Siemens SIMOTICS S-1FL6, SINAMICS V90 Compact Operating Instructions

© Siemens AG 2016 - 2017. All rights reserved

A5E37208904-003, 04/2017

1

SINAMICS V90, SIMOTICS S-1FL6

PROFINET (PN) interface

Getting Started

Compact Operating Instructions

Table of contents

1 Fundamental safety instructions .............................................................................................................................. 3

1.1 General safety instructions ...................................................................................................................... 3

1.2 Handling electrostatic sensitive devices (ESD) ....................................................................................... 7

1.3 Industrial security .................................................................................................................................... 7

1.4 Residual risks of power drive systems..................................................................................................... 8

2 General information ................................................................................................................................................ 9

2.1 Deliverables ............................................................................................................................................. 9

2.1.1 Drive components.................................................................................................................................... 9

2.1.2 Motor components ................................................................................................................................. 14

2.2 Device combination ............................................................................................................................... 17

2.3 Accessories ........................................................................................................................................... 20

2.4 Function list ........................................................................................................................................... 22

2.5 Technical data ....................................................................................................................................... 23

2.5.1 Technical data - servo drives ................................................................................................................. 23

2.5.2 Technical data - servo motors ............................................................................................................... 25

2.5.3 Address of CE-authorized manufacturer ............................................................................................... 28

3 Mounting .............................................................................................................................................................. 29

3.1 Mounting the drive ................................................................................................................................. 29

3.2 Mounting the motor................................................................................................................................ 33

4 Connecting ........................................................................................................................................................... 40

4.1 System connection ................................................................................................................................ 40

4.2 Main circuit wiring .................................................................................................................................. 45

4.2.1 Line supply - L1, L2, L3 ......................................................................................................................... 45

4.2.2 Motor power - U, V, W ........................................................................................................................... 46

4.3 Control/Status interface - X8 ................................................................................................................. 48

4.3.1 Interface definition ................................................................................................................................. 48

4.3.2 Standard wiring ..................................................................................................................................... 48

4.4 24 V power supply/STO ......................................................................................................................... 49

4.5 Encoder interface - X9 ........................................................................................................................... 51

4.6 External braking resistor - DCP, R1 ...................................................................................................... 54

4.7 Motor holding brake ............................................................................................................................... 54

4.8 PROFINET interface - X150 .................................................................................................................. 55

5 Commissioning ..................................................................................................................................................... 56

5.1 Introduction to the BOP ......................................................................................................................... 57

5.2 Initial commissioning in JOG mode ....................................................................................................... 62

5.3 Commissioning in basic positioner control mode (EPOS) ..................................................................... 63

Getting Started

2 A5E37208904-003, 04/2017

5.4 Commissioning in speed control mode (S) ............................................................................................ 64

5.5 Commissioning control functions........................................................................................................... 65

5.5.1 Speed limit ............................................................................................................................................ 65

5.5.2 Torque limit ........................................................................................................................................... 66

5.5.3 EJOG .................................................................................................................................................... 67

6 PROFINET communication ....................................................................................................................................68

6.1 Supported telegrams ............................................................................................................................. 68

6.2 I/O data signals ..................................................................................................................................... 70

6.3 Control word definition .......................................................................................................................... 71

6.3.1 STW1 control word (for telegrams 1, 2, 3, 5) ........................................................................................ 71

6.3.2 STW2 control word (for telegrams 2, 3, 5) ............................................................................................ 72

6.3.3 STW1 control word (for telegrams 102, 105) ........................................................................................ 72

6.3.4 STW2 control word (for telegrams 102, 105) ........................................................................................ 73

6.3.5 STW1 control word (for telegrams 7, 9, 110, 111) ................................................................................ 74

6.3.6 STW2 control word (for telegrams 9, 110, 111) .................................................................................... 74

6.3.7 G1_STW encoder 1 control word .......................................................................................................... 75

6.3.8 SATZANW control word ........................................................................................................................ 75

6.3.9 MDI_MOD control word ......................................................................................................................... 76

6.3.10 POS_STW control word ........................................................................................................................ 76

6.3.11 POS_STW1 positioning control word .................................................................................................... 77

6.3.12 POS_STW2 positioning control word .................................................................................................... 77

6.4 Status word definition ............................................................................................................................ 78

6.4.1 ZSW1 status word (for telegrams 1, 2, 3, 5) .......................................................................................... 78

6.4.2 ZSW2 status word (for telegram 2, 3, 5) ............................................................................................... 78

6.4.3 ZSW1 status word (for telegrams 102, 105) .......................................................................................... 79

6.4.4 ZSW2 status word (for telegram 102, 105) ........................................................................................... 79

6.4.5 ZSW1 status word (for telegram 7, 9, 110, 111) ................................................................................... 80

6.4.6 ZSW2 status word (for telegrams 9, 110, 111) ...................................................................................... 80

6.4.7 G1_ZSW encoder 1 status word ........................................................................................................... 81

6.4.8 MELDW status word ............................................................................................................................. 81

6.4.9 POS_ZSW1 positioning status word ..................................................................................................... 82

6.4.10 POS_ZSW2 positioning status word ..................................................................................................... 82

7 Parameters ...........................................................................................................................................................83

7.1 Overview ............................................................................................................................................... 83

7.2 Parameter list ........................................................................................................................................ 84

8 Diagnostics ......................................................................................................................................................... 114

8.1 Overview ............................................................................................................................................. 114

8.2 List of faults and alarms ...................................................................................................................... 116

Getting Started

A5E37208904-003, 04/2017

3

1

Fundamental safety instructions

1.1

General safety instructions

DANGER

Danger to life due to live parts and other energy sources

Death or serious injury can result when live parts are touched.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase conductor and phase

conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or water.

4. Isolate or neutralize all hazardous energy sources by closing switches, grounding or short-circuiting or

closing valves, for example.

5. Secure the energy sources against switching on again.

6. Ensure that the correct machine is completely interlocked.

After you have completed the work, restore the operational readiness in the inverse sequence.

WARNING

Danger to life through a hazardous voltage when connecting an unsuitable power supply

Touching live components can result in death or severe injury.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV- (Protective Extra Low

Voltage) output voltages for all connections and terminals of the electronics modules.

WARNING

Danger to life when live parts are touched on damaged motors/devices

Improper handling of motors/devices can damage them.

For damaged motors/devices, hazardous voltages can be present at the enclosure or at exposed components.

• Ensure compliance with the limit values specified in the technical data during transport, storage and

operation.

•

Do not use any damaged motors/devices.

WARNING

Danger to life through electric shock due to unconnected cable shields

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected cable shields.

• As a minimum, connect cable shields and the cores of cables that are not used at one end at the grounded

housing potential.

Getting Started

4 A5E37208904-003, 04/2017

WARNING

Danger to life due to electric shock when not grounded

For missing or incorrectly implemented protective conducto

r connection for devices with protection class I, high

voltages can be present at open, exposed parts, which when touched, can result in death or severe injury.

•

Ground the device in compliance with the applicable regulations.

WARNING

Danger to life due to electric shock when opening plug connections in operation

When opening plug connections in operation, arcs can result in severe injury or death.

• Only open plug connections when the equipment is in a no-

voltage state, unless it has been explicitly stated

that they can be opened in operation.

WARNING

Danger to life through electric shock due to the residual charge of the power component capacitors

Because of the capacitors, a hazardous voltage is present for up to 5 minutes after the power supply has been

switched off. Contact with live parts can result in death or serious injury.

• Wait for 5 minutes before you check that the unit really is in a no-voltage condition and start work.

NOTICE

Material damage due to loose power connections

Insufficient tightening torques or vibrations can result in loose electrical connections. This can result in damage due to fire,

device defects or malfunctions.

• Tighten all power connections with the specified tightening torques, e.g. line supply connection, motor connection, DC

link connections.

•

Check all power connections at regular intervals. This applies in particular after transport.

WARNING

Danger to life due to fire spreading if housing is inadequate

Fire and smoke development can cause severe personal injury or material damage.

• Install devices without a protective housing in a metal control cabinet (or protect the device by another equivalent

measure) in such a way that contact with fire is prevented.

•

Ensure that smoke can only escape via controlled and monitored paths.

WARNING

Danger to life from electromagnetic fields

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment, such as transformers,

converters, or motors.

People with pacemakers or implants are at particular risk in the immediate vicinity of this equipment.

• If you have a heart pacemaker or implant, maintain a minimum distance of 2 m from electrical power equipment.

WARNING

Danger to life from permanent-magnet fields

Even when switched off, electric motors with permanent magnets represent a potential risk for persons with heart

pacemakers or implants if they are close to converters/motors.

• If you have a heart pacemaker or implant, maintain a minimum distance of 2 m.

• When transporting or storing permanent-magnet motors always use the original packing materials with the warning

labels attached.

• Clearly mark the storage locations with the appropriate warning labels.

•

IATA regulations must be observed when transported by air.

Getting Started

A5E37208904-003, 04/2017

5

WARNING

Danger to life through unexpected movement of machines when using mobile wireless devices or mobile phones

Using mobile wireless devices or mobile phones with a transmit power > 1 W closer than approx. 2 m to the components

may cause the devices to malfunction, influence the functional safety of machines therefore putting people at risk or

causing material damage.

• Switch the wireless devices or mobile phones off in the immediate vicinity of the components.

WARNING

Danger to life due to the motor catching fire in the event of insulation overload

There is higher stress on the motor insulation through a ground fault in an IT system. If the insulation fails, it is possible that

death or severe injury can occur as a result of smoke and fire.

• Use a monitoring device that signals an insulation fault.

•

Correct the fault as quickly as possible so the motor insulation is not overloaded.

WARNING

Danger to life due to fire if overheating occurs because of insufficient ventilation clearances

Inadequate ventilation clearances can cause overheating of components with subsequent fire and smoke. This can cause

severe injury or even death. This can also result in increased downtime and reduced service lives for devices/systems.

• Ensure compliance with the specified minimum clearance as ventilation clearance for the respective component.

WARNING

Danger of an accident occurring due to missing or illegible warning labels

Missing or illegible warning labels can result in accidents involving death or serious injury.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, in the national language if necessary.

•

Replace illegible warning labels.

NOTICE

Device damage caused by incorrect voltage/insulation tests

Incorrect voltage/insulation tests can damage the device.

• Before carrying out a voltage/insulation check of the system/machine, disconnect the devices as all converters and

motors have been subject to a high voltage test by the manufacturer, and therefore it is not necessary to perform an

additional test within the system/machine.

WARNING

Danger to life when safety functions are inactive

Safety functions that are inactive or that have not been adjusted accordingly can cause operational faults on machines that

could lead to serious injury or death.

• Observe the information in the appropriate product documentation before commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system, including all safety-related

components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted and activated through

appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions relevant to safety are running

correctly.

Getting Started

6 A5E37208904-003, 04/2017

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the Safety Integrated manuals

.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed parameterization

As a result of incorrect or changed parameterization, machines can malfunction, which in turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

•

Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY STOP or EMERGENCY OFF).

WARNING

Risk of injury caused by moving parts or parts that are flung out

Touching moving motor parts or drive output elements and loose motor parts that are flung out (e.g. feather keys) in

operation can result in severe injury or death.

• Remove any loose parts or secure them so that they cannot be flung out.

• Do not touch any moving parts.

• Safeguard all moving parts using the appropriate safety guards.

WARNING

Danger to life due to fire if overheating occurs because of insufficient cooling

Inadequate cooling can cause overheating resulting in death or severe injury as a result of smoke and fire. This can also

result in increased failures and reduced service lives of motors.

•

Comply with the specified coolant requirements for the motor.

WARNING

Danger to life due to fire as a result of overheating caused by incorrect operation

When incorrectly operated and in the case of a fault, the motor can overheat resulting in fire and smoke. This can result in

severe injury or death. Further, excessively high temperatures destroy motor components and result in increased failures

as well as shorter service lives of motors.

• Operate the motor according to the relevant specifications.

• Only operate the motors in conjunction with effective temperature monitoring.

•

Immediately switch off the motor if excessively high temperatures occur.

CAUTION

Risk of injury due to touching hot surfaces

In operation, the motor can reach high temperatures, which can cause burns if touched.

• Mount the motor so that it is not accessible in operation.

Measures when maintenance is required:

• Allow the motor to cool down before starting any work.

•

Use the appropriate personnel protection equipment, e.g. gloves.

Getting Started

A5E37208904-003, 04/2017

7

1.2

Handling electrostatic sensitive devices (ESD)

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be

damaged by either electric fields or electrostatic discharge.

NOTICE

Damage through electric fields or electrostatic discharge

Electric fields or electrostatic discharge can cause malfunctions through damaged individual components,

integrated circuits, modules or devices.

•

Only pack, store, transport and send electronic components, modules or devices in their original packaging

or in other suitable materials, e.g conductive foam rubber of aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table with ESD surface,

conductive ESD foam, ESD packaging, ESD transport container).

1.3

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the secure operation of plants,

s

ystems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is necessary to implement

– and

continuously maintain

– a holistic, state-of-the-art industrial security concept. Siemens products and solut

ions only represent

one component of such a concept.

The customer is responsible for preventing unauthorized access to its plants, systems, machines and networks. Systems,

machines and components should only be connected to the enterprise network or the internet if and to the extent necessary

and with appropriate security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into account. For more information about

industrial security, please visit:

Industrial security (

http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more secure. Sie

mens strongly

recommends to apply product updates as soon as available and to always use the latest product versions. Use of product

versions that are no longer supported, and failure to apply latest updates may increase customer’s exposure to cyber

threat

s.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS Feed at:

Industrial security (

http://www.siemens.com/industrialsecurity).

WARNING

Danger to life as a result of unsafe operating states resulting from software manipulation

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating states in your system that

may lead to death, serious injury, and property damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art industrial security concept for the

installation or machine.

• Make sure that you include all installed products into the holistic industrial security concept.

• Protect files stored on exchangeable storage media from malicious software by with suitable protection measures, e.g.

virus scanners.

Getting Started

8 A5E37208904-003, 04/2017

1.4

Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery

Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from

the control and drive components of a drive system:

1. Unintentional movements of driven machine or system components during commissioning, operation, maintenance, and

repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise, particles, gases, etc., can occur

inside and outside the components under fault conditions caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk to people with a pacemaker,

implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the system and/or failure to

dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters or data communication via the

network

For more information about the residual risks of the drive system components, see the relevant sections in the technical user

documentation.

Getting Started

A5E37208904-003, 04/2017

9

2

General information

The SINAMICS V90 drives with the PROFINET interface (referred to as SINAMICS V90 PN) are available in two variants,

400 V variant and 200 V variant.

The 200 V variant is available in three frame sizes: FSB, FSC, and FSD. Frame sizes B, and C are used on the single phase

or three phase power network while frame size D is used on the three phase power network only.

The 400 V variant is available in four frame sizes: FSAA, FSA, FSB, and FSC. All the frame sizes are used on three phase

power network only.

2.1

Deliverables

2.1.1

Drive components

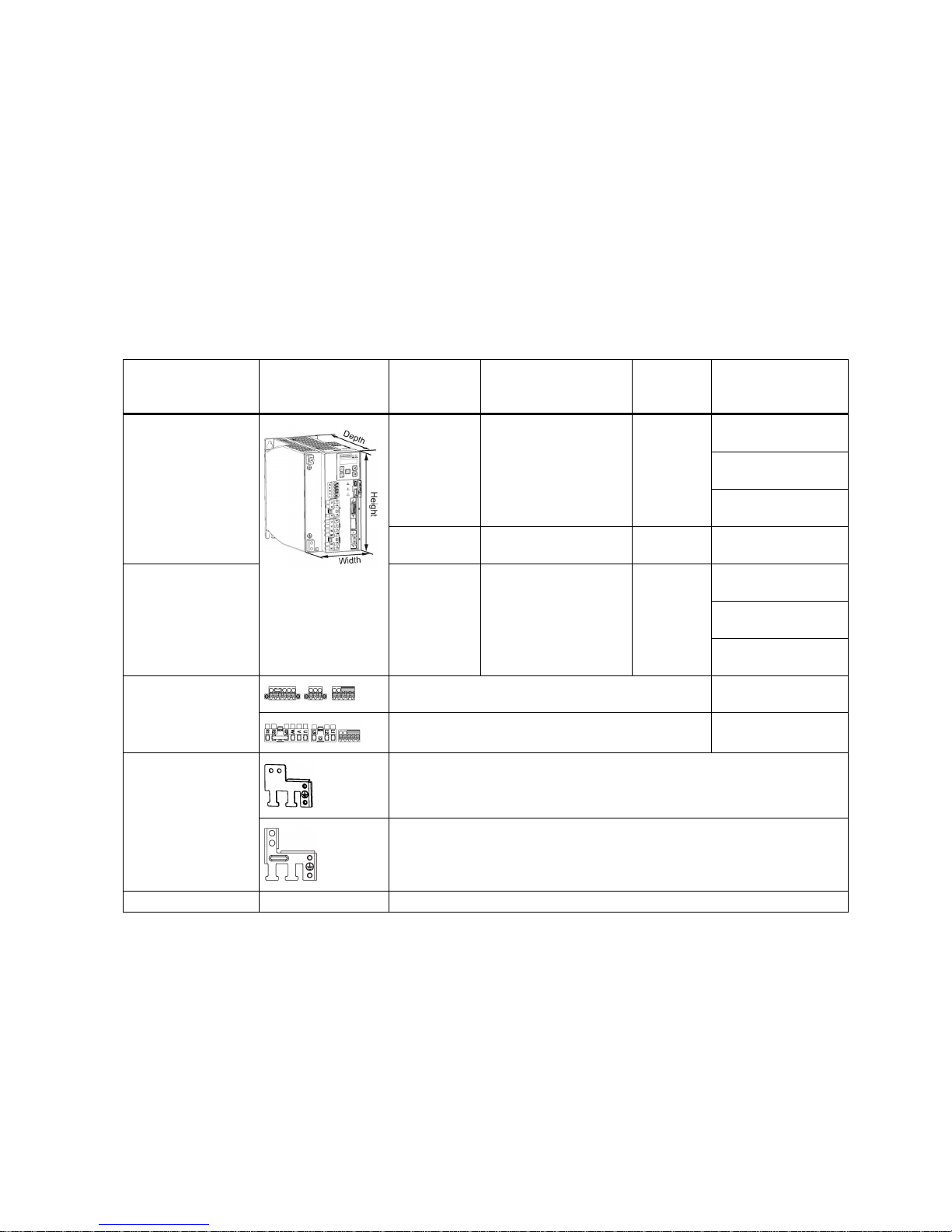

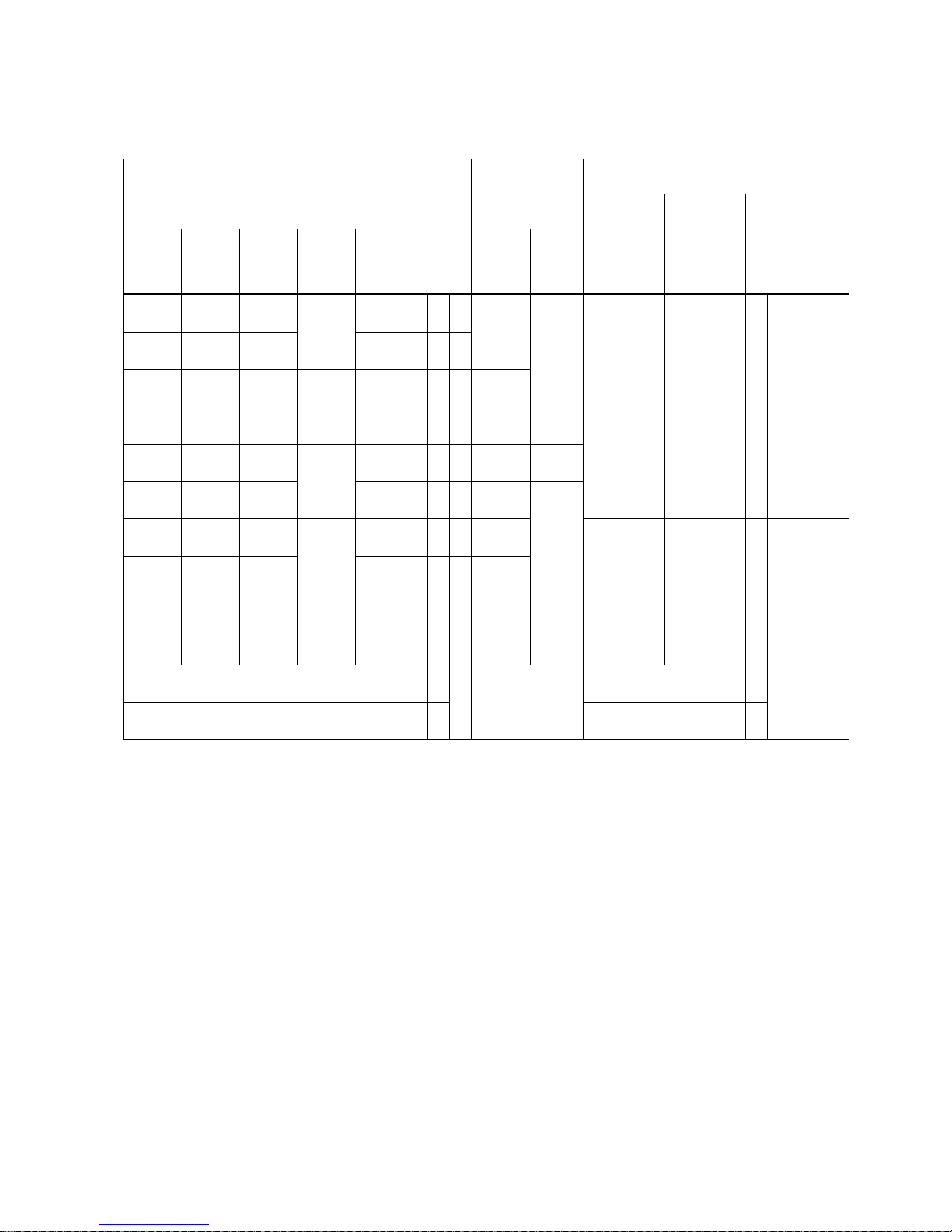

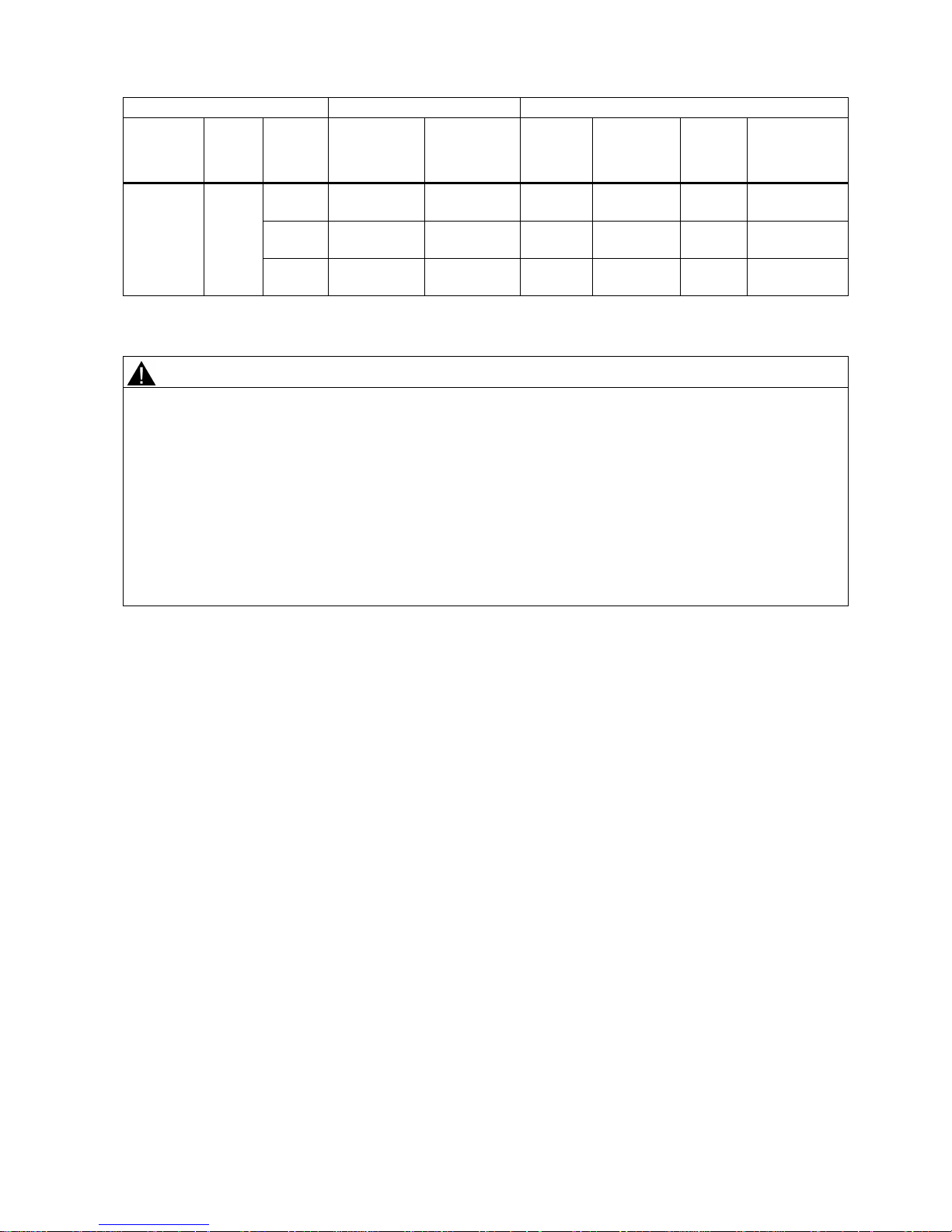

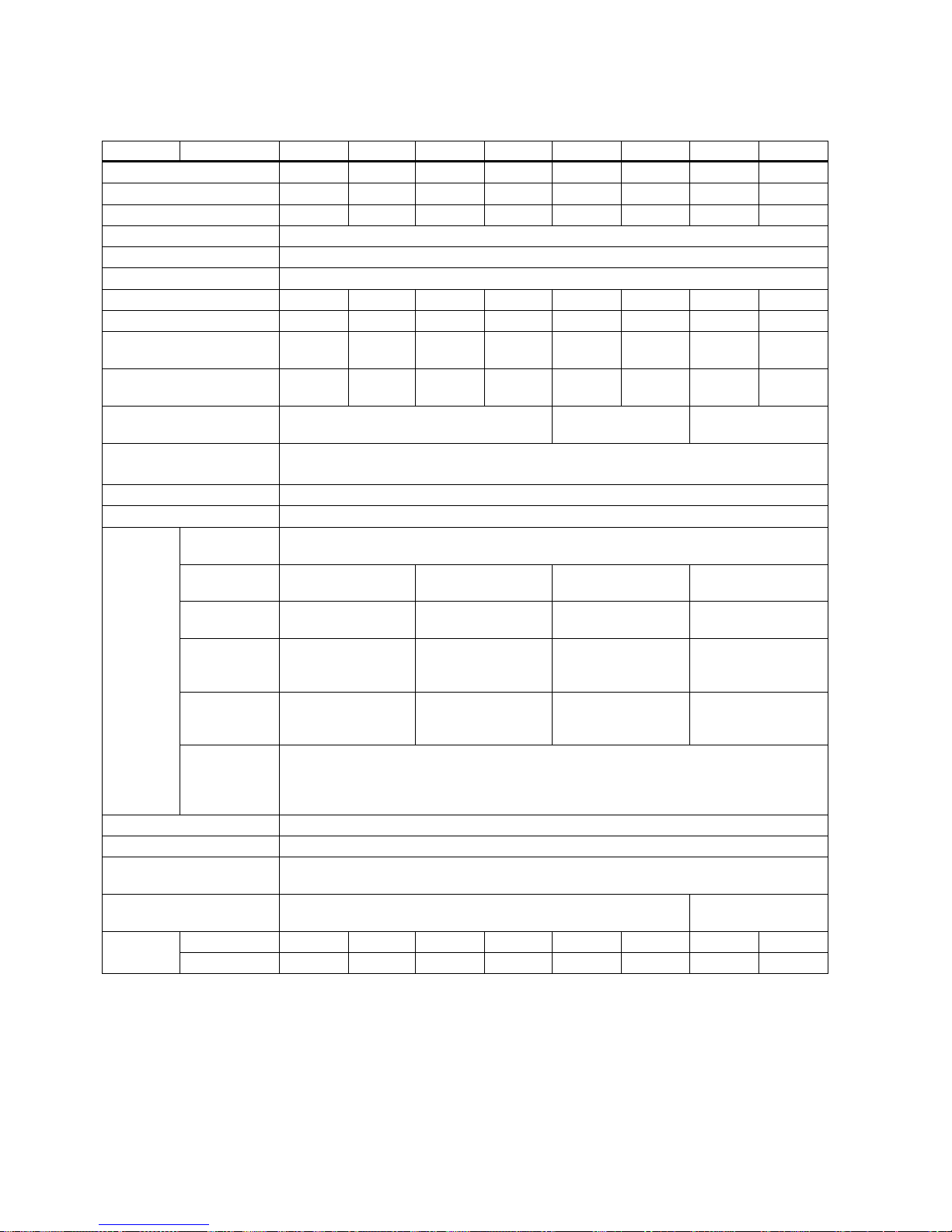

Components in the SINAMICS V90 PN 200 V variant drive package

Component

Illustration

Rated power

(kW)

Outline dimension

(Width x Height x

Depth, mm)

Frame size

Article number

SINAMICS V90 PN,

single/three-phase,

200 V

0.1/0.2/0.4 55 x 170 x 170

FSB 6SL3210-5FB10-

1UF0

6SL3210-5FB10-

2UF0

6SL3210-5FB10-

4UF1

0.75 80 x 170 x 195 FSC 6SL3210-5FB10-

8UF0

SINAMICS V90 PN,

three-phase, 200 V

1.0/1.5/2.0 95 x 170 x 195 FSD 6SL3210-5FB11-

0UF1

6SL3210-5FB11-

5UF0

6SL3210-5FB12-

0UF0

Connectors

For FSB 6SL3200-0WT02-

0AA0

For FSC and FSD 6SL3200-0WT03-

0AA0

Shielding plate

For FSB

For FSC and FSD

User documentation

Information Guide

English-Chinese bilingual version

Getting Started

10 A5E37208904-003, 04/2017

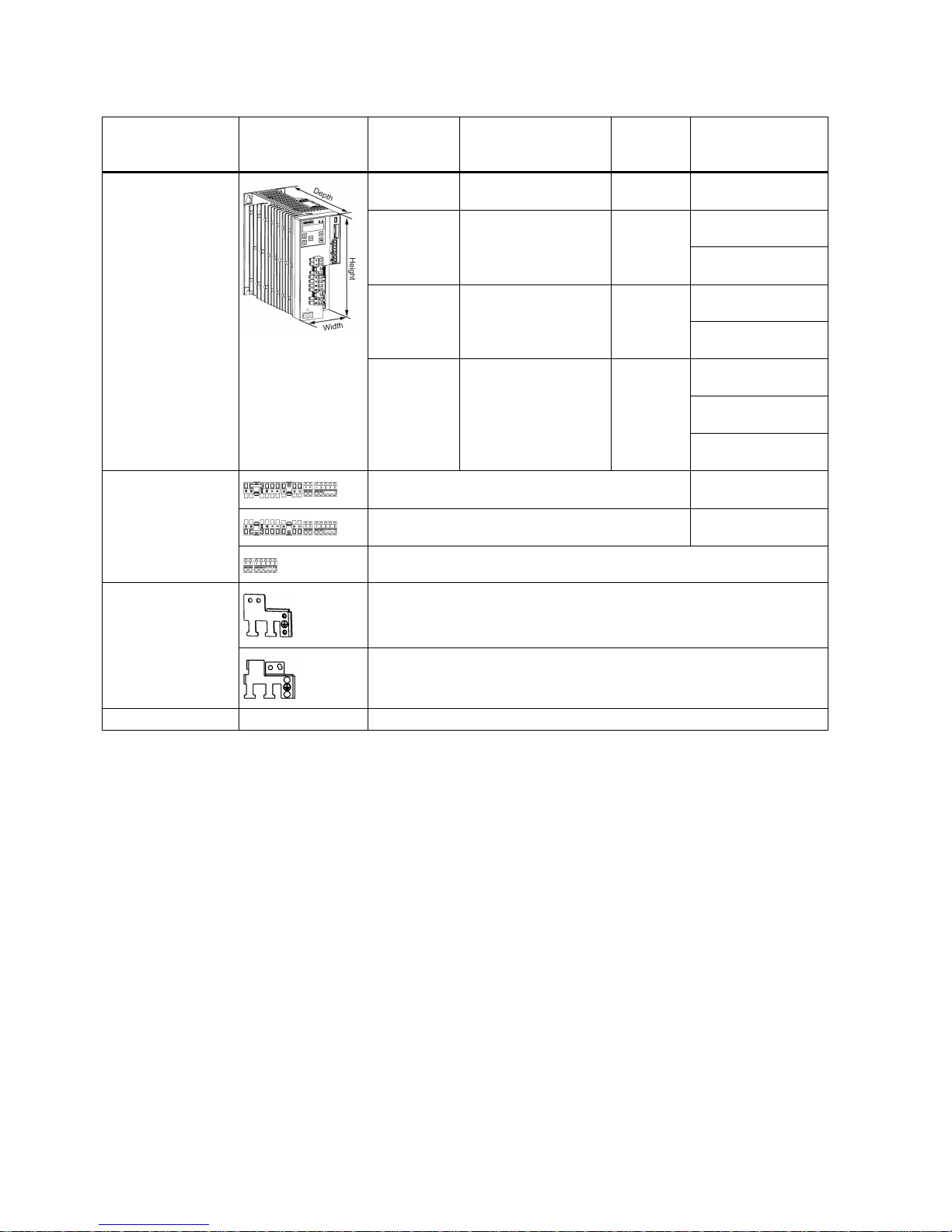

Components in the SINAMICS V90 PN 400 V variant drive package

Component

Illustration

Rated power

(kW)

Outline dimension

(Width x Height x

Depth, mm)

Frame size

Article number

SINAMICS V90 PN,

three-phase, 400 V

0.4 60 x 180 x 200 FSAA 6SL3210-5FE10-

4UF0

0.75/1.0 80 x 180 x 200 FSA 6SL3210-5FE10-

8UF0

6SL3210-5FE11-

0UF0

1.5/2.0 100 x 180 x 220 FSB 6SL3210-5FE11-

5UF0

6SL3210-5FE12-

0UF0

3.5/5.0/7.0 140 x 260 x 240 FSC 6SL3210-5FE13-

5UF0

6SL3210-5FE150UF0

6SL3210-5FE17-

0UF0

Connectors

For FSAA

6SL3200-0WT000AA0

For FSA 6SL3200-0WT01-

0AA0

For FSB and FSC *

Shielding plate

For FSAA and FSA

For FSB and FSC

User documentation Information Guide English-Chinese bilingual version

* You can obtain the connectors for SINAMICS V90 PN 400V servo drives of FSB and FSC from the connector kits for

SINAMICS V90 PN 400V servo drives of FSAA or FSA.

Getting Started

A5E37208904-003, 04/2017

11

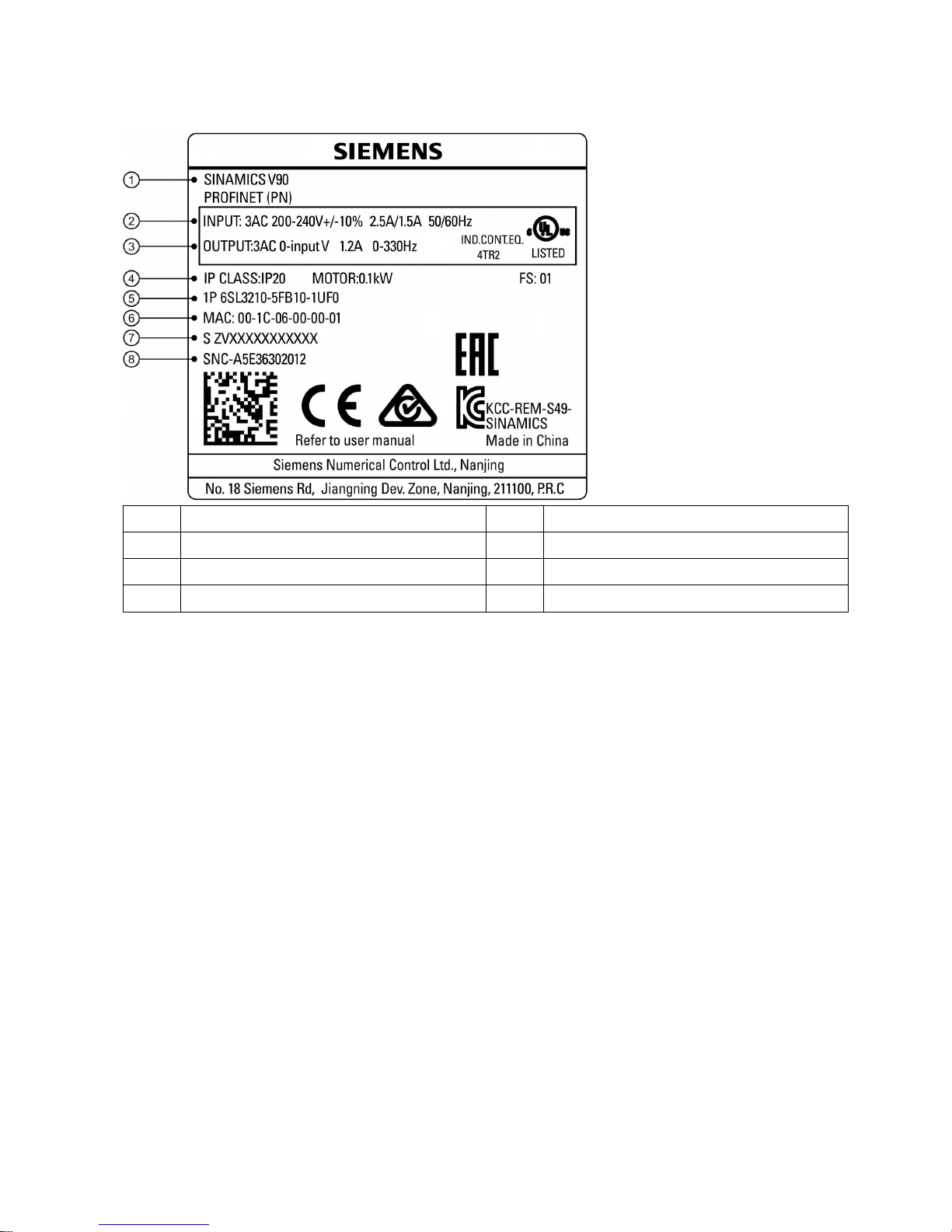

Drive rating plate (example)

①

Drive name

⑤

Article number

②

Power input

⑥

MAC address

③

Power output

⑦

Product serial number

④

Rated motor power

⑧

Part number

Getting Started

12 A5E37208904-003, 04/2017

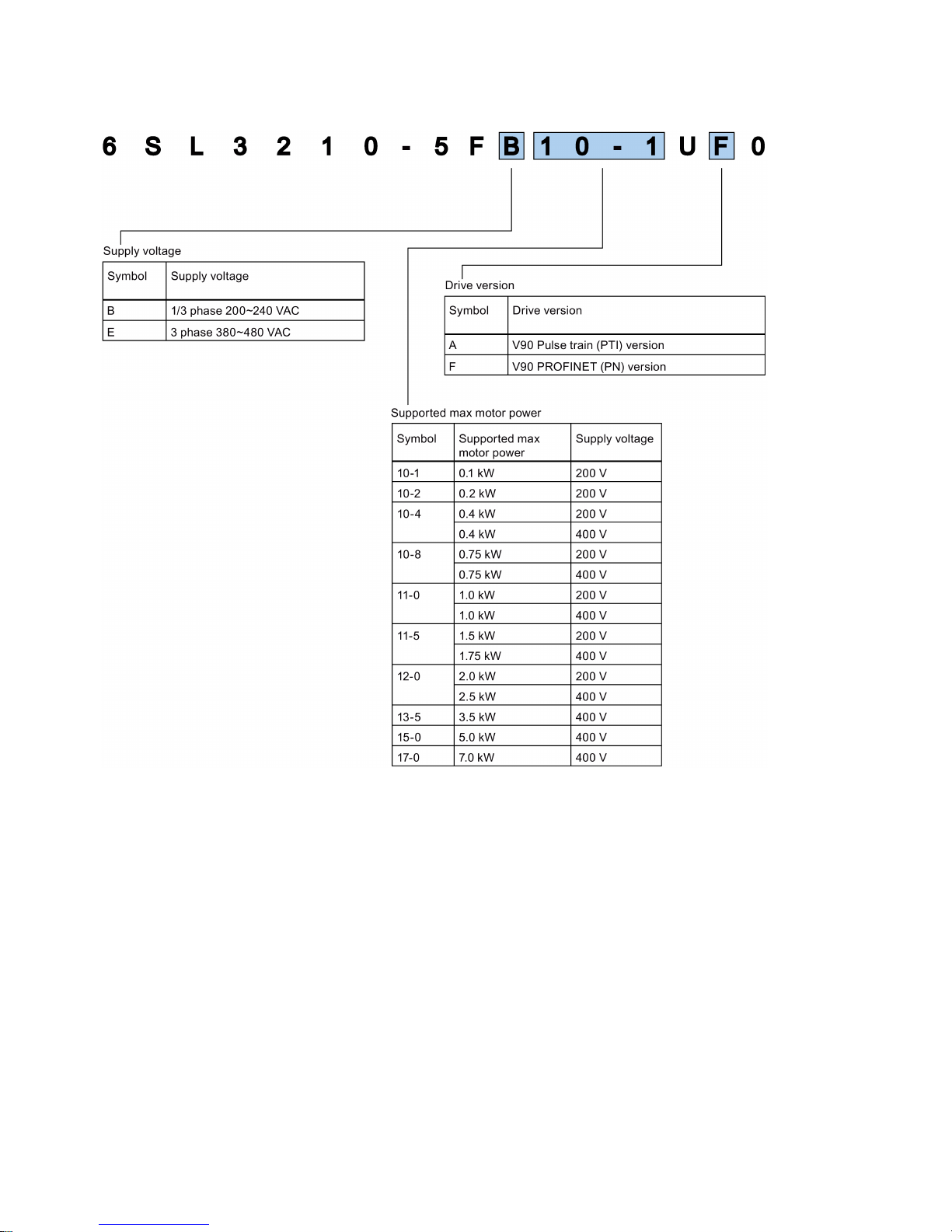

Article number explanation (example)

Getting Started

A5E37208904-003, 04/2017

13

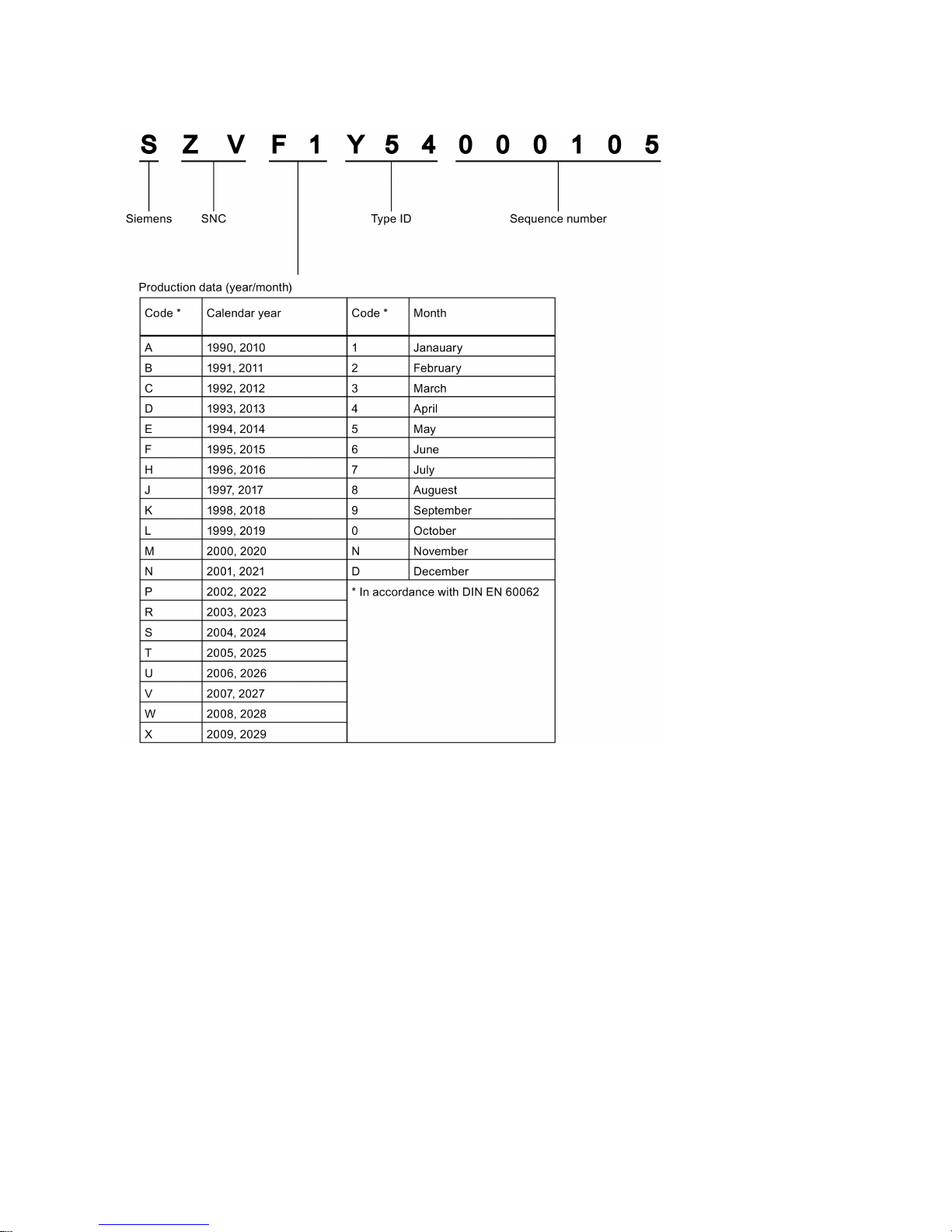

Serial number explanation (example)

Getting Started

14 A5E37208904-003, 04/2017

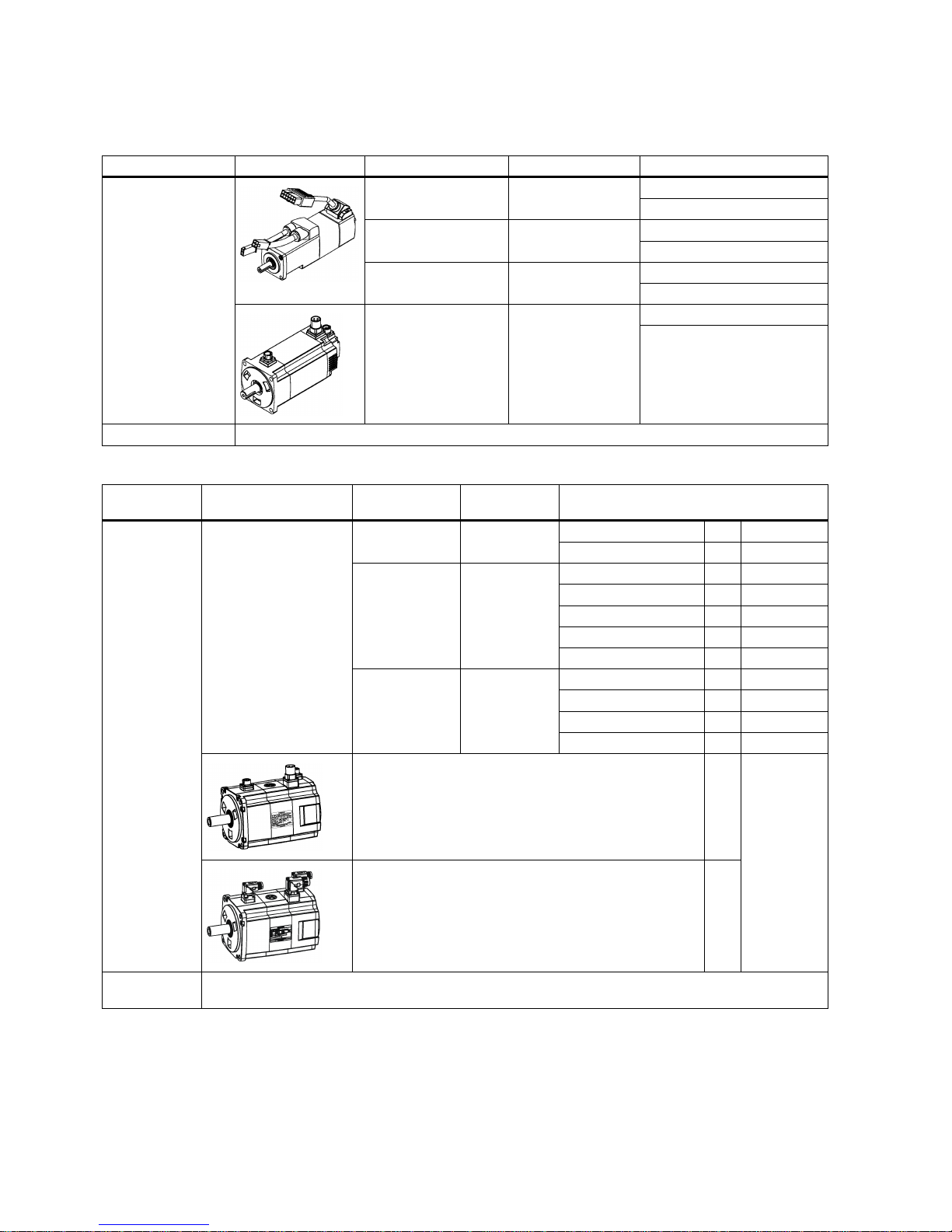

2.1.2

Motor components

Components in the SIMOTICS S-1FL6 low inertia motor package

Component

Illustration

Rated power (kW)

Shaft height (mm)

Article number

SIMOTICS S-1FL6,

low inertia

0.05/0.1 20

1FL6022-2AF21-1❑❑1

1FL6024-2AF21-1❑❑1

0.2/0.4 30

1FL6032-2AF21-1❑❑1

1FL6034-2AF21-1❑❑1

0.75/1.0 40

1FL6042-2AF21-1❑❑1

1FL6044-2AF21-1❑❑1

1.5/2.0 50

1FL6052-2AF21-0❑❑1

1FL6054-2AF21-0❑❑1

User documentation

SIMOTICS S-1FL6 Servo Motors Installation Guide

Components in the SIMOTICS S-1FL6 high inertia motor package

Component

Illustration

Rated power

(kW)

Shaft height

(mm)

Article number

SIMOTICS S1FL6, high

inertia

0.4/0.75 45

1FL6042-1AF61-

❑

❑❑1

1FL6044-1AF61- ❑ ❑❑1

0.75/1.0/1.5/1.7

5/2.0

65

1FL6061-1AC61-

❑

❑❑1

1FL6062-1AC61-

❑

❑❑1

1FL6064-1AC61-

❑

❑❑1

1FL6066-1AC61-

❑

❑❑1

1FL6067-1AC61-

❑

❑❑1

2.5/3.5/5.0/7.0 90

1FL6090-1AC61-

❑

❑❑1

1FL6092-1AC61-

❑

❑❑1

1FL6094-1AC61-

❑

❑❑1

1FL6096-1AC61-

❑

❑❑1

Straight connectors with a fixed outlet direction 0

Angular connectors with a flexible outlet direction 2

User docu-

mentation

SIMOTICS S-1FL6 Servo Motors Installation Guide

Getting Started

A5E37208904-003, 04/2017

15

Motor rating plate (example)

①

Motor type

⑦

Rated power

⑬

Rated current

②

Article number

⑧

Encoder type and resolution

⑭

Holding brake

③

Serial number

⑨

Thermal class

⑮

Motor ID

④

Rated torque

⑩

Degree of protection

⑯

Weight

⑤

Stall torque

⑪

Motor operating mode

⑰

Maximum speed

⑥

Rated voltage

⑫

Stall current

⑱

Rated speed

Getting Started

16 A5E37208904-003, 04/2017

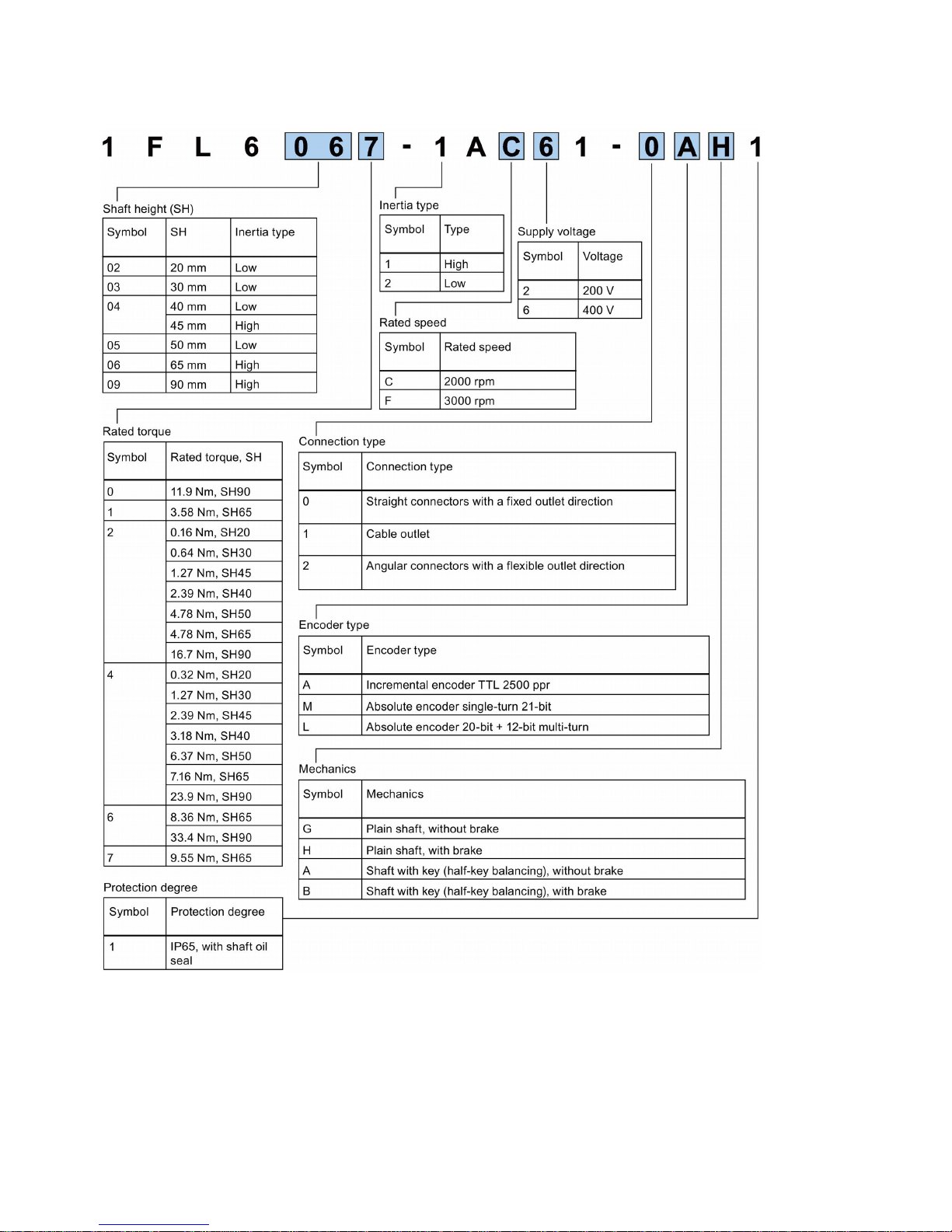

Article number explanation

Getting Started

A5E37208904-003, 04/2017

17

2.2

Device combination

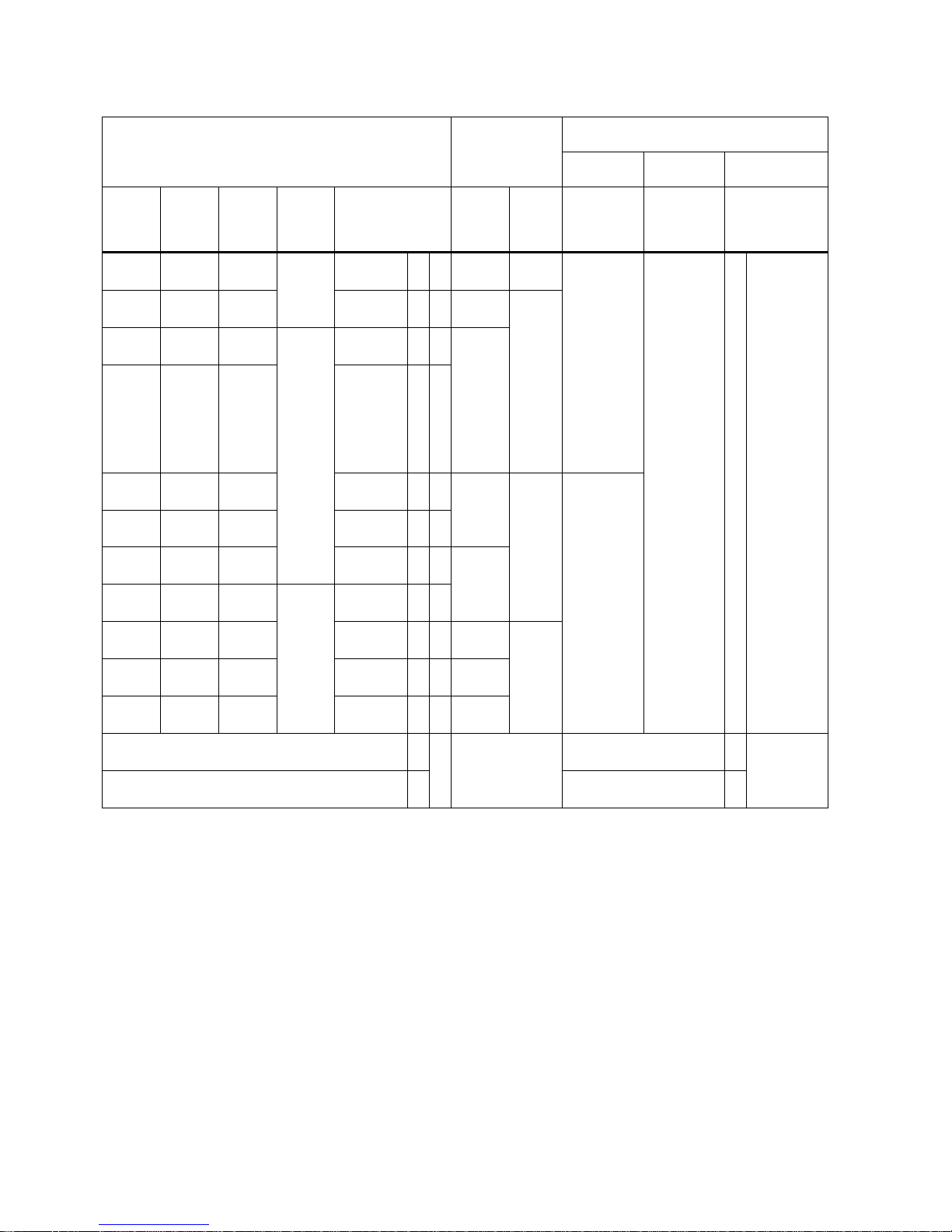

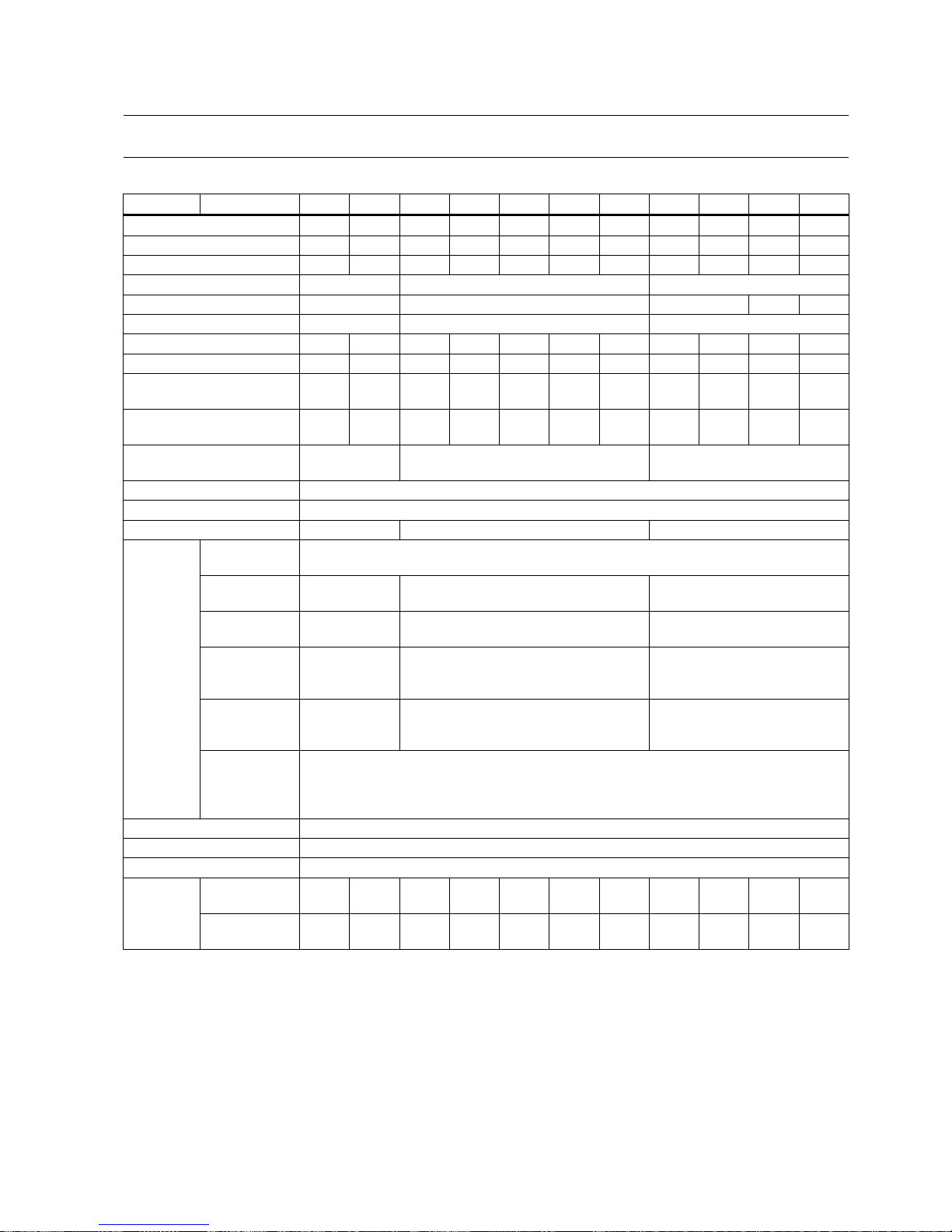

V90 PN 200 V servo system

SIMOTICS S-1FL6 low inertia servo motors

SINAMICS V90

PN 200 V servo

drives

MOTION-CONNECT 300 pre-assembled

cables

Power

cable

Brake cable

Encoder cable

Rated

torque

(Nm)

Rated

power

(kW)

Rated

speed

(rpm)

Shaft

height

(mm)

Article number

1FL60

Article

number

6SL321

0-5

Frame

size

Article

number

6FX3002-5

Article

number

6FX3002-5

Article number

6FX3002-2

0.16 0.05 3000 20 22-2AF21-1 ❑ ❑1 FB101UF0

FSB CK01-1AD0

(3 m)

CK01-1AF0

(5 m)

CK01-1BA0

(10 m)

CK01-1CA0

(20 m)

BK02-1AD0

(3 m)

BK02-1AF0

(5 m)

BK02-1BA0

(10 m)

BK02-1CA0

(20 m)

❑❑ 20-1AD0 (3

m)

20-1AF0 (5

m)

20-1BA0

(10 m)

20-1CA0

(20 m)

0.32 0.1 3000 24-2AF21-1 ❑ ❑

1

0.64 0.2 3000 30 32-2AF21-1 ❑ ❑1 FB10-

2UF0

1.27 0.4 3000 34-2AF21-1 ❑ ❑1 FB10-

4UF1

2.39 0.75 3000 40 42-2AF21-1 ❑ ❑1 FB10-

8UF0

FSC

3.18 1 3000 44-2AF21-1 ❑ ❑1 FB11-

0UF1

FSD

4.78 1.5 3000 50 52-2AF21-0 ❑ ❑1 FB11-

5UF0

CK31-1AD0

(3 m)

CK31-1AF0

(5 m)

CK31-1BA0

(10 m)

CK31-1CA0

(20 m)

BL02-1AD0

(3 m)

BL02-1AF0

(5 m)

BL02-1BA0

(10 m)

BL02-1CA0

(20 m)

❑❑ 10-1AD0 (3

m)

10-1AF0 (5

m)

10-1BA0

(10 m)

10-1CA0

(20 m)

6.37 2 3000 54-2AF21-0 ❑ ❑1 FB120UF0

Incremental encoder TTL 2500 ppr A Incremental encoder TTL

2500 ppr

CT

Absolute encoder single-turn 21-bit M Absolute encoder single-

turn 21-bit

D

B

Getting Started

18 A5E37208904-003, 04/2017

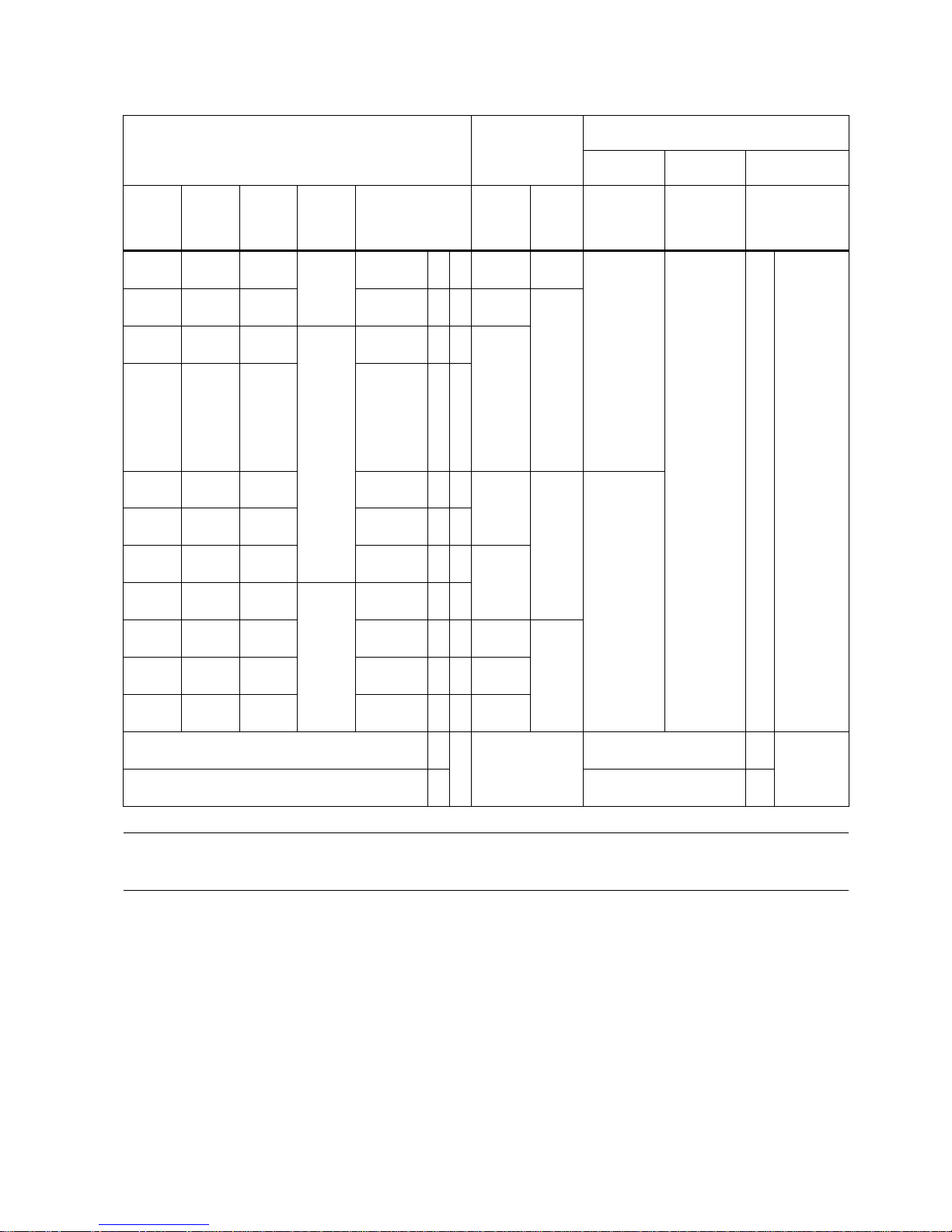

V90 PN 400 V servo system

SIMOTICS S-1FL6 high inertia servo motors with straight

connectors

SINAMICS V90

PN 400 V servo

drives

MOTION-CONNECT 300 pre-assembled

cables

Power

cable

Brake cable

Encoder cable

Rated

torque

(Nm)

Rated

power

(kW)

Rated

speed

(rpm)

Shaft

height

(mm)

Article number

1FL60

Article

number

6SL321

0-5

Frame

size

Article

number

6FX3002-5

Article

number

6FX3002-5

Article number

6FX3002-2

1.27 0.4 3000 45 42-1AF61-0 ❑ ❑1 FE10-

4UF0

FSAA CL01-1AD0

(3 m)

CL01-1AF0

(5 m)

CL01-1AH0

(7 m)

CL01-1BA0

(10 m)

CL01-1BF0

(15 m)

CL01-1CA0

(20 m)

BL02-1AD0

(3 m)

BL02-1AF0

(5 m)

BL02-1AH0

(7 m)

BL02-1BA0

(10 m)

BL02-1BF0

(15 m)

BL02-1CA0

(20 m)

❑❑ 10-1AD0 (3

m)

10-1AF0 (5

m)

10-1AH0 (7

m)

10-1BA0

(10 m)

10-1BF0

(15 m)

10-1CA0

(20 m)

2.39 0.75 3000 44-1AF61-0 ❑ ❑1 FE10-

8UF0

FSA

3.58 0.75 2000 65 61-

1AC61-0

❑ ❑1 FE11-

0UF0

4.78 1.0 2000 621AC61-0

❑ ❑

1

7.16 1.5 2000 64-

1AC61-0

❑ ❑1 FE11-

5UF0

FSB CL11-1AD0

(3 m)

CL11-1AF0

(5 m)

CL11-1AH0

(7 m)

CL11-1BA0

(10 m)

CL11-1BF0

(15 m)

CL11-1CA0

(20 m)

8.36 1.75 2000 66-

1AC61-0

❑ ❑

1

9.55 2.0 2000 67-

1AC61-0

❑ ❑1 FE12-

0UF0

11.9 2.5 2000 90 90-

1AC61-0

❑ ❑

1

16.7 3.5 2000 92-

1AC61-0

❑ ❑1 FE13-

5UF0

FSC

23.9 5.0 2000 94-

1AC61-0

❑ ❑1 FE15-

0UF0

33.4 7.0 2000 96-

1AC61-0

❑ ❑1 FE17-

0UF0

Incremental encoder TTL 2500 ppr A Incremental encoder TTL

2500 ppr

CT

Absolute encoder 20-bit + 12-bit multi-turn L Absolute encoder 20-bit +

12-bit multi-turn

D

B

Getting Started

A5E37208904-003, 04/2017

19

SIMOTICS S-1FL6 high inertia servo motors with angular

connectors

SINAMICS V90

PN 400 V servo

drives

MOTION-CONNECT 300 pre-assembled

cables

Power

cable

Brake cable

Encoder cable

Rated

torque

(Nm)

Rated

power

(kW)

Rated

speed

(rpm)

Shaft

height

(mm)

Article number

1FL60

Article

number

6SL321

0-5

Frame

size

Article

number

6FX3002-5

Article

number

6FX3002-5

Article number

6FX3002-2

1.27 0.4 3000 45 42-1AF61-2 ❑ ❑1 FE10-

4UF0

FSAA CL02-1AD0

(3 m)

CL02-1AF0

(5 m)

CL02-1AH0

(7 m)

CL02-1BA0

(10 m)

CL02-1BF0

(15 m)

CL02-1CA0

(20 m)

BL03-1AD0

(3 m)

BL03-1AF0

(5 m)

BL03-1AH0

(7 m)

BL03-1BA0

(10 m)

BL03-1BF0

(15 m)

BL03-1CA0

(20 m)

❑

❑

❑

❑

-1AD0 (3

m)

-1AF0 (5

m)

-1AH0 (7

m)

-1BA0 (10

m)

-1BF0 (15

m)

-1CA0 (20

m)

2.39 0.75 3000 44-1AF61-2 ❑ ❑1 FE10-

8UF0

FSA

3.58 0.75 2000 65 611AC61-2

❑ ❑1 FE11-

0UF0

4.78 1.0 2000 621AC61-2

❑ ❑

1

7.16 1.5 2000 64-

1AC61-2

❑ ❑1 FE11-

5UF0

FSB CL12-1AD0

(3 m)

CL12-1AF0

(5 m)

CL12-1AH0

(7 m)

CL12-1BA0

(10 m)

CL12-1BF0

(15 m)

CL12-1CA0

(20 m)

8.36 1.75 2000 66-

1AC61-2

❑ ❑

1

9.55 2.0 2000 67-

1AC61-2

❑ ❑1 FE12-

0UF0

11.9 2.5 2000 90 90-

1AC61-2

❑ ❑

1

16.7 3.5 2000 92-

1AC61-2

❑ ❑1 FE13-

5UF0

FSC

23.9 5.0 2000 94-

1AC61-2

❑ ❑1 FE15-

0UF0

33.4 7.0 2000 961AC61-2

❑ ❑1 FE17-

0UF0

Incremental encoder TTL 2500 ppr A Incremental encoder TTL

2500 ppr

CT

12

Absolute encoder 20-bit + 12-bit multi-turn L Absolute encoder 20-bit +

12-bit multi-turn

DB

10

Note

You can select a SINAMICS V90 PN servo drive for all the SIMOTICS S

-1FL6 servo motors whose rated power values are

equal to or smaller than that specified as matching with this servo drive in the table above.

Getting Started

20 A5E37208904-003, 04/2017

2.3

Accessories

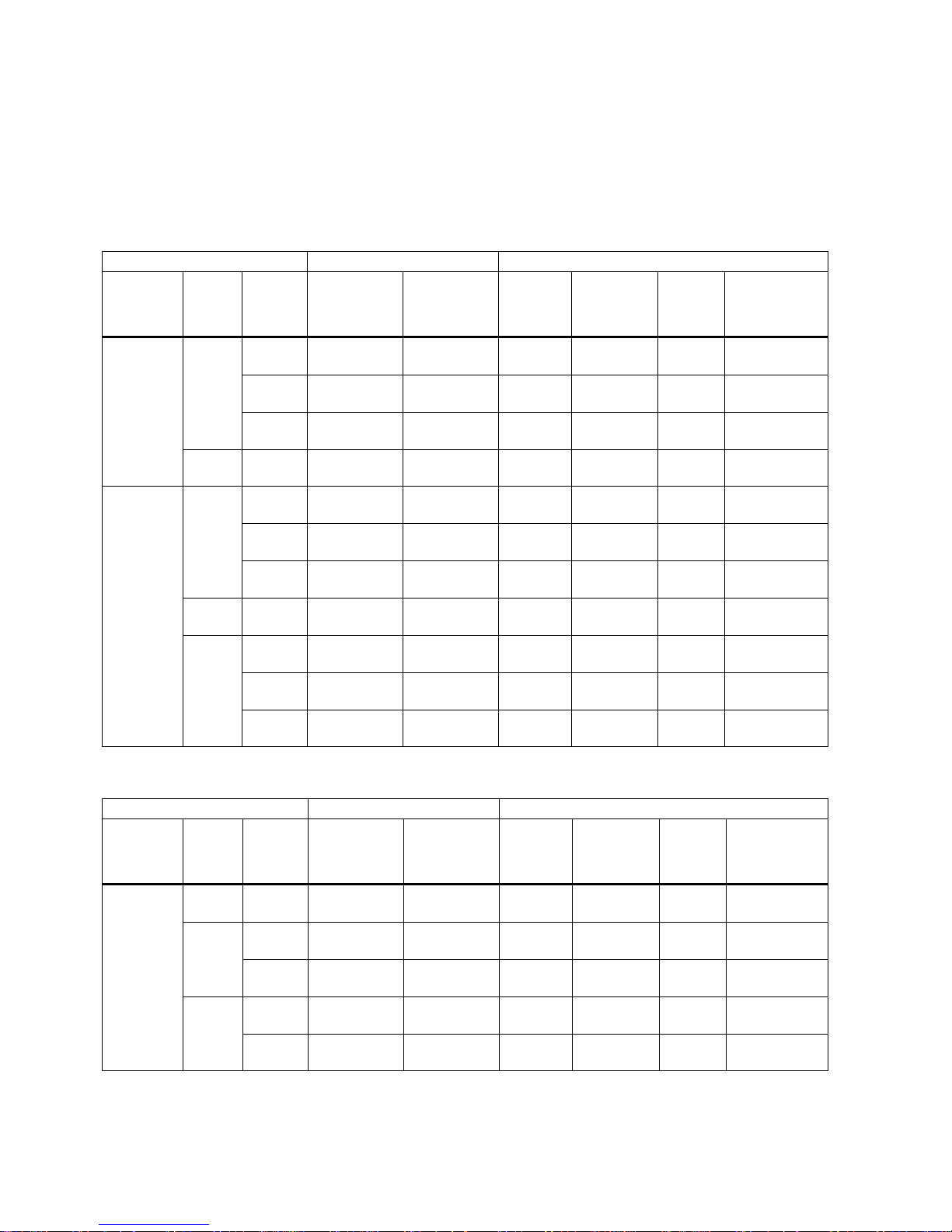

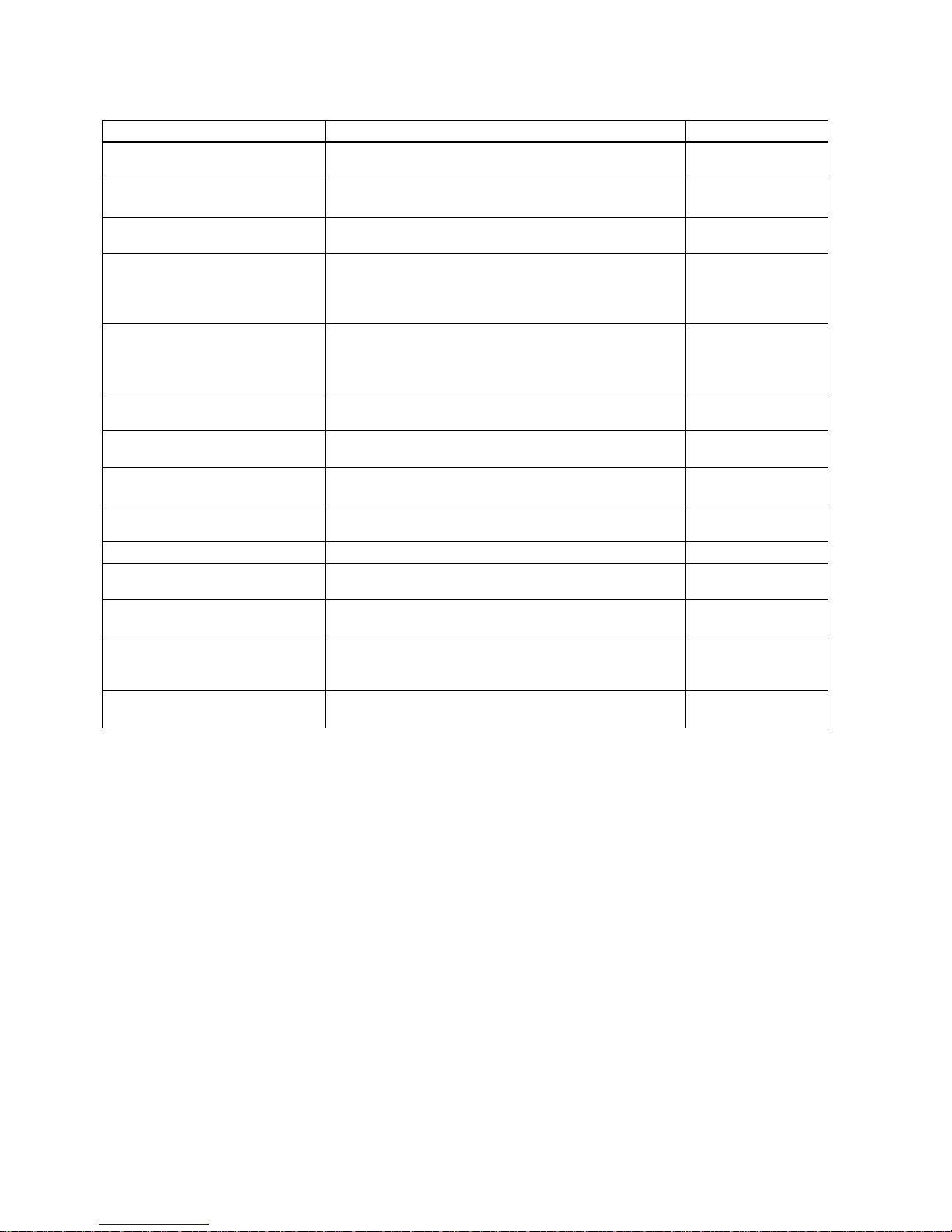

Fuse/Type-E combination motor controller

A fuse/type-E combination motor controller/circuit breaker can be used to protect the system. Integral solid state short circuit

protection does not provide branch circuit protection. Branch circuit protection must be provided in accordance with the

National Electrical Code and any additional local codes. Refer to the following table for the selection of fuses, type-E

combination motor controllers, and circuit breakers:

SINAMICS V90 PN 200 V variant

SINAMICS V90 PN

Recommended fuse

Type-E combination motor controller 1)

Power

supply

Frame

size

Rated

power

(kW)

CE-compliant

UL/cULcompliant

listed (JDDZ)

fuse

Rated

current

(A)

Rated voltage (VAC)

Rated

power

(hp)

Article number

1-phase,

200 VAC to

240 VAC

FSB 0.1 3NA3 801 (6

A)

6 A 2.8 to 4 230/240 1/3 3RV 2011-

1EA10

0.2 3NA3 801 (6

A)

6 A 2.8 to 4 230/240 1/3 3RV 2011-

1EA10

0.4 3NA3 803 (10

A)

10 A 5.5 to 8 230/240 1 3RV 2011-

1HA10

FSC 0.75 3NA3 805 (16

A)

20 A 9 to 12.5 230/240 2 3RV 2011-

1KA10

3-phase,

200 VAC to

240 VAC

FSB 0.1 3NA3 801 (6

A)

6 A 2.8 to 4 230/240 3/4 3RV 2011-

1EA10

0.2 3NA3 801 (6

A)

6 A 2.8 to 4 230/240 3/4 3RV 2011-

1EA10

0.4 3NA3 803 (10

A)

10 A 2.8 to 4 230/240 3/4 3RV 2011-

1EA10

FSC 0.75 3NA3 805 (16

A)

20 A 5.5 to 8 230/240 2 3RV 2011-

1HA10

FSD 1.0 3NA3 805 (16

A)

20 A 7 to 10 230/240 3 3RV 2011-

1JA10

1.5 3NA3 810 (25

A)

25 A 10 to 16 230/240 5 3RV 2011-

4AA10

2.0 3NA3 810 (25

A)

25 A 10 to 16 230/240 5 3RV 2011-

4AA10

1)

The above types for type-E combination motor controllers are listed in compliance with both CE and UL/cUL standards.

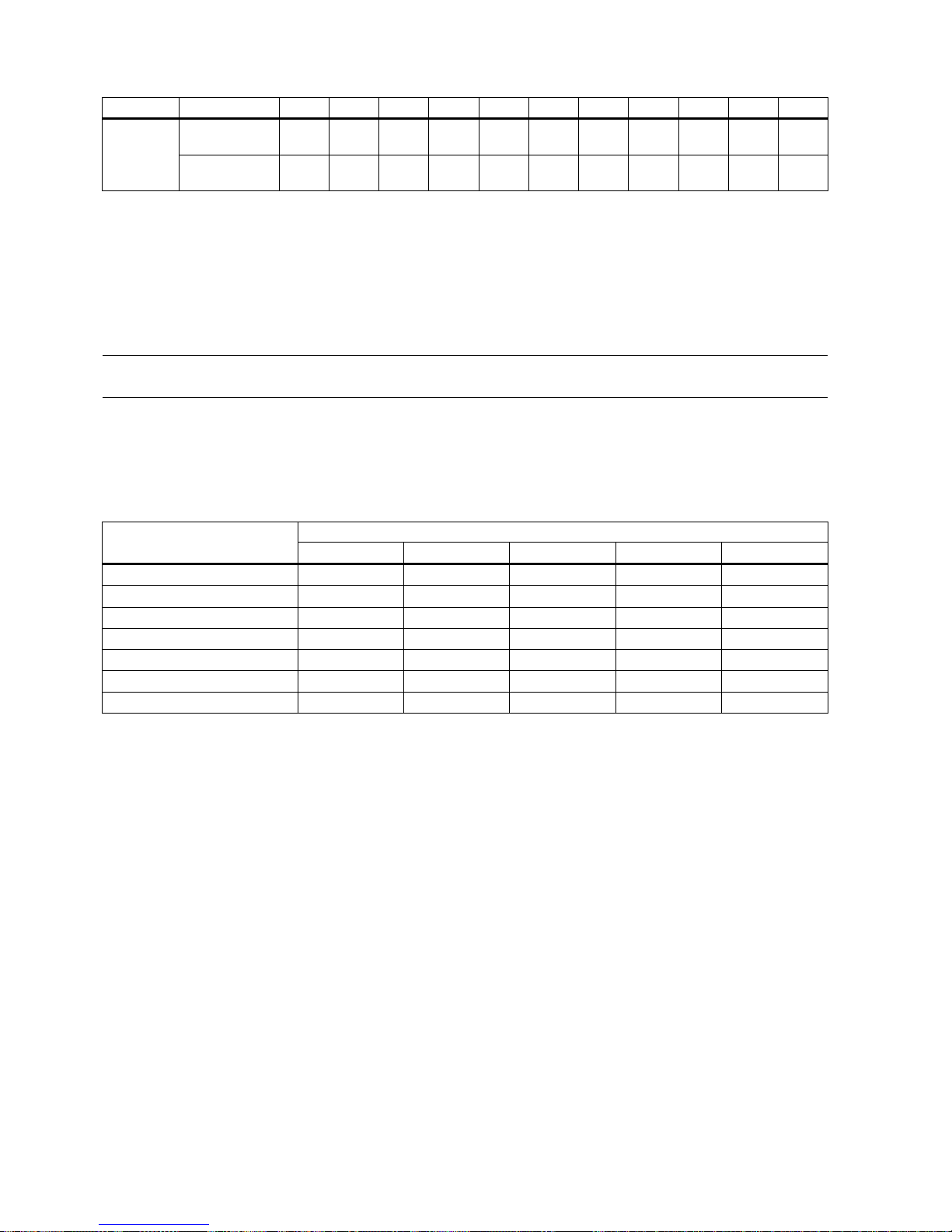

SINAMICS V90 PN 400 V variant

SINAMICS V90 PN

Recommended fuse type

Type-E combination motor controller 1)

Power

supply

Frame

size

Rated

power

(kW)

CE-compliant

UL/cULcompliant

listed (JDDZ)

fuse

Rated

current (A)

Rated voltage (VAC)

Rated

power

(hp)

Article number

3-phase,

380 VAC to

480 VAC

FSAA 0.4 3NA3 801-6

(6 A)

10 A 2.2 to 3.2 380/480 0.5 3RV 2021-

1DA10

FSA 0.75 3NA3 801-6

(6 A)

10 A 2.8 to 4 380/480 1 3RV 2021-

1EA10

1.0 3NA3 803-6

(10 A)

10 A 3.5 to 5 380/480 1.34 3RV 2021-

1FA10

FSB 1.5 3NA3 803-6

(10 A)

15 A 5.5 to 8 380/480 2 3RV 2021-

1HA10

2.0 3NA3 805-6

(16 A)

15 A 11 to 16 380/480 2.68 3RV 2021-

4AA10

Getting Started

A5E37208904-003, 04/2017

21

SINAMICS V90 PN

Recommended fuse type

Type-E combination motor controller 1)

Power

supply

Frame

size

Rated

power

(kW)

CE-compliant

UL/cULcompliant

listed (JDDZ)

fuse

Rated

current (A)

Rated voltage (VAC)

Rated

power

(hp)

Article number

FSC 3.5 3NA3 807-6

(20 A)

25 A 14 to 20 380/480 4.7 3RV 2021-

4BA10

5.0 3NA3 807-6

(20 A)

25 A 14 to 20 380/480 6.7 3RV 2021-

4BA10

7.0 3NA3 810-6

(25 A)

25 A 20 to 25 380/480 9.4 3RV 2021-

4DA10

1)

The above types for Type-E combination motor controllers are listed in compliance with both CE and UL/cUL standards.

For more information about the accessories, refer to SINAMICS V90, SIMOTICS S-1FL6 Operating Instructions.

WARNING

Requirements for United States/Canadian installations (UL/cUL)

Suitable for use on a circuit capable of delivering not more than 65000 rms Symmetrical Amperes, 480 VAC maximum for

400 V variants of drives or 240 VAC maximum for 200 V variant drives, when protected by UL/cUL listed (JDDZ) fuse or

type E combination motor controller. For each frame size AA, A, B, C and D, use 75 °C copper wire only.

This equipment is capable of providing internal motor overload protection according to UL508C.

For Canadian (cUL) installations the drive mains supply must be fitted with any external recommended suppressor with the

following features:

• Surge-protective devices; device shall be a Listed Surge-protective device (Category code VZCA and VZCA7)

• Rated nominal voltage 480/277 VAC, 50/60 Hz, 3-phase

• Clamping voltage VPR = 2000 V, IN = 3kA min, MCOV = 508 VAC, SCCR = 65 kA

• Suitable for Type 2 SPD application

•

Clamping shall be provided between phases and also between phase and ground

Product maintenance

The components are subject to continuous further development within the scope of product maintenance (improvements to

robustness, discontinuations of components, etc).

These further developments are "spare parts-compatible" and do not change the article number.

In the scope of such spare parts-compatible further developments, connector positions are sometimes changed slightly. This

does not cause any problems with proper use of the components. Please take this fact into consideration in special

installation situations (e.g. allow sufficient clearance for the cable length).

Use of third-party products

This document contains recommendations relating to third-party products. Siemens accepts the fundamental suitability of

these third-party products.

You can use equivalent products from other manufacturers.

Siemens does not accept any warranty for the properties of third-party products.

Getting Started

22 A5E37208904-003, 04/2017

2.4

Function list

Function

Description

Control mode

Basic positioner (EPOS) Positions axes in absolute/relative terms with a motor en-

coder

EPOS

Speed control (S) Flexibly controls motor speed and direction through

PROFINET communication port

S

Safe Torque Off (STO) Safely disconnects torque-generating motor power supply

to prevent an unintentional motor restart

EPOS, S

One-button auto tuning Estimates the machine characteristic and sets the closed

loop control parameters (speed loop gain, speed integral

compensation, filter if necessary, etc.) without any user

intervention

EPOS, S

Real-time auto tuning Estimates the machine characteristic and sets the closed

loop control parameters (speed loop gain, speed integral

compensation, filter if necessary, etc.) continuously in real

time without any user intervention

EPOS, S

Resonance suppression Suppresses the mechanical resonance, such as workpiece

vibration and base shake

EPOS, S

Low frequency vibration suppres-

sion

Suppresses the low frequency vibration in the machine

system

EPOS

Speed limit Limits motor speed through internal speed limit commands

(two groups)

EPOS, S

Torque limit Limits motor torque through internal torque limit commands

(two groups)

EPOS, S

Basic operator panel (BOP)

Displays servo status on a 6-digit 7-segment LED display

EPOS, S

External braking resistor - DCP, R1 An external braking resistor can be used when the internal

braking resistor is insufficient for regenerative energy

EPOS, S

Digital inputs/outputs (DIs/Dos) Control signals and status signals can be assigned to four

programmable digital inputs and two digital outputs

EPOS, S

PROFINET communication Supports communication between the SINAMICS V90 PN

servo drive and PLC with PROFINET communication protocol

EPOS, S

SINAMICS V-ASSISTANT You can perform parameter settings, test operation, ad-

justment and other operations with a PC

EPOS, S

Getting Started

A5E37208904-003, 04/2017

23

2.5

Technical data

2.5.1

Technical data - servo drives

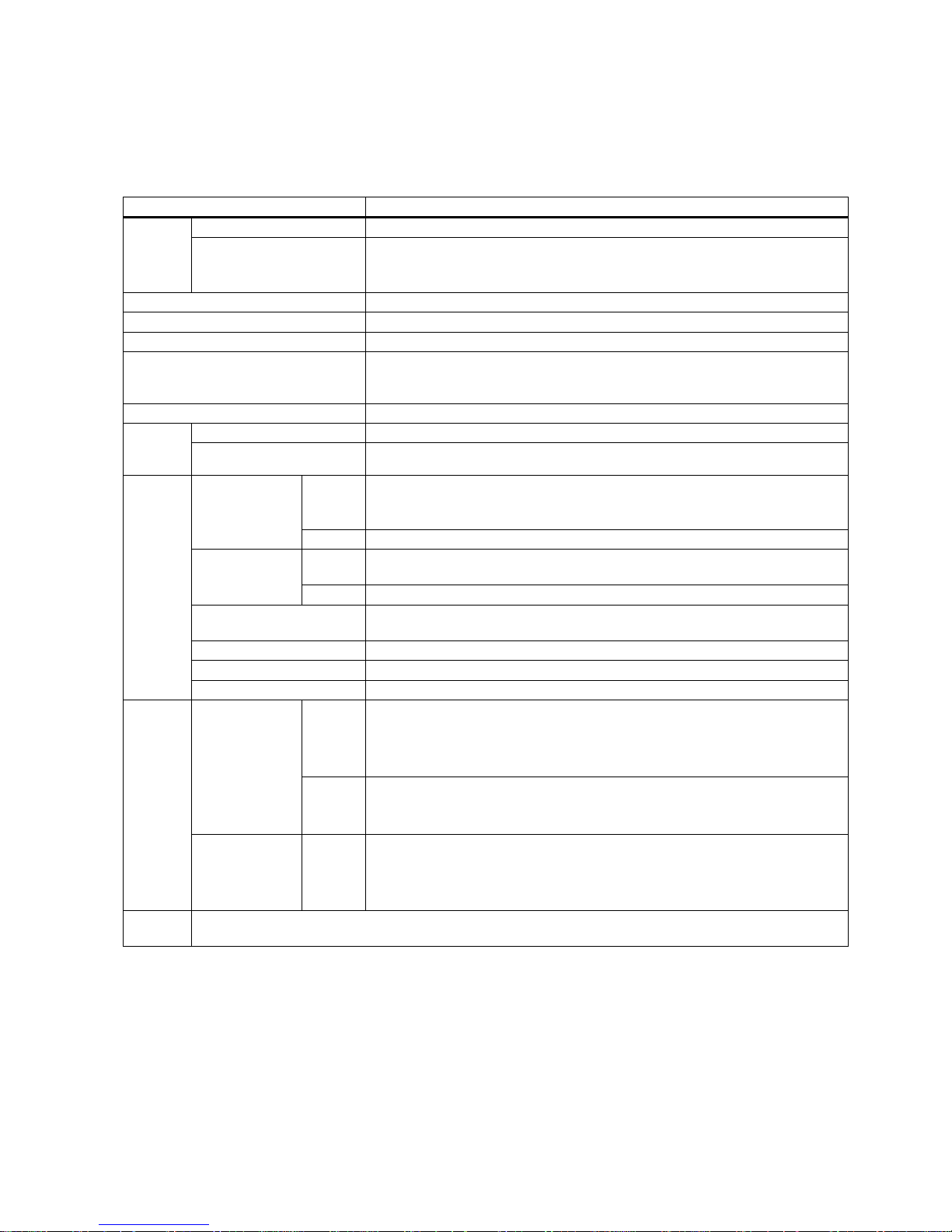

General technical data

Parameter

Description

24 VDC

power

supply

Voltage (V)

24 (-15% to +20%)

1)

Maximum current (A)

When using a motor without a brake: 1.5 A

When using a motor with a brake: 1.5 A + motor holding brake rated current (See

Section "Technical data - servo motors (Page 25)".)

Overload capability

300%

Control system

Servo control

Dynamic brake

Built-in

Protective functions Earthing fault protection, output short-circuit protection 2), overvolt-

age/undervoltage protection

3)

, I2t inverter,I2t motor, IGBT overtemperature pro-

tection 4)

Overvoltage criteria

Category III

Speed

control

mode

Speed control range

Internal speed command 1:5000

Torque limit

Set through a parameter

Environ-

mental

conditions

Surrounding air

temperature

Opera-

tion

0 °C to 45 °C: without power derating

45 °C to 55 °C: with power derating

Storage

-40 °C to +70 °C

Ambient humidi-

ty

Opera-

tion

< 90% (non-condensing)

Storage

90% (non-condensing)

Operating environment Indoors (without direct sunlight), free from corrosive gas, combustible gas, oil

gas, or dust

Altitude

≤ 1000 m (without power derating)

Degree of protection

IP 20

Degree of pollution

Class 2

Vibration Operation Shock Operational area II

Peak acceleration: 5 g, 30 ms and 15 g, 11 ms

Quantity of shocks: 3 per direction × 6 directions

Duration of shock: 1 s

Vibration

Operational area II

10 Hz to 58 Hz: 0.075 mm deflection

58 Hz to 200 Hz: 1 g vibration

Product packag-

ing

Vibration

2 Hz to 9 Hz: 3.5 mm deflection

9 Hz to 200 Hz: 1 g vibration

Quantity of cycles: 10 per axis

Sweep seed: 1 octave/min

Certifica-

tion

UL, CE, KC, C-Tick, EAC

1 )

When SINAMICS V90 PN works with a motor with a brake, the voltage tolerance of 24 VDC power supply must be -10%

to +10% to meet the voltage requirement of the brake.

2)

Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must be

provided in accordance with the National Electrical Code and any additional local codes.

3)

The V90 PN 200 V servo drive has an overvoltage threshold of 410 VDC and an undervoltage threshold of 150 VDC;

the V90 PN 400 V servo drive has an overvoltage threshold of 820 VDC and an undervoltage threshold of 320 VDC.

4)

SINAMICS V90 PN does not support motor overtemperature protection. Motor overtemperature is calculated by I2t and

protected by the output current from the drive.

Getting Started

24 A5E37208904-003, 04/2017

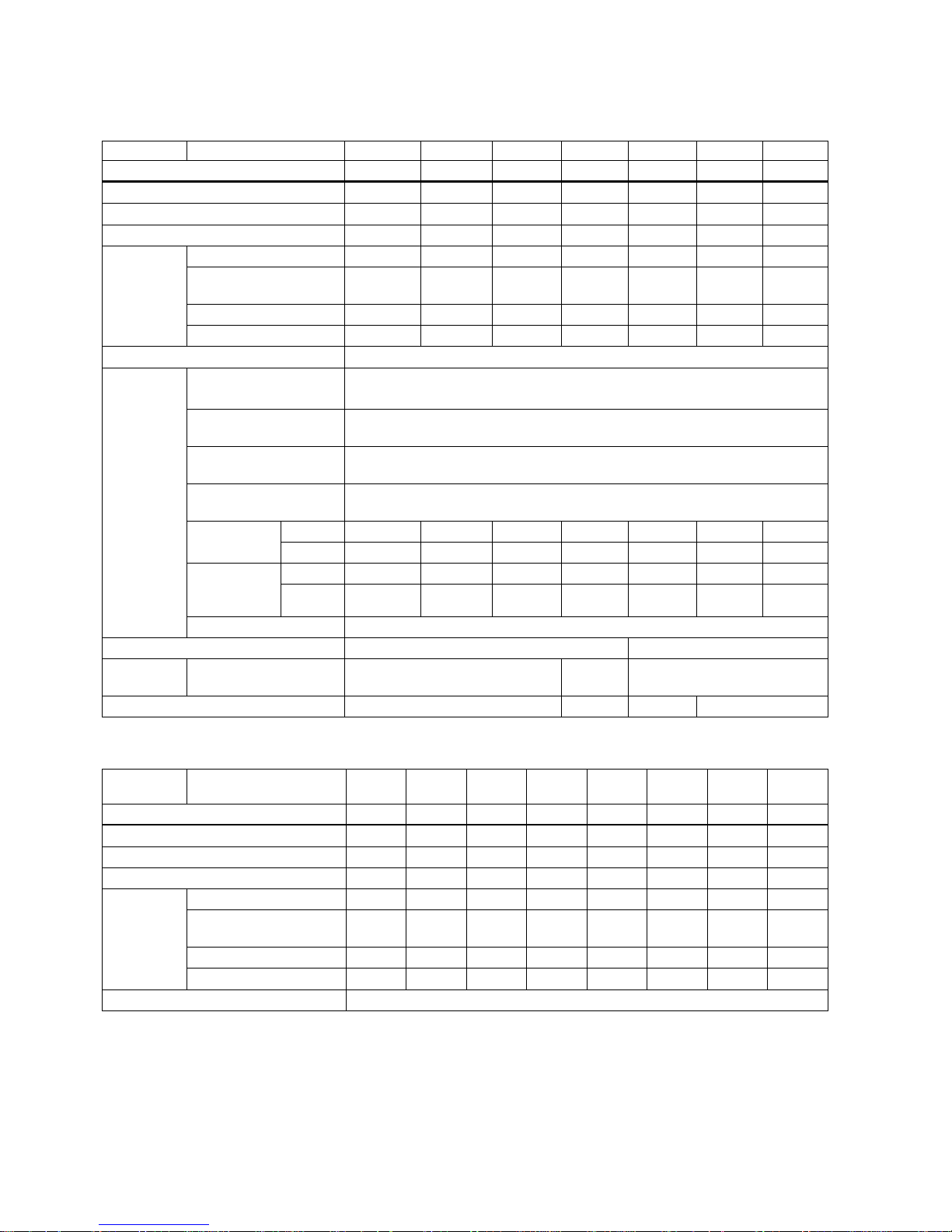

Specific technical data

SINAMICS V90 PN 200V variant

Article No.

6SL3210-5FB...

10-1UF0

10-2UF0

10-4UF1

10-8UF0

11-0UF1

11-5UF0

12-0UF0

Frame size

FSB

FSB

FSB

FSC

FSD

FSD

FSD

Rated output current (A)

1.2

1.4

2.6

4.7

6.3

10.6

11.6

Max. output current (A)

3.6

4.2

7.8

14.1

18.9

31.8

34.8

Max. supported motor power (kW)

0.1

0.2

0.4

0.75

1.0

1.5

2.0

Power loss

1)

Main circuit (W)

8

15

33

48

65

105

113

Regenerative resistor

(W)

5 5 7 9 13 25 25

Control circuit (W)

16

16

16

16

16

18

18

Total (W)

29

36

56

73

94

148

156

Output frequency (Hz)

0 to 330

Power supply

Voltage/frequency FSB and FSC: single phase/three phase 200 VAC to 240 VAC, 50/60 Hz

FSD: three phase 200 VAC to 240 VAC, 50/60 Hz

Permissible voltage

fluctuation

-15% to +10%

Permissible frequency

fluctuation

-10% to +10%

Permissible supply con-

figuration

TN, TT, IT

Rated input

current (A)

1-phase

2.5

3.0

5.0

10.4 - -

-

3-phase 1.5 1.8 3.0 5.0 7.0 11.0 12.0

Power supply

capacity

(kVA)

1-phase

0.5

0.7

1.2

2.0 - -

-

3-phase 0.5 0.7 1.1 1.9 2.7 4.2 4.6

Inrush current (A)

8.0

Cooling method

Self-cooled

Fan-cooled

Mechanical

design

Outline dimensions (W x

H x D, mm)

50 x 170 x 170 80 x 170

x 195

95 x 170 x 195

Weight (kg)

1.25

1.95

2.3

2.4

1)

The values here are calculated at rated load.

SINAMICS V90 PN 400V variant

Article No.

6SL3210-5FE...

104UF0

108UF0

110UF0

115UF0

120UF0

135UF0

150UF0

170UF0

Frame size

FSAA

FSA

FSA

FSB

FSB

FSC

FSC

FSC

Rated output current (A)

1.2

2.1

3.0

5.3

7.8

11.0

12.6

13.2

Max. output current (A)

3.6

6.3

9.0

13.8

23.4

33.0

37.8

39.6

Max. supported motor power (kW)

0.4

0.75

1.0

1.75

2.5

3.5

5.0

7.0

Power loss

1)

Main circuit (W)

12

29

32

84

96

92

115

138

Regenerative resistor

(W)

17 57 57 131 131 339 339 339

Control circuit (W)

32

32

35

35

35

36

36

36

Total (W)

61

118

124

250

262

467

490

513

Output frequency (Hz) 0 to 330

Getting Started

A5E37208904-003, 04/2017

25

Article No.

6SL3210-5FE...

104UF0

108UF0

110UF0

115UF0

120UF0

135UF0

150UF0

170UF0

Frame size

FSAA

FSA

FSA

FSB

FSB

FSC

FSC

FSC

Power supply

Voltage/frequency

Three phase 380 VAC to 480 VAC, 50/60 Hz

Permissible voltage fluc-

tuation

-15% to +10%

Permissible frequency

fluctuation

-10% to +10%

Permissible supply con-

figuration

TN, TT, IT

Rated input current (A)

1.5

2.6

3.8

6.6

9.8

13.8

15.8

16.5

Power supply capacity

(kVA)

1.7 3.0 4.3 7.6 11.1 15.7 18.0 18.9

Inrush current (A)

8.0

8.0

8.0

4.0

4.0

2.5

2.5

2.5

Cooling method

Self-cooled

Fan-cooled

Mechanical

design

Outline dimensions (W x

H x D, mm)

60 x

180 x

200

80 x 180 x 200 100 x 180 x 220 140 x 260 x 240

Weight (kg)

1.5

1.9

1.9

2.5

2.5

5.0

5.5

5.75

1)

The values here are calculated at rated load.

2.5.2

Technical data - servo motors

General technical data

Parameter

Description

Type of motor

Permanent-magnet synchronous motor

Cooling

Self-cooled

Relative humidity [RH]

90% (non-condensing at 30°C )

Installation altitude [m]

≤ 1000 (without power derating)

Thermal class

B

Vibration severity grade

A (according to IEC 60034-14)

Shock resistance [m/s2]

25 (continuous in axial direction); 50 (continuous in radial direction); 250

(in a short time of 6 ms)

Bearing lifetime [h]

> 20000

1)

Paint finish

Black

Protection degree of shaft

IP 65, with shaft oil seal

Type of construction

IM B5, IM V1, and IM V3

Positive rotation

Clockwise (default setting in servo drives)

Certification

CE, EAC

1)

This lifetime is only for refere

nce. When a motor keeps running at rated speed under rated load, replace its bearing after

20,000 to 30,000 hours of service time. Even if the time is not reached, the bearing must be replaced when unusual

noise, vibration, or faults are found.

Getting Started

26 A5E37208904-003, 04/2017

Specific technical data

SIMOTICS S-1FL6, low inertia servo motor

Article No.

1FL60...

22

24

32

34

42

44

52

54

Rated power [kW]

0.05

0.1

0.2

0.4

0.75 1 1.5 2 Rated torque [Nm]

0.16

0.32

0.64

1.27

2.39

3.18

4.78

6.37

Maximum torque [Nm]

0.48

0.96

1.91

3.82

7.2

9.54

14.3

19.1

Rated speed [rpm]

3000

Maximum speed [rpm]

5000

Rated frequency [Hz]

200

Rated current [A] 1.2 1.2 1.4 2.6 4.7 6.3 10.6 11.6

Maximum current [A]

3.6

3.6

4.2

7.8

14.2

18.9

31.8

34.8

Moment of inertia [10-4

kgm2]

0.031 0.052 0.214 0.351 0.897 1.15 2.04 2.62

Moment of inertia (with

brake) [10-4 kgm2]

0.038 0.059 0.245 0.381 1.06 1.31 2.24 2.82

Recommended load to mo-

tor inertia ratio

Max. 30x Max. 20x Max. 15x

Operating temperature [°C] 1FL602❑, 1FL603❑ and 1FL604❑: 0 to 40 (without power derating)

1FL605❑: 0 to 30 (without power derating) 1)

Storage temperature [°C]

-20 to +65

Maximum noise level [dB]

60

Holding

brake

Rated voltage

(V)

24 ± 10%

Rated current

(A)

0.25 0.3 0.35 0.57

Holding brake

torque [Nm]

0.32 1.27 3.18 6.37

Maximum

brake opening

time [ms]

35 75 105 90

Maximum

brake closing

time [ms]

10 10 15 35

Maximum

number of

emergency

stops

2000

2)

Oil seal lifetime [h]

3000 to 5000

Encoder lifetime [h]

> 20000 3)

Protection degree of motor

body

IP 65

Protection degree of cable

end connector

IP20 -

Weight [kg]

With brake

0.70

0.86

1.48

1.92

3.68

4.20

6.76

8.00

Without brake

0.47

0.63

1.02

1.46

2.80

3.39

5.35

6.56

1)

When the surrounding temperature is between 30 °C and 40 °C, the 1FL605 motor will have a power derating of 10%.

2)

Restricted emergency stop operation is permissible. Up to 2000 braking operations for the motors of 0.05 kW to 1 kW,

and 200 braking operations for the motors of 1.5 kW to 2 kW can be executed with 300% rotor moment of inertia as external moment of inertia from a speed of 3000 rpm without the brake being subject to an inadmissible amount of wear.

3)

This lifetime is only for reference. When a motor keeps running at 80% rated value and the surrounding temperature is

30 °C, the encoder lifetime can be ensured.

Getting Started

A5E37208904-003, 04/2017

27

Note

The data of rated torque, rated power, maximum torque in the above table allows a tolerance of 10%.

SIMOTICS S-1FL6, high inertia servo motor

Article No.

1FL60...

42

44

61

62

64

66

67

90

92

94

96

Rated power [kW]

0.40

0.75

0.75

1.00

1.50

1.75

2.00

2.5

3.5

5.0

7.0 1)

Rated torque [Nm]

1.27

2.39

3.58

4.78

7.16

8.36

9.55

11.9

16.7

23.9

33.4

Maximum torque [Nm]

3.8

7.2

10.7

14.3

21.5

25.1

28.7

35.7

50.0

70.0

90.0

Rated speed [rpm]

3000

2000

2000

Maximum speed [rpm]

4000

3000

3000

2500

2000

Rated frequency [Hz]

200

133

133

Rated current [A]

1.2

2.1

2.5

3.0

4.6

5.3

5.9

7.8

11.0

12.6

13.2

Maximum current [A]

3.6

6.3

7.5

9.0

13.8

15.9

17.7

23.4

33.0

36.9

35.6

Moment of inertia [10-4

kgm2]

2.7

5.2

8.0

15.3/1

1.7

2)

15.3

22.6

29.9

47.4

69.1

90.8

134.3

Moment of inertia (with

brake) [10-4 kgm2]

3.2

5.7

9.1

16.4/1

3.5 2)

16.4

23.7

31.0

56.3

77.9

99.7

143.2

Recommended load to

motor inertia ratio

Max. 10x

Max. 5x

Max. 5x

Operating temperature [°C]

0 to 40 (without power derating)

Storage temperature [°C]

-20 to +65

Maximum noise level [dB]

65

70

70

Holding

brake

Rated voltage

(V)

24 ± 10%

Rated current

(A)

0.88 1.44 1.88

Holding brake

torque [Nm]

3.5

12

30

Maximum

brake opening

time [ms]

60 180 220

Maximum

brake closing

time [ms]

45

60

115

Maximum

number of

emergency

stops

2000 3)

Oil seal lifetime [h]

5000

Encoder lifetime [h]

> 20000

4)

Degree of protection

IP65, with shaft oil seal

Weight of

incremental encoder

motor [kg]

With brake 2)

4.6/4.

8

6.4/6.

6

8.6/8.

8

11.3/1

0.1

11.3/1

1.5

14.0/1

4.2

16.6/1

6.8

21.3/2

1.5

25.7/2

5.9

30.3/3

0.5

39.1/3

9.3

Without brake

2)

3.3/3.4 5.1/5.2 5.6/5.7 8.3/7.0 8.3/8.4 11.0/1

1.1

13.6/1

3.7

15.3/1

5.4

19.7/1

9.8

24.3/2

4.4

33.2/3

3.3

Getting Started

28 A5E37208904-003, 04/2017

Article No.

1FL60...

42

44

61

62

64

66

67

90

92

94

96

Weight of

absolute

encoder

motor [kg]

With brake 2) 4.4/4.5 6.2/6.3 8.3/8.4 11.0/9

.7

11.0/1

1.1

13.6/1

3.7

16.3/1

6.4

20.9/2

1.0

25.3/2

5.4

29.9/3

0.0

38.7/3

8.8

Without brake

2)

3.1/3.

2

4.9/5.

0

5.3/5.

4

8.0/6.

7

8.0/8.

1

10.7/1

0.8

13.3/1

3.4

14.8/1

4.9

19.3/1

9.4

23.9/2

4.0

32.7/3

2.8

1)

When the surrounding temperature is higher than 30 °C, the 1FL6096 motors with brake will have a power derating of

10%.

2)

The former value indicates the data for high inertia motors with straight connectors; the latter value indicates the data for

high inertia motors with angular connectors.

3)

Restricted emergency stop operation is permissible. Up to 2000 braking operations can be executed with 300% rotor

moment of inertia as external moment of inertia from a speed of 3000 rpm without the brake being subject to an inadmissible amount of wear.

4)

This lifetime is only for reference. When a motor keeps running at 80% rated value and the surrounding temperature is

30 °C, the encoder lifetime can be ensured.

Note

The data of rated torque, rated power, and maximum torque in th

e above table allows a tolerance of 10%.

Power derating

For deviating conditions (surrounding temperature > 40 °C or installation altitude > 1000 m above sea level) the permissible

torque/power must be determined from the following table. Surrounding temperatures and installation altitudes are rounded

off to 5 °C and 500 m respectively.

Power derating as a function of the installation altitude and ambient temperature

Installation altitude above sea

level (m)

Surrounding temperature in °C

< 30

30 to 40

45

50

55

1000

1.07

1.00

0.96

0.92

0.87

1500 1.04 0.97 0.93 0.89 0.84

2000

1.00

0.94

0.90

0.86

0.82

2500

0.96

0.90

0.86

0.83

0.78

3000

0.92

0.86

0.82

0.79

0.75

3500

0.88

0.82

0.79

0.75

0.71

4000

0.82

0.77

0.74

0.71

0.67

2.5.3

Address of CE-authorized manufacturer

The address of CE-authorized manufacturer is as follows:

Siemens AG

Digital Factory

Motion Control

Frauenauracher Straße 80

DE-91056 Erlangen

Germany

Getting Started

A5E37208904-003, 04/2017

29

3

Mounting

3.1

Mounting the drive

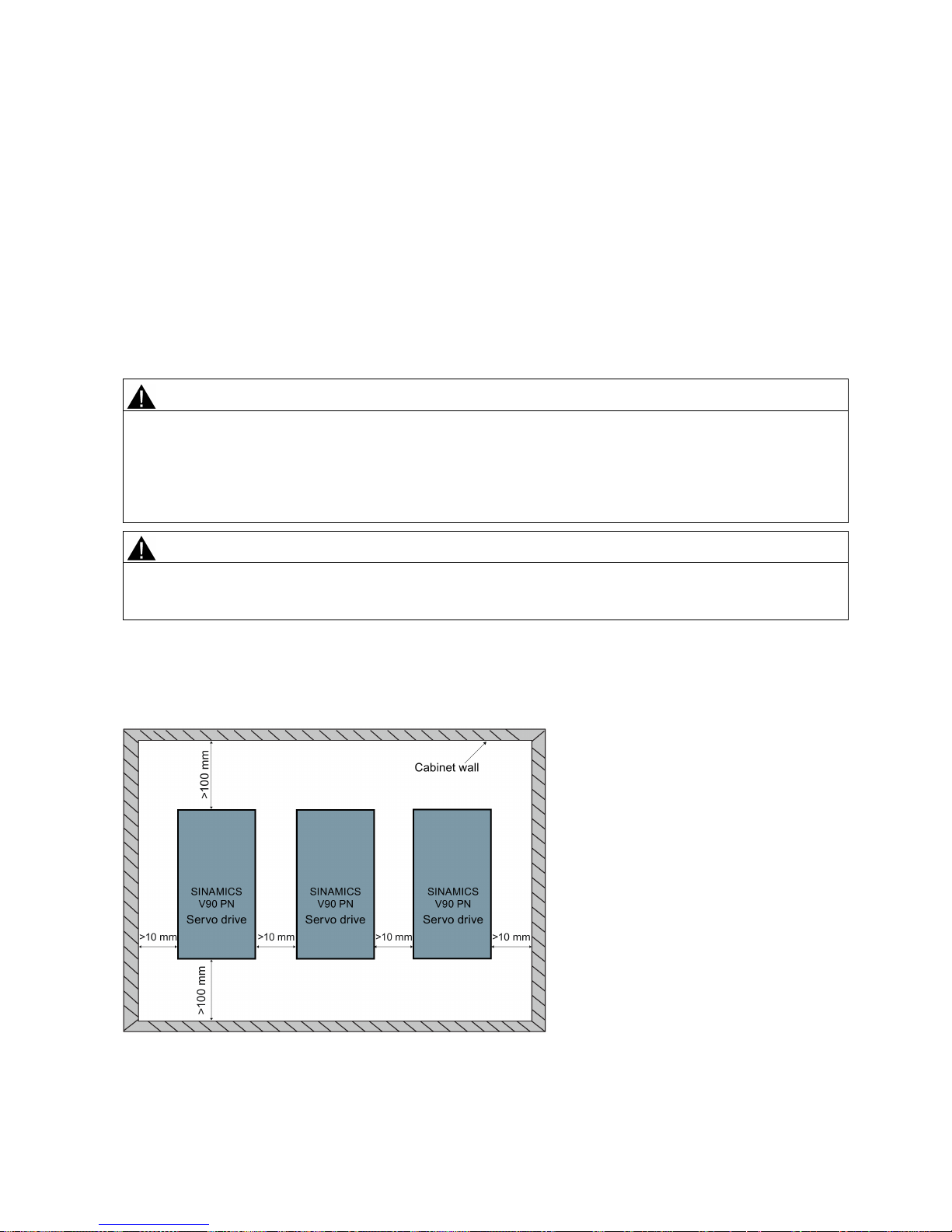

Protection against the spread of fire

The device may be operated only in closed housings or in control cabinets with protective covers that are closed, and when

all of the protective devices are used. The installation of the device in a metal control cabinet or the protection with another

equivalent measure must prevent the spread of fire and emissions outside the control cabinet.

Protection against condensation or electrically conductive contamination

Protect the device, e.g. by installing it in a control cabinet with degree of protection IP54 according to IEC 60529 or

NEMA 12. Further measures may be necessary for particularly critical operating conditions.

If condensation or conductive pollution can be excluded at the installation site, a lower degree of control cabinet protection

may be permitted.

WARNING

Death or severe personal injury from harsh installation environment

A harsh installation environment will jeopardize personal safety and equipment. Therefore,

• Do not install the drive and the motor in an area subject to inflammables or combustibles, water or corrosion hazards.

• Do not install the drive and the motor in an area where it is likely to be exposed to constant vibrations or physical

shocks.

•

Do not keep the drive exposed to strong electro-magnetic interference.

CAUTION

Hot surface

During operation and for a short time after switching-off the drive, the surfaces of the drive can reach a high temperature.

Avoid coming into direct contact with the drive surface.

For mounting conditions, see Technical data - servo drives (Page 23).

Mounting orientation and clearance

Mount the drive vertically in a shielded cabinet and observe the mounting clearances specified in the illustration below:

Getting Started

30 A5E37208904-003, 04/2017

Note

The drive must be derated to 80% when the following conditions are satisfied:

•

The surrounding temperature is 0 °C to 45 °C, and the mounting clearance is less than 10

mm. In this case, the minimum

mounting clearance should not be less than 5 mm.

•

The surrounding temperature is 45 °C to 55 °C. In this case, the minimum mounting clearance should not be less than

20 mm.

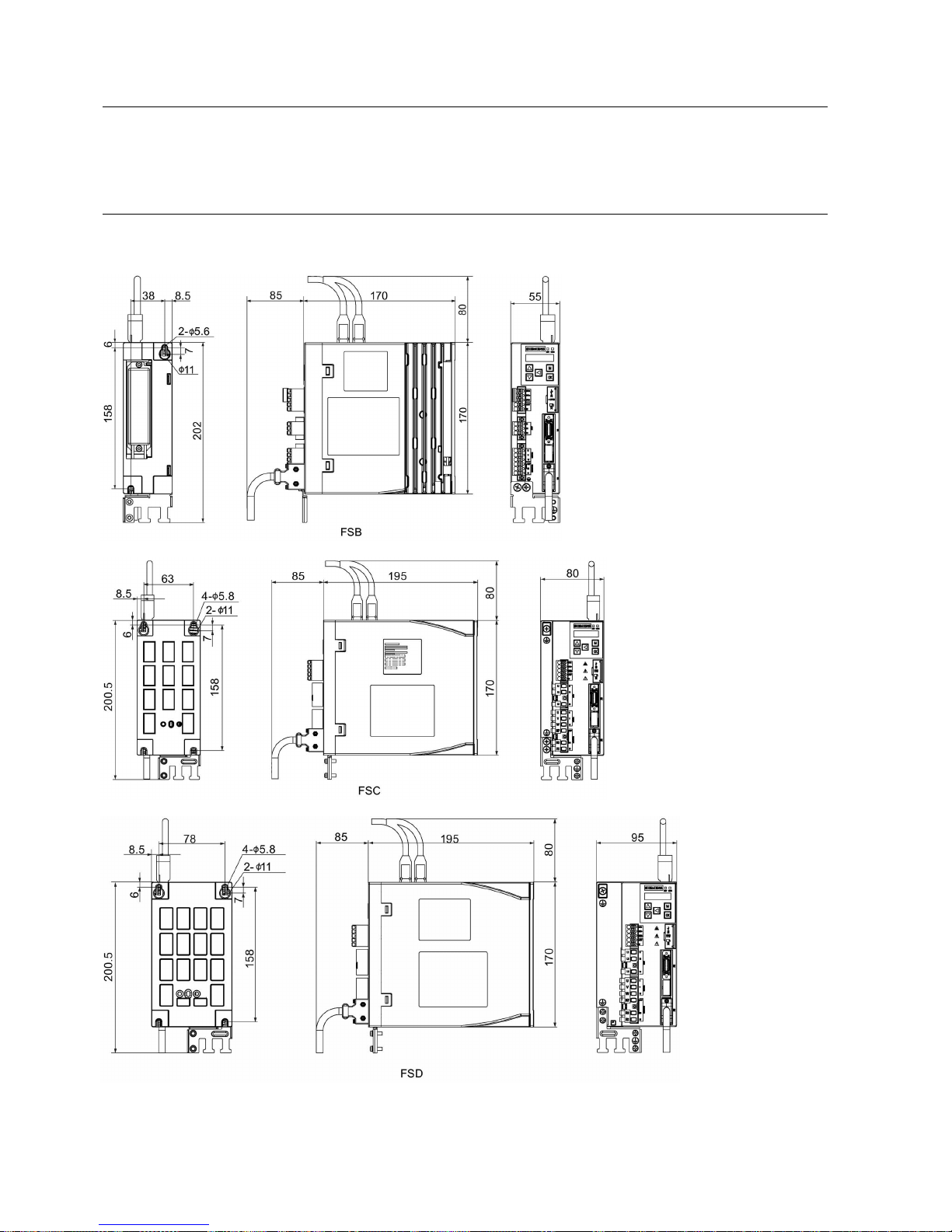

SINAMICS V90 PN 200V variant (unit: mm)

Loading...

Loading...