Siemens SIMATIC TP900 Comfort INOX PCT, SIMATIC TP1200 Comfort INOX PCT Compact Operating Instructions

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

HMI devices

Comfort Panels INOX PCT

Compact Operating Instructions

05/2018

A5E38804191

Preface

Overview

1

Safety instructions and

additional information

2

Mounting the device

3

Maintenance and repairs

4

Technical specifications

5

Technical Support

A

List of abbreviations

B

-AA

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E38804191-AA

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

05/2018 Subject to change

Preface

Scope of validity

Note

This document belongs to the device and will also be required for repeat commissioning.

Keep all supplied and supplementary documentation for the entire service life of the device.

Pass on all of these documents to a future owner of the device.

Style conventions

Style Convention

Scope

"File > Edit"

Operating sequences, for example, menu item, shortcut menu command

<F1>, <Alt+P>

Designation of a key on a keyboard

These compact operating instructions are valid for the following INOX devices:

● SIMATIC TP900 Comfort INOX PCT, article number 6AV2144-8JC20-0AA0

● SIMATIC TP1200 Comfort INOX PCT,, article number 6AV2144-8MC20-0AA0

The INOX devices are based on the following standard devices:

● SIMATIC TP900 Comfort, article number 6AV2124-0JC01-0AX0

● SIMATIC TP1200 Comfort,, article number 6AV2124-0MC01-0AX0

These compact operating instructions describe the technical differences between the

SIMATIC TP900/1200 Comfort INOX PCT and the corresponding standard device.

The notes in these compact operating instructions take precedence over statements in the

basic operating instructions, the release notes and online help.

Comfort Panels operating instructions

(http://support.automation.siemens.com/WW/view/en/49313233)

Unless otherwise described in this document, all of the specifications for the corresponding

standard device that are described in the operating instructions of the associated standard

device are valid for the TP900/1200 Comfort INOX PCT, in particular the specifications on

hardware, operating system, software, configuration, maintenance, and servicing.

"Add screen"

• Terms that occur in the user interface, for example, dialog name, tab,

button, menu command

• Necessary entries, for example, limit value, tag value

• Path specification

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

3

Preface

Note

A note contains important information about the product described

handling, or a specific section of the document to which you should pay particular attention.

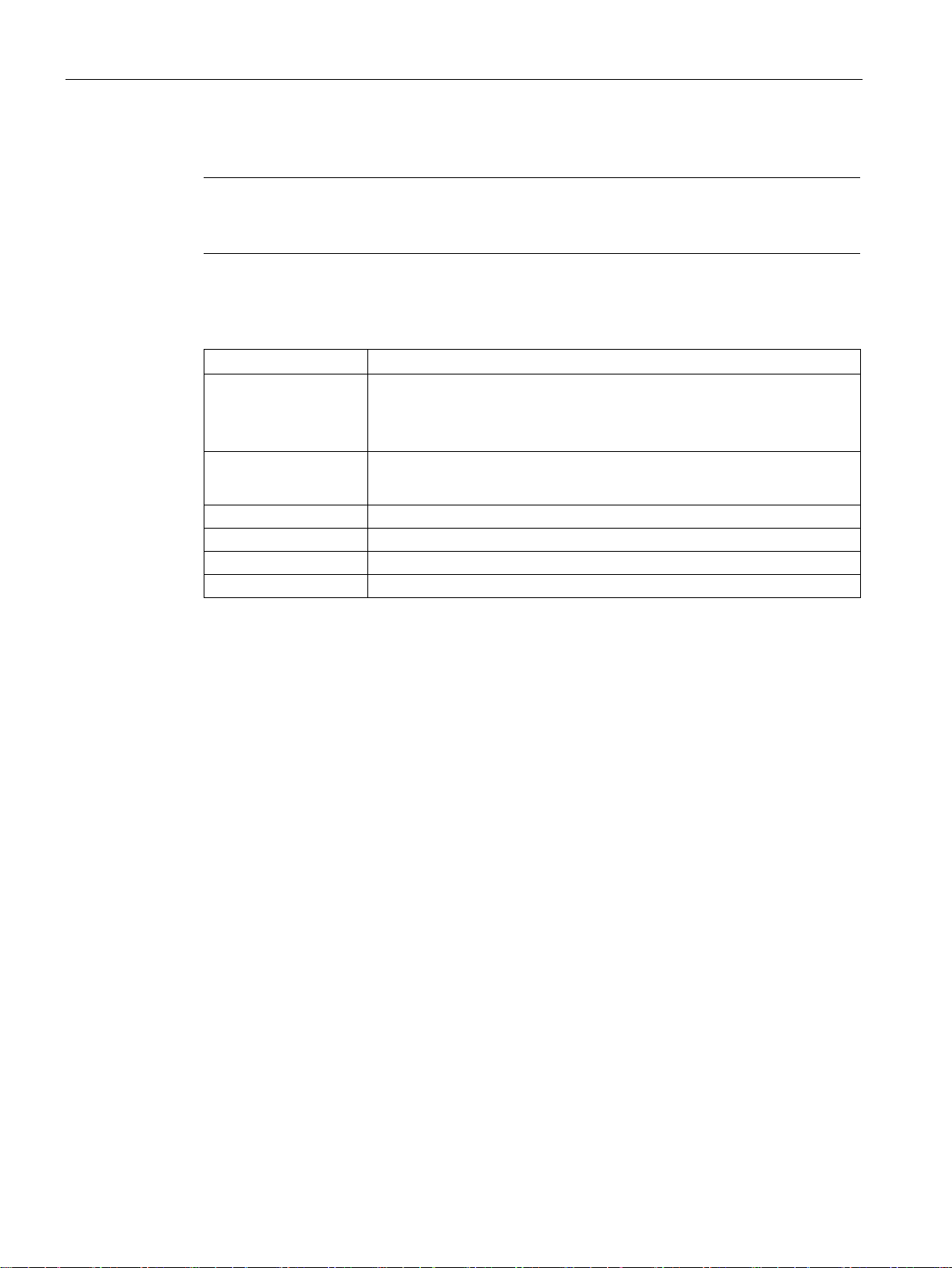

Naming conventions

Term

Applies to

PCT

Projected Capacitive Touch

Touch HMI device

Device with capacitive single-touch screen

Touch screen

Single touch screen

Touch operation

Single touch

Figures

You should also observe notes that are marked as follows:

in the document and its

System

Device, INOX PCT

device

• System

• Machining center

• One or more machines

• SIMATIC TP900 Comfort INOX PCT

• SIMATIC TP1200 Comfort INOX PCT

This document contains illustrations of the described devices. The figures can deviate from

the particularities of the delivered device.

Comfort Panels INOX PCT

4 Compact Operating Instructions, 05/2018, A5E38804191-AA

Table of contents

Preface ................................................................................................................................................... 3

1 Overview................................................................................................................................................. 7

2 Safety instructions and additional information ........................................................................................ 11

3 Mounting the device .............................................................................................................................. 19

4 Maintenance and repairs ....................................................................................................................... 27

1.1 Product overview ...................................................................................................................... 7

1.2 Scope of delivery ...................................................................................................................... 8

1.3 Layout of the devices ................................................................................................................ 8

1.4 Interfaces .................................................................................................................................. 9

1.5 Accessories ............................................................................................................................. 10

2.1 General safety instructions ..................................................................................................... 11

2.2 Security management for HMI devices ................................................................................... 13

2.3 Notes about usage .................................................................................................................. 14

2.4 Use in hazardous areas .......................................................................................................... 15

2.5 Notes on commissioning and operating .................................................................................. 16

2.6 Operating the capacitive single-touch screen ......................................................................... 18

3.1 Preparing for installation ......................................................................................................... 19

3.1.1 Check the scope of delivery .................................................................................................... 19

3.1.2 Checking the operating conditions .......................................................................................... 19

3.1.3 Permitted mounting positions ................................................................................................. 19

3.1.4 Notes on installation................................................................................................................ 22

3.1.5 Checking clearances............................................................................................................... 22

3.2 Inserting the mounting seal ..................................................................................................... 23

3.3 Mounting the device ................................................................................................................ 24

3.4 Wiring rules ............................................................................................................................. 26

4.1 Cleaning and maintenance ..................................................................................................... 27

4.2 Working with pressure washers .............................................................................................. 29

4.3 Working with stainless steel surfaces ..................................................................................... 30

4.4 Clean screen for Touch HMI devices ...................................................................................... 31

4.5 Chemical Resistance .............................................................................................................. 31

4.6 Calibrate touch screen ............................................................................................................ 32

4.7 Recycling and disposal ........................................................................................................... 32

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

5

Table of contents

5 Technical specifications ........................................................................................................................ 33

A Technical Support ................................................................................................................................. 45

B List of abbreviations .............................................................................................................................. 46

Index .................................................................................................................................................... 47

5.1 Software license agreements ................................................................................................. 33

5.2 Certificates and approvals ..................................................................................................... 33

5.3 Electromagnetic compatibility ................................................................................................ 36

5.4 Mechanical ambient conditions .............................................................................................. 37

5.4.1 Storage conditions ................................................................................................................. 37

5.4.2 Operating Conditions ............................................................................................................. 38

5.5 Climatic ambient conditions ................................................................................................... 38

5.5.1 Long-term storage .................................................................................................................. 38

5.5.2 Transport and short-term storage .......................................................................................... 38

5.5.3 Operating Conditions ............................................................................................................. 39

5.6 Information on insulation tests, protection class and degree of protection ............................ 40

5.7 Dimension drawings ............................................................................................................... 41

5.7.1 9" device dimension drawing ................................................................................................. 41

5.7.2 Dimension drawing 12" device ............................................................................................... 42

5.7.3 Dimension drawing 12" device clamping frame ..................................................................... 43

5.8 Technical specifications ......................................................................................................... 43

A.1 Service and support ............................................................................................................... 45

Comfort Panels INOX PCT

6 Compact Operating Instructions, 05/2018, A5E38804191-AA

1

1.1

Product overview

The INOX devices with touch screen and glass front are designed for use in ambient

conditions that prevail in the food and beverage industry and the pharmaceutical industry.

The devices are suitable for use in the spray area (according to DIN 1762-2) as well as for

indirect contact with acidic, alcoholic and dry food (intended use).

Indirect contact in this case means alternating contact of the device and food in the process

by the operating personnel.

To comply with the permissible limits for indirect contact with food, the device must be

regularly cleaned (see section "Cleaning and maintenance (Page 27)").

Particular attention has been paid to ensuring that the device is easy to clean and can be

disinfected when needed. The devices with stainless steel front have therefore been

developed according to DIN EN 1672-2 "Food Processing Machinery - Safety and Hygiene

Requirements".

● Resistant to scratch and impact, hardened glass (Mohs 6) in stainless steel frame

● Resistant glass and sturdy stainless steel front with minimized grooves and crevices

● Optimized frame design with minimized protrusions to the control cabinet and for

automatic runoff of liquids

● Stainless steel surface polished with grain size 240

● IP66K/P69K degree of protection on front

● Chemical resistance to cleaning agents and disinfectants as described in section

"Chemical Resistance (Page 31)".

● Replaceable device mounting gasket

● Rear clamping frame for even application pressure of the mounting gasket

● Mounting cutout and interfaces correspond to the standard device.

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

7

Overview

1.2

Scope of delivery

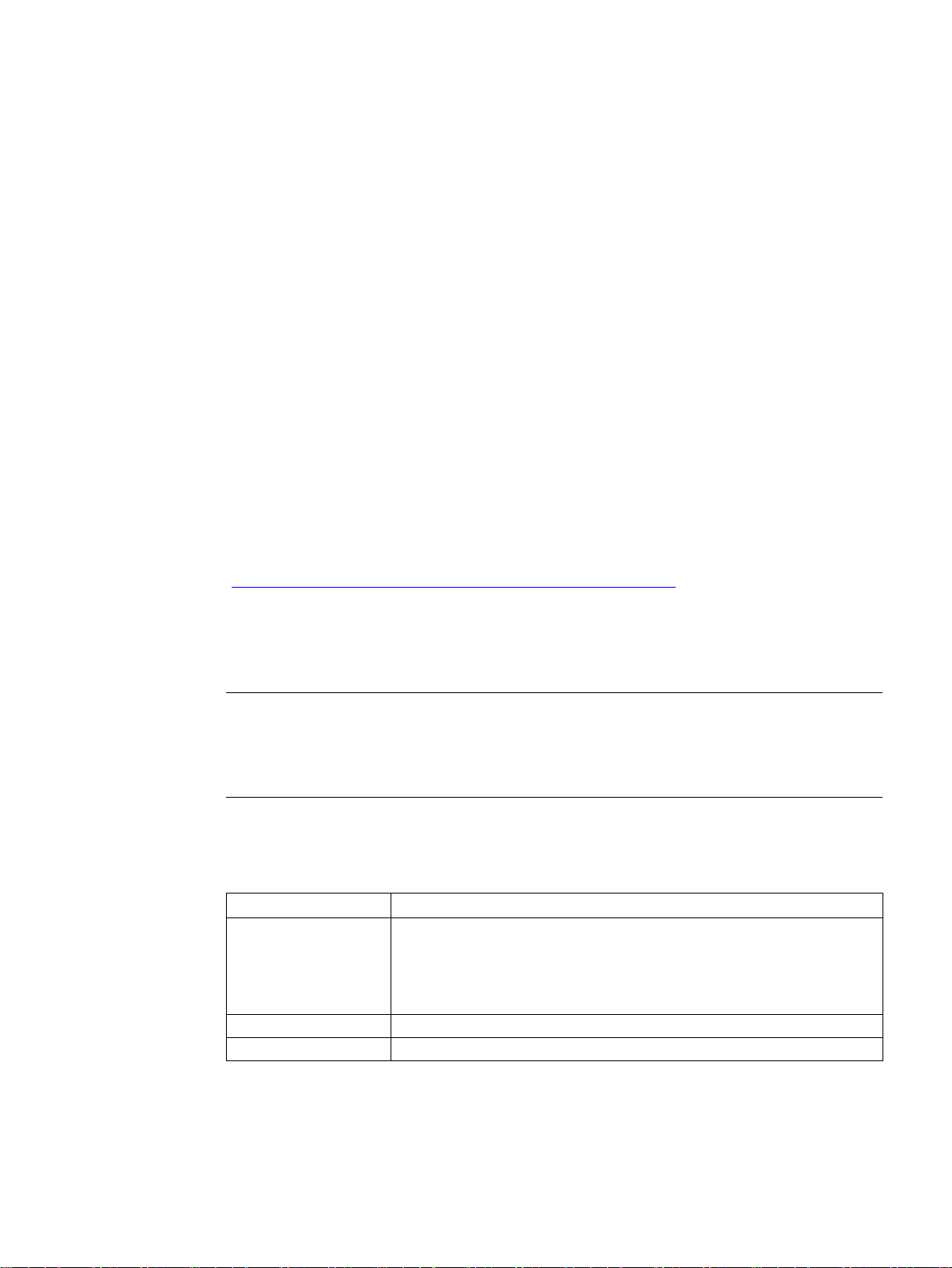

1.3

Layout of the devices

Front view and side view

①

Cutout for mounting clip

②

Stainless steel front

③

Display with touch screen

④

Positioning hooks for mounting gasket

1.2 Scope of delivery

Depending on the order, the scope of delivery includes:

● 1 × device

● 1 × accessory pack with the following contents:

– 1 mounting gasket

– 1 clamping frame

– 1 power supply connector

– Mounting clips (see section "Mounting the device (Page 24)")

● Product information, mounting instructions

● 3 × product information (approvals, explosion protection), individually enclosed

The figures in this section show the layout using the 12" device as an example.

Comfort Panels INOX PCT

8 Compact Operating Instructions, 05/2018, A5E38804191-AA

Overview

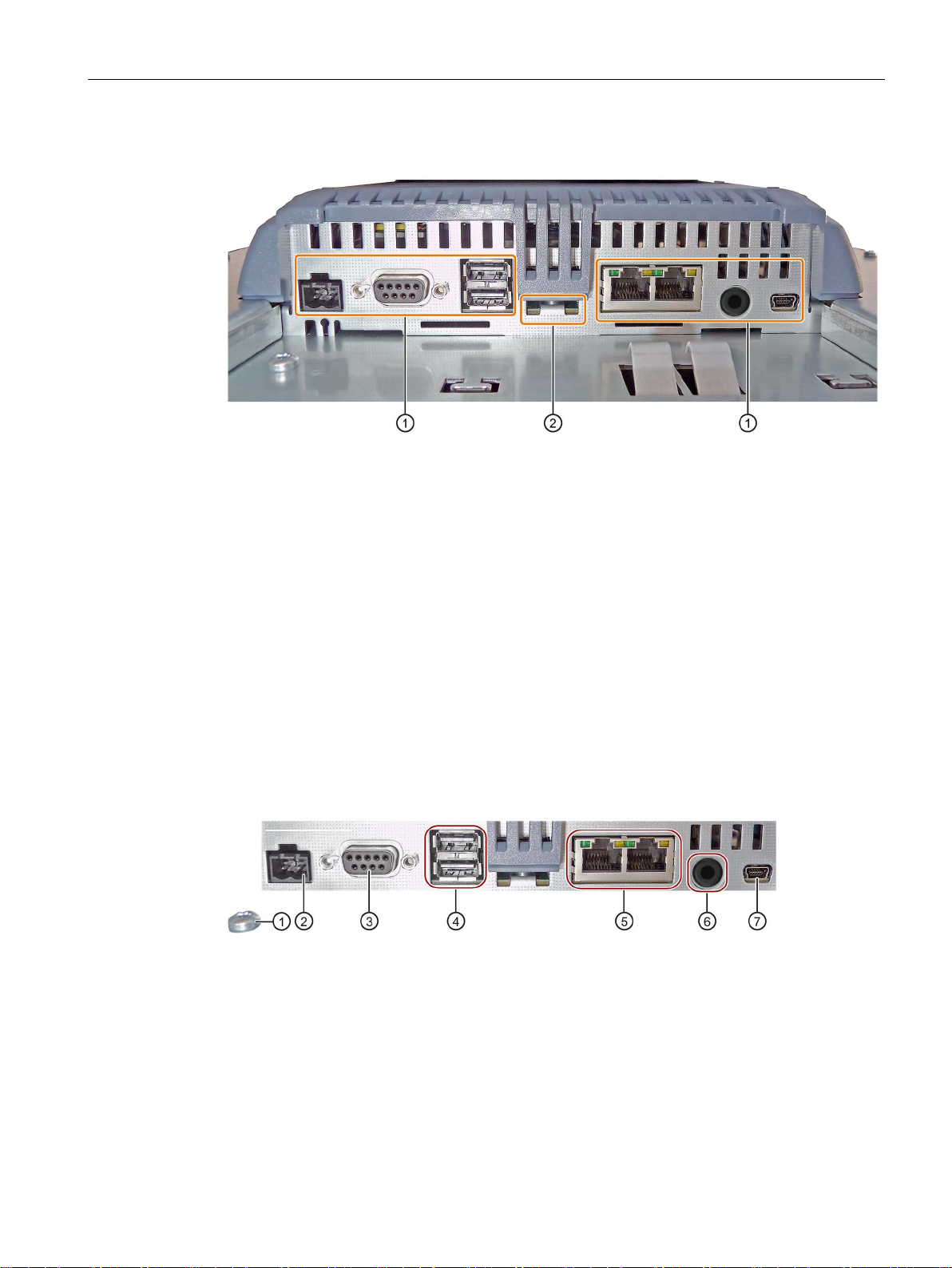

Bottom view

①

Ports

②

Cutout for mounting clip

Rear view

1.4

Interfaces

Interfaces of the 9" and 12" variants

①

Connection for equipotential bonding (ground)

⑤

X1 PROFINET (LAN), 10/100 Mb

②

X80 power supply connector

⑥

X90 Audio Line OUT

③

X2 PROFIBUS (Sub-D RS422/485)

⑦

X60 USB type Mini B

④

X61 / X62 USB type A

1.4 Interfaces

See standard device, Comfort Panels operating instructions

The figure shows the interfaces of the following HMI devices:

● TP900 Comfort INOX PCT

● TP1200 Comfort INOX PCT

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

9

Overview

Additional information

1.5

Accessories

Other accessories

1.5 Accessories

Use the X1 or X60 interface to connect a configuration PC. Use the X61 / X62 interfaces to

connect peripheral devices such as a printer or keyboard. Use the X90 interface to connect

headphones.

You can fasten the USB and PROFINET connecting cables to the rear panel of the HMI

device with cable ties.

Accessories can be ordered on the Internet at:

Industry Mall (https://mall.industry.siemens.com)

The following service packs with clamping frame, mounting gasket and mounting clips are

available for the INOX devices:

● TP900 INOX Service Pack, article number 6AV2185-4JA10-0AX0

● TP1200 INOX Service Pack, article number 6AV2185-4MA00-0AX0

You need service packs to replace the gasket or as spare parts for the mounting material.

Additional USB accessories can be found on the Internet in the following entry: FAQ

19188460 (https://support.industry.siemens.com/cs/ww/en/view/19188460)

Comfort Panels INOX PCT

10 Compact Operating Instructions, 05/2018, A5E38804191-AA

2

2.1

General safety instructions

Installation according to the instructions

WARNING

The device may only be used in machines which comply with the Machinery Directive

Notes on the touch screen

WARNING

Danger of explosion in hazardous areas, personal injury or property damage due to

defective touch screen

ESD

The "Machinery Directive" governs, among other things, the precautions to be taken when

commissioning and operating machines within the European Economic Area.

Failure to follow these precautions is a breach of the Machinery Directive. Such failure may

also cause personal injury and damage depending on the machine operated.

The machine in which the HMI device is to be operated must conform to Directive

2006/42/EC.

Massive force applied to the front of the device is not intended use of the device and can

destroy its touch screen, e.g. break the glass front. In hazardous areas, there is then a risk

of explosion, injury and food contamination with further consequential and health damages.

Make sure that excessive force cannot be applied to the device front.

If the touch screen of the device is defective, follow these steps:

• Stop production.

• Immediately shut down the affected machine and label it accordingly.

• Handle any potentially contaminated product in accordance with legal regulations.

• Replace the device immediately. When replacing the device, please note the section

"Mounting the device (Page 19)".

• Clean the machine before putting it back into operation.

Electrostatically sensitive components include almost all electrical, electronic, optoelectronic

and electromechanical components. These components are sensitive to overvoltage for

technical reasons and their function may be impaired or destroyed by electrostatic discharge.

Observe the regulations governing the handling of ESD components.

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

11

Safety instructions and additional information

Open equipment and control cabinet

WARNING

The device constitutes open equipment on the back side

Electrocution risk when control cabinet is open

Strong high-frequency radiation

NOTICE

Observe immunity to high-frequency radiation

Industrial Security

2.1 General safety instructions

The device constitutes open equipment on the back side. This means that the device may

only be integrated in an enclosure or cabinet which provides front access for operating the

device. The enclosure, the cabinet or the electrical operating rooms must provide protection

against electric shock and the spread of fire. The requirements regarding the mechanical

strength must also be considered.

Access to the enclosure or cabinet in which the device is installed should only be possible

by means of a key or tool and for trained and qualified personnel.

When you open the control cabinet, there may be a dangerous voltage at certain areas or

components.

Touching these areas or components can cause electrocution.

Always disconnect the cabinet from the mains before opening it.

Observe the safety and accident prevention instructions applicable to your application in

addition to the safety information given in the device documentation.

The device has an increased immunity to high frequency radiation according to the

specifications on electromagnetic compatibility in the technical specifications.

Radiation exposure in excess of the specified immunity limits can impair device functions

and result in malfunctions and therefore injuries or damage.

Read the information on immunity to high frequency radiation in the technical specifications.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

Comfort Panels INOX PCT

12 Compact Operating Instructions, 05/2018, A5E38804191-AA

Safety instructions and additional information

Disclaimer for third-party software updates

Notes on protecting administrator accounts

2.2

Security management for HMI devices

2.2 Security management for HMI devices

necessary and only when appropriate security measures (e.g. use of firewalls and network

segmentation) are in place.

For additional information on industrial security measures that may be implemented please

visit (http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply latest updates may increase customer’s exposure to

cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service

(http://www.automation.siemens.com/mcms/automation-software/en/software-update-

service).

A user with administrator privileges has extensive access and manipulation options in the

system.

Therefore, ensure there are adequate safeguards for protecting the administrator accounts

to prevent unauthorized changes. To do this, use secure passwords and a standard user

account for normal operation. Other measures, such as the use of security policies, should

be applied as needed.

You can find additional information on security management of HMI devices on the Internet

at the following address:

Panel Security Guidelines (https://support.industry.siemens.com/cs/de/en/view/109481300)

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

13

Safety instructions and additional information

2.3

Notes about usage

NOTICE

The HMI device is approved for indoor use only.

Note

Operate the device only in a normal atmospheric environment

The technical characteristics of the device described in the operating instructions are

guaranteed if you operate the device in normal ambient air conditions with usual air

composition.

Note

The device is

a dry environment, i.e. dry environment at the rear of the device.

You can find additional information in the section "

Industrial applications

Use in mixed-use zone

2.3 Notes about usage

The HMI device may be damaged if it is operated outdoors.

Operate the HMI device indoors only.

intended for operation in an SELV circuit according to IEC/EN 61010-2-201 in

The HMI device is designed for industrial applications. It conforms to the following standards:

● Requirements for emissions EN 61000-6-4: 2007

● Requirements for interference immunity EN 61000-6-2: 2005

Under certain circumstances, you can use the HMI device in a mixed-use zone. A mixed-use

zone is used for housing and commercial operations that do not have a significant impact on

residents.

When you use the HMI device in a mixed-use zone, you must ensure that the limits of the

generic standard EN 61000-6-3 regarding emission of radio frequency interference are

observed. Suitable measures for achieving these limits for use in a mixed-use zone include:

● Installation of the HMI device in grounded control cabinets

● Use of filters in electrical supply lines

Individual acceptance is required.

Operating Conditions (Page 39)".

Comfort Panels INOX PCT

14 Compact Operating Instructions, 05/2018, A5E38804191-AA

Safety instructions and additional information

Use in residential areas

Note

HMI device not intended for use in residential area

The HMI device is not intended for use in r

residential areas can have a negative influence on radio or TV reception.

Use with additional measures

2.4

Use in hazardous areas

WARNING

Explosion Hazard

Risque d'Explosion

2.4 Use in hazardous areas

esidential areas. Operation of an HMI device in

The HMI device should not be used at the following locations unless additional measures are

taken:

● In locations with a high degree of ionizing radiation

● In locations with severe operating conditions, for example, due to:

– Corrosive vapors, gases, oils or chemicals

– Strong electrical or magnetic fields of high intensity

● In systems that require special monitoring, for example, in:

– Elevators

– Systems in especially hazardous rooms

The following warnings apply to operating a device with Ex approval in hazardous areas.

Do not disconnect while circuit is live unless area is known to be non-hazardous.

Substitution of components may impair suitability for Class I, Division 2 or Zone 2.

Ne pas déconnecter pendant que le circuit est sous tension, sauf si la zone est nondangereuse. Le remplacement de composants peut compromettre leur capacité à satisfaire

à la Classe I, Division 2 ou Zone 2.

Comfort Panels INOX PCT

Compact Operating Instructions, 05/2018, A5E38804191-AA

15

Loading...

Loading...