Siemens SIMOTION D4 Series, SIMOTION D435, SIMOTION D445, SIMOTION D425 Equipment Manual

SIMOTION D4xx

Equipment Manual

Preface

Introduction

Description

Operator control (hardware)

Interfaces

Technical Data

Dimension drawings

1

2

3

4

5

6

Spare parts/accessories

Appendices

ESD guidelines

7

A

B

12.2004

6AU1900-1AJ32-0BA0

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring to property damage only have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Attention

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Copyright Siemens AG . All rights reserved.

The distribution and duplication of this document or the utiliz ation and transmission of its

contents are not permitted without express written permission. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of a utility

model or design, are reserved.

Siemens AG

Automation and Drives

Postfach 4848, 90327 Nuremberg, Germany

Siemens Aktiengesellschaft 6AU1900-1AJ32-0BA0

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the

hardware and software described. Since variance cannot be precluded entirely, we cannot

guarantee full consistency. However, the information in this publication is reviewed

regularly and any necessary corrections are included in subsequent editions.

Siemens AG 2004

Technical data subject to change

Preface

Contents of manual

This manual describes the SIMOTION D425, D435, and D445 devices.

This document is part of the SIMOTION D documentation package with order number:

6AU1900-1AJ32-0BA0 12.2004 Edition

Scope

This manual is applicable for SIMOTION D425, SIMOTION D435, and SIMOTION D445.

Standards

Contents

The SIMOTION system was developed according to the quality guidelines of ISO 9001.

The following is a description of the purpose and use of the product manual:

• Description

Provides information about the SIMOTION system and its incorporation in the automation

landscape.

• Device Description

Provides information about the structure and architecture of the devices.

• Operator control (hardware)

Provides information about the various operator control and display elements of the devices

as well as the memory concept and Compact Flash Card.

• Interfaces

Provides information about the different interfaces of the devices, their pin assignment, and

possible applications.

• Service and maintenance

Provides information about service and maintenance procedures that must be performed on

the devices.

• Technical Data

• Dimension drawings

• Appendices

Provides information about the various standards and specifications fulfilled by the device.

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

iii

Preface

Contacts

If you have any problems or questions when using this manual, please contact the office

listed on the reply form at the end of this manual.

Hotline and Web addresses

Hotline

If you have any questions, please contact our hotline (worldwide):

• A & D Technical Support: Phone: +49 (180) 50 50 222

• Fax: +49 (180) 50 50 223

• E-mail: ad.support@siemens.com

If you have any questions, suggestions, or corrections regarding the documentation, please

send them to the following fax number or e-mail address:

• Fax: +49 (9131) 98 2176

• E-mail: motioncontrol.docu@erlf.siemens.de

• Fax form: Refer to the reply form at the end of this manual

Additional support

We also offer introductory SIMOTION courses.

Please contact your regional training center or our main training center at D-90027

Nuremberg/Germany, phone +49 (911) 895 3202.

Siemens Internet address

The latest up-to-date information about SIMOTION products can be found in the Internet

under:

General information http://www.siemens.com/simotion

Technical information http://www4.ad.siemens.de/view/cs/en/10805438

D4xx

iv Manual, 12.2004, 6AU1900-1AJ32-0BA0

Preface

Disposal and recycling

Product disposal

SIMOTION D4xx is an environmentally friendly product. It includes the following features:

• In spite of its excellent resistance to fire, the flame-resistant agent in the plastic used for

the housing does not contain halogens.

• Identification of plastic materials in accordance with DIN 54840

• Less material used due to more compact size, fewer components due to integration in

ASICs. SIMOTION D4xxx is recyclable due to its environmentally compatible materials.

For environmentally friendly recycling and appropriate disposal of your old components,

please contact your local Automation & Drives representative. Contact details can be found

in our contacts database on the Internet at:

http://www3.ad.siemens.de/partner/search.asp

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

v

Table of contents

Preface ...................................................................................................................................................... iii

1 Introduction............................................................................................................................................. 1-1

1.1 Hardware components............................................................................................................... 1-1

1.2 Product description of D4xx ....................................................................................................... 1-2

1.3 Software components ................................................................................................................ 1-2

1.4 Product variants ......................................................................................................................... 1-3

1.5 System components .................................................................................................................. 1-5

2 Description.............................................................................................................................................. 2-1

2.1 Safety notes ............................................................................................................................... 2-1

2.2 D435 and D425 .......................................................................................................................... 2-2

2.3 D445........................................................................................................................................... 2-3

2.4 Clock .......................................................................................................................................... 2-4

2.5 Power supply of D425 and D435 ............................................................................................... 2-5

2.6 Power supply of D445................................................................................................................ 2-6

3 Operator control (hardware).................................................................................................................... 3-1

3.1 Operator control and display elements ......................................................................................3-1

3.1.1 LED displays .............................................................................................................................. 3-1

3.1.2 Nameplates................................................................................................................................ 3-5

3.1.3 Mode selector............................................................................................................................. 3-7

3.1.4 Reset button............................................................................................................................... 3-8

3.2 SIMOTION CF............................................................................................................................ 3-9

3.2.1 Properties of the CompactFlash card ........................................................................................ 3-9

3.2.2 CompactFlash slot ................................................................................................................... 3-10

3.2.3 Changing the Compact Flash card .......................................................................................... 3-11

3.2.4 Writing to CompactFlash card.................................................................................................. 3-12

3.3 Memory concept ...................................................................................................................... 3-13

3.3.1 Memory concept of SIMOTION D............................................................................................ 3-13

3.3.2 Persistent data (non-volatile data) ........................................................................................... 3-14

3.3.3 Monitoring persistent data (non-volatile data).......................................................................... 3-14

3.3.4 Power off behavior ................................................................................................................... 3-16

4 Interfaces................................................................................................................................................ 4-1

4.1 Interface overview ...................................................................................................................... 4-1

4.2 DRIVE CLiQ interfaces .............................................................................................................. 4-2

4.2.1 DRIVE CLiQ interfaces .............................................................................................................. 4-2

4.2.2 Use of DRIVE CLiQ interface..................................................................................................... 4-3

4.3 Ethernet interfaces ..................................................................................................................... 4-4

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

vii

Table of contents

4.3.1 Ethernet interfaces X120 and X130 ........................................................................................... 4-4

4.3.2 Use of Ethernet interfaces.......................................................................................................... 4-5

4.4 Digital inputs/outputs.................................................................................................................. 4-6

4.4.1 X122 and X132 digital inputs ..................................................................................................... 4-6

4.4.2 Pin assignment for interfaces X122 and X132........................................................................... 4-8

4.4.3 Technical data for X122 and X132............................................................................................. 4-9

4.4.4 Use of X122 and X123 interfaces ............................................................................................ 4-10

4.5 Power supply............................................................................................................................ 4-11

4.5.1 Power supply X124 .................................................................................................................. 4-11

4.6 PROFIBUS-DP interfaces ........................................................................................................ 4-12

4.6.1 PROFIBUS-DP interfaces X126 and X136 .............................................................................. 4-12

4.6.2 Use of PROFIBUS-DP interfaces ............................................................................................ 4-14

4.7 CompactFlash slot ................................................................................................................... 4-15

4.7.1 Compact Flash slot .................................................................................................................. 4-15

4.8 Measuring sockets ................................................................................................................... 4-15

4.8.1 Measuring sockets X131 - X134 .............................................................................................. 4-15

5 Technical Data........................................................................................................................................ 5-1

5.1 Technical data for D435 and D425 ............................................................................................ 5-1

5.2 Technical data for D445 ............................................................................................................. 5-2

6 Dimension drawings ............................................................................................................................... 6-1

6.1 Dimension drawing of D435 and D425 ...................................................................................... 6-1

6.2 Dimension drawing of D445 ....................................................................................................... 6-2

7 Spare parts/accessories ......................................................................................................................... 7-1

7.1 Fan/battery module .................................................................................................................... 7-1

7.1.1 Cooling the SIMOTION D4xx..................................................................................................... 7-1

7.1.2 Fan/battery module assembly.................................................................................................... 7-2

7.1.3 Battery replacement in the fan/battery module. ......................................................................... 7-3

7.2 Supplemental system components ............................................................................................ 7-4

7.3 Terminal board TB30 ................................................................................................................. 7-5

7.4 Terminal module TM31 .............................................................................................................. 7-5

7.5 Terminal module TM41 .............................................................................................................. 7-6

7.6 Terminal modules TM15 and TM17 High Feature ..................................................................... 7-7

7.7 CX32 module ............................................................................................................................. 7-8

A Appendices.............................................................................................................................................A-1

A.1 Standards................................................................................................................................... A-1

A.2 Information on insulation tests, safety class, and degree of protection .....................................A-1

A.3 Rated voltage for operation of the D4xx ....................................................................................A-2

A.4 Safety of electronic controllers...................................................................................................A-3

A.5 EC Declaration of Conformity.....................................................................................................A-4

B ESD guidelines .......................................................................................................................................B-1

B.1 Electrostatically sensitive modules ............................................................................................ B-1

B.2 Electrostatic accumulation on individuals ..................................................................................B-2

D4xx

viii Manual, 12.2004, 6AU1900-1AJ32-0BA0

Table of contents

B.3 Basic measures for protection against discharge of static electricity ........................................B-3

Index

Tables

Table 1-1

Product variants ......................................................................................................................... 1-3

Table 1-2 Central components................................................................................................................... 1-5

Table 1-3 System components .................................................................................................................. 1-5

Table 1-4 Distributed I/O systems.............................................................................................................. 1-6

Table 1-5 Optional components for the control unit: .................................................................................. 1-6

Table 1-6 Additional components that can be connected to the control unit ............................................. 1-7

Table 2-1 Clock features ............................................................................................................................ 2-4

Table 2-2 Input voltage specification.......................................................................................................... 2-5

Table 2-3 Input voltage specification.......................................................................................................... 2-6

Table 3-1 Meaning of LED states............................................................................................................... 3-2

Table 3-2 Selector positions and their meaning......................................................................................... 3-7

Table 3-3 Mode selector settings ............................................................................................................... 3-8

Table 3-4 Alarm messages of the diagnostics buffer............................................................................... 3-15

Table 4-1 Overview of available external interfaces .................................................................................. 4-1

Table 4-2 Overview of interfaces that cannot be used for SIMOTION D................................................... 4-2

Table 4-3 X100 - X103 or X100 – X105 .....................................................................................................4-2

Table 4-4 DRIVE CLiQ interface (X100 - X103 or X100 – X105) .............................................................. 4-2

Table 4-5 X120 and X130 .......................................................................................................................... 4-4

Table 4-6 Ethernet interfaces (X120, X130, X127) .................................................................................... 4-4

Table 4-7 Interfaces X122 and X132 ......................................................................................................... 4-6

Table 4-8 X122 Digital inputs/outputs ........................................................................................................ 4-8

Table 4-9 Technical data of digital inputs X122/X132................................................................................ 4-9

Table 4-10 Technical data of the digital inputs/output of X122/X132 ........................................................ 4-10

Table 4-11 Interface X124.......................................................................................................................... 4-11

Table 4-12 Power supply X124 .................................................................................................................. 4-11

Table 4-13 Interfaces X126 and X136 .......................................................................................................4-12

Table 4-14 PROFIBUS-DP X126 interface ................................................................................................ 4-13

Table 4-15 PROFIBUS-DP X136 interface ................................................................................................ 4-13

Table 5-1 Memories for user data and their memory size ......................................................................... 5-1

Table 5-2 Electrical connection values....................................................................................................... 5-1

Table 5-3 Dimension and weight of D435 and D425 ................................................................................. 5-1

Table 5-4 Environmental requirements ...................................................................................................... 5-2

Table 5-5 Memories for user data and their memory size ......................................................................... 5-2

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

ix

Table of contents

Table 5-6 Electrical connection values....................................................................................................... 5-3

Table 5-7 Dimensions and weight of a D445 ............................................................................................. 5-3

Table 5-8 Environmental requirements ...................................................................................................... 5-3

Table 7-1 Overview of TB30 interface........................................................................................................ 7-5

Table 7-2 Interface overview of the TM31.................................................................................................. 7-5

Table 7-3 TM41 interface overview ............................................................................................................ 7-6

Table A-1 Electromagnetic compatibility (EMC) .........................................................................................A-1

Table A-2 Test voltages..............................................................................................................................A-2

Table A-3 Rated voltage for the control unit ............................................................................................... A-2

D4xx

x Manual, 12.2004, 6AU1900-1AJ32-0BA0

Introduction

1.1 Hardware components

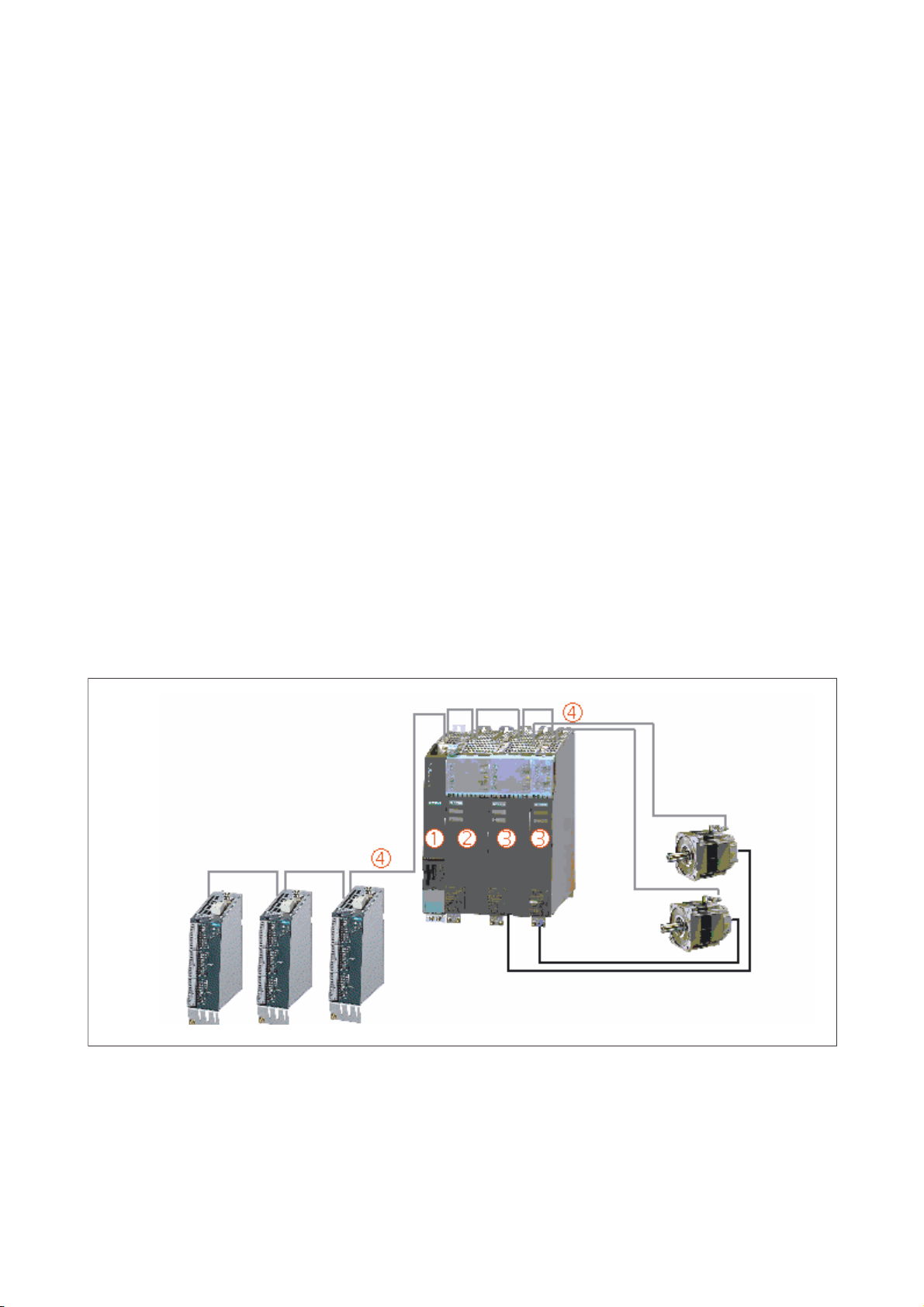

SIMOTION runtime module and SINAMICS drive module

As the central hardware, SIMOTION D uses the SIMOTION D4xx as a control unit consisting

of the SIMOTION runtime module and the SINAMICS firmware. The control unit uses the

SINAMICS Integrated drive with various SINAMICS S120 drive modules (line and motor

modules) to perform open-loop and closed-loop control of the axis assembly. In addition, a

series of other SINAMICS 120 components such as SMC encoder systems or terminal

modules can be connected via DRIVE-CLiQ. Likewise, the functionality can be expanded

with distributed I/O via PROFIBUS.

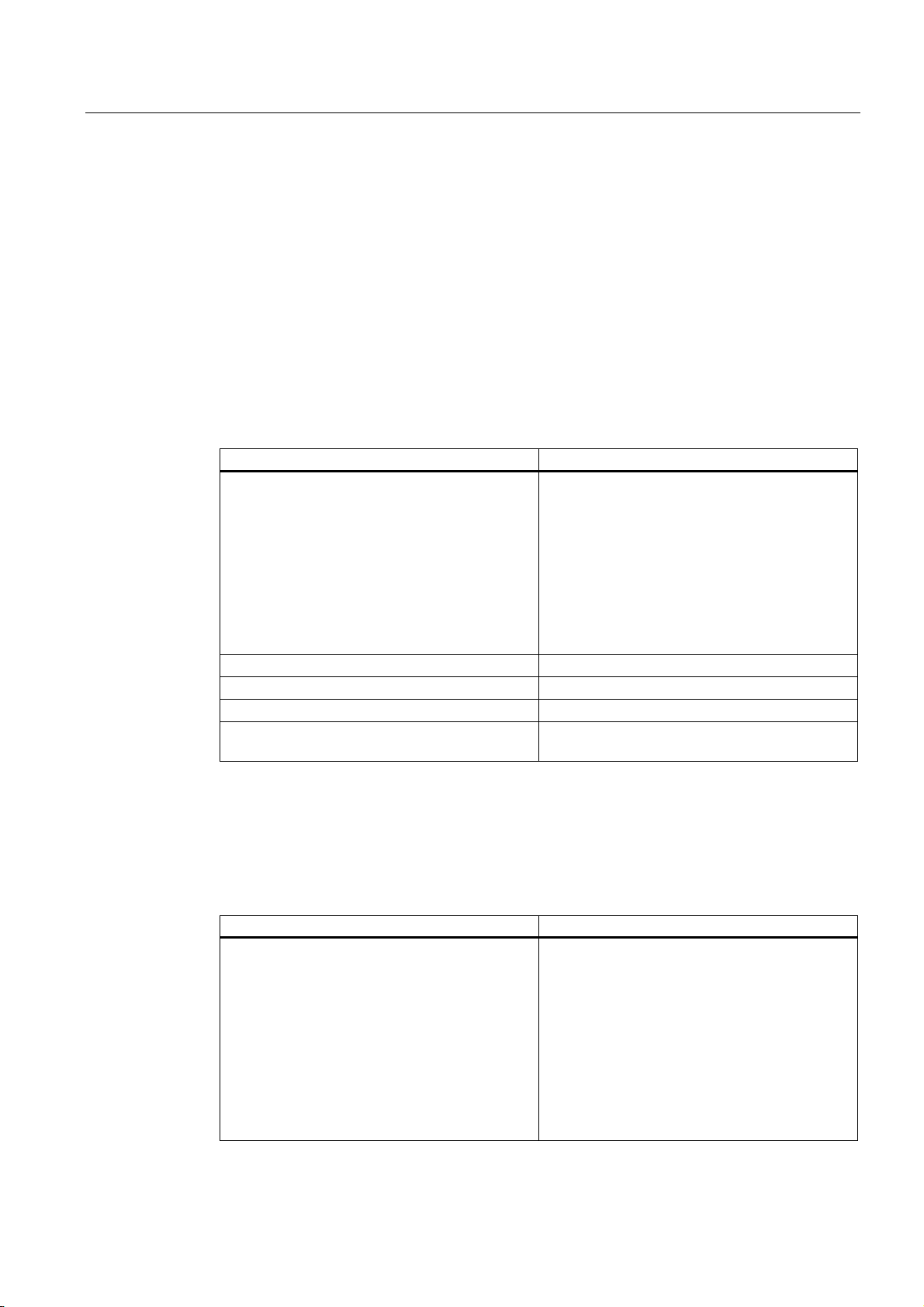

SIMOTION D axis assembly

This illustration shows a typical SIMOTION D axis assembly.

1

'5,9(&/L4

'5,9(&/L4,2

Figure 1-1 Example of a SIMOTION D4xx axis assembly

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

'5,9(&/L4

3RZHU

1-1

Introduction

1.2 Product description of D4xx

In general, a SIMOTION D axis assembly consists of the following elements:

• SIMOTION D (control unit) (1)

This unit contains the programmable runtime system of SIMOTION and the drive software

of SINAMICS S120. As a general principle, SIMOTION D is capable of controlling multiple

axes/drives.

• SINAMICS infeed (line module) (2)

This module generates a DC link from the supply system.

• SINAMICS power units (motor modules) (3)

These modules are used to control motors.

• DRIVE-CLiQ components (4)

In SINAMICS S120/SIMOTION D, the individual components of the drive system

communicate with each other via DRIVE-CLiQ. In addition to power components, you can

link encoder systems and special DRIVE-CLiQ I/O devices via DRIVE-CLiQ.

1.2 Product description of D4xx

Design of SIMOTION D4xx

SIMOTION D is the drive-based variant of the SIMOTION Motion Control System based on

the new SINAMICS S120 family of drives. With SIMOTION D, the SIMOTION motion control

functionalities and the SINAMICS drive software run on a SINAMICS closed-loop control

hardware device.

As with SINAMICS S120, SIMOTION D subscribes to the Totally Integrated Automation

(TIA) concept, thus providing a comprehensive set of automation blocks.

1.3 Software components

SIMOTION runtime system and SINAMICS closed-loop drive control

The basic functionality of SIMOTION D is furnished with a Compact Flash card and includes

the following:

SIMOTION runtime system including the following functions:

• User-programmable runtime system (IEC 61131)

• Various runtime levels

• Logic and arithmetic functionality

• Communication functions

Motion control functions are available in the form of optional technology packages.

D4xx

1-2 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Introduction

1.4 Product variants

SINAMICS S120 closed-loop drive control including the following functions:

• Closed-loop current and torque control

• Closed-loop speed control

• Regulated infeed

1.4 Product variants

SIMOTION D

There are several variants of SIMOTION D (differing in performance and number of axes

that can be operated):

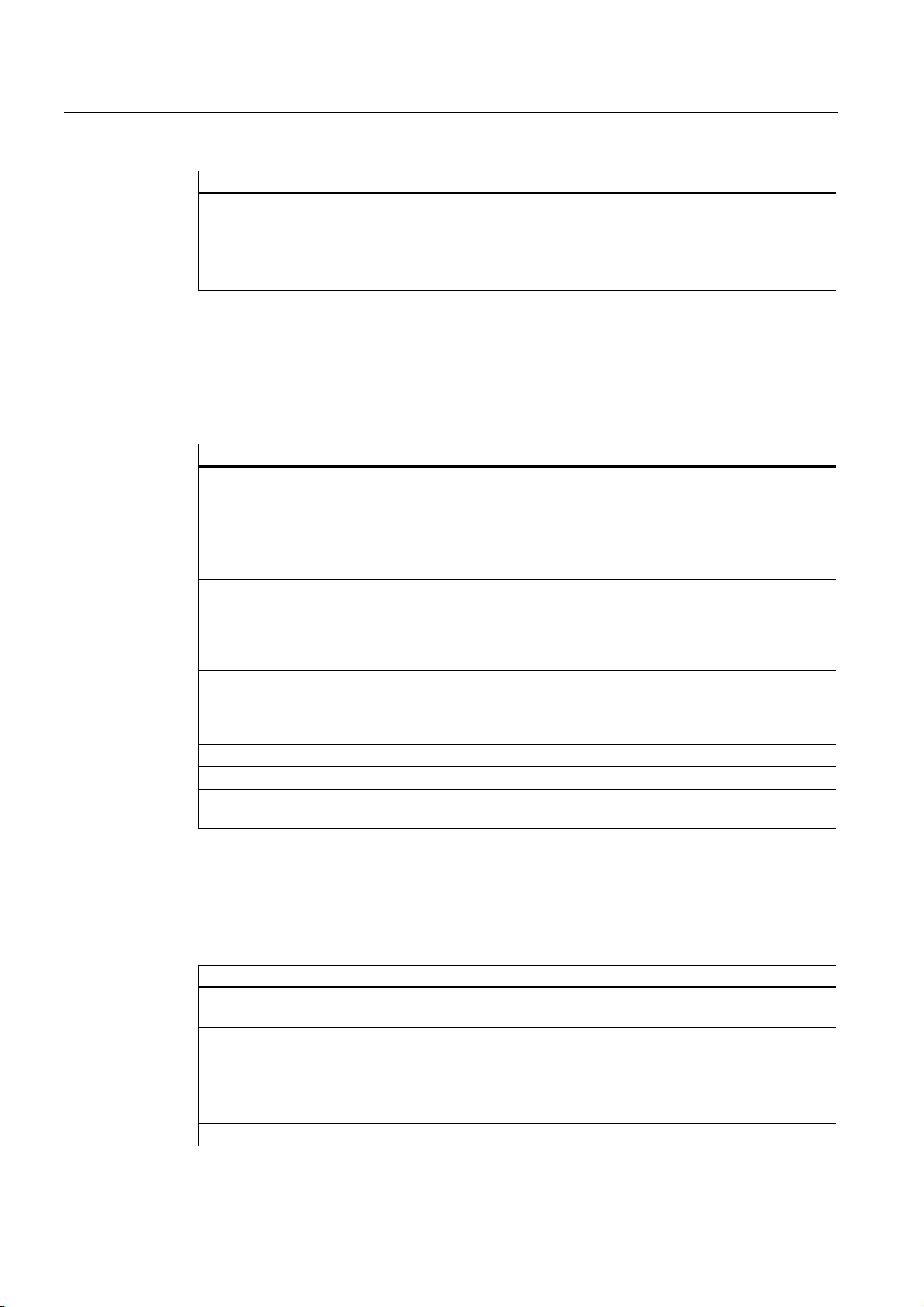

The following table shows the different SIMOTION D versions.

Table 1-1 Product variants

Feature SIMOTION D435 SIMOTION D435 SIMOTION D445

DRIVE CLiQ ports 4 4 6

Axes Up to 4 Up to 16 Up to 64

Fan/battery module Optional Optional Required

Caution

For a SIMOTION D445, a fan/battery module is required for operation.

For a SIMOTION D435 with MLFB 6AU1 435-0AA00-0AA0, a fan/battery module is required

at an ambient temperature of 43°C or higher.

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

1-3

Introduction

1.4 Product variants

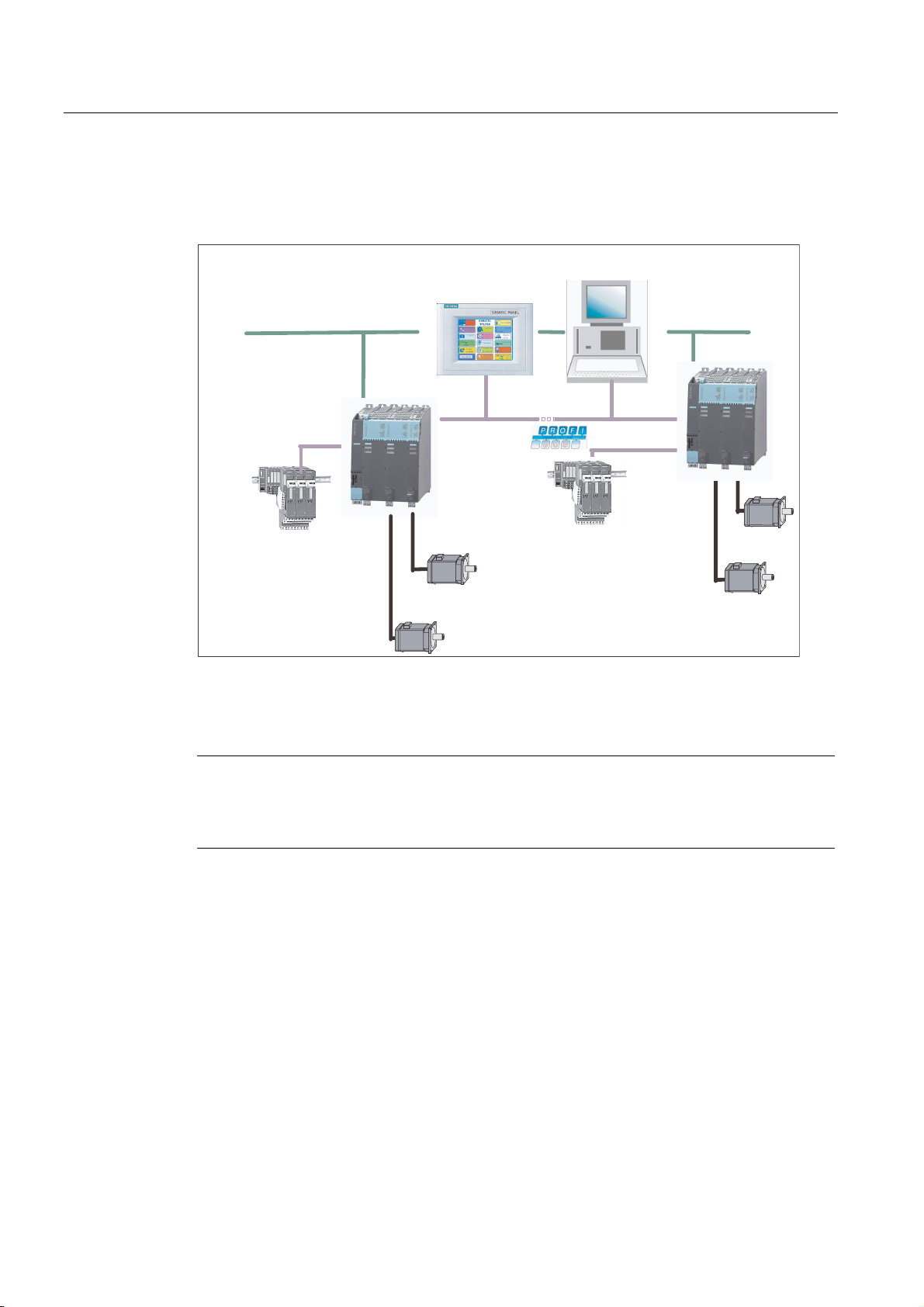

The following figure shows a possible system configuration with a SIMOTION D435.

6,027,216&287

+0,

(WKHUQHW

'LVWULEXWHG,2

'LVWULEXWHG,2

Figure 1-2 System configuration using SIMOTION D with two axes each

(WKHUQHW

Note

In order to cover all variants of SIMOTION D, the product will be referred to as "D4xx".

Specific product designations will be used for information that applies only to one product

version, e.g., D435.

D4xx

1-4 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Introduction

g

1.5 System components

1.5 System components

Introduction

The most important components of the system and their functions are shown below.

Table 1-2 Central components

Component Function

Control unit ... The central unit in the axis assembly

You can use the integrated fast digital I/O as:

• Homing inputs

• Inputs for measuring inputs

• User-addressable process inputs/outputs

The measuring sockets can output any analog

signals.

The DRIVE CLiQ interfaces permit a fast

connection to the SINAMICS drive components.

Line module (SINAMICS S120) ... Generates a DC link from the supply system

Motor module (SINAMICS S120) ... Used to control motors

CX32 ... Enables connection of additional axes

Power supply ... Provides the electronics power supply for

SIMOTION D, e.g., SITOP

System components

The control unit communicates with various components in the automation landscape using

two PROFIBUS-DP and two Ethernet interfaces.

Table 1-3 System components

Component Function

Control unit ... Central motion control module

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

The control unit communicates via two

PROFIBUS-DP interfaces with the following:

• S7 controllers with PROFIBUS interface

• SIMATIC HMI devices

• Other drives, e.g., SINAMICS S120

• Other control units

• Programming devices (PG/PC)

The control unit can communicate with the

followin

components or be embedded in an

1-5

Introduction

1.5 System components

Component Function

automation landscape by means of Ethernet

interfaces:

• Programming devices (PGs/PCs)

• SIMATIC HMI devices

• Other devices via UDP

Distributed I/O systems

The control unit can communicate via two PROFIBUS-DP interfaces with the following

distributed I/O systems:

Table 1-4 Distributed I/O systems

Distributed I/O Function

SIMATIC ET 200M Modular I/O system for control cabinet installation

and high channel density

SIMATIC ET 200S Highly modular I/O system for control cabinet

installation including motor starters, safety

technology, and individual grouping of the load

groups

SIMATIC ET 200X Modular I/O system with IP 65/67 degree of

protection for machine-related use outside a

control cabinet including motor starters and

pneumatic modules as well as DESINA and

ECOFAST-compliant modules

SIMATIC ET 200eco I/O system with IP 67 degree of protection for

machine-related use without a control cabinet

with flexible and fast ECOFAST or M12

connection methods

Drive units Also as an isochronous slave on PROFIBUS-DP

Other PROFIBUS I/O

ADI4 For the connection of drives with analog ±10 V

setpoint interface

Optional components

The following components enable an expansion of the functionality.

Table 1-5 Optional components for the control unit:

Component Function

Terminal board TB30 ... Enables a terminal expansion (additional

analog and digital I/O)

Terminal module TM31 ... Enables a terminal expansion via DRIVE CLiQ

(additional analog and digital I/O)

Terminal module TM41 ... ... Enables a terminal expansion and encoder

simulation (additional analog and digital I/O) via

DRIVE CLiQ.

Terminal modules TM15 and TM17 High Feature The terminal modules TM15 and TM17 High

D4xx

1-6 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Introduction

1.5 System components

Component Function

Feature are used to implement measuring inputs

and cam outputs. In addition, these terminal

modules provide drive-related digital inputs and

outputs with short signal delay times.

Sensor module cabinets (SMC) ... Enables acquisition of encoder data from

connected motors via DRIVE CLiQ

Operator input and monitoring components

Table 1-6 Additional components that can be connected to the control unit

Component Function

Programming device (PG/PC) ... configures, assigns parameters, programs, and

tests

SIMATIC HMI device ... used for operating and monitoring functions.

This is not an essential requirement for the

operation of a control unit.

Drive units ... convert speed setpoints into signals for

controlling the motor and supply the power

required to operate the motors.

DRIVE CLiQ technology

DRIVE CLiQ (DRIVE Component Link with IQ) is a communication system used to connect

the control unit with the various components of the SINAMICS S120 product family, such as

line modules, motor modules, and encoders.

All components are connected via DRIVE CLiQ.

DRIVE CLiQ offers the following advantages:

• Independent expansion of components possible

• Automatic detection of components by the control unit

• Standardized interfaces to all components

• Uniform diagnostics down to the components

• Complete service down to the components

• Simple mechanical handling

Additional references

You can find detailed information about components in the SINAMICS S120 family of

products in the SINAMICS S120 equipment manual.

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

1-7

Introduction

1.5 System components

Approved components for SIMOTION D

Note

Modules and devices approved for SIMOTION D are listed in the SIMOTION Motion Control

System, PM 10 Catalog and the "SINAMICS Catalog."

For catalog order numbers, refer to the list of references.

Note

Note that not all modules in the ET 200 I/O family are approved for SIMOTION. Moreover,

system-related functional differences can come into play when these I/O or I/O systems are

used on SIMOTION vs. on SIMATIC. For example, special process-control functions (e.g.

insertion and removal under voltage) are not supported by SIMOTION for the ET 200M

distributed I/O system.

A detailed, regularly updated list of the I/O modules approved for use with SIMOTION, as

well as notes on their use, can be found on the Internet at:

http://www4.ad.siemens.de/view/cs/en/11886029

Besides the I/O modules released for use with SIMOTION, in principle, any certified standard

slave that supports cyclic data exchange (DP V0) and, if required, acyclic data exchange

(DP V1) can be connected to SIMOTION.

These modules are integrated via the GSD file of the device's manufacturer.

Note

Please note that in individual cases further boundary conditions must be fulfilled in order to

integrate a standard slave into SIMOTION. Some modules need "driver modules", e.g. in the

form of function blocks, which make integration possible or much easier.

For modules approved for use with SIMOTION (e.g. S7-300 module FM 350-1, etc.) these

driver blocks are part of the Function Library.

D4xx

1-8 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Description

2.1 Safety notes

Note safety information

Note the following safety information when working with the control unit and its components.

Caution

An option board may only be inserted and removed when the control unit and option board

are disconnected from the power supply.

Notice

The 80 mm clearances above and below the components must be observed. The unit

protects itself from overheating by shutting down.

2

Caution

The Compact Flash card may only be inserted or removed when the control unit is

disconnected from the power supply.

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

2-1

Description

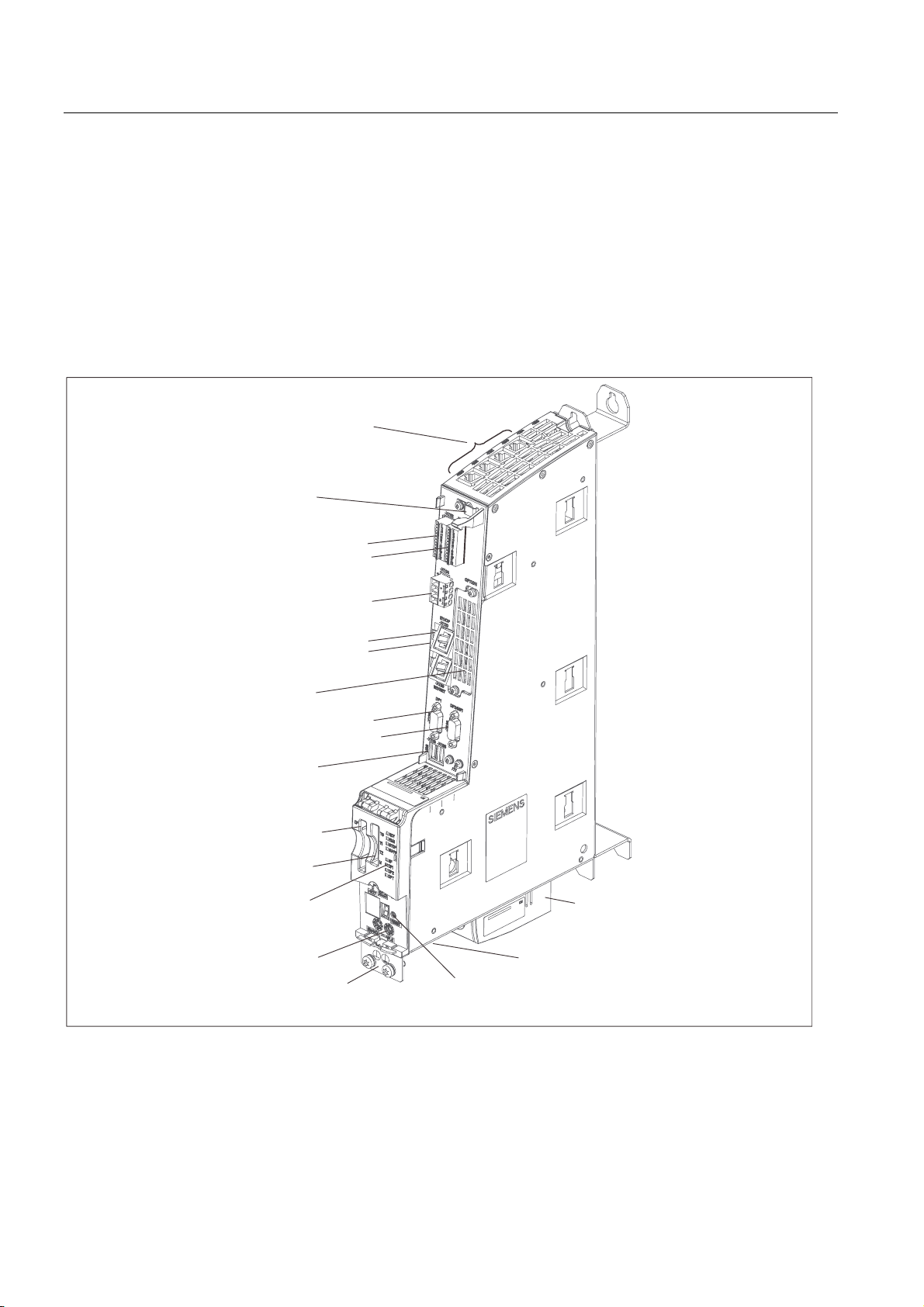

2.2 D435 and D425

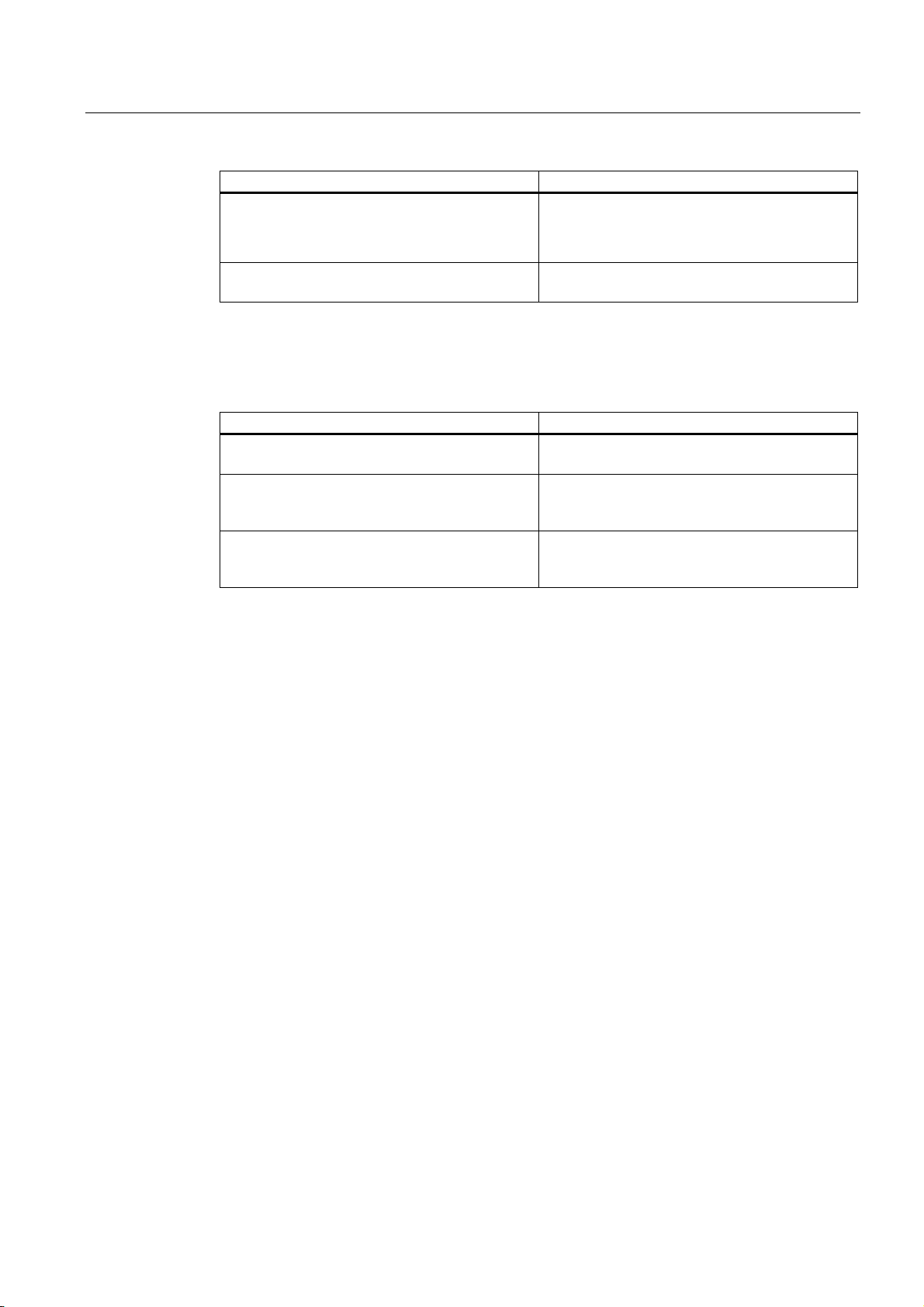

2.2 D435 and D425

Device image

The following figure shows a control unit with its interfaces and front panel components (fault

and status displays).

;;

'5,9(&/L4LQWHUIDFHV

6KLHOGFRQQHFWLRQ

'LJLWDOLQSXWVBRXWSXWV

(OHFWURQLFSRZHUVXSSO\

(WKHUQHWFRQQHFWLRQV

2SWLRQVORW

352),%86'3

352),%86'303, ;

86%[QRIXQFWLRQ

&RPSDFW)ODVKVORW

;

0HDVXULQJVRFNHWV

;;

/('GLVSOD\

0RGHVHOHFWRU

;

;

;

;

;

;

3RWHQWLDOFRQQHFWLRQ

5(6(7EXWWRQ

;

)DQEDWWHU\PRGXOHRSWLRQDO

;ERWWRP56QRIXQFWLRQ

Figure 2-1 Position of interfaces and front panel components

D4xx

2-2 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Description

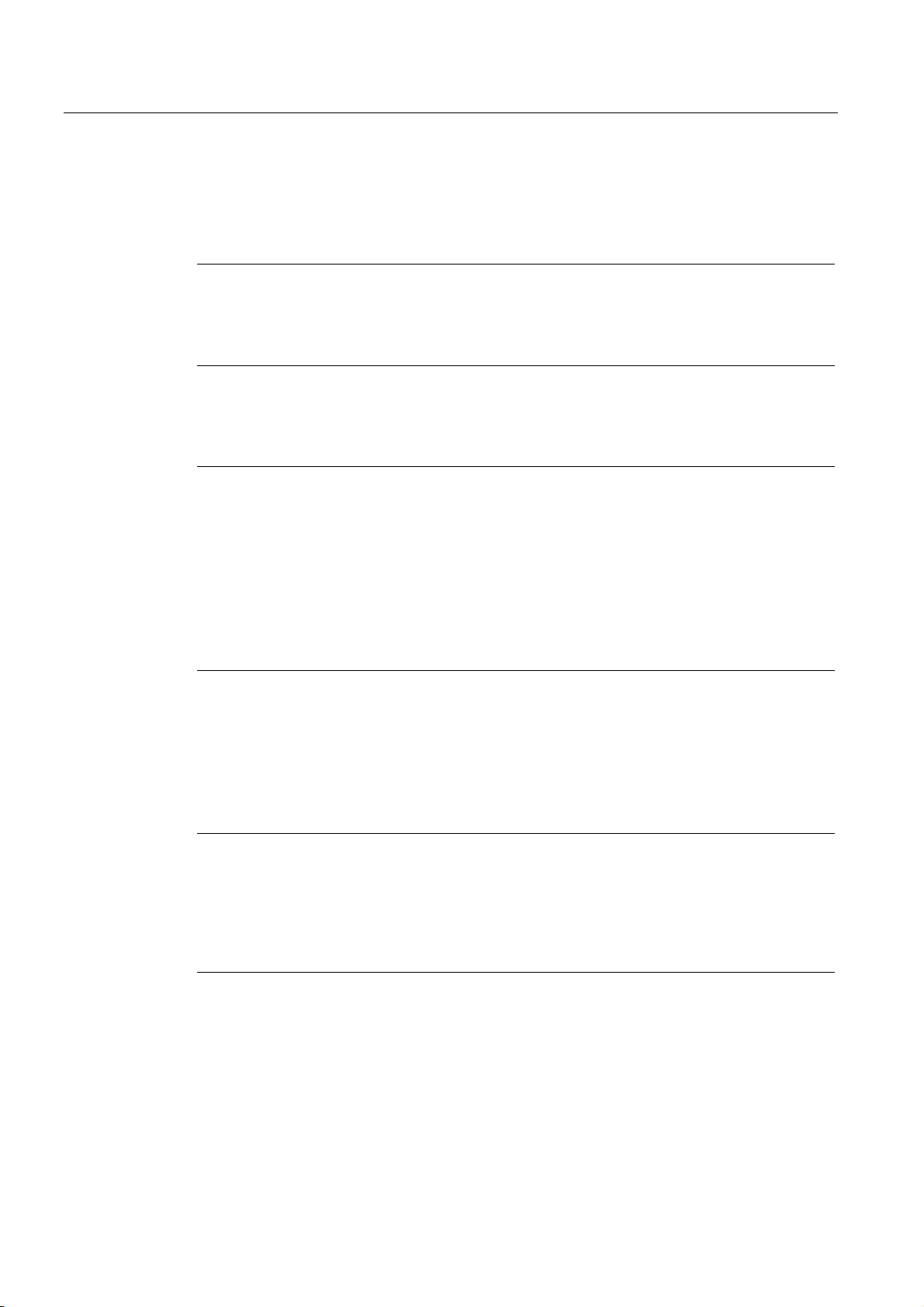

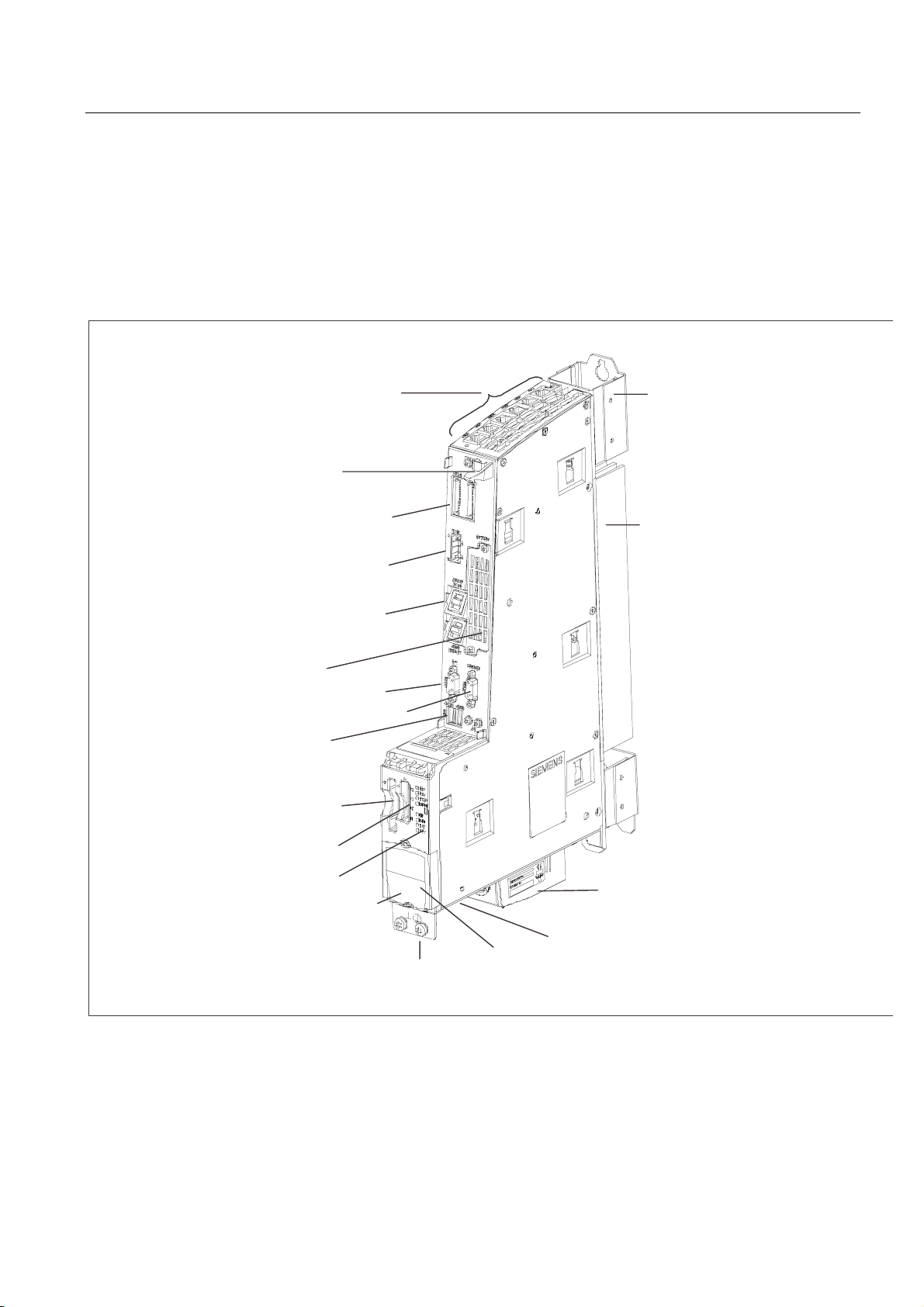

2.3 D445

2.3 D445

Device image

The following figure shows the control unit with its interfaces and front panel components

(fault and status displays).

'5,9(&/L4LQWHUIDFHV

;;

6KLHOG&RQQHFWLRQ

'LJLWDOLQSXWVRXWSXWV ;

(OHFWURQLFSRZHUVXSSO\

(WKHUQHWFRQQHFWLRQV

2SWLRQVORW

352),%86'3

352),%86'303,

86%[QRIXQFWLRQ

&RPSDFW)ODVKVORW

;

0HDVXULQJVRFNHWV

;;

/('GLVSOD\

0RGHVHOHFWRU

EHKLQGFRYHU

;

;

;

;

;

;

6SDFHU

&RROLQJULEV

;

)DQEDWWHU\PRGXOH

;ERWWRP56QRIXQFWLRQ

3RWHQWLDOFRQQHFWLRQ

Figure 2-2 Interfaces and display elements

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

5(6(7EXWWRQEHKLQGFRYHU

2-3

Description

2.4 Clock

Caution

This control unit must be operated with a fan/battery module for heat dissipation. Without a

fan/battery module, the control unit will not start up and cannot be commissioned.

2.4 Clock

Features of real-time clock

The following table contains the features and functions of the control unit clock.

Table 2-1 Clock features

Features Meaning

Type Hardware clock (integrated "realtime clock")

Default setting when delivered DT#1994-01-01-00:00:00

Accuracy

With supply voltage on

0 to 55° C

With supply voltage off

25° C

-20° C to 70° C

Backup time Typically 5 days (at 0 to 25° C)

Charging time 1 hr

Max. deviation per day:

±9 s

±2 s

+2 s to -9 s

With power OFF

In the power OFF state, the control unit clock continues to run during the the backup time

(with the exception of the software clock). The buffer is recharged in the power ON state.

An error message is output if the backup function is defective. With power ON, the clock

resumes at the time set at the factory.

When the control unit is reset to the factory settings, the clock is also reset to the "factory

default setting."

D4xx

2-4 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Description

2.5 Power supply of D425 and D435

2.5 Power supply of D425 and D435

External 24 V power supply

Power is supplied to the control unit by an external 24 V power supply (e.g., SITOP).

Table 2-2 Input voltage specification

Input voltage Typical power

Minimum input voltage 20,4 V 0.7 A 9.8 A

Nominal Input voltage 24 V 0.6 A 8.4 A

Maximum input voltage 28,8 V 0.5 A 7.0 A

Additional references

Recommended power supply units and tables for calculating power consumption for the

assembly with SINAMICS S120 modules can be found in the section on Control-Cabinet

Construction and EMC - Booksize in the SINAMICS S120 Booksize Power Units manual.

Note

A primary-side voltage dip for 20 ms must not cause the voltage on the secondary side

(24 V) to fall below the minimum permissible input voltage to the control unit.

consumption

Maximum power

consumption

D4xx

Manual, 12.2004, 6AU1900-1AJ32-0BA0

2-5

Description

2.6 Power supply of D445

2.6 Power supply of D445

External 24 V power supply

Power is supplied to this control unit by an external 24 V power supply (e.g., SITOP).

Table 2-3 Input voltage specification

Input voltage Typical power

Minimum input voltage 20,4 V 2.35 A 10.6 A

Nominal Input voltage 24 V 2.0 A 9.0 A

Maximum input voltage 28,8 V 1.67 A 7.5 A

Additional references

Recommended power supply units and tables for calculating power consumption for the

assembly with SINAMICS S120 modules can be found in the section on Control-Cabinet

Construction and EMC - Booksize in the SINAMICS S120 Booksize Power Units manual.

Note

A primary-side voltage dip for 20 ms must not cause the voltage on the secondary side

(24 V) to fall below the minimum permissible input voltage to the control unit.

consumption

Maximum power

consumption

D4xx

2-6 Manual, 12.2004, 6AU1900-1AJ32-0BA0

Loading...

Loading...