Siemens Simovert P 6SE21 Series Operating Instructions Manual

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

3

Contents Page

Warning and Caution Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Control Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Monitoring Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Motor Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Voltage/Frequency Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Low Frequency Voltage Boost (Ku) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 Current Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

8

9

9

9

10

10

10

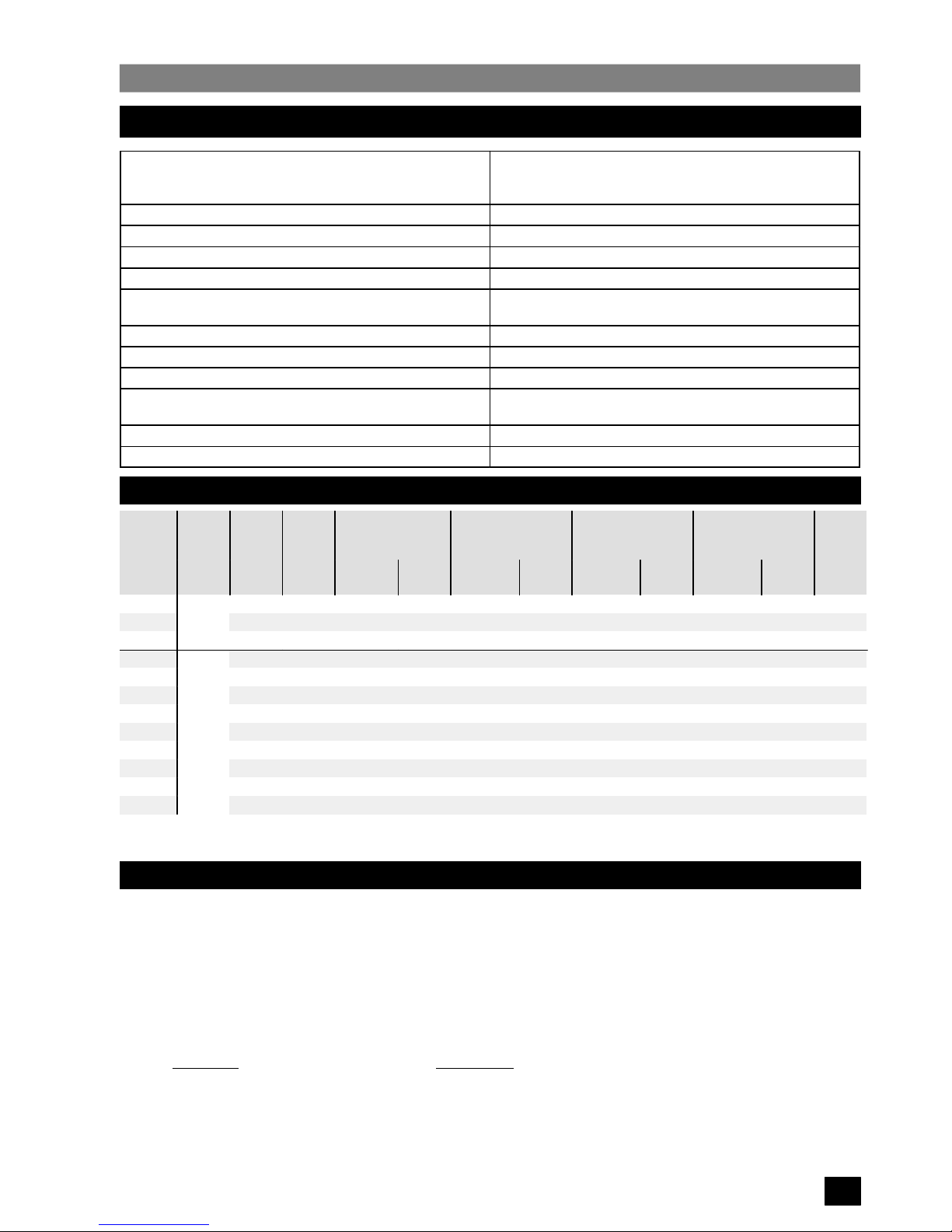

2. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Equipment Ratings Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1111

3. MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Mains Input / Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1416

5. COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Preparation for Switch–On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Starting and Stopping the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Direction of Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Jog Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 First Switch–On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Changing Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Fault Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Fault Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

18

20

20

20

20

21

21

22

30

31

6. USING CLOSED LOOP SPEED CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Installation of Control Loop Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Scaling Factor of ‘Actual Speed’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Speed Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Speed Control Optimisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 Slip Limit (P35) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.5 Sample Rate (P36) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

32

32

33

33

33

33

7. QUICK REFERENCE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

35

35

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

4

Contents (continued) Page

Figures

1 Block Diagram Simovert P 6SE21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Voltage/Frequency Characteristic Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Connection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Fault Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Closed Loop Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

10

15

17

30

32

Note

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation or maintenance.

Should further information be desired or should particular problems arise which are not covered sufficiently

for the Purchaser’s purposes, the matter should be referred to the local Siemens Sales Office.

The contents of this instruction manual shall not become part of or modify any prior or existing agreement,

commitment or relationship. The Sales Contract contains the entire obligations of Siemens. The warranty

contained in the contract between the parties is the sole warranty of Siemens. Any statements contained

herein do not create any new warranties or modify the existing warranty.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

5

Warning and Caution Notes

This equipment contains hazardous voltages and controls hazardous rotating mechanical parts. Loss

of life, severe personal injury or property damage can result if instructions contained in this manual

are not followed.

Only suitable qualified personnel should work on this equipment, and only after becoming familiar with

all safety notices, installation, operation and maintenance procedures contained in this manual. The

successful and safe operation of this equipment is dependent upon its proper handling, installation,

operation and maintenance.

WARNING

Definitions

• Qualified Person

For the purposes of this manual and product labels, a qualified person is one who is familiar with the installation,

construction, operation and maintenance of this equipment and with the hazards involved. In addition, the person must

be:

(1) Trained and authorised to energise, de–energise, clear, ground and tag circuits and equipment in

accordance with established safety practices.

(2) Trained in the proper care and use of protective equipment in accordance with established safety

practices.

(3) Trained in rendering first aid.

• DANGER

For the purposes of this manual and product labels, DANGER indicates that loss of life, severe personal injury or

substantial property damage WILL result if proper precautions are not taken.

• WARNING

For the purposes of this manual and product labels, WARNING indicates that loss of life, severe personal injury or

substantial property damage CAN result if proper precautions are not taken.

• CAUTION

For the purposes of this manual and product labels, CAUTION indicates that minor personal injury or property damage

CAN result if proper precautions are not taken.

• Note

For the purposes of this manual and product labels, Notes merely call attention to information that is especially

significant in understanding and operating the drive.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

6

Hot Line

Siemens operates a telephone ‘hot line’ for users of their 6SE21 range of

inverters. This service is available during normal working hours, Monday to

Friday. If you require assistance, contact our customer support personnel

on the following number:

Tel: (49) 9131 7 23212

Fax: (49) 9131 7 29900

Please have the following information available before dialling:

•

inverter model number

•

hardware type (stored in P49)

•

software version (stored in P50)

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

7

1. DESCRIPTION

SIMOVERT P transistorised voltage–source inverters operate with high voltages.

Connection, commissioning and fault–finding should only be carried out by qualified personnel who

are fully conversant with the relevant documentation, installation regulations, etc.

Only permanently–wired input power connections are allowed. This equipment must be grounded

(IEC 536 Class 1, NEC and other applicable standards).

Safety Note:

Do not apply input power to the equipment when the plastic cover has been removed. Dangerous

voltages are present within the equipment which could cause serious injury or death if touched. After

removing mains power, always allow a minimum of five minutes for the internal capacitors to

discharge before removing the cover.

When the 3–phase mains input is protected by a current–operated earth–leakage breaker, the input

to the inverter must be isolated from the mains if the earth–leakage breaker is to operate effectively.

The dc–link capacitors remain charged to dangerous voltages for up to five minutes after the incoming

power has been switched off.

When the motor is not running, dangerous voltages are still present on the power input terminals AND

motor output terminals and also on the dc–link terminals.

Under certain set–up conditions, the inverter may restart automatically after an input power failure.

WARNING

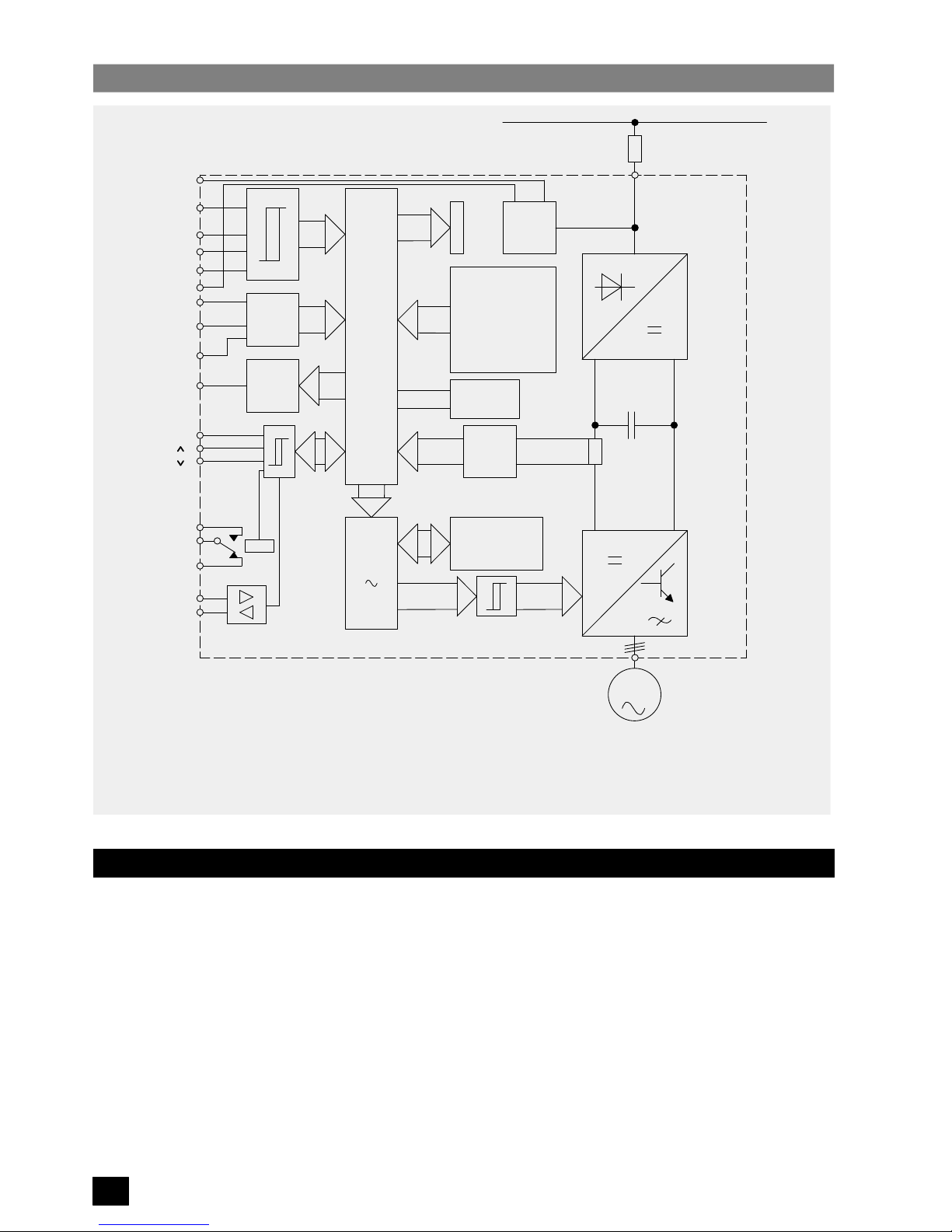

1.1 Introduction

SIMOVERT P inverters of the 6SE21 series are designed for low–loss speed control of three–phase motors. This is

achieved by rectifying input voltage to establish a dc link voltage, and modulating this link voltage with a three–phase

transistor bridge to produce a Pulse–Width Modulated (PWM) three–phase output voltage

(see Figure 1)

. The

inductance of the motor windings converts this PWM voltage to a sinusoidal motor current. By varying the frequency of

this sinusoidal current, the rotational speed of the motor is controlled without significantly affecting the losses in the

motor. The output frequency can be adjusted between 0 and 400 Hz.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

8

Block Diagram – SIMOVERT P 6SE21

Figure 1:

3

M

PWM

SE

PROM

CPU

A/D

D/A

SV

SI

GR

ZK

WR

Run/Stop

0 – 10 V

0 – 20 mA

4 – 20 mA

BUS

+

Power Supply

Mains Fuse(s)

DC Link

Power Supply

Microprocessor

Analog/Digital Converter

Bus Connector

GR Rectifier

WR Inverter

SE Current Monitoring

PWM Pulse Width Modulator

D/A Digital/Analog Converter

R/L Clockwise/Counter–clockwise

Frequency, Current Indicator

Jog

FRONT

PANEL

F

u/Iu

PROM

Fault

Trip

Tacho

F

u/Iu

P

RS485

X11

X1

X1

ZK

CPU

A/D

BUS

+15 V

+10 V

2

3

4

13

6

7

9

12

11

16

17

18

19

20

21

14

15

SI

SV

R/L

5

1.2 Control Facilities

The inverter can be started/stopped by any of the following means

(see parameter P05 in section 5.3.2 and also Figure

3)

:

(1) Connection of a latching switch to the run/stop input (terminals X11.2/3).

(2) Applying a rising edge (i.e. momentary push–button) to the Run/Stop input (terminals X11.2/3) and a falling

edge to the trip input terminal X11.2/4.

(3) Connection of a voltage level of 7 – 33 V to the Run/Stop input (terminals X11.3/1).

(4) Automatic starting on application of input power (shorting link terminals X11.2/3).

(5) Connection of a voltage level of 7 – 33 V to the jog input (terminal X11.13/1).

(6) Control via the serial I/O connections.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

9

The output frequency of the inverter, and hence the speed of the motor , can be controlled by any of the following means

(see 5.3.2, parameter P04 and also Figure 3)

:

(1) Connection of 0–10 V control voltage (terminals X11.7/8).

(2) Connection of a 0–20 mA current loop control input (terminals X11.9/10).

(3) Connection of a 4–20 mA current loop control input (terminals X11.9/10).

(4) Connection of a 5 kΩ control potentiometer (terminals X11.6/7/8).

(5) By digital parameterisation via the push–buttons fitted to the inverter, or via equivalent external push–buttons

connected to terminals X11.17 and X11.18.

(6) Via the serial I/O connection.

1.3 Monitoring Facilities

The following monitoring facilities are available:

(1) Seven–segment display for output frequency, output current, fault indication or parameterisation. This is

viewed through a window in the cover.

(2) A 0–10 V analogue signal, proportional to output frequency or output current.

(3) A changeover relay, normally energised when the drive is connected to a suitable input supply . The relay is

de–energised when a fault is indicated

(see section 5.5)

.

(4) The drive may be interrogated via the serial I/O connection.

1.4 Motor Characteristics

The inverter can be adjusted to suit individual motor characteristics in the ways described in 1.4.1 and 1.4.2.

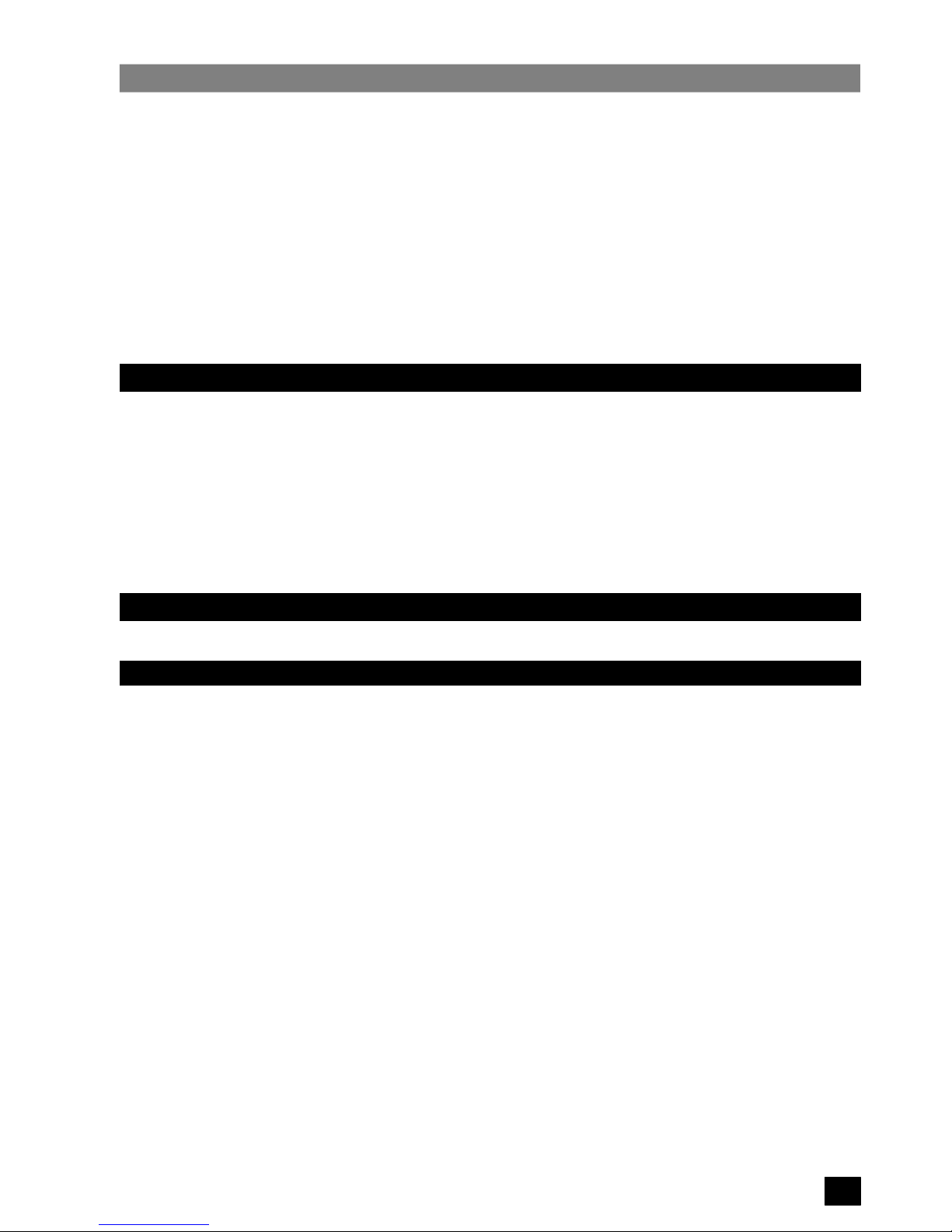

1.4.1 Voltage/Frequency Characteristic

Six voltage/frequency characteristic curves are available plus one programmable curve

(see Figure 2)

. They are

intended for the following applications:

Curve 0: V

N/50 Hz (constant torque)

For standard 50 Hz induction motors with linear speed/torque characteristics.

Curve 1: V

N/60 Hz (constant torque)

For standard 60 Hz induction motors with linear speed/torque characteristics.

Curve 2: V

N/87 Hz (constant torque)

For delta–connection of standard induction motors designed for star–connection of 50 Hz input voltage.

This increases the speed range over which constant motor torque can be achieved.

Curve 3: V

N/120 Hz (constant torque)

For applications where a constant torque is required over the full operating speed range 0.1 to 120 Hz.

Curve 4*: V

N/50 Hz (torque proportional to speed

1.5

)

For operation of 50 Hz motors driving loads where torque is proportional to (speed)

1.5

. Typical examples

of such loads are fans and pumps.

Curve 5*: V

N/60 Hz (torque proportional to speed

1.5

)

For operation of 60 Hz motors driving loads where torque is proportional to (speed)

1.5

.

Curve 6*: Programmable

(not shown in Figure 2)

The curve type and corner frequency may be selected by the user.

* Curves 4 and 5 allow variable torque output current values (see section 2.1) to be loaded into parameter P17. Curve

6 may allow variable torque output currents depending on the user–defined curve specified.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

10

Figure 2:

Voltage/Frequency Characteristic Curves

0 10 20 30 40 50 60 70 80 90 100 110 120

10

20

30

40

50

60

70

80

90

100

Voltage

%

Frequency

0

1 2 3

4

5

Boost

Ku

400

1.4.2 Low Frequency Voltage Boost (Ku)

The output voltage can be boosted in 0.1% steps up to 30% for low frequencies from 0 Hz. This may be required to give

additional starting torque in some applications. The amount of voltage boost decreases linearly until 100% voltage is

achieved.

If required, automatic boost may be used

(see section 5.3.2, Parameter P19)

. This measures the motor characteristics

and selects a suitable boost voltage at first switch–on.

1.4.3 Current Limit

The maximum output current available from the inverter can be adjusted to provide thermal protection of the motor

and/or limit the maximum motor torque

(see section 5.3.2, parameters P17 and P18)

.

1.5 Options

The following options are available for use with 6SE21 inverters:

Sinewave Filter Module Part No. 6SE2100–1FC51/53/55

NAMUR Interface Module Part No. 6SE2100–1FC50/52/54

Relay Module * Part No. 6SE2100–1GA00

Tachometer Interface Unit * Part No. 6SE2100–1DA00

Clear Text Operator Panel * Part No. 6SE2100–1CA00

*

These options cannot be fitted in combination with each other.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

11

2. TECHNICAL DATA

Rated supply voltage: Models 6SE21**–1AA1 1

Models 6SE21**–3AA21

** – May be any number

1 AC 50/60 Hz +/–1%, 220 – 240 V +/–10%

3 AC 50/60 Hz +/–1%, 380 – 500 V +/–10%

Output voltage 0 V – rated supply voltage

Output frequency 0.0 – 400 Hz

Efficiency ≥ 0.94

Motor power factor ≤ 0.9 lagging/inductive

Ambient operating temperature

(unit must not be exposed to direct sunlight)

0 – 40oC

Storage/transport temperature –30 – +85oC

Degree of protection IP21 (NEMA 1)

Humidity 0 – 95% at 25oC

Frequency stability at T

max

10oC referred to f

max

Analogue setpoint 1%

Digital setpoint 0.01%

Frequency resolution 0.1 Hz

Overload rating 1.5 x rated current for up to 60 seconds

2.1 Equipment Ratings Table

Input

Max.

Cont.

Circuit

Constant Torque

Output

Variable Torque

Output **

Variable Torque

Output **

460 V (USA)

Variable Torque

Output **

500 V

Overload

Model

6SE21..

Voltage

Range

Input

Current

Breaker

Continuous

Current

Motor

Rating *

Continuous

Current

Motor

Rating *

Continuous

Current

Motor

Rating *

Continuous

Current

Motor

Rating *

Current

01–1AA11

9.8 A 16.0 A 2.8 A .55 kW 3.9 A .75 kW – – – – 4.2 A

02–1AA11

198–264 V

1 phase

13.5 A 16.0 A 3.9 A .75 kW 4.8 A 1.1 kW – – – – 5.8 A

03–1AA11

1 phase

26.5 A 32.0 A 6.8 A 1.5 kW 10.0 A 2.2 kW – – – – 10.2 A

03–3AA21 5.5 A 10.0 A 4.0 A 1.5 kW 5.5 A 2.2 kW 4.8 A 3 hp 4.8 A 2.2 kW 6.0 A

05–3AA21 10.0 A 16.0 A 7.6 A 3.0 kW 9.5 A 4.0 kW 8.1 A 5 hp 8.1 A 4.0 kW 11.4 A

08–3AA21 17.0 A 20.0 A 12.0 A 5.5 kW 17.0 A 7.5 kW 14.0 A 10 hp 12.0 A 7.5 kW 18.0 A

13–3AA21

342–550 V

28.0 A 32.0 A 19.0 A 7.5 kW 23.0 A 11.0 kW 21.0 A 15 hp 19.0 A 11.0 kW 28.5 A

17–3AA21

342–550 V

3 phase

38.0 A 40.0 A 25.0 A 11.0 kW 32.0 A 15.0 kW 27.0 A 20 hp 25.0 A 15.0 kW 37.5 A

22–3AA21

40.0 A 50.0 A 32.0 A 15.0 kW 38.0 A 18.5 kW 34.0 A 25 hp 32.0 A 18.5 kW 48.0 A

27–3AA21 48.0 A 63.0 A 38.0 A 18.5 kW 46.0 A 22.0 kW 40.0 A 30 hp 38.0 A 22.0 kW 57.0 A

33–3AA21

70.0 A 80.0 A 46.0 A 22.0 kW 60.0 A 30.0 kW 52.0 A 40 hp 46.0 A 30.0 kW 69.0 A

42–3AA21 87.0 A 100.0 A 60.0 A 30.0 kW 75.0 A 37.0 kW 65.0 A 50 hp 60.0 A 37.0 kW 90.0 A

*

Siemens 4–pole motor, 1LA5 series or equivalent.

** Automatically selected on voltage/frequency curve types 4 and 5 (see section 1.4.1).

2.2 Cable Lengths

The inverters will operate satisfactorily with unscreened cables of up to 150 m in length and screened or armoured

cable of up to 50 m in length. For applications where longer cables are required, inductors must be fitted to reduce

capacitive currents.

Note

If long cables are used, it may be necessary to change the value of parameter P52 to compensate for any

inaccuracies in the output current reading.

The following chokes are suitable for applications where up to 100/200 m screened/unscreened cables are required:

Model No.

Choke Type

6SE210*–1AA11 & 6SE2103–3AA21 4EP3601–8DB

6SE2105–/6SE2108–3AA21 4EP3801–4DB

6SE2113–/6SE2117–/6SE2122–3AA21 4EP3800–4DB

6SE2127–/6SE2133–3AA21 4EP4002–1DB

6SE2142–3AA21 4EU2421–8AA00

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

12

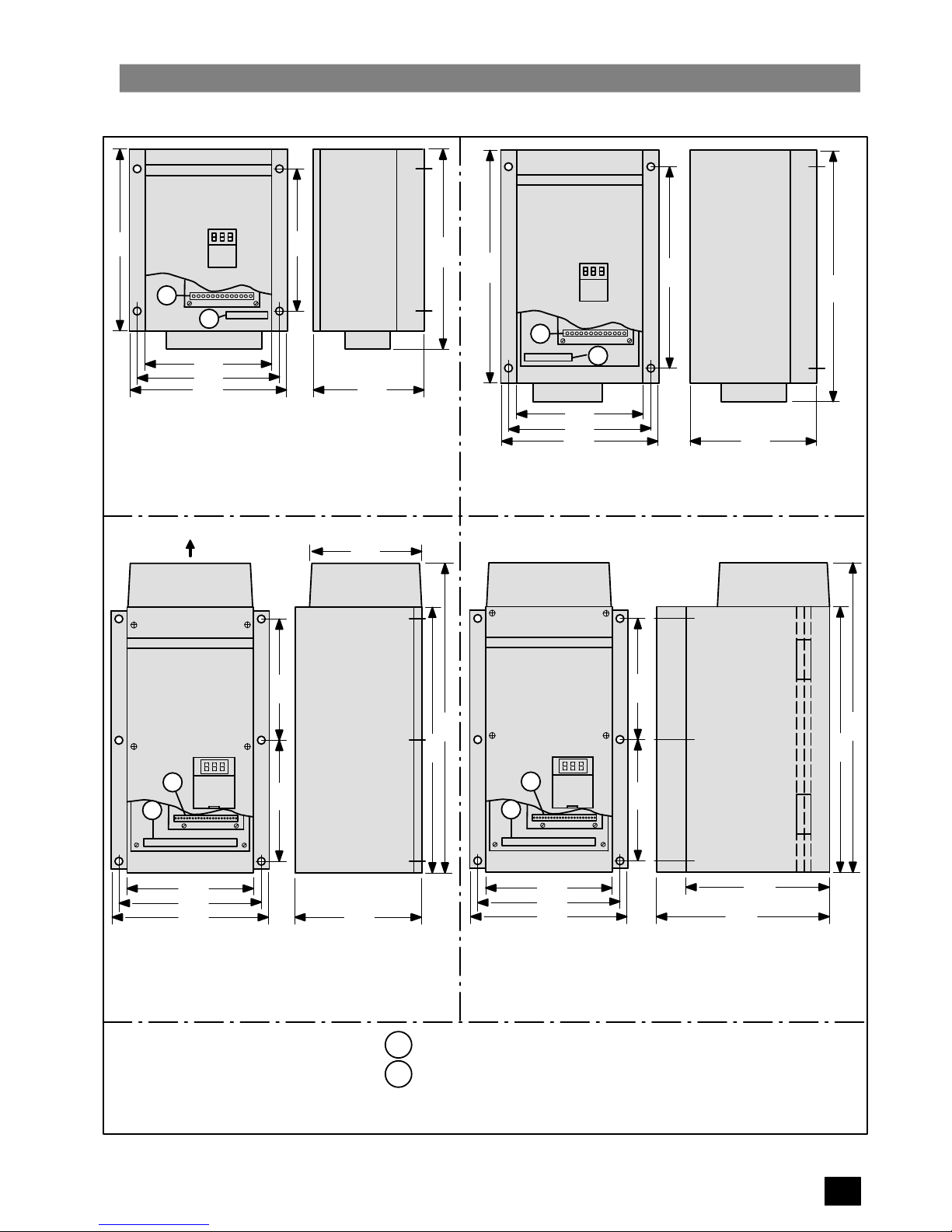

3. MECHANICAL INSTALLATION

High voltages are generated within this equipment. It must only be installed and operated by qualified

personnel who are familiar with the equipment, its operating requirements and instructions.

The User is responsible for installation of the motor, drive controller, transformer and other devices

in accordance with regulations and local safety codes which may apply .

Adequate protective clothing (e.g. safety gloves, goggles, etc.) should be worn by the person

installing this equipment.

Failure to observe the appropriate warnings and regulations may result in serious injury or death.

WARNING

The inverter must be installed in a vertical position and fixed to a solid surface via its four mounting holes. It is suitable

for wall–mounting or installation within a cubicle.

All inverter variants are air–cooled. Ensure that a free space of at least 100 mm (4 in.) is left both above

and below the unit to allow an unimpeded air flow.

Avoid subjecting the inverter to excessive shock and vibration.

CAUTION

Installation drawings for the inverters are shown on the next page.

SIMOVERT P 6SE21 Series Inverters

English

Operating Instructions

Siemens plc 1995

G85139–A1615–U156–A

02.95

13

Dimension Drawings

SIEMENS SIMOVERT

A

B

Control Terminals X11

Mains Input/Motor Terminals X1

All dimensions in millimetres

185

209

197

144

257

197

293

SIEMENS SIMOVERT

A

B

375

325

225

249

237

411

162

SIEMENS SIMOVERT

Exhaust Air

COOLING FAN

258258

225

249

237

172

561

667

190

A

SIEMENS SIMOVERT

258258

225

249

237

561

667

315

250

6SE2101–1AA11

6SE2102–1AA11

6SE2103–1AA11

6SE2103–3AA21

6SE2105–3AA21

6SE2108–3AA21

6SE2113–3AA21

6SE2117–3AA21

6SE2122–3AA21

6SE2127–3AA21

6SE2133–3AA21

6SE2142–3AA21

Notes:

A

B

B

A

B

Loading...

Loading...