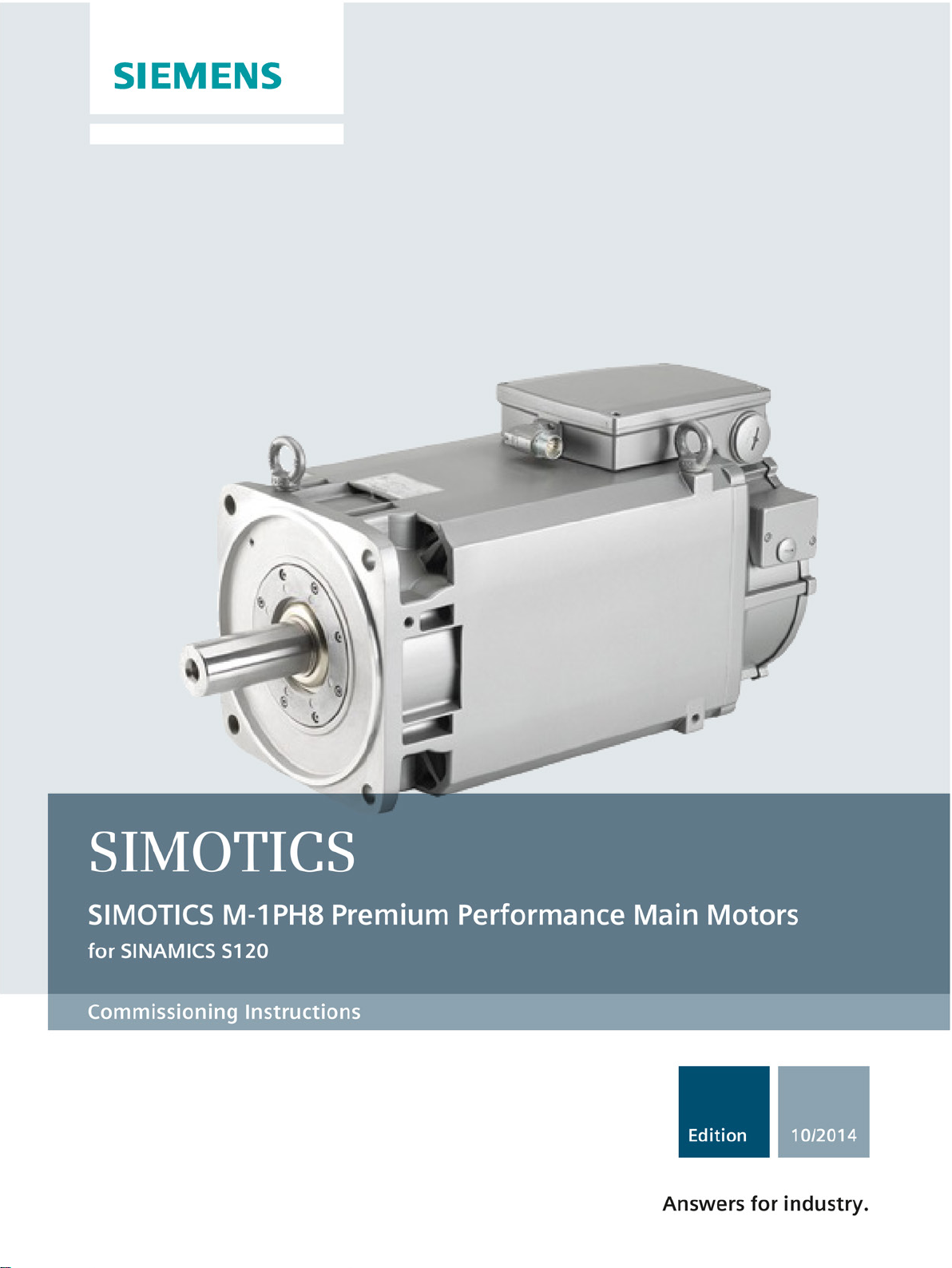

Siemens SIMOTICS M-1PH8 Commissioning Instructions

Commissioning instructions for

SIMOTICS M-1PH8 Premium

Performance

___________________

___________

___________________

___________________

___________________

___________________

SIMOTICS

Commissioning Manual

10/2014

610.40106.40

Introduction

Fundamental safety

instructions for the

SIMOTICS documentation

1

Installing the motor

2

Parameter

assignment/addressing

3

Converter data sheets and

characteristics

4

Characteristics

5

Drive technology

Commissioning instructions for

SIMOTICS M-1PH8

Premium Performance

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: 610.40106.40

Ⓟ

Copyright © Siemens AG .

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

01/2016 Subject to change

Introduction

Text features

Action instructions

Enumerations

These commissioning instructions describe the manual parameterization adaptations that

you have to carry out following auto commissioning.

● Follow the explanations in these commissioning instructions. This will ensure safe,

problem-free operation and maximize the service life of the motor.

These commissioning instructions apply in conjunction with the operating instructions for the

1PH8 Premium Performance motor and the commissioning manual for the SINAMICS S120

converter.

Siemens strives continually to improve the quality of information provided in its manuals and

instructions.

● If you find any mistakes or would like to offer suggestions about how this document could

be improved, contact the Siemens Service Center.

● Always follow the safety instructions and notices in these operating instructions.

The warning notice system is explained on the rear of the inside front.

In addition to the instructions that you must observe for your own personal safety as well as

to avoid material damage, you will find the following text features in these operating

instructions:

Action instructions to be carried out in a fixed sequence are designated using the following

symbols:

The arrow indicates the start of the action instructions.

The individual handling steps are numbered.

1. Execute the action instructions in the specified order.

The square indicates the end of the action instruction.

Action instructions without a specified sequence are identified using bullet points:

● Carry out the action instruction.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

● Enumerations are identified by a bullet point without any additional symbols.

– Enumerations at the second level are hyphenated.

5

Introduction

Notes

Note

A Note is an important item of information about the product, handling o

relevant section of the document. Notes provide you with help or further suggestions/ideas.

More information

My Documentation Manager

Training

Technical Support

Notes are shown as follows:

f the product or the

Information on the following topics is available under the link:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

More information (https://support.industry.siemens.com/cs/de/en/view/108998034)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following e-mail address:

docu.motioncontrol@siemens.com

The following link provides information on how to create your own individual documentation

based on Siemens content, and adapt it for your own machine documentation:

http://www.siemens.com/mdm

The following link provides information on SITRAIN - training from Siemens for products,

systems and automation engineering solutions:

http://siemens.com/sitrain

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

Technical Support (https://support.industry.siemens.com/sc/ww/en/sc/2090)

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

6 Commissioning Manual, 10/2014, 610.40106.40

Introduction

Internet addresses for drive technology

Internet address for motors: http://www.siemens.com/motors

Internet address for products: http://www.siemens.com/motioncontrol

Internet address for SINAMICS: http://www.siemens.com/sinamics

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

7

Introduction

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

8 Commissioning Manual, 10/2014, 610.40106.40

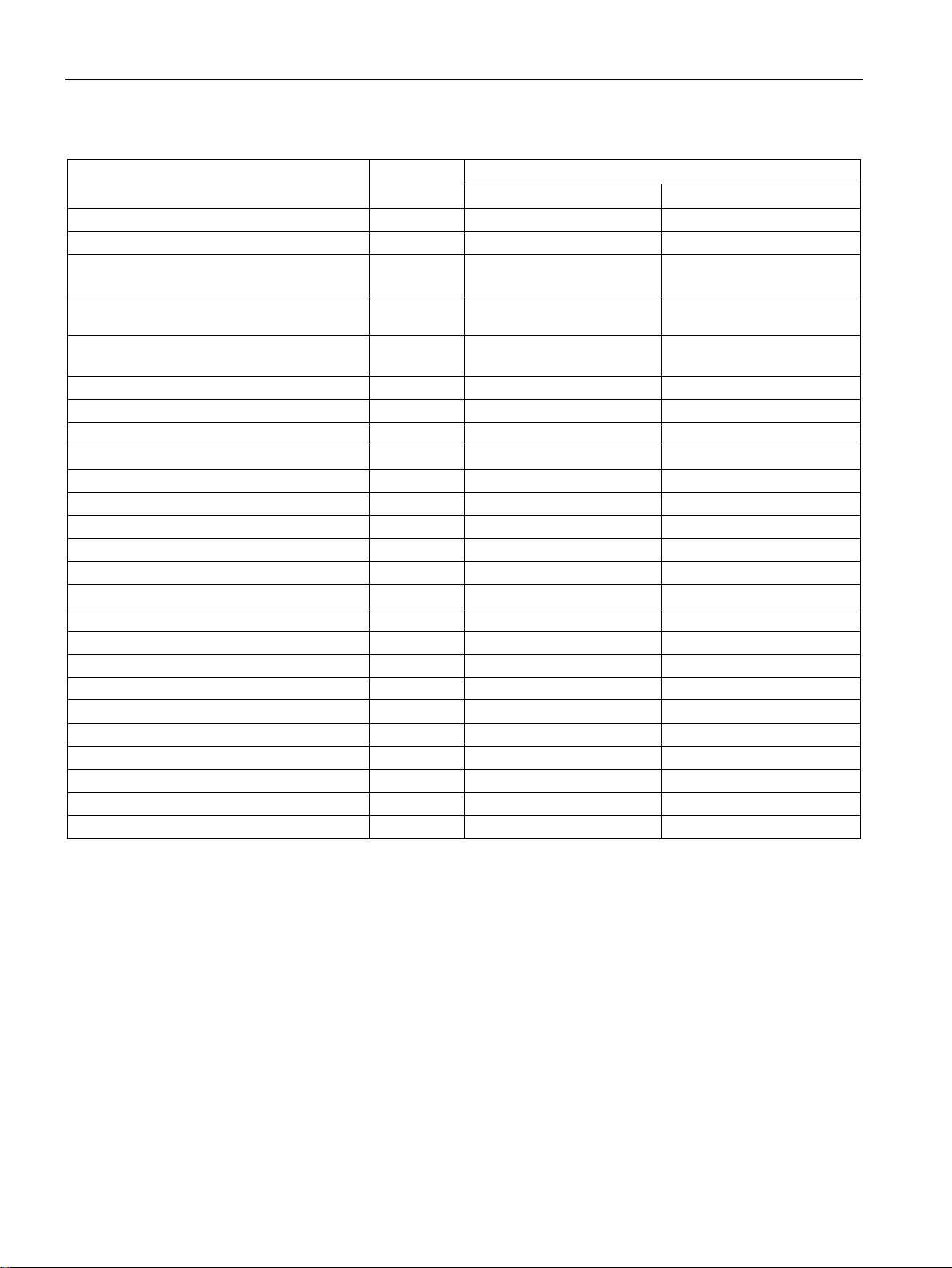

Table of contents

Introduction ............................................................................................................................................. 5

1 Fundamental safety instructions for the SIMOTICS documentation ........................................................ 11

2 Installing the motor ................................................................................................................................ 19

3 Parameter assignment/addressing ........................................................................................................ 21

4 Converter data sheets and characteristics ............................................................................................. 23

5 Characteristics ...................................................................................................................................... 71

1.1 Fundamental safety instructions ............................................................................................. 11

1.1.1 General safety instructions ..................................................................................................... 11

1.1.2 Handling electrostatic sensitive devices (ESD) ...................................................................... 15

1.1.3 Industrial security .................................................................................................................... 16

1.1.4 Residual risks during the operation of electric motors ............................................................ 17

3.1 Notes on commissioning ......................................................................................................... 21

3.2 Sequence of commissioning steps ......................................................................................... 21

4.1 Forced ventilation .................................................................................................................... 23

4.1.1 1PH8081-1_U0_1 (fp = 4 kHz) ................................................................................................ 23

4.1.2 1PH8081-1_V0_1 (fp = 8 kHz) ................................................................................................ 29

4.1.3 1PH8081-1_W0_1 (fp = 8 kHz) ............................................................................................... 35

4.1.4 1PH8083-1_V0_1 (fp = 8 kHz) ................................................................................................ 41

4.1.5 1PH8083-1_W0_1 (fp = 8 kHz) ............................................................................................... 45

4.1.6 1PH8087-1_V0_1 (fp = 8 kHz) ................................................................................................ 49

4.2 Water cooling .......................................................................................................................... 53

4.2.1 1PH8081-1_U2 (fp = 4 kHz) .................................................................................................... 53

4.2.2 1PH8081-1_T2 (fp = 4 kHz) .................................................................................................... 55

4.2.3 1PH8081-1_V2 (fp = 8 kHz) .................................................................................................... 57

4.2.4 1PH8081-1_W2 (fp = 8 kHz) ................................................................................................... 59

4.2.5 1PH8083-1_T2 (fp = 4 kHz) .................................................................................................... 61

4.2.6 1PH8083-1_U2 (fp = 4 kHz) .................................................................................................... 65

4.2.7 1PH8087-1_U2 (fp = 4 kHz) .................................................................................................... 67

5.1 Forced ventilation .................................................................................................................... 72

5.1.1 1PH8081-1_U0_1 (fp = 4 kHz) ................................................................................................ 72

5.1.2 1PH8081-1_V0_1 (fp = 8 kHz) ................................................................................................ 76

5.1.3 1PH8081-1_W0_1 (fp = 8 kHz) ............................................................................................... 80

5.1.4 1PH8083-1_V0_1 (fp = 8 kHz) ................................................................................................ 84

5.1.5 1PH8083-1_W0_1 (fp = 8 kHz) ............................................................................................... 88

5.1.6 1PH8087-1_V0_1 (fp = 8 kHz) ................................................................................................ 92

5.2 Water cooling .......................................................................................................................... 96

5.2.1 1PH8081-1_U2 (fp = 4 kHz) .................................................................................................... 96

5.2.2 1PH8081-1_T2 (fp = 4 kHz) .................................................................................................. 100

5.2.3 1PH8081-1_V2 (fp = 8 kHz) .................................................................................................. 104

5.2.4 1PH8081-1_W2 (fp = 8 kHz) ................................................................................................. 108

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

9

Table of contents

Index ................................................................................................................................................... 125

5.2.5 1PH8083-1_T2 (fp = 4 kHz) ................................................................................................. 112

5.2.6 1PH8083-1_U2 (fp = 4 kHz) ................................................................................................. 116

5.2.7 1PH8087-1_U2 (fp = 4 kHz) ................................................................................................. 120

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

10 Commissioning Manual, 10/2014, 610.40106.40

documentation

1

1.1

Fundamental safety instructions

1.1.1

General safety instructions

DANGER

Danger to life due to live parts and other energy sources

WARNING

Danger to life through a hazardous voltage when connecting an unsuitable power supply

Death or serious injury can result when live parts are touched.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase

conductor and phase conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water.

4. Isolate or neutralize all hazardous energy sources by closing switches, grounding or

short-circuiting or closing valves, for example.

5. Secure the energy sources against switching on again.

6. Ensure that the correct machine is completely interlocked.

After you have completed the work, restore the operational readiness in the inverse

sequence.

Touching live components can result in death or severe injury.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV-

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

11

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Danger to life when live parts are touched on damaged motors/devices

WARNING

Danger to life through electric shock due to unconnected cable shields

WARNING

Danger to life due to electric shock when not grounded

WARNING

Danger to life due to electric shock when opening plug connections in operation

1.1 Fundamental safety instructions

Improper handling of motors/devices can damage them.

For damaged motors/devices, hazardous voltages can be present at the enclosure or at

exposed components.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged motors/devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the conductors of power cables that are not

used (e.g. brake cores) at one end at the grounded housing potential.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

When opening plug connections in operation, arcs can result in severe injury or death.

• Only open plug connections when the equipment is in a no-voltage state, unless it has

been explicitly stated that they can be opened in operation.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

12 Commissioning Manual, 10/2014, 610.40106.40

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Danger to life through unexpected movement of machines when using mobile wireless

devices or mobile phones

WARNING

Danger of an accident occurring due to missing or illegible warning labels

WARNING

Danger to life when safety functions are inactive

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the

Safety Integrated manuals.

1.1 Fundamental safety instructions

Using mobile wireless devices or mobile phones with a transmit power > 1 W closer than

approx. 2 m to the components may cause the devices to malfunction, influence the

functional safety of machines therefore putting people at risk or causing material damage.

• Switch the wireless devices or mobile phones off in the immediate vicinity of the

components.

Missing or illegible warning labels can result in accidents involving death or serious injury.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, in the national language if

necessary.

• Replace illegible warning labels.

Safety functions that are inactive or that have not been adjusted accordingly can cause

operational faults on machines that could lead to serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

13

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Danger to life from electromagnetic fields

WARNING

Danger to life from permanent magnet fields

WARNING

Injury caused by moving parts or those that are flung out

WARNING

Danger to life due to fire if overheating occurs because of insufficient cooling

1.1 Fundamental safety instructions

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment

such as transformers, converters or motors.

People with pacemakers or implants are at a special risk in the immediate vicinity of these

devices/systems.

• Ensure that the persons involved are the necessary distance away (minimum 2 m).

Even when switched off, electric motors with permanent magnets represent a potential risk

for persons with heart pacemakers or implants if they are close to converters/motors.

• If you are such a person (with heart pacemaker or implant) then keep a minimum

distance of 2 m.

• When transporting or storing permanent magnet motors always use the original packing

materials with the warning labels attached.

• Clearly mark the storage locations with the appropriate warning labels.

• IATA regulations must be observed when transported by air.

Touching moving motor parts or drive output elements and loose motor parts that are flung

out (e.g. feather keys) in operation can result in severe injury or death.

• Remove any loose parts or secure them so that they cannot be flung out.

• Do not touch any moving parts.

• Safeguard all moving parts using the appropriate safety guards.

Inadequate cooling can cause overheating resulting in death or severe injury as a result of

smoke and fire. This can also result in increased failures and reduced service lives of

motors.

• Comply with the specified coolant requirements for the motor.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

14 Commissioning Manual, 10/2014, 610.40106.40

Fundamental safety instructions for the SIMOTICS documentation

WARNING

Danger to life due to fire as a result of overheating caused by incorrect operation

CAUTION

Risk of injury due to touching hot surfaces

1.1.2

Handling electrostatic sensitive devices (ESD)

NOTICE

Damage through electric fields or electrostatic discharge

1.1 Fundamental safety instructions

When incorrectly operated and in the case of a fault, the motor can overheat resulting in fire

and smoke. This can result in severe injury or death. Further, excessively high

temperatures destroy motor components and result in increased failures as well as shorter

service lives of motors.

• Operate the motor according to the relevant specifications.

• Only operate the motors in conjunction with effective temperature monitoring.

• Immediately switch off the motor if excessively high temperatures occur.

In operation, the motor can reach high temperatures, which can cause burns if touched.

• Mount the motor so that it is not accessible in operation.

When maintenance is required

• allow the motor to cool down before starting any work.

• Use the appropriate personnel protection equipment, e.g. gloves.

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

15

Fundamental safety instructions for the SIMOTICS documentation

1.1.3

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this i

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action

state

also be considered. For more information about industrial security, visit this addres

(

To stay informed about product updates as they occur, sign up for a product

newsletter. For more information, visit this address (

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

1.1 Fundamental safety instructions

n mind, Siemens’

(e.g. cell protection concept) and integrate each component into a holistic,

-of-the-art industrial security concept. Third-party products that may be in use should

s

http://www.siemens.com/industrialsecurity).

-specific

http://support.industry.siemens.com).

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can result in death, severe injuries

and/or material damage.

• Keep the software up to date.

You will find relevant information and newsletters at this address

(http://support.industry.siemens.com).

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

You will find further information at this address

(http://www.siemens.com/industrialsecurity).

• Make sure that you include all installed products into the holistic industrial security

concept.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

16 Commissioning Manual, 10/2014, 610.40106.40

Fundamental safety instructions for the SIMOTICS documentation

1.1.4

Residual risks during the operation of electric motors

1.1 Fundamental safety instructions

The motors may be operated only when all protective equipment is used.

Motors may be handled only by qualified and instructed qualified personnel that knows and

observes all safety instructions for the motors that are explained in the associated technical

user documentation.

When assessing the machine's risk in accordance with the respective local regulations (e.g.,

EC Machinery Directive), the machine manufacturer must take into account the following

residual risks emanating from the control and drive components of a drive system:

1. Unintentional movements of driven machine components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Errors during the assembly, installation, programming and parameterization

– Use of wireless devices/mobile phones in the immediate vicinity of the control system

– External influences/damage

2. In case of failure, unusually high temperatures inside and outside the motor, including

open fire as well as the emission of light, noise, particles, gases, etc. can result, for

example in

– Component failure

– Software errors in converter operation

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example,

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too

close

5. Release of noxious substances and emissions in the case of improper operation and/or

improper disposal of components

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

17

Fundamental safety instructions for the SIMOTICS documentation

1.1 Fundamental safety instructions

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

18 Commissioning Manual, 10/2014, 610.40106.40

2

Install the motor in accordance with the operating instructions and the commissioning

instructions for the SINAMICS S120 converter.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

19

3

3.1

Notes on commissioning

Note

Compatibility

The 1PH808x Premium Performance motor can only be operated o

that include the "Higher current controller dynamic response" option.

•

3.2

Sequence of commissioning steps

WARNING

Danger to life due to unexpected movements of motors resulting from incorrect

parameterization of the converter

n SINAMICS controllers

Check the availability of the option in accordance with Step 1 of the following sequence of

steps.

1PH8 motors in the "Premium Performance" version are presently not plug & play

components.

Following automatic commissioning you must make additional parameter adaptations. This

also applies to motor versions with DRIVE CLiQ.

A converter setting data sheet is available for every 1PH8 motor in the Premium

Performance version. (See the chapter "Converter data sheets and characteristics")

The motors are commissioned in 10 steps.

The required setting values can be found in the relevant converter setting data sheet.

Incorrect or incomplete parameterization of the converter can cause unexpected

movements in the motor and the machine. Unexpected movements can cause death,

severe injury or damage to property.

• Fully parameterize the converter.

• Do not switch the motor on until parameterization has been completed.

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

21

Parameter assignment/addressing

Motors with DRIVE-CLiQ

Motors without DRIVE-CLiQ

Via automatic configuration (Auto Config)

Offline using the motor code number.

Sequence of commissioning steps

3.2 Sequence of commissioning steps

Commission the motor in accordance with the two versions.

1. Check the activation "Higher current controller dynamic response"

– p1810.11 = "Yes" or p1810 = "x8xx" (hex)

– p118 = 20.5 µs

2. Select motor parameterization p10 = 3

3. Select a general asynchronous motor (rotary) p300 = 1

4. Parameterize the following values in accordance with the converter setting data sheet

– the current controller adaptation p352 and

– the line resistors p391, p392, p393

5. Exit motor parameterization

– p10 = 0

6. Parameterize the following values in accordance with the converter setting data sheet

– the current limit p640,

– the maximum speed p1082

– the torque limits p1520 and p1521

– the power limits p1530 and p1531

– the maximum value for the field-generating current p1603

7. Set the setpoint of the pulse frequency p1800 according to the converter setting data

sheet to 4 kHz or 8 kHz

8. Re-calculate the control parameters → p340 = 4

9. Set the current controller P gain p1715 to the value suggested in the converter setting

data sheet

10.Check or change the following values in accordance with the converter setting data sheet

– the reference variables p2000, p2002 and p2003 and

– the hysteresis speed p2162

Following Step 10, continue commissioning in the familiar way (e.g. take account of load

inertia, and optimize speed and position controllers)

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

22 Commissioning Manual, 10/2014, 610.40106.40

4

4.1

Forced ventilation

4.1.1

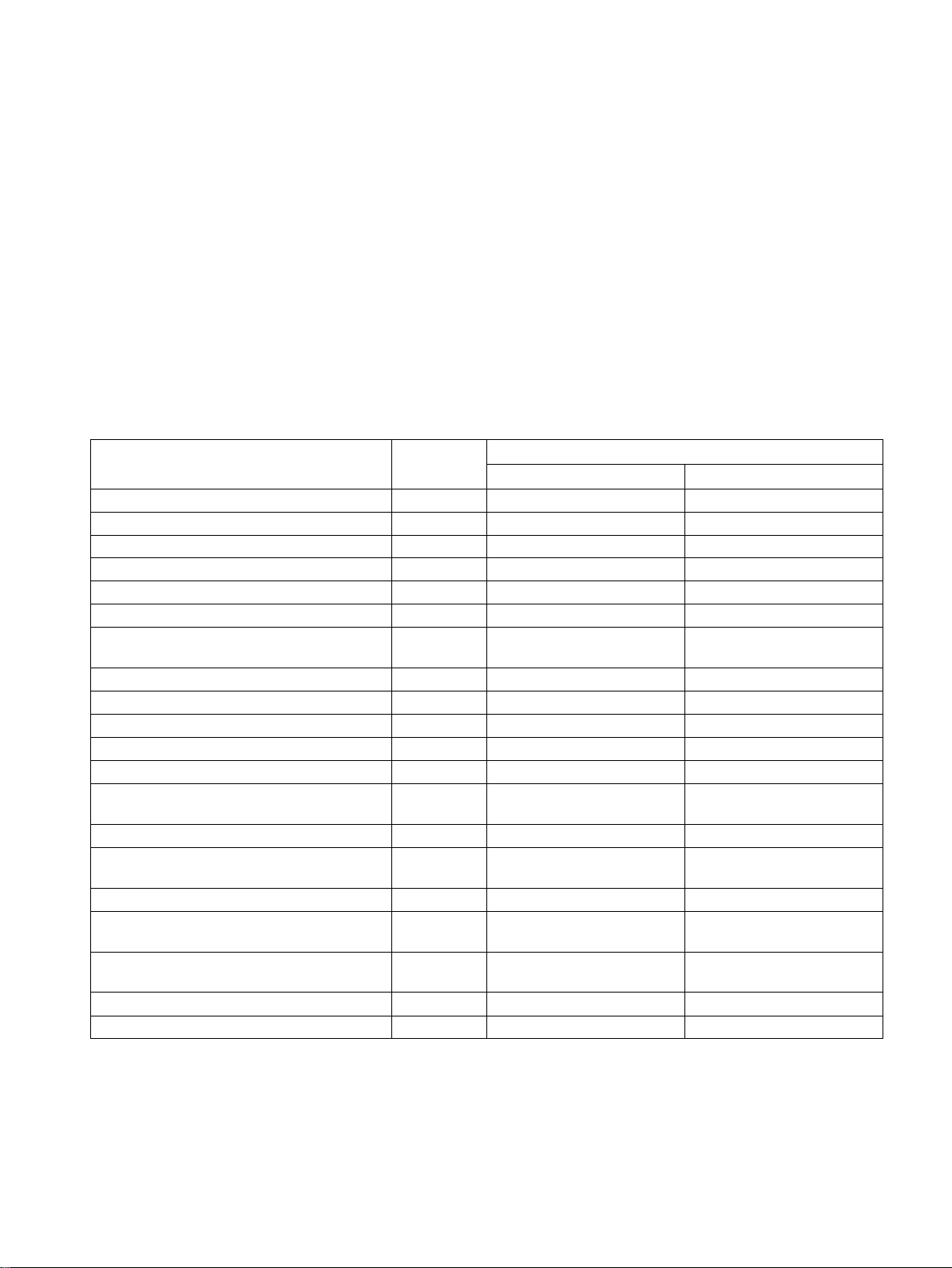

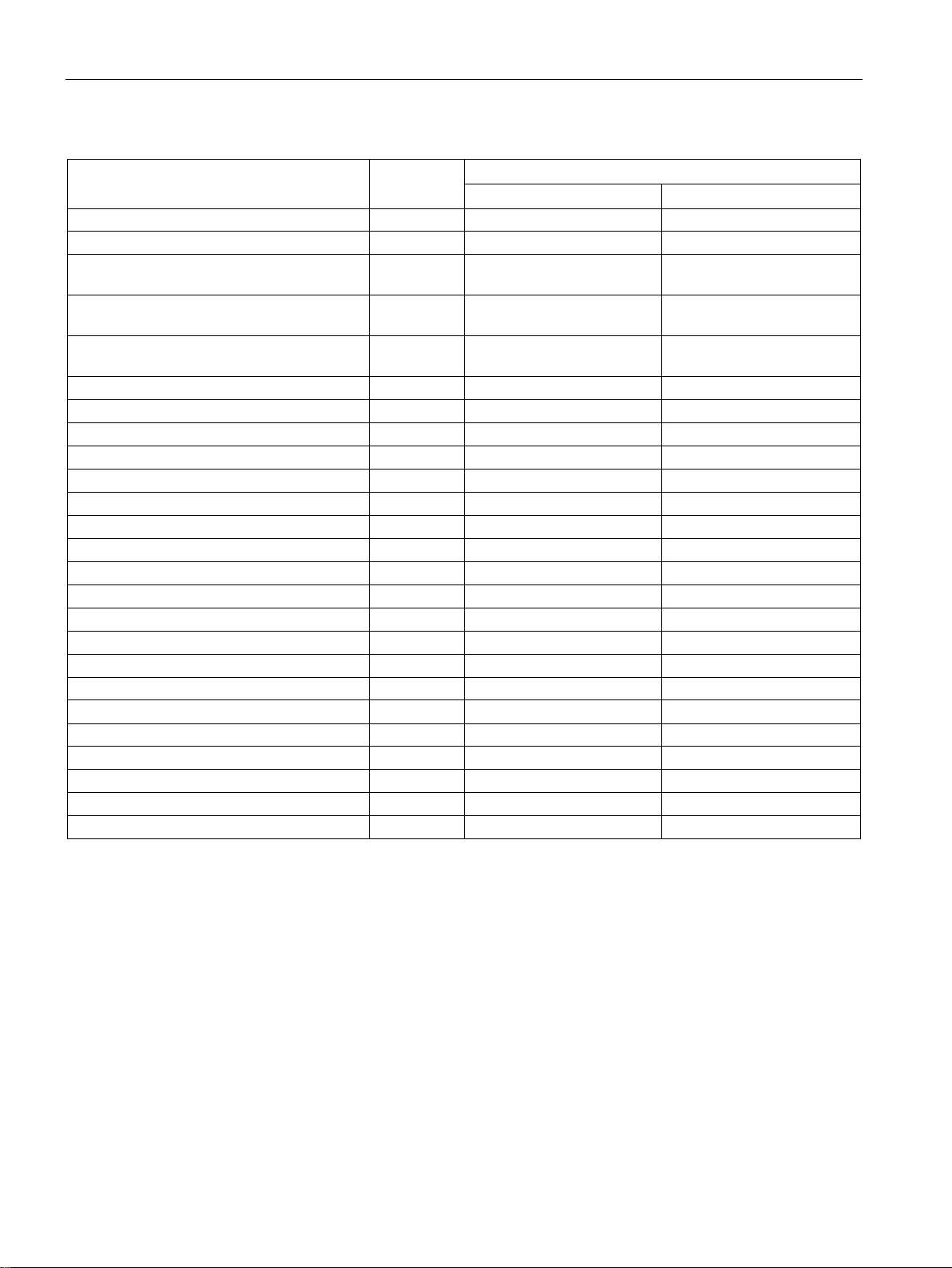

1PH8081-1_U0_1 (fp = 4 kHz)

1PH8081-1_U0/1, operation on Booksize Combi 18 A with 300% overload/Booksize 30 A

Motor/DRIVE CLiQ data

Booksize Combi 18 A with 300% overload/Booksize 30 A

400 V

480 V

Rated motor voltage

p304

264

264

Rated motor power

p307

2.8

2.8

Rated motor frequency

p310

302.7

302.7

Rated motor speed

p311

9,000

9,000

current

Maximum motor speed

p322

24,000

24,000

Motor stall torque correction factor

p326

78

78

Type of motor cooling

p335 1 1

Motor moment of inertia

p341

0.0045

0.0045

Motor weight (for thermal motor type)

p344

24

24

600 V

Motor stator resistance, cold

p350

0.149

0.149

sistance d-axis

Motor stator leakage inductance

p356

0.325

0.325

inductance d axis, saturated

Mot_temp_mod 1/2 threshold

p605

170

170

Rated motor voltage p305 12.2 12.2

Rated motor power factor p308 0.58 0.58

Motor rated magnetizing current/short-circuit

Speed at the start of field weakening Vdc =

Cold motor rotor resistance/damper re-

Motor rotor leakage inductance/damping

inductance d axis

Motor magnetizing inductance/magnetizing

Mot_temp_mod 2/KTY warning threshold p604 150 150

p320 8.3 8.3

p348

p354 0.095 0.095

p358 0.816 0.816

p360 9.000 9.000

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

23

Converter data sheets and characteristics

Additional parameterization

Booksize Combi 18 A with 300% overload/Booksize 30 A

400 V

480 V

Motor type selection

p300 1 1

Line resistance

p352

0.12

0.12

KP adapted

tion

Current limit

p640

54

50

Maximum rotation speed

p1082

24,000

24,000

Torque limit, upper/motoring

p1520

19

19

Torque limit, lower/regenerative

p1521

-19

-19

Power limit, motoring

p1530

17.9

19.9

Power limit, regenerative

p1531

-17.9

-19.9

Maximum field-generating current

p1603 0 0

Pulse frequency setpoint

p1800 4 4

Modulator configuration

p1810

&H800

&H800

Current controller P gain

p1715 3 3

Reference speed reference frequency

p2000

24,000

24,000

Reference torque

p2003

19

19

Hysteresis speed n_act > n_max

p2162

480

480

4.1 Forced ventilation

Current controller adaptation, starting point

KP

Current controller adaptation, starting point

Current controller adaptation, P gain adapta-

p391 8 8

p392 10 10

p393 60 60

Reference current p2002 54 50

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

24 Commissioning Manual, 10/2014, 610.40106.40

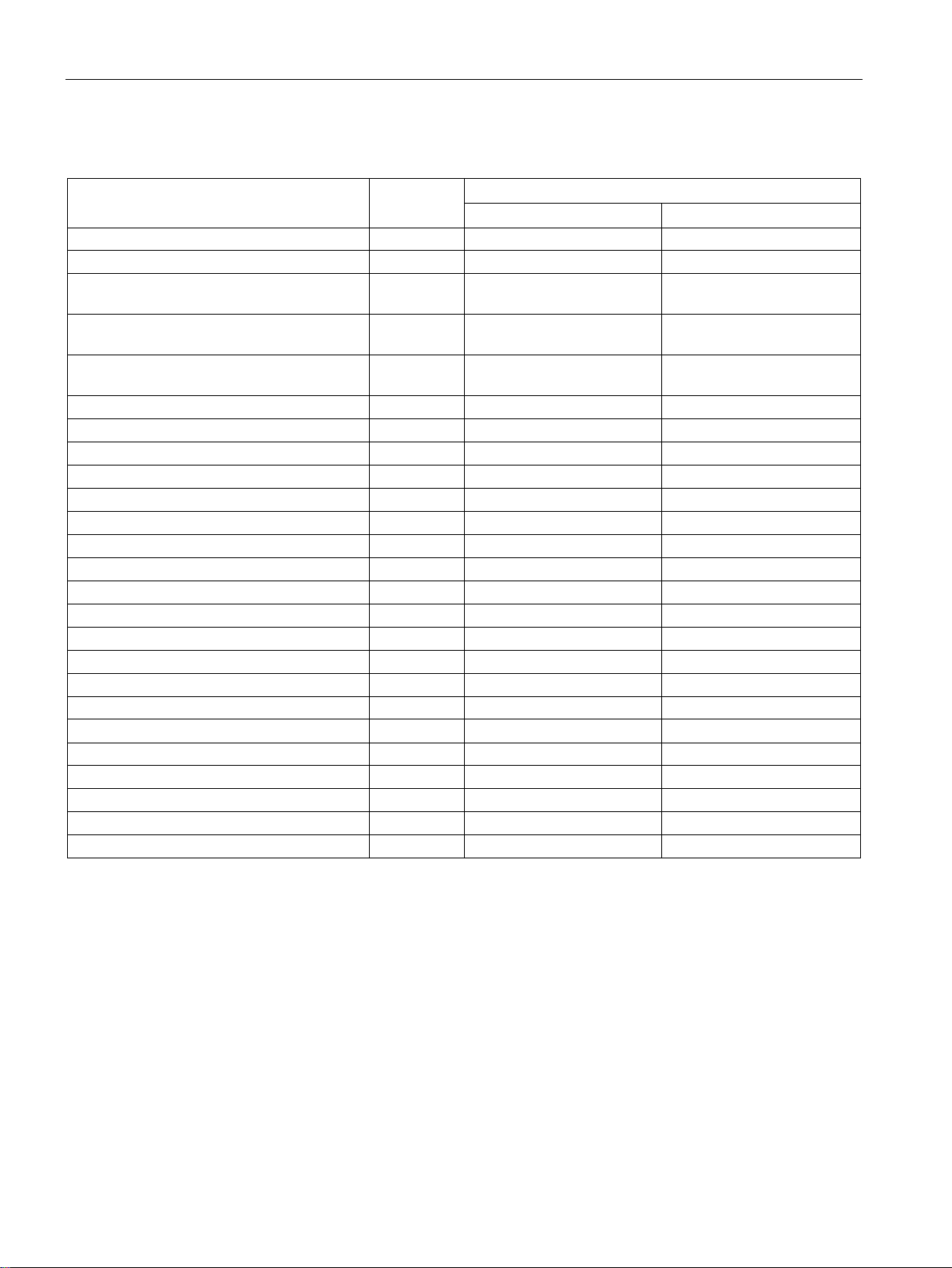

Converter data sheets and characteristics

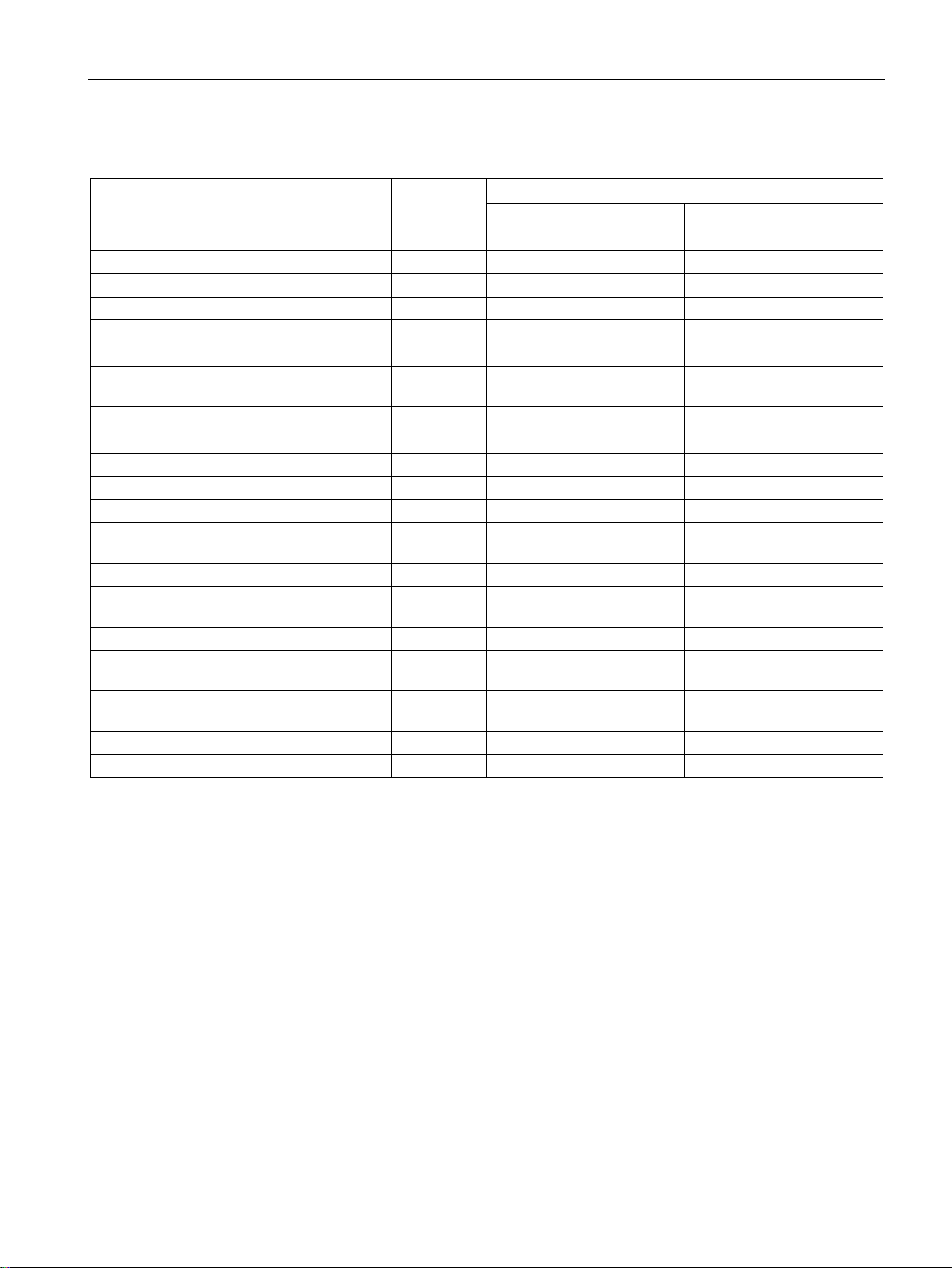

1PH8081-1_U0/1, operation on Booksize Combi

Motor/DRIVE CLiQ data

Booksize Combi

400 V

480 V

Rated motor voltage

p304

264

264

Rated motor voltage

p305

12.2

12.2

Rated motor power factor

p308

0.58

0.58

Rated motor speed

p311

9,000

9,000

current

Maximum motor speed

p322

24,000

24,000

Motor stall torque correction factor

p326

78

78

Type of motor cooling

p335 1 1

Motor moment of inertia

p341

0.0045

0.0045

Motor weight (for thermal motor type)

p344

24

24

600 V

Motor stator resistance, cold

p350

0.149

0.149

sistance d-axis

Motor stator leakage inductance

p356

0.325

0.325

inductance d axis

Mot_temp_mod 2/KTY warning threshold

p604

150

150

4.1 Forced ventilation

Rated motor power p307 2.8 2.8

Rated motor frequency p310 302.7 302.7

Motor rated magnetizing current/short-circuit

Speed at the start of field weakening Vdc =

Cold motor rotor resistance/damper re-

Motor rotor leakage inductance/damping

Motor magnetizing inductance/magnetizing

inductance d axis, saturated

Mot_temp_mod 1/2 threshold p605 170 170

p320 8.3 8.3

p348

p354 0.095 0.095

p358 0.816 0.816

p360 9.000 9.000

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

25

Converter data sheets and characteristics

Additional parameterization

Booksize Combi

400 V

480 V

Motor type selection

p300 1 1

Line resistance

p352

0.12

0.12

KP

KP adapted

tion

Current limit

p640

48

48

Maximum rotation speed

p1082

24,000

24,000

Torque limit, upper/motoring

p1520

16

16

Torque limit, lower/regenerative

p1521

-16

-16

Power limit, motoring

p1530

15.1

16.8

Power limit, regenerative

p1531

-15.1

-16.8

Maximum field-generating current

p1603 0 0

Pulse frequency setpoint

p1800 4 4

Modulator configuration

p1810

&H800

&H800

Current controller P gain

p1715 3 3

Reference speed reference frequency

p2000

24,000

24,000

Reference current

p2002

48

48

Reference torque

p2003

16

16

Hysteresis speed n_act > n_max

p2162

480

480

4.1 Forced ventilation

Current controller adaptation, starting point

Current controller adaptation, starting point

Current controller adaptation, P gain adapta-

p391 8 8

p392 10 10

p393 60 60

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

26 Commissioning Manual, 10/2014, 610.40106.40

Converter data sheets and characteristics

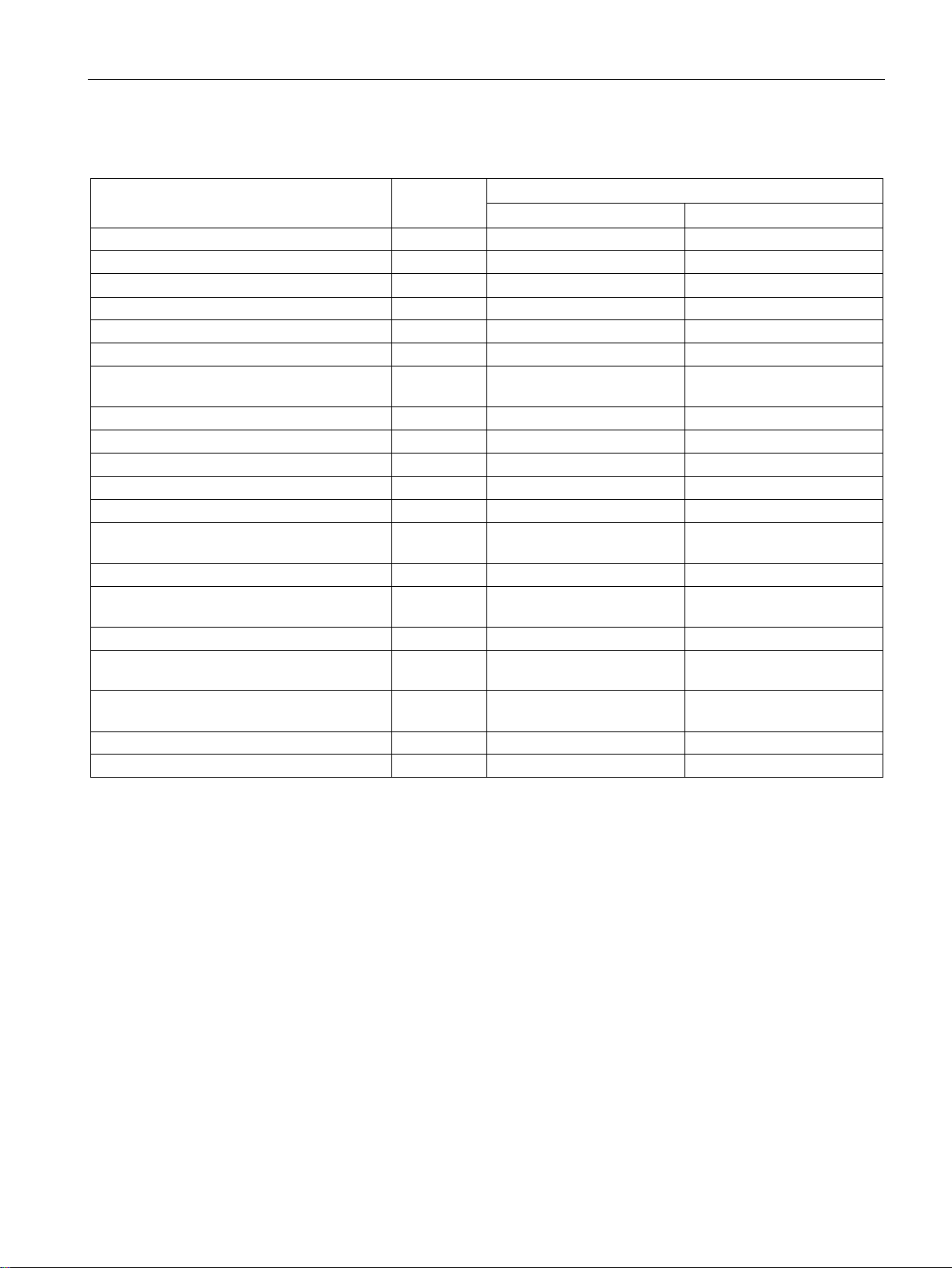

1PH8081-1_U0/1, operation on Booksize Combi with 300% overload

Motor/DRIVE CLiQ data

Booksize Combi with 300% overload

400 V

480 V

Rated motor voltage

p304

264

264

Rated motor voltage

p305

12.2

12.2

Rated motor power factor

p308

0.58

0.58

Rated motor speed

p311

9,000

9,000

current

Maximum motor speed

p322

24,000

24,000

Motor stall torque correction factor

p326

78

78

Type of motor cooling

p335 1 1

Motor moment of inertia

p341

0.0045

0.0045

Motor weight (for thermal motor type)

p344

24

24

600 V

Motor stator resistance, cold

p350

0.149

0.149

sistance d-axis

Motor stator leakage inductance

p356

0.325

0.325

inductance d axis

Mot_temp_mod 2/KTY warning threshold

p604

150

150

4.1 Forced ventilation

Rated motor power p307 2.8 2.8

Rated motor frequency p310 302.7 302.7

Motor rated magnetizing current/short-circuit

Speed at the start of field weakening Vdc =

Cold motor rotor resistance/damper re-

Motor rotor leakage inductance/damping

Motor magnetizing inductance/magnetizing

inductance d axis, saturated

Mot_temp_mod 1/2 threshold p605 170 170

p320 8.3 8.3

p348

p354 0.095 0.095

p358 0.816 0.816

p360 9.000 9.000

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

27

Converter data sheets and characteristics

Additional parameterization

Booksize Combi with 300% overload

400 V

480 V

Motor type selection

p300 1 1

Line resistance

p352

0.12

0.12

KP

KP adapted

tion

Current limit

p640

60

60

Maximum rotation speed

p1082

24,000

24,000

Torque limit, upper/motoring

p1520

20

20

Torque limit, lower/regenerative

p1521

-20

-20

Power limit, motoring

p1530

18.8

21.2

Power limit, regenerative

p1531

-18.8

-21.2

Maximum field-generating current

p1603 0 0

Pulse frequency setpoint

p1800 4 4

Modulator configuration

p1810

&H800

&H800

Current controller P gain

p1715 3 3

Reference speed reference frequency

p2000

24,000

24,000

Reference current

p2002

60

60

Reference torque

p2003

20

20

Hysteresis speed n_act > n_max

p2162

480

480

4.1 Forced ventilation

Current controller adaptation, starting point

Current controller adaptation, starting point

Current controller adaptation, P gain adapta-

p391 8 8

p392 10 10

p393 60 60

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

28 Commissioning Manual, 10/2014, 610.40106.40

Converter data sheets and characteristics

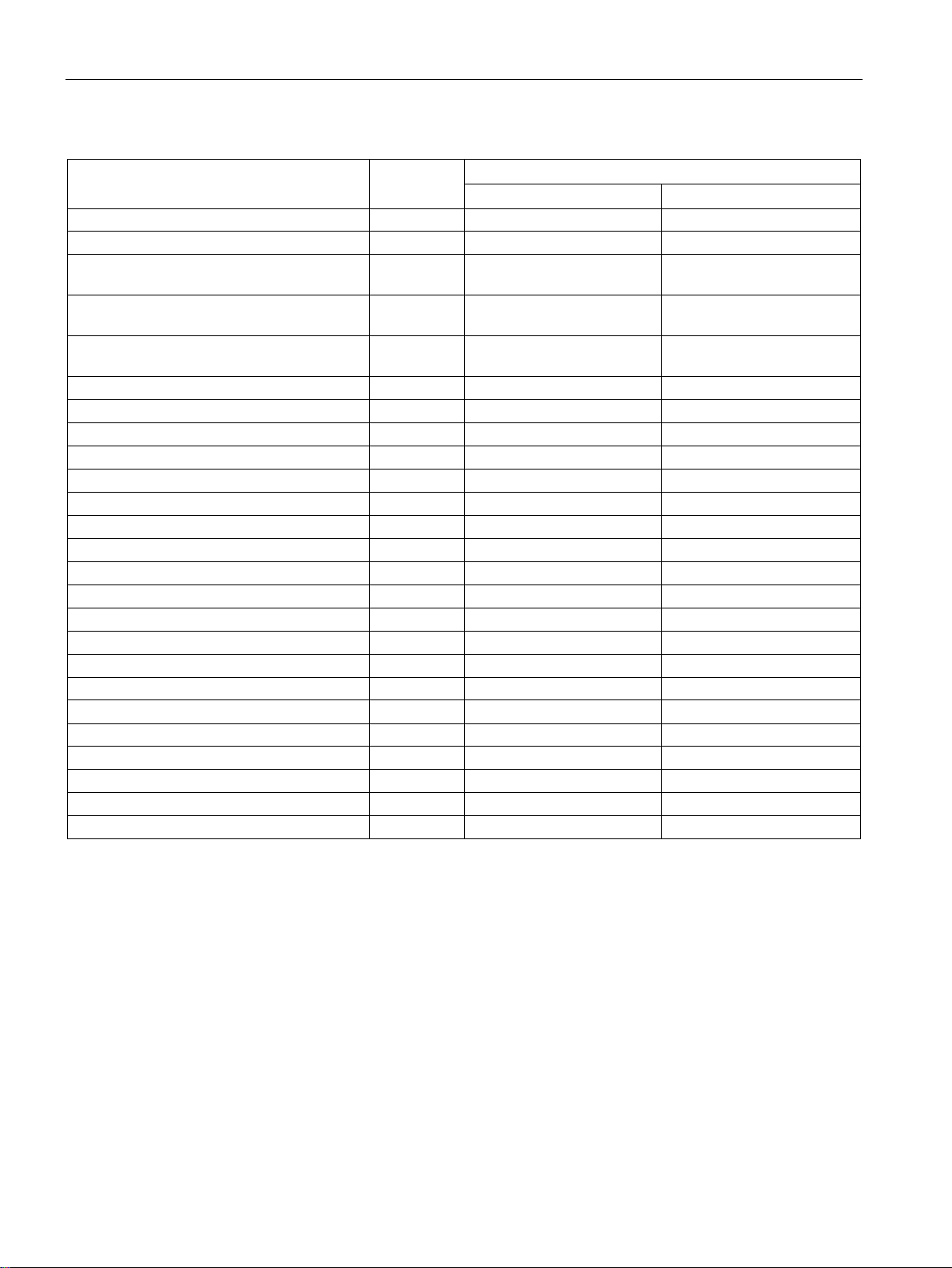

4.1.2

1PH8081-1_V0_1 (fp = 8 kHz)

1PH8081-1_V0/1, operation on Booksize 30 A

Motor/DRIVE CLiQ data

Booksize 30 A

400 V

480 V

Rated motor voltage

p304

279

279

Rated motor voltage

p305

15.5

15.5

Rated motor power factor

p308

0.5

0.5

Rated motor frequency

p310

301.4

301.4

Rated motor speed

p311

9,000

9,000

current

Maximum motor speed

p322

24,000

24,000

Motor stall torque correction factor

p326

100

100

Type of motor cooling

p335 1 1

Motor moment of inertia

p341

0.0045

0.0045

Motor weight (for thermal motor type)

p344

24

24

600 V

Motor stator resistance, cold

p350

0.119

0.119

sistance d-axis

Motor stator leakage inductance

p356

0.430

0.430

inductance d axis

Mot_temp_mod 2/KTY warning threshold

p604

150

150

4.1 Forced ventilation

Rated motor power p307 3.5 3.5

Motor rated magnetizing current/short-circuit

Speed at the start of field weakening Vdc =

Cold motor rotor resistance/damper re-

Motor rotor leakage inductance/damping

Motor magnetizing inductance/magnetizing

inductance d axis, saturated

Mot_temp_mod 1/2 threshold p605 170 170

p320 12.4 12.4

p348

p354 0.082 0.082

p358 1.000 1.000

p360 6.610 6.610

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

Commissioning Manual, 10/2014, 610.40106.40

29

Converter data sheets and characteristics

Additional parameterization

Booksize 30 A

400 V

480 V

Motor type selection

p300 1 1

Line resistance

p352

0.12

0.12

KP

KP adapted

tion

Current limit

p640

33

33

Maximum rotation speed

p1082

24,000

24,000

Torque limit, upper/motoring

p1520

12.5

12.5

Torque limit, lower/regenerative

p1521

-12.5

-12.5

Power limit, motoring

p1530

11.8

13.1

Power limit, regenerative

p1531

-11.8

-13.1

Maximum field-generating current

p1603 0 0

Pulse frequency setpoint

p1800 8 8

Modulator configuration

p1810

"&H800"

"&H800"

Current controller P gain

p1715

3.2

3.2

Reference speed reference frequency

p2000

24,000

24,000

Reference current

p2002

33

33

Reference torque

p2003

12.5

12.5

Hysteresis speed n_act > n_max

p2162

480

480

4.1 Forced ventilation

Current controller adaptation, starting point

Current controller adaptation, starting point

Current controller adaptation, P gain adapta-

p391 8 8

p392 10 10

p393 60 60

Commissioning instructions for SIMOTICS M-1PH8 Premium Performance

30 Commissioning Manual, 10/2014, 610.40106.40

Loading...

Loading...