Page 1

Preface, Contents

SIMATIC

SM 335 – High-Speed

Analog Input/Output Module for

the SIMATIC S7-300

Manual

Characteristics and Technical

Specifications of the SM 335

Connecting the Inputs and

Outputs of the SM 335

Data Exchange with the SM 335

Interval Counter Input

Special SM 335 Operating Modes

Detecting and Correcting Faults

List of Abbreviations

Index

1

2

3

4

5

6

A

08/2004 Edition

6ES7 335-7HG00-8BA1

Page 2

OChapter

Safety-Related Guidelines

This manual contains notices intended to ensure personal safety, as well as to protect the products and

connected equipment against damage. These notices are highlighted by a warning triangle and are graded

according to severity by the following texts:

Danger

!

Indicates that death, severe personal injury or substantial property damage will result if proper

precautions are not taken.

Warning

!

Indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

!

Indicates that minor personal injury or property damage can result if proper precautions are not taken.

Caution

indicates that property damage can result if proper precautions are not taken.

Notice

contains important information about the product, its operation or a part of the document, to which special

attention is drawn.

Qualified Personnel

A device/system may only be commissioned or operated by qualified personnel. Qualified personnel as

referred to in the safety guidelines in this document are persons authorized to start up, ground and tag

circuits, equipment and systems in accordance with established safety practice.

Proper Usage

Please observe the following:

Warning

!

Registered Trademarks

The equipment/system or the system components may only be used for the applications described in the

catalog or the technical description, and only in combination with the equipment, components, and

devices of other manufacturers as far as this is recommended or permitted by Siemens.

The product will function correctly and safely only if it is transported, stored, set up, and installed as

intended, and operated and maintained with care.

SIMATIC, SIMATIC HMI and SIMATIC NET are registered trademarks of SIEMENS AG.

Other designations used in this document may be registered trademarks; the owner’s rights may be viola-

ted if they are used by third parties for their own purposes.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design, are

reserved.

Siemens AG

Automation & Drives

Motion Control Systems

P.O. Box 3180, D-91050 Erlangen

Index-2

Siemens Aktiengesellschaft

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

Exclusion of LiabilityCopyright W Siemens AG, 1999 – 2004. All rights reserved

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be

precluded entirely, we cannot guarantee full agreement. However,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

Siemens AG, 2004.

Technical data subject to change.

6ES7 335-7HG00-8BA1

Page 3

Preface

Important

In order to obtain SIMATIC interference immunity, the SM 335 module must

always be operated with an interference suppression filter (see Section 2.6).

Content of this manual

This manual describes the function of the SM 335 analog input/output module;

AI4/AO4 x 14/12 bits. In the following, this module will simply be called SM 335.

Aim of this manual

The information contained in this manual will enable you to:

• Use a SM 335 in a SIMATIC S7-300.

• See operator inputs, function descriptions and technical specifications in con-

nection with the SM 335.

Scope of this manual

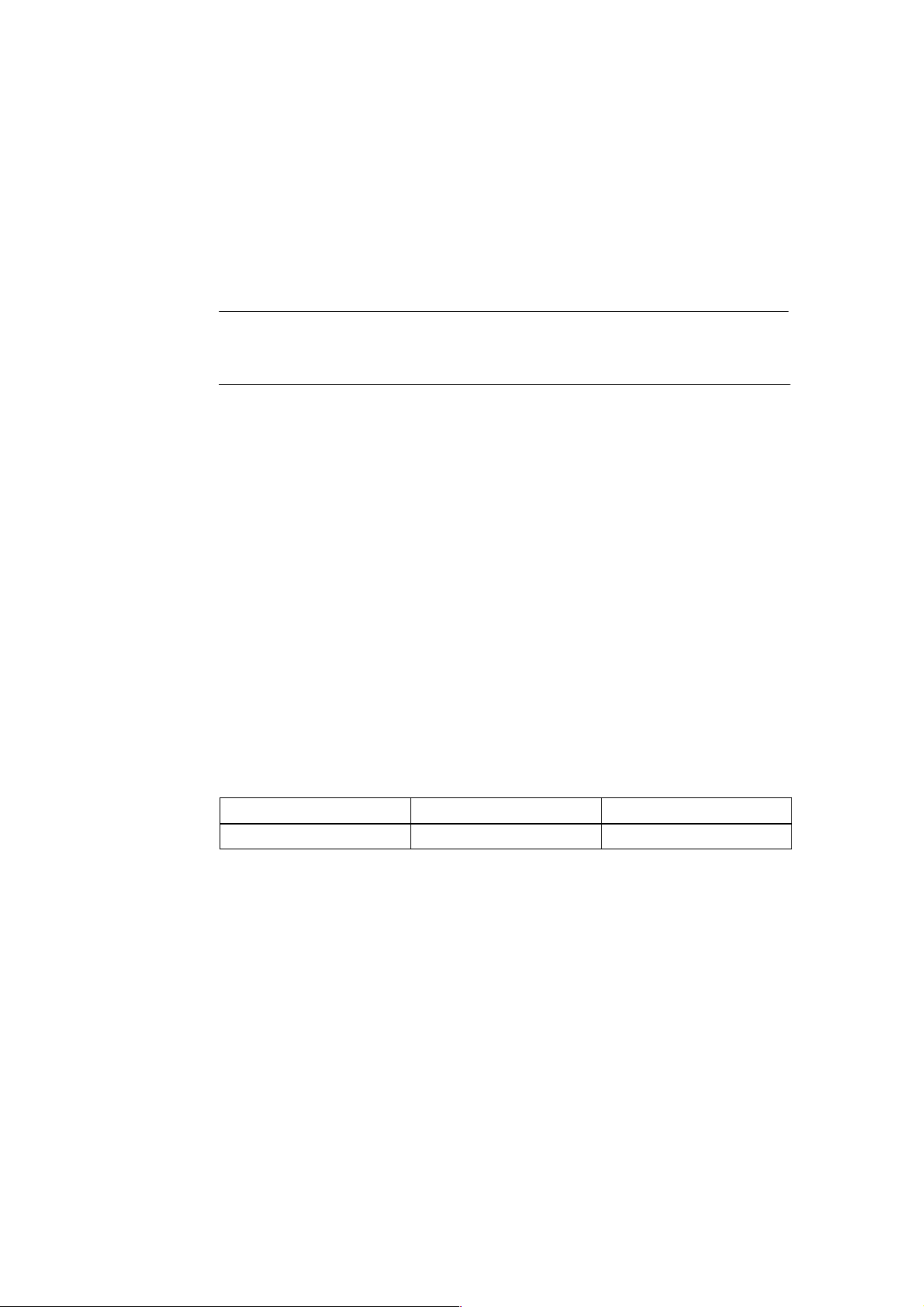

The manual is valid for the following modules:

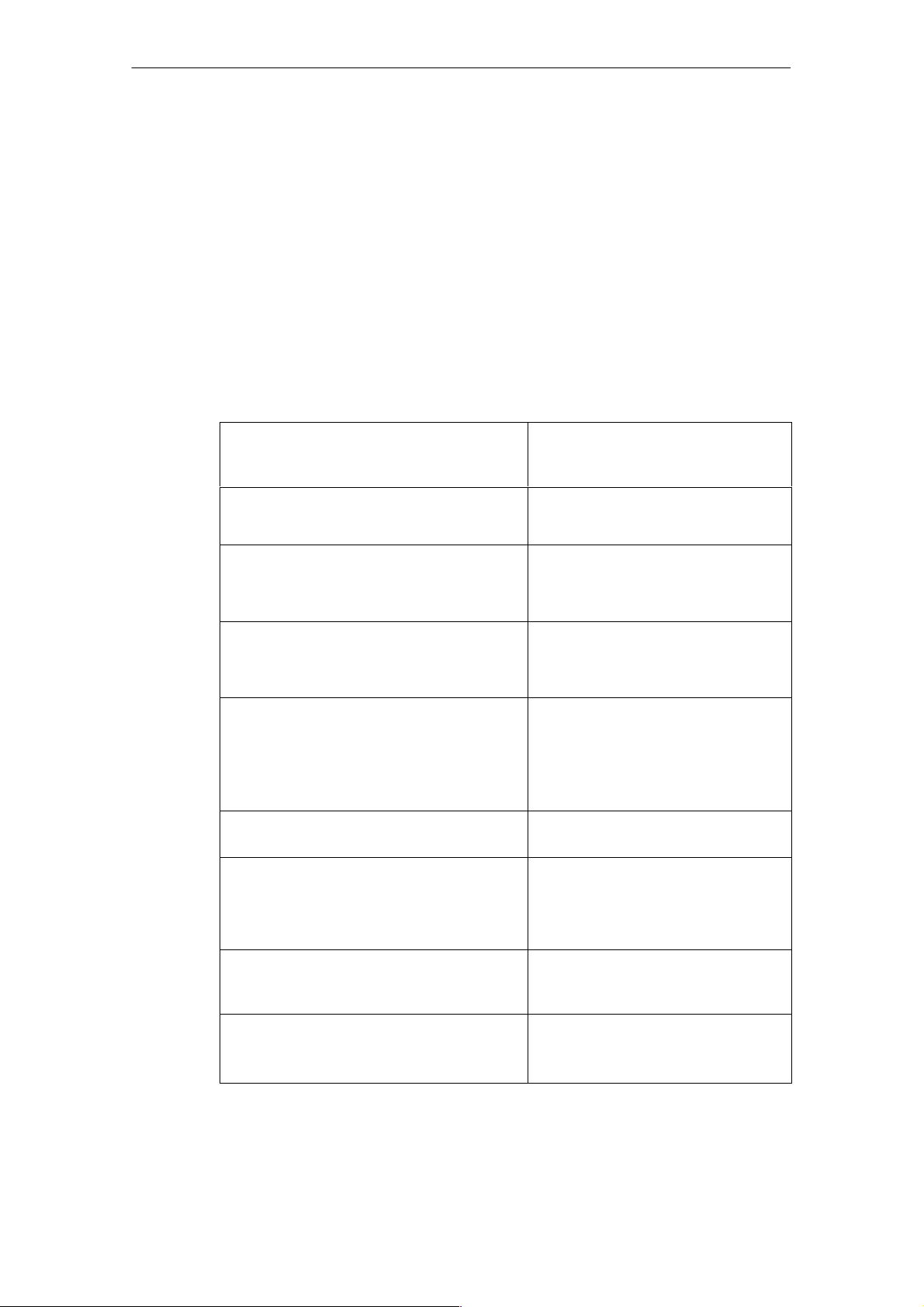

Module Order Number From Revision Level

SM 335 6ES7 335-7HG01-0AB0 02

This manual contains the descriptions of these modules that are valid at the time

the manual is released. For new modules and new versions of modules, we reserve the right to add to the manual a product information containing the current

information about this module. Section 1.2 describes how to determine the revision

level of a module.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

iii

Page 4

PrefacePreface

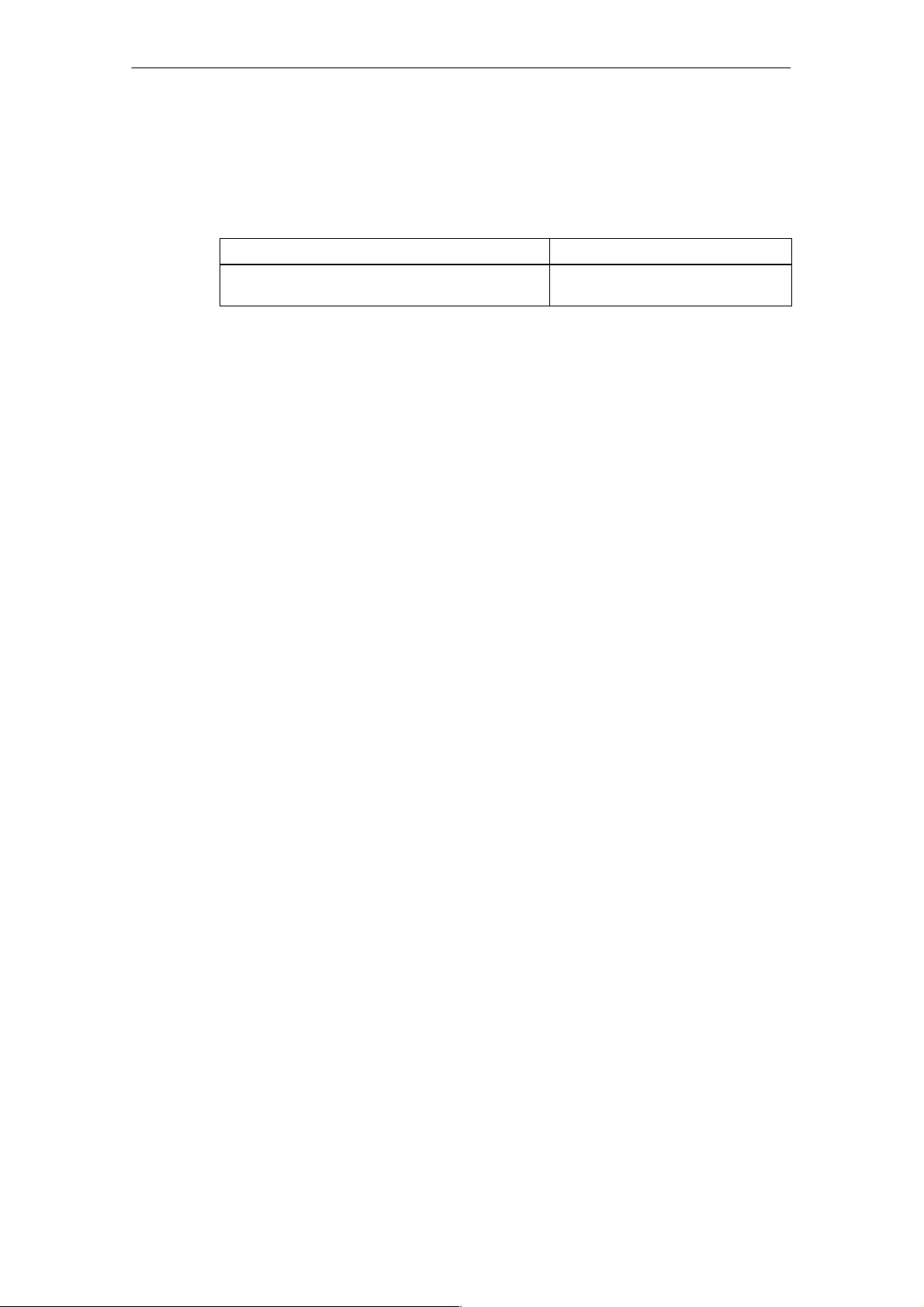

Scope of the documentation package

You can order the documentation for the SM 335 separately from the module.

The order number for the manual appears in the table below:

Documentation Order Number

• SM 335 - High-Speed Analog Input/Output

Module for the SIMATIC S7-300

Other references

More information about using and installing SIMATIC S7-300 analog modules can

be found in:

• SIMATIC Programmable Controller, S7-300 Module Data Reference Manual

• SIMATIC S7-300, Hardware and Installation Manual

6ES7 335-7HG00-8BA1

The installation guidelines described in this document also relate to the SM 335.

Required basic knowledge

This manual assumes general knowledge of automation engineering.

Knowledge of the SIMATIC S7 programmable controller and the STEP 7 Engineering System is also required.

Approbations

The S7-300 programmable controller has obtained the following approvals:

• Underwriters Laboratories, Inc.: UL 508 registered (Industrial Control Equip-

ment)

• Canadian Standards Association: CSA C22.2 number 142, (Process Con-

trol Equipment)

• Factory Mutual Research: Approval Standard Class Number 3611.

CE Approval

The S7-300 programmable controller meets the requirements and safety-related

requirements of the following EC directives:

• EC Directive 73/23/EEC “Low-Voltage Directive”

• EC Directive 89/336/EEC “EMC Directive”

iv

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 5

C-Tick-Mark

The S7-300 programmable controller meets the requirements of the AS/NZS 2064

standard (Australia and New Zealand).

Standards

The S7-300 programmable controller meets the requirements and criteria of the

IEC 61131-2 standard (Programmable Controllers, Part 2: Equipment Requirements and Tests).

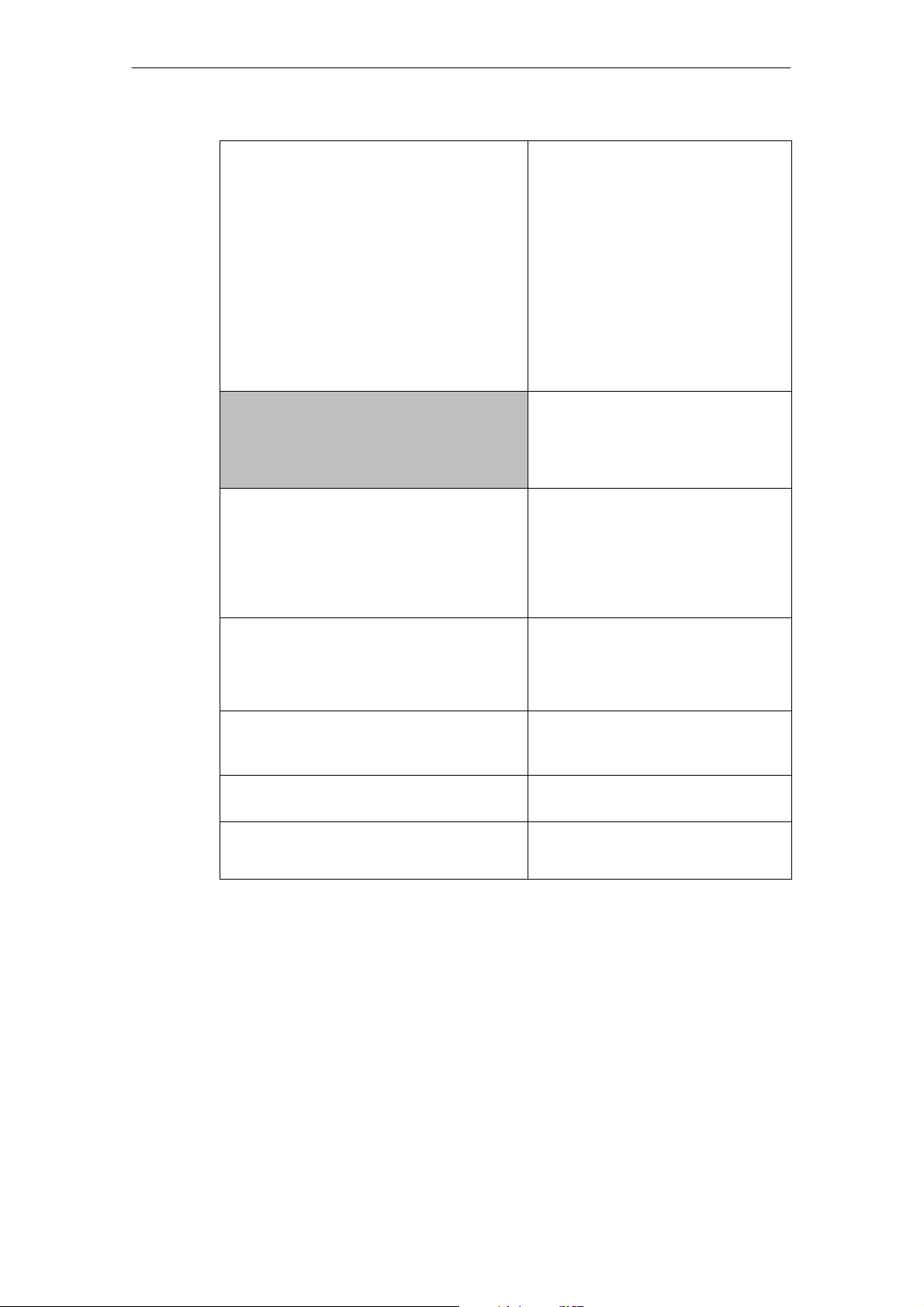

How the manual fits in

PrefacePreface

Manual

• CPU 31xC and CPU 31x, Technical Specifi-

cations

Reference Manual

• CPU data: CPU 312 IFM - 318-2 DP

Manual

• S7-300, CPU 31xC and CPU 31x: Hard-

ware and Installation

Installation Manual

• S7-300 Programmable Controller: Hardware

and Installation: CPU 312 IFM - 318-2 DP

System Manual

• PROFINET system description

Programming Manual

• From PROFIBUS DP to PROFINET IO

Manual

• CPU 31xC: Technological Functions

• Examples

Reference Manual

• S7-300 Programmable Controller:Module

Data

Operation and display elements, communication, memory concept, cycle and

response times, technical specifications.

Operation and display elements, communication, memory concept, cycle and

response times, technical specifications.

Configuration, installation, wiring, addressing, commissioning, maintenance,

diagnostics, and interference suppression.

Configuration, installation, wiring, addressing, commissioning, maintenance,

diagnostics, and interference suppression.

Basic information about PROFINET:

Network components, data exchange

and communication, PROFINET IO,

component based automation, application example PROFINET IO and component based automation.

Guide to migration from PROFIBUS DP

to PROFINET IO.

Description of individual technological

functions: Positioning, counting,

point-to-point coupling, control.

The CD contains examples for the technological functions.

Descriptions of functions and technical

specifications of signal modules, power

supply modules and interface modules.

Instruction List

• CPU 312 IFM - 318-2 DP

• CPU 31xC and CPU 31x

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

The instruction set lists of the CPUs and

their execution times;

A list of executable blocks.

v

Page 6

PrefacePreface

Getting Started

The Getting Started documents below are available as an anthology:

• CPU 31x: Commissioning

• CPU 31xC: Commissioning

• CPU 31xC: Positioning with analog output

• CPU 314C: Positioning with digital output

• CPU 31xC: Counting

• CPU 31xC: Rules

• CPU 31xC: Point-to-point connection

• CPU 31x-2 PN/DP: Commissioning of a

PROFINET IO subnet

Manual

You are reading manual

• SM 335 - High-Speed Analog Input/Output

Module for the SIMATIC S7-300

Reference Manual

System software for the S7-300/400 system

and standard functions

Manual

SIMATIC NET: Twisted Pair and Fiber Optic Networks

Manual

Component based Automation:

Configuring systems with SIMATIC iMap

Manual

Programming with STEP 7 V5.3

Manual

Communication with SIMATIC

Getting Started documents use a concrete example to guide you through the

individual commissioning steps until you

have a functioning application.

Description of how you use the SM 335

module in a SIMATIC S7-300.

Overview of operations, descriptions of

functions and technical specifications of

the SM 335.

Description of system functions (SFC),

system function blocks (SFB) and organization blocks (OB).

This manual is part of the STEP 7 documentation package.

The description can also be found in the

STEP 7 online help.

Description of industrial Ethernet networks, network configuration, components, installation guidelines for networked automation systems in buildings,

etc.

Description of SIMATIC iMAP configuration software.

Programming with STEP 7.

Fundamentals, services, networks, communication functions, connection of

PG/OP, configuration in STEP 7.

Additional Support

Please contact your local Siemens representative if you have any queries about

the product described in this manual, which are not answered here.

http://www.ad.siemens.com/automation/partner

vi

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 7

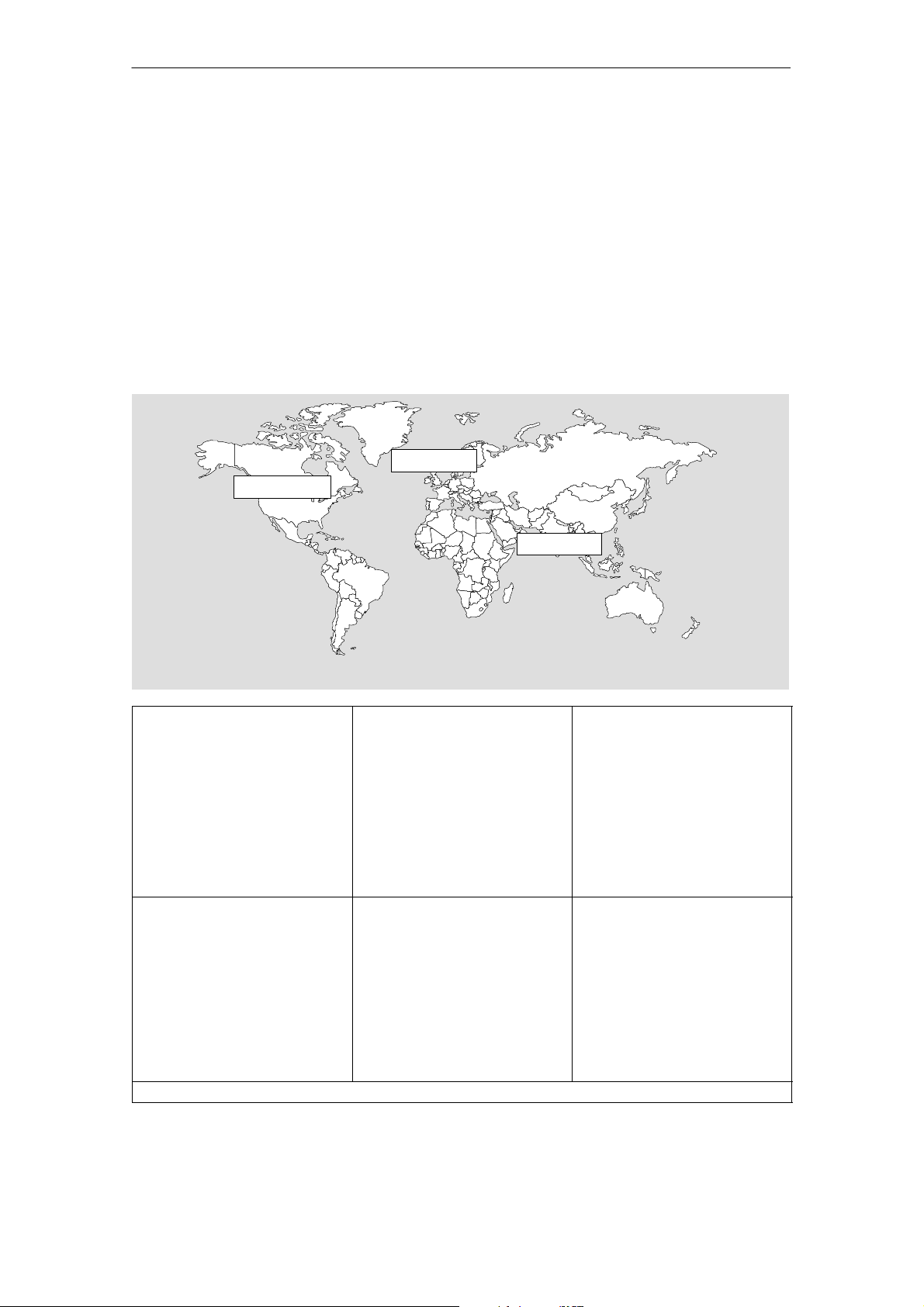

Training center

We offer a range of relevant courses to help you to get started with the

SIMATIC S7 programmable controller. Please contact your local training center or

the central training center in Nuremberg, D 90327 Germany.

Phone: +49 (911) 895-3200

Internet: http://www.sitrain.com

A&D Technical Support

Worldwide, available 24 hours a day:

Johnson City

PrefacePreface

Nuremberg

Beijing

Technical Support

Worldwide (Nuremberg)

Technical Support

Local time: 24 hours a day,

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-mail: adsupport@

GMT: +1:00

Europe/Africa (Nuremberg)

Authorization

Local time: Mon.-Fri. 8:00 AM

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

E-mail: adsupport@

GMT: +1:00

The languages of the technical support and authorization hotlines are generally German and English.

365 days a year

siemens.com

to 5:00 PM

siemens.com

United States (Johnson City)

Technical Support and

Authorization

Local time: Mon.-Fri. 8:00 AM

to 5:00 PM

Phone: +1 (423) 262 2522

Fax: +1 (423) 262 2289

E-mail: simatic.hotline@

sea.siemens.com

GMT: –5:00

Asia/Australia (Beijing)

Technical Support and

Authorization

Local time: Mon.-Fri. 8:30:00

to 5:00 PM

Phone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-mail: adsupport.asia@

siemens.com

GMT: +8:00

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

vii

Page 8

PrefacePreface

Service & Support on the Internet

In addition to our documentation, our whole range of expertise can be accessed

online at:

http://www.siemens.com/automation/service&support

Where you will find:

• The Newsletter, which constantly provides you with up-to-date information

about your products.

• The documents you need via our Search function in Service & Support.

• A forum, where users and experts from all over the world exchange their experi-

ences.

• Your local representative for Automation & Drives, via our database of repre-

sentatives.

• Information about field service, repairs and spare parts. Much more can be

found under “Services”.

Queries

If you have any queries about the S7-300 programmable controller, please contact

your local Siemens representative.

In case you have any questions or suggestions concerning this manual, please fill

in the correction sheet and return it to us. The correction sheet can be found at the

end of the manual.

viii

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 9

Contents

1 Characteristics and Technical Specifications of the SM 335 1-1. . . . . . . . . . . . . . . .

1.1 Characteristics features of the SM 335 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Terminal connection diagram for the SM 335 1-3. . . . . . . . . . . . . . . . . . . . . . . .

1.3 Block diagram of the SM 335 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Setting the measuring range with the measuring range module 1-6. . . . . . . .

1.5 Technical specifications for the SM 335 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 General technical specifications 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Technical specifications for the analog inputs 1-8. . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 Technical specifications for the analog outputs 1-10. . . . . . . . . . . . . . . . . . . . . .

1.5.4 Technical specifications for the interval counter 1-11. . . . . . . . . . . . . . . . . . . . . .

1.6 SM 335 operating modes 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Free Cycle mode 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Conditional Cycle mode 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Connecting the Inputs and Outputs of the SM 335 2-1. . . . . . . . . . . . . . . . . . . . . . . .

2.1 Basic information about connecting the SM 335 2-2. . . . . . . . . . . . . . . . . . . . .

2.2 Connecting the analog inputs 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Connecting the analog outputs 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Connecting the interval counter input 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Connecting the sensor power supply 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Correcting the sensor power supply 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Interference suppression filter for 24 V supply voltage 2-10. . . . . . . . . . . . . . . .

3 Data Exchange with the SM 335 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Access via the I/O addresses 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Output values 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Output values 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Analog value representation for analog input channels 3-8. . . . . . . . . . . . . . . .

3.1.4 Analog value representation for analog output channels 3-10. . . . . . . . . . . . . .

3.2 Setting parameters via HW Config 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 SM 335 default settings 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 SM 335 parameters assignable with HW Config 3-13. . . . . . . . . . . . . . . . . . . . .

3.3 Modifying SM 335 parameters with the help of system function 55 3-16. . . . .

3.3.1 SM 335 static parameters 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 SM 335 parameters in the Free Cycle and Conditional Cycle Modes 3-18. . . .

3.3.3 SM 335 parameter for “Comparator” mode 3-23. . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 SM 335 parameters for “Measuring Only” special mode 3-27. . . . . . . . . . . . . . .

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

ix

Page 10

ContentsContents

3.4 Evaluating SM 335 diagnostics 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Hardware interrupt 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Format of diagnostic data for the SM 335 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Module diagnostic byte 1 (byte 0) 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Module diagnostic byte 2 (byte 1) 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 Module diagnostic byte 3 (byte 2) 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.6 Module diagnostic byte 4 (byte 3) 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.7 Channel-specific diagnostic bytes (bytes 4-15) 3-37. . . . . . . . . . . . . . . . . . . . . .

4 Interval Counter Input 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Principle of an interval counter 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Principles of measuring with the interval counter 4-3. . . . . . . . . . . . . . . . . . . . .

4.3 Wiring the interval counter input 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Initializing the SM 335’s interval counter input 4-7. . . . . . . . . . . . . . . . . . . . . . .

4.5 Interval counter values 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Example for determining the speed by means of the interval counter 4-9. . .

5 Special SM 335 Operating Modes 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Switching to the special operating modes 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 “Comparator” mode 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 How comparator mode works 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 SM 335 parameters for Comparator mode 5-10. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 “Measuring Only” mode 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Switching to “Measuring Only” mode 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Detecting and Correcting Faults 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Principle of diagnostics 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Configuring diagnostics with HW Config 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Evaluating diagnostic data in OB 82 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 SM 335 error tree 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Troubleshooting 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A List of Abbreviations A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 11

Characteristics and Technical Specifications of the SM 335

SIMATIC S7-300

The SM 335 is an input/output module (signal module) for the SIMATIC S7-300.

The SM 335 has the same general technical specifications as all signal modules of

the SIMATIC S7-300.

Order number

Order the SM 335 under the following order number:

6ES7 335-7HG01-0AB0

In this chapter

We deal with the following topics in this chapter:

Topic Section

Characteristics of the SM 335 1.1

1

Terminal connection diagram for the SM 335 1.2

Block diagram of the SM 335 1.3

Setting the measuring range with the measuring range module 1.4

Technical specifications for the SM 335 1.5

Operating modes of the SM 335 1.6

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

1-1

Page 12

Characteristics and Technical Specifications of the SM 335

1.1 Characteristics features of the SM 335

Characteristic features

The SM 335; AI4/AO4 14/12 bit has the following characteristic features:

Analog inputs:

• Four isolated analog inputs

• Integrated 10 V/25 mA sensor power supply

• Measured-value resolution:

– Bipolar: 13 bits + sign

– Unipolar: 14 bits

• Selectable measured value:

– Two voltage inputs

– Two inputs, which can be used as either current or voltage inputs

Analog outputs:

• Four isolated analog outputs

• Selectable range for each analog output

For the analog outputs, you can connect loads over a two-wire connection only!

• Analog value resolution:

– Bipolar: 11 bits + sign

– Unipolar: 12 bits

Operating modes:

• 2 standard operating modes:

– Free cycle

– Conditional cycle

• 2 special operating modes:

– Comparator

– Measuring Only

Interrupts/diagnostics:

• Programmable diagnostics

1-2

• Programmable diagnostic interrupt

• Programmable end-of-cycle interrupt (generates a hardware interrupt on the

CPU)

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 13

Characteristics and Technical Specifications of the SM 335

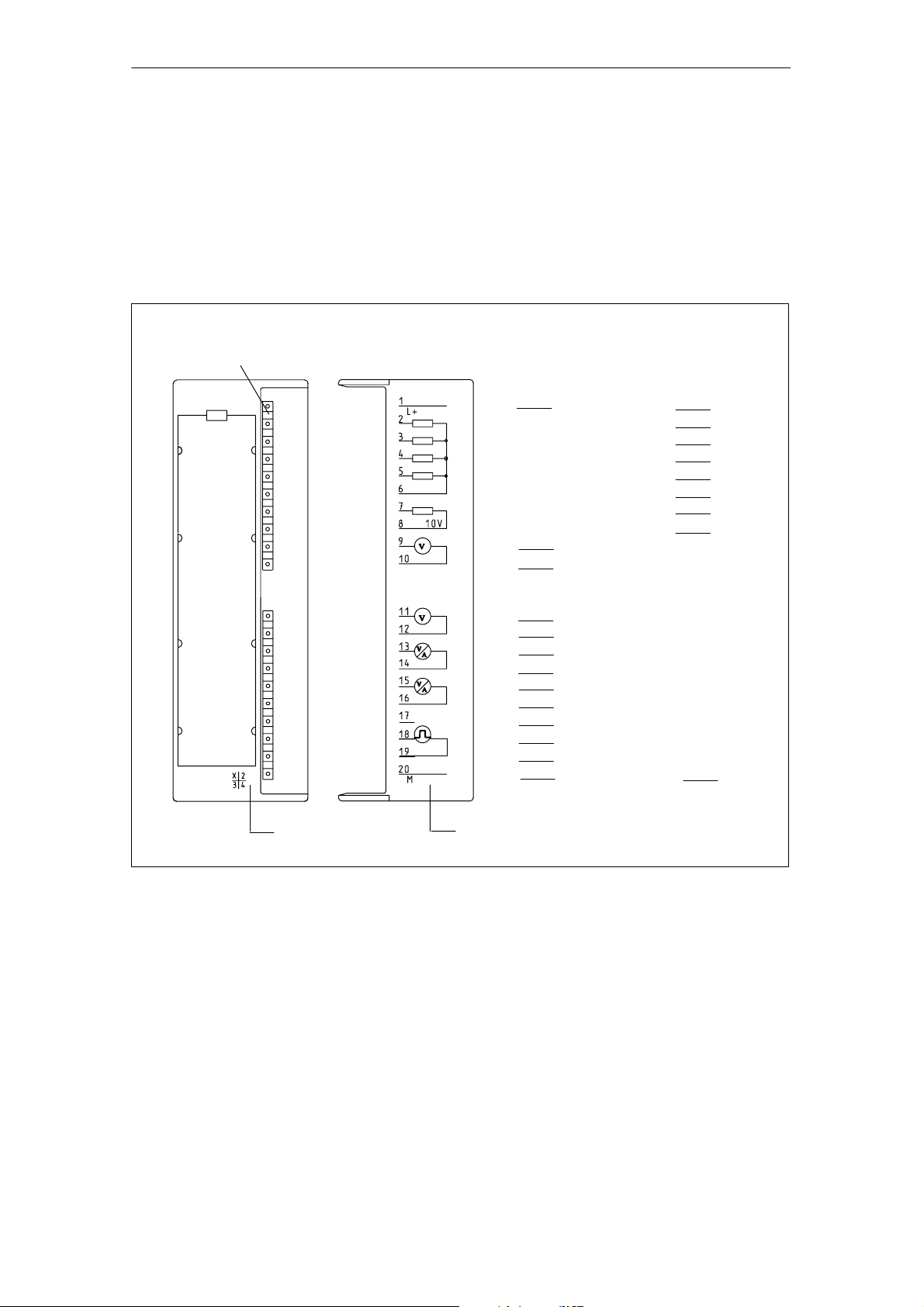

1.2 Terminal connection diagram for the SM 335

Terminal connection diagram

Figure 1-1 shows the terminal connections for the SM 335 analog input/output

module.

Fault LEDs – red

SF

Reserved

Analog inputs:

Voltage/

current measurement

L+

24 V

M

0+

CH0

M

0–

M

1+

CH1

M

1–

M

2+

CH2

M

2–

M

3+

CH3

M

3–

IZ

M

M

Interval counter IZ

IZ

M

Analog outputs:

Voltage output

Sensor

power

supply

L+

QV

QV

QV

QV

M

QV

M

M

0

1

2

3

ANA

Ref

ANA

24 V

CH0

CH1

CH2

CH3

10 V

M

Revision level

Connection

Diagram

Fig. 1-1 Terminal connection diagram of the SM 335

Wiring

See Chapter 2 and to the SIMATIC S7-300, Hardware and Installation Manual for

information about how to wire inputs and outputs on the SM 335.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Terminal

1-3

Page 14

Characteristics and Technical Specifications of the SM 335

Revision Level

Products with the same number can be distinguished by the revision level.

The revision level is incremented by upwardly-compatible function expansions or

fault corrections.

The revision level of the module is identified by “X” (see Figure 1-1); in this case

the revision level is 1.

1-4

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 15

Characteristics and Technical Specifications of the SM 335

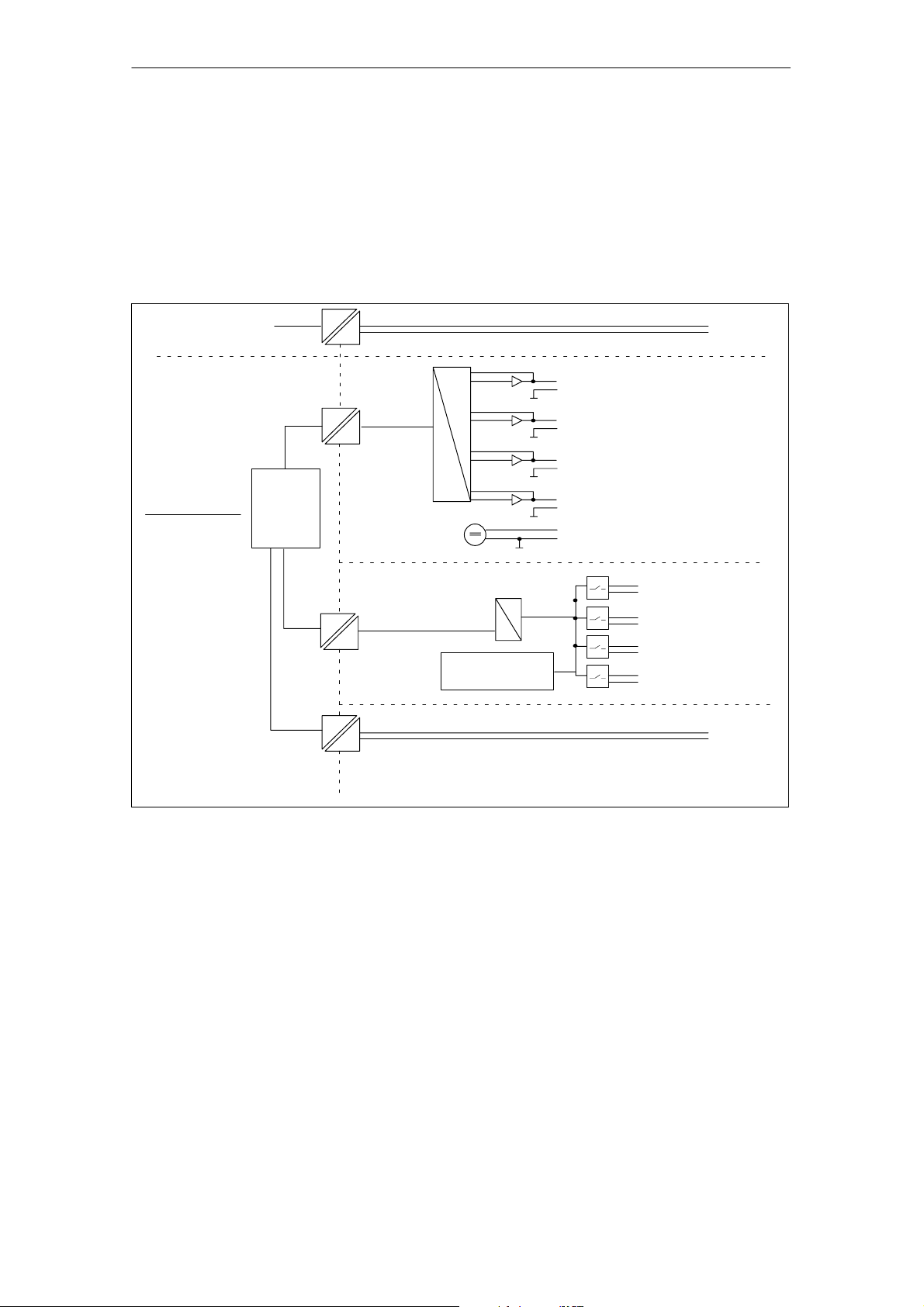

1.3 Block diagram of the SM 335

Block diagram

Figure 1-2 shows the block diagram of the SM 335. You will find detailed technical

specifications for the SM 335 on the following pages.

Internal power supply

SIMATIC S7-300

backplane bus

Galvanic isolation

Logic

A

D

Open-wire

test circuit

24 V

CH0

Analog outputs

CH1

CH2

CH3

10 V

Sensor power

supply

CH0

A

D

CH1

Analog inputs

CH2

CH3

IZ

Interval Counter Input

Fig. 1-2 Block Diagram of the SM 335

Galvanic isolation

As you can see from Figure 1-2, the SM 335 contains different analog parts.

The analog outputs are isolated from the backplane bus of the SIMATIC S7-300.

The outputs are on the same potential M

same potential M

as the analog outputs.

ANA

The analog inputs are isolated from each other and from the backplane bus of the

SIMATIC S7-300.

The input for the interval counter IZ is isolated from the other analog parts and

from the backplane bus of the SIMATIC S7-300.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

ANA

. The output for sensor supply has the

1-5

Page 16

Characteristics and Technical Specifications of the SM 335

1.4 Setting the measuring range with the measuring range module

Measuring range module

A measuring range module is located on the left of the input/output module. The

measuring range module is used to set the method of measuring on the analog

inputs, that is, to choose between voltage and current measuring.

Settings

The measuring range module can be set for “A”, “C” or “D”.

The default setting is “D”.

Table 1-1 shows the allocation of measuring range module settings to possible

connections of the analog inputs.

The measuring range is set using HW Config. You can select from different current

or voltage ranges (see Section 3.2).

The required measuring range module setting is also displayed in HW Config.

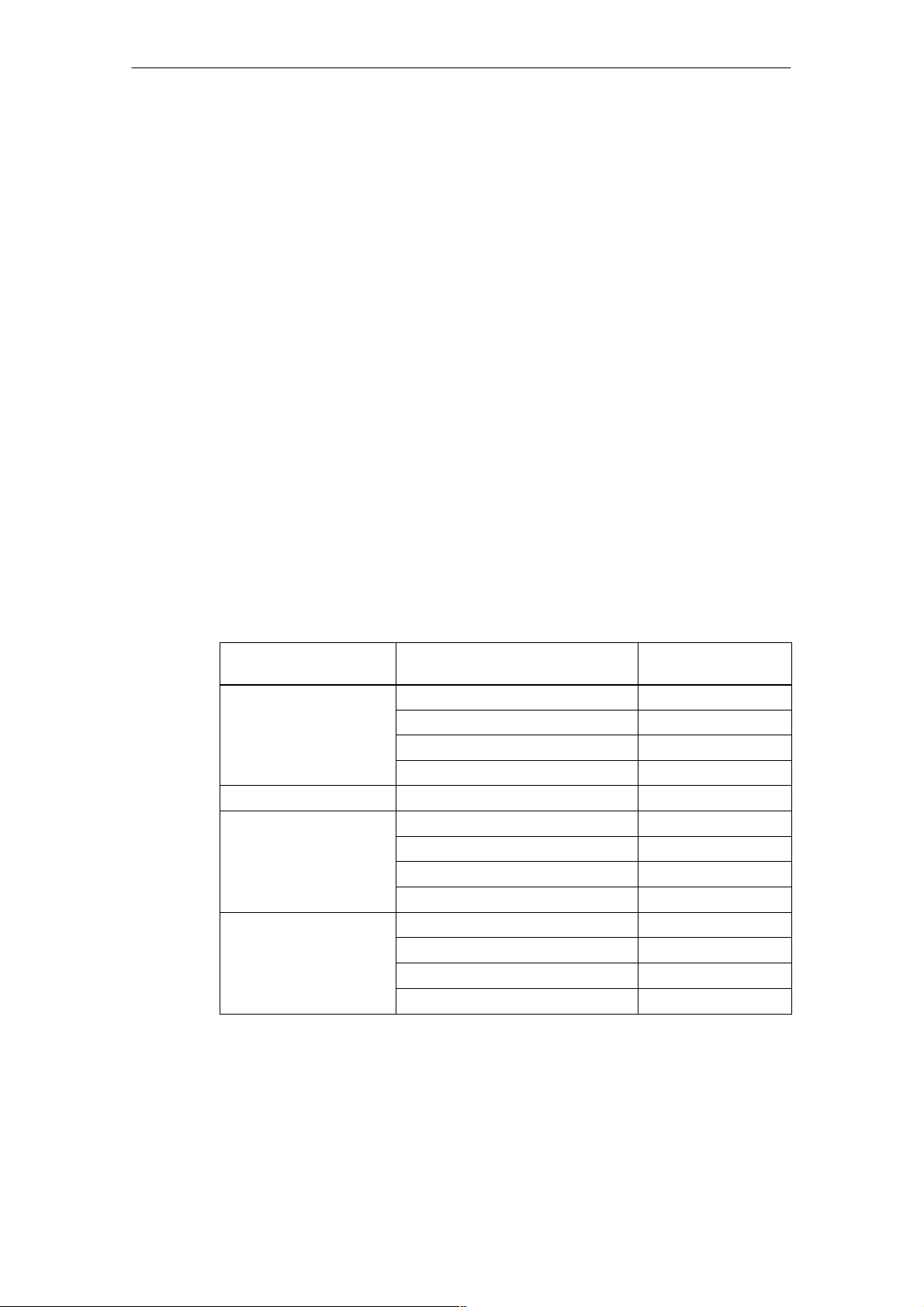

Table 1-1 Measuring range module settings and measuring range defaults on the

SM 335

Setting of the measuring

range module

A Input 0: Voltage "10 V

B Not assigned –

C Input 0: Voltage "10 V

D Input 0: Voltage "10 V

Analog input

wiring

Input 1: Voltage "10 V

Input 2: Voltage "10 V

Input 3: Current 4 to 20 mA

Input 1: Voltage "10 V

Input 2: Current 4 to 20 mA

Input 3: Current 4 to 20 mA

Input 1: Voltage "10 V

Input 2: Voltage "10 V

Input 3: Voltage "10 V

Measuring range

(default value)

1-6

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 17

Characteristics and Technical Specifications of the SM 335

1.5 Technical specifications for the SM 335

1.5.1 General technical specifications

Table 1-2 General technical specifications

Dimensions and weight

Dimensions W x H x D (mm) 40 x 125 x 120

Weight Approx. 300 g

Module-specific data

Number of inputs 4

Number of outputs 4

Cable length shielded 200 m

With open-wire test in the range 0 to 10 V 30 m

Voltages, currents, potentials

Rated load voltage L+

• Polarized

Galvanic isolation

Permissible potential difference

• Between inputs (U

• Between input (M terminal) and central

grounding point

• Isolation tested with 500 V DC

CM

)

3 V/1.5 V (10 V ranges)

24 V DC

Yes

Yes

75 V DC/60 V AC

Power consumption

• From SIMATIC S7-300 backplane bus

• From L+

• Module power loss

Status, interrupts, diagnostics

Interrupts

• Comparator interrupt

• End-of-cycle interrupt

• Diagnostic interrupt

Diagnostic functions

• Fault indication on the module in the event

of a group fault

• Diagnostic information can be read out

Miscellaneous

UL/CSA/FM Yes

Max. 75 mA

Max. 150 mA

Max. 3.6 W

NO

Yes, programmable

Yes, programmable

Yes, programmable

Yes, red LED

Yes

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

1-7

Page 18

Characteristics and Technical Specifications of the SM 335

1.5.2 Technical specifications for the analog inputs

Table 1-3 Technical specifications for the analog inputs

Noise suppression and error limits for the inputs

Suppression of noise voltage for

f = n x (f1"1%), (f1 = interference frequency)

• Common-mode noise (U

• Series-mode noise

(peak noise value < rated value of the input range)

Crosstalk between inputs

• At 50 Hz

• At 60 Hz

Operational limit for voltage measuring

(over entire temperature range,

based on input range)

Operational limit for current measuring

(over entire temperature range, based on input range)

pp

< 3 V)

> 65 dB

0 dB

–65 dB

–65 dB

" 0.15%

(for 14-bit resolution)

0.25%

Basic error

(operational limit at 25 °C, based on input range)

Temperature drift (based on input range) " 0.13%

Linearity error (based on input range) " 0.015%

Repeatability

(in steady state at 25 °C, based on input range)

Sensor selection data

Input ranges (rated values)/input resistance

• Voltage

• Current (max. 2 channels)

Permissible input voltage for voltage input

(destruction limit)

Permissible input current for current input

(destruction limit)

Connecting of sensors

" 1 V

" 10 V

" 2.5 V

0 to 2 V

0 to 10 V

" 10 mA

0 to 20 mA

4 to 20 mA

• For measuring voltage

" 0.1%

(for 14-bit resolution)

" 0.05%

"30 V

25 mA

Possible

• For measuring current

– As 2-wire measuring transducer

– As 4-wire measuring transducer

• For measuring resistance

Not possible

Possible

Not possible

10 MW

10 MW

10 MW

10 MW

10 MW

100 W

100 W

100 W

1-8

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 19

Characteristics and Technical Specifications of the SM 335

Table 1-3 Technical specifications for the analog inputs

Analog value formation for the outputs

Measuring principle Successive approximation

Conversion time (per channel) in ms

• Basic conversion time for 4 channels in ms

Resolution

• Bipolar

• Unipolar

Data of output to sensor supply

Rated voltage 10 V

Max. output current 25 mA

Short-circuit-proof Yes

Operational limit

(over entire temperature range)

Temperature drift 0.002%/K

Basic error for rated voltage 0.1%

Max. 200

Max. 1

13 bits + sign

14 bits

0.2%

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

1-9

Page 20

Characteristics and Technical Specifications of the SM 335

1.5.3 Technical specifications for the analog outputs

Table 1-4 Technical specifications for the analog outputs

Analog value formation for the outputs

Resolution (incl. overrange)

• " 10 V

• From 0 to 10 V

Conversion time in ms Max. 800

Setting time

• For resistive load

• For capacitive load

• For inductive load

Injection of substitute values Ye s

Noise suppression and error limits for the outputs

Crosstalk between outputs –40 dB

Operational limit (over entire temperature

range, based on output range)

Basic error

(operational limit at 25_C, based on output range)

Temperature drift

(based on output range)

Linearity error (based on output range) " 0.05%

Repeatability

(in steady state at 25 _C, based on output range)

Output ripple (based on output range) " 0.05%

Actuator Selection Data

Output range (rated values) " 10 V

Burden resistance

• For voltage outputs

• For capacitive load

• For inductive load

Voltage output

• Short-circuit protection

• Short-circuit current

Connection of actuators

• For voltage output

– 2-wire connection

– 4-wire connection (measuring circuit)

11 bits + sign

12 bits (+ sign)

t 0.1 ms

v 3.3 ms

t 0.5 ms

0.5%

0.2%

0.02%/K

" 0.05%

From 0 to 10 V

Min. 3 kW

Max. 1 mF

Max. 1 mH

Yes

Max. 8 mA

Possible

Not possible

1-10

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 21

Characteristics and Technical Specifications of the SM 335

1.5.4 Technical specifications for the interval counter

Table 1-5 Technical specifications for the interval counter

Interval-counter-specific data

Number of inputs 1

Cable length shielded 200 m

Voltages, currents, potentials

Rated load voltage L+

• Polarized

Galvanic isolation Yes

Permissible potential difference

• Interval counter input (M

to the four analog inputs

• Between input (M

point

Measuring principle Detection of a rising edge and

Resolution of the time difference 0.5 ms

Max. frequency

IZ

Analog value formation for the interval counter input

• Programmable

• Interference suppression for

interference frequency f1 in dB

Noise suppression and error limits for the input

Noise suppression for

F = n (f1 " 1%), (f1 = interference frequency)

• Common-mode noise (U

• Series-mode noise

(peak noise value t rated value of the input range)

Operational limit

(over entire temperature range)

Basic error

(operational limit at 25 oC)

Temperature drift (0 to 60 oC) " 0.003%/K

Linearity error 0

terminal)

IZ

terminal) and central grounding

t 3 V)

pp

75 V DC/60 V AC

75 V DC/60 V AC

measuring the amount of time

between two edges

Max. 1% at 400 Hz

24 V DC

Yes

400 Hz

NO

0

u 80 dB

0 dB

0.005%

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

1-11

Page 22

Characteristics and Technical Specifications of the SM 335

Table 1-5 Technical specifications for the interval counter

Sensor selection data

Permissible input voltage (destruction limit) " 30 V

Permissible input current for interval input (destruction

limit)

Minimum permissible pulse widths at the counter input

• “Low”

• “High”

Permissible voltage range between IZ and MIZ terminals

• For “Low” pulse

• For “High” pulse

5 mA

1 ms

1 ms

– 30 V to + 5 V

(– 4.4 mA to 0.7 mA)

+ 18 V to + 30 V

(2.5 mA to 4.4 mA)

1-12

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 23

Characteristics and Technical Specifications of the SM 335

1.6 SM 335 operating modes

Operating modes

The SM 335 can operate in the following modes:

• Free cycle (corresponds to HW Config setting for SM 335: 0.5 ms cycle time)

• Conditional cycle (corresponds to HW Config setting for SM 335:

1 to 16 ms cycle time)

Special operating modes

In addition, the SM 335 can be switched to the following modes for a brief period of

time:

• “Comparator” special mode

• “Measuring Only” special mode

The special operating modes are described in Chapter 5, where there is also a description of how to switch to the special operating modes.

1.6.1 Free Cycle mode

Cycle

In conjunction with the SM 335, the word “cycle” is used to mean the measuring of

the analog value at all analog inputs in succession. Once the measuring cycle is

complete and all inputs have been read, the cycle starts again from the beginning.

This cycle has nothing to do with cyclic program scanning on a SIMATIC S7 CPU.

Free Cycle

When the SM 335 operates in Free Cycle mode, all SM 335 analog inputs and outputs are processed successively and without interruption. After all inputs and outputs have been processed, conversion once again begins with the first analog input.

Free Cycle mode is activated when a cycle time of 0.5 ms is set for the SM 335 in

HW Config.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

1-13

Page 24

Characteristics and Technical Specifications of the SM 335

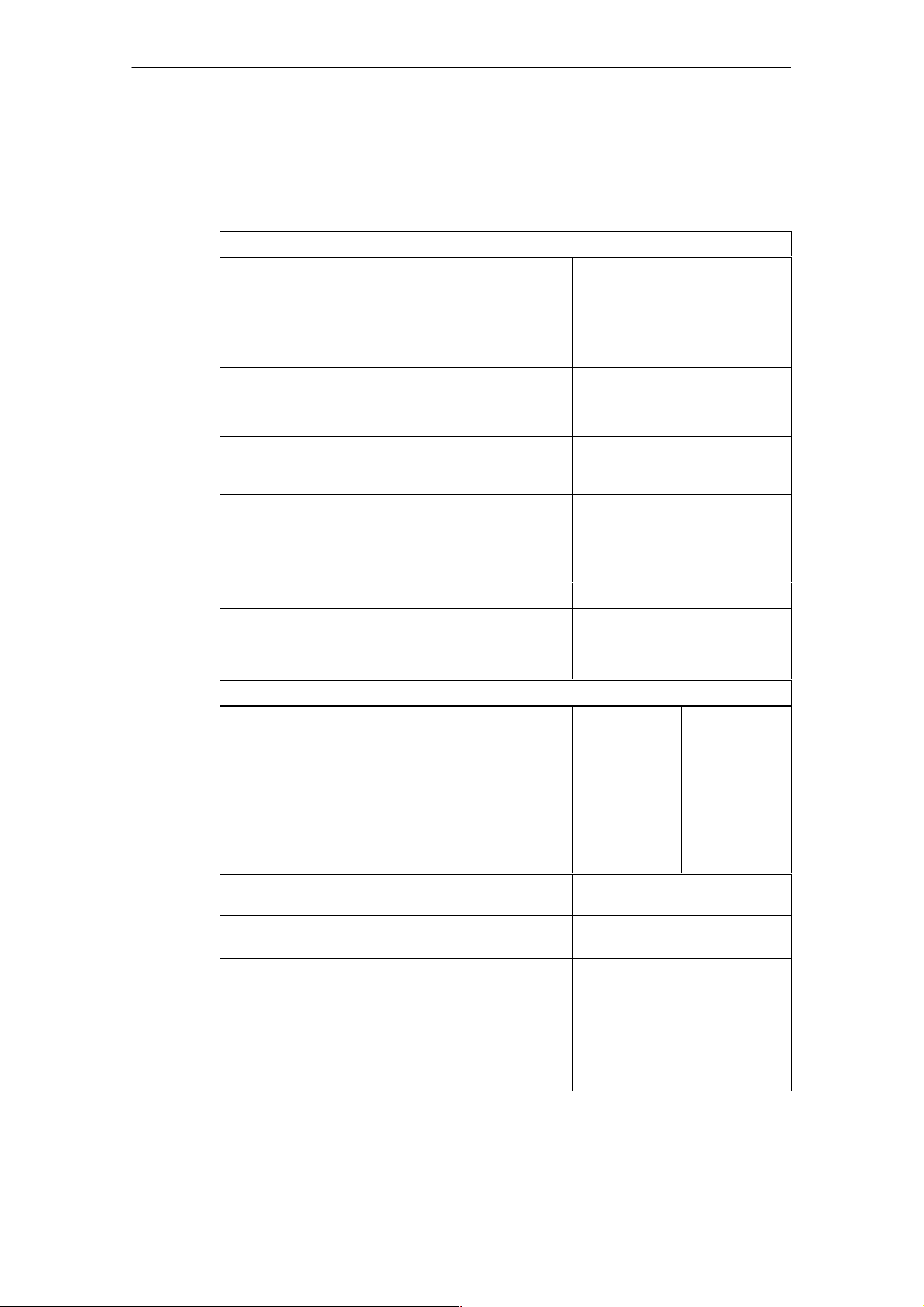

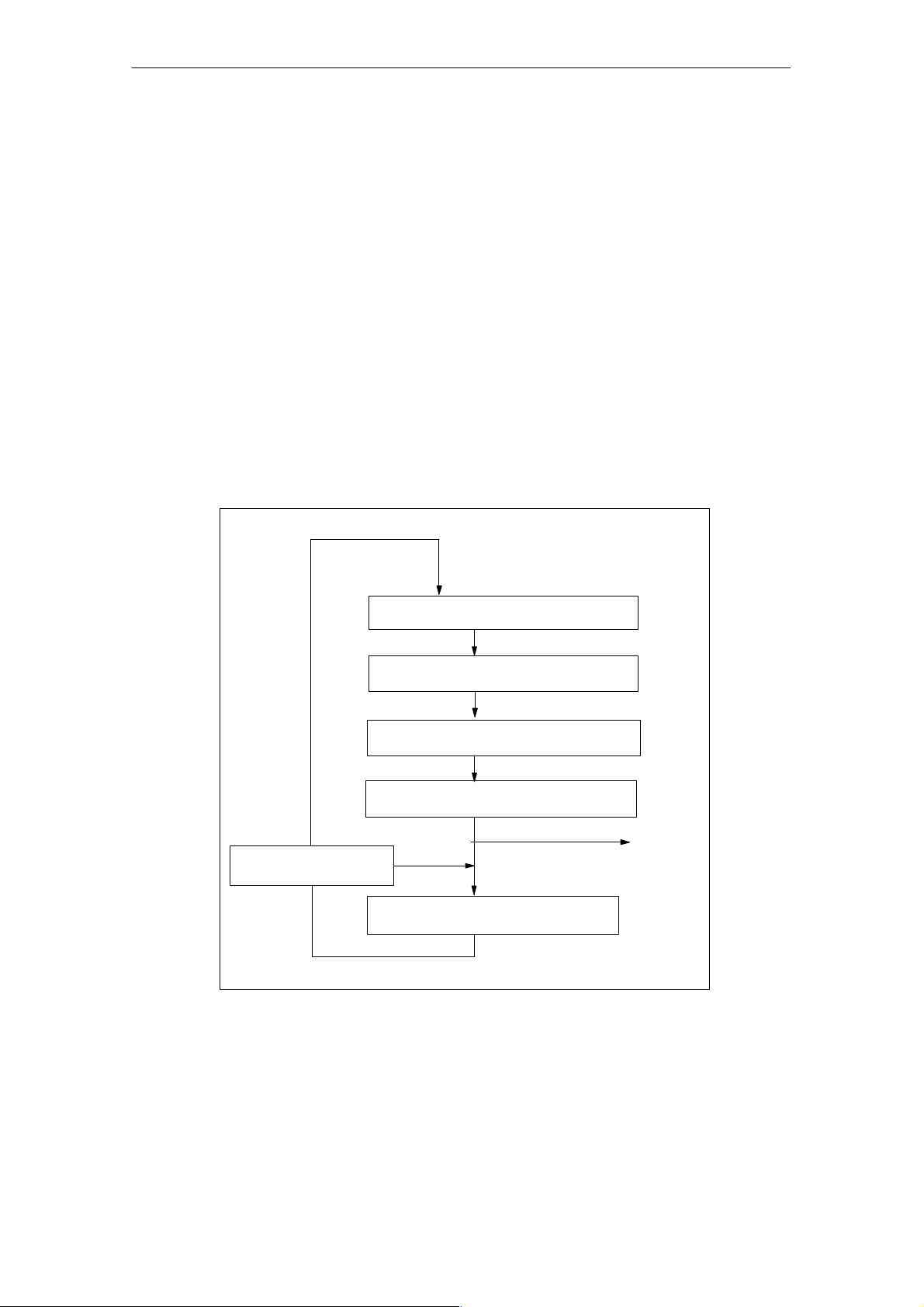

Figure 1-3 shows the various components of the cycle time for a free cycle.

Conversion time for analog input

channel CH3

Conversion time for analog input

channel CH2

Conversion time for analog input

channel CH1

Conversion time for analog input

channel CH0

Conversion time for analog output

channel CH3

Cycle

time

Conversion time for analog output

channel CH2

Conversion time for analog output

channel CH1

Conversion time for analog output

channel CH0

Fig. 1-3 Cycle time for the SM 335 free cycle

The execution times in Free Cycle mode are comprised as follows:

• Base load of a cycle: approx. 200 µs

• Execution times for the reading in of an analog channel: approx. 200 µs

• Execution time for the output of an analog value: approx. 50 µs

1-14

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 25

Characteristics and Technical Specifications of the SM 335

The SM 335 only updates the relevant analog output channel when modifications

are made to the output value.

• Four activated input channels and four activated output channels with the re-

quired output, which is dependent on constantly changing values, yields a cycle

time of 1200 µs (200 µs + 4 x 200 µs + 4 x 50 µs).

• Four activated input channels and four activated output channels with unchanged or rarely changing output values, yields a cycle time of 1000 µs

(200 µs + 4 x 200 µs + 4 x 0 µs).

• One activated input channel and four activated output channels with unchanged

or rarely changing output values, yields a cycle time of 400 µs (200 µs +

1 x 200 µs + 4 x 0 µs).

Deselecting diagnostics does not affect the cycle time.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

1-15

Page 26

Characteristics and Technical Specifications of the SM 335

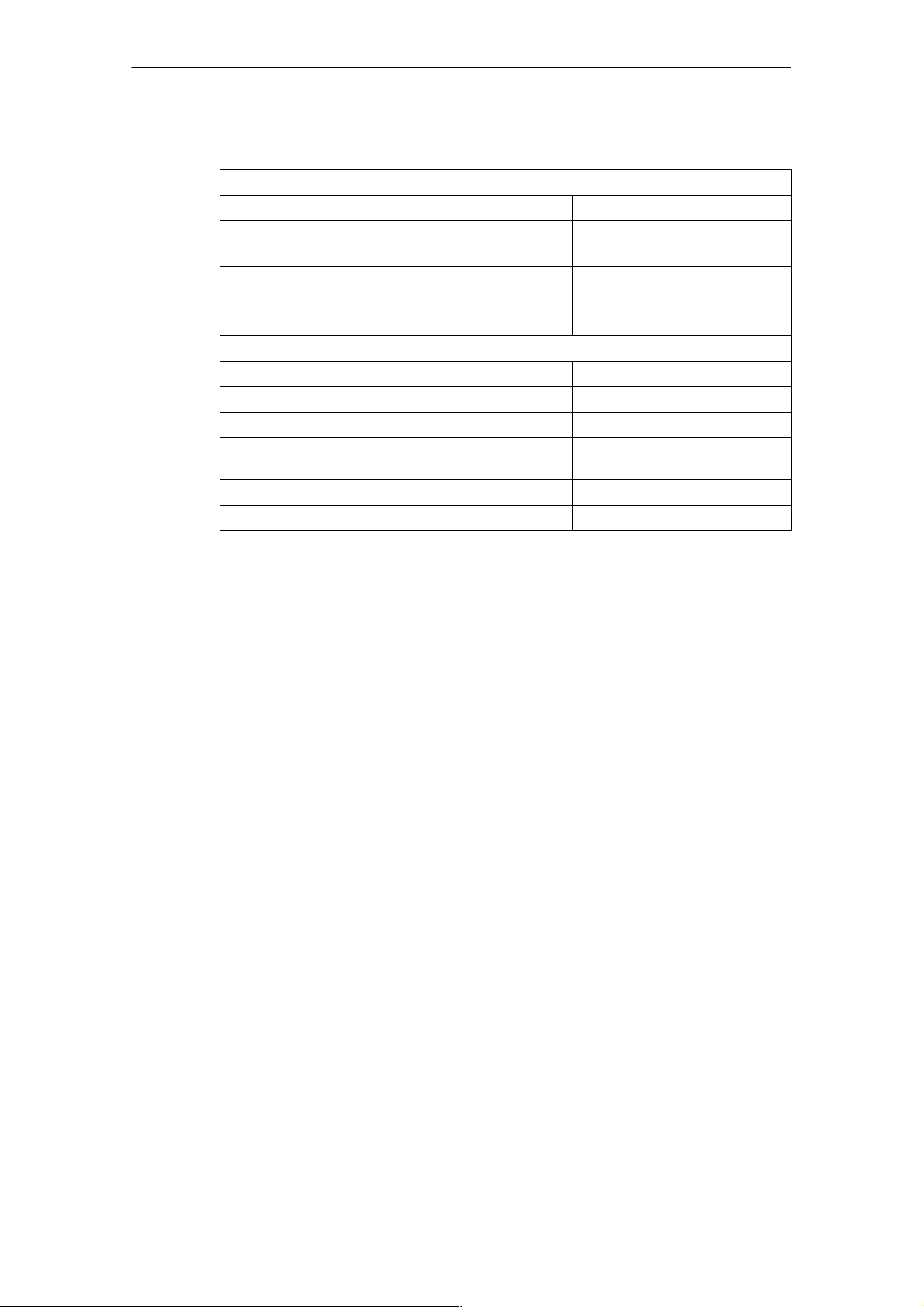

1.6.2 Conditional Cycle mode

Conditional Cycle

In the conditional cycle operating mode, you can define the cycle time. Following conversion of all analog inputs, the SM 335 can generate an end-of-cycle interrupt to the CPU (see Subsection 3.4.1 Hardware Interrupt). The SM 335 then

waits while the analog outputs are updated and begins the next processing cycle

after the specified cycle time has expired.

The end-of-cycle interrupt can be used to synchronize a user program via OB 40.

Furthermore, the interrupt enables high-speed processing of the user program

(e.g., for closed-loop control routines).

Conditional Cycle mode is activated when a cycle time of 1 to 16 ms is set for the

SM 335 in HW Config.

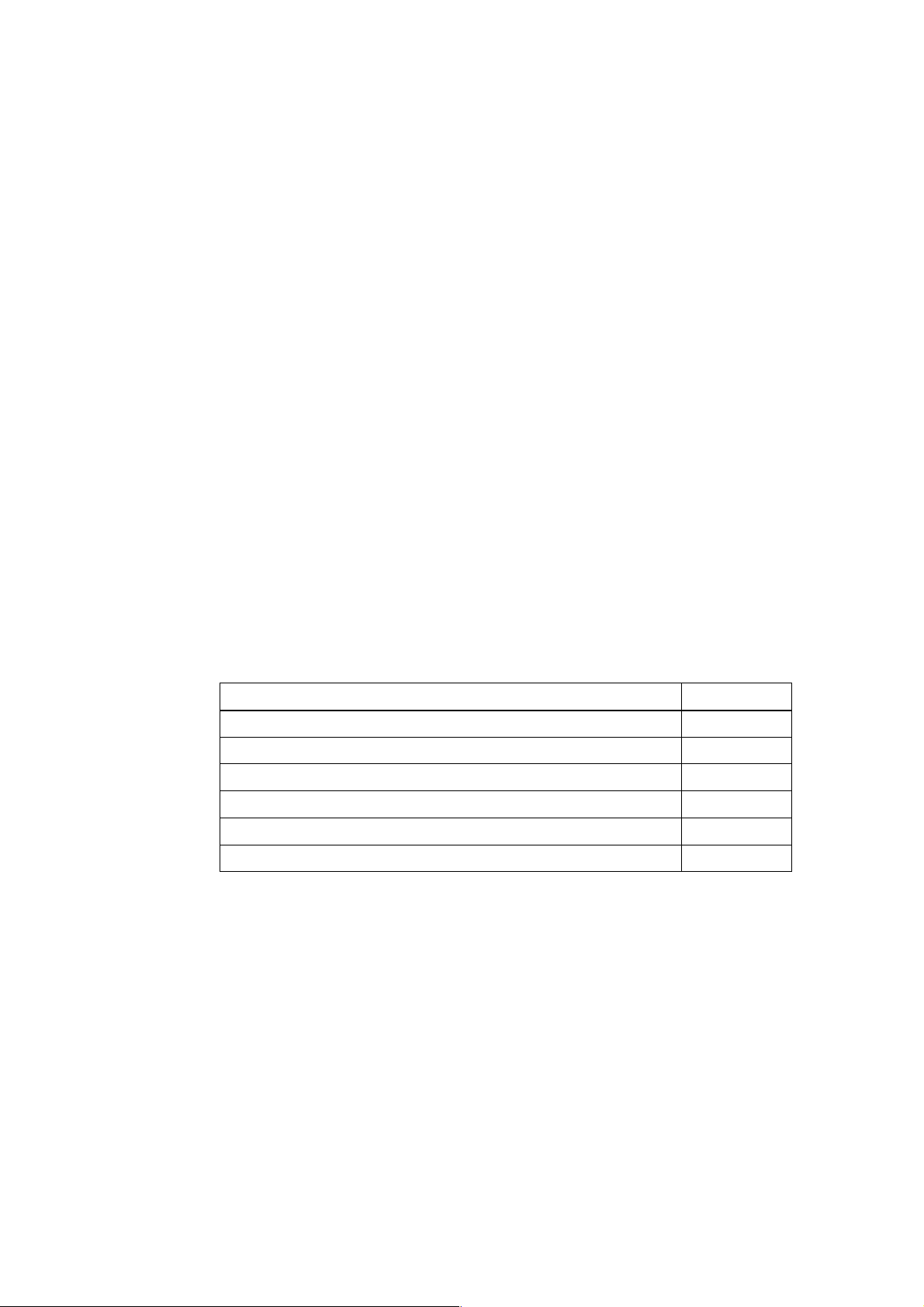

Figure 1-4 shows the various components of the cycle time for a conditional cycle.

Yes

Time condition:

Start new cycle

every 1 ms, 1.5 ms, etc., up to 16 ms

Conversion time for analog input

channel CH3

Conversion time for analog input

channel CH2

Conversion time for analog input

channel CH1

Conversion time for analog input

channel CH0

Optional

NO

Updating of the analog outputs

End-of-cycle

interrupt

1-16

Fig. 1-4 Cycle time for a conditional SM 335 cycle

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 27

Connecting the Inputs and Outputs of the SM 335

Assembly

Before connecting the SM 335, you must first assemble the SM 335. The SM 335

is assembled in the same way as all other SIMATIC S7-300 I/O modules. Please

read the SIMATIC S7-300 Hardware and Installation Manual.

SIMATIC S7-300

When connecting the SM 335, please note the installation guidelines in the

SIMATIC S7-300 Hardware and Installation Manual. In the SM 335 Manual, we

describe special features that only apply to the SM 335.

In this chapter

We deal with the following topics in this chapter:

2

Topic Section

Basic information about connecting the SM 335 2.1

Connecting the analog inputs 2.2

Connecting the analog outputs 2.3

Connecting the interval counter input 2.4

Connecting the sensor supply 2.5

Interference suppression filter for 24 V supply voltage 2.6

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

2-1

Page 28

Connecting the Inputs and Outputs of the SM 335

2.1 Basic information about connecting the SM 335

Connecting the analog inputs and outputs

You can find detailed information about connecting the analog inputs and outputs in

the SIMATIC Programmable Logic Controller, S7-300 Module Data Reference Ma-

nual.

Rules

The following applies:

• The cables must be twisted-pair cables, protected against interference and

shielded.

• The accuracy of your measurements depends on the following:

– Load

Power supply

The SM 335 must be supplied with 24 V DC. The 24 V must be connected to

L+ (PIN 1), the 24 V’s zero potential to M (PIN 20).

Grounding

You can ground the 24 V power supply in the following way:

• Direct on the 24 V power supply unit or

• On the S7 CPU (if you use the 24 V power supply on the CPU).

– Cable between the SM 335 and the load

– Reference voltage

2-2

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 29

Connecting the Inputs and Outputs of the SM 335

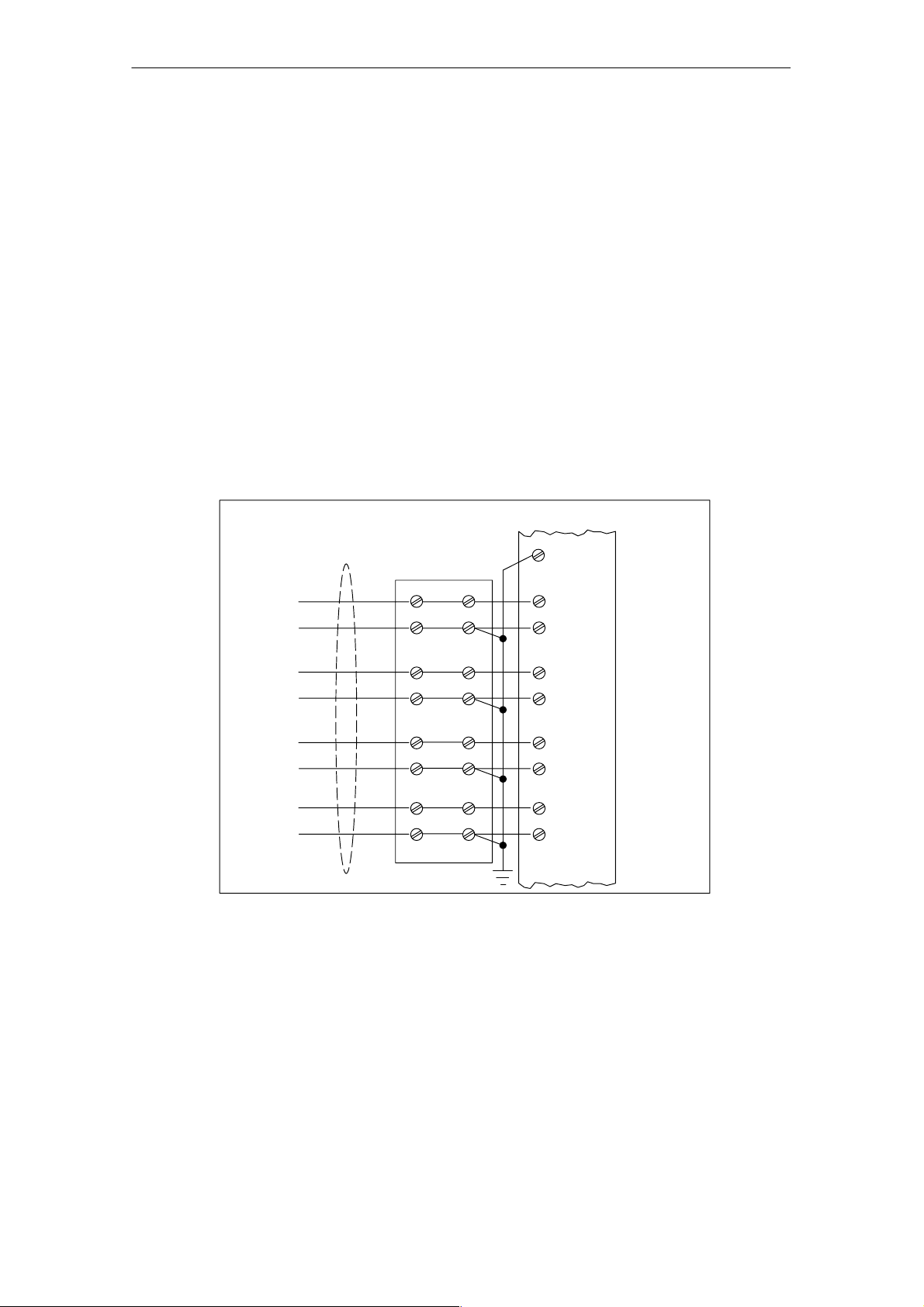

2.2 Connecting the analog inputs

Recommendation

The high conversion speed of the SM 335 means that the interference produced

can have a negative effect on the measurement input voltages in particular.

The configuration described below is in general the configuration, which is least

susceptible to interference.

The SM 335’s analog inputs and the associated zero potential should be connected to a terminal block, and the zero potential for the analog inputs distributed over the block.

Configuration

The result is the following basic configuration:

Twisted-pair,

shielded

Terminal block

Sensor 0

Sensor 1

Sensor 2

Sensor 3

Sensor 3

CGP=Central Grounding Point

Fig. 2-1 Connecting Sensors to the Analog Inputs on the SM 335

CGP

SM 335

6 M

ANA

9M

10 M

11 M

12 M

13 M

14 M

15 M

16 M

0+

0–

1+

1–

2+

2–

3+

3–

CH0

CH1

CH2

CH3

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

2-3

Page 30

Connecting the Inputs and Outputs of the SM 335

Non-Isolated

In contrast to other applications (e. g., when connecting thermocouples), you

should ground the sensors’ analog zero potential in the vicinity of the SM 335. The

easiest way to do so is to connect pins 10, 12, 14 and 16 with analog zero potential

M

(PIN 6) and connect M

ANA

central grounding point (CGP) of the module. This connection should be as short

as possible.

Do not ground the sensors twice, however, as this would produce ground loops,

which could result in interference. When using sensors, which are shielded and

whose shields are connected to the analog zero potential, you must disconnect the

shield from the analog zero potential.

in the vicinity of the module in the rack with the

ANA

Limited potential difference U

Only a limited potential difference UCM (common mode voltage) may occur between the measuring lines M- of the input channels and the reference point of the

measuring circuit M

ANA

In order to prevent the permissible value being exceeded, you must take various

action, described below, depending on the potential connection of the sensors.

For details please see the SIMATIC Programmable Logic Controller, S7-300 Mod-

ule Data Reference Manual.

If you use the SM 335 isolated, the maximum permissible common mode voltage

must not be exceeded between the zero potential of the sensor and M

wise the SM 335 triggers a diagnostic alarm and 7FFFH is read in from the relevant

channel.

60 V AC/75 V DC must not be exceeded between M

24 V voltage supply.

Unused analog inputs

Unused analog inputs on the SM 335 must be short-circuited and connected to

M

. Deactivate the unused analog inputs as described in HW Config. This

ANA

achieves the optimum in interference immunity for the SM 335 and the cycle time

is reduced in the operating mode “free cycle”.

CM

.

and the ground of the

ANA

ANA

, other-

2-4

You can also employ unused analog inputs to monitor the sensor power supply or

analog outputs. This also enhances interference immunity.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 31

Connecting the Inputs and Outputs of the SM 335

2.3 Connecting the analog outputs

Connecting the analog outputs

The analog outputs must be connected as voltage outputs. Detailed information can be found in the SIMATIC Programmable Logic Controller, S7-300 Module

Data Reference Manual.

Recommendation

If possible, the SM 335’s analog outputs, with the associated zero potential, should

be connected to a terminal block from where you can tap the zero potential for the

analog outputs.

Configuration

The result is the following basic configuration:

SM 335

CH0 2

CH1 3

CH2 4

CH3 5

M

6

ANA

Actuator 0

Actuator 1

Actuator 2

Actuator 3

Twisted-pair,

shielded

Fig. 2-2 Connecting Actuators to the SM 335

Non-Isolated

Actuators, which are shielded and whose shields are grounded and connected to

the actuator’s zero potential conductor, form a ground loop. You must therefore

break the connection between shield and zero potential conductor on the actuator

or use an actuator whose zero potential conductor is not connected to ground.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

2-5

Page 32

Connecting the Inputs and Outputs of the SM 335

Unused analog outputs

To ensure that unused analog outputs on the SM 335 are dead, you must deactivate them and leave them open. An analog output is deactivated with HW Config.

2.4 Connecting the interval counter input

Non-Isolated

If you wire the interval counter input as a non-isolated input, connect pin 19 (MIZ)

and pin 20 (24 V power supply’s zero potential).

Isolated

If you wire the interval counter input as an isolated input, you may not connect pin

19 (MIZ) to pin 20 (24 V power supply’s zero potential).

Additional information

See Section 4.3 for more information about connecting the interval counter input.

2-6

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 33

Connecting the Inputs and Outputs of the SM 335

2.5 Connecting the sensor power supply

Purpose

The sensor power supply is designed for resistance-type sensors (e. g., linear potentiometers).

Connections

Figure 2-3 shows an example of how to connect the sensor power supply.

SM 335

6 M

ANA

10 V

0 V

Fig. 2-3 Example of How to Supply the Sensors with Power via the SM 335

Non-isolated configuration

Internally, the SM 335’s analog zero potential (pin 6) is connected with the 10 V

sensor power supply’s zero potential.

7 10 V

U

=10 V

Ref

U

8

9M

10 M

0+

0–

Sensor

power

supply

Measuring

signal

If you use the four-wire measuring method shown in Figure 2-3, you must not connect pin 10 to pin 6 or to zero potential. To do so would create a ground loop,

which could cause interference.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

2-7

Page 34

Connecting the Inputs and Outputs of the SM 335

Cable

There is a voltage drop on the cable between SM 335 and the linear potentiometer.

Because of the SM 335’s high resolution, this can play a role in the measuring of

the analog signal. You can compute the voltage drop on an electric cable as follows:

U: Voltage drop along the cable

: Resistivity of the cable used

r

0

r0· I · L

U +

A

Because of this, we would recommend keeping the cables as short as possible

and using a cable with the largest possible cross-section.

(for Cu: 0,0172 W mm2/m)

I: Current flowing through the cable in

amperes

L: Length of the cable in meters

A: Cross-section of the cable in mm

2

2-8

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 35

Connecting the Inputs and Outputs of the SM 335

2.5.1 Correcting the sensor power supply

Purpose

The power supply for the sensors is a 10 V output voltage. This voltage may deviate slightly from 10 V. The deviation results from the tolerances of the components

used on the SM 335. You can therefore read off the exact value of the sensor

power supply for applications requiring very high accuracy.

Sensor voltage (ModAdd + 10, 11)

The analog value of the sensor voltage (UG) is factory-set and stored in the module. The SM 335 supplies the analog value of the sensor voltage UG in input bytes

ModAdd + 10 and ModAdd + 11 (see Table 3-1 in Subsection 3.1.1).

Correction factor

The correction factor K is computed from the sensor voltage UG and the desired

voltage.

27648 (6C00H)

K +

UG lies between 27620 (6BE4H) and 27676 (6C1CH), producing correction factors

from 0.9989883 to 1.0010127.

Measured value

The corrected analog measured value is computed as follows:

U

+ K · U

Corr

U

G

U

= Corrected analog value

Corr

K = Correction factor

AI

= Analog value measured at the analog input

U

AI

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

2-9

Page 36

Connecting the Inputs and Outputs of the SM 335

2.6 Interference suppression filter for 24 V supply voltage

Caution

The SM 335 module must always be used with an interference suppression filter to

obtain interference immunity for SIMATIC.

Interference

Interference may reach the SM 335 via the 24 V voltage supply. One cause of

such interference is the switching of loads connected to the 24 V circuit. The interference has a high-frequency content, which can impair proper functioning of the

SM 335.

2-10

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 37

Interference suppression filter

The SM 335 is protected from the high-frequency content by an interference suppression filter. Connect this filter to the 24 V voltage supply circuit of the SM 335

module (see Figure 2-4).

Connecting the Inputs and Outputs of the SM 335

Interference

Suppression

Filter

SM 335

L+

24 V

power

supply

M

Other modules

Fig. 2-4 Interference Suppression Filter for the 24 V Power Supply of the

SM 335

1

2 2’

1’

1L

+

20 M

Other analog

modules that

generate no

interference

The interference suppression filter can be used for a maximum of 4 SM 335 modules and should be located as close as possible to the SM 335.

The interference suppression filter is brought into the 24 V supply circuit even if it

can be used with a higher voltage.

The interference suppression filter can be obtained by quoting order number:

6ES7 335-7HG00-6AA0

Type: e. g., EPCOS SIFI C, order reference B84113-C-B30

Please contact your local Siemens representative for more information.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

2-11

Page 38

Connecting the Inputs and Outputs of the SM 335

2-12

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 39

Data Exchange with the SM 335

Preliminary remark

Data exchange with the SM 335 is defined here as follows:

• Transfer of data to the SM 335 from the CPU and

• Reading of data from the SM 335 by the CPU.

Overview

In this chapter, we have summarized all the data that can be transferred to the

SM 335 or supplied by the SM 335.

Methods

There are basically several methods of reading or writing data:

• Access via the I/O addresses (e. g., with L PIW, T PQW)

• Setting parameters via HW Config

3

• Writing parameters with the help of system function 55

• Reading diagnostics data via system function 59

• Other methods: see Reference Manual

System Software for S7-300/400 System and Standard Functions.

Measuring range module

Before you plug in the SM 335, you must insert the measuring range module into

the SM 335. The SIMATIC Programmable Logic Controller, S7-300 Module Data

Reference Manual describes how to insert the measuring range module into the

SM 335.

The measuring method (current/voltage measurement) is set for the analog inputs

depending on the position in which you plug in the measuring range module.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-1

Page 40

Data Exchange with the SM 335

In this chapter

We deal with the following topics in this chapter:

Access via the I/O addresses 3.1

Setting parameters via HW Config 3.2

Topic Section

Modifying SM 335 parameters with the help of system func-

3.3

tion 55

Evaluating SM 335 diagnostics 3.4

3-2

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 41

3.1 Access via the I/O addresses

Principle

You can access the SM 335 via I/O addresses.

Input values

Input values are values supplied by the SM 335. The input values contain measured values of the SM 335.

You can load the input values via L PIB (or L PIW or L PID) operation. As an alternative, read access is possible within the process image via L IB (or L IW or L ID).

(see Table 3-1, Subsection 3.1.1)

Output values

Data Exchange with the SM 335

Output values are values you write to the SM 335 via T PQB (or T PQW or T PQD)

operation. As an alternative, write access is possible within the process image via

T IB (or T IW or T ID).

You can transfer analog values to the SM 335 via output values. The output values

are output via the SM 355’s analog outputs. (see Table 3-4, Subsection 3.1.2)

3.1.1 Output values

Principle

The SM 335 converts the signals measured at the inputs into binary values.

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-3

Page 42

Data Exchange with the SM 335

Configuration

The input values are located in bytes ModAdd (module start address) to ModAdd + 15. See the SIMATIC Programmable Logic Controller, S7-300 Module Data

Reference Manual for information about how to compute the module start address.

Table 3-1 lists the input values, their addresses, and their default values.

Table 3-1 SM 335 Input Values

Byte

ModAdd + 0 High-order byte of the measuring value from measuring

channel CH0

ModAdd + 1 Low-order byte of the measuring value from measuring

channel CH0

ModAdd + 2 High-order byte of the measuring value from measuring

channel CH1

ModAdd + 3 Low-order byte of the measuring value from measuring

channel CH1

ModAdd + 4 High-order byte of the measuring value from measuring

channel CH2

ModAdd + 5 Low-order byte of the measuring value from measuring

channel CH2

ModAdd + 6 High-order byte of the measuring value from measuring

channel CH3

ModAdd + 7 Low-order byte of the measuring value from measuring

channel CH3

ModAdd + 8 Number of end-of-cycle interrupts, only for “Comparator”

and “Measuring Only” modes

Default = 1;

If end-of-cycle interrupts have been suppressed:

1 + number of suppressed end-of-cycle interrupts

ModAdd + 9 Comparator mode (on power-up) or Return code for

“Comparator” and “Measuring Only” modes.

ModAdd + 10 High-order byte of the sensor voltage (see Subsec-

tion 2.5.1)

ModAdd + 11 Low-order byte of the sensor voltage (see Subsec-

tion 2.5.1)

ModAdd + 12 Interval counter (see Section 4.5) 00H *) or ***)

ModAdd + 13 Interval time values in bits 16 to 24 (see Section 4.5) FF

ModAdd + 14 Interval time values in bits 8 to 15 (see Section 4.5) FF

ModAdd + 15 Interval time values in bits 0 to 7 (see Section 4.5) FF

Content Value

7FH *) or ***)

FFH *) or ***)

7FH *) or ***)

FFH *) or ***)

7FH *) or ***)

FFH *) or ***)

7FH *) or ***)

FFH *) or ***)

00H *) or ***)

00H *) or

01H *) or ***)

**)

**)

*) or ***)

H

*) or ***)

H

*) or ***)

H

*) Initial value

**) factory-set

***) current value

Analog values (ModAdd + 0...7)

See Subsections 3.1.3 and 3.1.4 for information about how an analog value is represented in binary in the CPU and on which binary value corresponds to which

analog value.

3-4

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 43

Number of end-of-cycle interrupts (ModAdd + 8)

A user program can be synchronized via OB 40 using the end-of-cycle interrupt.

Fast processing of the user program is also possible via the interrupt (e. g., for adjustment routines).

There are however situations in which the SM 335 cannot send an interrupt:

• when several hardware interrupts occur simultaneously, or

• in the special “Comparator” mode.

The SM 335 suppresses end-of-cycle interrupts when the Comparator mode is enabled.

The SM 335 enters the number of suppressed end-of-cycle interrupts (1 + number

of suppressed end-of-cycle interrupts) in byte ModAdd + 8 when the “Comparator

mode” is exited.

Example: Content of byte 8 = 5, i. e., for 5 end-of-cycle interrupts, OB 40 is called

only once.

The value is also stored in the local data of OB 40 (see Subsection 3.4.1, Hardware interrupt). Evaluation via OB 40 has the advantage of ensuring the consistency of the measured value and the number end-of-cycle interrupts.

Data Exchange with the SM 335

Return code (ModAdd + 9)

When the “Comparator” or “Measuring Only” mode is activated, the SM 335

SM 335 enters the return code in byte ModAdd + 9. Figure 3-1 shows the format of

the return code:

76543210

Comparator is active/was last active mode

Measuring Only is active/was last active mode

Measuring Only/Comparator mode activated

Fig. 3-1 SM 335 Return Codes

The return code bits, with their descriptions, are shown in Table 3-2.

Comparator mode is displayed instead of the return code on power-up of the

SM 335.

Error code

Measured value not current

Parameter assignment error

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-5

Page 44

Data Exchange with the SM 335

Table 3-2 Meaning of the bits in the SM 335 return code

Bit

Description

7 = 1: SM 335 is in “Measuring Only” or “Comparator” mode

= 0: SM 335 is in “Conditional Cycle” or “Free Cycle” mode

1)

6

5

= 1: “Measuring Only” mode is activated / was last activated

1)

= 1: “Comparator” mode is activated / was last activated

4 = 1: Mode cannot be activated. Reason:

• The “Comparator” mode cannot be activated when “Measuring Only” mode

is enabled.

• The “Measuring Only” mode cannot be activated when the “Comparator”

mode is enabled or when the “Measuring Only” mode is already active.

3 = 1: The measured value from the analog inputs is not current

(for “Comparator” mode only – with Comparator 2, see Subsection 5.2.1,

Principle of special “Comparator” mode)

2, 1, 0 Error code see Table 3-3

1)

Only bit 5 or 6 can be set but not both

Table 3-3 Description of Bits 0, 1, 2 in the Return Code of the SM 335

Bit2 Bit1 Bit0 Description

0 0 0 No error

0 0 1 Parameter for operating mode ‘Comparator’ faulty

(no analog input designated as comparator input).

0 1 0 Analog input to be used for measuring is disabled.

0 1 1 Error detected at the analog input assigned to the comparator while

‘Comparator’ mode was in force.

1 0 0 Operating mode exited. Reason:

• Comparator: Comparator time expired (see Subsection 5.2.2)

• Measuring Only (see Section 5.3 ):

Measurement at one analog input: 60 ms expired.

Measurement at 2, 3 or 4 analog inputs: 40 ms expired.

1 0 1 “Comparator” mode exited because new parameters were transferred

via system function to the SM 335.

3-6

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 45

3.1.2 Output values

Principle

The analog output values converted into binary in the CPU can be transferred to

the SM 335 e. g., with the command “T PQW”.

The SM 335 converts the binary form of the analog output signals into analog signals and forwards them to the relevant outputs.

Configuration

The output values can be transferred to bytes ModAdd (module start address) to

ModAdd + 7 (module start address + 7).

See Configuring the SM 335 in HW Config from STEP 7 onwards for how to compute the module start address.

Data Exchange with the SM 335

Table 3-4 SM 335 Output Values

ModAdd + 0 High-order byte of the output value for analog output channel CH0

ModAdd + 1 Low-order byte of the output value for analog output channel CH0

ModAdd + 2 High-order byte of the output value for analog output channel CH1

ModAdd + 3 Low-order byte of the output value for analog output channel CH1

ModAdd + 4 High-order byte of the output value for analog output channel CH2

ModAdd + 5 Low-order byte of the output value for analog output channel CH2

ModAdd + 6 High-order byte of the output value for analog output channel CH3

ModAdd + 7 Low-order byte of the output value for analog output channel CH3

Analog values

See Subsections 3.1.3 and 3.1.4 for information about how an analog value is represented in binary in the CPU and on which binary value corresponds to which

analog value.

Byte

Content

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-7

Page 46

Data Exchange with the SM 335

3.1.3 Analog value representation for analog input channels

The tables contain representations of the measuring values of individual measuring

ranges of the analog inputs.

Table 3-5 Analog Value Representation in the Bipolar Input Ranges

Measuring Range

Units Range

+ 1 V + 10 V + 2.5 V + 10 mA decimal hexa-

1.185 V

:

:

1,1758 V

:

:

1 V

:

0.75 V

:

144.68 µV

0 V

–144.68 µV

:

–0.75

:

–1 V

:

:

–1.176 V

:

:

–1.185 V

11.851 V

:

:

11,758 V

:

:

10 V

:

7.5 V

:

1446.8 µV

0 V

–1446.8 µV

:

–7.5 V

:

–10 V

:

:

–11.759 V

:

:

–11.851 V

2.963 V

:

:

2,938 V

:

:

2.5 V

:

1.875 V

:

361.69 µV

0 V

–361.69 µV

:

–1.875 V

:

–2.5 V

:

:

–2.940 V

:

:

–2.963 V

11,85 mA

:

:

11,758 mA

:

:

10 mA

:

7.5 mA

:

1446.8 nA

0 mA

–1446.8 nA

:

–7.5 mA

:

–10 mA

:

:

–11.76 mA

:

:

–11.85 mA

32767

:

32512

32508

:

27652

27648

:

20736

:

4

0

–4

:

–20736

:

–27648

–27652

:

–32512

–32516

:

–32768

decimal

7FFF

:

7F00

7EFC

:

6C04

6C00

:

5100

H

:

4

H

0

FFFC

:

AF00

:

9400

H

93FC

:

8100

H

80FC

:

8000

H

H

H

H

H

H

H

H

H

H

Overflow

Overrange

Rated

range

Underrange

Underflow

3-8

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 47

Data Exchange with the SM 335

Table 3-6 Analog Value Representation in the Unipolar Input Ranges

Measuring Range

Units Range

0 – 2 V 0 –10 V 0 – 20 mA 4 – 20 mA decimal hexa-

decimal

2.370 V

:

:

2.35 V

:

:

2 V

:

1.5 V

:

144.68 µV

11.852 V

:

:

11,75 V

:

:

10 V

:

7.5 V

:

723.4µV

23.70 mA

:

:

23.5 mA

:

:

20 mA

:

15 mA

:

1446.8 nA

22.96 mA

:

:

22.8 mA

:

:

20 mA

:

15 mA

:

4 mA +

32767

:

32512

32510

:

27650

27648

:

20736

:

2

7FFF

:

7F00

7EFE

:

6C02

6C00

:

5100

:

2

H

1157.4 nA

0 V

–144,68 µV

:

–18.446 mV

0 V

–723,4 µV

:

–92.223 mV

0 mA

1446.8 nA

:

18.448 µA

4 mA

<4 mA

Open wire

(7FFFH)

0

–2

:

–255

0

FFFE

:

FF00

<–18.446 mV <–92.223 mV <–18.448 µA –32768 8000

H

H

H

H

H

H

H

H

H

Overflow

Overrange

Rated range

Underrange

Underflow

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-9

Page 48

Data Exchange with the SM 335

3.1.4 Analog value representation for analog output channels

The table contains the analog value representation of the SM 335’s output channels.

12 bits (+VZ) of the output value are converted in the 0-10 Volt range.

Bit 0, Bit 1 and Bit 2 are not converted.

11 bits + VZ of the output value are converted in the + 10 Volt range.

Bit 0, Bit 1, Bit 2 and Bit 3 are not converted.

Table 3-7 Analog Value Representation in the Output Ranges from 0 to 10 V and + 10 V

Output Value

decimal hexa-

32767

:

32512

32504

32496

:

27664

27656

27648

:

20736

:

16

8

0

–8

–16

:

–20736

:

–27648

–27656

–27648

:

–32496

–32504

–32512

:

–32768

7FFF

:

7F00

7EF8

7EF0

:

6C10

6C08

6C00

:

5100

:

10

8

H

0

H

FFF8

FFF0

:

AF00

:

9400

93F8

93F0

:

8110

8108

8100

:

8000

decimal

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

Range Output Voltage

0-10 V +10 V

Overflow

(off circuit and de-energized)

0 V

:

0 V

Overrange 11.756 V

11.753 V

:

10.006 V

10.003 V

Rated range 10 V

:

7.5 V

:

5.787 mV

2.8936 mV

0 V

0 V

0 V

:

0 V

:

0 V

Underrange 0 V

0 V

:

0 V

0 V

Underflow

(off circuit and de-energized)

0 V

:

0 V

0 V

:

0 V

11.753 V

11.753 V

:

10.006 V

10 V

10 V

:

7.5 V

:

5.787 mV

0 V

0 V

0 V

–5.787 mV

:

–7.5 V

:

–10 V

–10 V

–10.006 V

:

–11.753 V

–11.753 V

0 V

:

0 V

3-10

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 49

3.2 Setting parameters via HW Config

Measuring Range Module

You must plug in the measuring range module into the side of the SM 335.

You can learn how to do this in Reference Manual SIMATIC Programmable Logic

Controller, S7-300 Module Data. Section 1.4 describes the measuring ranges to be

set.

HW Config

Certain features of the SM 335 (e. g., cycle time, A/D conversion) are explained in

HW Config, Parameter Assignment of STEP 7.

The measuring range modules in the module must also be set to the necessary

settings if required (see Section 1.4).

Data Exchange with the SM 335

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-11

Page 50

Data Exchange with the SM 335

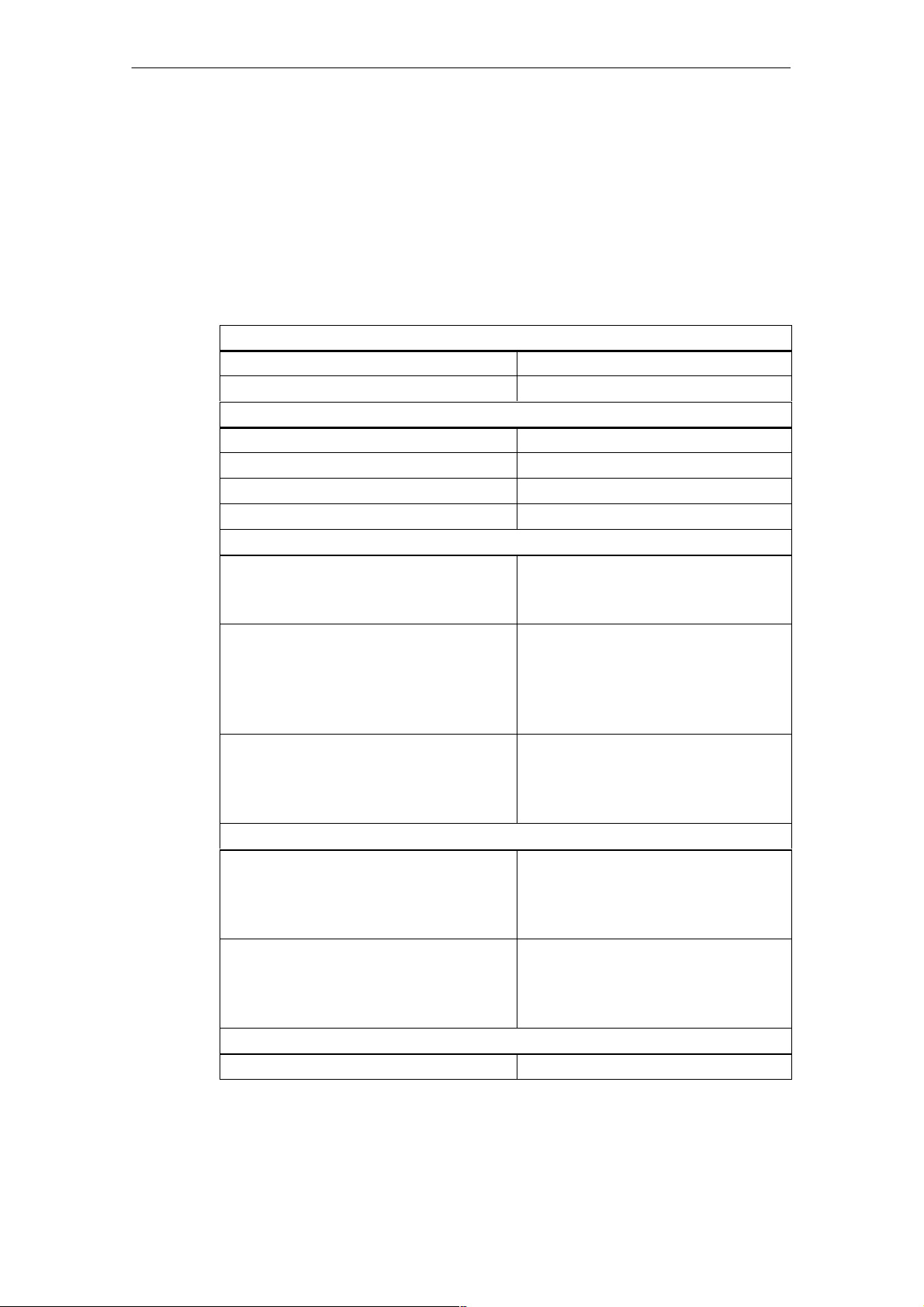

3.2.1 SM 335 default settings

Default settings

The analog input/output module has default settings. These default settings are

used when no parameters are set using the STEP 7 “HW Config” tool.

The defaults are listed in table 3-8.

Table 3-8 SM 335 Default Settings

Parameters

Cycle time *) Free Cycle (equivalent to 0.5 ms

Measuring method U or I (4 DMU) as per measuring

Measuring Range with U: +/– 10 V

Diagnostic interrupt *) no no

Hardware interrupt on

end-of-cycle

Group diagnostics

(= short-circuit test on analog output)

Open-wire test no –

Response with CPU-STOP – OCV (output have no cur-

Number of active channels 4 4

*) Setting is valid for entire module.

Default Setting for

Analog Inputs

[SM 335 cycle time] setting)

range module setting (see

Table 1-1)

with I (4 DMU): 4 - 20 mA

no no

no no

Default Setting for Analog

Outputs

U

+/– 10 V

rent or voltage)

3-12

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

Page 51

Data Exchange with the SM 335

3.2.2 SM 335 parameters assignable with HW Config

Parameter assignment application

The STEP 7 tool used to initialize the analog modules in a STEP 7 environment is

called “HW Config”.

SM 335 parameters

Table 3-9 provides an overview of the SM 335 parameters which can be assigned

with HW Config.

Table 3-9 SM 335 parameters in HW Config

Parameters

Basic settings for inputs

• Hardware interrupt for end-of-cycle

• Diagnostic interrupt enable

Diagnostics for inputs: Enable

includes:

Value Range Default

yes/no

yes/no

yes/no no

SM 335

no

no

• Measuring range underrange

• Measuring range overrange

• Overrange of permitted common mode

voltage

Open-wire test yes/no no

Measurement

• Method Deactivated

Voltage

Current (4-wire trans-

ducer)

Voltage

• Range Voltage: " 1 V; " 2.5 V; 0 to 10 V;

0 V to + 2 V (channel CH0 to CH3)

default" 10 V;

Current: " 10 mA; 0 mA to + 20 mA

+ 4 mA to + 20 mA (channel CH2 to CH3)

• Cycle time for A/D conversion 0,5;

Diagnostics for outputs (short-circuit test) yes/no no

Response with CPU-STOP “Keep last value

*)

The setting 0.5 ms in HW Config means: Free Cycle

The setting of 1 to 16 ms in HW Config means: Conditional Cycle

*)

1 to 16 ms 0.5 ms

(KLV)” or

“Output have no cur-

rent or voltage

(OCV)”

“Output have no

current or voltage

(OCV)”

*)

SM 335 – High-Speed Analog Input/Output Module for the SIMATIC S7-300

6ES7 335-7HG00-8BA1

3-13

Page 52

Data Exchange with the SM 335

Table 3-9 SM 335 parameters in HW Config

Parameters SM 335Parameters

Output

• Method Deactivated / Voltage Voltage

• Range from – 10 V to + 10 V

*)

The setting 0.5 ms in HW Config means: Free Cycle

The setting 1 to 16 ms in HW Config means: Conditional Cycle

End-of-cycle interrupt enable

When you enable the end-of-cycle interrupt, the SM 335 generates a hardware

interrupt after A/D conversion of the active channels. You can use this to call OB

40 at fixed intervals. You can set the cycle time for the A/D conversion. The

SM 335 can generate the end-of-cycle interrupt starting from a cycle time for A/D

conversion of 1 ms.

(see Subsection 3.4.1, Hardware Interrupt)

DefaultValue Range

from 0 V to + 10 V

Diagnostic interrupt enable

When diagnostic interrupts are enabled, the SM 335 generates a diagnostic interrupt as soon as an error is found.

Enable diagnostics