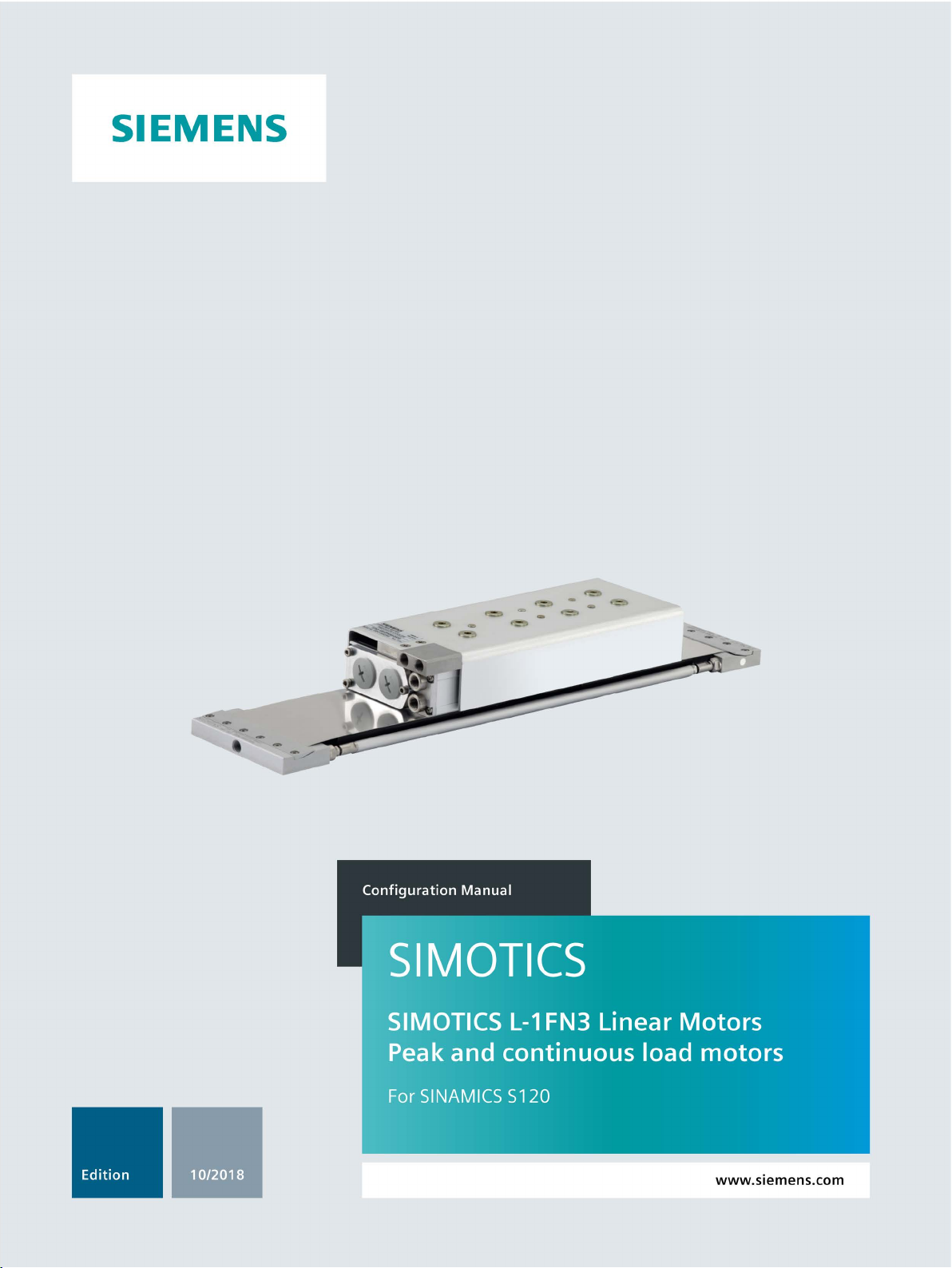

Page 1

Page 2

Page 3

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMOTICS

Drive technology

1FN3 linear motors

Configuration Manual

10/2018

6SN1197

Introduction

Fundamental safety

instructions

1

Description of the motor

2

Mechanical properties

3

Motor components and

options

4

Configuration

5

Technical data and

characteristics

6

Preparation for use

7

Electrical connection

8

Assembly drawings/

dimension sheets

9

Coupled motors

10

Appendix

A

-0AB86-0BP2

Page 4

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: 6SN1197-0AB86-0BP2

Ⓟ

Copyright © Siemens AG 2010 - 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

10/2018 Subject to change

Page 5

Introduction

Standard version

Target group

Benefits

Text features

Operating instructions

This documentation only describes the functionality of the standard version. The machine

OEM documents any extensions or changes to the motor made by it.

For reasons of clarity, this documentation cannot contain all of the detailed information on all

of the product types. Moreover, this documentation cannot take into consideration every

possible type of installation, operation, and maintenance.

This documentation should be kept in a location where it can be easily accessed and made

available to the personnel responsible.

This manual is aimed at planning, project, and design engineers as well as electricians,

fitters, and service personnel.

This manual provides information on the rules and guidelines that must be observed when

configuring a system with motors from the 1FN3 product family. It also helps with the

selection of peak and continuous load motors within this range.

In addition to the notes that you must observe for your own personal safety as well as to

avoid material damage, in this document you will find the following text features:

Operating instructions with the specified sequence are designated using the following

symbols:

The arrow indicates the start of the operating instructions.

The individual handling steps are numbered.

1. Execute the operating instructions in the specified sequence.

The square indicates the end of the operating instruction.

Operating instructions without a specified sequence are identified using a bullet point:

● Execute the operating instructions.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

3

Page 6

Introduction

Enumerations

Notes

Note

A Note is an important item of information about the product, handling of the product or the

relevant section of the document. Notes provide you with help or further suggestions/ideas.

More information

Internet address for products

My support

Note

If you want to use this function, you must first register.

Later, you can log on with your login data.

● Enumerations are identified by a bullet point without any additional symbols.

– Enumerations at the second level are hyphenated.

Notes are shown as follows:

Information on the following topics is available at:

● Ordering documentation / overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals / information)

More information (https://support.industry.siemens.com/cs/de/en/view/108998034)

If you have any questions regarding the technical documentation (e.g. suggestions,

corrections), please send an e-mail to the following address E-mail

(mailto:docu.motioncontrol@siemens.com).

Products (http://www.siemens.com/motioncontrol)

The following link provides information on how to create your own individual documentation

based on Siemens content, and adapt it for your own machine documentation:

My support (https://support.industry.siemens.com/My/de/en/documentation)

1FN3 linear motors

4 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 7

Introduction

Training

Technical Support

Usage phases and their documents/tools

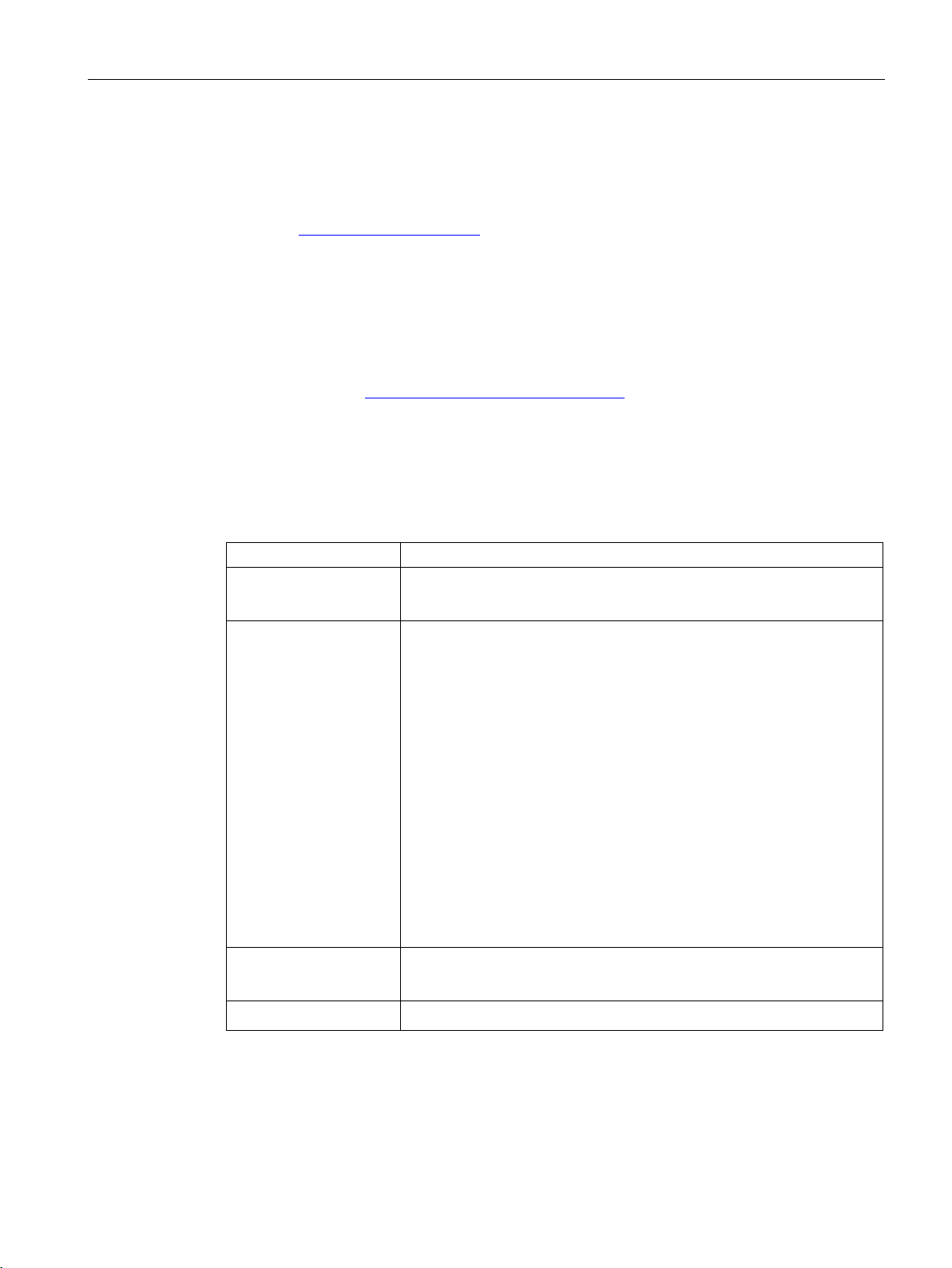

Usage phase

Document / tool / measure

The following link provides information on SITRAIN – training from Siemens for products,

systems and automation engineering solutions:

SITRAIN (http://siemens.com/sitrain)

Country-specific telephone numbers for technical support are provided on the Internet under

Contact:

Technical Support (https://support.industry.siemens.com)

Table 1 Usage phases and the required documents/tools

Orientation

Planning / configuring

Deciding / ordering

Transporting / storing

• SINAMICS S Sales Documentation

• Siemens Internet pages Motion Control

• SIZER configuration tool

• CAD-Creator selection and engineering tool

for dimension drawings, 2D/3D CAD data, generating system documentation

• DT Configurator to select and configure drive products

• Configuration Manuals, Motors

• Configuring notes from Catalog NC 62

• SINAMICS S120 Configuration Manuals

• SINAMICS S120 Safety Integrated Function Manual

• SINAMICS S120 List Manual

• Technical Support

– Mechatronic support

– Application support

– Technical Application Center

• Catalogs NC 62, PM 21

• SIZER configuring tool (generating parts lists)

• Operating instructions, motors

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

5

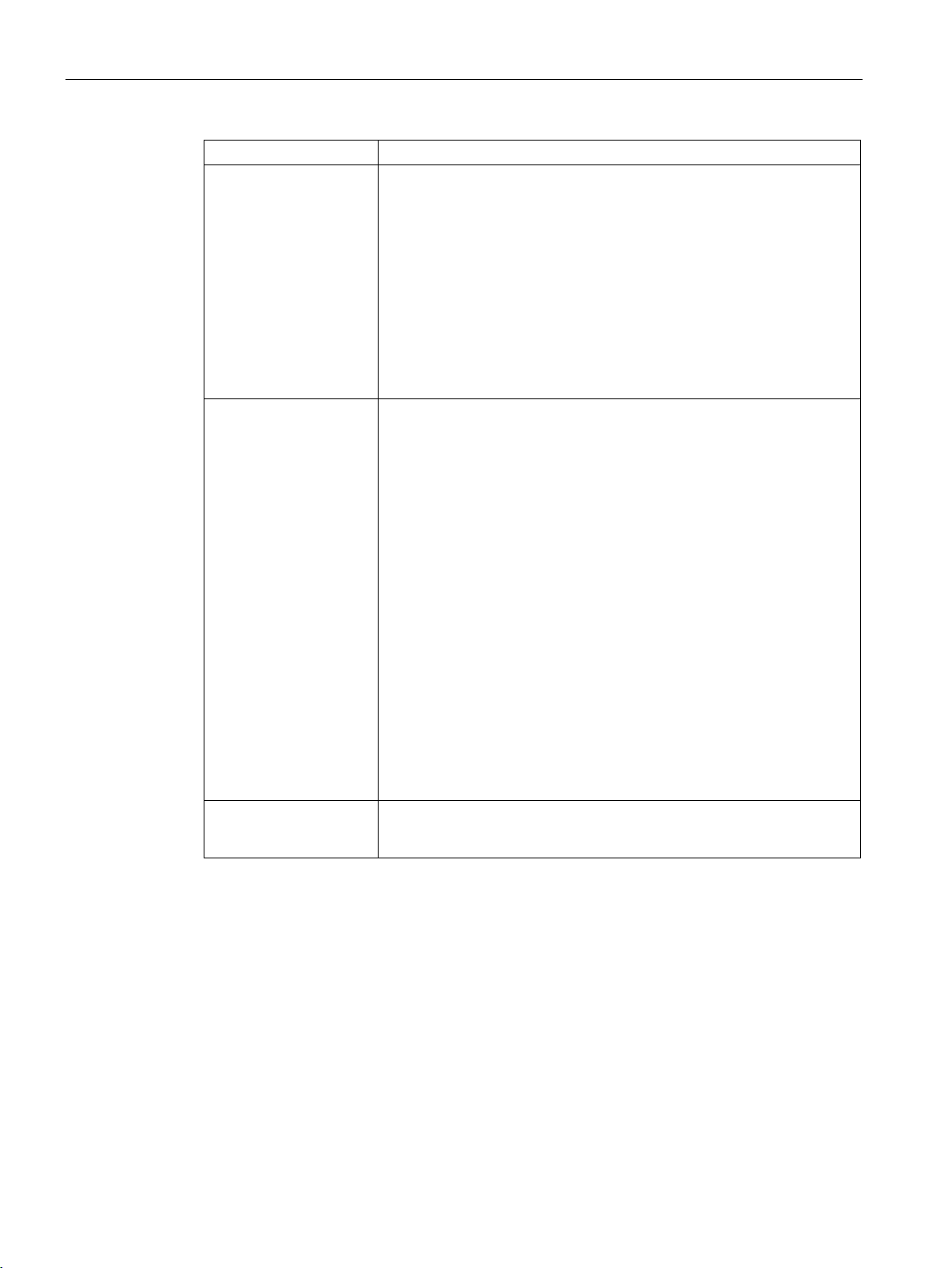

Page 8

Introduction

Usage phase

Document / tool / measure

disposal

Websites of third parties

Installation / mounting

Commissioning /

operating

Maintenance /

decommissioning /

• Operating instructions, motors

• Installation instructions for the machine

• SINAMICS S120 Equipment Manuals

• Documentation for encoders

• Examples of additional, possibly necessary documentation for the

following system components:

– Cooling system

– Brake

– Line filter

– HFD reactor or Active Interface Module

• Siemens commissioning training courses (SITRAIN courses)

• Commissioning support provided by Siemens

• Operating instructions, motors

• Configuration Manual Motors

• STARTER commissioning tool

• SINAMICS S120 Getting Started

• SINAMICS S120 Manuals

• SINAMICS S120 Commissioning Manual

• SINAMICS S120 List Manual

• SINAMICS S120 Function Manuals

• Documentation for encoders

• Examples of additional, possibly necessary documentation for the

following system components:

– Cooling system

– Brake

– Line filter

– HFD reactor or Active Interface Module

• Operating instructions, motors

This publication contains hyperlinks to websites of third parties. Siemens does not take any

responsibility for the contents of these websites or adopt any of these websites or their

contents as their own, because Siemens does not control the information on these websites

and is also not responsible for the contents and information provided there. Use of these

websites is at the risk of the person doing so.

1FN3 linear motors

6 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 9

Introduction

Information regarding third-party products

Note

Recommendation relating to third-party products

This document contains recommendations relating to third

the fundamental suitability of these third

You can use equivalent products from other manufacturers.

Siemens does not accept any warranty for the pro

-party products. Siemens accepts

-party products.

perties of third-party products.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

7

Page 10

Introduction

1FN3 linear motors

8 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 11

Table of contents

Introduction ............................................................................................................................................. 3

1 Fundamental safety instructions ............................................................................................................ 13

2 Description of the motor ........................................................................................................................ 23

3 Mechanical properties ........................................................................................................................... 59

1.1 General safety instructions ..................................................................................................... 13

1.2 Equipment damage due to electric fields or electrostatic discharge ...................................... 18

1.3 Industrial security .................................................................................................................... 19

1.4 Residual risks of power drive systems .................................................................................... 21

2.1 Highlights and benefits............................................................................................................ 23

2.1.1 Overview ................................................................................................................................. 23

2.1.2 Benefits ................................................................................................................................... 24

2.2 Use for the intended purpose ................................................................................................. 26

2.3 Technical features and environmental conditions .................................................................. 27

2.3.1 Directives and standards ........................................................................................................ 27

2.3.2 Danger from strong magnetic fields ........................................................................................ 29

2.3.3 Technical features ................................................................................................................... 34

2.3.4 Direction of motion of the motor .............................................................................................. 35

2.3.5 Ambient conditions for stationary use ..................................................................................... 36

2.3.6 Scope of delivery .................................................................................................................... 37

2.3.6.1 Scope of delivery linear motor ................................................................................................ 37

2.3.6.2 Supplied pictograms ............................................................................................................... 38

2.4 Derating factors ....................................................................................................................... 40

2.5 Selection and ordering data .................................................................................................... 40

2.5.1 Order designation ................................................................................................................... 40

2.5.1.1 Primary sections ..................................................................................................................... 41

2.5.1.2 Secondary sections ................................................................................................................. 41

2.5.1.3 Primary section accessories ................................................................................................... 42

2.5.1.4 Accessories for the secondary section track .......................................................................... 44

2.5.1.5 Ordering examples .................................................................................................................. 47

2.5.2 Selection and ordering data 1FN3 .......................................................................................... 50

2.6 Rating plate data ..................................................................................................................... 57

3.1 Cooling .................................................................................................................................... 59

3.1.1 Design of the cooling .............................................................................................................. 59

3.1.2 Cooling circuits ........................................................................................................................ 65

3.1.3 Coolants .................................................................................................................................. 70

3.2 Degree of protection ............................................................................................................... 71

3.3 Vibration response .................................................................................................................. 72

3.4 Noise emission ........................................................................................................................ 72

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

9

Page 12

Table of contents

4 Motor components and options ............................................................................................................. 83

5 Configuration ....................................................................................................................................... 103

3.5 Service and inspection intervals ............................................................................................ 73

3.5.1 Safety instructions for maintenance ....................................................................................... 73

3.5.2 Maintenance ........................................................................................................................... 78

3.5.3 Checking the insulation resistance ........................................................................................ 80

3.5.4 The inspection and change intervals for the coolant ............................................................. 81

4.1 Motor components ................................................................................................................. 83

4.1.1 Overview of the motor construction ....................................................................................... 83

4.1.2 Temperature monitoring and thermal motor protection ......................................................... 85

4.1.2.1 Temperature monitoring circuits Temp-S and Temp-F .......................................................... 85

4.1.2.2 Technical features of temperature sensors ........................................................................... 88

4.1.3 Encoders ................................................................................................................................ 91

4.1.4 Hall Sensor Box ..................................................................................................................... 95

4.1.5 Braking concepts.................................................................................................................... 97

4.2 Options ................................................................................................................................... 99

5.1 Configuring software ............................................................................................................ 103

5.1.1 SIZER configuration tool ...................................................................................................... 103

5.1.2 STARTER drive/commissioning software ............................................................................ 104

5.2 Configuring workflow ............................................................................................................ 104

5.2.1 Mechanical boundary conditions.......................................................................................... 106

5.2.2 Type of duty cycle ................................................................................................................ 109

5.2.3 Calculating forces................................................................................................................. 113

5.2.4 Selection of the primary sections ......................................................................................... 114

5.2.5 Specifying the number of secondary sections ..................................................................... 116

5.2.6 Operation in the area of reduced magnetic coverage.......................................................... 118

5.2.7 Checking the dynamic mass ................................................................................................ 119

5.2.8 Selecting the power module ................................................................................................. 119

5.2.9 Calculation of the required infeed ........................................................................................ 120

5.3 Examples ............................................................................................................................. 121

5.3.1 Positioning in a specified time .............................................................................................. 121

5.3.2 Gantry with transverse axis .................................................................................................. 130

5.3.3 Dimensioning the cooling system ........................................................................................ 132

5.3.3.1 Basic information.................................................................................................................. 132

5.3.3.2 Example: Dimensioning the cooling ..................................................................................... 133

5.4 Mounting .............................................................................................................................. 136

5.4.1 Safety instructions for mounting........................................................................................... 136

5.4.2 Mechanical design ............................................................................................................... 139

5.4.3 Specifications for mounting linear motors ............................................................................ 140

5.4.4 Procedure when installing the motor ................................................................................... 142

5.4.4.1 Comply with the installation dimensions .............................................................................. 143

5.4.4.2 Motor installation procedures ............................................................................................... 144

5.4.5 Assembling individual motor components ........................................................................... 150

5.4.6 Cooler connection ................................................................................................................ 158

5.4.6.1 Primary section cooling connection ..................................................................................... 158

5.4.6.2 Secondary section cooling connection ................................................................................ 160

1FN3 linear motors

10 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 13

Table of contents

6 Technical data and characteristics ...................................................................................................... 165

7 Preparation for use ............................................................................................................................. 473

8 Electrical connection ........................................................................................................................... 483

9 Assembly drawings/dimension sheets ................................................................................................. 509

5.4.7 Checking the work carried out .............................................................................................. 162

5.4.7.1 Smooth running of the slide .................................................................................................. 162

5.4.7.2 Check of the air gap height ................................................................................................... 163

6.1 Explanations ......................................................................................................................... 166

6.1.1 Explanations of the formula abbreviations ............................................................................ 166

6.1.2 Explanations of the characteristic curves ............................................................................. 170

6.2 Data sheets and characteristics ............................................................................................ 174

6.2.1 1FN3050-xxxxx-xxxx ............................................................................................................. 174

6.2.2 1FN3100-xxxxx-xxxx ............................................................................................................. 186

6.2.3 1FN3150-xxxxx-xxxx ............................................................................................................. 228

6.2.4 1FN3300-xxxxx-xxxx ............................................................................................................. 261

6.2.5 1FN3450-xxxxx-xxxx ............................................................................................................. 303

6.2.6 1FN3600-xxxxx-xxxx ............................................................................................................. 372

6.2.7 1FN3900-xxxxx-xxxx ............................................................................................................. 432

6.2.8 Additional characteristic curves ............................................................................................ 471

7.1 Transporting .......................................................................................................................... 474

7.1.1 Ambient conditions for transportation ................................................................................... 474

7.1.2 Packaging specifications for air transportation ..................................................................... 475

7.1.3 Lifting primary sections ......................................................................................................... 478

7.2 Storage ................................................................................................................................. 479

7.2.1 Ambient conditions for long-term storage ............................................................................. 479

7.2.2 Storage in rooms and protection against humidity ............................................................... 480

8.1 Permissible line system types ............................................................................................... 485

8.2 Motor circuit diagram ............................................................................................................ 486

8.3 System integration ................................................................................................................ 486

8.3.1 Drive system ......................................................................................................................... 486

8.3.2 Sensor Module SME12x ....................................................................................................... 490

8.3.3 TM120 Terminal Module ....................................................................................................... 490

8.3.4 SMC20 Sensor Module ......................................................................................................... 490

8.3.5 Pin assignments and connection types ................................................................................ 490

8.3.6 Terminal panel ...................................................................................................................... 493

8.3.7 Power connection ................................................................................................................. 498

8.3.8 Signal connection .................................................................................................................. 500

8.3.9 Shielding, grounding, and equipotential bonding .................................................................. 506

8.3.10 Requirements for the motor supply cables ........................................................................... 507

9.1 Position tolerance for mounting holes................................................................................... 510

9.2 Installation dimensions.......................................................................................................... 511

9.3 1FN3050, 1FN3100, 1FN3150 ............................................................................................. 512

9.3.1 1FN3050 ............................................................................................................................... 512

9.3.2 1FN3100, 1FN3150 .............................................................................................................. 519

9.3.3 Mounting the Hall sensor box ............................................................................................... 527

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

11

Page 14

Table of contents

10 Coupled motors ................................................................................................................................... 569

A Appendix ............................................................................................................................................. 585

Glossary .............................................................................................................................................. 593

Index ................................................................................................................................................... 595

9.3.4 Heatsink profiles................................................................................................................... 531

9.4 1FN3300, 1FN3450 ............................................................................................................. 533

9.4.1 Mounting the Hall sensor box .............................................................................................. 543

9.4.2 Heatsink profiles................................................................................................................... 547

9.5 1FN3600 .............................................................................................................................. 549

9.5.1 Mounting the Hall sensor box .............................................................................................. 554

9.5.2 Heatsink profiles................................................................................................................... 558

9.6 1FN3900 .............................................................................................................................. 559

9.6.1 Mounting the Hall sensor box .............................................................................................. 564

9.6.2 Heatsink profiles................................................................................................................... 568

10.1 Operating motors connected to an axis in parallel ............................................................... 569

10.2 Master and stoker ................................................................................................................ 570

10.2.1 Tandem arrangement .......................................................................................................... 572

10.2.2 Janus arrangement .............................................................................................................. 573

10.2.3 Parallel arrangement ............................................................................................................ 576

10.2.4 Anti-parallel arrangement ..................................................................................................... 578

10.2.5 Double-sided arrangement .................................................................................................. 580

10.3 Connection examples for parallel operation ........................................................................ 582

A.1 Recommended manufacturers ............................................................................................. 585

A.1.1 Manufacturers of braking elements...................................................................................... 585

A.1.2 Manufacturers of cold water units ........................................................................................ 586

A.1.3 Manufacturers of anti-corrosion agents ............................................................................... 586

A.1.4 Manufacturers of connectors for cooling .............................................................................. 586

A.1.5 Manufacturers of plastic hose manufacturers ...................................................................... 587

A.1.6 Manufacturers of connector nipples and reinforcing sleeves .............................................. 587

A.1.7 Manufacturers of spacer foils ............................................................................................... 587

A.2 List of abbreviations ............................................................................................................. 588

A.3 Environmental compatibility ................................................................................................. 589

A.3.1 Environmental compatibility during production .................................................................... 589

A.3.2 Disposal ............................................................................................................................... 589

A.3.2.1 Guidelines for disposal ......................................................................................................... 590

A.3.2.2 Disposing of secondary sections ......................................................................................... 590

A.3.2.3 Disposal of packaging .......................................................................................................... 591

A.4 Terminal markings according to EN 60034-8:2002 ............................................................. 591

1FN3 linear motors

12 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 15

1

1.1

General safety instructions

WARNING

Electric shock and danger to life due to other energy sources

WARNING

Electric shock due to connection to an unsuitable power supply

Touching live components can result in death or severe injury.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, the following six steps apply when establishing safety:

1. Prepare for disconnection. Notify all those who will be affected by the procedure.

2. Isolate the drive system from the power supply and take measures to prevent it being

switched back on again.

3. Wait until the discharge time specified on the warning labels has elapsed.

4. Check that there is no voltage between any of the power connections, and between any

of the power connections and the protective conductor connection.

5. Check whether the existing auxiliary supply circuits are de-energized.

6. Ensure that the motors cannot move.

7. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water. Switch the energy sources to a safe state.

8. Check that the correct drive system is completely locked.

After you have completed the work, restore the operational readiness in the inverse

sequence.

When equipment is connected to an unsuitable power supply, exposed components may

carry a hazardous voltage that might result in serious injury or death.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

13

Page 16

Fundamental safety instructions

WARNING

Electric shock due to damaged motors or devices

WARNING

Electric shock due to unconnected cable shield

WARNING

Electric shock if there is no ground connection

WARNING

Arcing when a plug connection is opened during operation

1.1 General safety instructions

Improper handling of motors or devices can damage them.

Hazardous voltages can be present at the enclosure or at exposed components on

damaged motors or devices.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged motors or devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the conductors of power cables that are not

used (e.g. brake cores) at one end at the grounded housing potential.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

Opening a plug connection when a system is operation can result in arcing that may cause

serious injury or death.

• Only open plug connections when the equipment is in a voltage-free state, unless it has

been explicitly stated that they can be opened in operation.

1FN3 linear motors

14 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 17

Fundamental safety instructions

NOTICE

Property damage due to loose power connections

WARNING

Unexpected movement of machines caused by radio devices or mobile phones

WARNING

Unrecognized dangers due to missing or illegible warning labels

1.1 General safety instructions

Insufficient tightening torques or vibration can result in loose power connections. This can

result in damage due to fire, device defects or malfunctions.

• Tighten all power connections to the prescribed torque.

• Check all power connections at regular intervals, particularly after equipment has been

transported.

When radio devices or mobile phones with a transmission power > 1 W are used in the

immediate vicinity of components, they may cause the equipment to malfunction.

Malfunctions may impair the functional safety of machines and can therefore put people in

danger or lead to property damage.

• If you come closer than around 2 m to such components, switch off any radios or mobile

phones.

• Use the "SIEMENS Industry Online Support app" only on equipment that has already

been switched off.

Dangers might not be recognized if warning labels are missing or illegible. Unrecognized

dangers may cause accidents resulting in serious injury or death.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, where necessary in the national

language.

• Replace illegible warning labels.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

15

Page 18

Fundamental safety instructions

WARNING

Unexpected movement of machines caused by inactive safety functions

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, you must observe the safety notices in the

Safety Integrated manuals.

WARNING

Active implant malfunctions due to electromagnetic fields

1.1 General safety instructions

Inactive or non-adapted safety functions can trigger unexpected machine movements that

may result in serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment,

such as transformers, converters, or motors. People with pacemakers or implants are at

particular risk in the immediate vicinity of this equipment.

• If you have a heart pacemaker or implant, maintain the minimum distance specified in

chapter "Correct usage" from such motors.

1FN3 linear motors

16 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 19

Fundamental safety instructions

WARNING

Active implant malfunctions due to permanent-magnet fields

WARNING

Injury caused by moving or ejected parts

WARNING

Fire due to inadequate cooling

WARNING

Fire due to incorrect operation of the motor

1.1 General safety instructions

Even when switched off, electric motors with permanent magnets represent a potential risk

for persons with heart pacemakers or implants if they are close to converters/motors.

• If you have a heart pacemaker or implant, maintain the minimum distance specified in

chapter "Correct usage".

• When transporting or storing permanent-magnet motors always use the original packing

materials with the warning labels attached.

• Clearly mark the storage locations with the appropriate warning labels.

• IATA regulations must be observed when transported by air.

Contact with moving motor parts or drive output elements and the ejection of loose motor

parts (e.g. feather keys) out of the motor enclosure can result in severe injury or death.

• Remove any loose parts or secure them so that they cannot be flung out.

• Do not touch any moving parts.

• Safeguard all moving parts using the appropriate safety guards.

Inadequate cooling can cause the motor to overheat, resulting in death or severe injury as a

result of smoke and fire. This can also result in increased failures and reduced service lives

of motors.

• Comply with the specified cooling requirements for the motor.

When incorrectly operated and in the case of a fault, the motor can overheat resulting in fire

and smoke. This can result in severe injury or death. Further, excessively high temperatures destroy motor components and result in increased failures as well as shorter service

lives of motors.

• Operate the motor according to the relevant specifications.

• Only operate the motors in conjunction with effective temperature monitoring.

• Immediately switch off the motor if excessively high temperatures occur.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

17

Page 20

Fundamental safety instructions

CAUTION

Burn injuries caused by hot surfaces

1.2

Equipment damage due to electric fields or electrostatic discharge

NOTICE

Equipment damage due to electric fields or electrostatic discharge

1.2 Equipment damage due to electric fields or electrostatic discharge

In operation, the motor can reach high temperatures, which can cause burns if touched.

• Mount the motor so that it is not accessible in operation.

Measures when maintenance is required:

• Allow the motor to cool down before starting any work.

• Use the appropriate personnel protection equipment, e.g. gloves.

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

1FN3 linear motors

18 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 21

Fundamental safety instructions

1.3

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it

necessary to implement

security concept. Siemens

Customers are responsible for preventing unauthorized access to the

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the Internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewal

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit:

Industrial security (

Siemens

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product v

longer supported, and failure to apply the latest updates may increase customer

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (

1.3 Industrial security

is

– and continuously maintain – a holistic, state-of-the-art industrial

’ products and solutions constitute one element of such a concept.

ir plants, systems,

ls and/or network

http://www.siemens.com/industrialsecurity)

’ products and solutions undergo continuous development to make them more

http://www.siemens.com/industrialsecurity)

Further information is provided on the Internet:

Industrial Security Configuration Manual

(https://support.industry.siemens.com/cs/ww/en/view/108862708)

ersions that are no

’s exposure

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

19

Page 22

Fundamental safety instructions

WARNING

Unsafe operating states resulting from software manipulation

1.3 Industrial security

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe

operating states in your system that may lead to death, serious injury, and property

damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

• Protect the drive against unauthorized changes by activating the "know-how protection"

drive function.

1FN3 linear motors

20 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 23

Fundamental safety instructions

1.4

Residual risks of power drive systems

1.4 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer

must take into account the following residual risks emanating from the control and drive

components of a drive system:

1. Unintentional movements of driven machine or system components during

commissioning, operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too

close

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

21

Page 24

Fundamental safety instructions

1.4 Residual risks of power drive systems

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters

or data communication via the network

For more information about the residual risks of the drive system components, see the

relevant sections in the technical user documentation.

1FN3 linear motors

22 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 25

2

2.1

Highlights and benefits

2.1.1

Overview

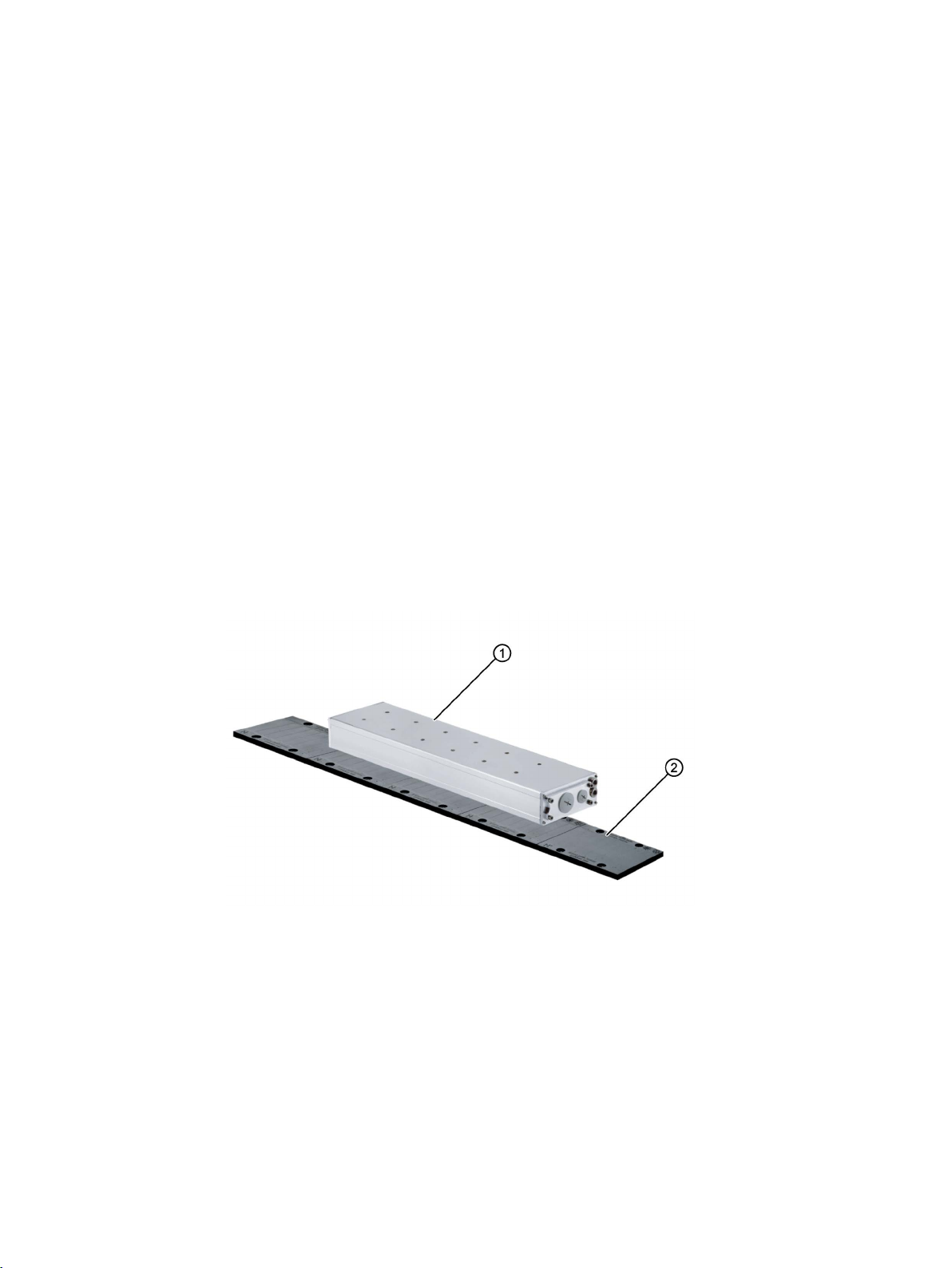

Basic characteristics of the motor

①

Primary section

②

Secondary section

1FN3 motors are permanent-magnet synchronous linear motors with a modular cooling

concept. Depending on the accuracy requirements, the motor can be optionally operated

with a primary section precision cooler and/or a secondary section cooling. To a large extent,

the motors are then thermally neutral with respect to the machine itself.

The motor is delivered in components (at least primary section and secondary sections) and

installed directly in the machine. Due to the series connection of primary and secondary

sections, user-defined motor forces and straight traversing distances of various lengths can

be achieved.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

The motors are designed for the SINAMICS S120 drive system.

You can use Motor Modules in the "blocksize", "booksize" or "chassis" formats.

23

Page 26

Description of the motor

Overview of the connection variants

Peak and continuous load motor

with two pre

with/without connector

Peak and continuous load motor

with connection cover for two cables

Peak load motor

with connector cover for one cable

or

with a fixed cable without a connector

2.1.2

Benefits

2.1 Highlights and benefits

-assembled cables

The general-purpose motors in the 1FN3 product family are powerful linear motors with a

broad range of types. These motors have the following properties:

● High power density

● High dynamic response

● High forces

● Compact design

● Low sensitivity to corrosive ambient conditions

While the peak load motors have high overload capability, the continuous load motors have

a rated force with high availability.

The motors of the 1FN3 product family can be operated in parallel. You will find information

on this in Chapter "Coupled motors (Page 569)".

1FN3 linear motors

24 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 27

Description of the motor

Special features

Additional feature on the peak load motor

Additional features on the continuous load motor

2.1 Highlights and benefits

● Modular design: The motor can therefore be configured to optimally match the technical

requirements. The modularity of the motor is explained in Chapter "Motor components

and options (Page 83)".

● The motor is thermally decoupled from the machine using a primary section precision

cooler and secondary section cooling, based on the Thermo-Sandwich

● Simple coolant connection.

● The secondary section track can be fully covered: This provides a smooth surface and

prevents unwanted particle deposits, especially in the gaps between the secondary

sections.

● Simple electrical connection via an integrated terminal panel or permanent cable

connections.

● Low mass and high overload capability: The motor is ideally suited for acceleration drive

applications.

● Low mass and high continuous load capability. The motor is ideally suited to load cycles

with continuous acceleration and braking phases and continuous loads, such as weight

force or process forces.

● Low force ripple. The motor is suitable for high-precision applications.

®

principle.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

25

Page 28

Description of the motor

2.2

Use for the intended purpose

WARNING

Risk of death and material damage as a result of incorrect use

WARNING

Danger to life for wearers of active implants due to magnetic and electrical fields

Applications for peak load motors

2.2 Use for the intended purpose

There is a risk of death, serious injury and/or material damage when direct drives or their

components are used for a purpose for which they were not intended.

• Only use the motors for industrial or commercial plants and systems.

• Do not install the motors in hazardous zones if the motors have not been expressly and

explicitly designed and authorized for this purpose. Carefully observe any special

additional notes provided.

• Only use direct drives and their components for applications that Siemens has explicitly

specified.

• Protect the motors against dirt and contact with corrosive substances.

• Ensure that the installation conditions comply with the rating plate specifications and the

condition specifications contained in this documentation. Where relevant, take into

account deviations regarding approvals or country-specific regulations.

• Contact your local Siemens office if you have any questions relating to correct use.

• If you wish to use special versions and design versions whose technical details vary

from the motors described in this document, then you must contact your local Siemens

office.

Electric motors pose a danger to people with active medical implants, e.g. cardiac

stimulators, who come close to the motors.

• If you are affected, stay at a minimum distance of 500 mm from the motors (tripping

threshold for static magnetic fields of 0.5 mT according to the Directive 2013/35/EU).

Combined with a drive system with closed-loop control, peak load motors are well suited as

direct drives for linear motion, e.g. for:

● Highly dynamic and flexible machine tools

● Laser machining

● Handling

1FN3 linear motors

26 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 29

Description of the motor

Applications for continuous load motors

WARNING

Personal injury and material damage by noncompliance with directive 2006/42/EC

2.3

Technical features and environmental conditions

2.3.1

Directives and standards

Standards that are complied with

2.3 Technical features and environmental conditions

Combined with a drive system with closed-loop control, continuous load motors are well

suited as direct drives for linear motion, e.g. for:

● Oscillating motion (e.g. out-of-center machining)

● Applications with high process forces (e.g. grinding, turning, etc.)

● Vertical axes without weight compensation, quills

● Handling, Cartesian robots

You can use Motor Modules in the "blocksize", "booksize" or "chassis" formats.

There is a risk of death, serious injury and/or material damage if Directive 2006/42/EC is

not carefully observed.

• The products included in the scope of delivery are exclusively designed for installation in

a machine. Commissioning is prohibited until it has been fully established that the end

product conforms with Directive 2006/42/EC.

• Please take into account all safety instructions and provide these to end users.

Please take note of national and international license terms when operating direct motors so

that no patent rights are violated.

The motors of the type series SIMOTICS S, SIMOTICS M, SIMOTICS L, SIMOTICS T,

SIMOTICS A, called "SIMOTICS motor series" below, fulfill the requirements of the following

directives and standards:

● EN 60034-1 – Rotating electrical machines – Dimensioning and operating behavior

● EN 60204-1 – Safety of machinery – Electrical equipment of machines; general

requirements

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

27

Page 30

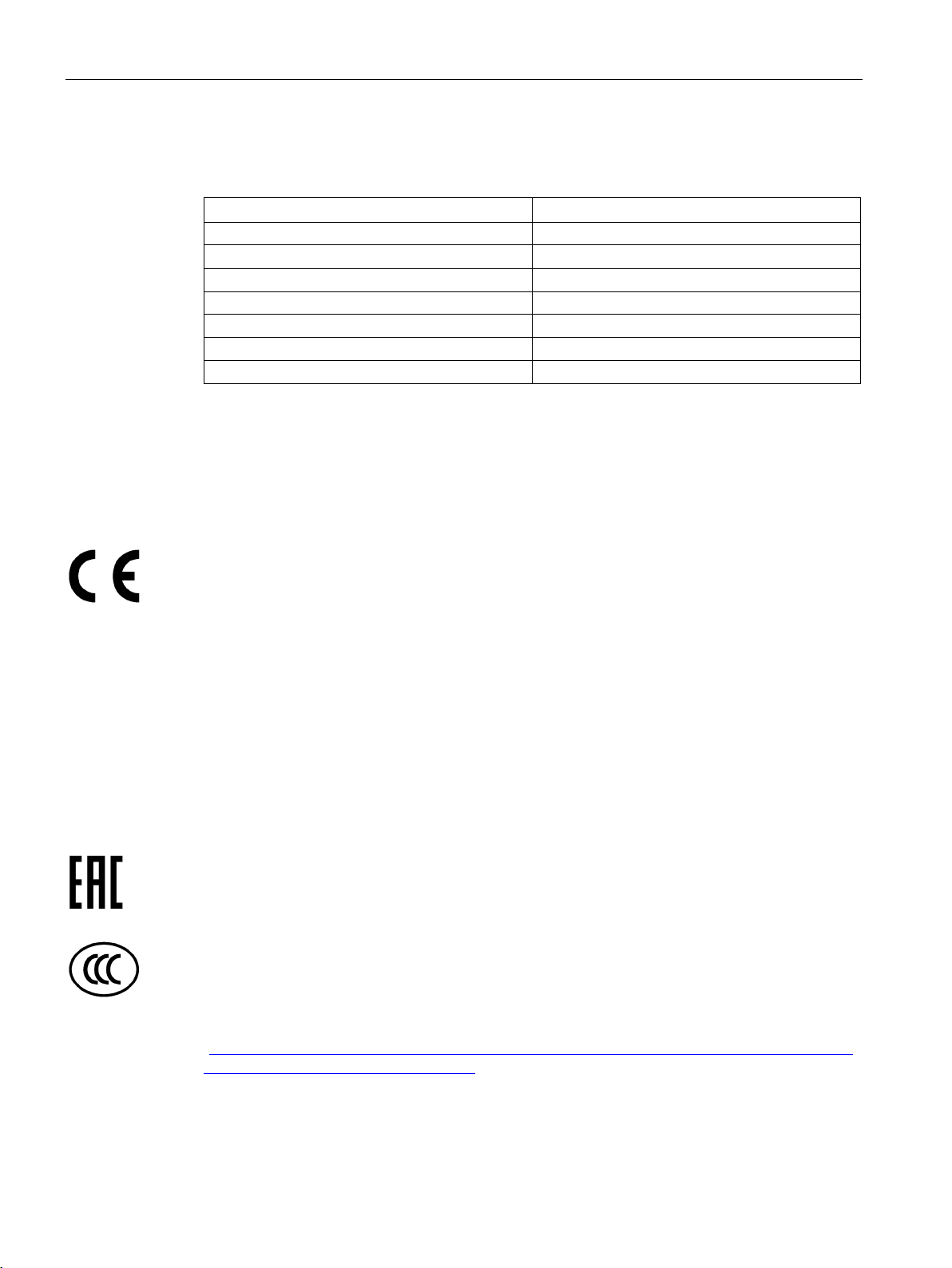

Description of the motor

Feature

Standard

Degree of protection

IEC / EN 60034-5

Type of construction

IEC / EN 60034-7

Noise levels 1)

IEC / EN 60034-9

Temperature monitoring

IEC / EN 60034-11

Vibration severity grades 1)

IEC / EN 60034-14

1)

Standard component, e.g. cannot be applied to built-in motors

Relevant directives

European Low-Voltage Directive

European Machinery Directive

European EMC Directive

Eurasian conformity

China Compulsory Certification

2.3 Technical features and environmental conditions

Where applicable, the SIMOTICS motor series are in conformance with the following parts of

IEC / EN 60034:

Cooling 1) IEC / EN 60034-6

Connection designations IEC / EN 60034-8

The following directives are relevant for SIMOTICS motors.

SIMOTICS motors comply with the Low-Voltage Directive 2014/35/EU.

SIMOTICS motors do not fall within the scope covered by the Machinery Directive.

However, the use of the products in a typical machine application has been fully assessed

for compliance with the main regulations in this directive concerning health and safety.

SIMOTICS motors do not fall within the scope covered by the EMC Directive. The products

are not considered as devices in the sense of the directive. Installed and operated with a

converter, the motor – together with the Power Drive System – must comply with the

requirements laid down in the applicable EMC Directive.

SIMOTICS motors comply with the requirements of the Russia/Belarus/Kazakhstan (EAC)

customs union.

SIMOTICS motors do not fall within the scope covered by the China Compulsory

Certification (CCC).

CCC negative certification:

CCC product certification

(https://support.industry.siemens.com/cs/products?search=CCC&dtp=Certificate&mfn=ps&o

=DefaultRankingDesc&pnid=13347&lc)

1FN3 linear motors

28 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 31

Description of the motor

Underwriters Laboratories

Quality systems

European RoHS Directive

European Directive on Waste Electrical and Electronic Equipment (WEEE)

2.3.2

Danger from strong magnetic fields

Occurrence of magnetic fields

2.3 Technical features and environmental conditions

SIMOTICS motors are generally in compliance with UL and cUL as components of motor

applications, and are appropriately listed.

Specifically developed motors and functions are the exceptions in this case. Here, it is

important that you carefully observe the contents of the quotation and that there is a cUL

mark on the rating plate!

Siemens AG employs a quality management system that meets the requirements of

ISO 9001 and ISO 14001.

Certificates for SIMOTICS motors can be downloaded from the Internet at the following link:

Certificates for SIMOTICS motors

(https://support.industry.siemens.com/cs/ww/de/ps/13347/cert)

The SIMOTICS motor series complies with the Directive 2011/65/EU regarding limiting the

use of certain hazardous substances.

The SIMOTICS motor series complies with the 2012/19/EU directive on taking back and

recycling waste electrical and electronic equipment.

Motor components with permanent magnets generate very strong magnetic fields. In the

no-current condition, the magnetic field strength of the motors comes exclusively from the

magnetic fields of components equipped with permanent magnets. Additional

electromagnetic fields occur in operation.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

29

Page 32

Description of the motor

Components with permanent magnets

2.3 Technical features and environmental conditions

For the linear motors described in this manual, the permanent magnets are in the secondary

sections.

Figure 2-1 Secondary section with permanent magnets

Figure 2-2 Schematic representation of the static magnetic field of a secondary section, depending

on distance

1FN3 linear motors

30 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 33

Description of the motor

Risk to persons as a result of strong magnetic fields

WARNING

Risk of death as a result of permanent magnet fields

CAUTION

Handling secondary sections

WARNING

Risk of electric shock

2.3 Technical features and environmental conditions

Even when the motor is switched off, the permanent magnets can put people with active

medical implants at risk if they are close to the motor.

Examples of active medical implants include: Heart pacemakers, insulin pumps.

• As the affected person, maintain a minimum distance of 500 mm from the permanent

magnets (trigger threshold for static magnetic fields of 0.5 mT as per directive

2013/35/EU).

With regard to the effect of strong magnetic fields on people, the DGUV rule 103-013

"Electromagnetic Fields" of the German Social Accident Insurance applies in Germany.

This rule specifies all the requirements that must be observed in the workplace. In other

countries, the relevant applicable national and local regulations and requirements must be

taken into account.

When dealing with magnetic fields, you must consider the requirements of DGUV rule

103-013 of the German Social Accident Insurance.

The magnetic fields of the secondary sections are permanent. When you come into direct

bodily contact with the secondary sections, a static magnetic flux density of 2 T is not

exceeded.

• Observe DGUV rule 103-013, § 14 "Systems with high static magnetic fields".

Voltage is induced at the power connections of the primary section each time a primary

section moves with respect to a secondary section – and vice versa. If you touch the power

connections you may suffer an electric shock.

• Do not touch the power connections.

• Connect the motor cable ports correctly, or insulate them properly.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

31

Page 34

Description of the motor

WARNING

Danger of crushing by permanent magnets of the secondary section

made of solid, non-magnetizable material (e.g. hard wood).

2.3 Technical features and environmental conditions

The forces of attraction of magnetic secondary sections act on materials that can be

magnetized. The forces of attraction increase significantly close to the secondary section.

The trigger threshold of 3 mT for a risk of injury due to attraction and projectile effect is

reached at a distance of 150 mm (directive 2013/35/EU). Secondary sections and materials

that can be magnetized can suddenly slam together unintentionally. Two secondary

sections can also unintentionally slam together.

There is a significant risk of crushing when you are close to a secondary section.

Close to the secondary section, the forces of attraction can be several kN - example:

Magnetic attractive forces are equivalent to a force of 100 kg, which is sufficient to trap a

body part.

• Do not underestimate the strength of the attractive forces, and work very carefully.

• Wear safety gloves.

• The work should be done by at least two people.

• Do not unpack the secondary section until immediately before assembly.

• Never unpack several secondary sections at the same time.

• Never place secondary sections next to one another without taking the appropriate

precautions.

• Never place any metals on magnetic surfaces and vice versa.

• Never carry any objects made of magnetizable materials (for example watches, steel or

iron tools) and/or permanent magnets close to the secondary section! If tools that can

be magnetized are nevertheless required, then hold the tool firmly using both hands.

Slowly bring the tool to the secondary section.

• Immediately mount the secondary section that has just been unpacked.

• Always comply with the specified procedure.

• Avoid inadvertently traversing direct drives.

• Keep the following tools at hand to release parts of the body (hand, fingers, foot etc.)

trapped between two components:

– A hammer (about 3 kg) made of solid, non-magnetizable material

– Two pointed wedges (wedge angle approx. 10° to 15°, minimum height 50 mm)

1FN3 linear motors

32 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 35

Description of the motor

First aid in the case of accidents involving permanent magnets

Material damage caused by strong magnetic fields

NOTICE

Data loss caused by strong magnetic fields

2.3 Technical features and environmental conditions

● Stay calm.

● If the machine is energized, press the emergency stop switch and open the main switch if

necessary.

● Administer FIRST AID. Call for further help if required.

● To free jammed parts of the body (e.g. hands, fingers, feet), pull apart components that

are clamped together.

– Do this using the non-magnetic hammer to drive the non-magnetic wedges into the

separating rift.

– Release the jammed body parts.

● If necessary, call the emergency medical service or an emergency physician.

If you are close to a secondary section (< 150 mm) any magnetic or electronic data medium

as well as electronic devices that you are carrying can be destroyed. For example, credit

cards, USB sticks, floppy disks and watches are at risk.

• Do not carry any magnetic/electronic data media and no electronic devices when you

are close to a secondary section!

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

33

Page 36

Description of the motor

2.3.3

Technical features

Technical feature

Design

Motor type

Permanently excited synchronous linear motor

(according to DIN 44081/44082)

(according to EN 60751)

2nd rating plate

Enclosed separately

sections

EN 60034-1

(IEC 60034-18-41)

1FN3100-xW ... 1FN3900-xW

2.3 Technical features and environmental conditions

Table 2- 1 Standard version of the 1FN3 range of motors: Technical features

Type of construction Individual components

Degree of protection

according to EN 60034-5

Cooling method Water cooling

Thermal motor protection In the primary section:

• Primary section: IP65

• Mounted motor: The degree of protection depends on the

machine design and must therefore be realized by the machine

manufacturer; minimum requirement: IP23

• Maximum pressure in the cooling circuit: 10 bar = 1 MPa

• Wiring: with G1/8 pipe thread (in compliance with

DIN EN ISO 228-1); special connectors are required to connect

hoses/pipes

1x PTC for thermistor triplet with response threshold +120 °C

Temperature monitoring In the primary section:

1FN3xxx-xxxxx-xxx1 with 1 x KTY 84

(according to EN 60034-11)

1FN3xxx-xxxxx-xxx3 with 1 x Pt1000

Nameplate for secondary

Insulation class of motor

winding according to

Impulse withstand voltage

insulation class according to

EN 60034-18-41

Magnet material Rare earth material

Connection, electrical 1FN3050:

Enclosed separately

Temperature class 155 (F)

IVIC: C

Signal and power cables with connectors or open core ends

permanently connected to the motor

1FN3100 ... 1FN3900:

Terminal panel with cover integrated in the motor, with metric cable

glands for signal and power cables. Additional cover with heavygauge threaded joint for combined cables for

Encoder system

1FN3 linear motors

34 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

• Not included in the scope of supply

• Selection based on application-specific and converter-specific

constraints

Page 37

Description of the motor

2.3.4

Direction of motion of the motor

Defining the traversing direction

2.3 Technical features and environmental conditions

If the primary section is connected to the terminals of the terminal box with the phase

sequence U-V-W and is supplied with current by a three-phase system with a clockwise

rotating field, the direction of motion of the primary or secondary section is positive.

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

35

Page 38

Description of the motor

2.3.5

Ambient conditions for stationary use

Ambient conditions are based on climate class 3K3

Ambient parameter

Unit

Value

a)

Low air temperature

°C

- 5

c)

Low relative humidity

%

5

d)

High relative humidity

%

85

e)

Low absolute humidity

g/m3

1

f)

High absolute humidity

g/m3

25

g)

Rate of temperature change1)

°C/min

0.5

h)

Low air pressure4)

kPa

78.4

i)

High air pressure2)

kPa

106

j)

Solar radiation (insolation)

W/m2

700

k)

Thermal radiation

-

-

l)

Air movement3)

m/s

1.0

m)

Condensation

-

Not permissible

(rain, snow, hail, etc.)

protection

p)

Formation of ice

-

-

1)

2)

3)

4)

The limit value of 78.4 KPa covers altitudes up to 2000 m.

Mechanical ambient conditions

Class 3M3

2.3 Technical features and environmental conditions

You can classify the ambient conditions for stationary use at weatherprotected locations

according to the standard DIN IEC 60721-3-3. The environmental effects and their limit

values are defined in various classes in this standard.

With the exception of "Low air temperature" and "Low air pressure" ambient parameters,

you can assign the motors to climatic class 3K3.

Table 2- 2

b) High air temperature °C + 40

n) Wind-driven precipitation

o) Water (other than rain) - See degree of

- -

Averaged over a period of 5 min

Conditions in mines are not considered.

A cooling system based on natural convection can be disturbed by unforeseen air movements.

Additional ambient conditions applicable for the motors for stationary use at weatherprotected locations according to standard DIN IEC 60721-3-3 include.

Mechanically active ambient conditions Class 3S1

1FN3 linear motors

36 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 39

Description of the motor

Note

Installation instructions

The motors are not suitable for operation

•

•

2.3.6

Scope of delivery

2.3.6.1

Scope of delivery linear motor

Primary section

Secondary section

Note

Nameplates for secondary sections

The

or to the secondary section cover. Apply the nameplates for secondary sections in a clearly

visible position next to the secondary section track or in the vicinity of t

2.3 Technical features and environmental conditions

In salt-laden or corrosive atmospheres

Outdoors

You can find additional data on the environmental conditions, such as ambient temperatures

or conditions for transport and storage of the motors, in the relevant chapters of this

documentation.

● Primary section

● One rating plate (attached); additional loose rating plate

● Accessory pack note (safety accessory pack)

● Safety warning instructions (pictograms)

● For the terminal box design: Accessories (mounting accessories) for the terminal box with

● Secondary section

● A nameplate included as a separate item

● Accessory pack note (safety accessory pack)

● Safety warning instructions (pictograms)

terminal cover and enclosed information slip with terminal assignments

nameplates for secondary sections are not suitable for applying to a secondary section

1FN3 linear motors

Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

he motor.

37

Page 40

Description of the motor

2.3.6.2

Supplied pictograms

Primary sections

Sign

Meaning

Sign

Meaning

Sign

Meaning

Sign

Meaning

Secondary sections

Sign

Meaning

Sign

Meaning

2.3 Technical features and environmental conditions

To identify hazards, warning signs in the form of permanent adhesive stickers are enclosed

with all primary sections in the packaging:

Table 2- 3 Warning signs included with primary sections according to BGV A8 and EN ISO 7010

and their meaning

Warning against

hot surface

(W017)

Warning against

electric voltage

(W012)

The following safety instructions are attached at the signal port of the primary section:

Table 2- 4 Safety instructions for temperature protection according to BGV A8 and EN ISO 7010

and their significance

General

warning sign

(W001)

Observe

instruction

(M002)

To identify hazards, warning and prohibition signs in the form of permanent adhesive stickers

are enclosed with all secondary sections in the packaging:

Table 2- 5 Warning signs according to BGV A8 and EN ISO 7010 included with secondary sections

and their meaning

Warning: strong

magnetic field

(W006)

Warning:

hand injuries

(W024)

1FN3 linear motors

38 Configuration Manual, 10/2018, 6SN1197-0AB86-0BP2

Page 41

Description of the motor

Sign

Meaning

Sign

Meaning

Note

Applying the stickers

The stickers are not suitable for applying to a secondary section or on the secondary section

cover.

•

Note

The quality of the label can diminish as result of extreme environmental conditions.

2.3 Technical features and environmental conditions

Table 2- 6 Prohibiting signs according to BGV A8 and EN ISO 7010 included with secondary