Page 1

SIMOTION

Motion Control

SIMOTION SCOUT

Valid as of Version 4.5

Preface

Fundamental safety

instructions

1

2

Configuration Manual

Introduction

Installation

User interface

Configuring/parameterizing

Target system

Upgrading and project

updates

Diagnostics

Service with SIMOTON

SCOUT

3

4

5

6

7

8

9

10

11/2016

Siemens SIMOTION

Diagnostics

Configuring a further

connection (such as HMI)

Product combinations

Technical specifications

Appendix

11

12

13

14

A

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ 10/2016 Subject to change

Copyright © Siemens AG 2016.

All rights reserved

Page 3

Table of contents

1 Preface.........................................................................................................................................................9

1.1 Validity......................................................................................................................................9

1.2 Sections in this manual............................................................................................................9

1.3 SIMOTION Documentation....................................................................................................10

1.4 Hotline and Internet addresses..............................................................................................10

2 Fundamental safety instructions.................................................................................................................13

2.1 General safety instructions.....................................................................................................13

2.2 Industrial security...................................................................................................................14

2.3 Danger to life due to software manipulation when using removable storage media..............15

3 Introduction.................................................................................................................................................17

3.1 Content of the configuring manual.........................................................................................17

3.2 SIMOTION SCOUT engineering system................................................................................17

3.3 SIMOTION hardware platforms..............................................................................................18

3.4 Programming languages........................................................................................................19

3.4.1 Programming languages in SIMOTION SCOUT....................................................................19

3.4.2 Motion Control Chart (MCC)..................................................................................................21

3.4.3 Ladder Logic / Function Block Diagram (LAD/FBD)...............................................................22

3.4.4 Structured Text (ST)...............................................................................................................23

3.5 CamEdit cam editor................................................................................................................24

3.6 CamTool options package.....................................................................................................24

3.7 Technology packages and technology objects......................................................................25

3.8 CLib Studio option package...................................................................................................26

4 Installation..................................................................................................................................................27

4.1 SCOUT and SCOUT Standalone system requirements........................................................27

4.2 Installing SIMOTION SCOUT.................................................................................................27

4.2.1 Installing SIMOTION SCOUT.................................................................................................27

4.2.2 Installing SIMOTION SCOUT Standalone.............................................................................28

4.2.3 SINAMICS Support Package (SSP).......................................................................................29

4.3 Uninstalling SIMOTION SCOUT ...........................................................................................29

4.4 Licenses.................................................................................................................................30

4.4.1 To install the authorization.....................................................................................................30

4.4.2 Saving and moving the license key........................................................................................31

5 User interface.............................................................................................................................................33

5.1 SIMOTION SCOUT - workbench...........................................................................................33

SIMOTION SCOUT

Configuration Manual, 11/2016 3

Page 4

Table of contents

5.2 SIMOTION SCOUT - working area........................................................................................35

5.3 SIMOTION SCOUT project navigator ...................................................................................36

5.3.1 Using the project navigator....................................................................................................36

5.3.2 Creating elements..................................................................................................................37

5.3.3 Inserting a folder....................................................................................................................39

5.3.4 Changing properties of the elements.....................................................................................40

5.3.5 Wizards for configuration support..........................................................................................41

5.4 SIMOTION SCOUT - menus..................................................................................................41

5.5 SIMOTION SCOUT - menu items..........................................................................................44

5.6 SIMOTION SCOUT - keyboard operation and shortcuts.......................................................49

5.7 SIMOTION SCOUT - using the context menus......................................................................50

5.8 SIMOTION SCOUT - detailed view........................................................................................51

5.8.1 Using the detail view..............................................................................................................51

5.8.2 Using the symbol browser......................................................................................................51

5.8.3 Address list.............................................................................................................................52

5.8.4 Watch table............................................................................................................................52

5.8.5 Working with lists...................................................................................................................54

5.9 SIMOTION SCOUT - language settings................................................................................54

5.10 SIMOTION SCOUT - using help............................................................................................54

5.10.1 SIMOTION SCOUT Online Help............................................................................................54

5.10.2 Searching in the online help...................................................................................................60

5.10.3 Getting Started with SIMOTION SCOUT...............................................................................61

5.10.4 Error remedy..........................................................................................................................62

5.11 Adding add-ons to the workbench..........................................................................................63

6 Configuring/parameterizing........................................................................................................................65

6.1 Configuration overview...........................................................................................................65

6.2 SIMOTION SCOUT - basic settings.......................................................................................65

6.3 Managing projects..................................................................................................................66

6.3.1 SIMOTION SCOUT project....................................................................................................66

6.3.2 Creating a new project...........................................................................................................67

6.3.3 Open project...........................................................................................................................70

6.3.4 Saving and compiling.............................................................................................................71

6.3.5 Performing a consistency check............................................................................................72

6.3.6 Archiving and backing up projects on memory cards.............................................................72

6.3.7 Exporting and importing a project in XML format...................................................................73

6.3.8 Searching in the project.........................................................................................................74

6.3.9 Replacing in the project..........................................................................................................76

6.3.10 Printing projects.....................................................................................................................76

6.4 Configuring devices................................................................................................................77

6.4.1 Adding a SIMOTION device...................................................................................................77

6.4.1.1 Starting HW Config................................................................................................................78

6.4.1.2 The HW Config program........................................................................................................79

6.4.1.3 HW Config: Opening the hardware catalog............................................................................79

6.4.1.4 SIMOTION devices in the hardware catalog..........................................................................80

6.4.2 Selecting technology packages..............................................................................................80

SIMOTION SCOUT

4 Configuration Manual, 11/2016

Page 5

Table of contents

6.4.3 Connecting to the target system............................................................................................82

6.4.3.1 Installing the interface card....................................................................................................82

6.4.3.2 Set PG/PC interface...............................................................................................................84

6.4.3.3 Specifying the access point....................................................................................................85

6.4.3.4 Communication via PROFIBUS DP.......................................................................................86

6.4.3.5 Ethernet communication........................................................................................................87

6.4.3.6 Communication via PROFINET.............................................................................................87

6.4.4 Inserting a drive......................................................................................................................88

6.4.4.1 Drives with SIMOTION...........................................................................................................88

6.4.4.2 Inserting a SINAMICS drive on PROFIBUS DP.....................................................................89

6.4.4.3 Inserting a SINAMICS drive on PROFINET IO......................................................................90

6.4.4.4 Commissioning the drives......................................................................................................91

6.4.4.5 SINAMICS S120 on SIMOTION.............................................................................................92

6.4.4.6 Configuring the infeed............................................................................................................94

6.4.4.7 Testing the drive with the drive control panel.........................................................................96

6.5 Creating and testing an axis.................................................................................................100

6.5.1 TO axis technology object....................................................................................................100

6.5.2 Configuring Axes..................................................................................................................102

6.5.3 Testing the axis with the axis control panel..........................................................................106

6.6 Programming the SIMOTION application.............................................................................110

6.6.1 Using tags............................................................................................................................110

6.6.2 Using MCC...........................................................................................................................113

6.6.2.1 Overview..............................................................................................................................113

6.6.2.2 Creating the MCC unit..........................................................................................................114

6.6.2.3 Creating an MCC chart........................................................................................................115

6.6.2.4 Using MCC command blocks...............................................................................................117

6.6.2.5 Backing up the MCC program..............................................................................................119

6.6.3 Using LAD/FBD....................................................................................................................120

6.6.3.1 Overview..............................................................................................................................120

6.6.3.2 Create LAD/FBD unit...........................................................................................................121

6.6.3.3 Create LAD/FBD program....................................................................................................122

6.6.3.4 Using the LAD/FBD toolbar..................................................................................................124

6.6.3.5 Backing up the LAD/FBD program.......................................................................................125

6.6.4 Using ST..............................................................................................................................125

6.6.4.1 Overview..............................................................................................................................125

6.6.4.2 Creating an ST source.........................................................................................................126

6.6.4.3 Backing up the ST program ................................................................................................127

6.6.4.4 Executing the ST program...................................................................................................128

6.7 Configure execution system.................................................................................................128

6.8 Project generator..................................................................................................................131

6.8.1 Overview..............................................................................................................................131

6.8.2 Integrating the ProjectGenerator..........................................................................................132

6.9 Configuring multilingual messages......................................................................................132

6.10 Know-how Protection...........................................................................................................133

6.11 Saving and restoring variables from the device...................................................................134

6.12 Online multiuser mode.........................................................................................................137

6.12.1 Overview..............................................................................................................................137

6.12.2 Working in online multiuser mode........................................................................................139

SIMOTION SCOUT

Configuration Manual, 11/2016 5

Page 6

Table of contents

6.13 Licensing runtime.................................................................................................................140

6.13.1 Licensing of the runtime components..................................................................................140

6.13.1.1 Overview for the licensing....................................................................................................140

6.13.1.2 Licenses and license key ....................................................................................................140

6.13.1.3 Determining licensing requirements.....................................................................................141

6.13.1.4 Displaying existing licenses of the SIMOTION device.........................................................142

6.13.1.5 Performing the licensing.......................................................................................................143

6.13.2 Changing the license key.....................................................................................................144

6.13.3 License key is protected from being deleted (as from Kernel V4.1).....................................144

6.13.4 Licensing during hardware replacement..............................................................................144

6.13.5 Underlicensing.....................................................................................................................144

6.14 Writing the boot sector.........................................................................................................145

7 Target system...........................................................................................................................................147

7.1 Overview..............................................................................................................................147

7.2 Going online/offline with SIMOTION SCOUT ......................................................................148

7.2.1 Online access points............................................................................................................148

7.2.2 Available nodes....................................................................................................................149

7.2.3 Setting the access point on the PG/PC................................................................................151

7.2.4 Select target devices............................................................................................................152

7.3 Controlling the operating mode with SIMOTION SCOUT....................................................154

7.4 Overall reset.........................................................................................................................160

7.5 Setting the time of day.........................................................................................................161

7.6 Loading data to the target system........................................................................................161

7.7 Archive project data to memory card...................................................................................162

7.8 Loading to the file system....................................................................................................162

8 Upgrading and project updates................................................................................................................163

8.1 General information..............................................................................................................163

8.2 Upgrading and changing platforms for a SIMOTION device................................................163

8.2.1 Changing a SIMOTION device and subsequent TP upgrade (within a platform).................163

8.2.2 Changing the SIMOTION platform.......................................................................................165

8.2.3 Upgrading technology packages.........................................................................................166

8.3 Upgrading devices and project updates using the device update tool ................................168

9 Diagnostics...............................................................................................................................................173

9.1 Overview of the possible diagnostic functions.....................................................................173

9.2 Using the diagnostics overview............................................................................................174

9.3 Device diagnostics...............................................................................................................174

9.3.1 Device diagnostics...............................................................................................................174

9.3.2 Device diagnostics: General................................................................................................175

9.3.3 Device diagnostics: Diagnostics buffer................................................................................176

9.3.4 Device diagnostics: Task Manager......................................................................................177

9.3.5 Device diagnostics: Checking memory utilization................................................................180

9.3.6 Device diagnostics: Checking the system utilization............................................................181

9.3.7 Device diagnostics: User log file..........................................................................................182

SIMOTION SCOUT

6 Configuration Manual, 11/2016

Page 7

Table of contents

9.3.8 Device diagnostics: Syslog file.............................................................................................183

9.3.9 Device diagnostics: Version overview..................................................................................183

9.3.10 Device diagnostics: Alarms..................................................................................................184

9.4 Diagnostic functions in the address list................................................................................185

9.5 Interconnection overview.....................................................................................................186

9.6 Service Overview.................................................................................................................187

9.7 Trace and measuring functions............................................................................................188

9.7.1 Trace, measuring function, and automatic controller setting................................................188

9.7.2 Task Trace...........................................................................................................................189

9.7.3 Technology object trace.......................................................................................................190

9.8 Accessible nodes.................................................................................................................192

9.9 Program testing and debugging...........................................................................................193

9.10 Project comparison..............................................................................................................193

9.11 Project overview...................................................................................................................196

9.12 Services and diagnostics without an Engineering System...................................................196

10 Service with SIMOTON SCOUT...............................................................................................................197

10.1 Selecting the right project with SCOUT................................................................................197

10.2 Project was created in Version V4.1 / V4.2 / V4.3 / V4.4.....................................................199

10.3 Project V4.1 / V4.2 / V4.3 / V4.4 has been edited with SCOUT V4.5..................................200

10.4 Introduction of versioning with standard library and software components..........................201

11 Siemens SIMOTION Diagnostics.............................................................................................................203

12 Configuring a further connection (such as HMI).......................................................................................205

12.1 Rules for arranging modules in the HW Config....................................................................205

12.2 Routing.................................................................................................................................206

12.3 HMI (Human Machine Interface) connection........................................................................206

12.4 Higher-level automation systems.........................................................................................208

12.5 TCP ports for access to SIMOTION/SINAMICS..................................................................208

13 Product combinations...............................................................................................................................211

13.1 Compatibility.........................................................................................................................211

13.1.1 General compatibility............................................................................................................211

13.1.2 Software compatibility..........................................................................................................211

13.2 Memory media of the SIMOTION devices...........................................................................212

13.3 STEP 7.................................................................................................................................213

13.3.1 SIMATIC Manager...............................................................................................................213

13.3.2 SIMATIC Logon....................................................................................................................213

13.3.3 SIMATIC Version Trail.........................................................................................................217

13.4 NetPro..................................................................................................................................218

13.5 HMI.......................................................................................................................................219

SIMOTION SCOUT

Configuration Manual, 11/2016 7

Page 8

Table of contents

13.6 Drive ES...............................................................................................................................220

13.7 Commissioning drives (STARTER)......................................................................................221

13.8 CamTool...............................................................................................................................222

13.9 DCC programming system...................................................................................................222

14 Technical specifications............................................................................................................................225

14.1 Quantity framework..............................................................................................................225

14.2 Memory requirement............................................................................................................225

A Appendix...................................................................................................................................................227

A.1 Scripts for SIMOTION..........................................................................................................227

A.2 Creating an example program for axis positioning in SIMOTION SCOUT...........................227

Index.........................................................................................................................................................239

SIMOTION SCOUT

8 Configuration Manual, 11/2016

Page 9

Preface

1.1 Validity

This document is part of the Engineering System Handling documentation package.

Validity

This manual is valid for SIMOTION SCOUT in conjunction with the SIMOTION CamTool

optional package for product version V4.5.

1.2 Sections in this manual

The following is a list of sections included in this manual along with a description of the

information presented in each section.

● Introduction

This chapter contains an overview of the SIMOTION SCOUT Engineering System.

● Installation

This chapter contains the system requirements for SIMOTION SCOUT, describes the

procedure for installing and uninstalling it, and provides important information on the

communications link to the SIMOTION device.

1

● User interface

This chapter contains an overview of the SIMOTION SCOUT Workbench. It also provides

notes concerning the language setting and the use of online help.

● Configuring/parameterizing

This chapter describes the basic steps for operating SIMOTION SCOUT.

● Target system

This chapter contains information on controlling the target system. You also learn how you

can control the operating state with SIMOTION SCOUT and how you can upload data to

the target system.

● Diagnostics

This chapter contains information about which diagnostic functions are available and how

these are operated.

● Service with SIMOTION SCOUT

This chapter contains information about the service.

● Siemens SIMOTION Diagnostics

This chapter contains information on how you can use the Siemens Simotion Diagnostics

diagnostic tool for troubleshooting.

● Configuring a further connection (such as HMI)

This chapter contains information on how to configure the HMI connection among other

things.

SIMOTION SCOUT

Configuration Manual, 11/2016 9

Page 10

Preface

1.4 Hotline and Internet addresses

● Product combinations

This chapter describes topics such as compatibility and storage media as well as STEP 7,

NetPro, Drive ES, HMI, and other interfaces.

● Technical specifications

This chapter contains information about the quantity structure and the storage capacity

requirement.

● Appendix

The appendix contains the scripts for SIOMTION and a sample program for an axis

configuration in SIOMOTION SCOUT.

● Index

1.3 SIMOTION Documentation

An overview of the SIMOTION documentation can be found in the SIMOTION Documentation

Overview document.

This documentation is included as electronic documentation in the scope of delivery of

SIMOTION SCOUT. It comprises ten documentation packages.

The following documentation packages are available for SIMOTION V4.5:

● SIMOTION Engineering System Handling

● SIMOTION System and Function Descriptions

● SIMOTION Service and Diagnostics

● SIMOTION IT

● SIMOTION Programming

● SIMOTION Programming - References

● SIMOTION C

● SIMOTION P

● SIMOTION D

● SIMOTION Supplementary Documentation

1.4 Hotline and Internet addresses

SIMOTION at a glance

We have compiled an overview page from our range of information about SIMOTION with the

most important information on frequently asked topics - which can be opened with only one

click.

Whether beginner or experienced SIMOTION user – the most important downloads, manuals,

tutorials, FAQs, application examples, etc. can be found at

https://support.industry.siemens.com/cs/ww/en/view/109480700

SIMOTION SCOUT

10 Configuration Manual, 11/2016

Page 11

Additional information

Click the following link to find information on the following topics:

● Documentation overview

● Additional links to download documents

● Using documentation online (find and search manuals/information)

https://support.industry.siemens.com/cs/ww/en/view/109479653

My Documentation Manager

Click the following link for information on how to compile documentation individually on the

basis of Siemens content and how to adapt it for the purpose of your own machine

documentation:

https://support.industry.siemens.com/My/ww/en/documentation

Training

Click the following link for information on SITRAIN - Siemens training courses for automation

products, systems and solutions:

Preface

1.4 Hotline and Internet addresses

FAQs

Technical support

http://www.siemens.com/sitrain

Frequently Asked Questions can be found in SIMOTION Utilities & Applications, which are

included in the scope of delivery of SIMOTION SCOUT, and in the Service&Support pages in

Product Support:

https://support.industry.siemens.com/cs/de/en/ps/14505/faq

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

https://support.industry.siemens.com/cs/ww/en/sc/2090

SIMOTION SCOUT

Configuration Manual, 11/2016 11

Page 12

Preface

1.4 Hotline and Internet addresses

SIMOTION SCOUT

12 Configuration Manual, 11/2016

Page 13

Fundamental safety instructions

2.1 General safety instructions

WARNING

Danger to life if the safety instructions and residual risks are not observed

The non-observance of the safety instructions and residual risks stated in the associated

hardware documentation can result in accidents with severe injuries or death.

● Observe the safety instructions given in the hardware documentation.

● Consider the residual risks for the risk evaluation.

WARNING

Danger to life caused by machine malfunctions caused by incorrect or changed

parameterization

Incorrect or changed parameterization can cause malfunctions on machines that can result

in injuries or death.

● Protect the parameterization (parameter assignments) against unauthorized access.

● Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

2

SIMOTION SCOUT

Configuration Manual, 11/2016 13

Page 14

Fundamental safety instructions

2.2 Industrial security

2.2 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines and

networks. Systems, machines and components should only be connected to the enterprise

network or the internet if and to the extent necessary and with appropriate security measures

(e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit http://www.siemens.com/

industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends to apply product updates as soon as available and to always

use the latest product versions. Use of product versions that are no longer supported, and

failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under http://www.siemens.com/industrialsecurity..

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can lead to death, severe injuries and/

or material damage.

● Keep the software up to date.

Information and newsletters can be found at:

http://support.automation.siemens.com

● Incorporate the automation and drive components into a state-of-the-art, integrated

industrial security concept for the installation or machine.

For more detailed information, go to:

http://www.siemens.com/industrialsecurity

● Make sure that you include all installed products into the integrated industrial security

concept.

SIMOTION SCOUT

14 Configuration Manual, 11/2016

Page 15

Fundamental safety instructions

2.3 Danger to life due to software manipulation when using removable storage media

2.3 Danger to life due to software manipulation when using removable

storage media

WARNING

Danger to life due to software manipulation when using removable storage media

The storage of files on removable storage media involves a high risk of infection, e.g. via

viruses or malware. Incorrect parameter assignment can cause machines to malfunction,

which can lead to injuries or death.

● Protect the files on removable storage media against harmful software through appropriate

protective measures, e.g. virus scanners.

SIMOTION SCOUT

Configuration Manual, 11/2016 15

Page 16

Fundamental safety instructions

2.3 Danger to life due to software manipulation when using removable storage media

SIMOTION SCOUT

16 Configuration Manual, 11/2016

Page 17

Introduction

3.1 Content of the configuring manual

The SIMOTION SCOUT Configuration Manual is a general description of the software. Not all

available software functions are described in this document. All detailed, subject-specific

information can be found in the context-sensitive online help and the corresponding

documentation.

Important notes and information on the SIMOTION Motion Control system are contained in

the following catalog:

● SIMOTION, SINAMICS S120 and Motors for Production Machines, PM 21 Catalog

3.2 SIMOTION SCOUT engineering system

Introduction

While the Motion Control system SIMOTION provides a wide variety of preprogrammed

functions, it is also parameterizable and programmable for individual requirements. Highperformance tools, which provide optimum support and ease of use for the necessary

engineering steps, are required for this.

3

The SIMOTION SCOUT Engineering System is the environment for the uniform automation

of production machines with SIMOTION and integrates into the SIMATIC environment in

accordance with TIA (Totally Integrated Automation).

SIMOTION SCOUT provides a uniform, function-oriented view for your automation task, and

at the same time it is very easy to use.

The possible SIMOTION applications range from simple, parameterizable, speed-controlled

single axes through to complex, mechatronically-coupled and programmable multi-axis

machines. Therefore, SIMOTION SCOUT provides views adapted to the task and can be

expanded with additional tools (e.g. tool for the graphic creation of cams).

SIMOTION SCOUT is the engineering system for SIMOTION. It is integrated into STEP 7 and

provides all the required tools for the following functionalities:

● Configuration

● Parameter assignment

● Programming

● Test

● Diagnostics

SIMOTION SCOUT

Configuration Manual, 11/2016 17

Page 18

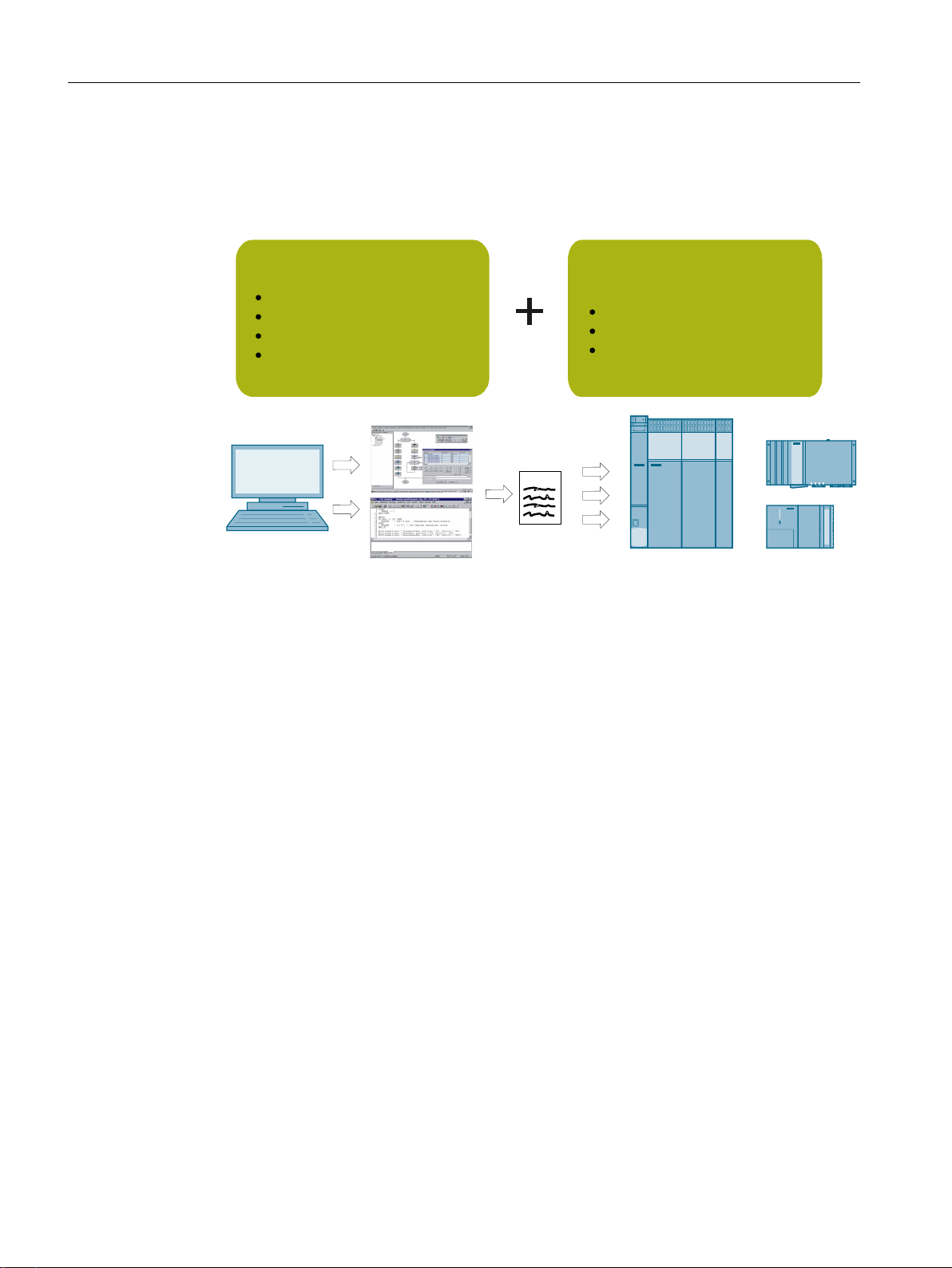

6,027,21'6,027,21&

6,027,213

21(UXQWLPHV\VWHPIRU

YDULRXVSODWIRUPV

7HFKQRORJ\SDFNDJHV+DUGZDUHSODWIRUPV6,027,216&287

HQJLQHHULQJV\VWHP

21(6&287HQJLQHHULQJV\VWHP

57FRGH

IRUFRQILJXULQJ

SDUDPHWHUL]LQJJUDSKLFRU

WH[WXDOSURJUDPPLQJ

IRUGLDJQRVWLFVWURXEOHVKRR

WLQJGHEXJJLQJ

&RQWUROOHUEDVHG6,027,21&

3&EDVHG6,027,213

'ULYHEDVHG6,027,21'

Introduction

3.3 SIMOTION hardware platforms

The following tasks are graphically supported with operator guidance:

● Creation of the hardware and network configuration

● Creation, configuration and parameter assignment of technology objects

such as axes, output cams and cams.

Figure 3-1 SIMOTION system overview

The automation topology is defined in the first engineering steps. The hardware and network

configuration is created by parameterizing the required components and networks.

3.3 SIMOTION hardware platforms

To meet the complex requirements of machine construction, SIMOTION offers three hardware

variants with different performance, packaging formats and expandability options. The basic

system characteristics, like the engineering, are identical.

SIMOTION D (Drive-based)

SIMOTION D is a compact, drive-based version of SIMOTION based on the SINAMICS S120

drives family. For SIMOTION D, the SIMOTION runtime environment and the SINAMICS drive

software run concurrently on the controller hardware in the SINAMICS S120 packaging format.

SIMOTION P (PC-based)

SIMOTION P is a PC-based, open motion control system from SIMOTION. Control, motion

control, and HMI functions are executed together with standard PC applications on the

SIMOTION P hardware platform.

SIMOTION SCOUT

18 Configuration Manual, 11/2016

Page 19

SIMOTION P combines the openness of the Windows operating system with the real-time

capability of SIMOTION P Runtime.

SIMOTION C (Controller-based)

SIMOTION C is the modular controller variant in the tried and trusted packaging system of the

SIMATIC S7-300 with its very varied expandability options on the I/O bus. SIMOTION C240

high-performance motion controllers are available for control functions and motion control

tasks. The integrated interface for four analog coupled drives makes the SIMOTION C

particularly suitable for compact applications with the control of analog electrical drives and

the operation of hydraulic axes. SIMOTION C also supports operation of four stepper motors

at these interfaces. SIMOTION C240 PN offers a PROFINET interface instead of the encoder

and drive interfaces.

3.4 Programming languages

Introduction

3.4 Programming languages

3.4.1 Programming languages in SIMOTION SCOUT

SIMOTION provides different programming languages for the solution of Motion Control tasks,

control logic, arithmetic calculations, etc. During runtime, the selected programming language

has no effect – except in the different displays when debugging. You can create user

applications in different programming languages and use them jointly in a project.

The following programming languages are available in SIMOTION SCOUT:

● Motion Control Chart (MCC)

Graphical programming as a flow chart.

In particular, for sequential tasks with a high level of motion control functionality.

● Ladder Logic / Function Block Diagram (LAD/ FBD)

Graphical Programming as Ladder Logic / Function Block Diagram, supplemented by

Motion Control Functions via PLCopen Function Blocks.

In particular, for cyclic tasks with a high logic proportion.

● Structured Text (ST)

textual programming in a high-level language.

As the base language of the SIMOTION system, ST supports all system features and

functions of the technology packages and is thus suitable for all tasks.

● Drive Control Chart (DCC)

In many applications, the control of the drive system requires a linking logic which combines

multiple statuses (e.g. entry control, system status) into one control signal (e.g. ON

command).

As well as logical links, drive systems are increasingly calling for arithmetic operations and/

or saving elements. This kind of functionality is available on drive objects of the SINAMICS

drive system and the SIMOTION control system in the form of a Drive Control Chart (DCC).

With the Drive Control Chart Editor (DCC Editor) based on CFC, SIMOTION controllers

and SINAMICS drives can be configured graphically.

For further information, see Section DCC programming system (Page 222).

SIMOTION SCOUT

Configuration Manual, 11/2016 19

Page 20

Introduction

3.4 Programming languages

Sources (units)

Programs are created in program containers, the so-called sources (units). They are compiled

in the engineering system. Any errors or warnings that occur during compilation are output in

the diagnostics window. Sources compiled without error can then be loaded into the associated

controller.

A source contains any number of programs, functions, function blocks and classes. Each

executable part of a source (program, function, function block, class) is called a POU (Program

Organization Unit).

A source is divided into an interface and an implementation section.

Interface section

All parts exported by the source are defined in the interface section. Other sources and external

components (e.g. HMI systems) can access these parts. These include user-defined data

types, data (variables and constants) as well as names of programs, functions, and function

blocks.

Implementation section

Tasks

The data types and data defined in the implementation section are global throughout the source

and can be used by all POUs. The implementation section also contains the program code of

the POUs. Any POUs not specified in the interface section can only be used within the source.

Note

Source concept

The source concept with encapsulation of code and data allows you to structure applications.

For example, the functionality of an entire machine module with a defined external interface

can be implemented in a single source.

Programs are processed in tasks. A task is a job which is executed in a certain chronological

sequence. The advantage of the task system (execution system) is that processes appended

to the appropriate task levels can run simultaneously.

The SIMOTION Motion Control system uses high-performance CPUs on which a real-time

operating system - suitable for fast control processes - is implemented. Each task is allocated

a slice of the computing time. The organization of the task executions is performed by the

operating system. A differentiation is made between user and system tasks that are

independent of one another.

Additional references

For detailed information on the programming languages and the execution system, refer to the

SIMOTION SCOUT online help and the appropriate programming and operating manuals.

SIMOTION SCOUT

20 Configuration Manual, 11/2016

Page 21

3.4.2 Motion Control Chart (MCC)

MCC (Motion Control Chart) is a "flow diagram language" that graphically formulates the

process sequences in production machines in a simple manner. The result is one or more flow

diagrams, comprising MCC blocks that describe the chronological sequence of the individual

machine actions. Due to its special means of expression, an MCC is ideally suited to

programming sequential processes.

Motion Control Chart supports the simple description of the motion sequences of machines

using powerful motion control commands, such as reference axis, position axis, synchronize

or desynchronize cam, and many more.

To control the machine sequence, commands are available for awaiting conditions and for

formulating computations, as well as for programming various control structures, such as

polling (IF), case determination (CASE) and loops (FOR, WHILE, UNTIL). Several MCC

programs may be created to describe different process situations. For example, you can create

one MCC program to bring the machine to a defined initial state when it is switched on, a

second MCC program for the normal production sequence, and a third MCC program to specify

what the machine has to do in the event of a fault.

All MCC blocks – a selection of the most important SIMOTION functions – are available in tool

bars. They are grouped according to function and are automatically inserted in the flow diagram

at the marked point by means of a click. A click on the individual elements opens specific

dialogs for parameterization. Obviously, you can also add your own comments for the further

documentation of the process sequence. Functions from the SIMOTION command library that

are not individually offered as MCC blocks can be used in an MCC program by means of a

special command.

Introduction

3.4 Programming languages

Performance features:

● Easy-to-use due to graphical illustration in the form of flow diagrams

● Hierarchical command library for motion control, PLC, and technology functions

● Control structures (IF, WHILE, CASE, etc.)

● Zooming for LAD, FBD and ST

● Subroutine calls (FB/FC, programs, methods (OOP))

● Structuring based on command module generation, i.e. combination of command

sequences to form a module command

● User-friendly debug functions for online test and diagnosis, for example, single-step,

program status or breakpoints for easier troubleshooting (debugging)

● Monitor, trace

Note

Implicit conversion to ST

When being compiled, programs written in MCC are implicitly converted to ST programs and

then compiled.

You can export the intermediate result as an ST and use it as a basis for your own ST programs.

SIMOTION SCOUT

Configuration Manual, 11/2016 21

Page 22

Introduction

3.4 Programming languages

Additional references

Detailed information can be found in the SIMOTION SCOUT online help and in the SIMOTION

MCC (Motion Control Chart) Programming and Operating Manual.

3.4.3 Ladder Logic / Function Block Diagram (LAD/FBD)

LAD/FBD is a graphical programming language and is available for Ladder Logic / Function

Block Diagram. The statement syntax corresponds to a circuit diagram (LAD) or a function

block diagram (FBD). LAD/FBD enable simple tracking of the signal flow between power rails

via inputs, outputs, and operations. LAD and FBD programs are usually suitable for application

in cyclic tasks (in particular, BackgroundTask).

LAD/FBD programs consist of elements and boxes that are graphically connected to networks.

Their operations work mostly according to the rules of Boolean logic or simple arithmetic

expressions and equations. Therefore, they are suitable only for control-relevant programs or

also for motion control tasks by using the PLCopen blocks.

Functions, function blocks and programs can be programmed in LAD/FBD. A source can

contain several LAD and FBD blocks. Only one POU can be implemented in an LAD or FBD

block.

LAD/FBD also include commands for SIMOTION system control using standard logic

functions. These commands are added from the command library. Motion Control tasks are

preferably programmed with PLCopen blocks. Blocks which have been programmed in other

SIMOTION languages can be called. User-friendly functions such as "on the fly" variable

declarations or automatic syntax checks are available when programming in LAD or FBD. It

is possible to switch over between LAD and FBD in the editor at any time. A program can

therefore be viewed and processed in either LAD or FBD.

The following user-friendly debug functions are available for online testing and diagnostics:

● Program status

● Breakpoints

Note

Direct editing of motion commands is not recommended. Instead, it is better to use the

PLCopen blocks. These blocks are designed for integration in logic-oriented programs.

Additional references

Detailed information can be found in the SIMOTION SCOUT online help and in the SIMOTION

LAD/FBD Programming and Operating Manual.

SIMOTION SCOUT

22 Configuration Manual, 11/2016

Page 23

3.4.4 Structured Text (ST)

Structured Text

ST is a high-level, PASCAL-based programming language. ST is based on the IEC 61131-3

standard. This standard harmonizes programming languages for programmable logic

controllers (PLC).

The basic command scope is sufficient for the implementation of everything related to data

management, arithmetic functions, control structures and I/O access. The addition of

technology packages for Motion Control expands the scope of commands by other

comprehensive, extremely flexible Motion Control commands.

In addition, applications can be subdivided into any number of sections. Such a section might

be a program allocated to a runtime level, an instantiatable function block with its own memory,

or a function without its own memory. In this case, the function blocks and functions are not

allocated to a runtime level, but are instead called in programs.

Note

As of SIMOTION SCOUT V4.5, ST also supports object-oriented programming. Further

information can be found in the SIMOTION SCOUT online help and in the SIMOTION ST

(Structured Text) Programming and Operating Manual.

Introduction

3.4 Programming languages

Performance features:

● Motion Control, PLC and technology functions in a single language

● Well-structured programs with comment capability

● Powerful editor functions, such as:

● Convenient debug functions for online testing and diagnostics, e.g. display of up-to-date

Additional references

– Syntax coloring

– Automatic indenting

– Automatic completion

– Bookmarks

– Fold (show and hide blocks)

– Displaying sets of parentheses

– Select text, e.g. by column

– Using the command library

variable content of the code sequence selected in the editor (program status) and

breakpoints

Detailed information can be found in the SIMOTION SCOUT online help and in the SIMOTION

ST (Structured Text) Programming and Operating Manual.

SIMOTION SCOUT

Configuration Manual, 11/2016 23

Page 24

Introduction

3.6 CamTool options package

3.5 CamEdit cam editor

CamEdit can be used to describe curves by means of either interpolation points or segments.

A combination is not possible. If the curve is to be created from segments using polynomials,

SIMOTION SCOUT provides the VDI wizard to assist in creation of the curve. Cam geometries

are created in offline mode.

Information on the graphical creation of cams can be found in the CamTool section.

3.6 CamTool options package

SIMOTION CamTool is a powerful, graphical editor for creating and optimizing cams.

SIMOTION CamTool can be used as an expansion package for SIMOTION SCOUT and is

completely integrated in the SIMOTION SCOUT user interface.

Basic functions

SIMOTION CamTool provides the following basic functions:

● Insert and edit cams.

● Customize display of the cam in CamTool.

● Convert cams from SIMOTION CamTool to SIMOTION CamEdit.

● Export cams to a text file.

● Load cams into a SIMOTION device.

Additional references

Detailed information can be found in the SIMOTION SCOUT online help and in the SIMOTION

CamTool Configuration Manual.

See also

CamEdit cam editor (Page 24)

Cams can be inserted in a SIMOTION SCOUT project using the SIMOTION CamTool. You

can also edit a cam created with CamEdit using CamTool: Cams can also be imported from

a text file or read from a SIMOTION device.

In SIMOTION CamTool, you can show and hide diagrams, change display parameters of

the axes and diagrams and adjust the lines and fonts. You can also display auxiliary lines

in the diagram.

To edit a cam that is edited in SIMOTION CamTool using SIMOTION CamEdit, the cam

needs to be converted.

SIMOTION SCOUT

24 Configuration Manual, 11/2016

Page 25

3.7 Technology packages and technology objects

3.7 Technology packages and technology objects

Technology packages in SIMOTION SCOUT

Technology packages combine software functions which are required for automation in

mechanical engineering in various sectors. They are loaded into the controller during

configuration and expand the basic functionality through additional system functions. The

functions of the technology packages can be accessed easily during engineering in the

SIMOTION SCOUT command library. Access to the technology package functions is provided

by additional language commands and system variables. Programming of motional sequences

is therefore simple and integrated.

The following standard technology packages are available for SIMOTION SCOUT:

CAM technology package

The SIMOTION CAM technology package contains the basic Motion Control technologies,

such as drive axis, position axis, following axis, synchronous object, cam, output cam, cam

track, and measuring input.

Introduction

PATH technology package

The SIMOTION PATH technology package contains additionally the path interpolation

technology.

Path interpolation generates the traversing profile for the path, calculates the path interpolation

points in the interpolation cycle, and uses the kinematic transformation to derive the axis

setpoints for the interpolation cycle points.

CAM_EXT technology package

The CAM_EXT technology package also contains objects for preparing technological data at

the system level, e.g. addition object, formula object.

TControl technology package

The SIMOTION technology package for temperature control (TControl) provides temperature

channels with extensive functions. These functions are also accessed via additional language

commands and system variables.

DCBlib

The SIMOTION DCBlib technology package contains interconnectable DCC (Drive Control

Chart) blocks for drive-related control functions.

More sector-specific technology packages are also available as separate products.

The loadable technology packages support the creation of technology objects (e.g. positioning

and synchronous axis, cam tracks, external encoders) which can be accessed over system

functions and system variables for use in every SIMOTION programming language.

SIMOTION SCOUT

Configuration Manual, 11/2016 25

Page 26

Introduction

3.8 CLib Studio option package

Technology objects in SIMOTION SCOUT

SIMOTION SCOUT uses technology objects (TOs) to represent the functionality of axes, cams,

output cams, etc. After creating a technology object (e.g. axis) and configuring it (e.g. as

positioning axis), you can access it when programming with system functions.

Note

Missing licenses

All TOs outside the basic functionality (Motion Control Basic) must be licensed. Missing

licenses are indicated by a flashing group error LED. The number and type of missing licenses

is stated by the online diagnostics. They are also displayed during downloading.

Additional references

Detailed information is provided in the SIMOTION SCOUT online help and in the following

documents:

● Function Manual: SIMOTION Basic Functions

● Function Manual: SIMOTION Motion Control, TO Axis, Electric/Hydraulic, TO External

Encoder

● Function Manual: SIMOTION Motion Control, Synchronous Operation TO, TO Cam

● Function Manual: SIMOTION Motion Control, Supplementary Technology Objects

● Function Manual: SIMOTION Motion Control Output Cams and Measuring Inputs

● Function Manual: SIMOTION Motion Control, TO Path Object

● Function Manual: SIMOTION Motion Control, Basic Functions for Modular Machines

See also

Licensing of the runtime components (Page 140)

3.8 CLib Studio option package

SIMOTION CLib Studio

If required, further functions and function blocks can be created in user libraries (SIMOTION

CLib Studio) by means of C/C++ programming in the Windows environment.

They can be used in all SIMOTION languages (MCC, LAD, FBD, ST).

That allows the creation of application-specific and high-performance function extensions as

well as adaptations including know-how protection.

SIMOTION SCOUT

26 Configuration Manual, 11/2016

Page 27

Installation

4.1 SCOUT and SCOUT Standalone system requirements

Minimum requirements of the system

The readme file on the SIMOTION SCOUT DVD contains information on SIMOTION SCOUT

system requirements; alternatively, you can access this information after installation at Start > All Programs -> Siemens Automation -> Documentation -> Readmes -> [English].

Note

Simultaneous operation of SIMOTION SCOUT, Starter and SIMATIC S7-Technology on one

PC is not intended and is not possible.

SIMATIC S7-Technology is integrated as of SIMOTION SCOUT V4.0.

4.2 Installing SIMOTION SCOUT

4

4.2.1 Installing SIMOTION SCOUT

SIMOTION SCOUT is available as software packages with full license and upgrade license.

Requirements:

● SIMATIC STEP 7 is installed.

● You are logged on to the operating system with administrator rights.

Note

Read the readme file and the important information on the SIMOTION SCOUT Add-Ons

DVD contained in the SIMOTION SCOUT software packages.

To install SIMOTION SCOUT

1. Insert the DVD 1 with SIMOTION SCOUT into the CD-ROM drive.

2. Start Windows Explorer and select the CD-ROM drive.

3. Open the root directory on the DVD.

4. Double-click Setup.exe.

SIMOTION SCOUT

Configuration Manual, 11/2016 27

Page 28

Installation

4.2 Installing SIMOTION SCOUT

5. Now follow the instructions in the installation program.

The installation program prompts you to insert or connect the supplied data medium that

contains the authorization. You can install the authorization during this setup. Or install the

authorization with the Automation License Manager after installing SIMOTION SCOUT.

For information.

6. If a restart of the PC is required during the installation, carry this out.

After restart of the operating system, log on at least as main user.

7. After the installation:

Restart the PC and log on at least as main user.

All users who are logged on as main user are now able to start and operate SIMOTION SCOUT.

4.2.2 Installing SIMOTION SCOUT Standalone

Prerequisite

● No SIMATIC STEP 7 may be installed or

● No previous version of SIMOTION SCOUT Standalone must be installed.

● You are logged on to the operating system with administrator rights.

Note

Read the readme file and important information on the Add-On CD supplied with SCOUT.

To install SIMOTION SCOUT Standalone

Insert DVD 1 with SIMOTION SCOUT Standalone into the CD-ROM drive.

1.

2. Start Windows Explorer and select the CD-ROM drive.

3. Open the root directory on the DVD.

4. Double-click Setup.exe.

5. Now follow the instructions in the installation program.

The installation program prompts you to insert or connect the supplied data medium that

contains the authorization. You can install the authorization during this setup. Or install the

authorization with the Automation License Manager after installing SIMOTION SCOUT.

Information on this can be found in the section titled "To install the authorization".

6. A restart of the PC is required during the installation, carry this out. You are requested to

insert the CD"/".

After the restart of the operating system, log on at least as main user.

7. After the installation:

Restart the PC and log on at least as main user.

All users who are logged on as main user are now able to start and operate SIMOTION SCOUT.

SIMOTION SCOUT

28 Configuration Manual, 11/2016

Page 29

4.2.3 SINAMICS Support Package (SSP)

You can use a SINAMICS Support Package (SSP) to upgrade the version of the drive units

on a STARTER integrated into SIMOTION SCOUT.

This permits the use of new functions which only become available with new drive unit FW

versions.

SSPs are available when installing SCOUT or can be installed at a later time.

In this regard, the following SSPs are relevant for SIMOTION SCOUT:

● "SINAMICS" SSP for upgrading single drive units (e.g. CU3xx)

● "SIMOTION SINAMICS Integrated" SSP for upgrading the SINAMICS drives integrated into

SIMOTION D.

The readme files for the relevant SSP contain detailed information regarding installation.

4.3 Uninstalling SIMOTION SCOUT

Installation

4.3 Uninstalling SIMOTION SCOUT

Requirements:

You are logged on to the operating system with administrator rights.

Note

Note that the SIMATIC STEP 7 software must be uninstalled separately.

To uninstall SIMOTION SCOUT from the hard disk

1. Open the Windows Control Panel. Go to the Programs and Functions page (Windows 7).

2. Select SIMOTION SCOUT Vx.x.x.x and click Uninstall/change (Windows 7). Follow the

instructions.

3. After the uninstall has completed, restart the PC.

Uninstalling SIMOTION SCOUT Standalone

Uninstall SIMOTION SCOUT Standalone as described in the "How to uninstall

SIMOTION SCOUT from the hard disk" section.

SIMOTION SCOUT

Configuration Manual, 11/2016 29

Page 30

Installation

4.4 Licenses

4.4 Licenses

4.4.1 To install the authorization

Installing the authorization for SIMOTION SCOUT

A data medium containing the authorization is supplied along with the product CD so that you

can use SIMOTION SCOUT. This contains the license key for the SIMOTION SCOUT

Engineering System.

The authorization for SIMOTION SCOUT and SIMOTION SCOUT Standalone can be installed as

follows:

1. Connect or insert the data medium containing the authorization and the license key.

2. Start the Automation License Manager:

– In the start menu, Start > All programs > Siemens Automation

> Automation License Manager or

– Double-click the Automation License Manager icon

3. In the navigation area (left-hand window), select the drive where the data medium

containing the authorization is located. The license key is displayed in the right-hand

window.

4. Mark the license key and drag this with drag-and-drop to the target drive.

5. Exit the Automation License Manager.

6. Remove the data medium containing the authorization.

Note

Information on operating the Automation License Manager and transferring the license key

can be found in the online help for the Automation License Manager.

The authorization for SIMOTION SCOUT and SIMOTION SCOUT Standalone can be upgraded as

follows:

As of Version 4.0, the authorization for SIMOTION SCOUT has been upgraded from

authorization (

Automation License Manager program manages the licenses.

1. Connect or insert the data medium containing the authorization and the upgrade license

key.

single license

) to the licensing procedure involving a

floating license

. The

2. Start the Automation License Manager:

– In the start menu, Start > All programs > Siemens Automation

> Automation License Manager or

– Double-click the Automation License Manager

icon. A new window opens.

SIMOTION SCOUT

30 Configuration Manual, 11/2016

Page 31

Installation

4.4 Licenses

3. In the navigation area (left-hand window), select the drive where the authorization for the

old version of SIMOTION SCOUT is located. Generally, the authorization will be installed

on a hard disk drive on the PC.

4. Transfer the authorization to the data medium containing the upgrade license key.

To do this, select the license in the right-hand window and select

License key > Transfer... via the menu.

5. In the Transfer license key dialog, select the connected data medium. Start the transfer by

clicking OK.

The authorization and upgrade license key will then be located on the data medium.

6. Select License key > Upgrade... in the menu.

The previous authorization will be deleted and a new

the upgrade is complete.

Note

Do not interrupt the upgrade while it is in progress. Interrupting this process can lead to the

license key being lost.

7. Now transfer the new floating license onto the hard disk drive. To do this, follow the same

procedure as before: Via License key > Transfer... in the menu

floating license

will be available once

8. After the transfer has completed successfully, remove the automation data medium.

9. Exit the Automation License Manager. SIMOTION SCOUT can now be operated without

restrictions.

4.4.2 Saving and moving the license key

Saving and moving the license key

You can transfer the license key to a removable disk. This is useful when you want to save

the license key when reinstalling a PC or when you want to use it on another PC. A copy of

the license key is not created during this operation, it is moved.

Note

More detailed information on the license keys can be found in the online help for the

Automation License Manager.

SIMOTION SCOUT

Configuration Manual, 11/2016 31

Page 32

Installation

4.4 Licenses

SIMOTION SCOUT

32 Configuration Manual, 11/2016

Page 33

User interface

2

1

7

6

5

4

3

5.1 SIMOTION SCOUT - workbench

The SIMOTION SCOUT Workbench is the common framework for all other tools of the

engineering system. The workbench is the navigation center of the individual engineering steps

and offers a uniform and integrated view of all data and programs.

The following figure shows an example of the Workbench components:

5

① Menu bar

② Tool bars

③ Working area

④ Project navigator

⑤ Snap-in

⑥ Tab

⑦ Detail view

SIMOTION SCOUT

Configuration Manual, 11/2016 33

Page 34

User interface

5.1 SIMOTION SCOUT - workbench

Workbench components

The workbench comprises the following components:

● Menu bar:

You call the functions of SIMOTION SCOUT via the menus in the menu bar.

● Tool bars:

Frequently used menu commands are also available in tool bars, which can be activated

or deactivated as required. These provide quick access to the functions. The tool bars can

be undocked from the header and relocated to a different position (e.g. at right, left, lower

border) or as a window.

● Working area:

The task-specific windows are displayed in the working area. In these windows, you can

perform the configuration with wizards for the axis configuration and drive configuration.

You also create programs in the working area. Further information about the active window

in the working area is provided in the detail view.

● Project navigator:

The project navigator provides an overview of the entire project. All defined elements, such

as devices, drives, axes, etc., are displayed here in a tree structure.

● Snap-in / tab:

A Snap-in is a program integrated automatically in the working area of the SIMOTION

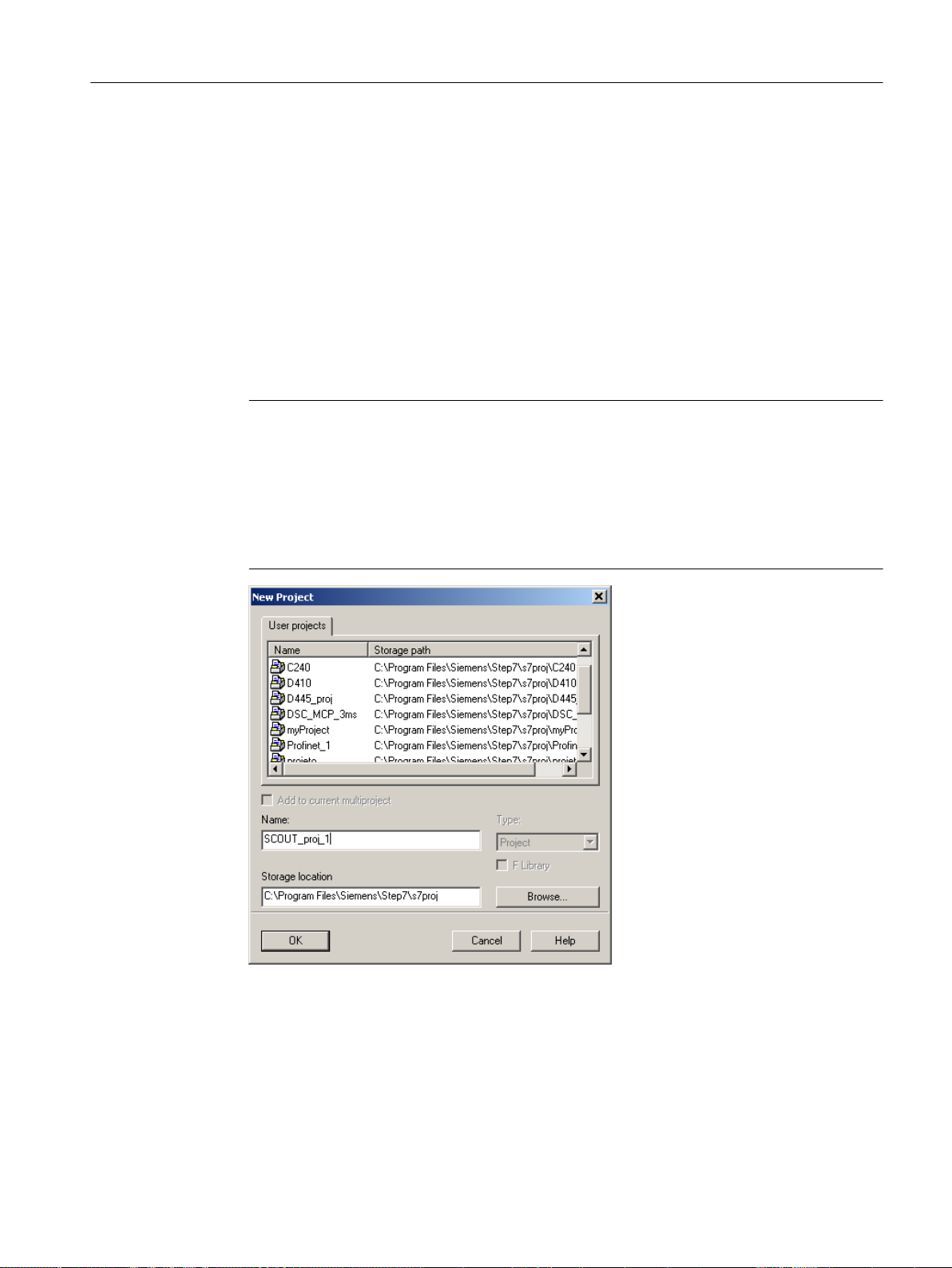

SCOUT Workbench. Snap-ins provide functions for processing SIMOTION SCOUT