Siemens SINAMICS CONNECT 500 Operating Instructions Manual

Operating Instructions

SINAMICS CONNECT 500

Connectivity module

10/2019Edition

www.siemens.com/drives

SINAMICS CONNECT 500

Introduction

1

Operating Instructions

Safety instructions

Description

Preparation for use

Mounting and installation

Connection

Commissioning

Operation

2

3

4

5

6

7

8

Maintenance

Replacement parts

Disposal

Service & Support

Standard topology

9

10

11

A

B

10/2019

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Large Drives Applications

Vogelweiherstr. 1-15

90441 NÜRNBERG

GERMANY

Ⓟ 11/2019 Subject to change

Copyright © Siemens AG 2019.

All rights reserved

Table of contents

1 Introduction...................................................................................................................................................5

1.1 About these instructions...........................................................................................................5

1.2 Naming convention ..................................................................................................................5

2 Safety instructions ........................................................................................................................................7

2.1 General safety instructions.......................................................................................................7

2.2 Qualified personnel ..................................................................................................................7

2.3 The 5 safety rules.....................................................................................................................8

2.4 Electrostatic sensitive devices .................................................................................................8

2.5 Security information .................................................................................................................9

2.6 Security recommendations.......................................................................................................9

3 Description..................................................................................................................................................13

3.1 Overview of the connectivity module......................................................................................13

3.2 Documentation of the components ........................................................................................15

3.3 SIDRIVE IQ ............................................................................................................................16

3.4 Overview of the overall system ..............................................................................................17

3.5 Data security ..........................................................................................................................17

4 Preparation for use .....................................................................................................................................19

4.1 Transportation and storage ....................................................................................................19

4.2 Prerequisites ..........................................................................................................................19

4.3 Windows Security Center.......................................................................................................21

4.4 Operation without antivirus software ......................................................................................21

5 Mounting and installation............................................................................................................................23

5.1 Mounting and installation (premounted version of the connectivity module)..........................23

5.2 Mounting and installation (connectivity module version that can be retrofitted).....................23

6 Connection .................................................................................................................................................25

6.1 Connect the LAN cable to the IPC (premounted version of the connectivity module) ...........25

6.2 Connection (connectivity module version that can be retrofitted) ..........................................25

7 Commissioning ...........................................................................................................................................27

7.1 Setting up the remote desktop connection to the IPC............................................................27

7.2 Activating the internet time.....................................................................................................28

7.3 Setting recovery points...........................................................................................................29

SINAMICS CONNECT 500

Operating Instructions, 10/2019 3

Table of contents

7.4 Updating Windows .................................................................................................................29

7.5 Setting up the IP address (optional).......................................................................................30

7.6 Inserting the connection key on the IPC ................................................................................30

7.7 Replacing parameter lists and alarm lists ..............................................................................31

7.8 Checking the connections to the converter Control Unit ........................................................35

7.9 Completing commissioning ....................................................................................................37

8 Operation....................................................................................................................................................39

8.1 Data evaluation with SIDRIVE IQ...........................................................................................39

9 Maintenance ...............................................................................................................................................41

9.1 Updating, backing up and restoring software components ....................................................41

9.2 Activating/deactivating the service mode ...............................................................................41

9.3 Updating Windows .................................................................................................................42

9.4 Siemens Security Advisories via CERT .................................................................................43

9.5 Replacing connectivity module components ..........................................................................43

9.6 Deleting the data of the connectivity module .........................................................................44

9.7 Fault rectification ....................................................................................................................44

9.7.1 Restart service "Drive System Connect"................................................................................44

9.7.2 Setting-up the connection to the converter Control Unit ........................................................45

9.7.3 Activating FTP on the Control Unit.........................................................................................46

10 Replacement parts .....................................................................................................................................47

10.1 Spares on Web ......................................................................................................................47

10.2 Replacement parts for the connectivity module .....................................................................47

11 Disposal......................................................................................................................................................49

11.1 Country-specific legislation ....................................................................................................49

11.2 Disposing of the connectivity module.....................................................................................49

A Service & Support.......................................................................................................................................51

B Standard topology ......................................................................................................................................53

B.1 Standard topology medium-voltage converter with CU320-2 ................................................53

Index...........................................................................................................................................................55

SINAMICS CONNECT 500

4 Operating Instructions, 10/2019

Introduction

1.1 About these instructions

These instructions describe the connectivity module and provide you with information on how

to use the product – from installation through to maintenance.

Keep these instructions in a safe place for subsequent use.

Read these instructions before you use the connectivity module, and follow the instructions and

notes carefully. In this way you can ensure safe, problem-free operation and a long service life.

Text format features

You can find the following text format features in these instructions:

1. Handling instructions are always formatted as a numbered list. Always perform the steps in

the order given.

● Lists are formatted as bulleted lists.

– Lists on the second level are hyphenated.

1

Note

The note provides you with additional information about the product itself, handling the product

- and the relevant documentation.

References to other texts always refer to the beginning of the chapter.

1.2 Naming convention

In this documentation, the term "Connectivity module" is subsequently used for the

"SINAMICS CONNECT 500" product.

In this documentation, the term "IPC" is subsequently used for the "SIDRIVE IQ Drive System

Connect Nano" product.

SINAMICS CONNECT 500

Operating Instructions, 10/2019 5

Introduction

1.2 Naming convention

SINAMICS CONNECT 500

6 Operating Instructions, 10/2019

Safety instructions

2.1 General safety instructions

The connectivity module conforms to the pertinent safety regulations according to IEC, VDE

and EN. If you have questions about the validity of the installation in the planned environment,

please contact your service representative.

When working with the connectivity module, carefully observe the following safety notes and

instructions. Also observe the safety notes and instructions in the operating instructions of the

components (Page 15).

Battery

WARNING

Risk of explosion and the risk of the emission of toxic substances (valid for IPC127E)

Improper handling of lithium batteries can cause them to explode.

Explosion of the batteries and the released toxic substances can cause severe physical injury.

Worn batteries jeopardize the function of the device.

Note the following when handling lithium batteries:

● Replace used batteries in good time. Additional information on replacing batteries is

provided in the SIMATIC IPC127E Operating Instructions, Section "Replacing buffer

batteries".

● Do not throw the batteries into a fire.

● Do not solder at the cell body of the battery.

● Do not recharge the battery.

● Do not open the battery.

● Do not short-circuit the battery.

● Do not connect the battery with the incorrect polarity.

● Do not heat up the battery to over 100 °C.

● Protect the battery from direct solar radiation, humidity and condensation.

2

2.2 Qualified personnel

Only qualified personnel may perform work on the connectivity module. For the purpose of this

documentation, qualified personnel is taken to mean people who fulfill the following

requirements:

● Through appropriate training and experience, they are able to recognize and avoid risks and

potential dangers in their particular field of activity.

● Those responsible have instructed them to carry out the work.

SINAMICS CONNECT 500

Operating Instructions, 10/2019 7

Safety instructions

2.4 Electrostatic sensitive devices

2.3 The 5 safety rules

For your own personal safety and to prevent material damage when carrying out any work,

always observe the safety-relevant instructions and the following five safety rules according to

EN 50110‑1 "Working in a voltage-free state". Apply the five safety rules in the sequence stated

before starting work.

5 safety rules

1. Disconnect the system.

Also disconnect the auxiliary circuits, for example, anti-condensation heating.

2. Secure against reconnection.

3. Verify absence of operating voltage.

4. Ground and short-circuit.

5. Provide protection against adjacent live parts.

To energize the system, apply the measures in reverse order.

2.4 Electrostatic sensitive devices

Material damage due to electrostatic discharge

Electronic modules contain components that can be destroyed by electrostatic discharge.

These components can be damaged or destroyed if they are not handled correctly. To protect

equipment against damage, follow the instructions given below.

● Only touch electronic modules if you absolutely have to work on them.

● The body of the person concerned must have been electrostatically discharged and

grounded immediately before any electronic modules are touched.

● Electronic modules should not be brought into contact with electrically insulating materials,

such as:

– Plastic film

– Plastic parts

– Insulating table supports

– Clothing made of synthetic fibers

● Always place electrostatic sensitive devices on conductive bases.

● Always pack, store and transport electronic modules or components in conductive

packaging, such as:

– Metallized plastic or metal containers

– Conductive foam material

– Domestic aluminum foil

SINAMICS CONNECT 500

8 Operating Instructions, 10/2019

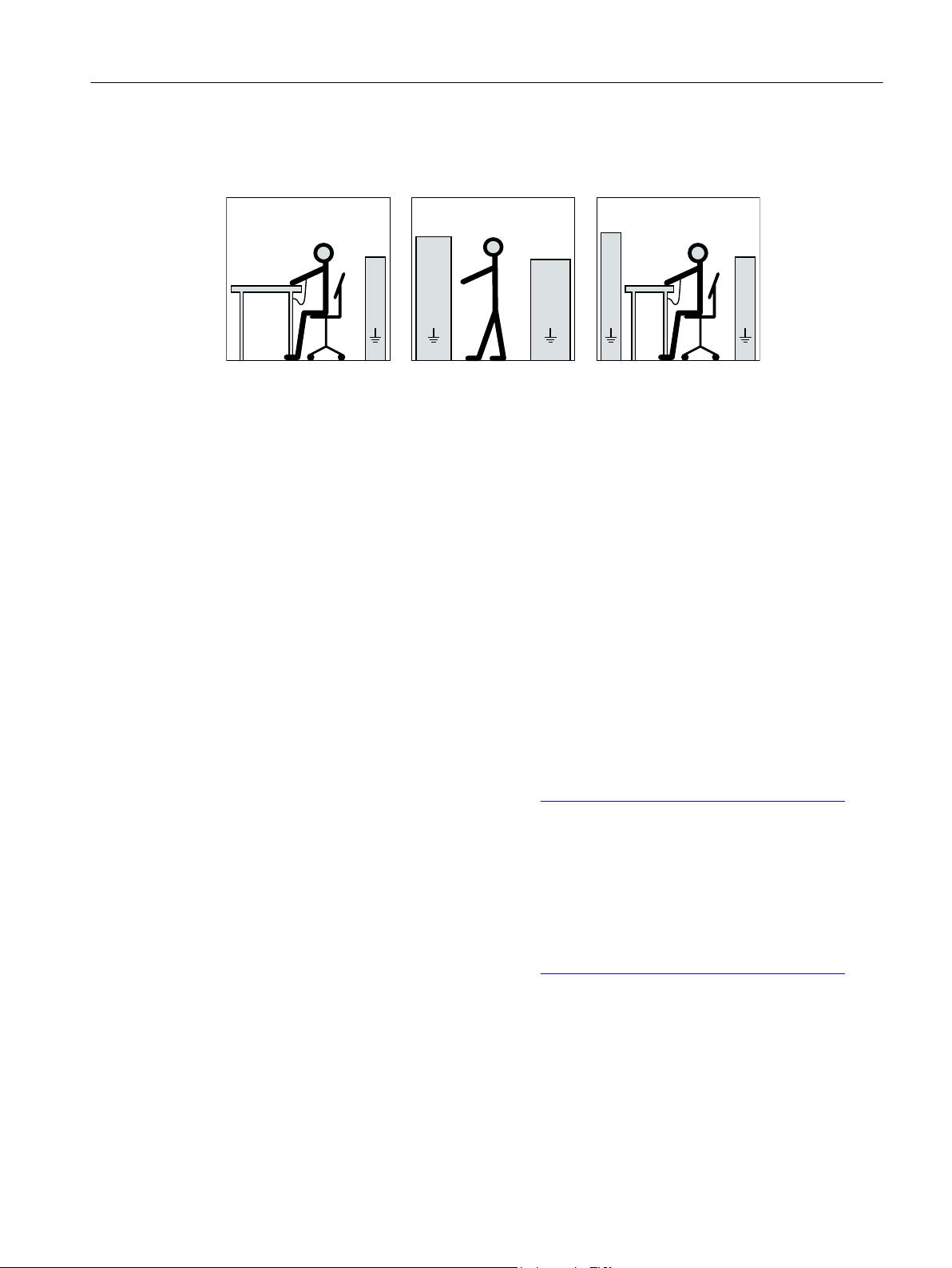

6HDWLQJSRVLWLRQ

6WDQGLQJSRVLWLRQ

6WDQGLQJVHDWLQJSRVLWLRQ

EE

D

F

D

IIIII

D

FF

H

GG

H

G

Safety instructions

2.6 Security recommendations

The necessary ESD protective measures for electrostatic sensitive devices are illustrated once

again in the following drawings:

a = conductive floor sur‐

face

d = ESD overall e = ESD wristband f = cabinet ground connection

2.5 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be connected

to an enterprise network or the internet if and to the extent such a connection is necessary and

only when appropriate security measures (e.g. firewalls and/or network segmentation) are in

place.

For additional information on industrial security measures that may be implemented, please

visit

https://www.siemens.com/industrialsecurity (https://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they are available

and that the latest product versions are used. Use of product versions that are no longer

supported, and failure to apply the latest updates may increase customer’s exposure to cyber

threats.

b = ESD table c = ESD shoes

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

https://www.siemens.com/industrialsecurity (https://www.siemens.com/industrialsecurity).

2.6 Security recommendations

Carefully observe the following security recommendations to prevent unauthorized access.

Carefully comply with the security recommendations in the component documentation

SINAMICS CONNECT 500

Operating Instructions, 10/2019 9

(Page 15).

Safety instructions

2.6 Security recommendations

General

● Regularly check that the device satisfies these recommendations and/or other internal

security guidelines.

● Holistically analyze your complete system regarding security. Utilize the cell protection

concept based on the appropriate products.

● Correctly disconnect the various connections (WBM, Telnet, SSH etc.).

Physical access

● Restrict physical access to the device to qualified personnel only.

● Do not open any additional physical ports. Further, observe the hardening measures and

network configurations in the following chapters:

– Data security (Page 17)

– Overview of the overall system (Page 17)

– Prerequisites (Page 19)

Software (security functions)

● Keep the software up to date. Regularly inform yourself about product security updates. You

can find information about this topic on the Internet pages for Industrial Security (Page 9).

● Keep yourself up to date with security advisories and bulletins, published by Siemens

ProductCERT (

https://www.siemens.com/global/en/home/products/services/cert.html).

Passwords

● Regularly update passwords and keys in order to increase the security level.

● Only use strong passwords. Avoid weak passwords, e.g. password1, 123456789, abcdefgh.

● Ensure that all passwords are protected, and cannot be accessed by unauthorized

personnel.

● Do not use the same password for various users and systems.

"SINAMICS Industrial Security" for medium-voltage converters Configuration Manual

Notes relating to Industrial Security are provided here (https://

support.industry.siemens.com/cs/ww/en/view/109751848).

System Manual "SIMATIC NET: Industrial Ethernet/PROFINET Industrial Ethernet"

Information relating to SIMATIC NET products is provided here (https://

support.industry.siemens.com/cs/ww/en/view/27069465).

SINAMICS CONNECT 500

10 Operating Instructions, 10/2019

Safety instructions

2.6 Security recommendations

"SIMATIC NET Industrial Ethernet / PROFINET Passive network components" System Manual

Information relating to the most commonly used components and installation guidelines for

networked automation systems in buildings is provided here (

support.industry.siemens.com/cs/ww/en/view/84922825).

https://

SINAMICS CONNECT 500

Operating Instructions, 10/2019 11

Safety instructions

2.6 Security recommendations

SINAMICS CONNECT 500

12 Operating Instructions, 10/2019

Description

3.1 Overview of the connectivity module

The connectivity module captures important operating and status data of the drive. The

captured data is preprocessed, transferred via a LAN interface, and made available in

SIDRIVE IQ for analysis.

Two connectivity module versions are available:

● Premounted version of the connectivity module

● Connectivity module version that can be retrofitted

The connectivity module comprises the following components:

● SIDRIVE IQ - Drive System Connect Nano

– Industrial PC SIMATIC IPC127E

– Software image

● SCALANCE X005 LAN switch

Note

3

The connectivity module and SIDRIVE IQ are used to monitor the state/condition of the

converter. The connectivity module cannot be used to influence the converter. The connectivity

module is not a remote maintenance system.

SINAMICS CONNECT 500

Operating Instructions, 10/2019 13

Description

3.1 Overview of the connectivity module

SIDRIVE IQ - Drive System Connect Nano

The IPC captures the converter data and processes the data for transfer to SIDRIVE IQ.

Installed software

Figure 3-1 SIMATIC IPC127E

The connectivity module includes the following pre-installed software:

● Windows 10

● 7-zip

● Siemens Bany Scope

● Siemens Drive System Connect

● MindConnect Bridge

● MCB feeder

Additionally available software:

● Siemens CMS X-Tools

● Siemens CMS X-Tools Analysis Library

● Omicron OMSSystemSW

Do not exit or deactivate any of the active services so as not to diminish the functionality of the

connectivity module.

SINAMICS CONNECT 500

14 Operating Instructions, 10/2019

SCALANCE X005 LAN switch

The SCALANCE switch multiplies the service interface of the Control Unit (CU) of the converter.

Description

3.2 Documentation of the components

Figure 3-2 SCALANCE X005 LAN switch

3.2 Documentation of the components

The configuration, operation and diagnostics - as well as information about the security of the

components - are described in the following documentation:

● SIMATIC IPC127E Operating Instructions (

view/109762673)

● SCALANCE X005 LAN switch Operating Instructions (https://

support.industry.siemens.com/cs/ww/en/view/22261701)

● Information about network security (https://support.industry.siemens.com/cs/ww/en/view/

109751848)

● Instructions for the connectivity module version that can be retrofitted (https://

support.industry.siemens.com/cs/ww/en/ps/25520)

The documentation of the software installed on the IPC is provided on the IPC in the relevant

program folder.

SINAMICS CONNECT 500

Operating Instructions, 10/2019 15

https://support.industry.siemens.com/cs/ww/en/

Description

3.3 SIDRIVE IQ

3.3 SIDRIVE IQ

What is SIDRIVE IQ?

SIDRIVE IQ is the digital platform for drive systems. The platform connects networked drive

components with the Cloud-based analytics in SIDRIVE IQ to improve the productivity, the

reliability and the service options for the particular drive component.

Using the connectivity module you can transfer, save and analyze operating data in

SIDRIVE IQ. Operating data can be displayed using SIDRIVE IQ. SIDRIVE IQ provides

technical data on the drive components and the results of the analysis in operation and the

status for users. Further, it provides suggestions relating to preventive maintenance activities,

for example.

SINAMICS CONNECT 500

16 Operating Instructions, 10/2019

Loading...

Loading...