Siemens SIMATIC TI505,SIMATIC TI500 User Manual

SIMA

TIC TI505/TI500

MODNIM

User

Manual

Order Number: PPX:505-8122-1

Manual Assembly Number: 2586546-0083

Original Edition

Copyright

1993 by Siemens Industrial Automation, Inc.

All Rights Reserved — Printed in USA

Reproduction,

contents is not permitted without express consent of

Siemens Industrial

created by patent grant or registration of a utility model or

design, are reserved.

Since Siemens Industrial Automation, Inc. does not possess

full access to data concerning all of the uses and applications

of customer’s products, we do not assume responsibility either

for customer product design or for any infringements of patents

or rights of others which may result from our assistance.

01/21/92

transmission or use of this document or

Automation, Inc. All rights, including rights

T

echnical data is subject to change.

W

e check the contents of every manual for accuracy at the

time it is approved for printing; however

undetected errors. Any errors found will be corrected in

subsequent editions. Any suggestions for improvement are

welcomed.

, there may be

MANUAL PUBLICA

TION HISTOR

Y

SIMATIC

Or

Refer to this history in all correspondence and/or discussion about this manual.

Event Date Description

Original Issue

TI505/TI500 MODNIM User Manual

der Manual Number: PPX:505-8122-1

03/93

Original Issue (2801280–0001), Softwar

e Release 3.0

LIST

OF EFFECTIVE P

Pages Description Pages Description

Cover/Copyright Original

History/Effective

iii — ix

1-1 — 1-20 Original

2-1 — 2-39 Original

A-1 — A-4

B-1 — B-2

C-1 — C-3

D-1 — D-6

Index-1 — Index-3

Registration Original

Pages

AGES

Original

Original

Original

Original

Original

Original

Original

Preface

Chapter 1 Installation and Set-up

Contents

1.1 Modbus

Modbus

Modbus

Transmission

1.2 Quick

1.3 Setting

1.4 Installing

Refer

General

Procedures 1-4

Handling

Inspecting

Getting

the Dipswitches

Dipswitch

Setting

Selecting

Data T

Stopbit

Parity/No

Odd/Even

ASCII/RTU

RTS/CTS

Y/C

Installing

Installing

the Network Addr

ransmission Rate

Selection

Coil Selection

Communications Overview

Network Characteristics

Pr

otocol 1-2.

Modes

ence Installation Steps

Requir

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Module

the Module

Started with Configuration and Installation

Functions

Network Configuration Parameters

Parity Selection

Parity Selection

Mode Selection

Handshaking

the MODNIM

the Series 505 MODNIM in the I/O Base

the Series 500 MODNIM in the I/O Base

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ements 1-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ess 1-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2.

1-2.

1-2.

1-4.

1-5.

1-5.

1-5.

1-6.

1-6.

1-7.

1-7.

1-7.

1-7.

1-7.

1-7.

1-7.

1-7.

1-10.

1-10.

1-12.

1.5 Switches

Switches

Reset

Test

Local/Remote

Status

1.6 Diagnostic Tests 1-16.

Built-in

Power-up

Run-time

User-Initiated

and Indicator Lights

and Buttons

Button

Button

Indicator Lights

Diagnostic T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch

Self T

est 1-16.

Self T

ests 1-17.

Self T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 1-16.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 1-18.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents iii

1-14.

1-14.

1-14.

1-14.

1-14.

1-15.

1.7 Establishing

Verifying

Connecting

Recommended

Building

Communications

that the MODNIM is Logged into the PLC

the Network Cables

Communication Cables

a Cable

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Modbus Commands

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-19.

1-19.

1-20.

1-20.

1-20.

2.1 Modbus

Modbus

The

The

The

The

The

The

The

The

2.2 Modbus

The R

The R

Message

Checksum 2-5

Invalid

2.3 Comparing

Modbus

Addressing 2-7

Address

2.4 Modbus

Introduction 2-8

Code

Code

Code

Code

Code 05 — W

Code 06 — W

Code

Code

Code

Code

Code 15 — W

Code 16 — W

Code

Pr

Pr

ASCII T

Start Field

Addr

ess Field

Function Field

Data Field

LRC Field

EOF Field

Ready Field

Pr

TU T

ransmission Frame

TU Frame Fields

Delineation

Characters and Messages

Functions vs. TIWAY Commands

Limits

Function Descriptions

01 — Read Coil Status

02 — Read Input Status

03 — Read Output Registers

04 — Read Input Registers

07 — Read Exception Status

08 — Execute Diagnostics

11 — Get Comms Event Counter

12 — Get Comms Event Log

17 — Report Slave ID

otocol Overview — ASCII T

otocol 2-2.

ransmission Frame

otocol Overview — R

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Functions with TIWAY I Network Commands

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rite a Single Coil

rite a Single Register

rite Multiple Coils

rite Multiple Registers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ransmission Mode

TU T

ransmission Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

2-2.

2-2.

2-2.

2-2.

2-2.

2-3.

2-3.

2-3.

2-3.

2-4.

2-4.

2-4.

2-4.

2-5.

2-6.

2-6.

2-7.

2-8.

2-8.

2-10.

2-12.

2-13.

2-14.

2-16.

2-17.

2-19.

2-30.

2-31.

2-33.

2-35.

2-36.

2.5 Error

iv Contents

Responses

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-38.

Appendix A Network Cable Communications

A.1 Network

Recommended

Building

Cable

A.2 Communications

RS-232-C

Recommended

Appendix

B.1 Exception

Appendix

C.1 Environmental

C.2 MODNIM

Appendix

D.1 Getting

Overview D-2

Hardware

Running

Running

Cables

Cables

Pinouts

Pin Assignments

B

Exception Codes

Codes Supported by the MODNIM

C

Specifications

Specifications

Communications Specifications

D

Using the MODASST Program

Started

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requir

the Pr

the Pr

ogram from the Floppy Disk

ogram fr

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Cables

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters

Communications Parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ements D-2.

om the Har

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

d Disk

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2.

A-2.

A-2.

A-2.

A-4.

A-4.

A-4.

B-2.

C-2.

C-3.

D-2.

D-2.

D-3.

D.2 Starting

Setting

Setting

D.3 Using

Pr

Setup

Options

Run

Diagnostics

Find

Module Settings

Talk

to Module

Batch

Send fr

Verifying

Pr

ogram Operation

the Communication Port Options

the Remaining Options

ogram Options

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

om File

Communications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents v

D-4.

D-4.

D-5.

D-5.

D-5.

D-6.

D-6.

D-6.

D-6.

List of Figures

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

e 1-1

e 1-2

e 1-3

e 1-4

e 1-5

e 1-6

e 1-7

e 1-8

e 1-9

e 1-10

e 1-11

e 1-12

e 1-13

e 1-14

e 2-1

e 2-2

e 2-3

e 2-4

e 2-5

e 2-6

e 2-7

e 2-8

e 2-9

e 2-10

e 2-11

e 2-12

e 2-13

e 2-14

e 2-15

e 2-16

e 2-17

e 2-18

e 2-19

e 2-20

e 2-21

e 2-22

e 2-23

e 2-24

e 2-25

e 2-26

e 2-27

Multidrop

Quick

Address

Dipswitch

Series

Series

Installing

Series

Keying

Installing

Series

LED

LED

Sample

ASCII T

RTU T

Bit

Orientation

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Write

Read

Write

Write

Read

Read

Exception

Execute

Execute

Get

Get

Get

Get

Write

and Point-to-point Configurations

Reference Installation Pr

Setting Examples

Settings for Network Data T

505 MODNIM Switches and LEDs

500 MODNIM Switches and LEDs

the Series 505 MODNIM in the I/O Base

505 MODNIM Example Dipswitch Settings

the I/O Base Slot for the Series 500 MODNIM

the Series 500 MODNIM in the I/O Base

505 and 500 MODNIM Indicator Lights

Status during Power-Up Self T

Status during Nor

I/O Definition Chart

ransmission Frame

ransmission Frame

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coil Status Example — Request

Coil Status Example — Response

Coil Status Example — Data Field

Input Status Example — Request

Input Status Example — Response

Input Status Example — Data Field

Output Register Example — Request

Output Register Example — Response

Input Register Example — Request

Input Register Example — Response

a Single Coil Example — Request

Input Register Example — Response

a Single Register Example — Request

a Single Register Example — Response

Exception Status Example — Request

Exception Status Example — Response

Status Bits

Diagnostics Example — Request

Diagnostics Example — Response

Comms Event Counter Example — Request

Comms Event Counter Example — Response

Comms Event Log Example — Request

Comms Event Log Example — Response

Multiple Coils Example — Request

mal Run-T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ocedures 1-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ransmission Rates

est 1-16.

ime Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

1-3.

1-6.

1-7.

1-8.

1-9.

1-10.

1-11.

1-12.

1-13.

1-15.

1-17.

1-19.

2-2.

2-4.

2-6.

2-8.

2-9.

2-9.

2-10.

2-10.

2-11.

2-12.

2-12.

2-13.

2-13.

2-14.

2-15.

2-16.

2-16.

2-17.

2-17.

2-18.

2-19.

2-19.

2-30.

2-30.

2-31.

2-31.

2-33.

vi Contents

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

Figur

e 2-28

e 2-29

e 2-30

e 2-31

e 2-32

e 2-33

e 2-34

e 2-35

e A-1

e A-2

e A-3

e D-1

e D-2

Coil

Bit Patter

Write

Multiple Coils Example — Response

Write

Multiple Registers Example — Request

Write

Multiple Registers Example — Response

Report

Report

Slave ID Example — Request

Slave ID Example — Response

Exception

Exception

MODNIM

MODNIM

MODNIM

First

Configuration Scr

MODASST

n 2-34.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Response Frame— ASCII Mode

Response Frame — R

TU Mode

to Host (without Handshaking)

to Host (with Handshaking)

to Commer

cial Modem (with Handshaking)

een after Start-Up

Setup Menu

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-34.

2-35.

2-35.

2-36.

2-36.

2-38.

2-38.

A-2.

A-3.

A-3.

D-3.

D-5.

Contents vii

List

of T

T

able 1-1

T

able 1-2

T

able 1-3

T

able 1-4

T

able 2-1

T

able 2-2

T

able 2-3

T

able 2-4

T

able 2-5

T

able 2-6

T

able 2-7

T

able 2-8

T

able A-1

T

able A-2

T

able B-1

T

able C-1

T

able C-2

T

able C-3

ables

Transmission

Status

of Indicator Lights

Indicator

Standard

Modbus

RTU

Terminology

Diagnostic

Diagnostic

Event

Function

Exception

RS-232-C

Communications

Exception

Environmental

MODNIM

Modbus

Status after User-Initiated T

Communication Cables

Functions Supported

Mode T

Byte T

Code 17 Response Options

Connector Pin Assignments

Codes vs. TIWAY Primitives Chart

Mode Characteristics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iming 2-4.

Dif

Codes Supported

Bits

ypes 2-32.

Responses

Codes

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ferences 2-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 1-18.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3.

1-15.

1-20.

2-3.

2-20.

2-22.

2-37.

2-39.

A-4.

A-4.

B-2.

C-2.

C-3.

C-3.

viii Contents

Purpose of this Manual

Preface

This

manual provides the following information on the Series 505 and

Series 500 MODNIM (Modbus Network Interface Module), model

numbers PPX:505–5184 and PPX:500–5184.

•

Basic features of the MODNIM

•

Installation and configuration

•

Diagnostic self-testing procedures

•

Operating instructions

•

Modbus commands and error responses

•

MODNIM specifications

Related Manuals

The following publications contain related information which supplement

this manual.

Series 505 Manuals

• SIMATIC TI505

• SIMA

• SIMATIC TI525/TI535

• SIMATIC TI545

Series 500 Manuals

• SIMATIC

•

• SIMATIC TI560/TI565

The following Gould Modicon publications are also recommended.

•

•

TIC TI505 TISOFT User Manual

TI520C

Series 500 I/O Base User’s Manual

Gould Modbus Protocol

Modbus System Planning

Programming Reference Manual

Hardware and Installation Manual

System Manual

/TI530C

(part no. PI-MBUS-300 Rev B)

Programmable Controller Manual

Programming Manual

(part no. PI-MBUS-PLN)

•

Gould Modicon J474/J475 Interface

Technical Assistance

SIMATIC TI505/TI500 MODNIM User Manual

If you need information that is not included in this manual, or if you have

problems using the module, contact your Siemens Industrial Automation,

Inc. distributor or sales office. If you need assistance in contacting your

distributor or sales office in the United States, call 1–800–964-41

(part no. PI-J475-001 Rev B)

14.

Preface

ix

Chapter 1

1.1 Modbus

Modbus

Modbus

Transmission

1.2 Quick

1.3 Setting

Refer

General

Procedures 1-4

Handling

Inspecting

Getting

Dipswitch

Setting

Selecting

Data T

Stopbit

Parity/No

Odd/Even

ASCII/RTU

RTS/CTS

Y/C

Coil Selection

Installation

Communications Overview

Network Characteristics

Pr

otocol 1-2.

Modes

ence Installation Steps

Requir

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Module

the Module

Started with Configuration and Installation

the Dipswitches

Functions

the Network Addr

Network Configuration Parameters

ransmission Rate

Selection

Parity Selection

Parity Selection

Mode Selection

Handshaking

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ements 1-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ess 1-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Set-up

1-2.

1-2.

1-2.

1-4.

1-5.

1-5.

1-5.

1-6.

1-6.

1-7.

1-7.

1-7.

1-7.

1-7.

1-7.

1-7.

1-7.

1.4 Installing

Installing

Installing

1.5 Switches

Switches

Reset

Test

Local/Remote

Status

1.6 Diagnostic Tests 1-16.

Built-in

Power-up

Run-time

User-Initiated

1.7 Establishing

Verifying

Connecting

Recommended

Building

SIMATIC TI505/TI500 MODNIM User Manual

the MODNIM

the Series 505 MODNIM in the I/O Base

the Series 500 MODNIM in the I/O Base

and Indicator Lights

and Buttons

Button

Button

Indicator Lights

Diagnostic T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self T

est 1-16.

Self T

ests 1-17.

Self T

Communications

that the MODNIM is Logged into the PLC

the Network Cables

Communication Cables

a Cable

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 1-16.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 1-18.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Set-up

1-10.

1-12.

1-14.

1-14.

1-14.

1-14.

1-14.

1-15.

1-19.

1-19.

1-20.

1-20.

1-20.

1-1

1.1 Modbus Communications Overview

Modbus Network Characteristics

Modbus Pr

otocol

The

Modbus system is a Local Area Network (LAN) designed to work in an

industrial environment. It is a master/slave network in which a number of

slave nodes (e.g., Programmable Logic Controllers, or PLCs) are connected

to a Master Node, which is a host computer

.

The Modbus protocol determines how messages are passed between the host

computer and the secondary nodes. Up to 247 slaves can reside on a single

network. Each node in that network must have a unique address ranging

from 1 to 247.

Because it is a master/slave network, each request is paired to one response.

The exception to this is broadcast mode, when no response is returned. This

mode is only valid for Modbus functions 5, 6, 8, 15, and 16.

NOTE:

Only the master can initiate a message in a Modbus network.

The following two types of messages are used.

•

The Request/Response type, where a single node is addressed.

•

The Broadcast/No Response type, where all nodes are addressed but

none respond.

Transmission Modes

The Modbus message consists of an “envelope” which contains different

types of data. The envelope enables the data to be directed to the correct

address on the network. It also contains information to determine if the

contents were received correctly and instructions about what to do with the

data.

T

wo modes of data transmission are available for a given network; however

only one mode can be selected at a given time, and every node on the

network must conform to that mode. Usually

, the requirements of the host

computer determine which mode should be selected. The two modes are the

following.

ASCII (American Standard Code for Information Interchange)

•

•

RTU (Remote T

erminal Unit)

The MODNIM can be set to operate in either mode.

,

1-2

Installation and Set-up

SIMATIC TI505/TI500 MODNIM User Manual

Details

of the ASCII and RTU modes of transmission are listed in T

T

able 1-1Transmission Mode Characteristics

Characteristic ASCII RTU

able 1-1.

Modbus

Modem

host

Code used:

Bits per character:

Start

Data 7 8

Stop 1 or 2 1 or 2

Parity Optional Optional

Checksum LRC CRC

7 bits hexadecimal

(ASCII printable)

1 1

8 bits binary

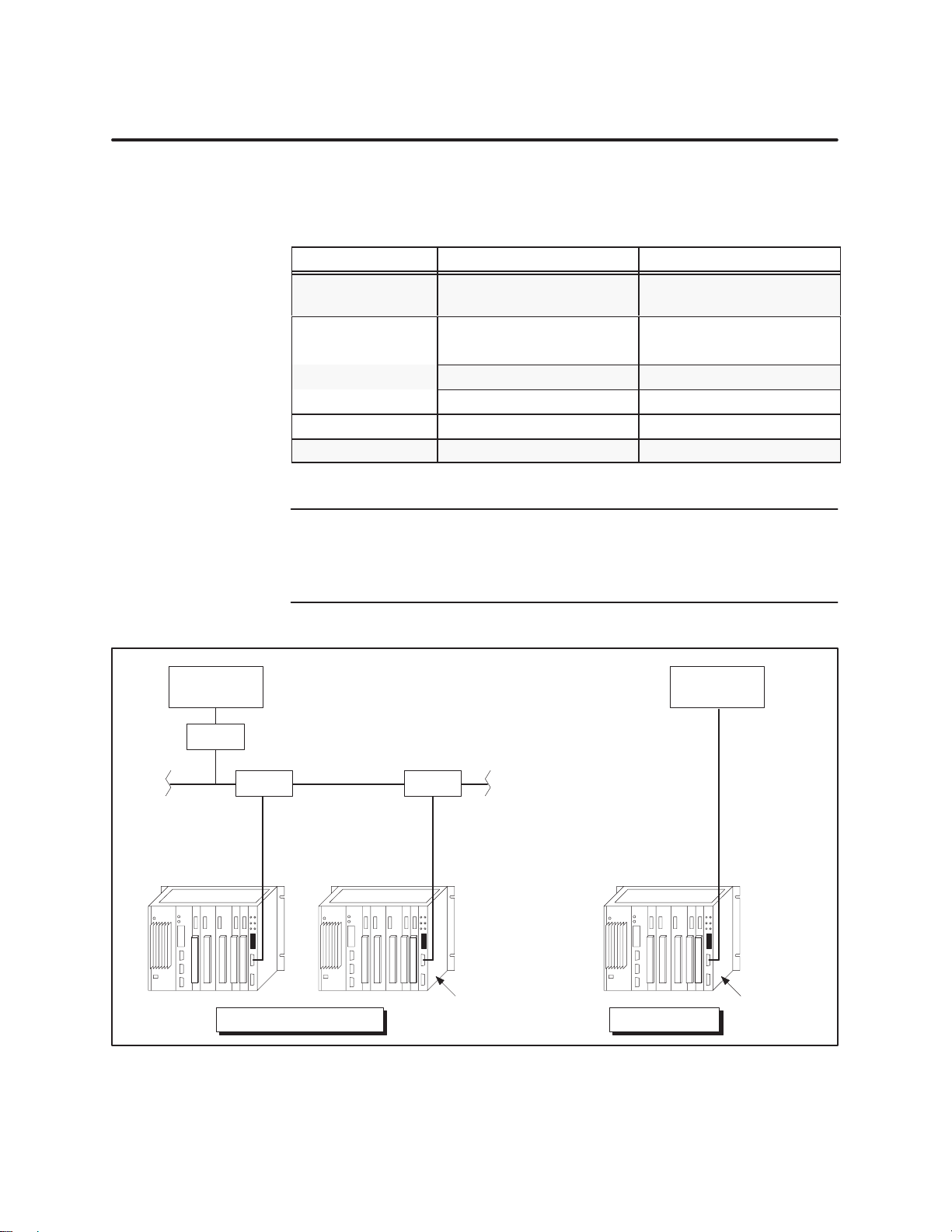

NOTE: On multidrop networks, the MODNIM requires a commercial modem

to connect to the Modbus network, as shown in Figure 1-1. The MODNIM

connected to a Series 505 PLC is equivalent to the use of the Modicon J475

modem interface with a Modicon PLC.

Modbus host

Modem Modem

Multidrop

Modbus Network

Programmable

Configuration

Controllers

Figure 1-1 Multidrop

SIMATIC TI505/TI500 MODNIM User Manual

MODNIM

Point-to-point

and Point-to-point Configurations

Installation and Set-up

MODNIM

1-3

1.2 Quick Reference Installation Steps

General Requirements

Procedures

In

order to install and use the MODNIM module correctly

, you must meet

the following requirements.

•

Ensure that you have the appropriate MODNIM model.

•

The communications configurations of all devices attached to the

network must match; i.e., they must all have the same baud rate, stop

bits, parity

, handshaking, and transmission mode (ASCII or RTU).

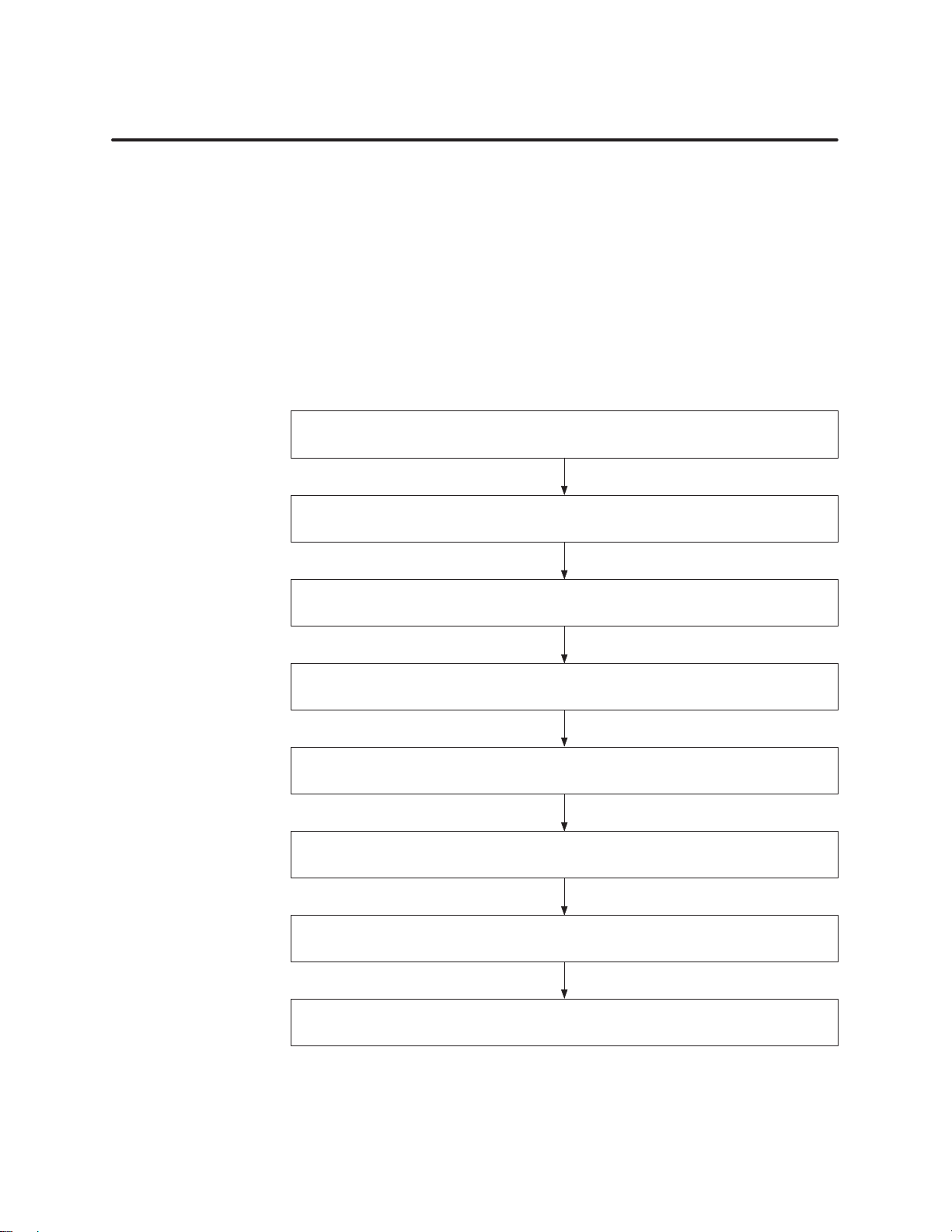

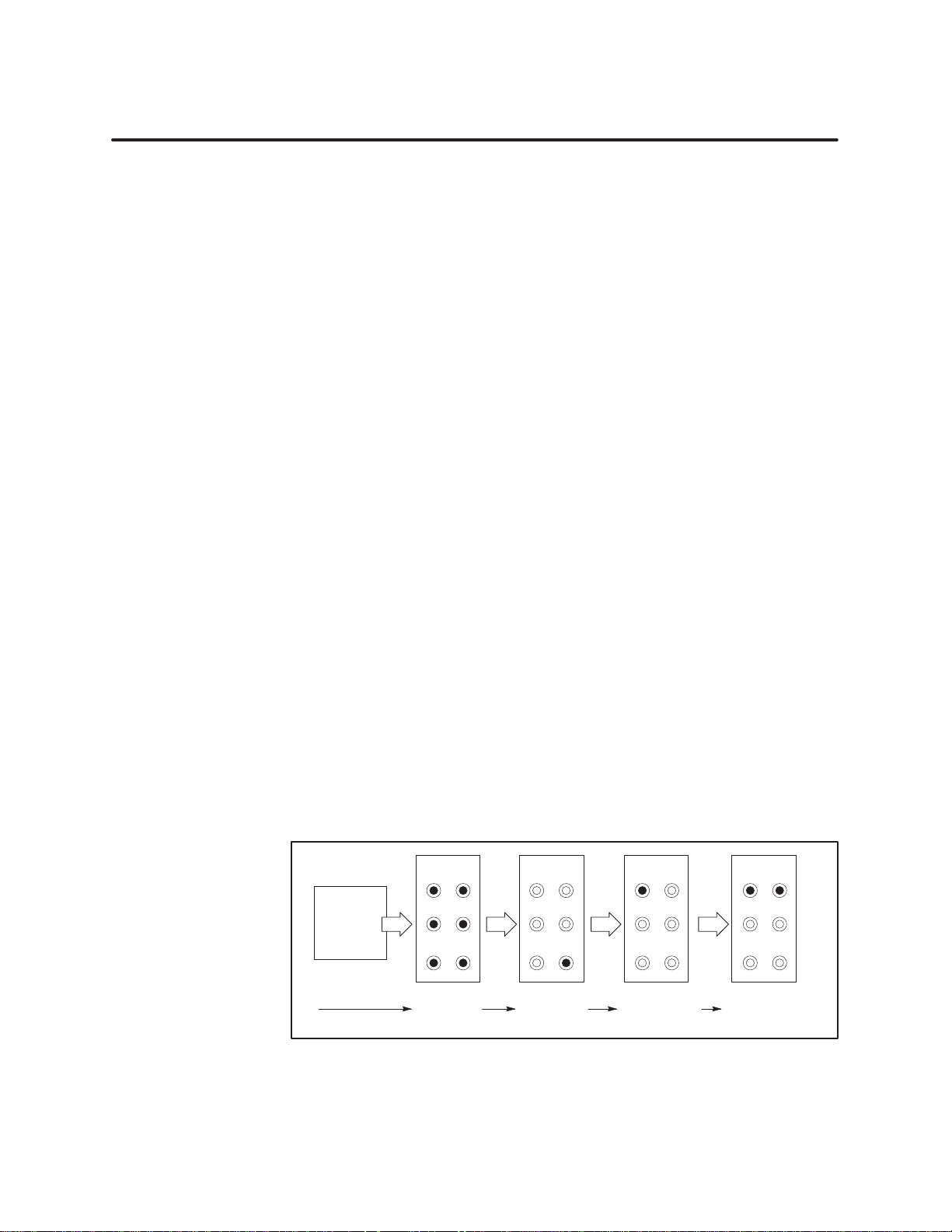

Figure 1-2 provides a quick reference list of the basic steps for installing the

MODNIM.

Install power and I/O cabling.

Disconnect power to the I/O base.

Set configuration dipswitches.

Insert

module into selected I/O slot (Series 505) or two adjacent slots (Series 500).

Power up the I/O base.

Check MODNIM indicator lights.

V

erify MODNIM is logged into PLC.

Connect network cables.

Figure 1-2 Quick

Refer

ence Installation Pr

ocedures

1-4

Installation and Set-up

SIMATIC TI505/TI500 MODNIM User Manual

Handling the Module

Many

integrated circuit (IC) devices are susceptible to damage by the

discharge of static electricity

. Follow the suggestions listed below to reduce

the probability of damage to these devices when you are handling this

Network Interface module, the PLC, a base controller

, or any of the I/O

modules.

Both the module and the person handling the module should be at the same

ground potential. Also, follow these guidelines.

• T

ransport the module in an anti-static container or antistatic material.

•

Ensure that the work area has a conductive pad with a lead connecting

it to a common ground.

•

Ground yourself by making contact with the conductive pad and/or by

wearing a grounded wrist strap.

Inspecting the Module

Getting Started with Configuration and Installation

Inspect the module for any visible damage before setting any selectable

features. If damage is detected, contact your distributor or sales office for

further instructions.

The following sections describe the procedures for configuring the module,

installing the module in the base, connecting the communications cables to

the MODNIM, and initializing the system for operation. Before installing

the MODNIM, make sure that the PLC is installed and the programming

device is connected to the system.

SIMATIC TI505/TI500 MODNIM User Manual

Installation and Set-up

1-5

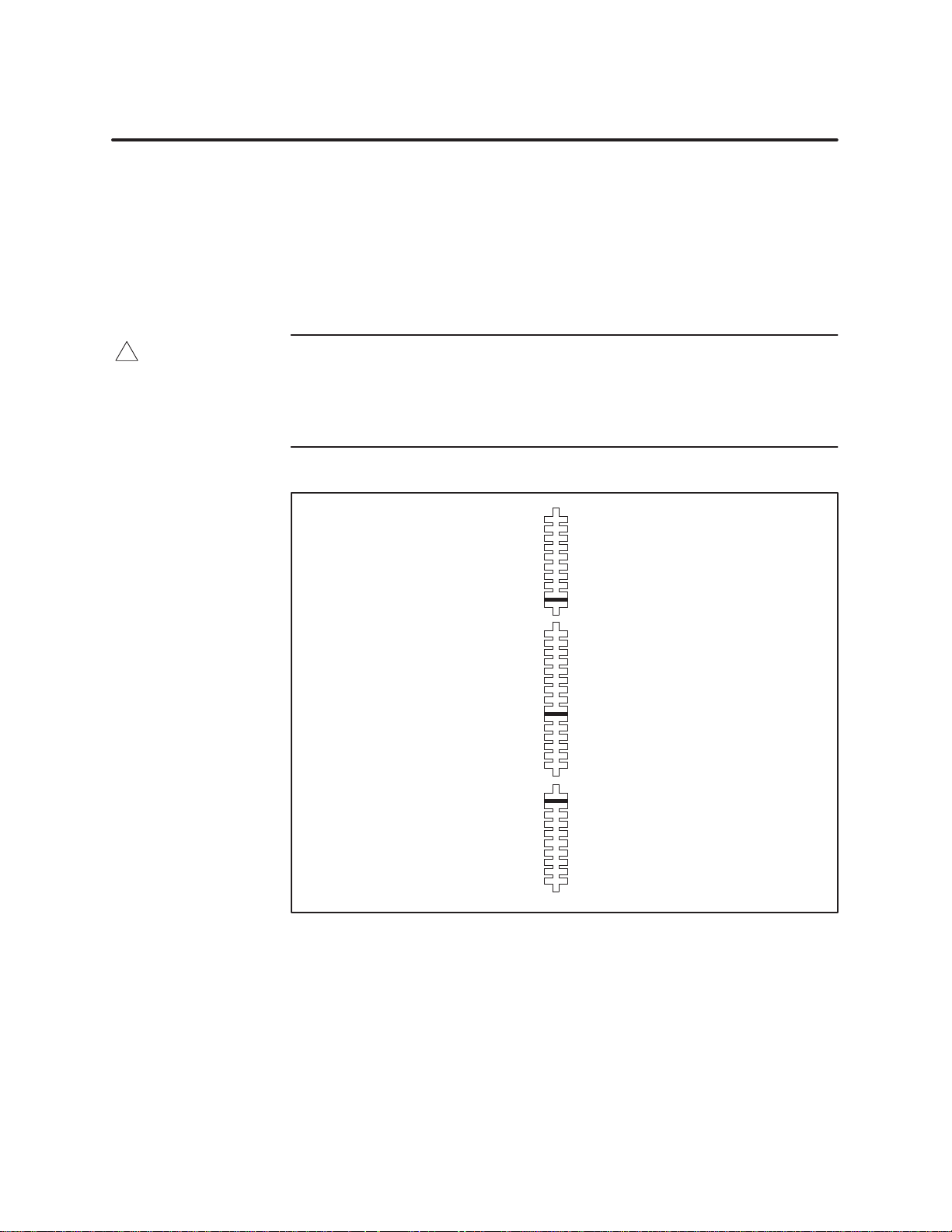

1.3 Setting the Dipswitches

Dipswitch Functions

Setting the Network Address

The

MODNIM module has two blocks of dipswitches.

•

The block of 8 dipswitches is used to select the MODNIM’s address on

the network.

•

The block of 10 dipswitches is used to configure the network

communications parameters.

NOTE:

following a power-up or RESET

The configuration and address switch settings are read only once

. Be sure to reset the MODNIM following

any change in dipswitch settings or PLC memory configuration. In addition,

be aware that when the MODNIM is reset, no communication can occur

from the host to the module for several seconds.

Each node on a Modbus network must have a unique address. The range of

valid addresses is 1 to

247

(0000 0001 to 1111 0111). The address is set in

binary numbers using the block of 8 dipswitches.

NOTE:

invalid addresses and, if selected, cause the module to go into T

Addresses 0 or 248 to 255 (0000 0000 or 1111 1000 to 1111 1111) are

est mode.

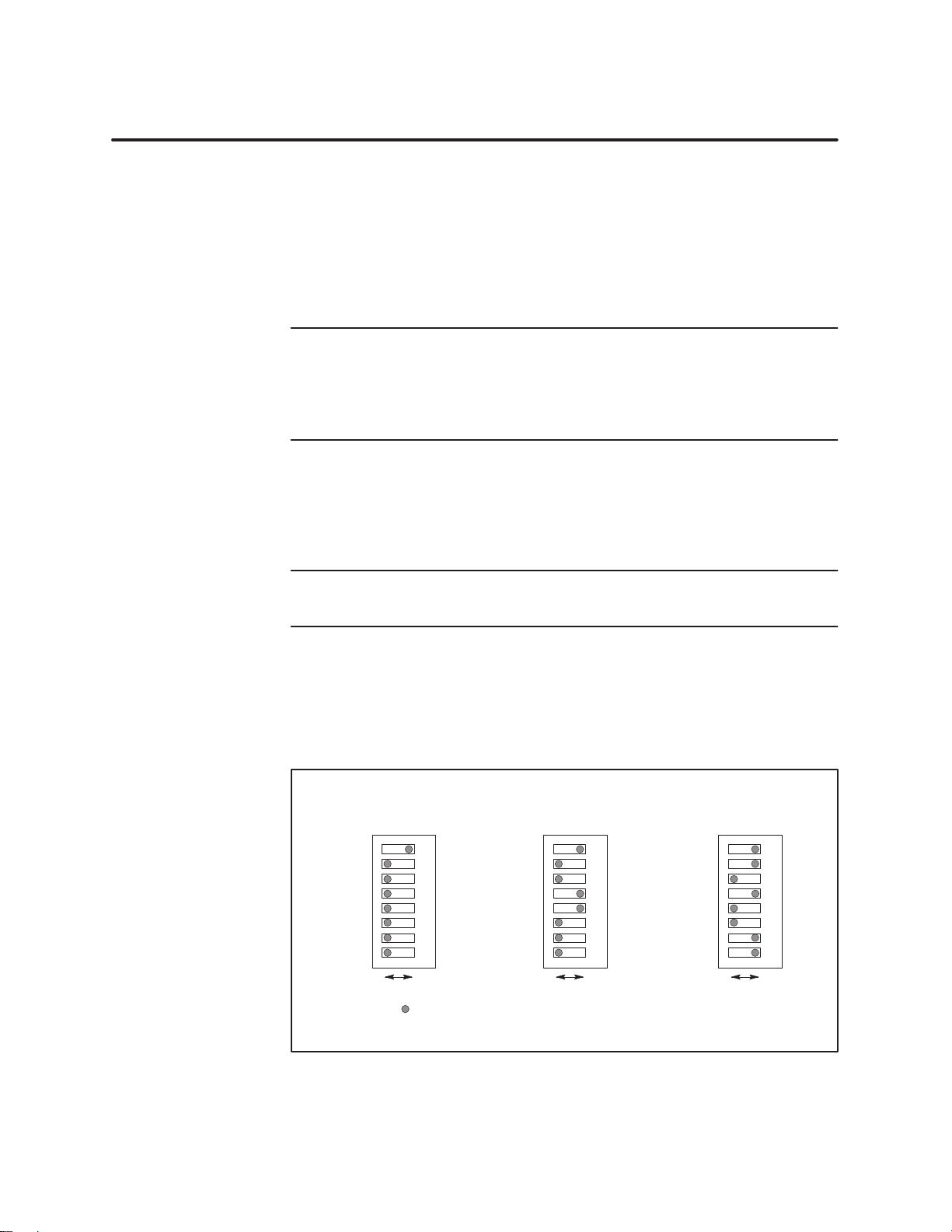

Figure 1-3 shows examples of network addresses and their corresponding

dipswitch settings. (W

ith the Series 505 MODNIM, hold the module with

the faceplate pointing upward, as shown in Figure 1-5. For the Series 500

MODNIM, refer to Figure 1-6 for dipswitch orientation.)

Bit

Weight

Address

(0000

1

2

4

8

16

32

64

128

01

1

0001)

12345678

00000001

Represents direction to slide a sliding-type switch, or

=

side of switch to press down on a rocker-type switch

on Series 505 MODNIM.

Figure 1-3 Address

Address

(0001 1001)

1

2

4

8

16

32

64

128

01

25

12345678

00011001

Setting Examples

Address

(1

100 101

1

2

4

8

16

32

64

128

01

203

1)

12345678

11001011

1-6

Installation and Set-up

SIMATIC TI505/TI500 MODNIM User Manual

Selecting Network Configuration Parameters

The

block of 10 dipswitches is used to configure the network communication

parameters, which include data transmission rate, stopbit selection, parity

transmission mode, RTS/CTS handshaking, and output coil mapping.

(NOTE:

For all Series 500 MODNIM dipswitch settings, see Figure 1-6.)

,

Data T

ransmission

Rate

Stopbit Selection

Switches 1 through 4 are used to set the data transmission rate. All devices

on the network must be configured to communicate at the same data rate.

Switch settings for each of the available data rates are shown in Figure 1-4.

Network

Configuration

Dipswitches

10

9

8

7

6

5

4

3

2

1

For

Series 505:

For Series 500:

10

01

Figure 1-4 Dipswitch

Data

Rate

Settings for Network Data T

Switches

1234 Baud

0000 – 50

0001 – 50

0010 – 75

0011 – 110

0100 – 150

0101 – 200

0110 – 300

0111 – 600

1000 –1200

1001 –1800

1010 –2400

1011 –3600

1100 –4800

1101 –7200

1110 –9600

1111 –19200

ransmission Rates

Switch 5 is used to select 1 or 2 stopbits. Set switch to the left for 1 stopbit,

to the right for 2 stopbits (on Series 505; for Series 500, see Figure 1-6).

Parity/No Parity Selection

Switch 6 is used to select Parity or No Parity when communicating over an

RS-232-C data link. T

whether you need odd or even parity and set switch 7 accordingly

Odd/Even Parity Selection

ASCII/R

TU Mode

Selection

RTS/CTS Handshaking

If you selected Parity with switch 6, then you must also select either Odd or

Even Parity using switch 7. This switch is active only if switch 6 is set to

Parity

. Set switch to the left for Even parity

Switch 8 is used to select ASCII or RTU mode of transmission. Slide switch

to the left for ASCII mode, to the right for RTU mode.

Switch 9 is used to enable or disable RTS/CTS handshaking. If you are

using point-to-point connections without using modems, you can disable

RTS/CTS handshaking by setting switch 9 to the left. Set switch 9 to the

right to select RTS/CTS handshaking for use with modems.

Y/C Coil Selection

Switch 10 is used to determine whether the MODNIM collects data from the

PLC’

s Discrete Output (Y) memory or the Control Relay (C) memory

switch to the left for C coils, to the right for Y outputs.

SIMATIC TI505/TI500 MODNIM User Manual

o select Parity

, set switch to the left, then determine

.

, to the right for Odd parity

.

. Set

Installation and Set-up

1-7

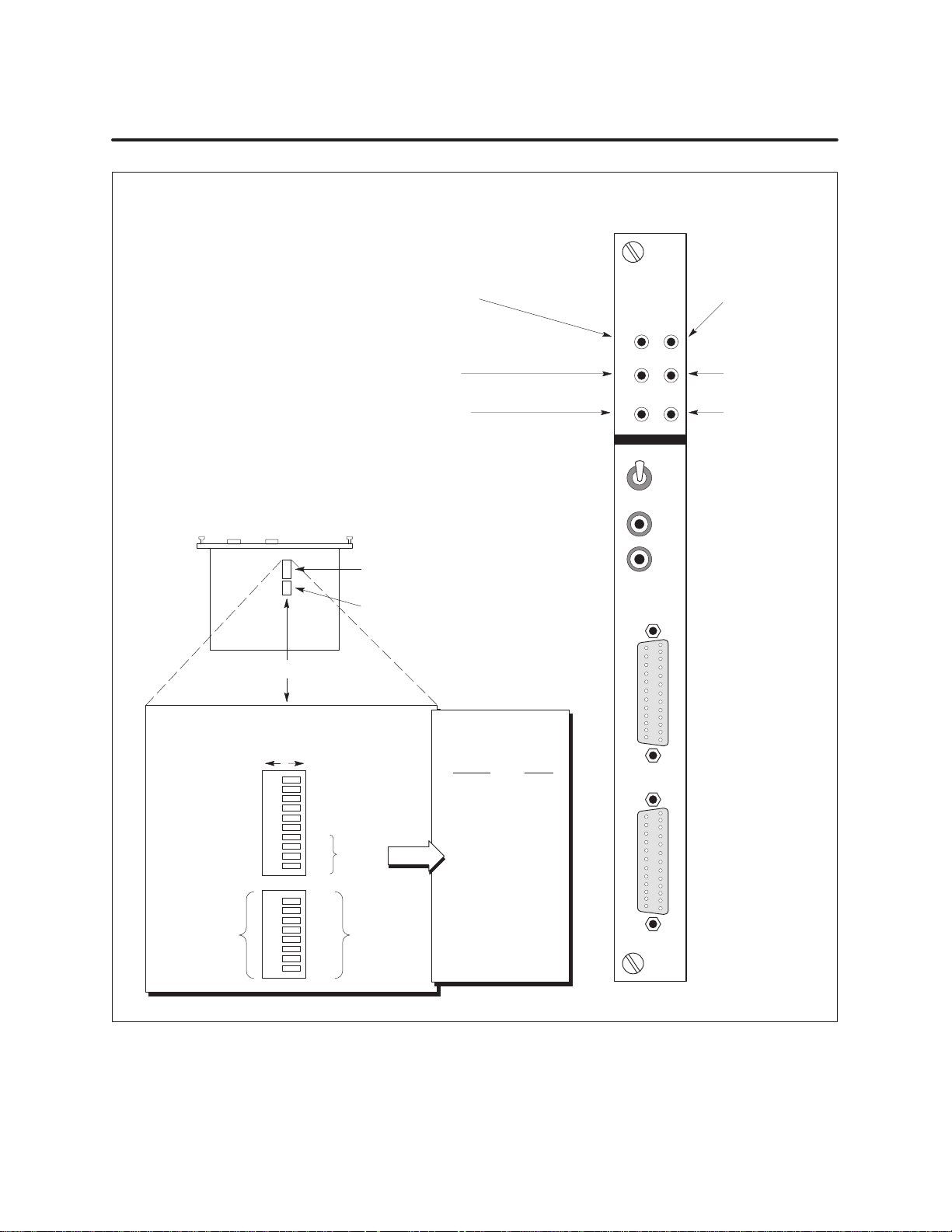

Setting the Dipswitches (continued)

NIM GOOD —

Base power and

MODNIM operating status

XMT —

Data T

ON LINE —

Connected to the Modbus network.

Continuous

flashing

ransmit indicator

ON indicates

indicates

local

remote

mode

Series

mode;

505 MODNIM

MODNIM

NIM

GOODPCGOOD

XMT REC

ON

LINE TEST

REMOTE

PC GOOD —

PLC/MODNIM

communication

link status

REC —

Receiving Data

indicator

TEST —

T

est mode status

Side V

Faceplate Up

Dipswitch

Push

Down

Left

C COILS

RTS/CTS: OFF

ASCII MODE

PARITY: EVEN

PARITY

: ON

STOPBITS: 1

0

iew of Module,

Dipswitches

Settings

Push Down

Right

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

Y OUTPUT

RTS/CTS: ON

RTU MODE

PARITY: ODD

PARITY

STOPBITS: 2

1

1

1

1

1

2

4

8

16

32

64

128

10

0

0

0

0

Network

Configuration

Network

Address

: OFF

DATA

RATE

SELECT

Network

Address

Data Transmission

Rate Settings

Switches

1 2 3 4

0

0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

0 1 1 1

1 0 0 0

1 0 0 1

1 0 1 0

1 0 1 1

1 1 0 0

1 1 0 1

1 1 1 0

1 1 1 1

Baud

–50

–50

–75

–110

– 150

– 200

– 300

– 600

– 1200

– 1800

– 2400

– 3600

– 4800

– 7200

– 9600

– 19200

PORT

POR

505-5184

LOCAL

TEST

RESET

A

T B

1-8

Figure 1-5 Series

Installation and Set-up

505 MODNIM Switches and LEDs

SIMATIC TI505/TI500 MODNIM User Manual

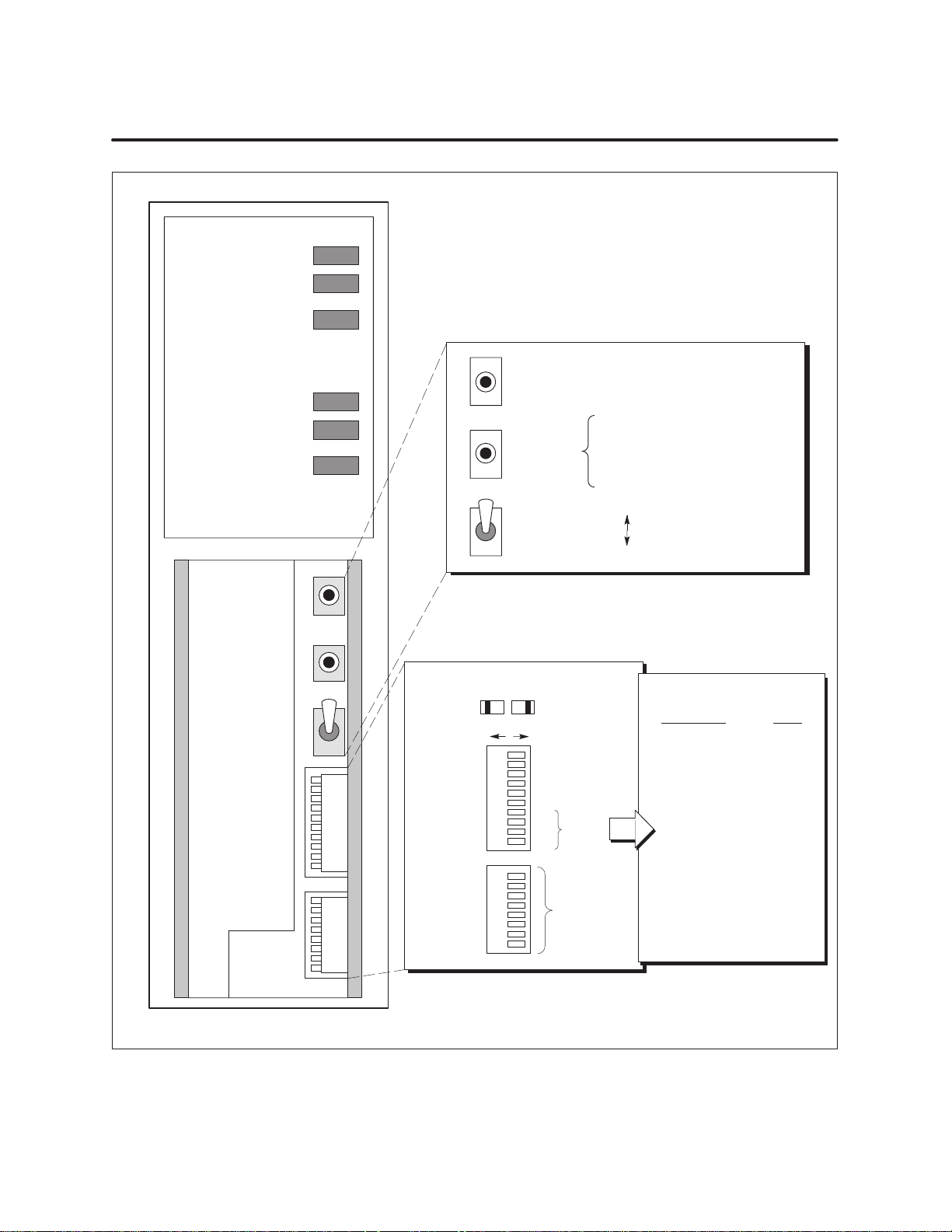

Series

500 MODNIM

NIM GOOD

PC/NIM COMM GOOD

ONLINE

RECEIVE

TRANSMIT

TEST MODE

Local/Remote

Configuration

Switches

Switches

Reset

Self-Test

Network

Address

DIPSWITCH

Y OUTPUTS

RTS/CTS: ON

RTU MODE

PARITY: ODD

PARITY

STOPBITS: 2

Network

Address

: OFF

128

10

9

8

7

6

5

4

1

3

1

2

1

1

1

8

1

7

2

6

4

5

8

4

16

3

32

2

64

1

Reset

Self-Test

Local/Remote

Settings

01

C COILS

RTS/CTS: OFF

ASCII MODE

PARITY: EVEN

PARITY

: ON

STOPBITS: 1

0

DATA

0

RATE

0

SELECT

0

0

• Push

1. Select

2.

3.

4.

to reset

Local control

Remove network cables

Install Loopback connectors

Press Reset and Self-T

together and hold 5 seconds.

Remote control (on-line)

Local control (of

f-line)

Data Transmission Rates

Switches

1234 Baud

0000 – 50

0001 – 50

0010 – 75

0011 – 110

0100 – 150

0101 – 200

0110 – 300

0111 – 600

1000 –1200

1001 –1800

1010 –2400

1011 –3600

1100 –4800

1101 –7200

1110 –9600

1111 –19200

est

Figure 1-6 Series

SIMATIC TI505/TI500 MODNIM User Manual

500 MODNIM Switches and LEDs

Installation and Set-up

1-9

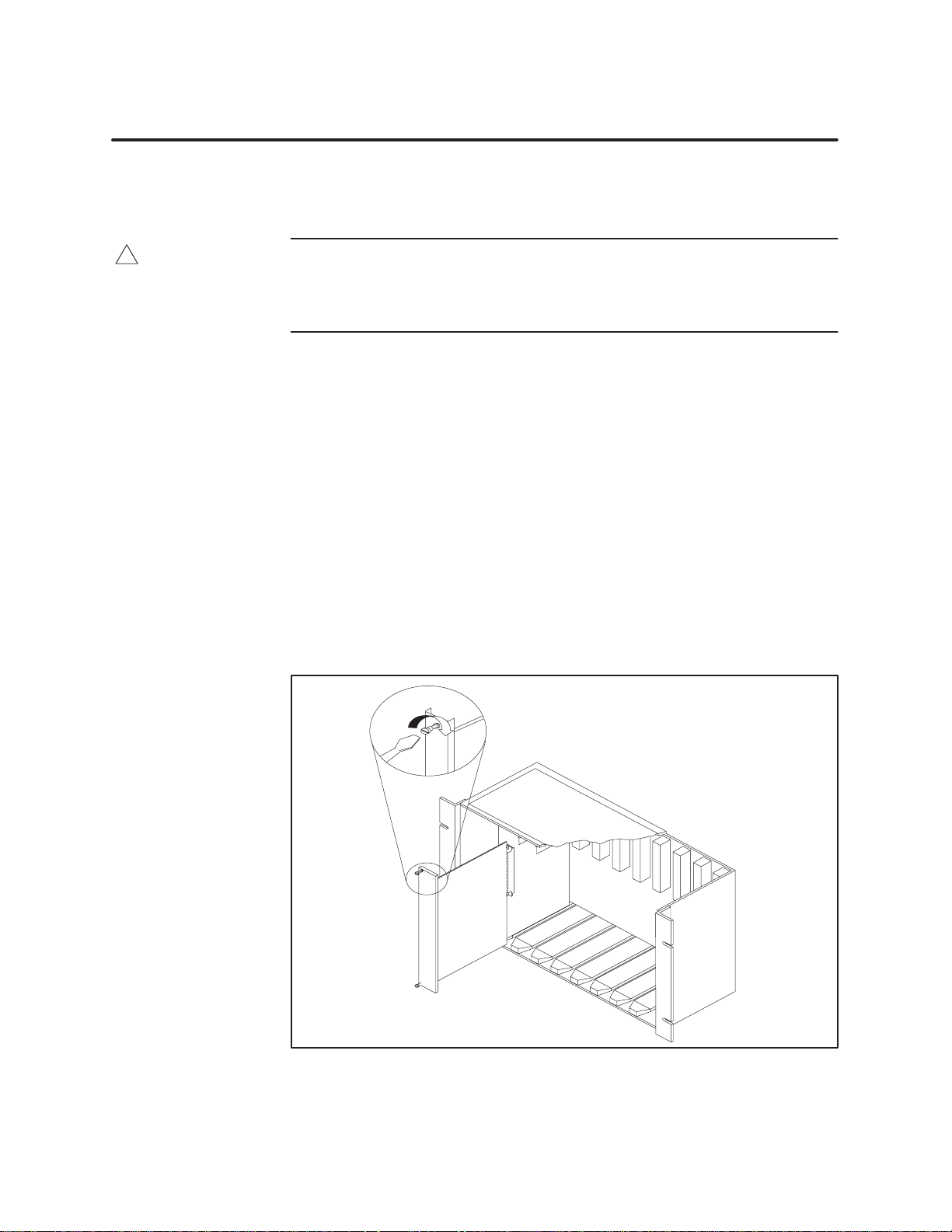

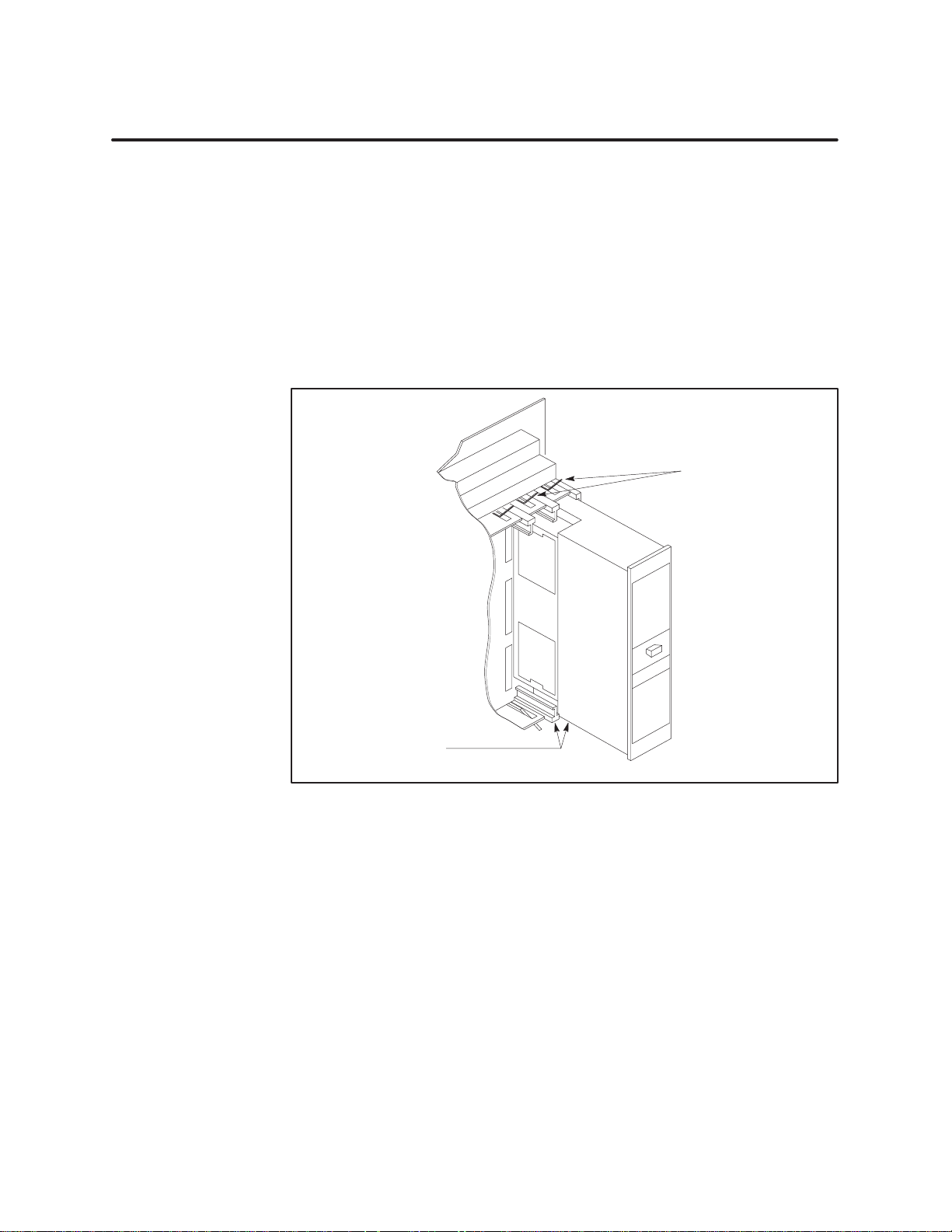

1.4 Installing the MODNIM

Installing the Series 505 MODNIM in the I/O Base

!

WARNING

To

install the Series 505 MODNIM in the selected slot of the I/O base, follow

these steps.

To

avoid the possibility of personal injury, damage to the module,

altering the PLC memory

power to the base’

s power supply and to any modules installed in

, or causing a PLC fatal error

, disconnect

the base before inserting or removing the MODNIM.

1. Disconnect

2.

Set the dipswitches, as described in Section 1.3. (See also Figure 1-8 for

power to the I/O base.

example dipswitch configuration settings.)

3.

Position the module so that the front bezel is facing you.

4.

Hold the top and bottom of the bezel and carefully slide the module into

the slot, pushing it all the way into the base connector

5.

Ensure that the edge card connector is firmly seated in the I/O base

. (See Figure 1-7.)

connector.

ighten the screws at the top and bottom of the faceplate with a flat-

6. T

bladed screwdriver

. (These screws also ground the module to the base.)

1-10

Installation and Set-up

Figure 1-7 Installing

Minimum

Maximum torque: 5.22 in-lb (0.6 N-m)

torque: 2.61 in-lb (0.3 N-m)

the Series 505 MODNIM in the I/O Base

SIMATIC TI505/TI500 MODNIM User Manual

Network

Configuration

Network Address

1 2 4 8 16 32 64 128

1

Figure 1-8 Series

Parity ODD/EVEN

Mode R

R

TS/CTS: OFF

C

coils/Y outputs

Baud Rate

(19200 shown)

Stop bits 2 or 1

Parity OFF

TU/ASCII

/ON

/ON

0

Network

address is

determined by the

sum of the values of

selected switches.

(Address

Note:

switch to press down.

2 shown)

D

= side of

505 MODNIM Example Dipswitch Settings

SIMATIC TI505/TI500 MODNIM User Manual

Installation and Set-up

1-11

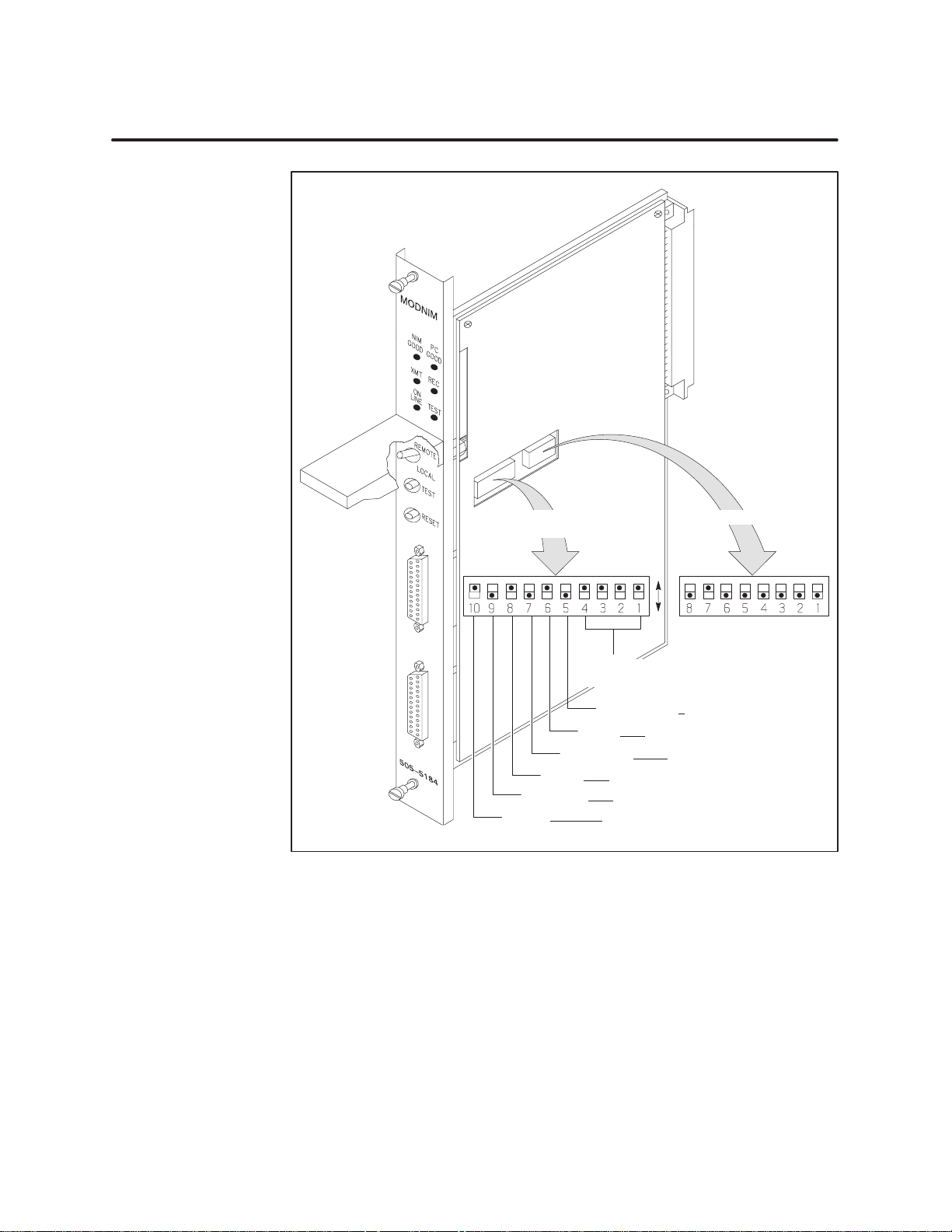

Installing the MODNIM (continued)

Installing the Series 500 MODNIM in the I/O Base

!

WARNING

You

can key the Series 500 MODNIM module to prevent another I/O module

from being inserted by mistake into the two slots reserved for the MODNIM

module.

T

o do this, insert the three keys provided in the right slot of the two slots

occupied by the module so that they fit into the notches in the edge card of

the module. (See Figure 1-9.)

To

avoid the possibility of personal injury, damage to the module,

altering the PLC memory

power to the base’

the base before inserting or removing the MODNIM or the I/O slot

keys.

s power supply and to any modules installed in

, or causing a PLC fatal error

, disconnect

1-12

Installation and Set-up

Figure 1-9 Keying

the I/O Base Slot for the Series 500 MODNIM

SIMATIC TI505/TI500 MODNIM User Manual

Once

the I/O slot keys are in place, you can insert the module as follows.

1.

Set the dipswitches, described in Section 1.3.

2.

Position the module so that the front bezel is facing you.

3.

Hold the top and bottom of the bezel and carefully slide the module into

the slot, pushing it all the way into the base connector

. When the

module is fully seated in the I/O base, locking tabs will hold the module

in place. (See Figure 1-10.)

Locking

tabs

Locking tabs

Figure 1-10 Installing

4. T

o remove the module, pull the tabs away from the module and slide it

out of the base, being careful not to damage the edge card.

SIMATIC TI505/TI500 MODNIM User Manual

the Series 500 MODNIM in the I/O Base

Installation and Set-up

1-13

1.5 Switches and Indicator Lights

Switches and Buttons

Reset Button

The

three switches located on the face of the module behind the access door

are Reset, Self T

est, and Local/Remote, and are described in the following

paragraphs.

The Reset button is a momentary-contact switch which initializes the

MODNIM and initiates the power

-up self test. When you press Reset, all the

indicators turn on for approximately 1 second. Then, all indicators except

TEST go off for about 5 seconds. During this time, the MODNIM runs a

series of diagnostic tests to verify that the hardware components of the

module are operating properly

. In addition, buffers and counters that

service the Modbus Diagnostic Functions are initialized.

If the tests have been successfully completed, only the NIM GOOD and the

PC GOOD (PC/NIM COMM GOOD) indicators will turn back on, while the

TEST indicator turns off. If, however

the User Initiated Self-Test to determine the source of the error

NOTE:

Always press the Reset button after you change any of the

, the TEST indicator

remains on, run

.

configuration dipswitches or address selection dipswitches. In addition, be

aware that when the MODNIM is reset, no communication can occur from

the host to the module for several seconds.

T

est Button

Local/Remote Switch

The T

est button initiates a series of diagnostic tests when it is held down for

3 seconds after a Reset operation. Before running the diagnostic tests,

disconnect all communications cables and install loopback connectors on the

RS-232-C communications ports. These tests are described in more detail in

Section 1.6.

When set to Remote, this two-position toggle switch enables the MODNIM

to perform write operations to PLC memory

. In the Local position, the

MODNIM cannot write to the PLC.

In either position, the MODNIM can monitor PLC memory and mode of

operation. After the MODNIM is set to Online state, local or remote status

is indicated as follows.

• Local

• Remote

When set to Local mode, only the Read functions 1, 2, 3, 4, 7, 1

mode is indicated by a

mode is indicated by a

flashing

steady

ONLINE indicator

ONLINE indicator

.

.

1, 12, and 17

plus diagnostics function 8 can be performed. All other functions (write

operations) will be rejected with Exception Code 01.

1-14

Installation and Set-up

SIMATIC TI505/TI500 MODNIM User Manual

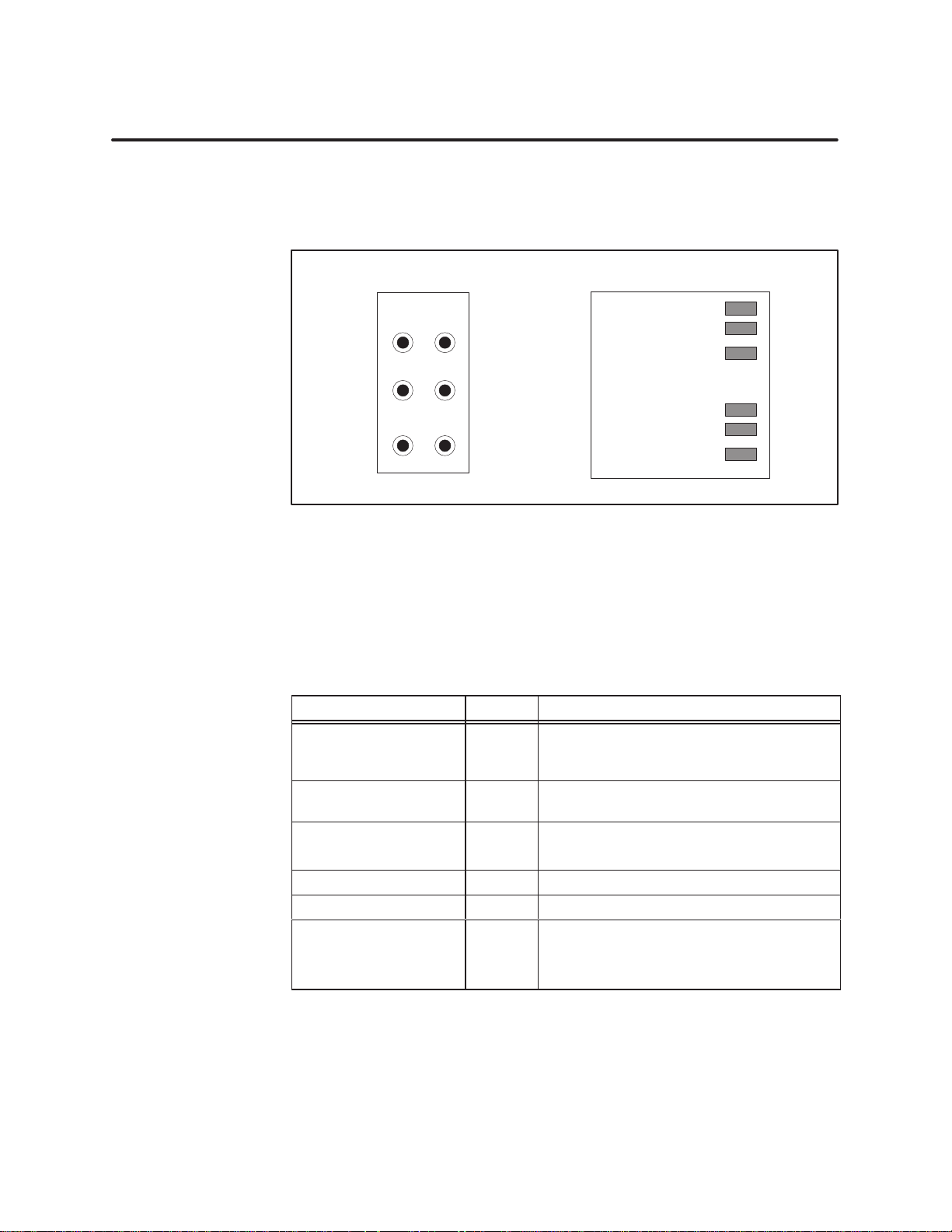

Status

Lights

Indicator

The

MODNIM has six indicator lights (or LEDs) located on the faceplate of

the module (see Figure 1-1

diagnostic status of the module as described below

Series 505 MODNIM

NIM

GOODPCGOOD

XMT REC

1). These lights indicate the operational or

.

Series

500 MODNIM

NIM

GOOD

PC/NIM COMM GOOD

ONLINE

ON

LINE TEST

Figure 1-11 Series

T

able 1-2 shows how to interpret the status of the six indicator lights on the

505 and 500 MODNIM Indicator Lights

RECEIVE

TRANSMIT

TEST MODE

faceplate of the MODNIM during normal operation. Section 1.6 describes

additional interpretations of the indicator lights during diagnostic testing.

T

able 1-2

Indicator Status Description

NIM GOOD On

PC/NIM COMM GOOD

(PC GOOD)

ONLINE

RECEIVE (REC) On Receiving data over the network

TRANSMIT (XMT) On Transmitting data over the network

TEST MODE (TEST)

Status of Indicator Lights

All power-on, reset, or run-time diagnostic

tests have been passed successfully;

MODNIM operating correctly.

On Communicating successfully with PLC

On

Flashing

On

On

Flashing

Connected to the network: Remote mode

Connected to the network: Local mode

MODNIM in Test mode

Failure detected after power-up diagnostics

Tests completed

SIMATIC TI505/TI500 MODNIM User Manual

Installation and Set-up

1-15

1.6 Diagnostic Tests

Built-in Diagnostic Tests

Power

-up Self T

est

The

MODNIM has the following three levels of self tests available.

• Power

•

• User

The MODNIM executes a Power

•

-up Self T

Run-time Self T

-initiated Self T

ests

ests

ests

-up Self T

est in the following cases.

Immediately after you apply +5 VDC power from the I/O base as part of

initialization.

•

Any time the Reset button is pressed.

The Power

-up Self T

est checks the processor and performs a test of on-board

RAM and ROM. At the start of the test, all MODNIM indicators are turned

on for approximately 1 second, then all except the TEST MODE indicator go

off for about 5 seconds.

If the Power

-up Self T

est is successful, the NIM GOOD light turns on, and

the MODNIM attempts to establish communications with the PLC. If this is

successful, the PC GOOD (PC/NIM COMM GOOD) light turns on and the

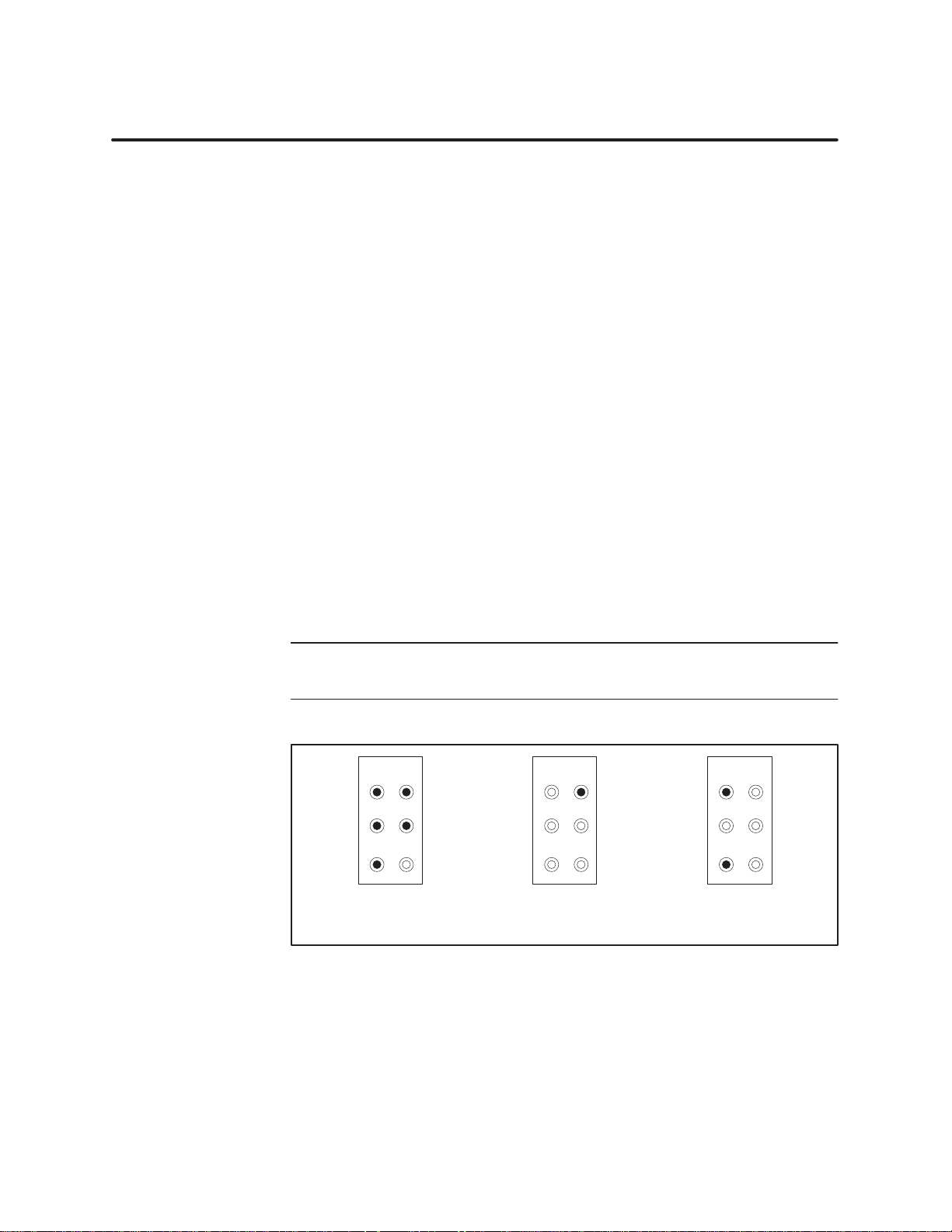

MODNIM is ready for normal network control (see Figure 1-12).

If the Power

-up Self T

est fails, the TEST MODE indicator remains on and

the MODNIM will not respond to any communication attempts.

If the PLC does not respond, the PC GOOD (PC/NIM COMM GOOD)

indicator remains off, and the MODNIM will issue an exception response

with Error Code 04 (failure in associated device) to any host computer

initiating an interactive request to this MODNIM. In addition, the TEST

MODE indicator flashes at a 3-second interval, remaining on for 1 second.

Reset

or

Power-up

NIM

GOODPCGOOD

XMT REC

ON

LINE

TEST

1 second

Figure 1-12 LED

NIM

GOODPCGOOD

XMT REC

ON

LINE

TEST

5 seconds

NIM

GOODPCGOOD

XMT REC

ON

LINE

Successful

internal tests

Status during Power

TEST

-Up Self T

NIM

GOODPCGOOD

XMT REC

ON

LINE

TEST

Communicating

with PLC

est

1-16

Installation and Set-up

SIMATIC TI505/TI500 MODNIM User Manual

Run-time Self T

ests

The

MODNIM monitors itself continuously during normal operation as

follows.

The operating system continuously performs a ROM integrity test as a

•

background process.

•

The MODNIM periodically verifies that it is capable of communicating

with the PLC.

•

A W

atchdog T

imer circuit in the MODNIM guards against software

lockup.

If any failures are detected in the ROM integrity test, the NIM GOOD

indicator light turns off and the MODNIM is forced into the failed state. In

this condition, the module goes into the Offline Mode and will not respond to

any requests. (See Figure 1-13.)

When the MODNIM is in its normal operating mode but fails to

communicate with the PLC, it reports this failure to the host computer with

an exception response. Error code 04 (failure in associated device) is sent,

and the PC GOOD (PC/NIM COMM GOOD) indicator goes out. (See

Figure 1-13.) If communication is re-established, the MODNIM returns to

normal mode and the PC GOOD indicator goes back on.

NOTE:

goes on and remains on as long as everything is operating properly

The W

The first time a valid request is received, the ON LINE indicator

.

NIM

GOODPCGOOD

XMT REC

ON

LINE

TEST

All Run-time

tests OK

Figure 1-13 LED

atchdog T

imer circuit provides an extra measure of protection against

NIM

GOODPCGOOD

XMT REC

ON

LINE

TEST

ROM

Integrity Failure:

goes to Offline Mode

Status during Normal Run-T

Not Communicating with

PLC: reports Error Code 04

NIM

GOODPCGOOD

XMT REC

ON

LINE

TEST

ime Operation

network lockup due to a failed MODNIM. This circuit will force a RESET if

the operating software fails to execute normally

.

SIMATIC TI505/TI500 MODNIM User Manual

Installation and Set-up

1-17

Loading...

Loading...