Page 1

SIMOTION

D410

Manual

Preface

Description

Operation (hardware)

Interfaces

Assembling

Connecting

Technical data

1

2

3

4

5

6

Spare parts/Accessories

Standards and approvals

ESD directives

Appendix

7

A

B

C

Valid for SIMOTION D410 DP and D410 PN

03/2007 Edition

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended by

Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.:

Ⓟ 03/2007

Copyright © Siemens AG 2007.

Technical data subject to change

Page 3

Preface

Equipment Manual contents

This document is part of the SIMOTION D4xx Programming documentation package,

Version 03/2007.

The Manual describes the SIMOTION devices D410 DP and D410 PN.

Information in this Manual

The following is a description of the purpose and use of the equipment Manual:

• Description

This chapter provides information on the SIMOTION System and how it integrates into

the information landscape.

• Operator Control (hardware)

This chapter describes the operating elements and how to operate them.

• Dimensional diagrams

This chapter contains the SIMOTION D410 dimensional diagrams.

• Interfaces

This section provides information on the interfaces, pin assignments and application

options.

• Installation

This section explains how you configure a mechanical layout and install the

SIMOTION D410 in a control cabinet.

• Connecting

This chapter describes how to connect and network the SIMOTION D410.

• Technical data

This chapter describes the properties and features of the SIMOTION D410.

• Spare Parts/Accessories

This chapter provides information on accessories and spare parts for the

SIMOTION D410.

• Appendix

D410

Manual, 03/2007 Edition

This section provides information on the various standards and specifications that the

device complies with.

• Index to locate information

3

Page 4

Preface

SIMOTION Documentation

An overview of the SIMOTION documentation can be found in a separate list of references.

This documentation is included as electronic documentation with the supplied

SIMOTION SCOUT.

The SIMOTION documentation consists of 9 documentation packages containing

approximately 60 SIMOTION documents and documents on other products (e.g.

SINAMICS).

The following documentation packages are available for SIMOTION V4.1:

• SIMOTION Engineering System

• SIMOTION System and Function Descriptions

• SIMOTION Diagnostics

• SIMOTION Programming

• SIMOTION Programming - References

• SIMOTION C2xx

• SIMOTION P350

• SIMOTION D4xx

• SIMOTION Supplementary Documentation

Hotline and Internet addresses

If you have any technical questions, please contact our hotline (worldwide):

A&D Technical Support:

• Phone: +49 (180) 50 50 222

• Fax: +49 (180) 50 50 223

• E–mail: adsupport@siemens.com

• Internet: http://www.siemens.de/automation/support-request

If you have any questions, suggestions, or corrections regarding the documentation, please

fax or e-mail them to:

• Fax: +49 (9131) 98 63315

• E–mail: docu.motioncontrol@siemens.com

Siemens Internet address

The latest information about SIMOTION products, product support, and FAQs can be found

on the Internet at:

• General information:

– http://www.siemens.de/simotion (German)

– http://www.siemens.com/simotion (international)

• Product support:

– http://support.automation.siemens.com/WW/view/en/10805436

D410

4 Manual, 03/2007 Edition

Page 5

Preface

Additional support

We also offer introductory courses to help you familiarize yourself with SIMOTION.

Please contact your regional training center or our main training center at D-90027

Nuremberg, phone +49 (911) 895 3202.

Disposal and recycling

SIMOTION D410 is an environmentally friendly product! It includes the following features:

• In spite of its excellent resistance to fire, the flame-resistant agent in the plastic used for

the housing does not contain halogens.

• Identification of plastic materials in accordance with DIN 54840

• Less material used because the unit is smaller and with fewer components thanks to

integration in ASICs

SIMOTION D410 can be recycled because it is made with low-polluting materials.

For state-of-the art environmentally friendly recycling and disposal of your old modules,

contact your Siemens representative. To locate your representative, visit us online at:

http://www.ad.siemens.com/partner

D410

Manual, 03/2007 Edition

5

Page 6

Page 7

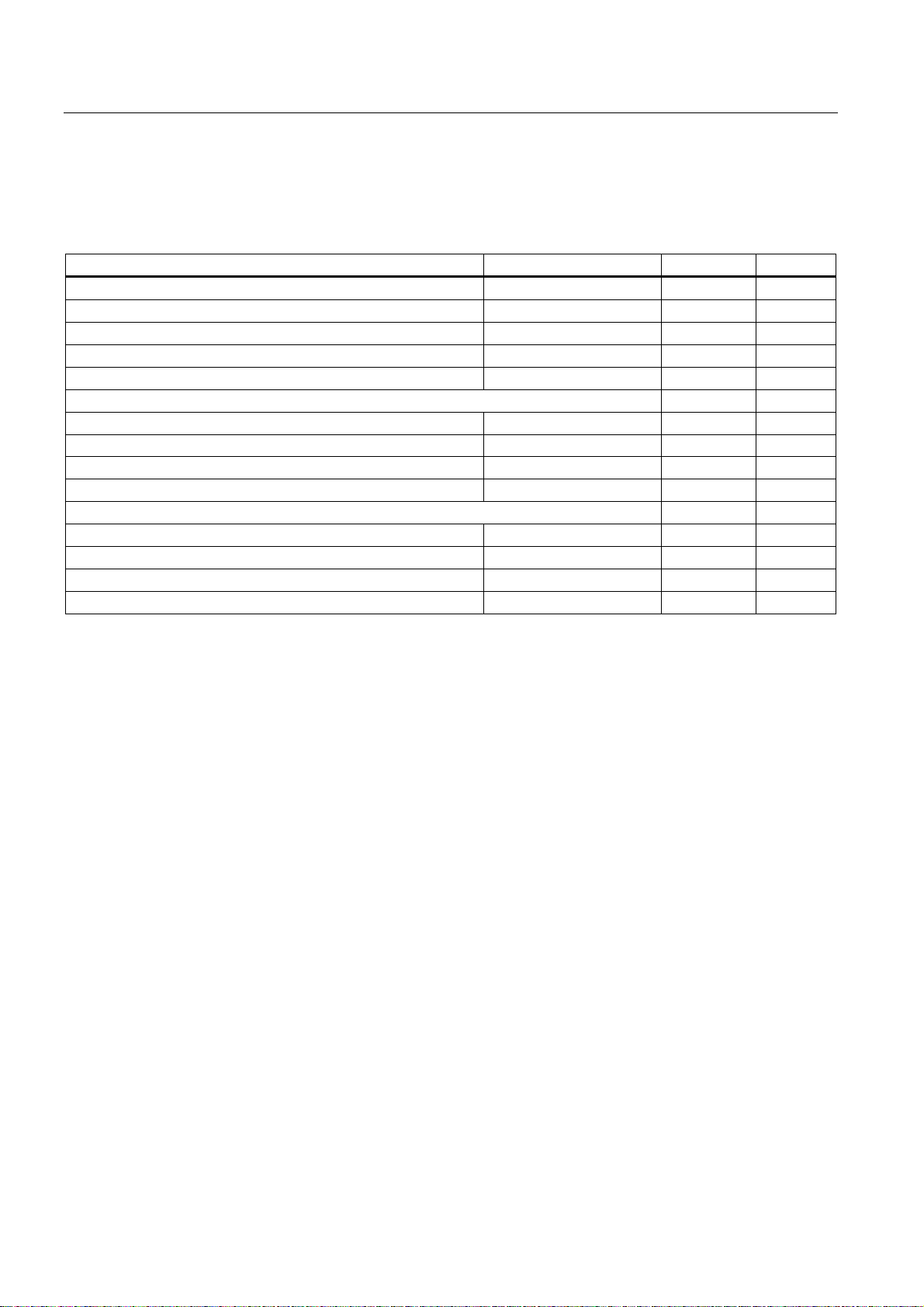

Table of contents

Preface ...................................................................................................................................................... 3

1 Description............................................................................................................................................... 11

1.1 System overview ..........................................................................................................................11

1.2 System components ....................................................................................................................13

1.3 SIMOTION D410 DP display .......................................................................................................17

1.4 SIMOTION D410 PN display .......................................................................................................20

1.5 Safety information ........................................................................................................................22

2 Operation (hardware)............................................................................................................................... 23

2.1 Overview of operator controls and indicators ..............................................................................23

2.2 Operator controls .........................................................................................................................24

2.2.1 Mode selector switch ...................................................................................................................24

2.2.2 SIMOTION CompactFlash card...................................................................................................25

2.3 Error and status indicators ...........................................................................................................26

3 Interfaces................................................................................................................................................. 27

3.1 Overview of interfaces .................................................................................................................27

3.2 Digital inputs/outputs....................................................................................................................28

3.3 DRIVE-CLiQ interface..................................................................................................................32

3.4 PROFIBUS DP interface (SIMOTION D410 DP only) .................................................................35

3.5 PROFINET interface (SIMOTION D410 PN only) .......................................................................37

3.6 HTL/TTL encoder interface ..........................................................................................................38

3.7 EP terminals/temperature sensor connection..............................................................................39

3.8 Power supply................................................................................................................................40

3.9 Measuring sockets .......................................................................................................................42

3.10 Power Module Interface ...............................................................................................................42

4 Assembling.............................................................................................................................................. 43

4.1 General requirements ..................................................................................................................43

4.2 SIMOTION D410 mounted on the power module..................

......................................................43

4.3 Mounting SIMOTION D410 on the mounting plate......................................................................46

5 Connecting .............................................................................................................................................. 47

5.1 Overview ......................................................................................................................................47

5.2 General rules for operating the SIMOTION D410........................................................................48

5.3 Overview of SIMOTION D410 connections .................................................................................50

D410

Manual, 03/2007 Edition

7

Page 8

Table of contents

5.4 Connecting the protective ground ............................................................................................... 50

5.5 Connecting the power supply...................................................................................................... 51

5.6 Connecting DRIVE-CLiQ components........................................................................................ 52

5.7 Connecting the digital inputs/outputs .......................................................................................... 53

5.8 Connecting the PROFINET interface (410 PN only)................................................................... 54

5.9 Connecting the PROFIBUS DP interface (410 DP only) ............................................................ 55

5.9.1 Connection components in PROFIBUS...................................................................................... 55

5.9.2 PROFIBUS cables and connectors............................................................................................. 55

5.9.3 PROFIBUS cable lengths............................................................................................................ 56

5.9.4 Rules for routing PROFIBUS cables........................................................................................... 56

5.9.5 Connecting PROFIBUS DP (interface X21)................................................................................ 57

5.9.6 Connection rules in the PROFIBUS subnet................................................................................ 58

5.10 Connecting an external encoder ................................................................................................. 60

6 Technical data ......................................................................................................................................... 61

6.1 SIMOTION D410 dimensional diagram ...................................................................................... 61

6.2 System data, connection values, dimensions and weight .......................................................... 62

6.3 Digital inputs/outputs................................................................................................................... 63

6.4 Shipping and storage conditions................................................................................................. 64

6.5 Mechanical and climatic ambient conditions............................................................................... 64

6.6 Specifications for dielectric tests, safety class and degree of protection.................................... 66

7 Spare parts/Accessories.......................................................................................................................... 67

7.1 Terminal module TM31 ............................................................................................................... 67

7.2 Terminal module TM41 ............................................................................................................... 68

7.3 Terminal modules TM15 and TM17 High Feature ...................................................................... 69

7.4 CUA31 control unit adapter......................................................................................................... 70

7.5 DMC20 DRIVE-CLiQ hub............................................................................................................ 71

7.6 List of spare parts and accessories ............................................................................................ 72

A Standards and approvals......................................

................................................................................... 73

A.1 General rules............................................................................................................................... 73

A.2 Safety of electronic controllers.................................................................................................... 74

A.3 Electromagnetic Compatibility..................................................................................................... 75

B ESD directives......................................................................................................................................... 77

B.1 ESD definition ............................................................................................................................. 77

B.2 Electrostatic charging of individuals............................................................................................ 78

B.3 Basic measures for protection against discharge of static electricity ......................................... 78

C Appendix.................................................................................................................................................. 79

C.1 References.................................................................................................................................. 79

C.2 List of abbreviations .................................................................................................................... 81

D410

8 Manual, 03/2007 Edition

Page 9

Table of contents

Index........................................................................................................................................................ 83

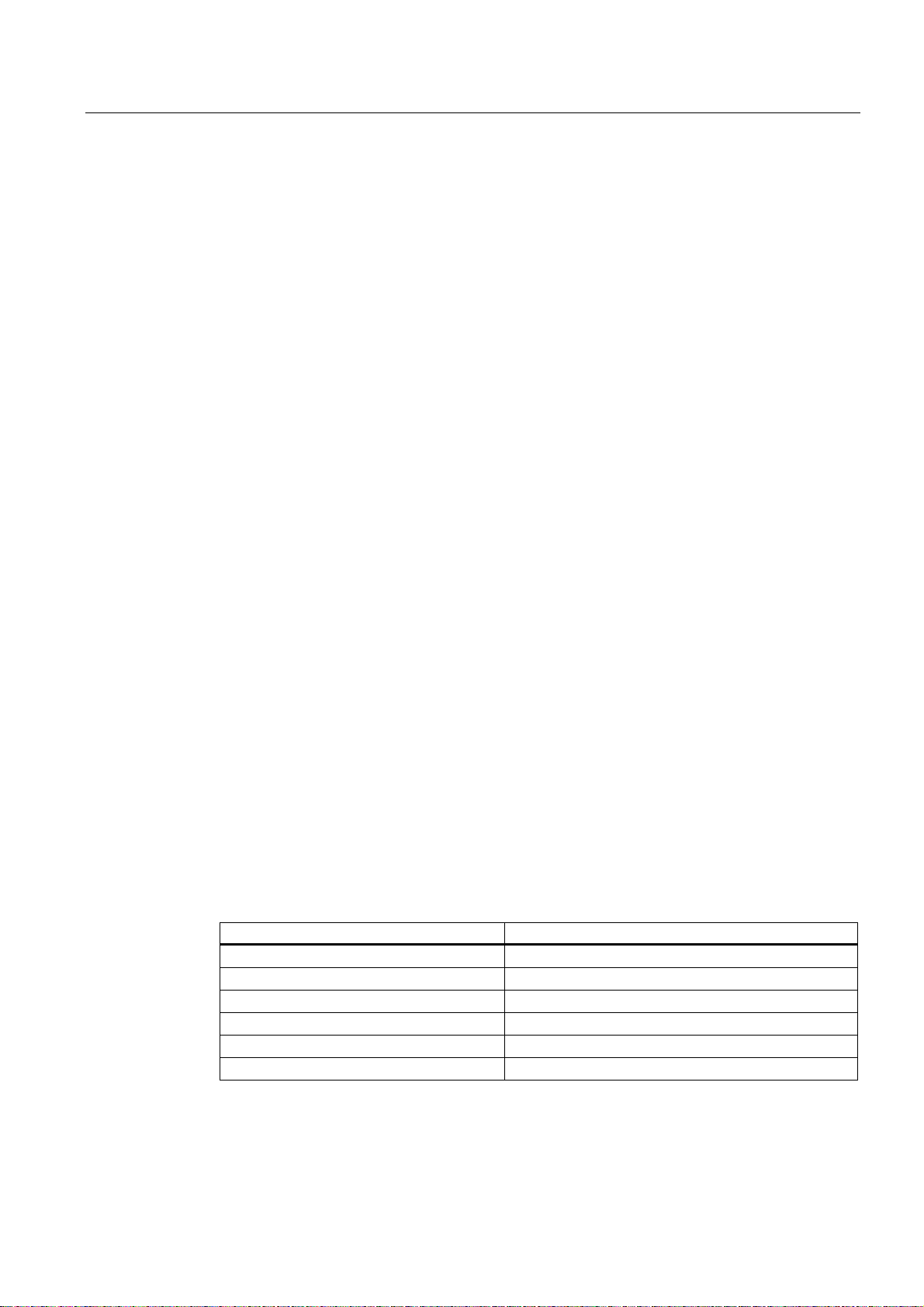

Tables

Table 1-1

System components ....................................................................................................................13

Table 1-2 Components on PROFIBUS DP ..................................................................................................14

Table 1-3 Components on PROFINET ........................................................................................................15

Table 1-4 Components on DRIVE-CLiQ ......................................................................................................16

Table 1-5 SIMOTION D410 interfaces.........................................................................................................18

Table 1-6 SIMOTION D410 interfaces.........................................................................................................21

Table 2-1 Mode selector switch settings......................................................................................................24

Table 3-1 Overview of available SIMOTION D410 interfaces......................................................................27

Table 3-2 Overview of non-usable SIMOTION D410 interfaces..................................................................27

Table 3-3 Interface X121..............................................................................................................................28

Table 3-4 Interface assignment X121 ..........................................................................................................29

Table 3-5 Interface X100..............................................................................................................................32

Table 3-6 Interface assignment X100 ..........................................................................................................32

Table 3-7 DRIVE-CLiQ connection topology................................................................................................33

Table 3-8 Interface X21................................................................................................................................35

Table 3-9 Interface assignment X21 ............................................................................................................35

Table 3-10 Ports X200 and X201...................................................................................................................37

Table 3-11 Assignment of ports X200 - X201 ................................................................................................37

Table 3-12 Interface X23................................................................................................................................38

Table 3-13 Interface assignment X23 ............................................................................................................38

Table 3-14 Interface X120..............................................................................................................................39

Table 3-15 Interface assignment X120 ..........................................................................................................39

Table 3-16 Interface X124..............................................................................................................................41

Table 3-17 Interface assignments T0, T1 and T2 ..........................................................................................42

Table 5-1 System startup .............................................................................................................................48

Table 5-2 Supply voltage .............................................................................................................................48

Table 5-3 24 V DC supply voltage ...............................................................................................................48

Table 5-4 Protection against external electrical interference .......................................................................49

Table 5-5 Electrical parameters of the required load power supply.............................................................51

Table 5-6 Features of PROFIBUS cables....................................................................................................55

Table 5-7 Permitted cable length of a subnet segment for specific baud rates ...........................................56

Table 5-8 Boundary conditions for routing of PROFIBUS cables ................................................................57

Table 6-1 Memory for system data and its memory size .............................................................................62

D410

Manual, 03/2007 Edition

9

Page 10

Table of contents

Table 6-2 SIMOTION D410 electrical connection values............................................................................ 62

Table 6-3 SIMOTION D410 dimensions and weight ................................................................................... 62

Table 6-4 CF card........................................................................................................................................ 62

Table 6-5 Digital input technical data .......................................................................................................... 63

Table 6-6 Digital output technical data........................................................................................................ 63

Table 6-7 Shipping and storage conditions................................................................................................. 64

Table 6-8 Mechanical ambient conditions................................................................................................... 65

Table 6-9 Climatic ambient conditions ........................................................................................................ 65

Table 6-10 Test voltages............................................................................................................................... 66

Table 7-1 Interface overview of the TM31................................................................................................... 67

Table 7-2 TM41 interface overview ............................................................................................................. 68

Table 7-3 Overview of CUA31 interfaces.................................................................................................... 70

Table 7-4 Spare parts and accessories ...................................................................................................... 72

Table A-1 EMC Directive ............................................................................................................................. 73

Table A-2 EMC standards ........................................................................................................................... 75

Table C-1 Abbreviations .............................................................................................................................. 81

D410

10 Manual, 03/2007 Edition

Page 11

Description

1.1 System overview

Overview

In SIMOTION D, the SIMOTION functionality is integrated directly in the closed-loop control

module of the SINAMICS S120 drive system.

SIMOTION D410 is a module drive system for single axes, which solves demanding drive

tasks for a very wide range of industrial applications. SIMOTION D410 supplements D425,

D435 and D445, the three power levels for multi-axis connections.

SIMOTION D is an integral part of the Totally Integrated Automation (TIA) concept. TIA

features standardized data management, configuration and communication over all products

and systems. Thus, an extensive toolbox of automation modules is also available for

SIMOTION D410.

Application

Combining a power module with SIMOTION D410 forms a compact single drive for machine

and plant engineering.

1

Product variants

D410

Manual, 03/2007 Edition

Applications include:

• Machine concepts with central drive (e.g., pressing, printing, packaging)

• Modular machine concepts where the machine modules broken down to single axes

• Single drives with high accuracy, stability and concentricity requirements (compared with

standard drives) in machine and industrial plant engineering

• Single drives for transport tasks (conveying, raising, lowering)

• Single drives with integrated PLC functionality and expanded motion control functionality

such as output cam or cams

• Drives without power recovery (wire drawing, extruding)

• Drive connections with high availability requirements (incoming supply failure may not

cause all axes to fail)

SIMOTION D410 comes in two variants:

• SIMOTION D410 DP with PROFIBUS DP interface.

• SIMOTION D410 PN with PROFINET interface.

11

Page 12

Description

1.1 System overview

System integration

SIMOTION provides an optimized system platform for automation and drive solutions where

the main focus is on motion control applications and technology tasks.

The SIMOTION system is made up of three components:

• SIMOTION SCOUT Engineering System

• Runtime Software

• Hardware platforms

The innovative SIMOTION concept involves integrating pure automation and motion

functions, which have been traditionally isolated in the past.

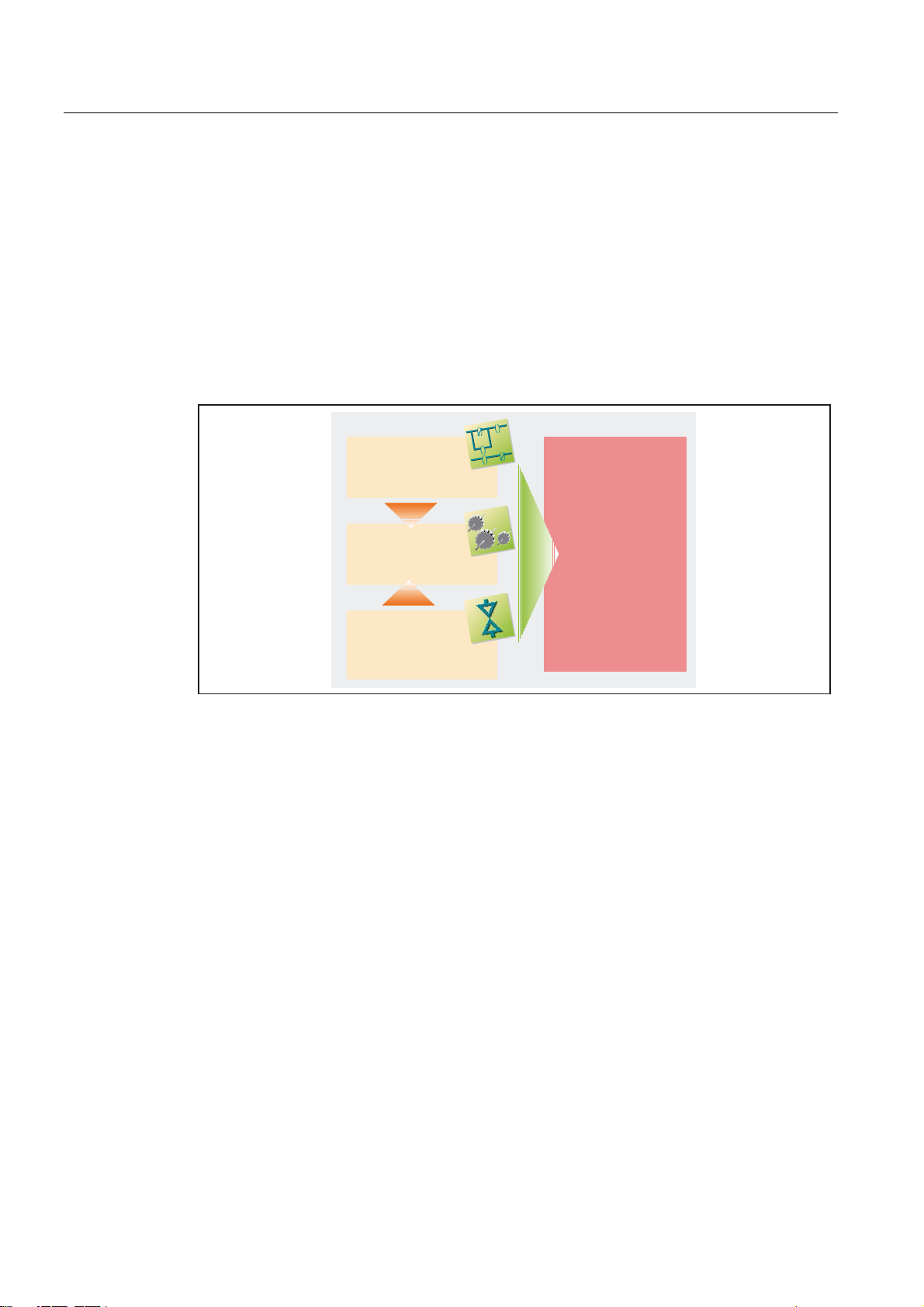

3/&IXQFWLRQDOLW\

,(&

7KHV\VWHPDSSURDFKRI

0RWLRQ&RQWURO

HJSRVLWLRQLQJ

V\QFKURQRXV

RSHUDWLRQHWF

7HFKQRORJ\

IXQFWLRQV

HJK\GUDXOLFV

WHPSHUDWXUHFRQWUROHWF

Figure 1-1 System solution

6,027,21

7KHIXVLRQRI0RWLRQ

&RQWURO3/&DQG

WHFKQRORJ\IXQFWLRQV

SIMOTION can be used with all machines with motion control tasks. The focus is on a

simple and flexible solution to a wide variety of motion control tasks. In order to achieve this

in the best way possible, a new system approach has been introduced:

the fusion of motion control with two other control functions, which are found in most

machines: PLC and technology functions.

This approach enables motion control of axes and machines with only one system. The

same applies to technology functions, such as pressure control of a hydraulic axis. A

seamless switch can be made from position-controlled positioning mode to pressure control.

The fusion the three control functions motion control, PLC and technology has the following

advantages:

• Lower engineering expenditure and higher machine performance.

• Interfaces between individual components requiring rapid response are no longer

needed.

• Simple, standardized and transparent programming and diagnostics for the complete

machine.

D410

12 Manual, 03/2007 Edition

Page 13

Description

1.2 System components

1.2 System components

Overview

SIMOTION D410 communicates with the components of the automation landscape via the

following interfaces:

• PROFIBUS DP (SIMOTION D410 DP only)

• PROFINET (SIMOTION D410 PN only)

• DRIVE-CLiQ (DRIVE Component Link with IQ)

• Power Module Interface (PM-IF)

The most important system components and their functions are listed in the following table.

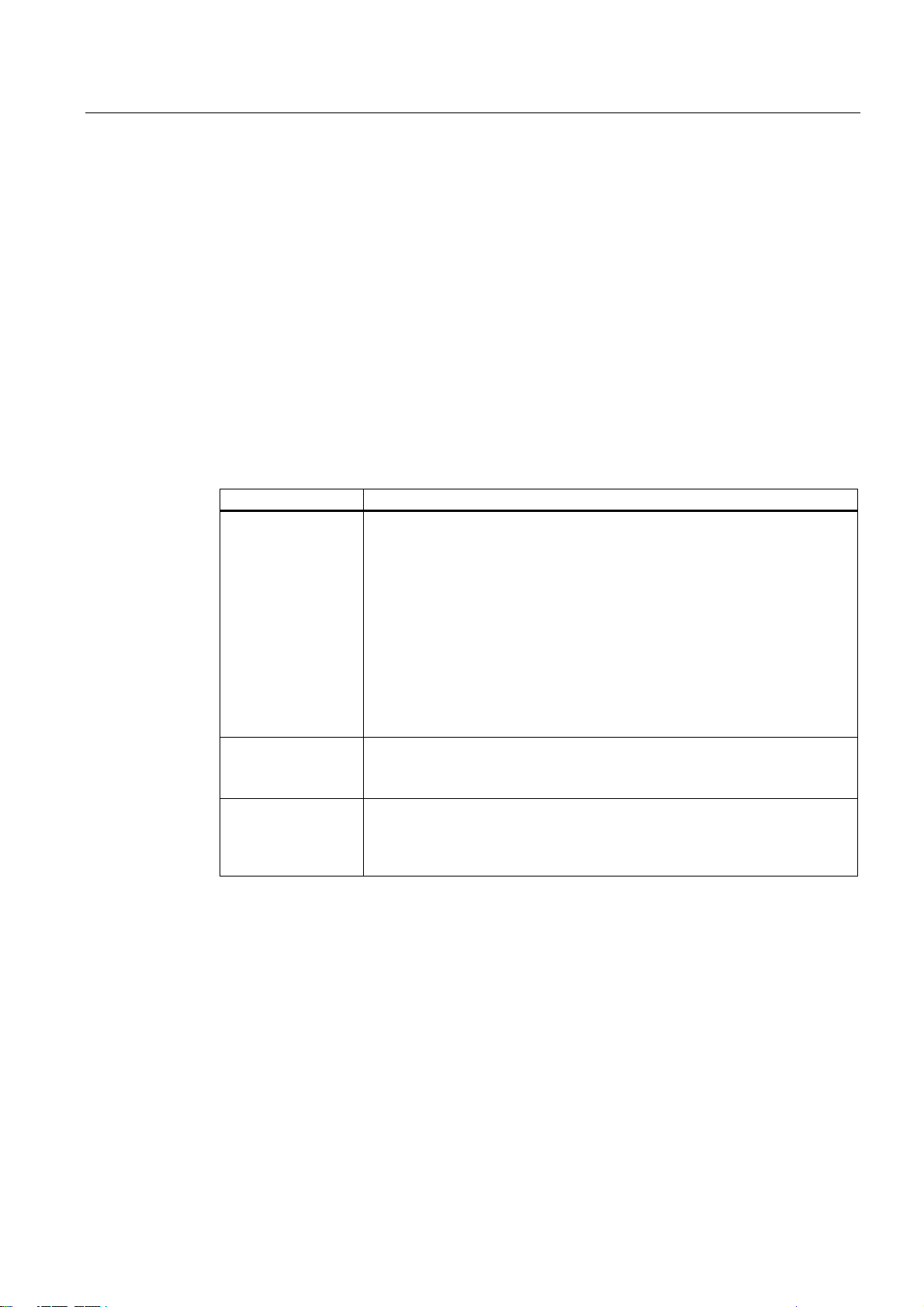

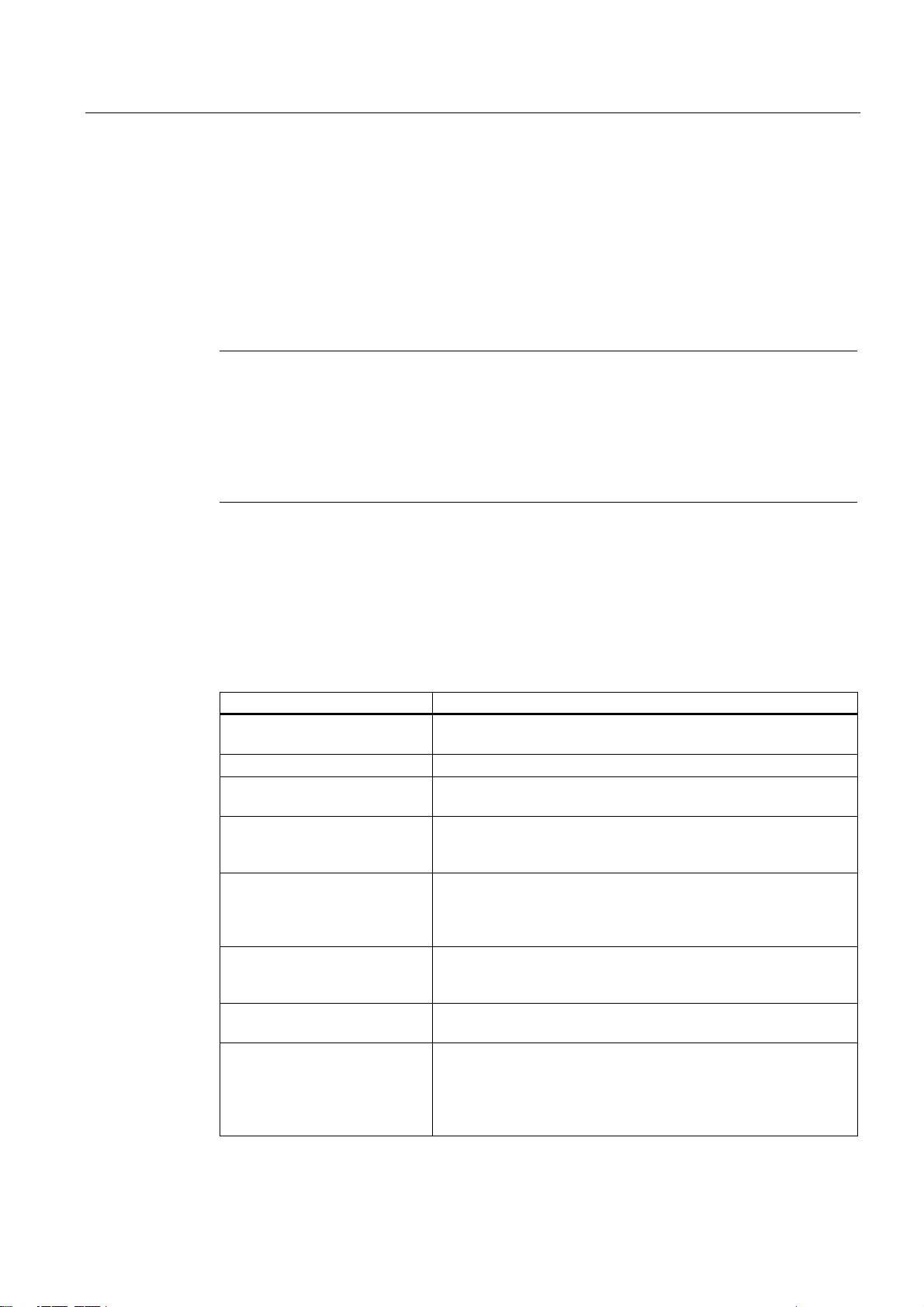

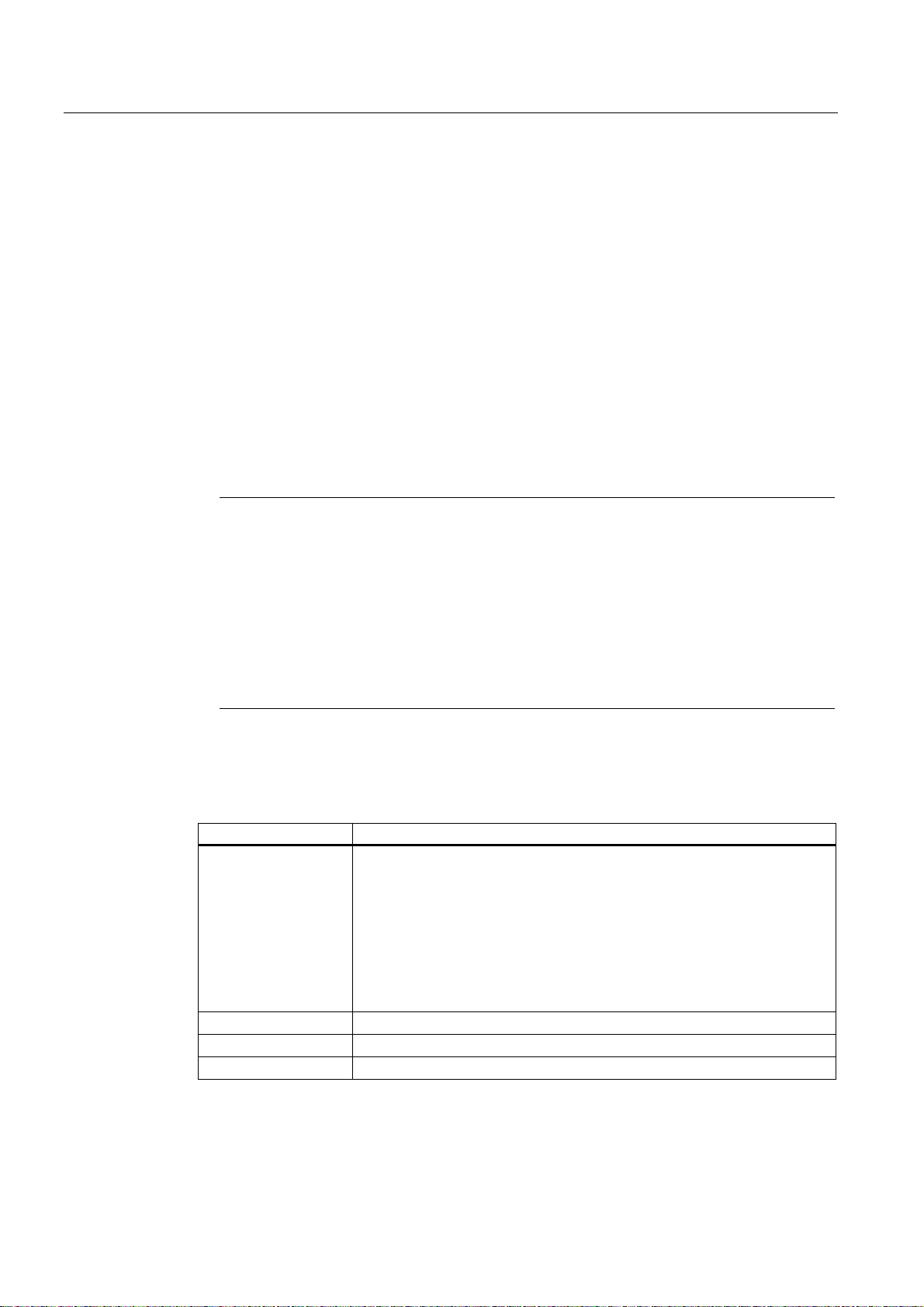

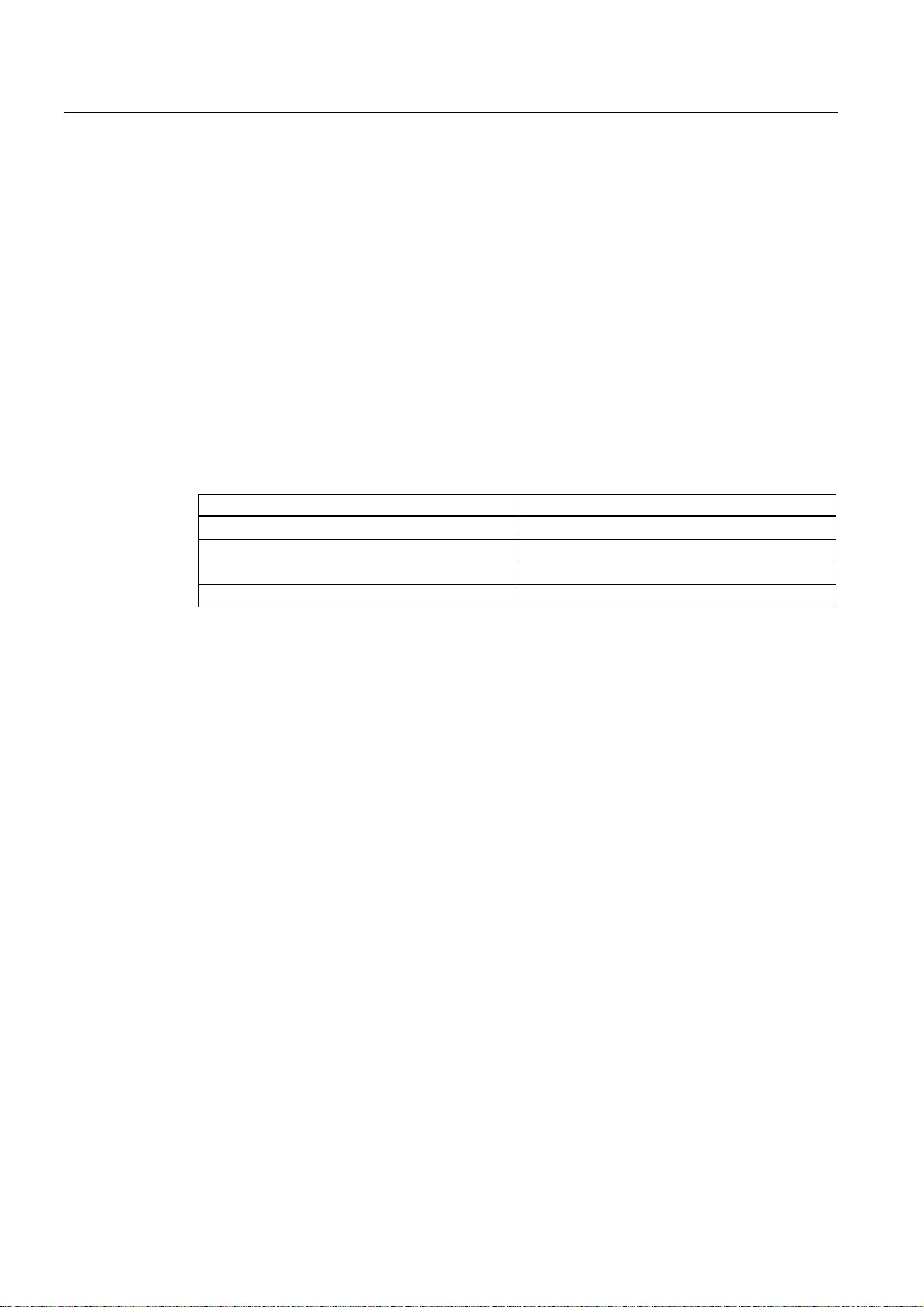

Table 1-1 System components

Components Function

SIMOTION D410 ... is the central motion control module.

The module contains the programmable SIMOTION Runtime in

SIMOTION D410 and the SINAMICS S120 drive software.

You can use the integrated rapid digital I/Os as:

• Homing inputs

• Inputs for measuring inputs

• User-addressable process inputs/outputs

• Outputs for fast output cams

The measuring sockets can output any analog signals.

The DRIVE-CLiQ interfaces permit a fast connection to the SINAMICS drive

components.

System software The system software is delivered separately on a CompactFlash card (not

included in the scope of delivery).

Note: An additional license is not required for the real axis technology.

Power supply (PS) ... provides the electronic power supply for SIMOTION D410, e.g., SITOP.

Note: If SIMOTION D410 is to be mounted on the power module, the power is

supplied via the power module (e.g., PM340). The digital outputs of

SIMOTION D410 are not supplied by the power supply.

D410

Manual, 03/2007 Edition

13

Page 14

Description

1.2 System components

PROFIBUS DP

SIMOTION D410 DP can communicate via PROFIBUS DP interface to the following

components:

Table 1-2 Components on PROFIBUS DP

Components Function

PG/PC programming device ... configures, sets parameters, programs and tests using the

SIMOTION SCOUT Engineering System (ES).

Drive units with

PROFIBUS DP interface

(e.g., SINAMICS,

SIMODRIVE 611 universal)

SIMATIC ET 200M Modular I/O system for control cabinet installation and high channel

SIMATIC ET 200S Precision modular I/O system for control cabinet installation, including

SIMATIC ET 200pro Modular I/O system with IP65/66/67 rating for near-machine

SIMATIC ET 200eco I/O system with IP 67 rating for near-machine applications with no

Gateways

Teleservice adapter Remote diagnosis

Other controls (e.g.,

SIMOTION or SIMATIC)

... convert speed setpoints into signals for controlling the motor and

supply the power required to operate the motors.

Can also be operated as an isochronous, equidistant Slave on the

PROFIBUS DP.

densities.

motor starters, safety technology and connecting load groups to

common potential.

applications with no control cabinet; with new features like more

compact designs, integrated PROFIsafe safety technology,

PROFINET connection and live module replacement.

control cabinet, including flexible and fast connection system in

ECOFAST or M12.

• DP/AS Interface Link 20E and DP/AS Interface Link Advanced for

the PROFIBUS DP gateway to AS Interface

• DP/DP coupler to connect two PROFIBUS DP networks

Note

Note that only a real axis can be used on a SIMOTION D410!

D410

14 Manual, 03/2007 Edition

Note

Please note that not all modules for the I/O systems listed above are enabled for SIMOTION.

Moreover, system-related functional differences can come into play when these I/O or I/O

systems are used on SIMOTION vs. on SIMATIC. For example, SIMOTION does not support

special process control functions (e.g., live plugging and unplugging, etc.) in the ET 200M

distributed I/O system.

For a detailed and routinely updated list of I/O modules enabled with SIMOTION as well as

application information, visit us online at:

http://support.automation.siemens.com/WW/view/de/11886029

Page 15

Description

1.2 System components

In addition to the I/O modules enabled for SIMOTION, all certified standard slaves can, in

principle, be connected to SIMOTION if they support the following:

• Cyclic data traffic (DP-V0) and, possibly

• Acyclic data traffic (DP-V1) or

• Isochronous data traffic (DP-V2)

These modules are integrated via the GSD file from the device manufacturer.

PROFINET

Note

Please note that in individual cases further boundary conditions must be fulfilled in order to

integrate a standard slave into SIMOTION. For example, "driver modules" in the form of

function blocks are required for some modules, which enable integration or make it

especially easy.

For modules enabled for SIMOTION (e.g., S7-300 module FM 350-1, etc.), these driver

modules are part of the SIMOTION SCOUT Engineering System command library.

SIMOTION D410 PN can communicate via PROFINET interface to the following

components:

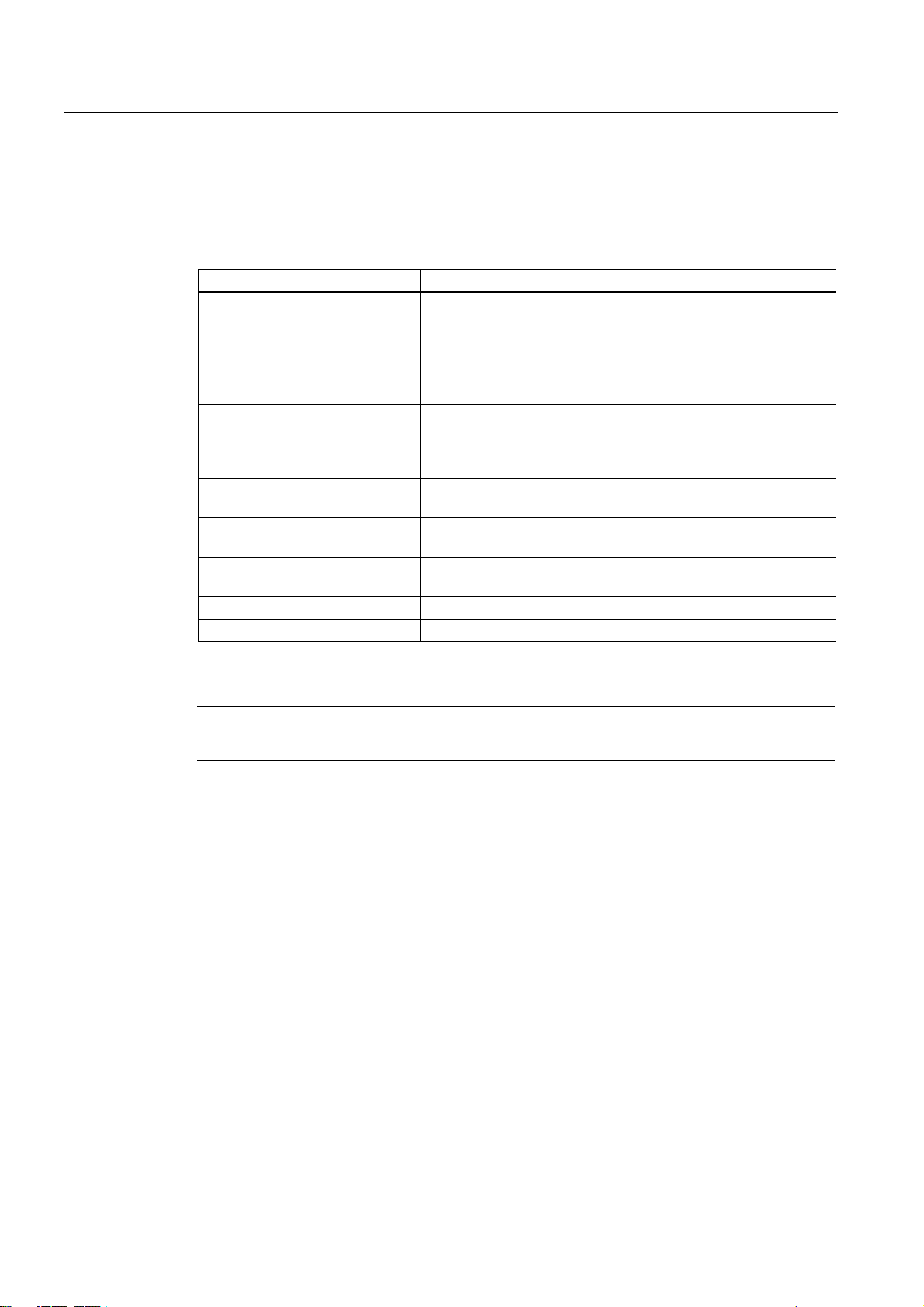

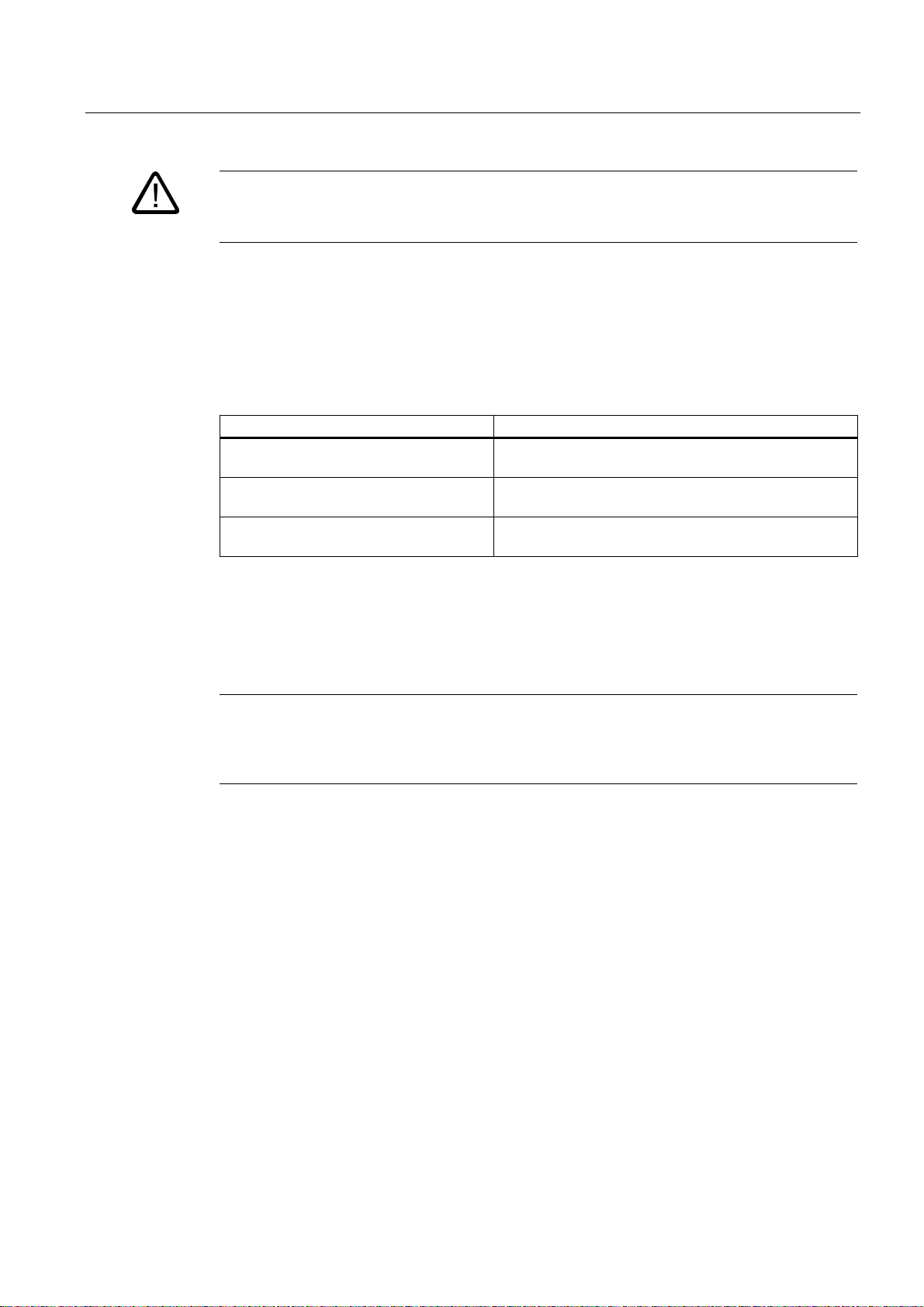

Table 1-3 Components on PROFINET

Components Function

PG/PC programming device ... communicates with the SIMOTION SCOUT Engineering

Systems (ES), STEP 7 and HMI (Human Machine Interface).

Host computer ... communicates to other devices via TCP/IP.

SIMATIC HMI device ... is used for operator control and monitoring functions. It is not

absolutely required to run SIMOTION D410.

SIMATIC ET 200S Precision modular I/O system for control cabinet installation,

including motor starters, safety technology and connecting load

groups to common potential.

SIMATIC ET 200pro Modular I/O system with IP65/66/67 rating for near-machine

applications with no control cabinet; with new features like more

compact designs, integrated PROFIsafe safety technology,

PROFINET connection and live module replacement.

Drive units with PROFINET

interface (e.g., SINAMICS S120

with CBE20)

Other controls (e.g., SIMOTION

or SIMATIC)

Gateways

... convert speed setpoints into signals for controlling the motor

and supply the power required to operate the motors.

• IE/AS Interface Link PN IO for the PROFINET IO gateway to

AS Interface

• PN/PN coupler to connect two PROFINET IO networks

• IE/PB Link PN IO for the PROFINET IO gateway to PROFIBUS

DP

D410

Manual, 03/2007 Edition

15

Page 16

Description

1.2 System components

DRIVE-CLiQ

SIMOTION D410 can communicate via DRIVE-CLiQ interface to the following components:

Table 1-4 Components on DRIVE-CLiQ

Components Function

Drive units

SINAMICS S120 AC DRIVE

(with CUA31)

TM15 and TM17 High Feature

terminal modules

TM31 terminal module ... enables terminal expansion via DRIVE-CLiQ (additional

TM41 terminal module ... enables terminal expansion (analog and digital inputs/outputs)

Sensor Module Integrated (SMI) The integrated sensor module delivers the encoder signals

Sensor Module Cabinets (SMC) ... converts the encoder signals into DRIVE-CLiQ signals.

DMC20 ... expands the number of DRIVE-CLiQ nodes

... convert speed setpoints into signals for controlling the motor

and supply the power required to operate the motors. The

AC DRIVE component PM340 is connected via CUA31. No more

than one PM340 can be connected. Chassis power module is

connected via DRIVE-CLiQ.

Note: Booksize components are not supported!

The TM15 and TM17 High Feature terminal modules can be

used to set up inputs of measuring inputs and outputs of output

cams. In addition, these terminal modules provide drive-related

digital inputs and outputs with short signal delay times.

analog and digital inputs/outputs).

and encoder simulation via DRIVE-CLiQ.

directly as DRIVE-CLiQ signals.

Note

Note that SIMOTION D410 does not support the CX32 expansion!

D410

16 Manual, 03/2007 Edition

Page 17

Description

1.3 SIMOTION D410 DP display

1.3 SIMOTION D410 DP display

View

The following figure shows SIMOTION D410 DP with the interfaces and front elements.

3RZHUPRGXOHLQWHUIDFH30,)

6HULDOLQWHUIDFHQR

IXQFWLRQ

;

352),%86

0VFUHZRQVKLHOG

FRQQHFWLRQ

;

(QFRGHULQWHUIDFH+7/77/

;

'5,9(&/L4LQWHUIDFH

;

(OHFWURQLFVSRZHUVXSSO\

&RPSDFW)ODVKb&DUG

;

(3WHUPLQDOVWHPSHUDWXUH

VHQVRUFRQQHFWLRQ

;

'LJLWDOLQSXWVRXWSXWV

Figure 1-2 Location of interfaces and front elements in SIMOTION D410 DP

6LGHQDPHSODWH

7770

0HDVXULQJVRFNHWV

/('GLVSOD\V

1DPHSODWH

5(6(7EXWWRQ

0RGHVHOHFWRUVZLWFK

',/VZLWFK

D410

Manual, 03/2007 Edition

Note

The lettering "DP ADDRESS" below the DIL switch is of no interest.

17

Page 18

Description

1.3 SIMOTION D410 DP display

Interfaces

The SIMOTION D410 DP interfaces are described in the following tables.

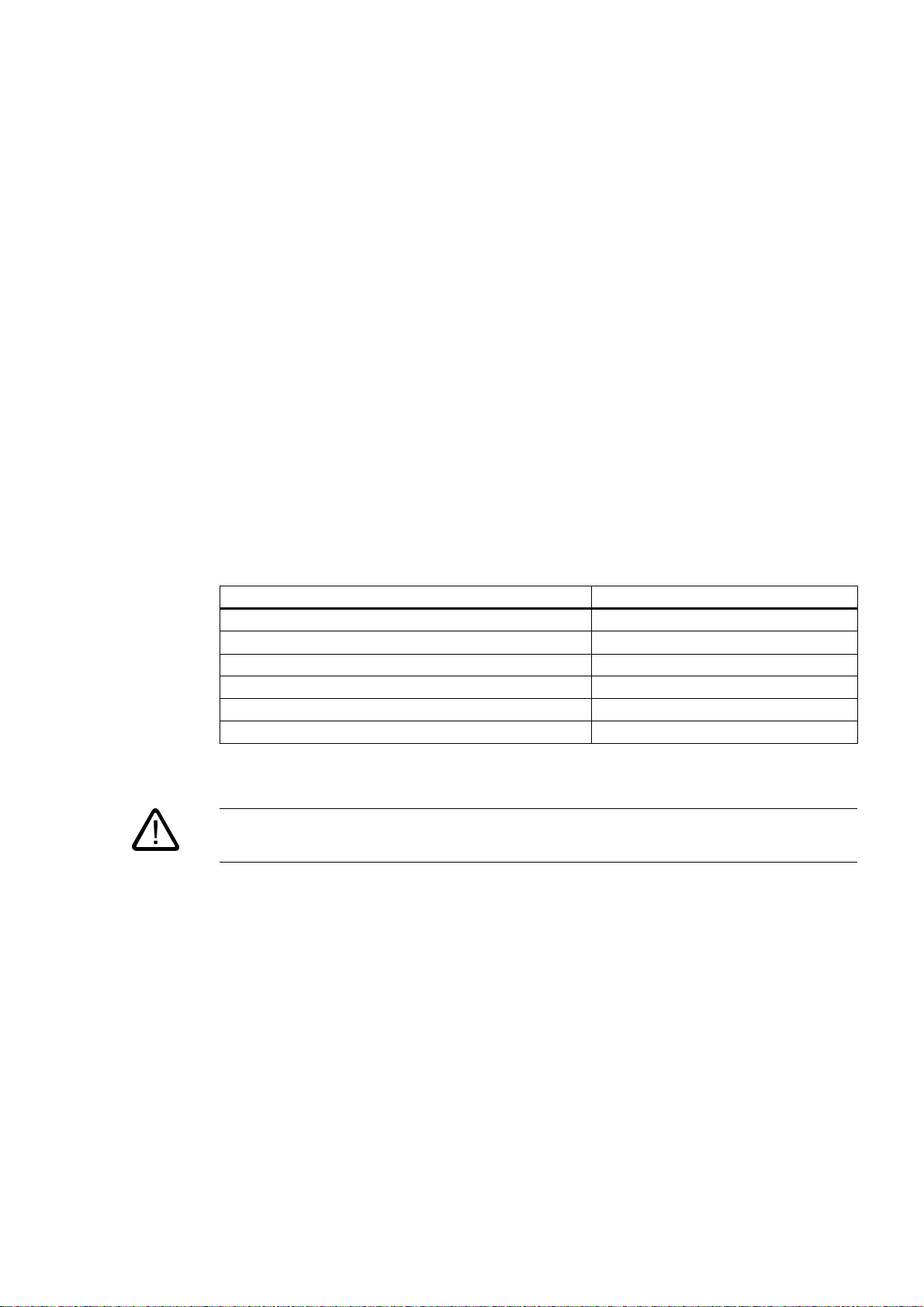

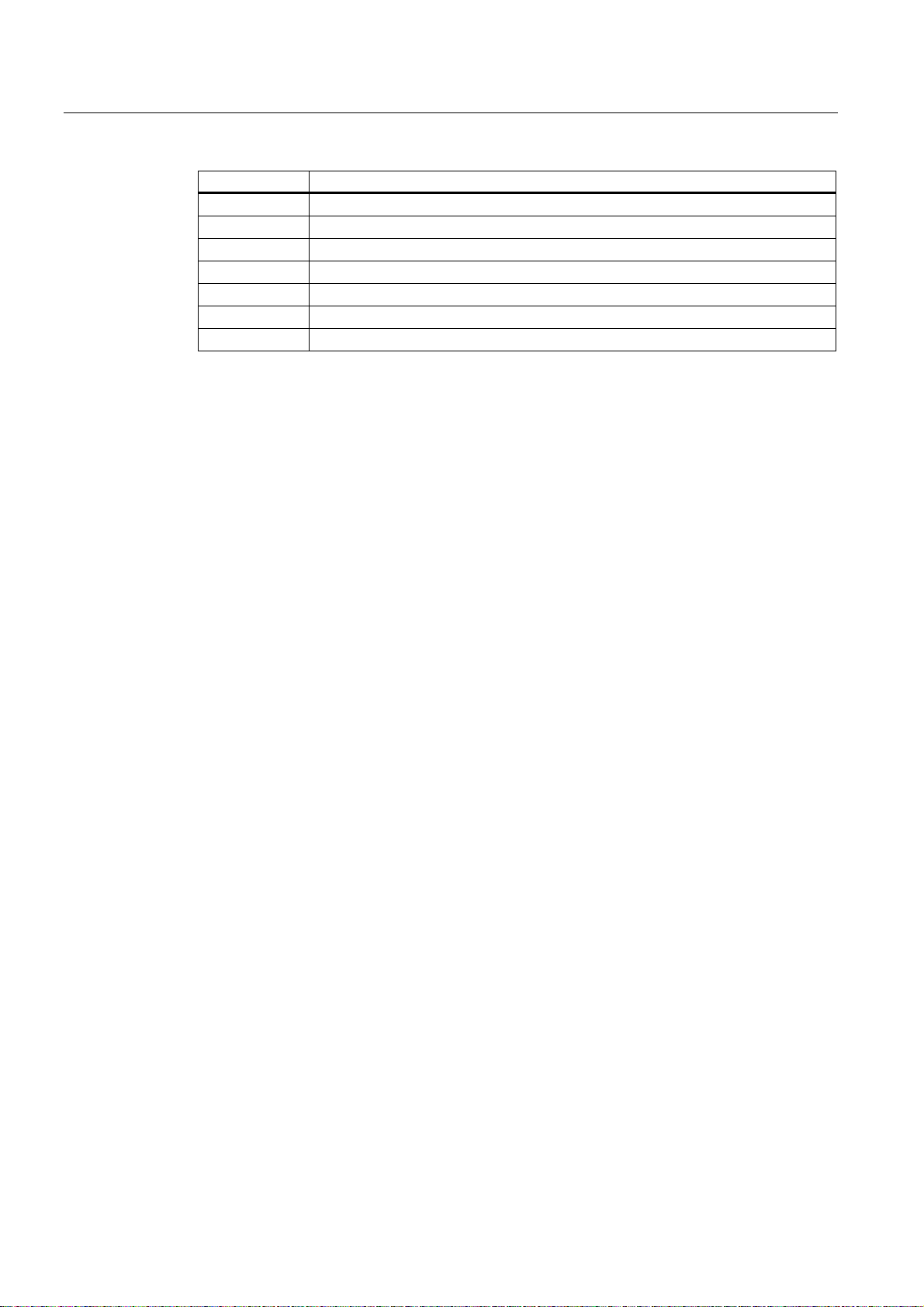

Table 1-5 SIMOTION D410 interfaces

Interface Description

Digital inputs/outputs

X121

DRIVE-CLiQ interface

X100

PROFIBUS DP interface

X21

Power Module Interface

(PM-IF)

Encoder interface (HTL/TTL)

X23

EP terminals/temperature

sensor connection

X120

Power supply connection

X124

Measuring sockets

T0, T1, T2 and M

• 4 digital inputs: Socket to connect switches or proximity sensors

• 4 digital inputs/outputs: 12-pin socket to connect actuators and

sensors

8-pin RJ45plus socket to connect DRIVE-CLiQ nodes

9-pin SUB-D socket to connect to PROFIBUS DP

8-pin direct connector to connect to a blocksize power module

15-pin SUB-D socket to connect HTL and TTL encoders.

8-pin Mini Combicon to connect input terminals ("safe standstill") or

to connect temperature sensing via KTY or PTC

4-pin screw terminal connection to connect the 24 V DC load power

supply

Sockets to output analog signals

Nameplates

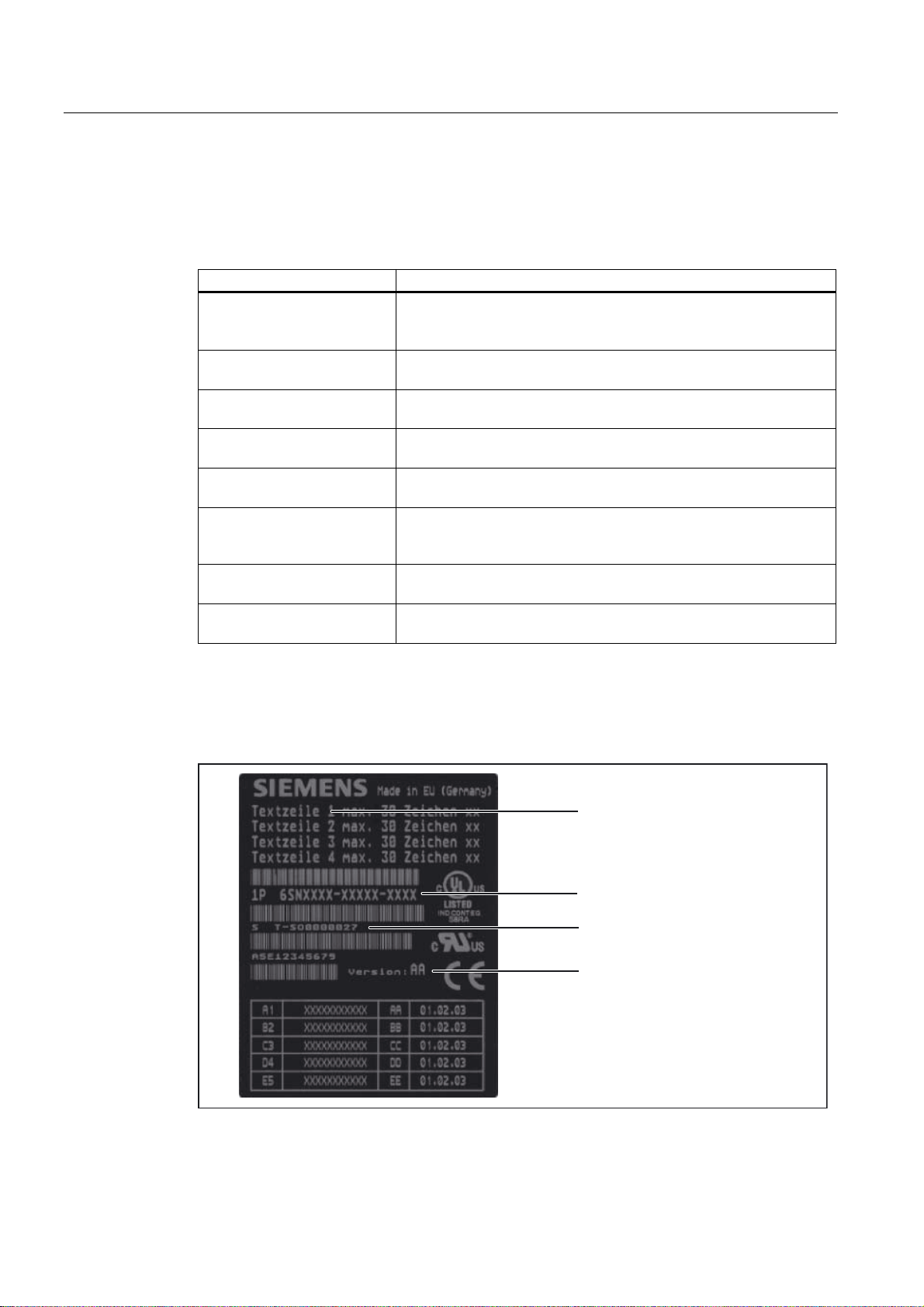

The following figure shows you all the information included on the nameplates located on the

side of the unit.

0RGXOHGHVLJQDWLRQ

2UGHUQXPEHU

6HULDOQXPEHU

+:YHUVLRQ

Figure 1-3 SIMOTION D410 nameplate

D410

18 Manual, 03/2007 Edition

Page 19

Description

$8$$$$

81,.$761U

6DFK1U$(

9HUVLRQ

$$

1.3 SIMOTION D410 DP display

The following nameplate includes the SIMOTION D410 DP barcode numbers and is located

on the front side of the module.

%DUFRGH0/)%1R$8$$$$

%DUFRGH8QLTXH1R

%DUFRGH3URGXFW1R$(

3URGXFWQXPEHU

8QLTXHQXPEHU

2UGHUQXPEHU0/)%1R

$UHDIRU&(8/LGHQWLILFDWLRQ

3URGXFWYHUVLRQ

Figure 1-4 SIMOTION D410 DP nameplate (example)

Note

The contents of the individual nameplate fields on the current module may differ from those

described in this Manual (e.g., updated product status, approvals and identifications not yet

issued, etc.).

D410

Manual, 03/2007 Edition

19

Page 20

Description

1.4 SIMOTION D410 PN display

1.4 SIMOTION D410 PN display

View

The following figure shows SIMOTION D410 PN with the interfaces and front elements.

3RZHUPRGXOHLQWHUIDFH30,)

6HULDOLQWHUIDFHQR

IXQFWLRQ

;;

352),1(7VRFNHWV

0VFUHZRQVKLHOG

FRQQHFWLRQ

;

(QFRGHULQWHUIDFH+7/77/

;

'5,9(&/L4LQWHUIDFH

;

(OHFWURQLFVSRZHUVXSSO\

&RPSDFW)ODVKb&DUG

;

(3WHUPLQDOVWHPSHUDWXUH

VHQVRUFRQQHFWLRQ

;

'LJLWDOLQSXWVRXWSXWV

Figure 1-5 Location of interfaces and front elements in SIMOTION D410 PN

6LGHQDPHSODWH

7770

0HDVXULQJVRFNHWV

/('GLVSOD\V

1DPHSODWH

5(6(7EXWWRQ

0RGHVHOHFWRUVZLWFK

',/VZLWFK

Note

The lettering "DP ADDRESS" below the DIL switch is of no interest.

D410

20 Manual, 03/2007 Edition

Page 21

Description

1.4 SIMOTION D410 PN display

Interfaces

The SIMOTION D410 PN interfaces are described in the following tables.

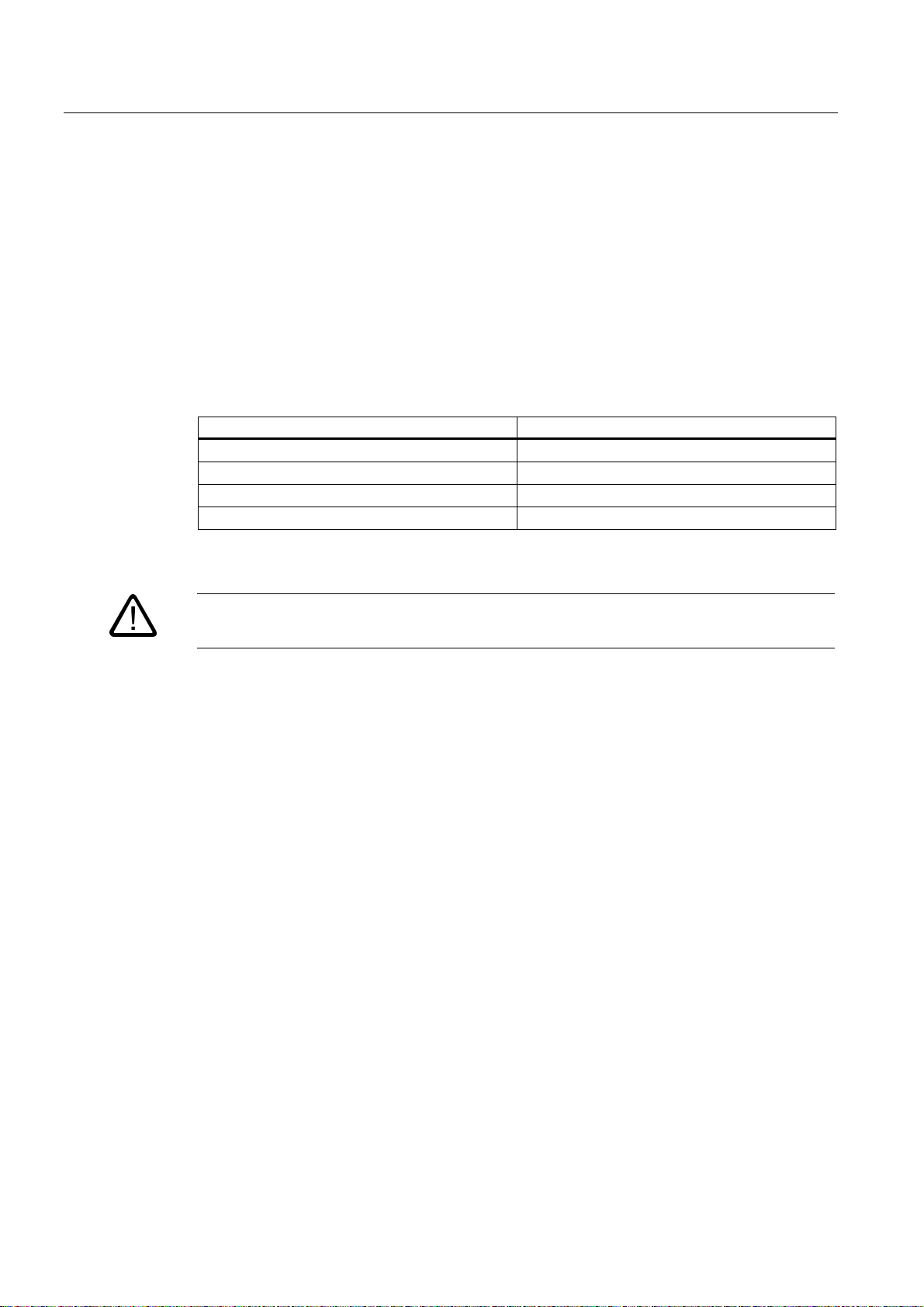

Table 1-6 SIMOTION D410 interfaces

Interface Description

Digital inputs/outputs

X121

DRIVE-CLiQ interface

X100

PROFINET interface

(ports X200 and X201)

Power Module Interface

(PM-IF)

Encoder interface (HTL/TTL)

X23

EP terminals/temperature

sensor connection

X120

Power supply connection

X124

Measuring sockets

T0, T1, T2 and M

• 4 digital inputs: Socket to connect switches and proximity

sensors

• 4 digital inputs/outputs: 12-pin socket to connect actuators and

sensors

8-pin RJ45plus socket to connect DRIVE-CLiQ nodes

8-pin RJ45plus socket to connect to PROFINET

8-pin direct connector to connect to a blocksize power module

15-pin SUB-D socket to connect HTL and TTL encoders.

8-pin Mini Combicon to connect input terminals ("safe standstill")

or to connect temperature sensing via KTY or PTC

4-pin screw terminal connection to connect the 24 V DC load

power supply

Sockets to output analog signals

Nameplates

The following figure shows you all the information included on the nameplates located on the

side of the unit.

0RGXOHGHVLJQDWLRQ

2UGHUQXPEHU

6HULDOQXPEHU

+:YHUVLRQ

Figure 1-6 SIMOTION D410 nameplate

D410

Manual, 03/2007 Edition

21

Page 22

Description

9HUVLRQ

$(

;;;;;;

$8$%$$

1.5 Safety information

The following nameplate includes the MAC address of the PROFINET interface (ports X200

and X201) and is located on the front side of the module.

%DUFRGH0$&$GGUHVV

0$&DGGUHVV

3URGXFWQXPEHU

2UGHUQXPEHU0/)%1R

Figure 1-7 SIMOTION PN nameplate (example)

Note

The contents of the individual nameplate fields on the current module may differ from those

described in this Manual (e.g., updated product status, approvals and identifications not yet

issued, etc.).

1.5 Safety information

Observe the following safety information when working with SIMOTION D410 and its

components!

$UHDIRU&(8/LGHQWLILFDWLRQ

3URGXFWYHUVLRQ

Caution

The CompactFlash card may only be unplugged and plugged in when SIMOTION D410 is

switched off (zero current)!

Caution

The 50 mm clearances above and below the components must be observed. The ventilation

openings may not be covered by connecting cables.

D410

22 Manual, 03/2007 Edition

Page 23

Operation (hardware)

2.1 Overview of operator controls and indicators

The following figure shows the operator controls and indicators arrangement on the

SIMOTION D410.

&RPSDFW)ODVKFDUG

VORW

&RPSDFW)ODVKb&DUG

/('GLVSOD\V

2

%ODQNLQJSODWH

Figure 2-1 Operator controls and indicators

The operator controls and indicators are described below.

5'<

5816723

287!9

6)%)

5(6(7EXWWRQ

',/VZLWFKHV

D410

Manual, 03/2007 Edition

23

Page 24

Operation (hardware)

2.2 Operator controls

2.2 Operator controls

2.2.1 Mode selector switch

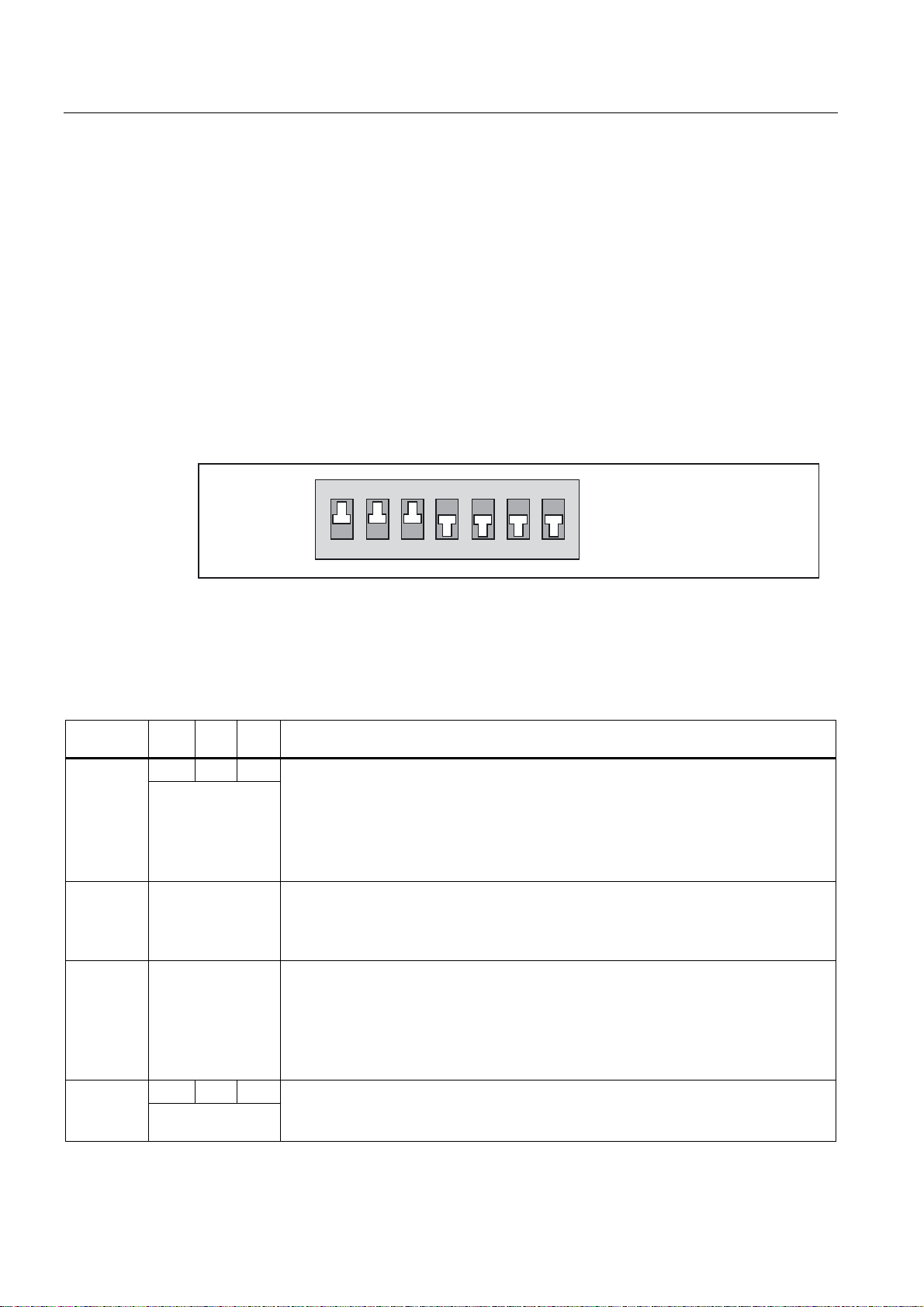

DIL switches

The mode selector switch function is realized in SIMOTION D410 by a DIL switch

(DIL = Dual In Line Package). The DIL switch is located in the lower front area of the

SIMOTION D410 (see "Overview of operator controls and indicators").

To set the SIMOTION operating mode, a binary code is used, which is entered via the DIL

switch (switch S1 - S3).

21

Figure 2-2 DIL switches

The following table contains the operating modes that can be set and the associated code.

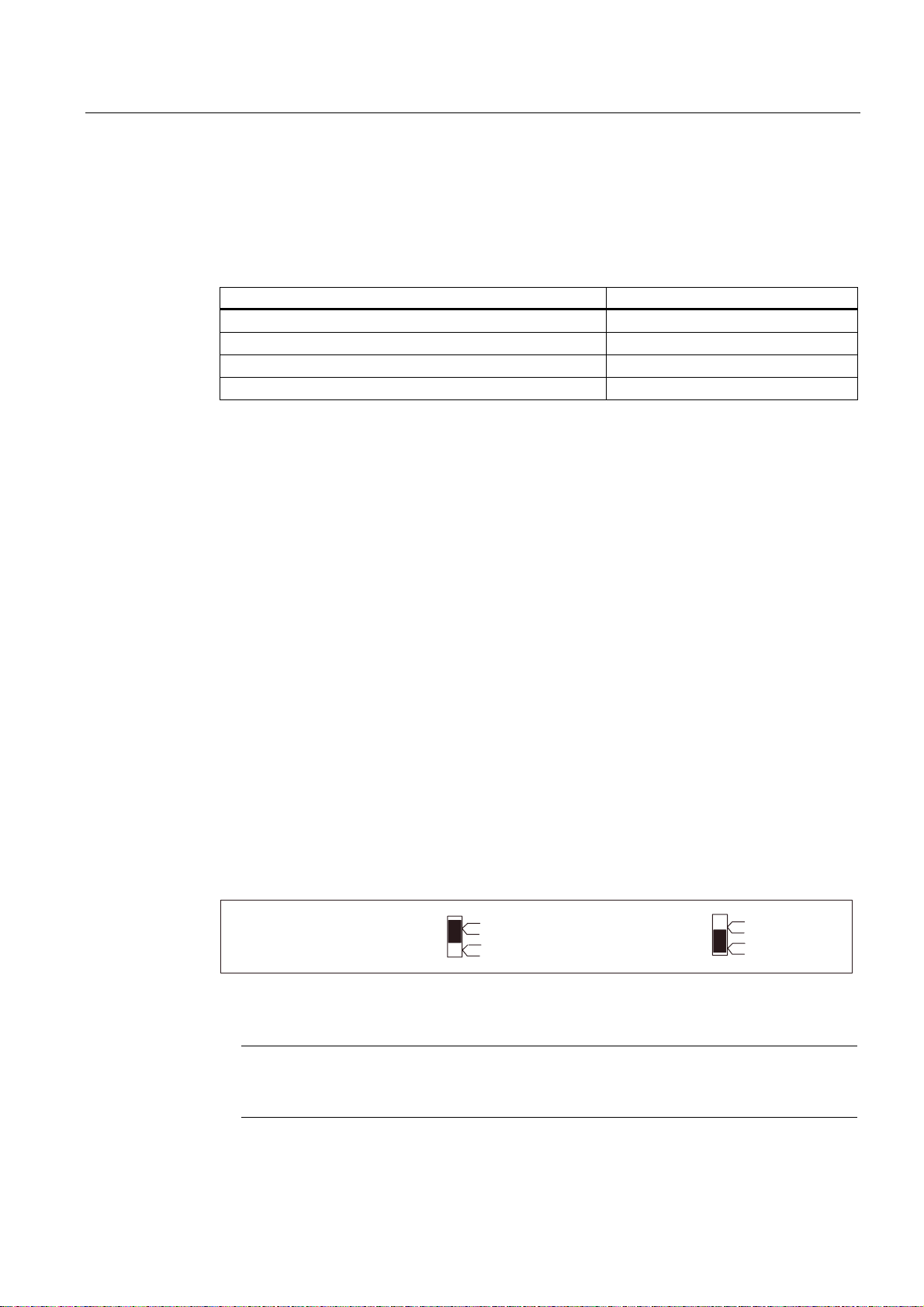

Table 2-1 Mode selector switch settings

Operating

mode

STOPU 110 / 101 / 011

STOP 100 / 010 / 001

S1 S2 S3 Description

1 1 1 RUN

(3 switch = ON)

(2 switch = ON)

(1 switch = ON)

0 0 0 MRES

(0 switch = ON)

SIMOTION D410 runs the user program and all connected system performances:

• Read process image of inputs.

• Execution of the user programs assigned to the execution system.

• Write process image of outputs.

The technology packages are active in this state. They can execute commands from the

user program.

SIMOTION D410 does not run a user program.

• The technology packages are active. Test and commissioning functions can be

executed. The user program is not active.

• The I/O modules are in a secure state.

SIMOTION D410 does not run a user program.

• It is possible to load a complete user program.

• All system services (communications, etc.) are active.

• The I/O modules are in a secure state.

• The technology packages are inactive, i.e., all enables are deleted. No axis motions

can be executed.

Overall module reset

You can reset SIMOTION D410 via the MRES switch setting. Observe the operating

sequence in the Commissioning Manual,

SIMOTION D410

6ZLWFKVHWWLQJ 21

6ZLWFKVHWWLQJ 2))

, /1/.

D410

24 Manual, 03/2007 Edition

Page 25

Operation (hardware)

2.2 Operator controls

Note

The factory DIL switch setting (switches S1 to S7) is 1110000. As a rule, it is not necessary

to adjust this switch. Use the SIMOTION SCOUT Engineering System to set the operating

mode (at switch setting 1110000).

Switches S4 - S7 are not used in SIMOTION D410 and must be set to "0" (OFF).

SIMOTION SCOUT mode selector switch

In SIMOTION SCOUT, you can control the SIMOTION D410 operating state using a

software switch.

To set the operating state via SIMOTION SCOUT, see the Configuring Manual,

SCOUT

, /9/.

2.2.2 SIMOTION CompactFlash card

CompactFlash card slot

The CompactFlash card (CF card) is inserted into the plug-in module over the blanking plate

(see "Overview of operator controls and indicators").

SIMOTION

CF card features

The CF card is mandatory to run SIMOTION D410. The CF card must be ordered as a

separate component; it is not included in the SIMOTION D410 scope of delivery.

The SIMOTION firmware is located on the CF card.

CF card functions:

• Backup technology packages and user data

• Update (e.g., SIMOTION firmware update)

Note

The CF card may only be unplugged and plugged in when the system is switched off

(zero current)!

If the CF card is being accessed, the RDY-LED on the SIMOTION D410 flashes green

(see chapter "Error and status indicators").

D410

Manual, 03/2007 Edition

25

Page 26

Operation (hardware)

2.3 Error and status indicators

Further information

For more information on writing and formatting the CF card, see the Commissioning Manual,

SIMOTION D410, /1/

.

See also

System data, connection values, dimensions and weight (Page 62)

2.3 Error and status indicators

Arrangement of LED displays

The LED displays are located under the CF card plug-in module on the SIMOTION D410

(see "Overview of operator controls and indicators").

Further information

For the LED statuses, see the Commissioning Manual,

SIMOTION D410,

/1/.

D410

26 Manual, 03/2007 Edition

Page 27

Interfaces

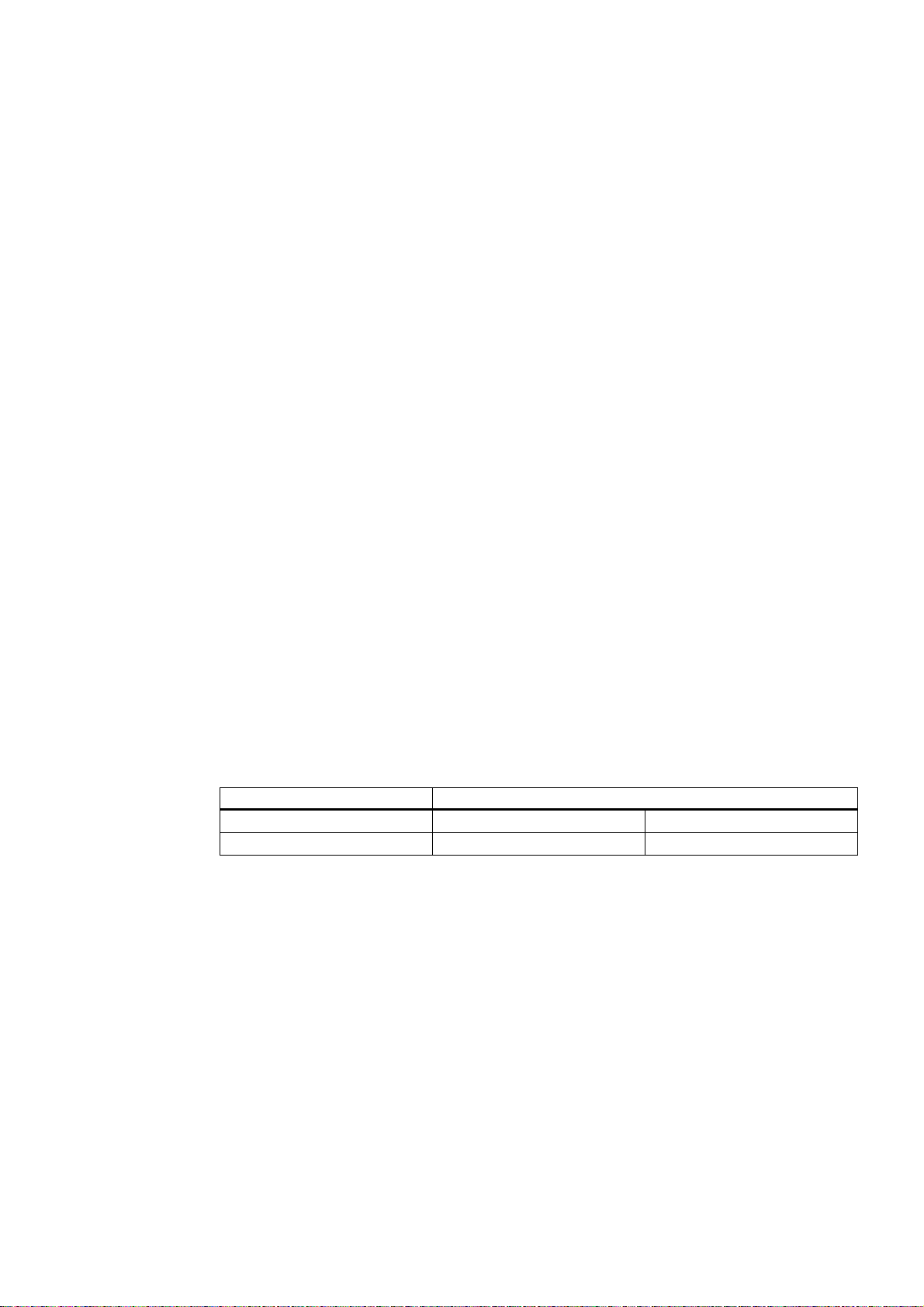

3.1 Overview of interfaces

This chapter describes the SIMOTION D410 interfaces.

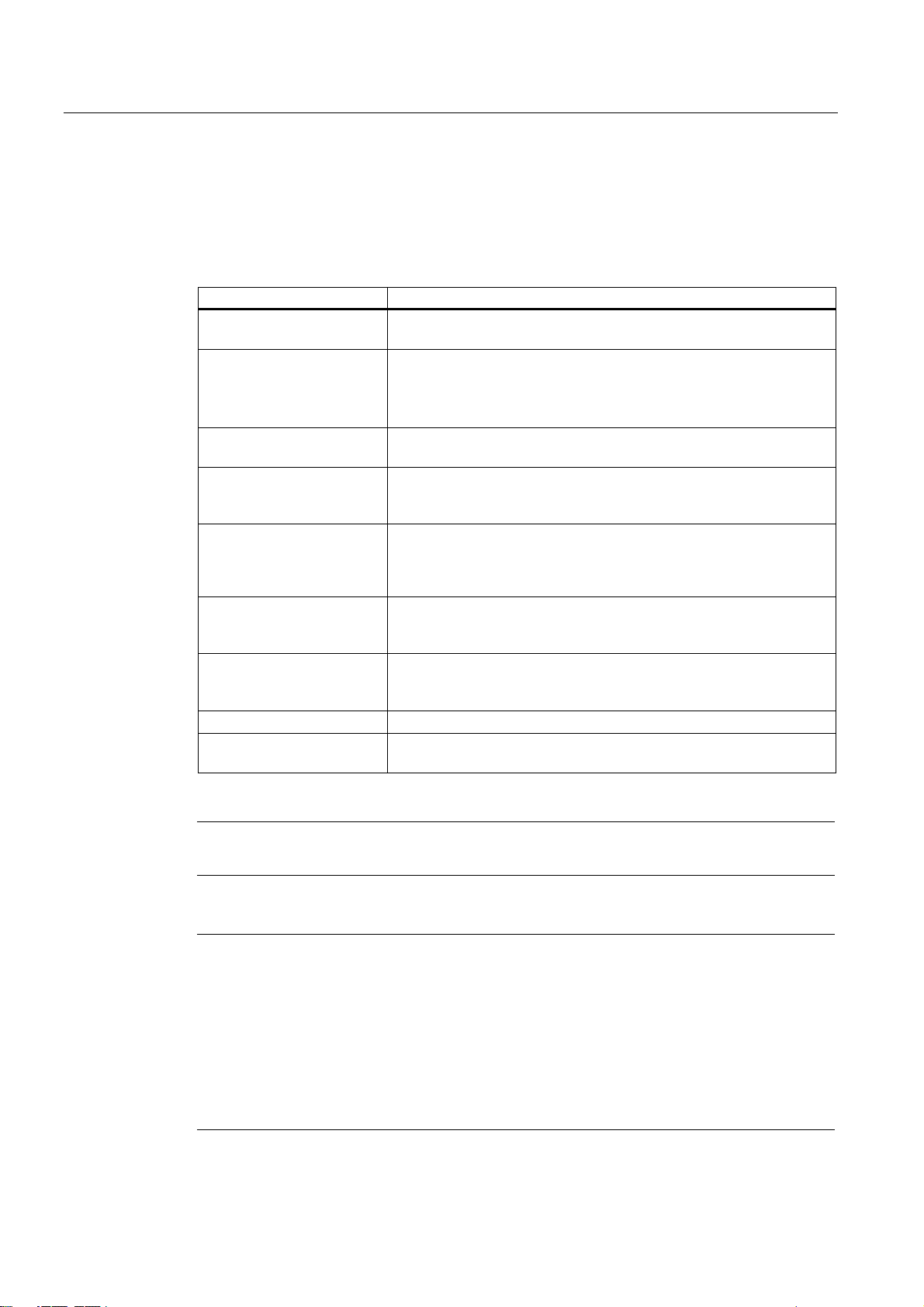

Available interfaces

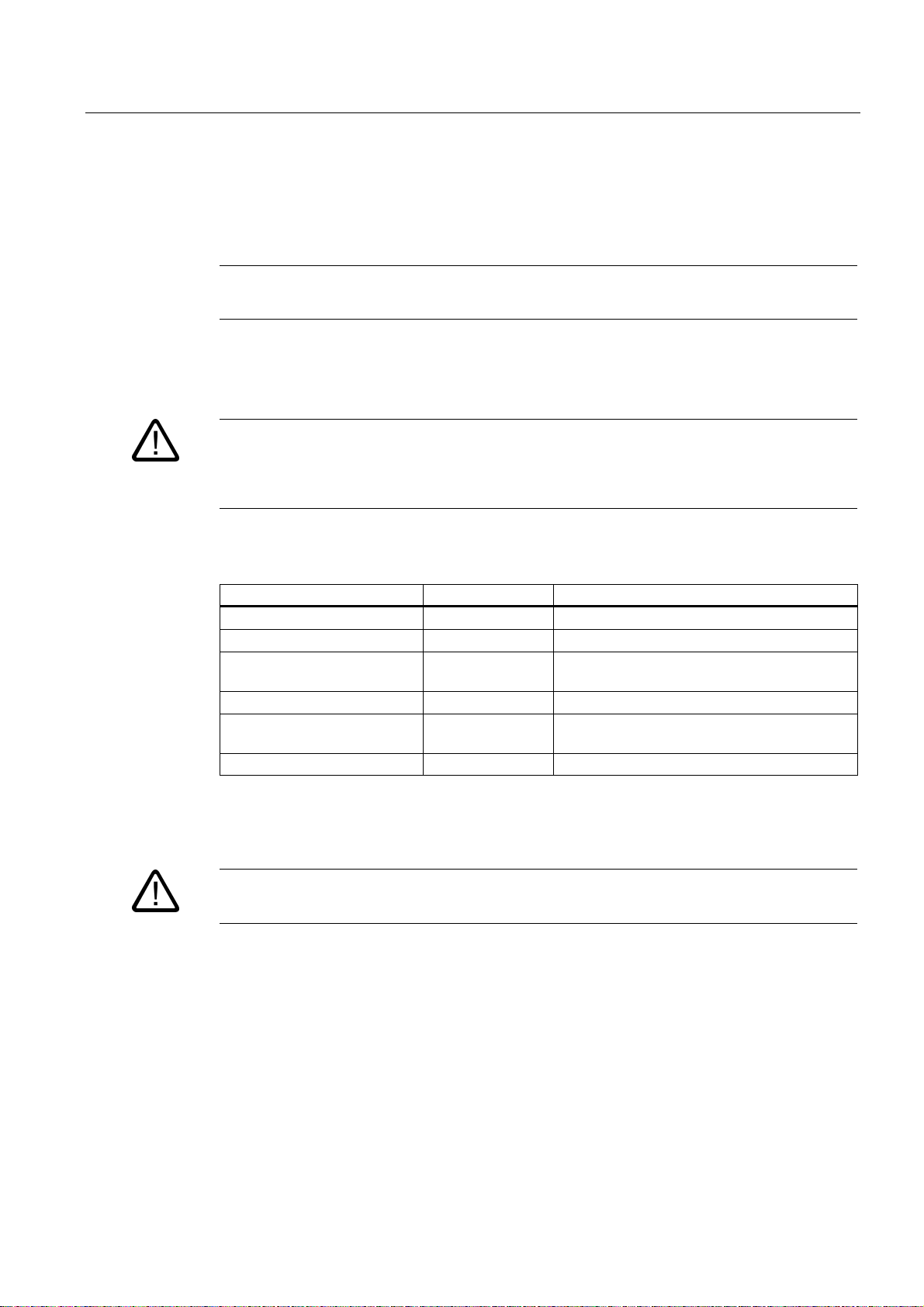

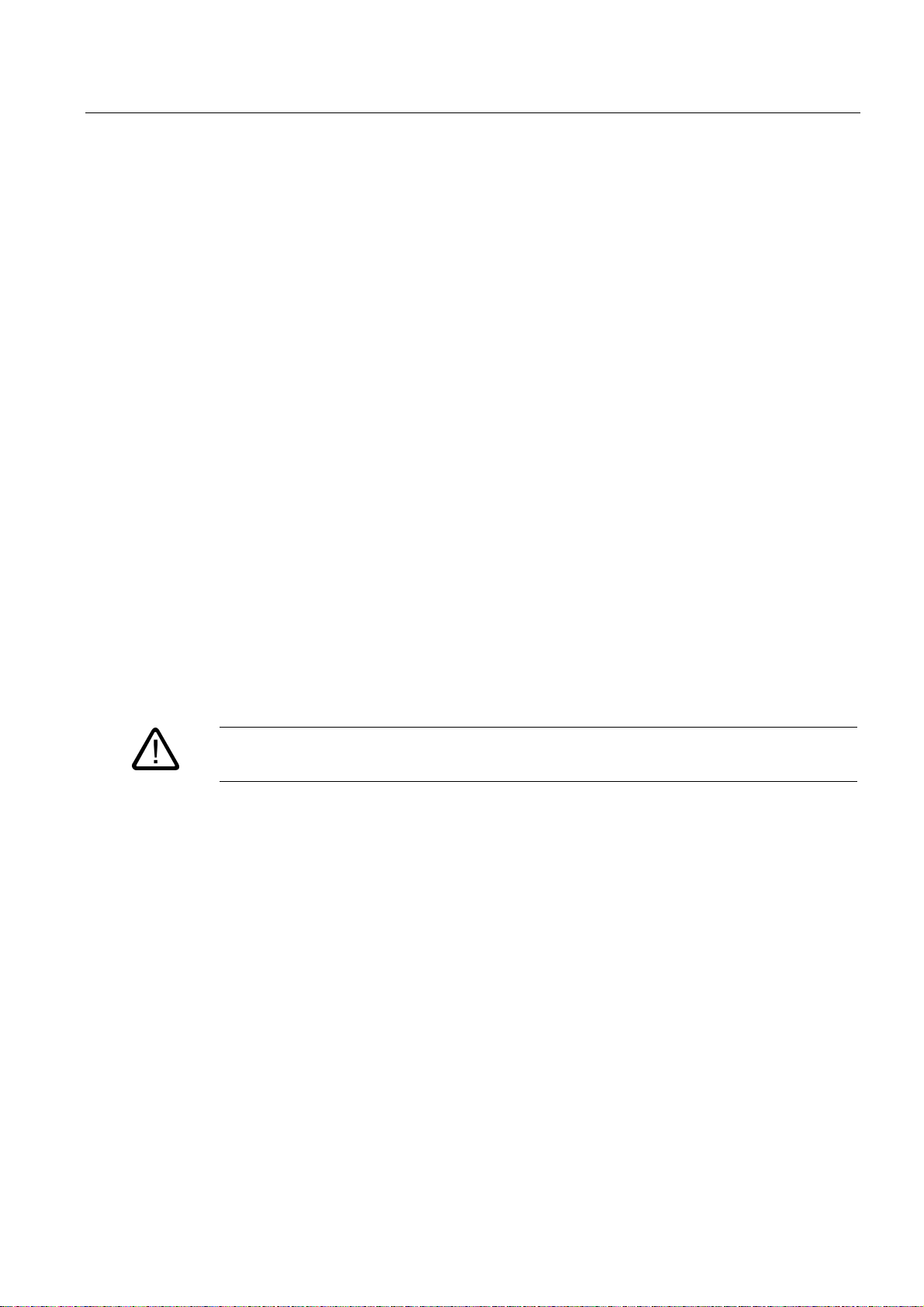

Table 3-1 Overview of available SIMOTION D410 interfaces

Interface Designation Connector type

Digital inputs X121 12-pin socket

Digital inputs/outputs X121 12-pin socket

DRIVE-CLiQ interface X100 DRIVE-CLiQ connector

PROFIBUS DP interface

(SIMOTION D410 DP only)

PROFINET interface

(SIMOTION D410 PN only)

Power Module Interface PM-IF 8-pin direct connector

Encoder interface (HTL/TTL) X23 15-pin SUB-D socket

EP terminals/temperature sensor connection X120 Mini Combicon, 8-pin

Power supply connection X124 Combicon 4-pin

Measuring sockets T0, T1, T2 and M Sockets

3

X21 9-pin SUB-D socket

X200 and X201 8-pin RJ45 socket

Non-usable interfaces

Table 3-2 Overview of non-usable SIMOTION D410 interfaces

Interface Designation Connector type

RS232 serial interface X22 9-pin SUB-D socket

Interface for BOP20 X142 8-pin multipoint connector

See also

SIMOTION D410 DP display (Page 17)

SIMOTION D410 PN display (Page 20)

D410

Manual, 03/2007 Edition

27

Page 28

Interfaces

3.2 Digital inputs/outputs

3.2 Digital inputs/outputs

Sensors and actuators can be connected to the X121 connector via digital inputs and

outputs. The following types of digital inputs/outputs are available:

• Digital inputs (4 pcs)

• Bidirectional digital inputs/outputs (4 pcs)

Bidirectional digital inputs and outputs can be configured individually as digital inputs or

outputs.

Assignment of the inputs/outputs to functions can be configured as required. Special

functions, such as measuring input and output of the output cam, can be assigned to the

inputs/outputs.

Interface features

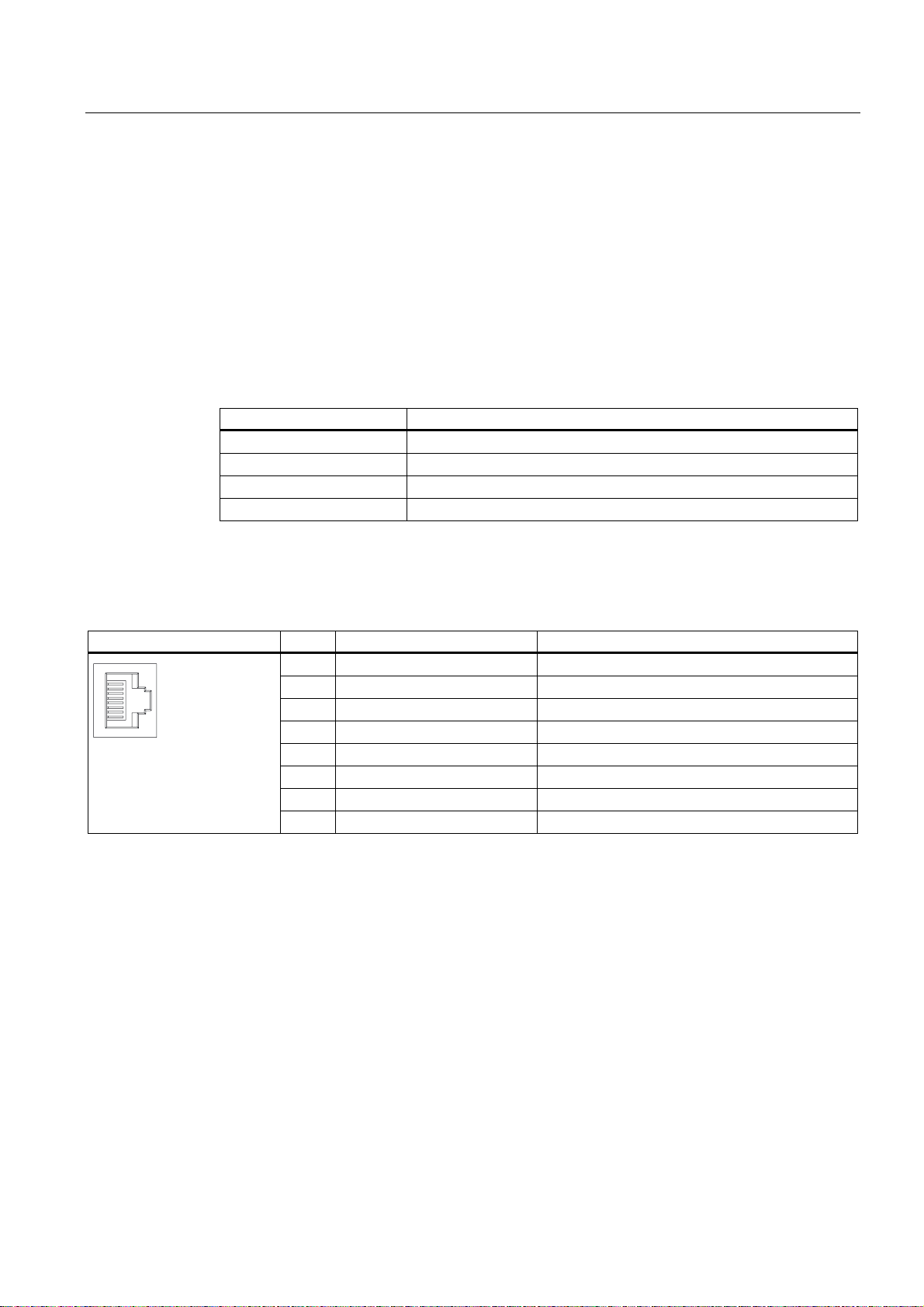

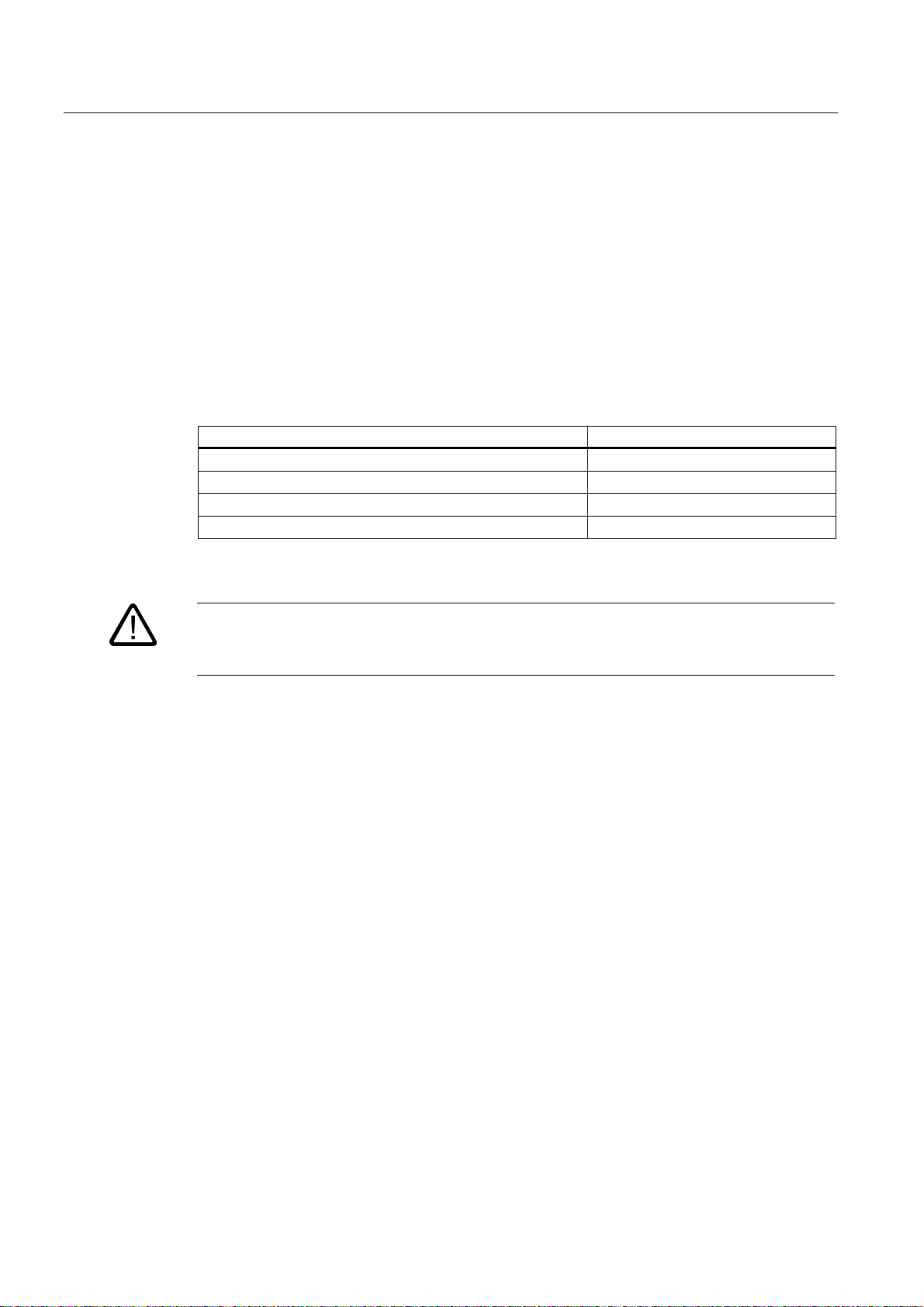

Table 3-3 Interface X121

Features Type

Connector type Mini Combicon

Connection possibility Up to 0.5 mm²

Load capacity Max. 4 A

D410

28 Manual, 03/2007 Edition

Page 29

Interfaces

3.2 Digital inputs/outputs

Interface assignments

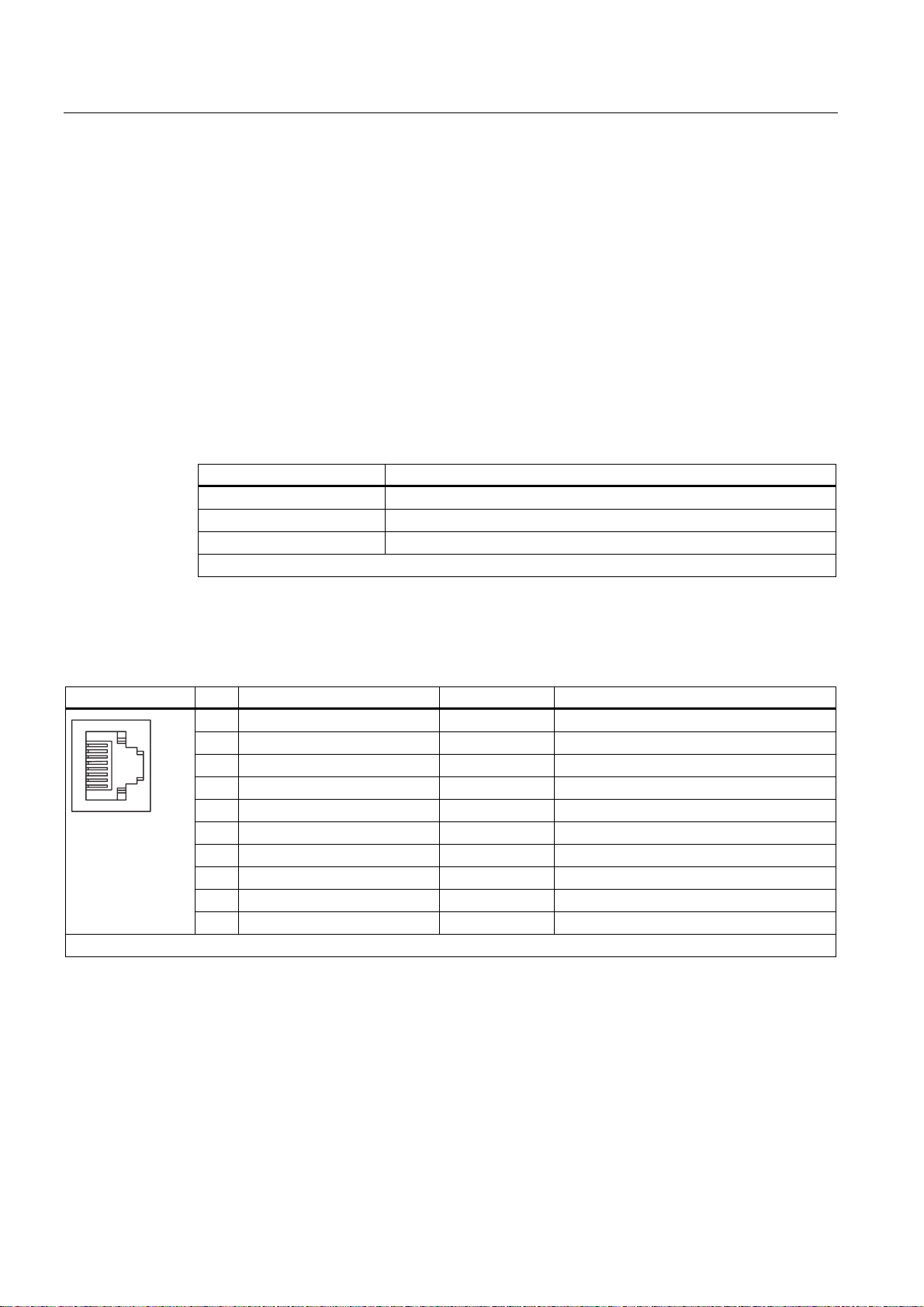

Table 3-4 Interface assignment X121

1)

View Pin Designation

1 DI0

2 DI1

3 DI2

4 DI3

5 G1 Ground for DI0 - DI3

6 G

7 DI/DO8

8 DI/DO9 fast DI/DO

9 G

10 DI/DO10 fast DI/DO

11 DI/DO11 fast DI/DO

12 G

1)

DI: digital input; DI/DO: bidirectional digital input/output; G: electronic ground;

Description Technical details

• Voltage: -3 to 30 V

• Current input (typical): 10 mA at 24 V DC

• Electrical isolation: reference potential is G1 terminal

• Level (including ripple):

– 0 signal: -3 to 5 V

(functionally-separated

relative to M)

– 1 signal: 15 to 30 V

• Input delay:

– 0 → 1 signal: 50 μs

– 1 → 0 signal: 100 μs

As input:

• Voltage: -3 to 30 V

• Current input (typical): 10 mA at 24 V DC

• Level (including ripple):

– 0 signal: -3 to 5 V

– 1 signal: 15 to 30 V

• Input delay / fast input delay:

– 0 → 1 signal: 50 μs / 5 μs

– 1 → 0 signal: 100 μs / 50 μs

As output:

• Voltage: 24 V DC

• Max. load current per output: 500 mA

• Sustained short-circuit proof

• Output delay:

– 0 → 1 signal: < 400 μs

– 1 → 0 signal: < 100 μs

G1: reference ground

D410

Manual, 03/2007 Edition

Note

An open input is interpreted as "low".

The "fast inputs" can be used for position acquisition with a measuring system.

The G1 terminal must be connected for the digital inputs (DI) 0 to 3 to function. This can be

done as follows:

• Connect the carried digital input reference ground.

• Connect a bridge to G terminal (Important: This will cancel the electrical isolation for

these digital inputs!)

Note

An external 24 V supply is required.

If a momentary interruption in the voltage occurs in the 24 V supply, the digital outputs will be

deactivated until the interruption has been rectified.

29

Page 30

Interfaces

3.2 Digital inputs/outputs

Wiring and block diagram

The following figure shows the wiring and block diagrams of the digital inputs/outputs on the

SIMOTION D410.

([WHUQDOVXSSO\YROWDJH9

'&

0

;

7['

5['

6HULDOLQWHUIDFH

0

;

'5,9(&/L4

;

;

0

0

;

352),%86

9

9

0

0

6,027,21

;

˽

XQDVVLJQHG

XQDVVLJQHG

0

7HPS

7HPS

XQDVVLJQHG

(39

(30

''3

0

(QFRGHULQWHUIDFH

30,)LQWHUIDFH

;

',

',

',

',

0

0

','2

','2

0

','2

','2

0

287

&RPSDFW)ODVKb

&DUG

Figure 3-1 Connection example

D410

30 Manual, 03/2007 Edition

Page 31

Interfaces

3.2 Digital inputs/outputs

Digital inputs

4 digital inputs are available on the control unit.

The electrically isolated inputs can be used as user-addressable inputs.

Switches or proximity encoders (2- or 3-wire encoders) can be connected.

The inputs comply with the standard IEC 1131-2/DIN EN 61131-2, characteristic type 2

(24 V P switching).

Bidirectional digital inputs/outputs

4 digital inputs/outputs (DI/DO) are available on the SIMOTION D410.

The following application options are available when configuring the DI/DO as digital inputs:

• DI/DO9, 10 and 11 can be used as "fast inputs" for measuring inputs.

The inputs can be arranged in any way; the special application is activated in the

SIMOTION SCOUT Engineering System when configuring the TO measuring inputs via

the HW address and the bit number.

• All 4 DI/DO can be used as user-addressable inputs or as homing inputs.

The following application options are available when configuring the DI/DO as digital outputs:

• Use as onboard outputs

• Use as "fast output cams"

The outputs comply with the standard IEC 1131-2/DIN EN 61131-2 (24 V P switching).

Additional references

For information on configuring the I/O addresses and on using the "fast inputs" as measuring

inputs, see the Commissioning Manual,

For further information on configuring the digital inputs as measuring inputs and the digital

outputs as fast output cams, see the Function Manual,

Measuring Inputs

, /8/.

SIMOTION D410

SIMOTION Output Cams and

, /1/.

D410

Manual, 03/2007 Edition

31

Page 32

Interfaces

3.3 DRIVE -CLiQ interface

3.3 DRIVE-CLiQ interface

Features

The DRIVE-CLiQ interface has the following features:

• Automatic detection of components

• For the DRIVE-CLiQ interface, 24 V / 450 mA are available to connect encoders and

measuring systems.

Interface features

Table 3-5 Interface X100

Features Type

Connector type: DRIVE-CLiQ connector

max. cable length: 50 m

Data rate: 100 Mbits

blanking plate on DRIVE-CLiQ interface: Molex, Order No.: 85999-3255

Interface assignments

Table 3-6 Interface assignment X100

View Pin Name Signal type Description

%

$

Signal type: I = Input; O = Output; VO = Voltage Output

1 TXP O Transmit data +

2 TXN O Transmit data 3 RXP I Receive data +

4 Reserved, do not use - 5 Reserved, do not use - 6 RXN I Receive data 7 Reserved, do not use - 8 Reserved, do not use - A + (24 V) VO Supply voltage

B M (0 V) VO Electronic ground

D410

32 Manual, 03/2007 Edition

Page 33

Interfaces

3.3 DRIVE -CLiQ interface

Connectable devices

The following table contains the components that can communicate with SIMOTION D410

via the DRIVE-CLiQ interface. Note the max. number of nodes that can be connected to the

DRIVE-CLiQ!

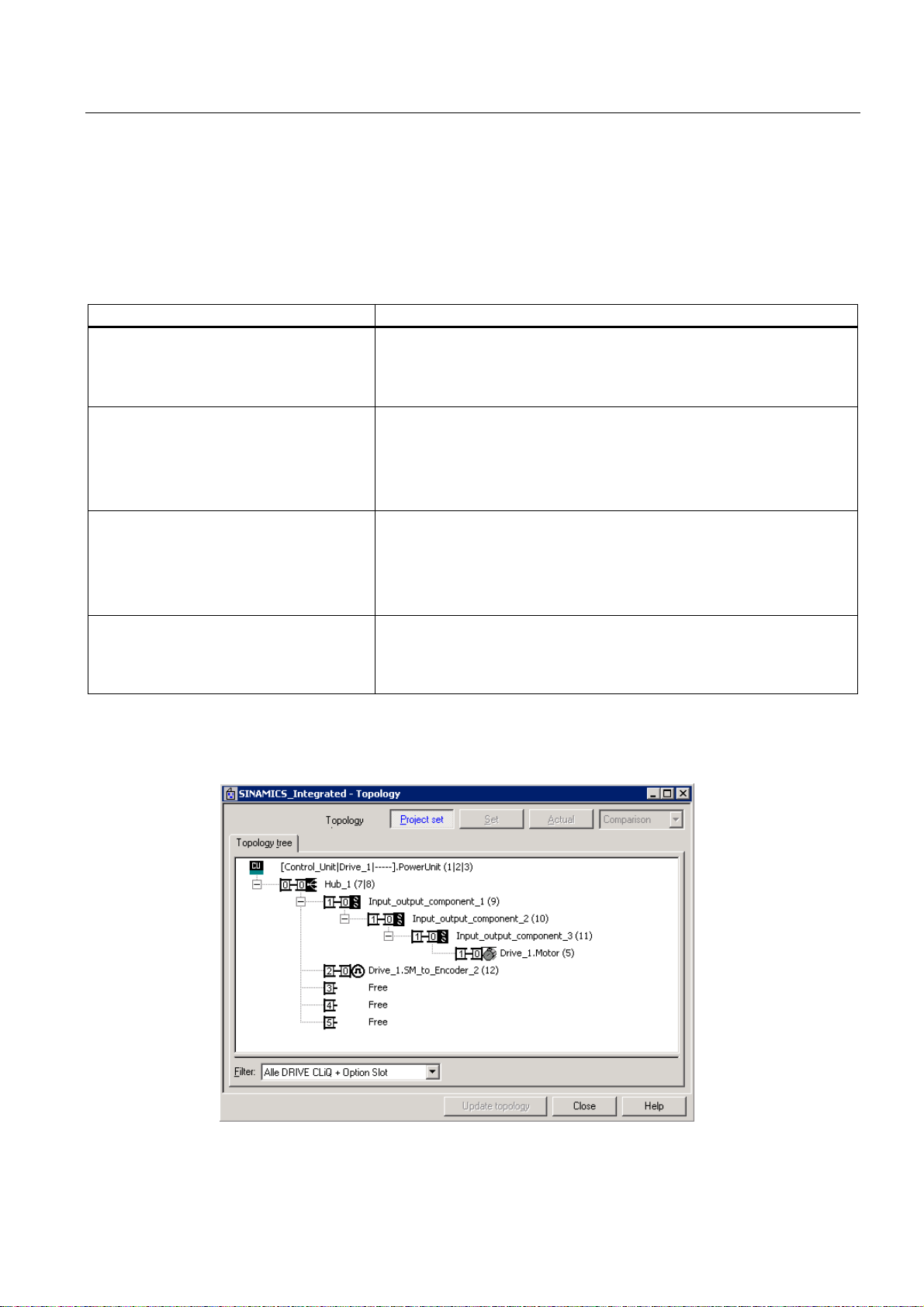

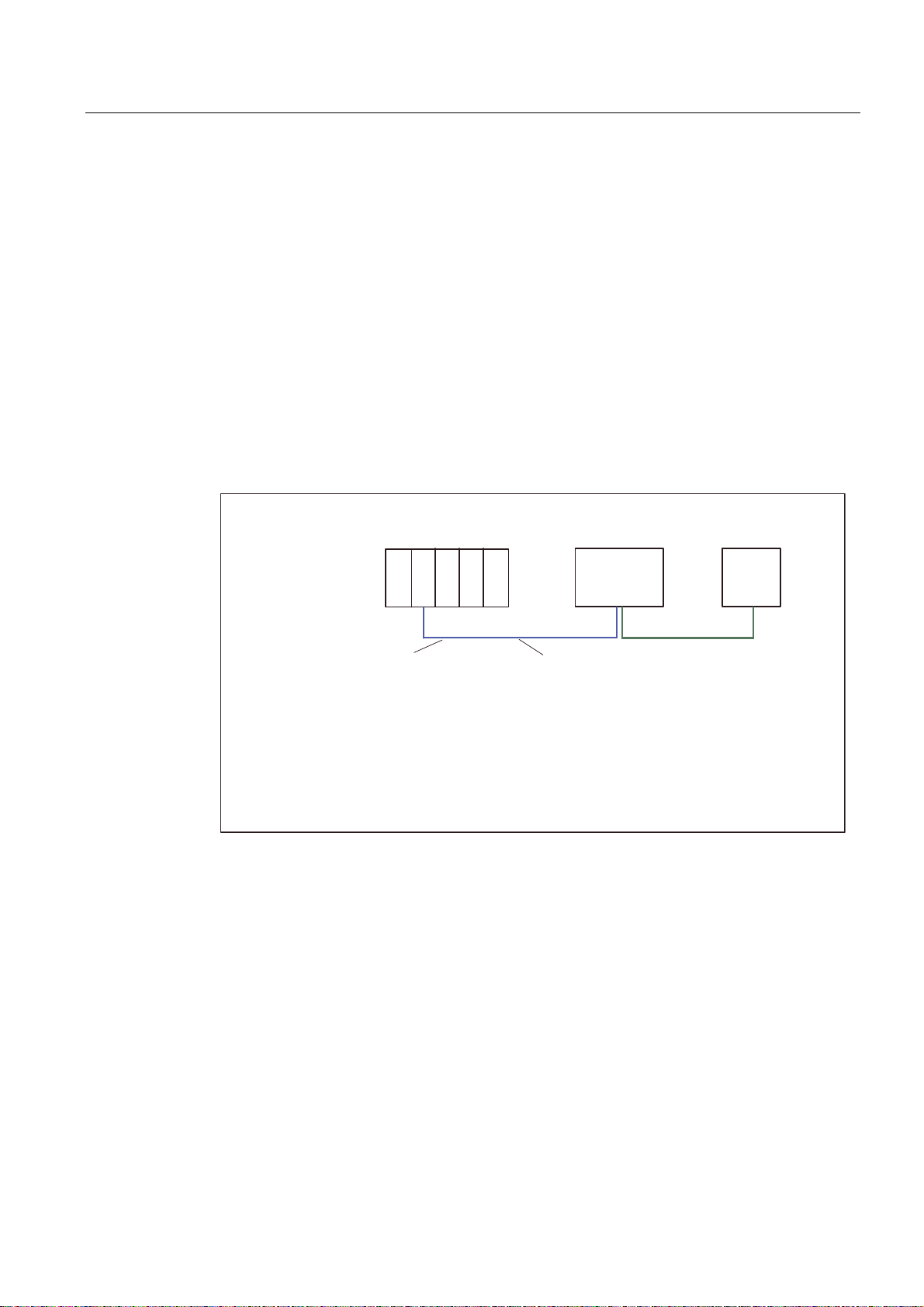

Table 3-7 DRIVE-CLiQ connection topology

Components Max. number of connectable nodes

Drive Max. 1 drive from the following:

• Blocksize power module (PM340), only possible for operation away from

the power module with CUA31 (see chapter "Installation")

• Power Module Chassis AC/AC

Encoder via Sensor Module Cabinet (SMC)

and Sensor Module Integrated (SMI)

Terminal expansion modules Max. 3 of the following terminal modules:

DRIVE-CLiQ hub module 20 (DMC20) Max. 1 DMC20

Max. 2 of the following encoder modules:

• SMC10

• SMC20

• SMC30

• Encoder connection via motor with DRIVE-CLiQ interface (SMI)

• TM15 terminal module

• High feature terminal module TM17

• TM31 terminal module

• TM41 terminal module

Note: Because an SMC and an SMI only have one DRIVE-CLiQ interface, a

DMC20 must be used for a second encoder on DRIVE-CLiQ. If a CUA31 is

used, then the DMC20 is not required.

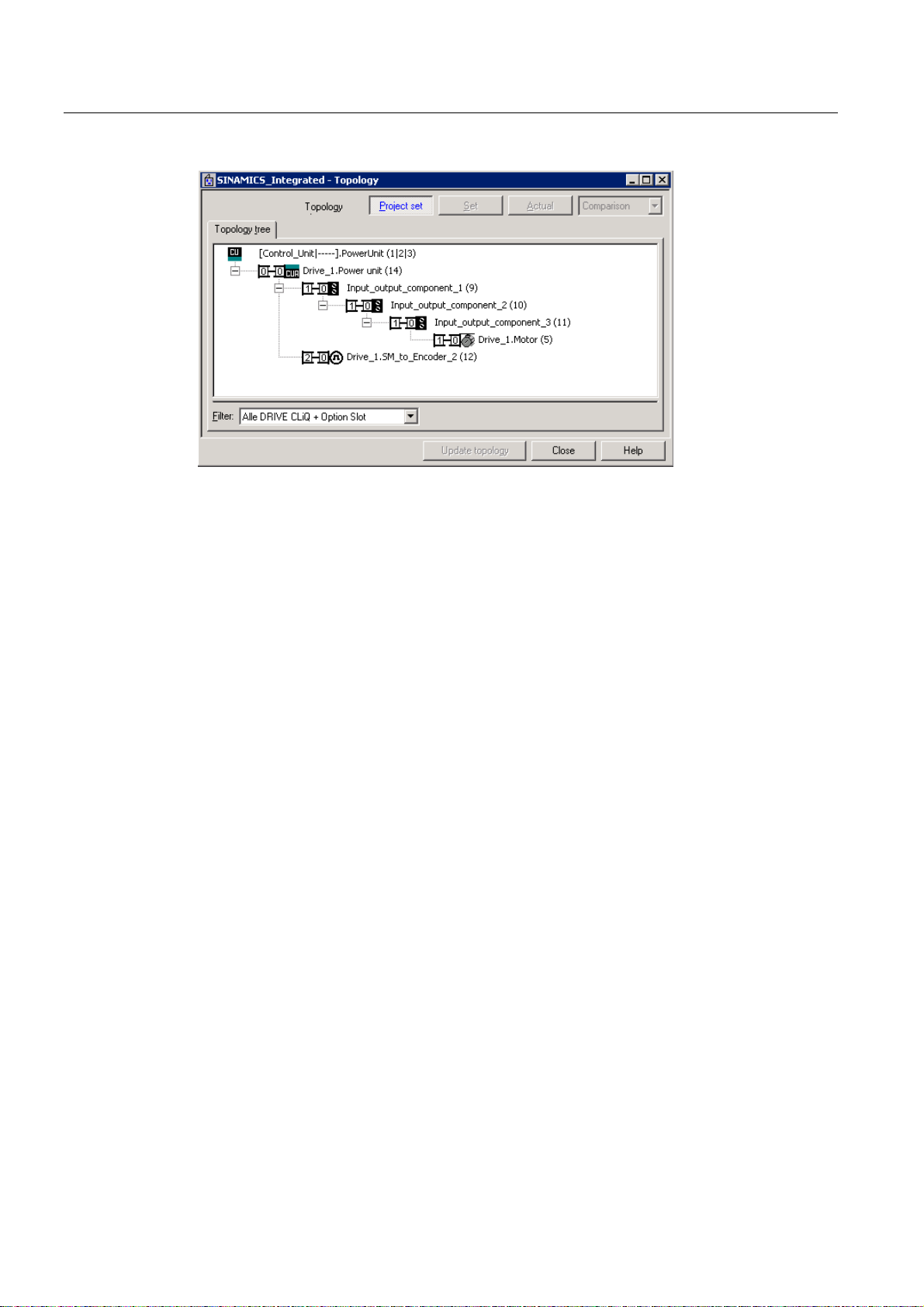

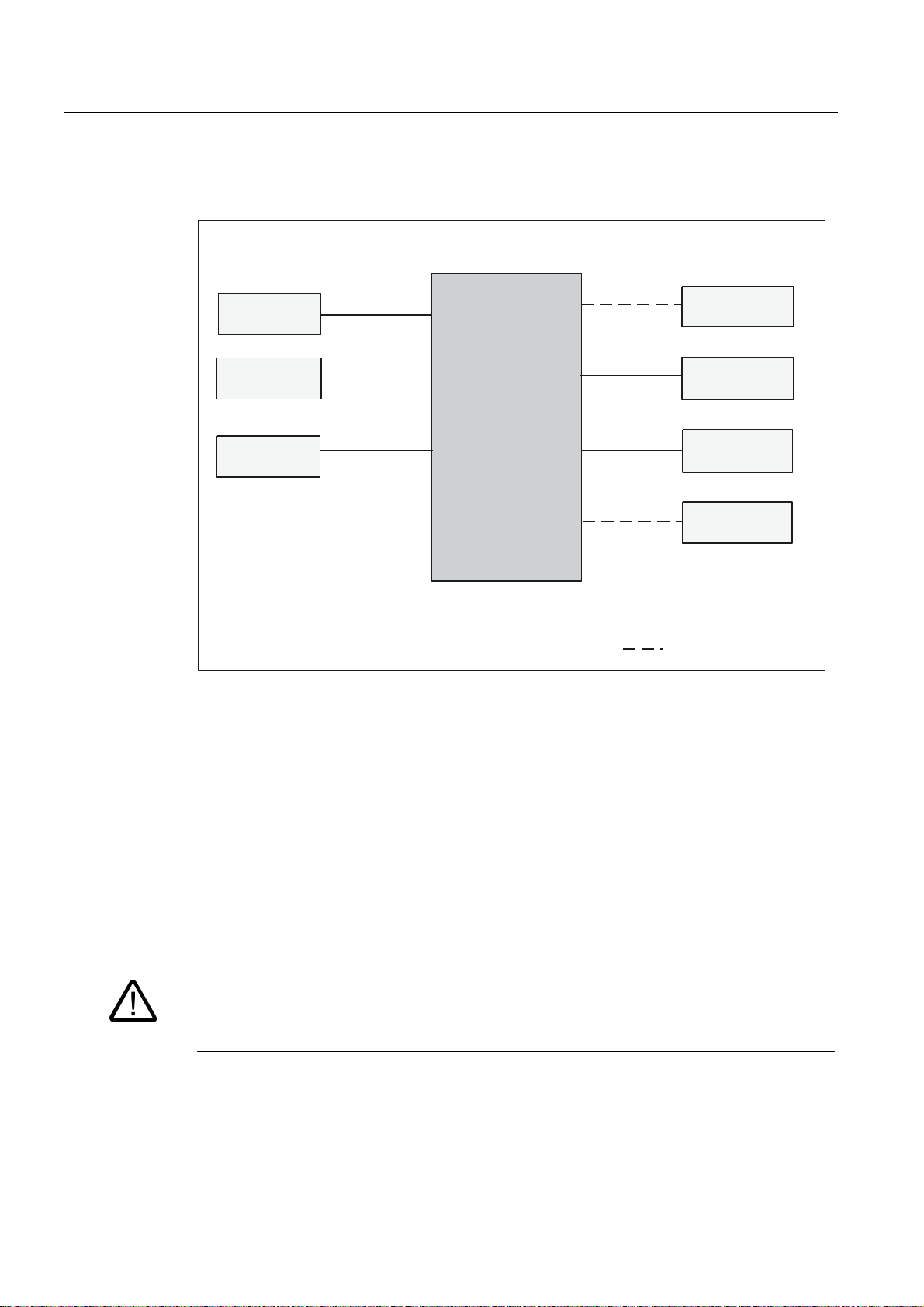

The following figures show 2 example topologies of components that can be connected to

the DRIVE-CLiQ.

Figure 3-2 Example topology: 3 terminal modules, 1 encoder via SMI, 1 encoder via SMC

D410

Manual, 03/2007 Edition

33

Page 34

Interfaces

3.3 DRIVE -CLiQ interface

Figure 3-3 Example topology: 3 terminal modules, 1 CUA31, 1 encoder via SMI, 1 encoder via SMC

Further information

For information on the components that can be connected via DRIVE-CLiQ (setup,

connection, configuration, etc.) see

SINAMICS S120 Control Units and Supplementary System Components

•

Manual, /2/

•

SINAMICS S120 AC Drive

•

SINAMICS S120

SINAMICS S120 Booksize Power Modules

•

•

SIMOTION TM15 and TM17 High Feature Terminal Modules

•

Supplementary SINAMICS System Components for SIMOTION

Commissioning Manual, /4/

Equipment Manual, /3/

Equipment Manual, /5/

Commissioning Manual, /6/

Equipment Manual, /7/

Equipment

D410

34 Manual, 03/2007 Edition

Page 35

Interfaces

3.4 PROFIBUS DP interface (SIMOTION D410 DP only)

3.4 PROFIBUS DP interface (SIMOTION D410 DP only)

SIMOTION D410 DP provides one interface to connect to PROFIBUS DP. The interface can

be run asynchronously or isochronously, equidistant.

A baud rate of 12 Mbits/s can be set for the PROFIBUS DP interface.

SIMOTION D410 includes master and I-slave functionality.

Interface features

Table 3-8 Interface X21

Features Type

Connector type: 9-pin D-Sub socket

Cable type: PROFIBUS cable

max. cable length: 100 m for 12 Mbits

max. data rate: 12 Mbits

Interface assignments

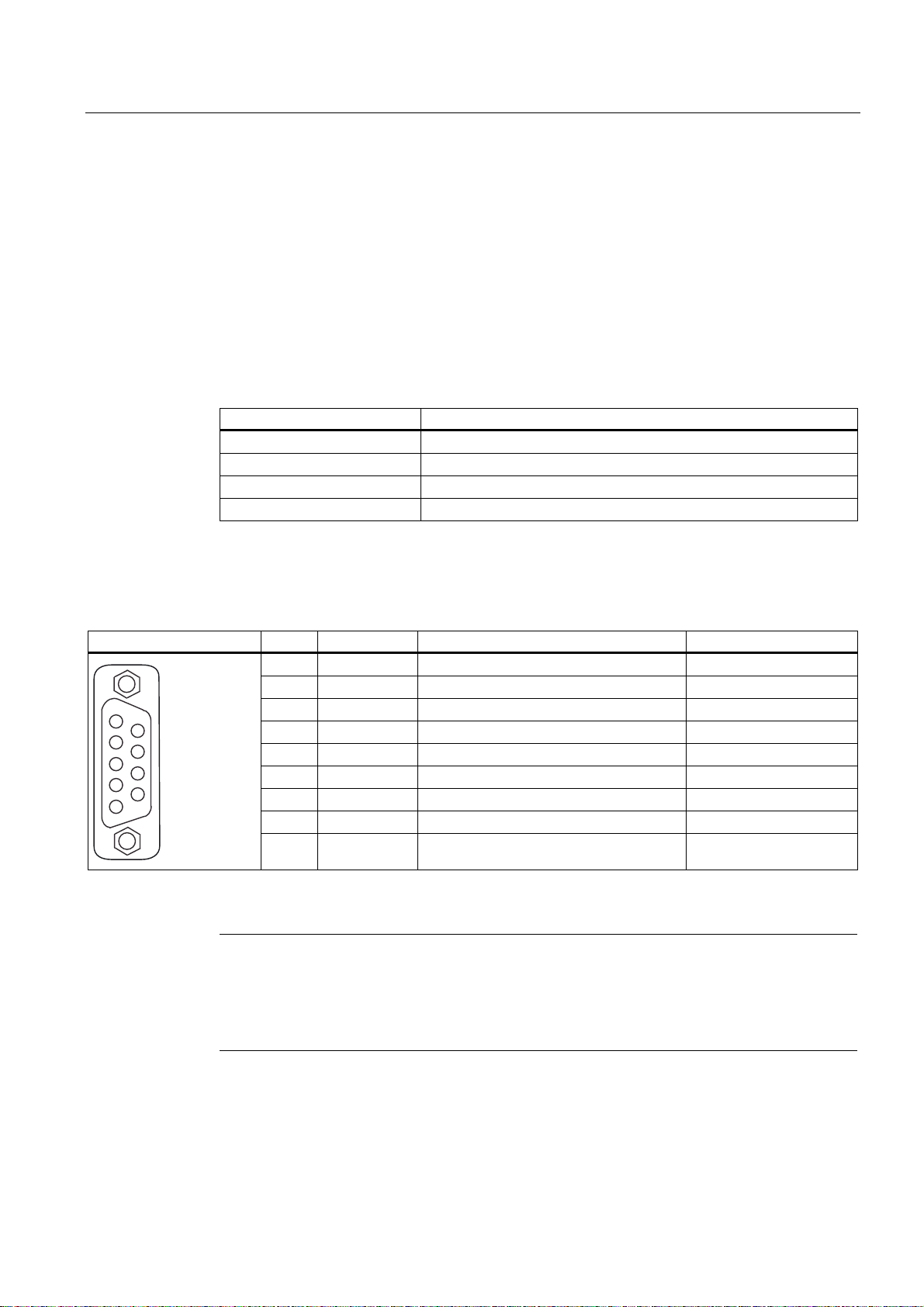

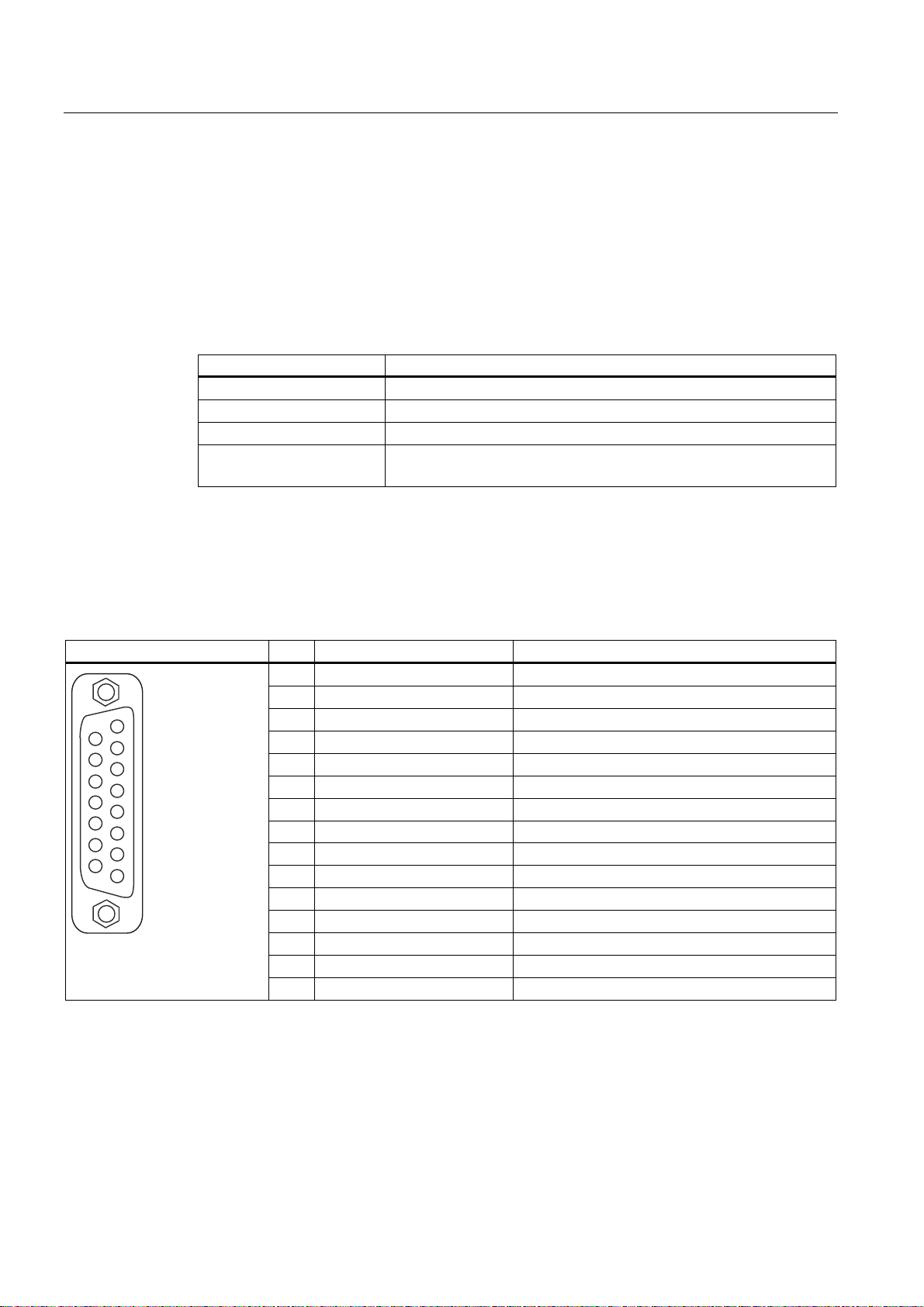

Table 3-9 Interface assignment X21

View Pin Name Description Area

1 - unassigned

2 M24_SERV Teleservice supply, ground 0 V

3 RxD/TxD-P Receive/transmit data P (B) RS485

4 CNTR-P Control signal TTL

5 DGND PROFIBUS data reference potential

6 VP Supply voltage plus 5 V +/- 10 %

7 P24_SERV Teleservice supply, + (24 V) 24 V (20.4 V - 28.8 V)

8 RxD/TxD-N Receive/transmit data P (N) RS485

9 - unassigned

Note

A teleservice adapter can be connected to the PROFIBUS interface (X21) for remote

diagnosis.

D410

Manual, 03/2007 Edition

The power supply for the teleservice (terminals 2 and 7) can take up to 150 mA and is

sustained short-circuit proof.

35

Page 36

Interfaces

3.4 PROFIBUS DP interface (SIMOTION D410 DP only)

PROFIBUS connector

The terminating resistors must be switched on at the first and last terminal in a line to ensure

uninterrupted communication.

The bus terminating resistors are activated in the connector.

The cable shield must be applied over a large area and on both sides.

Connectable devices

The following devices can be connected to the PROFIBUS DP interface:

• PG/OP programming devices

• SIMATIC HMI devices

• SIMATIC S7 controllers with PROFIBUS DP interface

• Distributed I/O

• Teleservice adapter

• Drive units with PROFIBUS DP interface (standard slaves)

Note

For all enabled modules and devices, see SIMOTION Motion Control System

Catalog

Take note of the documentation on the individual modules or devices!

, /11/.

PM 10

D410

36 Manual, 03/2007 Edition

Page 37

Interfaces

3.5 PROFINET interface (SIMOTION D410 PN only)

3.5 PROFINET interface (SIMOTION D410 PN only)

PROFINET is an open component-based industrial communication system using Ethernet

for distributed automation systems.

SIMOTION D410 PN includes a PROFINET interface with 2 ports (X200 and X201).

A SIMOTION D410 PN can be set as IO controller or I device via the PROFINET interface.

Interface features

Table 3-10 Ports X200 and X201

Features Type

Connector type: RJ45plus socket

Cable type: PROFINET

max. cable length: 100 m

min. transmit cycle: 0.5 ms

Interface assignments

Table 3-11 Assignment of ports X200 - X201

View Pin Name Description

%

$

1 TXP Transmit data +

2 TXN Transmit data 3 RXP Receive data +

4 Reserved, do not use

5 Reserved, do not use

6 RXN Receive data 7 Reserved, do not use

8 Reserved, do not use

Connectable devices

The following devices can be connected to the PROFINET interface:

• PG/PC programming devices (communication with SIMOTION SCOUT / STEP 7 and

HMI)

• SIMATIC HMI devices

• Distributed I/O

See also

D410

Manual, 03/2007 Edition

• Other SINAMICS drive units (e.g., with CBE20)

Connecting the PROFINET interface (410 PN only) (Page 54)

37

Page 38

Interfaces

3.6 HTL/TTL encoder interface

3.6 HTL/TTL encoder interface

The HTL-/TTL encoder interface is used to connect external encoders (HTL or TTL

encoders).

Interface features

Table 3-12 Interface X23

Features Type

Connector type: 15-pin D-Sub connector

Encoder interface: TTL/HTL incremental encoder

Limiting frequency: 500 kHz

max. cable length:

1)

As of a cable length of 200 m, use a power supply cable with a cable cross-section ≥

0.75 mm²!

• TTL encoder: 100 m (bipolar signals only)

• HTL encoder: 100 m unipolar signals, 300 m bipolar signals

1)

Interface assignments

Table 3-13 Interface assignment X23

View Pin Name Description

1 Reserved, do not use

2 SSI_CLK SSI clock positive

3 SSI_XCLK SSI clock negative

4 PENC Encoder power supply

5 PENC Encoder power supply

6 PSENSE Remote sense encoder power supply (P)

7 G Electronic ground

8 Reserved, do not use

9 MSENSE Remote sense encoder power supply (G)

10 RP R track positive

11 RN R track negative

12 BN B track negative

13 BP B track positive

14 AN_SSI_XDAT A track negative / SSI data negative

15 AP_SSI_DAT A track positive / SSI data positive

D410

38 Manual, 03/2007 Edition

Page 39

Interfaces

3.7 EP terminals/temperature sensor connection

3.7 EP terminals/temperature sensor connection

The EP terminal is the input terminal for the "safe standstill" and is wired to the motor

module. The "safe standstill" is activated, if the EP terminal on the motor module is activated

at the same time as the terminal X121 (DI) on the control unit.

Using the temperature sensor connection, you can connect the temperature sensing via KTY

(special temperature sensor) or PTC (positive temperature coefficient). The temperature

sensing provides thermal motor protection by detecting critical motor conditions.

For more information on "thermal motor protection", see the Commissioning Manual,

SINAMICS S120

Interface features

Table 3-14 Interface X120

Features Type

Connector type: Mini Combicon, 8-pin

Graduation: 2,5 mm

max. connectable cross-section 1.5 mm2

, /4/.

Interface assignments

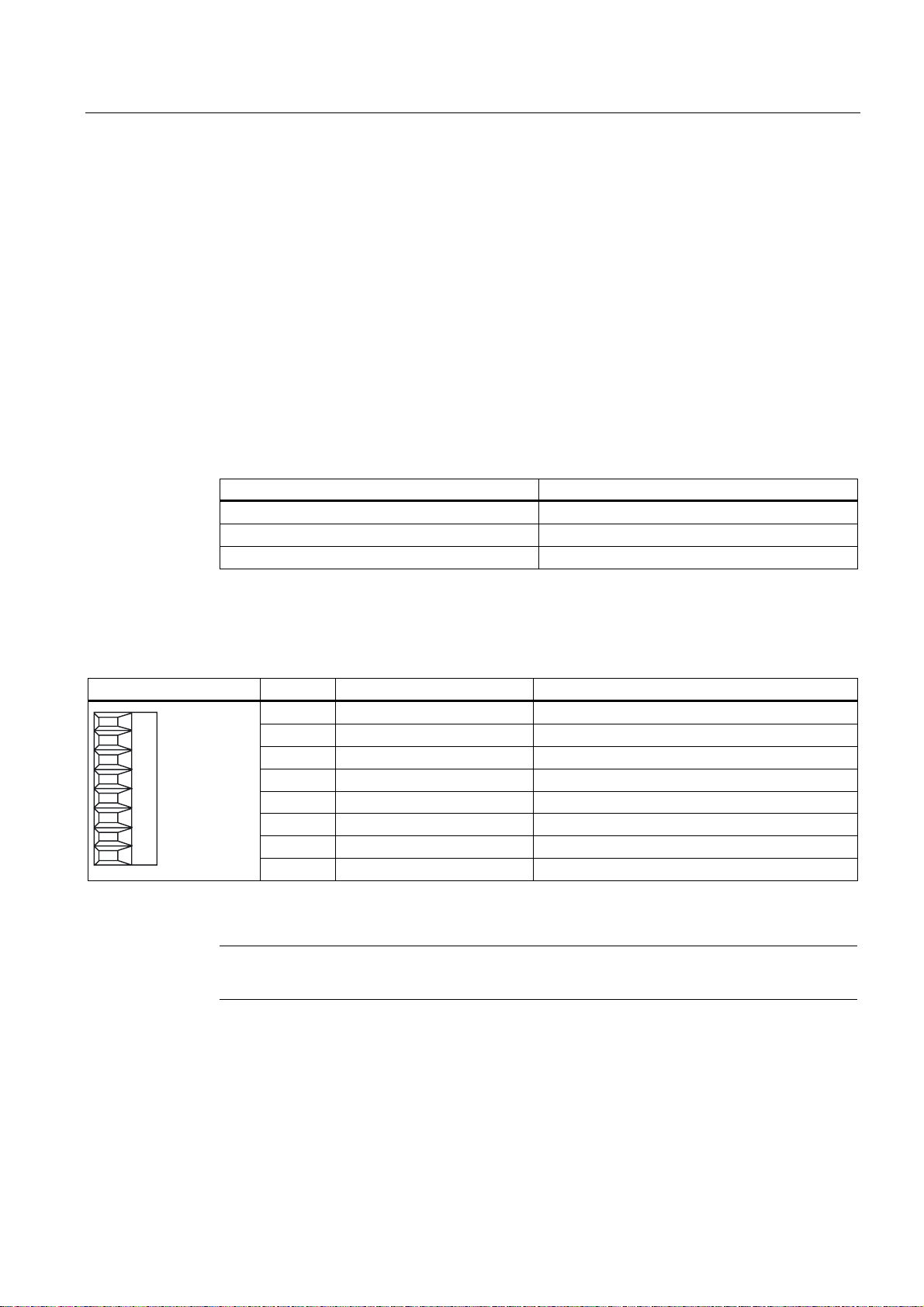

Table 3-15 Interface assignment X120

View Pin Name Description

1 Reserved, do not use

2 Reserved, do not use

3 G Ground

4 + Temp KTY or PTC input

5 - Temp Ground for KTY or PTC

6 Reserved, do not use

7 EP +24 V Safe standstill input (+)

8 EP M1 Safe standstill input (-)

Notice

The KTY and PTC temperature sensor must be connected with the correct polarity.

D410

Manual, 03/2007 Edition

39

Page 40

Interfaces

3.8 Power supply

3.8 Power supply

The interface X124 is used exclusively to connect the external power supply.

The 24 V DC load power supply is required for the supply

• of digital inputs/outputs (X121)

• SIMOTION D410 can be supplied with power by connecting a power module. Additional

24 V must be connected in the following situations:

– Commissioning/diagnosis with deactivated power module supply voltage

– Running the SIMOTION D410 digital inputs/outputs

– When SIMOTION D410 will not be mounted on a PM340

• of sensor module electronics

• of motor holding brake

Note

A control DC power supply is required to operate a motor with an integrated holding

brake. The supply voltage is realized via the 24 V connection (X124). Take note of the

motor holding brake voltage tolerances and the connecting cable voltage drop.

Interface features

Set the DC power supply to 26 V. This can ensure that the motor holding brake supply

voltage is in the permissible range if the following boundary conditions are fulfilled:

• You are using a Siemens AC motor.

• You are using Siemens Motion-Connect power cables.

• The motor cables are no longer than 100 m.

Features Type

Connector type: Screw terminal 2

• Connectable cable cross-sections:

– Flexible: 0.2 mm² to 2.5 mm²

– with wire-end sleeve without plastic sleeve: 0,25 mm² to 1 mm²

– with wire-end sleeve with plastic sleeve: 0,5 mm² to 1 mm²

• Wire length: 7 mm

• Tool: Screwdriver 0.6 x 3.5 mm

• Torque: 0.5 to 0.6 Nm

Connection possibility: up to 2.5 mm2

Load capacity: 10 A

max. cable length: 10 m

D410

40 Manual, 03/2007 Edition

Page 41

Interfaces

3.8 Power supply

Interface assignments

Table 3-16 Interface X124

View Pin Description Technical details

+ Electronic power supply

0

+ Electronic power supply

G Electronic ground

G Electronic ground

Voltage: 24 V DC (20.4 V - 28.8 V)

Current consumption: max. 0.8 A (without DRIVE-CLiQ and

digital outputs)

max. current via the bridges in the connector: 20 A at 55 °C

See also

Note

When using external power supplies, e.g., SITOP, the ground potential must be connected

with the protective ground terminal (PELV).

Connecting the power supply (Page 51)

D410

Manual, 03/2007 Edition

41

Page 42

Interfaces

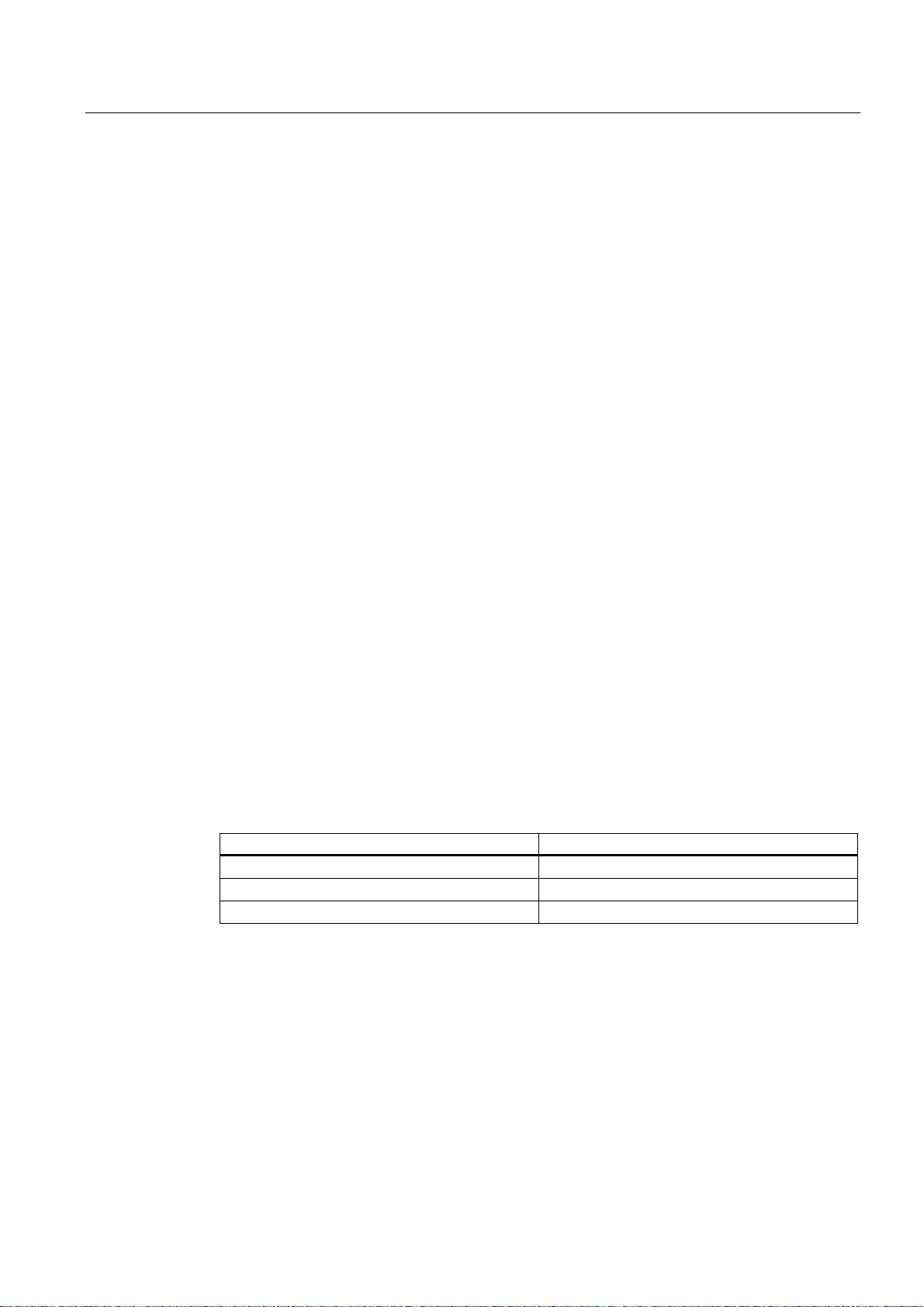

3.9 Measuring sockets

3.9 Measuring sockets

Interface features

The T0 - T2 measuring sockets are used to output analog signals Any interconnectable

signal can be output to any measuring socket on the control unit.

Interface assignments

Table 3-17 Interface assignments T0, T1 and T2

View Pin Designation Technical details

7

7

7

Note

The measuring sockets are suited for multiple-spring wire connectors with a diameter of

2 mm.

T0 Measuring socket 0

T1 Measuring socket 1

D2 Measuring socket 2

G Ground

• Voltage: 0 V to 5 V

• Resolution: 8-bit

• Load current: max. 3 mA

• sustained short-circuit proof

• Reference potential is G terminal

0

3.10 Power Module Interface

SIMOTION D410 can be connected to a blocksize power module via the power module

interface.

See also

Note

SIMOTION D410 can only be connected to a blocksize power module via the power module

interface. You must connect a chassis power module via the DRIVE-CLiQ interface (see

chapter "Connecting DRIVE-CLiQ Components").

SIMOTION D410 mounted on the power module (Page 43)

D410

42 Manual, 03/2007 Edition

Page 43

Assembling

4.1 General requirements

Mounting options

SIMOTION D410 comes in two designs:

• Mounted on the power module: SIMOTION D410 is mounted on the power module.

• Operation away from the power module: SIMOTION D410 is mounted on a mounting

plate.

Open device

SIMOTION D410 is an open device! This means, you can only install the modules in

housings, cabinets or electrical equipment rooms. These may only be accessible via key or

tool. Housings, cabinets, or electrical equipment rooms may only be accessed by trained or

authorized personnel. An external fire-protection housing is required.

Danger

The system must be without power when you mount the housing.

4

4.2 SIMOTION D410 mounted on the power module

Overview

SIMOTION D410 can be snapped directly on the blocksize power module (e.g., PM340) via

the PM-IF interface.

D410

Manual, 03/2007 Edition

Note

You can connect a blocksize or chassis power module to the DRIVE-CLiQ interface of

SIMOTION D410 using the CUA31 adapter module.

43

Page 44

Assembling

4.2 SIMOTION D410 mounted on the power module

Requirement

As soon as the power module (e.g., PM340) is properly installed, you can mount the

SIMOTION D410 to the power module.

Note

Take note of the associated user documentation when commissioning the power module!

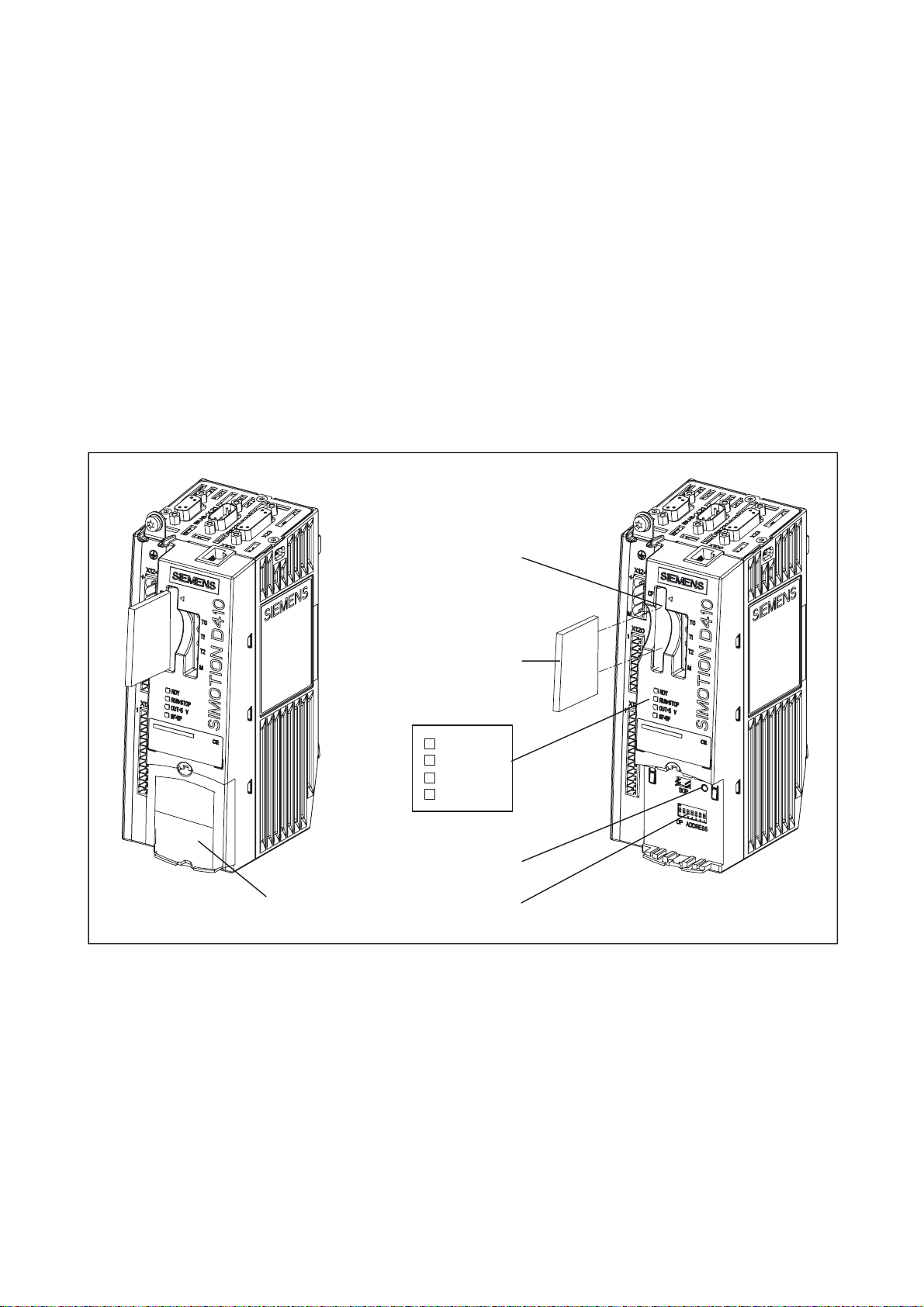

Mounting on the power module

Snapping the SIMOTION D410 onto the power

module (e.g., PM340)

D410

44 Manual, 03/2007 Edition

Power module (e.g., PM340) with

SIMOTION D410

Page 45

Assembling

4.2 SIMOTION D410 mounted on the power module

Disassembling SIMOTION D410

To remove SIMOTION D410 from the power module, the blue release, as shown in the

figure, must be pressed down and SIMOTION D410 tilted forward.

Figure 4-1 Removing the SIMOTION D410 from the power module (e.g., PM340)

D410

Manual, 03/2007 Edition

45

Page 46

Assembling

4.3 Mounting SIMOTION D410 on the mounting plate

4.3 Mounting SIMOTION D410 on the mounting plate

Overview

Using a mounting plate, SIMOTION D410 can be operated on a mounting plate, which

means it is not mounted directly to the power module.

Requirements

You must order the mounting plate for SIMOTION D410 separately. See chapter "Spare

Parts and Accessories" for the order number.

Mounting on mounting plate

1. The mounting plate is mounted to the rear panel of the control cabinet.

2. SIMOTION D410 is snapped onto the mounting plate.

Figure 4-2 Mounting SIMOTION D410 on the mounting plate

D410

46 Manual, 03/2007 Edition

Note

When operating SIMOTION D410 away from the power module, generally the power supply

must be realized via the power supply connection (X124).

Take note of the information on control cabinet installation in the equipment Manual,

SINAMICS S120 AC Drive

, /3/.

Page 47

Connecting

5.1 Overview

This chapter describes the basic guidelines for the electrical setup. You must observes these

guidelines to ensure uninterrupted operation.

Safety regulations

To safely operate your system, take the following measures and adapt them to your specific

conditions:

• An EMERGENCY-OFF concept based on applicable technical specifications

(e.g., European Standards EN 60204, EN 418 and associated standards).

• Additional measures to limit the travel of axes

(e.g., hardware limit switch).

• Equipment and measures to protect motors and power electronics according to the

SINAMICS installation guidelines.

In addition, in order to identify hazards, we recommend that a risk analysis be conducted on

the entire system in accordance with the basic safety requirements set out in Appendix 1 of

EU Machinery Directive 89/392/EEC.

5

Please note the chapter "Guidelines for handling electrostatic sensitive devices (EGB)" in

this Manual.

Additional references

As an additional resource on the topic of EMC guidelines, we recommend the description

EMC installation guidelines, engineering instructions (HW)

Standards and specifications

You must comply with the applicable VDE guidelines when wiring the SIMOTION D410, in

particular VDE 0100 and VDE 0113 for disconnecting devices, short-circuit and overload

protection.

D410

Manual, 03/2007 Edition

, /15/.

47

Page 48

Connecting

5.2 General rules for operating the SIMOTION D410

5.2 General rules for operating the SIMOTION D410

You must observe these general rules when integrating the SIMOTION D410 into a system.

System startup after certain events

The following table identifies considerations required for startup of a system following certain

events.

Table 5-1 System startup

When ... then ...

Startup after voltage drop or power loss no dangerous states must result. If necessary, force an

EMERGENCY OFF.

Startup after releasing the EMERGENCY

OFF equipment

Supply voltage

The following table identifies the considerations required for the supply voltage.

uncontrolled or undefined startup operations must be

excluded.

Table 5-2 Supply voltage

When ... make sure that ...

Stationary systems or systems

without all-pole power disconnect

switches

Load power supply, power supply

modules

All electric circuits deviation of the line voltage from the rated value must be

24 V DC supply voltage

The following table identifies the considerations required for the 24 V supply voltage.

Table 5-3 24 V DC supply voltage

When ... ensure ...

Buildings External lightning

24 V DC supply voltage cables,

signal cables

24 V supply voltage safe (electrical) isolation of the extra-low voltage

the building installation must be equipped with a power

disconnect switch or a fuse.

the set range of the rated voltage complies with the local

mains voltage.

within the permitted tolerance (refer to "Technical data of the

installed components").

Provide lightning protection (e.g.,

protection

internal lightning

protection

lightning protection devices)

D410

48 Manual, 03/2007 Edition

Page 49

Connecting

5.2 General rules for operating the SIMOTION D410

Danger

The 24 V DC voltage must be designed as functional extra-low voltage with safe isolation

(PELV according to DIN EN 60204-1).

Protection against external electrical interference

The following table identifies the considerations required for electrical interference or failures.

Table 5-4 Protection against external electrical interference

When ... make sure that ...

all installations or systems, in which

SIMOTION is installed

Supply, signal, and bus cables The wiring arrangement and installation complies with

Signal and bus cables A wire or conductor strand break must not cause any

The installation or system is connected to protective

ground to divert electromagnetic interferences.

EMC regulations.

undefined installation or system states.

Rules for current consumption and power loss in an installation

The power loss of all components used in a cabinet must not exceed the maximum amount

that can be dissipated from the cabinet.

Note

When designing the control cabinet, ensure that the temperature inside the cabinet does not

exceed the permitted ambient temperature for the components even at high external

temperatures.

D410

Manual, 03/2007 Edition

49

Page 50

Connecting

5.3 Overview of SIMOTION D410 connections

5.3 Overview of SIMOTION D410 connections

6,027,21b'

352),1(7

QRGH

'5,9(&/L4

QRGHV

352),%86

QRGH

RQO\LQ6,027,21b'b31

RQO\LQ6,027,21b'b'3

352),1(7

'5,9(&/L4

352),%86