Page 1

www.siemens.com/drives

Operating Instructions

Installation Instructions

Electric motor

SIMOTICS HV M

Type 1RN76308PR900CG0-Z

Edition 07/2018

Page 2

03.07.2018 13:28

V3.00

Page 3

Electric motor

SIMOTICS HV M

Type 1RN76308PR900CG0-Z

Introduction

1

Operating Instructions

Installation Instructions

Safety information

Description

Preparations for use

Assembly

Electrical connection

Commissioning

Operation

2

3

4

5

6

7

8

Maintenance

Spare parts

Disposal

Service and Support

Technical data and drawings

Quality documents

Additional documents

9

10

11

A

B

C

D

Edition 07/2018

Page 4

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: MUSTER

Ⓟ 07/2018 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Page 5

Table of contents

1 Introduction.................................................................................................................................................11

1.1 About these instructions.........................................................................................................11

1.2 Compiling personal documents..............................................................................................12

2 Safety information.......................................................................................................................................13

2.1 Information for those responsible for the plant.......................................................................13

2.2 The five safety rules...............................................................................................................13

2.3 Qualified personnel................................................................................................................14

2.4 Safe handling.........................................................................................................................14

2.5 Electrostatic sensitive devices...............................................................................................16

2.6 Interference immunity.............................................................................................................17

2.7 Electromagnetic fields when operating electrical power engineering installations.................17

3 Description..................................................................................................................................................19

4 Preparations for use...................................................................................................................................23

4.1 Safety-related aspects to consider when configuring the plant..............................................23

4.2 Observing the operating mode...............................................................................................23

4.3 Cooling water quality..............................................................................................................23

4.4 Insufficient cooling water quality............................................................................................24

4.5 Interlock circuit for the external fan motor..............................................................................24

4.6 Interlock circuit for anti-condensation heating........................................................................25

4.7 Space requirements...............................................................................................................25

4.8 Noise emission.......................................................................................................................25

4.9 Voltage and frequency fluctuations during line operation......................................................25

4.10 Phase synchronization during supply system switching........................................................26

4.11 System-inherent frequencies.................................................................................................26

4.12 Torsional loading of the shaft assembly.................................................................................26

4.13 Switching high-voltage motors...............................................................................................26

4.14 Thermal protection ................................................................................................................27

4.15 Transport and storage............................................................................................................27

4.15.1 Transport markings................................................................................................................27

4.15.2 Checking the delivery.............................................................................................................28

4.15.3 Checking the load handling attachments...............................................................................28

4.15.4 Lifting and transportation........................................................................................................29

4.15.5 Storage...................................................................................................................................32

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 5

Page 6

Table of contents

4.15.6 Protection against corrosion...................................................................................................34

4.15.7 Protecting the cooling water circuit during storage................................................................34

4.16 Converter operation...............................................................................................................35

4.16.1 Rotational speed limit values.................................................................................................35

4.16.2 Insulated bearings when operating the converter..................................................................36

4.16.3 Reducing bearing currents.....................................................................................................38

5 Assembly....................................................................................................................................................39

5.1 Preparations for installation....................................................................................................39

5.1.1 Requirements for installation..................................................................................................39

5.1.2 Parts delivery.........................................................................................................................40

5.1.3 Insulation resistance and polarization index..........................................................................40

5.1.4 Testing the insulation resistance and polarization index........................................................41

5.1.5 Preparing the mating faces....................................................................................................44

5.1.6 Do not bridge the bearing insulation......................................................................................44

5.2 Lift the machine to where it will be installed, and position it...................................................45

5.2.1 Checking the load handling attachments...............................................................................45

5.2.2 Preconditions for correct alignment and secure attachment .................................................45

5.2.3 Removing anti-corrosion protection.......................................................................................45

5.2.4 Mounting the output elements................................................................................................47

5.2.5 Lifting and transportation........................................................................................................48

5.2.6 Putting the machine down......................................................................................................50

5.2.7 Draining condensation...........................................................................................................51

5.2.8 Roughly aligning the machine................................................................................................51

5.3 Installing the machine............................................................................................................52

5.3.1 Safety instructions for installation...........................................................................................52

5.3.2 Selecting bolts........................................................................................................................53

5.3.3 Preconditions for smooth, vibration-free operation................................................................53

5.3.4 Aligning and attaching the machine to the driven machine....................................................53

5.4 Connecting the supply lines...................................................................................................55

5.4.1 Surfaces for mounted parts or cable fixing elements.............................................................55

5.4.2 Connecting the cooling water supply.....................................................................................55

5.5 Complete the installation work...............................................................................................57

6 Electrical connection...................................................................................................................................59

6.1 Preparation.............................................................................................................................59

6.1.1 Selecting cables.....................................................................................................................59

6.1.2 Route the cable with an appropriate loop so that water can drip off......................................60

6.1.3 Terminal designation..............................................................................................................60

6.1.4 Terminal box..........................................................................................................................61

6.1.5 Connecting the grounding conductor.....................................................................................61

6.1.6 Radio-frequency grounding for converter operation...............................................................62

6.2 Inserting and routing the cables.............................................................................................63

6.2.1 Connecting the machine for a specific direction of rotation....................................................63

6.2.2 Inserting the cable into the terminal box................................................................................63

6.2.3 Connecting cables with cable lugs.........................................................................................64

6.2.4 Minimum air clearances.........................................................................................................64

6.2.5 Connecting aluminum conductors..........................................................................................65

6.2.6 Internal equipotential bonding................................................................................................65

SIMOTICS HV M 1RN76308PR900CG0-Z

6 Operating Instructions 07/2018

Page 7

Table of contents

6.2.7 Stepless mating face for sealing in the terminal box cover....................................................65

6.2.8 Performing connection operations.........................................................................................66

6.3 Connecting the auxiliary circuits.............................................................................................66

6.3.1 Selecting cables.....................................................................................................................66

6.3.2 Bringing cables into the auxiliary terminal box and routing them...........................................67

6.3.3 Degree of protection of the auxiliary terminal box..................................................................67

6.3.4 Connecting an external fan motor..........................................................................................68

6.3.5 Connecting temperature monitoring for the stator winding....................................................68

6.3.6 Internal equipotential bonding in the auxiliary terminal box...................................................69

6.3.7 Terminating the connection work (auxiliary circuit)................................................................70

7 Commissioning...........................................................................................................................................71

7.1 Prior to commissioning ..........................................................................................................71

7.2 Commissioning an external fan..............................................................................................73

7.3 Greasing the roller bearings prior to commissioning..............................................................73

7.4 Overvoltages when switching high-voltage motors................................................................74

7.5 Test run..................................................................................................................................75

8 Operation....................................................................................................................................................77

8.1 Safety instructions in operation..............................................................................................77

8.2 Switching on with the anti-condensation heating active.........................................................78

8.3 Switching on the machine......................................................................................................79

8.4 Regreasing roller bearings.....................................................................................................79

8.5 Switching off...........................................................................................................................79

8.6 Switching off...........................................................................................................................79

8.7 Switching on again after an emergency switching-off............................................................80

8.8 Stoppages..............................................................................................................................80

8.8.1 Avoidance of condensation or formation of condensation within the machine.......................80

8.8.2 Avoidance of frost and corrosion damage to the air-to-water heat exchanger.......................80

8.8.3 Avoidance of damage to roller bearings during stoppages....................................................81

8.8.4 Measuring the insulation resistance after an extended stoppage..........................................81

8.9 Decommissioning the machine..............................................................................................82

8.10 Re-commissioning the machine.............................................................................................82

8.11 Faults.....................................................................................................................................82

8.11.1 Inspections in the event of faults............................................................................................82

8.11.2 Electrical faults.......................................................................................................................83

8.11.3 Mechanical faults...................................................................................................................83

8.11.4 Roller bearing faults...............................................................................................................84

8.11.5 Cooling system faults.............................................................................................................85

8.11.6 Cooling system faults.............................................................................................................85

9 Maintenance...............................................................................................................................................87

9.1 Inspection and maintenance..................................................................................................87

9.1.1 Safety instructions for inspection and maintenance...............................................................87

9.1.2 Inspections in the event of faults............................................................................................88

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 7

Page 8

Table of contents

9.1.3 First service after installation or repair...................................................................................89

9.1.4 General inspection.................................................................................................................90

9.1.5 Servicing the air-to-water heat exchanger.............................................................................90

9.1.6 Assessing the roller bearings.................................................................................................91

9.1.7 Regreasing intervals and types of grease for operating roller bearings.................................91

9.1.8 Removing spent grease.........................................................................................................94

9.1.9 Cleaning cooling air ducts and passages...............................................................................95

9.1.10 Cleaning the air-to-water heat exchanger..............................................................................95

9.1.11 Servicing the external fan.......................................................................................................95

9.1.12 Maintaining the anti-condensation heating.............................................................................96

9.1.13 Maintaining terminal boxes....................................................................................................96

9.1.14 Measuring the insulation resistance during the course of maintenance work........................97

9.1.15 Touch up any damaged paintwork.........................................................................................97

9.2 Corrective Maintenance.........................................................................................................98

9.2.1 Prepare servicing work...........................................................................................................98

9.2.2 Top enclosure........................................................................................................................99

9.2.2.1 Air-to-water heat exchanger...................................................................................................99

9.2.2.2 Removing the top enclosure................................................................................................100

9.2.2.3 Mounting the top enclosure..................................................................................................101

9.2.3 Roller bearings.....................................................................................................................102

9.2.3.1 Removing roller bearings.....................................................................................................102

9.2.3.2 Removing the labyrinth sealing ring.....................................................................................103

9.2.3.3 Remove V ring for roller bearing seal...................................................................................104

9.2.3.4 Installing the labyrinth sealing ring.......................................................................................105

9.2.3.5 Fitting V ring for roller bearing seal......................................................................................105

9.2.3.6 Installing felt rings for the inner bearing seal........................................................................106

9.2.4 Seal the motor......................................................................................................................107

10 Spare parts...............................................................................................................................................109

10.1 Ordering data.......................................................................................................................109

10.2 Ordering spare parts via the Internet...................................................................................110

10.3 Stator and rotor....................................................................................................................111

10.4 Top enclosure......................................................................................................................112

10.5 Roller bearings, DE..............................................................................................................113

10.6 Roller bearings, NDE...........................................................................................................114

10.7 Main terminal box, type 9-103A 732.60...............................................................................115

10.8 Auxiliary terminal box 1XB9014...........................................................................................116

11 Disposal....................................................................................................................................................117

11.1 RoHS - restricting the use of certain hazardous substances...............................................117

11.2 Preparing for disassembly....................................................................................................117

11.3 Dismantling the machine......................................................................................................118

11.4 Disposal of components.......................................................................................................118

SIMOTICS HV M 1RN76308PR900CG0-Z

8 Operating Instructions 07/2018

Page 9

Table of contents

A Service and Support.................................................................................................................................121

B Technical data and drawings....................................................................................................................123

B.1 Tightening torques for screw and bolt connections..............................................................123

B.2 Maximum weights of the coupling........................................................................................124

C Quality documents....................................................................................................................................127

D Additional documents...............................................................................................................................129

Index.........................................................................................................................................................131

Tables

Table 3-1 Machine design ..........................................................................................................................19

Table 3-2 Machine version with type of protection Ex ec or Ex nA ............................................................20

Table 4-1 Power limits.................................................................................................................................27

Table 5-1 Stator winding insulation resistance at 40° C..............................................................................42

Table 6-1 Terminal designations using the 1U1-1 as an example..............................................................60

Table 6-2 Determining the cross-section of the grounding conductor.........................................................61

Table 6-3 Minimum air clearances..............................................................................................................64

Table 8-1 Electrical faults .......................................................................................................................83

Table 8-2 Mechanical faults .....................................................................................................................83

Table 8-3 Rolling bearing faults ..............................................................................................................84

Table 8-4 Cooling system faults ...............................................................................................................85

Table 8-5 Cooling system faults .............................................................................................................85

Table 9-1 Criteria for selecting roller bearing greases.................................................................................91

Table 9-2 Roller bearing greases for vertical and horizontal types of construction ....................................92

Table 9-3 Alternative greases with NLGI class 2 for motors of horizontal construction..............................93

Table 10-1 Spare parts for the stator and rotor...........................................................................................111

Table 10-2 Spare parts for the top enclosure..............................................................................................112

Table 10-3 Spare parts for roller bearings, DE............................................................................................113

Table 10-4 Spare parts for roller bearings, NDE.........................................................................................114

Table B-1 Tightening torques for bolted connections with a tolerance of ±10%........................................123

Figures

Figure 4-1 Rotor transport lock with two screws in the bearing housing......................................................31

Figure 4-2 Schematic representation of a single drive.................................................................................36

Figure 4-3 Schematic representation of a tandem drive...............................................................................37

Figure 5-1 Balancing type on the drive-end side..........................................................................................47

Figure 5-2 Schematic representation of alignment of the machine to the driven machine...........................54

Figure 5-3 Areas for mounting parts.............................................................................................................55

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 9

Page 10

Table of contents

Figure 6-1 Water drip loop............................................................................................................................60

Figure 6-2 High-frequency grounding...........................................................................................................62

Figure 9-1 Top enclosure fastening ...........................................................................................................101

Figure 9-2 Mounting the top enclosure.......................................................................................................102

Figure 9-3 Dismantling the labyrinth ring....................................................................................................104

Figure 9-4 Remove the V ring.....................................................................................................................104

Figure 9-5 Position the set screws for the labyrinth sealing ring on the outer bearing cover.....................105

Figure 9-6 Install the V ring.........................................................................................................................106

Figure 10-1 Stator and rotor.........................................................................................................................111

Figure 10-2 Top enclosure............................................................................................................................112

Figure 10-3 Roller bearings, DE...................................................................................................................113

Figure 10-4 Roller bearings, NDE.................................................................................................................114

Figure 10-5 Terminal box 9-103A 732.60.....................................................................................................115

Figure 10-6 Auxiliary terminal box 1XB9014 .............................................................................................116

SIMOTICS HV M 1RN76308PR900CG0-Z

10 Operating Instructions 07/2018

Page 11

Introduction

In the following text, the motor is referred to as "electrical machine" – or abbreviated, just

"machine".

1.1 About these instructions

These instructions describe the machine and explain how to handle it, from initial delivery to

final disposal of the equipment. Keep these instructions for later use.

Read these operating instructions before you handle the machine and follow the instructions

to become familiar with its design and operating principles and thus ensure safe, problem-free

machine operation and long service life.

Please contact the Service Center (Page 121) if you have any suggestions on how to improve

this document.

Machine-specific data

Technical data for the machine and all of the necessary drawings, documents for verifying the

qualitative implementation of the machine and, where relevant, additional documents on the

components, are provided in the separate Appendixes to the Operating Instructions.

1

● Technical data and drawings

● Quality documents

● Additional documents

Text format features

The warning notice system is explained on the rear of the inside front. Carefully comply with

all of the safety-relevant information in these instructions and attached to the product itself.

In addition, you will find the following text format features in these instructions:

1. Handling instructions are always formatted as a numbered list. Always perform the steps

● Lists are formatted as bulleted lists.

Note

The note provides you with additional information about the product itself, handling the product

- and the relevant documentation.

in the order given.

– Lists on the second level are hyphenated.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 11

Page 12

Introduction

1.2 Compiling personal documents

1.2 Compiling personal documents

On the Internet pages in Industry Online Support you have the possibility of compiling personal

documents using the function Documentation (https://support.industry.siemens.com/My/ww/

en/documentation)

Using the "Documentation" function, from Product Support manuals, you can compile your

own "Documentation". However, you can also include other Product Support content such as

FAQs or characteristics in the documentation that you compile.

In the "Documentation" function, you have the option of creating your own compiled documents

in your own structure and managing them. You can delete or shift individual chapters or topics.

Further, using the note function you can import your own content. The compiled

"documentation" can be exported as PDF, for example.

Using the "Documentation" function, you can efficiently compile your own plant or system

documentation. The "Documentation" compiled in a specific language can also be

automatically exported in one of the other available languages.

The full functionality is only available for registered users.

SIMOTICS HV M 1RN76308PR900CG0-Z

12 Operating Instructions 07/2018

Page 13

Safety information

2.1 Information for those responsible for the plant

This machine has been designed for use in industrial plants in accordance with Directive

2006/42/EC ("Machinery Directive"). Commissioning in the European Community is forbidden

until the plant into which the machine will be installed has been shown to conform with this

directive. Please observe the country-specific regulations when using the machine outside the

European Community.

Follow the local and industry-specific safety and setup regulations.

The persons responsible for the plant must ensure the following:

● Planning and configuration work and all work carried out on and with the machine is only

to be done by qualified personnel.

● The operating instructions must always be available for all work.

● The technical data as well as the permissible installation, connection and operating

conditions are always consequentially taken into account.

● The specific setup and safety regulations as well as regulations on the use of personal

protective equipment are observed.

Note

2

Use the services and support provided by the local service center (Page 121) for planning,

installation, commissioning and service work.

In the individual chapters of this document, you will find warning and safety instructions that

must be observed without fail, for your own safety, to protect other people and to avoid material

damage.

Observe the following safety instructions for all activities on and with the machine.

2.2 The five safety rules

For your own personal safety and to prevent material damage when carrying out any work,

always observe the safety-relevant instructions and the following five safety rules according

to EN 50110‑1 "Working in a voltage-free state". Apply the five safety rules in the sequence

stated before starting work.

Five safety rules

1. Disconnect the system.

Also disconnect the auxiliary circuits, for example, anti-condensation heating.

2. Secure against reconnection.

3. Verify absence of operating voltage.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 13

Page 14

Safety information

2.3 Qualified personnel

4. Ground and short-circuit.

5. Provide protection against adjacent live parts.

To energize the system, apply the measures in reverse order.

2.3 Qualified personnel

All work at the machine must be carried out by qualified personnel only. For the purpose of

this documentation, qualified personnel is taken to mean people who fulfill the following

requirements:

● Through appropriate training and experience, they are able to recognize and avoid risks

and potential dangers in their particular field of activity.

● They have been instructed to carry out work on the machine by the appropriate person

responsible.

2.4 Safe handling

Workplace safety depends on the attentiveness, care, and common sense of the personnel

who install, operate, and maintain the machine. In addition to the safety measures cited, as a

matter of principle, the use of caution is necessary when you are near the machine. Always

pay attention to your safety.

Also observe the following to prevent accidents:

● General safety regulations applicable in the country where the machine is deployed.

● Manufacturer-specific and application-specific regulations

● Special agreements made with the operator

● Separate safety instructions supplied with the machine

● Safety symbols and instructions on the machine and its packaging

WARNING

Live parts

Electric machines contain live parts.

Fatal or severe injuries and substantial material damage can occur if the covers are removed

or if the machine is not handled, operated, or maintained properly.

● Always observe the “five safety rules" (Page 13) when carrying out any work on the

machine.

● Only remove covers in the manner described in the operating instructions.

● Operate the machine properly.

● Regularly and professionally maintain the machine according to the instructions provided

in the "Maintenance" (Page 87) chapter of the operating instructions.

SIMOTICS HV M 1RN76308PR900CG0-Z

14 Operating Instructions 07/2018

Page 15

Safety information

2.4 Safe handling

WARNING

Rotating parts

Electric machines contain dangerous rotating parts.

Fatal or severe injuries and substantial material damage can occur if the covers are removed

or if the machine is not handled, operated, or maintained properly.

● Only remove the covers using the methods described by these operating instructions.

● Operate the machine properly.

● Regularly and correctly maintain the machine.

● Secure free shaft extensions and other rotating part such as couplings and pulley belts

so that they cannot be touched.

WARNING

Hot surfaces

Electric machines have hot surfaces. Touching hot surfaces can result in severe burns.

● Allow the machine to cool before starting work on the machine.

● Only remove the covers using the methods described by these operating instructions.

● Operate the machine properly.

CAUTION

Hazardous substances

Chemical substances required for the setup, operation and maintenance of machines can

present a health risk.

● Read the information in these operating instructions and the product information supplied

by the manufacturer.

● Observe the relevant safety regulations and wear the personal protective equipment

specified.

CAUTION

Flammable substances

Chemical substances required for the setup, operation and maintenance of machines may

be flammable.

Burns and other damage to health and material may result.

● Read the information in these operating instructions and the product information supplied

by the manufacturer.

● Observe the relevant safety regulations and wear the personal protective equipment

specified.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 15

Page 16

Safety information

2.5 Electrostatic sensitive devices

WARNING

Noise emissions

During operation, the machine's noise emission levels can exceed those permitted at the

workplace, which can cause hearing damage.

Take steps to reduce noise, such as introducing covers and protective insulation or adopting

hearing protection measures, so that the machine can be operated safely within your system.

2.5 Electrostatic sensitive devices

Material damage due to electrostatic discharge

Electronic modules contain components that can be destroyed by electrostatic discharge.

These components can be damaged or destroyed if they are not handled correctly. To protect

equipment against damage, follow the instructions given below.

● Only touch electronic modules if you absolutely have to work on them.

● The body of the person concerned must have been electrostatically discharged and

grounded immediately before any electronic modules are touched.

● Electronic modules should not be brought into contact with electrically insulating materials,

such as:

– Plastic film

– Plastic parts

– Insulating table supports

– Clothing made of synthetic fibers

● Always place electrostatic sensitive devices on conductive bases.

● Always pack, store and transport electronic modules or components in conductive

packaging, such as:

– Metallized plastic or metal containers

– Conductive foam material

– Domestic aluminum foil

SIMOTICS HV M 1RN76308PR900CG0-Z

16 Operating Instructions 07/2018

Page 17

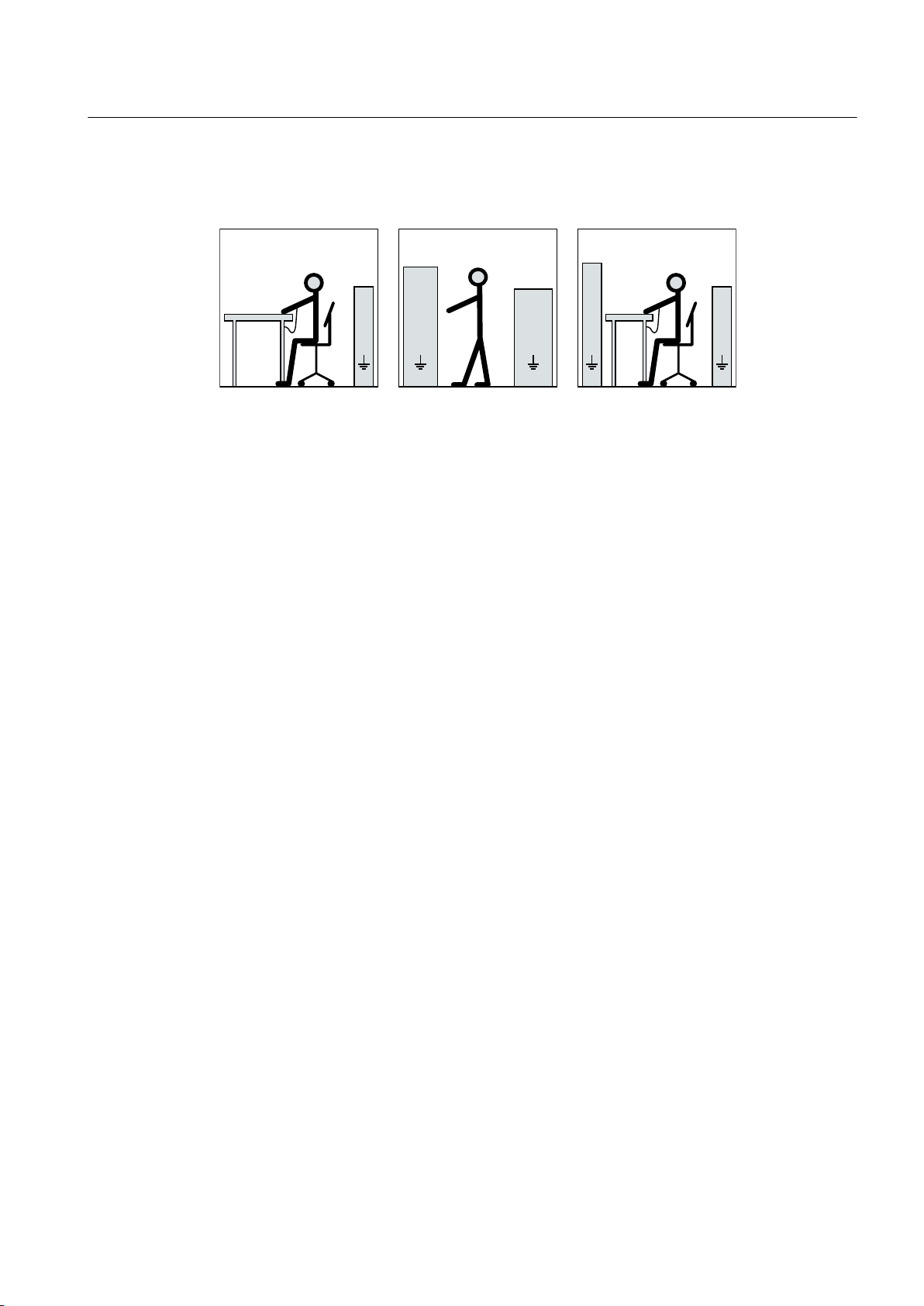

The necessary ESD protective measures for electrostatic sensitive devices are illustrated once

6HDWLQJSRVLWLRQ

6WDQGLQJSRVLWLRQ

6WDQGLQJVHDWLQJSRVLWLRQ

EE

D

F

D

IIIII

D

FF

H

GG

H

G

again in the following drawings:

a = conductive floor surfaceb = ESD table c = ESD shoes

d = ESD overall e = ESD wristband f = cabinet ground connection

2.6 Interference immunity

By selecting suitable signal cables and evaluation units, companies operating complete plants

and systems must ensure that the interference immunity of the machine is not diminished.

Safety information

2.6 Interference immunity

2.7 Electromagnetic fields when operating electrical power engineering installations

Interference to electronic devices caused by electrical power equipment

Electrical power equipment generate electric fields during operation. Potentially lethal

malfunctions can occur in medical implants, e.g. pacemakers, in the vicinity of electrical power

equipment. Data may be lost on magnetic or electronic data carriers.

● It is forbidden for people with pacemakers to enter the vicinity of the machine.

● Protect the personnel working in the plant by taking appropriate measures, such as erecting

identifying markings, safety barriers and warning signs and giving safety talks.

● Observe the nationally applicable health and safety regulations.

● Do not carry any magnetic or electronic data media.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 17

Page 18

Safety information

2.7 Electromagnetic fields when operating electrical power engineering installations

SIMOTICS HV M 1RN76308PR900CG0-Z

18 Operating Instructions 07/2018

Page 19

Description

Applications

3

This electrical machine is designed for driving rotating machines in industrial environments

and also for energy conversion. It is characterized by a high level of safety, long lifetime, and

overall reliability.

For details of the machine supplied and the permissible operating conditions, refer to the

"Technical data and drawings" (Page 123) section in the Appendix of these Operating

Instructions.

The machine was designed in accordance with the ordering party's specification and may only

be used for the contractually agreed purpose.

WARNING

Risk of explosion

This machine is not designed for use in hazardous areas. An explosion can occur if the

machine is operated in these areas. This can result in death, serious injury or material damage.

● Never operate this machine in hazardous areas.

Machine design

The regulations and standards used as the basis to design and test this machine are stamped

on the rating plate.

The machine design basically complies with the subsequent standards. Please refer to the EU

Declaration of Conformity for the versions of the harmonized standards referenced.

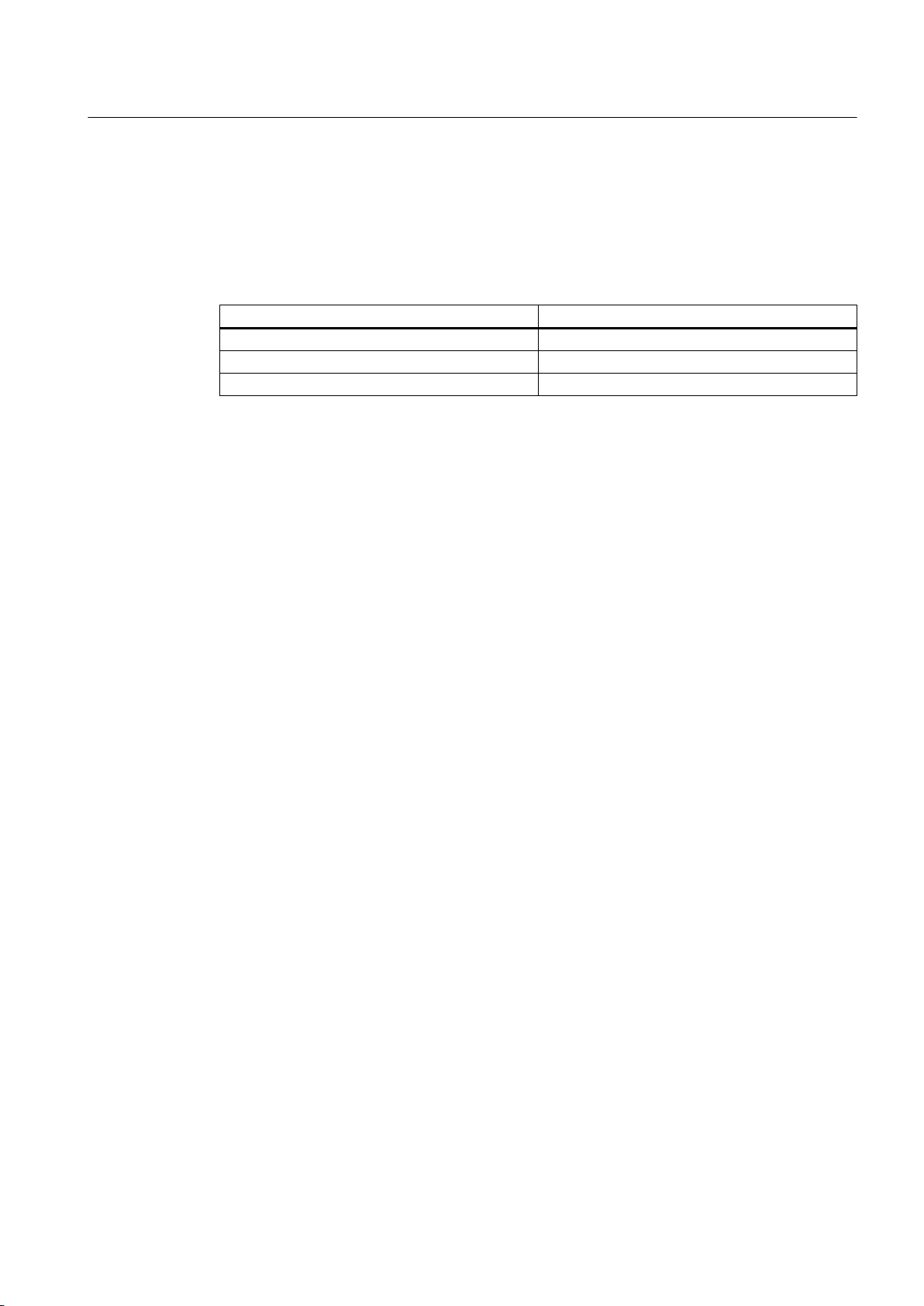

Table 3-1 Machine design

Feature Standard

Rating and performance IEC/EN 60034‑1

Degree of protection IEC/EN 60034‑5

Cooling IEC/EN 60034‑6

Type of construction IEC/EN 60034‑7

Terminal markings and direction of rotation IEC/EN 60034‑8

Noise emission IEC/EN 60034‑9

Starting characteristics, rotating electrical machines IEC/EN 60034‑12*

Vibration severity grades IEC/EN 60034‑14

Vibration limits DIN ISO 10816-3

* For machines in line operation only

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 19

Page 20

Description

See also

Rating plate

Rotor

Quality documents (Page 127)

Additionally, the following standards apply to these explosion-protected machines:

Table 3-2 Machine version with type of protection Ex ec or Ex nA

Characteristic Standard

Type of protection Ex ec (previously Ex nA) IEC / EN 60079‑0

IEC / EN 60079-7 (previously

-15)

The rating plate shows the identification data and the most important technical data. The data

on the rating plate and the contractual agreements define the limits of proper usage.

The rotor is designed as a squirrel-cage rotor. The number and design of the shaft extensions

are shown and described in the technical data.

Cooling

The cooling system is designed as a closed, internal cooling circuit. The mounted cooler is an

air-to-water heat exchanger with a pipe system. The heat lost from the machine is dissipated

via the surface of the cooling pipes to the cooling liquid flowing in the pipes. External fans

facilitate the circulation of the cooling air in the primary circuit.

External fan

The machine is fitted with an external fan. For IC 666, there are two external fans. The electrical

connection data are stamped on the rating plate of the external fan.

Supplementary devices

Temperature sensors are integrated in the stator winding to monitor the winding temperature.

Various supplementary devices can be integrated or mounted, depending on the order. These

include, for example, anti-condensation heating to prevent condensation or temperature

sensors for monitoring bearings.

See also

Technical data and drawings (Page 123)

SIMOTICS HV M 1RN76308PR900CG0-Z

20 Operating Instructions 07/2018

Page 21

Anti-condensation heating

The machine is fitted with anti-condensation heating. The connection data is listed on an

additional plate on the machine.

Paint finish

The machine is painted according to the instructions in your order.

Description

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 21

Page 22

Description

SIMOTICS HV M 1RN76308PR900CG0-Z

22 Operating Instructions 07/2018

Page 23

Preparations for use

Good planning and preparation of machine applications are essential in terms of keeping

installation simple and avoiding errors, ensuring safe operation, and allowing access to the

machine for servicing and corrective maintenance.

This chapter outlines what you need to consider when configuring your plant in relation to this

machine and the preparations you need to make before the machine is delivered.

4.1 Safety-related aspects to consider when configuring the plant

A number of residual risks are associated with the machine. These are described in the chapter

titled "Safety information" (Page 13) and in related sections.

Take appropriate safety precautions (covers, barriers, markings, etc.) to ensure the machine

is operated safely within your plant.

4.2 Observing the operating mode

Observe the machine's operating mode. Use a suitable control system to prevent overspeeds,

thus protecting the machine from damage.

4

4.3 Cooling water quality

● The specifications for the cooling water temperatures and cooling water quantities can be

found on the rating plate and in the Appendix "Technical data".

● In the case of a heat exchanger built for chemical purification (closed cooling-water circuit),

the cooling water quality recommended in the operating instructions provided by the

exchanger's manufacturer must be observed.

● For internally cooled motors, which are designed for pipe connection and/or operation with

separately driven/external fans. Connect the pipes and/or adequately dimensioned,

separately-driven/external fans with a suitable type of construction.

● Please refer to the operating instructions provided by the heat exchanger manufacturer

(Page 129).

See also

Technical data and drawings (Page 123)

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 23

Page 24

Preparations for use

4.4 Insufficient cooling water quality

4.4 Insufficient cooling water quality

NOTICE

Corrosion due to insufficient cooling water quality

The materials used in the cooler are selected to match the cooling water quality for which the

air-water cooler was ordered. The cooler cannot be simply used without taking any other

measures if other water conditions apply. If the cooling water quality is unsuitable, the air-towater heat exchanger may suffer corrosion and fail.

● The chemical composition of the cooling water must comply with the configuration

specifications.

● If the cooling water quality fails to satisfy the quality stated on the order, please contact

the Service Center.

● Please observe the recommended water quality in the operating instructions for the airwater cooler.

NOTICE

Overheating of the machine as a result of additives in the cooling water

Additives for antifreeze or corrosion protection can have a negative impact on the heat

transporting properties. The machine can overheat.

● Only operate the machine with the contractually agreed cooling water quality.

See also

Service and Support (Page 121)

4.5 Interlock circuit for the external fan motor

Interlock circuit for the external fan motor

For machines with external fans, install an interlock circuit that prevents the main machine

being switched on if the external fan is not operational.

See also

Connecting an external fan motor (Page 68)

SIMOTICS HV M 1RN76308PR900CG0-Z

24 Operating Instructions 07/2018

Page 25

4.6 Interlock circuit for anti-condensation heating

4.6 Interlock circuit for anti-condensation heating

If the anti-condensation heating is operated while the machine is running, this can increase

the temperatures inside the machine.

● Install an interlock circuit that switches off the anti-condensation heating once the main

machine is switched on.

● Only switch on the anti-condensation heating after the machine has been switched off.

See also

Switching on with the anti-condensation heating active (Page 78)

4.7 Space requirements

Ensure that there is sufficient space where the motor is to be installed so that when required,

the air-to-water exchanger can be removed and installed.

Preparations for use

4.8 Noise emission

Excessive sound pressure levels can lead to hearing impairment or hearing loss.

● When assessing the noise level of the system, make due allowance for the noise emissions

from the machine.

● If necessary, take suitable noise protection measures for personnel.

4.9 Voltage and frequency fluctuations during line operation

If nothing else is stamped on the rating plate, the permissible voltage fluctuation is ±5 % and

the permissible frequency fluctuation is ±2 %, corresponding to range A in IEC / EN 60034‑1.

Permissible fluctuations that go beyond this are stamped on the rating plate.

Under operating conditions a machine may sometimes have to be operated outside the limits

of range A.

● Exceeding the permissible tolerances for voltage and frequency can lead to an

impermissibly high temperature rise of the winding. This can result in long-term damage to

the machine.

● Limit exceptions of this sort with regard to the values that arise, how often, and for how long

they occur.

● Where possible and within a reasonable time take corrective actions such as reducing the

power. Such actions can avoid thermal ageing leading to a reduction in the service life of

the machine.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 25

Page 26

Preparations for use

4.10 Phase synchronization during supply system switching

4.10 Phase synchronization during supply system switching

Damage to the machine may be caused when switching to another supply system with different

phasing.

● The phasing must be synchronized during switching. Use appropriate means to

synchronize the phasing.

4.11 System-inherent frequencies

Excessively high vibration levels and system resonances can damage the machine set.

● Configure and match the system consisting of the foundation and machine set in such a

way that no system resonances can arise and result in the permissible vibration levels being

exceeded.

● The vibration limit values according to DIN ISO 10816-3 must not be exceeded.

4.12 Torsional loading of the shaft assembly

In the event of faults in the electrical connection, such as line switching operations with a

residual field or short circuit at the terminals, excessive air gap torques can occur. These

excessive air gap torques can lead to additional mechanical torsional loads on the shaft

assembly.

If the configuration does not correctly recognize the mechanical torsional loadings of the shaft

assembly, this can lead to serious damage to the machine. This can result in death, serious

injury or material damage.

● When planning the system, make due allowance for the maximum air gap torques that can

occur. This data can be found in the "Electrical data".

The system planner is responsible for the entire drive train.

4.13 Switching high-voltage motors

If vacuum circuit breakers and vacuum contactors are used, then what are known as multiple

restrikes can occur when the machine is switched off. This depends on various factors, such

as:

● Arc-extinguishing principle of the switch

● Machine size

● Length of the power supply cable

● System capacitance, etc.

A surge suppressor to ground is installed in the switchgear between the circuit breaker and

the cable termination for each of the three conductors. The level of protection for the machine

windings is sufficient when the limiter is correctly selected (machine rated voltage / response

voltage).

SIMOTICS HV M 1RN76308PR900CG0-Z

26 Operating Instructions 07/2018

Page 27

Preparations for use

4.14 Thermal protection

Example

This current limit corresponds to the following upper power limits, depending on the relationship

between the starting current IA and rated current IN and on the voltage dip (up to approximately

20%) while the machine is starting up:

Table 4-1 Power limits

Rated voltage V

3 kV 750 kW

6 kV 1500 kW

10 kV 2500 kW

See also

Prior to commissioning (Page 71)

4.14 Thermal protection

The machine is equipped with measuring equipment to directly monitor the motor temperature

to protect the machine against overheating during operation. Plan a corresponding circuit for

monitoring. You will find more information in the Technical Data in the "Explanatory text for the

machine dimension drawing".

4.15 Transport and storage

Observe the following when carrying out any work on the machine:

N

Power limit

● Comply with the general safety instructions (Page 13)

● Comply with the applicable national and sector-specific regulations at the place of

installation

● When using the machine within the European Union, comply with the specifications laid

down in EN 50110‑1 regarding safe operation of electrical equipment.

4.15.1 Transport markings

The packing differs depending on the transport type and size. If not otherwise contractually

agreed, the packaging corresponds to the packing guidelines for International Standards for

Phytosanitary Measures (ISPM).

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 27

Page 28

Preparations for use

4.15 Transport and storage

Note the symbols which appear on the packing. These have the following meanings:

Top Fragile material Keep dry Keep cool Center of

4.15.2 Checking the delivery

The components are assembled on an individual basis. When you take receipt of the delivery,

please check immediately whether the scope of the delivery matches up with the

accompanying documents. No claims relating to defects/items missing from the delivery will

be accepted if they are submitted at a later date.

● Report any apparent transport damage to the delivery agent immediately.

● Immediately report any apparent defects/missing components to your contact partner.

These Operating Instructions are part of the scope of delivery; keep them in a location where

they can be easily accessed.

4.15.3 Checking the load handling attachments

Inspect the load handling attachments such as the load trestles, lifting eyes and ring bolts and

also the lifting gear, before lifting the machine:

● Inspect the load handling attachments on the machine for possible damage. Replace any

load suspension equipment that is found to be damaged.

gravity

Do not use

hand hook

Attach here

● Before use, check that the load suspension equipment is correctly attached.

● When lifting the machine, use only approved and undamaged lifting gear of sufficient rated

capacity. Check the lifting gear prior to its use.

WARNING

The machine can be dropped

If the load handling attachments and lifting gear are damaged or not correctly secured,

the machine may be dropped during lifting. This can result in death, serious injury or

material damage.

● Inspect the load handling attachments and lifting gear before use.

SIMOTICS HV M 1RN76308PR900CG0-Z

28 Operating Instructions 07/2018

Page 29

4.15.4 Lifting and transportation

● Persons driving cranes and fork-lift trucks must hold appropriate licenses.

● If the motor is packed, depending on the weight, size and on-site conditions, lift crates and

transport frames using a fork-lift truck or a crane with slings. Use a crane or fork-lift truck

suitable for the load.

● When lifting the machine, use only approved and undamaged sling guides and spreaders

of sufficient rated capacity. Check this equipment before using it. The weight of the machine

is shown on the rating plate.

● If adapter flange and adapter plates are also supplied, then lift them and transport these

parts separately. The load suspension equipment for the motor is not rated for lifting the

motor with mounted adapter flange is or adapter plates

Preparations for use

4.15 Transport and storage

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 29

Page 30

Preparations for use

4.15 Transport and storage

● When lifting the machine, refer to the information on the lifting plate or in the "Technical

Data and Drawings":

– Comply with the specified spreading angles.

– Do not exceed the maximum lifting acceleration and lifting speed specified on the lifting

plate. Lift the machine without jerking it.

Acceleration a ≤ 0.4 g (≈ 4 m/s2)

Velocity v ≤ 20 m/min

● Use only the attachment points provided on the stator frame for lifting, such as lifting eyes

or ring bolts or the lifting eyebolts on the bearing shield.

Transport for a different type of construction

The machine or the machine set may be lifted and transported only using the load handling

attachments at the intended positions. Otherwise, the machine may tip over, slip in the

direction of lifting or fall.

This can result in death, serious injury or material damage.

1. Use only the attachment points (eyebolts, etc.) on the stator frame.

2. Use suitable rope guiding or spreading devices. You will find the weight of the motor

on the rating plate.

WARNING

WARNING

Center of gravity is not at the center.

If the center of gravity of a load is not located centrally between the attachment points,

the motor can tip over or slip out of the lifting equipment and fall when it is being transported

or lifted. This can result in death, serious injury or material damage.

1. Always take account of the center of gravity when transporting or lifting the motor. The

center of gravity of the machine is specified in the dimension drawing.

2. Comply with the handling instructions on the machine when transporting it. If the center

of gravity is not located centrally between the attachment points, position the hoisting

hook above the center of gravity.

3. Be aware of the possibility of different loads on the sling ropes or lifting straps and the

carrying capacity of the lifting equipment.

NOTICE

Risk of corrosion and reduction of the degree of protection

Empty holes can corrode; the degree of protection may then be no longer guaranteed.

● Do not remove the factory-fitted load suspension device. In operation, the loadsuspension device must remain screwed in.

● If you do remove the load-suspension device, then seal the holes so that they are

airtight.

SIMOTICS HV M 1RN76308PR900CG0-Z

30 Operating Instructions 07/2018

Page 31

WARNING

Lifting equipment can break at low temperatures

At low temperatures, the material of the lifting equipment can become brittle. When lifting and

transporting, the lifting equipment can tear off and the motor might be dropped.

This can result in death, serious injury, or material damage.

● Only lift the machine using the lifting equipment at temperatures that are not below -20 °C.

● Alternatively, warm up the lifting equipment or lift the machine in a different way.

The rotor is locked in the bearing housing using two screws

When delivered, the rotor is locked in the bearing housing ① using two M12 screws. The

maximum tightening torque is 20 Nm.

If you wish to remove the rotor transport lock, rotate the set screws out by about 15 mm, and

secure using a lock nut.

Preparations for use

4.15 Transport and storage

Figure 4-1 Rotor transport lock with two screws in the bearing housing

● Never remain under or in the immediate vicinity of the machine when it is lifted. If the lifting

gear or load handling attachments were to fail, the machine could fall. This can result in

death, serious injury or material damage.

● In order to gain easy and safe access to the underside of the machine, place it in a secure

and raised position.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 31

Page 32

Preparations for use

4.15 Transport and storage

4.15.5 Storage

You must correctly store the machine if you do not install and use it after it has been delivered.

NOTICE

Bearing seizure damage if incorrectly stored

If storage conditions are inappropriate there is a risk of bearing seizure damage. Resulting

damage can include scoring (brinelling) and corrosion.

● Follow the storage guidelines.

Preconditions and preparations

● Only store goods in undamaged packaging. Unpack the goods if the packaging is damaged.

Correctly store the goods corresponding to the type.

● Repair any damage to the packaging before putting the equipment into storage insofar as

this is necessary to ensure proper storage conditions.

General instructions for storage

Wherever possible, store the machine in a storage room. The place of storage must satisfy

the following general conditions:

● Select a sufficiently sized dry and horizontal place of storage that is above flood level and

free of vibration (v

– The place of storage must be well ventilated as well as free of dust and frost. Provide

protection against extreme weather conditions. Ensure that the temperature remains

stable in the range from 10 °C to 50 °C – or 50 °F to 120 °F. If there is a risk of

condensation, the room temperature should be approx. 10 K above the outside

temperature. The temperature should not fall below ‑20° C.

– The relative humidity of the air should be less than 60%.

– The floor of the place of storage must be sufficiently strong. The maximum permissible

floor loading or storage compartment loading may not be exceeded.

– The ambient air must not contain any harmful gases.

● Protect the machine from shocks and humidity.

● Position machines, devices and crates on pallets, wooden beams or foundations that

protect them against rising damp and water.

● Ensure that the air circulation under the equipment is not impeded.

– Place wooden spacer blocks between the covers and the machine.

≤ 0.2 mm/s).

eff

– Covers or tarpaulins must not trail on the floor around the machine.

SIMOTICS HV M 1RN76308PR900CG0-Z

32 Operating Instructions 07/2018

Page 33

Storing outdoors

When storing the machines outside, the storage location must comply with the following

conditions:

● The ground must be sufficiently strong. Prevent the machine from sinking into the ground.

● Covers or tarpaulins used to protect the equipment against the weather must not make

contact with the surfaces of the equipment. Otherwise air circulation under the stored items

will be prevented.

Protection against humidity

If a dry storage space is not available, protect the machine as follows against humidity:

● Wrap the machine in humidity-absorbent material.

● Wrap the machine in plastic film:

– Place a humidity meter inside the plastic film.

– Place desiccant within the plastic film.

– Pack the machine air-tight.

Preparations for use

4.15 Transport and storage

● Inspect the machine regularly.

Long-term storage

If you are storing a machine for more than six months, you must check its condition every six

months. Store the machine in accordance with the specifications in Section "Storage

(Page 32)", and if possible, packed.

● Check the motor for damage.

● Carry out any necessary maintenance work.

● Make sure that the storage conditions are such that condensation cannot form in the motor.

● If the machine is not sealed in plastic film, continually and slightly heat the machine, e.g.

with anti-condensation heating (if available), and ensure that the air circulates in the storage

room.

Storage for longer than three months

Lubricate the machine after every two years of storage.

1. Unpack the machine.

2. Remove the rotor shipping brace, if one is fitted.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 33

Page 34

Preparations for use

4.15 Transport and storage

3. When stored for longer than two years, lubricate with twice the grease quantity in

accordance with the lubricant plate. This ensures that the grease is evenly distributed and

covers all surfaces. Corrosion damage is avoided.

NOTICE

Rolling bearing damage due to unchanged resting position

Roller bearings can be damaged when kept in the same or almost the same position.

● Every three months, manually rotate the rotor through five revolutions.

● Make sure that the resting position of the rotor after the rotor has been turned over is

different from its previous position. Use the feather key as a reference point, if present.

4. Replace the corrosion protection.

5. Reattach the rotor shipping brace, if present.

6. Pack the machine again.

4.15.6 Protection against corrosion

If the machine is stored in dry conditions, then apply the subsequently listed anti-corrosion

measures:

● Storage up to six months:

Apply a coat of corrosion protective compound to all accessible bare metal parts such as

the exposed shaft extension, flange or machine feet.

● Storage for longer than six months:

Apply a coat of long-term anti-corrosion agent to all accessible bare parts.

● Inspect the machine regularly and if necessary, apply an additional coating of corrosion

protection.

Document all preservation measures taken so that they can be reversed before the machines

are put back into service.

4.15.7 Protecting the cooling water circuit during storage

Anti-freeze protection

When supplied, the machine is not filled with cooling water, so that there is no risk of frost

damage.

SIMOTICS HV M 1RN76308PR900CG0-Z

34 Operating Instructions 07/2018

Page 35

Protecting the cooling circuit against corrosion

You protect the cooling circuit against corrosion when the machine has already been in

operation and is then placed in storage or put out of operation. Also observe the information

in the operating instructions supplied by the manufacturer of the cooler.

1. Completely drain the cooling ducts. To be completely certain, use compressed air to clean

the cooling water ducts so that they are completely empty.

2. Flush the cooling water ducts with a corrosion-protection emulsion to avoid the buildup of

rust.

See also

Additional documents (Page 129)

4.16 Converter operation

Preparations for use

4.16 Converter operation

4.16.1 Rotational speed limit values

Danger as a result of resonance within certain speed ranges

At over-critical speeds, machines encounter resonance within certain speed ranges. Such

vibrations can reach impermissibly high levels. This can result in death, serious injury or

material damage.

● The controller must ensure that those speed ranges are blocked when the converter is in

operation. Refer to the "Electrical Data" section in the appendix for details of the blocked

speed ranges.

● The blocked speed ranges must be run through rapidly.

Machine damage due to excessively high speeds

Excessive rotational speed can lead to serious damage to the machine. This can result in

death, serious injury or material damage.

● Avoid operation above the permissible speed by using the appropriate control function.

● Observe the speeds stamped on the rating plate and specified in Chapter "Electrical data"

in the appendix.

In the case of converter operation, the motor is designed for operation with square-law load

characteristics. The motor overload must not exceed 110 % of the rated torque. The safety is

reduced for higher overloads. This can result in shaft breakage. Parts and components that

are flung off may result in death, serious injury or material damage.

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 35

Page 36

Preparations for use

4.16 Converter operation

4.16.2 Insulated bearings when operating the converter

Operation with a medium-voltage converter with insulated coupling and insulated bearings

If the machine is fed from a 3-level voltage-source DC link converter without a sine-wave filter,

then shaft grounding is fitted at the NDE. The shaft grounding can be implemented as a

grounding device or incorporated in the tachometer. The DE and NDE bearings are insulated.

● Comply with the plates on the machine relating to bearing insulation and possible bridging

options.

● Use an insulated coupling to connect the motor to the driven machine. Otherwise, the

bearing insulation at the DE is bypassed. The consequence of that would be a circulating

current through the motor shaft and the surrounding grounding system.

WARNING

Defective shaft grounding

If the shaft grounding does not function correctly, the shaft can be at a high voltage level that

does not decay quickly enough when the machine comes to a standstill. This can lead to

death or serious injury as a result of electric shock, or bearing damage caused by current

flowing through the bearing.

● Regularly check the shaft grounding and maintain it at the maintenance intervals.

● Observe the operating instructions for the shaft grounding.

① Driving machine ④ Insulated bearings

② Motor ⑤ Insulated tachometer fitting

③ Insulated coupling ⑥ Shaft grounding

Figure 4-2 Schematic representation of a single drive

36 Operating Instructions 07/2018

SIMOTICS HV M 1RN76308PR900CG0-Z

Page 37

Tandem operation

Preparations for use

4.16 Converter operation

WARNING

Bridging the bearing insulation

Bridging an insulated bearing can result in an electric current flowing through the machine

enclosure and possibly through the coupling to the driven machine. When touched, this can

lead to death or serious injury as a result of electric shock, and bearing damage caused by

current flowing through the bearing.

● Use insulated couplings.

● Do not bridge the bearing insulation on the insulated bearing while the machine is

operational.

● Be sure not to damage the bearing insulation when carrying out installation work, e.g.

when drilling holes, etc.

● Keep the insulation points clean.

● Observe the labels on the machine relating to the bearing insulation.

See also

If you connect two motors in series in "tandem operation", fit an insulated coupling between

the motor and the driven machine. It is not necessary to fit an insulated coupling between the

motors acting in tandem operation.

① Driving machine ④ Insulated bearings