SIMOVERT MASTER DRIVES

Operating Instructions

Types J to M

DC-AC

Part 1

Edition: AB Order No.: 6SE7087-6BM70

General 12.96

Overview of the MASTER DRIVES Operating Instructions:

Operating Instructions consists of

Part 1 Part 2

6SE708_-_AD10 6SE708_-_AD70 6SE708_-_XX10

6SE708_-_AD20 6SE708_-_AD70 6SE708_-_XX20

6SE708_-_AD30 6SE708_-_AD70 6SE708_-_XX30

6SE708_-_BD10 6SE708_-_BD70 6SE708_-_XX10

6SE708_-_BD20 6SE708_-_BD70 6SE708_-_XX20

6SE708_-_BD30 6SE708_-_BD70 6SE708_-_XX30

6SE708_-_AH10 6SE708_-_AH70 6SE708_-_XX10

6SE708_-_AH20 6SE708_-_AH70 6SE708_-_XX20

6SE708_-_AH30 6SE708_-_AH70 6SE708_-_XX30

6SE708_-_BH10 6SE708_-_BH70 6SE708_-_XX10

6SE708_-_BH20 6SE708_-_BH70 6SE708_-_XX20

6SE708_-_BH30 6SE708_-_BH70 6SE708_-_XX30

6SE708_-_BM20 6SE708_-_BM70 6SE708_-_XX20

You will receive Parts 1 and 2 of the Operating Instructions when you use this Order No. Parts 1

and 2 can be individually ordered by specifying the particular Order No.

_-_ stands for the language code, e.g. 0-0 for German Editions.

The following foreign language Editions of these Operating Instructions are available:

Language German French Spanish Italian

Language code 0-0 7-7 7-8 7-2

These Operating Instructions are valid for software release V1.2.

The reproduction, transmission or use of this document or i ts

contents is not permitted without express writ ten authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registrati on of a utility model or design,

are reserved.

We have checked the content s of this document to ens ure t hat

they coincide with the described hardware and software.

However, differences cannot be completely excluded, so that we

do not accept any guarantee for c om pl ete conformance.

However, the information in t hi s document is regularly checked

and necessary corrections will inc l uded in subsequent editions.

We are grateful for any recommendati ons for improvement.

Siemens AG 1996 All rights reserved

SIMOVERT Registered Trade Mark

12.96 General

Contents

0 Definitions................................................................................................................................. 0-6

Safety and operating instructions for drive converters....................................................... 0-8

1 Description................................................................................................................................ 1-1

1.1 Applications................................................................................................................................ 1-1

1.2 Mode of operation ...................................................................................................................... 1-1

1.3 Operator control- and open-loop control possibilities................................................................. 1-2

1.4 Block diagram............................................................................................................................. 1-3

2 Transport, Unpacking, Installation......................................................................................... 2-1

2.1 Transport and unpacking............................................................................................................ 2-1

2.2 Storage....................................................................................................................................... 2-1

2.3 Mounting..................................................................................................................................... 2-2

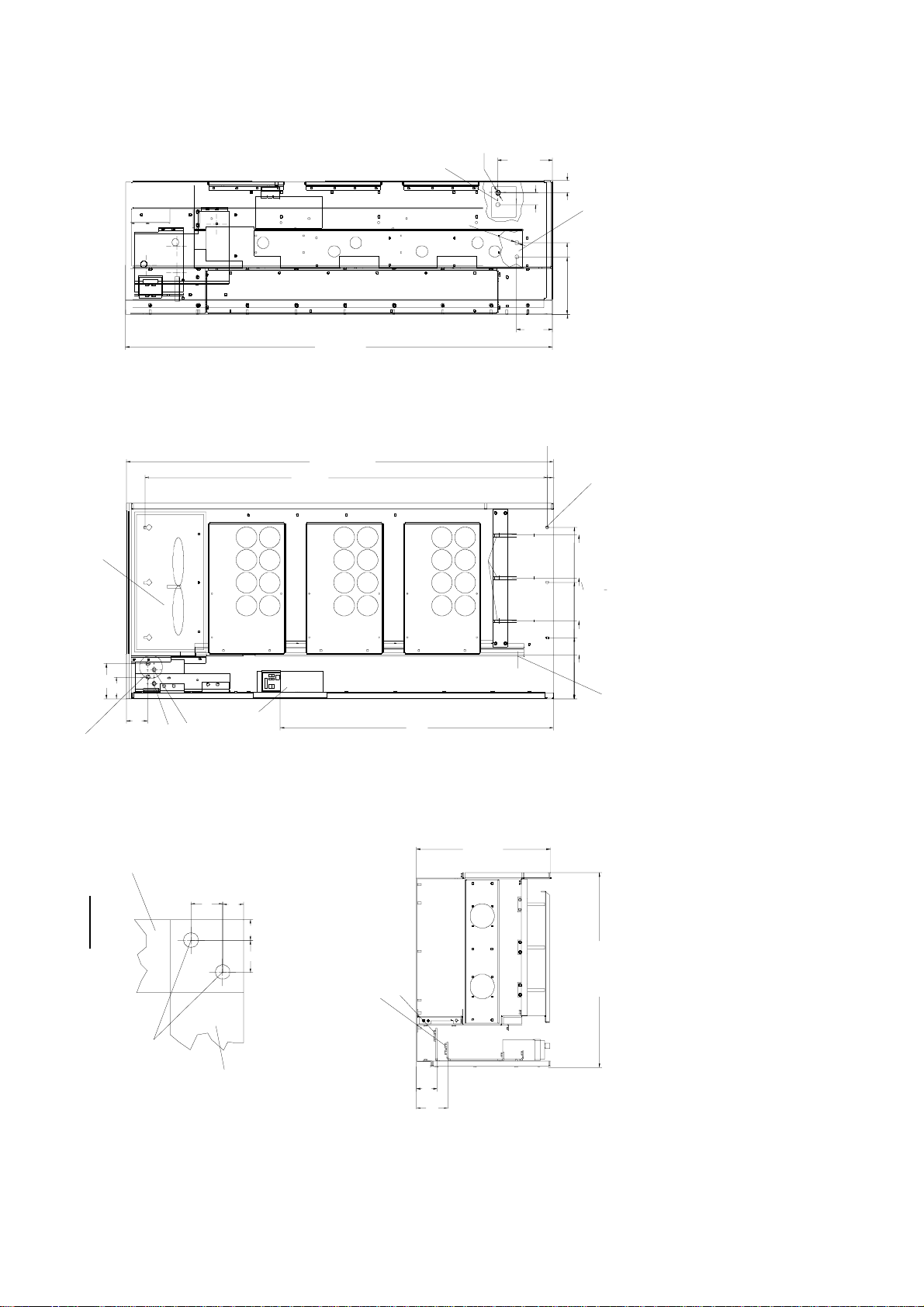

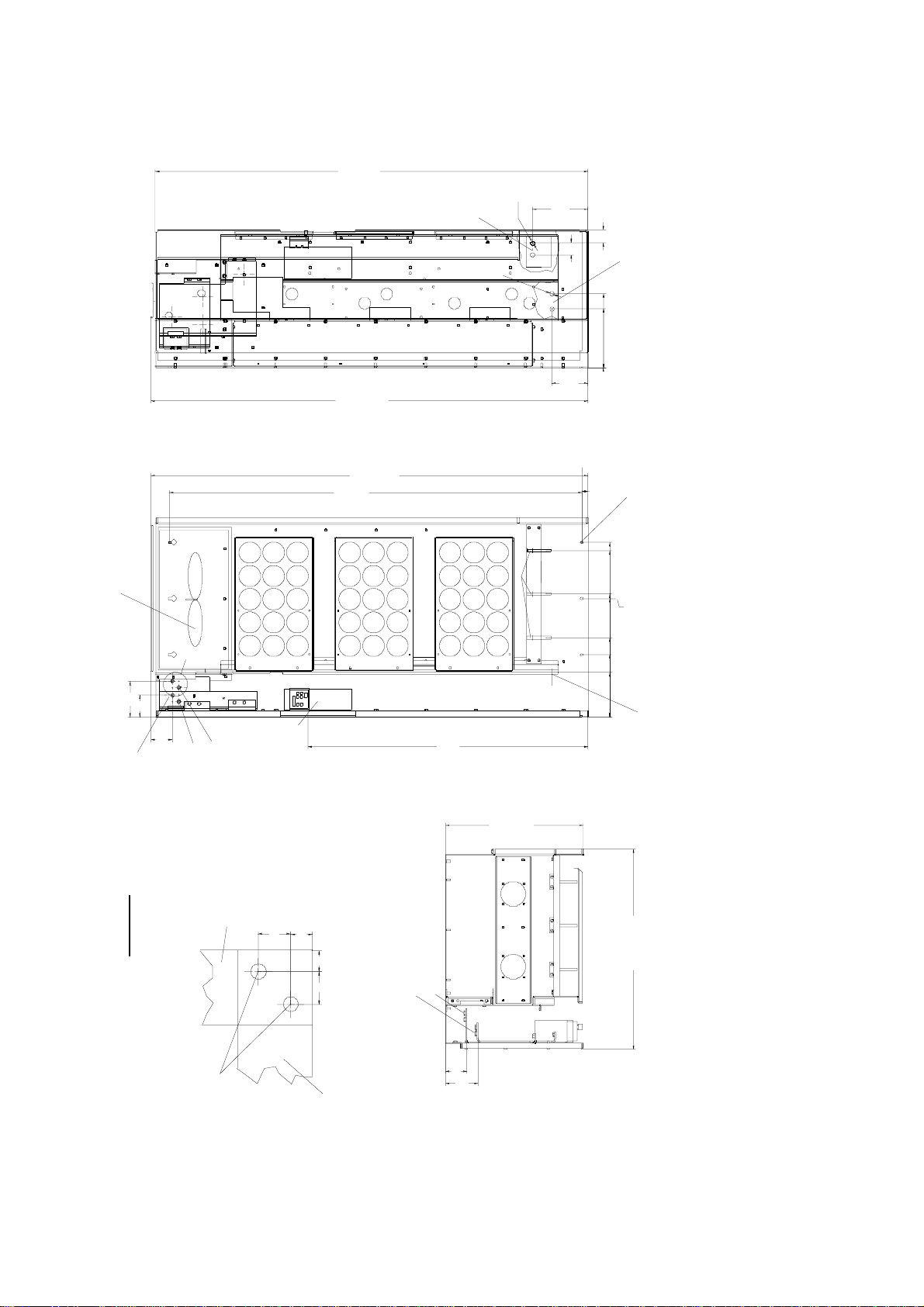

2.4 Dimension drawings................................................................................................................... 2-4

3 Connecting-up.......................................................................................................................... 3-1

3.1 Power connections..................................................................................................................... 3-2

3.1.1 Protective conductor connection ................................................................................................ 3-4

3.2 Auxiliary power supply/main contactor or bypass contactor....................................................... 3-4

4 Operator control....................................................................................................................... 4-1

4.1 Operator control elements.......................................................................................................... 4-1

4.2 Displays

.................................................................................................................... 4-2

5 Maintenance.............................................................................................................................. 5-1

5.1 Maintenance requirements......................................................................................................... 5-1

5.2 Replacing components...............................................................................................................5-2

5.2.1 Replacing the fan........................................................................................................................ 5-2

5.2.2 Replacing the fuses.................................................................................................................... 5-2

5.2.3 Replacing the starting capacitor ................................................................................................. 5-3

5.2.4 Replacing the capacitor bank ..................................................................................................... 5-3

5.2.5 Replacing SML and SMU ........................................................................................................... 5-3

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

0-3

General 12.96

5.2.6 Removing and installing the module busbars.............................................................................5-4

5.2.6.1 Replacing the balancing resistor.................................................................................................5-4

5.2.7 Replacing boards........................................................................................................................ 5-5

5.2.7.1 Replacing the IVI / IPI (type of construction M) .......................................................................... 5-5

5.2.7.2 Replacing the VDU and VDU resistor......................................................................................... 5-6

5.2.7.3 Replacing the PSU..................................................................................................................... 5-6

5.2.7.4 Replacing the IGD...................................................................................................................... 5-6

5.2.8 Replacing the snubber resistor...................................................................................................5-7

5.2.8.1 Replacing the IGBT modules...................................................................................................... 5-7

5.2.8.2 Replacing boards in the electronics box..................................................................................... 5-8

5.2.8.3 Replacing the PMU (Parameterization Unit)............................................................................... 5-8

6 Options...................................................................................................................................... 6-1

6.1 Options which can be integrated into the electronics box........................................................... 6-1

6.2 Interface boards.......................................................................................................................... 6-3

6.3 Power supplies ........................................................................................................................... 6-3

6.4 Isolating amplifiers...................................................................................................................... 6-4

6.5 Power section.............................................................................................................................6-4

6.5.1 Output reactor, dv/dt filter........................................................................................................... 6-5

6.5.1.1 Output reactor............................................................................................................................. 6-6

6.5.1.2 dv/dt filter....................................................................................................................................6-7

6.5.1.3 Selection criteria for the output reactor or dv/dt filter.................................................................. 6-8

6.6 Bypass- and output contactor..................................................................................................... 6-9

6.6.1 Bypass contactor (electrical DC link coupling)............................................................................ 6-9

6.6.1.1 Bypass contactor without I/R unit ............................................................................................... 6-9

6.6.1.2 Bypass contactor with I/R unit .................................................................................................. 6-10

6.6.1.3 Connecting and disconnecting individual converters to the DC bus......................................... 6-11

6.6.2 Output contactor....................................................................................................................... 6-11

6.7 Operator control........................................................................................................................ 6-12

7 Spare Parts................................................................................................................................ 7-1

7.1 Converter 510 V to 620 V DC..................................................................................................... 7-1

7.2 Converter 675 V to 780 V DC..................................................................................................... 7-4

7.3 Converter 890 V to 930 V DC..................................................................................................... 7-9

8 Environmental friendliness.....................................................................................................8-1

9 Technical Data.......................................................................................................................... 9-1

9.1 De-rating for an increased cooling medium temperature ...........................................................9-7

9.2 De-rating at installation altitudes > 1000 m above sea level....................................................... 9-7

0-4 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 General

10 Appendix................................................................................................................................. 10-1

10.1 Index......................................................................................................................................... 10-1

10.2 List of abbreviations.................................................................................................................. 10-2

11 Addresses............................................................................................................................... 11-1

12 Certificates.............................................................................................................................. 12-1

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

0-5

General 12.96

0 Definitions

QUALIFIED PERSONAL

•

For the purpose of these instructions and product labels, a "Qualified person" is someone who is familiar with

the installation, mounting, start-up and operation of the equipment and the hazards involved. He or she must

have the following qualifications:

1. Trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in

accordance with established safety procedures.

2. Trained in the proper care and use of protective equipment in accordance with established safety

procedures.

3. Trained in rendering first aid.

DANGER

•

For the purpose of these instructions and product labels, "Danger" indicates death, severe personal injury or

substantial property damage will result if proper precautions are not taken.

WARNING

•

For the purpose of these instructions and product labels, "Warning" indicates death, severe personal injury or

property damage can result if proper precautions are not taken.

CAUTION

•

For the purpose of these instructions and product labels, "Caution" indicates that minor personal injury or

material damage can result if proper precautions are not taken.

NOTE

•

For the purpose of these instructions, "Note" indicates information about the product or the respective part of

the Instruction Manual which is essential to highlight.

NOTE

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation or maintenance.

Should further information be desired or should particular problems arise which are not covered sufficiently for

the purchaser’s purposes, the matter should be referred to the local Siemens sales office.

The contents of this Instruction Manual shall not become part of or modify any prior or existing agreement,

committment or relationship. The sales contract contains the entire obligation of Siemens. The warranty

contained in the contract between the parties is the sole warranty of Siemens. Any statements contained herein

do not create new warranties or modify the existing warranty.

0-6 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 General

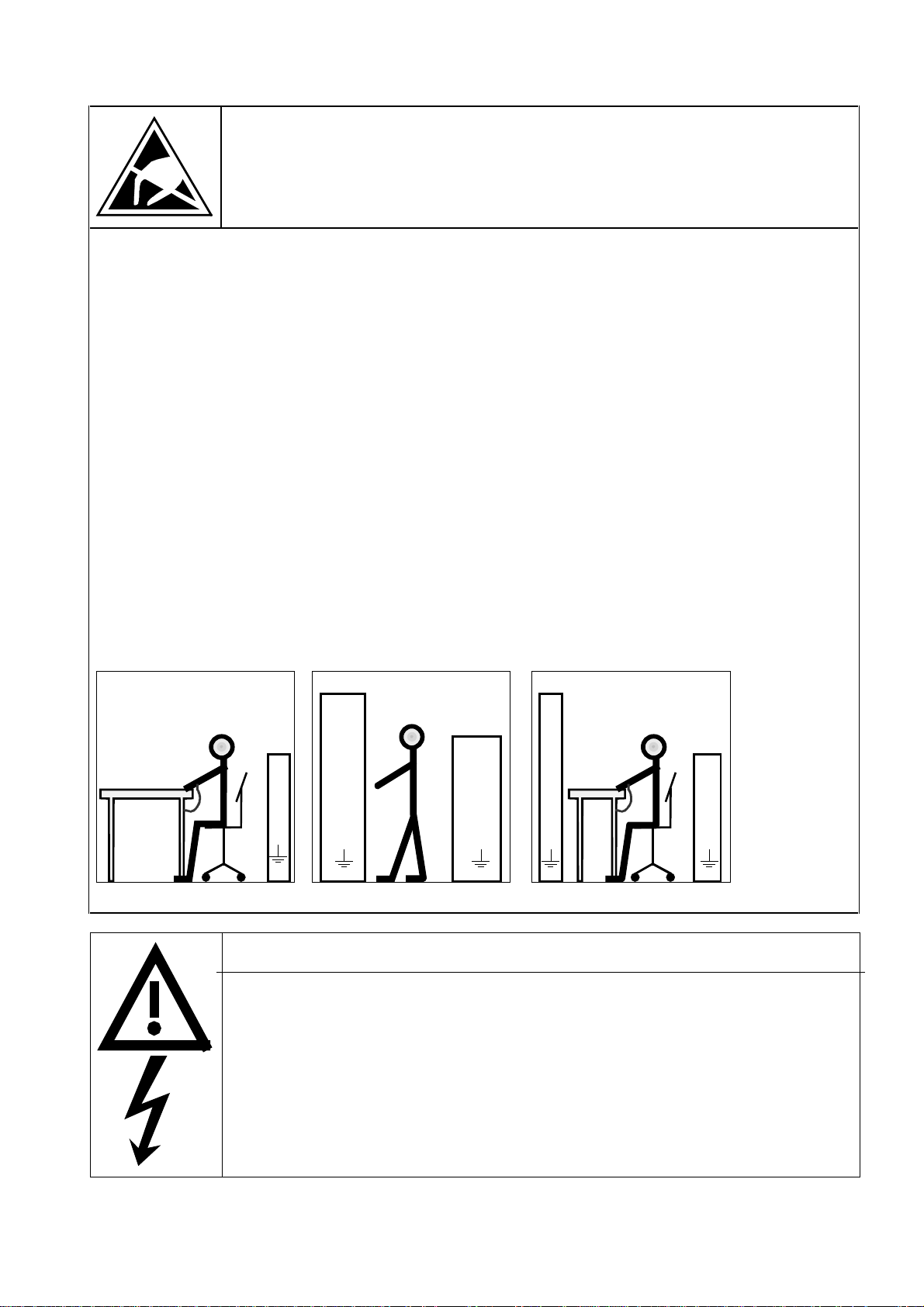

CAUTION

Components which can be destroyed by electrostatic discharge (ESD)

The converters contain components which can be destroyed by electrostatic discharge. These components can

be easily destroyed if not carefully handled. If you have to handle electronic boards please observe the

following:

Electronic boards should only be touched when absolutely necessary.

♦

The human body must be electrically discharged before touching an electronic board

♦

Boards must not come into contact with highly insulating materials - e.g. plastic foils, insulated desktops,

♦

articles of clothing manufactured from man-made fibers

Boards must only be placed on conductive surfaces

♦

When soldering, the soldering iron tip must be grounded

♦

Boards and components should only be stored and transported in conductive packaging (e.g. metalized

♦

plastic boxes, metal containers)

If the packing material is not conductive, the boards must be wrapped with a conductive packaging material,

♦

e.g. conductive foam rubber or household aluminum foil.

The necessary ECB protective measures are clearly shown in the following diagram:

a = Conductive floor surface d = ESD overall

b = ESD table e = ESD chain

c = ESD shoes f = Cubicle ground connection

b

c

a

d

e

f

f f f

d

b

f

c

StandingSitting Standing / Siting

a

c

d

e

WARNING

Hazardous voltages are present in this electrical equipment during operation.

Non-observance of the safety instructions can result in severe personal injury or property

damage.

a

Only qualified personnel should work on or around the equipment after first becoming

thoroughly familiar with all warning and safety notices and maintenance procedures

contained herein.

The successful and safe operation of this equipment is dependent on proper handling,

installation, operation and maintenance.

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

0-7

General 12.96

0.1 Safety and operating instructions for drive converters

Safety and operating instructions

for drive converters

(in conformity with the low-voltage directive 73/23/EEC)

1. General

In operation, drive converters, depending on their degree of protection, may have live, uninsulated, and

possibly also moving or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of improper use, wrong installation or maloperation,

there is the danger of serious personal injury and damage to property.

For further information, see documentation.

All operations serving transport, installation and commissioning as well as maintenance are to be carried out

by skilled technical personnel (Observe IEC 364 or CENELEC HD 384 or DIN VDE 0100 and IEC 664 or

DIN/VDE 0110 and national accident prevention rules!).

For the purposes of these basic safety instructions, "skilled technical personnel" means persons who are

familiar with the installation, mounting, commissioning and operation of the product and have the qualifications

needed for the performance of their functions.

2. Intended use

Drive converters are components designed for inclusion in electrical installations or machinery.

In case of installation in machinery, commissioning of the drive converter (i.e. the starting of normal operation)

is prohibited until the machinery has been proved to conform to the provisions of the directive 89/392/EEC

(Machinery Safety Directive - MSD). Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal opertion) is admissible only where conformity with the EMC directive

(89/336/EEC) has been established.

The drive converters meet the requirements of the low-voltage directive 73/23/EEC. They are subject to the

harmonized standards of the series prEN 50178/DIN VDE 0160 in conjunction with EN 60439-1/ VDE 0660,

part 500, and EN 60146/ VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken from the rating plate

and from the documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use shall be complied with.

The climatic conditions shall be in conformity with prEN 50178.

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications in the pertinent

documentation.

The drive converters shall be protected against excessive strains. In particular, no components must be bent

or isolating distances altered in the course of transportation or handling. No contact shall be made with

electronic components and contacts.

Drive converters contain electrostatic sensitive components which are liable to damage through improper use.

Electric components must not be mechanically damaged or destroyed (potential health risks).

0-8 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 General

5. Electrical connection

When working on live drive converters, the applicable national accident prevention rules (e.g. VBG 4) must be

complied with.

The electrical installation shall be carried out in accordance with the relevant requirements (e.g. cross-sectional

areas of conductors, fusing, PE connection). For further information, see documentation.

Instructions for the installation in accordance with EMC requirements, like screening, earthing, location of filters

and wiring, are contained in the drive converter documentation. They must always be complied with, also for

drive converters bearing a CE marking. Observance of the limit values required by EMC law is the

responsibility of the manufacturer of the installation or machine.

6. Operation

Installations which include drive converters shall be equipped with additional control and protective devices in

accordance with the relevant applicable safety requirements, e.g. Act respecting technical equipment, accident

prevention rules etc. Changes to the drive converters by means of the operating software are admissible.

After disconnection of the drive converter from the voltage supply, live appliance parts and power terminals

must not be touched immediately because of possibly energized capacitors. In this respect, the corresponding

signs and markings on the drive converter must be respected.

During operation, all covers and doors shall be kept closed.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

Keep safety instructions in a safe place!

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

0-9

08.96 Description

1 Description

SIMOVERT MASTER DRIVES are power electronic units. They are available as

♦ Compact units with three-phase- or DC current input

Output range: 2.2 kW to 37 kW

♦ Chassis units with three-phase- or DC current input

Output range: 45 kW to 200 kW

♦ Cabinet units with three-phase- or DC current input

Output range: 250 kW to 1500 kW

There are three versions depending on the particular application

♦ Frequency control FC simple applications (e.g. pumps and fans)

♦ Vector control VC high demands regarding dynamic performance and accuracy

♦ Servo Control SC servo drives

1.1 Applications

Drive converter with DC current input

DC drive converters generate a variable-frequency three-phase system at the motor side from a DC supply. This

variable-frequency three-phase system is used to continuously control the speed of three-phase motors.:

SIMOVERT MASTER DRIVES can be used with a common DC link, as well as for single-motor and multi-motor

drives.

Technological functions and expansions can be realized via defined interfaces in the open-loop control section.

1.2 Mode of operation

Converters with DC current input are suitable for coupling several converters to a common DC link bus. This

permits energy transfer between drives in the motoring and generating modes which in turn means energy

savings.

The DC converter must be connected to the DC bus through an E unit (rectifier unit) due to the pre-charging of

the DC link capacitors. If an I/R unit (rectifier and regenerative feedback unit) is used instead of the E unit, power

is fed back into the supply if the regenerative output for several drives is greater than the motor power required.

The converter is ready for operation after the DC link capacitors have been pre-charged.

The inverter, configured using IGBT modules, generates a three-phase system from the DC link voltage to feed

the motor.

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

1-1

Description 08.96

SIMOVERT VC

The inverter open-loop control uses a microprocessor and field-oriented vector control with an extremely fast

closed-loop current control. The drive can be precisely adapted to the demanded load torque as a result of the

field-oriented control, which in turn means that the drive has an extremely high dynamic performance.The pulse

frequency is preset to 2.5 kHz when the unit is shipped.

SIMOVERT VC is suitable for:

Induction motors in both single-motor or multi-motor drives.

♦

For multi-motor drives, the motors within the group must be the same.

Some of the applications are, for example:

Winder drives

♦

Rolling mill drives.

♦

When the drive is shipped, closed-loop V/f control is preset. Closed-loop frequency control with field-oriented

vector control must be parameterized.

The converter can be set, as a result of the precise motor simulation up to a maximum frequency of 300 Hz, with

and without stall protection and with and without tachometer feedback.

1.3 Operator control- and open-loop control possibilities

The unit can be controlled via

♦ the parameterization unit (PMU)

♦ an optional operator control panel (OP1)

♦ terminal strip

♦ a serial interface.

When networked with automation systems, the unit open-loop control is realized via optional interfaces and

technology boards.

1-2 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Description

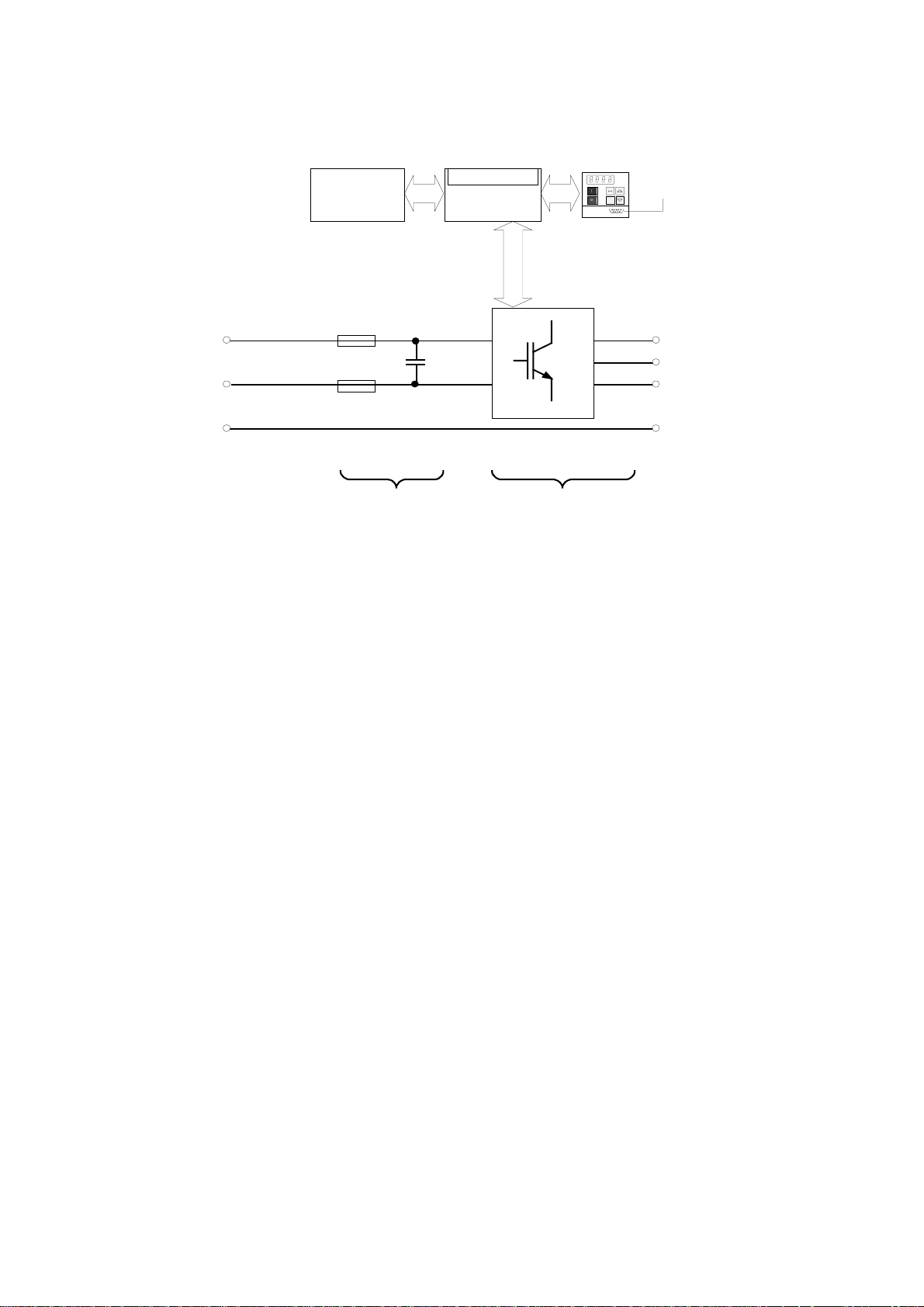

1.4 Block diagram

Option boards-

in the electronics box

C / L+

DC bus

connection

D / L -

PE1

Fusing and

DC link

Fig. 1.1 Block diagram, types of construction J and K

Terminal strip

CU

Inverter with

CU and PMU

Connector f or OP1

P

U2/T1

V2/T2

W2/T3

PE2

Motor

connection

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

1-3

Description 08.96

DC bus

connection

C / L+

D / L -

PE1

Option boards

in the electronics box

Master

Fusing and

DC link

Slave

Terminal strip

CU

Inverter with

CU and PMU

Connector for OP1

P

PE2

Motor

connection

U2/T1

V2/T2

W2/T3

PE1

Fusing and

Fig. 1.2 Block diagram, type of construction M

DC link

PE2

Inverter with

CU and PMU

1-4 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Transport, Unpacking, Installation

2 Transport, Unpacking, Installation

2.1 Transport and unpacking

The units are packed in the manufacturing plant corresponding to that specified when ordered. A product packing

label is located on the outside of the packing.

Please observe the instructions on the packaging for transport, storage and professional handling.

For transportation with a fork-lift truck the converter is mounted on a wooden pallet.

Vibration and jolts must be avoided during transport, e.g. when setting the unit down.

The converter can be installed after it has been unpacked and checked to ensure that everything is complete

and that the converter is not damaged.

If the converter is damaged you must inform your shipping company immediately.

The packaging consists of a wooden floor sectionand a PE foil to protect the equipment from humidity. It

can be disposed of in accordance with local regulations.

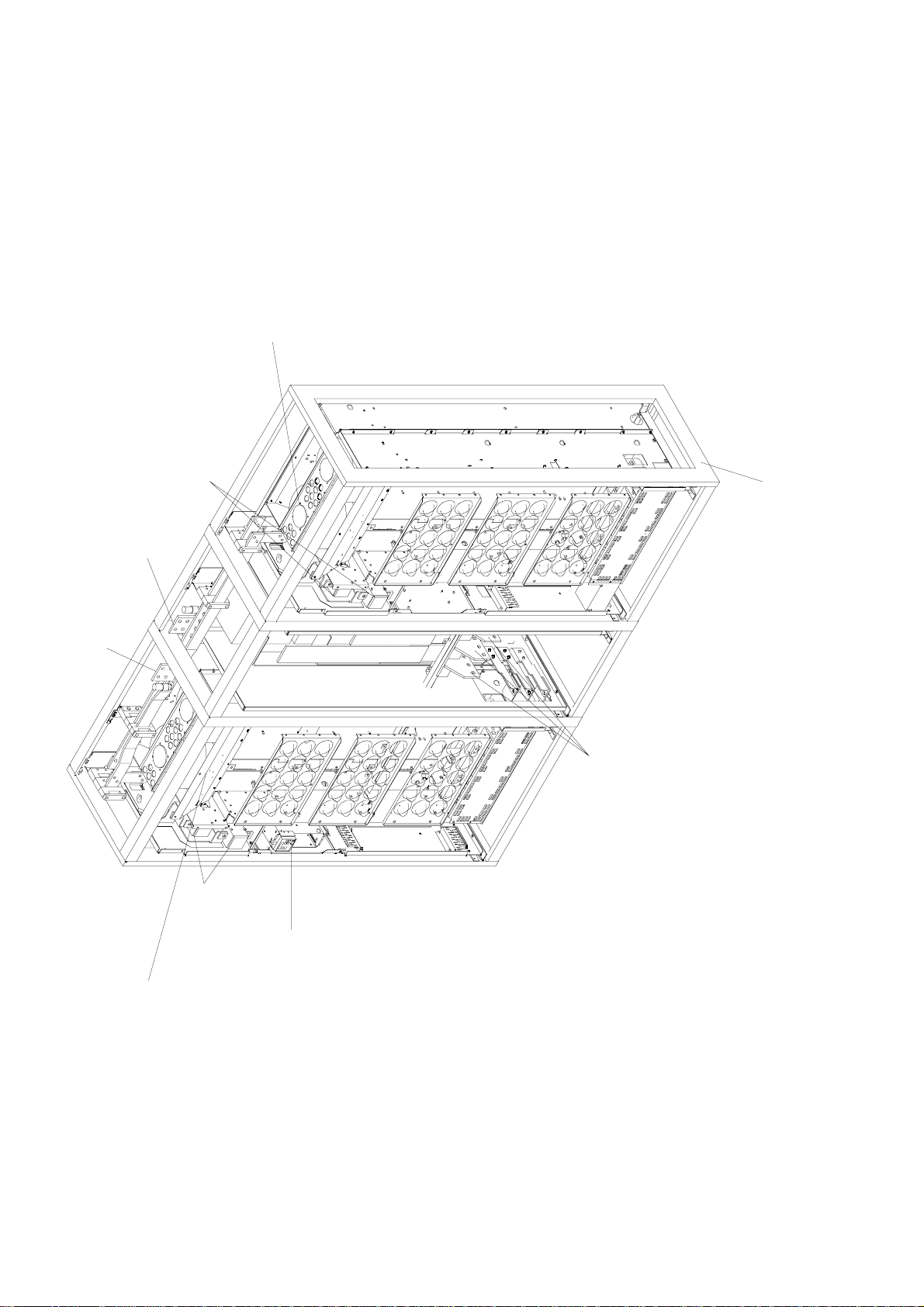

Depending on the degree of protection and type of construction, the units may be mounted on a pallet either with

or without transport rails.

♦ Degree of prot. IP00 Pallet

• Type of construction J one unit

• Type of construction K one unit

• Type of construction M three units

− master drive converter, type of construction K

− reactor

− slave drive converter, type of construction K without electronics box

♦ Degree of prot. IP20 8MC cabinet on transport rails and pallet

• Type of construction J one 8MC cabinet

• Type of construction K one 8MC cabinet

• Type of construction M three 8MC cabinets combined to form a single unit

− master type of construction K

− reactor

− slave drive converter, type of construction K without electronics box

Chassis units are supplied, as standard, with degree of protection IP00.

2.2 Storage

The converters must be stored in clean dry rooms.Temperatures between − 25 °C (−13 °F) and + 70 °C (158 °F)

are permissible. Temperature fluctuations > 20 K per hour are not permissible.

WARNING

The equipment should not be stored for longer than one year. If it is stored for longer

periods of time, the converter DC link capacitors must be formed at start-up.

Capacitor forming is described in Part 2 of the Operating Instructions.

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

2-1

Transport, Unpacking, Installation 12.96

2.3 Mounting

The following are required for mounting:

M8 bolt(s)

♦

♦ Dimension drawings: Fig. 2.1 for type of construction J, Fig. 2.2 for type of construction K and

Fig. 2.5 for type of construction M.

♦ Only type of construction M: Engineering support

WARNING

Safe converter operation requires that the equipment is mounted and commissioned by

qualified personnel taking into account the warning information provided in this Instruction

Manual.

The general and domestic installation and safety regulations for work on electrical power

equipment (e.g. VDE) must be observed as well as the professional handling of tools and

the use of personnal protective equipment.

Death, severe bodily injury or significant material damage could result if these instructions

are not followed.

Chassis units do not provide any protection against direct contact. It is the users

responsibility to ensure and provide the correct protection against contact according to the

relevant accident prevention regulations VBG4, by appropriately designing the enclosure or

enclosures around the chassis unit.

Remove shipping brace (marked).

The three units, type of construction M with degree of protection IP00, must be assembled according to the

instructions specified in the engineering support documentation.

The control connections between the master and slave must then be established.

Procedure: The control cables must be carefully routed through the cable duct in the reactor chassis in the

♦

master cabinet.

Insert connectors -X238 / -X234 / -X32 / -X42.

•

Insert the fiber-optic cables U41 / U51 / U61 / U42 / U43 / U52 / U53 / U62 / U63 in the

•

master, at the IPI.

NOTE

Inserting the fiber-optic cables: Insert the fiber-optic cable up to its end stop (approx. 16 mm), tighten up

the union nut by hand.

CAUTION

Fiber-optic cables may not be bent through a sharp angle.

Bending radius for fiber-optic cables ≥ 30 mm.

The unit is mounted corresponding to the dimension drawings in Section 2.4.

2-2 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Transport, Unpacking, Installation

Equipment rooms must be dry and dust-free. Ambient and cooling air must not contain any electrically conductive

gases, vapors and dusts which could diminish the functionality. Dust-laden air must be filtered.

WARNING

When mounting in cabinets, a clearance of above and below must be provided so that the

cooling air flow is not restricted (refer to dimension drawings, Section 2.4).

Dimension the cabinet cooling in line with the power loss! (+ Section „Technical data“)

The converter ambient climate in operating rooms may not exceed the values of code F according to DIN 40040.

For temperatures > 40 °C (104 °F) and installation altitudes > 1000 m, de-rating is required (+ Section

„Technical data“).

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

2-3

Transport, Unpacking, Installation 12.96

)

7

6SE70-IP0

0

2

2)Protectiveconductor4x300m

m

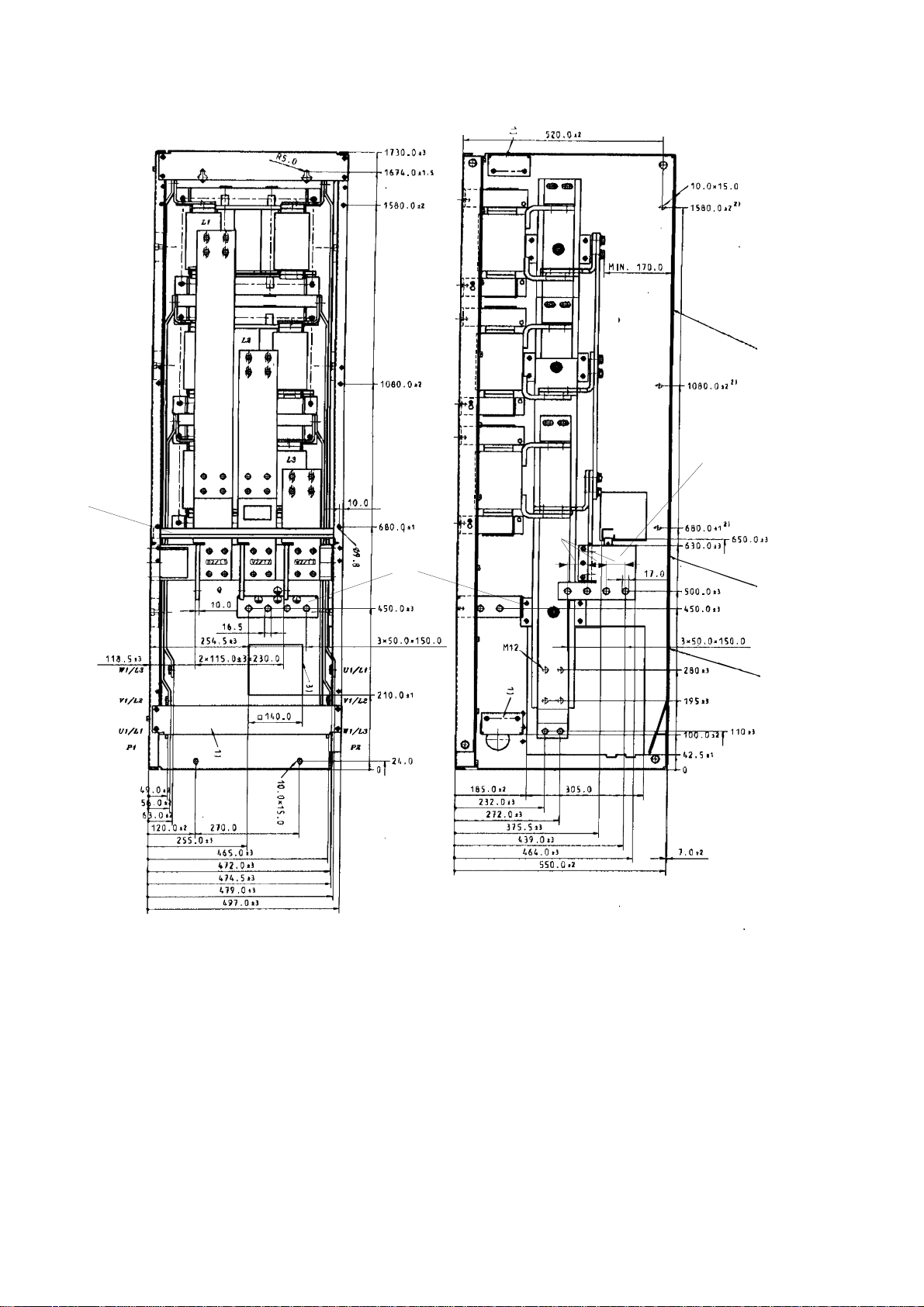

2.4 Dimension drawings

1

ø1

5

,

6

1

ø

1400 +5

222,5

45

50

2)

295

235

DC-AC chassis unit

0

145,5

Type of construction J

1400

+5

1345

1)

Fan assembly must be removed

to disassemble the unit

139

83

67

x

26

Electronics box

17

17

26

Detail X

DC positive

DC negative

to the DC busbar

ca. 710

550 +5

DC positive

DC negative

0

45

Elongated hole 9x12

708

+5

668,5

493,5

483

318,5

213

177

2)

0

2

Net weight, approx. 250 kg

With transport parts approx. 270 kg

1) - Conne ction for 4 x 300 mm

800

W

V

U

ø13,5 (M 12)

DC connection in accor dance with

DIN 43673 with 6 x 60 mm copper bar

to the rectifier/

regenerative

feedback unit

85

130

Fig. 2.1 Type of construction J

2-4 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Transport, Unpacking, Installation

6SE70IP00

1730

1)

ø17

5

,

6

1

ø

1750 +5

1750 +5

1675

)

1

Fan assembly must be removed

to disassemble the unit

x

222,5

5

4

0

5

145,5

25

VW

U

2)

295

235

0

DC-AC chassis unit

Type of construction

Elongated hole 9x12

708

668,5

493,5

483

318,5

213

177

3

139

8

87

X

DC positive

DC negative

to the DC busbar

Detail X

2)

1

M

(

5

,

DC connection in accordance with

3

DIN 43673 with 6 x 60 mm copper bar

1

ø

Fig. 2.2 Type of construction K

)

2

0

104

.

ca

Electronics box

26

17

17

6

2

to the rectifier/

regenerative

feedback unit

DC positive

DC negative

85

+5

550

130

0

0

800 +5

2

2

1) - Connection for 4 x 300 mm

2) - Protective co nductor , 4 x 3 00 mm

Net w ei ght , app r ox . 25 0 kg

With transport parts approx. 540 kg

Siemens AG 6SE7087-6BM70

2-5

SIMOVERT MASTER DRIVES Operating Instructions

Transport, Unpacking, Installation 12.96

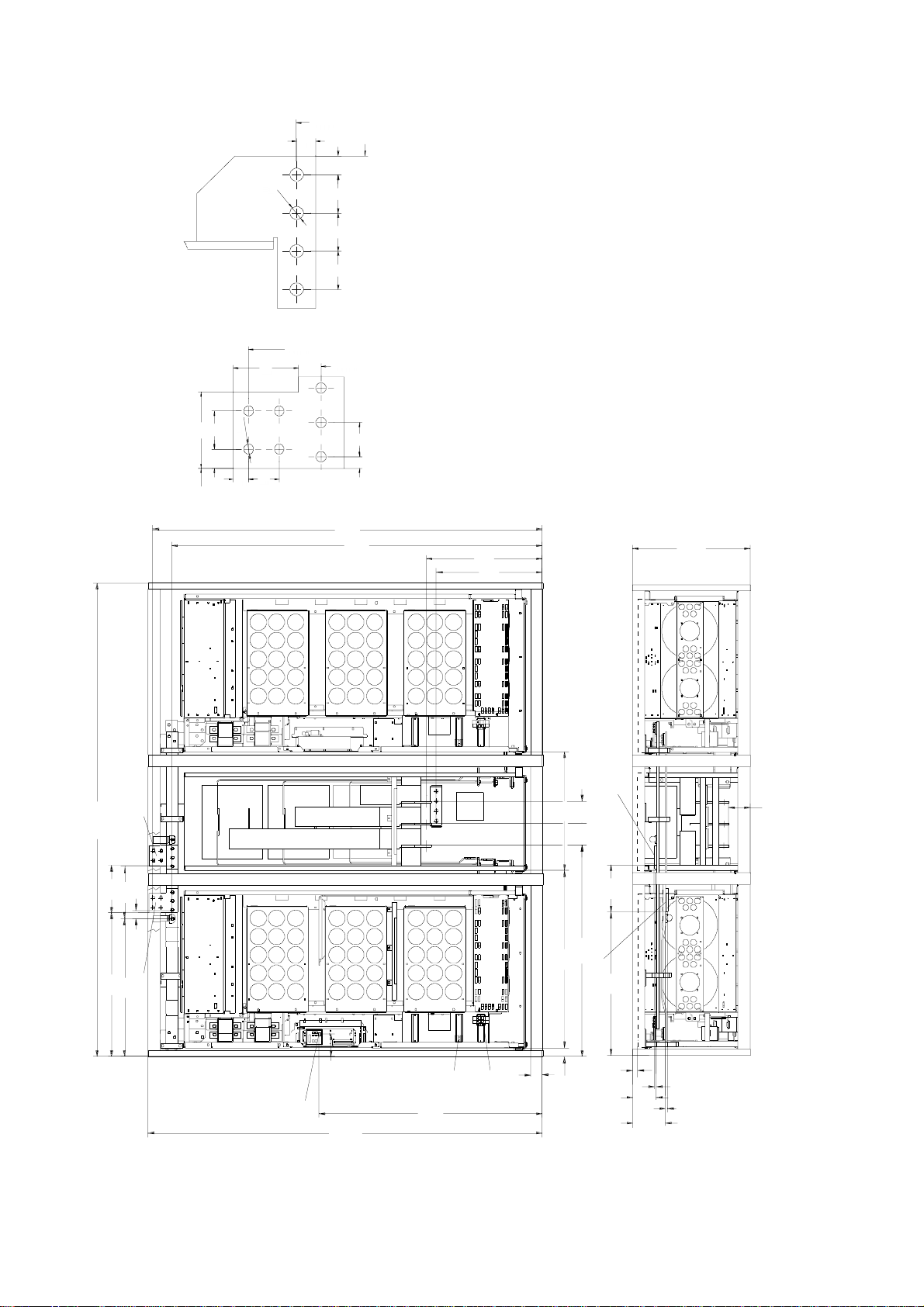

View without cover 10460/10470 View without side panel

Top cover: transparent

B)

C)

1) Painted transport rail

2) Only in the side panel left

3) Cut-out in the rear panel

50

A)

Divi ded cove rBottom cover: transparent

Cover including

bolt head

A) = PE conne ction (8 x 2 40 mm )

B) = Power connection output (8 x 240 mm )

C) = Cable duct for control cables from the Master to the Slave

Fig. 2.3 Reactor chassis, Type of construction M

2-6 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Transport, Unpacking, Installation

)

(589

25

)

100

(

25

7

2

1

10 mm th i ck

50

50

50

U, V, W connecting lugs

(max. 8 x 240 mm )

(1975)

85

2

13

50

25

C, D connecting lugs

alternatively 4 x cable lugs

directly at the C D bus

(max. 4 x 240 mm )

(13 mm diameter hole or M12)

20

40

(1880)

10 mm thick

45

15

Weight:

IP00: ~ 1200 kg

IP20: ~ 1550 kg

SIMOVERT MASTER DRIVES

Inverter

Components, frame size: M (12)

(Master, slave, reac tor chassis ) m ounted

in a cabinet frame (8MC)

(730) 100

1975

1880

589

600

+5

539

+10

D (-)

2400

5

6

240

2

45

C (+)

730

700

Fig. 2.4 Type of construction M

F102

X9

W

PE

V

U

F101

D (-)

600

112

112

~100

240

1072

900

C (+)

730

115

X9

F101

89

F102

45

1132

X300

(RS 485

Interf ace)

2000

+5

28

10

121

10

168

Siemens AG 6SE7087-6BM70

2-7

SIMOVERT MASTER DRIVES Operating Instructions

Transport, Unpacking, Installation 12.96

Cabinetfram

e

Fan a ss embly

Incoming fuse

F11, F12, F21, F22

D (-)

W

C (+)

V

U

SIMOVERT MASTER DRI VES

Inverter

Components, frame size: M (12)

(M ast er , s l ave, react or chassis) moun ted

in a cabinet frame ( 8MC)

Slave WR

Reactor

U, V, W

Ma ster WR

In coming fu ses

F11, F12, F21, F22

Elektronics box

with PMU

Fan a ssembly

Fig. 2.5 Type of construction M

2-8 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Connecting-up

3 Connecting-up

WARNING

SIMOVERT MASTER DRIVES are operated at high voltages.

The equipment must be in a no-voltage condition (disconnected from the supply) before any

work is carried-out!

Only professionally trained, qualified personnel must work on or with the unit.

Death, severe bodily injury or significant material damage could occur if these warning

instructions are not observed.

Extreme caution should be taken when working-on the unit when it is open, as external

power supplies may be connected. The power terminals and control terminals can still be at

hazardous potentials even when the motor is stationary.

Hazardous voltages are still present in the unit up to 5 minutes after it has been powereddown due to the DC link capacitors. Thus, the appropriate delay time must be observed

before opening-up the unit.

Forming the DC link capacitors:

The storage time should not exceed one year. The converter DC link capacitors must be

formed at start-up if the unit has been stored for a longer period of time.

Forming is described in the Instruction Manual, Part 2.

When the DC link is supplied from a central unit, it must be ensured that the converter is

reliably isolated from the DC link voltage!

The user is responsible, that the motor, converter and any other associated devices or units

are installed and connected-up according to all of the recognized regulations in that

particular country as well as other regionally valid regulations. Cable dimensioning, fusing,

grounding, shutdown, isolation and overcurrent protection should be especially observed.

INFORMATION

♦ In the factory setting, the converter protects the motor from overload:

• P362 = 0 (self-ventilated motor)

• P364.2 = 100 (motor load limit in %)

No evaluation for P364.2 = 0.

Supply rating: The converter is suitable for connecting to supplies with a short-circuit rating (supply)

♦

100 × rated output (converter).

≤

Thermal motor protection: Motor temperature sensor (thermistor, type M135 or KTY84) can be connected

♦

at -X103:41-42.

Cabling/wiring:Connecting cables should be dimensioned according to the local regulations and according

♦

to Table 3.1. The insulation should be suitable for 75°C.

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

3-1

Connecting-up 08.96

3.1 Power connections

WARNING

♦ By interchanging the input terminals, the converter or the rectifier will be destroyed!

♦ The drive converter or rectifier unit could be destroyed if the input terminals are

interchanged!

♦ The coils of contacts and relays which are connected to the same supply as the

converter or are located in the vicinity of the converter, must be provided with

overvoltage limiters, e.g. RC elements.

The position of the connecting terminals can be seen in the dimension drawings (+

DC connection: C/L+ D/L

Motor connection: U2/T1 V2/T2 W2/T3

Protective conductor connection: PE1

The power connections should be established using cable lugs with screws according to Table 3.2.

For type of construction J, jumpers are inserted after the inverter connections, which can be replaced by fuses.

For drive converters, type of construction K, fuses are installed as standard.

−

PE2

Section 2.4).

NOTE

The 230 V fans must be externally supplied with 230 V AC via terminal strip X9.

NOTE

Depending on the motor insulation strength and the length of the motor feeder cable, it may be necessary to

install one of the following options between the motor and the converter:

Output reactor

♦

dv/dt-filter

♦

Information regarding selection and dimensioning is provided in Section „Options“.

3-2 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Connecting-up

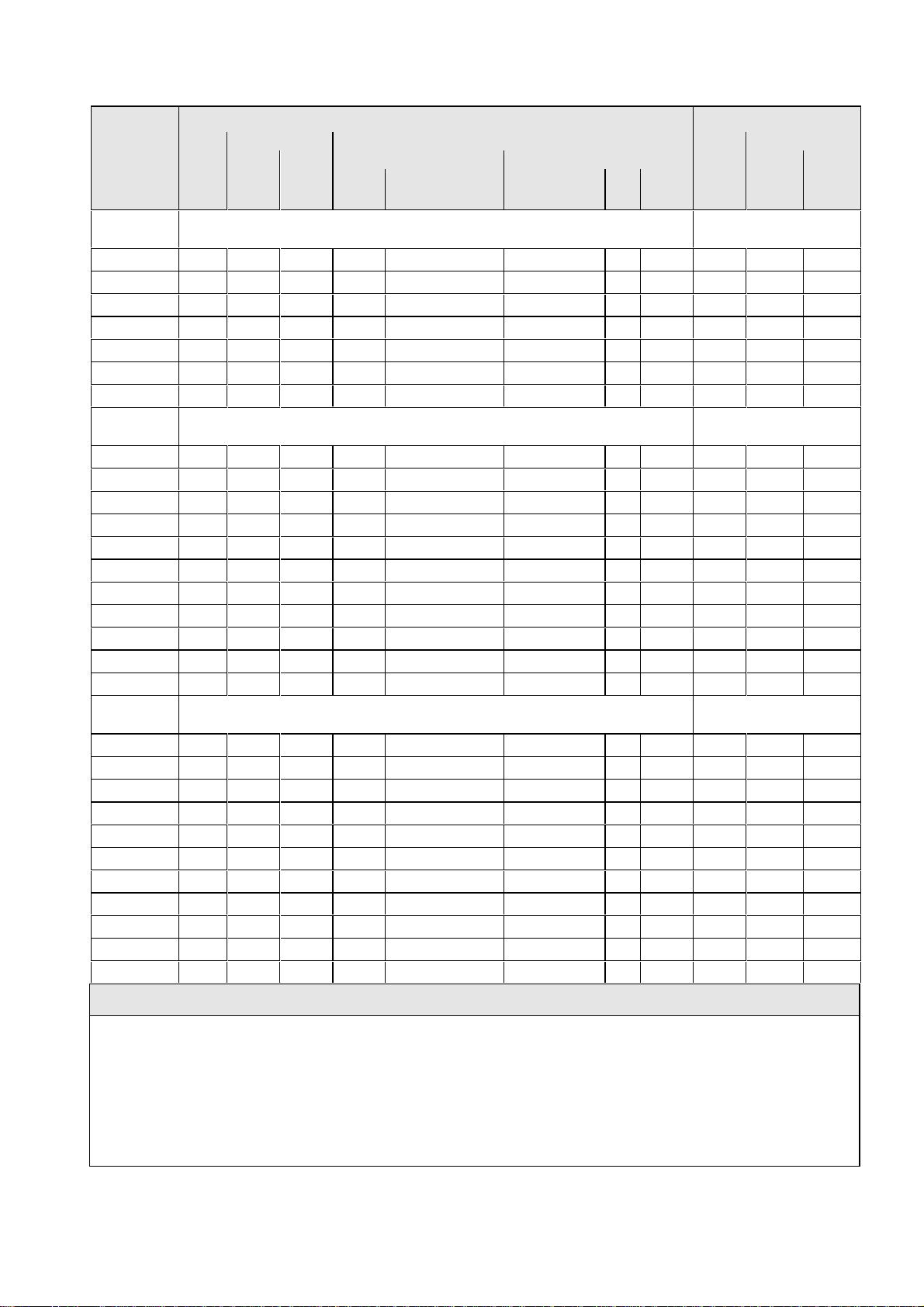

Supply side Motor side

Order Rated Cross-section Recommended fuse Rated Cross-section

No. DC North-America AC

Curr. VDE AWG Curr. VDE AWG

6SE70 (A) (mm2) MCM1)(A) Type Type (V) (A) (A) (mm2) MCM

Input voltage

DC 510 V to 620 V

Output voltage

3 AC 0 V to 620 V

35-1TJ20 607 4×300 4×800 2×450 2×3NE3233 2×170M6709 660 2×550 510 2×300 2×800

36-0TK20 702 4×300 4×800 2×560 2×3NE3335 2×170M6710 660 2×630 590 4×300 4×800

37-0TK20 821 4×300 4×800 2×560 2×3NE3335 2×170M6710 660 2×630 690 4×300 4×800

38-6TK20 1023 4×300 4×800 2×710 2×3NE3337-8 2×170M6711 660 2×700 860 4×300 4×800

41-1TK20 1309 6×300 6×800 2×800 2×3NE3338-8 1100 4×300 4×800

41-1TM20 1310 6×300 6×800 2×560 2×3NE3335 2×170M6710 660 2×650 1100 4×300 4×800

41-3TM20 1547 6×300 6×800 2×560 2×3NE3335 2×170M6710 660 2×650 1300 6×300 6×800

Input voltage

DC 675 V to 780 V

Output voltage

3 AC 0 V to 780 V

33-0UJ20 354 2×300 2×800 1×500 3NE3334-0B 170M5713 660 700 297 2×300 2×800

33-5UJ20 421 2×300 2×800 1×630 3NE3336 170M5713 660 700 354 2×300 2×800

34-5UK20 538 2×300 2×800 1×710 3NE3337-8 170M5714 660 900 452 2×300 2×800

35-7UK20 678 4×300 4×800 2×450 2×3NE3233 2×170M5712 660 2×630 570 2×300 2×800

36-5UK20 774 4×300 4×800 2×500 2×3NE3334-0B 2×170M5712 660 2×630 650 4×300 4×800

38-6UK20 1023 4×300 4×800 2×630 2×3NE3336 2×170M6712 660 2×800 860 4×300 4×800

41-0UM20 1178 6×300 6×800 1×710 3NE3337-8 170M5714 660 900 990 4×300 4×800

41-1UM20 1285 6×300 6×800 2×450 2×3NE3233 2×170M5712 660 2×630 1080 4×300 4×800

41-2UM20 1464 6×300 6×800 2×500 2×3NE3334-0B 2×170M5712 660 2×630 1230 6×800 6×800

41-4UM20 1666 6×300 6×800 2×630 2×3NE3336 2×170M6712 660 2×800 1400 6×800 6×800

41-6UM20 1880 8×300 8×800 2×630 2×3NE3336 2×170M6712 660 2×800 1580 6×800 6×800

Input voltage

DC 890 V to 930 V

Output voltage

3 AC 0 V to 930 V

33-0WJ20 354 2×300 2×800 1×500 3NE3334-0B 170M5713 660 700 297 2×300 2×800

33-5WJ20 421 2×300 2×800 1×630 3NE3336 170M5713 660 700 354 2×300 2×800

34-5WK20 538 2×300 2×800 1×710 3NE3337-8 170M5714 660 900 452 2×300 2×800

35-7WK20 678 4×300 4×800 2×450 2×3NE3233 2×170M5712 660 2×630 570 2×300 2×800

36-5WK20 774 4×300 4×800 2×500 2×3NE3334-0B 2×170M5712 660 2×630 650 4×300 4×800

38-6WK20 1023 4×300 4×800 2×630 2×3NE3336 2×170M6712 660 2×800 860 4×300 4×800

41-0WM20 1178 6×300 6×800 1×710 3NE3337-8 170M5714 660 900 990 4×300 4×800

41-1WM20 1285 6×300 6×800 2×450 2×3NE3233 2×170M5712 660 2×630 1080 4×300 4×800

41-2WM20 1464 6×300 6×800 2×500 2×3NE3334-0B 2×170M5712 660 2×630 1230 6×800 6×800

41-4WM20 1666 6×300 6×800 2×630 2×3NE3336 2×170M6712 660 2×800 1400 6×800 6×800

41-6WM20 1880 8×300 8×800 2×630 2×3NE3336 2×170M6712 660 2×800 1580 6×800 6×800

NOTES

♦ Current- and voltage data in this table are rated values

♦ The cables to the drive converter are protected using fuses with gL characteristics.

♦ The cross-sections are determined for three-core copper cables, routed horizontally in air at 30 °C (86°F)

ambient temperature (according to DIN VDE 0298 Part 2 / Group 5) and the recommended cable protection

according to DIN VDE 0100 Part 430.

2

♦ AWG (American Wire Gauge): American wire gauge for cross sections up to 120 mm

♦ MCM (Mille Circular Mil): American wire gauge for cross-sections above 120 mm

Table 3.1 Connection cross-sections and fusibles

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

;

2.

3-3

Connecting-up 08.96

Type of Order No. Max. cross-section Gland

construc.

(mm2) acc. to VDE MCM

J 6SE70_._.-._._J20 4×300 4×800 M16

K 6SE70_._.-._._K20 4×300 4×800 M16

M 6SE70_._.-._._M20 8×300 8×800 M16

Table 3.2 Maximum cross-section and gland

3.1.1 Protective conductor connection

The protective conductor should be connected-up on both the supply- and motor sides. It should be dimensioned

according to the power connections.

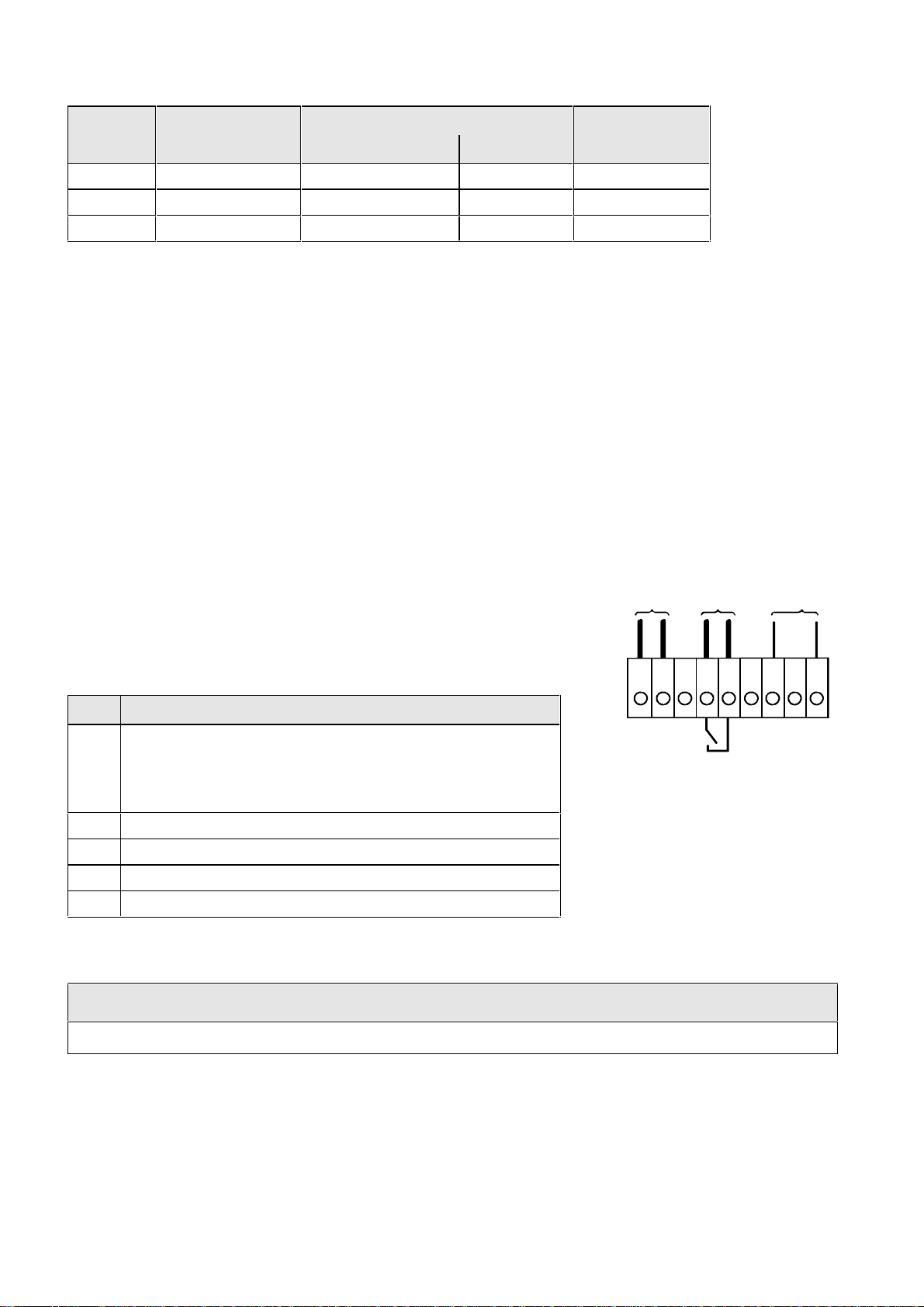

3.2 Auxiliary power supply/main contactor or bypass contactor

The auxiliary power supply and the main- or bypass contactor are connected through the 5-pin connector X9.

Connector X9 is supplied together with the connectors for the control terminal strip. Cables from 0.2 mm

2

2.5 mm

The auxiliary power supply is required if the drive converter is fed

through a main- and bypass contactor.

(AWG: 24 to 14) can be connected to X9.

E x t. 24 V

DC PS

Main contactor

control

The main- or monitoring contactor is controlled through floating contacts

-X9.4 and -X9.5 (software pre-setting).

More detailed information is provided in the Section „options“.

M

P

12345

6789

-X 9

Term. Function description

1 Types of construction J and K 24 V DC external ≥ 5 A (max.

8 A dependent on the options)

Type of construction M 24 V DC external ≥ 10 A (max.

16 A dependent on the options)

2 Reference potential to DC

3 Unassigned

4 Main contactor control

5 Main contactor control

Table 3.3 Connector assignment for -X9

Fig. 3.1 Connecting an external 24 V

power supply and main contact or

control

AC 230 V

1 kVA

2

to

230 V

fan

NOTES

The main contactor coil must be provided with overvoltage limiters, e.g. RC element.

3-4 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Operator control

4 Operator control

The converter can be controlled via:

the PMU (Parameterization Unit)

♦

the control terminal strip on the CU (+ section “Control terminal strip“)

♦

the OP1 operator control panel (+ section “Options“)

♦

the RS485 and RS232 serial interface on PMU-X300

♦

Operator control using the PMU is described in this section.

Seven-segment displays

On key

Off key

P

Fig. 4.1 Parameterization unit

4.1 Operator control elements

Operator control elements Function

Converter switch on (standard).

For faults: Return to the fault display.

Command is effective when the key is released.

Converter shutdown depending on the parameterization of OFF 1, OFF 2 or

OFF 3 (P554 to P560).

Command becomes effective when the key is released.

Field reversal / reversing for the appropriate parameterization.

Command becomes effective when the key is released.

Reversing key

Raise key

Changeover key, operator control leve

Lower key

X300

P

Changeover from parameter number to parameter value. In conjunction with

other keys, additional functions (see Operating Instructions, Part 2).

Command becomes effective when the key is released.

Values (raise, lower) change as long as the keys are depressed.

,

P

+ resp.

Table 4.1 Function of the operator control elements on the PMU

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

P

+

Depress P and hold, then depress the second key. The command becomes

effective when the key is released (e.g. fast changeover).

4-1

Operator control 08.96

4.2 Displays

Parameter number Index Parameter value

Pos. actual value

e.g

Neg. actual value

e.g e.g.. e.g.

Visualization

parameters

Setting

parameters

Table 4.2 Displaying visualization- and setting parameters on the PMU

Display

Table 4.3 Status display on the PMU

Basic converter

Technology board

Basic converter

Technology board

Actual value

Parameter value

not possible

Alarm Fault

NOTE

The parameter description is provided in the Operating Instructions, Part 2.

− − −

4-2 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Maintenance

5 Maintenance

WARNING

SIMOVERT MASTER DRIVES are operated at high voltages.

All work carried-out on or with the equipment must conform to all of the relevant national

electrical codes (VBG4 in Germany).

Maintenance and service work may only be executed by qualified personnel.

Only spare parts authorized by the manufacturer may be used.

The specified maintenance intervals and also the instructions for repair and replacement

must be adhered to.

The drive units have hazardous voltage levels up to 5 min after the converter has been

powered-down due to the DC link capacitors so that the unit must only be opened after an

appropriate delay time.

The power- and control terminals can still be at hazardous voltage levels even though the

motor is at a standstill.

If it is absolutely necessary that the drive converter must be worked on when powered-up:

never touch any live components.

♦

only use the appropriate measuring and test equipment and protective clothing.

♦

always stand on an ungrounded, isolated and ESD-compatible pad.

♦

If these warnings are not observed this can result in death, severe bodily injury or significant

material damage.

Always have your MASTER DRIVE converter Order No. and serial No. available when contacting the service

department. These numbers and other important data are located on the drive converter rating plate.

5.1 Maintenance requirements

The fans are designed for a service life of 35000 hours at an ambient temperature of TU = 40 °C. They must be

replaced before their service life expires so that the drive converter availability is guaranteed.

INSTRUCTIONS for type of construction M

Type of construction M consists of two chassis units (master, open-loop/closed-loop controlled and slave

♦

controlled), size K, a reactor chassis and the associated busbars

The slave unit has no PMU an no electronics box.

♦

♦ Service/maintenance is the same as chassis units, type of construction K. The differences are described.

♦ The busbar design and the design of the three components is described in the engineering support.

♦ The connection of the control cables between the slave and the master is described in Sections 2.1 and 2.3.

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

5-1

Maintenance 12.96

5.2 Replacing components

WARNING

The fan may only replaced by qualified personnel.

The drive converters are still at hazardous voltage levels up to 5 min. after the

unit has been powered-down as a result of the DC link capacitors.

If these warnings are not observed, death, severe bodily injury or considerable

material damage could occur.

5.2.1 Replacing the fan

The fan assembly consists of:

• the fan housing

• a fan type of construction J

• one or two fans, type of construction K

• the starting capacitors

The fans are mounted in the fan assembly in the upper section

of the chassis unit.

• Remove connector X20

• Release both mounting bolts (M8) of the fan assembly

• For type of construction K with

one fan, the air deflection plate below the fan must be disassembled

(2 × M8)

• Withdraw the fan assembly towards the front, and if required, tilt it gently downwards and place carefully on

a flat surface

CAUTION

The fan assembly can weigh up to 38 kg depending on the drive converter rating.

• Remove the cable ties and fan connections

• Remove the fan mounting panel from the fan assembly and remove the fan from the mounting panel

• Install the new fan assembly in the inverse sequence

• Before commissioning the drive check that the fan can run freely and check the airflow direction. The air

must be blown upwards out of the unit.

5.2.2 Replacing the fuses

The fuses are installed in a fuse holder. The fuse holder is

Fuse link

mounted on a DIN mounting rail at the bottom left in the chassis

unit. The fuse holder must be opened to replace fuses.

Fuse holder

closed

Fig. 5.1 Fuse holder

Fuse holder

open

5-2 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Maintenance

5.2.3 Replacing the starting capacitor

The starting capacitor is mounted next to the fan connection.

The starting capacitor is mounted on the fan assembly.

• Remove the plug connections from the starting capacitor

• Unbolt the starting capacitor

• Install a new starting capacitor in the inverse sequence

5.2.4 Replacing the capacitor bank

The capacitor assembly consists of three boards. Each board has a capacitor mounting element and a DC link

bus connection.

• Remove the plug connections

• Release the mechanical retaining elements (three screws: two at the left, one at the right)

• Remove the capacitor by slightly raising them and withdrawing them from the drive converter towards the

front.

The capacitors weight up to 30 kg depending on the drive converter rating.

• Install a new capacitor bank in the inverse sequence.

5.2.5 Replacing SML and SMU

SML Snubber Module Lower

SMU Snubber Module Upper

• Remove the capacitors

• Release the mounting screws (4 ×

M8 (torque: 8 - 10 Nm), 1 × M4 (max. 1.8 Nm))

• Remove the SML / SMU

Install the new board in the reverse sequence.

CAUTION

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

5-3

Maintenance 12.96

n

5.2.6 Removing and installing the module busbars

♦ Removal

• remove the capacitors

• release the bolts holding the module busbars

Bolts M8 power connections

M6 mounting and distance pieces

M4 snubber circuitry

• remove the SMU / SML insulation

• lift out the module busbars

♦ Installation

NOTE

There must be a 4 mm clearance between the positive and negative busbars. Thus, when installing the

module busbars, a template must be used (refer to Fig. 5.2), e.g. a 4 mm-thick plastic piece.

• hold the module busbars and insulation in place SMU / SML (M6)

Te mplate 4 mm

• the template is inserted in the module busbars instead of the DC link

busbars

• insert the SML- and SMU board (tighten-up the module connections

(M8, torque: 8-10 Nm)

• tighten-up the M6 nut on the distance studs (6 Nm)

Module busbars

+ connection

Module

busbars

- connectio

• connect-up the snubber resistors (M4 bolts, torque: max. 1.8 Nm)

• tighten-up the power connections (M8 bolts, torque: 13 Nm)

• remove the template from the module busbars.

Fig. 5.2 Install the module busbars

4

5.2.6.1 Replacing the balancing resistor

The balancing resistor is located at the rear mounting plane on the heatsink between the inverter modules, i.e.

behind the capacitors and the module busbars.

♦ Remove the capacitors

♦ Type of construction J

• remove the module busbars

• remove IGD

♦ type of construction K

• release the mounting bolts and remove the

balancing resistor.

• release the mounting bolts and remove the

balancing resistor.

Installation in the reverse sequence.

♦ The balancing resistor is tightened-up with 1.8 Nm.

A uniform coating of heat conducting paste must be applied to the base plate.

Observe the correct contact assignment!

5-4 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Maintenance

5.2.7 Replacing boards

WARNING

The boards may only be replaced by qualified personnel.

It is not permissible that the boards are withdrawn or inserted under voltage.

Death, severe bodily injury or significant materal damage might result if these

instructions are not observed.

CAUTION

Boards contain components which could be damaged by electrostatic discharge. The

human body must be discharged immediately before an electronics board is touched.

This can be simply done by touching a conductive, grounded object immediately beforehand

(e.g. bare metal cubicle components).

5.2.7.1 Replacing the IVI / IPI (type of construction M)

IVI Inverter-Value Interface

IPI Inverter-Parallel Interface (for type of construction M)

The IVI / IPI is bolted to the rear of the electronics box

♦ Remove the electronics module to the endstop

♦ Remove the ground connection at the electronics module

• Remove all boards from the electronics box

• Remove both mounting bolts from the electronics box (Fig. 5.4)

• Release the electronics box and remove towards the front.

• Release the cable ties

• Remove the ABO / ABI (Adaption Board)

• Release the fiber-optic cables

• Unbolt the IVI and remove

• Install the new IVI in the inverse sequence

• Unbolt the IVI / IPI and remove

• Install the new IVI / IPI in the inverse sequence

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

5-5

Maintenance 12.96

5.2.7.2 Replacing the VDU and VDU resistor

VDU Voltage-Dividing Unit

VDU and VDU resistor are only available for drive converters with higher supply voltages. The VDU mounting

bracket is part of the electronic module assembly.

♦ VDU

• Remove the plug connectors

• Release the mounting bolt

• Remove the VDU

Install the new VDU in the inverse sequence.

♦ VDU resistor

• Release the cable ties

• Remove the plug connections

• Unbolt the VDU resistor

Install the new VDU resistor in the inverse sequence

5.2.7.3 Replacing the PSU

PSU Power-Supply Unit (Power Supply)

♦ Remove the VDU and VDU resistor (if available)

♦ Remove the VDU mounting panel

♦ Release the plug connections on the PSU

♦ Release the bolts ( six Torx M4) on the PSU

♦ Remove the PSU

Install the new PSU in the inverse sequence

5.2.7.4 Replacing the IGD

IGD IGBT-Gate Drive

The IGD is located behind the module busbars and consists of one board for type of construction J

three boards for type of construction K

• Remove the capacitors

• Remove SML and SMU

• Remove the module busing

Type of construction J

♦

• Remove nine fiber-optic cables at the top of the

IGD

• Release the mounting bolts and remove the

Type of construction K

♦

• Remove the fiber-optic cables at the left of the

IGD (three per IGD)

• Remove the P15 cable

IGD.

• Release the mounting bolts

• Withdraw the IGD from the retaining bolts

towards the right and remove

• Insert a new IGD, and insert towards the left in

the groove of the mounting bolts under the

incoming busbars.

Install a new IGD in the reverse sequence.

5-6 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

12.96 Maintenance

5.2.8 Replacing the snubber resistor

♦ Remove the capacitors

♦ Remove the SML- and SMU modules

♦ Remove the module busbars

♦ Release the mounting bolts (2 ×

M5, torque: max. 1.8 Nm) and remove the snubber resistor

♦ A uniform coating of heat conducting paste must be applied to the resistor

Install the new snubber resistor in the inverse sequence.

5.2.8.1 Replacing the IGBT modules

• Replace as for IGD, but additionally

• Remove the mounting bolts of the defective IGBT modules and remove the

IGBT.

• Install the new IGBT module. Observe the following:

− Coat the module mounting surface with a

thin and uniform coating of

heat conducting paste.

− Tighten-up the IGBT module mounting bolts with 3 Nm, observe the

sequence (Fig. 5.3).

34

2

1

Tighten-up the IGBT modules

1. By hand (

sequence: 2 - 5 - 3 - 6 - 1 - 4

2. tighten-up with 3 Nm,

sequence: 2 - 5 - 3 - 6 - 1 - 4

Fig. 5.3 Tighten-up IGBT modules

CECE

0,5 Nm),

≈

5

6

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

5-7

Maintenance 12.96

n

5.2.8.2 Replacing boards in the electronics box

Loosen the board retaining screws above

♦

and below the handles for

inserting/withdrawing the boards

Carefully remove the board using these

♦

handles making sure that the board

doesn’t catch on anything

Carefully locate the new board on the

♦

guide rails and insert it completely into the

Slot 1 (CU)

Slot 3 (Options)

Slot 2 (Options)

electronics box

Tighten the retaining screws above and

♦

below the handles.

Fig. 5.4 Electronics box equipped wi th CU (slot 1)

5.2.8.3 Replacing the PMU

(Parameterization Unit)

Remove the ground cable at the side panel.

♦

Carefully depress the snap on the adapter section and

♦

remove the PMU with adapter section from the

electronics box.

♦ Withdraw connector X108 on the CU

♦ Carefully withdraw the PMU board out of the adapter

section towards the front using a screwdriver.

♦ Install the new PMU board in the invsere sequence.

and options (slot 2 (right) and 3 (mi ddl e))

PMU

E-Box

Fig. 5.5 PMU with adapter section on the E box

Adapter sectio

Snap

5-8 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Options

6 Options

6.1 Options which can be integrated into the electronics box

One or two option boards, listed in Table 6.1, can be inserted in the electronics box using the LBA option (local

bus adapter).

Before installing option boards in the electronics box, the

LBA (local Bus Adapter) has to be inserted.

Install the LBA bus expansion:

♦ Remove the CU (lefthand slot in the electronics box)

using the handles after first removing the connecting

cable to the PMU and both retaining screws.

♦ Insert the LBA bus expansion in the electronics box

(position, refer to the diagram) so that it snaps into

place.

♦ Re-insert the CU into the lefthand slot, screw the

retaining screws on the handles tight, and insert the

connecting cable to the PMU.

♦ Insert the option board in slot 2 (right) or slot 3

(center) of the electronics box, and screw into place.

Each option board may only by inserted in the

electronics box. If only one option is used, it must

always be inserted at slot 2 (right).

Slots in the electronics box Boards

Left Slot 1 (CU) CU

Center Slot 3 (options) CB1 / SCB1 / SCB2 / (TSY, not for T300)

Right Slots 2 (options) CB1 / SCB1 / SCB2 / TSY / TB

Fig. 6.1 Installing the Local B us Adapter

NOTE

Only one of each option board type may inserted in the electronics box.

TB (technology boards, e.g. T300) must always be inserted at slot 2. When a TB board is used, a TSY board

my not be inserted.

If only one option board is used it must always be inserted at slot 2.

Table 6.1 Possible arrangements of boards in the electronics box

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

6-1

Options 08.96

The options are supplied with the option description.

Desig-

Description Order No.

nation

LBA Local bus adapter for the electronics box. This is

required for installing T300, CB1, TSY, SCB1 and SCB2

T300 Technology board for controlling technological

processes

Board

description

Board

description

TSY Synchronizing board Board

description

SCB1 Serial communications board with fiber-optic cable for

serial I/O system and peer-to-peer connection

SCB2 Serial communications board for peer-to-peer

connection and USS protocol via RS485

Use of the serial interface with USS protocol

Board

description

Board

description

Application

description

CB1 Communications board with interface for SINEC- L2-DP,

(Profibus)

Use of the PROFIBUS DP interface

Board

description

Application

description

Table 6.2 Option boards and bus adapter

6SE7090-0XX84-4HA0

6SE7087-6CX84-4HA0

6SE7090-0XX84-0AH0

6SE7087-6CX84-0AH0

6SE7090-0XX84-0BA0

6SE7087-6CX84-0BA0

6SE7090-0XX84-0BC0

6SE7087-6CX84-0BC0

6SE7090-0XX84-0BD0

6SE7087-6CX84-0BD0

6SE7087-6CX87-4KB0

6SE7090-0XX84-0AK0

6SE7087-6CX84-0AK0

6SE7087-6CX87-0AK0

If the converter is supplied through an external main

contactor, the option board in the electronics box must

be supplied from an external power supply, according

to Table 6.3.

These values are required in addition to the current

drawn by the basic converter (+ section “Technical

Data“).

Board Current drain (mA)

CB1 190

SCB1 50

SCB2 150

TSY w/out tacho 150

T300 w/out tacho 620

Standard tacho

Type: 1PX 8001-1

Table 6.3 Current drain of the option boards

I0 95

(190 at 6000 RPM)

6-2 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Options

6.2 Interface boards

The boards, listed in the following table must be externally mounted and wired-up on the external system side.

Desig-

Description Order No.

nation

SCI1 Serial I/O board (only in conjunction with SCB1).

Analog and binary input and outputs for coupling to the

Board

description

SCB1 via fiber-optic cable

SCI2 Serial I/O board (only in conjunction with SCB1)

Binary inputs and outputs for coupling to the SCB1 via

Board

description

fiber-optic cable.

DTI Digital tachometer interface Board

description

ATI Analog tachometer interface Board

description

Table 6.4 Interface boards

6.3 Power supplies

Designation Description Order number

Option

6SE7090-0XX84-3EA0

6SE7087-6CX84-0BC0

6SE7090-0XX84-3EF0

6SE7087-6CX84-0BC0

6SE7090-0XX84-3DB0

6SE7087-6CX84-3DB0

6SE7090-0XX84-3DF0

6SE7087-6CX84-3DF0

Use with

Power supply, 0.3 A 115 V / 230 V AC - 24 V 0.3 A DC 6SX7010-0AC14 e.g.: DTI

Power supply 1 A 115 V / 230 V AC - 24 V 1 A DC 6SX7010-0AC15 e.g.: 1 x SCI

Power supply 5 A 115 V / 230 V AC - 24 V 5 A DC 6EP1333-1SL11 Basic conv

Power supply 8 A 115 V / 230 V AC - 24 V 8 A DC Basic conv. + options

Table 6.5 Recommended power supply

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

6-3

Options 08.96

6.4 Isolating amplifiers

Input Output Order number

Option

Power supply:

V = 24 V DC ±20 %

I = 90 mA

Input isolating amplifiers for analog inputs

10 V to +10 V

−

20 mA to +20 mA

−

10 V to +10 V 6SX7010-0AC00

−

10 V to +10 V 6SX7010-0AC02

−

4 mA to +20 mA 4 mA to +20 mA 6SX7010-0AC01

Output isolating amplifiers for analog outputs

10 V to +10 V

−

10 V to +10 V

−

10 V to +10 V 6SX7010-0AC00

−

20 mA to +20 mA 6SX7010-0AC03

−

(+) 5

Input Output

(-) 4

Fig. 6.2 Isolating amplifiers

6 (0 V) 1 (+24 V)

0 V to +10 V 4 mA to +20 mA 6SX7010-0AC04

Table 6.6 Overview of isolating amplifiers

6.5 Power section

Options Description/function

Braking unit For converting the regenerative energy into heat

Braking resistors Load resistor for the braking unit

Electrical DC link coupling Switching the DC-AC converter in and out under load

Mechanical DC link coupling Switching the DC-AC converter in and out in a no-voltage condition

Input rectifier Input rectifier for one or several DC-AC converters

Input rectifier with line-

commutated feedback

Supply rectifier for one or several DC-AC converters for motor or generator

operation

2 (+)

3 (-)

Table 6.7 Power section options

6-4 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Options

2

6.5.1 Output reactor, dv/dt filter

When longer feeder cables are used between the converter and motor:

the converter has to cope with additional current peaks due to re-charging the cable capacitances

♦

the motor insulation is additionally stressed as a result of transient voltage spikes caused by reflection.

♦

NOTE

In order to prevent premature aging of the motor

insulation and thus early failures, the following limit

values may not be exceeded at the motor terminals:

the permissible voltage gradient dv/dt and

♦

the permissible peak voltage between phase

♦

conductors

Fig. 6.3 Permissible limit values for the motor ins ul at i on

)

V

LL

)

[V]

V

LL

1500

1460

1000

500

*) Standard 1LA8 motors;

1LA8 motors with improvedi ns ul ation are available

for Siemens 1LA2, 1LA5, 1LA6

and 1LA8*) motors

for motors in accordance with IEC 34-17:199

(DIN VDE 0530, Part1, Sheet2)

1

234

Depending on the application, the voltagerate-of-rise, voltage and current peaks can be reduced using the

following options: Output reactor, dv/dt filter.

Characteristics of the output reactors and dv/dt filters:

t [µs]

Output

dv/dt filter

reactor

Reduces the current peaks for long cables yes yes

Reduces the voltage gradient (rate of rise) dv/dt at the motor

slightly yes

terminals

Limits the amplitude of the transient voltage peaks at the motor

no yes

terminals to the following typical values

800 V at 3AC 400 V to 460 V

≤

1000 V at 3AC 500 V to 575 V

≤

1250 V at 3AC 660 V to 690 V

≤

Reduces the supplementary losses in the motor no no

Reduces motor noise (corresponding to direct online operation) no no

Table 6.8

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

6-5

Options 08.96

6.5.1.1 Output reactor

The output reactor is especially used to limit additional current spikes caused by the cable capacitances when

long cables are used, i.e. it

♦ reduces the charge current spikes for long cables

♦ reduces the voltage rate-of-change dv/dt at the motor terminals.

It does

not reduce the magnitude of the transient voltage spikes at the motor terminals.

In order that the reactor temperature rise remains within the specified limits, the pulse frequency f

converter, rated motor frequency f

and the maximum drive converter output frequency f

mot N

max

the specified limits:

V/f = constant V = constant

510 V

to 620 V DC

675 V

to 930 V DC

510 V

to 620 V DC

Standard reactor (iron) fP ≤ 3 kHz

V/f / Vector control f

V/f textile f

≤ 87 Hz f

mot N

mot N

= f

max

≤

mot N

≤ 200 Hz f

≤ 200 Hz f

max

120 Hz not possible not possible not possible

Ferrite reactor fP ≤ 6 kHz

V/f / Vector control f

V/f textile f

Table 6.9 Output reactor design

600

500

≤ 150 Hz f

mot N

mot N

= f

600 Hz not possible

≤

max

2 output reactorss

(not permissible for ferrite reactors)

max

≤ 300 Hz

of the drive

p

must lie within

675 V

to 930 V DC

≤ 300 Hz

max

400

300

Max. cable length / m

200

100

Fig. 6.4 Permissible cable lengths with and without output reac t ors

1 output reactor

without output reactor

1000100101

Drive converter outputs / kW

NOTE

The specified lengths are valid for unshielded cables; for shielded cables, these values must be reduced to 2/3.

If several motors are connected to a drive converter, the sum of the cables lengths of all the motor feeder

cables must be less than the permissible cable length.

6-6 Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

08.96 Options

6.5.1.2 dv/dt filter

The dv/dt filter protects the motor insulation by limiting the voltage gradient and the transient peak voltage at the

motor winding to uncritical values in accordance with IEC 34-17:1992 (DIN VDE 0530, Part 1, Sheet 2):

♦ Voltage gradient (rate of rise) dv/dt ≤

500 V/µs

♦ Transient peak voltage at the motor terminals:

≤ 800 V for 380 V≤ UN ≤ 460 V (3 ph. AC)

Û

typ.

1000 V for 500 V≤ U

typ.

typ.

≤

1250 V for 660 V≤ U

≤

Û

Û

≤ 575 V (3 ph. AC)

N

≤ 690 V (3 ph. AC).

N

For long feeder cables, the dv/dt filter simultaneously reduces the current spikes, which additionally load the

drive converter due to the re-charging of the cable capacitances.

The dv/dt filter can be used for the following control versions

FC (Frequency Control) and

♦

VC (Vector Control)

♦

The dv/dt filter is suitable for use with

grounded supply networks (TN- and TT supply networks)

•

ungrounded supplies (IT supplies)

•

(exceptions: 6SE70_ _ - _ _ B _ _ -1FD0 and 6SE70 _ _ - _ _ C _ _ -1FD0 with version release A)

NOTE

The dv/dt filter is designed for a pulse frequency fp = 3 kHz and an output frequency fA ≤

In this case, when the drive converter is being set (P052 = 5), parameter P092 should be set to 2. Thus,

parameter P761 (pulse frequency) is automatically limited to values ≤ 3 kHz.

300 Hz.

400

300

200

100

Max. cable length / m

Fig. 6.5 Permissible cable lengths with dv/dt filter

dv/dt filter in series

with the output reactor

dv/dt filter

1000100101

Drive converter output / kW

NOTES

The specified cable lengths are valid for unshielded cables; for shielded cables, these values should be

reduced to 2/3.

If several motors are connected to a drive converter, the sum of the cable lengths of all of the motor feeder

cables must be less than the permissible cable length.

Siemens AG 6SE7087-6BM70

SIMOVERT MASTER DRIVES Operating Instructions

6-7

Options 08.96

6.5.1.3 Selection criteria for the output reactor or dv/dt filter

The following table indicates the selection criteria for the output reactor or dv/dt filter

Voltage range

510 V - 675 V (DC) 710 V - 780 V (DC) 890 V - 930 V (DC)

Motors, acc. to

IEC 34-17:1992

(DIN VDE 0530,

Part 1, Sheet 2)

Siemens motors

1LA2,

1LA5,

1LA6,

1)

1LA8

.

dv/dt filter required!

Cable lengths in accordance

with the Section „dv/dt filter“,

Fig. 6.5.

An output filter is not

required.

For longer motor cable

lengths, output reactors are

required in accordance with

dv/dt filter required!

Cable lengths in accordance

with the Section „dv/dt filter“,

Fig. 6.5.

dv/dt filter required!

Cable lengths in accordance

with the Section „dv/dt filter“,

Fig. 6.5.

dv/dt filter required!

Cable lengths in accordance

with the Section „dv/dt filter“,

Fig. 6.5.

dv/dt filter required!

Cable lengths in accordance

with the Section „dv/dt filter“,

Fig. 6.5.