.2.3 Home page ............................................................................................................................. 44

5.2.3.1 Overview ................................................................................................................................ 44

5.2.3.2 Viewing the port information .................................................................................................. 45

5.2.4 Quick configuration ................................................................................................................ 46

5.2.5 Acquiring the converter data .................................................................................................. 50

5.2.5.1 Configuring ports .................................................................................................................... 50

5.2.5.2 Configuring MindSphere ........................................................................................................ 53

5.2.6 Optional setting pages ........................................................................................................... 55

5.2.6.1 Rebooting the device ............................................................................................................. 55

5.2.6.2 Upgrading ............................................................................................................................... 55

5.2.6.3 Downloading system logs ...................................................................................................... 56

5.2.6.4 Synchronizing time ................................................................................................................. 57

5.2.7 Account related settings ......................................................................................................... 59

5.2.7.1 Changing the password ......................................................................................................... 59

5.2.7.2 Changing security questions .................................................................................................. 59

5.2.7.3 Logging out ............................................................................................................................ 60

6.1 Overview ................................................................................................................................ 61

6.2 Logging in to MindSphere ...................................................................................................... 61

6.3 Creating an asset in Asset Manager ...................................................................................... 62

6.3.1 Creating aspects and variables .............................................................................................. 62

6.3.2 Creating a type ....................................................................................................................... 66

6.3.3 Creating an asset ................................................................................................................... 69

6.4 Transferring configuration to the device ................................................................................ 70

6.5 Data mapping ......................................................................................................................... 73

6.6 Parameter list ......................................................................................................................... 76

7.1 Maintenance ........................................................................................................................... 78

7.2 Repair information .................................................................................................................. 78

7.3 Replacing the backup battery ................................................................................................ 78

7.4 Replacing the SD card ........................................................................................................... 80

7.5 Recycling and disposal .......................................................................................................... 80

8.1 Certificates and approvals ..................................................................................................... 81

8.2 Directives and declarations .................................................................................................... 82

8.2.1 Notes on CE marking ............................................................................................................. 82

8.2.2 ESD guideline ........................................................................................................................ 82

8.3 Dimension drawings ............................................................................................................... 84

SINAMICS CONNECT

6 Operating Instructions, 10/2018, A5E45421408

Table of contents

A Appendix .................................................................................................................................................. 91

Glossary .................................................................................................................................................. 94

Index ........................................................................................................................................................ 96

8.4 Technical data ......................................................................................................................... 85

8.4.1 General technical specifications ............................................................................................. 85

8.4.2 Ambient conditions .................................................................................................................. 86

8.4.3 Power demand of the components ......................................................................................... 87

8.4.4 Direct current power supply (DC) ........................................................................................... 87

8.4.5 Address of CE-authorized manufacturer ................................................................................ 88

8.5 Hardware description .............................................................................................................. 88

8.5.1 Interface overview ................................................................................................................... 88

8.5.2 Power supply .......................................................................................................................... 89

8.5.3 Ethernet interface .................................................................................................................... 89

8.5.4 RS232 interface ...................................................................................................................... 90

A.1 Assembly of cable terminals on the device side ..................................................................... 91

A.2 Technical support .................................................................................................................... 93

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

7

1

1.1

Fundamental safety instructions

1.1.1

General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

WARNING

Risk of electric shock and fire from supply networks with an excessively high impedance

Touching live components can result in death or severe injury.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, the following six steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any

of the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

After you have completed the work, restore the operational readiness in the inverse

sequence.

Excessively low short-circuit currents can lead to the protective devices not tripping or

tripping too late, and thus causing electric shock or a fire.

• In the case of a conductor-conductor or conductor-ground short-circuit, ensure that the

short-circuit current at the point where the inverter is connected to the line supply at

least meets the minimum requirements for the response of the protective device used.

• You must use an additional residual-current device (RCD) if a conductor-ground short

circuit does not reach the short-circuit current required for the protective device to

respond. The required short-circuit current can be too low, especially for TT supply

systems.

SINAMICS CONNECT

8 Operating Instructions, 10/2018, A5E45421408

Safety instructions

WARNING

Risk of electric shock and fire from supply networks with an excessively low impedance

WARNING

Electric shock if there is no ground connection

WARNING

Electric shock due to connection to an unsuitable power supply

WARNING

Electric shock due to equipment damage

WARNING

Electric shock due to unconnected cable shield

1.1 Fundamental safety instructions

Excessively high short-circuit currents can lead to the protective devices not being able to

interrupt these short-circuit currents and being destroyed, and thus causing electric shock

or a fire.

• Ensure that the prospective short-circuit current at the line terminal of the inverter does

not exceed the breaking capacity (SCCR or Icc) of the protective device used.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage that might result in serious injury or death.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV-

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

Improper handling may cause damage to equipment. For damaged devices, hazardous

voltages can be present at the enclosure or at exposed components; if touched, this can

result in death or severe injury.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the conductors of power cables that are not

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

used (e.g. brake cores) at one end at the grounded housing potential.

9

Safety instructions

WARNING

Arcing when a plug connection is opened during operation

WARNING

Electric shock due to residual charges in power components

NOTICE

Property damage due to loose power connections

WARNING

Spread of fire from built-in devices

WARNING

Active implant malfunctions due to electromagnetic fields

control cabinets

1.1 Fundamental safety instructions

Opening a plug connection when a system is operation can result in arcing that may cause

serious injury or death.

• Only open plug connections when the equipment is in a voltage-free state, unless it has

been explicitly stated that they can be opened in operation.

Because of the capacitors, a hazardous voltage is present for up to 5 minutes after the

power supply has been switched off. Contact with live parts can result in death or serious

injury.

• Wait for 5 minutes before you check that the unit really is in a no-voltage condition and

start work.

Insufficient tightening torques or vibration can result in loose power connections. This can

result in damage due to fire, device defects or malfunctions.

• Tighten all power connections to the prescribed torque.

• Check all power connections at regular intervals, particularly after equipment has been

transported.

In the event of fire outbreak, the enclosures of built-in devices cannot prevent the escape of

fire and smoke. This can result in serious personal injury or property damage.

• Install built-in units in a suitable metal cabinet in such a way that personnel are

protected against fire and smoke, or take other appropriate measures to protect

personnel.

• Ensure that smoke can only escape via controlled and monitored paths.

Inverters generate electromagnetic fields (EMF) in operation. People with active implants in

the immediate vicinity of this equipment are at particular risk.

• As the operator of an EMF-emitting installation, assess the individual risks of persons

with active implants. The following clearances are usually adequate:

– No clearance to closed control cabinets and shielded MOTION-CONNECT supply

cables

– Forearm length (approx. 35 cm clearance) to distributed drive systems and open

SINAMICS CONNECT

10 Operating Instructions, 10/2018, A5E45421408

Safety instructions

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

NOTICE

Damage to motor insulation due to excessive voltages

WARNING

Fire due to inadequate ventilation clearances

WARNING

Unrecognized dangers due to missing or illegible warning labels

1.1 Fundamental safety instructions

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

• If you come closer than around 2 m to such components, switch off any radios or mobile

phones.

• Use the "SIEMENS Industry Online Support app" only on equipment that has already

been switched off.

When operated on systems with grounded line conductor or in the event of a ground fault in

the IT system, the motor insulation can be damaged by the higher voltage to ground. If you

use motors that have insulation that is not designed for operation with grounded line

conductors, you must perform the following measures:

• IT system: Use a ground fault monitor and eliminate the fault as quickly as possible.

• TN or TT systems with grounded line conductor: Use an isolating transformer on the line

side.

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in

increased downtime and reduced service lives for devices/systems.

• Ensure compliance with the specified minimum clearance as ventilation clearance for

the respective component.

Dangers might not be recognized if warning labels are missing or illegible. Unrecognized

dangers may cause accidents resulting in serious injury or death.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, where necessary in the national

language.

• Replace illegible warning labels.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

11

Safety instructions

NOTICE

Device damage caused by incorrect voltage/insulation tests

WARNING

Unexpected movement of machines caused by inactive safety functions

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must

Safety Integrated manuals.

WARNING

Malfunctions of the machine as a result of incorrect or changed parameter settings

1.1 Fundamental safety instructions

Incorrect voltage/insulation tests can damage the device.

• Before carrying out a voltage/insulation check of the system/machine, disconnect the

devices as all converters and motors have been subject to a high voltage test by the

manufacturer, and therefore it is not necessary to perform an additional test within the

system/machine.

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Handle possible malfunctions by taking suitable measures, e.g. emergency stop or

emergency off.

observe the safety notices in the

SINAMICS CONNECT

12 Operating Instructions, 10/2018, A5E45421408

Safety instructions

1.1.2

Equipment damage due to electric fields or electrostatic discharge

NOTICE

Equipment damage due to electric fields or electrostatic discharge

1.1.3

Warranty and liability for application examples

1.1 Fundamental safety instructions

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

Application examples are not binding and do not claim to be complete regarding

configuration, equipment or any eventuality which may arise. Application examples do not

represent specific customer solutions, but are only intended to provide support for typical

tasks.

As the user you yourself are responsible for ensuring that the products described are

operated correctly. Application examples do not relieve you of your responsibility for safe

handling when using, installing, operating and maintaining the equipment.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

13

Safety instructions

1.1.4

Industrial security

Note

Industrial security

Siemens provides products and solutions with industr

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and co

connected to an enterprise network or the Internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional informatio

visit:

Industrial security (

Siemens’ products and solutions undergo continuous develop

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest u

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (

WARNING

Unsafe operating states resulting from software manipulation

1.1 Fundamental safety instructions

ial security functions that support the

– and continuously maintain – a holistic, state-of-the-art industrial

mponents should only be

n on industrial security measures that may be implemented, please

http://www.siemens.com/industrialsecurity)

ment to make them more

pdates may increase customer’s exposure

http://www.siemens.com/industrialsecurity)

Further information is provided on the Internet:

Industrial Security Configuration Manual

(https://support.industry.siemens.com/cs/ww/en/view/108862708)

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe

operating states in your system that may lead to death, serious injury, and property

damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

• Protect the drive against unauthorized changes by activating the "know-how protection"

drive function.

SINAMICS CONNECT

14 Operating Instructions, 10/2018, A5E45421408

Safety instructions

1.1.5

Residual risks of power drive systems

1.1 Fundamental safety instructions

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer

must take into account the following residual risks emanating from the control and drive

components of a drive system:

1. Unintentional movements of driven machine or system components during

commissioning, operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too

close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters

or data communication via the network

For more information about the residual risks of the drive system components, see the

relevant sections in the technical user documentation.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

15

Safety instructions

1.2

Additional safety instructions

1.2.1

General safety instructions

WARNING

Life-threatening voltages due to use of an open control cabinet

System expansions

NOTICE

Lost approval for an "Open Type" device due to incorrect use

NOTICE

Invalid approvals due to certain modifications

Note

Unauthorized changes due to administrator accounts without protection

•

•

•

1.2 Additional safety instructions

When you install the device in a control cabinet, some areas or components in the open

control cabinet may be carrying life-threatening voltages, which may result in death or

serious injury.

• Switch off the power supply to the cabinet before opening it.

For an "Open Type" device, approval is lost and the protection associated with it may be

impaired if the device is used in a manner not specified by the manufacturer.

• Use a UL61010-2-201 conform enclosure for an "Open Type" device.

The device approvals are voided if the following modifications are made:

• The enclosure was physically modified, for example, openings were created to make

LEDs on a plug-in card in the device visible.

• Cables are routed from the inside out of the device or from the outside into the device,

for example, to connect sensors or displays.

Recommendation:

• Submit the device for approval again after modifications are made.

Ensure there are adequate safeguards for protecting the administrator accounts to

prevent unauthorized changes.

Use secure passwords and a standard user account for normal operation.

Other measures, such as the use of security policies, should be applied as needed.

SINAMICS CONNECT

16 Operating Instructions, 10/2018, A5E45421408

Safety instructions

1.2.2

Notes on use

Note

Possible functional restrictions in case of non-validated plant operation

The device is tested and certified on the basis of th

functional restrictions can occur during plant operation.

•

Note

Use in an industrial environment without additional protective measures

This device was designed for use in a normal industrial environment according to

IEC

1.2 Additional safety instructions

e technical standards. In rare cases,

Validate the correct functioning of the plant to avoid functional restrictions.

60721-3-3.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

17

2

2.1

Product description

Overview

Highlights and benefits

Features

The SINAMICS CONNECT is designed to acquire data through the serial port on the

converter and synchronize the data to MindSphere, the Siemens Industrial IoT operating

system.

The SINAMICS CONNECT can be used to connect the following converters to MindSphere:

● SINAMICS V20

● SINAMICS G120 series (G120D excluded)

● MICROMASTER 440

● High degree of ruggedness

● Compact design

● RS232 and Ethernet interfaces

● Maintenance-free operation possible

The SINAMICS CONNECT is available with the following features:

● Intel Quark X1020 processor

● 1 GB RAM

● 2 x Ethernet interfaces

● 8 x RS232 ports

SINAMICS CONNECT

18 Operating Instructions, 10/2018, A5E45421408

Overview

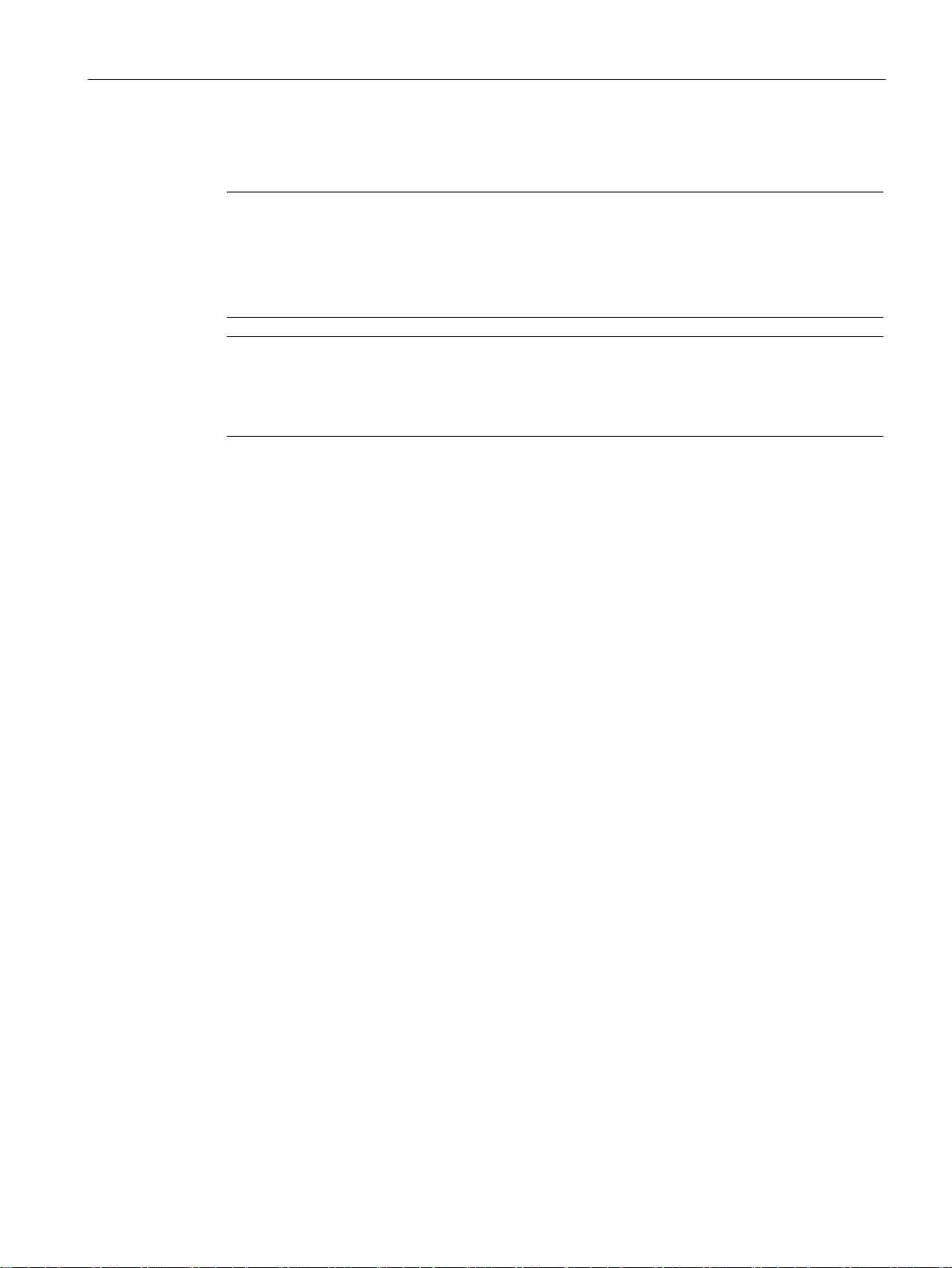

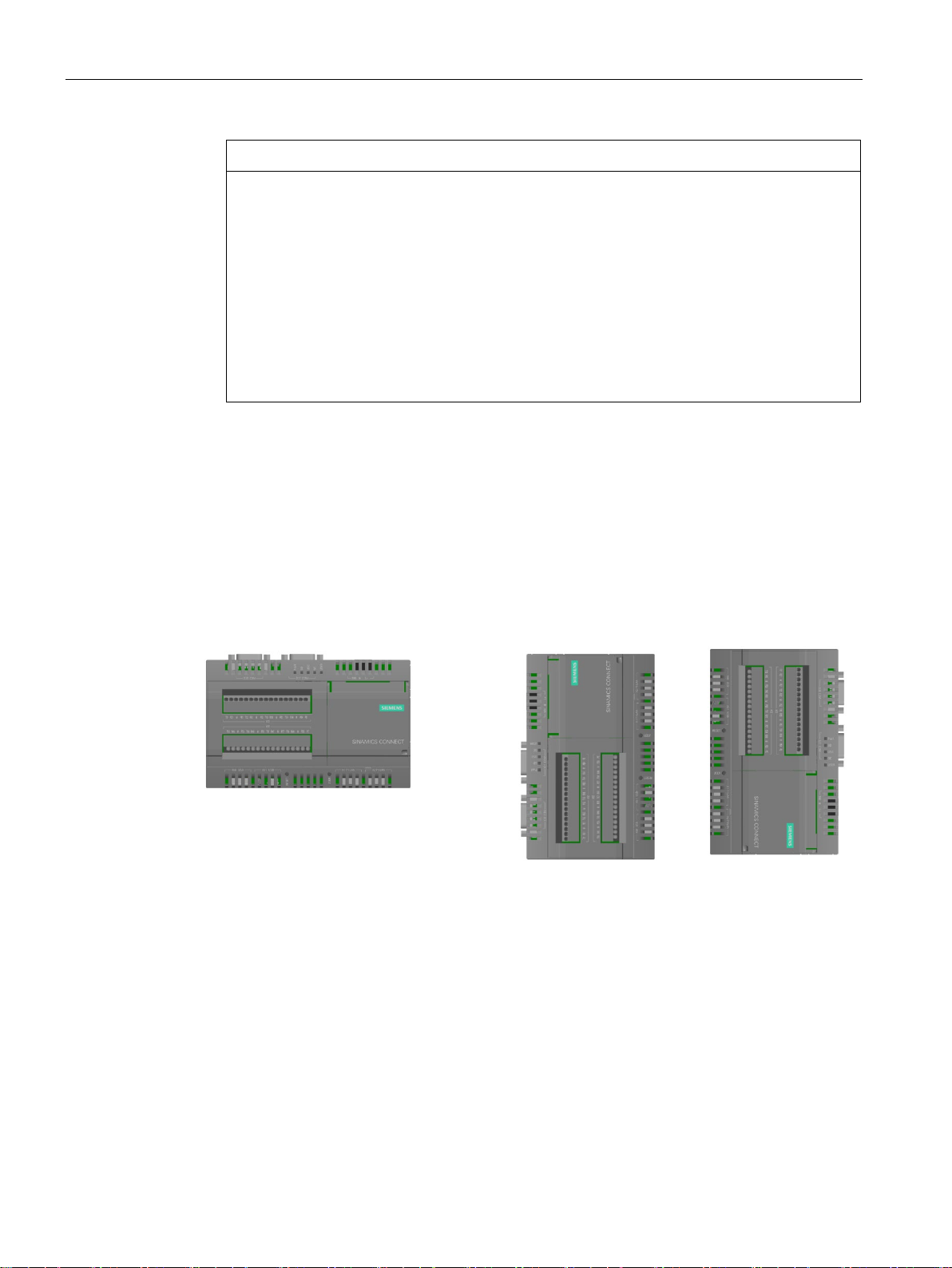

2.2

Structure of the device

Top view

Front view

Bottom view

①

Openings for push

mounting

⑧

Securing device

②

Power supply connector

⑨

RESET button for the CPU

③

COM interfaces (reserved)

⑩

USER button

④

LED display, see Section "

overview (Page 88)"

⑪

Ethernet interface 10/100

⑤

Cover on left

⑫ Ethernet interface 10/100

⑥

Cover on right

⑬

USB Type Micro B (reserved)

⑦

RS232 interface

⑭ USB Type A (reserved)

2.2 Structure of the device

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

-in lugs for wall

Interface

Mbps

Mbps

19

Overview

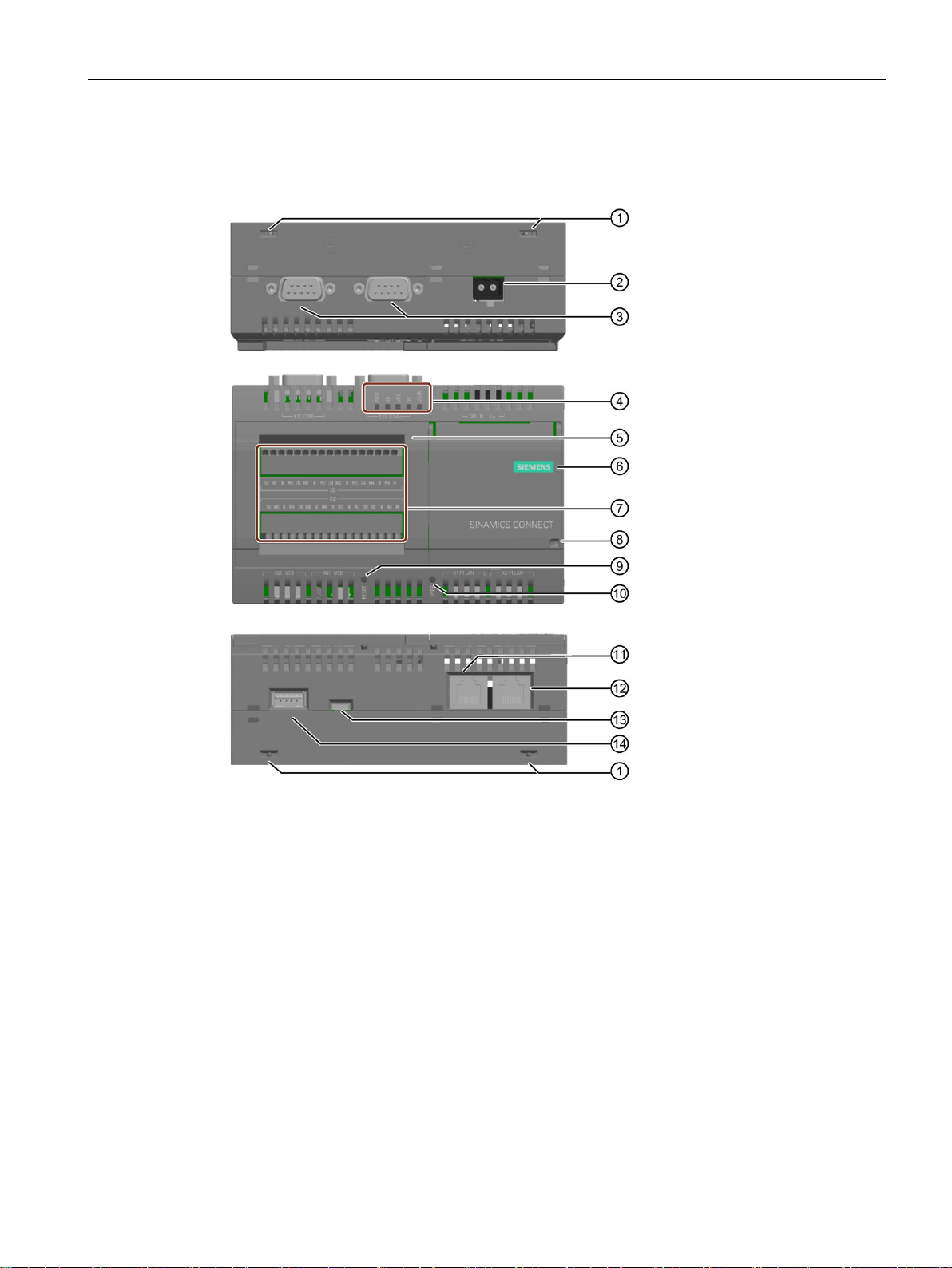

2.3

Scope of delivery

Note

The device contains open

device.

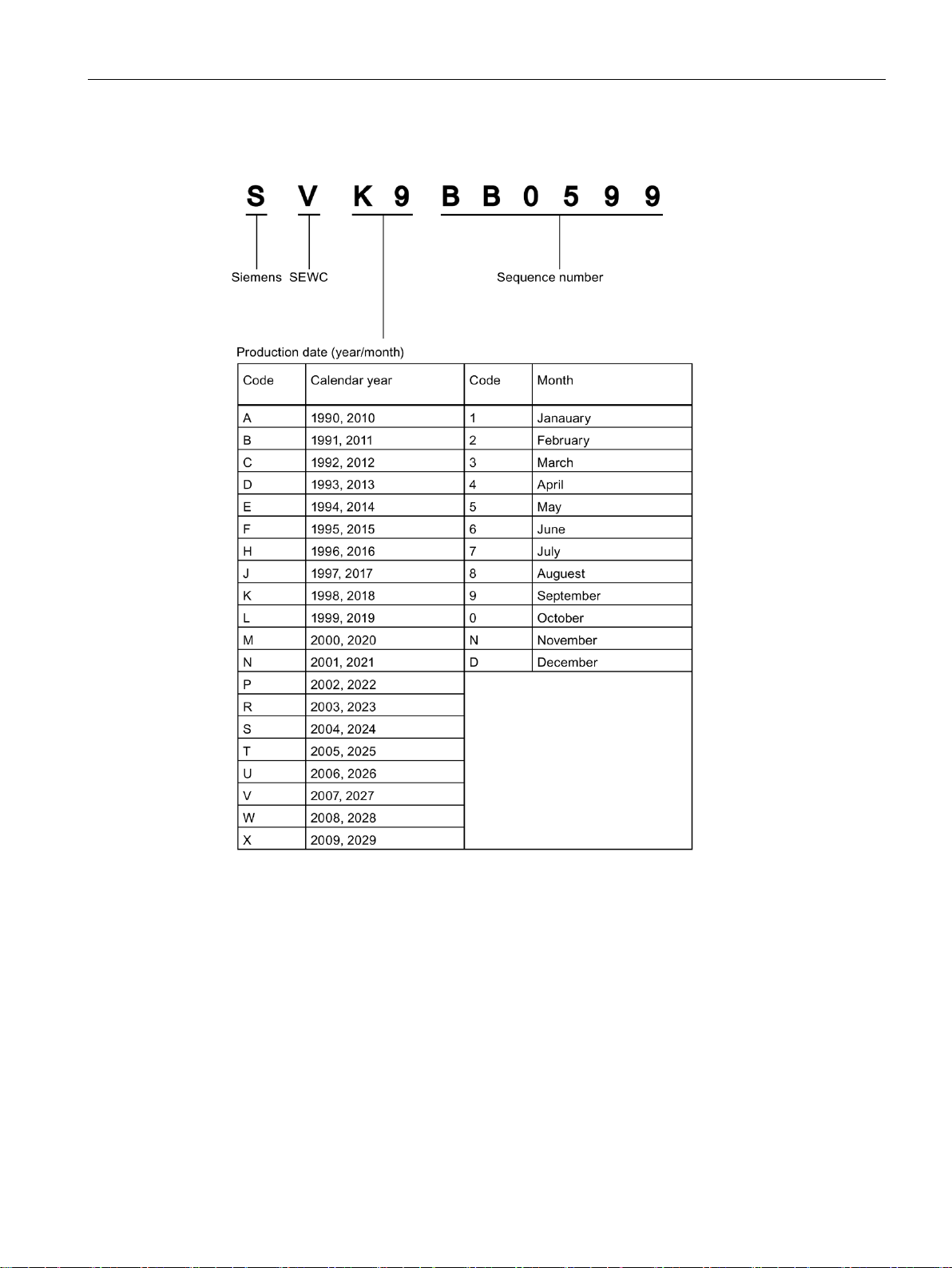

Identification data of the device

Example rating plate

Enter the identification data in the table below

Article number

6SL ...

Serial number

S V

Production version

FS

2.3 Scope of delivery

Check the scope of delivery for completeness and intactness:

● One SINAMICS CONNECT device with one DC terminal block mounted

● Quick Install Guide in English

-source software (OSS). The OSS license terms are saved in the

The device can be clearly identified with the help of this identification data in case of repairs

or theft.

You can find this information on the rating plate. The following illustration shows an example.

All existing Ethernet

addresses (MAC)

SINAMICS CONNECT

20 Operating Instructions, 10/2018, A5E45421408

Overview

Serial number explanation (example)

2.3 Scope of delivery

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

21

Overview

2.4

Accessories

Push-in lugs

2.4 Accessories

The following accessory is not included in the scope of delivery and can be ordered

separately.

Industry Mall (https://mall.industry.siemens.com)

Set with 100 push-in lugs for wall mounting

Article number: 3RB1900-0B

SINAMICS CONNECT

22 Operating Instructions, 10/2018, A5E45421408

3

3.1

Preparing for installation

3.1.1

Checking the delivery

Procedure

NOTICE

Damaged packaging of a device during transport and storage

WARNING

Electric shock and fire hazard due to damaged device

1. When accepting a delivery, please check the packaging for visible transport damage.

2. If any transport damage is present at the time of delivery, lodge a complaint at the

shipping company in charge. Have the shipper confirm the transport damage

immediately.

3. Unpack the device at its installation location.

4. Keep the original packaging in case you have to transport the unit again.

A damaged packaging indicates that ambient conditions have already had a massive

impact on the device. If a device is transported or stored without packaging, shocks,

vibrations, pressure and moisture may impact the unprotected unit. This may cause

damage to the device.

• Do not dispose the original packaging.

• Pack the device during transportation and storage.

5. Check the scope of delivery for completeness and intactness:

– One SINAMICS CONNECT device with one DC terminal block mounted

– Quick Install Guide in English

6. If the contents of the packaging are incomplete, damaged or do not match your order,

inform the responsible delivery service immediately.

A damaged device can be under hazardous voltage and trigger a fire in the machine or

plant. A damaged device has unpredictable properties and states. This may cause

death or serious injury.

• Make sure that the damaged device is not inadvertently installed and put into

operation.

• Label the damaged device and keep it locked away.

• Send off the device for immediate repair.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

23

Mounting

NOTICE

Damage from condensation

3.1.2

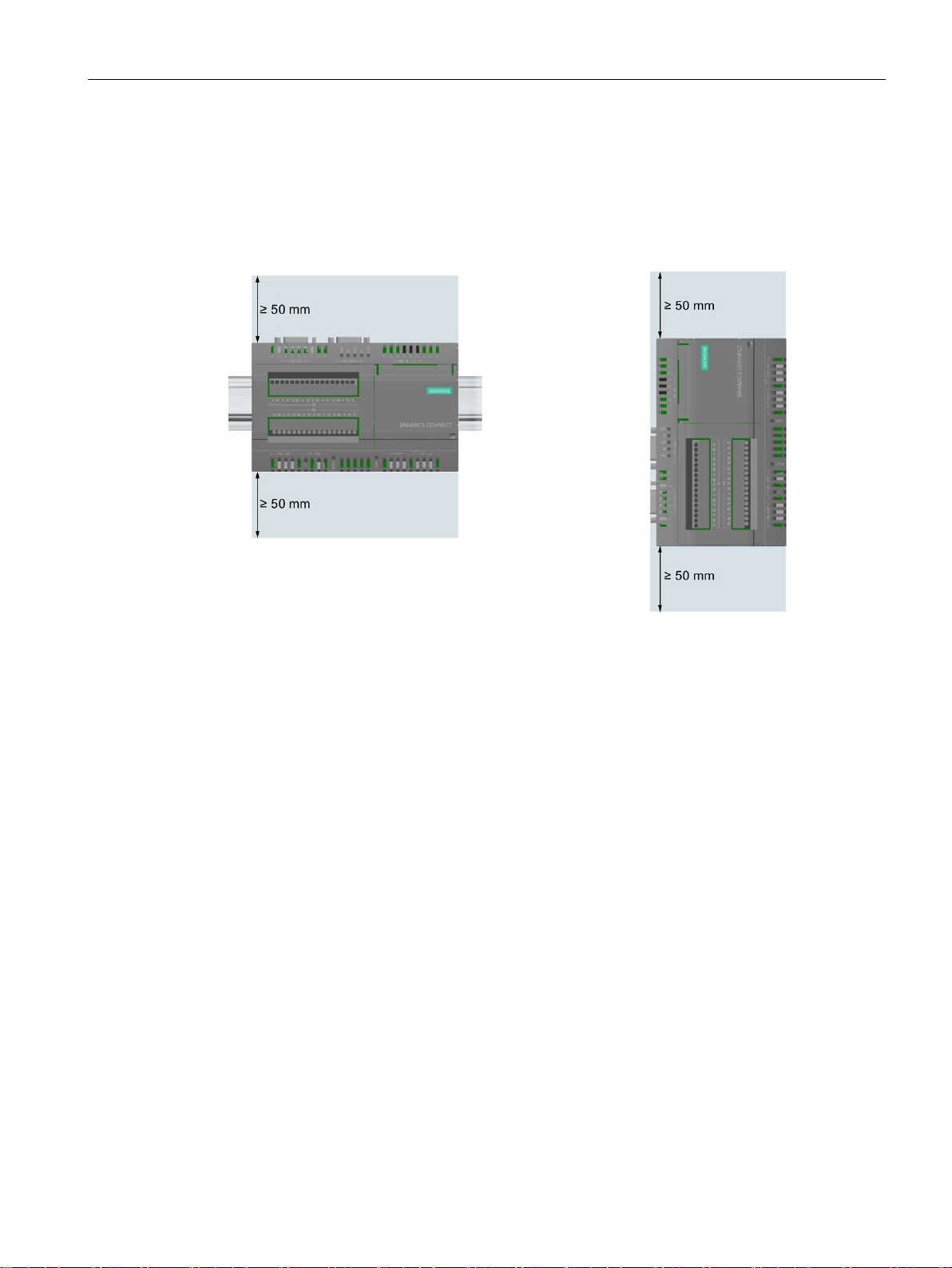

Permitted mounting orientation and mounting types

Horizontal mounting, preferred

Vertical mounting

3.1 Preparing for installation

If the device is subjected to low temperatures or extreme fluctuations in temperature

during transportation, for example in cold weather, moisture could build up on or inside

the HMI device (condensation). Moisture causes a short circuit in electrical circuits and

damages the device.

• Store the device in a dry place.

• Bring the device to room temperature before starting it up.

• Do not expose the device to direct heat radiation from a heating device.

• If condensation develops, wait approximately 12 hours or until the device is

completely dry before switching it on.

7. Please keep the enclosed documentation in a safe place. It belongs to the device. You

need the documentation when you commission the device for the first time.

8. Write down the identification data of the device.

The device can be attached horizontally or vertically on a DIN rail or to a wall.

Take into account the permitted temperature range for operation that depends on the

mounting position in accordance with Section "Ambient conditions (Page 86)".

SINAMICS CONNECT

24 Operating Instructions, 10/2018, A5E45421408

Mounting

Clearances

3.2

Mounting the device

Protection against the spread of fire

Protection against condensation or electrically conductive contamination

3.2 Mounting the device

Make sure that the following clearances to another component or to the wall of a housing are

complied with:

● Both above and below the device: ≥ 50 mm

The device may be operated only in closed housings or in control cabinets with protective

covers that are closed, and when all of the protective devices are used. The installation of

the device in a metal control cabinet or the protection with another equivalent measure must

prevent the spread of fire and emissions outside the control cabinet.

Protect the device, e.g. by installing it in a control cabinet with degree of protection IP54

according to IEC 60529 or NEMA 12. Further measures may be necessary for particularly

critical operating conditions.

If condensation or conductive pollution can be excluded at the installation site, a lower

degree of control cabinet protection may be permitted.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

25

Mounting

3.2.1

Mounting instructions

Fasten securely

NOTICE

Equipment falling due to insufficient load carrying capacity

NOTICE

Equipment falling due to incorrect fixing elements

Material

Bore diameter

Fixing element

3.2 Mounting the device

Note the following:

● The device is approved for indoor operation only.

● For installation in a cabinet, observe the relevant DIN/VDE requirements or the applicable

country-specific regulations.

● When the device is used in the area of Industrial Control Equipment in accordance with

UL61010-2-201, note that the device is classified as "Open Type". A UL61010-2-201

conform enclosure is therefore a mandatory requirement for approval or operation

according to UL61010-2-201.

● To protect the enclosure of the device against unauthorized opening, after installing the

expansions you can screw the rear panel of the enclosure to the front panel of the

enclosure using two screws. The screws are not included in the scope of delivery. Use

only screws of the type WN1452-K30x20-ST-A2F and tighten the screws using a torque

of 0.5 Nm.

● The device is designed for operation in the second environment (industrial area) and may

not be used in the first environment (residential area) unless the appropriate noise

suppression measures have been adopted.

If the mounting surface for wall mounting does not have a sufficient load-bearing capacity,

the device may fall and be damaged.

• Ensure that the mounting surface on the wall can bear four times the total weight of the

device, including fixing elements.

If you use anchors and screws other than those specified below for wall mounting, safe

mounting is not guaranteed. The device can fall and may be damaged.

• Use only the anchors and screws specified in the following table.

Concrete Select according to the specification

of the mounting elements used

Plasterboard,

(at least 13 mm thick)

Metal,

(at least 2 mm thick)

• Anchor, ∅ 6 mm, 40 mm long

• Screw, ∅ 4-5 mm, 40 mm long

• Toggle plug, ∅ 12 mm, 50 mm

long

• M4 screw × 15

• M4 nut

SINAMICS CONNECT

26 Operating Instructions, 10/2018, A5E45421408

Mounting

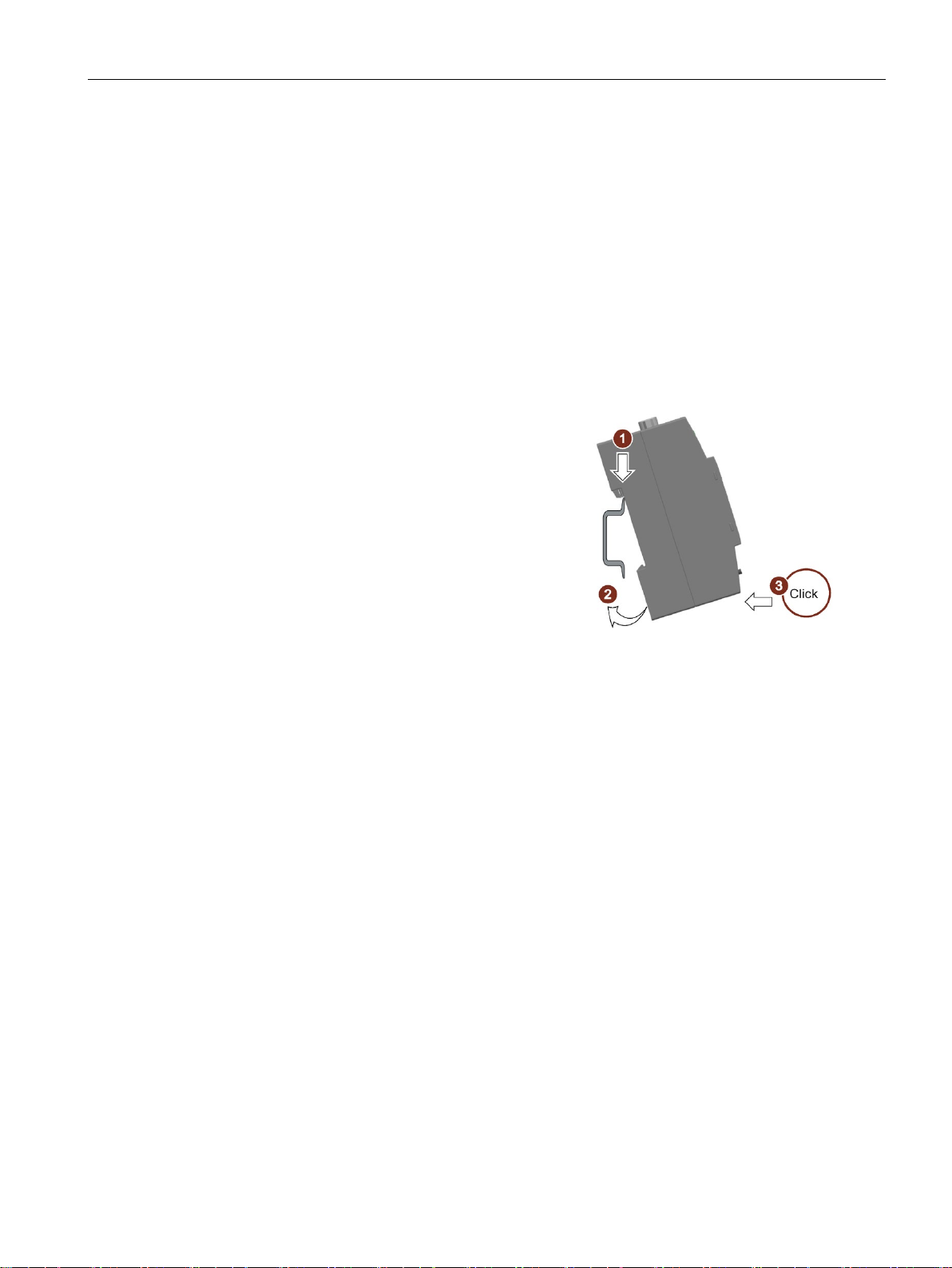

3.2.2

Mounting on DIN rails

Requirement

Procedure

Mounting

1.

2.

3.

Removing

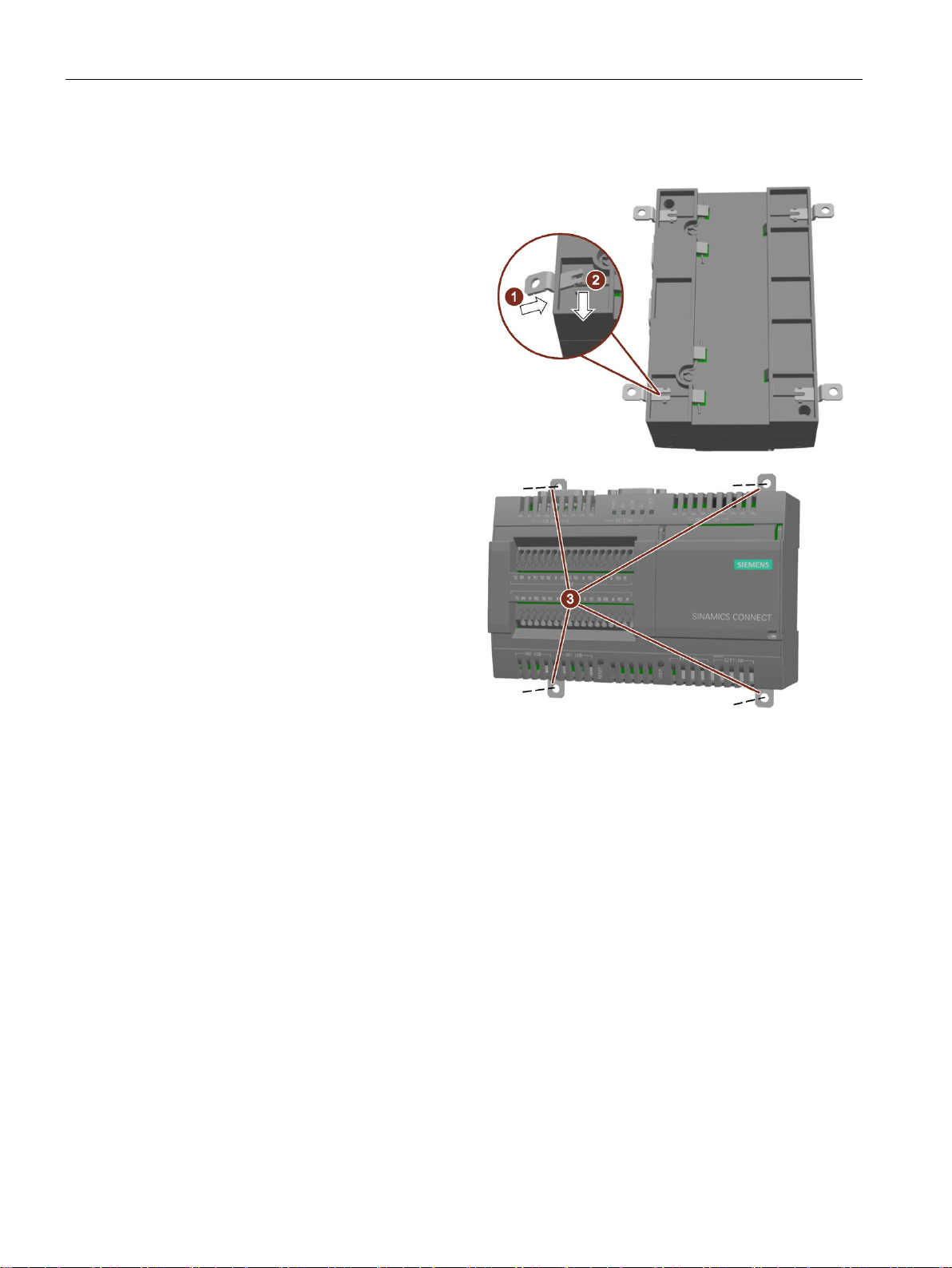

3.2.3

Wall mounting

Requirement

3.2 Mounting the device

● A DIN rail, 35 mm standard profile

The DIN rail is installed at the installation site.

Place the device and rail clip on the

upper edge of the standard profile rail at

the position shown and push the device

down.

Swing the rail clips of the device from

below via the standard profile rail.

Push the device in the direction of the

standard profile rail. You will hear the

device click into place.

1. Push down the device until it is released by the rail clips.

2. Swing the device out of the standard profile rail.

3. Lift the device up and off.

The device is suitable for horizontal or vertical wall mounting.

● Four push-in lugs.

The push-in lugs must be ordered separately, see Section "Accessories (Page 22)".

● Four anchors and four screws.

SINAMICS CONNECT

Operating Instructions, 10/2018, A5E45421408

27

Mounting

Procedure

1.

2.

3.

required holes in the wall and fasten

3.2 Mounting the device

Guide a push-in lug through the

corresponding opening at the top of

the device, as shown in the figure.

Press the push-in lug down.

Mark the bore holes, drill the

the device to the wall using four

screws and corresponding anchors.

SINAMICS CONNECT

28 Operating Instructions, 10/2018, A5E45421408

Loading...

Loading...