Page 1

SIMOVERT MASTERDRIVES

SLP – SIMOLINK Puls Generator

SLP – SIMOLINK Pulse Generator

Betriebsanleitung

Operating Instructions

Ausgabe / Edition: AA GWE-477 764 4070.76 J

Page 2

Änderungen von Funktionen, technischen Daten, Normen, Zeichnungen und Parametern vorbehalten.

We reserve the right to make changes to functions, technical data, standards, drawings and parameters.

Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und

Mitteilung ihres Inhalts ni cht gestattet, soweit ni cht ausdrücklich

zugestanden. Zuwiderhandlungen verpflichten zu Schadenersatz.

Alle Rechte vorbehalten, ins besondere für den Fall der

Patenterteilung oder GM-Eintragung.

Wir haben den Inhalt der Druckschrift auf Übereinstimmung mit der

beschriebenen Hard- und Software überprüft. Dennoch können

Abweichungen nicht ausgeschlos sen werden, so daß wir für die

vollständige Übereinstimmung keine Garantie übernehmen. Die

Angaben in dieser Druckschrift werden jedoch regelmäßig überprüft

und notwendige Korrekturen sind in den nachfolgenden A uflagen

enthalten. Für Verbesserungsvorschläge sind wir dankbar

The reproduction, transmi ssion or use of this document or its contents is not permi tted without express written authority. Off enders will

be liable for damages. Al l ri ghts, including rights c reated by patent

grant or registration of a utility m odel or design, are reserved.

We have checked t he contents of this document to ensure that they

coincide with the described hardware and soft ware. However,

differences cannot be completely excluded, so that we do not acc ept

any guarantee for complete conformance. However, the information

in this document is regularly checked and necessary c orrections will

be included in subsequent editi ons . We are grateful for any

recommendations for improvement.

Siemens AG 2001 All ri ghts reserved

SIMOVERT ist ein Warenzeichen von Siemens

SIMOVERT Registered Trade Mark

Page 3

SIMOLINK Puls Generator 02.2001 Contents

Contents

1 DEFINITIONS AND WARNINGS......................................................................1-1

2 PRODUCT DESCRIPTION...............................................................................2-1

2.1 Description of function.......................................................................................2-2

3 TECHNICAL DATA...........................................................................................3-1

4 INSTALLATION ................................................................................................4-1

4.1 EMC measures..................................................................................................4-1

4.2 Housing .............................................................................................................4-1

5 CONNECTIONS................................................................................................5-1

5.1 Connector X1.....................................................................................................5-1

5.2 Encoder interface X2.........................................................................................5-2

5.3 Fiber-optic cable connection .............................................................................5-5

6 START-UP ........................................................................................................6-1

6.1 Setting the DIL switch........................................................................................6-1

6.2 LED displays......................................................................................................6-2

6.3 SIMOLINK data interface ..................................................................................6-3

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 1

Page 4

Page 5

SIMOLINK Pulse Generator 02.2001 Definitions and Warnings

1 Definitions and Warnings

Qualified personnel

DANGER

WARNING

For the purpose of this documentation and the product warning labels,

a "Qualified person" is someone who is familiar with the installation,

mounting, start-up, operation and maintenance of the product. He or

she must have the following qualifications:

♦ Trained or authorized to energize, de-energize, ground and tag

circuits and equipment in accordance with established safety

procedures.

♦ Trained or authorized in the proper care and use of protective

equipment in accordance with established safety procedures.

♦ Trained in rendering first aid.

indicates an imminently hazardous situation which, if not avoided, will

result in death, serious injury and considerable damage to property.

indicates a potentially hazardous situation which, if not avoided, could

result in death, serious injury and considerable damage to property.

CAUTION

CAUTION

NOTICE

NOTE

used with the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in minor or moderate injury.

used without safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

NOTICE used without the safety alert symbol indicates a potential

situation which, if not avoided, may result in an undesirable result or

state.

For the purpose of this documentation, "Note" indicates important

information about the product or about the respective part of the

documentation which is essential to highlight.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 1-1

Page 6

Definitions and Warnings 02.2001 SIMOLINK Pulse Generator

WARNING

NOTE

Hazardous voltages are present in this electrical equipment dur ing

operation.

Non-observance of the warnings can thus result in severe personal

injury or property damage.

Only qualified personnel should work on or around the equipment

This personnel must be thoroughly familiar with all warning and

maintenance procedures contained in this documentation.

The successful and safe operation of this equipment is dependent on

correct transport, proper storage and ins ta l lat ion as well as caref ul

operation and maintenance.

This documentation does not purport to cover all details on all types of

the product, nor to provide for every possible contingency to be met in

connection with installation, operation or maintenance.

Should further information be des ired or should par t ic ular pr ob lems

arise which are not covered sufficiently for the purchaser’s purposes,

the matter should be referred to the local SIEMENS sales office.

The contents of this documentation shall not become part of or modify

any prior or existing agreement, commitment or relationship. The sales

contract contains the entire obligation of SIEMENS AG. The warranty

contained in the contract between the parties is the sole warranty of

SIEMENS AG. Any statements contained herein do not create new

warranties or modify the existing warranty.

GWE-477 764 4070.76 J Siemens AG

1-2 Operating Instructions SIMOVERT MASTERDRIVES

Page 7

SIMOLINK Pulse Generator 02.2001 Definitions and Warnings

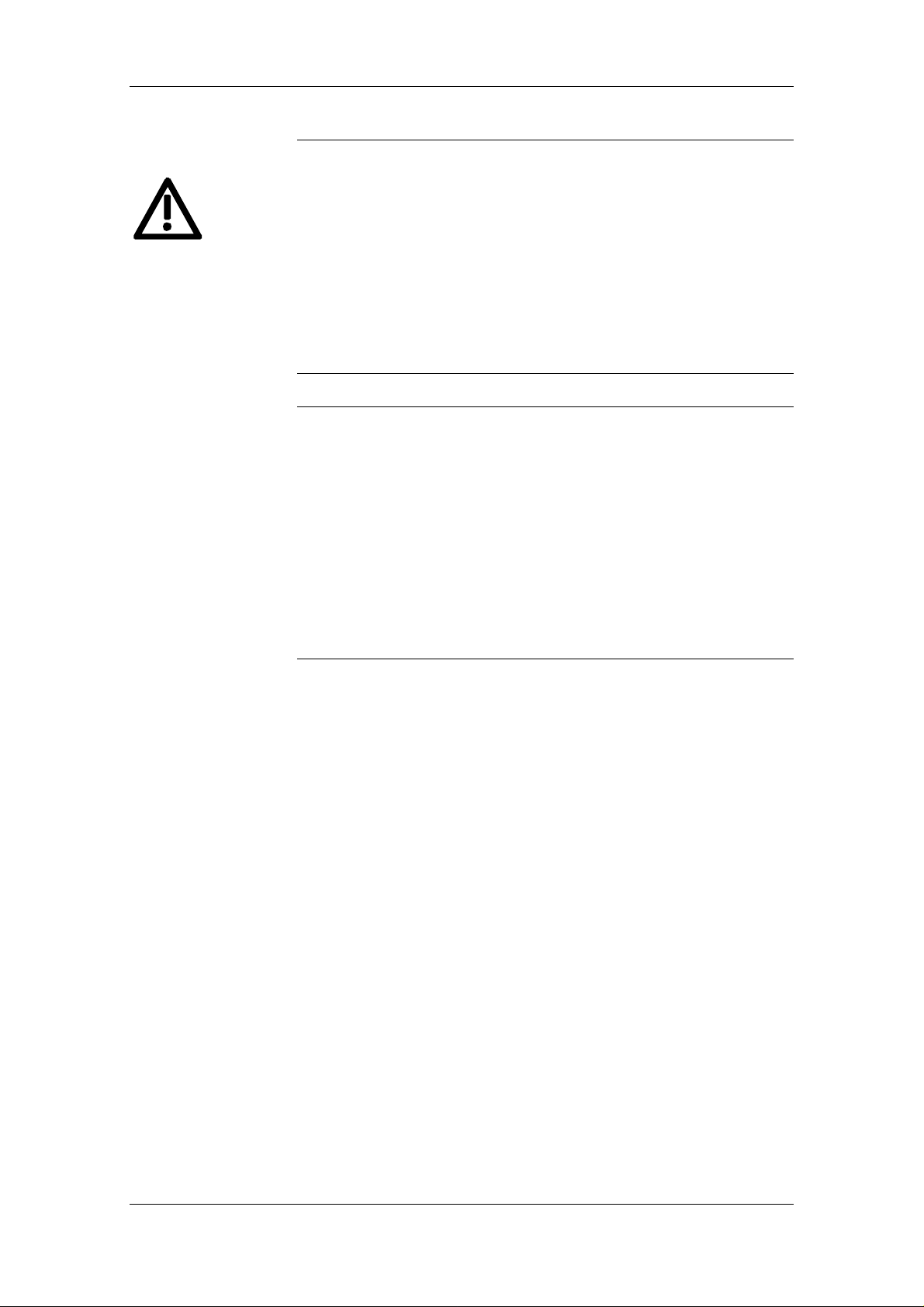

CAUTION

Components which can be destroyed by electrostatic discharge (ESD)

The board contains components which can be destroyed by

electrostatic discharge. These components can be easily destroyed if

not carefully handled. If you have to handle el ectr onic boards , pl eas e

observe the following:

Electronic boards should only be touched when absolutely necessary.

The human body must be electrically discharged before touching an

electronic board.

Boards must not come into contact with highly insulating materials - e.g.

plastic parts, insulated desktops, articles of clothing manufactured from

man-made fibers.

Boards must only be placed on conductive surfaces.

Boards and components should only be stored and transported in

conductive packaging (e.g. metalized plastic boxes or metal

containers).

If the packing material is not conductive, the boards must be wrapped

with a conductive packaging material, e.g. conductive foam rubber or

household aluminum foil.

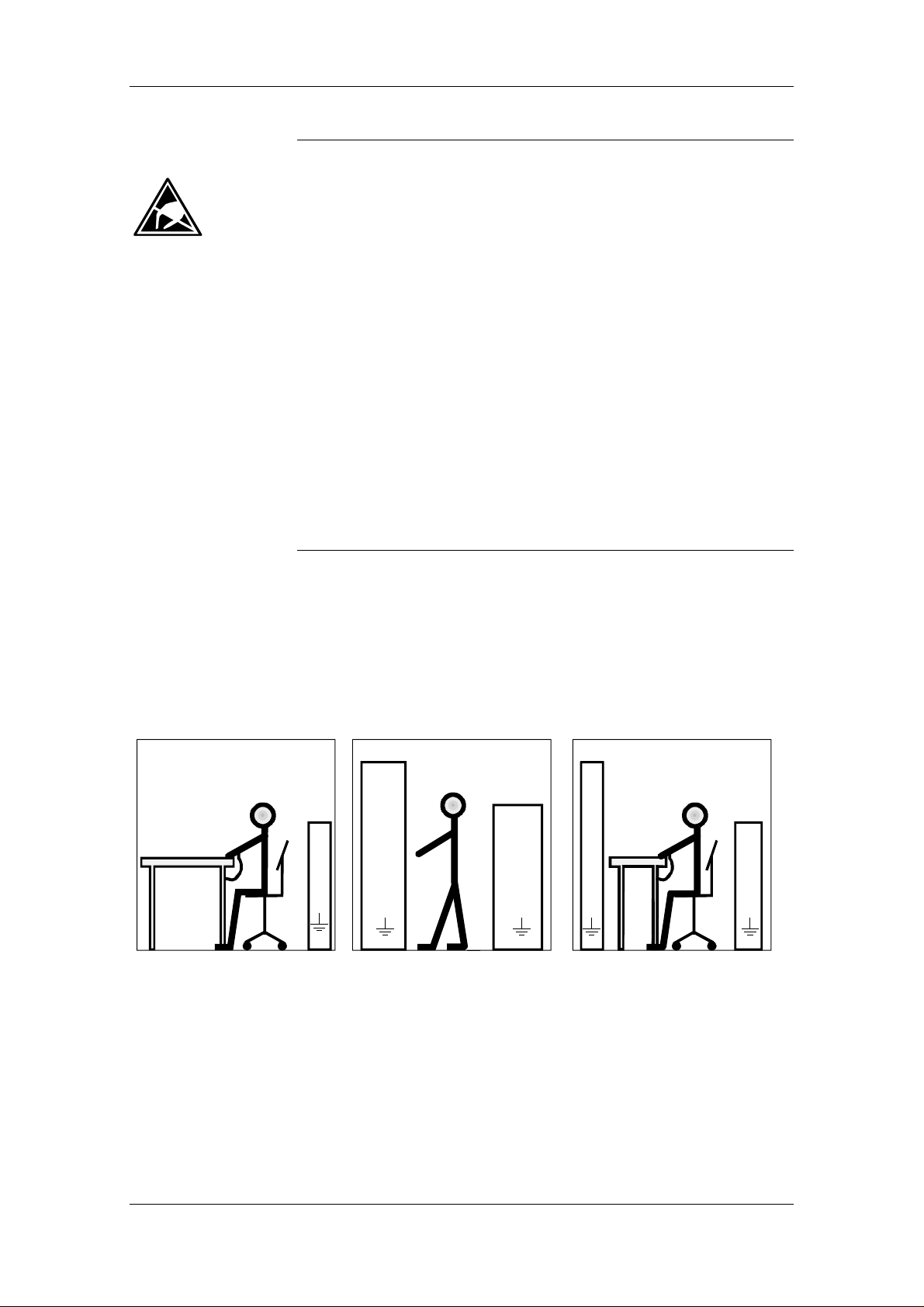

The necessary ESD protective measures are clearly shown again in the

following diagram :

♦ a = Conductive floor surface

♦ b = ESD table

♦ c = ESD shoes

♦ d = ESD overall

♦ e = ESD chain

♦ f = Cubicle ground connection

b

c

a

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 1-3

d

e

f

Fig. 1-1 ESD protective measures

f f f

d

f

c

StandingSitting Standi n g / Sitti ng

a

b

c

d

e

a

Page 8

Page 9

SIMOLINK Pulse Generator 02.2001 Product Description

2 Product Description

In drive configurations with an "electrical shaft", simple speedsynchronized auxiliary drives or other devices which require an actual

machine value proportional to velocity are frequently needed in addition

to the main position-controlled drives. These auxiliary drives and

devices have a pulse encoder input and read in the data supplied by a

pulse encoder mounted centrally on the line shaft. On drives with an

electrical shaft and flexible configuration, this central point is often

impossible to physically define. The SIMOLINK Pulse Generator (SLP)

thus simulates an encoder on the electrical shaft and supplies a central

actual machine value (machine velocity) which is generated from the

master setpoint. The electrical shaft with the position-controlled main

drives is implemented by means of SIMOLINK and MASTERDRIVES

Motion Control drives.

The SIMOLINK Pulse Generator uses a speed setpoint transported via

SIMOLINK to generate two pulse signals in quadrature of proportional

frequency (100 % = 25 kHz). These are supplied to further devices via

the RS422 (EIA422 standard). The frequency output corresponds to

that of a pulse encoder with 1000 pulses/rev and a speed normalization

of 100 % = 1500 rev/min.

A "100 kHz operating mode" can be activated optionally. Instead of the

signals in quadrature, one signal supplies the quadruple frequency

proportional to the setpoint (100 % = 100 kHz) and the other signal

supplies the sign.

The SIMOLINK transmission medium is a fiber-optic cable. Fiber optics

made of glass or plastic may be used. SIMOLINK has a ring-shaped

structure, with each node in the ring acting as a signal amplifier. A

maximum of 201 active nodes can be interconnected on the SIMOLINK

ring.

NOTE

For further information about SIMOLINK, please refer to Chapter

"Communication / SIMOLINK“ of the SIMOVERT MASTERDRIVES

Compendium Motion Control, Order No.: 6SE7087-6QX50.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 2-1

Page 10

Product Description 02.2001 SIMOLINK Pulse Generator

2.1 Description of function

The incoming optical signals from the fiber-optic cable are converted to

electrical signals by means of fiber optic receivers on all SIMOLINK

modules and then transferred to the fiber-optic transmitter where they

are converted back to optical signals. The propagation delays caused

by this process are calculated while SIMOLINK is booting and the dead

times compensated accordingly for active SIMOLINK nodes. The

receive information is derived, depending on parameterization, from the

buffered, electrical signals and transferred with the SYNC interrupt (last

telegram in SIMOLINK polling). The transmit information of the node is

transferred in the opposite direction and written to the associated

telegrams (electrical signals).

The SIMOLINK Pulse Generator is incorporated in the SIMOLINK ring

like a SIMOLINK slave; it is an active node and included in the deadtime calculation. However, it does not have its own node address and

cannot therefore write transmit telegrams to the SIMOLINK (SLP does

not supply a return value).

The SIMOLINK receive address (0 ... 200; dispatcher mode: Address of

node which is sending the speed setpoint) is set via the DIL switches

on the front panel. The momentary speed setpoint is read in the

MASTERDRIVES 32-bit format (4000 0000 hex = 100 %) from channel

0. Only the 10 highest bits are resolved with a maximum output of

112 %, resulting in a speed resolution of 0.4 %. The speed setpoint

must be updated (new setpoint or identical value if velocity is constant)

in every SIMOLINK cycle by the transmitting node.

The speed setpoint is transferred to the frequency generator with the

SYNC interrupt which then generates the equivalent frequency with the

correct phase sequence of the two output signals (tracks A and B). An

output frequency of 25 kHz corresponds to a speed setpoint of 100 %.

Alternatively, a jumper can be inserted in the mating connector of X2 to

activate the "100 kHz signal" operating mode. The frequency generator

can then output signals from 0 to 100 kHz. In this mode, the frequency

signal is output via track A and the sign (direction of rotation) via track

B. The sign is a static 0 (positive) or 1 (negative) signal.

The RS422 interface forms the desired signal levels which can be

picked off on SUB D socket X2.

The operating states are indicated by the three LEDs on the housing

front panel.

GWE-477 764 4070.76 J Siemens AG

2-2 Operating Instructions SIMOVERT MASTERDRIVES

Page 11

SIMOLINK Pulse Generator 02.2001 Technical Data

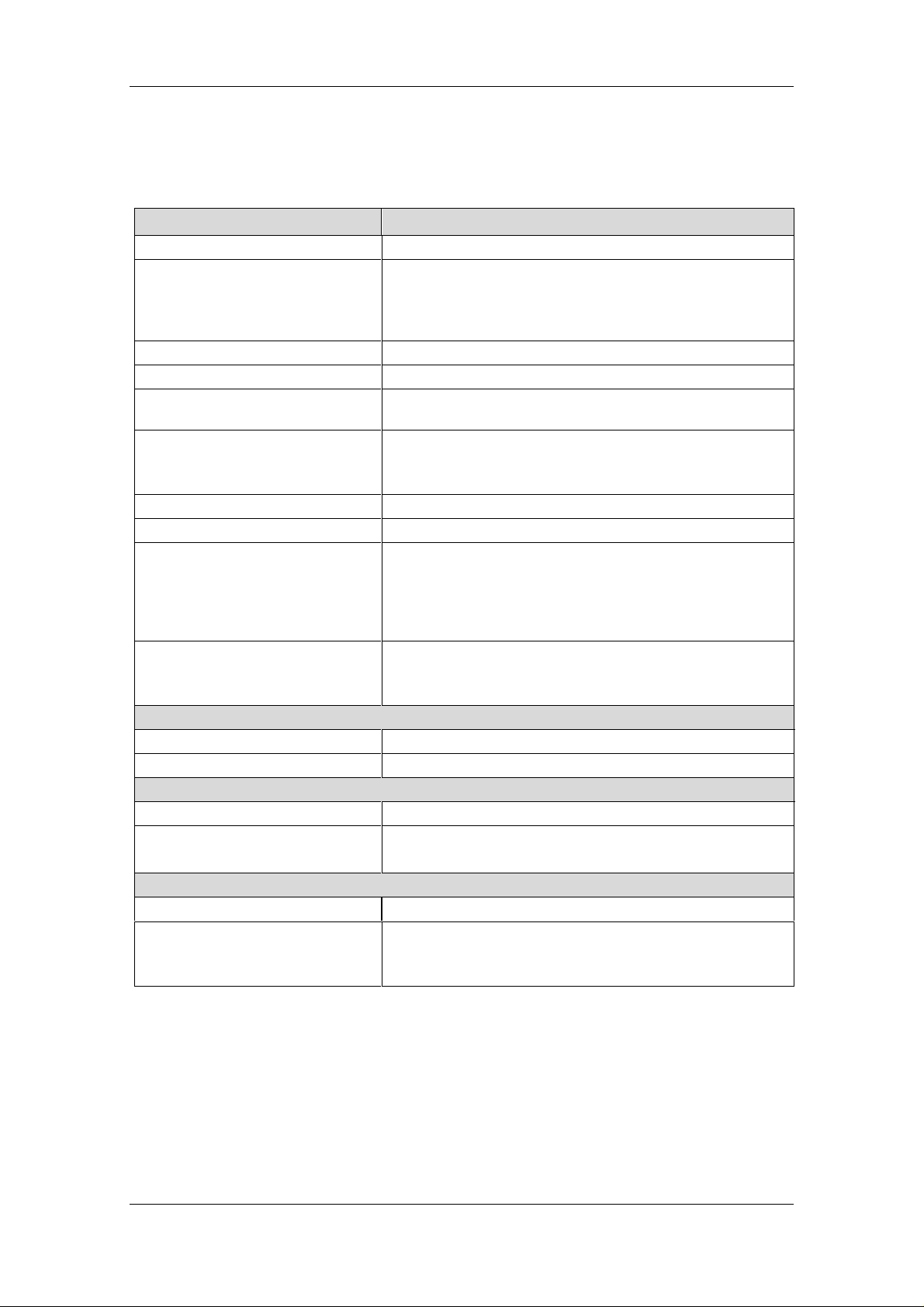

3 Technical Data

Product name SLP

Order number 6SX7005-0AD00

Size [mm]:

– Width

– Height

– Depth

Weight Approx. 280 g

Degree of protection IP20 to EN 60529

Degree of pollution

Mechanical strength:

– In steady-state operation

– During transportation

Climate class Class 3K3 to DIN IEC 721-3-3 (in operation)

Cooling method (operation) Convection

Permissible ambient or

coolant temperature:

– In operation

– In storage

– During transportation

Permissible humidity rating:

– Transport/storage

– In operation

Power supply

Rated supply voltage DC +24 V (+20.4 V to +28.8 V)

Power consumption Approx. 140 mA

Encoder interface

Tracks A and B RS422 to EIA422 standard

Supply voltage:

– Electrical isolation

Fiber-optic cable connection

Transmitter power Fixed (maximum transmitter power defined for SIMOLINK)

Fiber-optic cable modules

– Transmitter

– Receiver

Device dimensions (housing)

35 (35)

118 (107)

88 (80)

Not applicable

Moisture condensation is not permissib le in operat ion

Not applicable

0 °C to +55 °C

–25 °C to +70 °C

–25 °C to +70 °C

Relative air humidity

≤ 95 %

≤ 85 % (condensation not permitted)

Internal

Isolating voltage 500 V DC to 24 V voltage supply

Hewlett Packard

HFBR 1528

HFBR 2528

Table 3-1 Technical data

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 3-1

Page 12

Page 13

SIMOLINK Pulse Generator 02.2001 Installation

4 Installation

The SIMOLINK Pulse Generator module is snapped onto an EN 50022compliant TS 35 top-hat rail. The requisite mechanical mounting

elements are fitted in the housing.

4.1 EMC measures

The module is connected to ground via the top-hat rail. The ground

connection between the rail and the equipotential bonding conductor

must be made by the end-user during installation.

NOTE

For further information, please refer to Chapter "Instructions for Design

of Drives in Conformance with EMC Regulations" of the SIMOVERT

MASTERDRIVES Compendium Motion Control, Order No.:

6SE7087-6QX50.

4.2 Housing

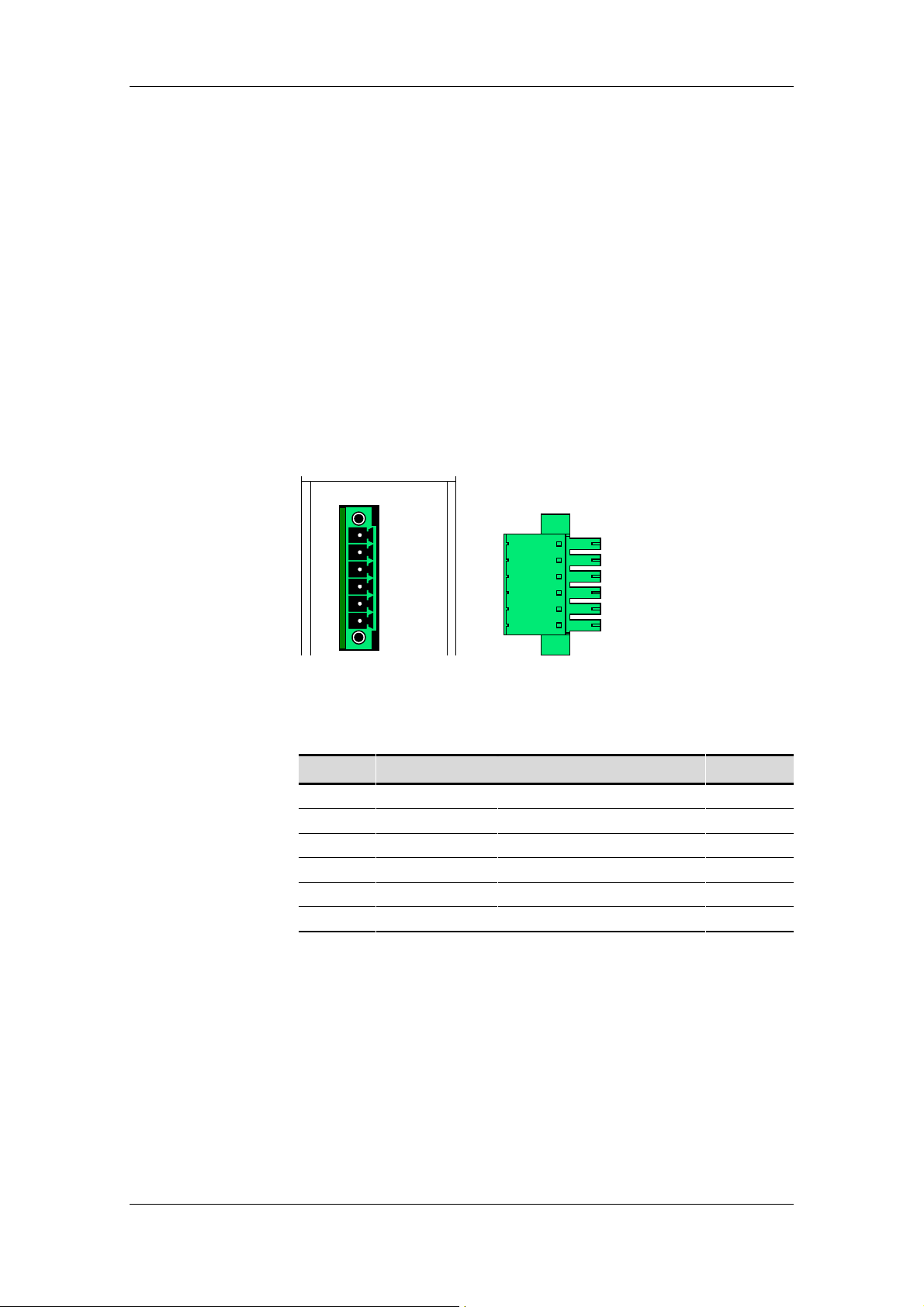

The following diagrams show a schematic illustration of the housing

and the layout of connections and operating elements.

POWER

SIMOLINK

PULS GENERATOR SLP

SYNC

0

2

KANAL

7

2

FREQ

ON

X2

Front view Side view

Fig. 4-1

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 4-1

Page 14

Installation 02.2001 SIMOLINK Pulse Generator

RX

RX

TX

TX

M

+24 V

X1

View from below Plan view

Fig. 4-2

GWE-477 764 4070.76 J Siemens AG

4-2 Operating Instructions SIMOVERT MASTERDRIVES

Page 15

SIMOLINK Pulse Generator 02.2001 Connections

5 Connections

The SIMOLINK Pulse Generator module has the following connectors

♦ X1 for power supply,

♦ X2 for signal output and

♦ a SIMOLINK fiber-optic cable connection with one transmit socket

and one receive socket.

5.1 Connector X1

The 6-pin connector is on top of the housing. The 24 V power supply to

the SIMOLINK Pulse Generator is connected via X1.

M

+24 V

ConnectorSocket X1

Fig. 5-1

Terminal Designation Meaning Range

1 - Unused

2 - Unused

3 - Unused

4 - Unused

5 M Ground

6 +24V 24 V power supply +21 ... 28 V

Connectable cross-section: 1.5 mm2 (AWG 16)

Terminal 1 is the terminal to the rear of the module top plate (see plan view).

Table 5-1 Connector assignments

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 5-1

Page 16

Connections 02.2001 SIMOLINK Pulse Generator

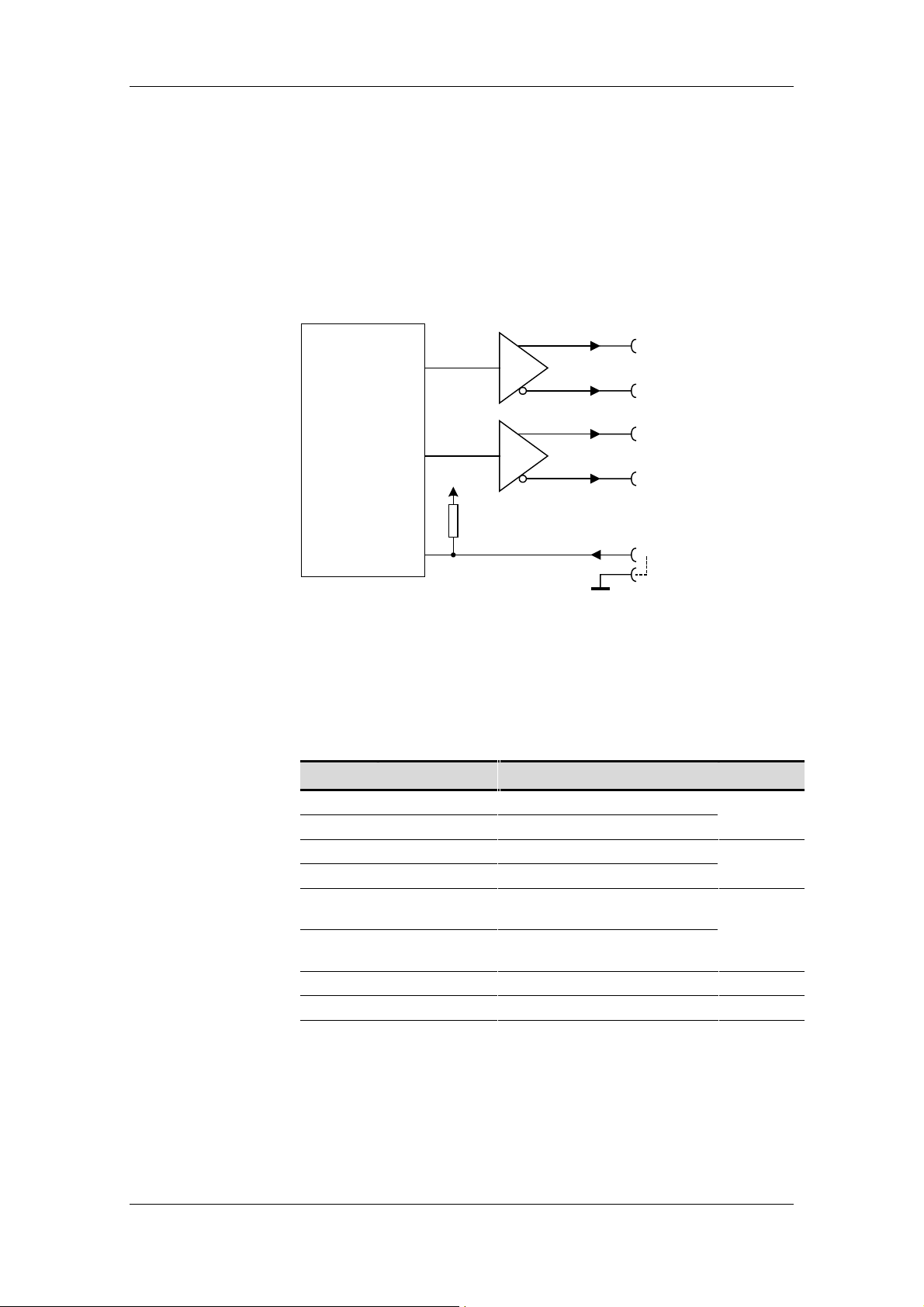

5.2 Encoder interface X2

The encoder interface of the SIMOLINK Pulse Generator is the 9-pin,

SUB D socket with screw locking mechanism (UNC) on the front of the

housing. Two RS422 drivers each supply two signals per pulse output,

one signal with non-inverted signal level and one signal with inverted

signal level. The driver voltage supply circuit is isolated from the 24 V

supply for the module.

2

A+

7

A

−

4

Frequency

generator

P5

B+

9

B

−

1

SEL_100 kHz

3,8

GND

Fig. 5-2 Schematic of output circuit (connector X2)

The two operating modes "90° pulses" and "100 kHz signal" are

selected via a jumper in the encoder connector. The 90° pulses setting

is the default and is activated when pin 1 in the encoder interface is

unused.

Pin Signal Meaning for 90° pulses Range

2 A+ Track A not inverted RS422

7 A– Track A inverted standard

4 B+ Track B not inverted RS422

9 B– Track B inverted standard

1 SEL_100 kHz Do not assign,

selection of 100-kHz signal

3, 8 GND Ground (see below) jumper to

5, 6 n.c. Unused

Housing Outer shield

Do not

insert

GND!

9-pin SUB D socket with screw locking mechanism (UNC)

Table 5-2 Assignment of connector X2 for 90° pulses mode

GWE-477 764 4070.76 J Siemens AG

5-2 Operating Instructions SIMOVERT MASTERDRIVES

Page 17

SIMOLINK Pulse Generator 02.2001 Connections

The SIMOLINK Pulse Generator can be switched over to the other

mode "100 kHz signal“ through insertion of a jumper between

connector pin "SEL_100kHz" and GND.

Pin Designation Meaning for 100 kHz signal Range

2 A+ Track A 100 kHz not inverted RS422

7 A– Track A 100 kHz inverted standard

4 B+ Sign not inverted RS422

9 B– Sign inverted standard

1 SEL_100 kHz Selection of 100 kHz signal Insert

3, 8 GND Ground (see below)

5, 6 n.c. Unused

Housing Outer shield

jumper to

GND!

9-pin SUB D socket with screw locking mechanism (UNC)

Table 5-3 Assignment of connector X2 for 100 kHz signal mode

NOTICE

CAUTION

To maintain immunity to interference, a shielded cable must be used

and the shield attached in the connector housing.

One or several drives/devices can be connected to the SLP module.

When the SLP is operated in conjunction with one drive/device, the

GND signal should be connected in the cable. If several drives/devices

are connected to the SLP, the GND signal should not be connected; it

must be noted in this respect that large deviations in the 0 V (GND) on

different drives/devices can cause disturbances or malfunctions on the

RS422 bus.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 5-3

Page 18

Connections 02.2001 SIMOLINK Pulse Generator

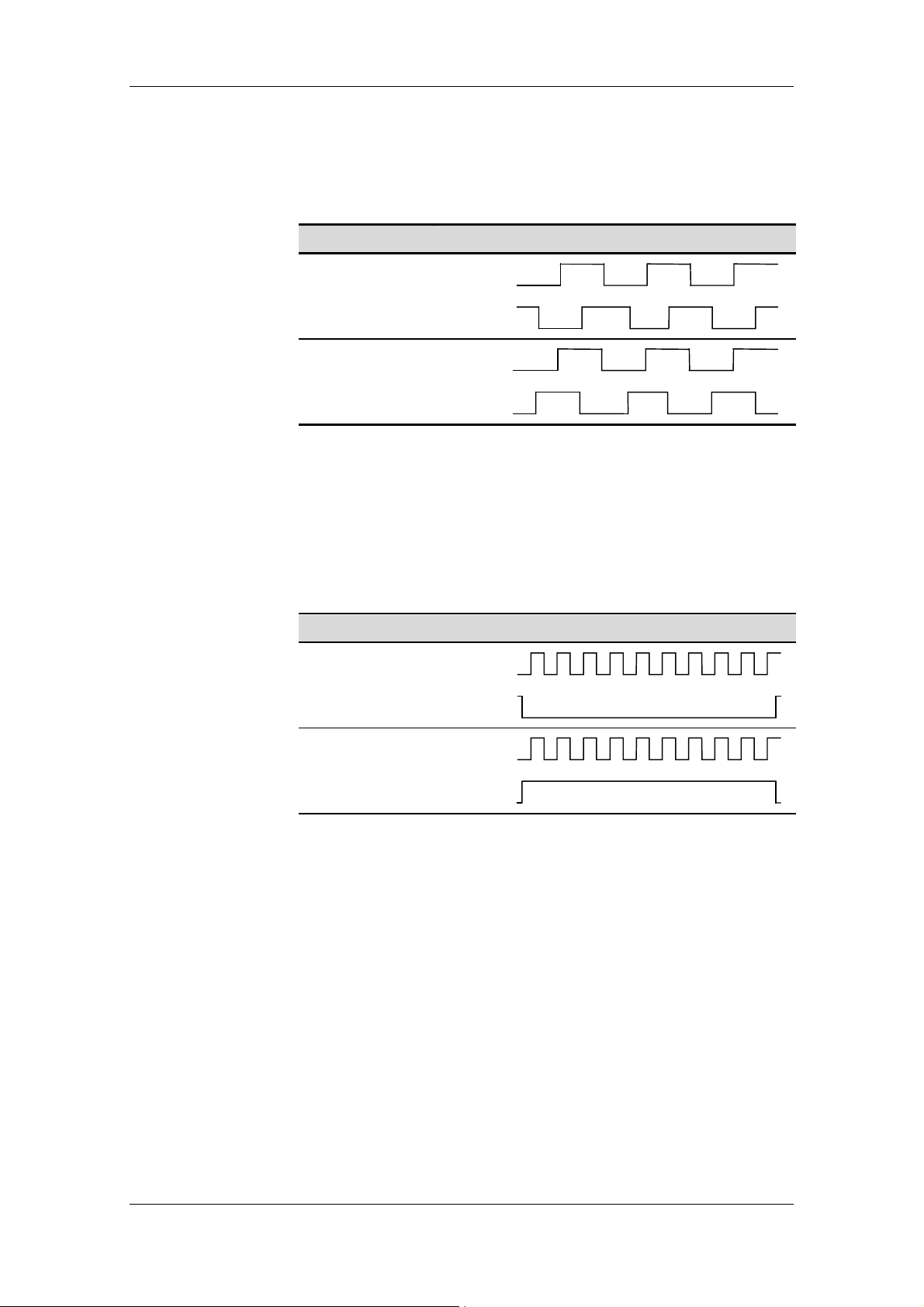

Signal output

90°pulses

Signal output

100 kHz signal

The SIMOLINK Pulse Generator produces two signals with a phase

displacement of ± 90°. The pulse-pause ratio for each of these signals

is 1:1.

Setpoint input Signal shape at output

Track A

Positive setpoint

Track B

Track A

Negative setpoint

Track B

Fig. 5-3 Signal shape in 90° pulses mode

In the "100 kHz signal“ mode, track A outputs 4 times the frequency,

i.e. 100 kHz correspond to 100%. Track B supplies the sign according

to the following rule: The signal is low for positive setpoints and high for

negative setpoints.

Setpoint input Signal shape at output

Positive setpoint

Track A

Track B

Track A

Negative setpoint

Track B

Fig. 5-4 Signal shape in 100 kHz signal mode

GWE-477 764 4070.76 J Siemens AG

5-4 Operating Instructions SIMOVERT MASTERDRIVES

Page 19

SIMOLINK Pulse Generator 02.2001 Connections

5.3 Fiber-optic cable connection

The fiber-optic cables are connected via plug-and-socket connectors.

The transmit and receive sockets are on the bottom of the housing (Fig.

4-2). The output power of the fiber-optic transmitter is not variable, but

permanently set to the maximum transmitter power defined for

SIMOLINK.

SIMOLINK is a clocked, ring-shaped

fiber-optic bus system. To allow the

flow of signal traffic, the transmit

socket of the first node must be

connected to the receive socket of

the next node and so on, until the

transmit socket of the last node is

connected to the receive socket of

the first node.

The receive socket is dark grey and

labeled RX. The transmit socket is

light gray and labeled TX.

The following Hewlett Packard fiberoptic modules are installed in the

SIMOLINK Pulse Generator :

♦ Transmitter: HFBR 1528

♦ Receiver: HFBR 2528

Fig. 5-5 Bus connector

RX

TX

Fig. 5-6 Fiber-opt i c

connector

NOTE

NOTICE

Plastic or glass fiber-optic cables can be used. Depending on the type

of cable selected, the inter-node distances are as follows:

♦ Max. 40 m between each node in the case of plastic cables or

♦ Max. 300 m between each node in the case of glass cables.

The maximum permissible ring bus length is 1000 m.

A components package for assembling plastic fiber-optic cable

connections can be ordered under number 6SX7010-0FJ50. This

contains: 100 m plastic fiber-optic cable, 40 fiber-optic connectors, 20

connectors for terminal strip X470 SLB.

If glass fiber optics are the selected medium, the connectors attached

to the fiber-optic cable must be suitable, i.e. they must fit into the

transmit and receive sockets on the SIMOLINK Pulse Generator.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 5-5

Page 20

Connections 02.2001 SIMOLINK Pulse Generator

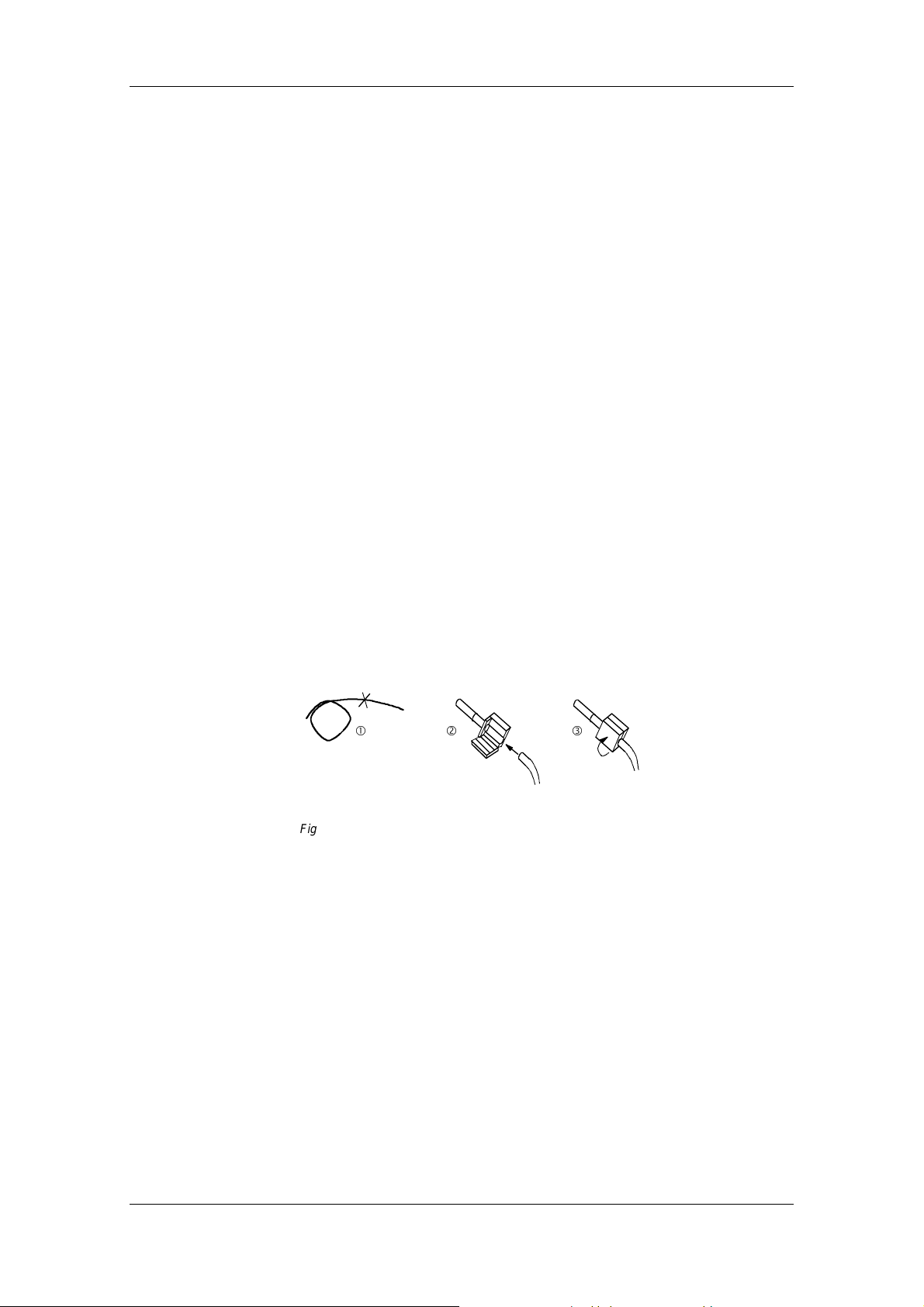

How to assemble a

bus cable

To make connections on a plastic fiber-optic cable, please follow the

instructions below:

1. Cut the correct length of fiber-optic cable. Make sure you cut the

cable at right angles, use a sharp knife. (Fig. 5-7 )

2. Remove approximately 7 mm of the outer, black sheath on the cable

using a suitable cable stripping device. Take great care not to

damage the fiber optic when removing the sheath!

3. Insert the fiber-optic cable into the connector (Fig. 5-7 ó) and push

it into the cylindrical sleeve as far as it will go. The transparent fiber

optic will protrude out of the other side of the sleeve.

4. Fold round the gripping half of the connector and close it by hand

(Fig. 5-7 ì). Once the top half of the connector is latched into the

lower half, the cable is lodged securely in the connector.

5. Use a sharp knife to cut the protruding end of the cable almost flush

with the connector surface. Cut at right angles to the fiber-optic

cable axis.

6. You now need to polish the surface of the fiber optic. To do this,

place the end of the sleeve flat on the surface of the matt, rough

side of the green polishing paper supplied, and "draw" a figure of 8.

Then clean the end with a clean, lint-free cloth.

7. The sleeve end can be polished finely to reduce throughput losses

to a minimum. Fine polishing reduces throughput losses by

approximately 2 dB. To fine polish the sleeve, place it vertically on

the matt, rough side of the pink polishing paper and "draw" a figure

of 8 about 25 times. Then clean the end again with a clean, lint-free

cloth.

Cut fiber-optic

cable to length

Fig. 5-7 Connecting a plastic cable

Insert cable i n

connector

ìó

Close

connector

GWE-477 764 4070.76 J Siemens AG

5-6 Operating Instructions SIMOVERT MASTERDRIVES

Page 21

SIMOLINK Pulse Generator 02.2001 Start-Up

6 Start-Up

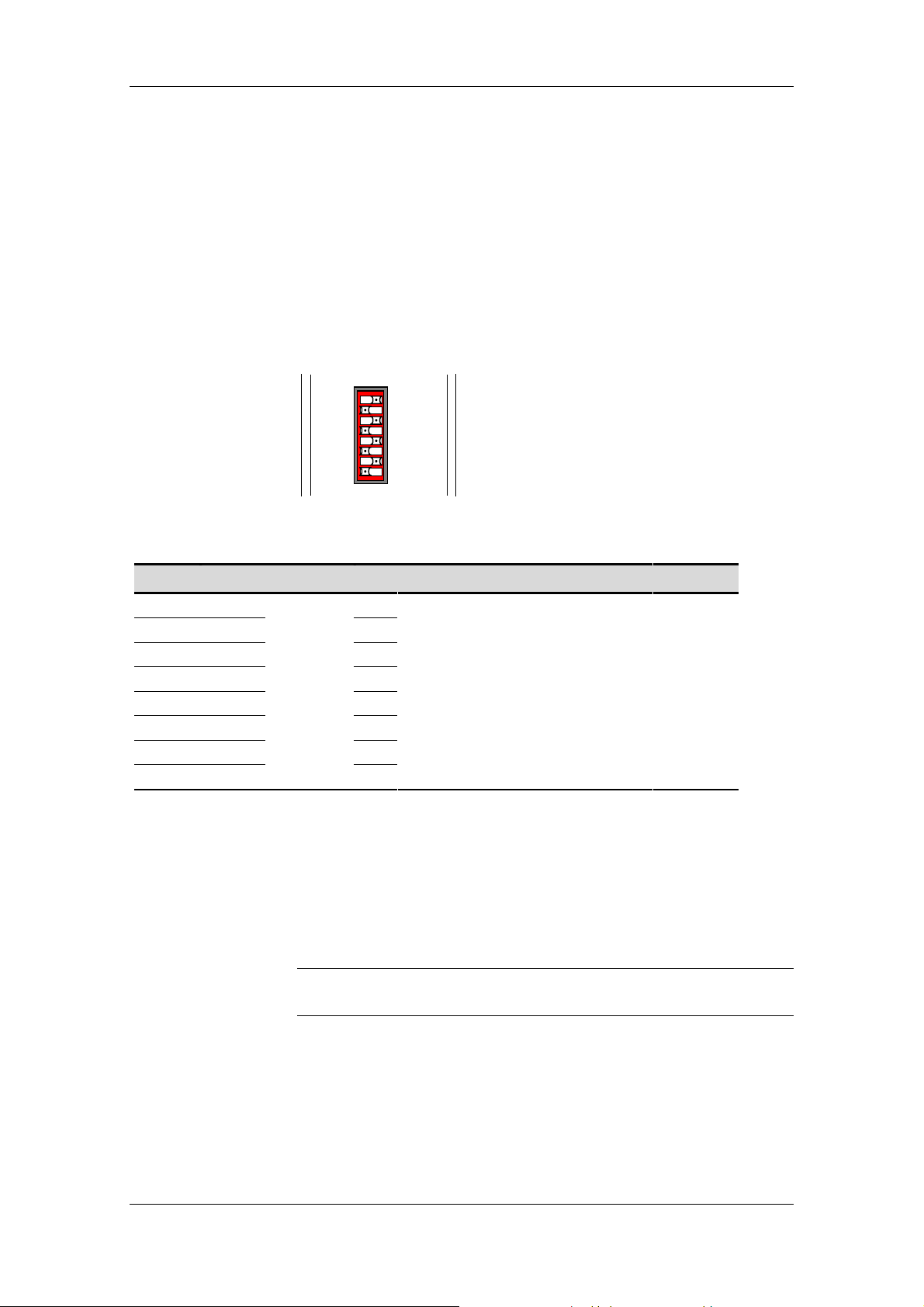

6.1 Setting the DIL switch

The SIMOLINK receive address (in dispatcher mode, address of the

node transmitting the speed setpoint to the SLP) for the SIMOLINK

Pulse Generator is set by means of an 8-channel DIL switch on the

front of the housing. The receive channel cannot be set; its default

setting is 0.

0

2

CHANNEL

7

2

Fig. 6-1 DIL switch for read address (address =75)

ON

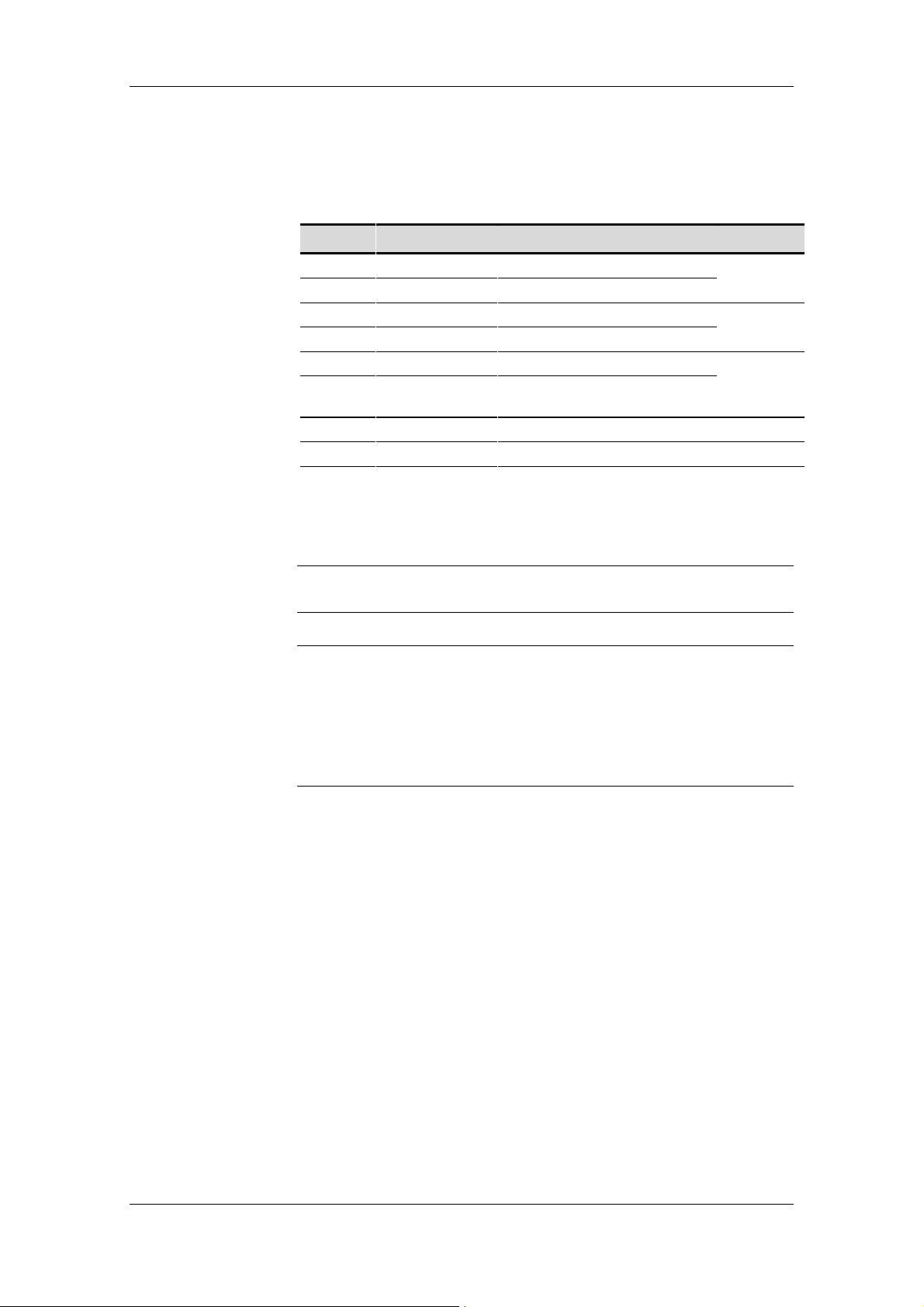

Switch Designation Meaning Range

.1 2

0

= 1

.2 (21)= 2

.3 (22)= 4

Channel

.4 (23)= 8

.5 (24)= 16

.6 (25)= 32

SIMOLINK receive address

Note:

Switch 1 is the least significant bit.

Switch position on right means "1“ or

"ON“.

0…200

.7 (26)= 64

.8 2

7

Channel 1 of the DIL switch is at the top of the housing front panel in the assembled

state.

=128

Table 6-1 Value assignments for DIL switch

When set via the DIL switches, the receive address is directly

transferred and the setpoint contained in the receive telegram is

available as an output frequency at the encoder interface.

NOTICE

Address settings 201 to 255 are invalid, LEDs "SYNC“ and "FREQ“

flash alternately and no frequency is output.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 6-1

Page 22

Start-Up 02.2001 SIMOLINK Pulse Generator

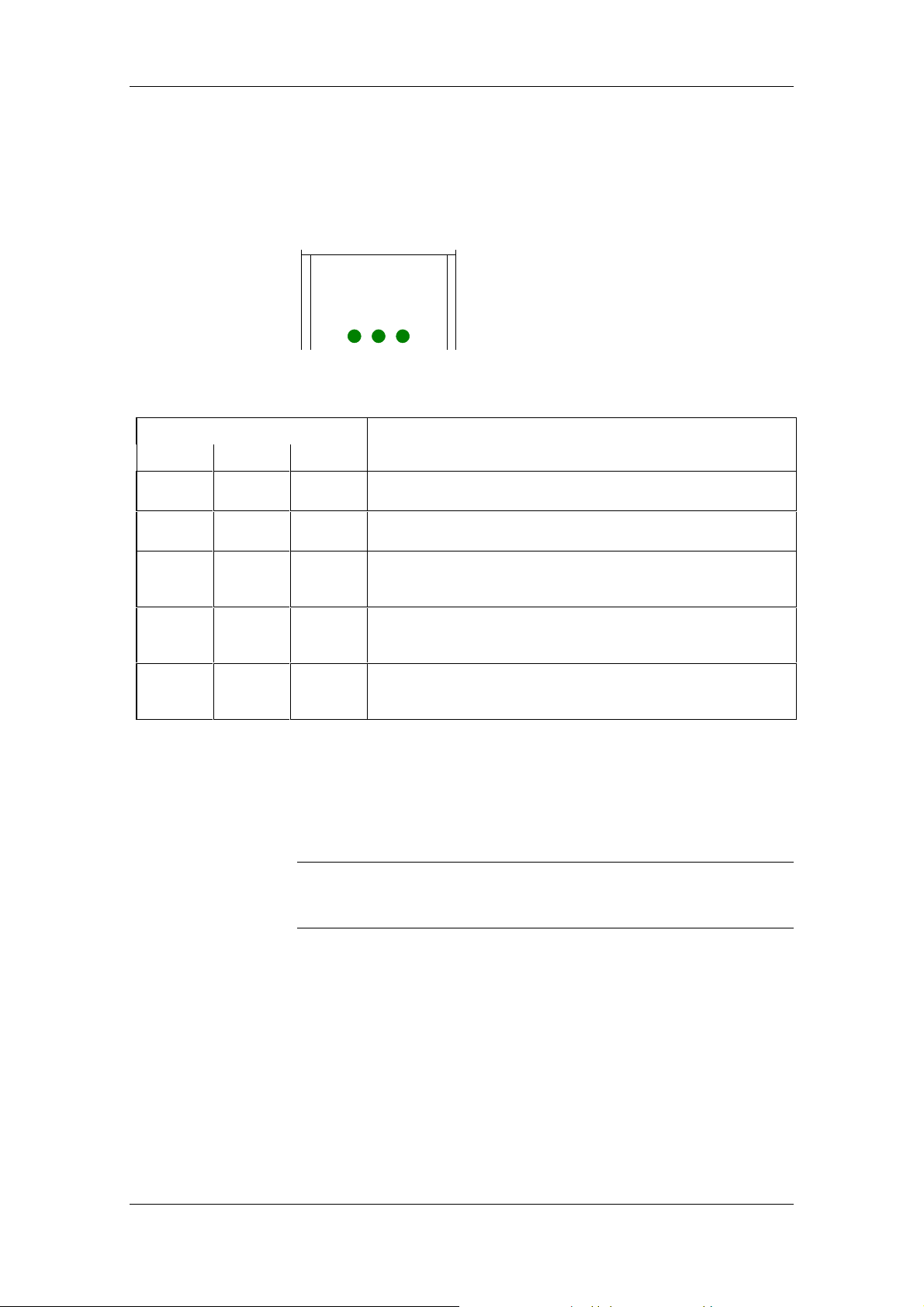

6.2 LED displays

The status of the SIMOLINK Pulse Generator is displayed on three

green LEDs on the housing front panel.

SIMOLINK

PULS GENERATOR SLP

POWER

Fig. 6-2 SLP display

LED Description

POWER SYNC FREQ

l

l

ll

lll

SYNC

FREQ

Device not connected to supply voltage

No + 24 V supply voltage available

Supply voltage connected:

SYNC interrupt is not being received

DIL switch is incorrectly set

SIMOLINK receive address higher than >200 set (alternate flashing

of SYNC and FREQ LEDs)

SYNC interrupt is being received:

Setpoint = 0 % or 0 Hz output frequency or

setpoint telegram is not being receiv ed

FREQ LED flashes at the output frequency:

Setpoint telegram is being received and setpoint not equal to 0 %

(flashing is perceptible at very low setpoints only)

LED off

l LED illuminated continuously

LED flashing (approximately twice per second)

Table 6-2 SLP operating states

NOTICE

An illuminated POWER LED does not necessarily confirm that the

supply voltage level is correct. The operator is responsible for ensuring

that the voltage supply remains stable within the specified limits.

GWE-477 764 4070.76 J Siemens AG

6-2 Operating Instructions SIMOVERT MASTERDRIVES

Page 23

SIMOLINK Pulse Generator 02.2001 Start-Up

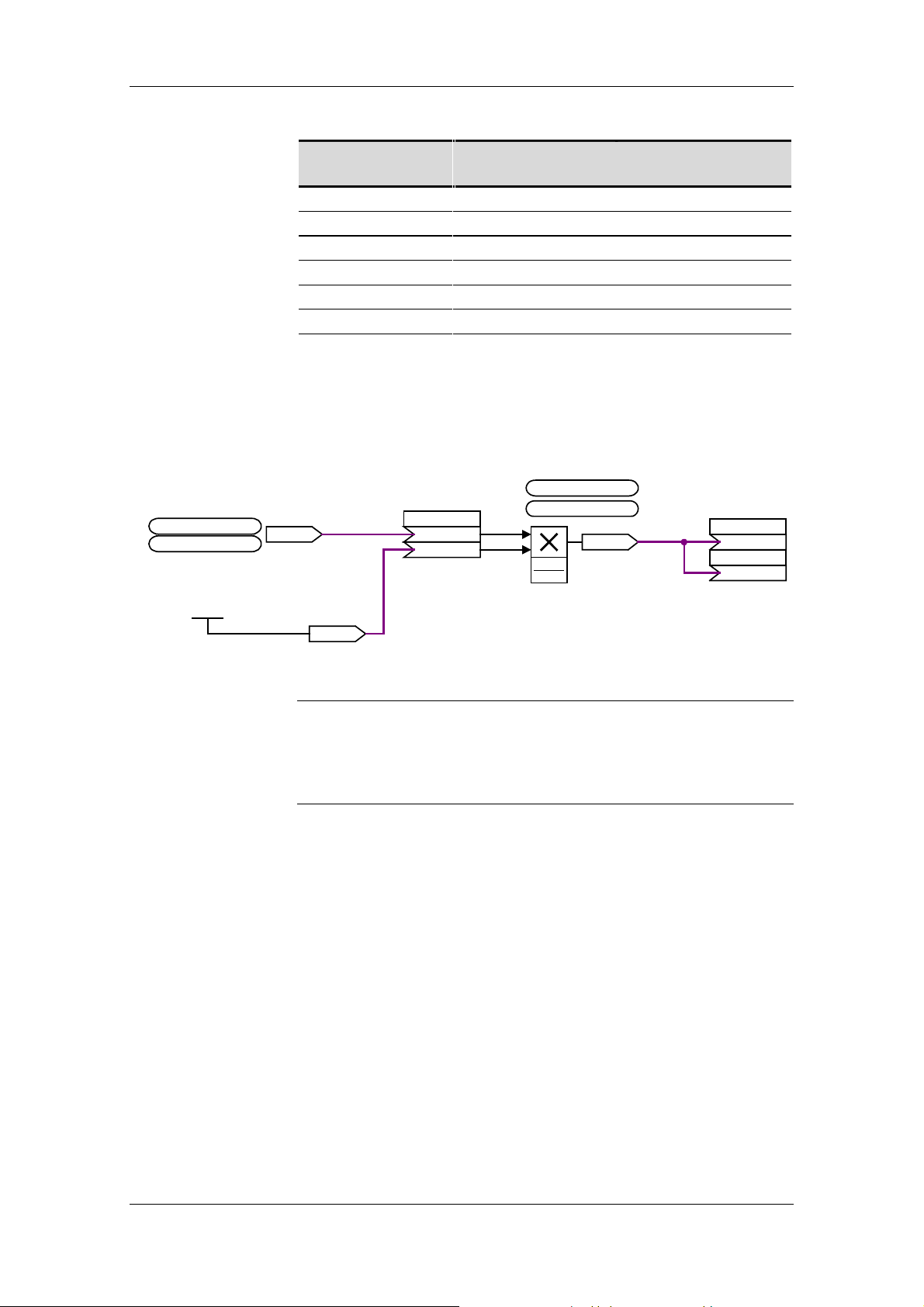

6.3 SIMOLINK data interface

The SIMOLINK data interface comprises a single-channel SIMOLINK

receive data word; it does not provide a transmit channel. It expects the

speed setpoint for the frequency generator in receive channel 0 of the

set receive address. The setpoint is read in the MASTERDRIVES 32-bit

format (4000 0000 hex = 100 %); only the 10 highest bits are resolved,

corresponding to a speed resolution of 0.4 %.

32-bit setpoint from SIMOLINK receive telegram

31 22 16 15 0

Evaluated by the SLP Irrelevant

Fig. 6-3 SLP setpoint telegram

The frequency generator has a frequency range of 0 Hz to 112 kHz (at

a rated frequency of 100 kHz). In the 90° pulses mode (4 edges

required for correct signal sequence from tracks A and B), the resulting

rated output frequency per track is 25 kHz and a maximum possible

setpoint output of approximately 112 %.

32-bit setpoint

(hex)

47C0 0000 + 112.1 28.027 112.1 kHz / Low

4780 0000 + 111.7 27.930 111.7 kHz / Low

4000 0000 + 100.0 25.000 100.0 kHz / Low

0000 0000 0.0 0.000 0.0 kHz / Low

C000 0000 − 100.0 25.000 100.0 kHz / High

B880 0000 − 111.7 27.930 111.7 kHz / High

B840 0000 − 112.1 28.027 112.1 kHz / High

NOTICE

Setpoint

[%]

Table 6-3 Relationship between setpoint and output frequency

Output frequency in

90°pulses mode [kHz]

Frequency in

100 kHz / sign mode

When the setpoint exceeds 112 %, the SIMOLINK Pulse Generator

outputs the maximum frequency of approximately 28 kHz. If "100 kHz

signal“ mode is active, then approximately 112 kHz.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 6-3

Page 24

Start-Up 02.2001 SIMOLINK Pulse Generator

Response to errored

SIMOLINK telegrams

Setpoint adjustment

to the machine

velocity

The SIMOLINK Pulse Generator updates the setpoint output in

response to every SYNC interrupt with which error-free data are

received. If a communications error occurs, the generator continues to

operate on the old setpoint. If CRC errors occur 8 times in succession,

it sets the frequency generator directly to 0 Hz and does not restart it

until an error-free setpoint is received. It switches to 0 Hz immediately if

communication on the SIMOLIN K is abort ed.

The frequency output of the SIMOLINK pulse generator in the 90°

pulses mode is identical to that of a pulse generator with 1000

pulses/rev and a speed normalization of 1 00 % = 1500 rev/min. If the

generator is to simulate shaft encoders with other pulse numbers per

revolution or different speed normalization, the setpoint to the SLP must

be renormalized. This can be done, for example, by multiplying the

machine setpoint. In this regard, it is important to note that the

maximum setpoint for the SLP on the SIMOLINK data interface must

not exceed 112 % (max. output frequency of approximately 28 kHz in

90° pulse mode).

Multiplier

=

×

×

frequency Output60

pulses/rev Encoder speed Reference

% 100x

Output frequency depending on operating mode:

♦ 25000 In 90° pulse mode

♦ 100000 In 100 kHz signal mode

Reference speed

[rev/min]

500 1000 33.333

1000 1000 66.667

1000 2000 133.333

1500 1000 100.000

1500 1024 102.400

1500 2048 Not displayable

1)

The speed range of the SLP cannot be output with this combination

Table 6-4 Examples for 90° pulses mode

No. of encoder

pulses per rev.

Multiplier

[%]

1)

GWE-477 764 4070.76 J Siemens AG

6-4 Operating Instructions SIMOVERT MASTERDRIVES

Page 25

SIMOLINK Pulse Generator 02.2001 Start-Up

a

Parameterization

example

Speed setpoint for

virtual master axis from

ramp-func t ion generator

U961.51 =

U951.51 = 04 (20)

Calcu lated m ultiplier in %

U014.F (0.000 %)

X

Reference speed

[rev/min]

No. of encoder

pulses per rev.

500 1024 8.53

1000 2000 66.66

1500 2048 51.200

2000 5000 166.667

2500 2000 83.333

3000 2000 100.000

1)

The speed range of the SLP cannot be output with this combination

Table 6-5 Examples for 100 kHz signal mode

KK0571

KK0414

U110 (0)

K 571

K 414

.01

.02

U961.31 =

U951.31 = 04 (20)

x1

x2

x1x2

100 %

X+n

y

KK0470

⋅

Multiplier

[%]

1)

SLB transmit dat

P751.1

P751.2

(0)

KK470

(0)

KK470

NOTICE

Fig. 6-4 Example of setpoint normalization parameter settings

The processing time slot and sequence must be taken into account in

the parameter settings. If a time slot other than the time slot for setpoint

calculation is used or the processing sequence altered, the resulting

dead times will cause a lag in the signal output when the setpoint is

changed.

Siemens AG GWE-477 764 4070.76 J

SIMOVERT MASTERDRIVES Operating Instructions 6-5

Page 26

Bisher sind folgende Ausgaben erschienen: Ausgabe Interne Sachnummer

AA GWE-477 764 4070.76 J AA-76

Ausgabe AA besteht aus folgenden Kapiteln:

Kapitel Änderungen Seitenzahl Ausgabedatum

1 Definitionen und Warnungen Erstausgabe 3 02.2001

2 Produktbeschreibung Erstausgabe 2 02.2001

3 Technische Daten Erstausgabe 1 02.2001

4 Montage Erstausgabe 2 02.2001

5 Anschließen Erstausgabe 6 02.2001

6 Inbetriebsetzen Erstausgabe 5 02.2001

The following editions have been published so far: Edition Internal Item Number

AA GWE-477 764 4070.76 J AA-76

Version AA consists of the following chapters:

Chapter Changes Pages Version date

1 Definitions and Warnings first edition 3 02.2001

2 Product Description first edition 2 02.2001

3 Technical Data first edition 1 02.2001

4 Installation first edition 2 02.2001

5 Connections first edition 6 02.2001

6 Start-up first edition 5 02.2001

Group: Automation and Drives (A&D)

Division: Variable-Speed Dri ve S ystems

Postfach 3269, D-91050 Erlangen

Siemens Aktiengesellschaft Subject to change GWE-477 764 4070.76

Printed in the Federal Republic of Germany

02.2001

Loading...

Loading...