Page 1

SIMOTION

SIMOTION P320-4 E / P320-4 S

Valid as of version V4.4

Preface

Manual

Safety instructions

Description

Application planning

Interfaces

Installation/mounting

Connection

Troubleshooting/FAQs

1

2

3

4

5

6

7

Technical data

Dimension drawings

Spare parts

Standards and approvals

ESD Guideline

8

9

10

A

B

01/2015

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used.

A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation.

If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ 03/2015 Subject to change

Copyright © Siemens AG 2015.

All rights reserved

Page 3

Preface

Preface

This document is part of the SIMOTION P documentation package.

This documentation describes the SIMOTION P320‑4 hardware platform which can be

delivered in the SIMOTION P320-4 E and SIMOTION P320-4 S hardware versions:

References

Validity range

Standards

● SIMOTION

real-time expansion for SIMOTION.

Successor to SIMOTION P320-3.

● SIMOTION P320‑4 E with the Windows 7 Ultimate 32-bit operating system and real-time

expansion for SIMOTION.

Successor to SIMOTION P350-3.

The following documents contain the descriptions for the SIMOTION P hardware platform:

● SIMOTION P320-4 E / P320-4 S, Manual, Edition 01/2015

● SIMOTION P320-4 E / P320-4 S, Commissioning and Hardware Installation Manual, Edition

01/2015

This manual applies to the SIMOTION P320-4 E and SIMOTION P320-4 S devices as of

product level SIMOTION V4.4.

The SIMOTION system was developed in accordance with ISO 9001 quality guidelines.

P320‑4 E with the Windows Embedded Standard 7 32-bit operating system and

Chapters in this documentation

The following sections describe the purpose and the use of this documentation:

● Safety instructions

Contains fundamental safety instructions for SIMOTION and specific safety instructions for

SIMOTION P320-4.

● Description

System overview and product description for SIMOTION P320-4. The communication

variants are also described.

● Use planning

Points to note in advance: upon delivery, the permitted installation positions, environmental

and ambient conditions and electromagnetic compatibility.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 3

Page 4

Preface

● Interfaces

Description of the interfaces and operator control and display elements for

SIMOTION P320-4.

Installation/mounting

●

An overview of the installation of the SIMOTION P320-4 taking into account the mounting

positions.

● Connecting

This section provides general information and important notes that you must observe when

connecting the SIMOTION P320‑4.

● Troubleshooting/FAQs

List of possible errors and their remedies.

● Technical specifications

This section contains an overview of the technical data, which is listed for the individual

components.

● Dimension drawings

In this section you can find dimension drawings and dimensions of the SIMOTION P320‑4.

● Spare parts

You can find information about the spare parts for the SIMOTION P320-4 here.

● Appendix

In addition to the safety information, the annexes also contain information about the

standards, approvals and EGB guideline.

● Index

Alphabetical directory for locating information.

SIMOTION Documentation

An overview of the SIMOTION documentation can be found in the SIMOTION Documentation

Overview document.

This documentation is included as electronic documentation in the scope of delivery of

SIMOTION SCOUT. It comprises ten documentation packages.

The following documentation packages are available for SIMOTION V4.4:

● SIMOTION Engineering System Handling

● SIMOTION System and Function Descriptions

● SIMOTION Service and Diagnostics

● SIMOTION IT

● SIMOTION Programming

● SIMOTION Programming - References

● SIMOTION C

● SIMOTION P

SIMOTION P320-4 E / P320-4 S

4 Manual, 01/2015

Page 5

● SIMOTION D

SIMOTION Supplementary Documentation

●

Hotline and Internet addresses

Additional information

Click the following link to find information on the following topics:

● Ordering documentation / overview of documentation

● Additional links to download documents

● Using documentation online (find and search manuals/information)

http://www.siemens.com/motioncontrol/docu

My Documentation Manager

Click the following link for information on how to compile documentation individually on the

basis of Siemens content and how to adapt it for the purpose of your own machine

documentation:

Preface

Training

FAQs

Technical support

http://www.siemens.com/mdm

Click the following link for information on SITRAIN - Siemens training courses for automation

products, systems and solutions:

http://www.siemens.com/sitrain

Frequently Asked Questions can be found in SIMOTION Utilities & Applications, which are

included in the scope of delivery of SIMOTION SCOUT, and in the Service&Support pages

in Product Support:

http://support.automation.siemens.com

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

http://www.siemens.com/automation/service&support

Disposal and recycling of the device

The disposal of the products described in this manual must be performed in compliance with

the valid national regulations.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 5

Page 6

Preface

To a great extent, the products can be recycled owing to their low pollutant content. To recycle

and dispose of your old device in an environmentally friendly way, please contact a waste

disposal service certified for electronic waste.

If you have any further questions about disposal and recycling, please contact your local

Siemens

contact person. Contact details can be found in our contacts database on the Internet

at: http://www.automation.siemens.com/partner/index.asp

SIMOTION P320-4 E / P320-4 S

6 Manual, 01/2015

Page 7

Table of contents

Preface.........................................................................................................................................................3

1 Safety instructions......................................................................................................................................11

1.1 Fundamental safety instructions............................................................................................11

1.1.1 General safety instructions.....................................................................................................11

1.1.2 Safety instructions for electromagnetic fields (EMF)..............................................................14

1.1.3 Handling electrostatic sensitive devices (ESD)......................................................................14

1.1.4 Industrial security...................................................................................................................15

1.1.5 Residual risks of power drive systems...................................................................................15

1.2 Specific safety instructions for the SIMOTION P320-4..........................................................18

1.2.1 General safety instructions for the SIMOTION P320-4..........................................................18

1.2.2 Notes on use..........................................................................................................................20

2 Description..................................................................................................................................................21

2.1 System overview....................................................................................................................21

2.2 SIMOTION P320-4 product description.................................................................................23

2.2.1 SIMOTION P320-4 overview..................................................................................................23

2.2.2 Features.................................................................................................................................24

2.2.3 SIMOTION P320-4 (hardware) structure...............................................................................26

2.2.4 Interfaces and operating elements.........................................................................................27

2.2.5 SIMOTION P Runtime (software) structure............................................................................27

2.2.6 Components...........................................................................................................................28

2.3 HMI and SIMOTION SCOUT.................................................................................................31

2.3.1 HMI and SIMOTION SCOUT Overview.................................................................................31

2.3.2 Local HMI or ES on SIMOTION P320-4.................................................................................31

2.3.3 HMI or ES via PROFINET......................................................................................................32

2.3.4 HMI or ES via Ethernet (external access) .............................................................................33

2.3.5 HMI or ES via IsoPROFIBUS (optional).................................................................................34

3 Application planning...................................................................................................................................37

3.1 Unpacking and checking the delivery.....................................................................................37

3.2 Identification data of the device..............................................................................................39

3.3 Permissible mounting positions..............................................................................................42

3.4 Environmental conditions.......................................................................................................43

3.5 Electromagnetic compatibility.................................................................................................45

4 Interfaces....................................................................................................................................................47

4.1 Hardware components of the SIMOTION P320-4..................................................................47

4.2 Overview of operator control and display elements...............................................................49

4.3 Control elements....................................................................................................................50

4.4 Status displays.......................................................................................................................51

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 7

Page 8

Table of contents

4.5 Overview of the SIMOTION P320-4 interfaces......................................................................53

4.6 PROFINET onboard...............................................................................................................54

4.7 Ethernet..................................................................................................................................55

4.8 DVI-I.......................................................................................................................................56

4.9 USB 3.0..................................................................................................................................58

4.10 CFast card .............................................................................................................................59

4.11 COM1.....................................................................................................................................60

4.12 IsoPROFIBUS board (optional)..............................................................................................61

5 Installation/mounting...................................................................................................................................63

5.1 Installing the device................................................................................................................63

5.2 Permissible mounting positions..............................................................................................64

5.2.1 Standard rail mounting and vertical mounting........................................................................65

5.2.1.1 Standard rail mounting...........................................................................................................65

5.2.1.2 Vertical mounting...................................................................................................................67

5.3 Installation notes....................................................................................................................69

5.4 Overview of operating modes for the SIMOTION P320-4......................................................71

5.5 Decentralized structure..........................................................................................................72

6 Connection.................................................................................................................................................73

6.1 Requirements.........................................................................................................................73

6.2 Overview of connections........................................................................................................74

6.3 Notes on connecting..............................................................................................................76

6.4 Protective conductor connection and potential equalization..................................................78

6.5 Connecting peripheral equipment..........................................................................................80

6.6 Connecting the power supply (24 VDC).................................................................................81

6.7 Connecting the device to networks........................................................................................83

6.8 Installing the strain relief........................................................................................................84

7 Troubleshooting/FAQs................................................................................................................................85

7.1 Error correction......................................................................................................................85

8 Technical data............................................................................................................................................87

8.1 Overview of the technical specifications................................................................................87

8.2 General technical specifications.............................................................................................88

8.3 Ambient conditions.................................................................................................................90

8.4 Technical data of the IsoPROFIBUS board...........................................................................92

8.5 Power requirements of the components................................................................................94

8.6 Integrated DC power supply...................................................................................................95

8.7 Technical data for the SITOP smart 24 V/10 A......................................................................96

SIMOTION P320-4 E / P320-4 S

8 Manual, 01/2015

Page 9

Table of contents

8.8 Typical power consumption....................................................................................................98

9 Dimension drawings...................................................................................................................................99

9.1 Overview of the dimensional drawings...................................................................................99

9.2 Device dimension drawing for standard rail mounting.........................................................100

9.3 Device dimension drawing for vertical mounting..................................................................102

9.4 Dimension drawing of device with one expansion card.......................................................105

10 Spare parts...............................................................................................................................................107

10.1 Available spare parts for SIMOTION P320-4.......................................................................107

A Standards and approvals..........................................................................................................................109

A.1 General rules........................................................................................................................109

B ESD Guideline..........................................................................................................................................111

B.1 ESD definition......................................................................................................................111

B.2 Electrostatic charging of individuals.....................................................................................112

B.3 Basic measures for protection against discharge of static electricity...................................113

Index.........................................................................................................................................................115

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 9

Page 10

Table of contents

SIMOTION P320-4 E / P320-4 S

10 Manual, 01/2015

Page 11

Safety instructions

1.1 Fundamental safety instructions

1

1.1.1

General safety instructions

DANGER

Danger to life due to live parts and other energy sources

Death or serious injury can result when live parts are touched.

Only work on electrical devices when you are qualified for this job.

●

● Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase

conductor and phase conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water.

4. Isolate or neutralize all hazardous energy sources by closing switches, grounding or shortcircuiting or closing valves, for example.

5. Secure the energy sources against switching on again.

6. Ensure that the correct machine is completely interlocked.

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Danger to life from hazardous voltage when connecting an unsuitable power supply

Touching live components can result in death or severe injury.

Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV

●

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 11

Page 12

Safety instructions

1.1 Fundamental safety instructions

WARNING

Danger to life from touching live parts on damaged devices

Improper handling of devices can result in damage.

For damaged devices, hazardous voltages can be present at the enclosure or at exposed

components; if touched, this can result in death or severe injury.

● Observe

the limit values specified in the technical specifications during transport, storage,

and operation.

● Do not use damaged devices.

WARNING

Danger to life through electric shock due to unconnected cable shields

Hazardous

touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

● As a minimum, connect cable shields and the cores of power cables that are not used

(e.g. brake cores) at one end at the grounded housing potential.

WARNING

Danger to life due to electric shock when not grounded

For missing or incorrectly implemented protective conductor connection for devices with

protection

class I, high voltages can be present at open, exposed parts, which when touched,

can result in death or severe injury.

● Ground the device in compliance with the applicable regulations.

WARNING

Danger to life due to fire spreading if housing is inadequate

Fire and smoke development can cause severe personal injury or material damage.

● Install

devices without a protective housing in a metal control cabinet (or protect the device

by another equivalent measure) in such a way that contact with fire inside and outside the

device is prevented.

● Ensure that smoke can only escape via controlled and monitored paths.

SIMOTION P320-4 E / P320-4 S

12 Manual, 01/2015

Page 13

Safety instructions

1.1 Fundamental safety instructions

WARNING

Danger to life from unexpected movement of machines when using mobile wireless devices

or mobile phones

Using mobile radios or mobile phones with a transmit power > 1 W closer than approx. 2 m

to the components may cause the devices to malfunction, influence the functional safety of

machines therefore putting people at risk or causing material damage.

● Switch

off wireless devices or mobile phones in the immediate vicinity of the components.

WARNING

Danger to life due to fire if overheating occurs because of insufficient ventilation clearances

Inadequate

ventilation clearances can cause overheating of components followed by fire and

smoke development. This can cause death or serious injury. This can also result in increased

downtime and reduced service life for devices/systems.

● Ensure compliance with the specified minimum clearance as ventilation clearance for the

respective component.

WARNING

Danger of an accident occurring due to missing or illegible warning labels

Missing or illegible warning labels can result in accidents involving death or serious injury.

●

Check that the warning labels are complete based on the documentation.

● Attach any missing warning labels to the components, in the national language if

necessary.

● Replace illegible warning labels.

WARNING

Danger to life when safety functions are inactive

Safety functions that are inactive or that have not been adjusted accordingly can cause

operational faults on machines that could lead to serious injury or death.

● Observe

the information in the appropriate product documentation before commissioning.

● Carry out a safety inspection for functions relevant to safety on the entire system, including

all safety-related components.

● Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

● Perform a function test.

● Only put your plant into live operation once you have guaranteed that the functions relevant

to safety are running correctly.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 13

Page 14

Safety instructions

1.1 Fundamental safety instructions

Note

Important safety notices for safety functions

If you want to use safety functions, you must observe the safety notices in the safety manuals.

1.1.2 Safety instructions for electromagnetic fields (EMF)

WARNING

Danger to life from electromagnetic fields

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment

such as transformers, converters or motors.

People with pacemakers or implants are at a special risk in the immediate vicinity of these

devices/systems.

Ensure that the persons involved are the necessary distance away (minimum 2 m).

●

1.1.3 Handling electrostatic sensitive devices (ESD)

Electrostatic

or devices that may be damaged by either electric fields or electrostatic discharge.

NOTICE

Damage through electric fields or electrostatic discharge

Electric

components, integrated circuits, modules or devices.

● Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of aluminum

foil.

● Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

● Only place electronic components, modules or devices on conductive surfaces (table with

ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

sensitive devices (ESD) are individual components, integrated circuits, modules

fields or electrostatic discharge can cause malfunctions through damaged individual

SIMOTION P320-4 E / P320-4 S

14 Manual, 01/2015

Page 15

1.1.4 Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly that

you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should also

be considered. For more information about industrial security, visit http://www.siemens.com/

industrialsecurity.

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit http://support.automation.siemens.com

Safety instructions

1.1 Fundamental safety instructions

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can lead to death, severe injuries and/

or material damage.

Keep the software up to date.

●

Information and newsletters can be found at:

http://support.automation.siemens.com

● Incorporate the automation and drive components into a state-of-the-art, integrated

industrial security concept for the installation or machine.

For more detailed information, go to:

http://www.siemens.com/industrialsecurity

● Make sure that you include all installed products into the integrated industrial security

concept.

1.1.5 Residual risks of power drive systems

control and drive components of a drive system are approved for industrial and commercial

The

use in industrial line supplies. Their use in public line supplies requires a different configuration

and/or additional measures.

These components may only be operated in closed housings or in higher-level control cabinets

with protective covers that are closed, and when all of the protective devices are enabled.

These components may only be handled by qualified and trained technical personnel who are

knowledgeable and observe all of the safety instructions on the components and in the

associated technical user documentation.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 15

Page 16

Safety instructions

1.1 Fundamental safety instructions

When assessing the machine's risk in accordance with the respective local regulations (e.g.

EC Machinery Directive), the machine manufacturer must take into account the following

residual risks emanating from the controller and drive components of a drive system:

1. Unintentional

movements of driven machine components during commissioning, operation,

maintenance, and repairs caused by, for example:

– Hardware defects and/or software errors in the sensors, controllers, actuators, and

connection technology

– Response times of the controller and drive

– Operating and/or ambient conditions outside of the specification

– Condensation / conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of radio devices / cellular phones in the immediate vicinity of the controller

– External influences / damage

2. In the event of a fault, exceptionally high temperatures, including an open fire, as well as

emissions of light, noise, particles, gases, etc. can occur inside and outside the inverter,

for example:

– Component malfunctions

– Software errors

– Operating and/or ambient conditions outside of the specification

– External influences / damage

Inverters of the Open Type / IP20 degree of protection must be installed in a metal control

cabinet (or protected by another equivalent measure) such that the contact with fire inside

and outside the inverter is not possible.

3. Hazardous touch voltages caused by, for example:

– Component malfunctions

– Influence of electrostatic charging

– Induction of voltages in moving motors

– Operating and/or ambient conditions outside of the specification

– Condensation / conductive contamination

– External influences / damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk

to people with a pacemaker, implants or metal replacement joints, etc. if they are too close.

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly.

SIMOTION P320-4 E / P320-4 S

16 Manual, 01/2015

Page 17

Safety instructions

1.1 Fundamental safety instructions

Note

The components must be protected against conductive contamination (e.g. by installing them

in a control cabinet with degree of protection IP54 according to IEC 60529 or NEMA 12).

Assuming that conductive contamination at the installation site can definitely be excluded, a

lower degree of cabinet protection may be permitted.

For more information about residual risks of the components in a drive system, see the relevant

sections in the technical user documentation.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 17

Page 18

Safety instructions

1.2 Specific safety instructions for the SIMOTION P320-4

1.2 Specific safety instructions for the SIMOTION P320-4

1.2.1

General safety instructions for the SIMOTION P320-4

Life-threatening voltages are present with an open control cabinet

When you install the device in a control cabinet, some areas or components in the open

control cabinet may be carrying life-threatening voltages.

If you touch these areas or components, you may be killed by electric shock.

Switch off the power supply to the cabinet before opening it.

System expansions

NOTICE

Damage through system expansions

Device and system expansions may be faulty and can affect the entire machine or plant.

The installation of expansions can damage the device, machine or plant.

Device and system expansions may violate safety rules and regulations regarding radio

interference suppression.

WARNING

you install or exchange system expansions and damage your device, the warranty becomes

If

void.

Note the following for system expansions:

●

Only install system expansion devices designed for this device. Contact your technical

support team or where you purchased your PC to find out which system expansion devices

may safely be installed.

● Observe the information on electromagnetic compatibility (Page 109).

NOTICE

"Open Type" UL508

Note that the device is classified as "Open Type" for use in the area of Industrial Control

Equipment (UL508). Installation of the device in an enclosure according to UL508 is

conditional for approval or operation according to UL508.

SIMOTION P320-4 E / P320-4 S

18 Manual, 01/2015

Page 19

Battery and rechargeable battery

WARNING

Risk of explosion and release of harmful substances

Improper handling of lithium batteries can result in an explosion of the batteries.

Safety instructions

1.2 Specific safety instructions for the SIMOTION P320-4

Explosion

batteries jeopardize the function of the device.

Note the following when handling lithium batteries:

● Replace used batteries in good time, see the section "Replacing the backup battery" in

the Commissioning and Hardware Installation Manual.

● Replace the lithium battery only with an identical battery or types recommended by the

manufacturer (Article No.: A5E30314053).

● Do not throw lithium batteries into fire, do not solder on the cell body, do not recharge, do

not open, do not short-circuit, do not reverse polarity, do not heat above 100°C and protect

from direct sunlight, moisture and condensation.

High frequency radiation

NOTICE

Unintentional operating situations

frequency radiation, e g. from a cellular phone, interferes with device functions and can

High

result in malfunctioning of the device.

Persons are injured and the plant is damaged.

Avoid high-frequency radiation:

● Remove radiation sources from the environment of the device.

● Switch off radiating devices.

● Reduce the radio output of radiating devices.

● Observe the information on electromagnetic compatibility (Page 109).

of the batteries and the released pollutants can cause severe physical injury. Worn

ESD Guideline

Electrostatic sensitive devices can be labeled with an appropriate symbol.

NOTICE

Electrostatic sensitive devices (ESD)

When

you touch electrostatic sensitive components, you can destroy them through voltages

that are far below the human perception threshold.

If you work with components that can be destroyed by electrostatic discharge, observe the

ESD Guideline.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 19

Page 20

Safety instructions

1.2 Specific safety instructions for the SIMOTION P320-4

Further information

can find more detailed information about the EGB Guideline in Annex B in the section with

You

the same name.

1.2.2 Notes on use

WARNING

Hazards on an unprotected machine or plant

According to the results of a risk analysis, hazards can occur on an unprotected machine.

The hazards can result in personal injury.

According to the risk analysis, the risk of personal injury can be avoided with the following

measures:

Additional protective devices on the machine or plant. With this, especially the

●

programming, configuration and wiring of the inserted I/O modules have to be executed,

in accordance with the necessary risk analysis identified safety performance (SIL, PL or

Cat.).

● The correct use of the device has to be verified with a function test on the system. This

test can detect programming, configuration and wiring errors.

● Documentation of the test results that you can enter in the relevant safety records when

required.

NOTICE

Ambient conditions

Ambient

Note the following:

● Operate the device only in closed rooms. Failure to comply nullifies the warranty.

● Operate the device only in accordance with the ambient conditions specified in the

● Protect the device against dust, moisture and heat.

● Do not expose the device to direct sunlight or other strong sources of light.

● Without additional measures, such as a supply of clean air, the device may not be used

● Observe the permissible mounting positions of the device.

● Do not obstruct the venting slots of the device.

Note

Use in an industrial environment without additional protective measures

This device was designed for use in a normal industrial environment according to

IEC 60721-3-3.

conditions for which the device is not suitable can cause faults or damage the device.

technical specifications.

in locations with harsh operating conditions caused by acidic vapors or gases.

SIMOTION P320-4 E / P320-4 S

20 Manual, 01/2015

Page 21

Description

2.1 System overview

Overview

SIMOTION P is a PC-based, open Motion Control System from SIMOTION.

Control, motion control, and HMI functions are executed together with standard PC

applications

of the Windows operating system with real-time capability of SIMOTION P Runtime.

The fully independent SIMOTION P Runtime runs in parallel to Windows on SIMOTION P.

This real-time expansion makes it possible to implement demanding motion control

applications with high performance requirements on platforms of the SIMOTION P range. The

hardware consists of a computing unit with innovative Intel technology, which is ready for

operation at the time of delivery.

The drives and I/O devices are connected either via PROFINET onboard or

IsoPROFIBUS board (optional).

The SIMATIC flat panels IFP1500, IFP1900 and IFP2200 can be used for the operation of the

SIMOTION P320-4 hardware platform in a distributed configuration.

on the SIMOTION P hardware platform. SIMOTION P combines the compatibility

2

Variants of the SIMOTION P320-4

The SIMOTION P320-4 S can control various I/O systems and HMI components via

PROFINET onboard or the optional IsoPROFIBUS board.

A USB DVD drive can be connected, for example.

The following variants of the SIMOTION P320-4 are available:

● SIMOTION P320-4 E

with the Windows Embedded Standard 7 32-bit operating system and real-time expansion

for SIMOTION.

● SIMOTION P320-4 S

with the Windows 7 Ultimate 32-bit operating system and real-time expansion for

SIMOTION.

Application

The SIMOTION P320-4 applications are directed at machines that require a high level of

integration of PLC, motion control and technology functions on account of the increasing use

of servo drives:

● Packaging machines

● Plastic and rubber processing machines

● Presses, wire-drawing machines

● Textile machines

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 21

Page 22

Description

2.1 System overview

● Printing machines

●

● Production lines in the renewable energy sector, e.g. solar technology, wind power

Machines for processing wood, glass, ceramics, and stone

installations

SIMOTION P320-4 E / P320-4 S

22 Manual, 01/2015

Page 23

2.2 SIMOTION P320-4 product description

Description

2.2 SIMOTION P320-4 product description

2.2.1

SIMOTION P320-4 overview

The SIMOTION P320-4 provides high-level industrial performance. It features:

● Compact design

● Maintenance-free operation

● High degree of ruggedness

● Long-term availability

Figure 2-1 SIMOTION P320-4 view

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 23

Page 24

Description

2.2 SIMOTION P320-4 product description

2.2.2

Figure 2-2 SIMOTION P320-4 (open perspective) with plugged-in optional IsoPROFIBUS board

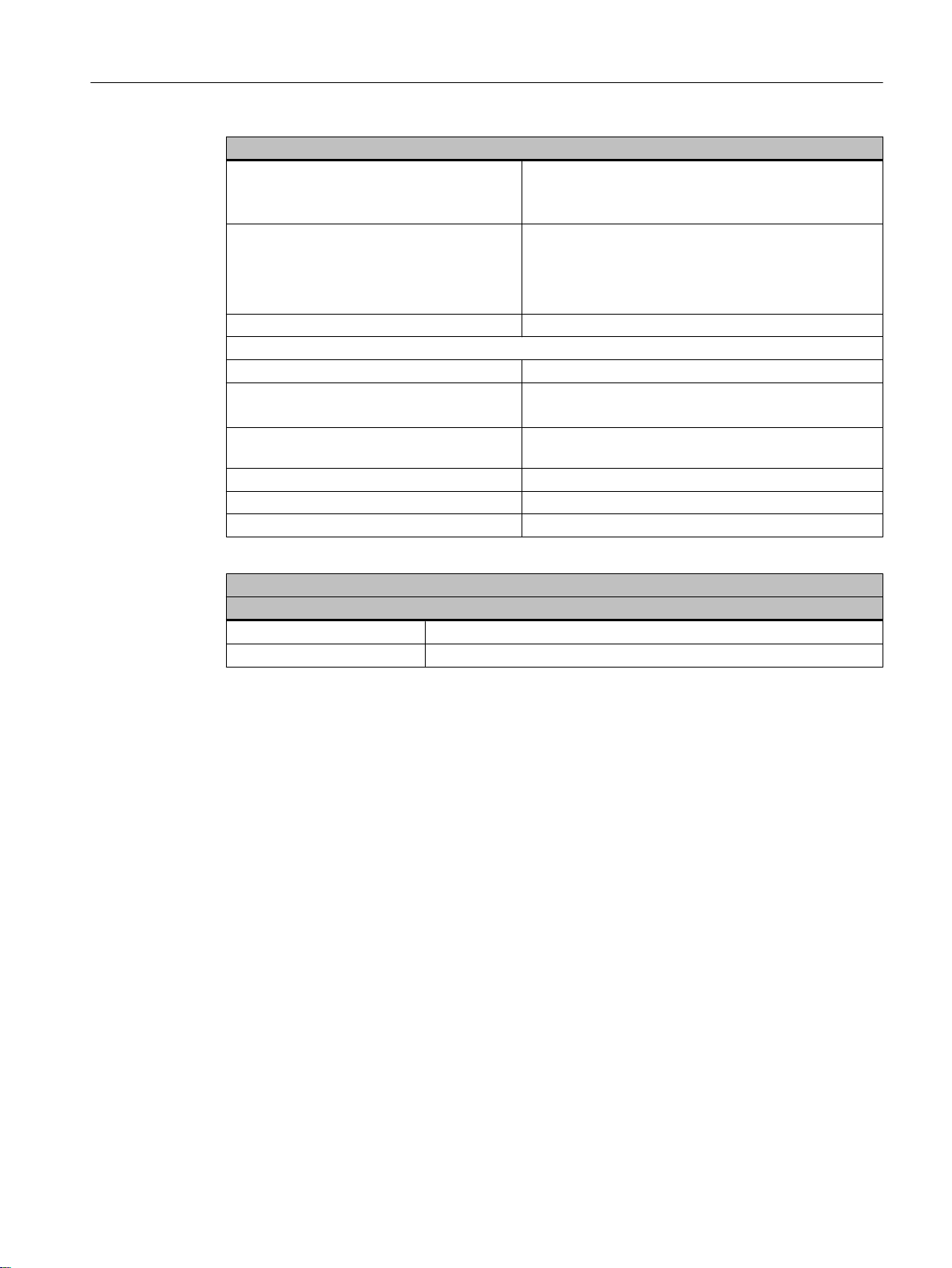

Features

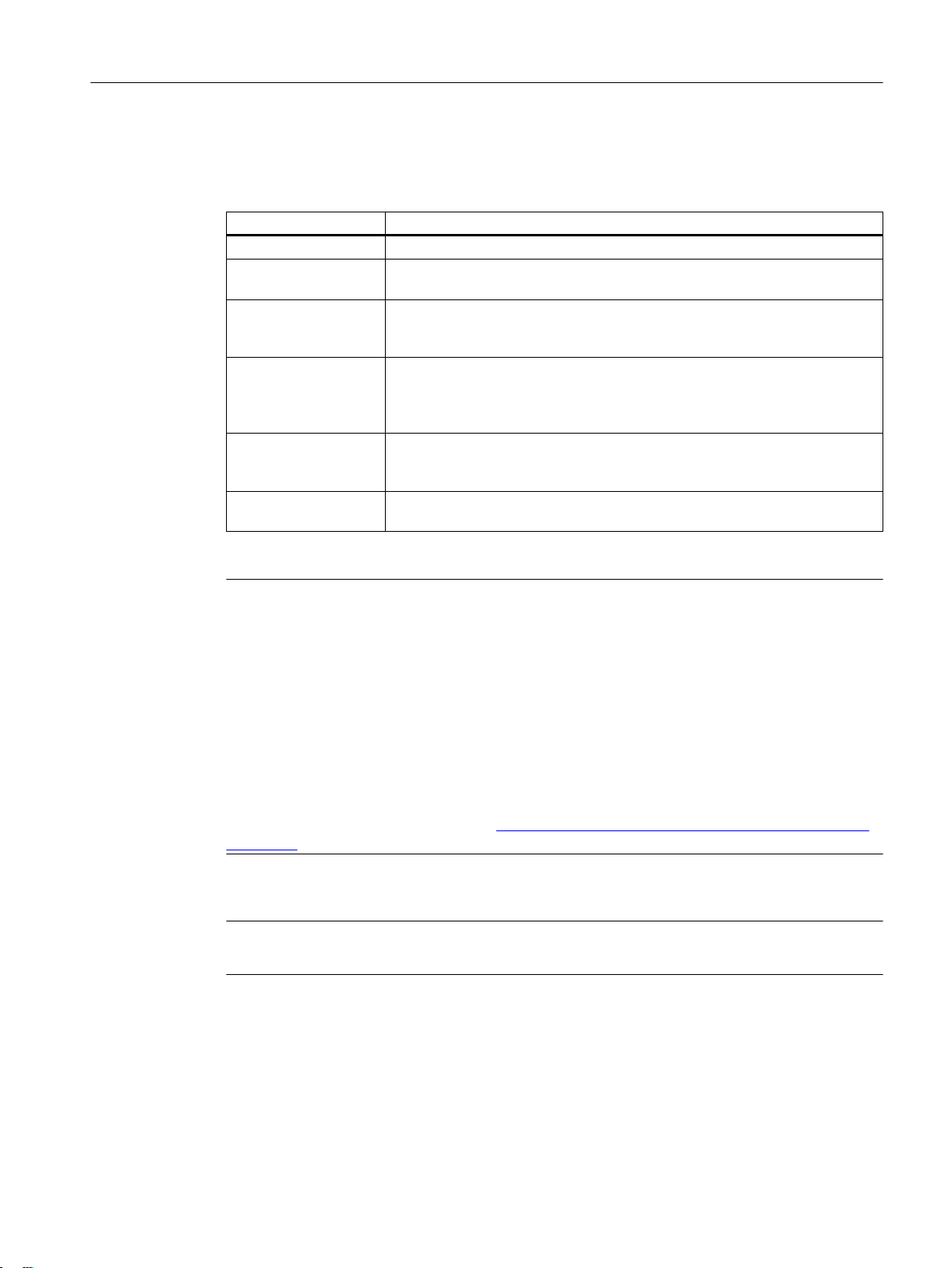

Basic data

Installation

Processor

P320-4 E

P320-4 S

Main memory 4 GB DDR3 RAM

Optional IsoPROFIBUS board

(PROFIBUS DP)

Graphics

Power supply 24 VDC (-20%/+20%) max. 4 A

Operating conditions Operation without fan

Drives and storage media

CFast card or SSD

(Solid State Disk)

● Standard rail mounting

Vertical mounting

●

Intel Core i3-3217UE, 2 x 1.6 GHz, 3 MB cache

Intel Core i7-3517UE, 2 x 1.7 GHz, 4 MB cache

2 x SUB-D socket with configurable baud rates (9.6 Kbit/

s - 12 Mbps)

● Integrated Intel HD2000 or HD4000

DVI resolution of 640 × 480 pixels up to

●

1920 × 1200 pixels

● Display port resolution max. 1920 × 1200 pixels

● Graphics memory is claimed in main memory

(dynamic UMA)

SIMOTION P320-4 E / P320-4 S

24 Manual, 01/2015

Page 25

Description

2.2 SIMOTION P320-4 product description

Basic data

P320-4 E 2 x CFast card

Internal interface: CFast

External interface: CFast

P320-4 S SSD (Solid State Disk)

Internal interface: SSD

CFast card

External interface: CFast

USB stick External, can be connected via USB interface

Interfaces

Serial COM (RS 232)

Graphics DVI-I: suitable for use as DVI or VGA

DPP++: Display port, DVI via DPP-to-DVI adapter

USB 4 × USB 3.0, simultaneous operation of high current,

backward compatible with USB 2.0/1.1

Ethernet 1 × RJ45 (10/100/1000 Mbps)

PROFINET I/O 3 × RJ45 (100 Mbps)

Keyboard, mouse Can be connected via USB interface

Software

Operating systems

P320-4 E Windows Embedded Standard 7 32-bit

P320-4 S Windows 7 Ultimate 32-bit

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 25

Page 26

7)7PRQLWRU

7)7PRQLWRU

'9,9*$

;

'LVSOD\SRUW

DOWHUQDWLYH

DOWHUQDWLYH

352),1(7GULYHV

HJ6,1$0,&66

352),1(7b,2

HJ(763

+0,3*(6

352),1(7

352),1(7

352),1(7

2QERDUG

(WKHUQHW

+0,3*(6

(WKHUQHW

.H\ERDUGDQG

0RXVH

86%

;

352),%86'3

352),1(7GULYHV

H

J6,1$0,&66

352),1(7b,2

HJ(763

+0,3*(6

352),1(7RQERDUGFRQWUROOHU

+0, +XPDQ0DFKLQH,QWHUIDFH

3* 3URJUDPPLQJ'HYLFH

(6 (QJLQHHULQJ6\VWHP

6HULDO

,QWHUIDFH

%XIIHUHG

65$0

5HWDLQGDWD

352),%86'3

ืP0EDXG

,VR352),%86ERDUGRSWLRQDO

$QDORJ,2PRGXOHV

$',GULYHLQWHUIDFH

6,0$7,&(7

HJ(763

352),%86'3

'ULYHV

6,0$7,&(7

HJ(763

$QDORJ,2PRGXOHV

$',GULYHLQWHUIDFH

352),%86GULYHV

HJ6,1$0,&66

6<1&,2FRQQHFWLQJFDEOH

3DQHOV

3DQHOV

;

;

;

;

6,027,213

Description

2.2 SIMOTION P320-4 product description

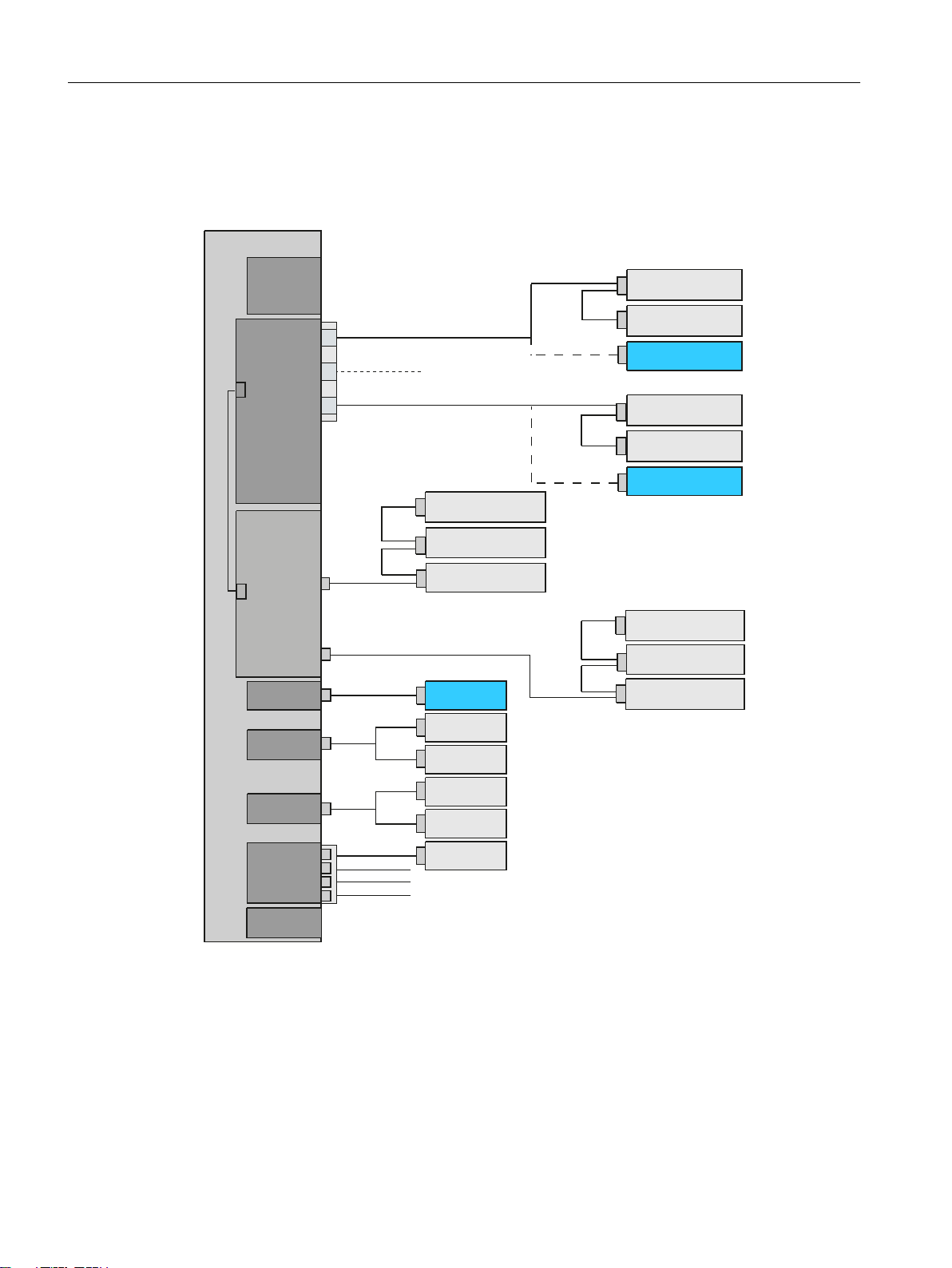

2.2.3 SIMOTION P320-4 (hardware) structure

following figure shows the integration of the SIMOTION P320-4 with integrated PROFINET

The

onboard and optional IsoPROFIBUS board in a target system.

Figure 2-3 System overview of the SIMOTION P320-4

26 Manual, 01/2015

SIMOTION P320-4 E / P320-4 S

Page 27

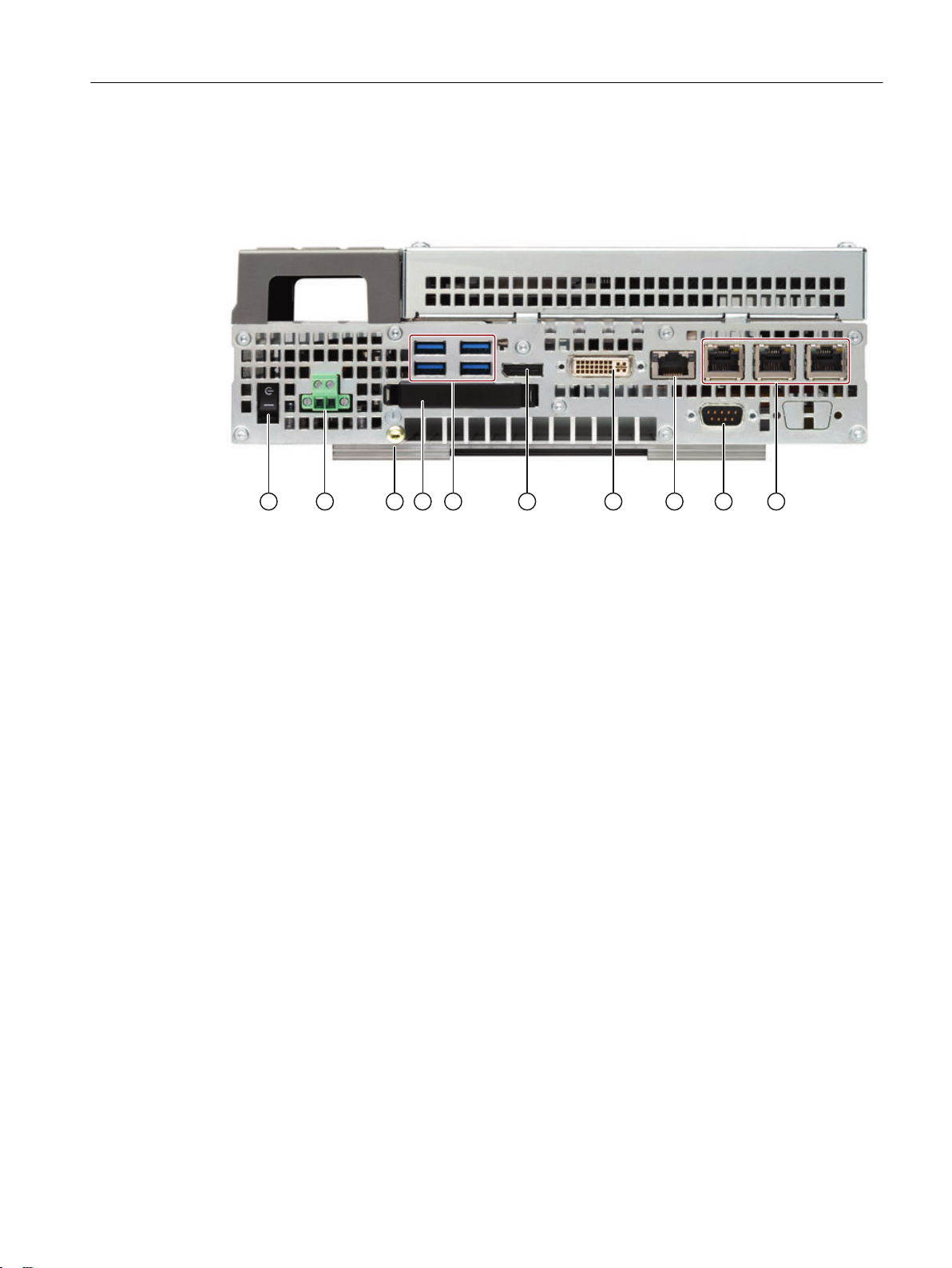

2.2.4 Interfaces and operating elements

SIMOTION P320-4

① On/off switch Position OFF is the delivery state.

The on/off switch does not isolate the device from the power sup‐

ply.

② 24 V DC Power supply connection

③ Protective conductor Protective conductor terminal

④ Memory card slot Cover for the CFast card

⑤ 4 × USB 3.0 USB 3.0 high current, backward compatible with USB 2.0/1.1

⑥ Display port Display port connection for digital monitor

⑦ DVI-I DVI connector for CRT or LCD monitor with DVI interface

⑧ Ethernet RJ45 Ethernet connection for 10/100/1000 Mbps

⑨ COM1 Serial interface

⑩ 3 × PROFINET PROFINET ports with three RJ45 sockets

Description

2.2 SIMOTION P320-4 product description

2.2.5 SIMOTION P Runtime (software) structure

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 27

SIMOTION P contains the SIMOTION P Kernel which performs the motion control and

interface control.

A SIMOTION P project is planned, configured, assigned parameters, commissioned, and

programmed by means of the SIMOTION SCOUT Engineering System (ES).

User data can be stored on the data media of the SIMOTION P320‑4.

Siemens

the machine. Third-party systems can be linked via the OPC interface.

WinCC flexible software can be used to visualize operational sequences or to operate

Page 28

Description

2.2 SIMOTION P320-4 product description

SIMOTION P Runtime

With the SIMOTION P320-4, the PLC and motion control functionality (starting from position

controller upwards) is located centrally in a strictly deterministic task outside the Windows

operating system.

Its main field of application is centralized motion control and control tasks requiring close

coordination between multiple axes and/or input/output modules.

Functionality ranges from simple positioning to high-performance synchronous operation.

SIMOTION SCOUT

The SIMOTION SCOUT engineering system can be installed on the SIMOTION P320-4 S or

connected via the interfaces integrated in SIMOTION P320‑4.

HMI software

HMI/Runtime software can be operated on the same PC, e.g. the Siemens WinCC flexible

software. Other software packages can be linked by means of the OPC interface.

The HMI software is used as the general term in the following.

Internal communication

A locally installed HMI can use the local communication to access the following:

Variables in SIMOTION RT

●

● Drives on PROFINET IO or PROFIBUS DP

● Other SIMOTION devices on PROFINET IO or PROFIBUS DP

Scope of delivery

The system software supplied with the SIMOTION P320-4 is either already installed on the

SIMOTION P320‑4 storage medium or is ready to be installed:

● SIMOTION P Kernel

● SIMOTION IT

● SIMOTION IT VM Virtual Machine (under license)

2.2.6 Components

The most important components of the SIMOTION P320-4 and their functions are listed below.

SIMOTION P320-4 E / P320-4 S

28 Manual, 01/2015

Page 29

Distributed I/O systems (PROFINET)

Description

2.2 SIMOTION P320-4 product description

Table 2-1

Component Function

SIMATIC ET 200M Modular I/O system for control cabinet installation and high channel densities.

SIMATIC ET 200S Finely modular I/O system for control cabinet installation including motor

SIMATIC ET 200SP Finely scalable I/O system for cabinet installation; SIMATIC ET 200SP fea‐

SIMATIC ET 200MP Modular I/O system for cabinet installation and high channel densities in the

SIMATIC ET 200eco I/O system with IP67 degree of protection for machine-related, cabinet-free

SIMATIC ET 200pro Modular I/O system with IP65/67 degree of protection for machine-related,

Components for distributed I/O

starters, safety technology, and individual grouping of the load groups.

tures a single-cable and multi-cable connection with push‑in terminals, com‐

pact dimensions, high performance, and low part variety.

SIMATIC S7‑1500 packaging system.

SIMATIC ET 200MP permits the shortest bus cycle times and fastest re‐

sponse time even with large volumes of data.

applications,

M12.

cabinet-free applications, including motor starters.

featuring a flexible and fast connection system in ECOFAST or

Note

Please

note that not all modules of the above-mentioned I/Os or I/O systems are approved for

SIMOTION.

Moreover, system-related functional differences can occur when these I/O or I/O systems are

used on SIMOTION rather than SIMATIC.

For example, special process-control functions (e.g., HART modules, etc.) are not supported

by SIMOTION for the ET 200M distributed I/O system.

For a detailed and routinely updated list of I/O modules enabled with SIMOTION as well as

application information, visit us online at:

siemens.com - Industry Automation and Drive Technologies - Product Support Supplementary System Components (

http://support.automation.siemens.com/WW/view/en/

11886029)

Further modules are integrated via the GSD file of the device's manufacturer.

Note

Please note that in individual cases, additional general conditions must be fulfilled.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 29

Page 30

Description

2.2 SIMOTION P320-4 product description

Drive systems (via PROFINET IO)

Table 2-2

Component Function

SINAMICS S120 Servo drives, innovative single-axis and multi-axis solution

Optional components

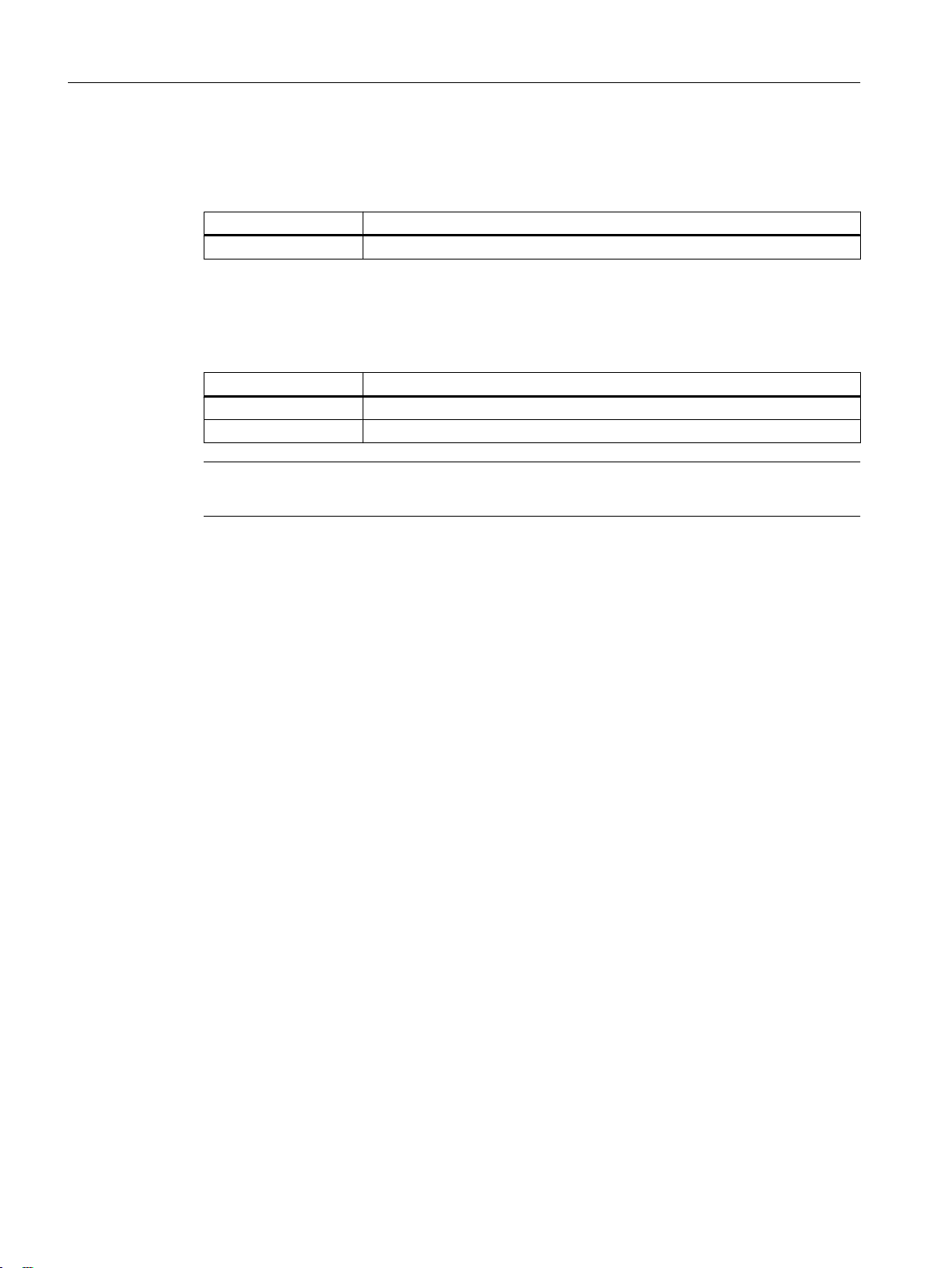

Table 2-3 Optional components

Centralized I/O Function

IsoPROFIBUS board PROFIBUS connection

UPS Uninterruptible Power Supply

Note

In addition, an IsoPROFIBUS board may be inserted for the PROFINET onboard.

List of typically connected drive systems

SIMOTION P320-4 E / P320-4 S

30 Manual, 01/2015

Page 31

2.3 HMI and SIMOTION SCOUT

Description

2.3 HMI and SIMOTION SCOUT

2.3.1

HMI and SIMOTION SCOUT Overview

The operational sequences on the SIMOTION P320-4 are either monitored via the HMI system

(Human Machine Interface) or the SIMOTION SCOUT engineering system.

The HMI or ES software can be connected using the following variants:

● Local (Page 31)

● via PROFINET (Page 32)

● via Ethernet (Page 33)

● via IsoPROFIBUS (optional) (Page 34)

Local communication of the HMI/ES

Only one local connection to the local SIMOTION Runtime is possible. If HMI or ES is also

installed locally, PC internal can access other controllers/devices via PROFINET / PROFIBUS.

See section Local HMI or ES on SIMOTION P320-4 (Page 31)

Communication of the HMI / ES via PROFINET / Ethernet / PROFIBUS

By using one of these communication variants, you can control and monitor several

SIMOTION devices.

2.3.2 Local HMI or ES on SIMOTION P320-4

For communication of the SIMOTION P320-4 with a local HMI or ES, the model described

below is used. The SIMOTION SCOUT engineering system or the HMI system can be installed

directly on the SIMOTION P320-4 S.

For this model, you must set the communication (access point) to PC internal. The

SIMOTION P320-4 is already configured for this communication variant at the time of delivery.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 31

Page 32

,2

GULYHV

,2

GULYHV

+0,(6

352),%86'3

352),1(7,2

6,027,213

Description

2.3 HMI and SIMOTION SCOUT

Figure 2-4 Set PG/PC Interface dialog

Note

Only HMI-Runtime can be installed on the SIMOTION P320-4 E version.

Figure 2-5 Model: Local HMI or ES

2.3.3 HMI or ES via PROFINET

Networking via PROFINET

PROFINET is the innovative and open Industrial Ethernet standard (EN 61158) for industrial

automation. With PROFINET, devices can be linked up from the field level through to the

management level.

32 Manual, 01/2015

SIMOTION P320-4 E / P320-4 S

Page 33

+0,(6

352),1(7

,2

'ULYHV

,2

'ULYHV

35

2),1(7b,2

352),%86'3

,2

'ULYHV

,2

'ULYHV

352),1(7b,2

352),%86'3

6,027,2136,027,213

References

,2

GULYHV

,2

GULYHV

,2

GULYHV

,2

GULYHV

352),1(7,2

352),%86'3

35

2),1(7,2

352),%86'3

(WKHUQHW

+0,(6

6,027,213

6,027,213

Description

2.3 HMI and SIMOTION SCOUT

With PROFINET, an external HMI or ES can also be integrated into the network and data can

be exchanged directly with the SIMOTION P320-4 device.

Figure 2-6 Model: Networking via PROFINET

You can find further information on the HMI in the documentation:

●

SIMOTION Runtime Basic Functions, section HMI (Human Machine Interface) coupling.

2.3.4 HMI or ES via Ethernet (external access)

Networking via Ethernet

A complex interconnection with several HMIs or ESs is only possible using an Ethernet

communication. This allows both an external HMI or ES to access several SIMOTION devices

or one SIMOTION device to access another one, for example, to display the production data.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 33

Figure 2-7 Model: Networking via Ethernet

Page 34

+0,(6

352),%86'3

,2

'ULYHV

352),%86'3

,2

'ULYHV

352),%86'3

6,027,2136,027,213

;

;;

;

Description

2.3 HMI and SIMOTION SCOUT

Using Ethernet, the following services are possible on a SIMOTION device:

HMI software

●

WinCC flexible or the OPC server can use Ethernet to access one or more SIMOTION

devices.

● SIMOTION SCOUT Engineering System

SIMOTION SCOUT can also use Ethernet to access one or more SIMOTION devices.

● SIMOTION IT

SIMOTION P320-4 offers communication with standard IT protocols (HTTP) over the

integrated Ethernet interface.

This makes it possible to access data or diagnostic information in the SIMOTION P320-4

from any location via intranet or the Internet.

References

You can find further information in the documentation for SIMOTION IT:

● SIMOTION IT Diagnostics and Configuration

● SIMOTION IT Programming and Web Services

● SIMOTION IT Virtual Machine and Servlets

2.3.5 HMI or ES via IsoPROFIBUS (optional)

Networking via PROFIBUS DP

If you connect a central HMI via PROFIBUS DP, the X101 and X102 interfaces of the

IsoPROFIBUS board are available.

Figure 2-8 Model: Networking via PROFIBUS DP

34 Manual, 01/2015

SIMOTION P320-4 E / P320-4 S

Page 35

References

Description

2.3 HMI and SIMOTION SCOUT

You can find further information on the HMI in the documentation:

SIMOTION Runtime Basic Functions, section HMI (Human Machine Interface) coupling.

●

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 35

Page 36

Description

2.3 HMI and SIMOTION SCOUT

SIMOTION P320-4 E / P320-4 S

36 Manual, 01/2015

Page 37

Application planning

3.1 Unpacking and checking the delivery

Procedure

When accepting a delivery, please check the packaging for visible transport damage.

1.

2. If any transport damage is present at the time of delivery, lodge a complaint at the shipping

company in charge. Have the shipper confirm the transport damage immediately.

3. Unpack the device at its installation location.

4. Keep the original packaging in case you have to transport the device again.

Note

Damage to the device during transport and storage

If a device is transported or stored without packaging, then shocks, vibrations, pressure

and moisture may impact the unprotected device.

damaged packaging indicates that ambient conditions have already had a massive impact

A

on the device.

The device may be damaged.

3

Do not dispose of the original packaging. Pack the device for transport and storage in the

original packaging.

5. Check the contents of the packaging and any accessories you may have ordered for

completeness and damage.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 37

Page 38

Application planning

3.1 Unpacking and checking the delivery

the contents of the packaging are incomplete, damaged or do not match your order, inform

6. If

the responsible delivery service immediately.

WARNING

Electric shock and fire hazard due to damaged device

A damaged device can be under hazardous voltage and trigger a fire in the machine or

plant. A damaged device has unpredictable properties and states.

Death or serious injury could occur.

Make sure that the damaged device is not inadvertently installed and put into operation.

Label the damaged device and keep it locked away. Send off the device for immediate

repair.

NOTICE

Damage from condensation

the device is subjected to low temperatures or extreme fluctuations in temperature during

If

transportation, for example in cold weather, moisture could build up on or inside the HMI

device.

Moisture can result in short-circuits in electrical circuits and damage the device.

In order to prevent damage to the device, proceed as follows:

● Store the device in a dry place.

● Bring the device to room temperature before starting it up.

● Do not expose the device to direct heat radiation from a heating device.

● If condensation develops, wait approximately 12 hours or until the device is completely

dry before switching it on.

7. Please keep the enclosed documentation, it belongs to the device. You need the

documentation when you commission the device for the first time.

8.

Write down the identification data of the device.

SIMOTION P320-4 E / P320-4 S

38 Manual, 01/2015

Page 39

3.2 Identification data of the device

Application planning

3.2 Identification data of the device

Based

on the identification data, the SIMOTION P320-4 device can be identified when service

is required or in case of theft.

You also require the identification data in order to view further information on your

SIMOTION P320-4 in the Product Equipment Data (PED) database.

All the important components of your SIMOTION P320-4 are stored in the PED. The entire

history of the device is stored there, including the service reports.

To identify yourself in the PED database, enter the article number and the serial number of

your device.

Link to the PED database

The Product Equipment Data database is available on the Internet via the following link (

www.siemens.com/ped).

Identification data

Enter the identification data in the following table:

Identification data Source Value

Serial number Type plate S VP ...

Article number of the device Type plate 6AU1320-...

Microsoft Windows Product Key

Certificate of Authenticity (COA)

Ethernet address 1 BIOS setup, menu "Advanced", "Pe‐

PROFINET onboard MAC Address Layer 2

PROFINET onboard MAC Address PROFINET

Rear of the device Only devices with preinstalled

Windows

COA labels

Input by the user.

ripheral Configuration"

http://

operating systems have

SIMOTION P320-4 type plate

Example of SIMOTION P320-4 S (standard)

You will find the following data on the type plate of the SIMOTION P320-4:

Device designation (here): SIMOTION P320-4 S

●

● Article number of the device (here): 6AU1320-4DS66-3AG0

● Serial number S VP<...>

The computing unit is uniquely identifiable with the serial number at S VP <...>.

<...> <...> is an 8-digit character string.

● cULus Approval

● CE marking

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 39

Page 40

Application planning

3.2 Identification data of the device

Figure 3-1 SIMOTION P320-4 type plate

MAC addresses

Example of SIMOTION P320-4 S (standard)

In addition to the data that is found on the SIMOTION P320-4 type plate, the MAC address

plate also contains the Onboard MAC addresses for:

●

ETHERNET (LAN) X1: VIPCTYSMAC1

● PROFINET (LAN) X3: VIPCTYSPROFINET

The data cited here is not real data.

Figure 3-2 Type plate SIMOTION P320-4 S - MAC addresses

SIMOTION P320-4 E / P320-4 S

40 Manual, 01/2015

Page 41

Example of a COA label

Microsoft Windows "Product Key" of the "Certificate of Authenticity" (COA):

COA label is attached to the rear of all devices containing a Windows Embedded Standard

The

7 or Windows 7 operating system.

● COA label of a device with Windows Embedded Standard 7 32-bit operating system

Figure 3-3 ipc477d label coa 01

COA label of a device with Windows 7 operating system

●

Application planning

3.2 Identification data of the device

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 41

Page 42

Application planning

3.3 Permissible mounting positions

3.3 Permissible mounting positions

Information

the section Installation/mounting > Permissible mounting positions (Page 64).

on the permissible mounting positions for the SIMOTION P320-4 can be found in

SIMOTION P320-4 E / P320-4 S

42 Manual, 01/2015

Page 43

3.4 Environmental conditions

Operating conditions

The SIMOTION P320-4 is designed for use in stationary, weather-protected locations.

The operating conditions exceed requirements according to EN 61131-2.

Observe the following points during installation:

Application planning

3.4 Environmental conditions

● Note

● The device is designed for use in a normal industrial environment. Without additional

● The clearance in the area of the ventilation slots must be at least 100 mm, so that the

● Do not cover the ventilation slots of the device.

● The DC power supply does not meet requirements according to EN 60950-1 in the area of

● Always observe the mounting positions permitted for this device.

● The connected or installed I/O should not generate a reverse voltage greater than 0.5 V in

the climatic and mechanical environmental conditions specified in Section Technical

specifications (Page 87).

protective measures (such as the provision of clean air), the SIMOTION P320-4 computing

unit cannot be used in places with severe operating environments, for example, locations

with corrosive vapors or gases.

SIMOTION P320-4 receives sufficient ventilation.

the power unit connection. As such, SIMOTION P320-4 must be installed so that it is part

of an operating area with restricted access (e.g. a locked control cabinet, console or server

room).

the device.

WARNING

Invalidation of the approvals

Failure to adhere to these conditions when installing the system will invalidate approvals

according to UL 60950-1, UL 508, and EN 60950-1!

Use prohibition

Without additional measures, the SIMOTION P320-4 should not be used in

●

Locations with a high percentage of ionizing radiation

● Aggressive environments characterized, for example, by:

– Dust accumulation

– Corrosive vapors or gases

● at locations outside of the prescribed ambient conditions

● Installations requiring special monitoring such as:

– Elevator installations

– Electrical plants in particularly hazardous areas

An additional measure for using the SIMOTION P320-4 could be its installation in a cabinet.

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 43

Page 44

Application planning

3.4 Environmental conditions

Ambient conditions

the mechanical and climatic environmental conditions, refer to the technical specifications

For

in the section Ambient conditions (Page 90).

SIMOTION P320-4 E / P320-4 S

44 Manual, 01/2015

Page 45

3.5 Electromagnetic compatibility

Definition

Application planning

3.5 Electromagnetic compatibility

See also:

Standards

is complied with.

Further information is provided in the Appendix, Section General regulations (Page 109).

for electromagnetic compatibility (EMC) are fulfilled if the EMC Installation Guideline

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 45

Page 46

Application planning

3.5 Electromagnetic compatibility

SIMOTION P320-4 E / P320-4 S

46 Manual, 01/2015

Page 47

Interfaces

4.1 Hardware components of the SIMOTION P320-4

Note

The article numbers of the components listed below can be obtained from the online catalog

in the Siemens Industry Mall (

SIMOTION P320-4 complete system

The SIMOTION P320-4 device is supplied with the integrated PROFINET onboard

communication module.

An additional IsoPROFIBUS board can be inserted as required.

SIMOTION P320-4 spare parts

The SIMOTION P320-4 consists of the following hardware components:

● SIMOTION P320-4 computing unit

http://www.siemens.com/industrymall).

4

● Back-up battery for the motherboard of the SIMOTION P320-4

● IsoPROFIBUS board (optional communication module for the SIMOTION P320-4)

Operation and display

The following hardware components for operation and display can be used:

● SIMATIC Industrial Flat Panel, in the variants IFP1500, IFP1900 or IFP2200.

Power supply of the SIMOTION P320-4

The power supply must satisfy the requirements as described in section Connecting the power

supply (24 VDC) (Page 81). This can be ensured by using the following devices, for example:

● SITOP smart 24 V / 10 A

● 24 VDC UPS (optional)

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 47

Page 48

Interfaces

4.1 Hardware components of the SIMOTION P320-4

Drives and I/O modules

The drives and I/O modules released for use with SIMOTION are specified on the website:

www.siemens.com/simotion (www.siemens.com/simotion)

Note

Please note that not all modules of the I/O or I/O systems mentioned are approved for

SIMOTION. Moreover, system-related functional differences can occur when these I/O or I/O

systems are used on SIMOTION rather than SIMATIC. For example, special process-control

functions (hot swapping, etc.) are not supported by SIMOTION for the ET 200M distributed I/

O system.

A detailed and routinely updated list of I/O modules released for SIMOTION as well as

instructions on their use is provided on the Internet at Siemens Product Support (http://

support.automation.siemens.com/WW/view/en/11886029).

In addition to the I/O modules approved for SIMOTION, all certified standard slaves can, in

principle, be connected to SIMOTION provided that they support the following data traffic:

●

Cyclic data traffic (DP V0)

● Acyclic data traffic (DP V1)

● Isochronous data traffic (DP V2)

These modules are integrated via the GSD file of the device's manufacturer.

Note

Please note that in individual cases, additional boundary conditions must be fulfilled in order

to integrate a standard slave into SIMOTION.

SIMOTION P320-4 E / P320-4 S

48 Manual, 01/2015

Page 49

4.2 Overview of operator control and display elements

4.2 Overview of operator control and display elements

The following figure shows the arrangement of the indication and control elements of the

SIMOTION P320-4.

Interfaces

① On/Off switch

② Operating displays (LEDs)

Figure 4-1 SIMOTION P320-4 control and display elements

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 49

Page 50

Interfaces

4.3 Control elements

4.3 Control elements

On/Off switch

① Requirement:

The BIOS setup entry After Power Failure is set to Power on.

The On/Off switch is used to switch the SIMOTION P320-4 on.

Figure 4-2 SIMOTION P320-4 - operator controls

WARNING

De-energize the SIMOTION P320-4!

The On/Off switch does not disconnect the device from the power supply system.

When the switch is in position 0 (Off), the device is still supplied with mains voltage.

To remove power from the device, the power supply plug must be removed.

NOTICE

Close down the operating system first

First close down the operating system before switching off the device with the on/off switch,

otherwise data may get lost.

SIMOTION P320-4 E / P320-4 S

50 Manual, 01/2015

Page 51

4.4 Status displays

The status indicators below the interfaces are described in the following table.

Figure 4-3 SIMOTION P320-4 status indicator

LED Meaning State Description

PC ON/

WD

RUN/STOP or L1 RUN

Power supply Green BIOS ready to boot.

Indicates

V from the integrated power unit.

Off Not relevant.

STOP

Green/yellow flash‐

ing

(1 Hz)

Yellow Idle state

Off SIMOTION P Runtime is not running.

Green SIMOTION P320-4 in RUN mode.

Yellow SIMOTION P320-4 in STOP mode.

Green/yellow:

Flashes quickly

(2 Hz)

Yellow: Flashes

quickly

(2 Hz)

BIOS in POST, power switch on.

DCP flashing

"FAULT" status

(only in combination with L2 and L3)

Interfaces

4.4 Status displays

the correct supply voltage of 3.3 V, 5 V and 12

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 51

Page 52

Interfaces

4.4 Status displays

LED Meaning State Description

ERROR or L2

(SF PROFINET LED)

MAINT or L3

(SF LED)

SYNC

- Off SIMOTION P320-4 works error-free.

Error Red: Continuous

light

Red: Flashes quick‐

ly

(2 Hz)

Red: Flashes quickly

(2 Hz)

INIT Red:

Flashes slowly

(0.5 Hz)

- Off SIMOTION P320-4 works error-free.

Error Red An event has occurred which needs to be acknowledged

Red:

Flashes slowly

(0.5 Hz)

Red: Flashes quickly

(2 Hz)

Red: Flashes quick‐

ly

(2 Hz)

Off The PROFINET interface has not yet synchronized with

the PROFINET

of

interface

Yellow The PROFINET interface has synchronized to the send

Yellow: Flashes

quickly

(2 Hz)

Bus error at the PROFINET interface.

Erroneous configuration.

"FAULT" status

(only in combination with L1 and L3)

During the INIT process, the SF PROFINET LED is con‐

trolled by the boot loader.

The precise flashing behavior therefore cannot be de‐

termined and displayed.

In the INIT state, 0.5 Hz flashing is displayed in the SI‐

MOTION P state.

no project has yet been loaded, 0.5 Hz flashing is also

If

displayed for the INIT, which, in this case, is also re‐

tained in the Running state.

(alarm, message, notification).

(See Diagnostics Guide)

License missing for licensed technology objects.

Carry out the licensing to correct the error.

Further

SIMOTION P320-4 E / SIMOTION P320-4 S Commis‐

sioning and Hardware Installation Manual.

A fault has occurred to which the user program cannot

respond.

following actions may be required to rectify the fault:

The

● Power OFF/ON

● Recommissioning

FAULT status

(only in combination with L1 and L2)

the send cycle clock of PROFINET IO with IRT, or

PROFINET IO with IRT has not been configured.

cycle clock of PROFINET IO with IRT.

A PROFINET firmware download is in progress.

information on the licensing can be found in the

SIMOTION P320-4 E / P320-4 S

52 Manual, 01/2015

Page 53

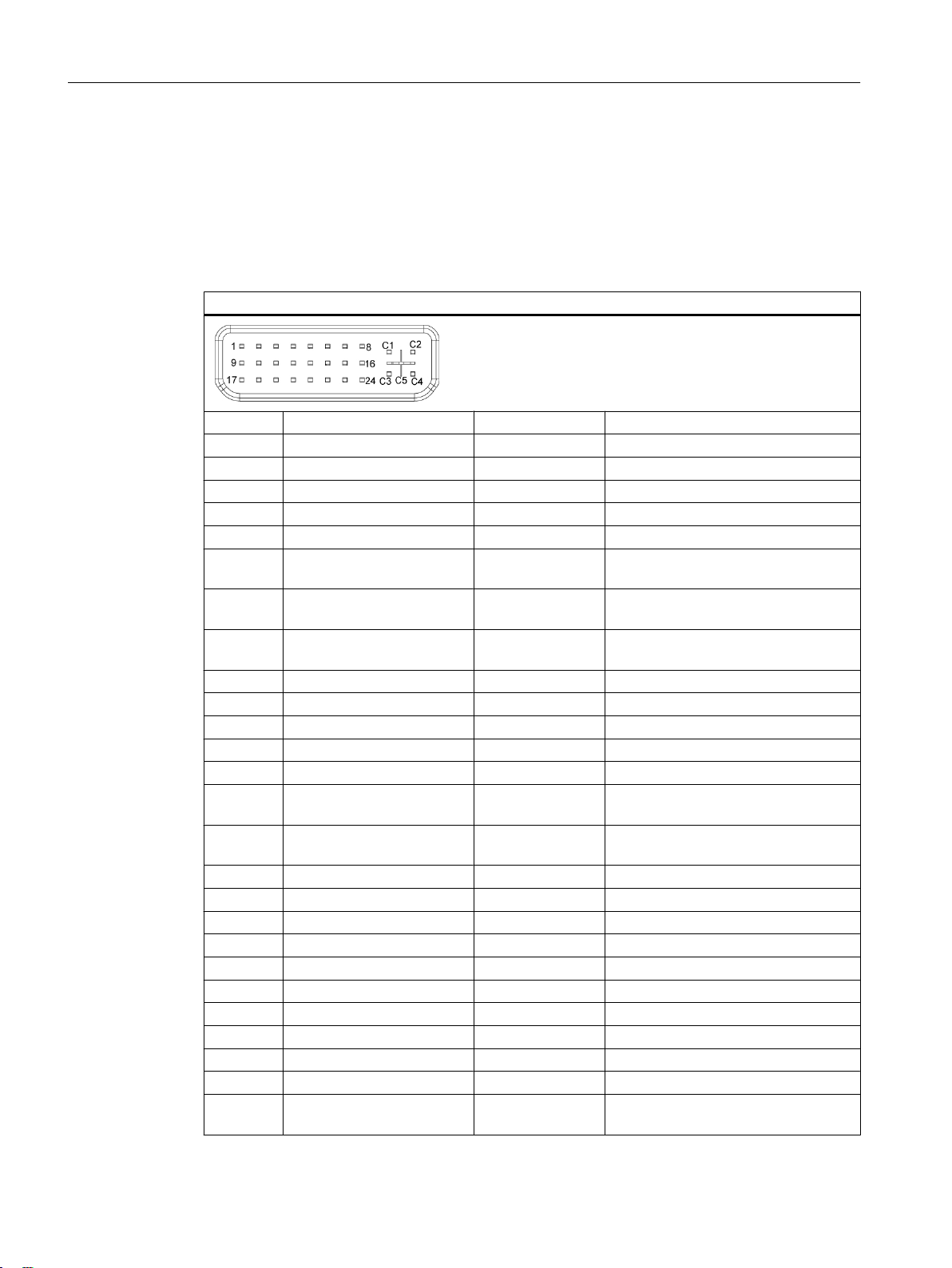

4.5 Overview of the SIMOTION P320-4 interfaces

4.5 Overview of the SIMOTION P320-4 interfaces

The following table provides an overview of the SIMOTION P320-4 interfaces.

Interfaces

Table 4-1

Interface Description Further information

PROFINET Three PROFINET ports with RJ45 socket PROFINET onboard interface (Page 54)

Ethernet 1 x 8-pole RJ45 interface Ethernet RJ45 interface (Page 55)

DVI-I 26-pin socket for connection of a CRT or LCD monitor

USB 3.0 Lower USB channel 0, upper USB channel 1

CFast card Slot for CFast card

COM1 Serial interface

IsoPROFIBUS board

(optional)

Overview of the interfaces

with DVI interface or VGA with DVI/VGA adapter

Lower USB channel 2, upper USB channel 3

50-pin CF socket, types I/II

2 x 9-pin socket IsoPROFIBUS board (optional) (Page 61

V.24

DVI-I interface (Page 56)

USB 3.0 interface (Page 58)

CFast card (Page 59)

Serial interface COM1 (Page 60)

)

SIMOTION P320-4 E / P320-4 S

Manual, 01/2015 53

Page 54

/

('/('

Interfaces

4.6 PROFINET onboard

4.6 PROFINET onboard

Interface assignment

Designation: PROFINET LAN, X3, 3 ports: P1, P2, P3

Type: 8-pin RJ45 socket

PROFINET onboard LAN (X3) interface

Pin no. Short description Meaning Input/output

1 RD+ Receive data

2 RD- Receive data

3 TD+ Send data

1

4, 5

6 TD- Receive data

7, 8

S - Shield -

- LED 1 Lights up green: Link -

- LED 2 Lights up yellow: Activity -

1

Optional product feature

2