Siemens SIMATIC TI500, SIMATIC TI505, PPX:500–7301, PPX:500–7302, PPX:500–7303 User Manual

...

SIMATIC TI500/TI505

TIWAY 1 Gateway

User Manual

Order Number PPX:TIWAY-8104-02

Manual Assembly Number: 2587871-0004

Second Edition

Copyright

1992 by Siemens Industrial Automation, Inc.

All Rights Reserved — Printed in USA

Reproduction,

contents is not permitted without express consent of

Siemens Industrial

created by patent grant or registration of a utility model or

design, are reserved.

Since Siemens Industrial Automation, Inc. does not possess

full access to data concerning all of the uses and applications

of customer’s products, we do not assume responsibility either

for customer product design or for any infringements of patents

or rights of others which may result from our assistance.

01/21/92

transmission or use of this document or

Automation, Inc. All rights, including rights

T

echnical data is subject to change.

W

e check the contents of every manual for accuracy at the

time it is approved for printing; however

undetected errors. Any errors found will be corrected in

subsequent editions. Any suggestions for improvement are

welcomed.

, there may be

MANUAL PUBLICA

TION HISTOR

Y

SIMATICTI500/TI505

Or

der Manual Number: PPX:TIW

Refer to this history in all correspondence and/or discussion about this manual.

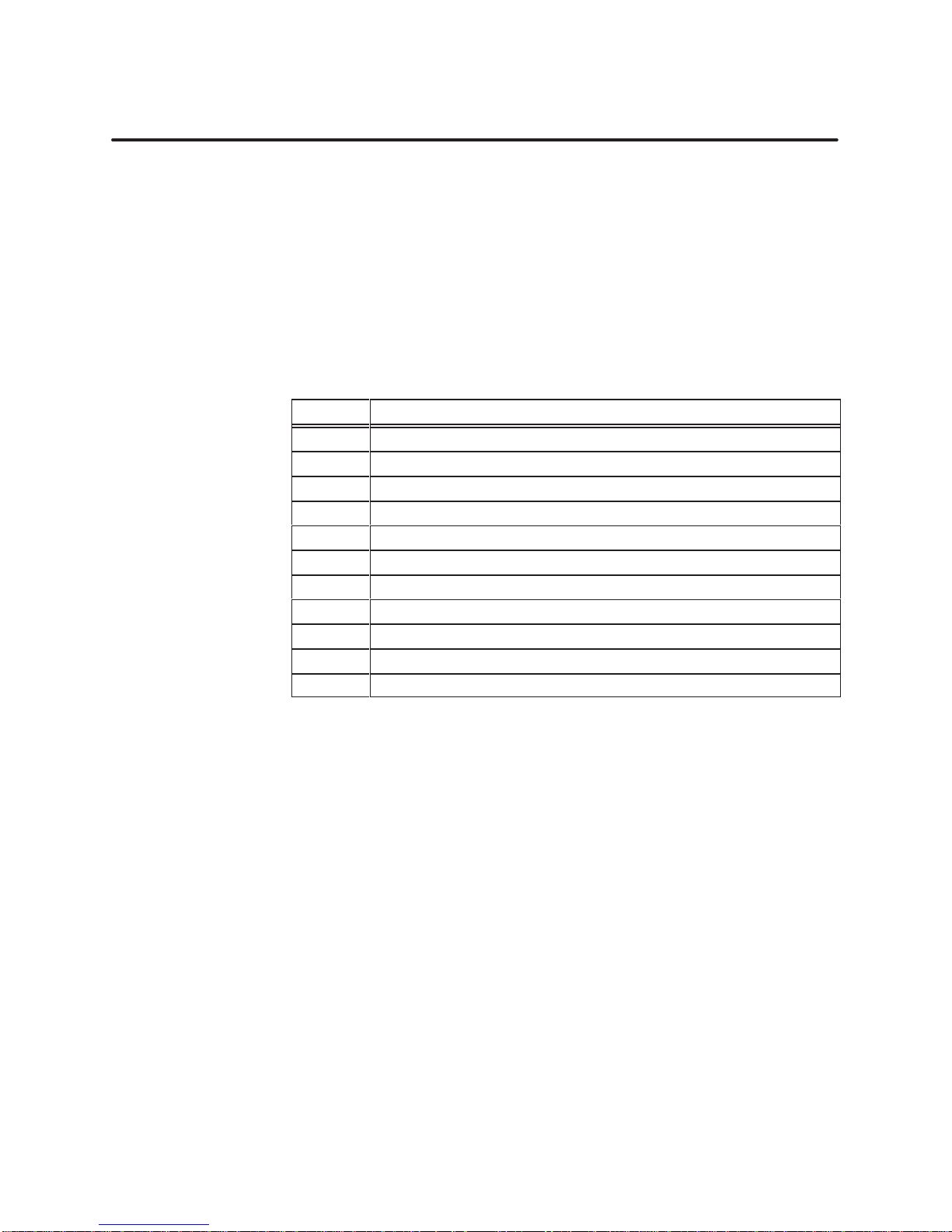

Event Date Description

Original Issue

Second Edition

TIWAY I Gateway User Manual

AY–8104–2

09/85

09/92

Original Issue (2491964–0001)

Second Edition (2491964–0002)

LIST

OF EFFECTIVE P

Pages Description Pages Description

Cover/Copyright Second

History/Effective

iii — x

1-1 — 1-4

2-1 — 2-12 Second

3-1 — 3-14 Second

A-1 — A-4

B-1 — B-3

C-1 — C-28

D-1 — D-11

Index-1 — Index-3

Registration Second

Pages

AGES

Second

Second

Second

Second

Second

Second

Second

Second

Preface

Chapter 1 Product Overview

Contents

1.1 Introduction 1-2.

The

Gateway Inter

Distributed

1.2 Basic

Operating Featur

Interface

Translating

Data T

Types

ransmission Rates Supported

of Data Accessed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

face 1-2.

Contr

ol Systems

Ports

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands between Host and PLC Network

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

es 1-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Network Installation

2.1 TIWAY

2.2 Network

I Network and Gateway Installation Checklist

Quick

Refer

ence Installation Steps

Basic

Installation Pr

Requirements

Media Installation — Local Line

Overview 2-4

Local

TIWAY

Local

Tap

Housing

Terminating

Twisted-Pair

Important

Local

Basic

Primary

Double

Short

Multidrop Taps 2-9.

Cable

Obstructions 2-11

Noise Avoidance 2-11.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Cable Characteristics

I Network Characteristics

Line Har

the Main Line Cable

Cabling

Planning Considerations

Line T

ap Spacing Rules

Considerations

Rule

Dr

ops 2-9.

Dr

ops 2-9.

Routing

ocedures 2-3.

for Installing the Gateway

dwar

e Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2.

1-3.

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4.

1-4.

1-4.

2-2.

2-2.

2-3.

2-4.

2-4.

2-5.

2-6.

2-6.

2-7.

2-7.

2-7.

2-8.

2-8.

2-8.

2-10.

2.3 Network

Data T

RS-232

Media Installation — RS-232-C Modem Inter

ransmission Characteristics

Pin Assignments

face 2-12.

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents iii

2-12.

2-12.

Chapter 3 Gateway Installation and Configuration

3.1 Installing

Basic

Power

3.2 Dipswitch

Overview 3-6

Dipswitch

Dipswitch

3.3 Switches

Online/Offline

Self-Test

Reset

Status

Gateway

Comm

Online 3-11

Receive 3-11

Transmit 3-11

Test

3.4 Diagnostic Tests 3-12.

Built-In

Power-On Test 3-12.

Operational

User-Initiated Test 3-13.

Burn-In

the TIWAY I Gateway

Mounting Guidelines

Connections and Initialization

Configuration and Function

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings for the Host Inter

Settings for the Network Interface Port

and Indicator Lights

Switch

Button

Button

Indicator Lights

Active

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode

Diagnostic T

and Final T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Good

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

face Port

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 3-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 3-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 3-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2.

3-2.

3-3.

3-6.

3-7.

3-8.

3-10.

3-10.

3-10.

3-10.

3-11.

3-11.

3-11.

3-11.

Appendix A Data Type Identification

A.1 Corresponding

A.2 SIMATIC

A.3 TIWAY

Appendix

B.1 System

B.2 V-Memory

iv Contents

TI PLCs Supported by TIWAY I Gateway

I Gateway Specifications

B

Configuration

Data T

ypes A-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Configuration Forms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Of

fset T

ables B-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-3.

A-4.

B-2.

Appendix

C

Modbus Commands

C.1 Modbus

The R

TU T

Message

The

Addr

The

Function Field

The

Data Field

Checksum C-3

Invalid

Modbus

Addressing C-5

Address

C.2 Modbus

Introduction C-6

Code

01 — Read Coil Status

Code

02 — Read Input Status

Code

03 — Read Output Registers

Code

04 — Read Input Registers

Code 05 — W

Code 06 — W

Code

07 — Read Exception Status

Code

08 — Execute Diagnostics

Code

11 — Get Comms Event Counter

Code

12 — Get Comms Event Log

Code 15 — W

Code 16 — W

Pr

otocol Overview

ransmission Frame

Delineation

ess Field

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characters and Messages

Functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limits

Function Descriptions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rite a Single Coil

rite a Single Register

rite Multiple Coils

rite Multiple Registers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-2.

C-2.

C-3.

C-3.

C-3.

C-3.

C-4.

C-4.

C-5.

C-6.

C-6.

C-8.

C-10.

C-11.

C-12.

C-14.

C-15.

C-17.

C-20.

C-21.

C-23.

C-25.

C.3 User-Defined

Command

Command

Command

C.4 Error

Appendix

D.1 Considerations

D.2 PLC

D.3 PLC

Responses

D

PLC

Configuration Requir

Network

Programming Considerations

Blocking

Writing

Writing

PLC

Status Register

Pr

ogramming Example

Data

to be Accessed

Relay

Ladder Logic Pr

Modbus Commands

65 — Read C Memory

66 — Read K Memory

67 — Read WY Memory

Configuring the PLC for Fisher PROVOX

Design Considerations

Network Data

to Integer Registers

to Discr

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

for Configuring a TIWAY I/PROVOX System

ements D-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ete Points

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ogram D-5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Contents v

C-26.

C-26.

C-27.

C-27.

C-28.

D-2.

D-2.

D-3.

D-3.

D-3.

D-3.

D-3.

D-4.

D-4.

List of Figures

1-1 TIWAY

1-2 TIWAY

2-1 Basic

2-2 Number

2-3 TIWAY I T

I Gateway as Inter

I Gateway

Installation and Set-up Steps

of Local Line Secondaries vs. Cable Distance

ap Housing

2-4 Terminating

2-5 Basic T

ap Spacing Rules

2-6 Additional T

3-1 Possible

3-2 AC

3-3 Dipswitch

3-4 Dipswitch

3-5 Gateway

3-6 Indicator

3-7 Indicator

C-1 RTU T

C-2 Bit

C-3 Read

C-4 Read

C-5 Read

C-6 Read

C-7 Read

C-8 Read

C-9 Read

C-10 Read

C-11 Read

C-12 Read

C-13 Write

C-14 Read

C-15 Write

C-16 Write

C-17 Read

C-18 Read

C-19 Exception

C-20 Execute

C-21 Execute

C-22 Get

C-23 Get

C-24 Get

C-25 Get

Bracket Locations for Mounting Gateway

Power Connections

Settings for the Network and Host Ports

Settings for Network Data T

Operation Switches

Lights

Status

ransmission Frame

Orientation

Coil Status Example — Request

Coil Status Example — Response

Coil Status Example — Data Field

Input Status Example — Request

Input Status Example — Response

Input Status Example — Data Field

Output Register Example — Request

Output Register Example — Response

Input Register Example — Request

Input Register Example — Response

a Single Coil Example — Request

Input Register Example — Response

a Single Register Example — Request

a Single Register Example — Response

Exception Status Example — Request

Exception Status Example — Response

Status Bits

Diagnostics Example — Request

Diagnostics Example — Response

Comms Event Counter Example — Request

Comms Event Counter Example — Response

Comms Event Log Example — Request

Comms Event Log Example — Response

face Between PLC Network and Host System

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Local Line

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ap Spacing Rules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ransmission Rates

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2.

1-3.

2-2.

2-5.

2-6.

2-7.

2-8.

2-9.

3-2.

3-3.

3-5.

3-8.

3-10.

3-11.

3-14.

C-2.

C-4.

C-6.

C-7.

C-7.

C-8.

C-8.

C-9.

C-10.

C-10.

C-11.

C-11.

C-12.

C-13.

C-14.

C-14.

C-15.

C-15.

C-16.

C-17.

C-17.

C-20.

C-20.

C-21.

C-21.

vi Contents

C-26 Write

C-27 Coil

C-28 Write

C-29 Write

C-30 Write

Multiple Coils Example — Request

Bit Patter

Multiple Coils Example — Response

Multiple Registers Example — Request

Multiple Registers Example — Response

C-31 Command

C-32 Command

C-33 Command

C-34 Command

C-35 Command

C-36 Command

C-37 Exception

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

n C-23.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

65 — Request

65 — Response

66 — Request

66 — Response

67 — Request

67 — Response

Response Frame

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-23.

C-24.

C-25.

C-25.

C-26.

C-26.

C-27.

C-27.

C-27.

C-27.

C-28.

Contents vii

List

of T

ables

1 TIWAY

1-1 Data T

2-1 Pin

2-2 RS-232-C

3-1 Host

3-2 Network

3-3 Data T

3-4 RS-232-C/423

3-5 Indicator

A-1 Data T

A-2 SIMATIC

A-3 TIWAY

A-4 TIWAY

B-1 System

B-2 V-Memory

B-3 V-Memory

C-1 Modbus

C-2 RTU Timing C-3.

C-3 Terminology

C-4 Diagnostic

C-5 Event

C-6 Exception

I Gateway Models

ransmission Rates Supported

Assignments for Local Line Connector

Connector Pin Assignments

Port Dipswitch Configuration

Port Dipswitch Configuration

ransmission Rates Supported

Status after User-Initiated T

ype Identification

TI PLCs Supported and Accessible Data

I Gateway Featur

I Gateway Physical and Envir

Configuration For

Of

Of

Functions Supported

Codes Supported

Byte T

Responses

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loopback Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

es A-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

m B-2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fset T

able (Resident Infor

fset T

able (Received Infor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dif

ferences C-5.

ypes C-22.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 3-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

onmental Specifications

mation) B-3.

mation) B-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

ix.

1-4.

2-4.

2-12.

3-6.

3-6.

3-7.

3-13.

A-2.

A-3.

A-4.

C-2.

C-18.

C-28.

D-1 PLC

D-2 V-Memory

viii Contents

Data to be Accessed

Block

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-4.

D-4.

Purpose of this

Manual

Preface

This

manual describes the basic features, operation, and installation of the

TIWAY

SIMATIC TIWAY I network and a distributed control system host using

Modbus protocol.

The TIWAY I Gateway translates Modbus commands from a host into the

TIWA

entirely different in protocol and interface requirements, the Gateway

serves as a protocol translator and as a type of network monitor

I Gateway. The Gateway provides an interface between the

Y I protocol format. Since the Modbus and TIWAY I systems are

.

Gateway System

Capacities

TIWA

Y I Gateway

Models

For example, the TIWAY I Gateway can provide protocol translation for the

following host systems.

•

The Honeywell TDC 2000 Data Highway Port (DHP) with one

Gateway can monitor up to eight programmable controller (PLC)

stations with one Network Interface Module (NIM) for each PLC.

•

The Foxboro SPECTRUM FOXNET Device Interface (FDG) with

one Gateway can monitor up to 64 stations equipped with NIMs.

•

The Fisher PROVOX Programmable Controller Interface Unit

(PCIU)

can monitor up to 8 stations with NIMs.

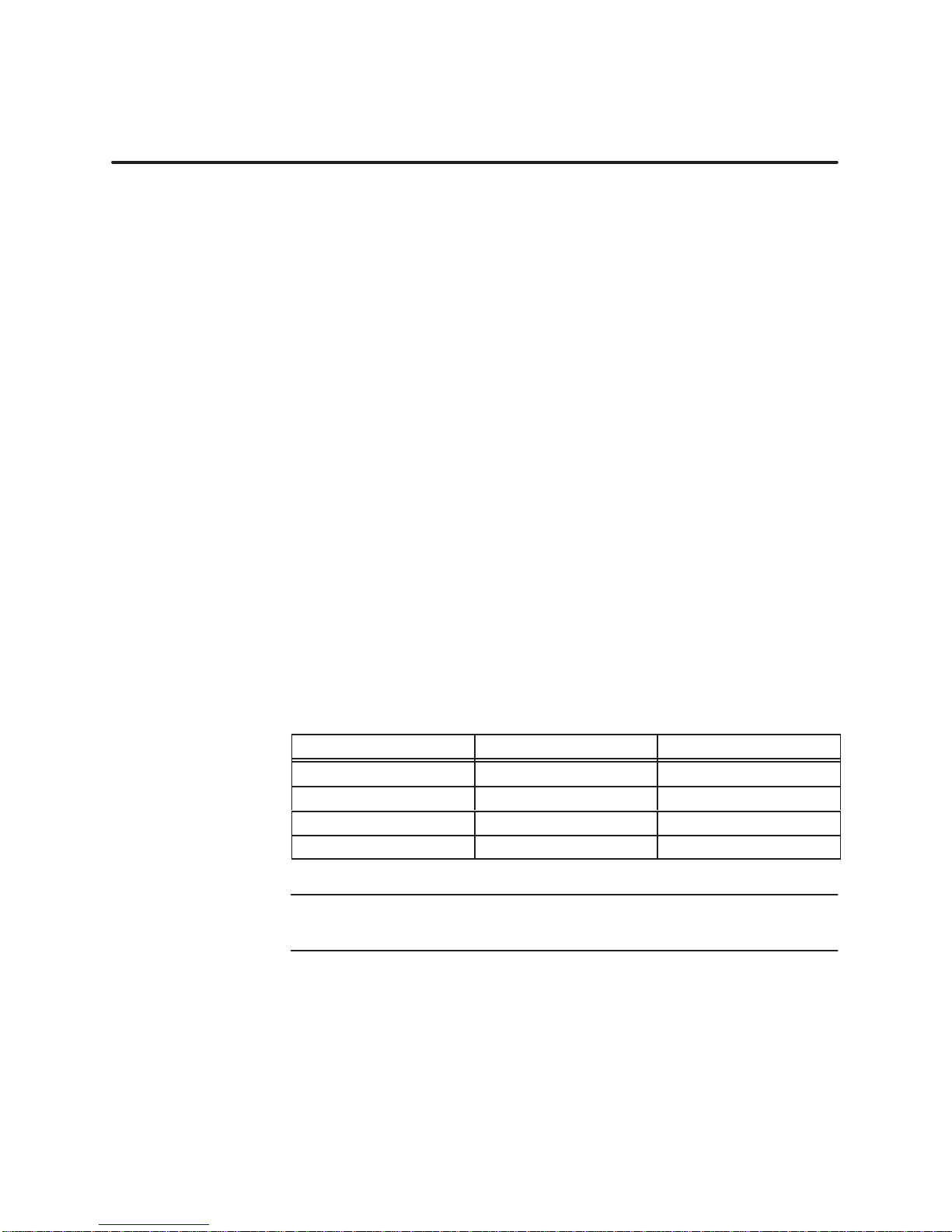

The TIWAY I Gateway is available in four models, offering a choice of

communication ports and voltage supplies, as listed in T

T

able 1

Model Number Communication Ports Supply Voltage

PPX:500–7301 RS-232-C/Local Line

PPX:500–7302 Dual RS-232-C

PPX:500–7303 RS-232-C/Local Line

PPX:500–7304 Dual RS-232-C

TIWA

Y I Gateway Models

able 1.

120 V

120 V

240 V

240 V

AC

AC

AC

AC

NOTE: These models replace the previously available model PPX:500–7200

series of the TIW

TIWAY I Gateway User Manual

A

Y I Gateway

.

Preface

ix

Related Manuals

The

information in this manual is supplemented by the following Siemens

manuals. Y

when using the TIWAY I Gateway

ou may find it helpful to refer to these or other related manuals

.

• TIWAY

• TIWA

• TIWA

• SIMATIC TI520C

• SIMATIC TI545

• SIMA

I Systems Manual

Y I Series 505 Network Interface User’s Manual

Y I Series 500 Network Interface User’s Manual

/TI530C/TI530T

Manual Set, V

TIC TI545 System Manual

• SIMATIC TI560T/TI565T

• SIMATIC TI500/TI505

(2587871–0001)

(2587871–0053)

(2587871–0054)

Manual Set

olumes 1 and 2

(2462158–0026)

(2586546–0023)

(2586546–0053)

System Manual

(2597773–0035)

TISOFT2 Release 4.2 User Manual

(2588081–0019)

ou should also refer to the appropriate user manual(s) for the Modbus host

Y

system’

s device interface.

x

Preface

TIWAY I Gateway User Manual

Chapter 1

1.1 Introduction 1-2.

The

Gateway Inter

Distributed

1.2 Basic

Interface

Translating

Data T

Types

Contr

Operating Featur

Ports

Commands between Host and PLC Network

ransmission Rates Supported

of Data Accessed

Product

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

face 1-2.

ol Systems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

es 1-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

1-2.

1-3.

1-4.

1-4.

1-4.

TIWAY I Gateway User Manual

Product Overview

1-1

1.1 Introduction

The Gateway

Interface

Distributed Contr

Systems

Foxboro

SPECTRUM

ol

The

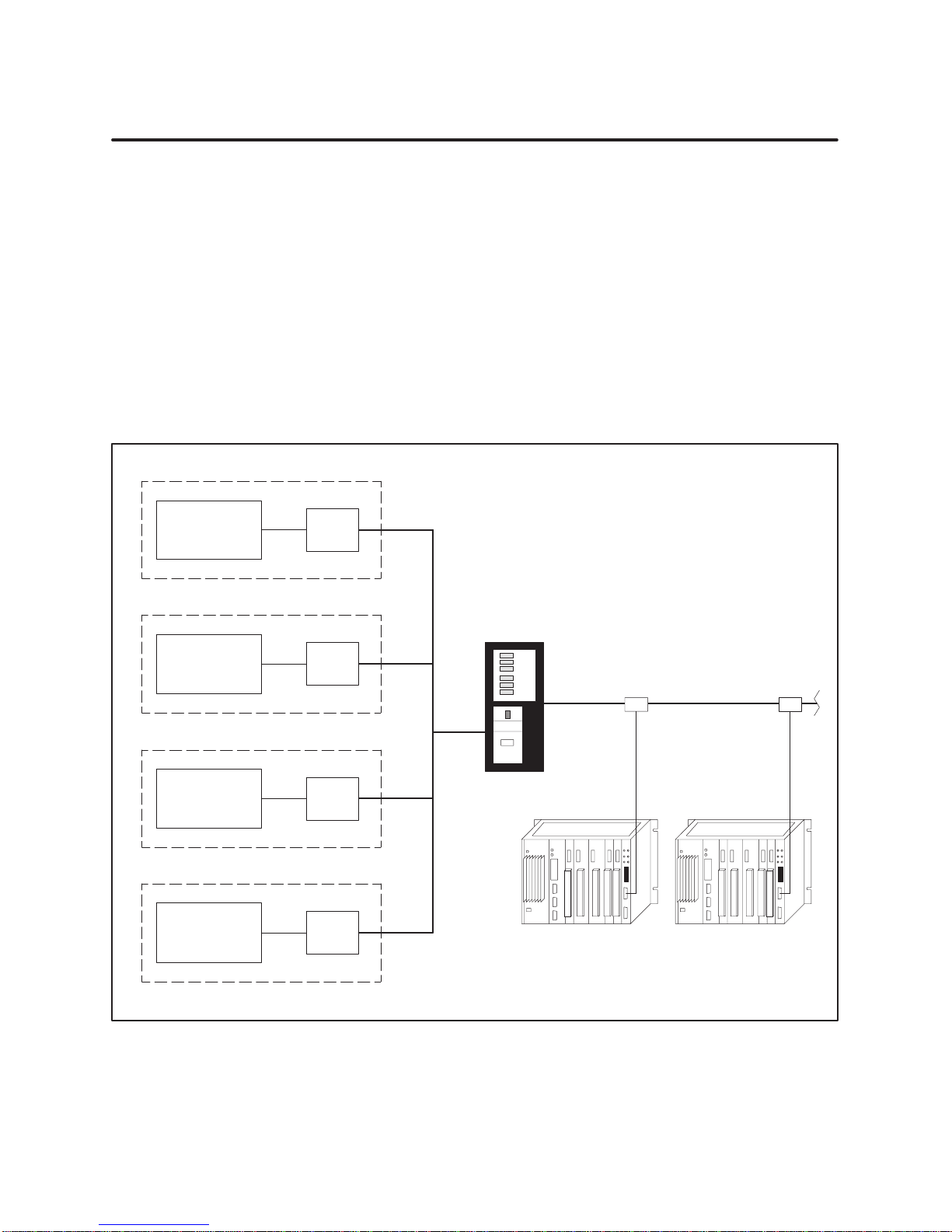

TIWAY I Gateway allows a TIWAY I network of PLCs to be hosted by a

Modbus-compatible host system. Figure 1-1 shows the relationship of the

Gateway to one of several possible Modbus-compatible host systems.

The Foxboro SPECTRUM, Fisher PROVOX, and Honeywell TDC 2000 are

distributed control systems which have interfaces to PLCs. These systems

primarily perform supervisory control and data acquisition functions to the

PLCs, using an RS-232-C type of connection into PLC data highways.

For example, the Honeywell TDC 2000 system communicates with the

Gateway by way of a Data Highway Port (DHP), the Fisher PROVOX

system uses a Programmable Controller Interface Unit (PCIU), and the

Foxboro SPECTRUM system uses a FOXNET Device Interface (FDG).

FDG

or

Fisher

PROVOX

or

Honeywell

TDC

2000

or

MODBUS

Compatible

Host System

Figure 1-1 TIWAY

PCIU

DHP

“xyz”

I Gateway as Inter

TIWA

Y I Gateway

TIWA

Y I Network

Programmable Controllers

face Between PLC Network and Host System

I000000

1-2

Product Overview

TIWAY I Gateway User Manual

1.2 Basic Operating Features

Inter

face Ports

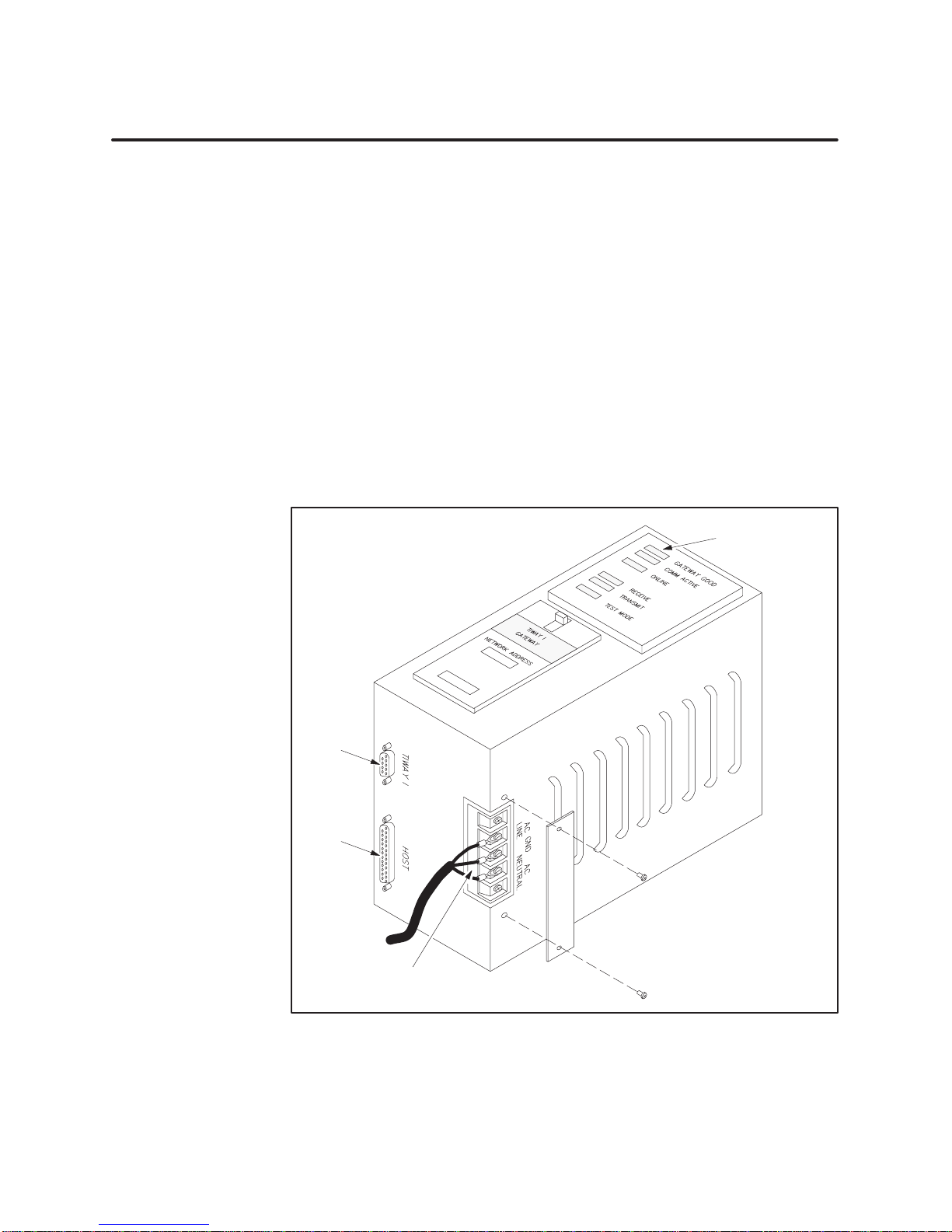

Two

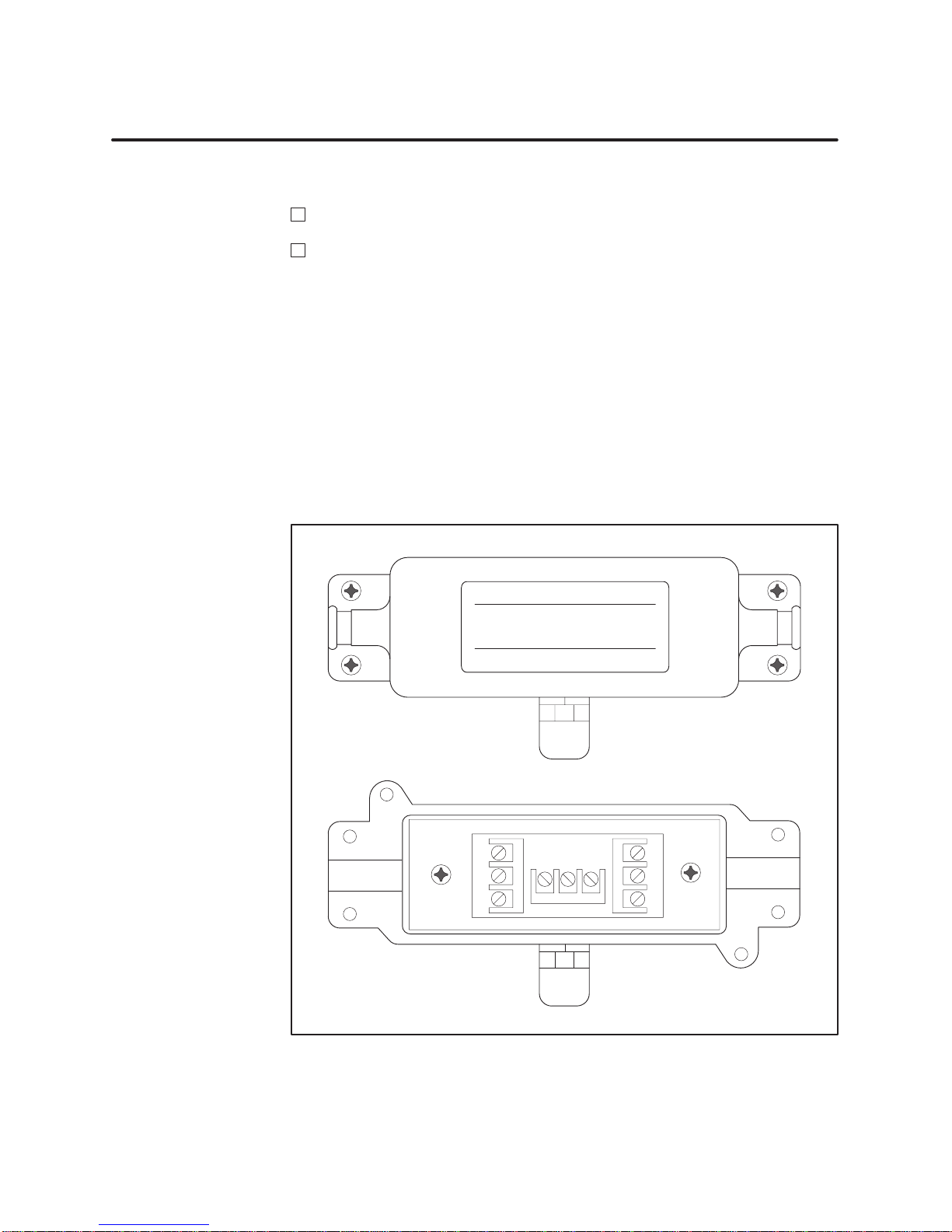

interface ports are located on the bottom of the TIWAY I Gateway unit.

The AC power connections are also located on the bottom, covered by a

protective plate. (See Figure 1-2.)

•

Host: an RS-232-C host interface port (25-pin female D-shell connector)

• TIWA

Y I: the network port (9-pin female D-shell connector)

The host system is connected by cable to the host interface on the Gateway

The communications cable is supplied with the Gateway

. The TIWAY I port

provides communication interface with the TIWAY I network of PLCs or

other secondary devices.

Refer to Chapter 2 for information on TIWAY I network installation.

Chapter 3 describes the procedures for installing and configuring the

TIWA

Y I Gateway and the communications cables.

Status indicators

TIWAY

I

port

.

Host

port

TIWAY I Gateway User Manual

AC Power

Connections

Figure 1-2 TIWAY

I Gateway

Product Overview

I00xxxx

1-3

Basic Operating Features (continued)

Translating

Commands

between Host and

PLC Network

Data T

ransmission

Rates Supported

The

Gateway provides protocol and electrical interface conversion. A

command issued by the host system is transmitted to the Gateway

. Once it

receives the command, the Gateway converts the protocol and electrical

signals and then relays the command to the PLC which was addressed.

After the PLC responds, the Gateway re-translates the information and

sends it back to the host system through the interface device.

The primary function of the Gateway

, then, is to translate host commands

into TIWAY I commands. These commands are described in Appendix C.

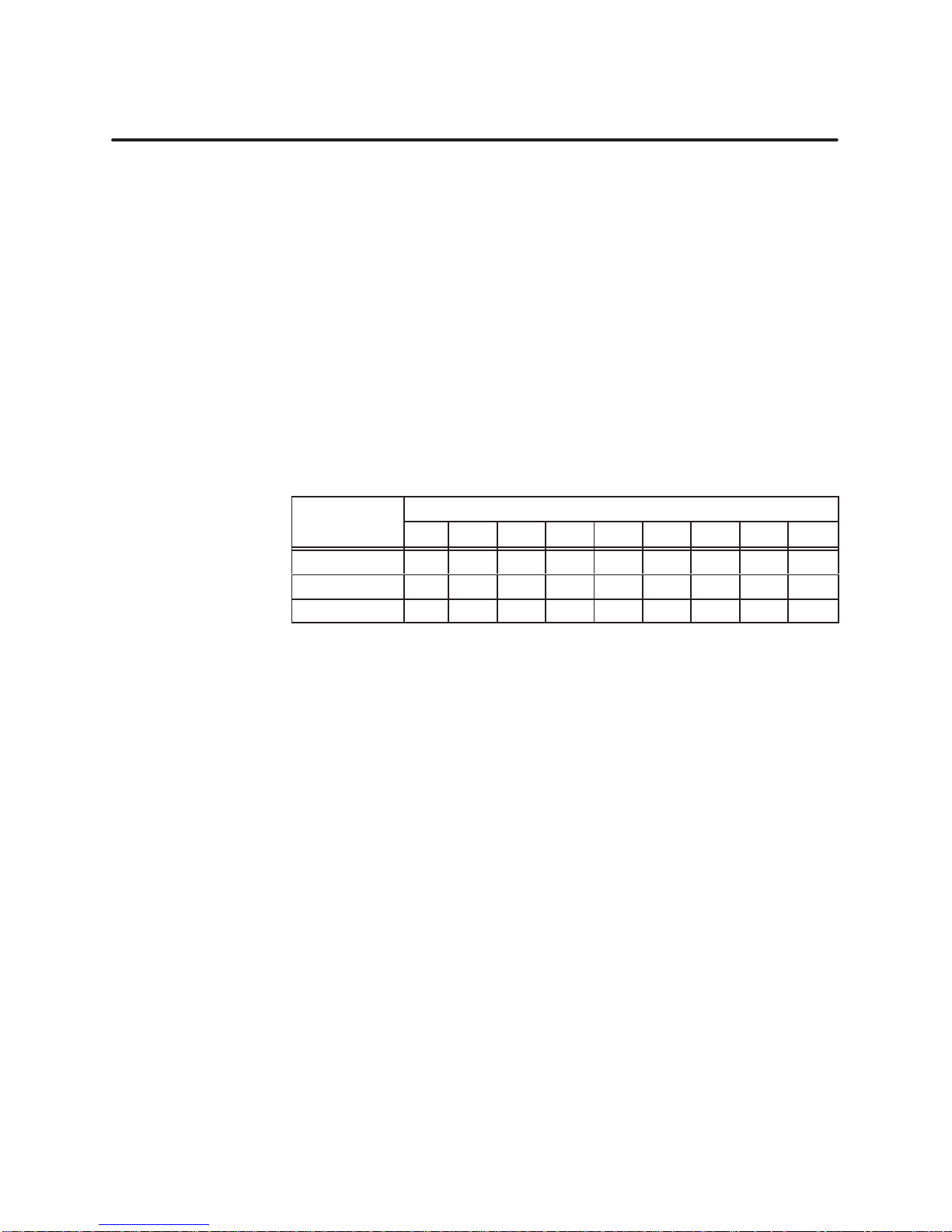

The TIWAY I Gateway supports data transmission rates from 1

second (bps) to 19.2 kbps with the host, and from 1

the network interface. T

able 1-1 summarizes the baud rates supported by

10 bps to 1

10 bits per

15.2 kbps on

the Foxboro, Honeywell, and Fisher host systems.

T

able 1-1

Host System Data Transmission Rates Supported

110 150 300 600 1200 2400 4800 9600 19.2k

Foxboro

Honeywell

Fisher

Data T

ransmission Rates Supported

T

ypes of Data

Accessed

The

Gateway allows access to discrete I/O points and Control Relays

(X, Y

, and C), holding registers (V

-memory), word input and output registers

(WX and WY), as well as performance statistics for each PLC network

interface. Information can be stored in variable (V) memory locations,

retrieved, and changed from the operator’s console of the distributed control

system. Appendix A provides information on the maximum numbers of

discrete inputs and outputs, holding registers, and word input registers.

Examples of data retrieval include the following:

•

If you want to retrieve a process control loop integer value from a PLC,

move this value into a register

, or V

-memory location, corresponding to

the one configured in the distributed control system (refer to the

appropriate DCS manuals).

•

If you want to look at the current value of a counter

into V

-memory (using the ladder logic program) to a location configured

, move this value

as a register in the host system.

Discrete inputs and outputs (Xs, Ys, and Cs) generally do not require special

conditioning in order to be read from the operator

’

s console (as in the Fisher

PROVOX system). See Appendix D for examples.

1-4

Product Overview

TIWAY I Gateway User Manual

Chapter 2

2.1 TIWAY

2.2 Network

I Network and Gateway Installation Checklist

Quick

Refer

Basic

Installation Pr

Requirements

Overview 2-4

Local

Line Cable Characteristics

TIWAY

I Network Characteristics

Local

Line Har

Tap

Housing

Terminating

Twisted-Pair

Important

Local

Line T

Basic

Considerations

Primary

Double

Short

Dr

Multidrop Taps 2-9.

Cable

Obstructions 2-11

Noise Avoidance 2-11.

Routing

Network

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ence Installation Steps

ocedures 2-3.

for Installing the Gateway

Media Installation — Local Line

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

dwar

e Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Main Line Cable

Cabling

Planning Considerations

ap Spacing Rules

Rule

Dr

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ops 2-9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ops 2-9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

2-2.

2-2.

2-3.

2-4.

2-4.

2-5.

2-6.

2-6.

2-7.

2-7.

2-7.

2-8.

2-8.

2-8.

2-10.

2.3 Network

Data T

RS-232

TIWAY I Gateway User Manual

Media Installation — RS-232-C Modem Inter

ransmission Characteristics

Pin Assignments

face 2-12.

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation

2-12.

2-12.

2-1

2.1 TIWAY I Network and Gateway Installation Checklist

Quick Refer

ence

Installation Steps

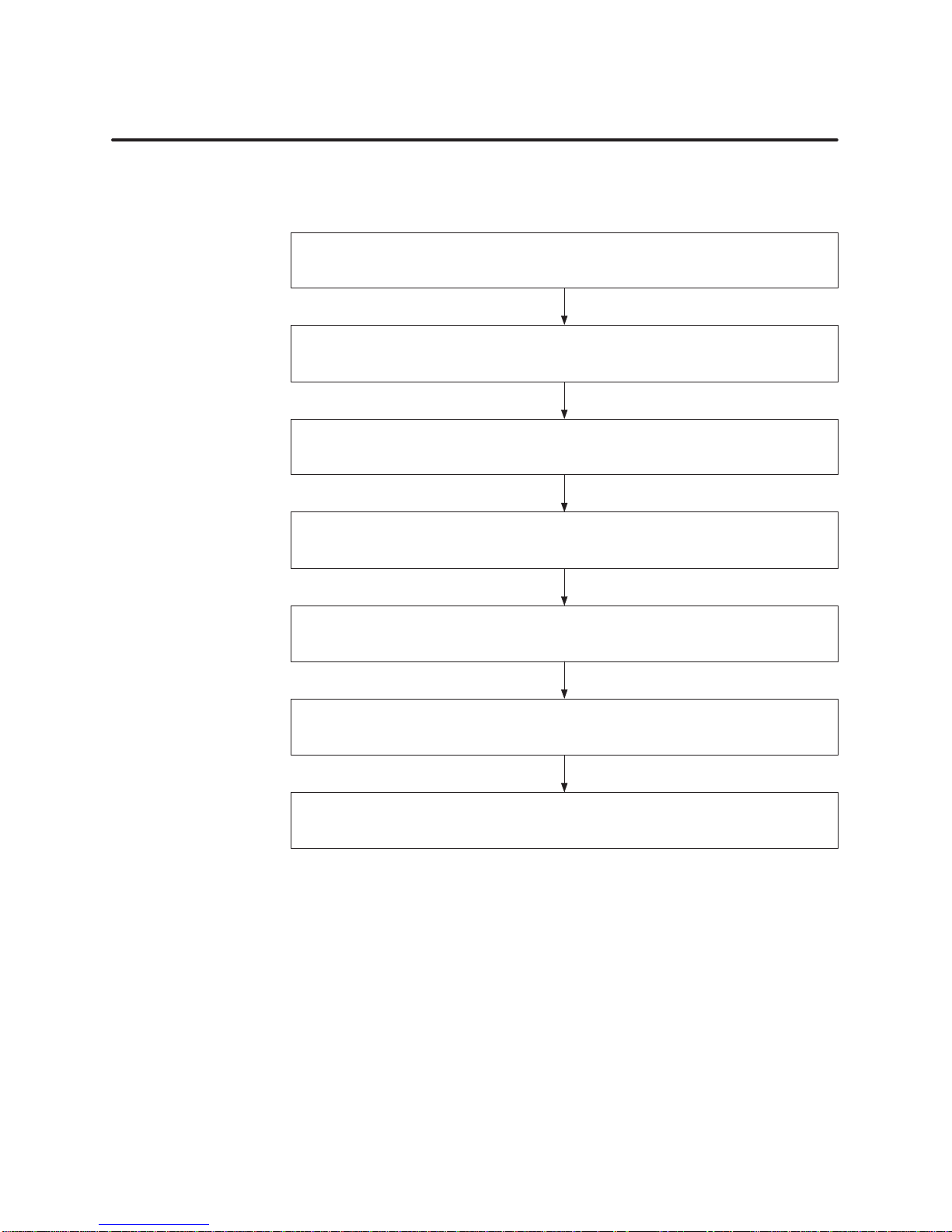

Figure 2-1

TIWA

Y I Gateway

is a quick reference list of steps to be taken when installing the

. Refer to Chapter 3 for specific procedures and cautions.

Attach

AC power cable to the Gateway

Run diagnostic tests.

Connect the network and host interface cables.

Configure the host system.

.

Configure the Gateway dipswitches.

Check Gateway indicators for proper operation.

Configure the variable memory of PLCs on the TIWAY I network.

Figure 2-1 Basic

Installation and Set-up Steps

2-2

Network Installation

TIWAY I Gateway User Manual

Basic Installation

Procedures

Some

basic procedures to follow when installing a Gateway system include

the following.

•

Be sure you have all components necessary to install the Gateway and

the network cables. (Refer to the checklist below for required parts.)

•

Install the TIWAY I network and host system interface cables (see

Section 2.2). Also refer to the appropriate host system installation

manuals for specific information on cabling between the host and the

Gateway.

•

Install the Gateway in a NEMA panel or other suitable enclosure (see

Chapter 3 for more details).

Requir

ements for

Installing the

Gateway

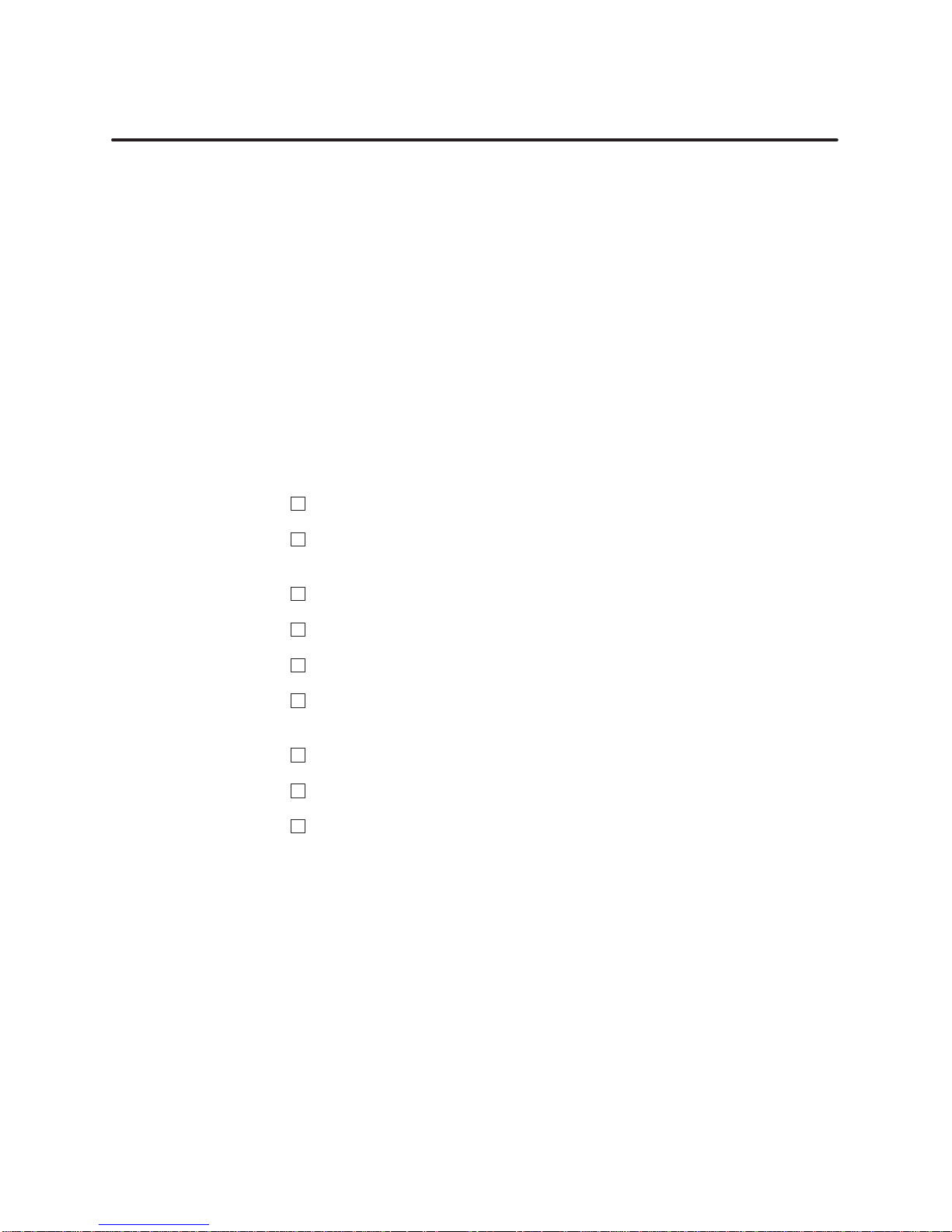

The items below are required to install the TIWAY I Gateway and to connect

it to a host system and the TIWAY I network.

TIWA

Y I Gateway

L-shaped mounting brackets and bracket screws, or optional rack

mount kit.

Host interface cable (included; PPX:2462553–0003)

Mounting screws (customer

AC power cable (customer

Loopback connector(s) for user

-supplied)

-supplied)

-initiated diagnostic test (included;

PPX:2703834–0001)

TIWA

Y I T

ap Housing (for Local Line installation) (PPX:500–5606)

T

ap cable for use with Local Line (customer

-supplied), or

RS-232-C/423 cable for use with modems (both cables and modems are

customer-supplied)

TIWAY I Gateway User Manual

Network Installation

2-3

2.2 Network Media Installation — Local Line

Overview

Line Cable

Local

Characteristics

TIWAY

I is a multi-drop communications network. It consists of a main

trunk cable (the “spine”) and dropline cables. The network can connect up to

248 secondaries to a host computer

NOTE:

Although addresses can range from 1 to 254 on TIWAY I, addresses

.

248 through 254 cannot be used because of the limitations of the Modbus

protocol.

The selection of the media interface depends primarily upon two criteria:

the distance to be spanned and the cost of installation. The main trunk can

be up to 25,000 feet long, and each dropline can be up to 100 feet long, with

Local Line. For distances exceeding 25,000 feet, the use of RS-232-C media

interfaces and modems is required.

If cable redundancy is required (two TIWAY I cables), you will need two

Gateways, two cables, and two host system interface devices. Refer to the

appropriate host system user manuals for more specific information on

redundant connections.

The TIWAY I Local Line is a physical signalling technique (baseband,

differential current drive) which operates over shielded, twisted-pair

cabling. The Local Line cable may be up to 25,000 feet long. The Local Line

uses tap housings to simplify the addition of connections onto TIWAY I.

The Local Line is designed to operate with shielded twisted-pair cable which

has a characteristic impedance of 124 ohms. The interface is a male, 9-pin

D-type connector with pin assignments as shown in T

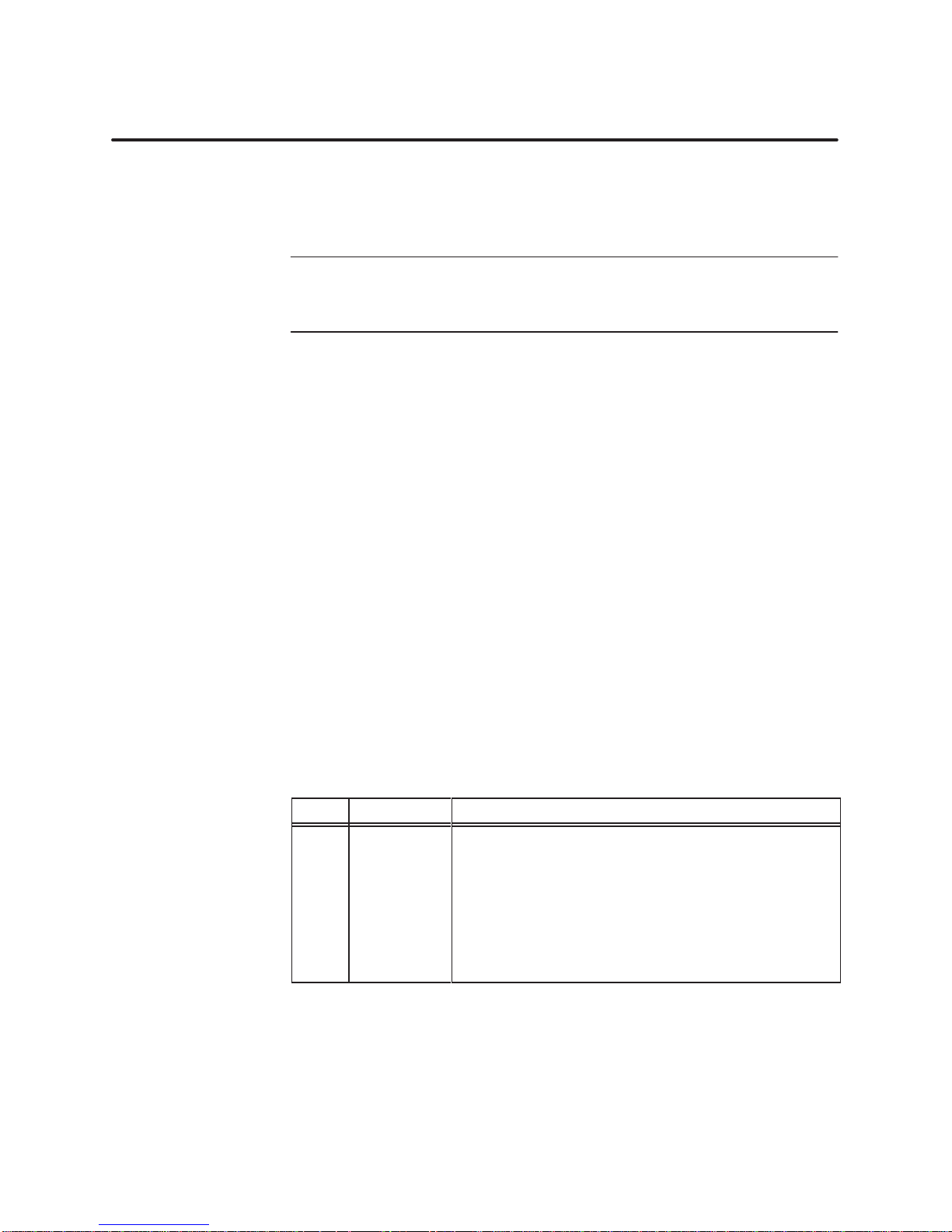

T

able 2-1

Pin Name Description

1

2

3

4

5

6

7

8

9

Shield

LLM+

LLM–

Pin Assignments for Local Line Connector

Reserved

Reserved

Cable shield and signal common

Reserved

Reserved

Positive biased signal line

Reserved

Reserved

Negative biased signal line

able 2-1.

2-4

Network Installation

TIWAY I Gateway User Manual

TIWA

Y I Network

Characteristics

The

TIWAY I network cable consists of a main cable or spine with droplines

or taps for each secondary

. The maximum main line cable length, cable type,

tap length, tap spacing, number of secondaries, and maximum baud rates

are interrelated network variables and have a direct influence upon

network performance.

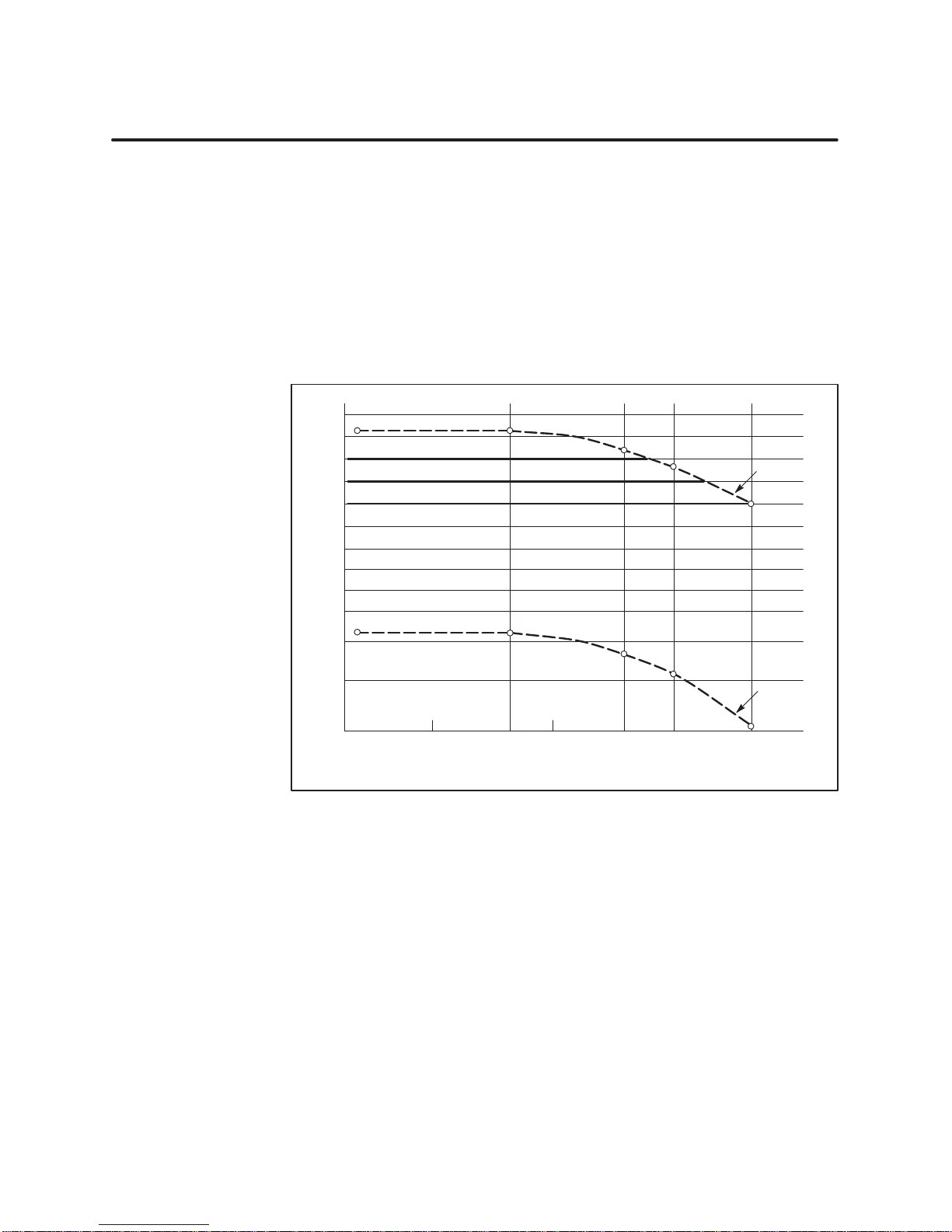

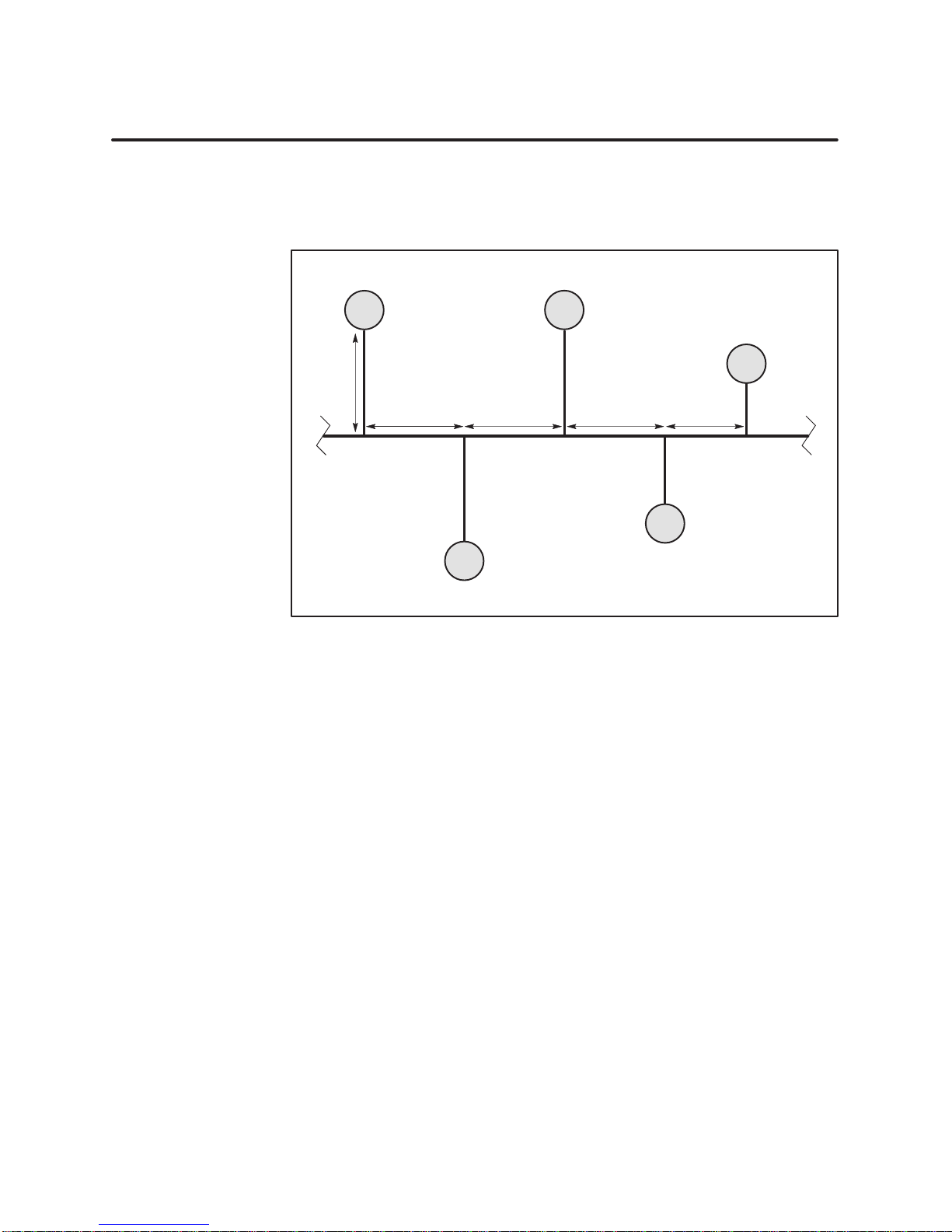

Figure 2-2 shows the relationship of cable distance to the number of

secondaries for different baud rates for two types of twisted-pair cable. The

cable distance (in thousands of feet) is shown vertically; the maximum

number of units that may be attached is shown horizontally

.

30

25

20

15

10

8

7

6

5

4

3

Cable Distance (1000’s of feet)

2

1

19.2

kbps

38.4 kbps

57.6 kbps

1

15.2 kbps

1

15.2 kbps or lower

Cable

Figure 2-2 Number

Belden 9860

Belden 9271

10 50 100 250

205

Unit Loading (Number of Stations)

of Local Line Secondaries vs. Cable Distance

I000000

As shown in Figure 2-2, when you use Belden 9860 cable (or its equivalent),

up to 75 stations can be attached to a network operating at 38.4 kbps and

having a spine length of 20,000 feet. At 1

a Local Line network having 248 stations is 10,000 feet.

TIWAY I Gateway User Manual

15.2 kbps, the maximum length of

Network Installation

2-5

Network Media Installation — Local Line (continued)

Local Line

Hardware

Components

T

ap Housing

The

hardware components of a Local Line network consist of the following:

TIWA

Y I T

ap Housing (PPX:500–5606)

Shielded, twisted-pair cabling (customer

-supplied)

These components are described in the following sections.

The TIWAY I T

ap Housing, shown in Figure 2-3, is designed specifically for

Local Line networks. The tap housing can be mounted rigidly to a NEMA

panel or other enclosure. It could also be used to splice cables in a cable tray

without being rigidly mounted.

The tap housing contains terminating resistors, and it also provides noise

isolation for attached cabling, resists moisture, and relieves strain, thus

allowing an orderly connection to the TIWAY I network. One tap housing is

provided with each Gateway Local Line connection.

Siemens

NETWORK TAP HOUSING

MODEL 500–5606 ASSY 2702766–0001

Siemens Industrial Automation, Inc.

2-6

Network Installation

G

W

B

T

op cover removed to show

cable connections.

Figure 2-3 TIWAY

GWB

I T

ap Housing

G

W

B

I000000

TIWAY I Gateway User Manual

Ter

minating the

Main Line Cable

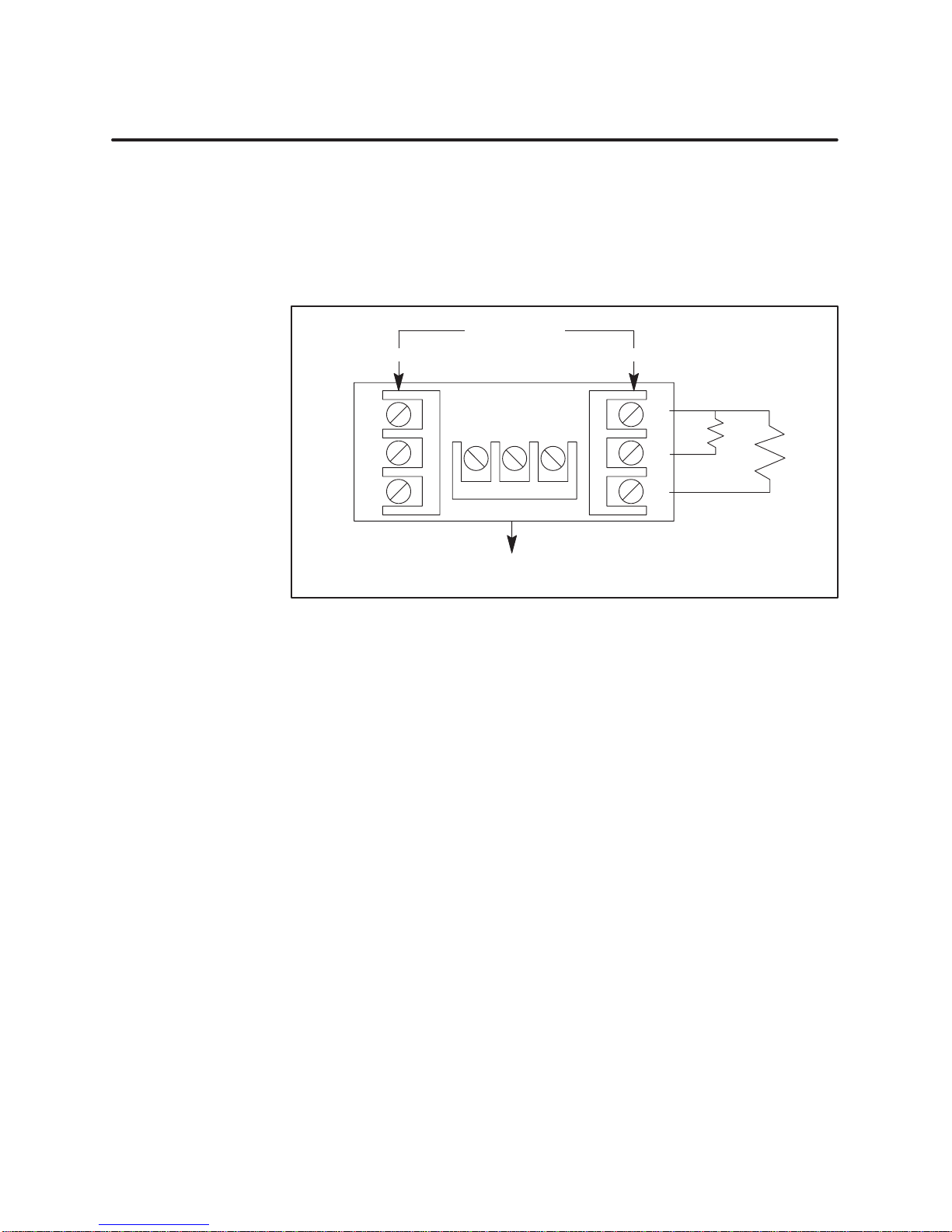

The

terminating resistors must be used to ensure that the main line cable is

properly terminated and biased for improved reliability

. Each tap housing is

supplied with terminating resistors to connect to the ends of the main line

cable. At each end, a terminating resistor must be connected between LLM+

and the cable shield and also between LLM– and the cable shield inside the

tap housing.

Network Cable

Input Output

Twisted-Pair

Cabling

Important Planning

Considerations

W

G

B

Cable

to Module

Figure 2-4 Terminating

GWB

the Local Line

W

G

B

Termination

Resistors:

68

ohms

5%

1/4 watt

Siemens Industrial Automation recommends Belden 9860 twisted-pair

cabling or its equivalent for use as the Local Line network spine. Belden

9271 or its equivalent should be used for the dropline. Brands other than

those listed here will be specified by Siemens upon request.

Some major points to consider during the planning phase of a Local Line

network are the following.

•

From the start, allow for system growth. Make provisions for the

attachment of additional computing devices by routing cables through

all probable areas of future plant expansion.

I000000

•

•

•

TIWAY I Gateway User Manual

Always make the network flexible enough to allow for re-arrangement

of plant equipment.

Since network system noise is usually picked up by its interconnecting

wiring, take steps during installation to bypass or eliminate noise

sources.

If cable redundancy is required, make sure the two cables are never

routed along the same path, since the environmental and other factors

which disable one cable will very likely disable the second cable.

Network Installation

2-7

Network Media Installation — Local Line (continued)

Local Line T

ap

Spacing Rules

Local

Line networks must adhere to specific tap spacing requirements to

maintain signal integrity

. These requirements are outlined in the following

sections.

100′ 100′

50′ min 50′min 50′ 30′

60′

100′

20′

Basic

Considerations

Primary Rule

I000000

Figure 2-5 Basic Tap Spacing Rules

The rules for determining the correct distances between taps exist simply

for the prevention of signal degradation caused by reflections.

Prior to configuring the distances between taps in the network cable, select

a single tap as a physical point to use as reference. This tap should be one of

the taps on the end of the network.

The primary rule is that the minimum distance from one tap to the next

cannot

(drop

be less than one half the distance of the previous tap cable

line) length. This rule should be applied starting at the first tap on the

network all the way to the end. Then, from the last tap on the network, the

same rule should be applied back to the first tap again.

2-8

Network Installation

TIWAY I Gateway User Manual

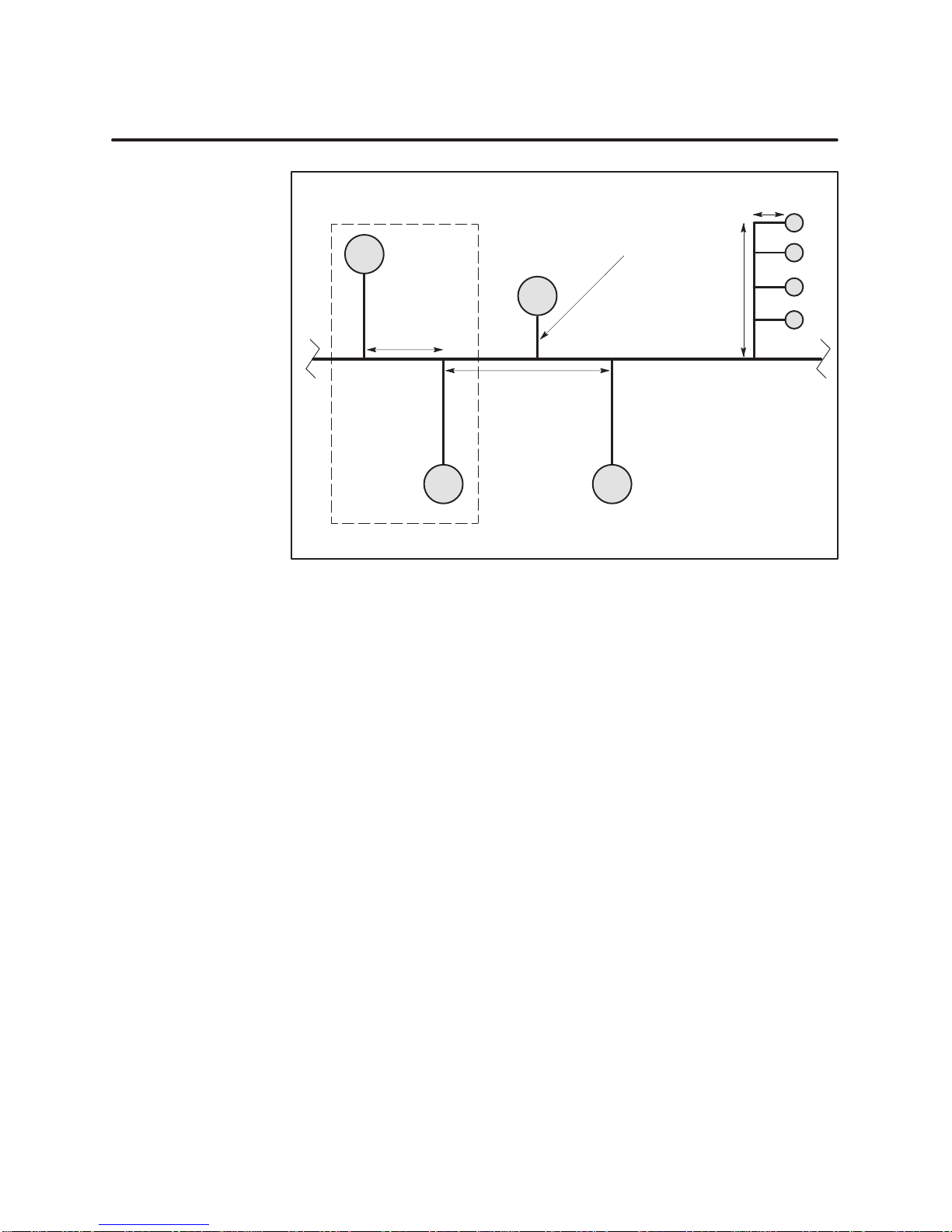

Double Drop

80′

Drop

lines less

than 36 inches

can be ignored.

36″max

100′

max

Double Dr

ops

30′

100′

30″

50′ min

100′

I000000

Figure 2-6 Additional Tap Spacing Rules

If a tap cable is installed

less than the minimum

distance as stated in the

primary rule, then the two drops, the previous one and the one being

installed, are considered a

Double

drops are allowed, but triple drops are not allowed.

double

drop

.

After installing a double drop, the next tap must be placed at the minimum

distance or farther

. In this case, the minimum distance would be one half

the distance of the longest of the two tap lines making up the double drop.

Short Dr

ops

Drops that have a tap line that is

calculating the minimum distance between taps.

Multidr

op T

aps

There is no limit to the number of drop stations that can be connected to the

same tap line.

Each station must have its own tap, and the overall drop line length cannot

exceed 100 feet. The cable used to attach each station to the drop line

cannot

TIWAY I Gateway User Manual

less than 36 inches

exceed the 36-inch maximum.

can be ignored in

Network Installation

2-9

Network Media Installation — Local Line (continued)

Cable Routing

!

CAUTION

Cable

routing should be planned as if the path between all stations on the

network were free of obstructions. The next step is to modify the first

routing to account for obstructions, then calculate the amount of cable

needed.

Observe

all local and national electrical and fire codes when

installing wiring.

In

general, there are three types of network cabling routes:

• Under-floor

• In-ceiling

•

Surface ducting

Any combination of these three routes may be used on a single network. The

choice is often determined by whether or not the building (or buildings) in

which the network is being installed is new construction or an existing

building. The following paragraphs describe some of the advantages and

disadvantages of each type of cable routing.

Under-floor

ducts or

in ducts are usually expensive, and while they are better

— For under

-floor routing, the cable can be enclosed within

, with raised flooring, in the “open air

.” Under

-floor systems enclosed

-protected against

unauthorized taps than are open-air systems, they often make future

expansion of the network more difficult and expensive.

Open-air under

maximum network expansion and flexibility

In-ceiling

-floor cabling systems usually provide good access, and allow

.

— For in-ceiling routing, network cables are usually supported

in troughs or with hooks and clamps every 10 or 15 feet. Some advantages

of in-ceiling installation are the following.

• Flexibility

•

Low-cost installation

•

Accessibility to cabling

2-10

Network Installation

TIWAY I Gateway User Manual

Some

disadvantages are the following.

•

Is is impractical for buildings without drop ceilings

Obstructions

• W

•

Surface

orking in high ceilings can be hazardous

Ceilings often collect dust and other debris

ducting

— Surface ducting for network cabling is usually

installed along the baseboards or is attached to walls at desktop height.

While surface ducting ordinarily protects cables from both physical and EMI

effects, it may also require that network computing devices be positioned

near a wall.

Aside from physical obstructions such as posts, walls, and partitions,

electrical interference should also be avoided. Some sources of interference

are the following.

•

Power distribution mains

•

Arcing motors

•

Fluorescent lighting

• Teletypes

Undesired signal transfer (cross-talk) between adjacent circuits

•

•

Noise A

voidance

In general, network cabling should never come into direct contact with any

electrical conductor

should be grounded in accordance with applicable electrical codes. Keep a

minimum of three feet of distance between all network cabling and the

following sources of noise.

•

•

• Transformers •

• Rectifiers •

TIWAY I Gateway User Manual

Poor cable-to-equipment impedance matching

. If cabling is installed inside a conduit, the conduit

Power lines

Electric motors

• Generators

•

Electric welders

Induction furnaces and heaters

All sources of microwave radiation

Network Installation

2-11

2.3 Network Media Installation — RS-232-C Modem Interface

Data Transmission

Characteristics

RS-232 Pin

Assignments

The

physical layer in TIWAY I provides a modem interface for synchronous

or asynchronous communications at data transmission rates up to 1

15.2 K

bps. The modem interface provides standard signals for control of two-way

alternate data transmission using both half and full duplex modems.

The modem interface is a standard T

ype E DTE configuration as defined in

the EIA RS-232-C standard. This interface uses a male 25-pin D-type

connector plug on the communication cable. The pin assignments are listed

in T

able 2-2.

T

able 2-2 RS-232-C Connector Pin Assignments

Pin No. Description

1 Protective Ground

2 Transmit Data

3 Receive Data

4 Request to Send (RTS)

5 Clear to Send (CTS)

6 Data Set Ready (DSR)

7 Signal Ground

8 Receive Line Signal Detector/Data Carrier Detect (RLSD/DCD)

15 Transmitter Signal Element Timing

17 Receiver Signal Element Timing

20 Data Terminal Ready (DTR)

2-12

Network Installation

TIWAY I Gateway User Manual

Chapter 3

Gateway

3.1 Installing

Basic

Power

3.2 Dipswitch

Overview 3-6

Dipswitch

Dipswitch

3.3 Switches

Online/Offline

Self-Test

Reset

Status

Gateway

Comm

Online 3-11

Receive 3-11

Transmit 3-11

Test

the TIWAY I Gateway

Mounting Guidelines

Connections and Initialization

Configuration and Function

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings for the Host Inter

Settings for the Network Interface Port

and Indicator Lights

Button

Button

Indicator Lights

Good

Active

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Configuration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

face Port

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2.

3-2.

3-3.

3-6.

3-7.

3-8.

3-10.

3-10.

3-10.

3-10.

3-11.

3-11.

3-11.

3-11.

3.4 Diagnostic Tests 3-12.

Built-In

Power-On Test 3-12.

Operational

User-Initiated Test 3-13.

Burn-In

Diagnostic T

Diagnostic T

and Final T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 3-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 3-12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 3-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIWAY I Gateway User Manual

Gateway Installation and Configuration

3-1

Loading...

Loading...