Page 1

www.siemens.com/drives

Operating Instructions

Installation Instructions

Low-voltage motor

SIMOTICS FD

Type 1LN1

Edition 01/2019

Page 2

23.01.2019 19:05

V11.01

Page 3

Low-voltage motor

SIMOTICS FD

Type 1LN1

Introduction

1

Operating Instructions

Installation Instructions

Safety information

Description

Preparations for use

Assembly

Electrical connection

Start-up

Operation

2

3

4

5

6

7

8

Maintenance

Spare parts

Disposal

Service and Support

Technical data and drawings

Quality documents

9

10

11

A

B

C

Edition 01/2019

Page 4

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E32582260

Ⓟ 01/2019 Subject to change

Copyright © Siemens AG 2018.

All rights reserved

Page 5

Table of contents

1 Introduction.................................................................................................................................................13

1.1 About these instructions.........................................................................................................13

1.2 Compiling personal documents..............................................................................................13

2 Safety information.......................................................................................................................................15

2.1 Information for the nominated person in control of the electrical installation .........................15

2.2 The 5 safety rules...................................................................................................................15

2.3 Qualified personnel ................................................................................................................16

2.4 Safe handling .........................................................................................................................16

2.5 Electrostatic sensitive devices ...............................................................................................18

2.6 Interference immunity.............................................................................................................18

2.7 Interference voltages when operating the converter ..............................................................19

2.8 Electromagnetic fields when operating electrical power engineering installations.................19

3 Description..................................................................................................................................................21

4 Preparations for use ...................................................................................................................................29

4.1 Safety-related aspects to consider when configuring the plant..............................................29

4.2 Observing the operating mode...............................................................................................29

4.3 Ensuring cooling.....................................................................................................................29

4.4 Space requirement.................................................................................................................30

4.5 Configuration of the cooling circuit and coolant supply ..........................................................31

4.5.1 Material selection for the cooling circuit .................................................................................31

4.5.2 Pressures and differential pressures in the cooling circuit.....................................................32

4.5.3 Components and materials of the cooling circuit ...................................................................32

4.5.4 Potential equalization on the cooling circuit components.......................................................33

4.6 Coolant specification ..............................................................................................................33

4.6.1 General coolant requirements................................................................................................33

4.6.2 Coolant specification..............................................................................................................35

4.6.3 Inhibitors, anti-freeze, biocides ..............................................................................................36

4.6.4 Cooling capacity derating.......................................................................................................37

4.7 Interlock circuit for the external fan motor ..............................................................................38

4.8 Thermal motor protection .......................................................................................................38

4.9 Thermal motor protection using PTC thermistors (option) .....................................................38

4.10 Interlock circuit for the automatic regreasing system (option)................................................38

4.11 Interlock circuit for anti-condensation heating........................................................................38

4.12 IM B5 type of construction with support foot ..........................................................................39

SIMOTICS FD 1LN1

Operating Instructions 01/2019 5

Page 6

Table of contents

4.13 Noise emissions .....................................................................................................................39

4.14 Rotational speed limit values .................................................................................................39

4.15 Voltage and frequency fluctuations during line operation ......................................................40

4.16 Phase synchronization during supply system switching ........................................................40

4.17 System-inherent frequencies .................................................................................................40

4.18 Torsional load of the drive train..............................................................................................40

4.19 Transport................................................................................................................................41

4.19.1 Safety instructions for transport .............................................................................................41

4.19.2 Checking the delivery.............................................................................................................43

4.19.3 Securing the rotor...................................................................................................................44

4.19.4 Lifting and transporting the machine ......................................................................................46

4.20 Storage...................................................................................................................................46

4.20.1 Storing the machine ...............................................................................................................46

4.20.2 Protecting the cooling water circuit during storage ................................................................49

4.20.3 Protection against corrosion...................................................................................................50

4.21 Converter operation ...............................................................................................................50

4.21.1 Supply line configuration ........................................................................................................50

4.21.2 Converter input voltage ..........................................................................................................51

4.21.3 Reducing bearing currents .....................................................................................................51

4.21.4 Insulated bearings when operating the converter ..................................................................52

4.21.5 Converter operation on a grounded network..........................................................................54

5 Assembly ....................................................................................................................................................55

5.1 Safety instructions for mounting.............................................................................................55

5.2 Preparations for installation....................................................................................................56

5.2.1 Requirements for installation..................................................................................................56

5.2.2 Insulation resistance and polarization index ..........................................................................56

5.2.3 Testing the insulation resistance and polarization index........................................................57

5.2.4 Prepare the mating faces (IM B3) ..........................................................................................60

5.2.5 Prepare the mating face for a flange connection ...................................................................60

5.2.6 Prepare the mating face for wall mounting ............................................................................60

5.3 Lift the machine to where it will be installed, and position it...................................................60

5.3.1 Preconditions for correct alignment and secure attachment .................................................60

5.3.2 Checking the load handling attachments ...............................................................................61

5.3.3 Removing the rotor shipping brace ........................................................................................61

5.3.4 Removing the rotor shipping brace from machines in vertical type........................................61

5.3.5 Removing anti-corrosion protection .......................................................................................62

5.3.6 Mounting the output elements................................................................................................62

5.3.7 Lifting and transportation........................................................................................................64

5.3.8 Putting the machine down......................................................................................................65

5.3.9 Draining condensation ...........................................................................................................66

5.3.10 Roughly aligning the machine ................................................................................................67

5.4 Installing the machine ............................................................................................................68

5.4.1 Preconditions for smooth, vibration-free operation ................................................................68

5.4.2 Aligning the machine to the driven machine and mounting (IM B3 / IM B35) ........................68

5.4.3 Aligning the machine to the driven machine and attaching it to it (IM B5) .............................70

SIMOTICS FD 1LN1

6 Operating Instructions 01/2019

Page 7

Table of contents

5.4.4 Aligning the machine to the driven machine and attaching it to it (IM V1, IM V10)................71

5.4.5 Axial and radial forces............................................................................................................71

5.5 Connecting the cooling water supply .....................................................................................72

6 Electrical connection...................................................................................................................................75

6.1 Safety instructions for the electrical connection .....................................................................75

6.2 Basic rules..............................................................................................................................75

6.3 Terminal box ..........................................................................................................................76

6.3.1 Terminal box 1XB1621...........................................................................................................77

6.3.2 Terminal box 1XB1631...........................................................................................................77

6.3.3 Terminal box 1XB7730...........................................................................................................78

6.3.4 Terminal box 1XB7731...........................................................................................................79

6.3.5 Terminal box 1XB7740...........................................................................................................79

6.3.6 Terminal box 1XB7750...........................................................................................................80

6.3.7 Rotating the terminal box .......................................................................................................80

6.3.8 Mounting/removing the terminal box......................................................................................83

6.4 Preparation.............................................................................................................................84

6.4.1 Terminal designation..............................................................................................................84

6.4.2 Selecting cables.....................................................................................................................84

6.4.3 Connecting the grounding conductor .....................................................................................85

6.4.4 Connection without terminal box............................................................................................86

6.4.5 Connecting the machine for a specific direction of rotation....................................................87

6.4.6 Undrilled entry plate ...............................................................................................................87

6.5 Inserting and routing the cables .............................................................................................88

6.5.1 Bringing cables into the terminal box 1XB... with sealing insert with break-off ring ...............88

6.5.2 Bringing cables into the terminal box 1XB... with cable gland................................................89

6.5.3 Laying cables .........................................................................................................................90

6.5.4 Connecting cables with cable lugs.........................................................................................90

6.5.5 Connecting cables without cable lugs....................................................................................91

6.5.6 Use of aluminum conductors..................................................................................................93

6.5.7 Using single-stranded cables.................................................................................................93

6.5.8 Internal equipotential bonding................................................................................................93

6.5.9 Stepless mating face for the seal in the terminal box cover ..................................................94

6.5.10 Minimum air clearances .........................................................................................................94

6.5.11 Finishing connection work......................................................................................................95

6.6 Connecting the auxiliary circuits.............................................................................................95

6.6.1 Selecting cables.....................................................................................................................95

6.6.2 Bringing cables into the auxiliary terminal box and routing them...........................................96

6.6.3 Connecting an external fan motor..........................................................................................96

6.6.4 Connecting temperature monitoring for the stator winding ....................................................97

6.6.5 Terminating the connection work (auxiliary circuit) ................................................................98

7 Start-up.......................................................................................................................................................99

7.1 Checks to be carried out prior to commissioning ..................................................................99

7.2 Converter operation .............................................................................................................101

7.3 Measuring the insulation resistance before commissioning.................................................101

7.4 Greasing the roller bearings prior to commissioning............................................................102

SIMOTICS FD 1LN1

Operating Instructions 01/2019 7

Page 8

Table of contents

7.5 Setting the automatic regreasing system .............................................................................103

7.6 Commissioning an external fan............................................................................................103

7.7 Setpoint values for monitoring the bearing temperature ......................................................104

7.8 Set values for monitoring the winding temperature..............................................................105

7.9 Test run ................................................................................................................................105

7.10 Switching off.........................................................................................................................107

7.11 Setting the motor parameters at the converter.....................................................................107

7.11.1 Selecting the motor type and motor data in the STARTER program ...................................107

7.11.2 Commissioning at the SINAMICS S/G converter using the AOP30.....................................110

7.11.3 Commissioning at the SINAMICS G120P inverter using the IOP ........................................113

8 Operation..................................................................................................................................................115

8.1 Safety instructions for operation...........................................................................................115

8.2 Switching on the machine ....................................................................................................117

8.3 Regreasing roller bearings ...................................................................................................117

8.4 Stoppages ............................................................................................................................117

8.4.1 Avoidance of frost and corrosion damage in the cooling system.........................................118

8.4.2 Avoidance of condensation or formation of condensation within the machine.....................118

8.4.3 Avoidance of damage to roller bearings during stoppages..................................................118

8.4.4 Measurement of the insulation resistance after an extended stoppage...............................119

8.5 Decommissioning the machine ............................................................................................119

8.6 Switch off the external fan....................................................................................................119

8.7 Switching off the water-cooling system ................................................................................119

8.8 Re-commissioning the machine ...........................................................................................120

8.9 Switching on again after an emergency switching-off ..........................................................120

8.10 faults.....................................................................................................................................120

8.10.1 Inspections in the event of faults..........................................................................................120

8.10.2 Electrical faults .....................................................................................................................121

8.10.3 Mechanical faults .................................................................................................................121

8.10.4 Air-to-water cooler faults ......................................................................................................122

8.10.5 Faults at the external fan......................................................................................................123

8.10.6 Roller bearing faults .............................................................................................................124

9 Maintenance .............................................................................................................................................125

9.1 Inspection and maintenance ................................................................................................125

9.1.1 Safety instructions for inspection and maintenance.............................................................125

9.1.2 Measuring the insulation resistance during the course of maintenance work......................127

9.1.3 Inspections in the event of faults..........................................................................................127

9.1.4 First service after installation or repair .................................................................................127

9.1.5 General inspection ...............................................................................................................128

9.1.6 Inspection of the cooling system..........................................................................................129

9.1.7 Servicing and maintaining the anti-condensation heating....................................................129

9.1.8 Assessing the roller bearings...............................................................................................129

9.1.9 Roller bearings with automatic regreasing system...............................................................129

SIMOTICS FD 1LN1

8 Operating Instructions 01/2019

Page 9

Table of contents

9.1.10 Regreasing intervals and types of grease for operating roller bearings...............................130

9.1.11 Sealing the rolling-contact bearings ("Increased degree of protection" option) ...................133

9.1.12 Cleaning the air-to-water heat exchanger ............................................................................134

9.1.13 Servicing the external fan.....................................................................................................134

9.1.14 Touch up any damaged paintwork .......................................................................................135

9.1.15 Maintaining terminal boxes ..................................................................................................135

9.2 Corrective Maintenance .......................................................................................................136

9.2.1 Prepare servicing work.........................................................................................................136

9.2.2 Screws with preCOTE coating .............................................................................................137

9.2.3 External fan..........................................................................................................................137

9.2.3.1 Replacing the external fan ...................................................................................................137

9.2.3.2 External fan unit ...................................................................................................................137

9.2.3.3 Adjusting the external fan.....................................................................................................138

9.2.4 Roller-contact bearings ........................................................................................................139

9.2.4.1 Removing roller bearing .......................................................................................................139

9.2.4.2 Remove V ring .....................................................................................................................139

9.2.4.3 Removing the labyrinth sealing ring .....................................................................................140

9.2.4.4 Installing roller bearings .......................................................................................................141

9.2.4.5 Install the V ring ...................................................................................................................142

9.2.4.6 Installing the V ring ("Increased degree of protection" option) .............................................143

9.2.4.7 Installing the labyrinth sealing ring .......................................................................................143

9.2.5 Top enclosure ......................................................................................................................144

9.2.5.1 Removing and installing the air-to-water-cooler...................................................................144

9.2.5.2 Removing the top enclosure ................................................................................................145

9.2.5.3 Mounting the top enclosure..................................................................................................147

9.2.6 Seal the motor......................................................................................................................148

10 Spare parts ...............................................................................................................................................149

10.1 Ordering data .......................................................................................................................149

10.2 Ordering spare parts via the Internet ...................................................................................150

10.3 Anti-condensation heating....................................................................................................150

10.4 Housing, stators and rotors ..................................................................................................151

10.5 Top enclosure ......................................................................................................................153

10.6 Roller bearing cartridge at the drive and non-drive end .......................................................154

10.7 Roller bearing cartridge at the drive and non-drive end .......................................................155

10.8 Terminal box 1XB1621.........................................................................................................156

10.9 Terminal box 1XB1631.........................................................................................................158

10.10 Terminal box 1XB7730.........................................................................................................159

10.11 Terminal box 1XB7731.........................................................................................................160

10.12 Terminal box 1XB7740.........................................................................................................161

10.13 Terminal box 1XB7750.........................................................................................................162

10.14 Auxiliary terminal box 1XB9014 ...........................................................................................163

10.15 Auxiliary terminal box 1XB9015 ...........................................................................................164

10.16 1XB9016 auxiliary terminal box............................................................................................165

SIMOTICS FD 1LN1

Operating Instructions 01/2019 9

Page 10

Table of contents

10.17 Auxiliary terminal box 1XB302. ............................................................................................166

11 Disposal....................................................................................................................................................167

11.1 RoHS - restricting the use of certain hazardous substances ...............................................167

11.2 Information according to Article 33 of the REACH regulation ..............................................167

11.3 Preparing for disassembly....................................................................................................168

11.4 Dismantling the machine......................................................................................................168

11.5 Disposal of components.......................................................................................................168

A Service and Support .................................................................................................................................171

B Technical data and drawings....................................................................................................................173

B.1 Tightening torques for screw and bolt connections..............................................................173

C Quality documents....................................................................................................................................175

Index.........................................................................................................................................................177

Tables

Table 3-1 Machine design ..........................................................................................................................21

Table 3-2 Data on the rating plate...............................................................................................................23

Table 3-3 Rolling-contact bearing variants..................................................................................................26

Table 4-1 Space required for the separately-driven fan ..............................................................................30

Table 4-2 Space required for removing/installing the water cooler .............................................................30

Table 4-3 Materials and components of a cooling circuit ............................................................................32

Table 4-4 Substances that can destroy the cooling system ........................................................................34

Table 4-5 Overview and application of coolant additives ............................................................................36

Table 5-1 Stator winding insulation resistance at 40° C..............................................................................58

Table 5-2 Permissible deviations for aligning the machine with flexible coupling .......................................69

Table 6-1 Terminal designations using the 1U1-1 as an example ..............................................................84

Table 6-2 Connection technology (with cable lug / connection without cable lug) ......................................88

Table 6-3 Cable entry plate versions...........................................................................................................89

Table 6-4 Minimum air clearance dependent on rms value of the alternating voltage U

.........................94

rms

Table 7-1 Set values for monitoring the bearing temperatures before commissioning .............................104

Table 7-2 Set values for monitoring the bearing temperatures .................................................................104

Table 7-3 Set value for commissioning ....................................................................................................105

Table 7-4 Set values during normal operation...........................................................................................105

Table 8-1 Electrical faults .....................................................................................................................121

Table 8-2 Mechanical faults.......................................................................................................................121

Table 8-3 Cooling system faults ...........................................................................................................122

Table 8-4 Cooling system faults .............................................................................................................123

Table 8-5 Roller bearing faults .............................................................................................................124

SIMOTICS FD 1LN1

10 Operating Instructions 01/2019

Page 11

Table of contents

Table 9-1 Checks after assembly or repair ...............................................................................................127

Table 9-2 Checks that have to be performed during the general inspection.............................................128

Table 9-3 Criteria for selecting rolling bearing greases.............................................................................130

Table 9-4 Rolling bearing greases for vertical and horizontal types of construction ................................131

Table 9-5 Alternative greases with NLGI class 2 for motors of horizontal construction ............................131

Table 10-1 Spare parts for housing, stators and rotors ...............................................................................151

Table 10-2 Spare parts for the top enclosure ..............................................................................................153

Table 10-3 Spare parts for the bearing cartridge at the drive end and non-drive end.................................154

Table 10-4 Spare parts for the bearing cartridge at the drive end and non-drive end.................................155

Table 10-5 Terminal box 1XB1621 spare parts...........................................................................................156

Table 10-6 Additional spare parts................................................................................................................157

Table 10-7 Additional spare parts for terminal box 1XB1631 with split cable entry.....................................158

Table 10-8 Main terminal box 1XB7730 spare parts ...................................................................................159

Table 10-9 Additional spare parts................................................................................................................159

Table 10-10 Main terminal box 1XB7731 spare parts ...................................................................................160

Table 10-11 Additional spare parts................................................................................................................160

Table 10-12 Main terminal box 1XB7740 spare parts ...................................................................................161

Table 10-13 Additional spare parts................................................................................................................161

Table 10-14 Terminal box 1XB7750..............................................................................................................162

Table B-1 Tightening torques for bolted connections with a tolerance of ±10%........................................173

Figures

Figure 3-1 Schematic of the rating plate.......................................................................................................23

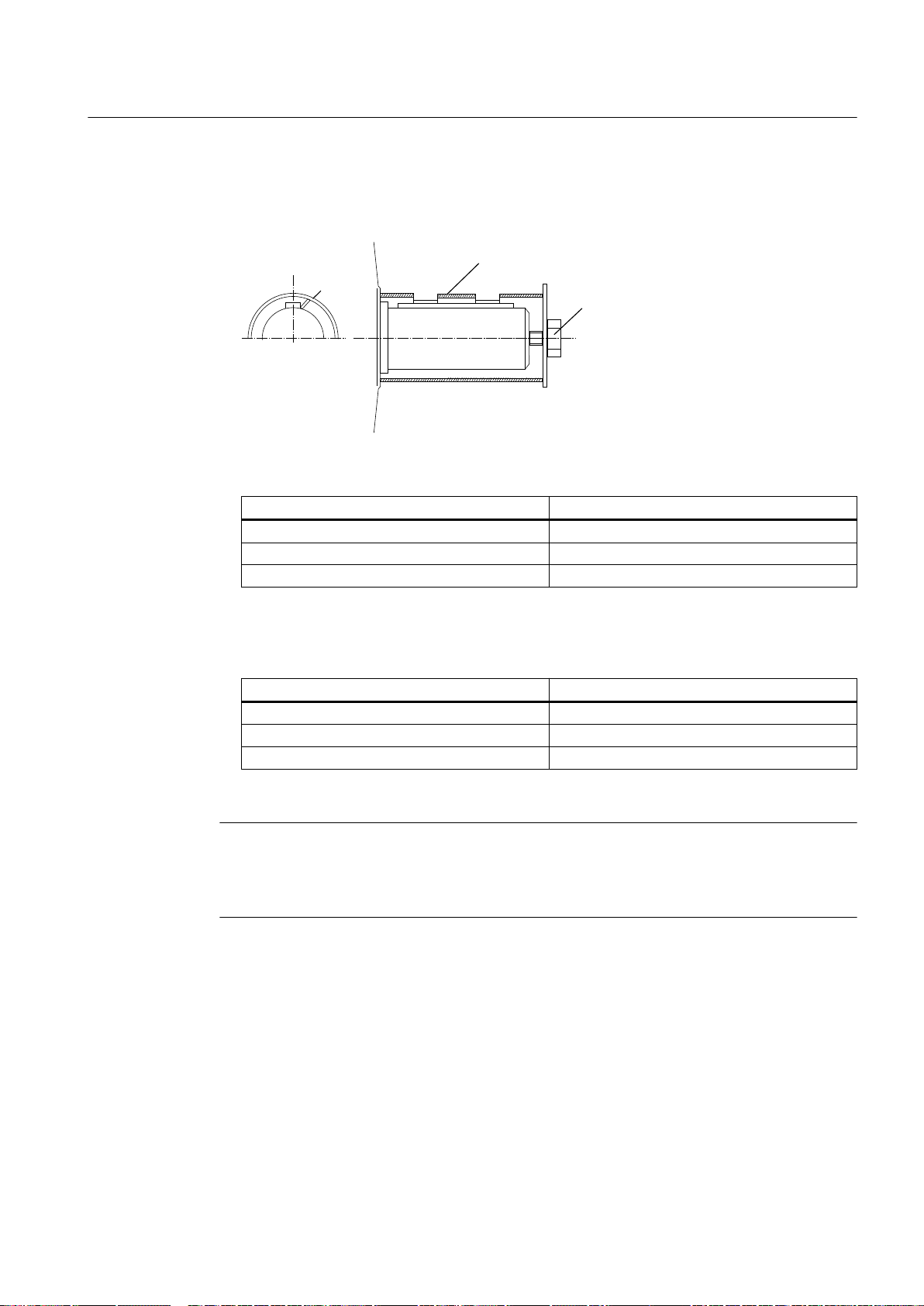

Figure 4-1 Axial fastening of the rotor...........................................................................................................45

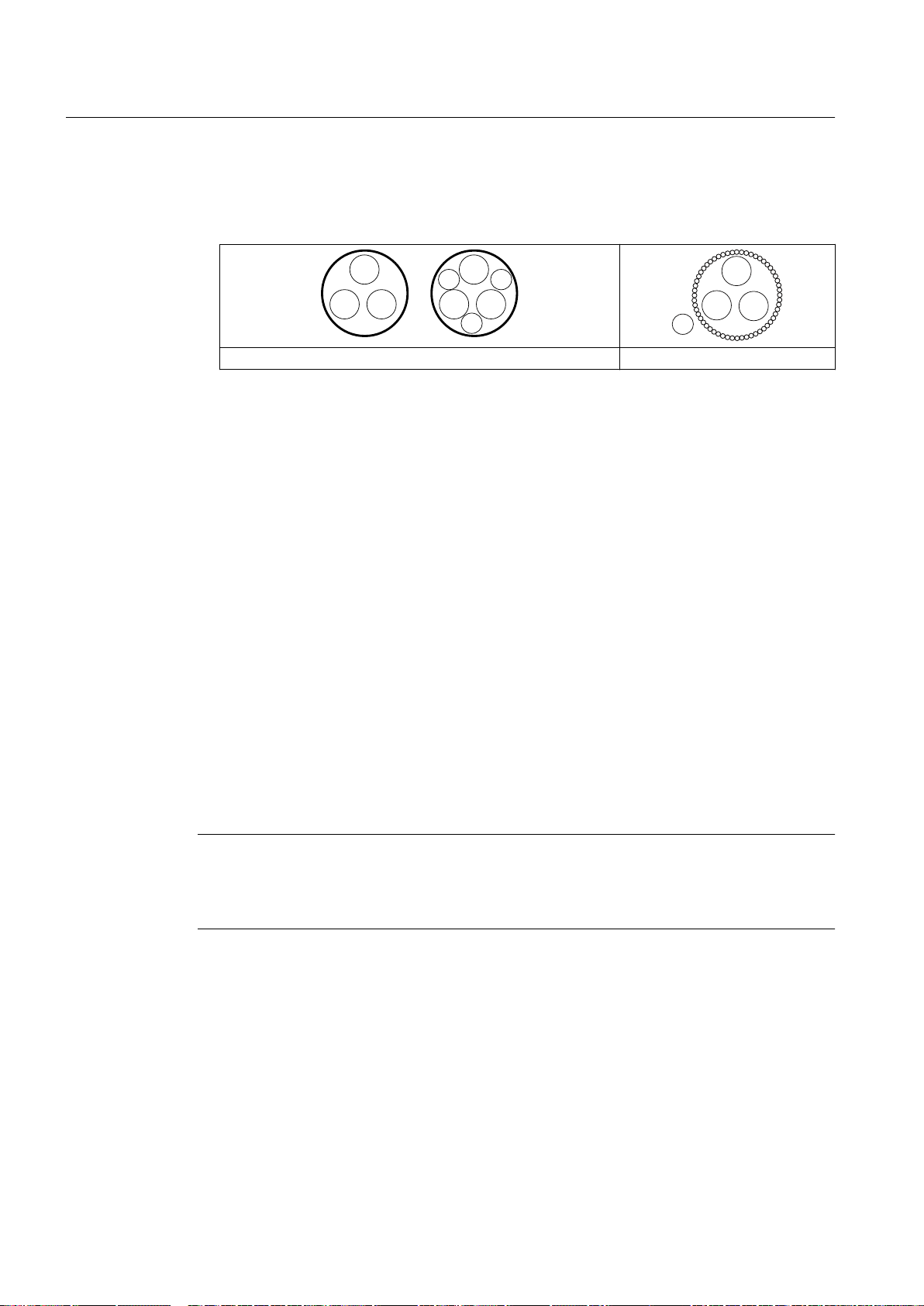

Figure 4-2 Schematic representation of a single drive .................................................................................53

Figure 4-3 Schematic representation of a tandem drive...............................................................................53

Figure 5-1 Balancing type on the drive-end side ..........................................................................................62

Figure 5-2 Condensation water drain for vertical mounting..........................................................................66

Figure 5-3 Condensation water drain for horizontal mounting......................................................................67

Figure 5-4 Schematic diagram: Aligning the machine to the driven machine...............................................69

Figure 6-1 Water drip loop............................................................................................................................76

Figure 6-2 Terminal box 1XB1621................................................................................................................77

Figure 6-3 Terminal box 1XB1631................................................................................................................77

Figure 6-4 Terminal box 1XB7730................................................................................................................78

Figure 6-5 Terminal box 1XB7731................................................................................................................79

Figure 6-6 Terminal box 1XB7740................................................................................................................79

Figure 6-7 Terminal box 1XB7750................................................................................................................80

Figure 6-8 Strain relief device and sealing insert..........................................................................................88

SIMOTICS FD 1LN1

Operating Instructions 01/2019 11

Page 12

Table of contents

Figure 6-9 Connection with cable lug and fixing screw (schematic diagram)...............................................91

Figure 6-10 Connection using terminal clamps (schematic diagram).............................................................92

Figure 7-1 Selecting a motor type...............................................................................................................108

Figure 7-2 Entering the motor data.............................................................................................................109

Figure 9-1 Remove the V ring.....................................................................................................................139

Figure 9-2 Disassembling the labyrinth sealing ring (schematic diagram) .................................................140

Figure 9-3 Install the V ring.........................................................................................................................142

Figure 9-4 Roller-contact bearing with grease chamber (schematic diagram) ...........................................143

Figure 9-5 Position the set screws for the labyrinth sealing ring on the outer bearing cover .....................144

Figure 10-1 Housing, stators and rotors .......................................................................................................151

Figure 10-2 Top enclosure............................................................................................................................153

Figure 10-3 Bearing cartridge at the drive end and non-drive end ...............................................................154

Figure 10-4 Bearing cartridge at the drive end and non-drive end ...............................................................155

Figure 10-5 Terminal box 1XB1621 with standard cable entry.....................................................................156

Figure 10-6 Two-part cable entry..................................................................................................................156

Figure 10-7 Terminal box 1XB1631..............................................................................................................158

Figure 10-8 Main terminal box 1XB7730 ......................................................................................................159

Figure 10-9 Main terminal box 1XB7731 ......................................................................................................160

Figure 10-10 Main terminal box 1XB7740 ......................................................................................................161

Figure 10-11 Terminal box 1XB7750 with standard cable entry.....................................................................162

Figure 10-12 Auxiliary terminal box 1XB9014 .............................................................................................163

Figure 10-13 Auxiliary terminal box 1XB9015 .............................................................................................164

Figure 10-14 1XB9016 auxiliary terminal box ...............................................................................................165

Figure 10-15 Auxiliary terminal box 1XB302. .................................................................................................166

SIMOTICS FD 1LN1

12 Operating Instructions 01/2019

Page 13

Introduction

In the following text, the motor is referred to as "electrical machine" – or abbreviated, just

"machine".

1.1 About these instructions

These instructions describe the machine and explain how to handle it, from initial delivery to

final disposal of the equipment. Keep these instructions for later use.

Read these operating instructions before you handle the machine and follow the instructions to

become familiar with its design and operating principles and thus ensure safe, problem-free

machine operation and long service life.

Safety instructions and handling-related warning notes are provided in these instructions.

When carrying out any activity at or with the machine, carefully comply with all of these notes

for your own safety, to protect other people and to avoid material damage.

Please contact the Service Center (Page 171) if you have any suggestions on how to improve

this document.

1

Text format features

You can find the following text format features in these instructions:

1. Handling instructions are always formatted as a numbered list. Always perform the steps in

the order given.

● Lists are formatted as bulleted lists.

– Lists on the second level are hyphenated.

Note

The note provides you with additional information about the product itself, handling the product

- and the relevant documentation.

1.2 Compiling personal documents

On the Internet pages in Industry Online Support you have the possibility of compiling personal

documents using the function Documentation (

support.industry.siemens.com/My/ww/en/documentation)

Using the "Documentation" function, from Product Support manuals, you can compile your own

"Documentation". However, you can also include other Product Support content such as FAQs

or characteristics in the documentation that you compile.

https://

SIMOTICS FD 1LN1

Operating Instructions 01/2019 13

Page 14

Introduction

1.2 Compiling personal documents

In the "Documentation" function, you have the option of creating your own compiled documents

in your own structure and managing them. You can delete or shift individual chapters or topics.

Further, using the note function you can import your own content. The compiled

"documentation" can be exported as PDF, for example.

Using the "Documentation" function, you can efficiently compile your own plant or system

documentation. The "Documentation" compiled in a specific language can also be

automatically exported in one of the other available languages.

The full functionality is only available for registered users.

SIMOTICS FD 1LN1

14 Operating Instructions 01/2019

Page 15

Safety information

2.1 Information for the nominated person in control of the electrical installation

This electric machine has been designed and built in accordance with the specifications

contained in Directive 2014/35/EU ("Low-Voltage Directive") and is intended for use in

industrial plants. Please observe the country-specific regulations when using the electric

machine outside the European Community. Follow the local and industry-specific safety and

setup regulations.

The persons responsible for the plant must ensure the following:

● Planning and configuration work and all work carried out on and with the machine is only to

be done by qualified personnel.

● The operating instructions must always be available for all work.

● The technical data as well as the specifications relating to the permissible installation,

connection, ambient and operating conditions are taken into account at all times.

● The specific setup and safety regulations as well as regulations on the use of personal

protective equipment are observed.

Note

2

Use the services and support provided by the local service center (Page 171) for planning,

installation, commissioning and service work.

2.2 The 5 safety rules

For your own personal safety and to prevent material damage when carrying out any work,

always observe the safety-relevant instructions and the following five safety rules according to

EN 50110‑1 "Working in a voltage-free state". Apply the five safety rules in the sequence stated

before starting work.

5 safety rules

1. Disconnect the system.

Also disconnect the auxiliary circuits, for example, anti-condensation heating.

2. Secure against reconnection.

3. Verify absence of operating voltage.

4. Ground and short-circuit.

5. Provide protection against adjacent live parts.

To energize the system, apply the measures in reverse order.

SIMOTICS FD 1LN1

Operating Instructions 01/2019 15

Page 16

Safety information

2.3 Qualified personnel

2.3 Qualified personnel

All work at the machine must be carried out by qualified personnel only. For the purpose of this

documentation, qualified personnel is taken to mean people who fulfill the following

requirements:

● Through appropriate training and experience, they are able to recognize and avoid risks and

potential dangers in their particular field of activity.

● They have been instructed to carry out work on the machine by the appropriate person

responsible.

2.4 Safe handling

Workplace safety depends on the attentiveness, care, and common sense of the personnel

who install, operate, and maintain the machine. In addition to the safety measures cited, as a

matter of principle, the use of caution is necessary when you are near the machine. Always pay

attention to your safety.

Also observe the following to prevent accidents:

● General safety regulations applicable in the country where the machine is deployed.

● Manufacturer-specific and application-specific regulations

● Special agreements made with the operator

● Separate safety instructions supplied with the machine

● Safety symbols and instructions on the machine and its packaging

Danger as a result of stationary parts under voltage (live parts)

Live parts represent a hazard. Touch protection against active (live) parts is no longer

guaranteed if covers are removed. The minimum clearance and creepage distances may be

violated when coming close to live parts. Touching or coming close to them can result in death,

serious injury or material damage.

● Ensure that all live parts are suitably covered.

● Switch off and disconnect the machine first if you want to remove covers. Observe the "5

safety rules".

Risk of injury due to rotating parts

Rotating parts are dangerous. Touch protection against rotating parts is no longer guaranteed

if covers are removed. Touching rotating parts can result in death, serious injury or material

damage.

● Ensure that all rotating parts are reliably covered.

● Switch off and disconnect the machine first if you want to remove covers. Observe the "5

safety rules".

● Only remove covers when the rotating parts have come to a complete standstill.

SIMOTICS FD 1LN1

16 Operating Instructions 01/2019

Page 17

Risk of burns due to hot surfaces

Individual machine parts can become hot in operation. Burns can result when coming into

contact with these parts.

● Never touch machine parts during operation.

● Allow the machine to cool before starting work on the machine.

● Check the temperature of parts before touching them. If required, wear suitable protective

equipment.

Health hazard due to chemical substances

Chemical substances required for the setup, operation and maintenance of machines can

present a health risk.

● Observe the product information provided by the manufacturer.

Flammable substances hazard

Chemical substances required for the setup, operation and maintenance of machines may be

flammable. These substances can ignite if handled incorrectly. They can cause burns and

property damage.

Safety information

2.4 Safe handling

See also

Noise emissions

● Observe the product information provided by the manufacturer.

The 5 safety rules (Page 15)

During operation, the machine's noise emission levels can exceed those permitted at the

workplace, which can cause hearing damage.

● Ensure that nobody is in the area of increased noise emissions during machine operation.

● Take steps to reduce noise so that the machine can be operated safely within your system.

The following measures may help to reduce noise.

– Covers

– Noise insulation

– Hearing protection measures

SIMOTICS FD 1LN1

Operating Instructions 01/2019 17

Page 18

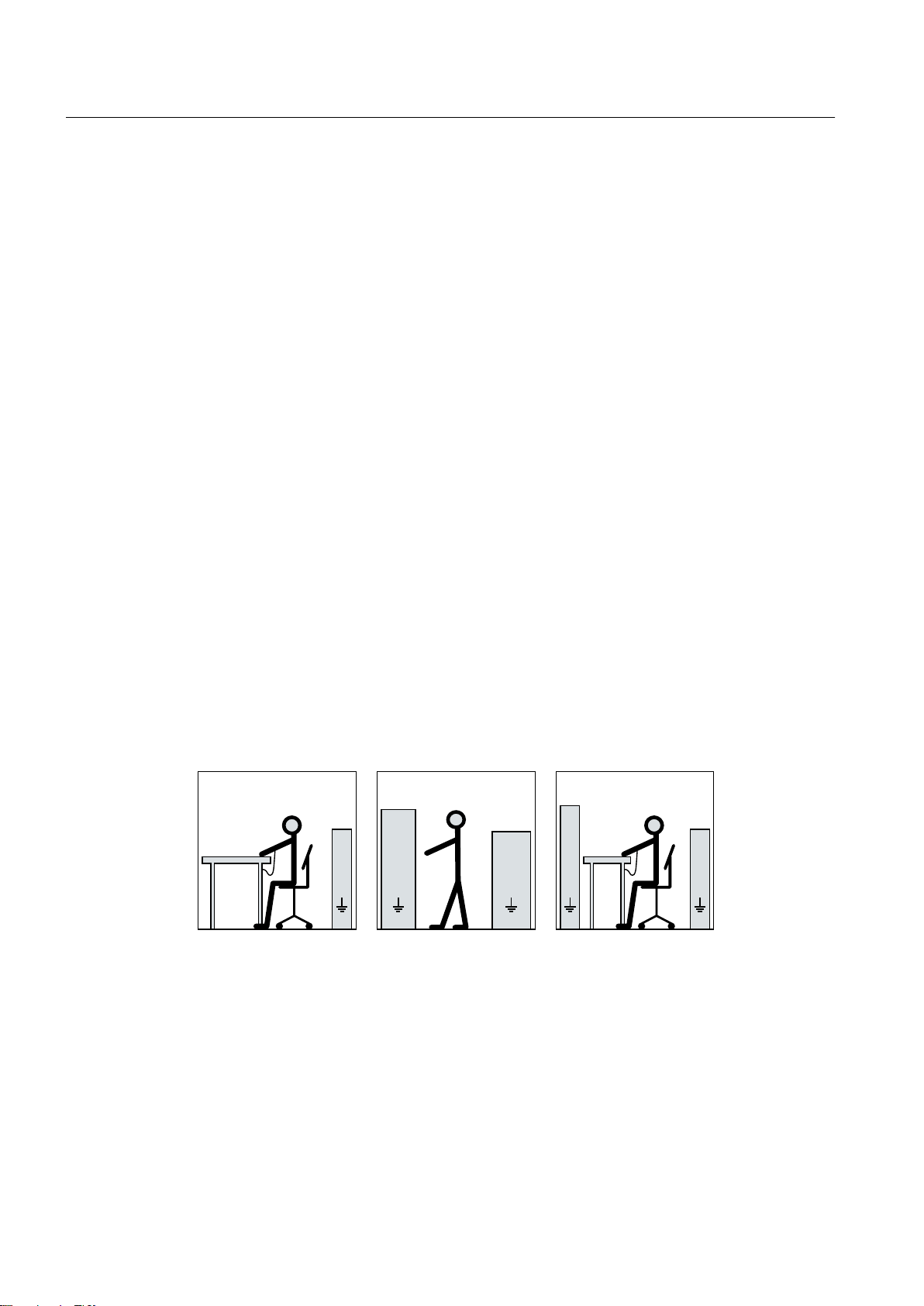

6HDWLQJSRVLWLRQ

6WDQGLQJSRVLWLRQ

6WDQGLQJVHDWLQJSRVLWLRQ

EE

D

F

D

IIIII

D

FF

H

GG

H

G

Safety information

2.5 Electrostatic sensitive devices

2.5 Electrostatic sensitive devices

Material damage due to electrostatic discharge

Electronic modules contain components that can be destroyed by electrostatic discharge.

These components can be damaged or destroyed if they are not handled correctly. To protect

equipment against damage, follow the instructions given below.

● Only touch electronic modules if you absolutely have to work on them.

● The body of the person concerned must have been electrostatically discharged and

grounded immediately before any electronic modules are touched.

● Electronic modules should not be brought into contact with electrically insulating materials,

such as:

– Plastic film

– Plastic parts

– Insulating table supports

– Clothing made of synthetic fibers

● Always place electrostatic sensitive devices on conductive bases.

● Always pack, store and transport electronic modules or components in conductive

packaging, such as:

– Metallized plastic or metal containers

– Conductive foam material

– Domestic aluminum foil

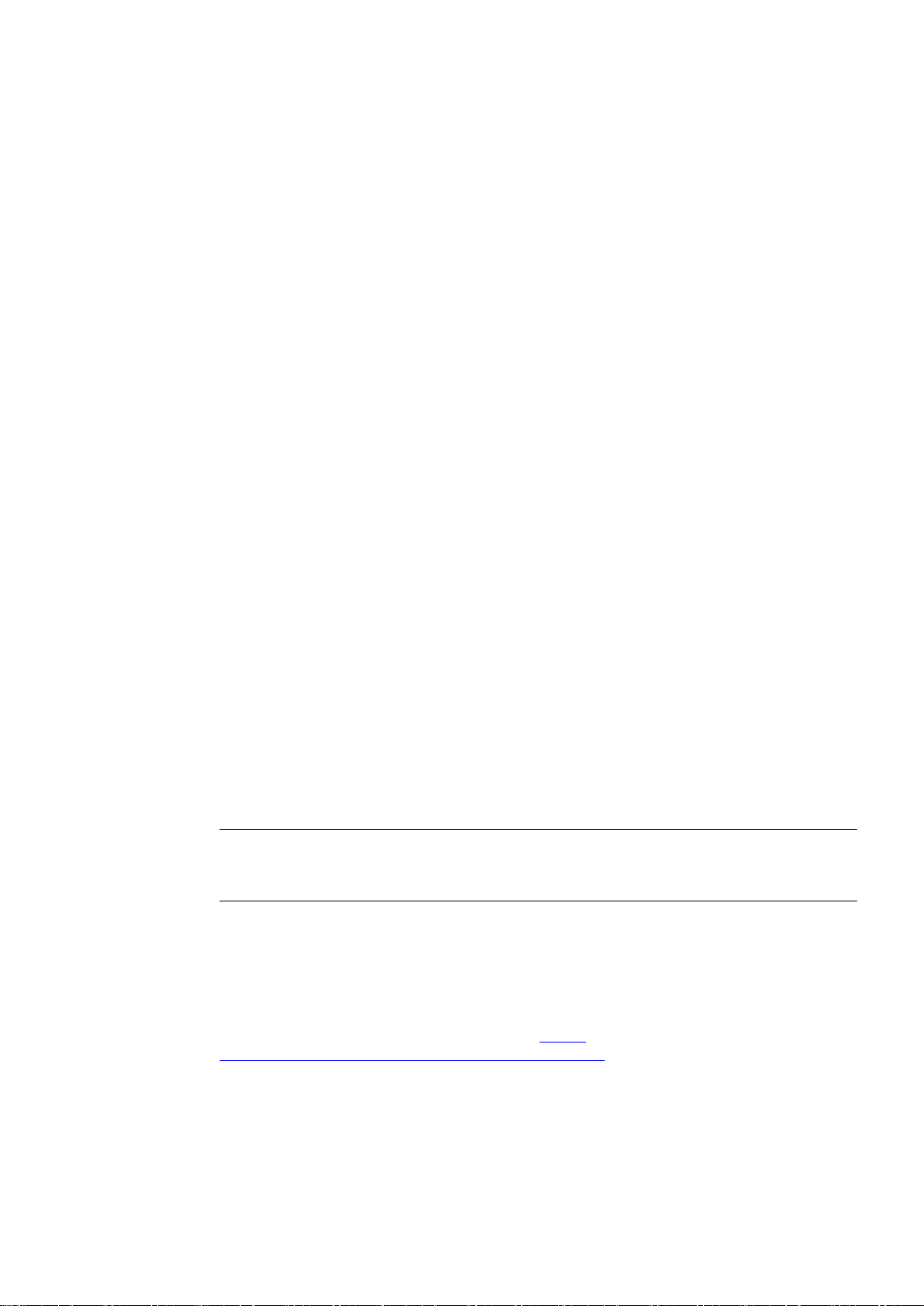

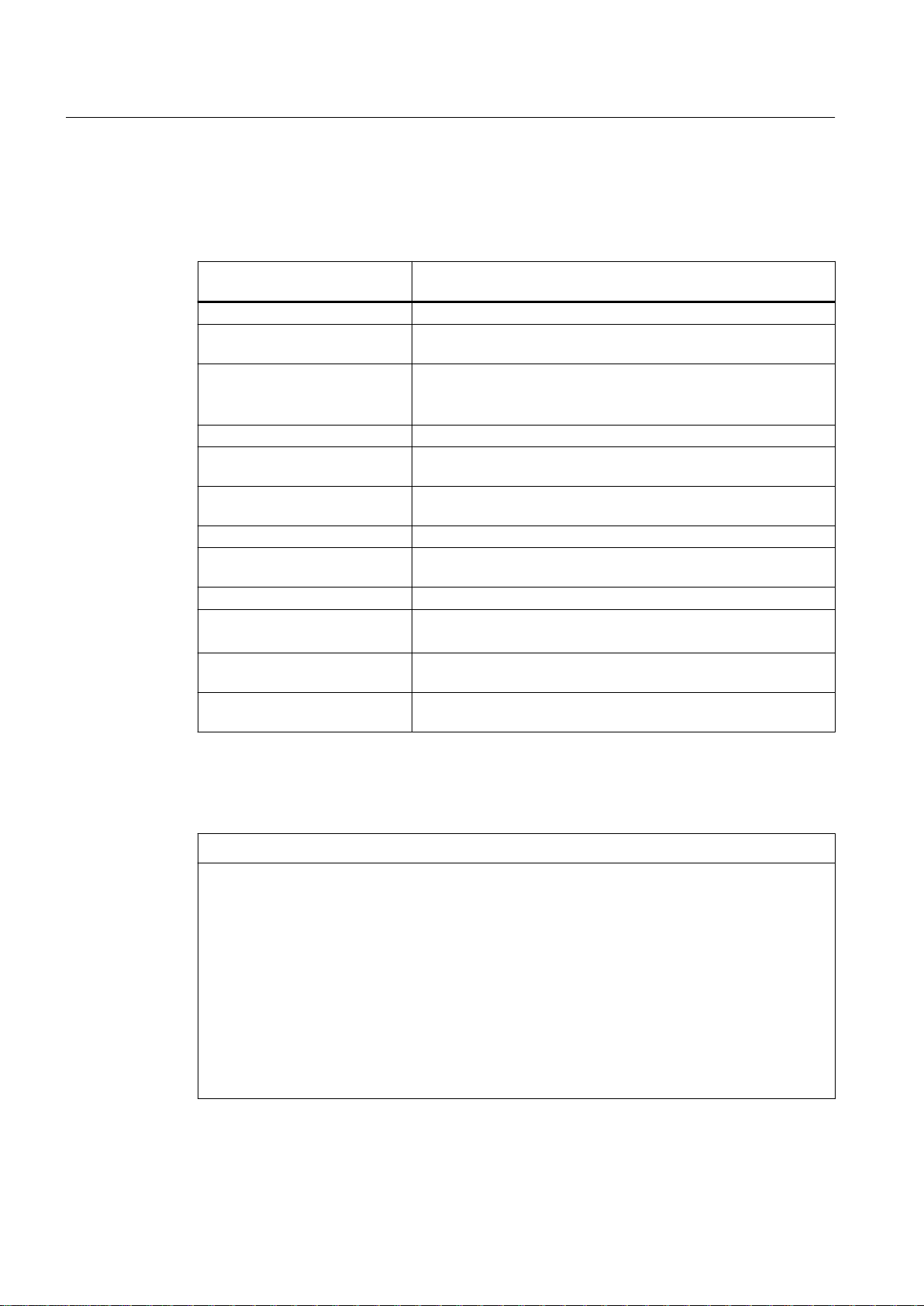

The necessary ESD protective measures for electrostatic sensitive devices are illustrated once

again in the following drawings:

a = conductive floor surfaceb = ESD table c = ESD shoes

d = ESD overall e = ESD wristband f = cabinet ground connection

2.6 Interference immunity

By selecting suitable signal cables and evaluation units, ensure that the interference immunity

of the machine is not diminished.

18 Operating Instructions 01/2019

SIMOTICS FD 1LN1

Page 19

Safety information

2.7 Interference voltages when operating the converter

2.7 Interference voltages when operating the converter

Interference voltages when operating the converter

When a converter is in operation, the emitted interference varies in strength depending on the

converter (manufacturer, type, interference suppression measures undertaken). On machines

with integrated sensors (e.g. PTC thermistors), interference voltages caused by the converter

may occur on the sensor lead. This can cause faults which can result in eventual or immediate

death, serious injury or material damage.

● Comply with the EMC information provided by the manufacturer of the converter. This is how

you prevent the limit values stipulated by IEC/EN 61000-6-3 for the drive system (consisting

of the machine and converter) from being exceeded.

● You must put appropriate EMC measures in place.

2.8 Electromagnetic fields when operating electrical power engineering installations

Electrical power equipment generate electromagnetic fields during operation. Potentially lethal

malfunctions can occur in medical implants, e.g. pacemakers, in the vicinity of electrical power

equipment. Data may be lost on magnetic or electronic data carriers.

● Protect the personnel working in the plant by taking appropriate measures, such as erecting

identifying markings, safety barriers and warning signs and giving safety talks.

● Observe the nationally applicable health and safety regulations.

● It is forbidden for people with pacemakers to be close to the machine.

● Do not carry any magnetic or electronic data media.

SIMOTICS FD 1LN1

Operating Instructions 01/2019 19

Page 20

Safety information

2.8 Electromagnetic fields when operating electrical power engineering installations

SIMOTICS FD 1LN1

20 Operating Instructions 01/2019

Page 21

Description

Applications

3

This electrical machine has been designed for a wide range of drive and energy conversion

applications. The machines are characterized by extreme ruggedness, long service life, and

overall reliability. They are also highly versatile, allowing them to be tailored to specific

functions.

Details of the supplied machine and permissible operating conditions can be found in this

documentation.

The machine was designed in accordance with the ordering party's specification and may only

be used for the contractually agreed purpose. The permissible operating conditions are

specified on the rating plate. The technical data are described in the catalog.

WARNING

Risk of explosion

This machine is not designed for use in hazardous areas. An explosion can occur if the

machine is operated in these areas. This can result in death, serious injury or material damage.

● Never operate this machine in hazardous areas.

Machine design

The regulations and standards used as the basis to design and test this machine are stamped

on the rating plate.

The machine design basically complies with the subsequent standards. Please refer to the EU

Declaration of Conformity for the versions of the harmonized standards referenced.

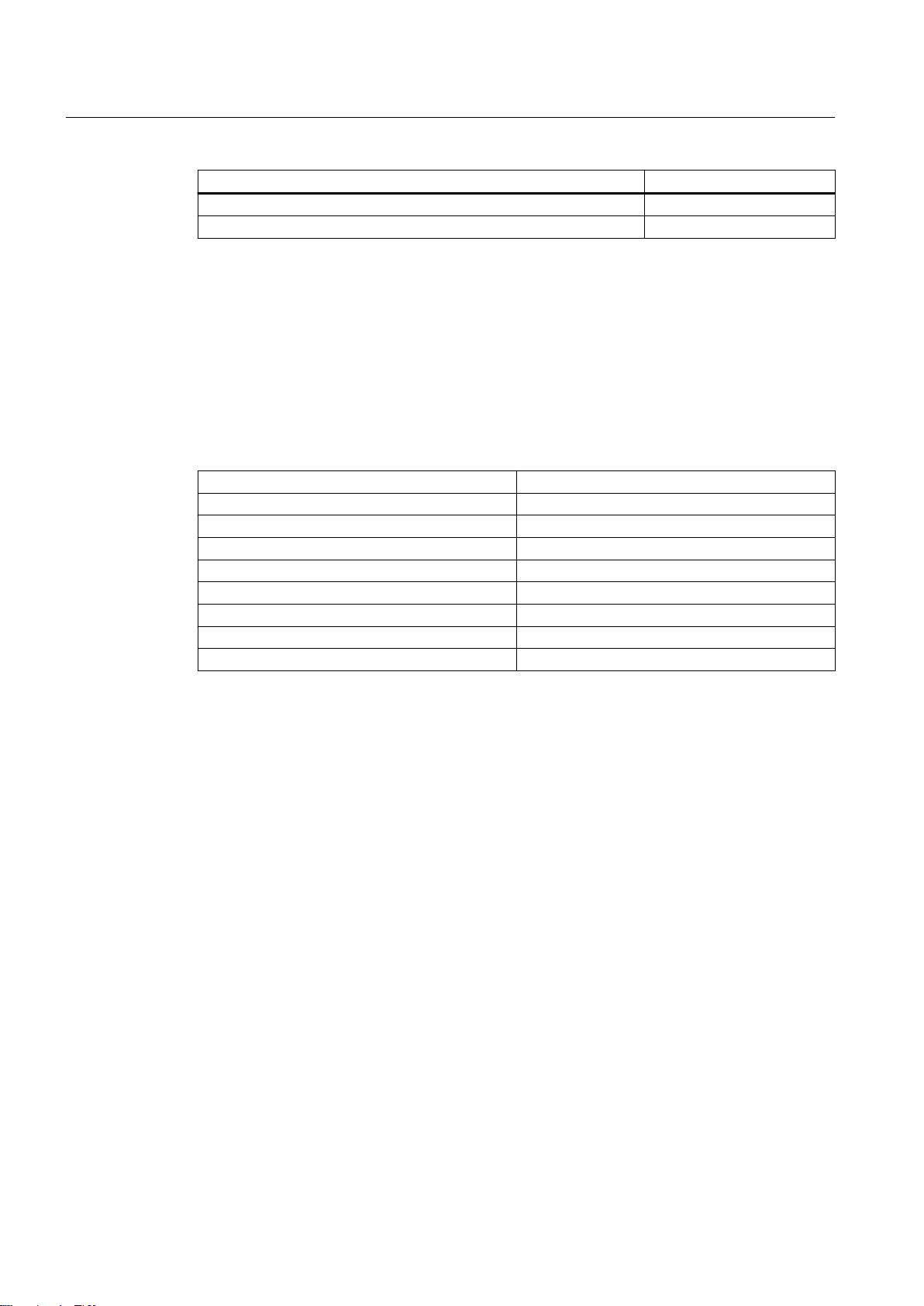

Table 3-1 Machine design

Feature Standard

Rating and performance IEC/EN 60034‑1

Degree of protection IEC/EN 60034‑5

Cooling IEC/EN 60034‑6

Type of construction IEC/EN 60034‑7

Terminal markings and direction of rotation IEC/EN 60034‑8

Noise emission IEC/EN 60034‑9

Starting characteristics of rotating electrical machines * IEC/EN 60034‑12

Vibration severity grades IEC/EN 60034‑14

SIMOTICS FD 1LN1

Operating Instructions 01/2019 21

Page 22

Description

Feature Standard

Efficiency classification of three-phase squirrel-cage induction motors ** IEC/EN 60034-30-1

Vibration limits DIN ISO 10816-3

* For machines in line operation only

** Exception: Pole-changing motors

See also

Quality documents (Page 175)

Comparison of IEC and GOST standards

The IEC/EN standards correspond to the following GOST standards.

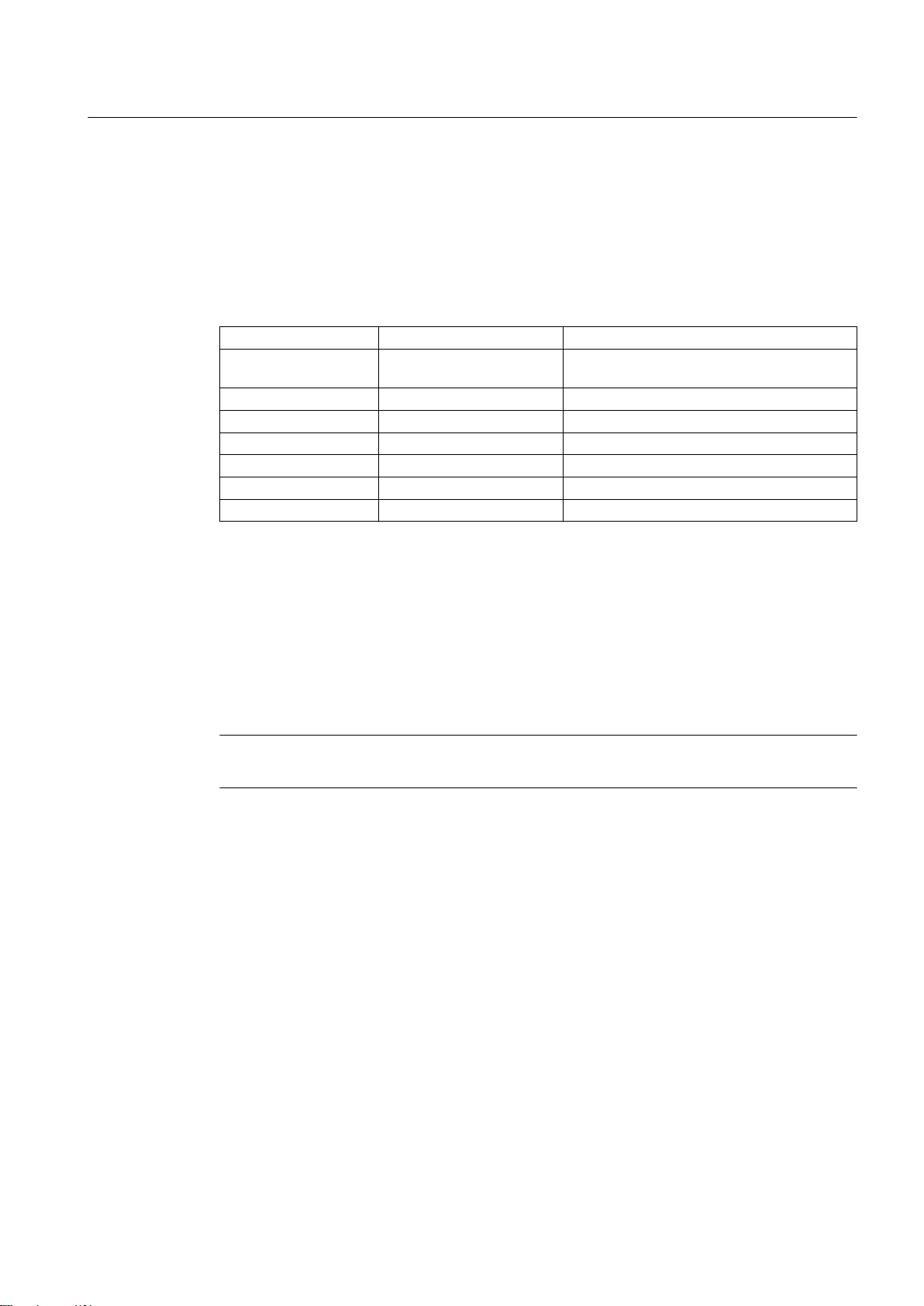

IEC/EN GOST

IEC/EN 60034-1 GOST R IEC 60034-1

IEC/EN 60034-5 GOST R IEC 60034-5

IEC/EN 60034-6 GOST R IEC 60034-6

IEC/EN 60034-7 GOST R IEC 60034-7

IEC/EN 60034-8 GOST R IEC 60034-8

IEC/EN 60034-9 GOST R IEC 60034-9

IEC/EN 60034-12 GOST R IEC 60034-12

IEC/EN 60034-14 GOST R IEC 60034-14

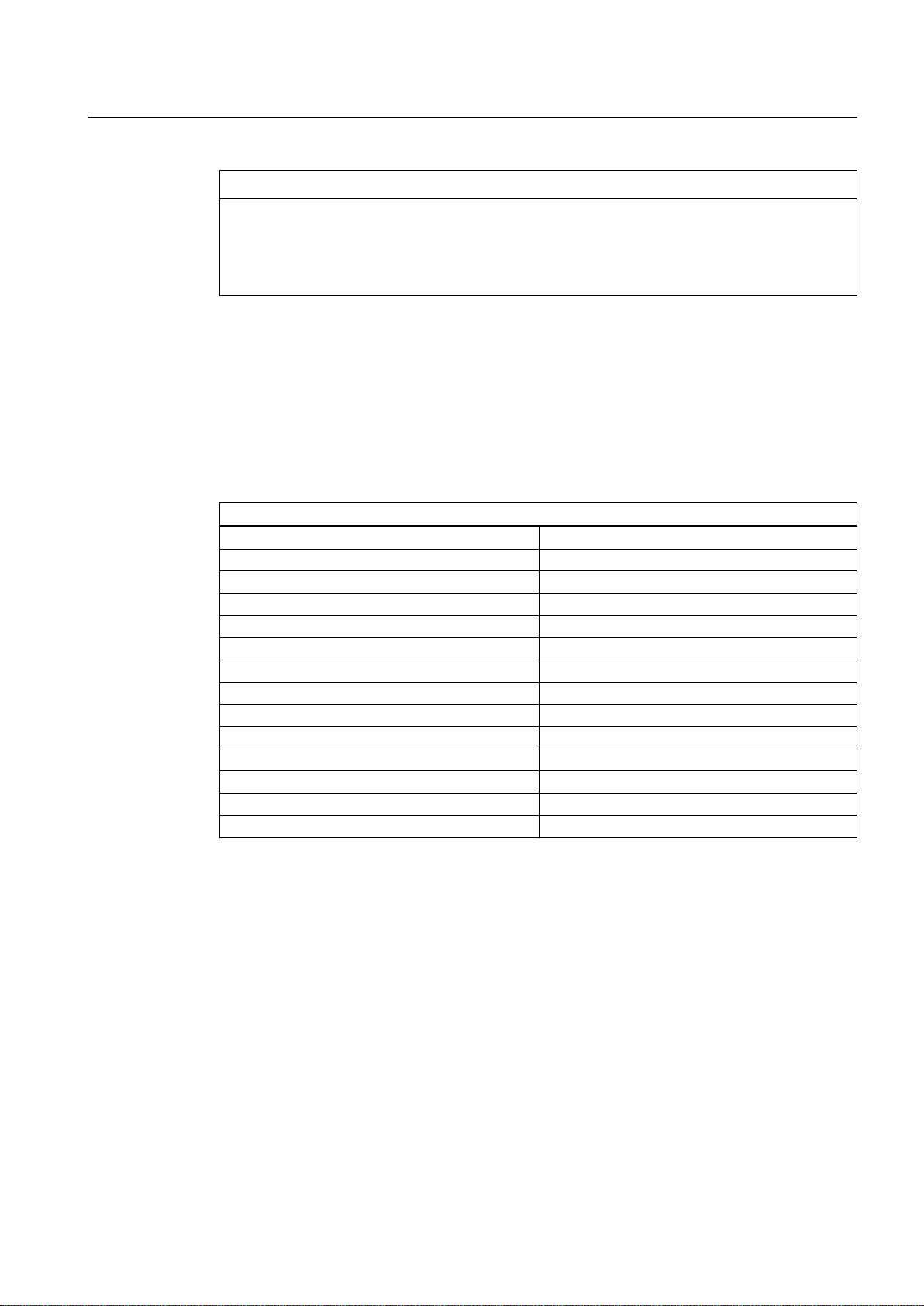

Rating plate

The rating plate shows the identification data and the most important technical data. The data

on the rating plate and the contractual agreements define the limits of proper usage.

SIMOTICS FD 1LN1

22 Operating Instructions 01/2019

Page 23

'(:

RR

RR

SIEMENS

Description

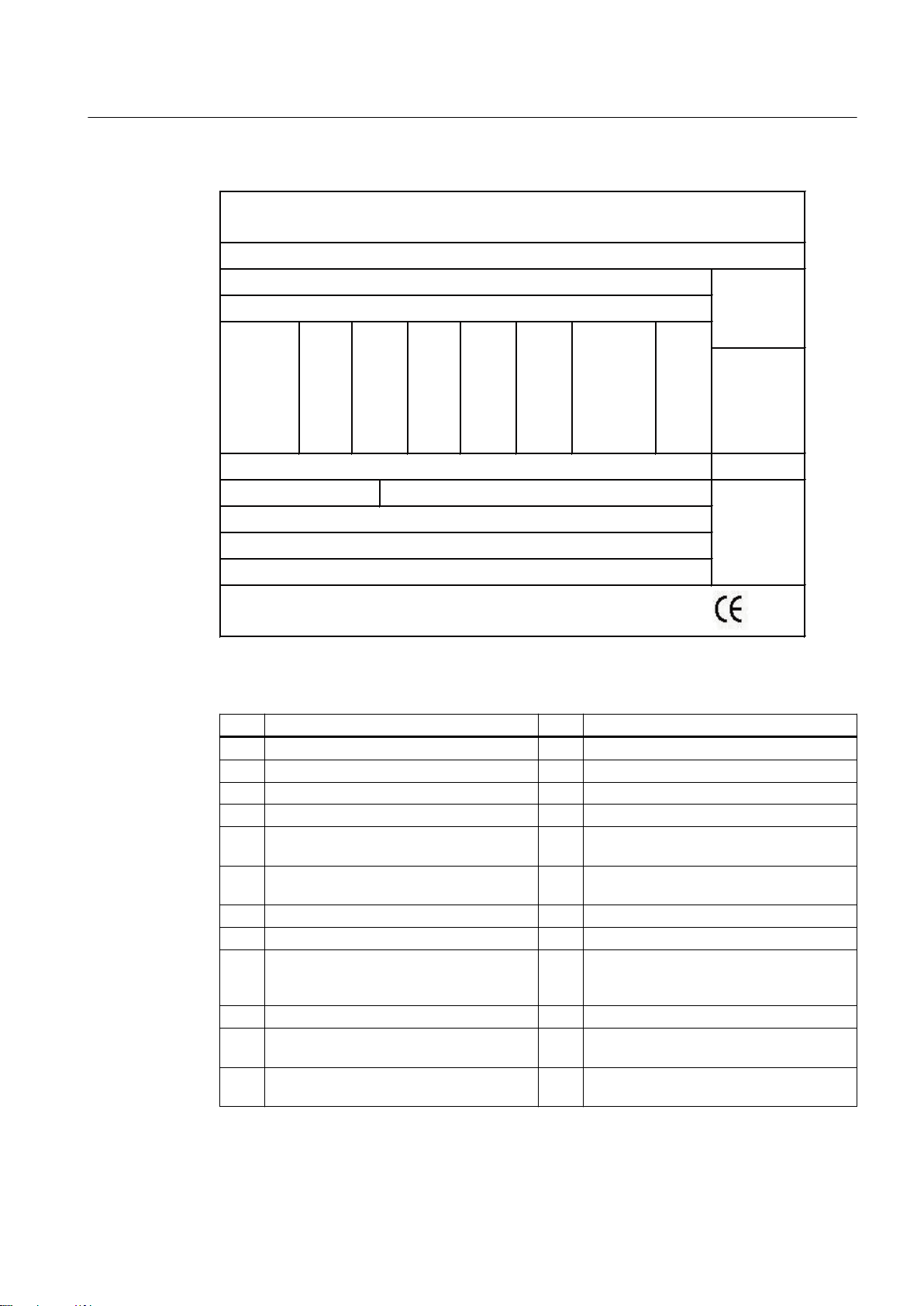

Figure 3-1 Schematic of the rating plate

Table 3-2 Data on the rating plate

Item Description Item Description

(1) Type of motor (15) Rated power [kW or HP]

(2) Order number (16) Rated efficiency factor

(3) Identifier of the motor series (17) Rated speed [rpm]

(4) Serial number (18) Rated frequency [Hz]

(5) Weight (19) Efficiency class (IE code) or efficiency ac‐

(6) Degree of protection (20) Efficiency according to IEC/EN 60034-2-1

(7) Type of construction (21) Motor design (converter or mains motor)

(8) Permissible ambient temperature range (22) Line voltage/frequency

(9) Thermal class of the insulation system (23) Optional additional data (e.g. service fac‐

(10) Thermal class of the utilization (24) Country of manufacture and location

(11) Maximum speed [rpm] (25) Certification mark for UL/CSA + file number

(12) Standards (26) Certificate number(s) for Ex motors for

cording to IEEE112B or empty

or current at service factor power

tor, design and code letter, amount of cool‐

ing water and intake temperature, etc.)

(optional)

Zone 2 (optional)

SIMOTICS FD 1LN1

Operating Instructions 01/2019 23

Page 24

Description

Relevant directives

Item Description Item Description

(13) Rated voltage [V] and connections (27) Direction of rotation

(14) Rated current [A] (28) Data matrix code (order number and serial

number)

The following directives are relevant for the SIMOTICS motor series.

European low-voltage directive

The SIMOTICS motor series complies with the requirements of the low-voltage directive

2014/35/EU.

Eurasian Conformity

The SIMOTICS motor series complies with the requirements of the Russia/Belarus/

Kazakhstan customs union (EAC).

Underwriters Laboratories

The SIMOTICS motor series generally complies with UL and cUL requirements as component

of motor applications - and is correspondingly listed. Specifically developed motors and

functions are the exceptions in this case. Carefully observe the content of the quotation, and

that there is a cUL-marking on the rating plate.

Rotors

Quality management system

Siemens AG employs a quality management system that meets the requirements of ISO 9001

and ISO 14001.

Certificates that can be downloaded

You can download certificates for the SIMOTICS motor series at the following link:

Certificates (https://support.industry.siemens.com/cs/ww/en/ps/13358/cert)

The following directives are not relevant

● European EMC directive: The products are not considered as devices in the sense of the

directive.

● European Machinery Directive: However, the use of the products in a typical machine

application has been fully assessed for compliance with the main regulations in this directive

concerning health and safety.

● China Compulsory Certification (CCC): The SIMOTICS motor series does not fall under the

area of application.

The rotor assembly is pressed onto the shaft together with the cage winding. The drive end of

the shaft usually has a cylindrical shaft end. Dependent on the design, a second shaft end may

be located at the non-drive end.

SIMOTICS FD 1LN1

24 Operating Instructions 01/2019

Page 25

Drive

The motor speed is controlled using a converter. It has been optimized for operation with

SINAMICS low-voltage converters.

Other converters must comply with certain requirements: You can find more information in the

catalog or in the engineering documentation.

Efficiency requirement

According to EU Regulation (EC) No. 640/2009, the IE3 efficiency requirement for low-voltage

motors with a power of 7.5 kW to 375 kW for line operation has been in force since January 01,

2015.

From January 1, 2017, the IE3 efficiency requirement for motors with a power of 0.75 kW to

375 kW applies for line operation.

Efficiency IE2 still applies for motors that are operated from a converter.

Please note the applicable country-specific rules and regulations.

Description

NOTICE

Destruction of the machine when operated directly from the line supply

The machine will be destroyed if it is directly connected to the line supply. Only operate the

machine using a converter.

Cooling

The cooling system is designed as a closed, internal cooling circuit. The mounted cooler is an

air-to-water heat exchanger with a pipe system. The heat lost from the machine is dissipated

via the surface of the cooling pipes to the cooling liquid flowing in the pipes. External fans

facilitate the circulation of the cooling air in the primary circuit.

Leakage-water sensor

The leakage-water sensor is fitted externally on the machine enclosure and provides additional

security in the event of leakage.

Degree of protection

The machine is available with degree of protection IP55.

SIMOTICS FD 1LN1

Operating Instructions 01/2019 25

Page 26

Description

Rolling-contact bearings

The machines are equipped with different types of rolling-contact bearings depending on the

version and the operating conditions described in the order. The different types are listed on the

lubricant plate of the machine. In converter operation an insulated bearing is usually installed

on the non-drive end. The following rolling-contact bearing variants are available:

Table 3-3 Rolling-contact bearing variants

Version Rolling-contact bearing

Horizontal type of construction,

coupling output

Horizontal type of construction,

for increased transverse forces

e.g. in the case of belt coupling

Vertical type of construction,

shaft height 315, coupling output

Vertical type of construction,

shaft height 355 ... 450

● Drive end: Deep-groove ball bearing as a fixed bearing

● Non-drive end: Deep-groove ball bearing as a floating bearing

with axial compression springs

● Drive end: Cylindrical-roller bearing as a floating bearing

● Non-drive end: Deep-groove ball bearing as a fixed bearing

● Drive end: Deep-groove ball bearing as a fixed bearing

● Non-drive end: Deep-groove ball bearing as a floating bearing

with axial compression springs

● Drive end: Pairing of angular-contact ball bearing / deep-groove

ball bearing as a fixed bearing

● Non-drive end: Deep-groove ball bearing as a floating bearing

with axial compression springs

The standard version of the machine is not suitable for belt couplings. This can result in damage

to the machine.

Automatic regreasing system (option)

The roller bearings are optionally equipped with an automatic regreasing system. The roller

bearings are supplied with new grease portions by the regreasing system in parameterized

time intervals.

Rolling-contact bearing design for "Increased degree of protection" (option)

Improved sealing of the bearing units to prevent dust and water from getting in can be achieved

by positioning a grease chamber ahead of the actual bearing unit. Although the same grease

is used in both cases for reasons of convenience, a distinction is made here between

"lubricating grease" and "sealing grease" because of their different functions.

Layout

The spent lubricating grease collects in the space between the bearing housing and the outer

bearing cap. The latter also forms the sealing grease chamber with the labyrinth sealing ring

(optional). The second lubricating nipple containing the grease duct for pressing in the sealing

grease is also located in the outer bearing cap. The chamber is sealed off from the space where

the lubricating grease collects by a V-ring or a V-ring and felt ring combination which prevents

the sealing grease in the chamber from penetrating into the lubricating grease collecting space.

SIMOTICS FD 1LN1

26 Operating Instructions 01/2019

Page 27

Terminal box

Description

During operation, the sealing grease in the chamber slowly runs out via the labyrinth and seals

it, additionally removing dust from inside and around the outside of the labyrinth ring.

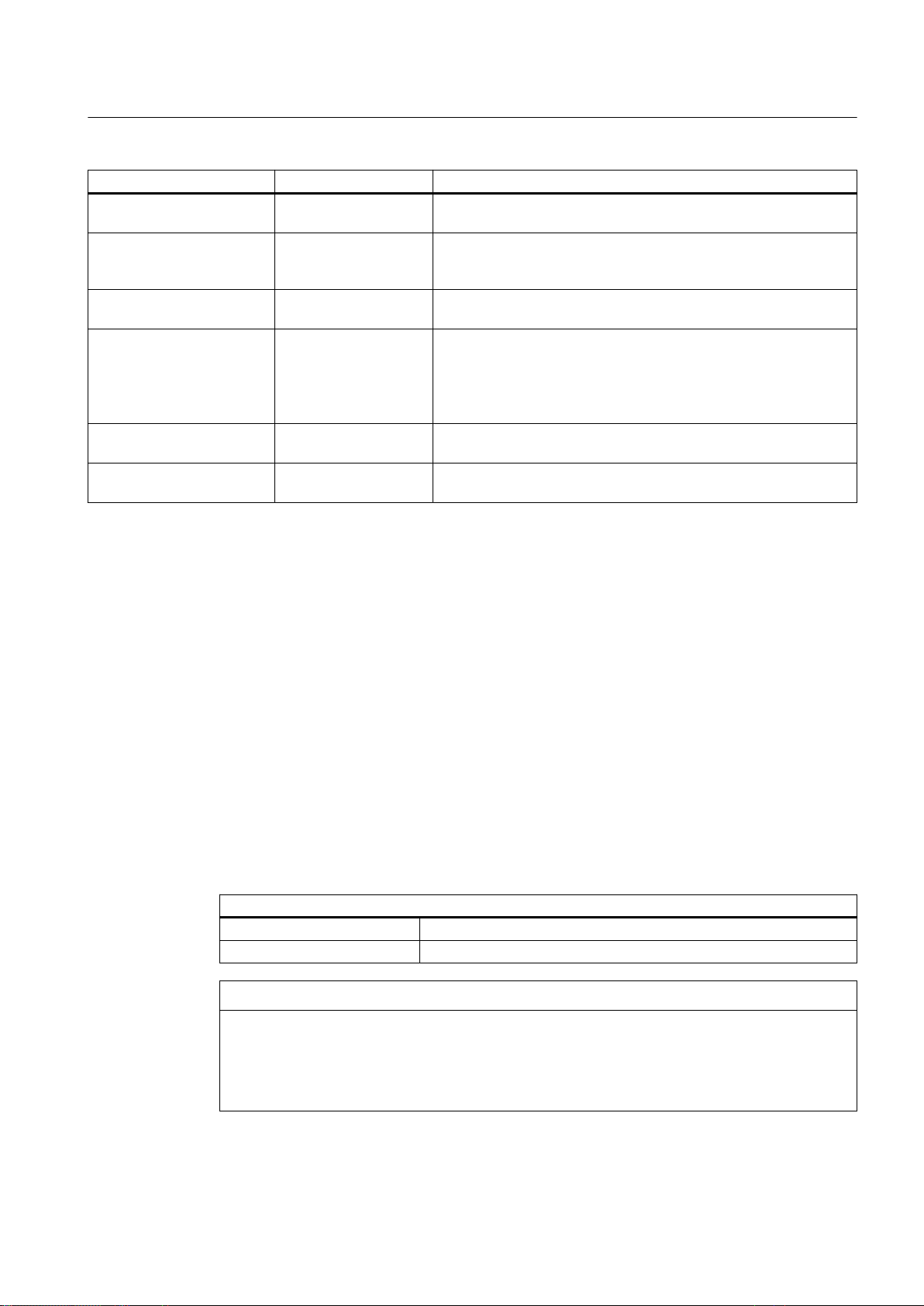

Depending on the machine design, the following terminal boxes are generally used for

connecting the cables:

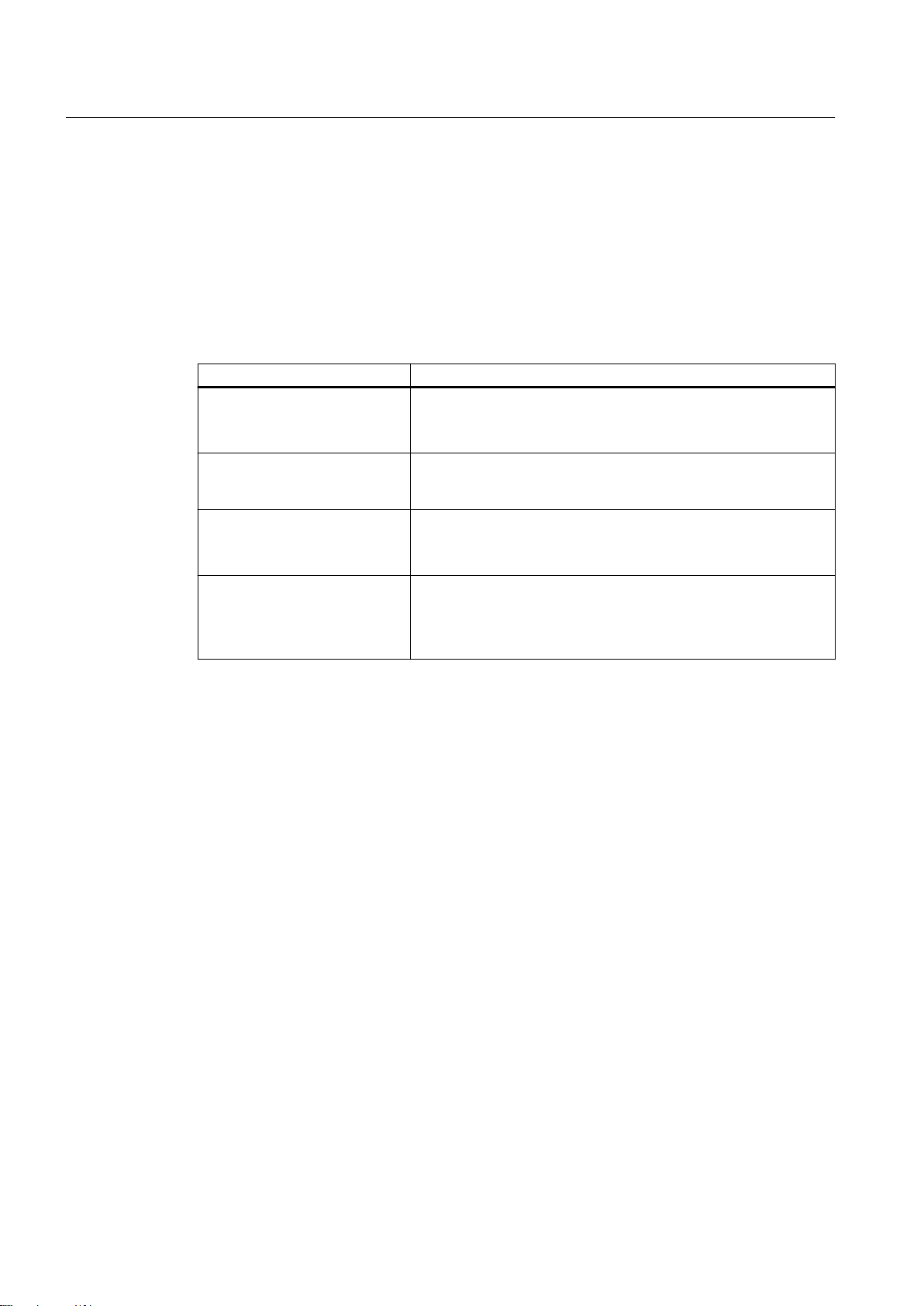

Terminal box Comment Application

GT640 Only for machines on the

power supply

1XB1621

1XB1631 2 × 1XB1631

1XB7730 Not for IEC explosion-proof versions

1XB7731 Not for IEC explosion-proof versions

1XB7740 2 × 1XB7740 Not for IEC explosion-proof versions

1XB7750

Not for explosion-proof versions

Depending on the terminal box and version, it is possible to rotate the terminal box through ±90°

in accordance with the connection direction. The implementation on the other motor side is

possible only with the support of the Service Center. If you wish to retrofit using a different

terminal box at a later date, please contact the Service Center (Page 171).

See also

Rotating the terminal box (Page 80)

Terminal box (Page 76)

Note

You can find more information in Chapter 2 of catalog D81.8.

Supplementary devices

Depending on the order, various supplementary devices can be installed or mounted. These

include sensors for bearing temperature monitoring or winding monitoring, for example.

Anti-condensation heating (option)

The machine is fitted with anti-condensation heating. The connection data is listed on an

additional plate on the machine.

SIMOTICS FD 1LN1

Operating Instructions 01/2019 27

Page 28

Description

SIMOTICS FD 1LN1

28 Operating Instructions 01/2019

Page 29

Preparations for use

Good planning and preparation of machine applications are essential in terms of keeping

installation simple and avoiding errors, ensuring safe operation, and allowing access to the

machine for servicing and corrective maintenance.

This chapter outlines what you need to consider when configuring your plant in relation to this

machine and the preparations you need to make before the machine is delivered.

4.1 Safety-related aspects to consider when configuring the plant

A number of residual risks are associated with the machine. These are described in the chapter

titled "Safety information" (Page 15) and in related sections.

Take appropriate safety precautions (covers, barriers, markings, etc.) to ensure the machine is

operated safely within your plant.

4.2 Observing the operating mode

Observe the machine's operating mode. Use a suitable control system to prevent overspeeds,

thus protecting the machine from damage.

4

4.3 Ensuring cooling

Ensure that the machine and/or any mounted external fan unit is sufficiently cooled by the

cooling air flow at the installation site:

● The cooling air can flow in and out freely. The full air flow provided by the fan is only achieved

if air can freely enter the impeller. Ensure that the required distance in accordance with the

dimensioned drawing is maintained.

● Hot discharged air must not be drawn in again.

● On the vertical design with air intake from above, the air inlets must be protected against the

ingress of foreign bodies and water.

See also

Connecting an external fan motor (Page 96)

SIMOTICS FD 1LN1

Operating Instructions 01/2019 29

Page 30

$

Preparations for use

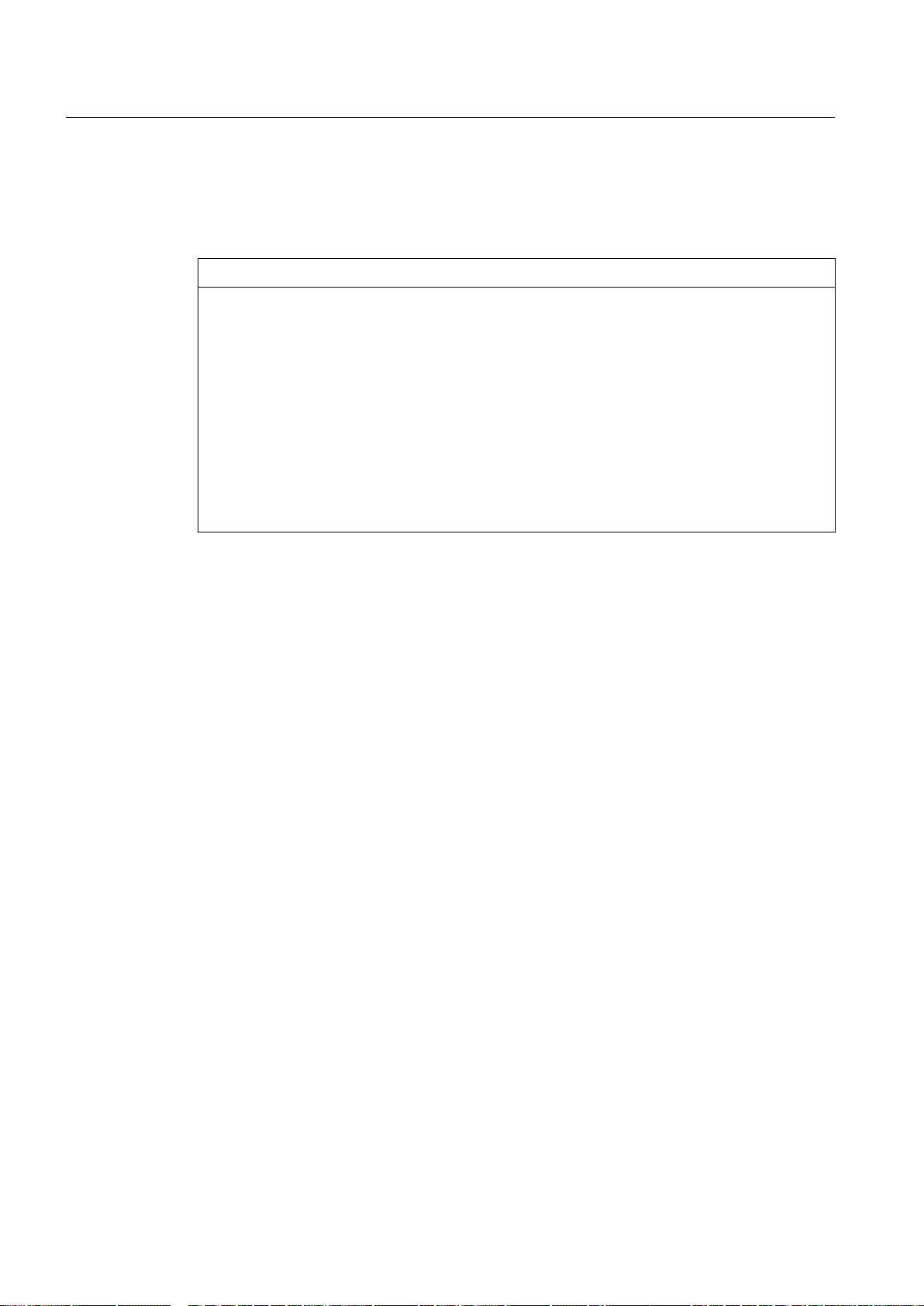

4.4 Space requirement

4.4 Space requirement

Maintain a clearance for the air intake where the machine is located (A). Plan sufficient space

on site for the machine so that the separately-driven fan can be removed and mounted again

as required. The necessary space requirements are listed in the following table:

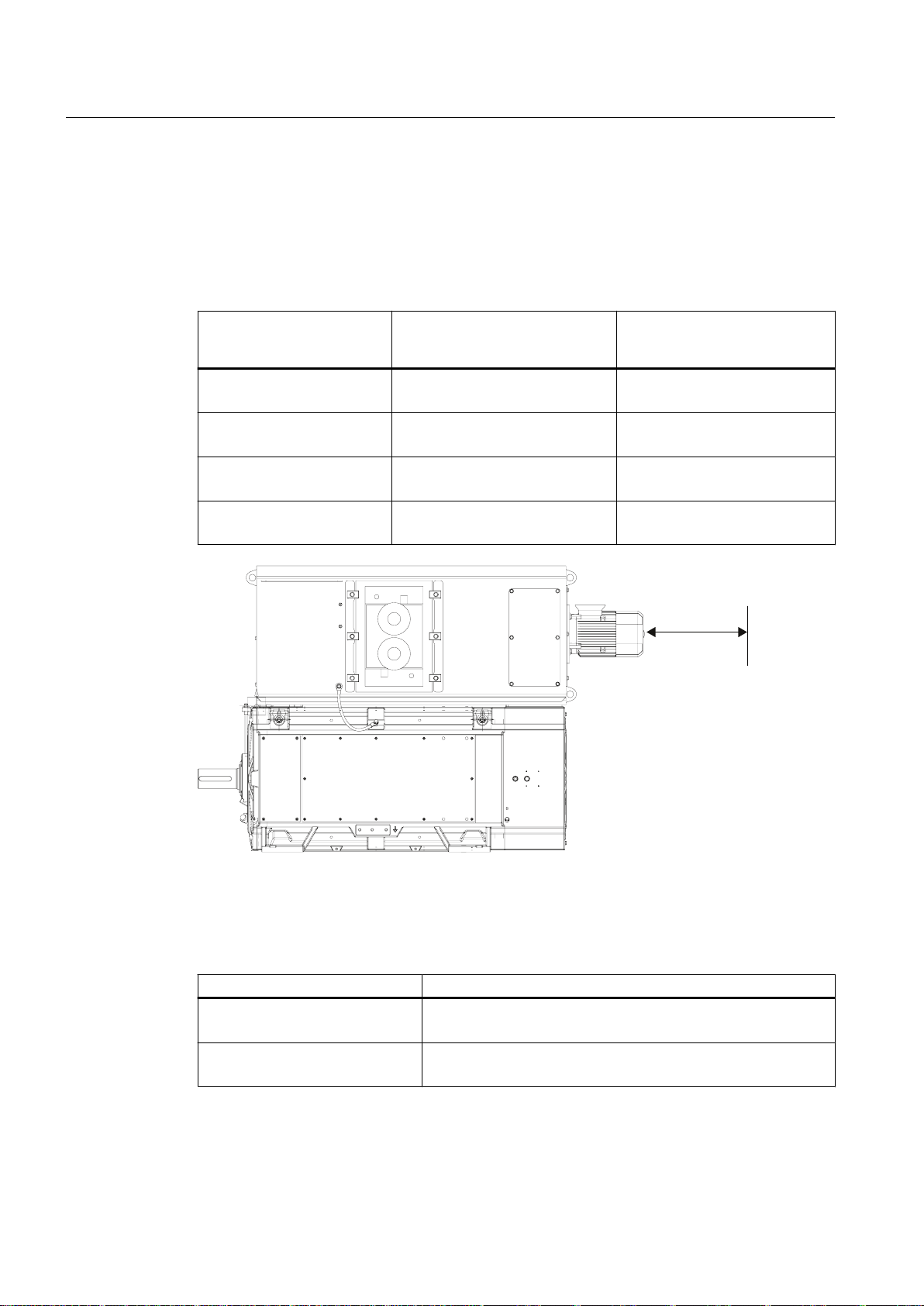

Table 4-1 Space required for the separately-driven fan

Type Space required to ventilate the

separately-driven fan

1LN….-3A…-….

1MN….-3A…-….

1LN….-3B…-….

1MN….-3B…-….

1LN….-4A…-….

1MN….-4A…-….

1LN….-4B…-….

1MN….-4B…-….

50 mm 210 mm

50 mm 210 mm

80 mm 240 mm

80 mm 240 mm

Space required for removing/

mounting the separately-driven

fan

Ensure there is sufficient space where the machine is installed so that the water cooler can be

removed and installed again when necessary. The necessary space requirements are listed in

the following table:

Table 4-2 Space required for removing/installing the water cooler

Type Space requirement / clearance A

1LN….-3A…-….

1MN….-3A…-….

1LN….-3B…-….

1MN….-3B…-….

950 mm

1000 mm

SIMOTICS FD 1LN1

30 Operating Instructions 01/2019

Page 31

$

4.5 Configuration of the cooling circuit and coolant supply

Type Space requirement / clearance A

1LN….-4A…-….

1MN….-4A…-….

1LN….-4B…-….

1MN….-4B…-….

1100 mm

1200 mm

Preparations for use

4.5 Configuration of the cooling circuit and coolant supply

4.5.1 Material selection for the cooling circuit

For optimum durability of the cooling system, use a closed or half open cooling circuit in

stainless steel or acrylic butadiene styrene (ABS).

Use either stainless steel or steel (S235JR) for the cooling circuit pipes and fittings.

SIMOTICS FD 1LN1

Operating Instructions 01/2019 31

Page 32

Preparations for use

4.5 Configuration of the cooling circuit and coolant supply

4.5.2 Pressures and differential pressures in the cooling circuit

The maximum permissible overpressure in the heat sink and thus in the cooling circuit can be

found on the air-to-water-cooler and in the associated operating instructions.

● If you are using a pump, which reaches more than this maximum pressure, then on the plant

or system side ensure that the maximum pressure is not exceeded.

● The lowest possible differential pressure between the coolant in the supply and return lines

should be selected to allow use of pumps with a flat characteristic.

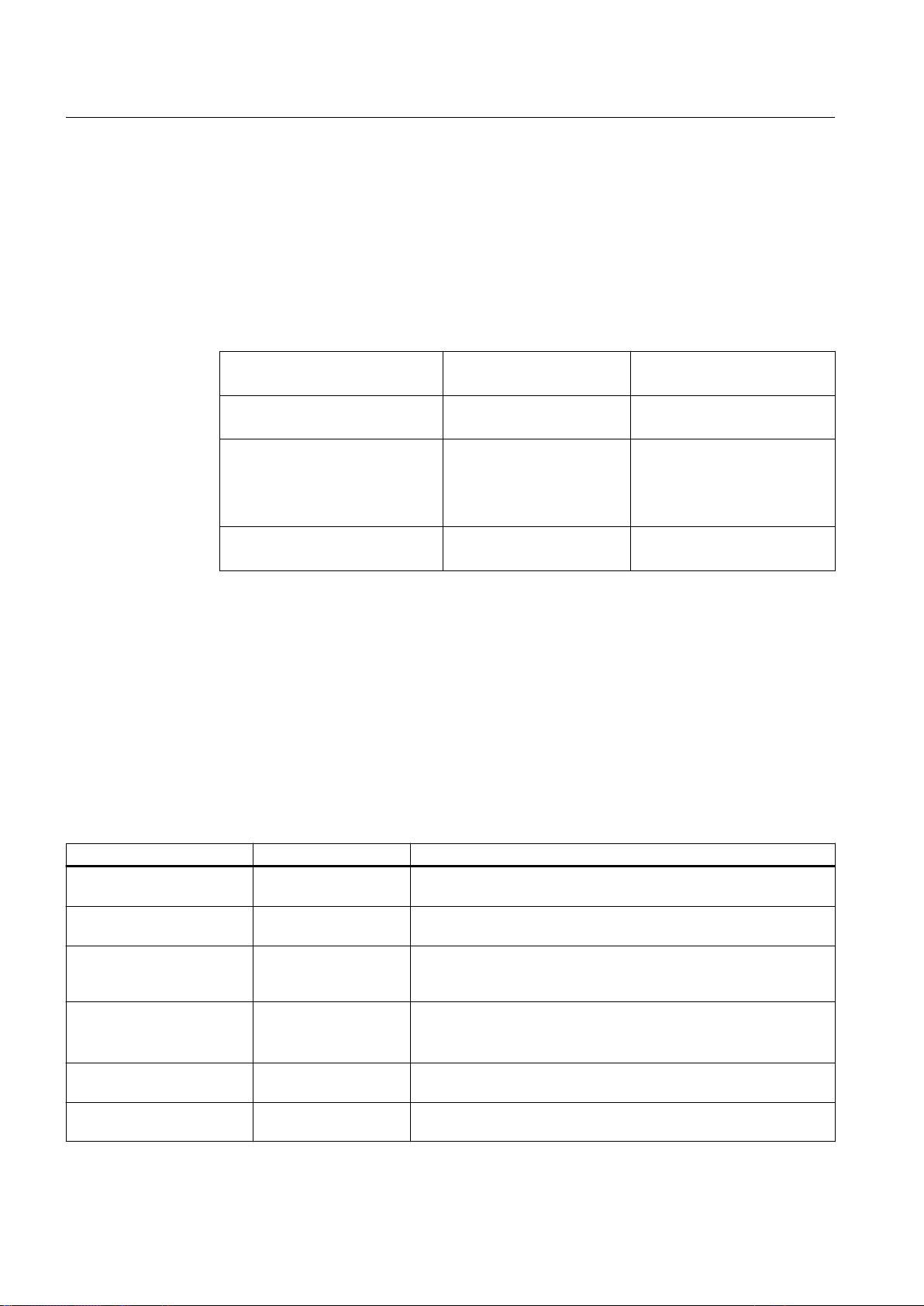

Machine type Flow rate ± 10 %

[l/min]

1LN….-3A…-….

1MN….-3A…-….

1LN….-3B…-….

1LN….-4A…-….

1MN….-3B…-….

1MN….-4A…-….

1LN….-4B…-….

1MN….-4B…-….

115 0.3

150 0.3

200 0.3

● The pressure drop is dependent on the machine type. The machine type is stamped on the

rating plate.

● If there is a risk of frost, use cooling water with antifreeze suitable for this temperature.

The pressure drop increases when antifreeze is added.

4.5.3 Components and materials of the cooling circuit

The following table lists a wide variety of materials and components which can occur in a

cooling circuit or which are prohibited.

Pressure drop for fresh water

[bar]

Table 4-3 Materials and components of a cooling circuit

Material Component Remark

Zinc Pipes, valves and fit‐

tings

Brass Pipes, valves and fit‐

tings

Copper Pipes, valves and fit‐

tings

Steel (e.g. S235JR) Cable Can be used in closed cooling circuits with inhibitors or anti-freeze.

Cast steel, cast iron Pipes, motors Can be used in closed cooling circuits. Use sieves and return flush

High-alloy steel, Group 1

(V2A)

Pipes, valves and fit‐

tings

Do not use any components manufactured out of zinc.

Can be used in closed cooling circuits with inhibitor.

Can only be used in closed cooling circuits with inhibitor. Locate an

isolating element, e.g. connecting pipe of the devices, between the

heat sink and copper component.

Check for the formation of oxide; to do this, use a sight glass, for

example.

filter; for stainless steel cooling systems, use a Fe separator.

Can be used for drinking or municipal water with a chloride content

< 250 ppm.

SIMOTICS FD 1LN1

32 Operating Instructions 01/2019

Page 33

Preparations for use

4.6 Coolant specification

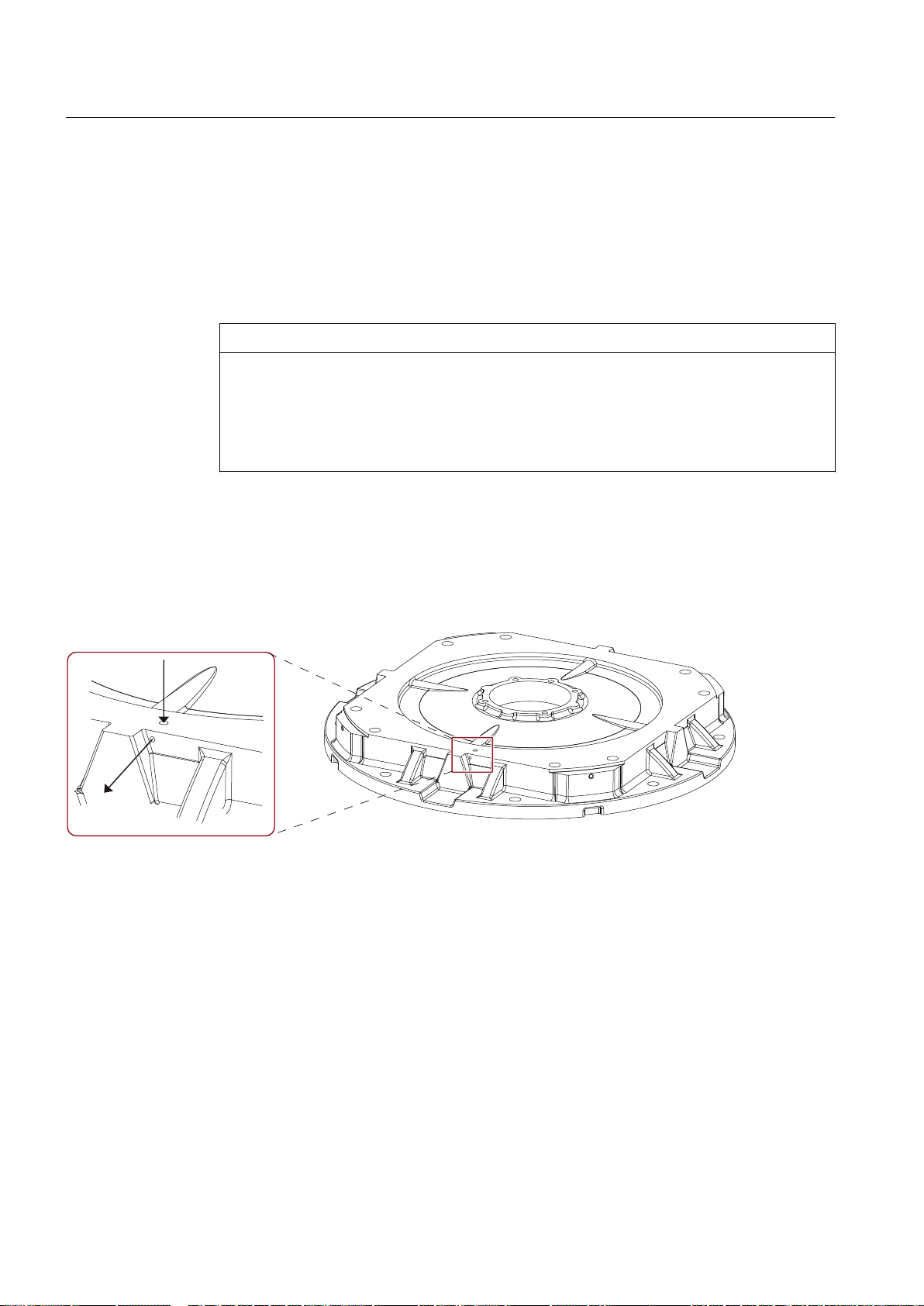

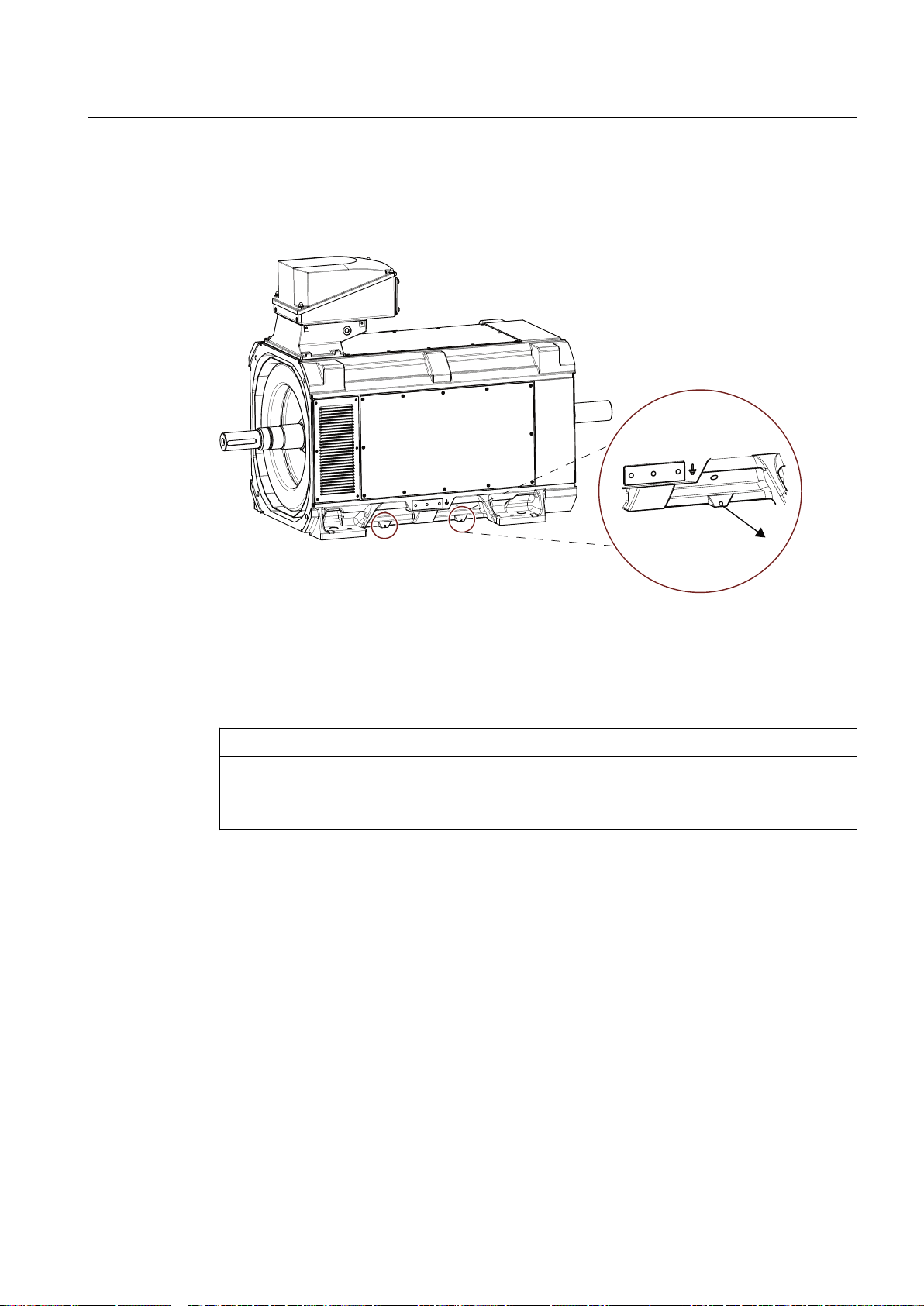

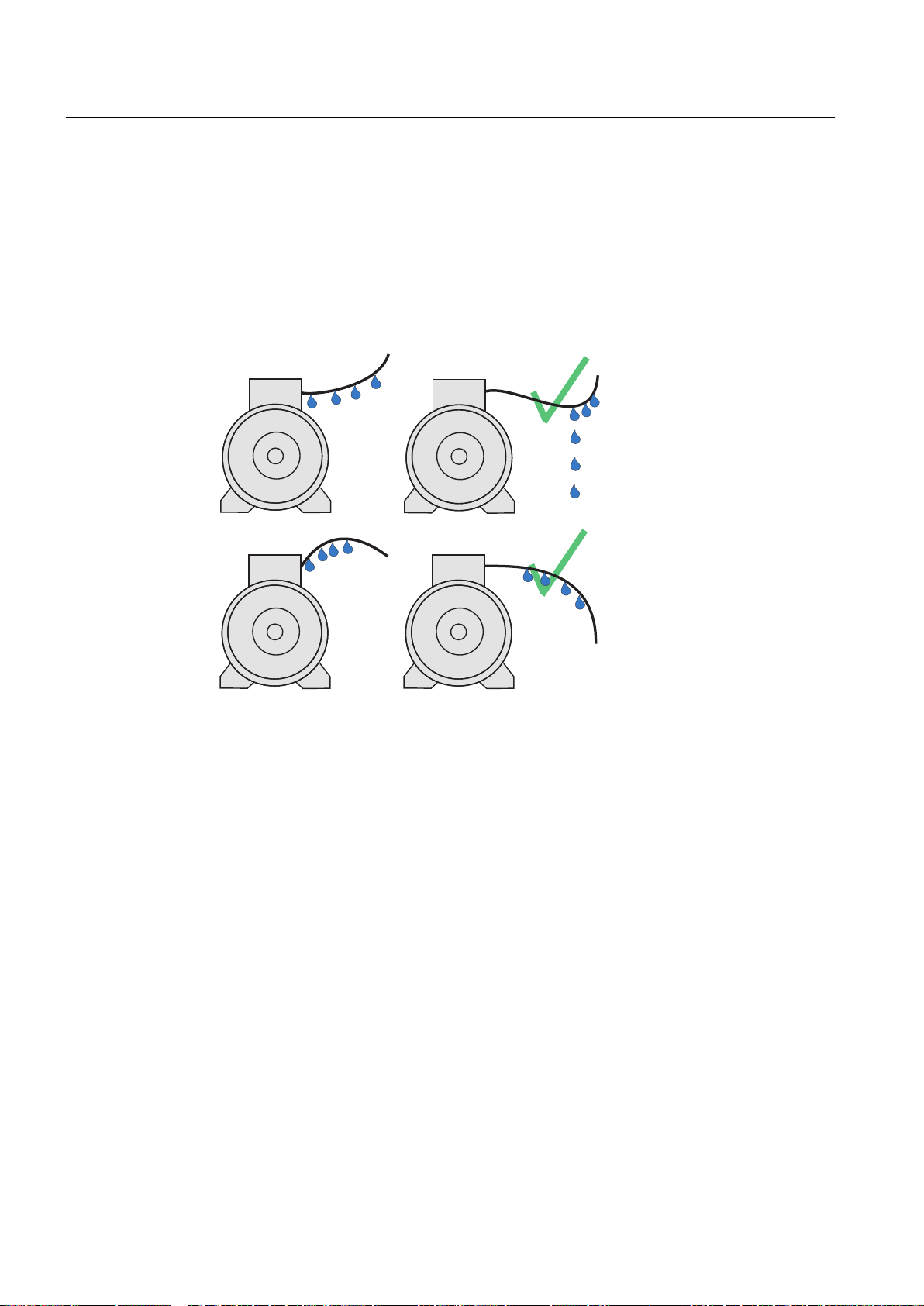

Material Component Remark