Siemens SINAMIC G130 Operating Instructions Manual

___________________

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS G130

Braking Module / braking resistor

Operating Instructions

Firmware version V5.1

11/2017

A5E00331454A

Safety information

1

General

2

Mechanical installation

3

Connection

4

Maintenance and servicing

5

Technical specifications

6

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E00331454A

Ⓟ

Copyright © Siemens AG 2004 - 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

03/2018 Subject to change

Table of contents

1 Safety information ................................................................................................................................... 5

2 General ................................................................................................................................................. 11

3 Mechanical installation .......................................................................................................................... 15

4 Connection ........................................................................................................................................... 29

5 Maintenance and servicing .................................................................................................................... 37

6 Technical specifications ........................................................................................................................ 39

1.1 General safety instructions ....................................................................................................... 5

1.2 Handling electrostatic sensitive devices (ESD) ...................................................................... 10

2.1 Braking Module ....................................................................................................................... 12

2.2 Braking resistor ....................................................................................................................... 14

3.1 General ................................................................................................................................... 15

3.2 Braking Modules: overview ..................................................................................................... 16

3.3 Installing the Braking Module .................................................................................................. 19

3.3.1 Installing the Braking Module in a Power Module, frame size FX .......................................... 19

3.3.2 Installing the Braking Module in a Power Module frame size GX ........................................... 22

3.3.3 Installing the Braking Module in a Power Module frame size HX ........................................... 25

3.3.4 Installing the Braking Module in a Power Module frame size JX ............................................ 26

3.4 Installing the braking resistor .................................................................................................. 27

4.1 Cable lugs ............................................................................................................................... 29

4.2 Connecting the Braking Module .............................................................................................. 30

4.3 Connecting the braking resistor .............................................................................................. 34

4.4 Disabling the Vdc-max controller ............................................................................................ 36

Braking Module / braking resistor

Operating Instructions, 11/2017, A5E00331454A

3

Table of contents

Braking Module / braking resistor

4 Operating Instructions, 11/2017, A5E00331454A

1

1.1

General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

WARNING

Electric shock due to connection to an unsuitable power supply

Touching live components can result in death or serious injury.

• Only work on electrical equipment if you are appropriately qualified.

• Always observe the country-specific safety rules for all work.

Generally, the following steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any

of the power connections and the protective conductor connection.

5. Check that every auxiliary circuit is de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

After you have completed the work, restore the operational readiness by following the

above steps in the reverse order.

Braking Module / braking resistor

Operating Instructions, 11/2017, A5E00331454A

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage that might result in serious injury or death.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

5

Safety information

WARNING

Electric shock due to equipment damage

WARNING

Electric shock due to unconnected cable shield

WARNING

Electric shock if there is no ground connection

WARNING

Arcing when a plug connection is opened during operation

NOTICE

Property damage due to loose power connections

1.1 General safety instructions

Improper handling may cause damage to equipment. For damaged devices, hazardous

voltages can be present at the enclosure or at exposed components; if touched, this can

result in death or severe injury.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• Connect cable shields and unused conductors of power cables (e.g. brake conductors)

at least on one side to the grounded housing potential.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

Opening a plug connection when a system is in operation can result in arcing that may

cause serious injury or death.

• Only open plug connections when the equipment is in a voltage-free state, unless it has

been explicitly stated that they can be opened in operation.

Insufficient tightening torques or vibration can result in loose power connections. This can

result in damage due to fire, device defects or malfunctions.

• Tighten all power connections to the prescribed torque.

• Check all power connections at regular intervals, particularly after equipment has been

transported.

Braking Module / braking resistor

6 Operating Instructions, 11/2017, A5E00331454A

Safety information

WARNING

Spread of fire from built-in devices

WARNING

Failure of pacemakers or implant malfunctions due to electromagnetic fields

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

WARNING

Motor fire in the event of insulation overload

1.1 General safety instructions

In the event of fire outbreak, the enclosures of built-in devices cannot prevent the escape of

fire and smoke. This can result in serious personal injury or property damage.

• Install built-in units in a suitable metal cabinet in such a way that personnel are

protected against fire and smoke, or take other appropriate measures to protect

personnel.

• Ensure that smoke can only escape via controlled and monitored paths.

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment,

such as transformers, converters, or motors. People with pacemakers or implants in the

immediate vicinity of this equipment are at particular risk.

• If you have a heart pacemaker or implant, maintain a minimum distance of 2 m from

electrical power equipment.

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

• If you come closer than around 2 m to such components, switch off any radio devices or

mobile phones.

• Use the "SIEMENS Industry Online Support App" only on equipment that has already

been switched off.

There is a greater load on the motor insulation as result of a ground fault in an IT system. If

the insulation fails, it is possible that death or severe injury can occur as a result of smoke

and fire.

• Use a monitoring device that signals an insulation fault.

• Correct the fault as quickly as possible so the motor insulation is not overloaded.

Braking Module / braking resistor

Operating Instructions, 11/2017, A5E00331454A

7

Safety information

WARNING

Fire due to inadequate ventilation clearances

WARNING

Unrecognized dangers due to missing or illegible warning labels

NOTICE

Device damage caused by incorrect voltage/insulation tests

WARNING

Unexpected movement of machines caused by inactive safety functions

1.1 General safety instructions

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in

increased downtime and reduced service lives for devices/systems.

• Ensure compliance with the specified minimum clearance as ventilation clearance for

the respective component.

Dangers might not be recognized if warning labels are missing or illegible. Unrecognized

dangers may cause accidents resulting in serious injury or death.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, where necessary in the national

language.

• Replace illegible warning labels.

Incorrect voltage/insulation tests can damage the device.

• Before carrying out a voltage/insulation check of the system/machine, disconnect the

devices as all converters and motors have been subject to a high-voltage test by the

manufacturer, and therefore it is not necessary to perform an additional test within the

system/machine.

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have absolutely guaranteed that the

functions relevant to safety are operating correctly.

Braking Module / braking resistor

8 Operating Instructions, 11/2017, A5E00331454A

Safety information

Note

Important safety instructions for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety instructions in

the Safety Integrated manuals.

1.1 General safety instructions

Braking Module / braking resistor

Operating Instructions, 11/2017, A5E00331454A

9

Safety information

1.2

Handling electrostatic sensitive devices (ESD)

NOTICE

Damage through electric fields or electrostatic discharge

1.2 Handling electrostatic sensitive devices (ESD)

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g. conductive foam rubber or

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

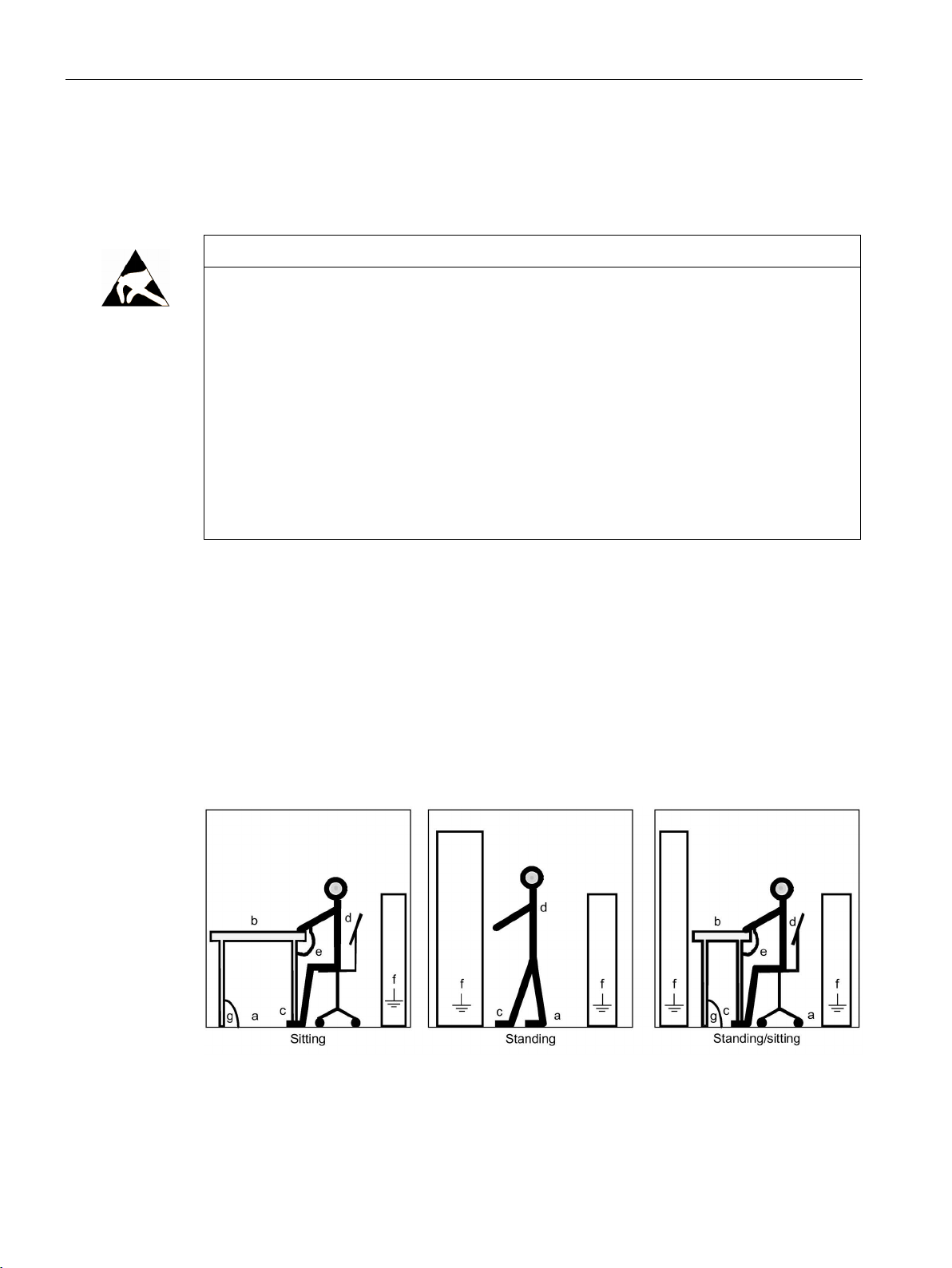

The necessary ESD protective measures are clearly illustrated in the following diagram:

● a = conductive floor surface

● b = ESD table

● c = ESD shoes

● d = ESD overall

● e = ESD wristband

● f = cabinet ground connection

● g = contact with conductive flooring

Figure 1-1 ESD protective measures

Braking Module / braking resistor

10 Operating Instructions, 11/2017, A5E00331454A

2

WARNING

Non-observance of the fundamental safety instructions and residual risks

WARNING

Fire and device damage as a result of ground fault/short-circuit

– Lay the cables in separate cable ducts or conduits.

WARNING

Fire due to overheating when the total length of the connecting cables is exceeded

WARNING

Fire through overheating due to insufficient ventilation clearances

The non-observance of the fundamental safety instructions and residual risks stated in

Chapter 1 can result in accidents with severe injuries or death.

• Adhere to the fundamental safety instructions.

• When assessing the risk, take into account residual risks.

Inadequate installation of the cables to the braking resistor can result in a ground

fault/short-circuit and place persons at risk as a result of the associated smoke and fire.

• Comply with local installation regulations that enable this fault to be ruled out.

• Protect the cables from mechanical damage.

• In addition, apply one of the following measures:

– Use cables with double insulation.

– Maintain adequate clearance, e.g. by using spacers.

Excessively long Braking Module connection cables can cause components to overheat

with the associated risk of fire and smoke.

• The Braking Module connecting cables may not be longer than 100 m.

Inadequate ventilation clearances can cause overheating with a risk for personnel through

smoke development and fire. This can also result in increased failures and reduced service

lives of braking resistors.

• It is essential that you maintain a ventilation clearance of 200 mm on all sides of the

component with ventilation grilles.

Braking Module / braking resistor

Operating Instructions, 11/2017, A5E00331454A

11

General

NOTICE

Material damage due to loose power connections

NOTICE

Damage through the use of non-released braking resistors

2.1

Braking Module

Description

Structure

2.1 Braking Module

Insufficient tightening torques or vibration can result in faulty electrical connections. This

can cause fire damage or malfunctions.

• Tighten all power connections with the specified tightening torques, e.g. line supply

connection, motor connection, DC-link connections.

• Check the tightening torques of all power connections at regular intervals and tighten

them when required. This applies in particular after transport.

Braking resistors can be damaged when using braking resistors other than those specified

in this manual.

• Only use braking resistors released by Siemens.

A Braking Module (and an external braking resistor) is required in certain cases when the

drive is to be braked or brought to a standstill (e.g. EMERGENCY STOP category 1). The

Braking Module contains the power electronics and the associated Control Unit. The supply

voltage for the electronics is drawn from the DC link.

During operation, the DC-link energy is converted to heat loss in an external braking resistor.

The Braking Module functions independently of the converter closed-loop controller. In the

case of Power Modules with frame sizes HX and JX, it is possible to operate several Braking

Modules in parallel in order to enhance performance. In this case, each Braking Module

must be fitted with its own braking resistor.

The Braking Module is inserted in a slot inside the Power Module, the fan of which ensures

forced cooling. The Braking Module is connected to the DC link by means of the busbar sets

and flexible cables, which are supplied as standard.

Braking Module / braking resistor

12 Operating Instructions, 11/2017, A5E00331454A

General

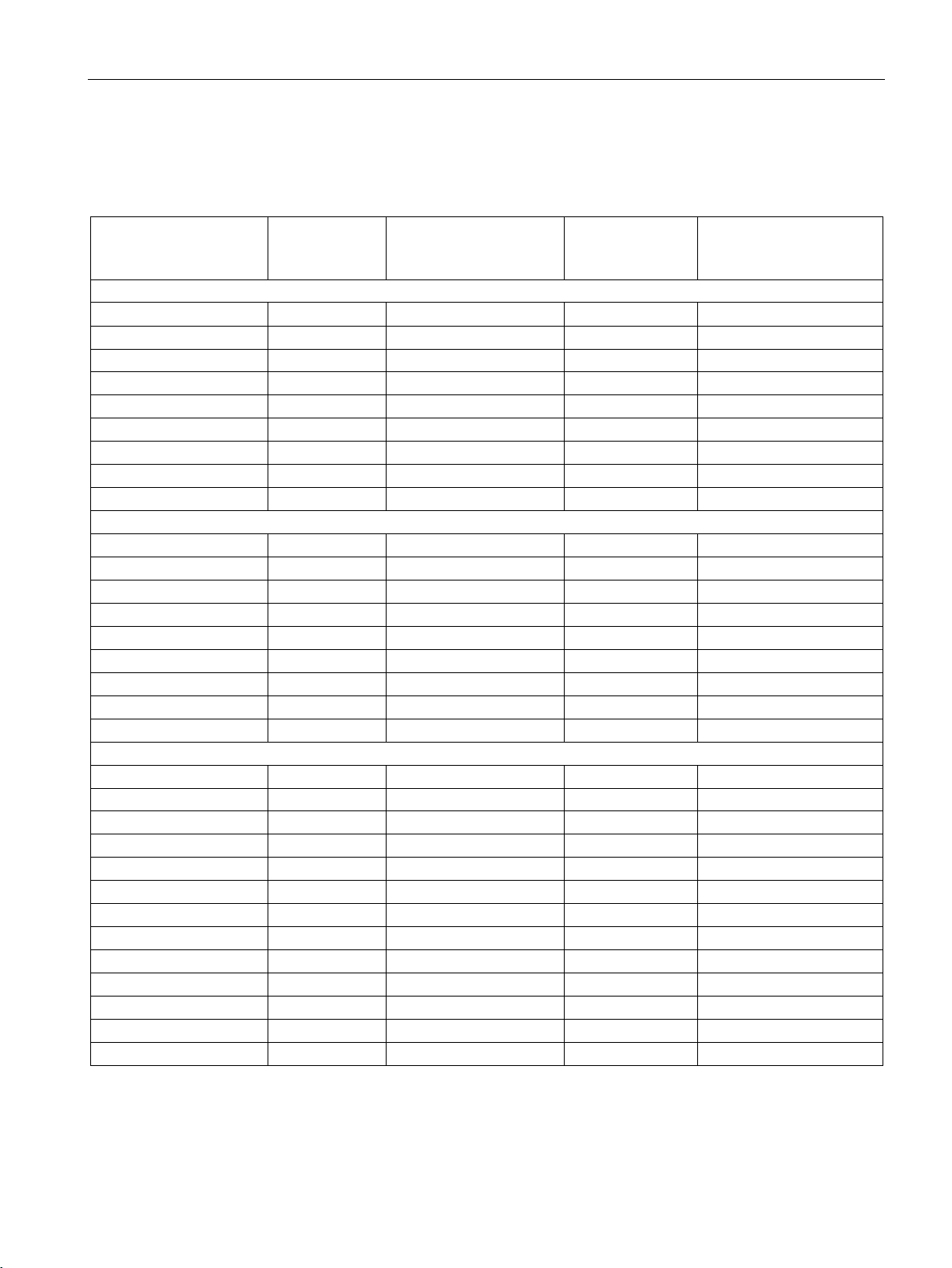

Assignment of Braking Module and Power Module

Power Module

Unit rating of the

Power Module

Suitable Braking Module

Rated power output of the Braking

Module

Suitable brake resistance

Line voltage 3-phase 380 – 480 VAC

6SL3310-1GE32-6AA3

132 kW

6SL3300-1AE31-3AA0

25 kW

6SL3000-1BE31-3AA0

6SL3310-1GE33-8AA3

200 kW

6SL3300-1AE32-5AA0

50 kW

6SL3000-1BE32-5AA0

6SL3310-1GE35-0AA3

250 kW

6SL3300-1AE32-5AA0

50 kW

6SL3000-1BE32-5AA0

6SL3310-1GE36-1AA3

315 kW

6SL3300-1AE32-5BA0

50 kW

6SL3000-1BE32-5AA0

6SL3310-1GE37-5AA3

400 kW

6SL3300-1AE32-5BA0

50 kW

6SL3000-1BE32-5AA0

6SL3310-1GE38-4AA3

450 kW

6SL3300-1AE32-5BA0

50 kW

6SL3000-1BE32-5AA0

6SL3310-1GE41-0AA3

560 kW

6SL3300-1AE32-5BA0

50 kW

6SL3000-1BE32-5AA0

Line voltage 3-phase 500 – 600 VAC

6SL3310-1GF31-8AA3

110 kW

6SL3300-1AF32-5AA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF32-2AA3

132 kW

6SL3300-1AF32-5AA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF32-6AA3

160 kW

6SL3300-1AF32-5AA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF33-3AA3

200 kW

6SL3300-1AF32-5AA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF34-1AA3

250 kW

6SL3300-1AF32-5BA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF34-7AA3

315 kW

6SL3300-1AF32-5BA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF35-8AA3

400 kW

6SL3300-1AF32-5BA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF37-4AA3

450 kW

6SL3300-1AF32-5BA0

50 kW

6SL3000-1BF32-5AA0

6SL3310-1GF38-1AA3

560 kW

6SL3300-1AF32-5BA0

50 kW

6SL3000-1BF32-5AA0

Line voltage 3-phase 660 – 690 VAC

6SL3310-1GH28-5AA3

75 kW

6SL3300-1AH31-3AA0

25 kW

6SL3000-1BH31-3AA0

6SL3310-1GH31-0AA3

90 kW

6SL3300-1AH31-3AA0

25 kW

6SL3000-1BH31-3AA0

6SL3310-1GH31-2AA3

110 kW

6SL3300-1AH31-3AA0

25 kW

6SL3000-1BH31-3AA0

6SL3310-1GH31-5AA3

132 kW

6SL3300-1AH31-3AA0

25 kW

6SL3000-1BH31-3AA0

6SL3310-1GH31-8AA3

160 kW

6SL3300-1AH32-5AA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH32-6AA3

250 kW

6SL3300-1AH32-5AA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH33-3AA3

315 kW

6SL3300-1AH32-5AA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH34-1AA3

400 kW

6SL3300-1AH32-5BA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH34-7AA3

450 kW

6SL3300-1AH32-5BA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH35-8AA3

560 kW

6SL3300-1AH32-5BA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH37-4AA3

710 kW

6SL3300-1AH32-5BA0

50 kW

6SL3000-1BH32-5AA0

6SL3310-1GH38-1AA3

800 kW

6SL3300-1AH32-5BA0

50 kW

6SL3000-1BH32-5AA0

2.1 Braking Module

Table 2- 1 Assignment of Braking Module and Power Module

6SL3310-1GE32-1AA3 110 kW 6SL3300-1AE31-3AA0 25 kW 6SL3000-1BE31-3AA0

6SL3310-1GE33-1AA3 160 kW 6SL3300-1AE32-5AA0 50 kW 6SL3000-1BE32-5AA0

6SL3310-1GH32-2AA3 200 kW 6SL3300-1AH32-5AA0 50 kW 6SL3000-1BH32-5AA0

Braking Module / braking resistor

Operating Instructions, 11/2017, A5E00331454A

13

Loading...

Loading...