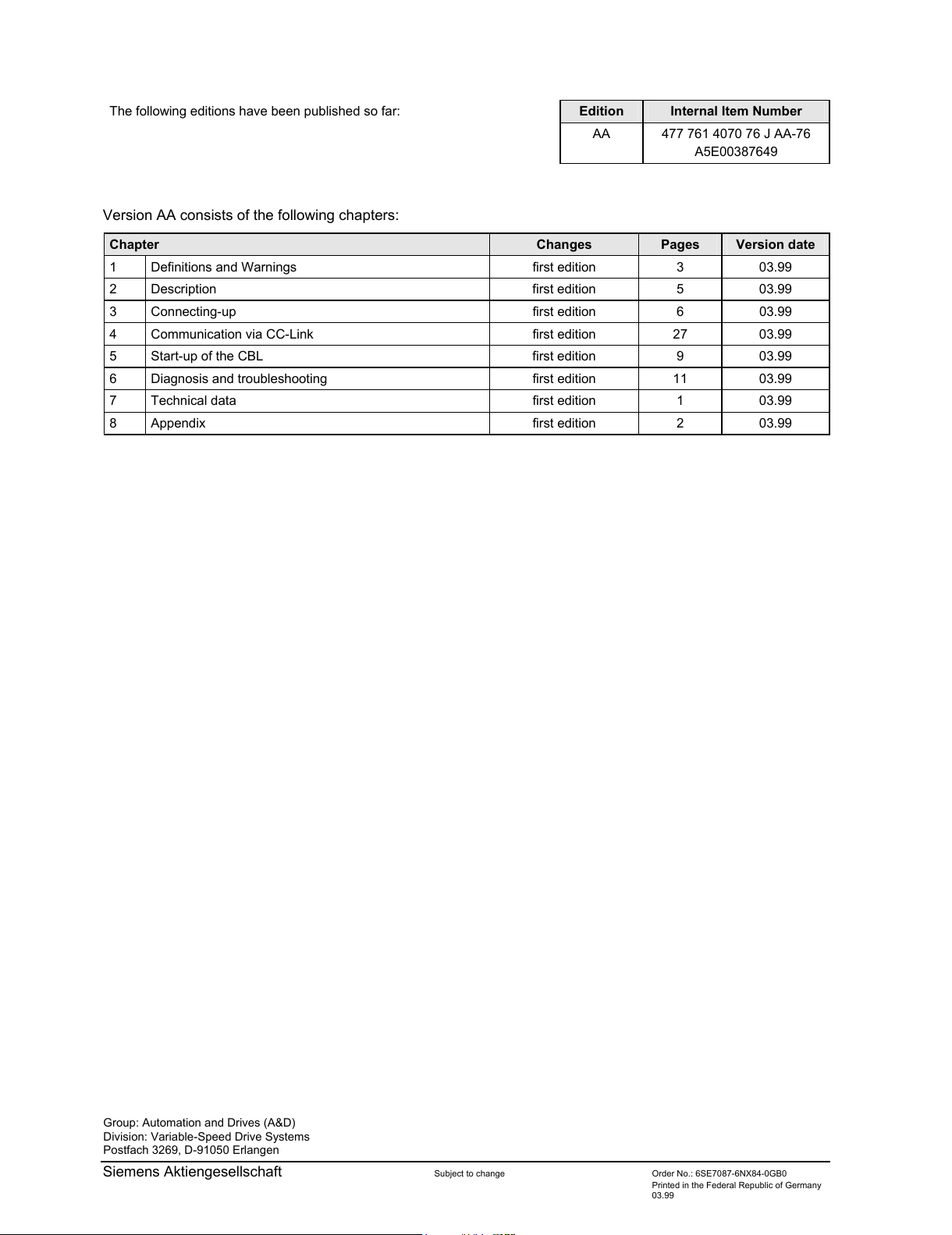

Siemens Simovert Masterdrive FANC-SB, Simovert Masterdrive FANC-SBH Operating Instructions Manual

Page 1

SIMOVERT MASTERDRIVES

Operating Instructions

CBL – Communication Board CC-Link

Edition: AA Order No.: 6SE7087-6NX84-0GB0

All manuals and user guides at all-guides.com

all-guides.com

Page 2

Weitergabe sowie Vervielf äl tigung dieser Unterlage, Verwertung

und Mitteilung ihres Inhalts ni cht gestattet, soweit nicht ausdrück-

lich zugestanden. Zuwiderhandlungen verpflicht en zu Schadener-

satz. Alle Rechte vorbehalten, insbesondere für den Fall der

Patenterteilung oder GM-Eintragung.

Wir haben den Inhalt der Druckschrift auf Übereinstimmung mit

der beschriebenen Hard- und Software überprüft. Dennoch kön-

nen Abweichungen nicht ausgeschlossen werden, so daß wir für

die vollständige Übereinstimmung keine Garantie übernehmen.

Die Angaben in dieser Druckschrift werden jedoch regelmäßig

überprüft und notwendige Korrekturen sind in den nachf ol genden

Auflagen enthalten. Für Verbess erungsvorschläge sind wir

dankbar

SIMOVERT ist ein Warenzeichen von Siem ens

The reproduction, transmission or use of this document or its

contents is not perm i tted without express written authority.

Offenders will be liable for damages. All rights, inc luding rights

created by patent grant or registration of a ut ilit y model or design,

are reserved.

We have checked the contents of this document to ensure that

they coincide with the described hardware and soft ware.

However, differences cannot be completely excluded, so that we

do not accept any guarantee for complete conformance.

However, the information in this document is regularly check ed

and necessary corrections will be included in subsequent

editions. We are grateful for any recommendat i ons for

improvement.

SIMOVERT Registered Trade Mark

Siemens AG 1997 All ri ghts reserved

These Operating Instructions are valid for software release V 1.2

We reserve the right to make changes to functions, technical data, standards, drawings and parameters.

All manuals and user guides at all-guides.com

Page 3

03.99 Contents

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 1

Contents

1 DEFINITIONS AND WARNINGS .....................................................................1-1

2 DESCRIPTION .................................................................................................2-1

2.1 Mounting methods / CBL slots..........................................................................2-3

2.1.1 Mounting positions of the CBL in MC Compact Plus units...............................2-3

2.1.2 Mounting positions of the CBL in Compact and chassis units of

MASTERDRIVES Vector Control (CUVC) and MASTERDRIVES (CUMC).....2-4

3 CONNECTING..................................................................................................3-1

3.1 EMC measures .................................................................................................3-4

4 COMMUNICATION VIA CC-LINK....................................................................4-1

4.1 CC-Link profile of SIMOVERT MASTERDRIVES.............................................4-1

4.2 CBL, converter between CC-Link and MASTERDRIVES.................................4-4

4.3 Initial process and initial data setting................................................................4-5

4.4 Setpoint handling ..............................................................................................4-6

4.5 Monitoring .........................................................................................................4-8

4.6 Command code execution ..............................................................................4-10

4.7 Parameter area (PKW) ...................................................................................4-11

4.8 Handling PKW via CC-Link.............................................................................4-17

4.9 Data formats and data conversion..................................................................4-22

4.10 Fault reaction on communication errors .........................................................4-26

4.11 Optional flags in CBL profile ...........................................................................4-27

5 START-UP OF THE CBL .................................................................................5-1

5.1 Basic parameterization of the units...................................................................5-1

5.2 Process-data softwiring in the units..................................................................5-6

All manuals and user guides at all-guides.com

Page 4

Contents 03.99

6SE7087-6NX84-0GB0 Siemens AG

2 Operating Instructions SIMOVERT MASTERDRIVES

6 DIAGNOSIS AND TROUBLESHOOTING .......................................................6-1

6.1 Evaluation of hardware diagnostics..................................................................6-1

6.2 Fault displays and alarms on the basic unit......................................................6-7

6.3 Evaluation of the CBL diagnostic parameter ....................................................6-9

6.4 Meaning of CBL diagnostics...........................................................................6-10

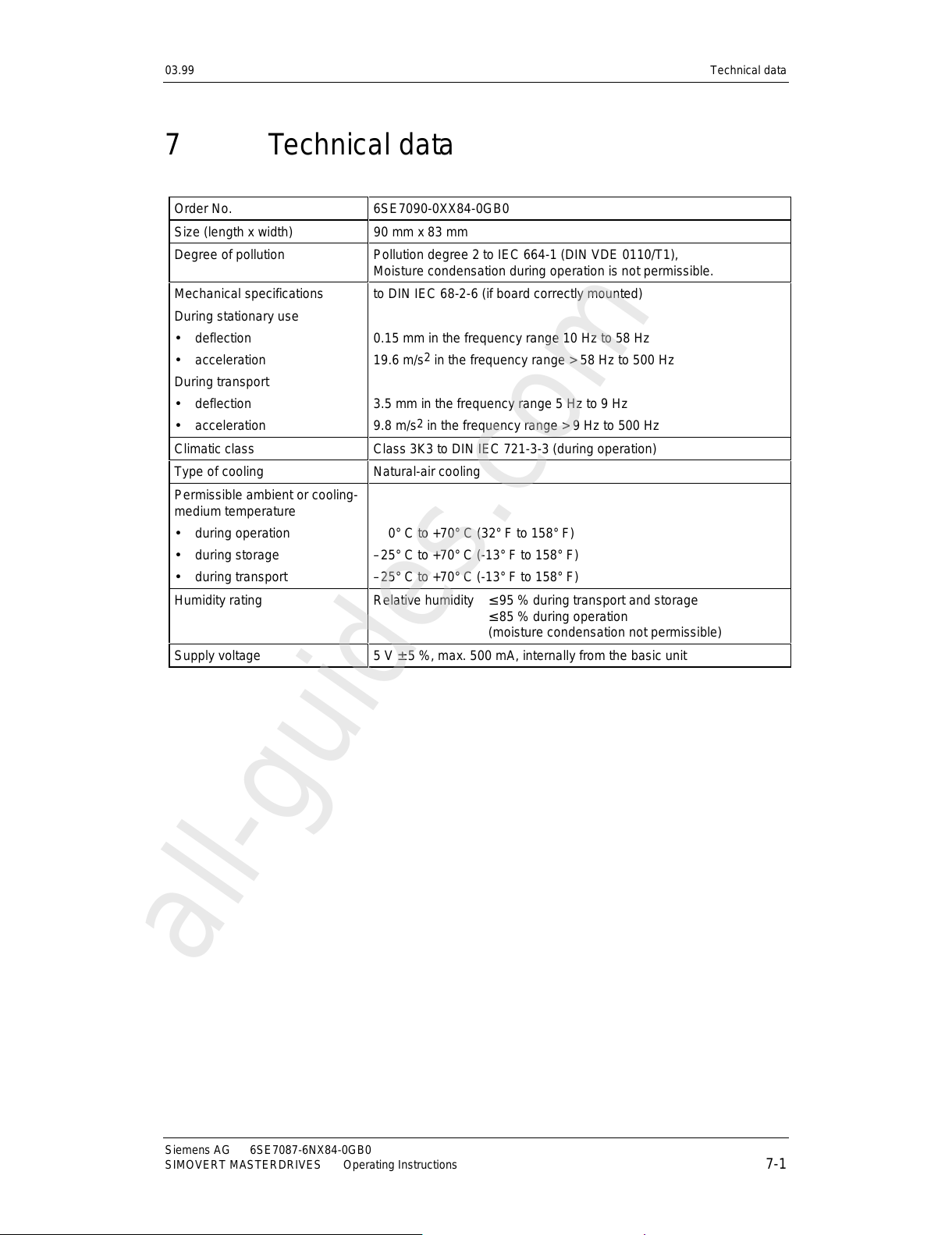

7 TECHNICAL DATA ..........................................................................................7-1

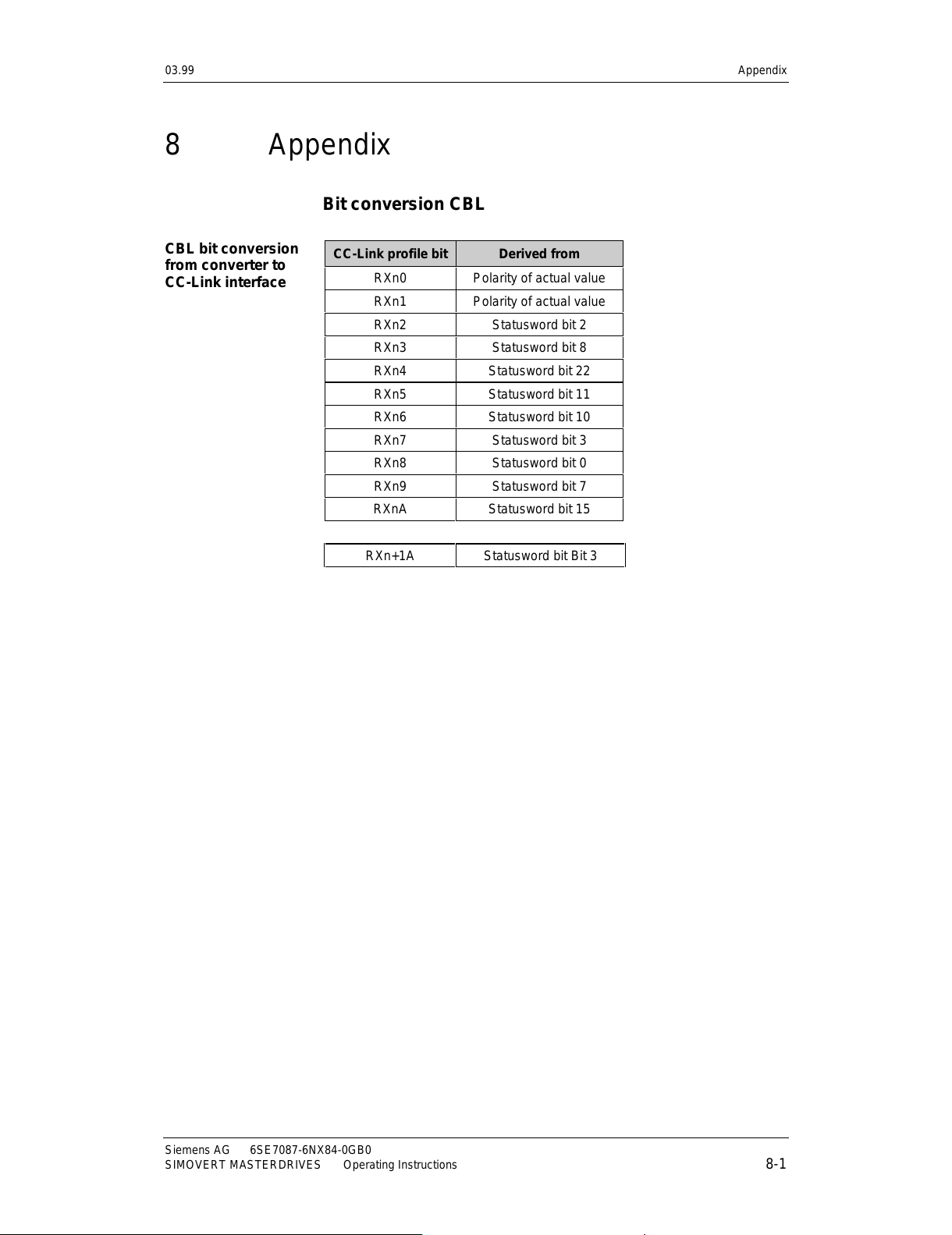

8 APPENDIX........................................................................................................8-1

All manuals and user guides at all-guides.com

Page 5

03.99 Definitions and Warnings

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 1-1

1 Definitions and Warnings

For the purpose of this documentation and the product warning labels,

a "Qualified person" is someone who is familiar with the installation,

mounting, start-up, operation and maintenance of the product. He or

she must have the following qualifications:

♦

Trained or authorized to energize, de-energize, ground and tag

circuits and equipment in accordance with established safety

procedures.

♦

Trained or authorized in the proper care and use of protective

equipment in accordance with established safety procedures.

♦

Trained in rendering first aid.

For the purpose of this documentation and the product warning labels,

"Danger" indicates death, severe personal injury or substantial property

damage will result if proper precautions are not taken.

For the purpose of this documentation and the product warning labels,

"Warning" indicates death, severe personal injury or property damage

can result if proper precautions are not taken.

For the purpose of this documentation and the product warning labels,

"Caution" indicates that minor personal injury or material damage can

result if proper precautions are not taken.

For the purpose of this documentation, "Note" indicates important

information about the product or about the respective part of the

documentation which is essential to highlight.

Qualified personnel

DANGER

WARNING

CAUTION

NOTE

All manuals and user guides at all-guides.com

Page 6

Definitions and Warnings 03.99

6SE7087-6NX84-0GB0 Siemens AG

1-2 Operating Instructions SIMOVERT MASTERDRIVES

Hazardous voltages are present in this electr ic al equ ipment during

operation.

Non-observance of the warnings can thus result in severe personal

injury or property damage.

Only qualified personnel should work on or around the equipment

This personnel must be thoroughly familiar with all warning and

maintenance procedures contained in this documentation.

The successful and safe operation of this equipment is dependent on

correct transport, proper storage and ins ta l lat ion as well as careful

operation and maintenance.

This documentation does not purport to cover all details on all types of

the product, nor to provide for every possible contingency to be met in

connection with installation, operation or maintenance.

Should further information be desir ed or shou ld par t icular prob lems

arise which are not covered sufficiently for the purchaser’s purposes,

the matter should be referred to the local SIEMENS sales office.

The contents of this documentation shall not become part of or modify

any prior or existing agreement, commitment or relationship. The sales

contract contains the entire obligation of SIEMENS AG. The warranty

contained in the contract between the parties is the sole warranty of

SIEMENS AG. Any statements contained herein do not create new

warranties or modify the existing warranty.

WARNING

NOTE

All manuals and user guides at all-guides.com

all-guides.com

Page 7

03.99 Definitions and Warnings

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 1-3

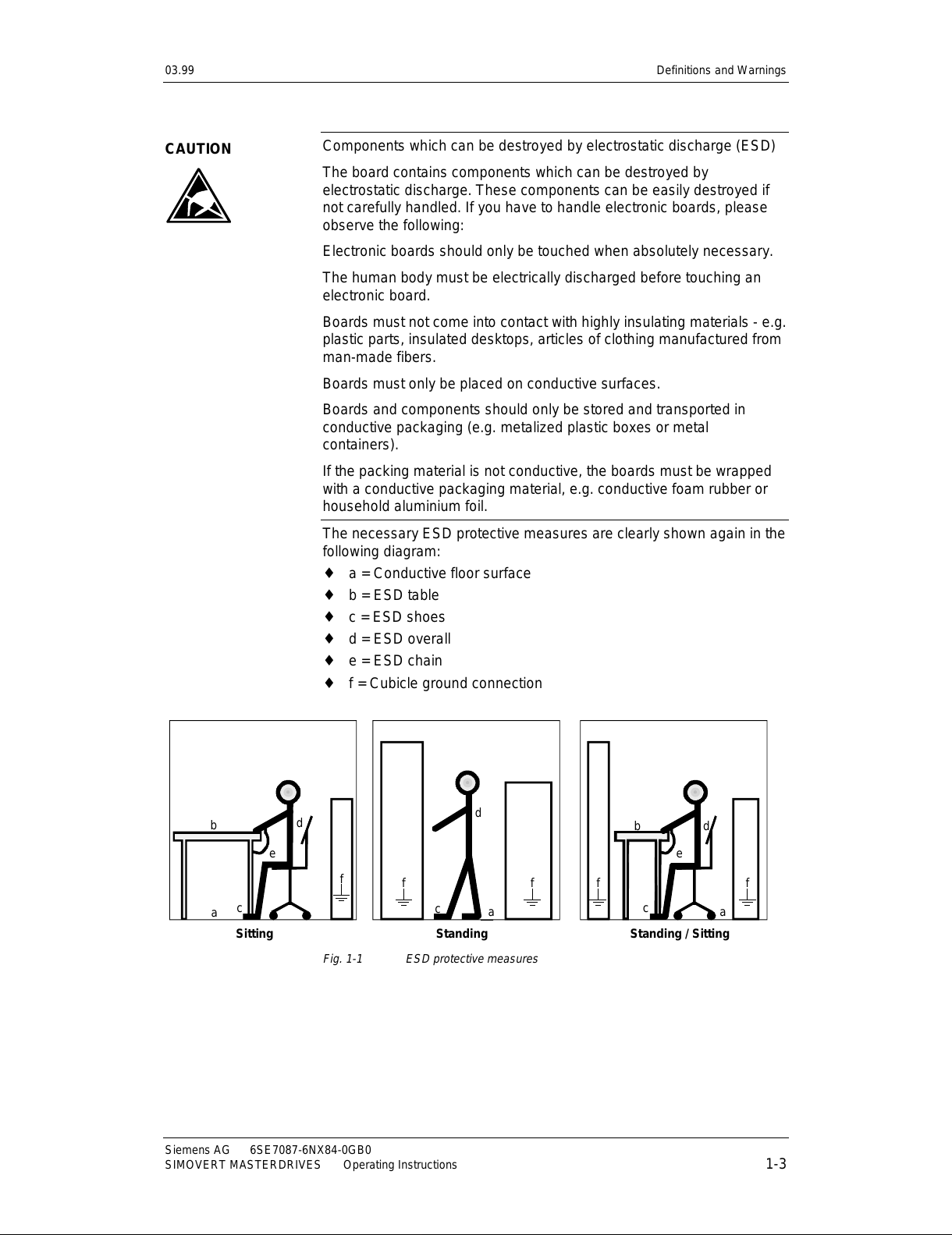

Components which can be destro yed by electros tat ic dischar g e (ESD)

The board contains components which can be destroyed by

electrostatic discharge. These components can be easily destroyed if

not carefully handled. If you have to handle elec tr onic boar ds , pleas e

observe the following:

Electronic boards should only be touched when absolutely necessary.

The human body must be electrically discharged before touching an

electronic board.

Boards must not come into contact with highly insulating materials - e.g.

plastic parts, insulated desktops, articles of clothing manufactured from

man-made fibers.

Boards must only be placed on conductive surfaces.

Boards and components should only be stored and transported in

conductive packaging (e.g. metalized plastic boxes or metal

containers).

If the packing material is not conductive, the boards must be wrapped

with a conductive packaging material, e.g. conductive foam rubber or

household aluminium foil.

The necessary ESD protective measures are clearly shown again in the

following diagram:

♦

a = Conductive floor surface

♦

b = ESD table

♦

c = ESD shoes

♦

d = ESD overall

♦

e = ESD chain

♦

f = Cubicle ground connection

StandingSitting Standing / Sitting

a

b

e

d

c

d

a

c

d

b

c

a

e

f

f

f f f

Fig. 1-1 ESD protective measures

CAUTION

All manuals and user guides at all-guides.com

Page 8

All manuals and user guides at all-guides.com

Page 9

03.99 Description

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 2-1

2 Description

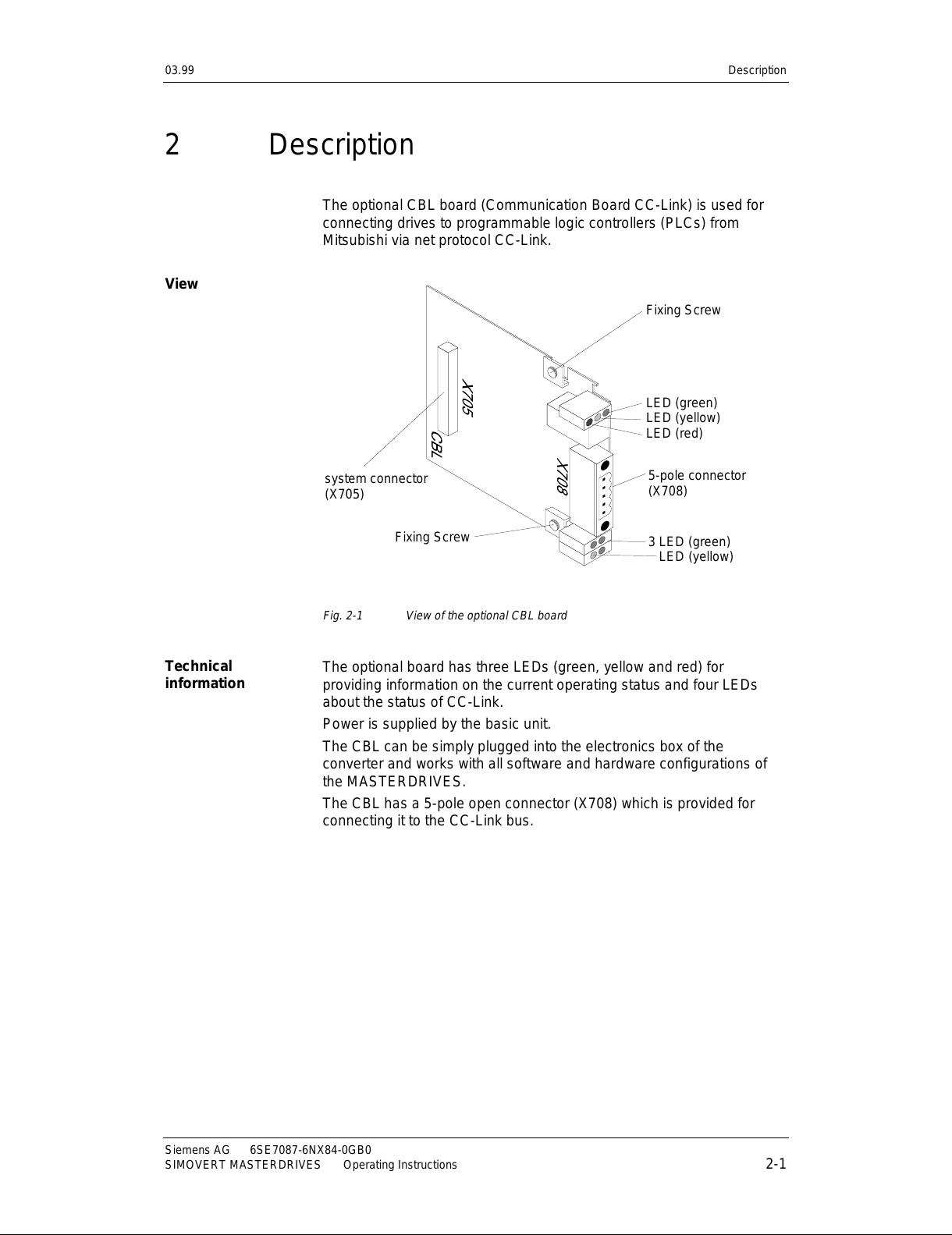

The optional CBL board (Communication Board CC-Link) is used for

connecting drives to programmable logic controllers (PLCs) from

Mitsubishi via net protocol CC-Link.

Fixing Screw

LED (green)

LED (yellow)

LED (red)

5-pole connector

(X708)

3 LED (green)

LED (yellow)

system connector

(X705)

Fixing Screw

Fig. 2-1 View of the optional CBL board

The optional board has three LEDs (green, yellow and red) for

providing information on the current operating status and four LEDs

about the status of CC-Link.

Power is supplied by the basic unit.

The CBL can be simply plugged into the electronics box of the

converter and works with all software and hardware configurations of

the MASTERDRIVES.

The CBL has a 5-pole open connector (X708) which is provided for

connecting it to the CC-Link bus.

View

Technical

information

All manuals and user guides at all-guides.com

Page 10

Description 03.99

6SE7087-6NX84-0GB0 Siemens AG

2-2 Operating Instructions SIMOVERT MASTERDRIVES

CC-Link is a field network developed by Mitsubishi Electric Corporation.

CC-Link is the abbreviation for "Control & Communication Link". From

programmable logic controllers (PLCs) you can communicate with

peripheral products like sensors, valves, inverters, etc.

At CC-Link there is one master and up to 64 slaves. The master has

address 0 and the slaves 1..64. CC-Link has a bus topology. The

communication speed can be set between 156 kBits/sec and 10

Mbits/sec. Depending on the transmission speed you have different

maximum bus length; see chapter 5 "Start-up of the CBL" (P711).

At CC-Link there are different data volumes and data types: bit control,

data control and messages (send/receive). These different data types

are realized with three types of devices:

♦

Remote IO device station

♦

Remote device station

♦

Intelligent device station

The different data volumes are realized at the remote device station by

occupying multiple (up to 4) slave addresses.

With the communication board CBL you can communicate from

Mitsubishi PLCs to SIMOVERT MASTERDRIVES systems. You can

control drives by setpoints of frequency or torque.

CBL CC-Link parameter:

Remote device station

1 station occupied

CC-Link standard profile for inverters

Vendor code: 0159h (Siemens AG)

At CC-Link there are restrictions for configuring the network. The

following conditions must be satisfied:

{(1 x a) + (2 x b) + (3 x c) + (4 x d)} ≤ 64

with a: Number of units occupying 1 station (like CBL)

b: Number of units occupying 2 stations

c: Number of units occupying 3 stations

d: Number of units occupying 4 stations

{(16 x A) + (54 x B) + (88 x C)} ≤ 2304

with A: Number of remote I/O stations (≤ 64)

B: Number of remote device stations (≤ 42)

C: Number of intelligent stations (≤ 26)

Õ Maximum number of CBLs connected: 42

CC-Link from

Mitsubishi

All manuals and user guides at all-guides.com

Page 11

03.99 Description

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 2-3

2.1 Mounting methods / CBL slots

The CBL can be directly mounted into Compact PLUS units. For all

other frame sizes, it is mounted on the CUMC or CUVC or connected in

the electronics box with an adapter board.

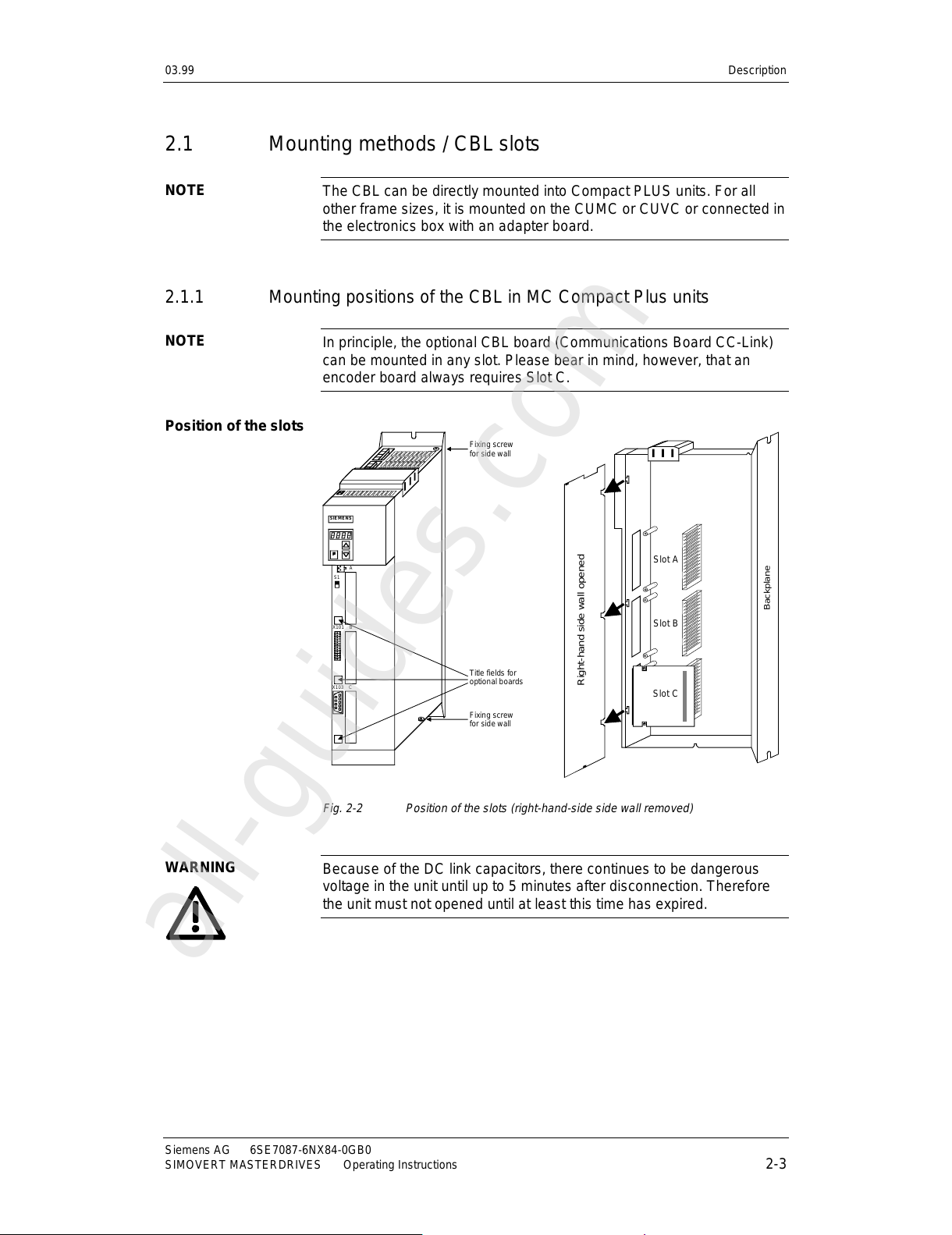

2.1.1 Mounting positions of the CBL in MC Compact Plus units

In principle, the optional CBL board (Communications Board CC-Link)

can be mounted in any slot. Please bear in mind, however, that an

encoder board always requires Slot C.

SIEM ENS

A

S1

BX101

CX103

Fixing screw

for side wall

Fixing screw

for side wall

Title fields for

optional boards

Slot A

Slot B

Slot C

Backplane

Right-hand side wall opened

Fig. 2-2 Position of the slots (right-hand-side side wall removed)

Because of the DC link capacitors, there continues to be dangerous

voltage in the unit until up to 5 minutes after disconnection. Therefore

the unit must not opened until at least this time has expired.

NOTE

NOTE

Position of the slots

WARNING

All manuals and user guides at all-guides.com

all-guides.com

Page 12

Description 03.99

6SE7087-6NX84-0GB0 Siemens AG

2-4 Operating Instructions SIMOVERT MASTERDRIVES

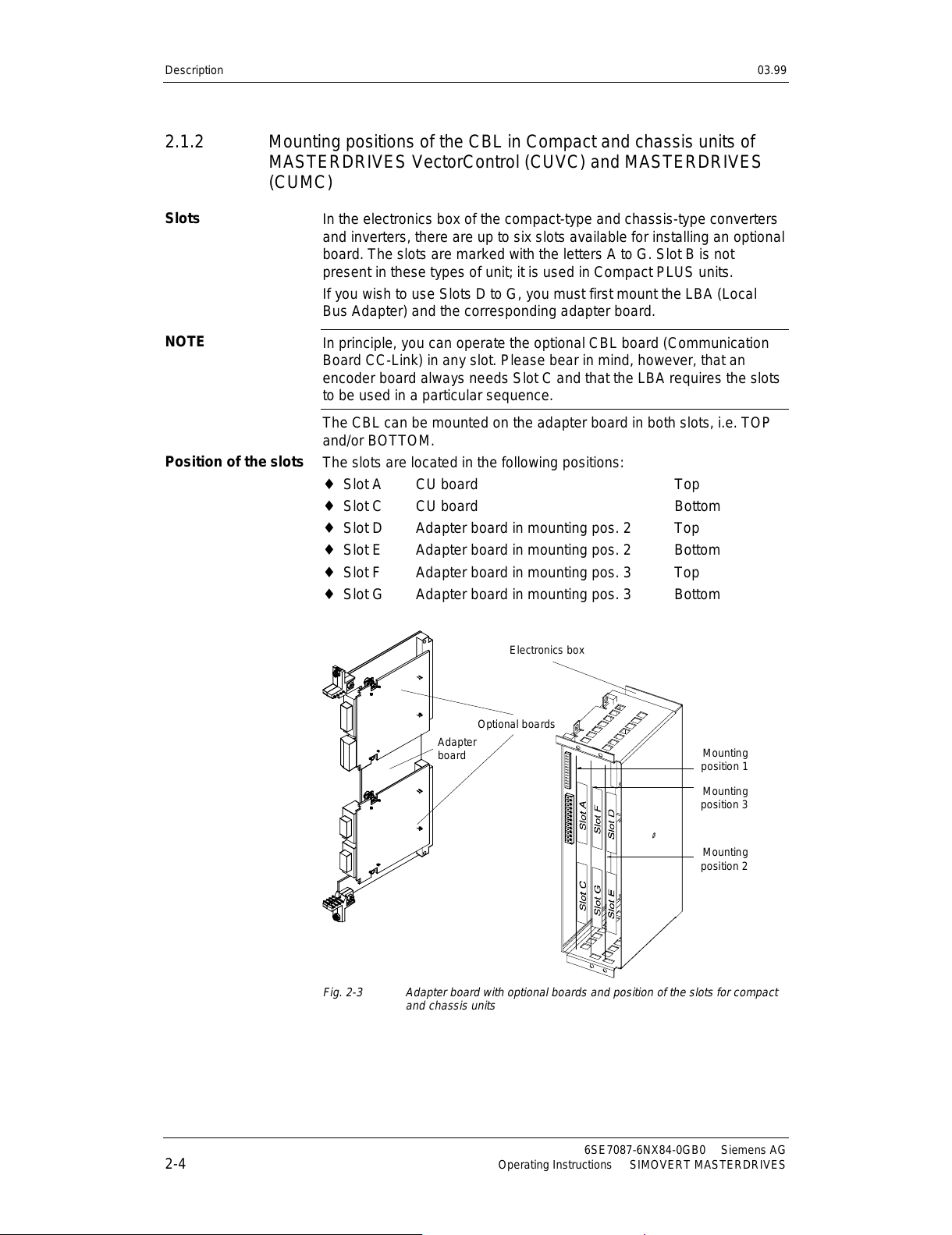

2.1.2 Mounting positions of the CBL in Compact and chassis units of

MASTERDRIVES VectorControl (CUVC) and MASTERDRIVES

(CUMC)

In the electronics box of the compact-type and chassis-type converters

and inverters, there are up to six slots available for installing an optional

board. The slots are marked with the letters A to G. Slot B is not

present in these types of unit; it is used in Compact PLUS units.

If you wish to use Slots D to G, you must first mount the LBA (Local

Bus Adapter) and the corresponding adapter board.

In principle, you can operate the optional CBL board (Communication

Board CC-Link) in any slot. Please bear in mind, however, that an

encoder board always needs Slot C and that the LBA requires the slots

to be used in a particular sequence.

The CBL can be mounted on the adapter board in both slots, i.e. TOP

and/or BOTTOM.

The slots are located in the following positions:

♦

Slot A CU board Top

♦

Slot C CU board Bottom

♦

Slot D Adapter board in mounting pos. 2 Top

♦

Slot E Adapter board in mounting pos. 2 Bottom

♦

Slot F Adapter board in mounting pos. 3 Top

♦

Slot G Adapter board in mounting pos. 3 Bottom

Adapter

board

Optional boards

Electronics box

Mounting

position 1

Mounting

position 2

Mounting

position 3

Fig. 2-3 Adapter board with optional boards and position of the slots for compact

and chassis units

Slots

NOTE

Position of the slots

All manuals and user guides at all-guides.com

Page 13

03.99 Description

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 2-5

Because of the DC link capacitors, there continues to be dangerous

voltage in the unit until up to 5 minutes after disconnection. Therefore

the unit must not opened until at least this time has expired.

Due to the technical structure of the LBA, certain sequences are

stipulated for use of the slots.

If only one adapter board with optional boards is insert ed into the

electronics box, it always must be plugged into mounting position 2.

If a T100 / T300 or T400 technology board is plugged into the

electronics box in addition to the adapter board with CBL, the

technology board must be plugged into mounting position 2. In this

case, the CBL is plugged into mounting position 3.

WARNING

All manuals and user guides at all-guides.com

Page 14

All manuals and user guides at all-guides.com

Page 15

03.99 Connecting

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 3-1

3 Connecting

The SIMOVERT MASTERDRIVES are operated with high voltages.

Any work on the unit may only be carried out by qualified personnel.

If this warning is ignored, serious injury or considerable damage to

property can occur as a consequence.

Because of the DC link capacitors, there continues to be dangerous

voltage in the unit until up to 5 minutes after disconnection. Therefore

the unit must not opened until at least this time has expired.

Even when the motor is at a standstill, the power terminals and the

control terminals can carry voltage. During work on the converter, it has

to be disconnected from the power supply.

When handling the opened converter, it must be kept in mind that live

components are exposed.

The CBL contains electrostatically sensitive components. These

components can very easily be destroyed by improper handling.

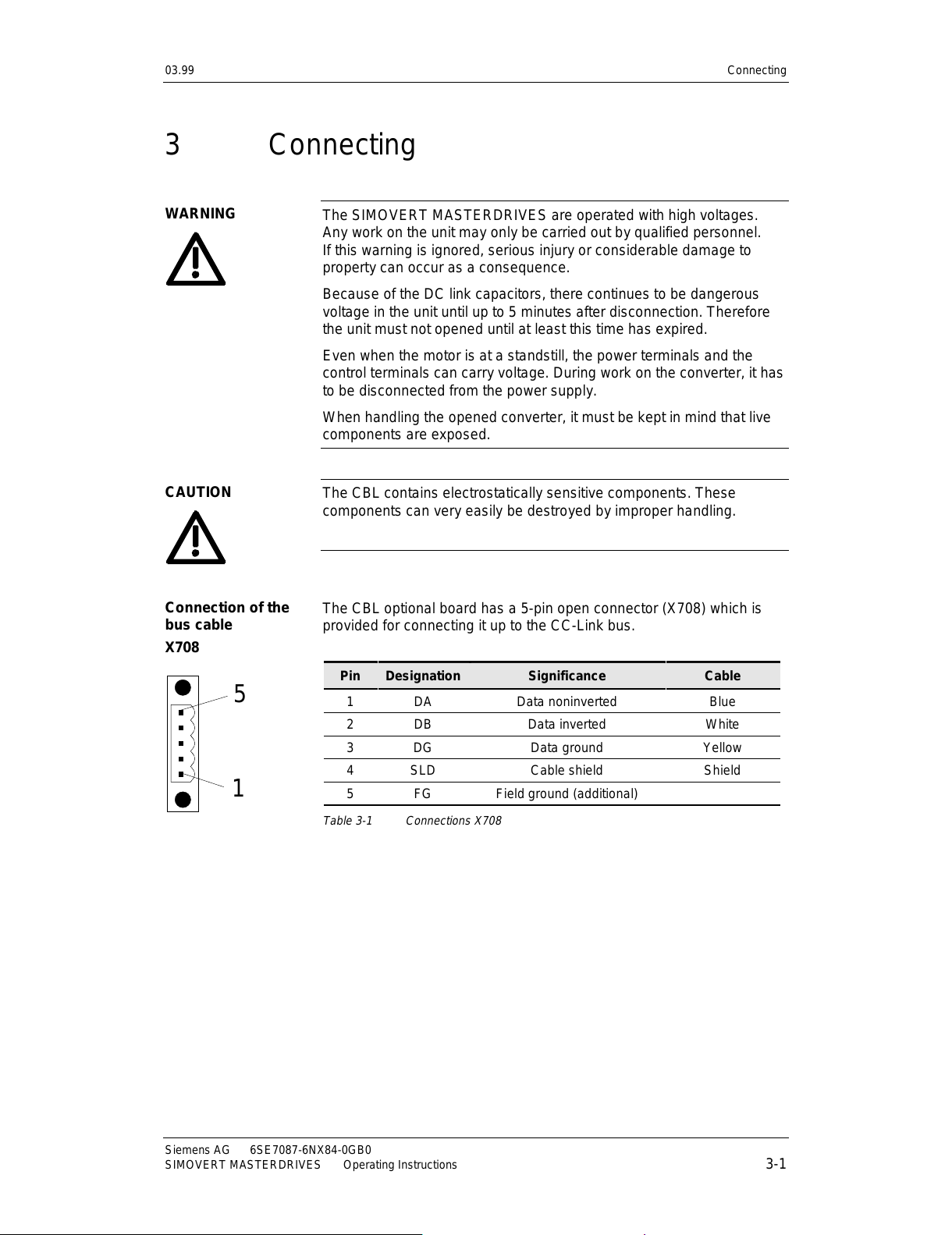

The CBL optional board has a 5-pin open connector (X708) which is

provided for connecting it up to the CC-Link bus.

Pin Designation Significance Cable

1 DA Data noninverted Blue

2 DB Data inverted White

3 DG Data ground Yellow

4 SLD C able shi eld Shield

5 FG Field ground (additional)

Table 3-1 Connections X708

WARNING

CAUTION

Connection of the

bus cable

X708

1

5

All manuals and user guides at all-guides.com

Page 16

Connecting 03.99

6SE7087-6NX84-0GB0 Siemens AG

3-2 Operating Instructions SIMOVERT MASTERDRIVES

Blue

White Yellow

Shielding

DA

DB

DG

Sheath

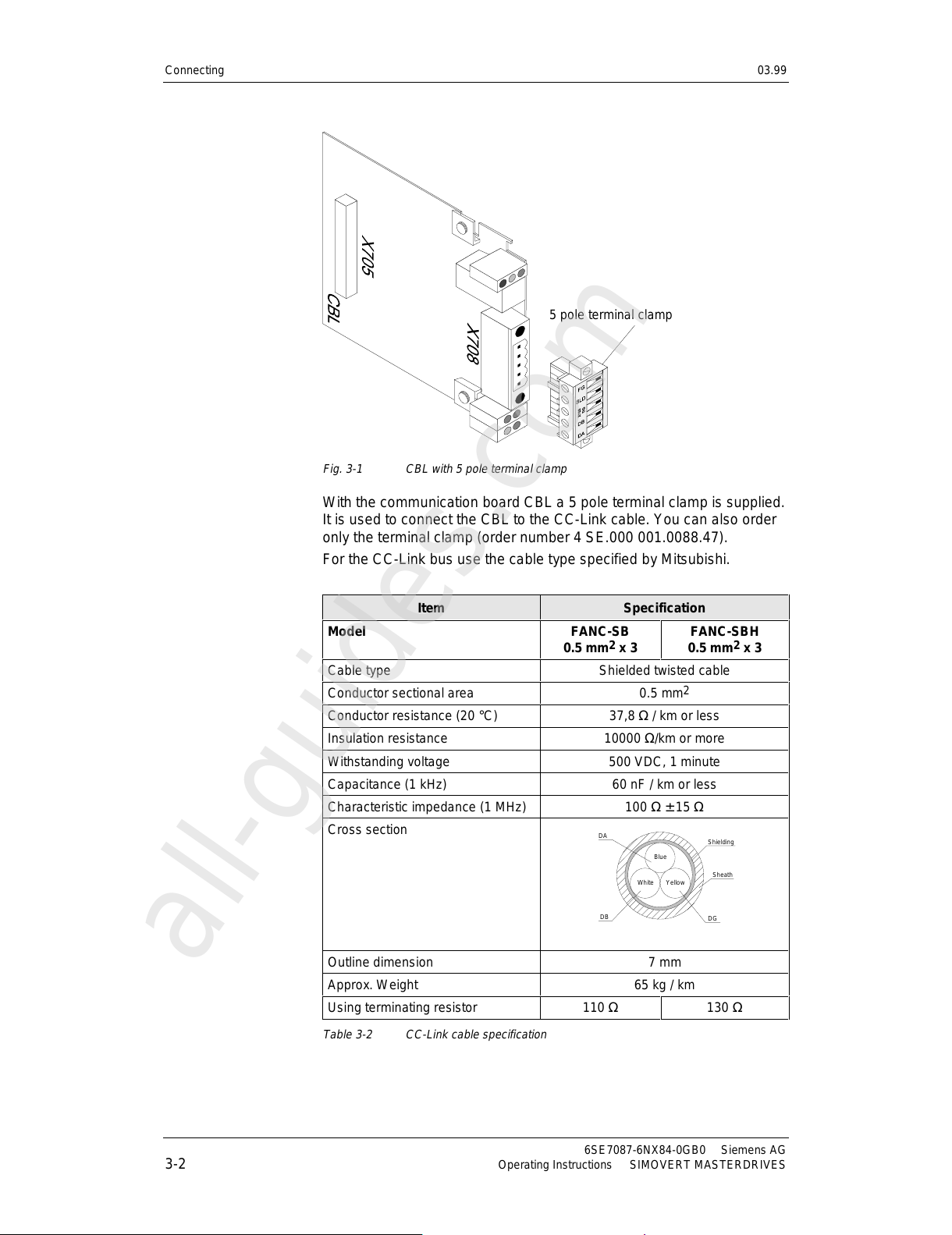

5 pole terminal clamp

Fig. 3-1 CBL with 5 pole terminal clamp

With the communication board CBL a 5 pole terminal clamp is supplied.

It is used to connect the CBL to the CC-Link cable. You can also order

only the terminal clamp (order number 4 SE.000 001.0088.47).

For the CC-Link bus use the cable type specified by Mitsubishi.

Item Specification

Model FANC-SB

0.5 mm

2

x 3

FANC-SBH

0.5 mm2 x 3

Cable type Shielded twisted cable

Conductor sectional area 0.5 mm

2

Conductor resistance (20 °C) 37,8 Ω / km or less

Insulation resistance 10000 Ω/km or more

Withstanding voltage 500 VDC, 1 minute

Capacitance (1 kHz) 60 nF / km or less

Characteristic impedance (1 MHz) 100 Ω ± 15 Ω

Cross section

Outline dimension 7 mm

Approx. Weight 65 kg / km

Using terminating resistor 110 Ω 130 Ω

Table 3-2 CC-Link cable specification

All manuals and user guides at all-guides.com

all-guides.com

Page 17

03.99 Connecting

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 3-3

Mitsubishi specifies a maximum cable length depending on the data

transfer rate. For more detailed information refer to documentation of

CC-Link by Mitsubishi.

Data transfer rate Total bus distance

10 MBit/s 100 m

5 Mbit/s 150 m

2.5 MBit/s 200 m

625 kBit/s 600 m

156 kBit/s 1200 m

Table 3-3 Cable length in relation to the baud rate

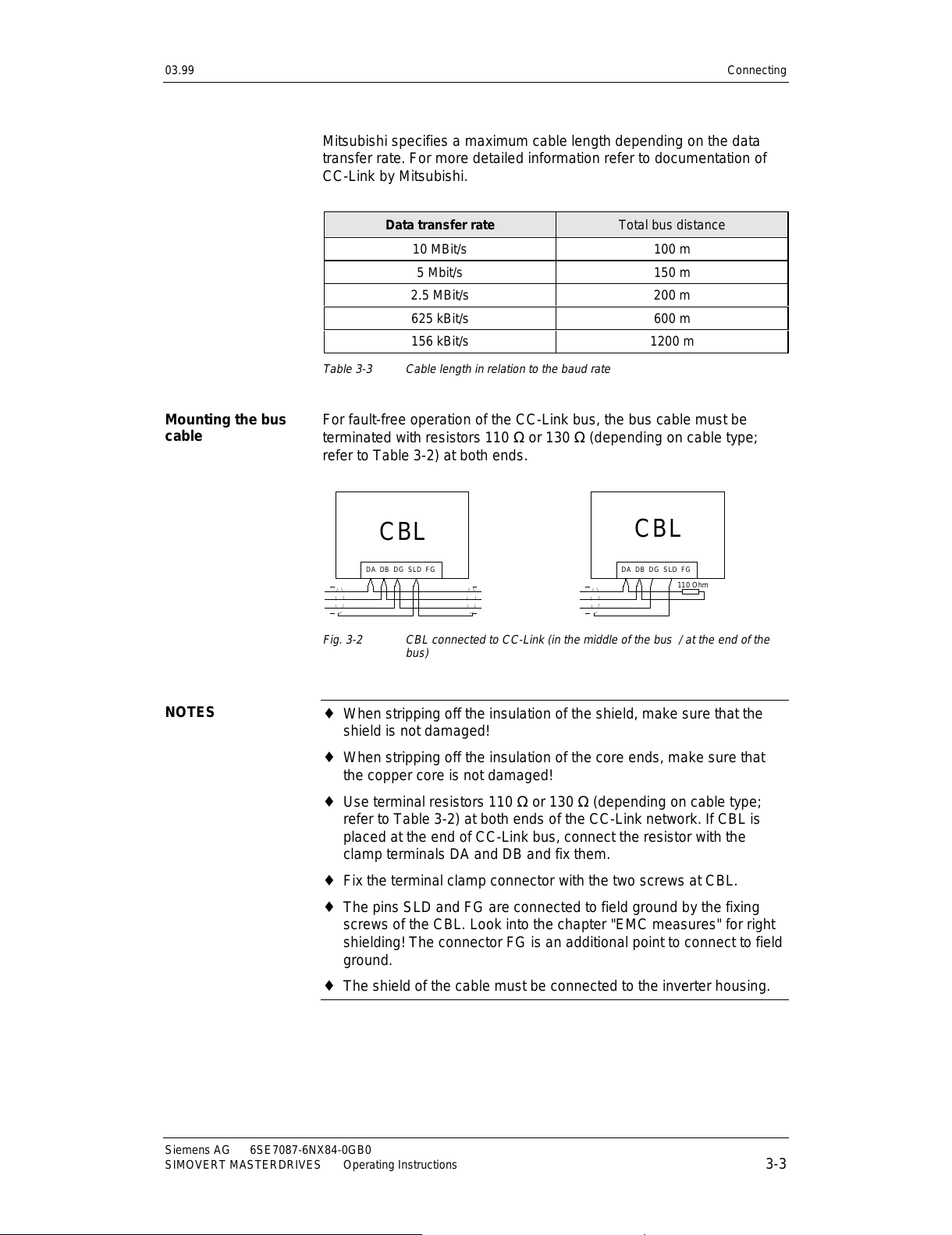

For fault-free operation of the CC-Link bus, the bus cable must be

terminated with resistors 110 Ω or 130 Ω (depending on cable type;

refer to Table 3-2) at both ends.

DA DB DG SLD FG

CBL

DA DB DG SLD FG

CBL

110 Ohm

Fig. 3-2 CBL connected to CC-Link (in the middle of the bus / at the end of the

bus)

♦

When stripping off the insulation of the shield, make sure that the

shield is not damaged!

♦

When stripping off the insulation of the core ends, make sure that

the copper core is not damaged!

♦

Use terminal resistors 110 Ω or 130 Ω (depending on cable type;

refer to Table 3-2) at both ends of the CC-Link network. If CBL is

placed at the end of CC-Link bus, connect the resistor with the

clamp terminals DA and DB and fix them.

♦

Fix the terminal clamp connector with the two screws at CBL.

♦

The pins SLD and FG are connected to field ground by the fixing

screws of the CBL. Look into the chapter "EMC measures" for right

shielding! The connector FG is an additional point to connect to field

ground.

♦ The shield of the cable must be connected to the inverter housing.

Mounting the bus

cable

NOTES

All manuals and user guides at all-guides.com

Page 18

Connecting 03.99

6SE7087-6NX84-0GB0 Siemens AG

3-4 Operating Instructions SIMOVERT MASTERDRIVES

3.1 EMC measures

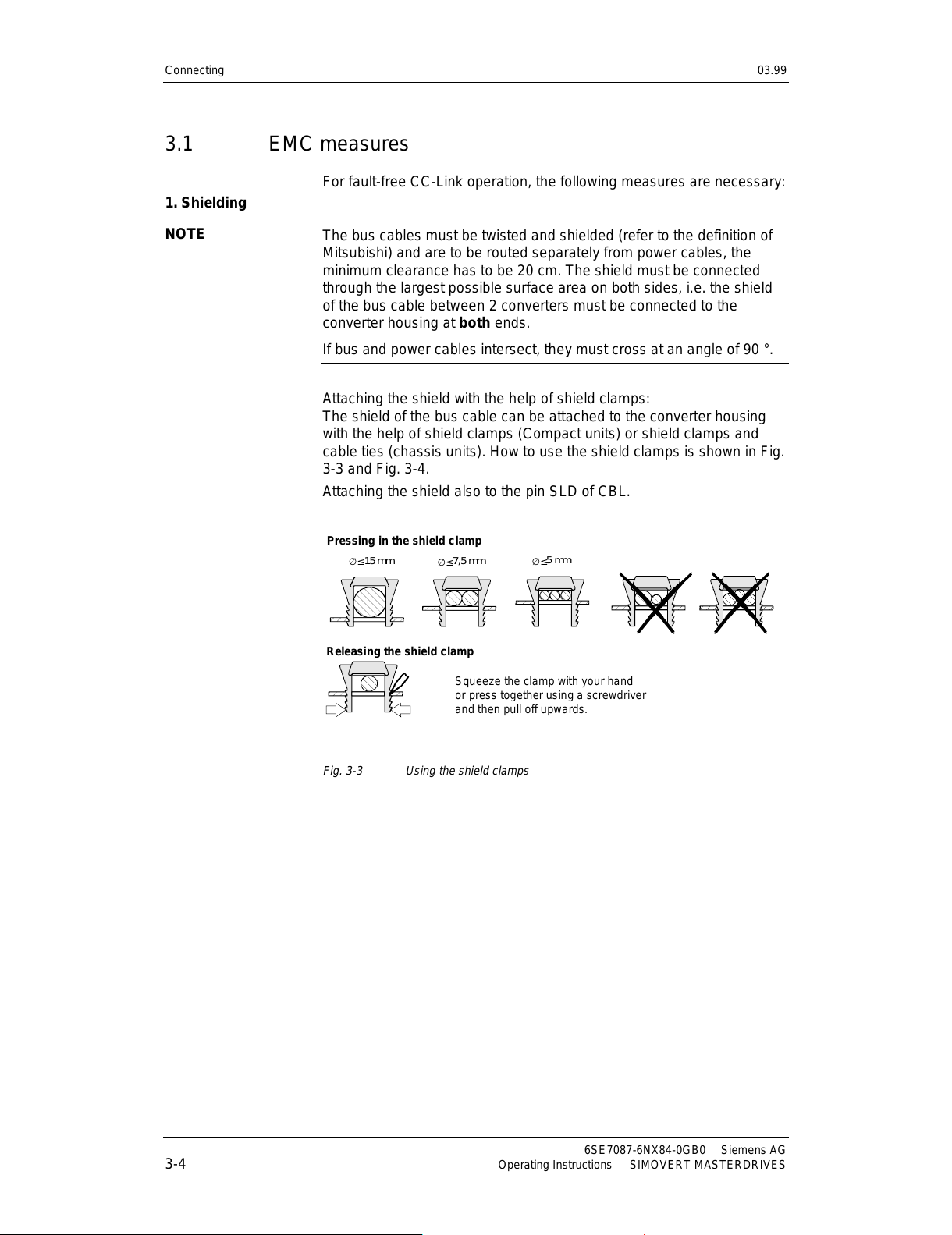

For fault-free CC-Link operation, the following measures are necessary:

The bus cables must be twisted and shielded (refer to the definition of

Mitsubishi) and are to be routed separately from power cables, the

minimum clearance has to be 20 cm. The shield must be connected

through the largest possible surface area on both sides, i.e. the shield

of the bus cable between 2 converters must be connected to the

converter housing at both ends.

If bus and power cables intersect, they must cross at an angle of 90 °.

Attaching the shield with the help of shield clamps:

The shield of the bus cable can be attached to the converter housing

with the help of shield clamps (Compact units) or shield clamps and

cable ties (chassis units). How to use the shield clamps is shown in Fig.

3-3 and Fig. 3-4.

Attaching the shield also to the pin SLD of CBL.

∅ ≤

15 mm

∅ ≤

7,5 mm

∅ ≤

5 mm

Pressing in the shield clamp

Releasing the shield clamp

Squeeze the clamp with your hand

or press together using a screwdriver

and then pull off upwards.

Fig. 3-3 Using the shield clamps

1. Shielding

NOTE

All manuals and user guides at all-guides.com

Page 19

03.99 Connecting

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 3-5

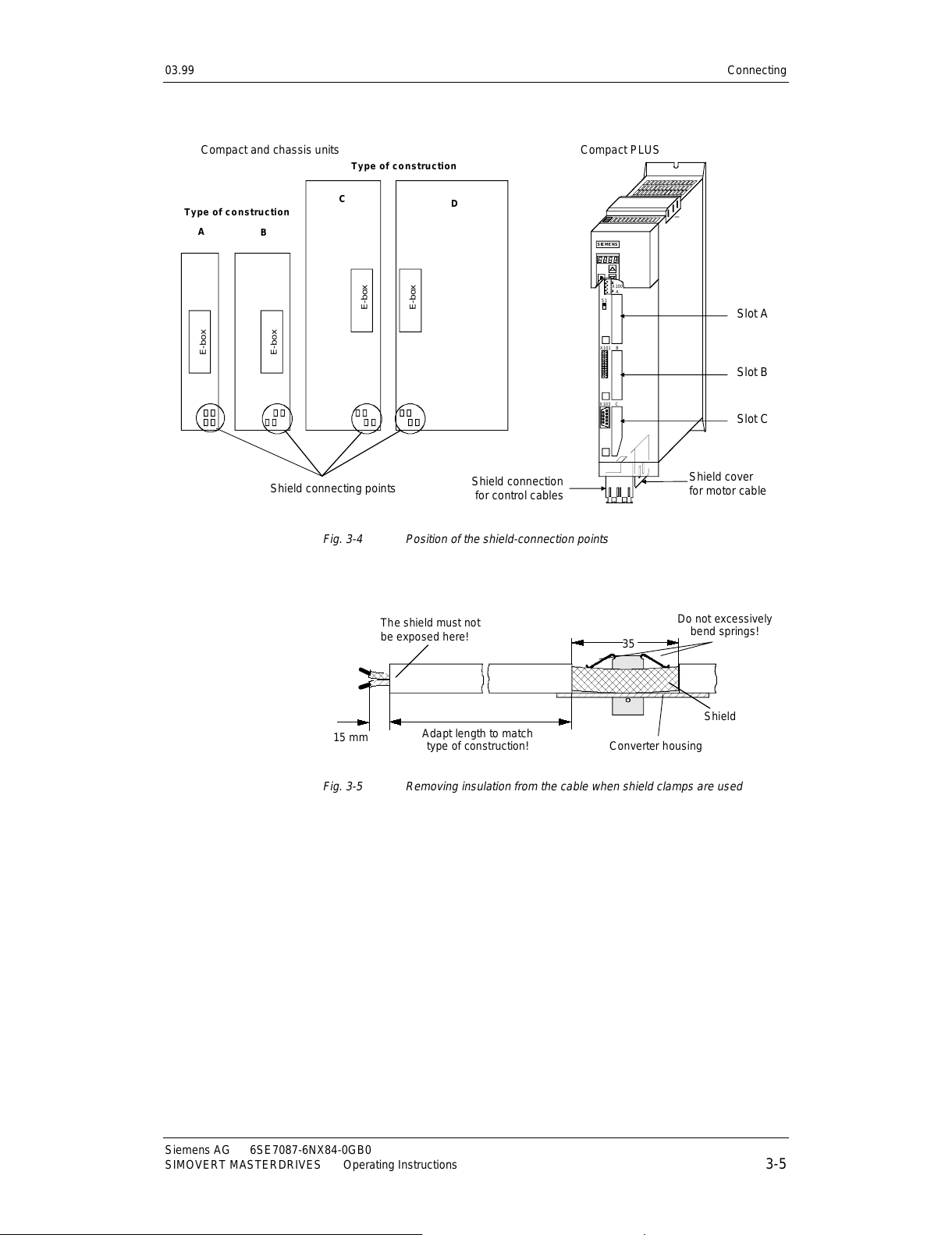

Type of co nstruc tion

E-box

E-box

E-box

E-box

SIEMENS

X100

A

S1

BX101

CX103

Slot A

Slot B

Slot C

Shield connection

for control cables

Shield cove r

for motor cable

−

Compact and chassis units Compact PLUS

Shield connecting points

A

B

Type of co nstruc tion

D

C

Fig. 3-4 Position of the shield-connection points

The shield must not

be exposed here!

Do not excessively

bend springs!

35

Shield

Adapt length to match

type of construction!

Convert er housing

15 mm

Fig. 3-5 Removing insulation from the cable when shield clamps are used

All manuals and user guides at all-guides.com

Page 20

Connecting 03.99

6SE7087-6NX84-0GB0 Siemens AG

3-6 Operating Instructions SIMOVERT MASTERDRIVES

Please avoid differences in potential (e.g. due to different supply levels)

between the converters and the CC-Link master:

♦

Use equipotential bonding cables:

•

16 mm

2

Cu for equipotential bonding cables up to 200 m

•

25 mm

2

Cu for equipotential bonding cables over 200 m

♦

Lay the equipotential bonding cables so that there is the smallest

possible surface area between the equipotential bonding cable and

signal cables.

♦

Connect equipotential bonding conductors to the earth/protective

conductor through the largest possible surface area.

Please comply with the following instructions when laying cables:

♦

Do not lay bus cables (signal cables) directly parallel to power

cables.

♦

Lay signal cables and the associated equipotential bonding cables

with the lowest possible distance between them and on the shortest

routes.

♦

Lay power cables and signal cables in separate cable ducts.

♦

Attach shields through a large surface area.

2. Equipotential

bonding

3. Laying cables

All manuals and user guides at all-guides.com

Page 21

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-1

4 Communication via CC-Link

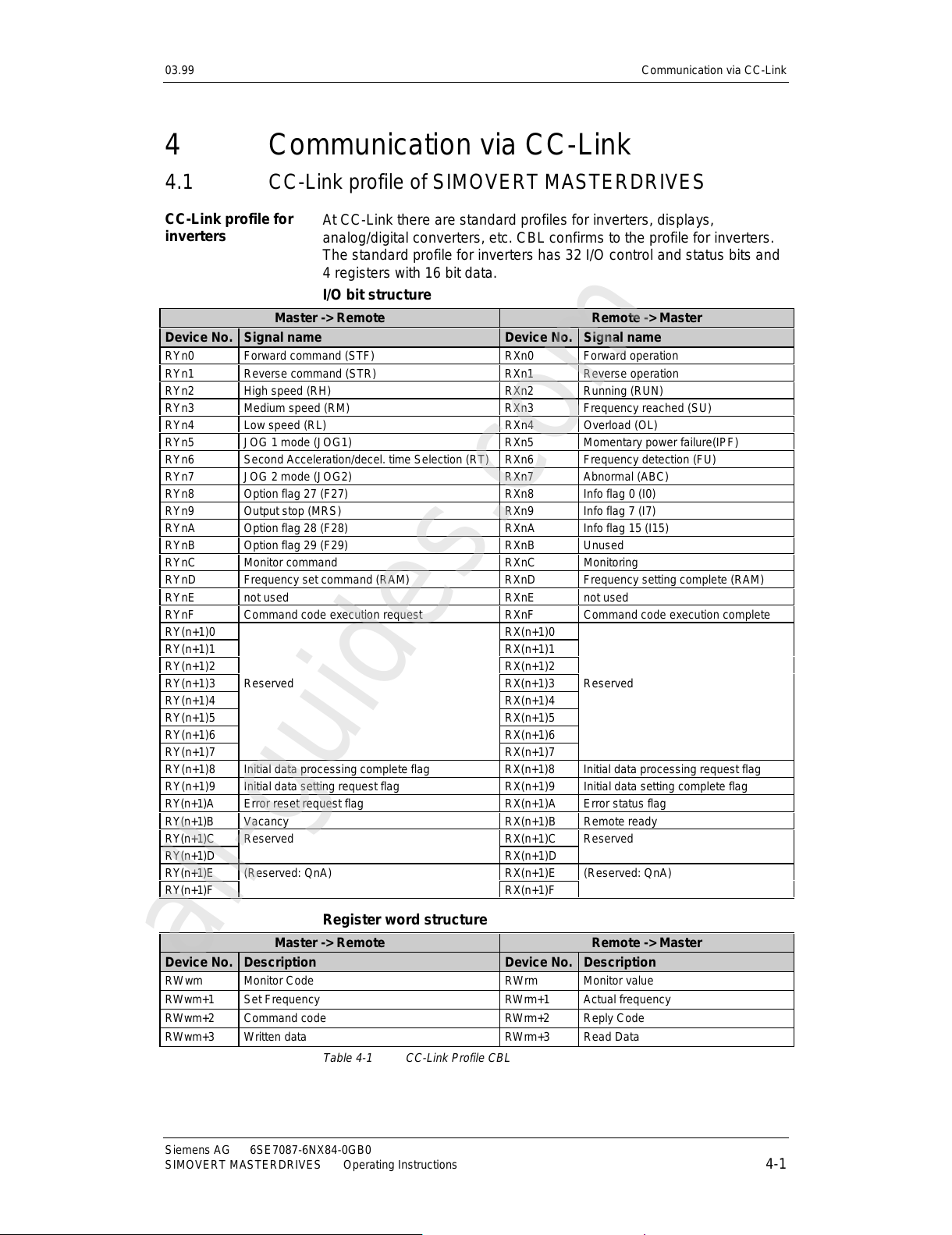

4.1 CC-Link profile of SIMOVERT MASTERDRIVES

At CC-Link there are standard profiles for inverters, displays,

analog/digital converters, etc. CBL confirms to the profile for inverters.

The standard profile for inverters has 32 I/O control and status bits and

4 registers with 16 bit data.

I/O bit structure

Master -> Remote Remote -> Master

Device No. Signal name Device No. Signal name

RYn0 Forward command (STF) RXn0 Forward operation

RYn1 Reverse command (STR) RXn1 Reverse operation

RYn2 High speed (RH) RXn2 Running (RUN)

RYn3 Medium speed (RM) RXn3 Frequency reached (SU)

RYn4 Low speed (RL) RXn4 Overload (OL)

RYn5 JOG 1 mode (JOG1) RXn5 Momentary power failure(IPF)

RYn6 Second Acceleration/decel. time Selection (RT) RXn6 Frequency detection (FU)

RYn7 JOG 2 mode (JOG2) RXn7 Abnormal (ABC)

RYn8 Option flag 27 (F27) RXn8 Info flag 0 (I0)

RYn9 Output stop (MRS) RXn9 Info flag 7 (I7)

RYnA Option flag 28 (F28) RXnA Info flag 15 (I15)

RYnB Option flag 29 (F29) RXnB Unused

RYnC Monitor command RXnC Monitoring

RYnD Frequency set command (RAM) RXnD Frequency setting complete (RAM)

RYnE not used RXnE not used

RYnF Command code execution request RXnF Comm and code executi on compl ete

RY(n+1)0 RX(n+1)0

RY(n+1)1 RX(n+1)1

RY(n+1)2 RX(n+1)2

RY(n+1)3 Reserved RX(n+1)3 Reserved

RY(n+1)4 RX(n+1)4

RY(n+1)5 RX(n+1)5

RY(n+1)6 RX(n+1)6

RY(n+1)7 RX(n+1)7

RY(n+1)8 Initial data processing complete flag RX(n+1)8 Initial data processing request flag

RY(n+1)9 Initial data setting request flag RX(n+1)9 Initial data setting complete flag

RY(n+1)A Error reset request flag RX(n+1)A Error status flag

RY(n+1)B Vacancy RX(n+1)B Remote ready

RY(n+1)C Reserved RX(n+1)C Reserved

RY(n+1)D RX(n+1)D

RY(n+1)E (Reserved: QnA) RX(n+1)E (Reserved: QnA)

RY(n+1)F RX(n+1)F

Register word structure

Master -> Remote Remote -> Master

Device No. Description Device No. Description

RWwm Monitor Code RWrm Monitor value

RWwm+1 Set Frequency RWrm+1 Actual frequency

RWwm+2 Command code RWrm+2 Reply Code

RWwm+3 Written data RWrm+3 Read Data

Table 4-1 CC-Link Profile CBL

CC-Link profile for

inverters

All manuals and user guides at all-guides.com

all-guides.com

Page 22

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-2 Operating Instructions SIMOVERT MASTERDRIVES

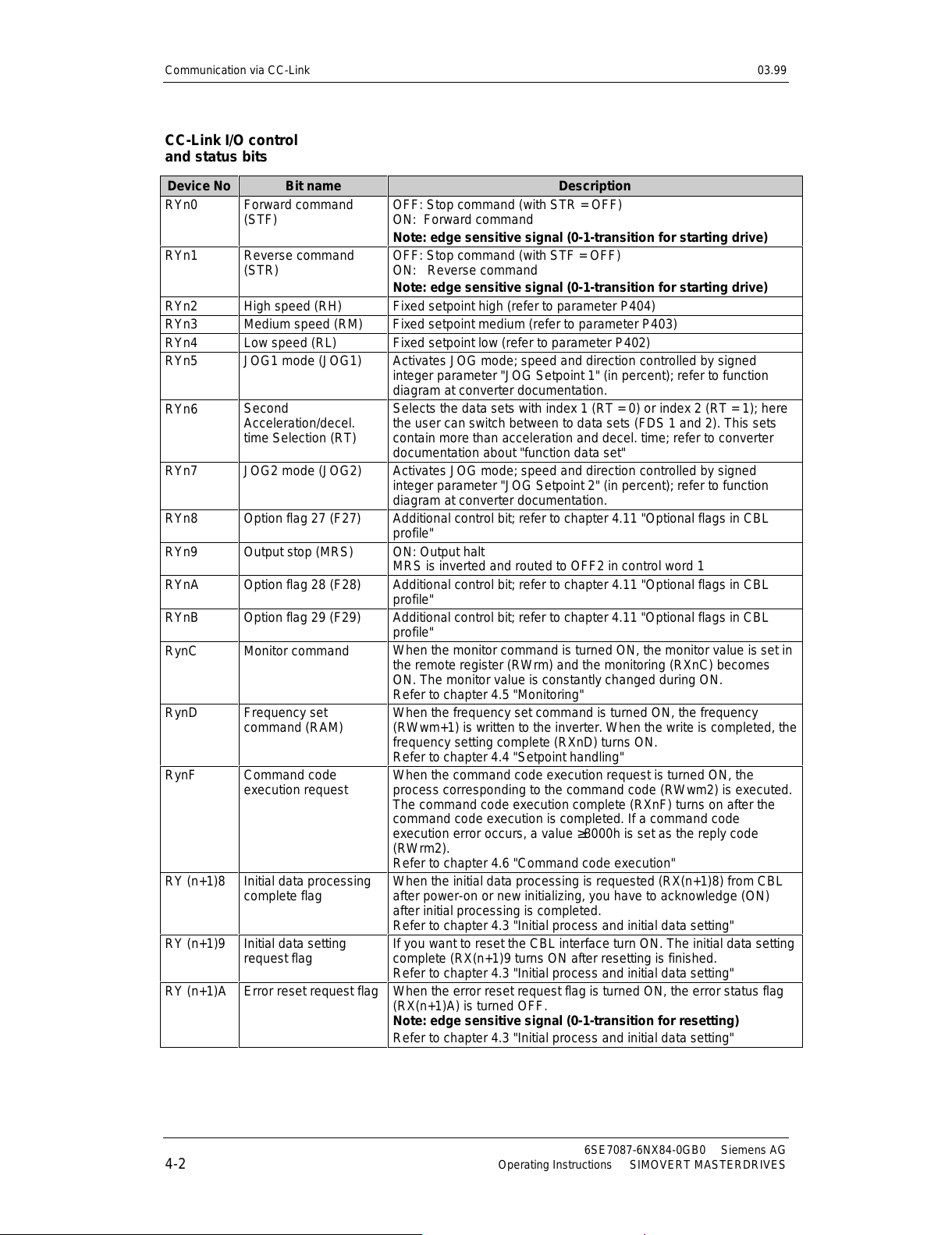

Device No Bit name Description

RYn0 Forward command

(STF)

OFF: Stop command (with STR = OFF)

ON: Forward command

Note: edge sensitive signal (0-1-transition for starting drive)

RYn1

Reverse command

(STR)

OFF: Stop command (with STF = OFF)

ON: Reverse command

Note: edge sensitive signal (0-1-transition for starting drive)

RYn2 High speed (RH) Fixed setpoint high (refer to parameter P404)

RYn3 Medium speed (RM) Fixed setpoint medium (refer to parameter P403)

RYn4 Low speed (RL) Fixed setpoint low (refer to parameter P402)

RYn5 JOG1 mode (JOG1)

Activates JOG mode; speed and direction controlled by signed

integer parameter "JOG Setpoint 1" (in percent); refer to function

diagram at converter documentation.

RYn6

Second

Acceleration/decel.

time Selection (RT)

Selects the data sets with index 1 (RT = 0) or index 2 (RT = 1); here

the user can switch between to data sets (FDS 1 and 2). This sets

contain more than acceleration and decel. time; refer to converter

documentation about "function data set"

RYn7 JOG2 mode (JOG2)

Activates JOG mode; speed and direction controlled by signed

integer parameter "JOG Setpoint 2" (in percent); refer to function

diagram at converter documentation.

RYn8 Option flag 27 (F27)

Additional control bit; refer to chapter 4.11 "Optional flags in CBL

profile"

RYn9 Output stop (MRS) ON: Output halt

MRS is inverted and routed to OFF2 in control word 1

RYnA Option flag 28 (F28)

Additional control bit; refer to chapter 4.11 "Optional flags in CBL

profile"

RYnB Option flag 29 (F29) Additional control bit; refer to chapter 4.11 "Optional flags in CBL

profile"

RynC Monitor command

When the monitor command is turned ON, the monitor value is set in

the remote register (RWrm) and the monitoring (RXnC) becomes

ON. The monitor value is constantly changed during ON.

Refer to chapter 4.5 "Monitoring"

RynD

Frequency set

command (RAM)

When the frequency set command is turned ON, the frequency

(RWwm+1) is written to the inverter. When the write is completed, the

frequency setting complete (RXnD) turns ON.

Refer to chapter 4.4 "Setpoint handling"

RynF Command code

execution request

When the command code execution request is turned ON, the

process corresponding to the command code (RWwm2) is executed.

The command code execution complete (RXnF) turns on after the

command code execution is completed. If a command code

execution error occurs, a value ≥8000h is set as the reply code

(RWrm2).

Refer to chapter 4.6 "Command code execution"

RY (n+1)8 Initial data processing

complete flag

When the initial data processing is requested (RX(n+1)8) from CBL

after power-on or new initializing, you have to acknowledge (ON)

after initial processing is completed.

Refer to chapter 4.3 "Initial process and initial data setting"

RY (n+1)9 Initial data setting

request flag

If you want to reset the CBL interface turn ON. The initial data setting

complete (RX(n+1)9 turns ON after resetting is finished.

Refer to chapter 4.3 "Initial process and initial data setting"

RY (n+1)A Error reset request flag When the error reset request flag is turned ON, the error status flag

(RX(n+1)A) is turned OFF.

Note: edge sensitive signal (0-1-transition for resetting)

Refer to chapter 4.3 "Initial process and initial data setting"

CC-Link I/O control

and status bits

All manuals and user guides at all-guides.com

Page 23

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-3

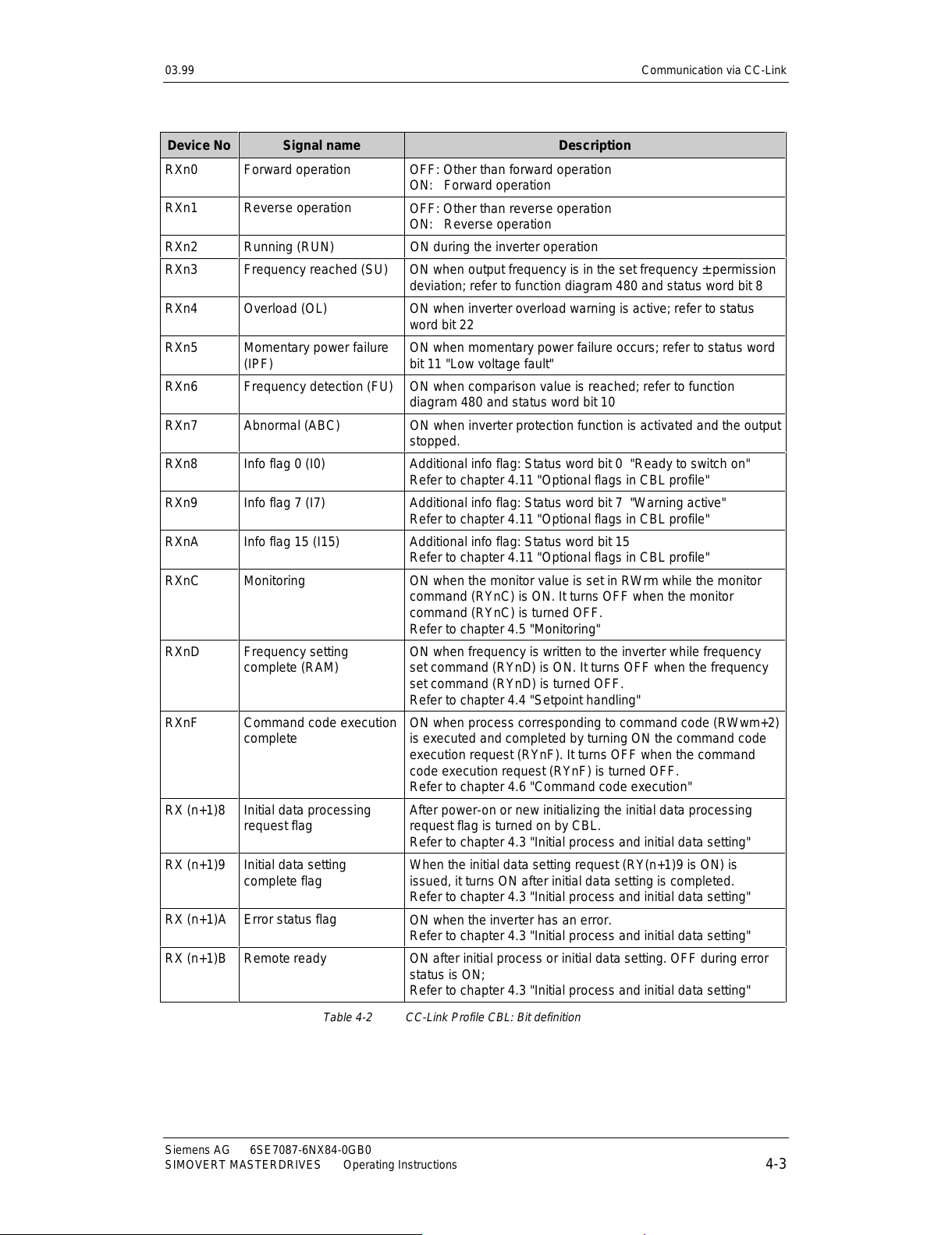

Device No Signal name Description

RXn0 Forward operation OFF: Other than forward operation

ON: Forward operation

RXn1 Reverse operation

OFF: Other than reverse operation

ON: Reverse operation

RXn2 Running (RUN) ON during the inverter operation

RXn3 Frequency reached (SU)

ON when output frequency is in the set frequency ± permission

deviation; refer to function diagram 480 and status word bit 8

RXn4 Overload (OL)

ON when inverter overload warning is active; refer to status

word bit 22

RXn5 Momentary power failure

(IPF)

ON when momentary power failure occurs; refer to status word

bit 11 "Low voltage fault"

RXn6 Frequency detection (FU) ON when comparison value is reached; refer to function

diagram 480 and status word bit 10

RXn7 Abnormal (ABC) ON when inverter protection function is activated and the output

stopped.

RXn8 Info flag 0 (I0) Additional info flag: Status word bit 0 "Ready to switch on"

Refer to chapter 4.11 "Optional flags in CBL profile"

RXn9 Info flag 7 (I7)

Additional info flag: Status word bit 7 "Warning active"

Refer to chapter 4.11 "Optional flags in CBL profile"

RXnA Info flag 15 (I15)

Additional info flag: Status word bit 15

Refer to chapter 4.11 "Optional flags in CBL profile"

RXnC Monitoring ON when the monitor value is set in RWrm while the monitor

command (RYnC) is ON. It turns OFF when the monitor

command (RYnC) is turned OFF.

Refer to chapter 4.5 "Monitoring"

RXnD

Frequency setting

complete (RAM)

ON when frequency is written to the inverter while frequency

set command (RYnD) is ON. It turns OFF when the frequency

set command (RYnD) is turned OFF.

Refer to chapter 4.4 "Setpoint handling"

RXnF

Command code execution

complete

ON when process corresponding to command code (RWwm+2)

is executed and completed by turning ON the command code

execution request (RYnF). It turns OFF when the command

code execution request (RYnF) is turned OFF.

Refer to chapter 4.6 "Command code execution"

RX (n+1)8

Initial data processing

request flag

After power-on or new initializing the initial data processing

request flag is turned on by CBL.

Refer to chapter 4.3 "Initial process and initial data setting"

RX (n+1)9 Initial data setting

complete flag

When the initial data setting request (RY(n+1)9 is ON) is

issued, it turns ON after initial data setting is completed.

Refer to chapter 4.3 "Initial process and initial data setting"

RX (n+1)A Error status flag

ON when the inverter has an error.

Refer to chapter 4.3 "Initial process and initial data setting"

RX (n+1)B Remote ready ON after initial process or initial data setting. OFF during error

status is ON;

Refer to chapter 4.3 "Initial process and initial data setting"

Table 4-2 CC-Link Profile CBL: Bit definition

All manuals and user guides at all-guides.com

Page 24

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-4 Operating Instructions SIMOVERT MASTERDRIVES

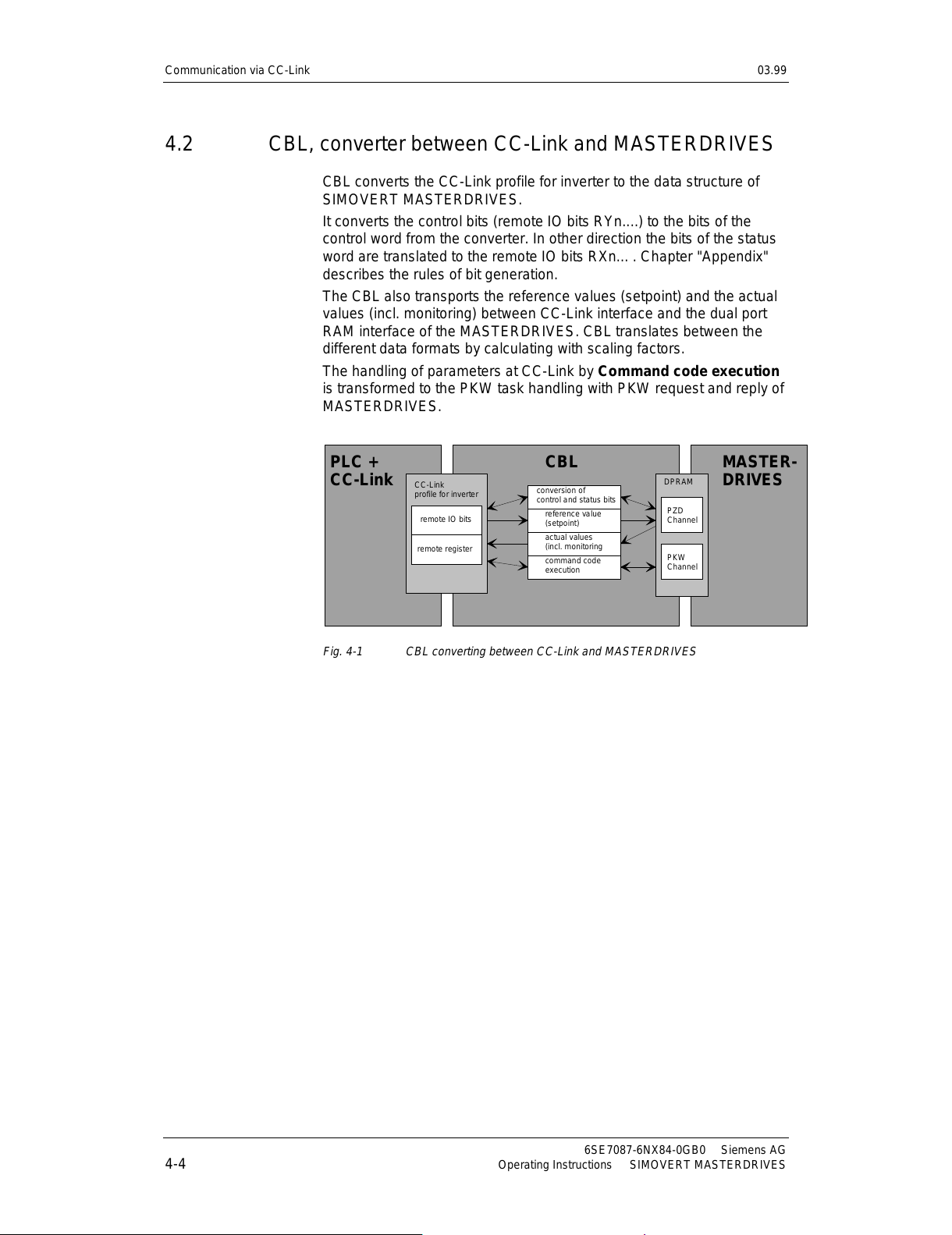

4.2 CBL, converter between CC-Link and MASTERDRIVES

CBL converts the CC-Link profile for inverter to the data structure of

SIMOVERT MASTERDRIVES.

It converts the control bits (remote IO bits RYn....) to the bits of the

control word from the converter. In other direction the bits of the status

word are translated to the remote IO bits RXn... . Chapter "Appendix"

describes the rules of bit generation.

The CBL also transports the reference values (setpoint) and the actual

values (incl. monitoring) between CC-Link interface and the dual port

RAM interface of the MASTERDRIVES. CBL translates between the

different data formats by calculating with scaling factors.

The handling of parameters at CC-Link by Command

code execution

is transformed to the PKW task handling with PKW request and reply of

MASTERDRIVES.

remote IO bits

remote register

reference value

(setpoi nt)

actual values

(incl. monitoring

command code

execution

conversion of

control and status bits

PZD

Channel

PKW

Channel

DPRAM

CC-Link

profile for inverter

CBLPLC +

CC-Link

MASTER-

DRIVES

Fig. 4-1 CBL converting between CC-Link and MASTERDRIVES

All manuals and user guides at all-guides.com

Page 25

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-5

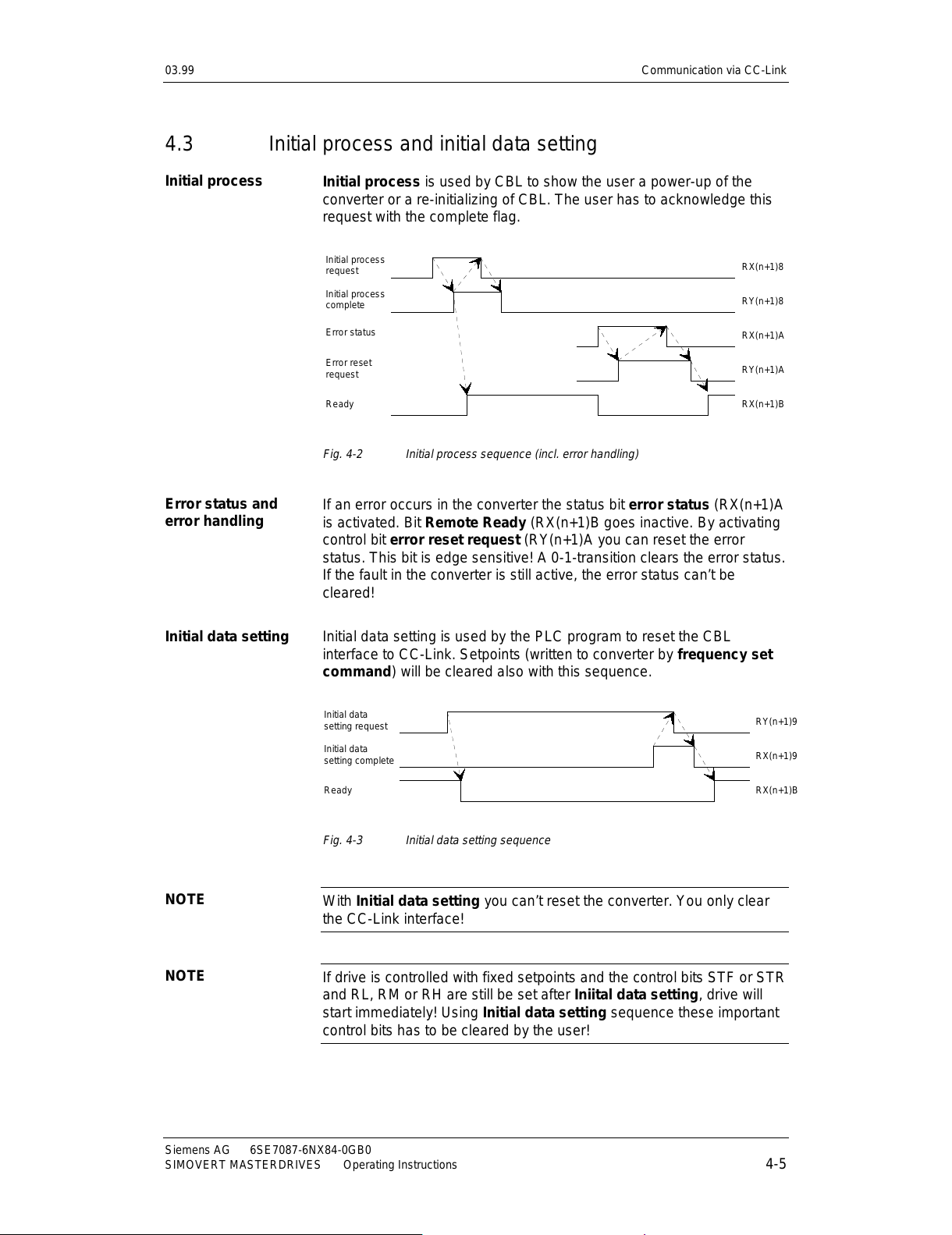

4.3 Initial process and initial data setting

Initial process is used by CBL to show the user a power-up of the

converter or a re-initializing of CBL. The user has to acknowledge this

request with the complete flag.

RX(n+1)8

RY(n+1)8

RX(n+1)A

RY(n+1)A

RX(n+1)B

Initial process

request

Initial process

complete

Error status

Error reset

request

Ready

Fig. 4-2 Initial process sequence (incl. error handling)

If an error occurs in the converter the status bit error status (RX(n+1)A

is activated. Bit Remote Ready

(RX(n+1)B goes inactive. By activating

control bit error reset request

(RY(n+1)A you can reset the error

status. This bit is edge sensitive! A 0-1-transition clears the error status.

If the fault in the converter is still active, the error status can’t be

cleared!

Initial data setting is used by the PLC program to reset the CBL

interface to CC-Link. Setpoints (written to converter by frequency set

command) will be cleared also with this sequence.

RY(n+1)9

RX(n+1)9

RX(n+1)B

Initial d ata

setting request

Initial d ata

setting complete

Ready

Fig. 4-3 Initial data setting sequence

With Initial data setting you can’t reset the converter. You only clear

the CC-Link interface!

If drive is controlled with fixed setpoints and the control bits STF or STR

and RL, RM or RH are still be set after Iniital data setting, drive will

start immediately! Using Initial data setting sequence these important

control bits has to be cleared by the user!

Initial process

Error status and

error handling

Initial data setting

NOTE

NOTE

All manuals and user guides at all-guides.com

Page 26

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-6 Operating Instructions SIMOVERT MASTERDRIVES

4.4 Setpoint handling

With SIMOVERT MASTERDRIVES converters there are several

possibilities to control a drive. In systems with CC-Link the drive can be

controlled by frequency setpoints or torque setpoints.

In the following sections there is the description how to handle the CBL

for controlling the drive with frequency setpoints. It is also valid for

torque control. Different handling is specially noted.

For more information about the possibilities of controlling and regulating

refer to converter documentation.

Giving setpoints from the PLC is possible in two ways:

♦

Working with fixed setpoints selected by control bits RL, RM and

RH. The fixed setpoints are stored in the fixed setpoint buffer of the

converter. They can parameterized from the panel of the converter

(PMU) or from PLC via CC-Link.

♦

Working with variable setpoints. They will be set with the frequency

set command

.

In the converter you can select (softwiring) one of the different sources

by the parameter P443 Source main setpoint. Refer to documentation

of converter; function diagram 316.

At regulation of torque use P486; refer to documentation of converter;

function diagram 320.

Example:

1) working with fixed setpoints RL, RM, RH:

=> P443 = 0040 Set frequency value from fix ed setpoi nt

buffer.

2) working with variable setpoints by frequency set command:

=> P443 = 3002 Set frequency value from first CBL to

Source main setpoint.

The different data formats for handling setpoints will be discribed in

chapter 4.9, "Data formats and data conversion".

The drive is started by activating control bit STF (RYn0: forward) or

STR (RYn1: reverse).

Regulation of

frequency or torque

Handling setpoints

All manuals and user guides at all-guides.com

all-guides.com

Page 27

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-7

The frequency set command is initiated by the user. First he writes

the new setpoint into register set frequency (RWwm+1). Second he

activates the command with the control bit frequency set command

request (RYnD). After the CBL has written the new value to the

converter it acknowledges with frequency setting complete (RXnD).

new setpoint

RYnD

RWwm+1

RXnD

Frequency set

command request

Set frequency

Frequency setting

complete

Fig. 4-4 Frequency set command sequence

Check, that P443 Source main setpoint is set to communication board

PZD2 (first CBL => 3002)!

With RL, RM and RH you have 3 selectable fixed setpoints. You have

to parameterize the fixed setpoint buffer:

fixed setpoint (1) => P401 = 0000 "speed 0"

fixed setpoint (2) => P402 = xxxx "speed RL = xxxx"

fixed setpoint (3) => P403 = yyyy "speed RM = yyyy"

fixed setpoint (4) => P404 = zzzz "speed RH = zzzz"

After you have selected P443 = 0040 (Source main setpoint = fixed

setpoint buffer

)

you can control the speed by the control bits RL, RM

and RH. If you activate more than one bit of them, the lower speed has

the higher priority. The control bits JOG1 (RYn5) and JOG2 (Ryn7)

have higher priority than RL, RM and RH.

Priority: High <= JOG RL RM RH => Low

The JOG function can be activated by control bits JOG1 (RYn5) or

JOG2 (RYn7). JOG1 is assigned to "JOG setpoint 1" and JOG2 is

assigned to "JOG setpoint 2" of the converter; refer to its

documentation. The JOG setpoints in the converter are signed integer

values in percent; so speed and direction at JOG mode can be handled

by the user.

Don’t use STF and STR to control direction at JOG mode! Refer to

function diagrams of converter.

Frequency set

command

Fixed Setpoints with

RL, RM, RH

Controlling drive

with JOG1 and

JOG2

NOTE

All manuals and user guides at all-guides.com

Page 28

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-8 Operating Instructions SIMOVERT MASTERDRIVES

4.5 Monitoring

With the monitoring command you can get a selectable actual value of

the process. First select one process value by writing selection number

into register monitor code (RWwm). Second you activate monitoring

with monitor command (RYnC). While this bit is active and the CBL

acknowledges with bit monitoring (RXnC), you get actual values in

register monitoring value (RWrm). You can change the monitor code

during monitoring command is active. But attention, you don’t know at

which time you get actual values from the new selected proc es s valu e!

Better you close the monitoring sequence, change the monitor code

and start a new sequence.

value a value a value b value b value b value bvalue a

monitor code a monitor code b

RYnC

RWwm

RXnC

RWrm

Monitor

command

Monitor

code

Monitoring

Monitor

value

Fig. 4-5 Monitor command sequence

If you write an invalid value into monitor code you get 0000 in monitor

value.

All manuals and user guides at all-guides.com

Page 29

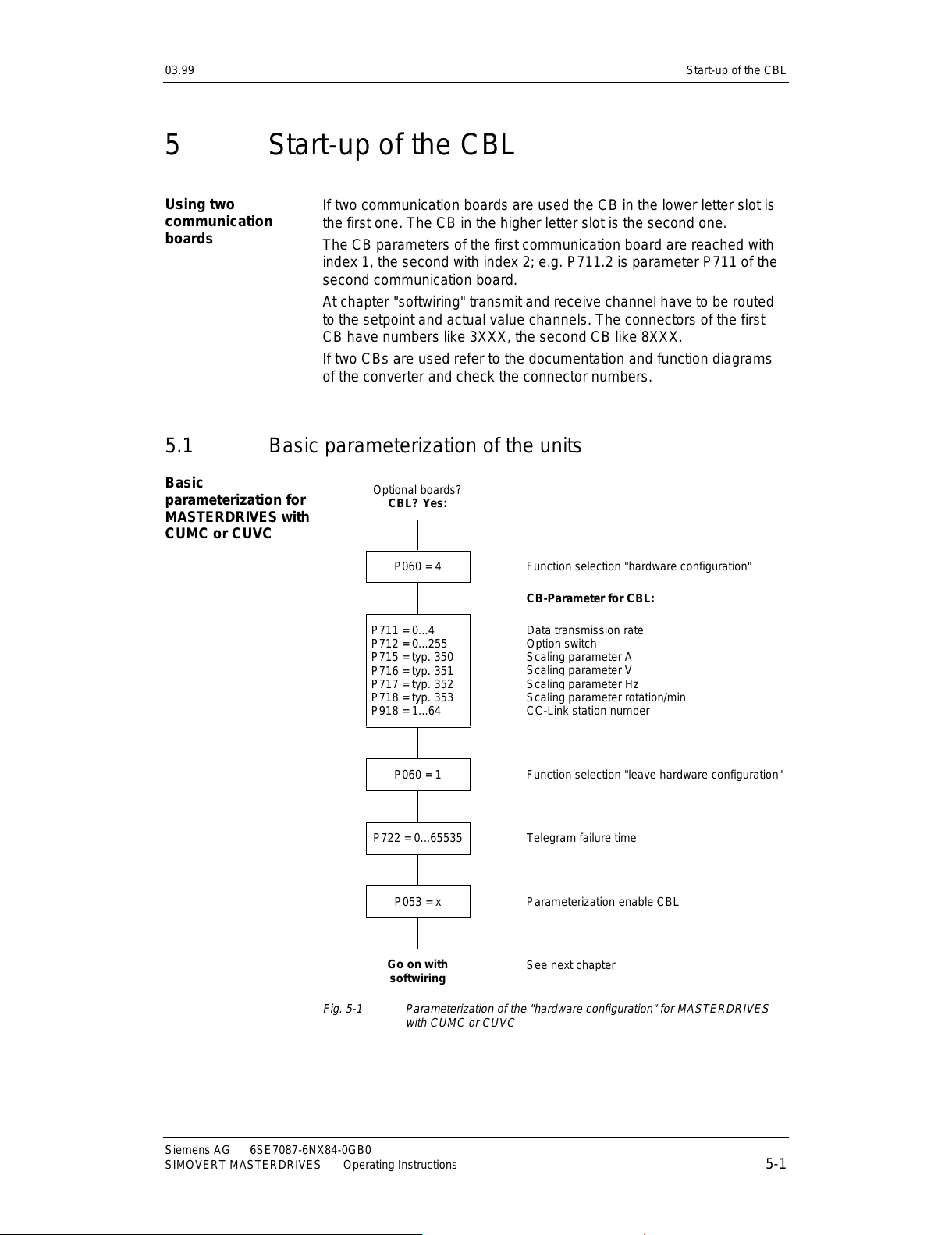

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-9

Monitoring

code

Description According

scaling

parameter

Precision of Mitsubishi

data format (1 digit)

0000h { Monitor value is 0000 } -

0001h Output frequency P717 0.01 Hz

0002h Output current P715 0.01 A

0003h Output voltage P716 0.1 V

0004h { Monitor value is 0000 } -

0005h Frequency set value P717 0.01 Hz

0006h Operating speed P718 1 rotation/min

0007h Motor torque - 0.1 %

000Fh Input terminal status - -

0010h Output terminal status - -

8001h Optional actual value 1 - MASTERDRIVES format

8002h Optional actual value 2 - MASTERDRIVES format

8003h Optional actual value 3 - MASTERDRIVES format

8004h Optional actual value 4 - MASTERDRIVES format

8005h Optional actual value 5 - MASTERDRIVES format

8006h Optional actual value 6 - MASTERDRIVES format

8007h Optional actual value 7 - MASTERDRIVES format

8008h Optional actual value 8 - MASTERDRIVES format

Table 4-3 Monitor code

The monitoring values can be read in Mi ts ubishi inverter data form at or

MASTERDRIVES data format (signed or unsigned); refer to chapter

4.9, "Data formats and data conversion". You select your data format

by the parameters P715 till P718.

The monitor values with monitor code

≤

0007 can be handled in both

data formats (depending on according scaling). The monitor values with

monitor code

≥

8001 are not converted. They have the original

MASTERDRIVES data format.

The monitor code 000Fh and 0010h shows some of the control bits

(remote IO bits):

Monitor Code 000Fh: input terminal status

Bit 15 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0000.000 MRS JOG RH RM RL RT 0 STR STF

Bit 7 JOG is set if JOG1 (RYn5) or JOG2 (RYn7) is activated.

Monitor Code 0010h: output terminal status

Bit 15 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0000.0000.000 FU OL IPF SU RUN

All manuals and user guides at all-guides.com

Page 30

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-10 Operating Instructions SIMOVERT MASTERDRIVES

4.6 Command code execution

With the command execution sequence you can read and change the

parameters of the converter. The CBL converts the Command code

execution into a PKW mechanism of the MASTERDRIVES converter.

This conversion needs a sequence of command code execution

which is described in next chapters.

The parameters are explained in the documentation of the converter

and the communication parameters of CBL in chapter 5 "Start-up of the

CBL".

A single command execution sequence is started by the user by writing

a command code in RWwm+2. To change, the new value of the

parameter is written into written data

(RWwm+3). After that the

sequence is activated with the control bit command code execution

request

.

After CBL has handled the command it acknowledges by

writing a reply code

(RMrm+2) and read data (RMrm+3) and then

activating command code execution complete

.

RYnF

RWwm+2

RXnF

RWrm+2

command code

reply code

Comman d code

execution request

Comman d code

Comman d code

execution complete

Reply code

Fig. 4-6 Command code execution sequence

The CBL handles the PKW mechanism with two 4-word-structures (16

bit words):

PKW request structure

PKE INDEX PWE1 PWE2

PKW reply structure

PKE INDEX PWE1 PWE2

The next chapters explains:

Chapter 4.7 "Parameter area (PKW)" explains you how the PKW

mechanism works.

Chapter 4.8 "Handling PKW via CC-Link" tells you how you can read or

change parameters.

Command code

execution

All manuals and user guides at all-guides.com

Page 31

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-11

4.7 Parameter area (PKW)

With the PKW mechanism, you can perform the following tasks:

♦

reading parameters

♦

writing parameters

♦

reading the parameter description

(parameter type, max./min. value, etc.)

The parameter area is always composed of 4 words.

1st word

Parameter ID (PKE)

Byte 1 Byte 0

Bit No.: 15 12 11 10 0

AK SPM PNU

2nd word

Parameter index (IND)

Byte 3 Byte 2

Bit No.: 15 12 11 10 9 8 7 0

Optional features Index

Parameter value (PWE)

3rd word:

Byte 5 Byte 4

Parameter value Low (PWE1)

4th word:

Byte 7 Byte 6

Parameter value High (PWE2)

AK:

SPM:

PNU:

Task or reply ID

Toggle bit for processing the parameter change report (not supported

by the CBL)

Parameter number

The parameter ID (PKE) is always a 16-bit value.

Bits 0 to 10 (PNU) contain the number of the required parameter. The

meaning of the parameters can be found in the section, "Parameter

list", of the converter operating instructions.

Bit 11 (SPM) is the toggle bit for parameter change reports.

Parameter change reports are not supported by the CBL.

Bits 12 to 15 (AK) contain the task reply ID.

The meaning of the task ID for the task telegram (master → converter)

is shown in Table 4-4. It corresponds to the specifications in the

"PROFIBUS profile for variable-speed drives". Task IDs 10 to 15 are

specific to SIMOVERT MASTERDRIVES and are not defined in the

PROFIBUS profile.

The meaning of the reply ID for the reply telegram (converter →

master) is shown in Table 4-5. This also corresponds to the

specifications in the "PROFIBUS profile for variable-speed drives".

Parameter ID (PKE)

NOTE

All manuals and user guides at all-guides.com

all-guides.com

Page 32

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-12 Operating Instructions SIMOVERT MASTERDRIVES

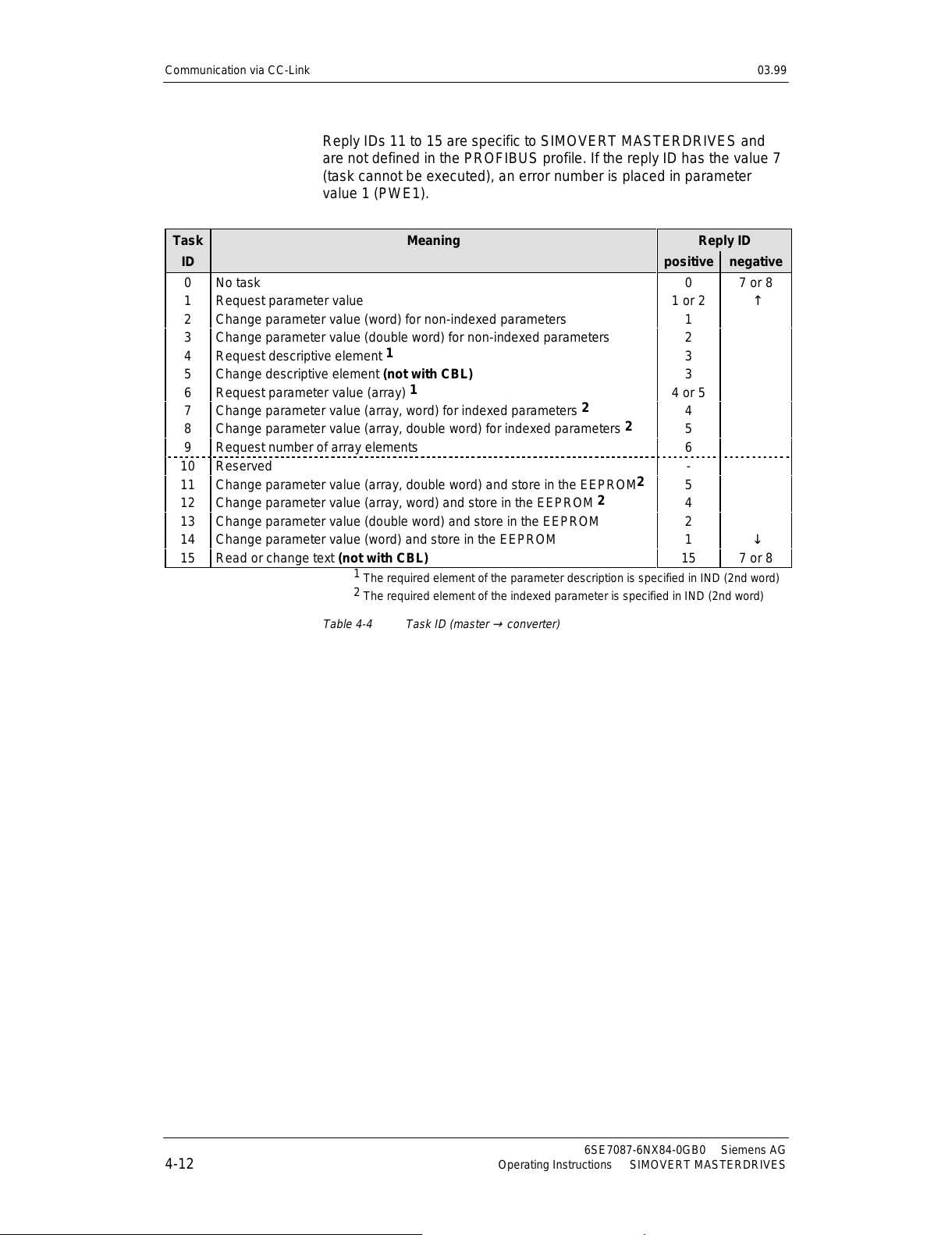

Reply IDs 11 to 15 are specific to SIMOVERT MASTERDRIVES and

are not defined in the PROFIBUS profile. If the reply ID has the value 7

(task cannot be executed), an error number is placed in parameter

value 1 (PWE1).

Task Meaning Reply ID

ID

positive negative

0 No task 0 7 or 8

1 Request parameter value 1 or 2 ↑

2 Change parameter value (word) for non-indexed parameters 1

3 Change parameter value (double word) for non-indexed parameters 2

4 Request descriptive element

1

3

5 Change descriptive element (not with CBL) 3

6 Request parameter value (array)

1

4 or 5

7 Change parameter value (array, word) for indexed parameters

2

4

8 Change parameter value (array, double word) for indexed parameters

2

5

9 Request number of array elements 6

10 Reserved -

11 Change parameter value (array, double word) and store in the EEPROM

2

5

12 Change parameter value (array, word) and store in the EEPROM

2

4

13 Change parameter value (double word) and store in the EEPROM 2

14 Change parameter value (word) and store in the EEPROM 1 ↓

15 Read or change text (not with CBL) 15 7 or 8

1

The required element of the parameter description is specified in IND (2nd word)

2

The required element of the indexed parameter is specified in IND (2nd word)

Table 4-4 Task ID (master → converter)

All manuals and user guides at all-guides.com

Page 33

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-13

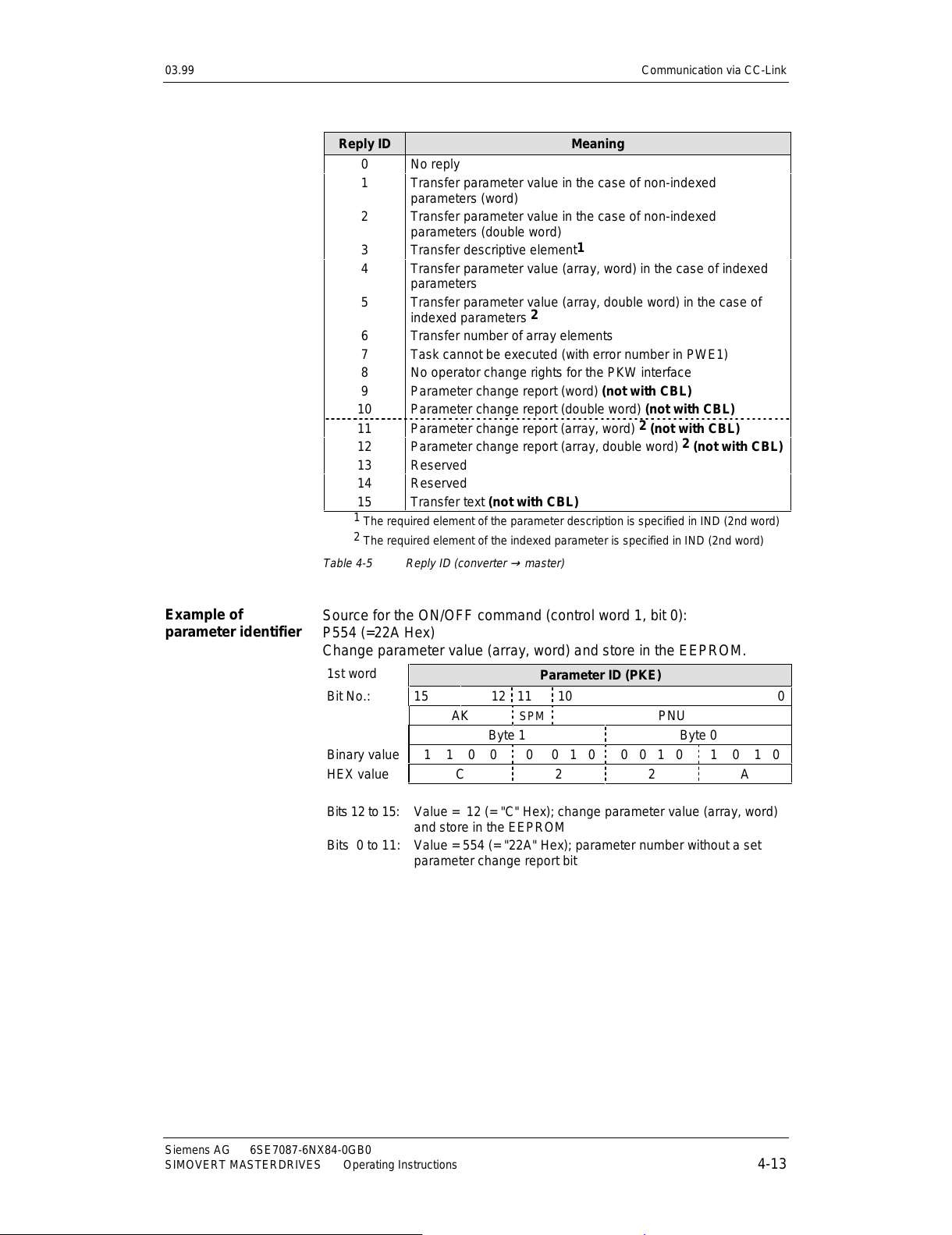

Reply ID Meaning

0 No reply

1 Transfer parameter value in the case of non-indexed

parameters (word)

2 Transfer parameter value in the case of non-indexed

parameters (double word)

3 Transfer descriptive element

1

4 Transfer parameter value (array, word) in the case of indexed

parameters

5

Transfer parameter value (array, double word) in the case of

indexed parameters

2

6 Transfer number of array elements

7 Task cannot be executed (with error number in PWE1)

8 No operator change rights for the PKW interface

9 Parameter change report (word) (not with CBL)

10 Parameter change report (double word) (not with CBL)

11 Parameter change report (array, word)

2

(not with CBL)

12 Parameter change report (array, double word)

2

(not with CBL)

13 Reserved

14 Reserved

15 Transfer text (not with CBL)

1

The required element of the parameter description is specified in IND (2nd word)

2

The required element of the indexed parameter is specified in IND (2nd word)

Table 4-5 Reply ID (converter → master)

Source for the ON/OFF command (control word 1, bit 0):

P554 (=22A Hex)

Change parameter value (array, word) and store in the EEPROM.

1st word

Parameter ID (PKE)

Bit No.: 15 12 11 10 0

AK SPM PNU

Byte 1 Byte 0

Binary value 1 1 0 0 0 0 1 0 0 0 1 0 1 0 1 0

HEX value C 2 2 A

Bits 12 to 15:

Bits 0 to 11:

Value = 12 (= "C" Hex); change parameter value (array, word)

and store in the EEPROM

Value = 554 (= "22A" Hex); parameter number without a set

parameter change report bit

Example of

parameter identifier

All manuals and user guides at all-guides.com

Page 34

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-14 Operating Instructions SIMOVERT MASTERDRIVES

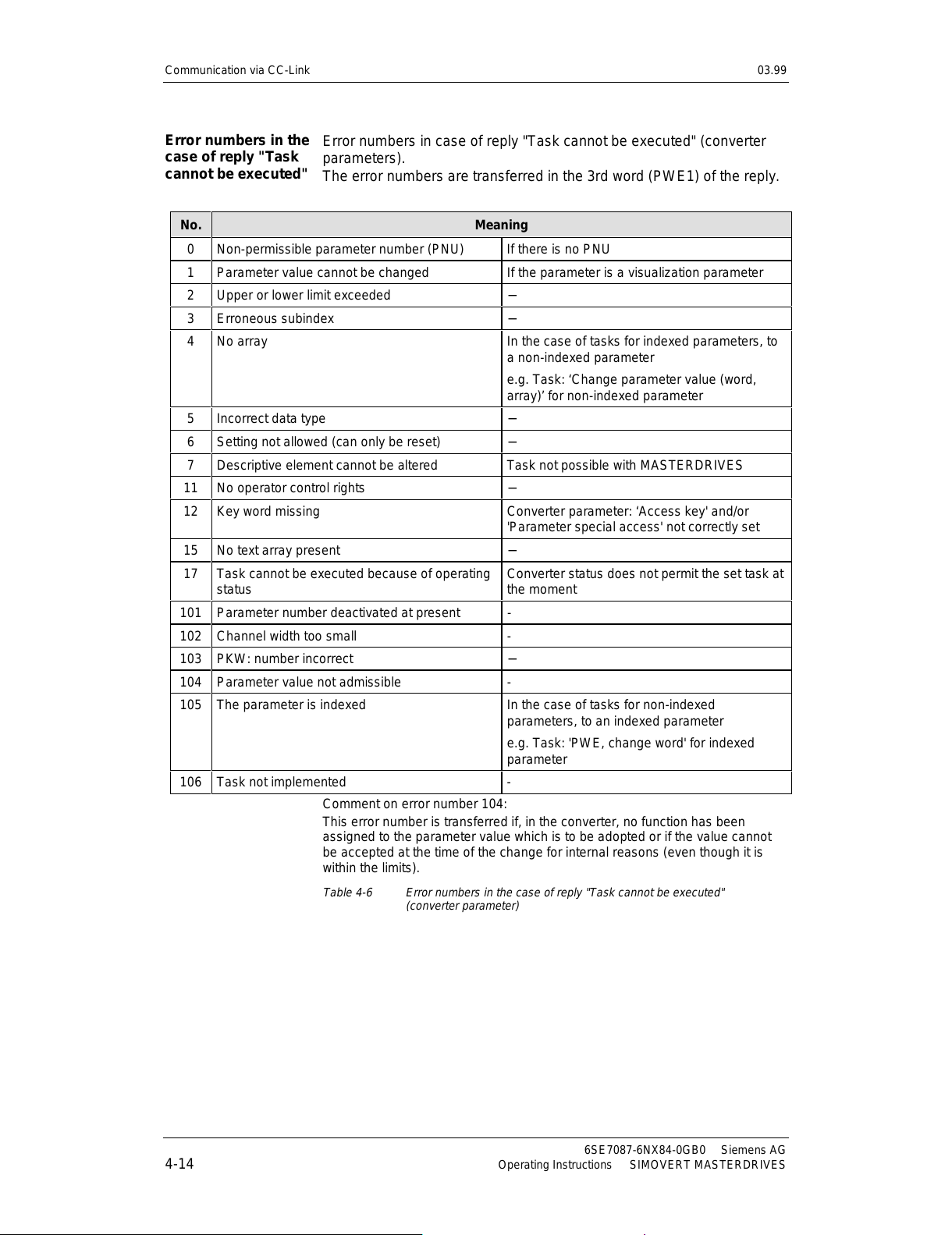

Error numbers in case of reply "Task cannot be executed" (converter

parameters).

The error numbers are transferred in the 3rd word (PWE1) of the reply.

No. Meaning

0 Non-permissible parameter number (PNU) If there is no PNU

1 Parameter value cannot be changed If the parameter is a visualization parameter

2 Upper or lower limit exceeded −

3 Erroneous subindex −

4 No array In the case of tasks for indexed parameters, to

a non-indexed parameter

e.g. Task: ‘Change parameter value (word,

array)’ for non-indexed parameter

5 Incorrect data type −

6 Setting not allowed (can only be reset) −

7 Descriptive element cannot be altered Task not possible with MASTERDRIVES

11 No operator control rights −

12 Key word missing

Converter parameter: ‘Access key' and/or

'Parameter special access' not correct ly set

15 No text array present −

17

Task cannot be executed because of operating

status

Converter status does not permit the set task at

the moment

101 Parameter number deactivated at present -

102 Channel width too small -

103 PKW: number incorrect −

104 Parameter value not admissible -

105 The parameter is indexed

In the case of tasks for non-indexed

parameters, to an indexed parameter

e.g. Task: 'PWE, change word' for indexed

parameter

106 Task not implemented -

Comment on error number 104:

This error number is transferred if, in the converter, no function has been

assigned to the parameter value which is to be adopted or if the value cannot

be accepted at the time of the change for internal reasons (even though it is

within the limits).

Table 4-6 Error numbers in the case of reply "Task cannot be executed"

(converter parameter)

Error numbers in the

case of reply "Task

cannot be executed"

All manuals and user guides at all-guides.com

Page 35

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-15

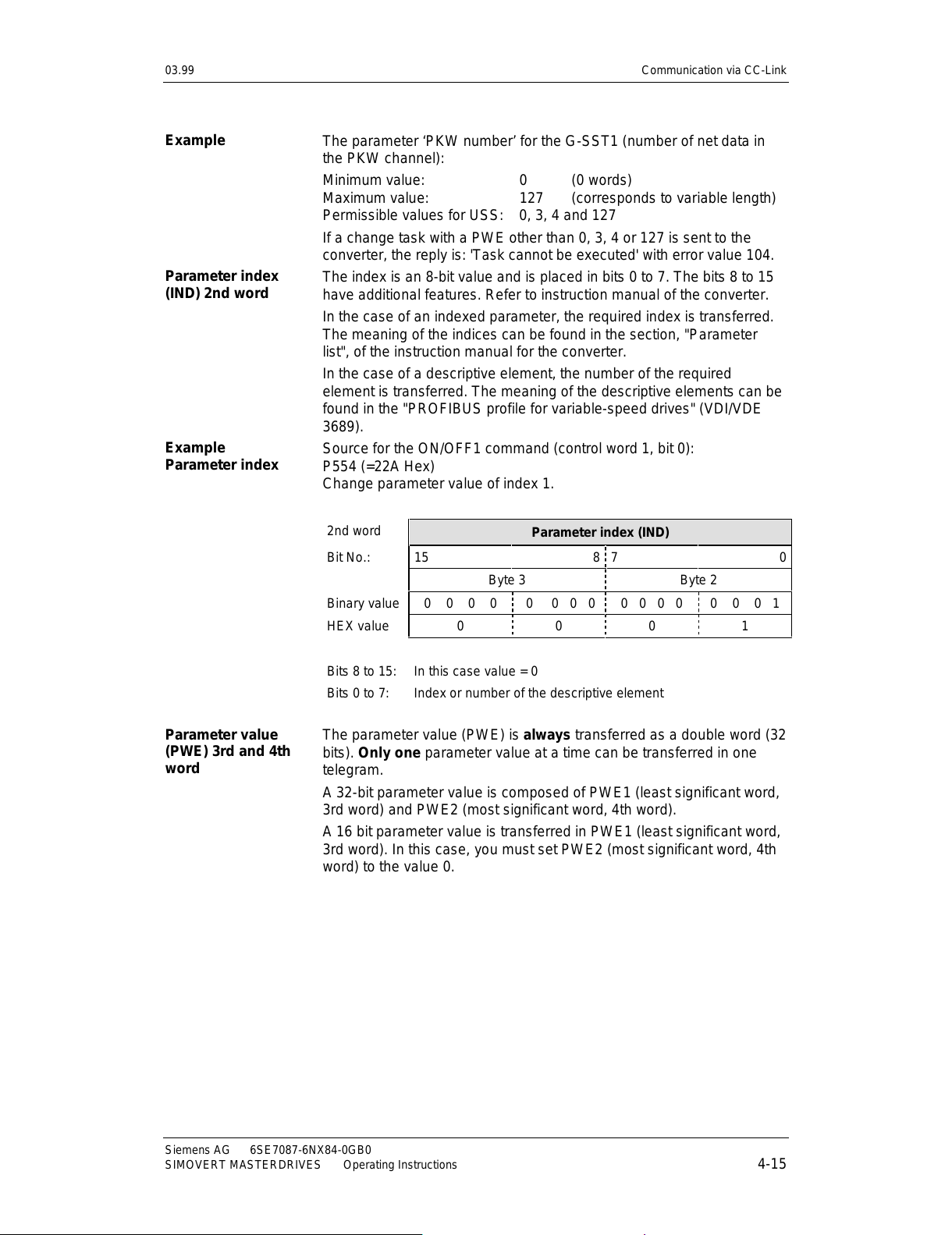

The parameter ‘PKW number’ for the G-SST1 (number of net data in

the PKW channel):

Minimum v alue: 0 (0 words)

Maximum value: 127 (corresponds to variable length)

Permissible values for USS: 0, 3, 4 and 127

If a change task with a PWE other than 0, 3, 4 or 127 is sent to the

converter, the reply is: 'Task cannot be executed' with error value 104.

The index is an 8-bit value and is placed in bits 0 to 7. The bits 8 to 15

have additional features. Refer to instruction manual of the converter.

In the case of an indexed parameter, the required index is transferred.

The meaning of the indices can be found in the section, "Parameter

list", of the instruction manual for the converter.

In the case of a descriptive element, the number of the required

element is transferred. The meaning of the descriptive elements can be

found in the "PROFIBUS profile for variable-speed drives" (VDI/VDE

3689).

Source for the ON/OFF1 command (control word 1, bit 0):

P554 (=22A Hex)

Change parameter value of index 1.

2nd word

Parameter index (IND)

Bit No.: 15 8 7 0

Byte 3 Byte 2

Binary value 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

HEX value0 001

Bits 8 to 15:

Bits 0 to 7:

In this case value = 0

Index or number of the descriptive element

The parameter value (PWE) is always transferred as a double word (32

bits). Only one parameter value at a time can be transferred in one

telegram.

A 32-bit parameter value is composed of PWE1 (least significant word,

3rd word) and PWE2 (most significant wor d, 4th wor d).

A 16 bit parameter value is transferred in PWE1 (least significant word,

3rd word). In this case, you must set PWE2 (most significant word, 4th

word) to the value 0.

Example

Parameter index

(IND) 2nd word

Example

Parameter index

Parameter value

(PWE) 3rd and 4th

word

All manuals and user guides at all-guides.com

Page 36

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-16 Operating Instructions SIMOVERT MASTERDRIVES

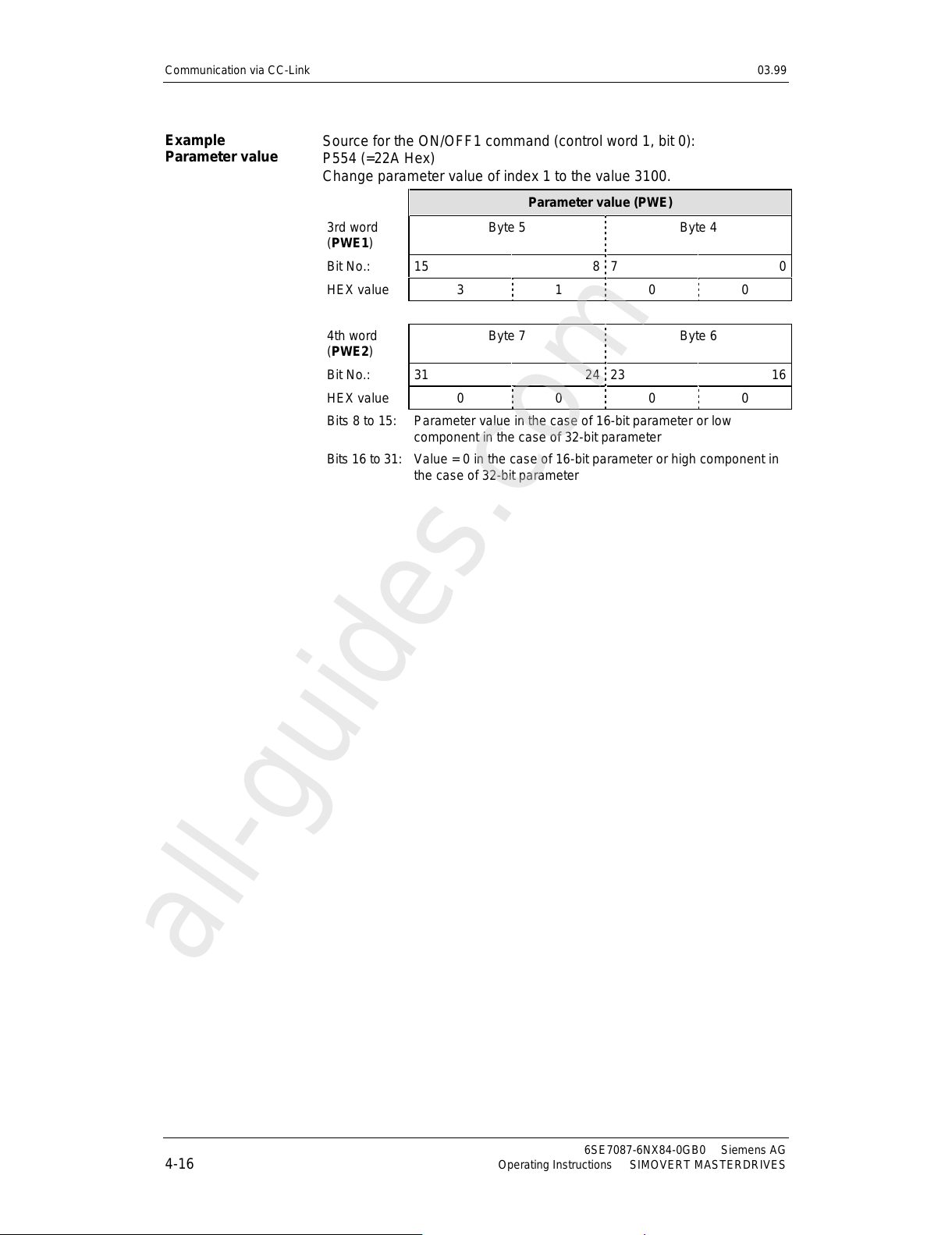

Source for the ON/OFF1 command (control word 1, bit 0):

P554 (=22A Hex)

Change parameter value of index 1 to the value 3100.

Parameter value (PWE)

3rd word

(PWE1)

Byte 5 Byte 4

Bit No.: 15 8 7 0

HEX value3 100

4th word

(PWE2)

Byte 7 Byte 6

Bit No.: 31 24 23 16

HEX value0 000

Bits 8 to 15:

Bits 16 to 31:

Parameter value in the case of 16-bit parameter or low

component in the case of 32-bit parameter

Value = 0 in the case of 16-bit parameter or high component in

the case of 32-bit parameter

Example

Parameter value

All manuals and user guides at all-guides.com

all-guides.com

Page 37

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-17

4.8 Handling PKW via CC-Link

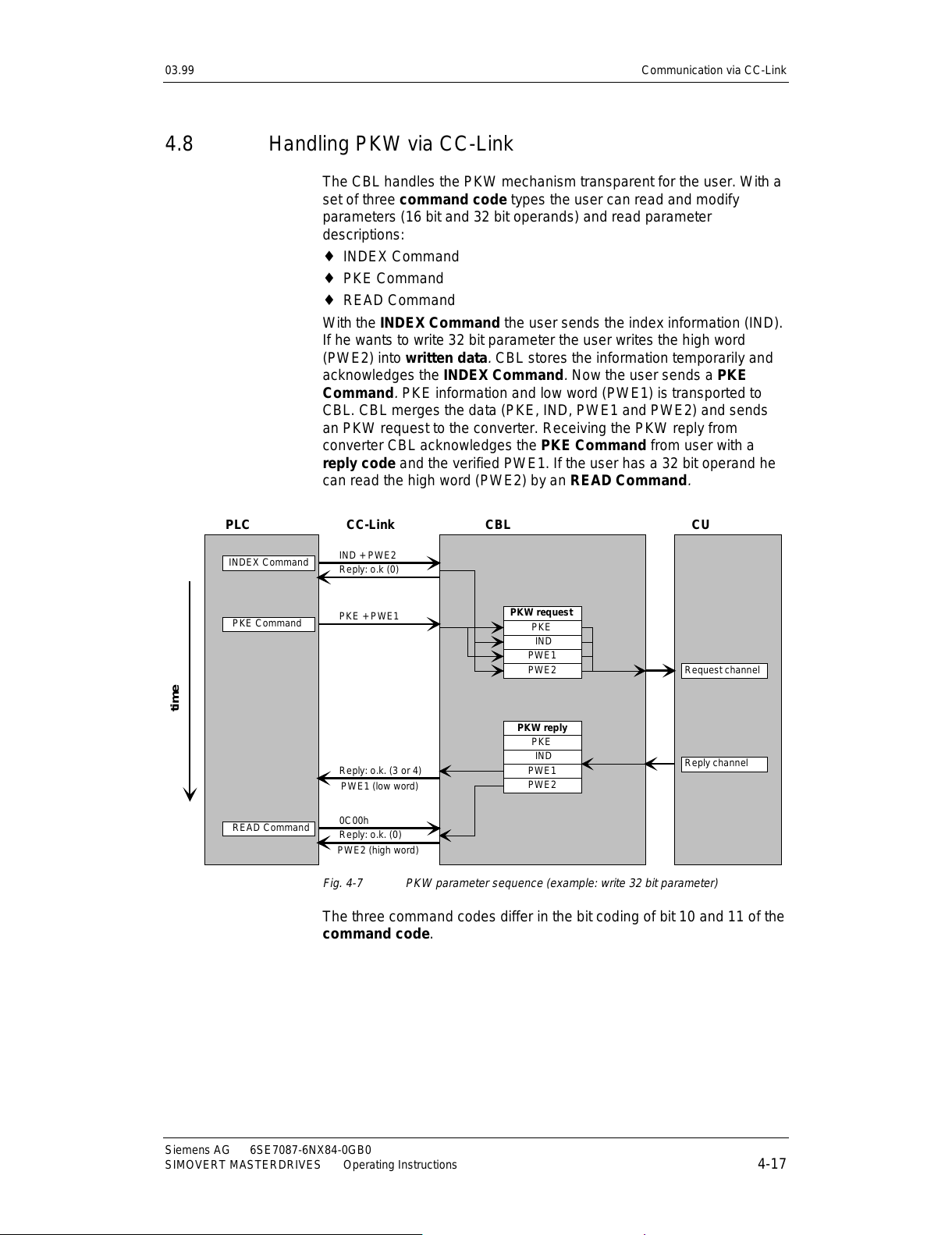

The CBL handles the PKW mechanism transparent for the user. With a

set of three command code types the user can read and modify

parameters (16 bit and 32 bit operands) and read parameter

descriptions:

♦

INDEX Command

♦

PKE Command

♦

READ Command

With the INDEX Command

the user sends the index information (IND).

If he wants to write 32 bit parameter the user writes the high word

(PWE2) into written data

.

CBL stores the information temporarily and

acknowledges the INDEX Command

.

Now the user sends a PKE

Command

.

PKE information and low word (PWE1) is transported to

CBL. CBL merges the data (PKE, IND, PWE1 and PWE2) and sends

an PKW request to the converter. Receiving the PKW reply from

converter CBL acknowledges the PKE Command

from user with a

reply code and the verified PWE1. If the user has a 32 bit operand he

can read the high word (PWE2) by an READ Command

.

PKW request

PKE

IND

PWE1

PWE2

PKW reply

PKE

IND

PWE1

PWE2

IND + PWE2

0C00h

time

Reply: o.k (0)

PKE + PWE1

Reply: o.k. (3 or 4)

Reply: o.k. (0)

INDEX Command

READ Command

PKE Command

PLC CBL CUCC-Link

Request channel

Reply channel

PWE1 (low word)

PWE2 (high word)

Fig. 4-7 PKW parameter sequence (example: write 32 bit parameter)

The three command codes differ in the bit coding of bit 10 and 11 of the

command code.

All manuals and user guides at all-guides.com

Page 38

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-18 Operating Instructions SIMOVERT MASTERDRIVES

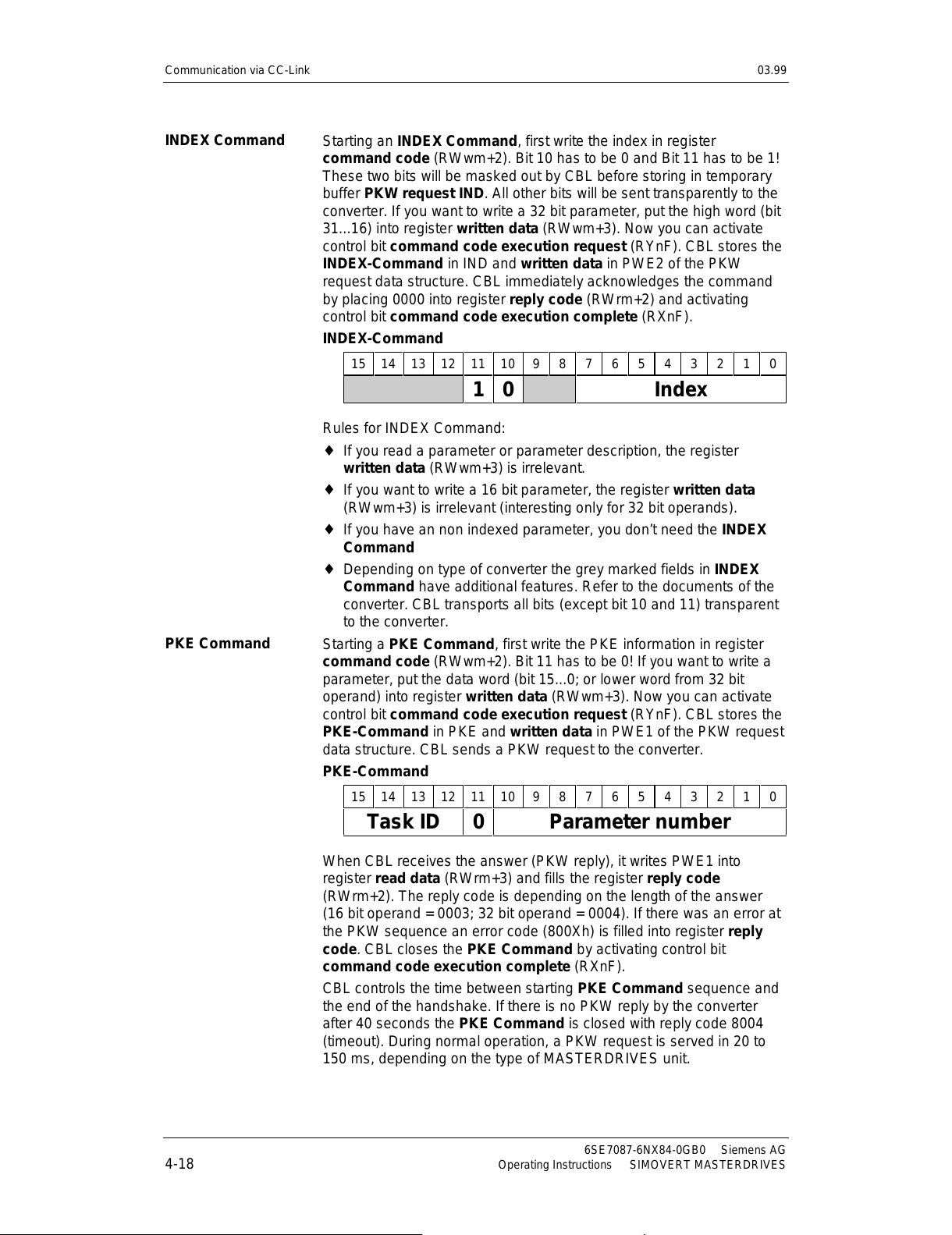

Starting an INDEX Command, first write the index in register

command code

(RWwm+2). Bit 10 has to be 0 and Bit 11 has to be 1!

These two bits will be masked out by CBL before storing in temporary

buffer PKW request IND

.

All other bits will be sent transparently to the

converter. If you want to write a 32 bit parameter, put the high word (bit

31...16) into register written data

(RWwm+3). Now you can activate

control bit command code execution request

(RYnF). CBL stores the

INDEX-Command

in IND and written data in PWE2 of the PKW

request data structure. CBL immediately acknowledges the command

by placing 0000 into register reply code

(RWrm+2) and activating

control bit command code execution complete

(RXnF).

INDEX-Command

1514131211109876543210

10 Index

Rules for INDEX Command:

♦

If you read a parameter or parameter description, the register

written data

(RWwm+3) is irrelevant.

♦

If you want to write a 16 bit parameter, the register written data

(RWwm+3) is irrelevant (interesting only for 32 bit operands).

♦

If you have an non indexed parameter, you don’t need the INDEX

Command

♦

Depending on type of converter the grey marked fields in INDEX

Command have additional features. Refer to the documents of the

converter. CBL transports all bits (except bit 10 and 11) transparent

to the converter.

Starting a PKE Command,

first write the PKE information in register

command code

(RWwm+2). Bit 11 has to be 0! If you want to write a

parameter, put the data word (bit 15...0; or lower word from 32 bit

operand) into register written data

(RWwm+3). Now you can activate

control bit command code execution request

(RYnF). CBL stores the

PKE-Command

in PKE and written data in PWE1 of the PKW request

data structure. CBL sends a PKW request to the converter.

PKE-Command

1514131211109876543210

Task ID 0 Parameter number

When CBL receives the answer (PKW reply), it writes PWE1 into

register read data

(RWrm+3) and fills the register reply code

(RWrm+2). The reply code is depending on the length of the answer

(16 bit operand = 0003; 32 bit operand = 0004). If there was an error at

the PKW sequence an error code (800Xh) is filled into register reply

code

.

CBL closes the PKE Command by activating control bit

command code execution complete

(RXnF).

CBL controls the time between starting PKE Command sequence and

the end of the handshake. If there is no PKW reply by the converter

after 40 seconds the PKE Command

is closed with reply code 8004

(timeout). During normal operation, a PKW request is served in 20 to

150 ms, depending on the type of MASTERDRIVES unit.

INDEX Command

PKE Command

All manuals and user guides at all-guides.com

Page 39

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-19

After PKE Command

is executed CBL clears the register IND in the

PKW request structure; reason: fault tolerant handling; if you forget to

handle the INDEX Command

before PKE Command by accessing

indexed parameters an error message will be generated from the

converter.

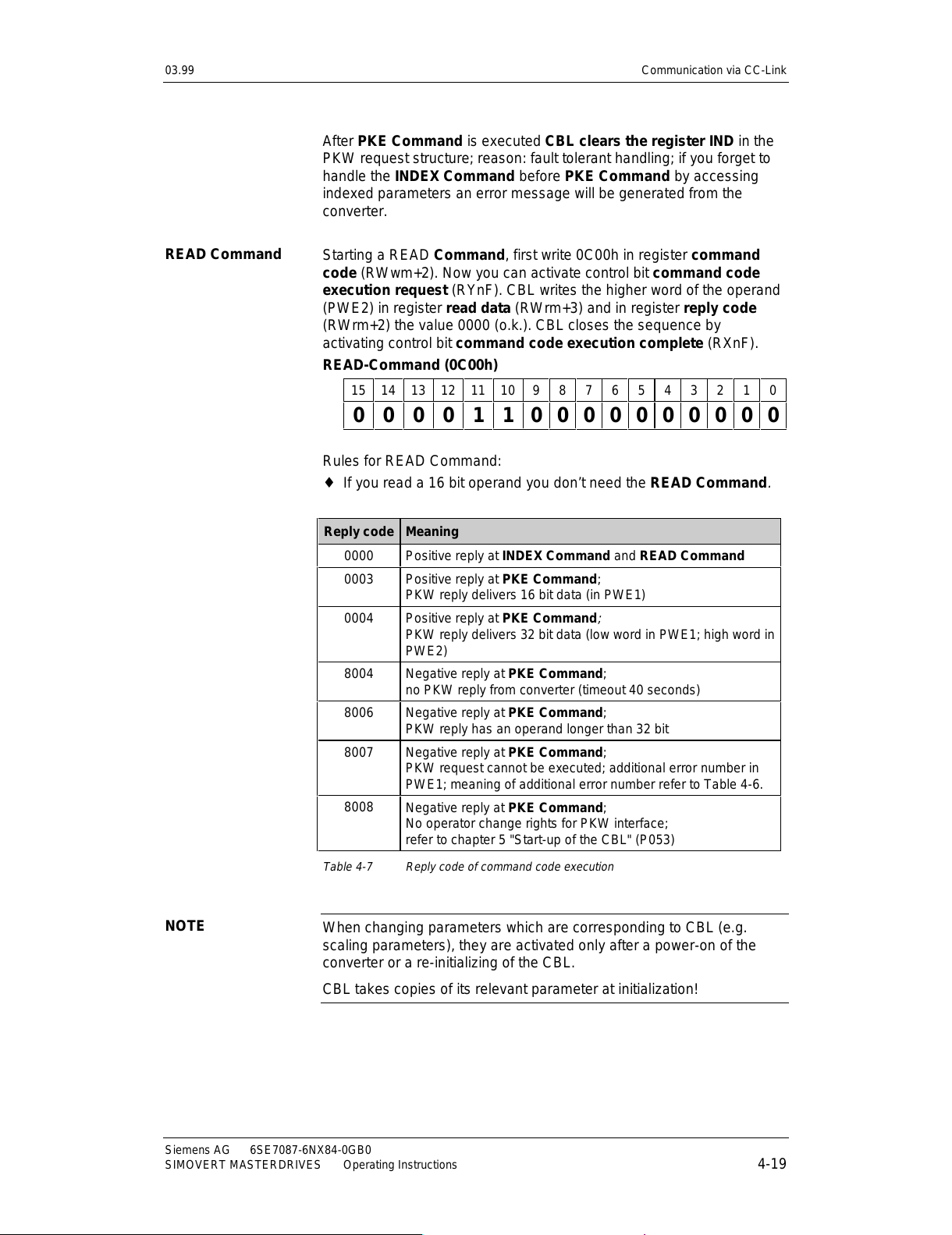

Starting a READ

Command, first write 0C00h in register command

code

(RWwm+2). Now you can activate control bit command code

execution request

(RYnF). CBL writes the higher word of the operand

(PWE2) in register read data

(RWrm+3) and in register reply code

(RWrm+2) the value 0000 (o.k.). CBL closes the sequence by

activating control bit command code execution complete

(RXnF).

READ-Command (0C00h)

1514131211109876543210

0000 1 10000000000

Rules for READ Command:

♦

If you read a 16 bit operand you don’t need the READ Command

.

Reply code Meaning

0000 Positive reply at INDEX Command and READ Command

0003

Positive reply at PKE Command;

PKW reply delivers 16 bit data (in PWE1)

0004

Positive reply at PKE Command

;

PKW reply delivers 32 bit data (low word in PWE1; high word in

PWE2)

8004 Negative reply at PKE Command;

no PKW reply from converter (timeout 40 seconds)

8006 Negative reply at PKE Command;

PKW reply has an operand longer than 32 bit

8007 Negative reply at PKE Command;

PKW request cannot be executed; additional error number in

PWE1; meaning of additional error number refer to Table 4-6.

8008

Negative reply at PKE Command;

No operator change rights for PKW interface;

refer to chapter 5 "Start-up of the CBL" (P053)

Table 4-7 Reply code of command code execution

When changing parameters which are corresponding to CBL (e.g.

scaling parameters), they are activated only after a power-on of the

converter or a re-initializing of the CBL.

CBL takes copies of its relevant parameter at initialization!

READ Command

NOTE

All manuals and user guides at all-guides.com

Page 40

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-20 Operating Instructions SIMOVERT MASTERDRIVES

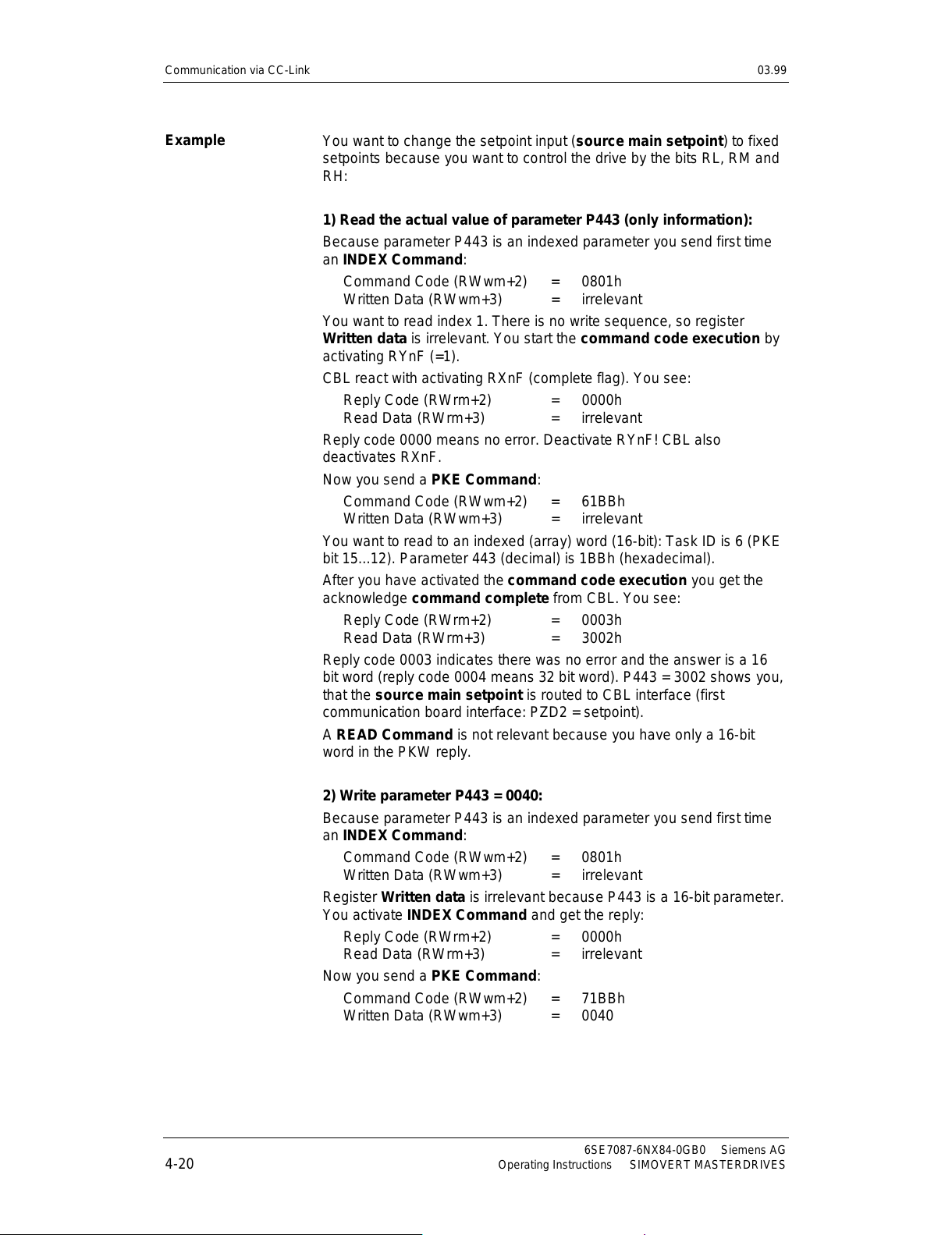

You want to change the setpoint input (source main setpoint) to fixed

setpoints because you want to control the drive by the bits RL, RM and

RH:

1) Read the actual value of parameter P443 (only information):

Because parameter P443 is an indexed parameter you send first time

an INDEX Command:

Command Code (RWwm+2) = 0801h

Written Data (RWwm+3) = irrelevant

You want to read index 1. There is no write sequence, so register

Written data is irrelevant. You start the command

code execution by

activating RYnF (=1).

CBL react with activating RXnF (complete flag). You see:

Reply Code (RWrm+2) = 0000h

Read Data (RWrm+3) = irrelevant

Reply code 0000 means no error. Deactivate RYnF! CBL also

deactivates RXnF.

Now you send a PKE Command:

Command Code (RWwm+2) = 61BBh

Written Data (RWwm+3) = irrelevant

You want to read to an indexed (array) word (16-bit): Task ID is 6 (PKE

bit 15...12). Parameter 443 (decimal) is 1BBh (hexadecimal).

After you have activated the command

code execution you get the

acknowledge command complete from CBL. You see:

Reply Code (RWrm+2) = 0003h

Read Data (RWrm+3) = 3002h

Reply code 0003 indicates there was no error and the answer is a 16

bit word (reply code 0004 means 32 bit word). P443 = 3002 shows you,

that the source main setpoint is routed to CBL interface (first

communication board interface: PZD2 = setpoint).

A READ Command is not relevant because you have only a 16-bit

word in the PKW reply.

2) Write parameter P443 = 0040:

Because parameter P443 is an indexed parameter you send first time

an INDEX Command:

Command Code (RWwm+2) = 0801h

Written Data (RWwm+3) = irrelevant

Register Written data is irrelevant because P443 is a 16-bit parameter.

You activate INDEX Command

and get the reply:

Reply Code (RWrm+2) = 0000h

Read Data (RWrm+3) = irrelevant

Now you send a PKE Command:

Command Code (RWwm+2) = 71BBh

Written Data (RWwm+3) = 0040

Example

All manuals and user guides at all-guides.com

Page 41

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-21

You want to write an indexed (array) word (16-bit): Task ID is 7 (PKE bit

15...12). Parameter 443 (decimal) is 1BBh (hexadecimal). You activate

PKE Command and get the reply:

Reply Code (RWrm+2) = 8007h

Read Data (RWrm+3) = 0011h

You get an error message:

8007h = PKW request cannot be executed;

additional error number in PWE1

At PKE Command the register Read data has the contents of PWE1;

that means 0011h is the additional error code; 0011h = 17 (decimal)

17 = Task cannot be executed because of operating status.

The error message occurs when you try to change the setpoint channel

with the motor running!

3) Write parameter P443 = 0040 (converter not in RUN-mode):

INDEX Command:

Command Code (RWwm+2) = 0801h

Written Data (RWwm+3) = irrelevant

You get the reply:

Reply Code (RWrm+2) = 0000h

Read Data (RWrm+3) = irrelevant

PKE Command:

Command Code (RWwm+2) = 71BBh

Written Data (RWwm+3) = 0040

You get the reply:

Reply Code (RWrm+2) = 0003h

Read Data (RWrm+3) = 0040h

Reply code: o.k.; information read back is a 16-bit operand.

Read Data: source main setpoint is really changed to 0040.

All manuals and user guides at all-guides.com

all-guides.com

Page 42

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-22 Operating Instructions SIMOVERT MASTERDRIVES

4.9 Data formats and data conversion

Mitsubishi converters handle data as unsigned 16 bit integer. The

direction of rotation is coded in control bits STF (RYn0) and STR

(RYn1). Depending on the process value (e.g. current, frequency) this

integer value gets a precision fa ctor :

Process

value

Precision integer

(1 digit)

Frequency 0.01 Hz

Current 0.01 A

Voltage 0.1 V

Torque 0.1 %

Rotation 1 Rotation/minute

Table 4-8 Mitsubishi data format; precision

SIMOVERT MASTERDRIVES works internally with process values in

16 bit or 32 bit signed integer (2nd-complement). These values are

normalized in percent:

Integer value

16 bit 32 bit Real value

.

.

4000h

.

.

0000h

.

.

C000h

.

.

.

.

4000.0000h

.

.

0000.0000h

.

.

C000.0000h

.

.

.

.

+ 100 %

.

.

0 %

.

.

– 100 %

.

.

Table 4-9 SIMOVERT MASTERDRIVES int ernal data format

The display of SIMOVERT MASTERDRIVES shows the absolute value.

For this reason there are parameters with scaling factors (e.g.

P350...P353). Their contents are the absolute value at + 100 %.

CBL has to convert the data from Mitsubishi data format in

MASTERDRIVES data format and vice versa. The CBL uses

parameters (P715...P718) pointing to the scaling parameters

(P350...P353). Other scaling factors may be parameterized. Normally

the user sets P715 = 350, P716 = 351, etc. In this way CBL use the

same scaling factors like display routines of the converter. CBL

automatically adapts the precision between Mitsubishi data format and

MASTERDRIVES display format. It uses the parameter description

(conversion index in IEEE format) of the scaling factor parameters.

Data format

Mitsubishi

converter

Data format

SIMOVERT

MASTERDRIVES

All manuals and user guides at all-guides.com

Page 43

03.99 Communication via CC-Link

Siemens AG 6SE7087-6NX84-0GB0

SIMOVERT MASTERDRIVES Operating Instructions 4-23

You have two ways to handle the process values:

1) Working with the Mitsubishi data format:

All reference values (setpoints) and actual values are in the format

like Table 4-8. The 16-bit-variables are unsigned integer values.

CBL converts all values in both communication directions incl.

monitoring; refer to figures in this chapter.

In this case you have to set the parameter:

P715 = 350 (current)

P716 = 351 (voltage)

P717 = 352 (frequency)

P718 = 353 (rotation per minute)

2) Working with the internal MASTERDRIVES format:

All reference values (setpoints) and actual values are in the format

like Table 4-9. Exception: At PLC side all values are positive

(unsigned)! The sign (positive or negative) is controlled by the

direction bits STF (RYn0) and STR (RYn1). CBL doesn’t convert the

setpoints. Actual values and monitoring values are converted to

unsigned integer.

In this case you have to set the parameter:

P715 = 0 (current)

P716 = 0 (voltage)

P717 = 0 (frequency)

P718 = 0 (rotation per minute)

The CB parameters P715...P718 are pointers to scaling parameters.

If a CB parameter (P715...P718) is 0, the corresponding type of

process value isn’t converted by CBL.

Normally use for parameter P715...P718 the scaling factor parameters

P350...P353.

Mixing is possible; that means some values are converted by CBL other

ones are not modified.

P717 = 352; ⇒ P352 = 50.00;

actual value frequency = 2000h (MASTERDRIVES internal data format)

P352 shows, that 100 % of a frequency value is 50.00 Hz. The CB

parameter P717 points to the parameter P352 "scaling factor

frequency"; 100 % equals 4000h. CBL calculates an actual value:

2000h / 4000h * 5000 = 2500 = 9C4h

The following function diagrams show the data conversion of CBL in the

different data channels:

NOTE

Example

All manuals and user guides at all-guides.com

Page 44

Communication via CC-Link 03.99

6SE7087-6NX84-0GB0 Siemens AG

4-24 Operating Instructions SIMOVERT MASTERDRIVES

Frequency control:

Set frequency (RWwm+1)

unsigned

16-bit-intege r

Pxxx

P717

P717 # 0

P717 = 0

P717 = xxx

MASTERDRIVES format

unsigned!

0 ... 200 %

STR (RYn1)

Forward enable (ct rl. word bit11)

XOR

ON/OFF1 (ctrl.word bit 0)

STF (RYn0)

STF STR Bit11 Bit 12

0 0 1 1

1 0 1 0

0 1 0 1

1 1 1 1

Reverse enable (ct rl. word bit12)

7FFFh

Fig. 4-8 Data conversion at setpoint channel "frequency control"

If P717 equals 0, then setpoints are interpreted from CBL as

percentage values in MASTERDRIVES format (unsigned in this case!)

between 0 and 7FFFh (0 % ... 200 %); e.g. set frequency

= 1000h

⇒

25 %. Values greater than 7FFFh will be set to 7FFFh.

If P717 greater than 0 (P717 is a pointer to scaling parameter), the

unsigned integer value corresponds to the frequency value; e.g. set

frequency = 2000 ⇒ 20.00 Hz.

Torque control:

Set frequency

(RWwm+1)

unsigned

16-bit-integer

fixed scaling parameter "torque"

MASTERDRIVES format

signed 16 bit!

-200 %... +200 %

STR (RYn1)

Forward enable (ctrl.word bit11)

XOR

ON/OFF1 (ctrl.word bit 0)

STF (RYn0)

STF STR Bit11 Bit 12

0 0 1 1

1 0 1 0

0 1 0 1

1 1 1 1

Reverse enable (ctrl.word bit12)

-1

STF,STR

1,0

0,0

1,1

0,1

0

not

relevant

for

torque

control

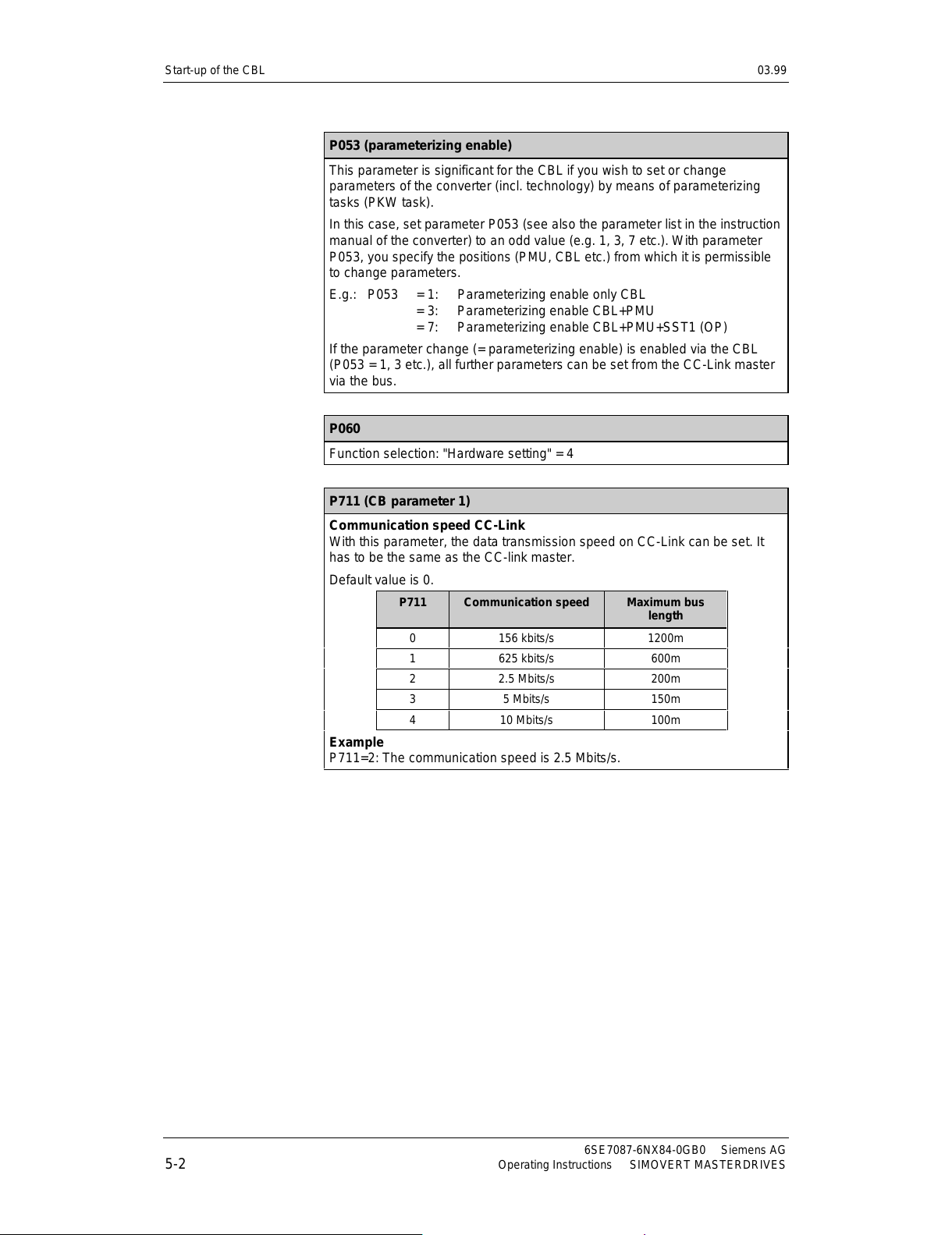

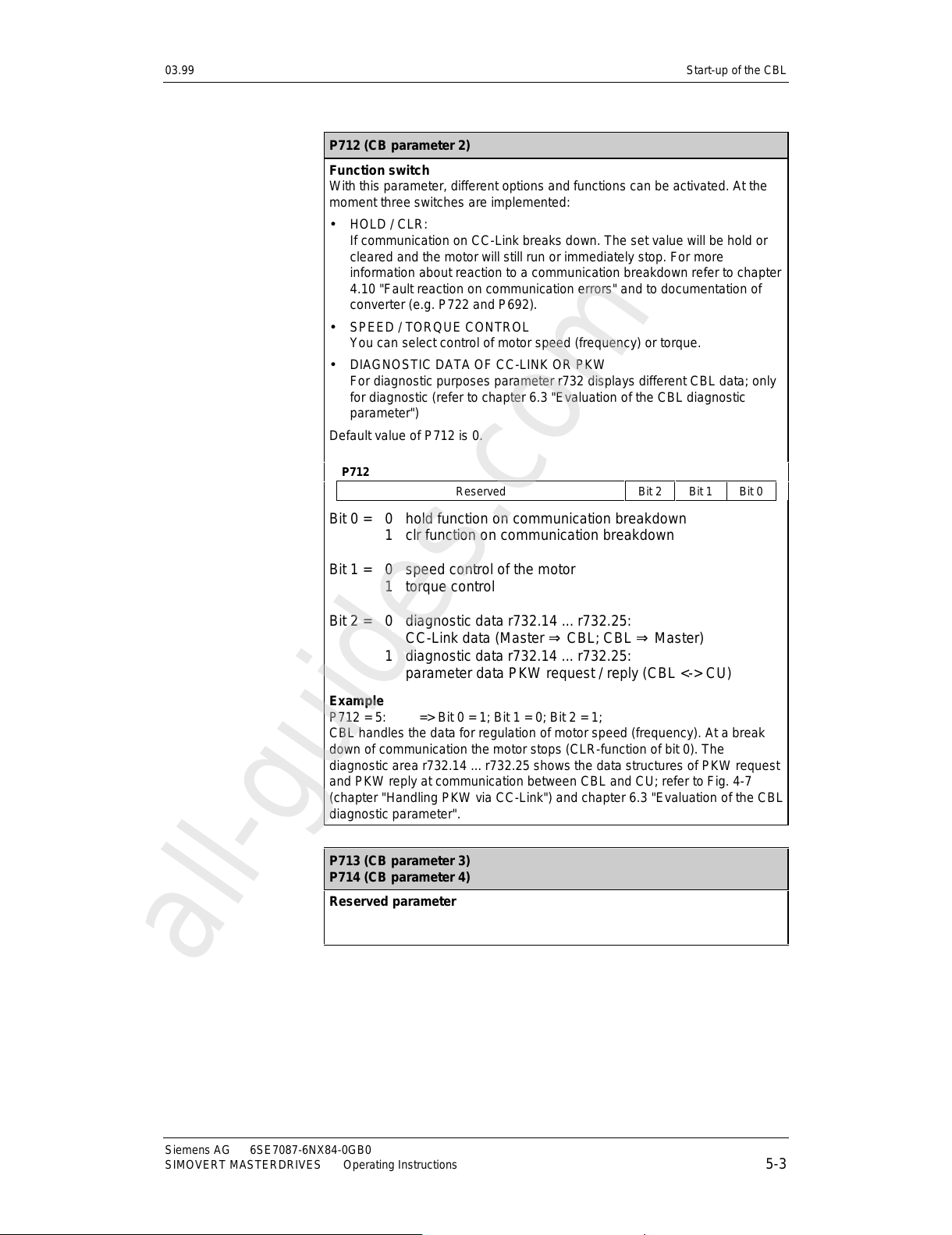

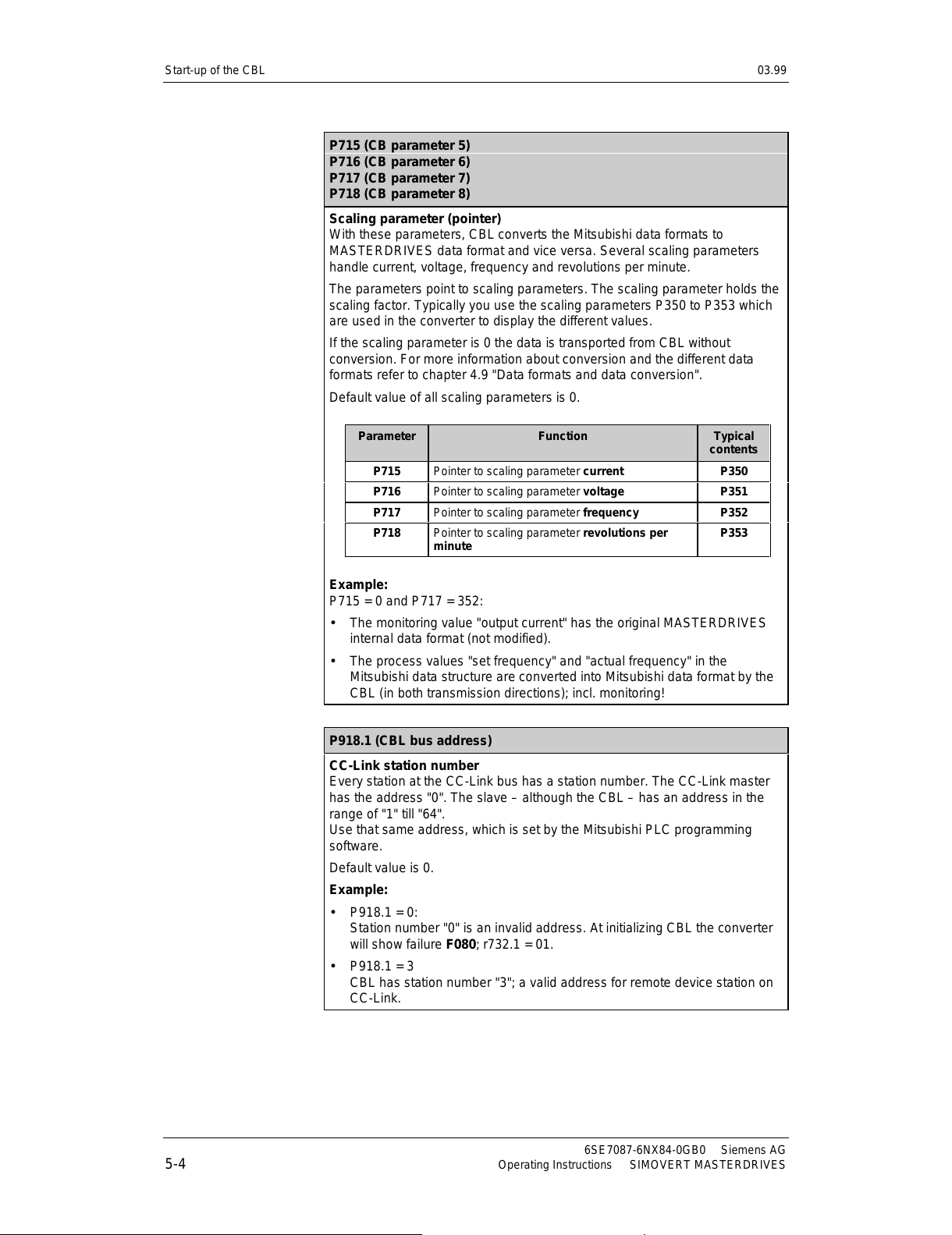

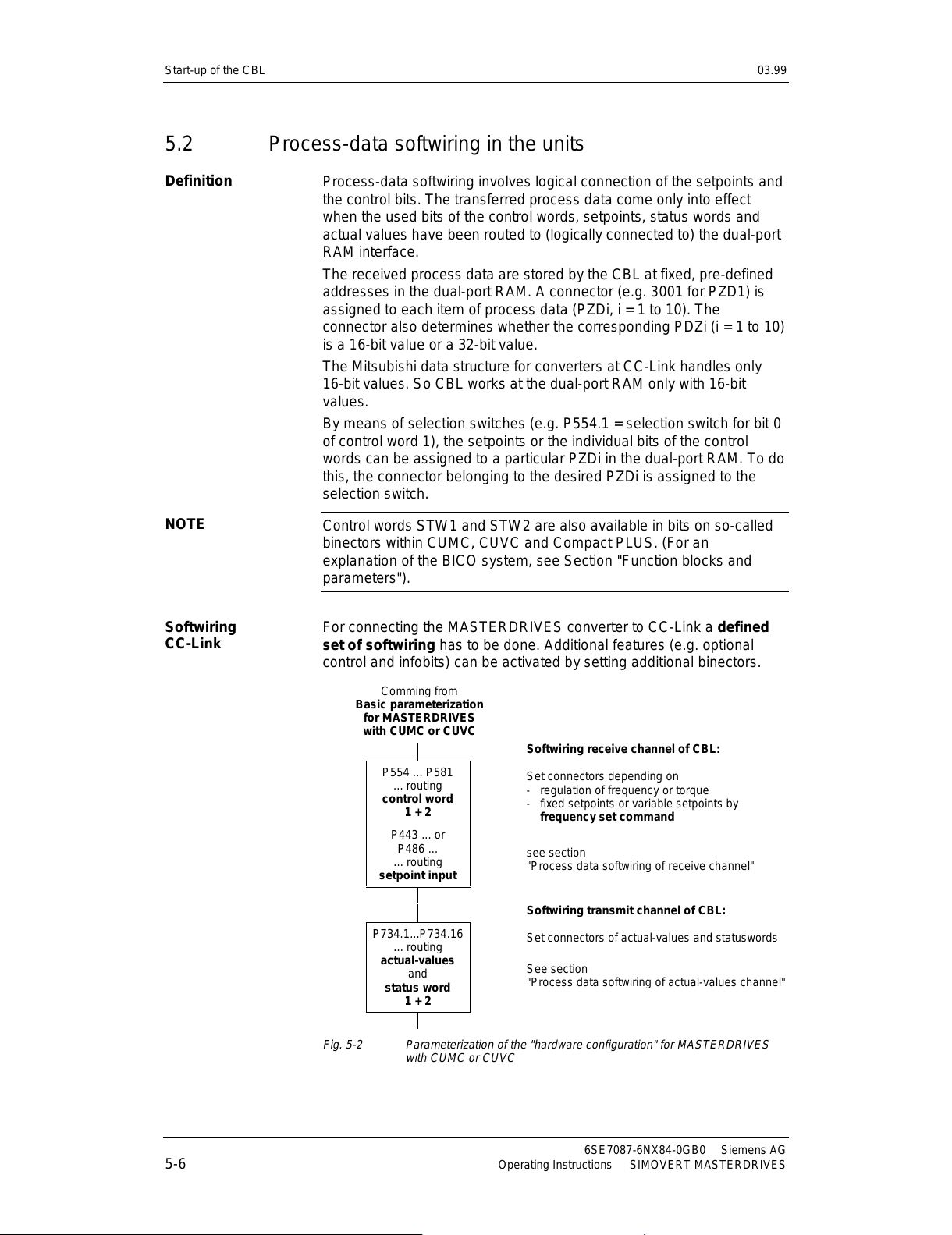

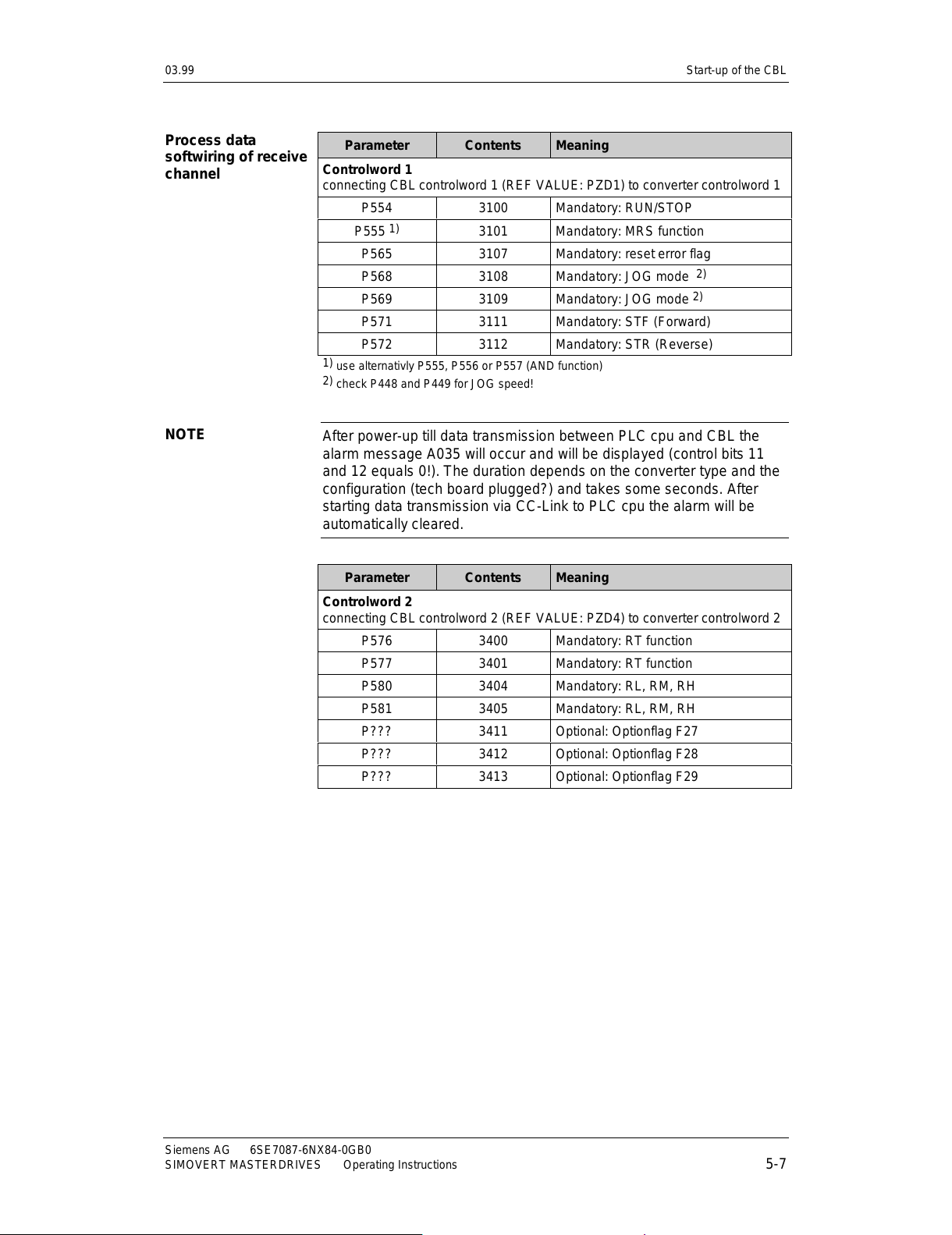

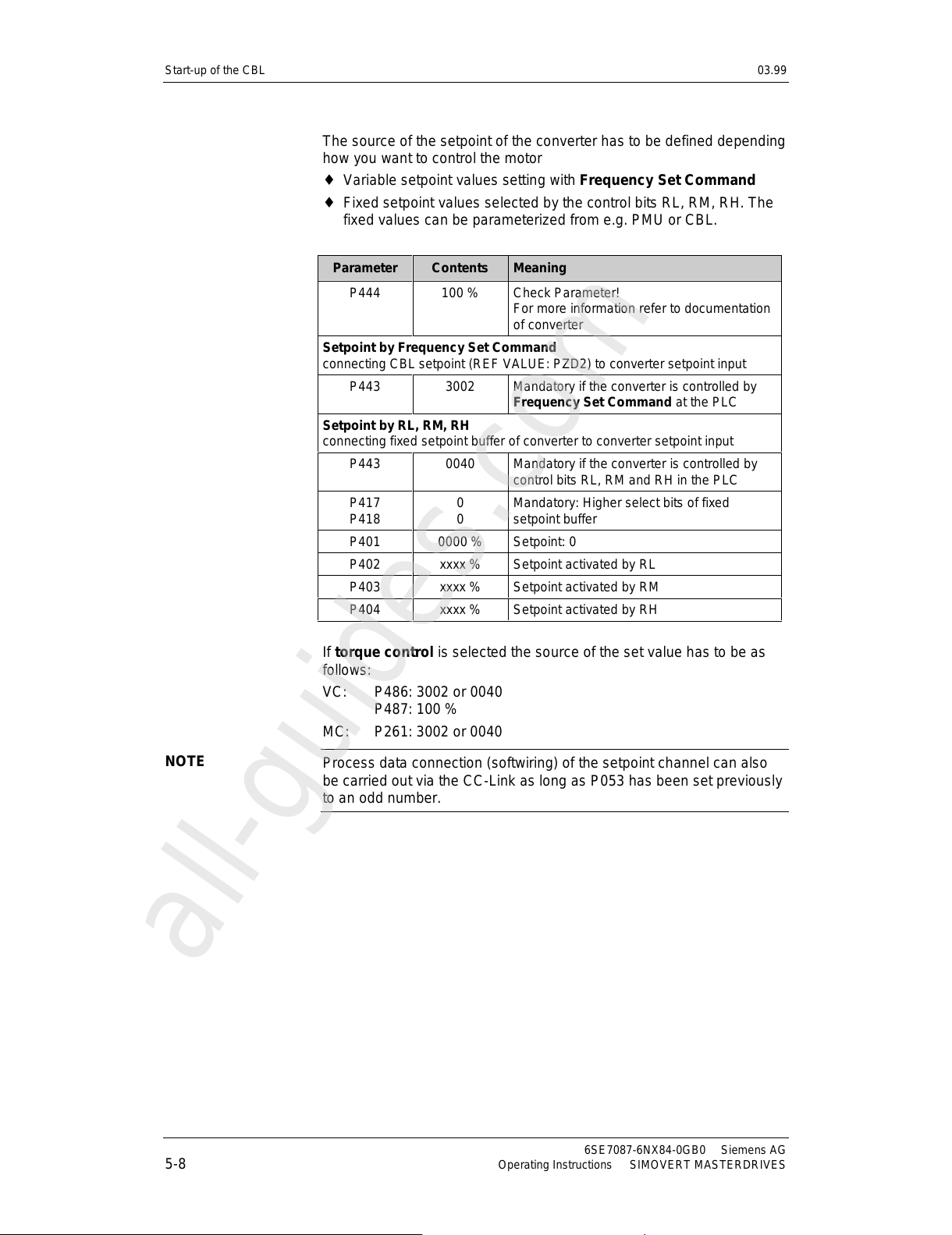

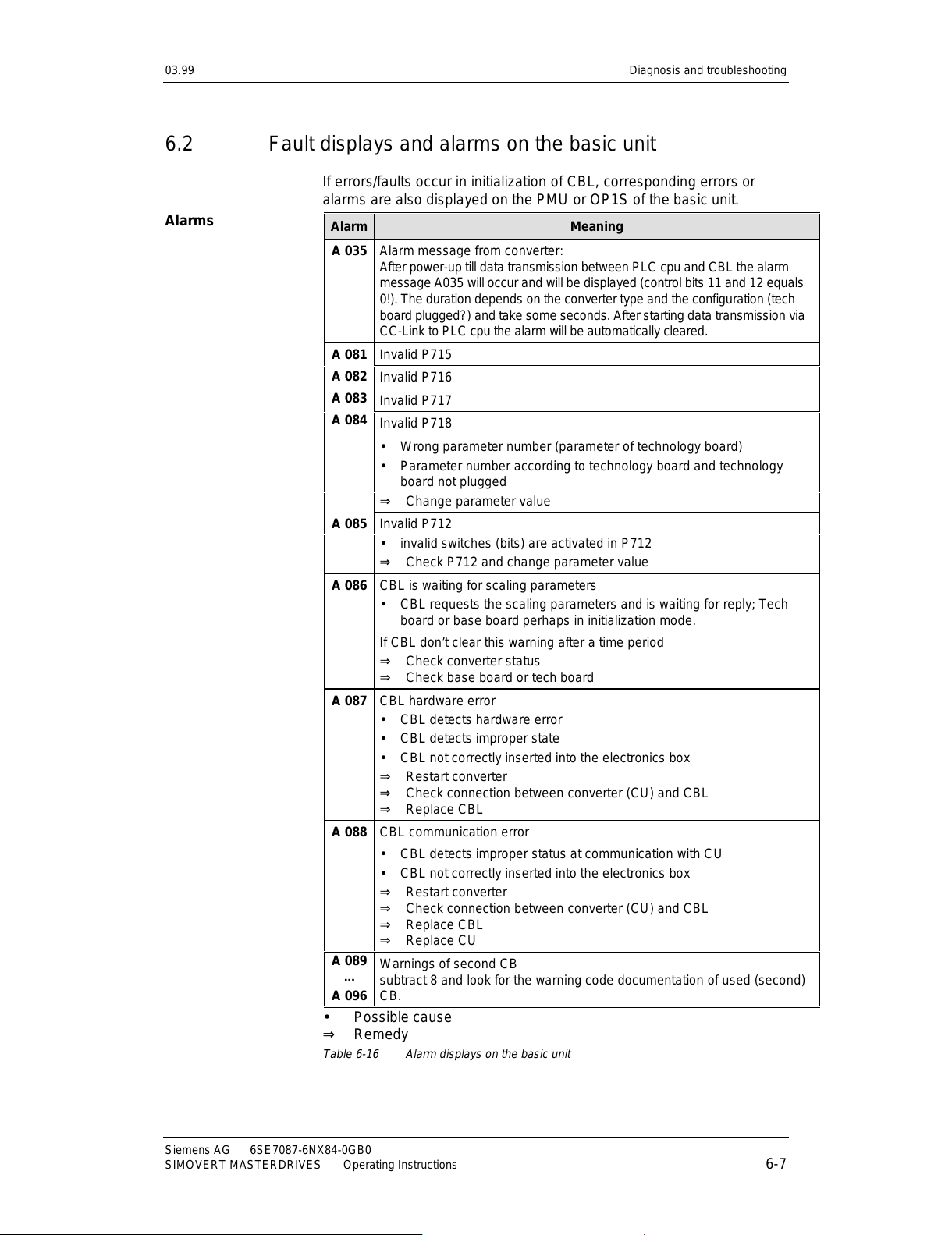

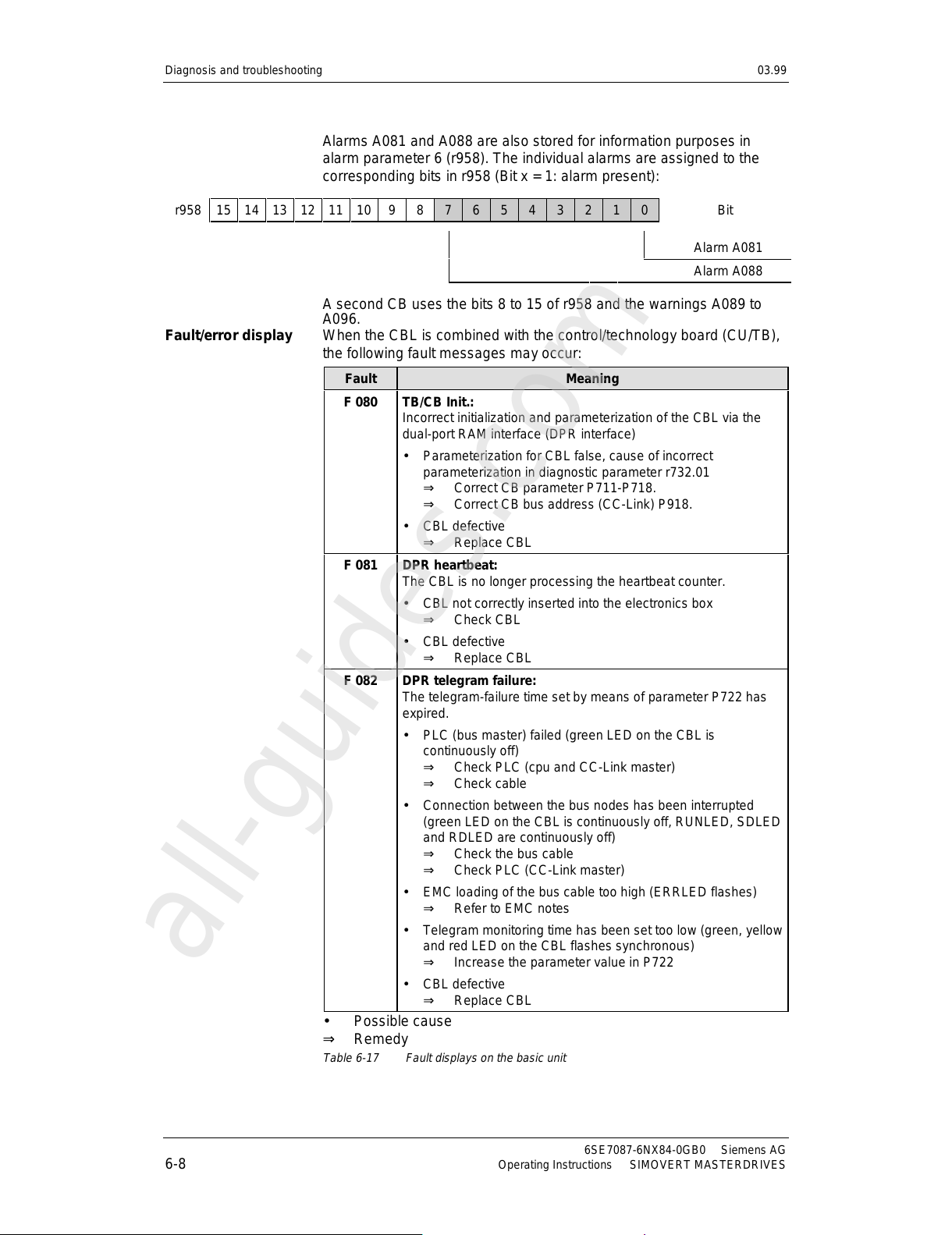

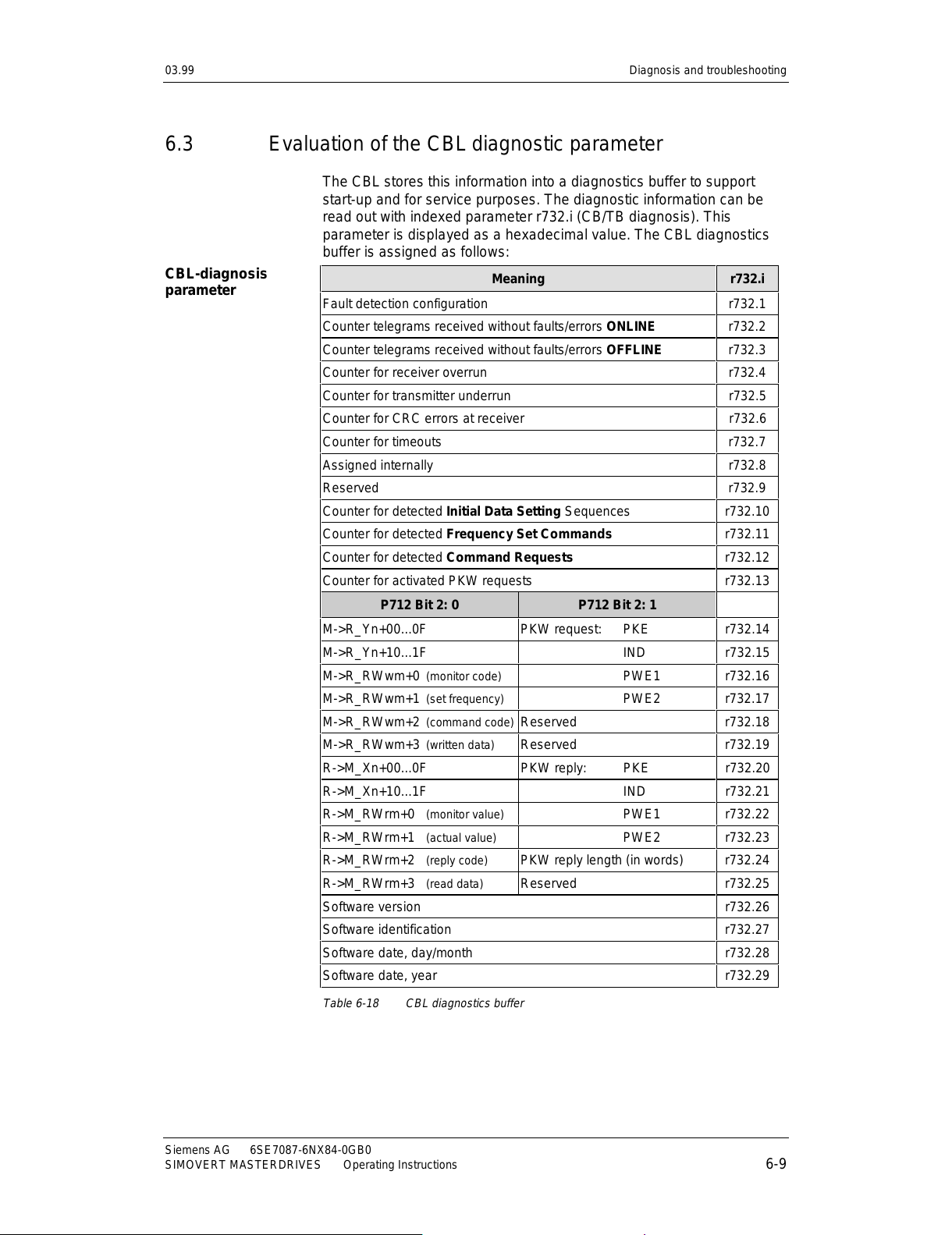

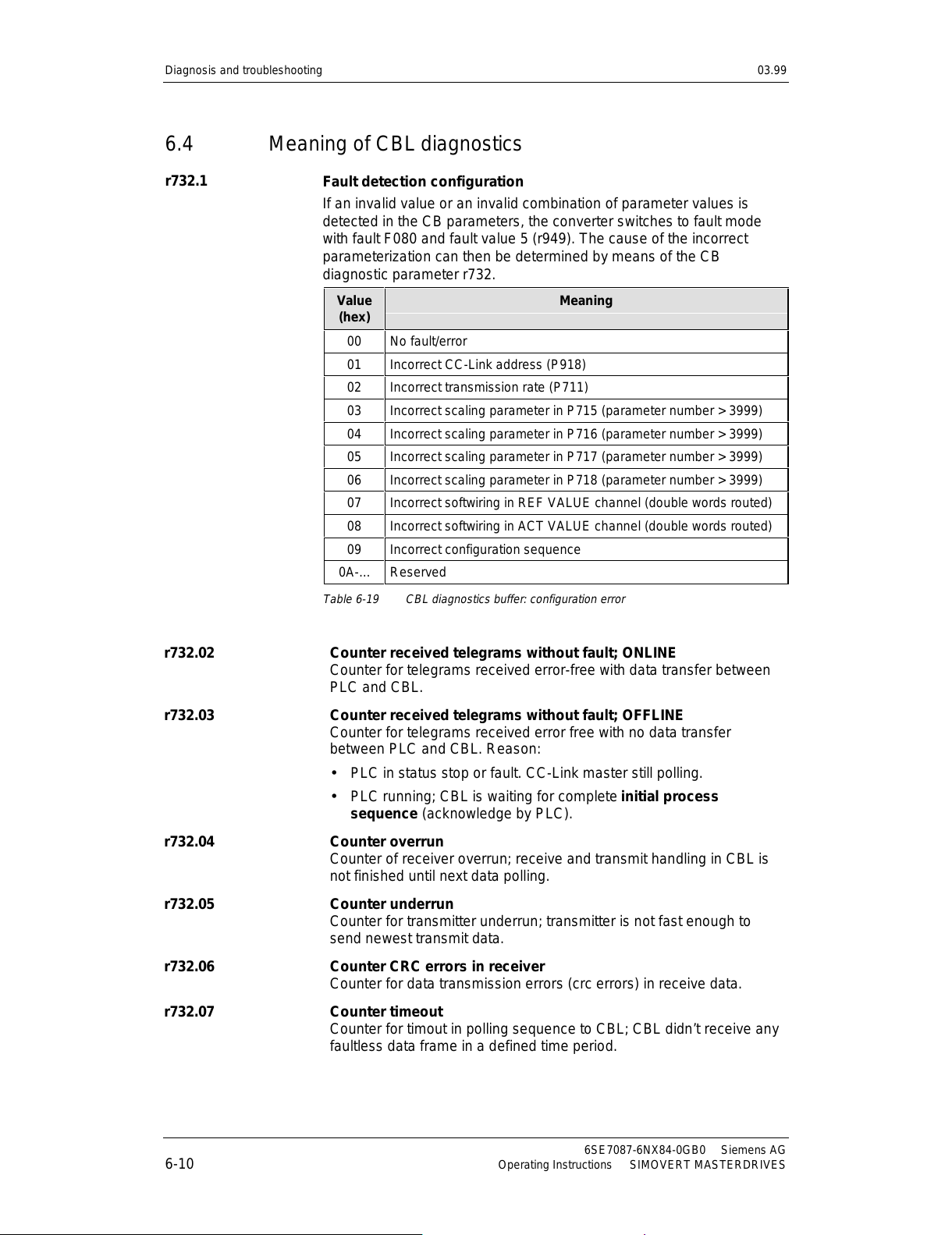

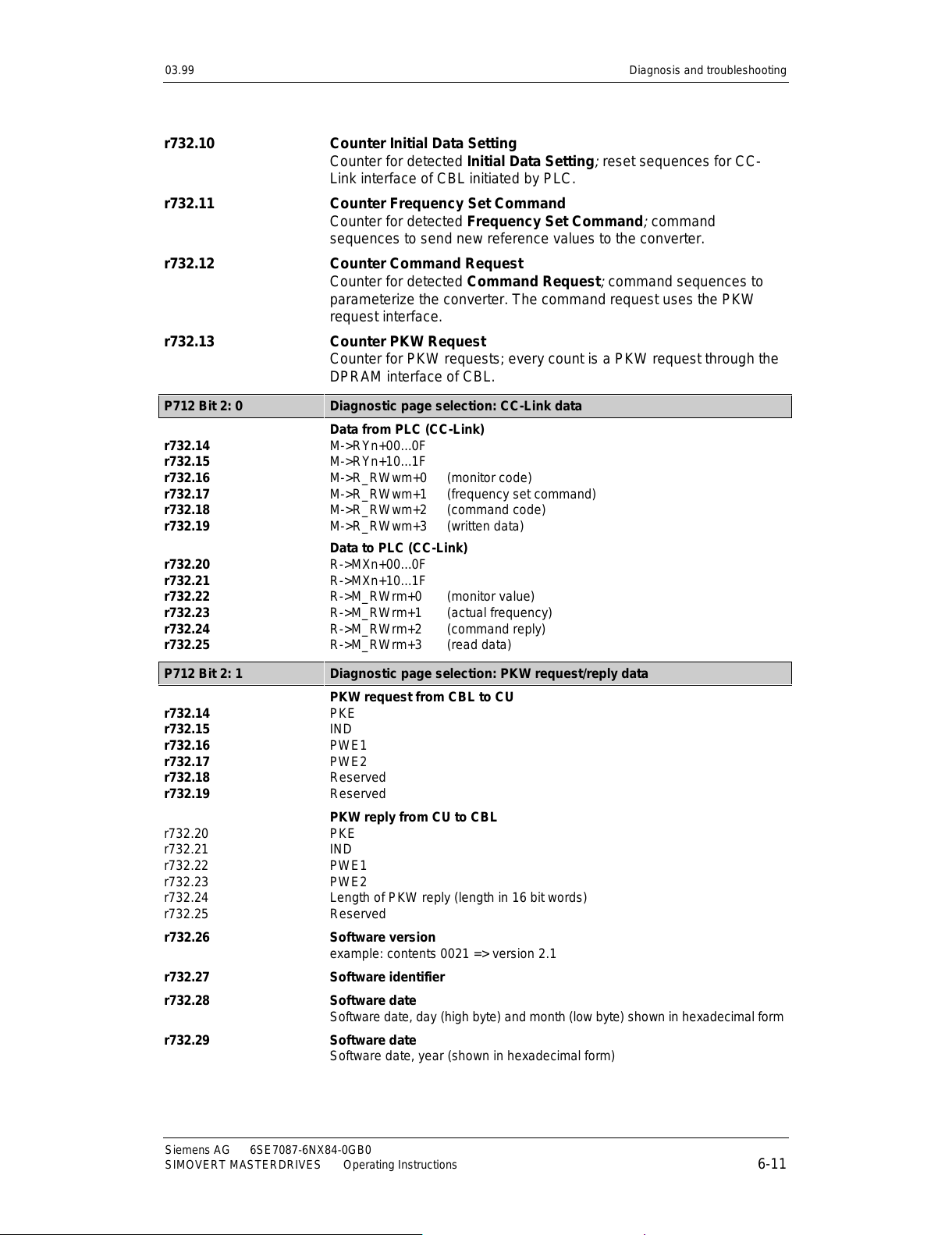

7FFFh