Siemens SIMOTICS S-1FK2 Operating Instructions Manual

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

SIMOTICS

Drive technology

SIMOTICS S-1FK2 synchronous

motors for SINAMICS S120

Operating Instructions

06/2019

A5E46089564B AB

Introduction

Fundamental safety

instructions for the

SIMOTICS documentation

1

Description of the motors

2

Mounting and options

3

Preparing for use

4

Mounting

5

Connecting

6

Commissioning

7

Operation

8

Faults and their rectification

9

Maintenance

10

Decommissioning and

disposal

11

Technical data and

characteristics

12

Dimension drawings

13

Glossary

14

A5E46089564B AB

Ⓟ

Copyright © Siemens AG 2018 - 2019.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

06/2019 Subject to change

Introduction

Keeping the documentation safe

Target group & benefits

Target group

Utilization phase

About these operating instructions

This documentation should be kept in a location where it can be easily accessed and made

available to the personnel responsible.

These Operating Instructions are intended for installation engineers, commissioning

personnel, machine operators, and service and maintenance personnel.

Planning and engineering phase, implementation phase, installation and commissioning

phase, application phase, maintenance and service phase.

These operating instructions apply to the SIMOTICS S-1FK2 servo motor, referred to as

"1FK2" in this document.

The Operating Instructions provide information about the components that enable the target

group to install, set up, test, commission, operate, and troubleshoot the products and

systems correctly and safely.

The operating instructions inform you about how to handle the 1FK2 from delivery to final

disposal.

You will find additional information in the configuration manual for the 1FK2.

Before you start using the motor, you must read these Operating Instructions to ensure safe,

problem-free operation and to maximize the service life.

Siemens strives continually to improve the quality of information provided in these Operating

Instructions.

● If you find any mistakes or would like to offer suggestions about how this document coul

be i

mproved, contact the Siemens Service Center.

● Always follow the safety instructions and notices in this Product Information.

The warning notice system is explained on the rear of the inside front.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

d

3

Introduction

Text features

Operating instructions

Enumerations

Notes

Note

A Note is an important item of information about the product, handling of the product or the

relevant section of the document. Notes provide you with help or further suggestions/ideas.

More information

In addition to the notes that you must observe for your own personal safety as well as to

avoid material damage, in this document you will find the following text features:

Handling instructions with a specified sequence start with the word "Procedure":

The individual handling steps are numbered.

1. Execute the operating instructions in the specified sequence.

❒

The square indicates the end of the operating instructions.

Operating instructions without a specified sequence are identified using a bullet point:

● Execute the operating instructions.

● Enumerations are identified by a bullet point without any additional symbols.

– Enumerations at the second level are hyphenated.

Notes are shown as follows:

Information on the following topics is available at:

● Ordering documentation / overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals / information)

More information (https://support.industry.siemens.com/cs/ww/en/view/108998034)

If you have any questions regarding the technical documentation (e.g. suggestions,

corrections), please send an e-mail to the following address:

E-mail (mailto:docu.motioncontrol@siemens.com)

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

4 Operating Instructions, 06/2019, A5E46089564B AB

Introduction

My support

Note

If you want to use this function, you must register once.

Later, you can log on with your login data.

Training

Technical Support

Internet address for products

Websites of third parties

Compliance with the General Data Protection Regulation

Information on how to produce individual contents for your own machine documentation

based on Siemens contents is available under the link:

My support (https://support.industry.siemens.com/My/ww/en/documentation)

The following link provides information on SITRAIN - training from Siemens for products,

systems and automation engineering solutions:

SITRAIN (http://siemens.com/sitrain)

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

Technical support (https://support.industry.siemens.com)

Products (http://www.siemens.com/motioncontrol)

This publication contains hyperlinks to websites of third parties. Siemens does not take any

responsibility for the contents of these websites or adopt any of these websites or their

contents as their own, because Siemens does not control the information on these websites

and is also not responsible for the contents and information provided there. Use of these

websites is at the risk of the person doing so.

Siemens respects the principles of data protection, in particular the data minimization rules

(privacy by design).

For this product, this means:

The product does not process neither store any person-related data, only technical function

data (e.g. time stamps). If the user links these data with other data (e.g. shift plans) or if he

stores person-related data on the same data medium (e.g. hard disk), thus personalizing

these data, he has to ensure compliance with the applicable data protection stipulations.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

5

Table of contents

Introduction ............................................................................................................................................. 3

1 Fundamental safety instructions for the SIMOTICS documentation ........................................................ 11

2 Description of the motors ...................................................................................................................... 19

3 Mounting and options ............................................................................................................................ 29

4 Preparing for use .................................................................................................................................. 39

1.1 Fundamental safety instructions ............................................................................................. 11

1.1.1 General safety instructions ..................................................................................................... 11

1.1.2 Equipment damage due to electric fields or electrostatic discharge ...................................... 15

1.1.3 Industrial security .................................................................................................................... 16

1.1.4 Residual risks of power drive systems .................................................................................... 17

2.1 Use for the intended purpose ................................................................................................. 19

2.2 Technical features and environmental conditions .................................................................. 20

2.2.1 Directives and standards ........................................................................................................ 20

2.2.2 General technical features ...................................................................................................... 22

2.2.3 Environmental conditions ........................................................................................................ 23

2.2.4 Degree of protection ............................................................................................................... 24

2.2.5 Noise emission ........................................................................................................................ 24

2.3 Derating factors ....................................................................................................................... 25

2.4 Structure of the article number ............................................................................................... 25

2.5 Rating plate data ..................................................................................................................... 27

3.1 Safety symbols on the motor .................................................................................................. 29

3.2 Shaft extension ....................................................................................................................... 29

3.3 Bearing version ....................................................................................................................... 30

3.4 Permissible radial and axial forces ......................................................................................... 30

3.4.1 Axial forces ............................................................................................................................. 30

3.4.2 Radial forces ........................................................................................................................... 30

3.5 Thermal motor protection ........................................................................................................ 35

3.6 Encoder ................................................................................................................................... 35

3.7 Cooling .................................................................................................................................... 36

3.8 Holding brake .......................................................................................................................... 36

4.1 Shipping and packaging ......................................................................................................... 39

4.2 Transportation and storage ..................................................................................................... 40

4.2.1 Transport ................................................................................................................................. 40

4.2.2 Storage ................................................................................................................................... 43

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

7

Table of contents

5 Mounting ............................................................................................................................................... 45

6 Connecting ........................................................................................................................................... 53

7 Commissioning ..................................................................................................................................... 65

8 Operation .............................................................................................................................................. 73

9 Faults and their rectification .................................................................................................................. 77

10 Maintenance ......................................................................................................................................... 79

5.1 Safety instructions .................................................................................................................. 45

5.2 Checklists prior to mounting ................................................................................................... 47

5.3 Mounting instructions ............................................................................................................. 48

5.4 Mounting the drive elements .................................................................................................. 49

5.5 Vibration response ................................................................................................................. 51

6.1 Safety instructions .................................................................................................................. 53

6.2 Permissible line system types ................................................................................................ 54

6.3 System integration ................................................................................................................. 54

6.3.1 Connection notes ................................................................................................................... 54

6.3.1.1 Motor connection.................................................................................................................... 54

6.3.1.2 Rotating the connector on the motor ..................................................................................... 56

6.3.2 Power connection................................................................................................................... 57

6.3.3 Signal connection ................................................................................................................... 58

6.3.4 Connecting to a converter ...................................................................................................... 58

6.3.4.1 Selecting and connecting the cables ..................................................................................... 58

6.3.4.2 Handling the quick-action locking .......................................................................................... 62

6.3.4.3 Routing cables in a damp environment ................................................................................. 64

7.1 Safety instructions .................................................................................................................. 65

7.2 Checklists for commissioning ................................................................................................. 68

7.3 Commissioning procedure ..................................................................................................... 70

7.4 Switching on and switching off ............................................................................................... 71

8.1 Safety instructions .................................................................................................................. 73

8.2 Switching on and switching off ............................................................................................... 74

8.3 During operation..................................................................................................................... 74

8.4 Stationary states .................................................................................................................... 75

10.1 Safety instructions .................................................................................................................. 79

10.2 Inspection and maintenance .................................................................................................. 81

10.2.1 Service and inspection intervals ............................................................................................ 81

10.2.2 Cleaning ................................................................................................................................. 82

10.2.3 Motor replacement on reaching the bearing life .................................................................... 83

10.3 Repair ..................................................................................................................................... 83

10.3.1 How to replace a 1FK2 motor ................................................................................................ 83

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

8 Operating Instructions, 06/2019, A5E46089564B AB

Table of contents

11 Decommissioning and disposal ............................................................................................................. 85

12 Technical data and characteristics ........................................................................................................ 87

13 Dimension drawings .............................................................................................................................. 89

14 Glossary ............................................................................................................................................... 93

Index..................................................................................................................................................... 95

11.1 Safety instructions ................................................................................................................... 85

11.2 Decommissioning .................................................................................................................... 85

11.2.1 Removing the motor ................................................................................................................ 85

11.2.2 Dismantling the motor ............................................................................................................. 86

11.3 Disposal .................................................................................................................................. 86

13.1 Dimension drawing 1FK2x03 and 1FK2x04 ........................................................................... 89

13.2 Dimension drawing 1FK2x05 ... 1FK2x10 .............................................................................. 91

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

9

documentation

1

1.1

Fundamental safety instructions

1.1.1

General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

WARNING

Electric shock due to connection to an unsuitable power supply

Touching live components can result in death or severe injury.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, the following six steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any

of the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

After you have completed the work, restore the operational readiness in the inverse

sequence.

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage. Contact with hazardous voltage can result in severe injury or

death.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV-

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

11

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Electric shock due to damaged motors or devices

WARNING

Electric shock due to unconnected cable shield

WARNING

Electric shock if there is no ground connection

WARNING

Arcing when a plug connection is opened during operation

NOTICE

Property damage due to loose power connections

1.1 Fundamental safety instructions

Improper handling of motors or devices can damage them.

Hazardous voltages can be present at the enclosure or at exposed components on

damaged motors or devices.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged motors or devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the conductors of power cables that are not

used (e.g. brake cores) at one end at the grounded housing potential.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

Opening a plug connection when a system is operation can result in arcing that may cause

serious injury or death.

• Only open plug connections when the equipment is in a voltage-free state, unless it has

been explicitly stated that they can be opened in operation.

Insufficient tightening torques or vibration can result in loose power connections. This can

result in damage due to fire, device defects or malfunctions.

• Tighten all power connections to the prescribed torque.

• Check all power connections at regular intervals, particularly after equipment has been

transported.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

12 Operating Instructions, 06/2019, A5E46089564B AB

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

WARNING

Unrecognized dangers due to missing or illegible warning labels

WARNING

Unexpected movement of machines caused by inactive safety functions

Note

Important safety notices for Safety Integrated functions

If

Safety Integrated manuals.

1.1 Fundamental safety instructions

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

• If you come closer than around 2 m to such components, switch off any radios or mobile

phones.

• Use the "SIEMENS Industry Online Support app" only on equipment that has already

been switched off.

Dangers might not be recognized if warning labels are missing or illegible. Unrecognized

dangers may cause accidents resulting in serious injury or death.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, where necessary in the national

language.

• Replace illegible warning labels.

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

you want to use Safety Integrated functions, you must observe the safety notices in the

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

13

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Active implant malfunctions due to electromagnetic fields

WARNING

Active implant malfunctions due to permanent-magnet fields

WARNING

Injury caused by moving or ejected parts

WARNING

Fire due to inadequate cooling

Inadequate cooling can cause the motor to overheat, resulting in death or severe injury as a

1.1 Fundamental safety instructions

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment,

such as transformers, converters, or motors. People with pacemakers or implants are at

particular risk in the immediate vicinity of this equipment.

• If you have a heart pacemaker or implant, maintain the minimum distance specified in

chapter "Correct usage" from such motors.

Even when switched off, electric motors with permanent magnets represent a potential risk

for persons with heart pacemakers or implants if they are close to converters/motors.

• If you have a heart pacemaker or implant, maintain the minimum distance specified in

chapter "Correct usage".

• When transporting or storing permanent-magnet motors always use the original packing

materials with the warning labels attached.

• Clearly mark the storage locations with the appropriate warning labels.

• IATA regulations must be observed when transported by air.

Contact with moving motor parts or drive output elements and the ejection of loose motor

parts (e.g. feather keys) out of the motor enclosure can result in severe injury or death.

• Remove any loose parts or secure them so that they cannot be flung out.

• Do not touch any moving parts.

• Safeguard all moving parts using the appropriate safety guards.

result of smoke and fire. This can also result in increased failures and reduced service lives

of motors.

• Comply with the specified cooling requirements for the motor.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

14 Operating Instructions, 06/2019, A5E46089564B AB

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Fire due to incorrect operation of the motor

CAUTION

Burn injuries caused by hot surfaces

1.1.2

Equipment damage due to electric fields or electrostatic discharge

NOTICE

Equipment damage due to electric fields or electrostatic discharge

1.1 Fundamental safety instructions

When incorrectly operated and in the case of a fault, the motor can overheat resulting in fire

and smoke. This can result in severe injury or death. Further, excessively high

temperatures destroy motor components and result in increased failures as well as shorter

service lives of motors.

• Operate the motor according to the relevant specifications.

• Only operate the motors in conjunction with effective temperature monitoring.

• Immediately switch off the motor if excessively high temperatures occur.

In operation, the motor can reach high temperatures, which can cause burns if touched.

• Mount the motor so that it is not accessible in operation.

Measures when maintenance is required:

• Allow the motor to cool down before starting any work.

• Use the appropriate personnel protection equipment, e.g. gloves.

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

15

Fundamental safety instructions for the SIMOTICS documentation

1.1.3

Industrial security

Note

Industrial security

Siemens provides products and

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement

security concept. Products and solutions from Siemens constitute one element of such a

concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Suc

connected to an enterprise network or the Internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. using firewalls and/or network

segmentation) are in p

For additional information on industrial security measures that can be implemented, please

visit:

Industrial security (

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they

become available, and that only the latest product versions are used. Use of product

versi

customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (

WARNING

Unsafe operating states resulting from software manipulation

1.1 Fundamental safety instructions

solutions with industrial security functions that support the

– and continuously maintain – a holistic, state-of-the-art industrial

h systems, machines and components should only be

lace.

https://www.siemens.com/industrialsecurity)

ons that are no longer supported, and failure to apply the latest updates may increase

https://www.siemens.com/industrialsecurity)

Further information is provided on the Internet:

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

16 Operating Instructions, 06/2019, A5E46089564B AB

Industrial Security Configuration Manual

(https://support.industry.siemens.com/cs/ww/en/view/108862708)

Software manipulations, e.g. viruses, Trojans, or worms, can cause unsafe operating states

in your system that may lead to death, serious injury, and property damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

• On completion of commissioning, check all security-related settings.

• Protect the drive against unauthorized changes by activating the "Know-how protection"

converter function.

Fundamental safety instructions for the SIMOTICS documentation

1.1.4

Residual risks of power drive systems

1.1 Fundamental safety instructions

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer

must take into account the following residual risks emanating from the control and drive

components of a drive system:

1. Unintentional movements of driven machine or system components during

commissioning, operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too

close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters

or data communication via the network

For more information about the residual risks of the drive system components, see the

relevant sections in the technical user documentation.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

17

Description of the motors

2

2.1

Use for the intended purpose

WARNING

Motors not used for the intended purpose

WARNING

Malfunctions of active active implants due to magnetic and electrical fields

If you do not use the motors correctly, there is a risk of death, severe injury and/or material

damage.

• Only use the motors for their intended purpose.

• Make sure that the conditions at the location of use comply with all the rating plate data.

• Make sure that the conditions at the location of use comply with the conditions specifi

n this documentation. When necessary, take into account deviations regardin

i

ovals or country-specific regulations.

appr

Electric motors endanger people with active implants, for example heart pacemakers, who

come close to the motors.

• If you are affected, stay a minimum distance of 300 mm from the motors (tripping

threshold for static magnetic fields of 0.5 mT according to Directive 2013/35/EU).

g

ed

If you wish to use special versions and design variants whose specifications vary from the

motors described in this document, then contact your local Siemens office.

If you have any questions regarding the intended usage, please contact your local Siemens

office.

The 1FK2 motor is intended for industrial or commercial plants.

The motor is designed for operation in sheltered areas under normal climatic conditions,

such as those found on shop floors.

For more detailed information, refer to Chapter "Environmental conditions (Page 23)".

The 1FK2 motor is certified only for operation through a converter.

Any other use of the motor is considered to be incorrect use.

Compliance with all specifications in the operating instructions is part of correct usage.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

Observe the details on the rating plate.

19

Description of the motors

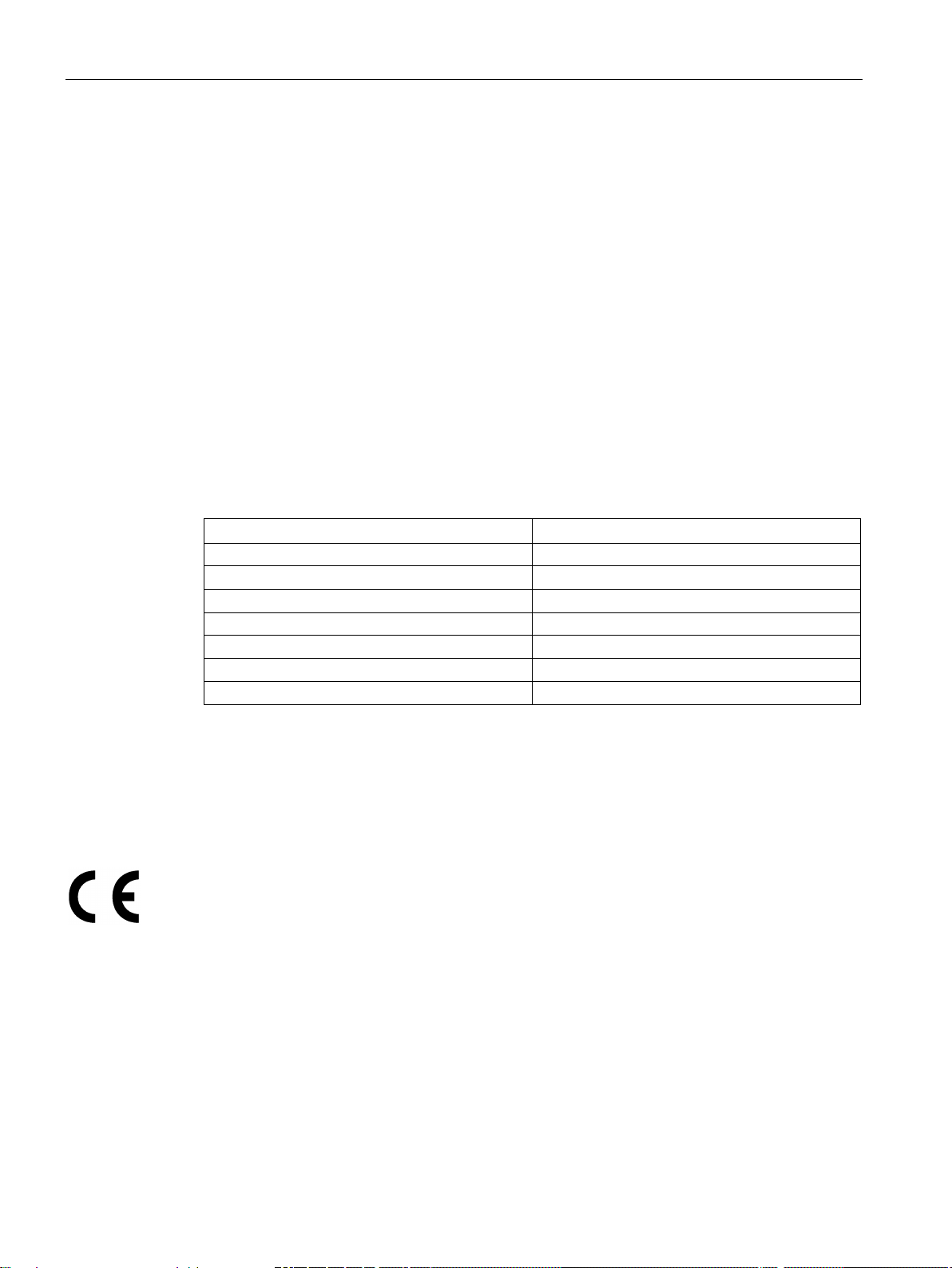

Feature

Standard

Degree of protection

EN 60034-5

Type of construction

EN 60034-7

Connection designations

EN 60034-8

Noise levels 1)

EN 60034-9

Temperature monitoring

EN 60034-11

Vibration severity grades 1)

EN 60034-14

1)

Standard component, e.g. cannot be applied to built-in motors

2.2 Technical features and environmental conditions

2.2 Technical features and environmental conditions

2.2.1 Directives and standards

Standards that are complied with

The motors of the type series SIMOTICS S, SIMOTICS M, SIMOTICS L, SIMOTICS T,

SIMOTICS A, called "SIMOTICS motor series" below, fulfill the requirements of the following

directives and standards:

● EN 60034-1 - Rotating electrical machines – Dimensioning and operating behavior

● EN 60204-1 - Safety of machinery – Electrical equipment of machines; general

requirements

Where applicable, the SIMOTICS motor series are in conformance with the following parts of

EN 60034:

Cooling 1) EN 60034-6

Relevant directives

The following directives are relevant for SIMOTICS motors.

European Low-Voltage Directive

SIMOTICS motors comply with the Low-Voltage Directive 2014/35/EU.

European Machinery Directive

SIMOTICS motors do not fall within the scope covered by the Machinery Directive.

However, the use of the products in a typical machine application has been fully assessed

for compliance with the main regulations in this directive concerning health and safety.

European EMC Directive

SIMOTICS motors do not fall within the scope covered by the EMC Directive. The products

are not considered as devices in the sense of the directive. Installed and operated with a

converter, the motor - together with the Power Drive System - must comply with the

requirements laid down in the applicable EMC Directive.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

20 Operating Instructions, 06/2019, A5E46089564B AB

Description of the motors

2.2 Technical features and environmental conditions

European RoHS Directive

The SIMOTICS motor series complies with the Directive 2011/65/EU regarding limiting the

use of certain hazardous substances.

European Directive on Waste Electrical and Electronic Equipment (WEEE)

The SIMOTICS motor series complies with the 2012/19/EU directive on taking back and

recycling waste electrical and electronic equipment.

Eurasian conformity

SIMOTICS motors comply with the requirements of the Russia/Belarus/Kazakhstan (EAC)

customs union.

China Compulsory Certification

SIMOTICS motors do not fall within the scope covered by the China Compulsory

Certification (CCC).

CCC negative certification:

CCC product certification

(https://support.industry.siemens.com/cs/products?search=CCC&dtp=Certificate&mfn=ps&o

=DefaultRankingDesc&pnid=13347&lc)

China RoHS

SIMOTICS motors comply with the China RoHS.

You can find additional information at:

China RoHS (https://support.industry.siemens.com/cs/ww/de/view/109738656/en)

Underwriters Laboratories

SIMOTICS motors are generally in compliance with UL and cUL as components of motor

applications, and are appropriately listed.

Specifically developed motors and functions are the exceptions in this case. Here, it is

important that you carefully observe the contents of the quotation and that there is a cUL

mark on the rating plate!

Quality systems

Siemens AG employs a quality management system that meets the requirements of ISO

9001 and ISO 14001.

Certificates for SIMOTICS motors can be downloaded from the Internet at the following link:

Certificates for SIMOTICS motors

(https://support.industry.siemens.com/cs/ww/de/ps/13347/cert)

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

21

Description of the motors

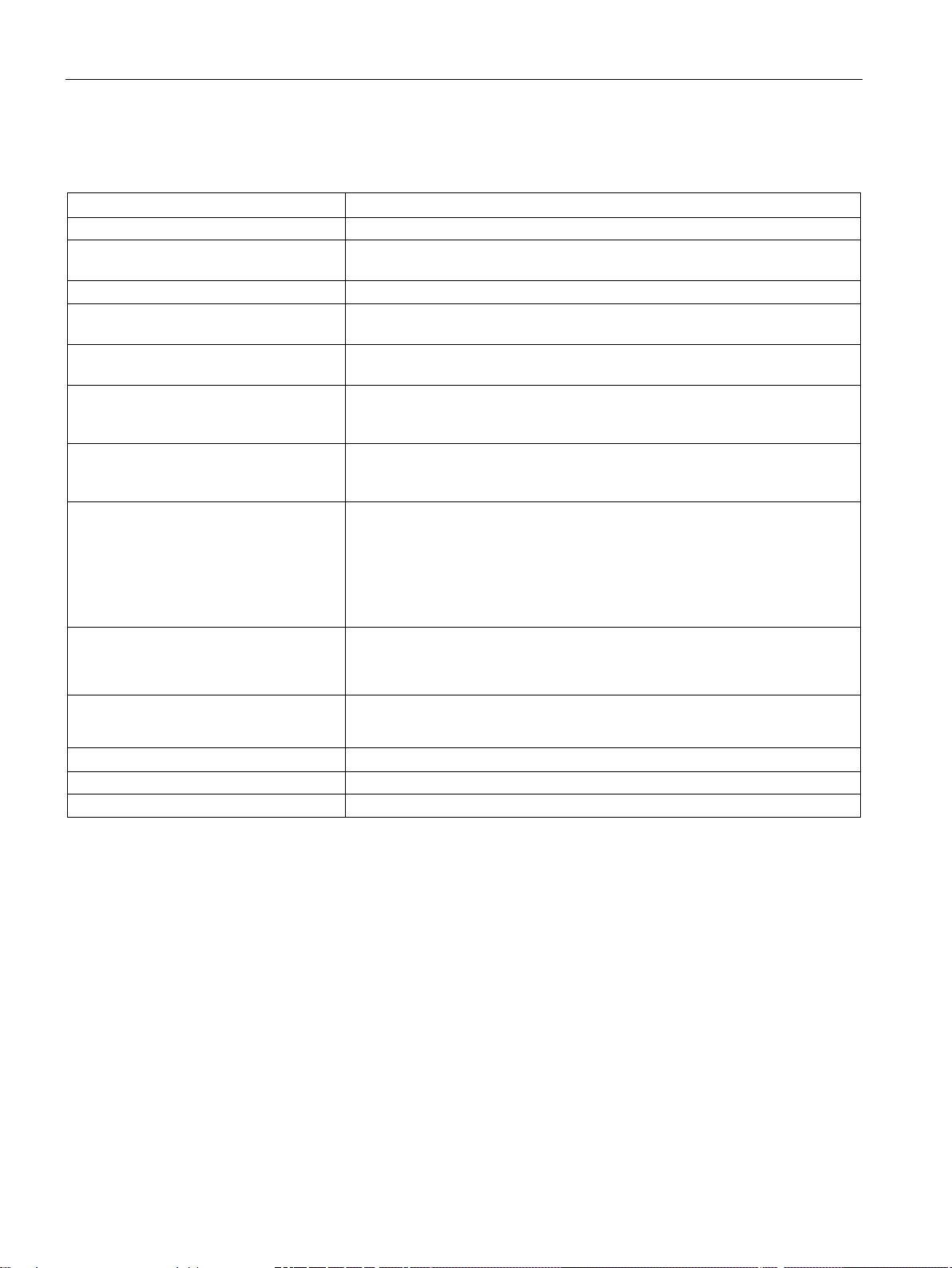

2.2.2

General technical features

Property

Version

Type of motor

Permanent-magnet synchronous motor

EN 60034-5 (IEC 60034-5)

Cooling acc. to EN 60034-6

Natural cooling (IC410)

EN 60034-7 (IEC 60034-7)

(IEC 60072-1)

the shaft extension

(IEC 60034-14)

bient temperature of +40 °C

Connection

Connectors for power and signals, rotatable

2.2 Technical features and environmental conditions

Degree of protection according to

Type of construction according to

Shaft extension according to DIN 748-3

Shaft and flange accuracy acc. to

DIN 42955 (IEC 60072–1)

Vibration severity grade according to EN

60034-14

Insulation of the stator winding according

to EN 60034-1

(IEC 60034-1)

Sound pressure level

to DIN EN ISO 1680, max. tolerance

+ 3 dB (A)

Encoder systems, built-in with DRIVECLiQ interface

Holding brake Optionally installed, 24 V DC

L

(1 m) according

pA

IP64, optionally IP65

IM B5 (IM V1, IM V3)

Plain shaft or with feather key (half key balancing)

Tolerance N (normal), for radial eccentricity of the shaft extension, concentricity of centering edge, and axial eccentricity of the mounting flange to the axis of

Grade A is maintained up to rated speed

1FK2❑03:

Temperature class 130 (B) for a winding temperature of

ent temperature of +40 °C

1FK2❑04 ... 1FK2❑10:

Temperature class 155 (F) for a winding temperature of ΔT = 100 K at an am-

1FK2❑03, 1FK2❑04: 55 dB (A);

1FK2❑05, 1FK2❑06: 65 dB (A);

1FK2❑08, 1FK2❑10: 70 dB (A)

• AS22DQC absolute encoder, singleturn, 22 bit

• AM22DQC absolute encoder 22 bit + 12 bit multiturn

ΔT

= 80 K at an ambi-

Paint finish Anthracite, similar to RAL7016

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

22 Operating Instructions, 06/2019, A5E46089564B AB

Description of the motors

2.2.3

Environmental conditions

Environmental parameter

Unit

Value

a)

Low air temperature

°C

-15

c)

Low relative humidity

%

5

d)

High relative humidity

%

95

e)

Low absolute humidity

g/m3

1

f)

High absolute humidity

g/m3

29

g)

Rate of temperature change1)

°C/min

0.5

h)

Low air pressure4)

kPa

89

i)

High air pressure2)

kPa

106

j)

Solar radiation

W/m2

700

k)

Thermal radiation

-

-

l)

Air movement3)

m/s

1.0

m)

Condensation

-

Not permissible

(rain, snow, hail, etc.)

class

p)

Formation of ice

-

-

1)

2)

3)

4)

The limit value of 89 kPa covers applications at altitudes up to 1000 m.

Note

Installation instructions

The motor is not suitable for operation

•

•

•

•

2.2 Technical features and environmental conditions

You can classify the environmental conditions for stationary use at weather-protected

locations according to the standard DIN EN 60721-3-3.

With the exception of environmental influences "Low air temperature", "Low air pressure",

and "Condensation", the motor complies with climate class 3K4.

Table 2- 1 Permissible environmental conditions for the motor based on climate class 3K4

b) High air temperature °C +40

n) Wind-driven precipitation

o) Water (other than rain) - See protection

Averaged over a period of 5 min

Conditions in mines are not considered.

A cooling system based on natural convection can be disturbed by unforeseen air movements.

- -

In salt-laden or aggressive atmospheres

Outdoors

In a vacuum

In hazardous areas with a danger of explosion

You will find additional data on the environmental conditions, such as for transport and

storage of the motor, in Chapter "Transportation and storage (Page 40)".

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

23

Description of the motors

2.2.4

Degree of protection

1FK2❑03 ... 1FK2❑04

1FK2❑05 ... 1FK2❑10

①

Radial shaft sealing ring

Note

It is permissible that the radial shaft sealing ring runs dry.

With degree of protection IP65, it is not permissible for liquid to collect in the flange.

The

2.2.5

Noise emission

Cooling method

Motor

Measuring surface sound pressure level

L

p

Naturally cooled

1FK2❑03

1FK2❑04

1FK2❑06

1FK2❑08

1FK2❑10

2.2 Technical features and environmental conditions

1FK2 motors can be delivered with degree of protection IP64 or IP65.

The degree of protection is stated on the rating plate.

The motors with degree of protection IP65 have a radial shaft sealing.

The radial shaft sealing ring shortens the usable shaft extension on the 1FK2❑03 and

1FK2❑04.

service life of the radial shaft sealing ring is approximately 25000 operating hours.

For additional information, see Chapter "Shaft extension (Page 29)".

When operated in the speed range 0 to rated speed, 1FK2 motors can reach the following

L

measuring surface sound pressure level

Table 2- 2 Sound pressure level

1FK2❑05

:

p

55 dB(A) + 3 dB tolerance

65 dB(A) + 3 dB tolerance

The motors are certified for a wide range of installation and operating conditions. These

conditions such as rigid or vibration-isolated foundation design influence noise emission,

sometimes significantly.

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

24 Operating Instructions, 06/2019, A5E46089564B AB

70 dB(A) + 3 dB tolerance

2.3

Derating factors

Installation altitude above sea

level in m

Ambient temperature in °C

30

40

45

50

1000

1.08

1.00

0.96

0.91

2000

1.02

0.93

0.89

0.84

Calculate the derating factor for ambient

= derating factor 0.965.

S1

reduced S1 characteristic curve for motor torque at required altitude and

ambient temperature

S1

S1 characteristic specified for ambient temperature of 40

above sea level (see Chapter "Datasheets and characteristics"

tion Manual)

n

motor speed

xd

derating factor from the table above

2.4

Structure of the article number

Description of the motors

2.3 Derating factors

With ambient temperatures > 40 °C or installation altitudes > 1000 m above sea level, the

permissible S1-characteristic must be reduced in speed and torque:

Table 2- 3 Derating of speed and torque depending on the installation altitude and ambient temper-

ature

temperatures that are not shown here and installation alti-

tudes below the maximum values by interpolating. For example: 40 °C at 1500 m above sea level

Calculate the reduced S1 line as follows:

S1

(n) = xd • S1

red

40 °C; 1000 m

(n / xd)

red

40 °C; 1000 m

°C at 1000 m

in Configura-

The article number describes the motor with the following structure.

Figure 2-1 Article number structure for 1FK2

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

25

Description of the motors

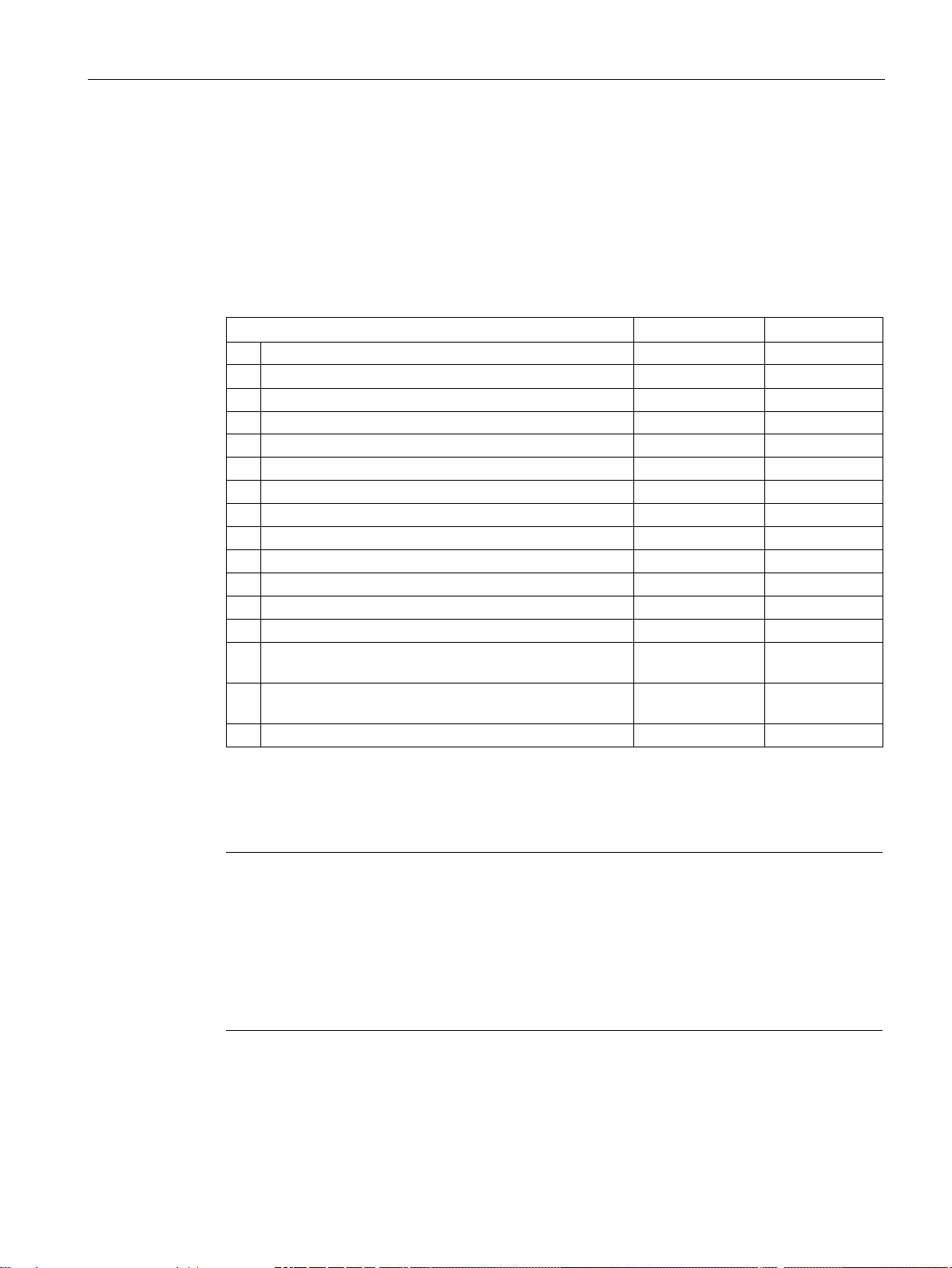

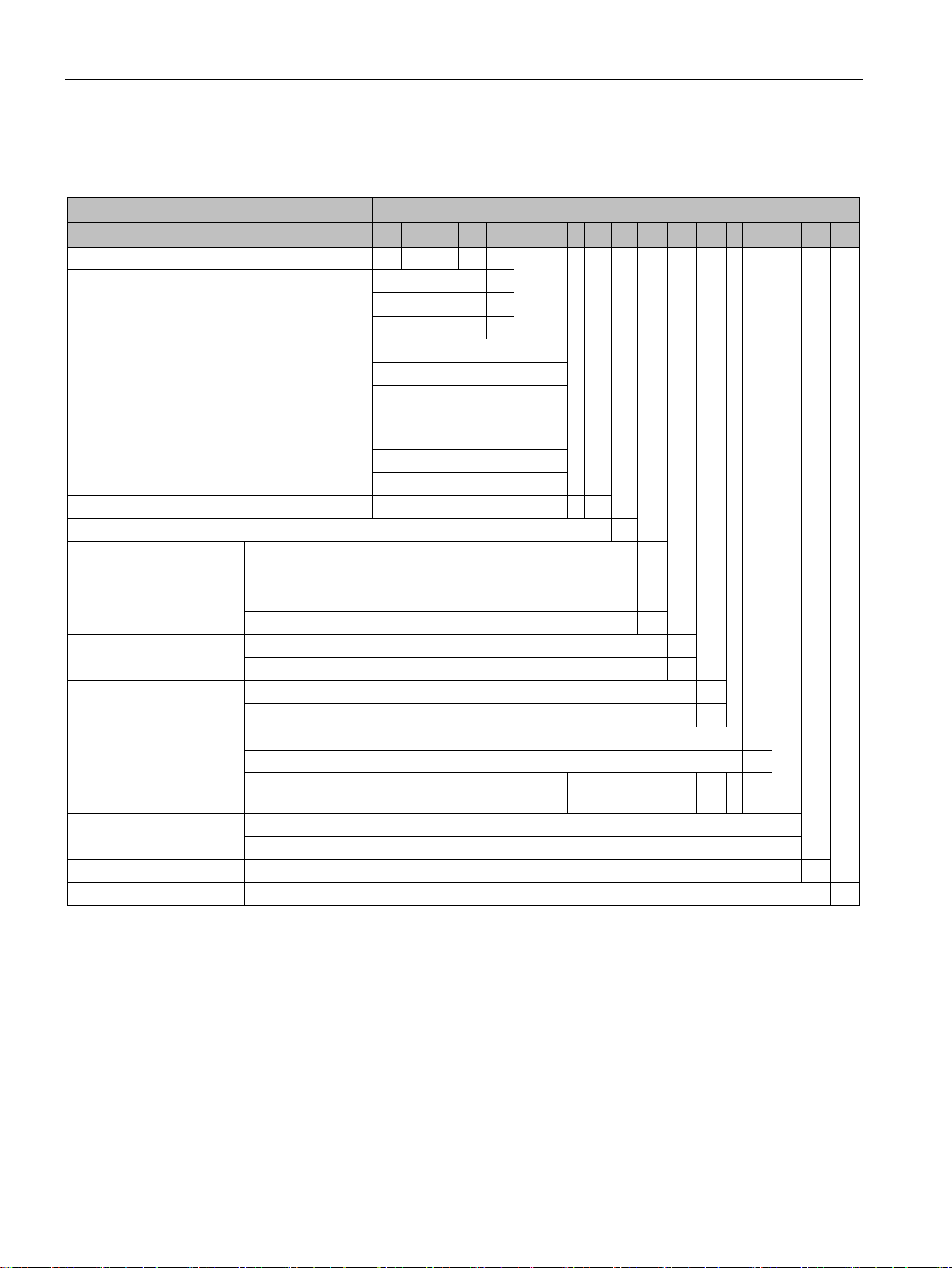

Description

Position of the article number

1 2 3 4 5 6 7 - 8 9 10

11

12 - 13

14

15

16

SIMOTICS S-1FK2 synchronous servomotors

1 F K

2

Inertia

High Dynamic

1

High Inertia

3

Shaft height

SH 30

0

3

SH 40

0

4

SH 52 HD

SH 63

0 6 SH 80

0

8

SH 100

1

0

Overall length

0 ... 8

-

❑

(Not defined)

A

Rated speed

1500 rpm @ 400 V

B

2000 rpm @ 400 V

C

3000 rpm @ 400 V

F

6000 rpm @ 400 V

K

Holding brake

None

0

With

1

Degree of protection

IP64

0

Shaft geometry

Plain shaft (without keyway)

0

Shaft with feather key

1

(11 mm x 23 mm), for 1FK2❑03 only

Encoder

Absolute encoder, singleturn, 22 bit (encoder AS22DQC)

S

Absolute encoder, multiturn, 22 bit + 12 bit (encoder AM22DQC)

M

Connection type

2CC (two-wire technology) for S 120

B

Revision number

Start

0

1) More detailed information is provided in the associated Catalog NC 82.

2.4 Structure of the article number

You can find possible combinations in the relevant catalog.

Please note that not every theoretical combination is possible.

Compact 2

SH 48 CT

IP65 with radial shaft seal ring, without spring 1

Plain shaft, alternative shaft extension

0 5

0 3 0 2

26 Operating Instructions, 06/2019, A5E46089564B AB

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

2.5

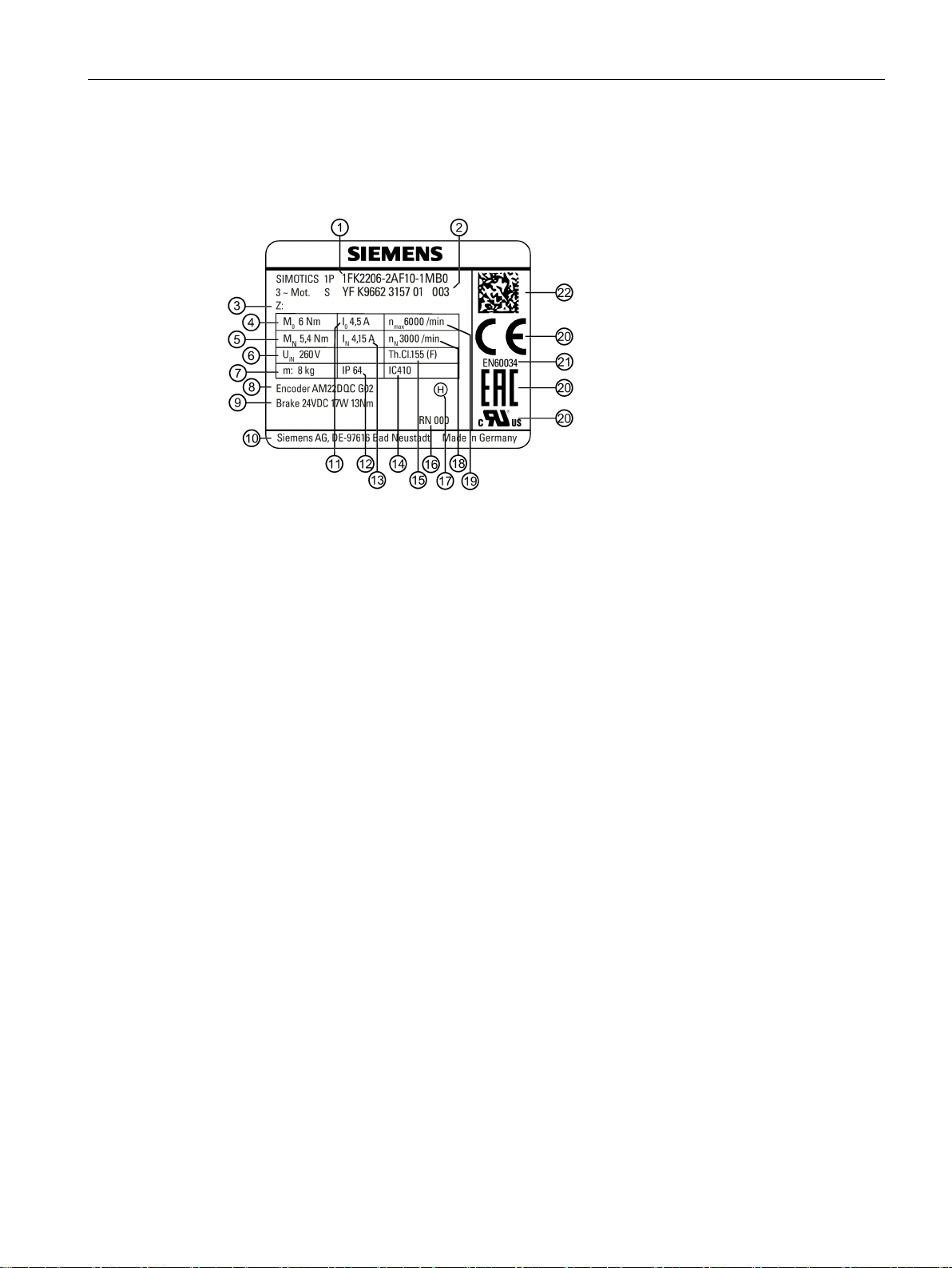

Rating plate data

1

Article number

12

Degree of protection

2

ID No., serial number

13

Rated current

I

/ A

Additional options specified as a suppl

ment to the article number

Cooling mode according to EN 60034

4

Static torque

M

/ Nm

15

Thermal class of the insulation system

5

Rated torque

M

/ Nm

16

Revision

Induced voltage at rated speed

Type of balancing (only for motors with

feather key)

7

Motor weight m / kg

18

Rated speed

n

N

/ rpm

8

Marking of encoder type

19

Maximum speed

n

/ rpm

9

Data of the holding brake

20

Certifications

Manufacturer's address

Standard for all rotating electrical m

chines

11

Stall current

I

0

/ A

22

Data matrix code

Description of the motors

2.5 Rating plate data

The rating plate contains the article number and the technical data of the motor.

Figure 2-2 1FK2 rating plate

3

6

10

N

e-

14

0

N

U

/ V 17

IN

max

21

-6

a-

SIMOTICS S-1FK2 synchronous motors for SINAMICS S120

Operating Instructions, 06/2019, A5E46089564B AB

27

Loading...

Loading...