Siemens SIMOTION C230-2 Equipment Manual

Preface, Table of Contents

SIMOTION

SIMOTION C230-2

Equipment Manual

Product Overview

The Fundamentals of Motion

Control

Device Data

Installation

Addressing the I/O

Wiring

Networking

Commissioning

Maintenance

1

2

3

4

5

6

7

8

9

6AU1 900-0AB30-0BA0

04.2003 Edition

Appendices

Standards and Approvals

EC Declaration of Conformity

ESD

References, Index

A

B

C

Safety notices

!

!

!

This manual contains notices that you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

Danger

Indicates a potentially hazardous situation which, if not avoided, will result in death or serious injury or in

substantial property damage.

Warning

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury or

in substantial property damage.

Caution

Used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or in property damage.

Caution

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

Notice

Used without the safety alert symbol indicates a potential situation which, if not avoided, may result in an

undesirable result or state.

Qualified personnel

This device/system may only be set up and operated by qualified personnel. Qualified persons are defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct usage

Note the following:

Warning

!

Trademarks

This device and its components may only be used for the applications described in the catalog or the

technical descriptions and only in connection with devices or components from other manufacturers that

have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

SIMATICR, SIMATIC HMIR, SIMATIC NETR, and SIMOTIONR are registered trademarks of

SIEMENS AG.

Other names in this publication might be trademarks the use of which by a third party for his own purposes

may violate the rights of the registered holder.

Disclaimer of liabilityE Siemens AG, 2003 All rights reserved

The reproduction, transmission, or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration of

a utility model or design, are reserved.

Siemens AG

Automation & Drives

Motion Control Systems

P.O. Box 3180, D-91050 Erlangen

Germany

-2

Siemens Aktiengesellschaft SIMOTION C230-2

We have checked the contents of this manual for agreement with the hardware and software described. Because deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the data in this manual

are reviewed regularly, and any necessary corrections are included in subsequent editions. Suggestions for improvement are welcomed.

E Siemens AG, 2003

Subject to technical changes.

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Preface

Sections of information in the manual

The following list describes the purpose of this manual and how you can benefit

from it.

S Product Overview (Chapter 1)

This part explains the purpose and potential applications of the module.

S The Fundamentals of Motion Control (Chapter 2)

Here you will find an introduction to motion control for individual axes and axis

groupings. The various terms are also explained.

S Device Data (Chapter 3)

This part introduces the C230-2 and its functions.

S Installation (Chapter 4)

This part explains the design of the mechanical configuration and how to install

the SIMOTION C230-2 components.

S Addressing the I/O (Chapter 5)

This part contains the information you will require to define the module initial

addresses of the modules used.

S Wiring (Chapter 6)

This part describes the connection and wiring for the drives, encoders and digital inputs/outputs (onboard).

S Networking (Chapter 7)

This part contains information that you need in order to create a PROFIBUS

subnet or Ethernet subnet.

S Commissioning (Chapter 8)

This part describes how you commission the hardware components and what

you must take into account.

S Maintenance (Chapter 9)

This part describes how you replace the module and update the SIMOTION

kernel.

S Appendices with factual information for reference (e.g. standards and approv-

als, ESD etc.)

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Preface-3

Preface

S List of References

Here you can find an overview and list of all SIMOTION documentation which

you need for the configuration and commissioning of the C230-2.

S Glossary and index to find the information

Standards and approvals

Our products meet the requirements of EU directive 89/336/EEC “Electromagnetic

Compatibility” and the harmonized European Standards (EN) listed there.

You can find detailed information on approvals and standards in Appendix A.

The EC declaration of conformity in accordance with the above EU directive, Ar-

ticle 10, is contained in this manual (see Appendix B).

Recycling and disposal

SIMOTION C230-2 is an environmentally friendly product! It includes the following

features:

S In spite of its excellent resistance to fire, the flame-resistant agent in the plastic

used for the housing does not contain halogens.

S Identification of plastic materials in accordance with DIN 54840

S Less material used because the unit is smaller and with fewer components

thanks to integration in ASICs

The C230-2 can be recycled because it is low in pollutants.

For environmentally friendly recycling and disposal of your old modules in accor-

dance with most advanced techniques, please get in touch with your contact person. You can find the correct contact person under the following Internet address:

http://www.ad.siemens.de/partner

Contacts

Preface-4

If you have any problems or questions when working with this manual, please contact the Siemens department indicated on the remarks form at the end of this

manual.

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Hotline

If you have any queries please contact our Hotline (worldwide):

A & D Technical Support: Phone: ++49-180-5050-222

If you have any comments on the documentation (suggestions, corrections),

please send them to the following fax number or e-mail address:

Fax form: See remarks form at the end of this document.

Additional support

We offer a range of courses to help you get started with the SIMOTION C230-2

system.

For more information, please contact your regional training center or the central

training center in D-90027 Nuremberg, Phone: ++49-911-895-3202.

Preface

Fax: ++49-180-5050-223

E-mail: ad.support@siemens.com

Fax: ++49-9131-98-2176

E-mail: motioncontrol.docu@erlf.siemens.de

Siemens Internet address

You can obtain constantly updated information on SIMOTION products on the

Internet at:

S General information http://www.siemens.de/simotion

S Technical information http://www4.ad.siemens.de/view/cs/en/10805436

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Preface-5

Preface

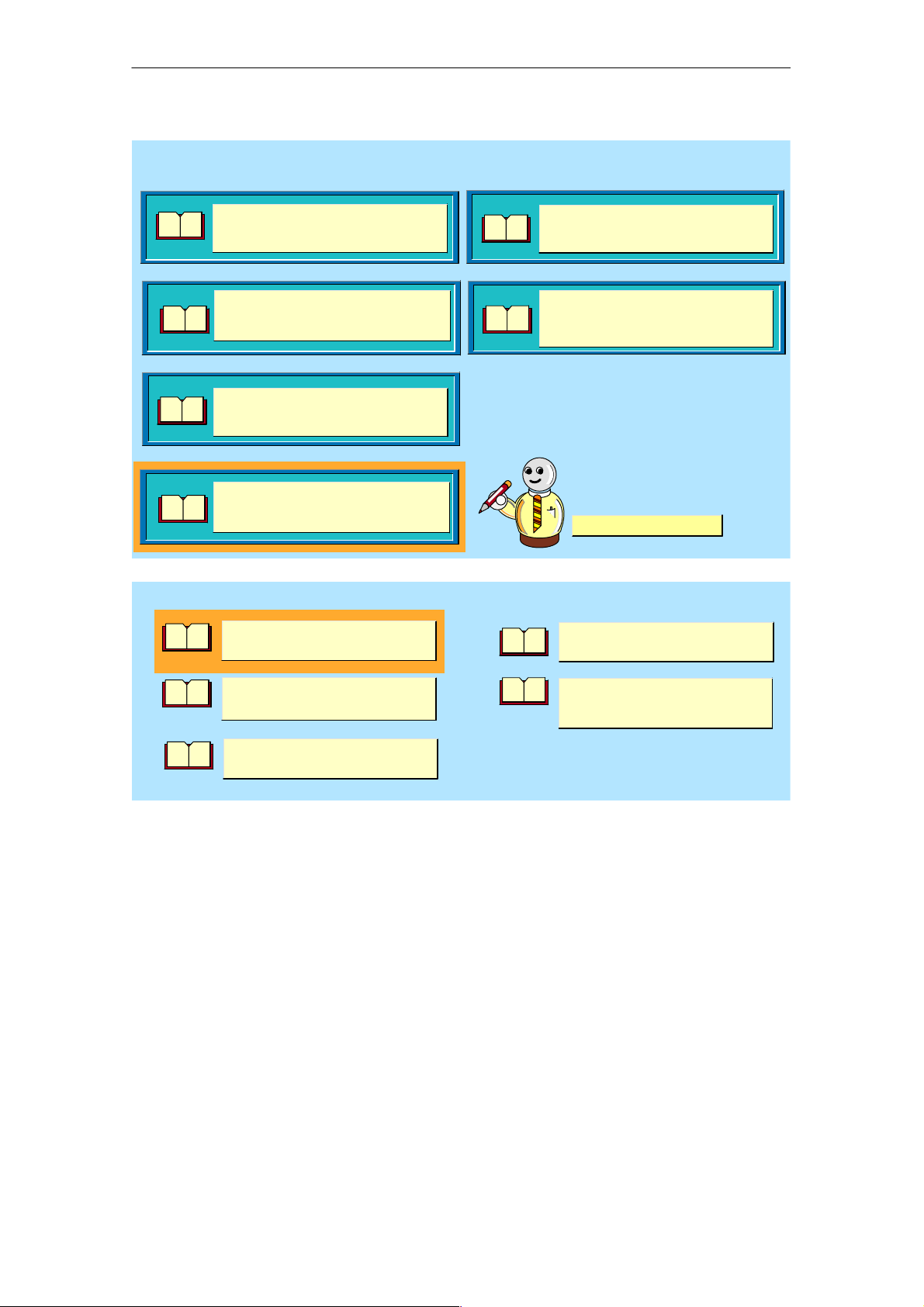

Documentation for SIMOTION

SIMOTION Engineering

Order No.: 6AU1 900-0BA30-0BA0

SIMOTION Technology Functions

Order No.: 6AU1 900-0BE30-0BA0

SIMOTION Reference Lists

Order No.: 6AU1 900-0BF30-0BA0

SIMOTION Hardware

Order No.: 6AU1 900-0BB30-0BA0

SIMOTION Hardware consists of the following documents:

SIMOTION C230-2

Equipment Manual

SIMOTION Function Library

Order No.: 6AU1 900-0BC30-0BA0

SIMOTION Plastics

Order No.: 6AU1 900-0CX30-0BA0

6AU1 900-0CN30-0BA0

Y ou are here ...

SIMOTION Panels

Equipment Manual

SIMOTION P350

Equipment Manual

SIMOTION D435

Equipment Manual

ADI4 – Analog Drive Interface

for Four Axes

Equipment Manual

Preface-6

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Table of Contents

1 Product Overview 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 The Fundamentals of Motion Control 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Device Data 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Layout of the module 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Mode selector 3-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Memory module slot 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Ethernet interface 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 PROFIBUS DP and drive interface 3-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.5 I/O modules approved for SIMOTION 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6 Analog drive interface 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7 Measuring system interface 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.8 I/O interface 3-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Clock 3-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Diagnosis using the LEDs 3-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Technical data 3-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Dimension drawing 3-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Accessories and spare parts 3-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Installation 4-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Design and configuration using SIMOTION C modules 4-58. . . . . . . . . . . . . . .

4.1.1 Horizontal and vertical configuration 4-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Clearances 4-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Mounting dimensions of modules 4-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 Layout of modules on a rack 4-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.5 Layout of modules on several racks 4-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Installation 4-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Fitting the mounting rail 4-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Installing modules on the mounting rail 4-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 After installation 4-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Addressing the I/O 5-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Assigning addresses on the basis of the module slot

(default addresses for centralized peripherals) 5-72. . . . . . . . . . . . . . . . . . . . . . .

5.2 User-assignable addressing on the C230-2

(centralized and distributed peripherals) 5-74. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Addressing signal modules 5-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Addressing the integrated digital inputs and outputs of the C230-2 5-78. . . . .

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Contents-7

Table of Contents

6 Wiring 6-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Project design of the electrical configuration 6-80. . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Wiring diagram - Overview 6-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Connecting the power supply 6-86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Connecting the drive units 6-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Connecting encoders 6-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 Wiring the front connector 6-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Connecting shielded cables via a shield connecting element 6-99. . . . . . . . . . .

7 Networking 7-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Designing a PROFIBUS subnet 7-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Requirements 7-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Rules for designing a subnet 7-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Cable lengths 7-105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Network components for PROFIBUS subnet 7-106. . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 PROFIBUS bus cable 7-106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Bus connector 7-107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Plugging the bus connector into the module 7-108. . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Ethernet subnet 7-109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 MPI subnet 7-110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Commissioning 8-111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Prerequisites for commissioning 8-112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Inserting and changing the Micro Memory Card 8-114. . . . . . . . . . . . . . . . . . . . . .

8.3 Switching on for the first time 8-115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Writing, formatting and erasing the Micro Memory Card 8-116. . . . . . . . . . . . . . .

8.5 Performing an overall reset on the C230-2 8-118. . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 User memory concept 8-120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Resetting the C230-2 to the default setting as delivered 8-123. . . . . . . . . . . . . .

9 Maintenance 9-125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 SIMOTION Kernel update 9-126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Removing and exchanging the C230-2 9-127. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Module exchange without PG/PC 9-129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Standards and Approvals A-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Electromagnetic compatibility A-132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Shipping and storage conditions for the C230-2 A-135. . . . . . . . . . . . . . . . . . . . .

A.3 Mechanical and climatic environmental conditions for the operation

of the C230-2 A-135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 Details of insulation testing, safety class and degree of protection A-138. . . . . .

A.5 Rated voltage to operate the C230-2 A-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.6 Safety of electronic controls A-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Siemens AG, 2003 All rights reserved

Contents-8

SIMOTION C230-2, 04.2003 Edition

Table of Contents

B EC Declaration of Conformity B-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Directive for the Handling of Electrostatically Sensitive Devices (ESD) C-145. . . . .

C.1 What does ESD mean? C-145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 Electrostatic discharge from persons C-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 Basic measures to protect against the discharge of static electricity C-147. . . .

References References-149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Contents-9

Table of Contents

Contents-10

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Product Overview

What can the C230-2 do?

The C230-2 is a motion control module for controlling servo drives via PROFIBUS

DP and four onboard drive interfaces.

The following configurations can be selected:

S Four axes via the onboard drive interface or

S Axes via PROFIBUS DP or

S Mixed operation with a maximum of four axes via the onboard drive interface

and axes via PROFIBUS DP

The number of operable axes on the PROFIBUS DP depends on the set system

cycle clocks, i.e. more than four axes can be operated with longer cycle times.

The C230-2 is a powerful module for positioning independent, single axes or motions in an axis grouping.

Both rotary axes and linear axes can be operated.

The configuration, parameterization, commissioning, programming and diagnostics

of the C230-2 is carried out via the Engineering System (ES).

1

For which applications can the C230-2 be used?

The C230-2 can be used both for positioning and synchronous operation (gearbox

and cam).

Typical areas in which the motion control module can be used are:

S Packaging industry

S Plastics industry

S Presses

S Textile industry

S Printing industry

S Wood, glass, ceramic, stone

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

1-11

Product Overview

System integration

SIMOTION offers an optimized system platform for automation and drive solutions

where priority is given to motion control applications and technological tasks.

The SIMOTION modular system consists of the Engineering System SIMOTION

SCOUT and a shared runtime system for various hardware platforms.

The truly innovative aspect of SIMOTION is that it does away with the traditional

separation between pure automation functions and motion functions.

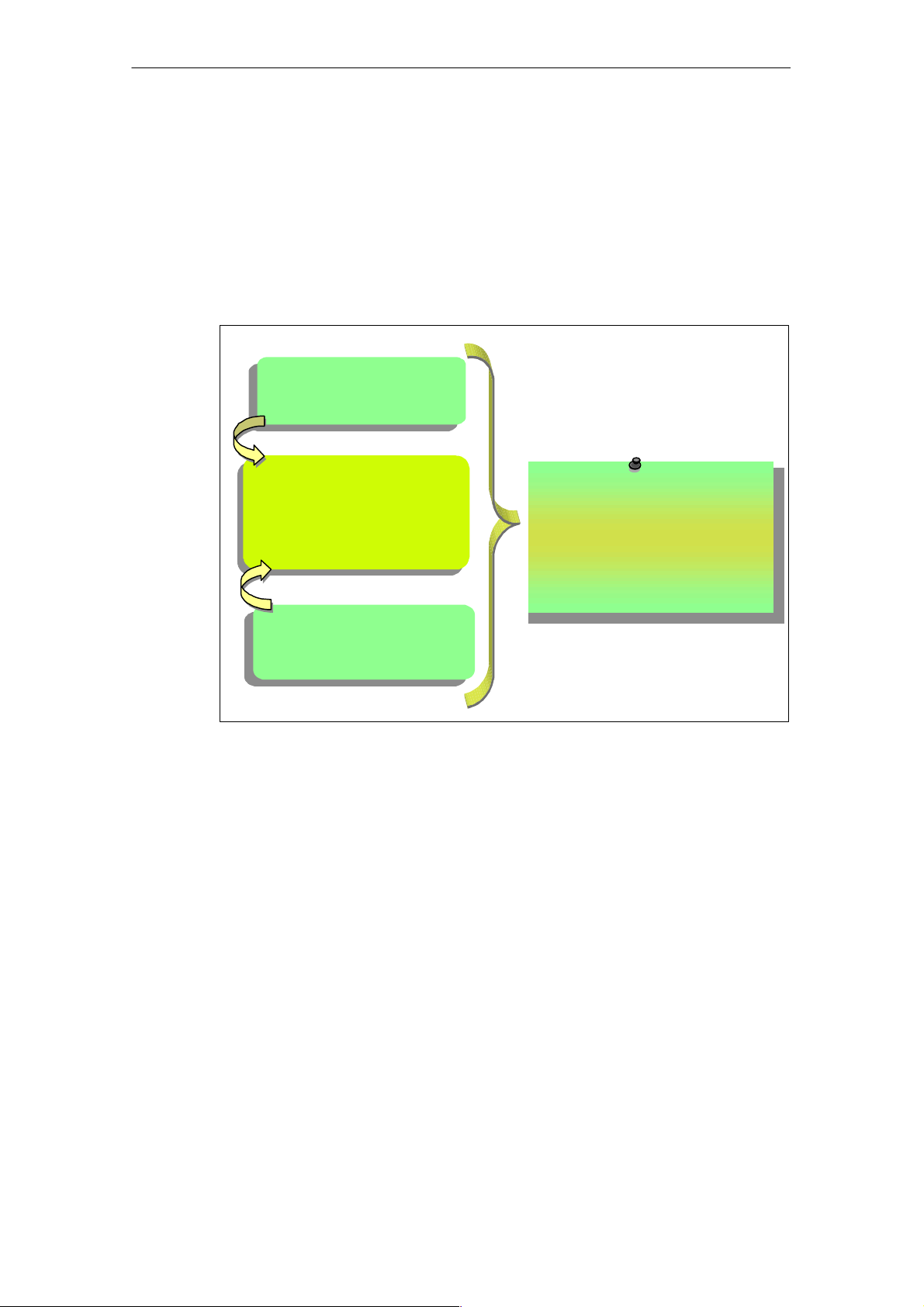

Logic

Motion control

(e.g. positioning,

synchronous operation,...)

The system approach of

SIMOTION

The fusion of motion control, logic

and other technology functions.

Further technology

functions

(e.g. pressure control,

temperature control)

Fig. 1-1 System solution for production machines

Individual automation tasks for production machines are formulated in a uniform

and consistent user interface. Logic and motion functions are programmed in this

graphic programming tool. The logic commands can also be programmed using the

structured text (ST) high-level language that complies with IEC 1131.

Technological tasks such as positioning or synchronous operation are available as

functions that are simple for you to incorporate in the program, as are the logic

commands too.

1-12

Consistency in the three areas of programming and project design, data management and communication is the core feature of Totally Integrated Automation (TIA).

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Product Overview

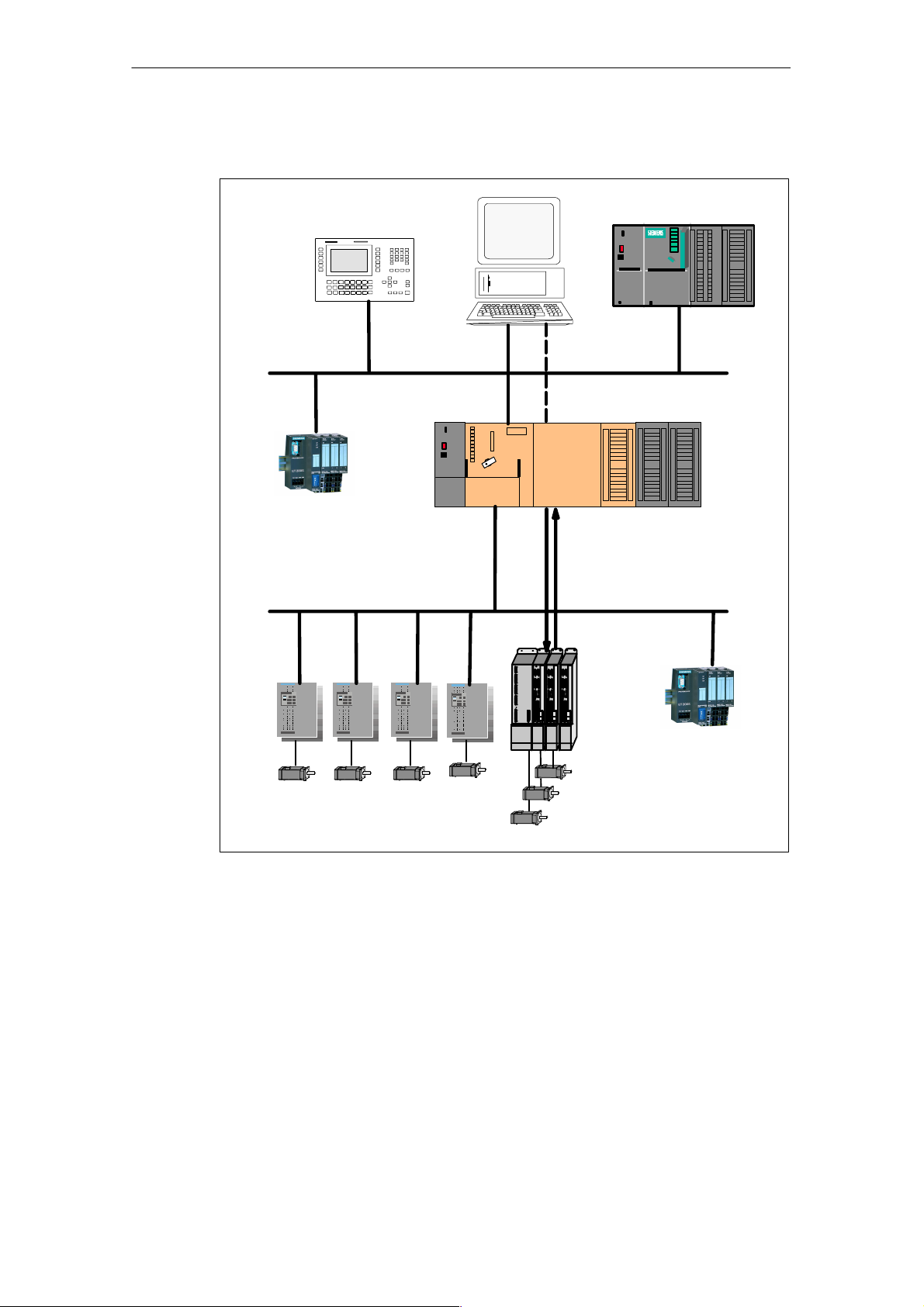

The following figure shows a system configuration with SIMOTION C230-2.

SIMATIC

HMI device

PROFIBUS DP

ET 200

PROFIBUS DP (isochronous)

PG/PC

PS

SIMATIC

S7

Ethernet

C230-2 SMs

S7-300

Fig. 1-2 System overview

ET 200

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

1-13

Product Overview

Components

The most important components of a SIMOTION application with C230-2 and their

functions are listed below.

Note

The modules or devices approved for the C230-2 can be found in the SIMOTION

PM 10 catalog.

Refer to the list of references for the order number of the catalog.

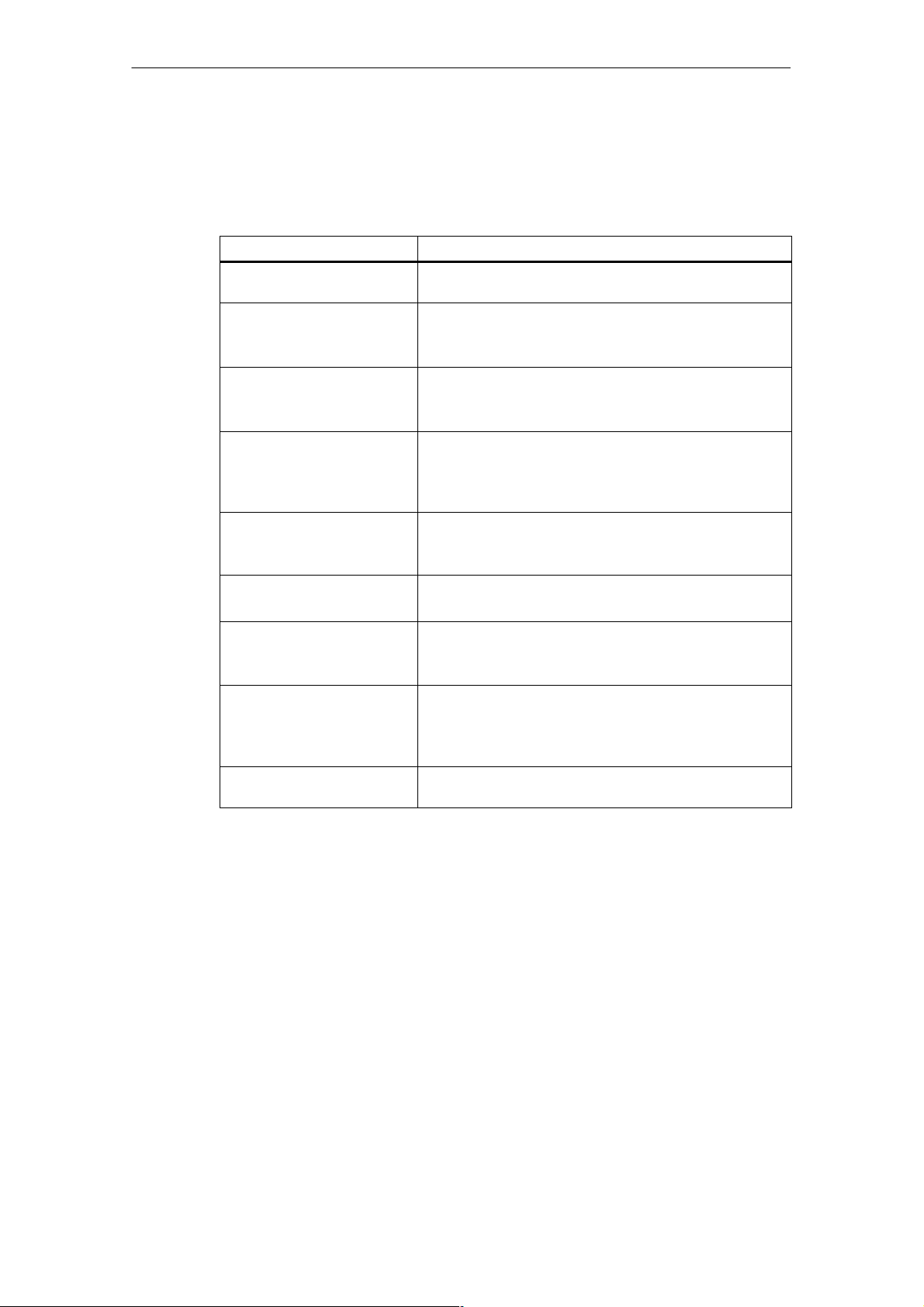

Centralized peripherals

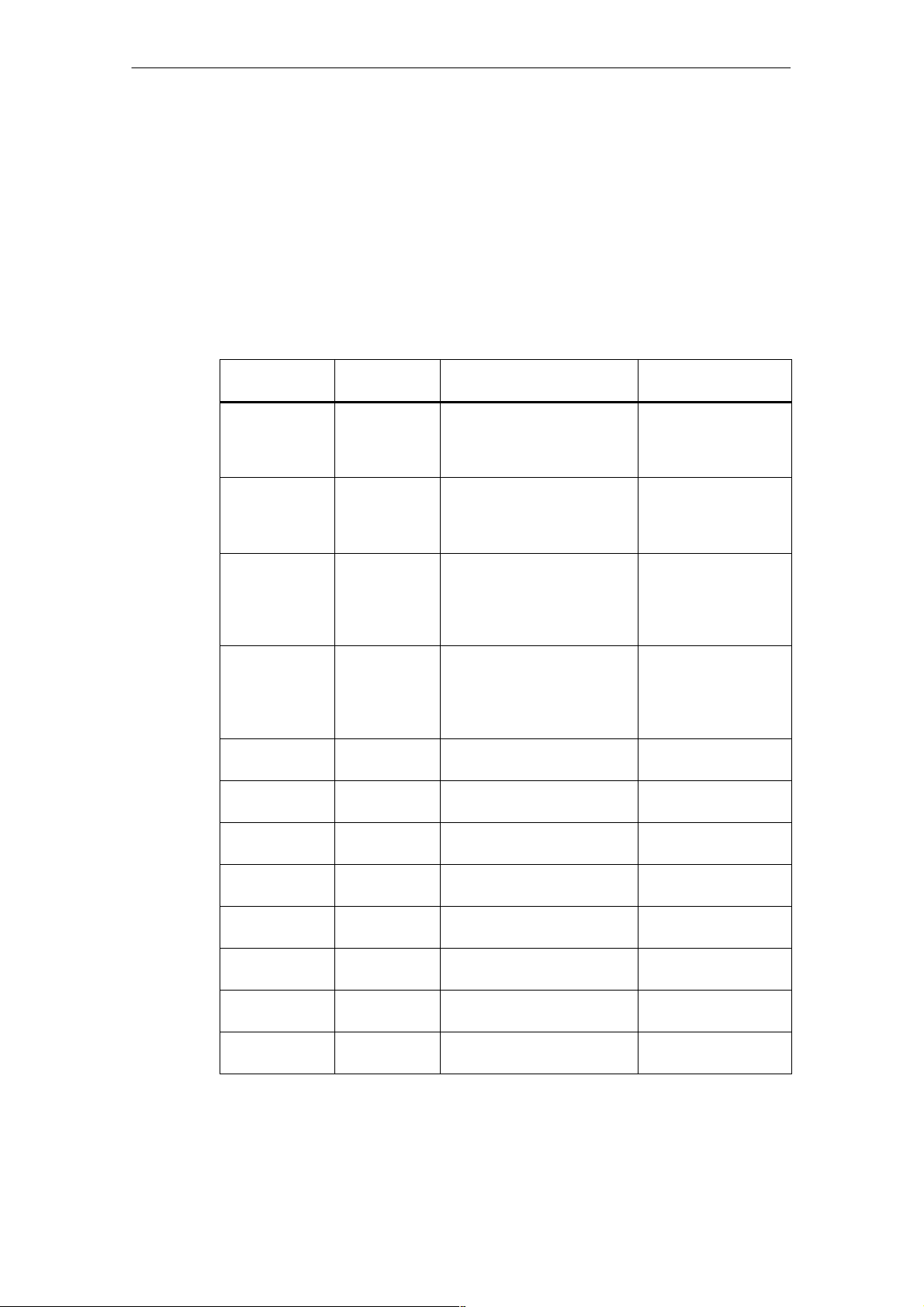

Table 1-1 C230-2 with centralized peripherals

Component

C230-2 ... is the motion control module. The C230-2 supplies the P-bus

with 5 V; communicates over the P-bus (backplane bus) with

the I/O modules.

You can use the C230-2’s integrated fast digital inputs/outputs

as:

Function

S Homing inputs

S Inputs for measuring inputs

S User-addressable process inputs/outputs

Drive devices with "10 V analog interfaces can be connected

to the onboard drive interface.

Incremental encoders or absolute encoders can be connected

to the measuring system interface.

Power supply (PS) ... converts the line voltage (120/230 VAC) into an operating

voltage of 24 VDC to supply the C230-2.

Signal modules (SM) ... adapt various process signal levels to the C230-2 (digital

input/output modules and analog input/output modules).

Note:

All approved modules are listed in the PM 10 catalog and in

Subsection 3.1.5.

Function modules (FM) ...relieve the CPU of computation-intensive tasks, for example,

counting.

Note:

All approved modules are listed in the PM 10 catalog and in

Subsection 3.1.5.

Communications processors (CP)

... for data exchange

Note:

All approved modules are listed in the PM 10 catalog and in

Subsection 3.1.5.

1-14

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

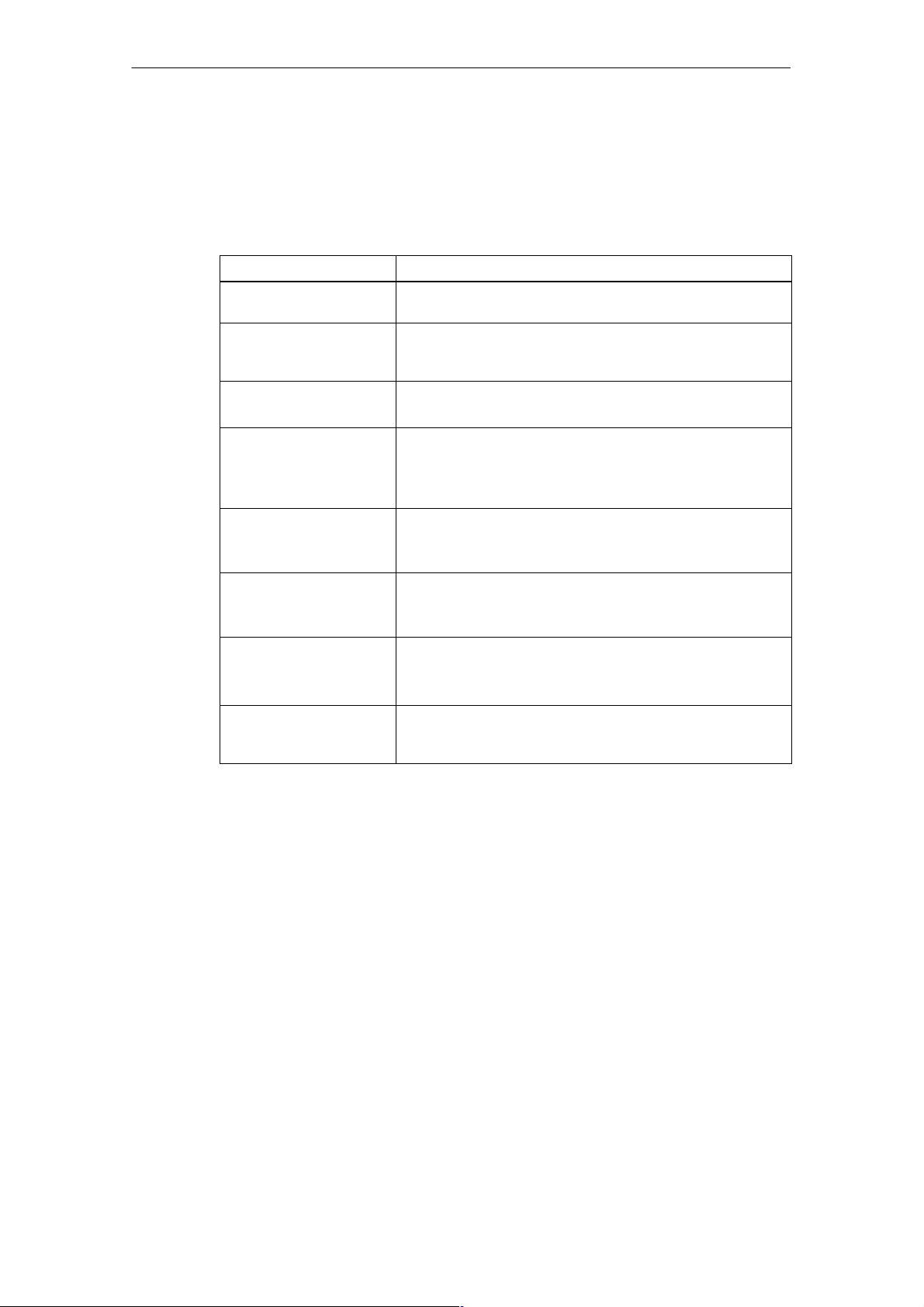

Distributed I/Os

Table 1-2 C230-2 with distributed I/Os

Product Overview

Component

C230-2 ... is the motion control module.

Function

S The C230-2 communicates via two PROFIBUS DP inter-

faces with the:

– Programming device (PG/PC)

– SIMATIC HMI devices

– S7 controllers with PROFIBUS DP interface

– I/O systems ET 200

– Drive units

– Further C230-2s

S The C230-2 communicates via an Ethernet interface with

the programming device (PG/PC).

Note:

All approved devicles are listed in the PM 10 catalog and in

Subsection 3.1.5.

Table 1-3 Further components that can be connected to the C230-2

Component

Programming device

(PG/PC)

... configures, parameterizes, programs and tests SIMOTION

and C230-2.

Function

SIMATIC HMI device ... is used for operating and monitoring functions. It is not abso-

lutely essential for the operation of a C230-2.

Note:

All released modules are listed in the PM 10 catalog.

Drive units ... convert speed setpoints into signals for controlling the motor

and provide the power required to operate the motors.

Note:

All released modules are listed in the PM 10 catalog.

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

1-15

Product Overview

1-16

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

The Fundamentals of Motion Control

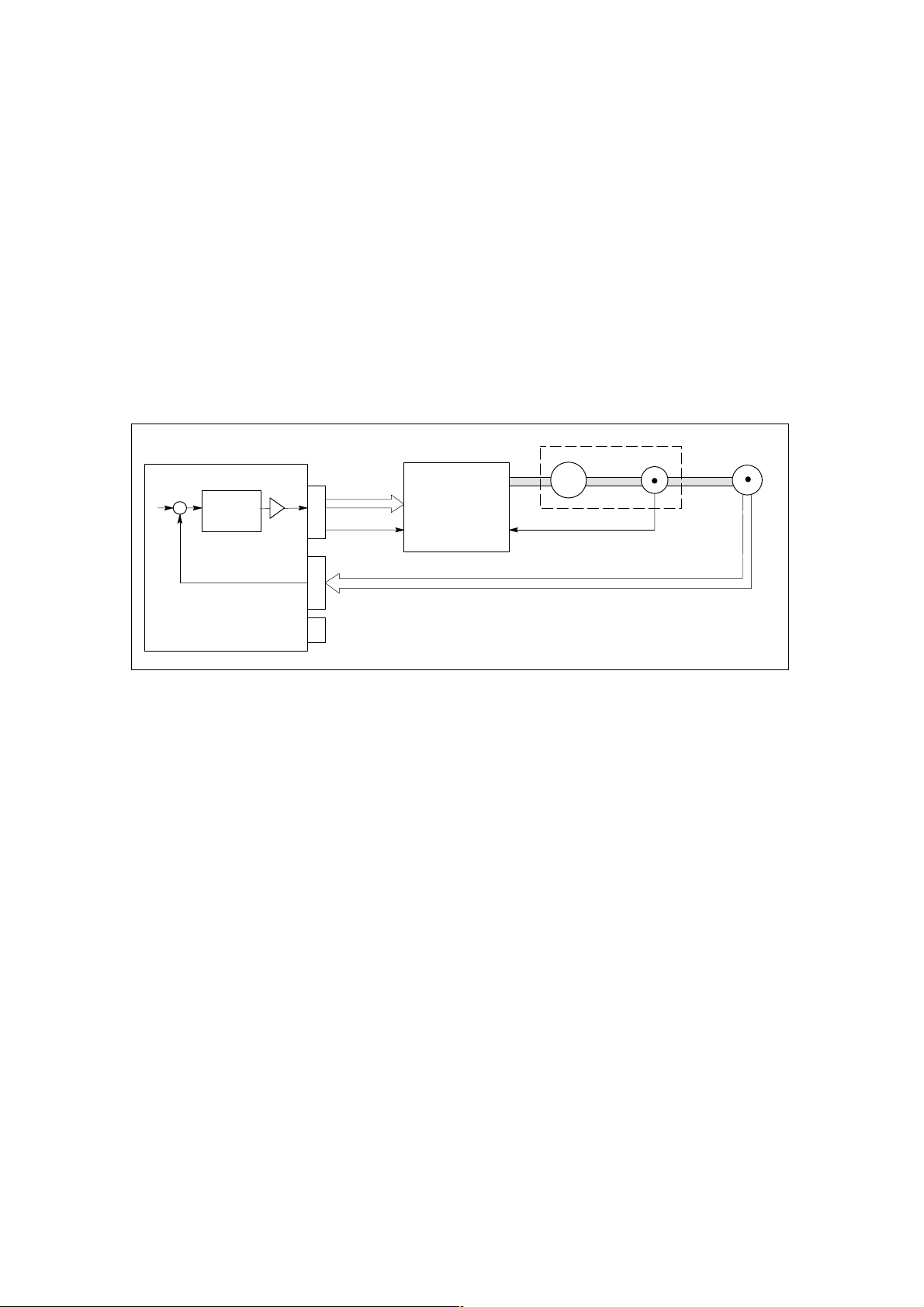

Position-controlled motion control for servo axes (onboard I/Os)

The C230-2 allows the position-controlled motion control of up to four axes. The

C230-2 provides an analog output for the speed setpoint for each axis and an

encoder input for the cyclic sensing of the actual position value.

2

C230-2

X2

X3

X4

X5

X6

X1

Speed

setpoint

Enable

+

Fig. 2-1 Servo system with converter, e.g. SIMODRIVE 611 analog, with external incremental encoder

–

Position

controller

DAC

Converter

Power section

Current controller

Speed controller

Actual position value, zero mark

Servo motor

M

3

Actual speed value

Encoder

Incremental encoder

Encoders are generally connected for position measurement. These supply

counting pulses, according to their resolution, for the incremental distance

travelled. They can be either rotary or linear.

A “homing” (referencing) operation must be performed in order to determine the

absolute position reference.

Absolute encoder (SSI)

Instead of conventional incremental encoders, which supply only one dimension for

the distance travelled, absolute encoders with a serial interface can be connected.

No homing operation need be performed for these encoders as they always supply

the absolute position as an actual value.

A one-off adjustment of the absolute encoder is required when the machine is initially commissioned.

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

2-17

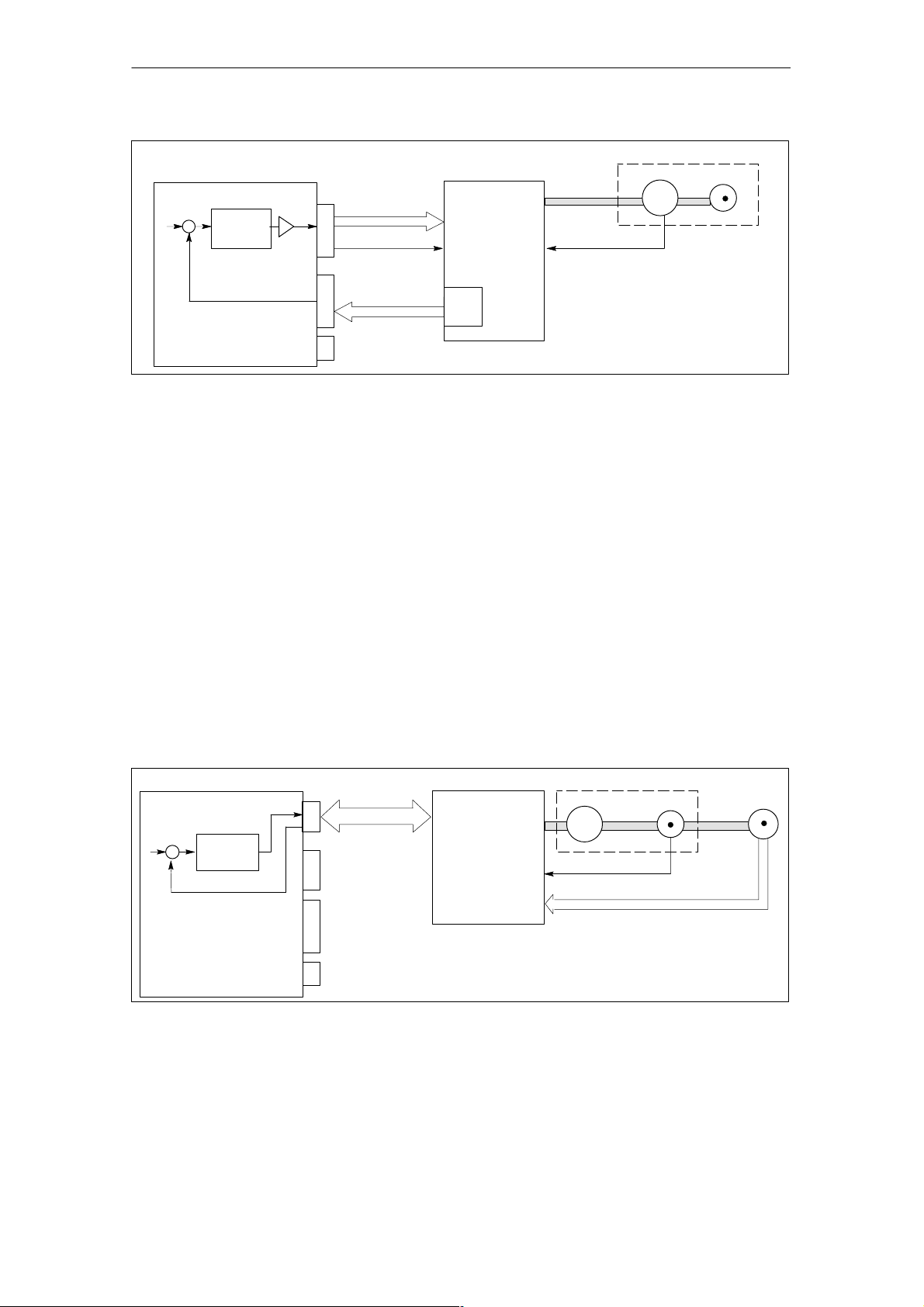

The Fundamentals of Motion Control

C230-2

+

–

Position

controller

DAC

Speed setpoint

X2

Enable

Actual position

X3

X4

value, zero mark

X5

X6

X1

Converter

Power section

Current controller

Speed controller

WSG

Rotor position

Servo motor

M

3

Encoder

Fig. 2-2 Servo system with converter, e.g. SIMODRIVE 611 universal, with encoder emulation

Encoder emulation

Modern motor/converter systems often have a high-resolution motor measuring

system (rotor position encoder) connected at the converter. Here the converter

provides the position information via an interface that emulates an incremental encoder (e.g. incremental shaft encoder (WSG) interface with SIMODRIVE). A separate position measuring system is not required in this case.

Position-controlled motion control for servo axes (PROFIBUS DP)

The C230-2 allows the position-controlled motion of axes via PROFIBUS DP.

The following PROFIBUS protocol is used for specifying the speed setpoint and

feeding back the actual position value:

PROFIdrive profile drive technology, Version 3 (isochronous)

C230-2

Converter

Speed setpoint

X9

PROFIBUS DP

+

Position

controller

–

Actual position value

X2

X3

X4

X5

X6

X1

Power section

Current controller

Speed controller

Fig. 2-3 Servo system with converter, e.g. SIMODRIVE 611 universal

Servo motor

M

3

Actual speed value

Actual position value, zero mark

Encoder

2-18

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Device Data

Overview

This chapter contains information on:

S Layout of the module

S Mode selector

S Memory module slot

S PROFIBUS DP and drive interface

S Analog drive interface

S Measuring system interface

S I/O interface

S Clock

S Diagnosis using the LEDs

S Technical data

S Dimension drawing

3

S Accessories and spare parts

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3-19

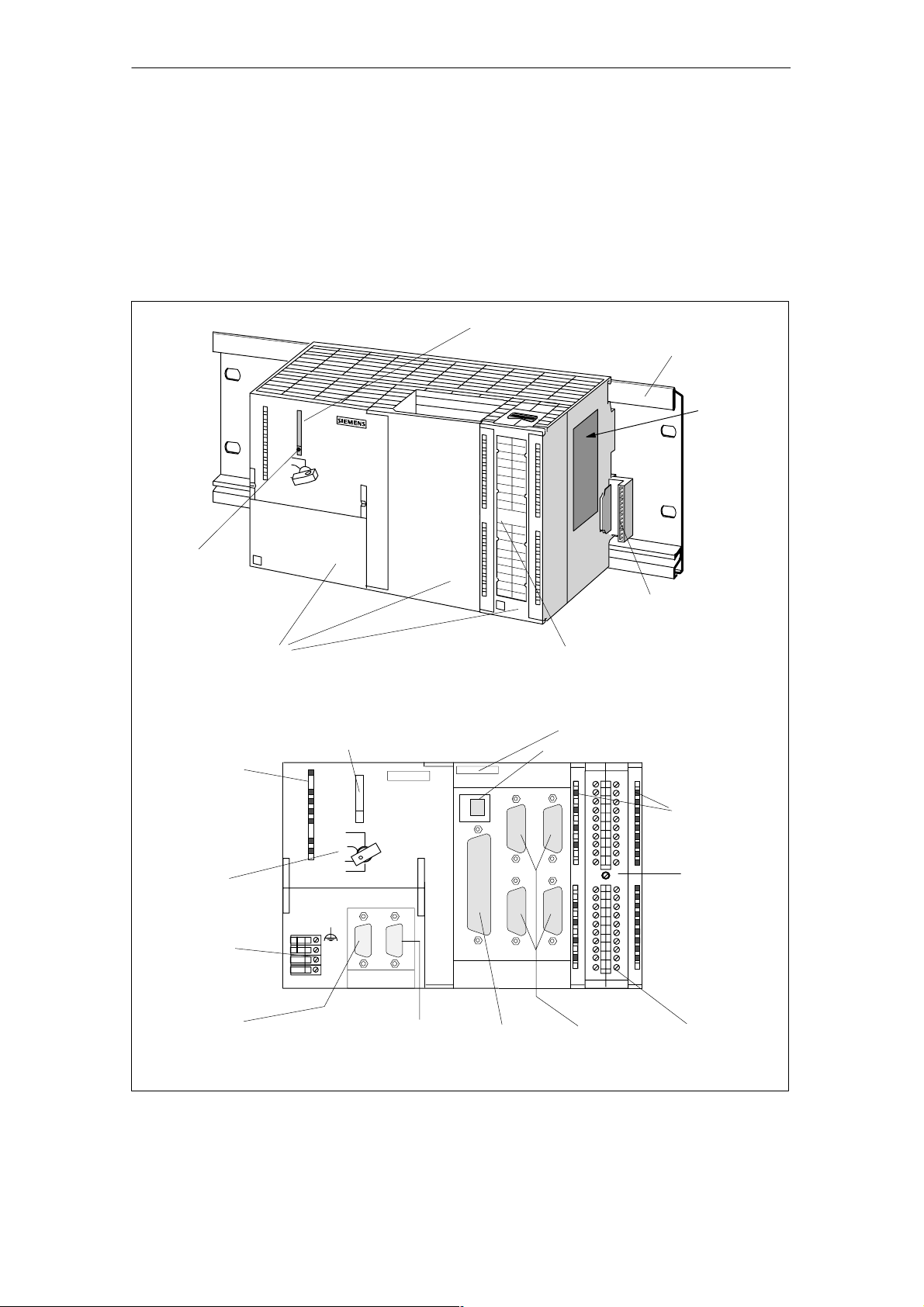

Device Data

3.1 Layout of the module

View of C230-2

Fig. 3-1 shows the C230-2 module, indicating the interfaces and components on

the front panel (fault and status displays).

Micro Memory Card (MMC)

Mounting rail

Rating plate

Ejector for

Micro Memory Card

Front covers

(hinged)

Fault and

status displays

Mode selector

Connection for

power supply

X10

Memory module slot for

micro memory card

SF

5 VDC

RUN

STOPU

STOP

BUS1F

BUS2F

24 VDC

C230-2

RUN

STOPU

STOP

MRES

M

L+

M

X8 DP1

SIEMENS

X9 DP2/MPI

Labeling plate

Front view

without front covers

X3 X4

X7

X2

X5 X6

Bus connector

for P-bus

Ethernet address (MAC address)

Ethernet interface X7

Status displays

dig. inputs/outputs

X1

Front connector

PROFIBUS DP1

interface X8

PROFIBUS DP2/MPI

interface X9

Drive

interface X2

Fig. 3-1 Position of interfaces and front panel components

3-20

Measuring system

interfaces X3...X6

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

I/O

interface X1

Interfaces

Device Data

The interfaces and their functions are described in Table 3-1.

Table 3-1 Interfaces

Interfaces

Bus connector A rear-mounted connector for connecting the C230-2 with

other S7-modules over the P-bus

Drive interface 50-pin Sub-D connector X2 for the analog connection of

drives (max. 4 axes)

See Subsection 3.1.6

Measuring system interface 15-pin Sub-D sockets X3 to X6 for connection of encoders

(max. 4)

See Subsection 3.1.7

I/O interface 40-pin front connectors X1 for connecting the fast digital

inputs/outputs including measuring inputs, BEROs, and for

wiring the READY relay

See Subsection 3.1.8

Power supply connection 4-pin screw-type terminal connection X10 for connecting

the 24 V load power supply

See Subsection 6.2.1

Memory module slot 7-pin connector for Micro Memory Card

See Subsection 3.1.2

PROFIBUS DP1 interface 9-pin Sub-D socket X8 for connection to the PROFIBUS

DP. This interface can be used for isochronous operation.

See Subsection 3.1.4

PROFIBUS DP2/MPI

interface

Ethernet interface 8-pin RJ45 socket X7 for connection to a Fast Industrial

9-pole X9 Sub-D socket for connection to PROFIBUS DP

(default setting) or an MPI bus.

This interface can be used for isochronous operation.

See Subsection 3.1.4

Ethernet

Description

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3-21

Device Data

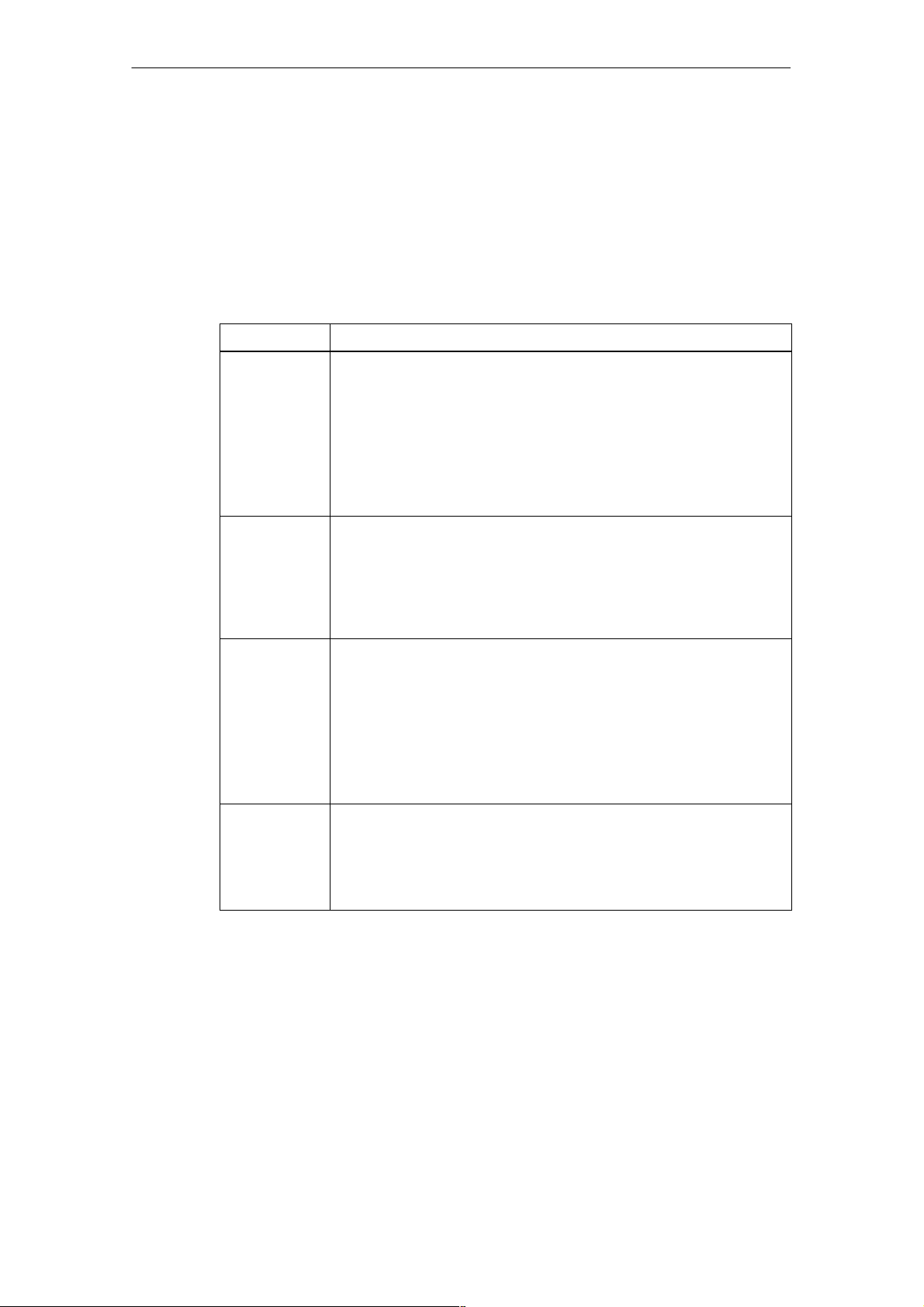

Display of LEDs

The following LEDs are on the front panel of the C230-2. The LEDs and their function are described in Table 3-2.

Table 3-2 Status and fault displays

LED

SF (red) This LED indicates a fault on the C230-2.

(See Section 3.3)

5 VDC (green) This LED indicates that the power supply for the electronics is

ready.

(See Section 3.3)

RUN (green) C230-2 in RUN

STOPU (yellow) –

C230-2 in STOP User

Program

STOP (yellow) –

C230-2 in STOP

BUS1F (red) –

group fault

BUS2F (red) –

group fault

Q0...Q7, I0...I1 1,

B1...B4, M1, M2 (green) –

digital inputs/outputs

This LED indicates that the user program is running.

(See Section 3.3)

This LED indicates that the technology packages (e.g.

synchronous operation, cam) are active. The user program is

not active.

(See Section 3.3)

This LED indicates that no user program is running. The

technology packages are not active.

(See Section 3.3)

This LED indicates a fault on the C230-2’s PROFIBUS DP1

interface (X8).

(See Section 3.3)

This LED indicates a fault on the C230-2’s PROFIBUS DP2

/MPI interface (X9).

(See Section 3.3)

These LEDs show the status of the digital inputs/outputs.

(See Subsection 3.1.8)

Function

Control elements

Mode selector

Certain operating modes can be selected using the mode selector (see Subsec-

tion 3.1.1).

3-22

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

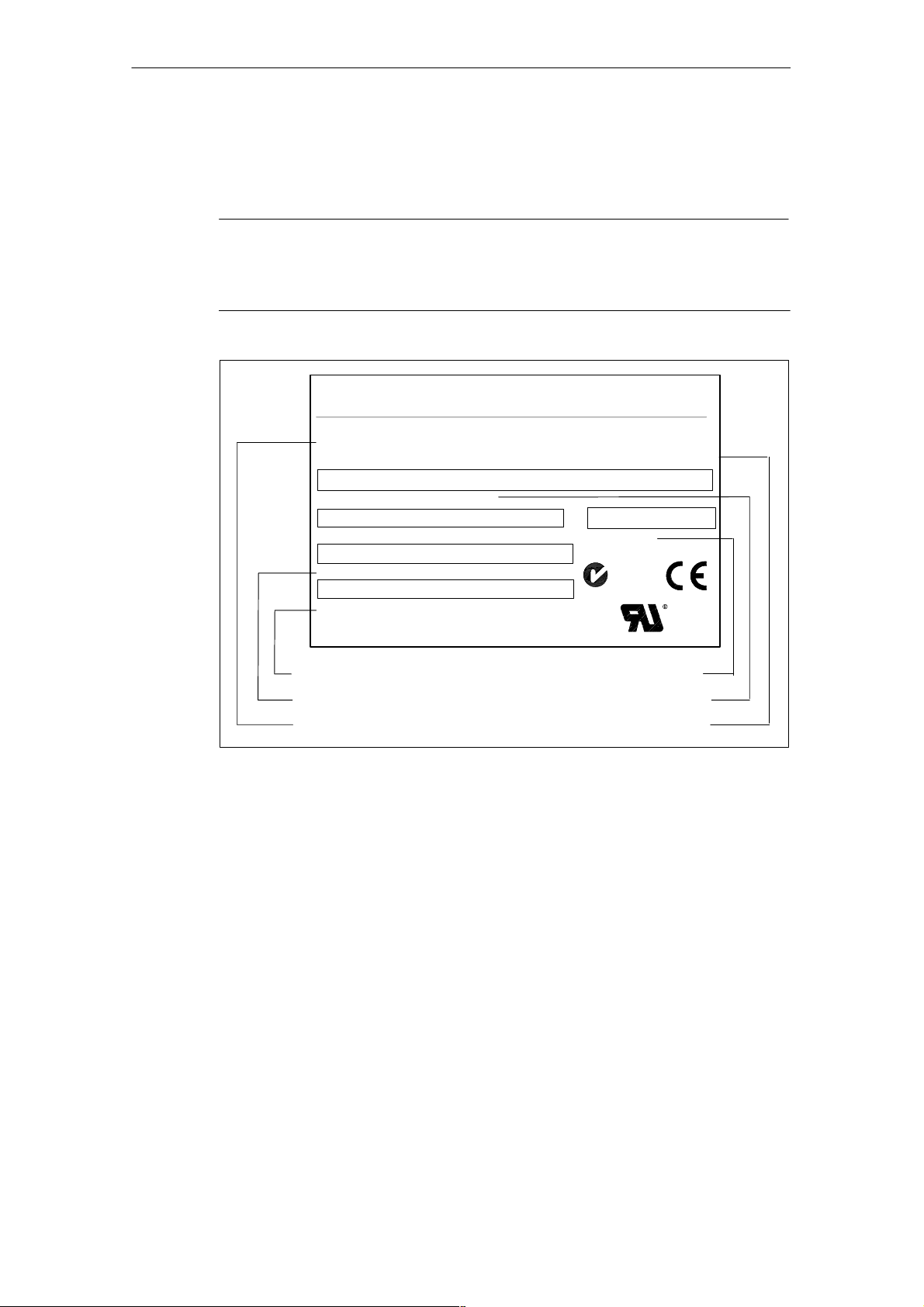

Rating plate

Device Data

Fig. 3-2 explains all the information on the rating plate.

Note

The information contained in the individual fields of the rating plate on the actual

module may differ from the information described in this manual (e.g. enhanced

product development, authorizations and designations not yet granted, etc.).

SIEMENS

C230-2

AXIS CONTROL

Barcode order no. (1P6AU1230-2AA00-0AA0)

6AU1230-2AA00-0AA0

1P

Barcode product no. (A5E00128707)

A5E00128707

Barcode serial no. (ST-P12345678)

S T-P12345678

MAC address bar code (000000000000)

000000000000

Made in Germany

MAC address

Serial number

Module name

Fig. 3-2 Rating plate for the C230-2

INPUT 24 VDC, 2 A

8DO 24 VDC/0.25 A/0.5 A; 18DI 24 VDC

SIMOTION

Version bar code

Vers.: A

N117

CUS

Product version

Order number

Connection parameters

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3-23

Device Data

3.1.1 Mode selector

Mode selector positions

The positions of the mode selector are explained in the sequence in which they are

arranged on the C230-2.

Table 3-3 Mode selector positions

Position

RUN

STOPU

STOP

MRES

(overall reset)

Explanations

The C230-2 is executing the user program (UP) and the associated system functions:

S Reading process image of inputs

S Processing user programs assigned to the execution system

S Writing process image of outputs

The technology packages are active in this state. They can execute

commands from the user program.

The key cannot be removed in this position.

The C230-2 is not executing a user program.

S The technology packages are active. Test and commissioning func-

tions can be executed. The user program is not active.

S The I/O modules (SMs) are in a secure state.

In this position the key can be removed so that no unauthorized person

can change the operating modes.

S The C230-2 is not executing a user program.

S It is possible to load a complete user program.

S All system services (communications, etc.) are active.

S The I/O modules (SMs) are in a secure state.

S The technology packages are inactive, i.e. all enables are deleted.

No axis movements can be executed.

In this position, the key can be removed so that no unauthorized person

can change the operating modes.

S Setting for overall reset on the C230-2

A specific sequence of operations is required to perform an overall

reset using the mode selector (see Section 8.5).

S Setting for Micro Memory Card formatting

Micro Memory Card formatting see Section 8.4

3-24

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3.1.2 Memory module slot

7-pin connector to plug in a Micro Memory Card (MMC)

Micro Memory Card

The following Micro Memory Card is available:

Order no.: 6AU1 700-0AA01-0AA0

The Micro Memory Card can be used:

S To save the SIMOTION Kernel (base system) in order to carry out an update

(see Section 9.1)

The SIMOTION Kernel should always be stored on the Micro Memory Card.

S To save the technology packages and user data (programs, configuration data,

parameterization)

Device Data

3.1.3 Ethernet interface

Interface for connecting a Fast Industrial Ethernet.

Fast Industrial Ethernet is a communication network with a transmission rate of

10/100 Mbit/s.

The C230-2 offers the following functions via the Ethernet interface:

S Communications with STEP 7 and SIMOTION SCOUT

The “SIMATIC NET SOFTNET-PG (Protocol TPC/IP RFC 1006)” software must

be installed on the PG/PC for this function.

S Communications between SIMOTION and SIMATIC NET OPC

The “SIMATIC NET SOFTNET-S7 (S7-OPC-Server)” software must be installed

on the PG/PC for this function.

Note:

SOFTNET-S7 is a superset of SOFTNET-PG, i.e. SOFTNET-S7 also contains

this Protocol TPC/IP RFC 1006.

For further information about the software packages, see Motion Control System

SIMOTION, PM 10 catalog, see List of References for the order number.

Connectable devices

A PG/PC can be connected to the Ethernet interface via a Fast Ethernet network.

The PG must be equipped with an Ethernet card and the corresponding software

must be available.

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3-25

Device Data

Position of the connectors

Fig. 3-4 shows the installation position and the designation of the connector on the

module.

Ethernet address

(MAC address)

(e.g. 08000673238B)

X7

8

1

Fig. 3-3 Position of connector X7

Connector pin assignment

Designation: X7 (Ethernet)

Type: 8-pin RJ45 socket

Table 3-4 Assignment of X7 connector

Pin

1 TDP O 5 Unassigned

2 TDM O 6 RDM I

3 RDP I 7 Unassigned

4 Unassigned 8 Unassigned

X3 X4

C230-2

X8 DP1

SIEMENS

X9 DP2/MPI

X7

X1

X2

X6X5

Name Type Pin Name Type

Signal names RDP, RDM Receive Data +/–

TDP, TDM Transmit Data +/–

Signal type I Signal input

O Signal output

3-26

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3.1.4 PROFIBUS DP and drive interface

PROFIBUS DP interface (X8, X9)

The C230-2 provides you with two interfaces for connection to the PROFIBUS DP.

Baud rates up to 12 Mbits/s are possible. Both interfaces can be used for isochronous operation.

The interfaces can be operated in the following combinations as master or slave

(isochronous/not isochronous):

Device Data

X8 X9 Remark

DP slave

isochronous

DP master

isochronous

DP slave

isochronous

DP master not

isochronous

DP master

isochronous

DP master

isochronous

DP master

isochronous

DP master not

isochronous

DP slave not

isochronous

DP master not

isochronous

DP slave not

isochronous

DP master not

isochronous

DP master

isochronous

DP slave

isochronous

DP master not

isochronous

DP slave

isochronous

DP master

isochronous

DP master not

isochronous

DP slave not

isochronous

DP master

isochronous

DP master

isochronous

DP master not

isochronous

DP master not

isochronous

DP slave not

isochronous

Application synchronized with

DP master (X9), application

controls synchronization with

DP slave (X8)

Application synchronized with

DP master (X8), application

controls synchronization with

DP slave (X9)

Application running freely or

synchronized to the DP slave

(X8)

(can be monitored by the application)

Application running freely or

automatically synchronized to

the DP slave (X9)

(can be monitored by the application)

Application synchronized with

DP master (X8, X9)

Application synchronized with

DP master (X8)

Application synchronized with

DP master (X8)

Application synchronized with

DP master (X9)

Application synchronized with

DP master (X9)

Application asynchronous None

Application asynchronous None

Application asynchronous None

Actions in the

application

DP master/DP slave

synchronization mechanisms

DP master/DP slave

synchronization mechanisms

DP slave synchronization mechanisms

DP slave synchronization mechanisms

None

None

None

None

None

1)

1) Actions in the application see function description SIMOTION Modular Machine Con-

cepts, order no. see List of References

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3-27

Device Data

If both interfaces (X8, X9) are to be operated isochronously, then they must both

be configured with the same DP cycle clock.

The X9 can alternatively be used as an MPI interface with a baud rate of up to

12 MBit/s.

Connectable devices

The following devices can be connected to the PROFIBUS DP interfaces:

S PG/PC

S SIMATIC HMI devices

S S7 controllers with PROFIBUS DP interface

S Distributed I/Os (e.g. ET 200M)

The updating of the digital inputs/outputs is carried out in the position control

cycle clock.

S C230-2

S Teleservice adapter

S Drives with digital interface (e.g. SIMODRIVE 611 universal)

Note

A teleservice adapter can only be connected to one of the two interfaces.

All approved modules and devices are listed in the PM 10 catalog and in Subsec-

tion 3.1.5. Refer to the list of references for the order number.

Please note the documentation regarding the individual modules or devices!

3-28

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Position of the connectors

Fig. 3-4 shows the mounting position and designation of the connectors on the

module.

Device Data

DP1

5

9

6

1

X8

Fig. 3-4 Position of connectors X8, X9

Connector pin assignment

Designation: X8, X9 DP1, DP2/MPI

Type: 9-pin Sub-D socket

Table 3-5 Assignment of X8, X9 connector

Pin

1 Unassigned 6 P5 VO

2 M24 VO 7 P24 VO

3 B I/O 8 A I/O

4 RTS I 9 Unassigned

5 GND VO

DP2/MPI

5

9

6

1

C230-2

SIEMENS

X3 X4

X7

X1

X9

X9 DP2/MPIX8 DP1

X2

X6X5

Name Type Pin Name Type

Signal names A, B Data input/output (RS485)

RTS Request to send

P5 5 V supply 60 mA, short-circuit-proof

GND Ground for 5 V voltage

P24 24 V supply 150 mA, short-circuit-proof, not isolated

M24 24 V reference potential

Signal type I Signal input

I/O Signal input/output

VO Voltage output

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

3-29

Device Data

3.1.5 I/O modules approved for SIMOTION

Preferred peripherals for use with SIMOTION C:

S Centralized peripherals:

SIMATIC S7-300 I/O modules (only with SIMOTION C)

S Distributed I/O systems:

– SIMATIC ET 200M (distributed use of SIMATIC S7-300 I/O modules):

The modular I/O system for control cabinet installation and high channel

densities

– SIMATIC ET 200S:

Fine modular I/O system for control cabinet installation including motor starters, safety technology and individual grouping of the load groups

– SIMATIC ET 200X:

The modular I/O system in the IP 65/67 degree of protection for use without

a control cabinet and in the machine’s proximity; includes motor starters and

pneumatic modules as well as DESINA- and ECOFAST-conform modules

– SIMATIC ET 200eco:

The compact, economical I/O system in the IP 67 degree of protection for

use without a control cabinet and in the machine’s proximity; with the flexible

and fast ECOFAST or M12 connection system

S Other PROFIBUS DP I/Os:

ADI 4 (Analog Drive Interface)

for connecting drives with a ± 10 V analog setpoint interface

Note

Please note that not all modules of the above-mentioned I/Os or I/O systems are

approved for SIMOTION. Additionally, system-related functional differences as

regards use with SIMOTION and SIMATIC may occur. For example, special process-control functions (e.g. insertion and removal under voltage...) are not supported by SIMOTION for the ET 200M distributed I/O system.

A detailed, regularly updated list of the I/O modules approved for use with SIMOTION, as well as notes on their use, can be found on the Internet at:

http://www4.ad.siemens.de/view/cs/en/10805436

...Motion Control System SIMOTION

Supplementary system components

FAQ (entry ID: 11886029)

3-30

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

Loading...

Loading...