Siemens SIMATIC S7 CP340, SIMATIC S7 CP341, SIMATIC S7 CP441, SIMATIC S7 CP440 Programming Manual

Page 1

http://support.automation.siemens.com/WW/view/en/ID 88867653

FAQ 02/2014

CP340/CP341/CP440/CP441

Communication and

Programming

SIMATIC S7

Page 2

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

2

Siemens AG 2014 All rights reserved

This entry is from the Siemens Industry Online Support. The general terms of use

(http://www.siemens.com/terms_of_use) apply.

Security

information

Siemens provides products and solutions with industrial security functions that

support the secure operation of plants, solutions, machines, equipment and/or

networks. They are important components in a holistic industrial security

concept. With this in mind, Siemens’ products and solutions undergo continuous

development. Siemens recommends strongly that you regularly check for

product updates.

For the secure operation of Siemens products and solutions, it is necessary to

take suitable preventive action (e.g. cell protection concept) and integrate each

component into a holistic, state-of-the-art industrial security concept. Third-party

products that may be in use should also be considered. For more information

about industrial security, visit http://www.siemens.com/industrialsecurity.

To stay informed about product updates as they occur, sign up for a productspecific newsletter. For more information, visit

http://support.automation.siemens.com.

Table of contents

1 <add your text here> ..................................... Fehler! Textmarke nicht definiert.

1.1 <add your text here> ..................... Fehler! Textmarke nicht definiert.

Page 3

1 Overview

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

3

Siemens AG 2014 All rights reserved

1 Overview

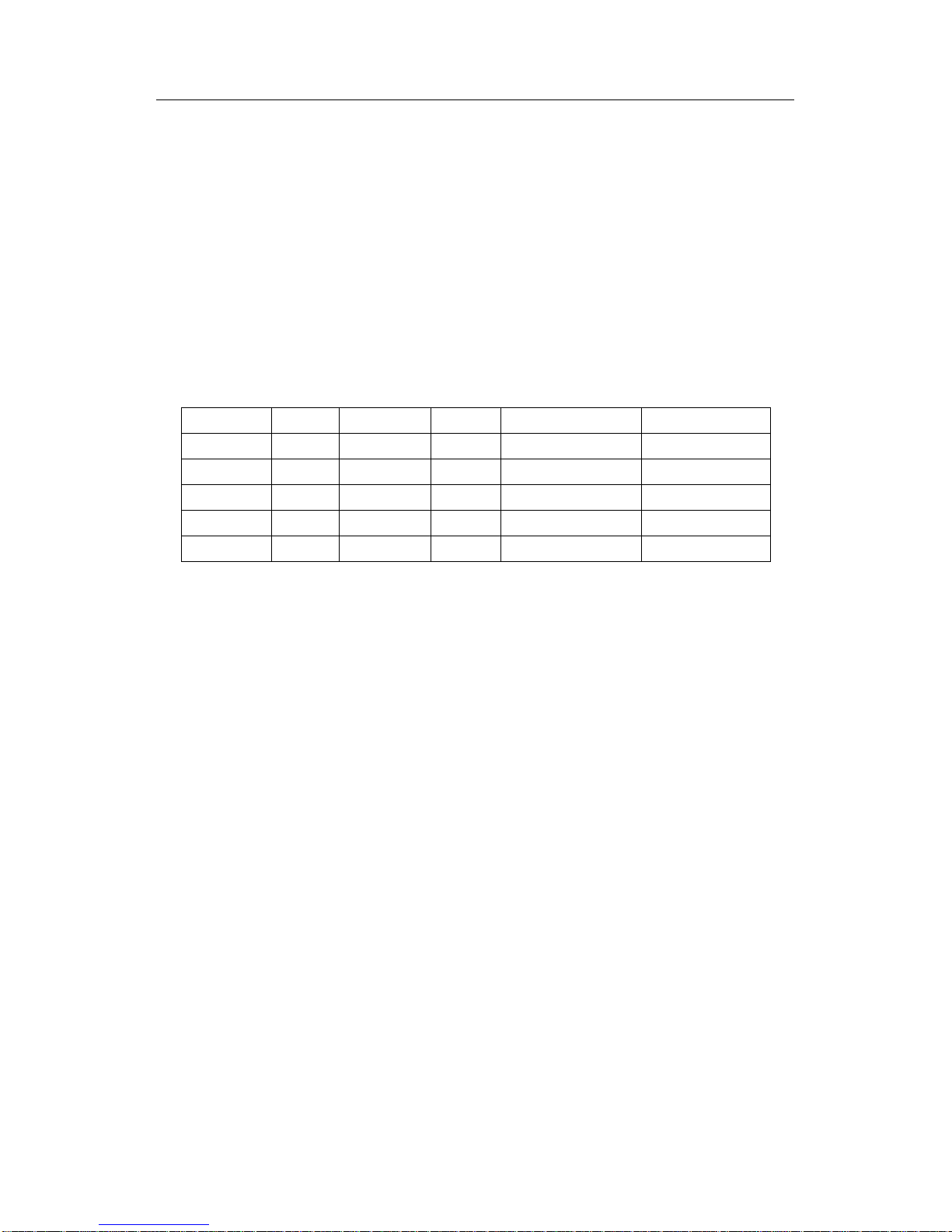

Siemens SIMATIC S7-series serial communication modules mainly include CP340,

CP341, CP440-1, CP441-1/2, as well as 1SI 3964/ASCII and 1SI MODBUS/USS of

ET200S, etc., and the communication protocols they support mainly include ASCII,

RK512, 3964(R), MODBUS Master, MODBUS Slave and other loadable protocols,

etc. SIMTIC S7-series serial communication modules and their supported

communication protocols are in the corresponding relations shown in the table

below:

ASCII

3964(R)

RK512

MODBUS Master

MODBUS Slave

CP340

X X - - -

CP341

X X X X X

CP440

X X - - -

CP441-1

X X - - -

CP441-2

X X X X X

X: support, -: not support

Table 1: Corresponding relations between modules and protocols

In actual application, the above-stated serial communication modules may be used

to realize serial communication for the following devices:

3rd-party DCS and PLC systems, etc.

3rd-party intelligent device and instrument, etc.

Receiving data from scanner and bar-code reader, etc.

Sending data to serial printer and other receiving devices

All other user-defined protocol devices that support ASCII and MODBUS

This document mainly introduces applications of CP340, CP341, CP440, CP441-1

and CP441-2, as well as ASCII, MODBUS RUT protocols they support, and it also

includes the routine used by each module for reference for readers.

Declaration: The virtual project stated in this document has major difference from

the real project example, and the example is not programmed in accordance with the

specified engineering design flow, and readers shall not confuse it with the real

project example. The example is free of charge, and any user may copy or release it

freely. The author of the program will not assume any liability for any functionality or

compatibility, and users shall assume the related risks. Siemens will not provide error

correction of this program example or hotline support. It is suggested that users

Page 4

1 Overview

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

4

Siemens AG 2014 All rights reserved

should read the related module operation manuals carefully to use them in a better

way.

Page 5

2 Introduction of related software and its applications

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

5

Siemens AG 2014 All rights reserved

2 Introduction of related software and its

applications

2.1 STEP7

STEP7 programming software is used to write PLC program, and it shall be

purchased from Siemens. All procedure codes in this document are written with

STEP7 V5.4 SP4.

2.2 PtP drive software package

PtP Param V5.1 is the drive software package for CP340/CP341/CP440/CP441,

and parameters may only be distributed to the serial communication module and

the function block necessary for communication programming may only be

integrated in STEP7 after this drive software package is installed. This drive will be

provided when the module is purchased, and it may also be downloaded through

the following linkage. The updated software version is PtP Param V5.1 SP11 at

present. http://support.automation.siemens.com/WW/view/en/27013524

2.3 MODBUS Master drive software package

This drive software package shall be installed when CP341 or CP441-2 is used in

MODBUS master, but PtP Param V5.1 drive program software package shall be

installed earlier. This drive software package may be purchased when purchasing

MODBUS Dongle or be downloaded through the following link:

MODBUS Master drive (RTU) software package:

http://support.automation.siemens.com/WW/view/en/27774018

MODBUS Master drive (ASCII) software package:

http://support.automation.siemens.com/WW/view/en/25356060

2.4 MODBUS Slave drive software package

This drive software package shall be installed when CP341 or CP441-2 is used in

MODBUS slave, but PtP Param V5.1 drive program software package shall be

installed earlier. This drive software package may be purchased when purchasing

MODBUS Dongle or be downloaded through the following link:

MODBUS Slave drive (RTU) software package:

http://support.automation.siemens.com/WW/view/en/27774276

MODBUS Slave drive (ASCII) software package:

http://support.automation.siemens.com/WW/view/en/25356060

2.5 ModScan32 / ModSlave

This is software provided by third party and may be downloaded from the Internet.

ModScan32 may be used to emulate MODBUS Master to test its communication

with MODBUS Slave. ModSlave may be used to emulate MODBUS Slave to test

its communication with MODBUS Master.

Page 6

3 Manual and related application documents

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

6

Siemens AG 2014 All rights reserved

3 Manual and related application documents

After all drive programs are installed, user may search for all CP module manuals

from the computer, whose detailed position is "Start-> SIMATIC-> Documentation -

> English”, or they may be found directly from the folder of STEP7 installation

path“… Program files-> Siemens -> Step7 -> S7MANUAL -> S7PtP_Cp”.

Fig. 1: Module manual path diagram

Page 7

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

7

Siemens AG 2014 All rights reserved

4 ASCII protocol communication

The communication mode in ASCII protocol is used to realize serial communication

of user-defined protocol, and it is applicable to communication with the intelligent

instrument, bar-code reader, scanner, and printer, etc. that support serial

communication.

The following examples are used to introduce the ASCII protocol communication of

Siemens serial communication modules CP340, CP341, CP440 and CP441.

4.1 ASCII protocol communication of CP340

4.1.1 Hardware catalog

PS 307

6ES7 307-1EA00-0AA0

CPU 315-2DP

6ES7 315-2AG10-0AB0

MMC

6ES7 953-8LG11-0AA0

CP340

6ES7 340-1AH01-0AE0

4.1.2 Configuration

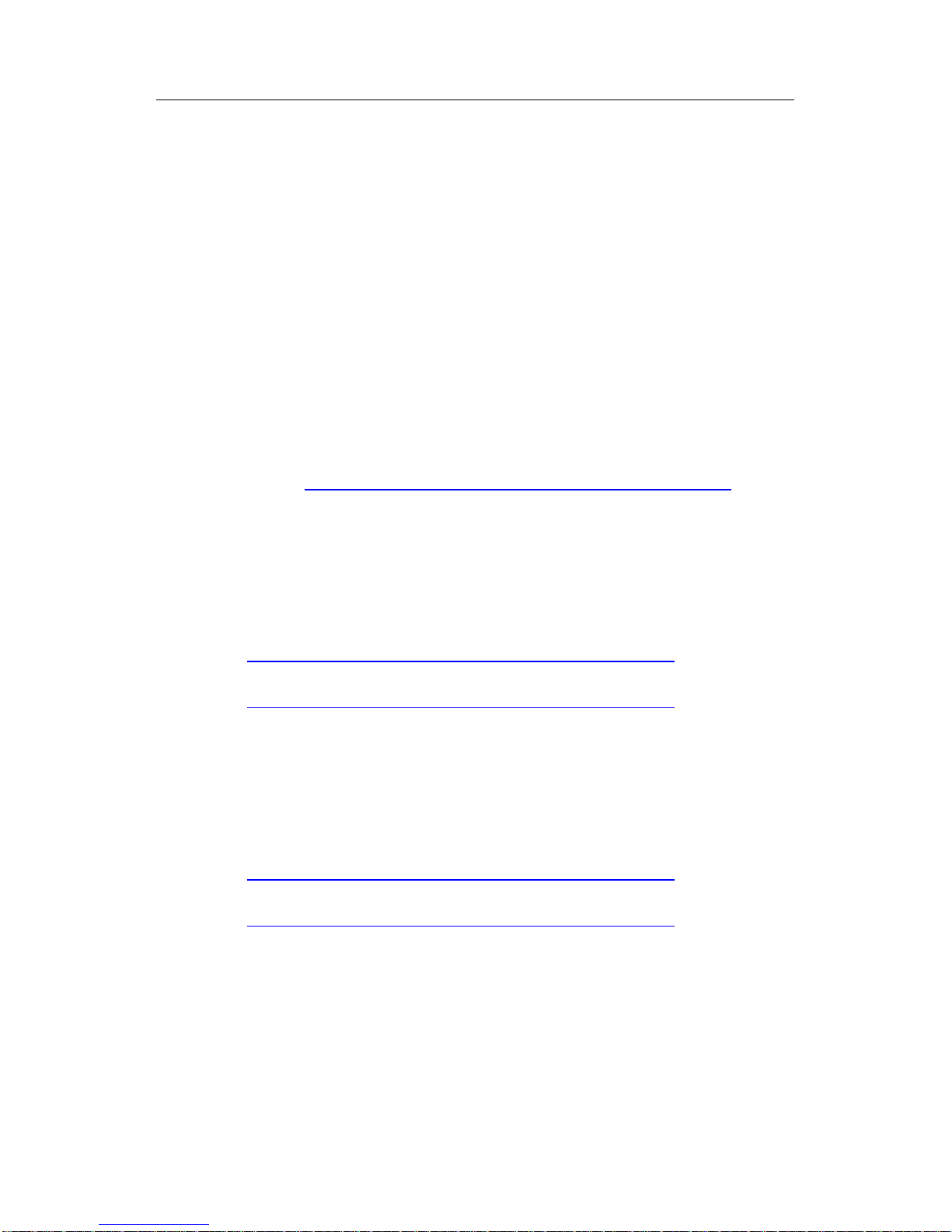

1. Open STEP 7,and click File->New...to create a new project in name of ptp.

Fig. 2: Dialog box of New project

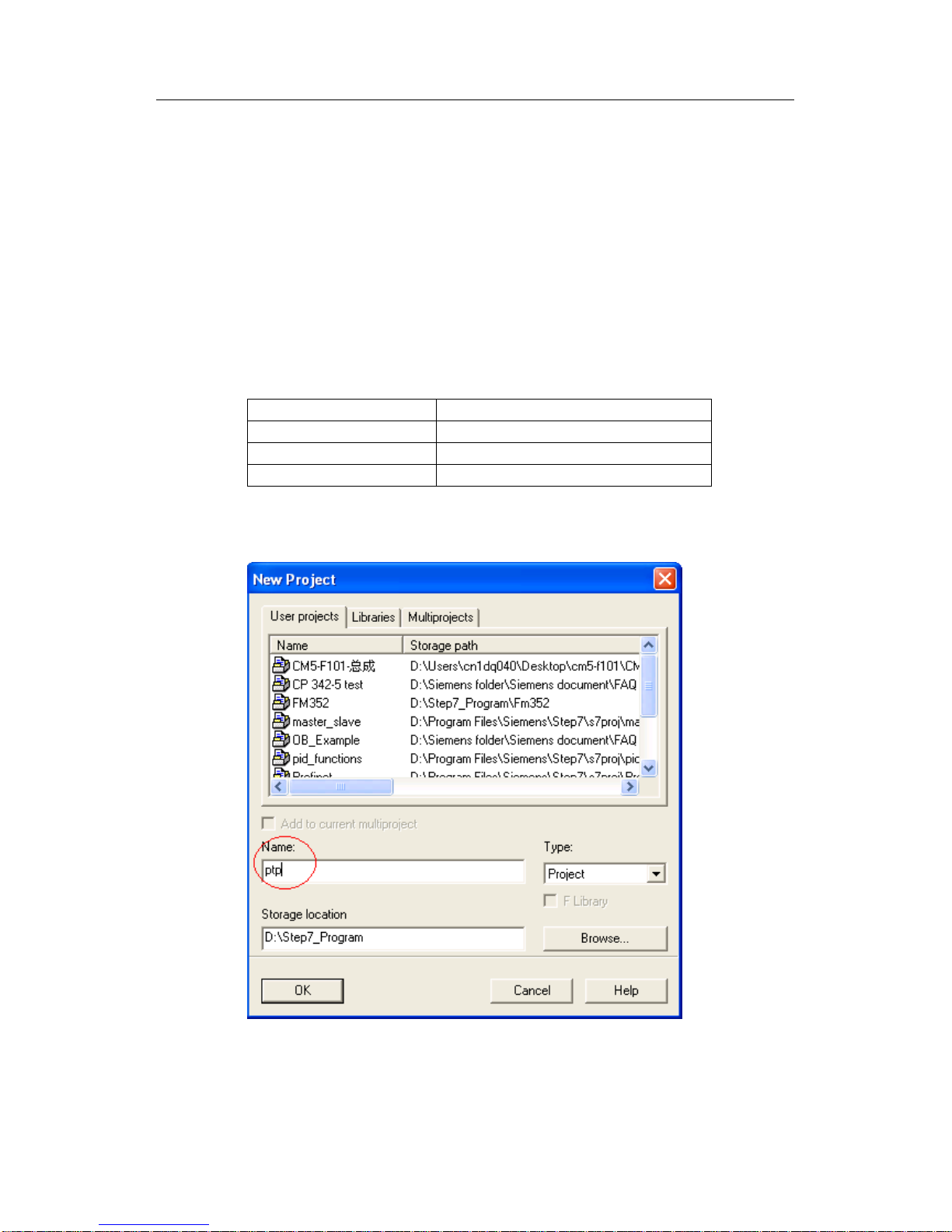

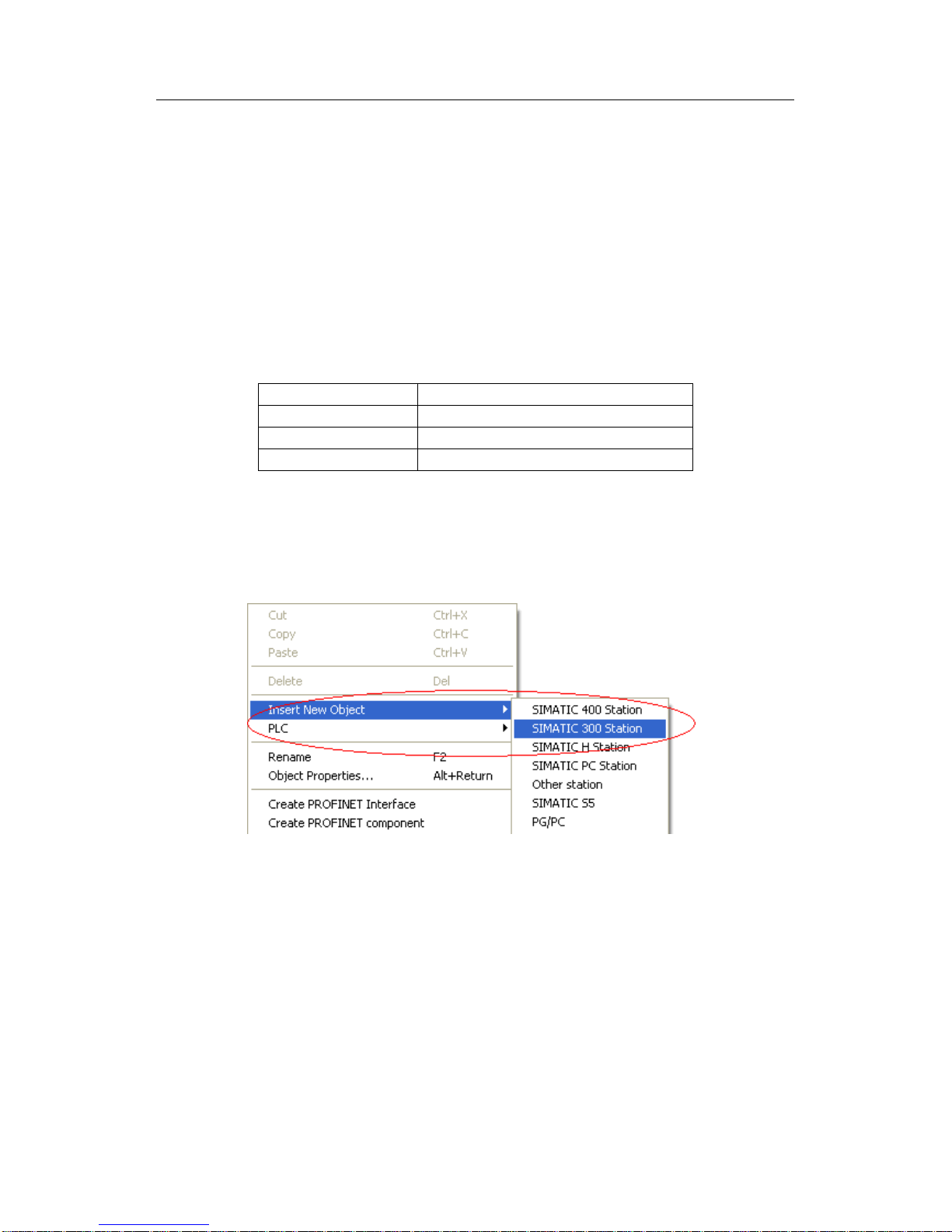

2. Right-click the project name, select Insert New Object->SIMATIC 300 Station to

change the station name to CP340 ASCII.

Page 8

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

8

Siemens AG 2014 All rights reserved

Fig. 3: Insert S7-300 station

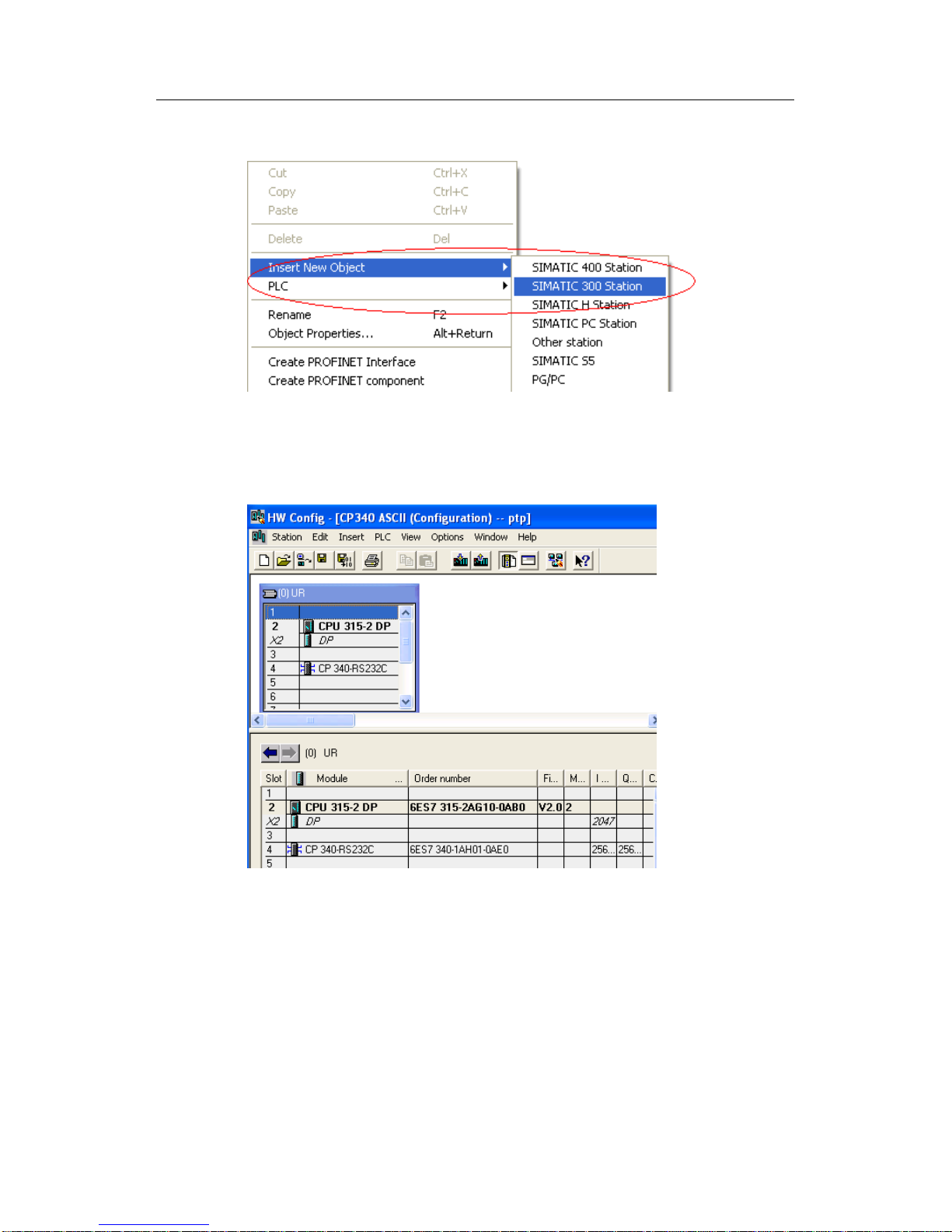

3. Double-click Hardware to enter the hardware configuration interface and insert

RACK, CPU315-2DP and CP340.

Fig. 4: Configuration hardware

Page 9

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

9

Siemens AG 2014 All rights reserved

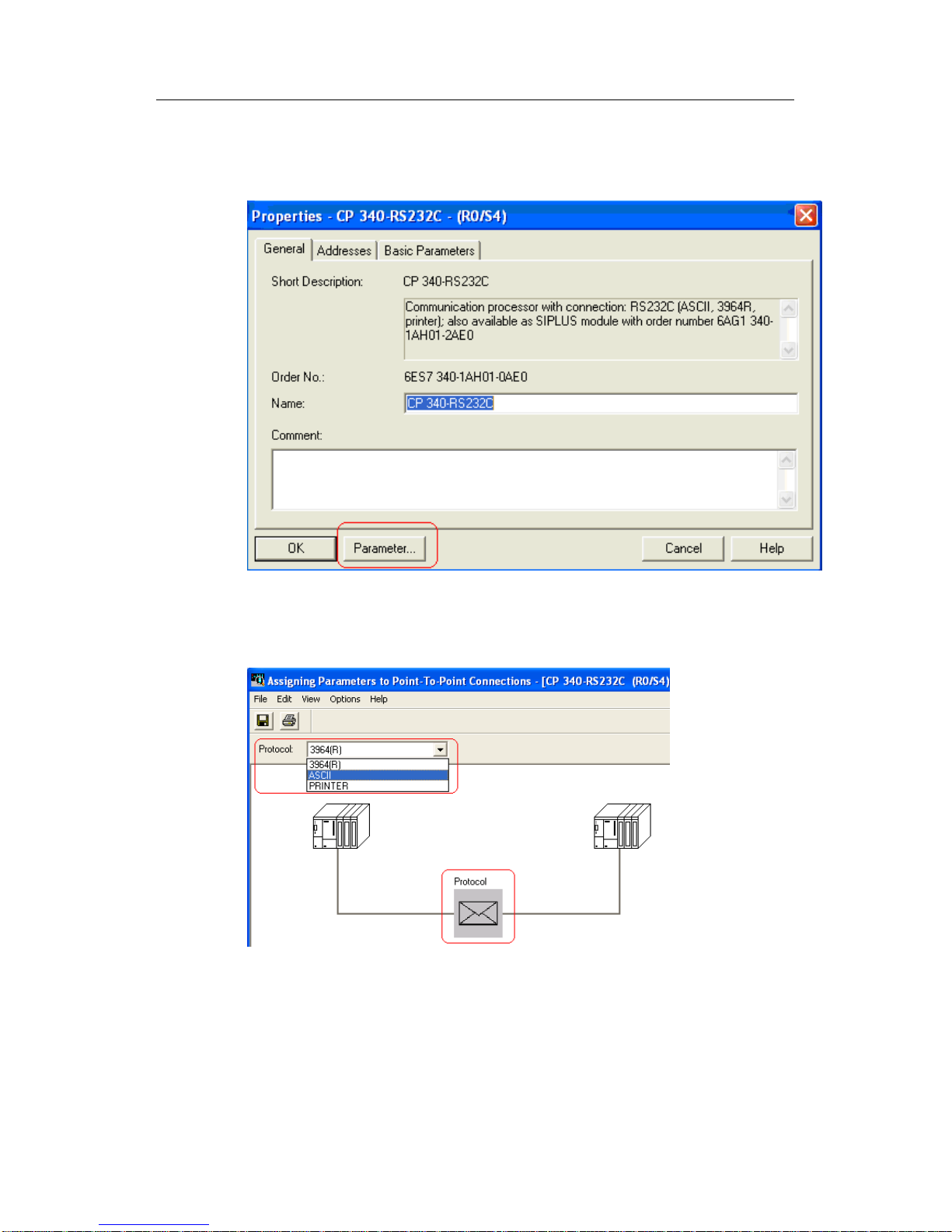

4. Double-click CP340 module, and click Parameter... to configure CP340

parameters.

Fig. 5: CP340 Properties dialog box

5. Select ASCII from Protocol options.

Fig. 6: Protocol selection

Page 10

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

10

Siemens AG 2014 All rights reserved

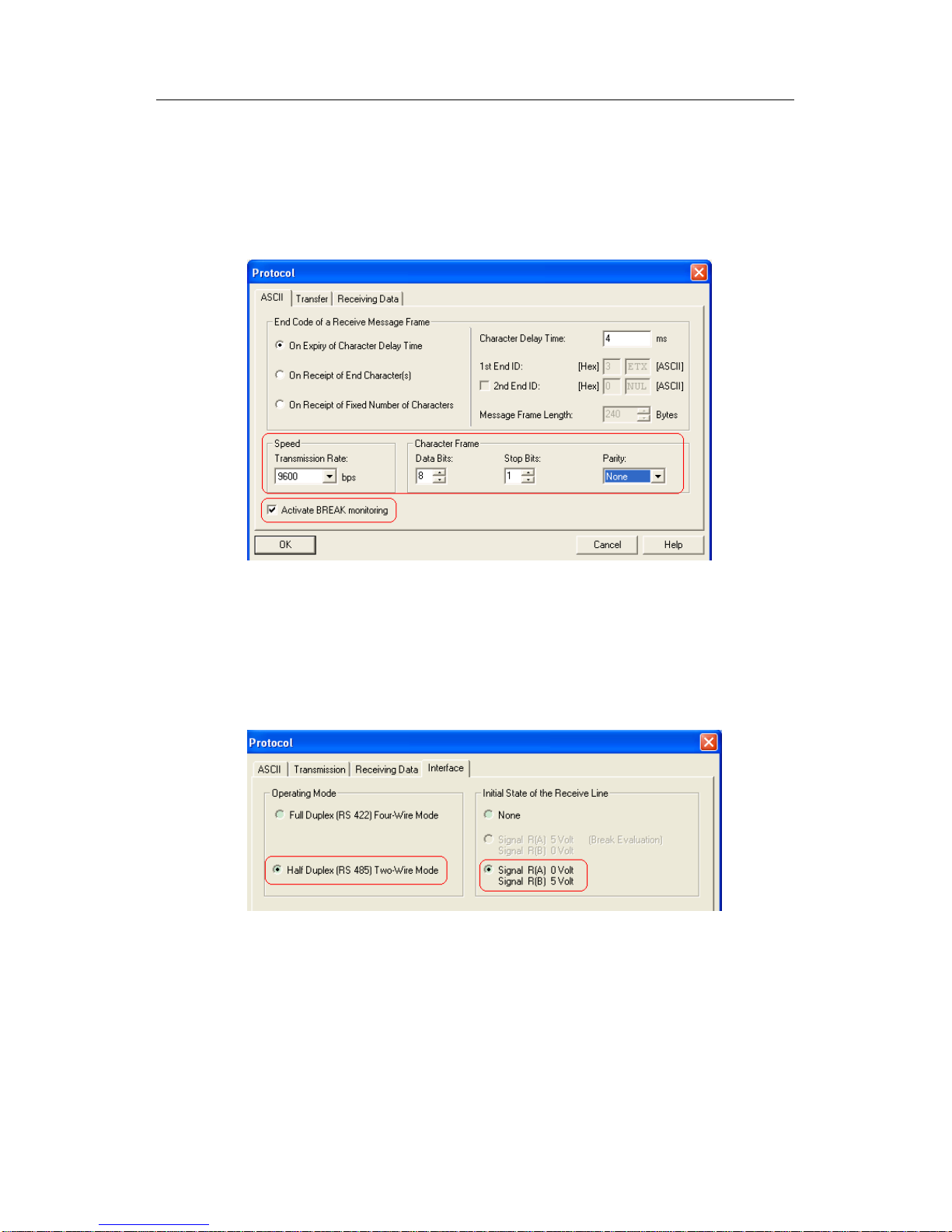

6. Double-click the envelop icon under Protocol to configure ASCII communication

parameters. The set communication parameters shall be the same as those of the

communication partner. Communication Baud rate: 9600bps,Data bit: 8 bits,

Stop bit: 1 bit, Parity: none, Character delay time: 4ms, Other parameters shall be

in default settings.

Fig. 7: Distributing communication parameters for ASCII protocol

As shown in the Fig. above, if "Activate BREAK monitoring" is selected, the SF red

indicator of CP340 will be on when RS232C cable is not connected or the serial

port of the communication partner is not activated.

7. If CP340 in RS422/485 interface is selected, the interface properties shall also

be set, as shown below:

Fig. 8: Configuration interface parameters

When the interface is in RS485 type (half-duplex mode), the initial state of the

receive side will be R(A)0V/R(B)5V, and it will not support wire-break detection

function. When the interface is in RS422 type (full-duplex mode) and the initial

state of the receive side is set as R(A)0V/R(B)5V, it will support wire-break

detection function. These 2 states correspond to the following interface pins of the

communication partner receive side:

Page 11

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

11

Siemens AG 2014 All rights reserved

Fig. 9: Wiring of receiver at interface RS485/422

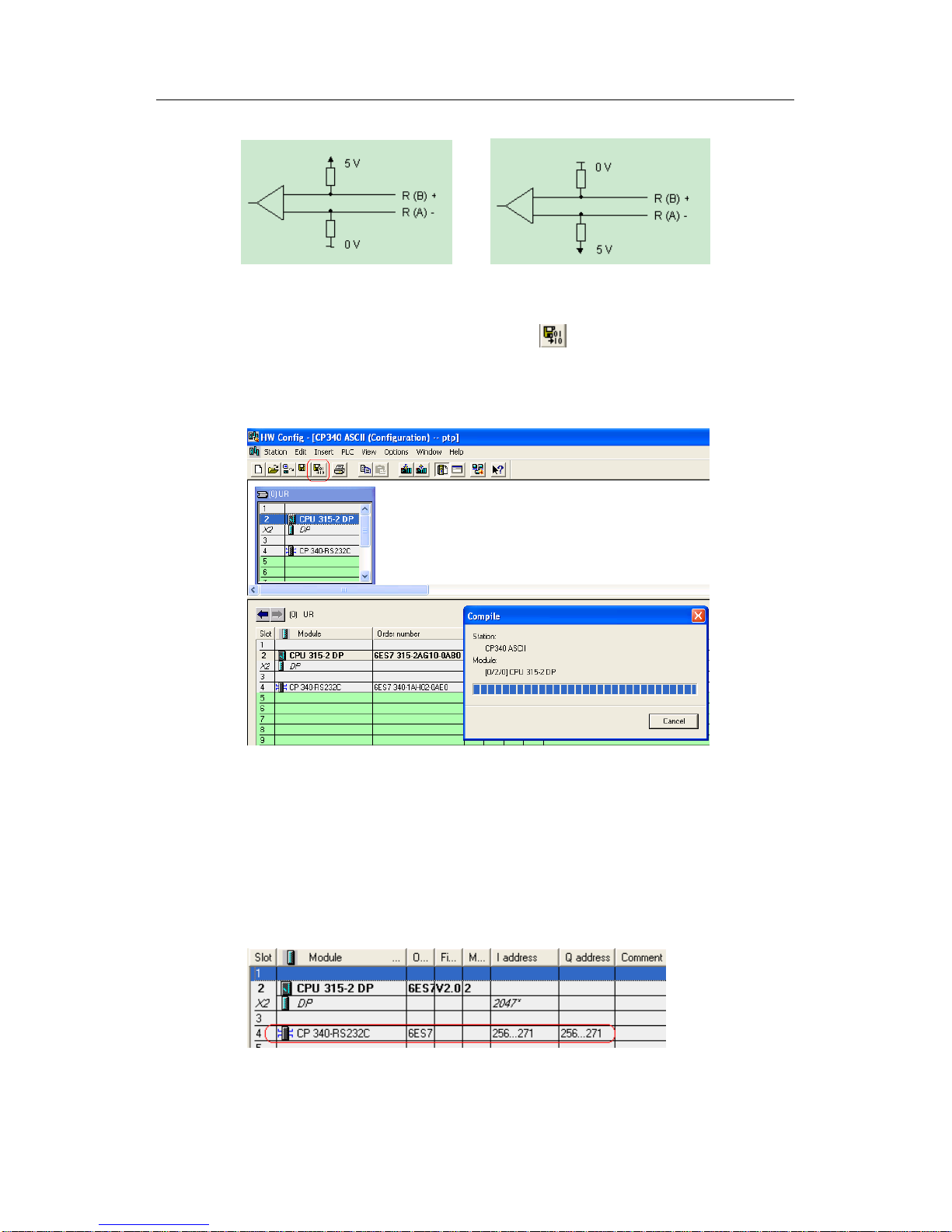

8. After the parameters are configured, click button to save and compile the

hardware configurations. After it is confirmed that no error exists, download the

hardware configurations to CPU to complete the whole hardware configuration

process.

Fig. 10: Compile and save hardware configuration

4.1.3 Write communication program

1. Double-click OB1 to open OB1 programming screen. Invoke Send Function

Block FB3 P_SEND from Libraries -> CP PtP -> CP340 and distribute instance

data block DB3 to it. Set the block parameter LADDR as the start logic address 256

for module CP340 in hardware configuration.

Fig. 11: Logic address of CP340

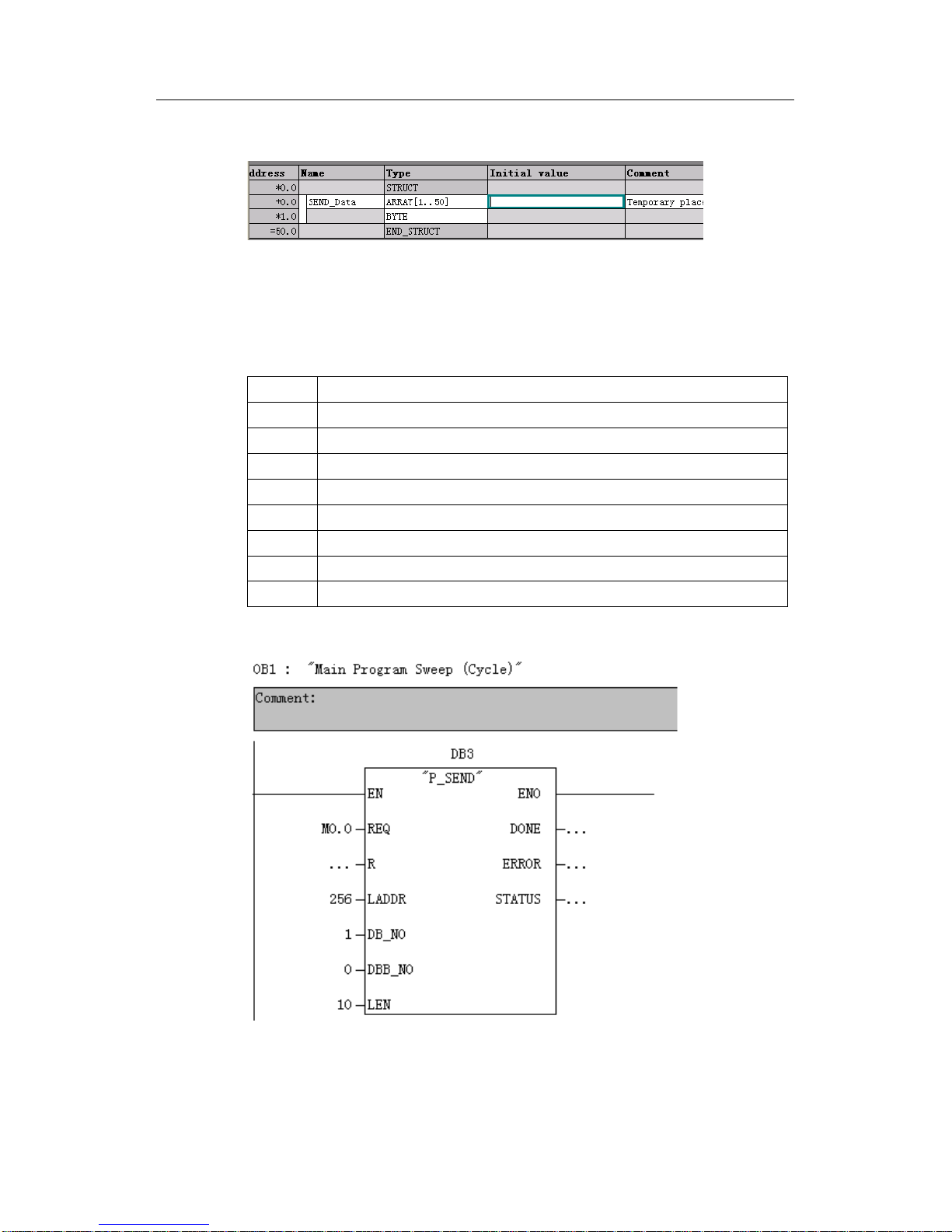

2. Create Send Data block DB1.

R(A)0V/R(B)5V

R(A)5V/R(B)0V

Page 12

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

12

Siemens AG 2014 All rights reserved

Fig. 12: Send Data block DB1

3. Invoke Send Function block

The parameters of the send function block FB3 P_SEND of CP340 are set as in

the table below:

LADDR

Start logic address in hardware configuration, which is 256 in this example

DB_NO

Send Data block number, which is 1(DB1) in this example

DBB_NO

Start address of Send Data, which is 0(DB1.DBB0) in this example

LEN

Length of send data, which is 10 in this example

REQ

trigger bit of Send Data, rising edge trigger, which is M0.0 in this example

R

Cancel communication, which is not available in this example

DONE

send complete bit, which is TRUE if Send completes and has no error

ERROR

error bit, TRUE indicating that it has an error

STATUS

Status word, ID error code. See CP340 manual for related descriptions

Table 3: Parameter definition of FB3 P_SEND

Fig. 13: Invoke FB3 P_SEND from OB1

4. Invoke Receive Function Block FB2 P_RCV from Libraries -> CP PtP -> CP340

and distribute instance data block DB2 to it. Set LADDR as the start logic address

256.

Page 13

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

13

Siemens AG 2014 All rights reserved

5. Create receive data block DB10.

Fig. 14: Receive data block DB10

6. Invoke receive function block

The parameters of the receive function block FB2 P_RCV of CP340 are set as in

the table below:

LADDR

Start logic address in hardware configuration, which is 256 in this example

DB_NO

Send Data block number, which is 10(DB10) in this example

DBB_NO

Start address of Send Data, which is 0(DB10.DBB0) in this example

LEN

Length of receive data, which is MW2 in this example. This value is not 0 only

in the current cycle when data are received. The length of received data may

be determined by checking the MW4 value.

EN_R

Enable receive bit, which is M0.1 in this example.

R

Cancel communication, which is not available in this example

NDR

Receive complete bit, which is TRUE if Receive completes and has no error

ERROR

error bit, TRUE indicating that it has an error

STATUS

status word, ID error code. See CP340 manual for related descriptions

Table 4: Parameter definition of FB2 P_RCV

Fig. 15: Invoke FB2 P_SEND from OB1

Page 14

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

14

Siemens AG 2014 All rights reserved

4.1.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP340 and computer. The

detailed cable connecting method may be seen in CP340 Manual - Chapter B:

Connecting cables.

4.2 ASCII protocol communication of CP341

4.2.1 Hardware catalog

PS 307

6ES7 307-1EA00-0AA0

CPU 315-2DP

6ES7 315-2AG10-0AB0

MMC

6ES7 953-8LG11-0AA0

CP341

6ES7 341-1AH01-0AE0

4.2.2 Configuration

1. Open the project ptp created above, and right-click the project name, select

Insert New Object->SIMATIC 300 Station to change the station name to CP341

ASCII.

Fig. 19: Insert S7-300 station

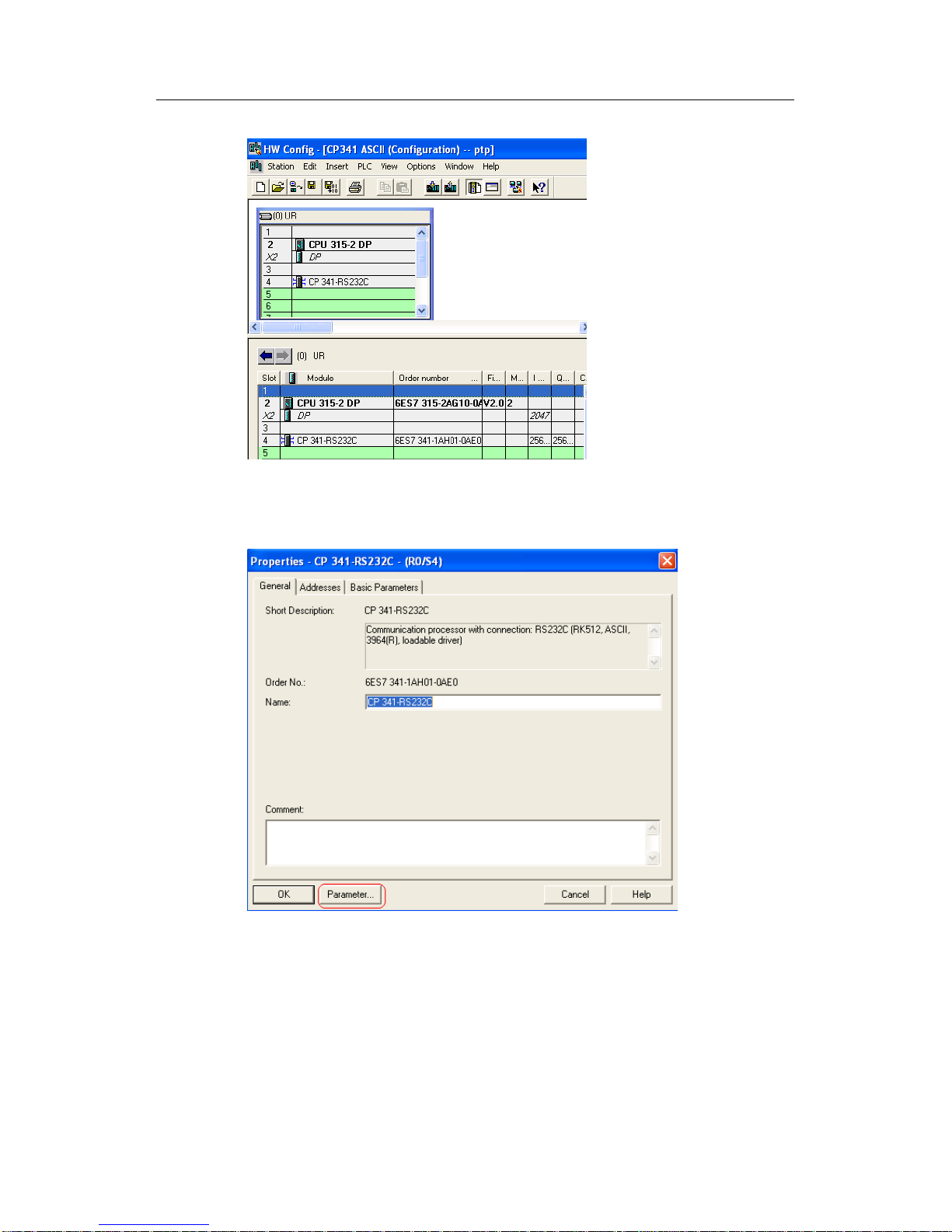

2. Double-click Hardware to enter the hardware configuration interface and insert

RACK, CPU315-2DP and CP341.

Page 15

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

15

Siemens AG 2014 All rights reserved

Fig. 20: Configuration hardware

3. Double-click CP341 module, and click Parameter... to configure CP341

parameters.

Fig. 21: CP341 Properties dialog box

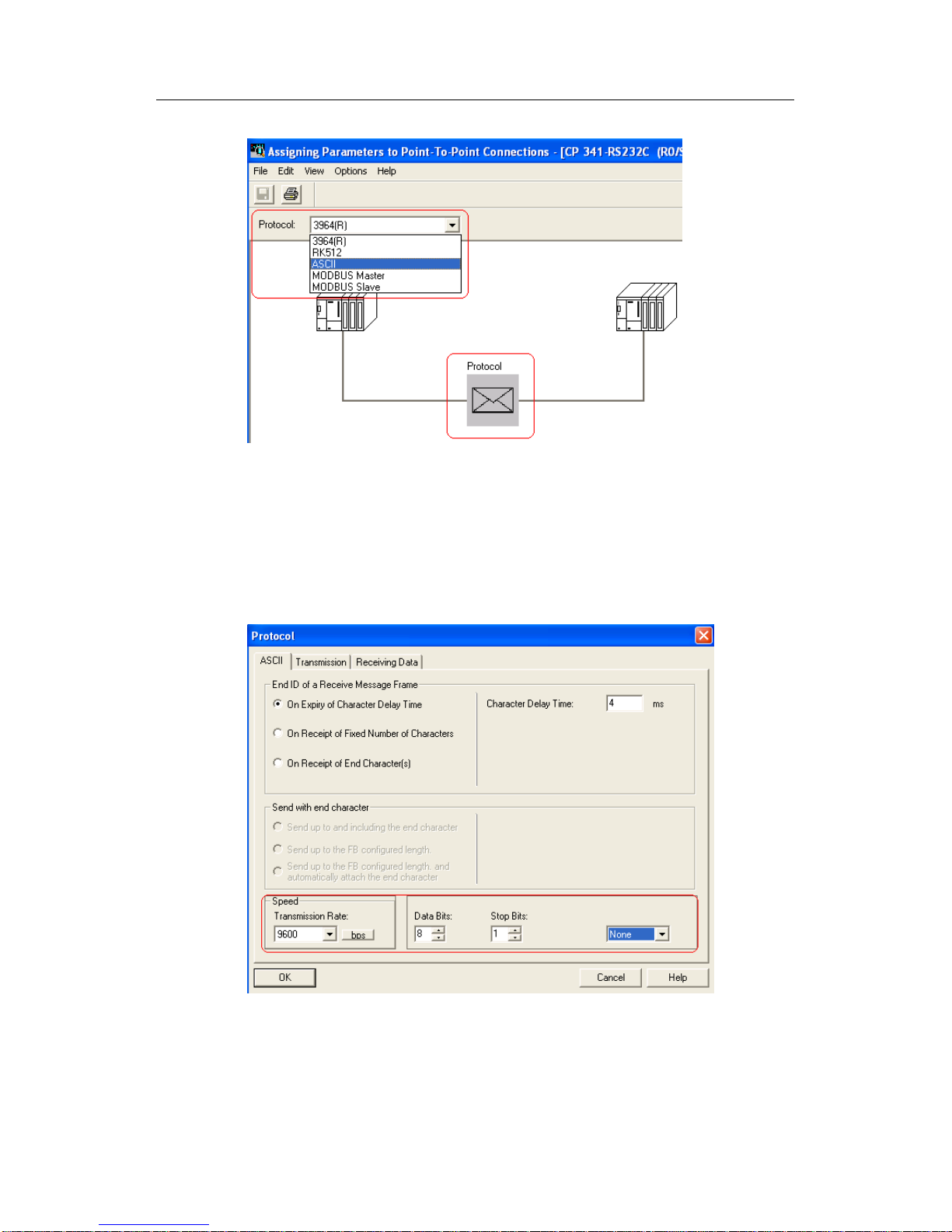

4. Select ASCII protocol from Protocol options.

Page 16

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

16

Siemens AG 2014 All rights reserved

Fig. 22: Protocol selection

5. Double-click the envelop icon under Protocol to configure ASCII communication

parameters. The set communication parameters shall be the same as those of the

communication partner. Communication Baud rate:9600bps,Data bit: 8 bits, Stop

bit: 1 bit, Parity: none, Character delay time:4ms,Other parameters shall be in

default settings.

Fig. 23: Distributing parameters for ASCII protocol

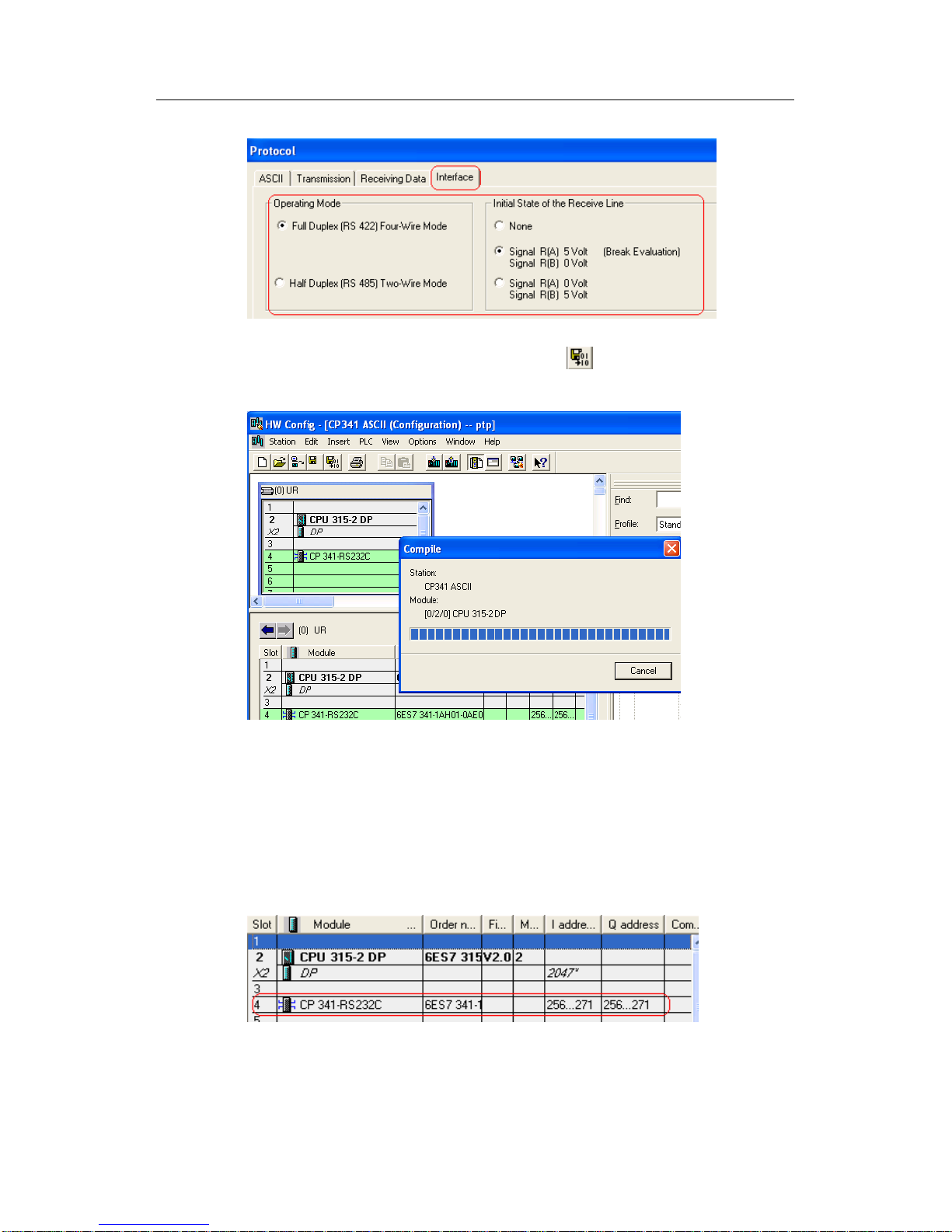

6. If CP341 in RS422/485 interface is selected, the interface properties shall also

be set, as shown in the Fig. below. Refer to the text above for initial state of receive

side.

Page 17

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

17

Siemens AG 2014 All rights reserved

Fig. 24: Configuration interface parameters

7. After completing configuration, user may click button to save and compile

the hardware configuration and download it to CPU after confirming that no error

exists. The whole hardware configuration process is completed by now.

Fig. 25: Compile and save hardware configuration

4.2.3 Write communication program

1. Double-click OB1 to open OB1 programming screen. Invoke Send Function

Block FB8 P_SND_RK from Libraries -> CP PtP -> CP341 and distribute instance

data block DB8 to it. Set the parameter LADDR as the start logic address 256 for

module CP340 in hardware configuration.

Fig. 26: Logic address of CP341

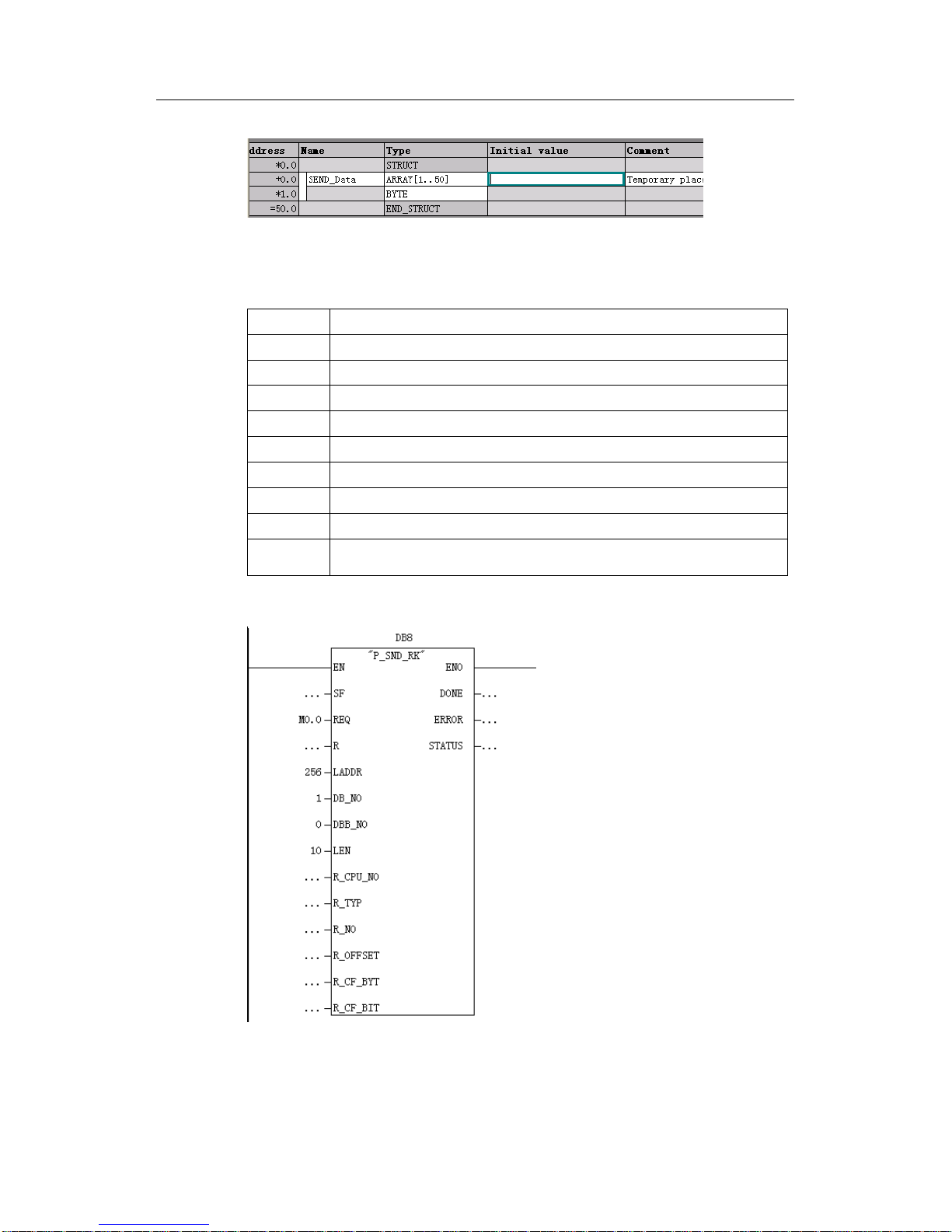

2. Create Send Data block DB1.

Page 18

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

18

Siemens AG 2014 All rights reserved

Fig. 27: Send Data block DB1

3. Invoke Send Function block

The parameters of the send function block FB8 P_SND_RK of CP341 are set as in

the table below:

LADDR

Start logic address in hardware configuration, which is 256 in this example

DB_NO

Send Data block number, which is 1(DB1) in this example

DBB_NO

Start address of Send Data, which is 0(DB1.DBB0) in this example

LEN

Length of send data, which is 10 in this example

REQ

trigger bit of Send Data, rising edge trigger, which is M0.0 in this example

R

Cancel communication

DONE

send complete bit, which is TRUE if Send completes and has no error

ERROR

error bit, TRUE indicating that it has an error

STATUS

status word, ID error code. See CP341 manual for related descriptions

Other

parameters

Irrelevant to ASCII communication protocol, and not available in this

example

Table 5: Parameter definition of FB8 P_SND_RK

Fig. 28: Invoke FB8 P_SND_RK from OB1

Page 19

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

19

Siemens AG 2014 All rights reserved

4. Invoke Receive Function Block FB7 P_RCV_RK from Libraries -> CP PtP ->

CP341 and distribute instance data block DB7 to it. Set LADDR as the start

logic address 256 in hardware configuration.

5. Create receive data block DB10

Fig. 29: Receive data block DB10

6. Invoke receive function block

The parameters of the receive function block FB8 FB7 P_RCV_RK of CP341

are set as in the table below:

LADDR

Start logic address in hardware configuration, which is

256 in this example

DB_NO

Send Data block number, which is 10(DB10) in this

example

DBB_NO

Start address of Send Data, which is 0(DB10.DBB0) in

this example

LEN

Length of receive data, which is MW2 in this example.

This value is not 0 only in the current cycle when data are

received. The length of received data may be determined

by checking the MW4 value.

EN_R

Enable receive bit, which is M0.1 in this example.

R

Cancel communication, which is not available in this

example

NDR

Receive complete bit, which is TRUE if Receive

completes and has no error

ERROR

error bit, TRUE indicating that it has an error

STATUS

status word, ID error code. See CP341 manual for related

descriptions

Other

parameters

Irrelevant to ASCII communication protocol, and not

available in this example

Table 6: Parameter definition of FB7 P_RCV_RK

Page 20

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

20

Siemens AG 2014 All rights reserved

Fig. 30: Invoke FB7 P_RCV_RK from OB1

4.2.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP341 and computer. The

detailed cable connecting method may be seen in CP341 Manual - Chapter B:

Connecting cables.

4.3 ASCII protocol communication of CP440

4.3.1 Hardware catalog

RACK-400

6ES7 400-1JA01-0AA0

PS407

6ES7 407-0KA02-0AA0

CPU

6ES7 414-3XJ04-0AB0

CP440

6ES7 440-1CS00-0YE0

4.3.2 Configuration

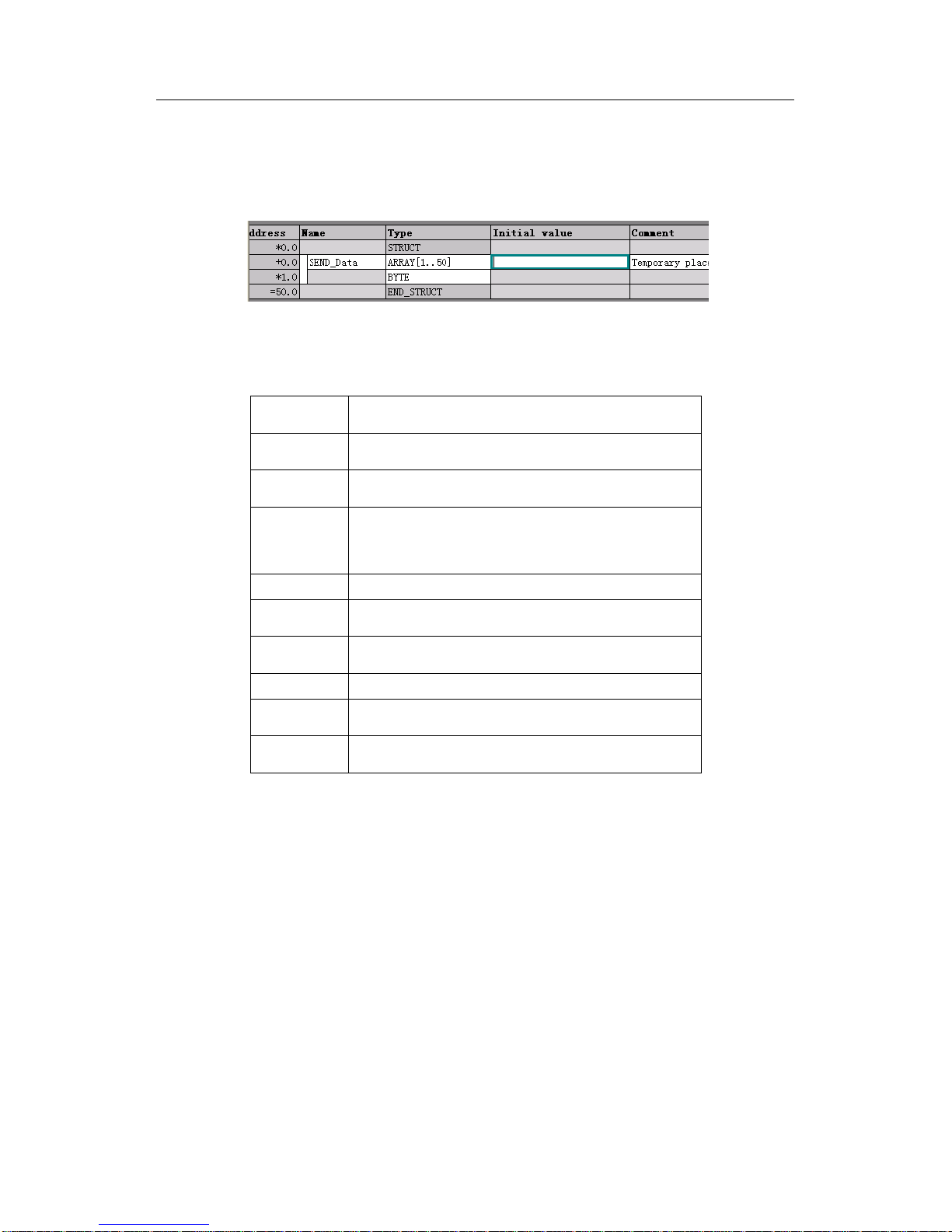

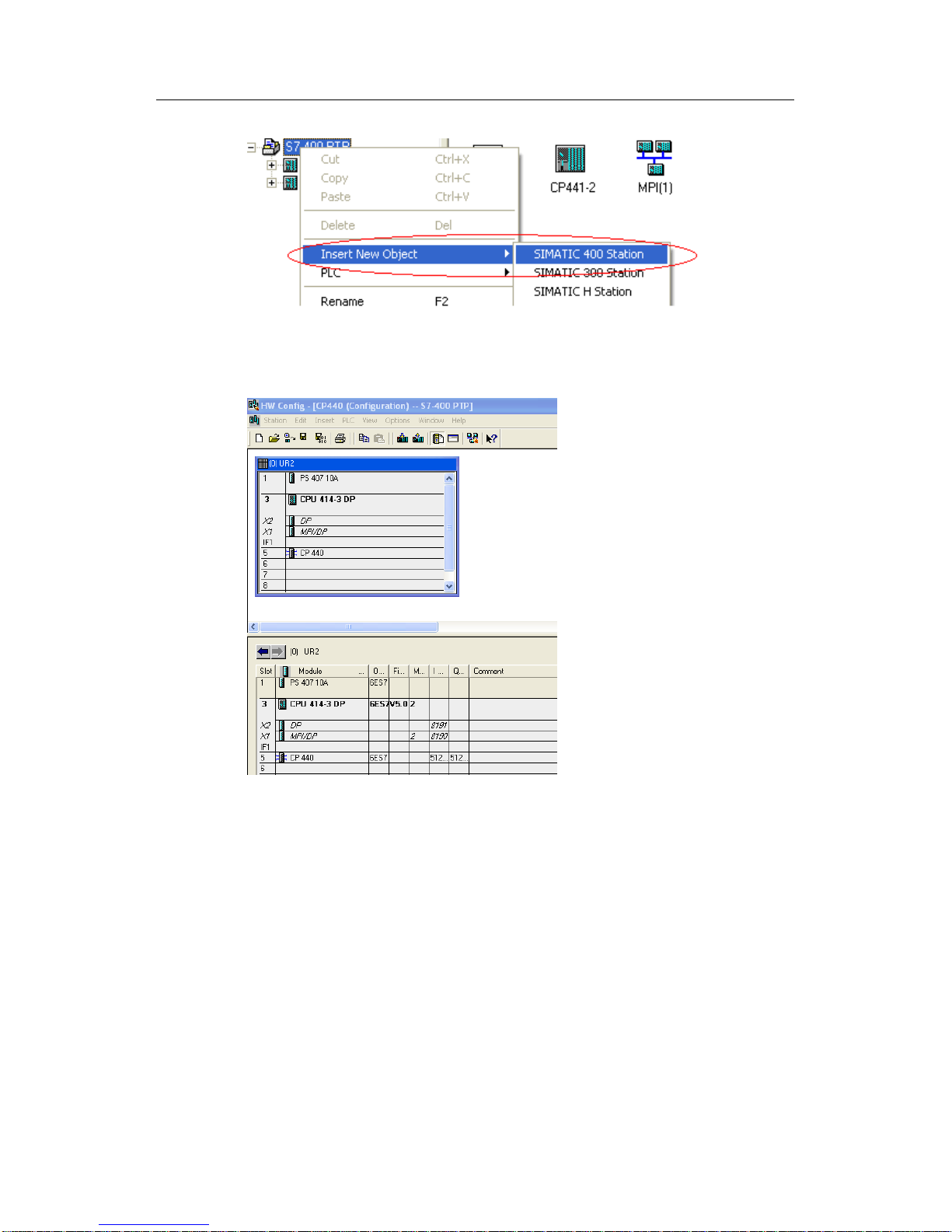

1. Open the project ptp that has been created, and right-click the project name,

select Insert a new SIMATIC 400 Station to change the station name to CP440

ASCII.

Page 21

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

21

Siemens AG 2014 All rights reserved

Fig. 34: Insert S7-400 station

2. Double-click Hardware to enter the hardware configuration screen and insert

RACK-400,PS407,CPU414-3DP and CP440.

Fig. 35: Configuration hardware

3. Double-click CP440 module and click Parameter to configure CP440

parameters, and select ASCII protocol in Protocol options.

Page 22

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

22

Siemens AG 2014 All rights reserved

Fig. 36: Protocol selection

4. Double-click the envelop icon in Protocol to configure the performance

parameters in it. The set communication parameters must match those of the

communication partner. Baud rate: 9600bps,Data bit: 8 bits,,Stop bit: 1 bit,

Parity: none, Character delay time:4ms,other parameters may use default data.

Fig. 37: Distributing parameters for ASCII protocol

5. As CP440 has only one type of RS422/485 interface, conversion equipment

shall be required if it has different interface from the communication partner, and all

other parameters shall be the same as CP340/341 when in ASCII communication.

Page 23

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

23

Siemens AG 2014 All rights reserved

Fig. 38: Configuration interface parameters

6. After configuration completes, compile and save the hardware configuration,

and download it after it is confirmed correct.

4.3.3 Write communication program

1. Double-click OB1 to open programming screen. Invoke Send Function Block

FB10 SEND_400 from Libraries->CP PtP->CP440 and distribute instance data

block DB10 to it. Set the parameter LADDR as the start logic address 512 in

hardware configuration.

Fig. 39: Logic address of CP440

2. Create a Send Data block DB1

Fig. 40: Send Data block DB1

3. Invoke Send Data block

The parameters of the send function block FB10 SEND_400 of CP440 are set as in

the table below:

Name

Data

comments

Page 24

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

24

Siemens AG 2014 All rights reserved

type

REQ

BOOL

Send Data trigger bit, rising edge

trigger, which is M0.0 in this

example

R

BOOL

Cancel send, discontinue

communication

LADDR

INT

Module start logic address in

hardware configuration, which is

512 in this example

DB_NO

INT

Send Data block number, which

is 1(DB1) in this example

DBB_NO

INT

Start address of Send Data,

which is 0(DB1.DBB0) in this

example

LEN

INT

Length of send data, which is 15

in this example

DONE

BOOL

send complete bit, which is TRUE

if Send completes and has no

error

ERROR

BOOL

error bit, which is TRUE if send

has error

STATUS

WORD

status word indicating error code.

If ERROR = 1, this status word

includes error information, and

user may check implication of the

information code online or obtain

the related instruction from

CP440 manual.

Table 7: Parameter definition of FB10 SEND_440

Page 25

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

25

Siemens AG 2014 All rights reserved

Fig. 41: Invoke FB10 SEND_440 from OB1

4. Invoke receive function block FB9 RECV_440 from the same folder in the library

and distribute instance data block DB9 to it, and set LADDR as input start logic

address 512 in hardware configuration.

5. Create receive data block DB2

6. Invoke receive function block

The parameters of the receive function block FB9 RECV_CP440 are set as in the

table below:

Name

Type

Data

format

comments

EN_R

Input

BOOL

Enable receive bit, which is M1.0 in this example.

R

Input

BOOL

Cancel communication and give up receive

LADDR

Input

INT

Module start logic address in hardware

configuration, which is 512 in this example

DB_NO

Input

INT

Receive Data block number, which is 2(DB2) in

this example

DBB_NO

Input

INT

Start address of Receive Data, which is

0(DB2.DBB0) in this example

NDR

Output

BOOL

Receive complete bit, which is TRUE if Receive

completes and has no error

ERROR

Output

BOOL

error bit, which is TRUE if receive has error

LEN

Output

INT

Length (in byte) of receive data, which is not 0 only

in the current cycle when data are received.

STATUS

Output

WORD

status word indicating error code. If ERROR = 1,

this status word includes error information, and

user may check implication of the information code

online or obtain the related instruction from CP440

manual.

Table 8: Parameter definition of FB9 RECV_440

Fig. 42: Invoke FB9 RECV_440 from OB1

Page 26

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

26

Siemens AG 2014 All rights reserved

4.3.4 Equipment connection

CP440 module only provides one 15-pin RS422/485 serial port. Select RS422 or

RS485 interface according to the wiring mode. Only one interface is valid. RS422

is 4-wire and in full-duplex mode while RS485 is 2-wire and in half-duplex mode.

The detailed cable connecting method may be seen in CP440 Manual - Appendix

B: Connecting cables.

4.4 ASCII protocol communication of CP441

CP441 communication module may select sub-module in different interface type

according to the actual application in order to realize communication with one or

more communication partners. CP441-1 (1 selectable sub-module interface),

CP441-2 (2 selectable sub-module interfaces). The sub-module interfaces are in 3

types:

Order number

Interface type

comments

6ES7963-1AA00-0AA0

RS232C

9-pin D type connection

6ES7963-2AA00-0AA0

20mA TTY

9-pin D type connection

6ES7963-3AA00-0AA0

RS422/485

15-pin D type connection

Table 9: CP441 interface sub-module

The configuration process is introduced below with CP441-2 as an example.

4.4.1 Hardware catalog

RACK-400

6ES7 400-1JA01-0AA0

PS407

6ES7 407-0KA02-0AA0

CPU

6ES7 414-3XJ04-0AB0

CP441-2

6ES7 441-2AA03-0AE0

(Interface1:RS232C, interface used in this example)

(Interface2:RS422/485)

Page 27

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

27

Siemens AG 2014 All rights reserved

4.4.2 Configuration

1. Open the project ptp that has been created, and insert a new SIMATIC 400

Station to change the station name to CP441 ASCII. Double-click Hardware to

enter the hardware configuration screen, and insert the related module in steps

stated above.

Fig. 43: Configuration hardware

2. Double-click CP441-2 module and click to enter Basic Parameters. Select

Interface address, and designate interface type of the sub-module. RS232C

interface is used in this example.

Page 28

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

28

Siemens AG 2014 All rights reserved

Fig. 44: Setting of basic interface parameters

3. Click Parameter, and configure CP441-2 parameters.

Fig. 45: Protocol selection

4. Double-click the envelop icon under Protocol to configure ASCII communication

parameters. The set communication parameters shall be the same as those of the

communication partner, and the others shall be in default values. The specific

operations may be seen in the text above, which are not repeated here.

5. After completing configuration, return to Sub-module interface type selection

interface, and click General to enter Interface ->PtP 1 and create a new PtP

subnet, and then click OK to confirm.

Page 29

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

29

Siemens AG 2014 All rights reserved

Fig. 46: Create new PtP network

PtP 1 interface is in connection status at this moment. PtP 2 has the same

configuration, which is not introduced for it is not used in this example.

Fig. 47: Interface status after PtP is connected

6. Then open the configure network icon in the hardware configuration

screen to enter the network configuration interface.

Click to select the CPU in this station, and user may see that communication

connection table appears under the page. Right-click the first line to insert new

connection, and the connection is in "point-to-point connection" type.

Page 30

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

30

Siemens AG 2014 All rights reserved

Fig. 48: Insert a new connection

7. Select "Unspecified" as the connection object. This option is used for

connection with third-party devices and the devices without communication bus,

including S7-CP PtP (CP340,CP341), S5-CP PtP and Printer, etc. If the

communication partner is CP441, it shall be confirmed that it has been connected

to a same PtP subnet and selected directly as the connection object.

Fig. 49: Insert a new connection

Page 31

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

31

Siemens AG 2014 All rights reserved

8. After completing configuration, click OK to confirm. PtP connection properties

screen will pop up at this moment.

Fig. 50: Configuration connection

One parameter Local ID (Hex) in this screen shall be noted for it will be used

when programming to invoke system function block. You may modify it in

manual way to fit the parameters in the program SFB that have been

configured, but its range shall be noted: W#16#1000---W#16#1400。

The "communication direction" may be selected according to the actual

demand. In this example, the third type is used: Two-way communication. Click

OK to confirm and compile the configuration, and download it after it is

confirmed correct.

9. Confirm the connection status online, and click as shown in the Fig.

below. It may be seen that "Connection status" is "set up", showing that the

connection has been created.

Fig. 51: Monitoring of connection status

Page 32

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

32

Siemens AG 2014 All rights reserved

4.4.3 Write communication program

1. Double-click OB1 to open the programming screen. Invoke SFB12 BSEND from

Libraries-> Standard library-> System function blocks, and distribute instance

data block DB12 to it and create send data block DB1.

Fig. 52: Send Data block DB1

2. Invoke send function block. The SFB12 BSEND parameters are set as shown in

the table below:

Name

Data

type

comments

REQ

BOOL

send request bit, rising edge trigger, which is M0.0 in this

example

R

BOOL

Cancel communication

ID

WORD

Local ID number, which is obtained from the PtP connection

properties and is hexadecimal.

R_ID

DWORD

Distinguish double word, which may be any data. However, if the

program uses multiple BSEND blocks, different serial numbers

shall be distributed to them.

SD_1

ANY

Data send area. DB area is used in this example, and the send

data are in 5 bytes.

Other addresses and data types may also be used for access,

and the detailed information may be obtained from Step7 SFB12

online help.

LEN

WORD

Send data length, which is counted in bytes.

DONE

BOOL

Send complete bit, which is set as 1 if the task completes and has

no error.

ERROR

BOOL

Error bit, which is set as 1 in case of error.

STATUS

WORD

Status word, indicating error code. The specific information may

be seen in online diagnosis of module or from CP441 Manual Chapter 9: Diagnosis information

Table 10: Parameter definition of SFB12 BSEND

Page 33

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

33

Siemens AG 2014 All rights reserved

Fig. 53: Invoke SFB12 BSEND from OB1

3. At the same time, invoke SFB13 BRCV to receive data, and distribute

instance data block DB13, and create a new DB block DB2 to receive data.

Fig. 54: Receive data block DB2

Name

Data type

comments

EN_R

BOOL

Receive enable bit, allowing receive when it is

1. M8.0 is used in this example.

ID

WORD

Local ID number, which is obtained from the

PtP connection properties and is hexadecimal.

R_ID

DWORD

W#16#0 must be used when in ASCII, 3964(R)

communication.

RD_1

ANY

Data receive area. DB2 is used in this example

to receive.

LEN

WORD

Receive data length memory area, in bytes

NDR

BOOL

Receive complete bit, which is TRUE if Receive

completes and has no error

ERROR

BOOL

error bit, 1 indicating that it has an error

STATUS

WORD

Status word, indicating error code. The specific

information may be seen in online diagnosis of

module or from CP441 Manual - Chapter 9:

Diagnosis information

Table 11: Parameter definition of SFB13 BRCV

Page 34

4 ASCII protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

34

Siemens AG 2014 All rights reserved

Fig. 55: Invoke SFB13 BRCV from OB1

4.4.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP441-2 interface1 and

computer. The detailed cable connecting method may be seen in CP441 Manual Appendix B: Connecting cables.

Page 35

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

35

Siemens AG 2014 All rights reserved

5 MODBUS RTU Protocol communication

MODBUS RTU communication protocol is in master-slave mode. In the

transmission process, the master sends a request telegram actively to the slave,

and the slave returns an answer telegram. For details of MODBUS RTU protocol,

please refer to related MODBUS RTU files or manuals.

5.1 MODBUS Slave protocol communication of CP341

5.1.1 Hardware catalog

PS 307

6ES7 307-1EA00-0AA0

CPU 315-2DP

6ES7 315-2AG10-0AB0

MMC

6ES7 953-8LG11-0AA0

CP341

6ES7 341-1AH01-0AE0

Dongle

6ES7 870-1AB01-0YA0

Dongle's support is necessary when using CP341 for MODBUS Protocol

communication. Before it is used, install Dongle in the Dongle slot at the back of

the CP341 module. Dongle and CP341 before and after inserting Dongle are

shown as in the Fig. below:

Fig. 57: Before and after inserting Dongle

Page 36

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

36

Siemens AG 2014 All rights reserved

5.1.2 Configuration

1. Open the project ptp created above, and right-click the project name, select

Insert New Object->SIMATIC 300 Station to change the station name to CP341

Modbus-S.

Fig. 58: Insert S7-300 station

2. Double-click Hardware to enter the hardware configuration interface and insert

RACK, CPU315-2DP and CP341.

Fig. 59: Configuration hardware

3. Double-click CP341 module, and click Parameter... to configure CP341

parameters. Select MODBUS Slave from Protocol options.

Page 37

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

37

Siemens AG 2014 All rights reserved

Fig. 60: Selecting communication protocol

4. Double-click the envelop icon under Protocol to configure MODBUS Slave

parameter, and click MODBUS-Slave button.

Fig. 61: Configure MODBUS Slave communication parameter

Step 1: set MODBUS Slave address, which is set as 2 in this example

Step 2: set parameters of MODBUS Slave, such as Baud rate, stop bit and check

bit, etc.

Then configure the parameters represented by the function codes. For details, see

the four figures below.

5. FC01,05,15: status of read and forced output bit. The left side is info transfer

address, and the right side is corresponding PLC address area, viz. the left

addresses from 0 to 100 match MODBUS address area 00001 to 00101, and the

Step 1

Step 2

Page 38

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

38

Siemens AG 2014 All rights reserved

corresponding Siemens data area is M0.0-M12.4. 101 to 200 match the MODBUS

Address area 00102 to 00201, and the corresponding Siemens data area is Q0.0

to Q12.3. The slave addresses 201 to 300 and 301 to 400 match the Modbus

address areas 00202 to 00301 and 00302 to 00401, and the corresponding

Siemens data area is Timer, Counter.

Fig. 62: Distribution of MODBUS Slave addresses

6. FC02 reads input data status, and the address matching is as stated above.

Fig. 63: Distribution of MODBUS Slave addresses

7. FC03,06,16 configuration output register data area corresponds to Siemens

data area DB block.

Fig. 64: Distribution of MODBUS Slave addresses

8. FC04 configuration input register data area also corresponds to Siemens data

area DB block.

Page 39

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

39

Siemens AG 2014 All rights reserved

Fig. 65: Distribution of MODBUS Slave addresses

9. Setting limit values for writing parameters

Fig. 66: Write parameter limit values for MODBUS Slave

10. If CP341 in RS422/485 interface is selected, the interface type shall also be set

as shown in the Fig. below, and other parameters shall be in default settings.

Fig. 67: Interface parameter assignment of MODBUS Slave

11. After configuration completes, a prompt will ask you whether you load the driver

before it is saved.

Page 40

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

40

Siemens AG 2014 All rights reserved

Fig. 68: Dialog box prompting loading driver

12. At this moment it must be connected to the actual PLC. Click Yes to load the

driver. The CPU must be in STOP mode when in loading. After the driver is loaded,

STEP7 will prompt "Driver already exists" if you load it another time. After

configuration completes, click button to save and compile the hardware

configuration and confirm that it has no error.

Fig. 69: Compile and save hardware configuration

5.1.3 Write communication program

1. Add FB7 and FB8 into the program Blocks in such method: double-click OB1 to

open OB1 programming screen, invoke send program block FB8 and receive

program block FB7 from Libraries->CP PtP->CP341, and then delete them from

OB1 because these two function blocks will be used in MODBUS Slave

communication.

2. Invoke MODBUS Slave function block FB80 at Libraries->Modbus->Modbus >FB80. Distribute instance data block DB80, and set the parameter LADDR as

start logic address 256 in the hardware configuration.

Page 41

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

41

Siemens AG 2014 All rights reserved

Fig. 70: Logic address of CP341

3. Invoke MODBUS Slave function block

LADDR

Start logic address in hardware configuration,

which is 256 in this example

START_TIME

timeout initialization timer, which is T1 in this

example

START_TIME

timeout initialization time value, which is 1s in

this example

OB_MASK

I/O access error mask bit, which is M100.0 in

this example

CP_START

FB initialization enable bit, which is M100.1 in

this example

CP_START_FM

CP_START initialization rising edge bit, which is

M100.2 in this example

CP_START_NDR

write from CP operation bit, which is M100.3 in

this example

CP_START_OK

initialization succeed flag, which is M100.4 in

this example

CP_START_ERROR

initialization fail flag, which is M100.5 in this

example

ERROR_NR

error number, which is MW102 in this example

ERROR_INFO

error message, which is MW104 in this

example. Refer to Modbus Slave Manual Chapter 10

Table 12: Parameter definition of FB80

Page 42

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

42

Siemens AG 2014 All rights reserved

Fig. 71: Invoke FB80 from OB1

4. Create FC03,06,16 function code communication data block DB1.

Fig. 72: Communication data block DB1

5. Create FC04 function code communication data block DB2.

Fig. 73: Communication data block DB2

5.1.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP341 and computer.

The detailed cable connecting method may be seen in CP341 Manual Chapter B: Connecting cables.

5.1.5 Communication test

1. Download hardware configuration and program into CPU315-2DP firstly. Open

MODBUS master emulation software Modscan32 in the computer.

Page 43

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

43

Siemens AG 2014 All rights reserved

Fig. 74: Open Modscan32 software

2. Click Connection->Connect in Modscan32, as shown in the screen below.

Select COM port COM1 connecting the computer with CP341, and set the Baud

rate, data bit, stop bit and check mode, as shown in the Fig. below:

Fig. 75: Setting of Modscan32 communication parameter

3. After setting completes, click OK, and the following screen will be shown.

Page 44

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

44

Siemens AG 2014 All rights reserved

Fig. 76: Modscan32 operation interface

4. The 10 address data of the data display area correspond to the numeric values

(1-10 for DBW0 - DBW10 respectively)of the first 10 words of DB1 in CPU, as

shown in the Fig. below.

Fig. 77: DB1 data monitor

5. It is only necessary to change the accessed data type in order to read other

data, which is not introduced here.

6. For display of floating point number, it shall be explained that the high 16 bits

and low 16 bits of the floating point number in PLC are opposite to those displayed

in Modscan32, or in other words, the high 16 bits of the floating point number in

PLC correspond to the low 16 bits of the floating point number displayed in

Modscan32, and the low 16 bits of the floating point number in PLC correspond to

the high 16 bits of the floating point number displayed in Modscan32, which may

be handled in the program, as shown in the Fig. below:

Set data display method

Modbus slave

address

Modbus initial

address and length

Type of data accessed by

Modbus

Data display area

Page 45

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

45

Siemens AG 2014 All rights reserved

Fig. 78: Floating point number data processing

At this moment, the floating point number 40001 displayed in Modscan32

corresponds to the floating point number value of MD200, but MODBUS address

corresponds to DB1.DBD0.

Fig. 79: Floating point number data exchange

If CP341 module with RS422/RS485 interface is used, RS422/485 converter shall

be used when using computer serial port debugging program.

5.2 MODBUS Master protocol communication of CP341

5.2.1 Hardware catalog

PS 307

6ES7 307-1EA00-0AA0

CPU 315-2DP

6ES7 315-2AG10-0AB0

MMC

6ES7 953-8LG11-0AA0

CP341

6ES7 341-1AH01-0AE0

Dongle

6ES7 870-1AA01-0YA0

Insert Dongle into CP341, and the Dongle and CP341 before and after Dongle is

inserted are shown in the Fig. below:

Page 46

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

46

Siemens AG 2014 All rights reserved

Fig. 80: Before and after inserting Dongle

5.2.2 Configuration

1. Open the project ptp created above, and right-click the project name, select

Insert New Object->SIMATIC 300 Station to change the station name to CP341

Modbus-M.

Fig. 81: Insert S7-300 station

2. Double-click Hardware to enter the hardware configuration interface and insert

RACK, CPU315-2DP and CP341.

Page 47

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

47

Siemens AG 2014 All rights reserved

Fig. 82: Configuration hardware

3. Double-click CP341 module, and click Parameter... to configure CP341

parameters. Select MODBUS Master from Protocol options.

Fig. 83: Selecting communication protocol

4. Double-click the envelop icon under Protocol to configure Modbus Master

parameter, and click Modbus-Master button to set communication Baud rate,

etc.

Page 48

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

48

Siemens AG 2014 All rights reserved

Fig. 84: Configure MODBUS Master communication parameter

5. After configuration completes, a prompt will ask you whether you load the

driver before it is saved.

Fig. 85: Dialog box prompting loading driver

6. At this moment, it must be connected to the actual PLC. Click Yes to load

the driver or click Load Drivers. The CPU must be in STOP mode when in

loading.

Fig. 86: Load drivers

After the driver is loaded, STEP7 will prompt "Driver already exists" if you load

it another time. After configuration completes, click button to save and

compile the hardware configuration and confirm that it has no error.

Page 49

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

49

Siemens AG 2014 All rights reserved

Fig. 87: Compile and save hardware configuration

5.2.3 Write communication program

1. Double-click OB1 to open OB1 programming screen. Invoke send program

block FB8 P_SND_RK from Libraries -> CP PtP -> CP341 and distribute instance

data block DB8 to it. Set the parameter LADDR as the input start logic address 256

in hardware configuration.

Fig. 88: Logic address of CP341

2. Create send data block DB1, in which the slave address is 2, the function code

is 3 and start address is 0. Read 4 register data. For use of the function code 3,

see Modbus Master Manual - 5.3: Function Code 03 - Read Output Registers.

Fig. 89: Send Data block DB1

3. Invoke Send Function block

The FB8 P_SND_RK parameter setting may be seen in the table below:

SF

"S" means send, which must be in capital form here.

LADDR

Start logic address in hardware configuration, which is 256 in this

Page 50

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

50

Siemens AG 2014 All rights reserved

example

REQ

trigger bit of Send Data, rising edge trigger, which is M0.0 in this

example

DB_NO

Send Data block number, which is 1(DB1) in this example

DBB_NO

Start address of Send Data, which is 0(DB1.DBB0) in this example

LEN

Length of send data, which is 6 in this example

R_TYP

"X" refers to extended data block, which must be in capital form here.

R

Cancel communication, which is not available in this example

DONE

send complete bit, which is TRUE if Send completes and has no error

ERROR

error bit, TRUE indicating that it has an error

STATUS

Status word, ID error code. See Modbus Master Manual - Chapter 7 for

related description.

Other

parameters

Not applicable in this example.

Table 13: Parameter definition of FB8 P_SND_RK

Fig. 90: Invoke FB8 P_SND_RK from OB1

4. Invoke Receive Function Block FB7 P_RCV_RK from Libraries -> CP PtP ->

CP341 and distribute instance data block DB7 to it. Set LADDR as the input

start logic address 256 in hardware configuration.

Page 51

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

51

Siemens AG 2014 All rights reserved

Fig. 91: Logic address of CP341

5. Create receive data block DB2

Fig. 92:Receive data block DB2

6. Invoke receive function block

The FB7 P_RCV_RK parameter setting may be seen in the table below:

LADDR

Start logic address in hardware configuration, which is 256 in this

example

DB_NO

Send Data block number, which is 2(DB2) in this example

DBB_NO

Start address of Send Data, which is 0(DB2.DBB0) in this example

LEN

Length of receive data, which is MW4 in this example.This value is not

0 only in the current cycle when data are received. The length of

received data may be determined by checking the MW8 value.

EN_R

Enable receive bit, which is M0.3 in this example.

R

Cancel communication, which is not applicable in this example

NDR

Receive complete bit, which is TRUE if Receive completes and has no

error

ERROR

error bit, TRUE indicating that it has an error

STATUS

Status word, ID error code. See Modbus Master Manual - Chapter 7 for

related description.

Other

parameters

Not applicable in this example.

Table 14: Parameter definition of FB7 P_RCV_RK

Page 52

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

52

Siemens AG 2014 All rights reserved

Fig. 93: Invoke FB7 P_RCV_RK from OB1

5.2.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP341 and computer. The

detailed cable connecting method may be seen in CP341 Manual - Chapter B:

Connecting cables.

5.2.5 Communication test

1. Install Modbus Slave test software. After installing, an icon will be

generated on the desktop. Double-click this icon to open Modbus Slave test

software, as shown in the Fig. below:

Page 53

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

53

Siemens AG 2014 All rights reserved

Fig. 94: Open Modbus Slave test software

2. Click the button Register Later. This software may be used for 30 days without

registration, but each time it may only be used for 15min. The software downloaded

from the Internet has no registration code. Then click the menu Connection>connect to configure the serial parameters, which shall be the same as the CP341

parameters.

Fig. 95: Setting communication parameters

3. Click OK, and then select the menu Setup->Slave Definition... to set the

communication data. As CP341 uses function code 3,03 Holding Register shall be

used. The address of the slave accessed by CP341 is 2, and Slave ID is set as 2.

The start address starts from 1. See the screen below:

Page 54

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

54

Siemens AG 2014 All rights reserved

Fig. 96: Setting communication parameters

4. Then set the address 1 to 4 as 111 to 444 respectively, set M0.3 as TRUE in

Step7 Variable table to enable receiving. Then set M0.0 as TRUE ( rising edge

trigger. If it is necessary to re-send, set M0.0 from TRUE to FALSE, and then set it

back to TRUE again). It may be monitored that the values from DB1.DBW0 to

DB1.DBW4 are 111 to 444, as shown in the Fig. below.

Fig. 97: Monitoring of receive data

5. If it is necessary to read the floating point number, it must be set in data format.

Click the menu Display->Float Inverse.

Fig. 98: Setting of floating point number data format

6. Set the values of address 1 and 3 as 1.234 and 5.678 respectively, and trigger

M0.0 to send. You may see that the received data are 1.234 and 5.678, as shown

in the Fig. below:

Page 55

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

55

Siemens AG 2014 All rights reserved

Fig. 99: Monitoring of receive data3

5.3 MODBUS Master protocol communication of CP441-2

5.3.1 Hardware catalog

RACK-400

6ES7400-1JA01-0AA0

PS407

6ES7407-0KA02-0AA0

CPU414-3

6ES7414-3XJ04-0AB0

CP441-2

6ES7441-2AA03-0AE0

Dongle

6ES7870-1AA01-0YA0

Dongle is installed in the same positions as S7-300 and CP341, and both are

behind the module. Refer to the pictures above.

5.3.2 Configuration

1. Open the created project ptp and insert a new SIMATIC 400 Station, and

change the station name to CP441-2 modbus Master. Double-click Hardware to

enter the hardware configuration screen, and insert RACK, PS, CPU and CP441-2.

The specific steps may be seen in the text above.

2. In the CP441-2 module, click Parameter to configure CP441-2 parameters, and

select MODBUS Master in Protocol options.

Page 56

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

56

Siemens AG 2014 All rights reserved

Fig. 100: Selecting communication protocol

3. Double-click the envelop icon under Protocol to configure Modbus Master

parameter, and click Modbus-master button to set the basic parameters such

as communication rate and message details, etc., and other parameters may

be in default settings.

Fig. 101: Configure MODBUS Master communication parameter

4. After completing configuration, click OK and save it, and close the dialog

box. Just as ASCII communication with CP441-2, create PtP connection for the

used interface, and record the Local ID (Hex) connection number.

Page 57

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

57

Siemens AG 2014 All rights reserved

Fig. 102: Configuration connection

5. Click to save and compile the configuration information. If there is no

error, select CPU to download the configuration information as a whole, and

use to check the connection status online till the displayed icon of

"connection status" is: * to indicate correct connection.

6. When CP441 makes MODBUS communication, the "Startup" parameter in

CPU properties shall also be changed.

Fig. 103: Change "Startup" parameter in CPU properties

Page 58

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

58

Siemens AG 2014 All rights reserved

Set “Monitoring Time for” “Transfer of parameters to modules(100ms)” to a

value as small as 3000 (=300s), by which an adequately long time may be

guaranteed to download the used load protocol driver into the CP card.

5.3.3 Write communication program

1. Open OB1. Just as ASCII communication, invoke SFB12 and SFB13 from the

library, and distribute the instance data blocks. The instance data block for SFB12

is DB12, and the data block for send data is DB1.

Fig. 104: Send Data block DB1

2. Invoke Send Function block. The used slave address is 5, the function code is

FC01, the start address is 0, and the statuses of 16 output bits are read. When

using different function code for communication, the definition of the request

telegram may be seen in the related description in MODBUS MASTER Manual Chapter 5: Function code.

Fig. 105: Invoke SFB12 in OB1

3. The supplementary instruction for SFB12 used in Modbus RTU communication

is seen below, and other parameters are defined similarly to those in CP441 ASCII

communication, for which the forgoing chapters may be referred to.

Name

comments

R_ID

For distinguishing of different blocks in a same connection, the value range

in Modbus RTU communication is 0-255, and DW#16#1 is used in this

example.

LEN

The value range depends on the used function code. Please refer to the

table below.

Page 59

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

59

Siemens AG 2014 All rights reserved

Function

code

01

02

03

04

05

06

07

08

11

12

15

16

Length

(in bytes)

6

6

6

6

6

6

2

6

2

2

>6

>6

4. The instance data block of FB13 is DB13, and the receive data DB block DB2 is

created.

Fig. 106: Receive data block DB2

5. Invoke receive function block

Fig. 107: Invoke SFB13 in OB1

The "R_ID" in SFB13 must be set in consistence with the "R_ID" in SFB12 that is

invoked in pair in order to activate the receive information program, so it must be

set as DW#16#1 here. The information on Receive Data length may be seen in

MW20.

Page 60

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

60

Siemens AG 2014 All rights reserved

5.3.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP441-2 interface1 and

computer. The detailed cable connecting method may be seen in CP441 Manual Appendix B: Connecting cables.

5.3.5 Communication test

1. Modbus slave test software is also used. Please refer to the above-stated

operation steps for CP341 test. The slave is set as shown in the Fig. below:

Fig. 108: Setting of Modbus Slave test software

2. Set M8.0 as TRUE in Step7 Variable table to enable receive, and trigger M0.0

in manual way to produce rising edge to enable send. The data communication

results may be shown as in the Fig. below.

Fig. 109: Online monitoring of communication status

corresponds

to DB2.DBB1

corresponds to

DB2.DBB0

Page 61

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

61

Siemens AG 2014 All rights reserved

3. When testing different function codes, just modify the data request telegram

sent by the master.

Fig. 110: Create send data frame

Fig. 111: Invoke SFB13 in OB1

5.4 MODBUS Slave protocol communication of CP441-2

5.4.1 Hardware catalog

RACK-400

6ES7400-1JA01-0AA0

PS407

6ES7407-0KA02-0AA0

CPU414-3

6ES7414-3XJ04-0AB0

CP441-2

6ES7441-2AA03-0AE0

Dongle

6ES7870-1AB01-0YA0

Page 62

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

62

Siemens AG 2014 All rights reserved

5.4.2 Configuration

1. Open the project ptp that has been created, insert a new SIMATIC 400 Station,

and change the station name to CP441-2 modbus Slave.

2. Double-click Hardware to enter the hardware configuration interface, and insert

RACK, PS, CPU, and CP441-2. Please refer to the forgoing chapters for specific

steps.

3. In the CP441-2 module, click Parameter to configure CP441-2 parameters, and

select MODBUS Slave in Protocol options.

Fig. 112: Selecting communication protocol

4. Double-click the envelop icon under Protocol to configure MODBUS Slave

parameter:

Fig. 113: Configure MODBUS Slave communication parameter

5. Set the basic parameters such as communication rate and message details,

etc. In this example, the slave address is set as 100 (the default setting is 222, with

value range from 1 to 255). Then enter the slave function code configuration

interface. The detailed information is seen below:

Page 63

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

63

Siemens AG 2014 All rights reserved

Fig. 114: Distribution of MODBUS Slave addresses

6. FC01, 05, 15: status of read and forced output bit. The left side is info transfer

address, and the right side is corresponding PLC address area, viz. the left

addresses from 0 to 23 match MODBUS address area 00001 to 00024, and the

corresponding Siemens data area is M0.0-M2.7.24 to 47 match the MODBUS

Address area 00025 to 00048, and the corresponding Siemens data area is Q0.0

to Q2.7.Slave addresses 48 to 79 and 80 to 111 match the Modbus address areas

00049 to 00080 and 00081 to 00112, and the corresponding Siemens data area is

Timer, Counter. FC02 reads input data status, and the address matching is as

stated above.

Fig. 115: Distribution of MODBUS Slave addresses

7. FC03,06,16 configuration output register data area corresponds to Siemens

data area DB block.

Page 64

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

64

Siemens AG 2014 All rights reserved

Fig. 116: Distribution of MODBUS Slave addresses

8. FC04 configuration output register data area also corresponds to Siemens data

area DB block.

Fig. 117: Distribution of MODBUS Slave addresses

9. Set write parameter limit values of FC05,06,15,16 :

Fig. 118: Distribution of MODBUS Slave addresses

Page 65

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

65

Siemens AG 2014 All rights reserved

10. After completing configuration, click OK and save it, and close the dialog box.

Just like ASCII-2 as stated above, create PtP connection for the used interface,

and record the Local ID (Hex) connection number.

Fig. 119: Configuration connection

11. Click to compile the configuration information. If no error exists, select CPU

to download the configuration information as a whole, and use to check the

connection status online till "connection status" icon is displayed as:

to indicate correct connection. Just like MODBUS

communication with CP441, the "Startup" parameter in CPU properties shall also

be changed.

Fig. 120: Change "Startup" parameter in CPU properties

Page 66

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

66

Siemens AG 2014 All rights reserved

Set “Monitoring Time for” “Transfer of parameters to modules(100ms)” to a

value as small as 1000 (=100s), by which an adequately long time may be

guaranteed to download the used load protocol driver into the CP card during the

parameter assignment process.

5.4.3 Write communication program

1. Double-click OB1 to open the programming screen. Invoke FB180 in Libraries > Modbus, and distribute instance data block DB180. The function code

communication data DB1 and DB2 for the newly created data block FC03 06 16

and FC04 are both in 50-word array structure.

Fig. 121: Communication data block DB1 and DB2

Page 67

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

67

Siemens AG 2014 All rights reserved

2. The FB180 parameter setting is shown in the table below:

Name

Data type

comments

ID

INPUT/INT

Local ID number, which is obtained from the

PtP connection properties and is

hexadecimal.

START_TIMER

INPUT/TIMER

Initialization timeout timer, which is T5 in

this example

START_TIME

INPUT/S5TIME

initialization timeout time value, which is 5s

in this example

STATUS_TIMER

INPUT/TIMER

communication status read timer, which is

T6 in this example

STATUS_TIME

INPUT/S5TIME

communication status read time value,

which is 2S in this example

OB_MASK

INPUT/BOOL

IO access error mask bit, which is M20.0 in

this example

0:Non-mask IO access error

1:Mask IO access error, and delaying the

alarm

CP_START

INPUT/BOOL

FB initialization enable bit, which is M20.1 in

this example

CP_START_FM

INPUT/BOOL

CP_START initialization rising edge bit,

which is M20.2 in this example

CP_NDR

OUTPUT/BOOL

CP write operation bit, which is M20.3 in this

example

CP_START_OK

OUTPUT/BOOL

initialization succeed complete bit, which is

M20.4 in this example

CP_START_ERR

OR

OUTPUT/BOOL

initialization error flag, which is M20.5 in this

example

ERROR_NR

OUTPUT/WORD

error number, which is MW22 in this

example

ERROR_INFO

OUTPUT/WORD

Error message, which is MW24 in this

example. Refer to the Manual for diagnosis

information

Table 15: Parameter definition of FB180

Page 68

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

68

Siemens AG 2014 All rights reserved

3. Invoke FB180 function block .

Fig. 122: Invoke FB180 function block

5.4.4 Equipment connection

Use standard RS232C cable to connect serial ports of CP341 and computer. The

detailed cable connecting method may be seen in CP341 Manual - Chapter B:

Connecting cables.

5.4.5 Communication test

Download the hardware configuration and program into CPU. Open the software

Modscan32 in the computer, and click Connection—〉Connect in Modscan32 to

display the following screen. Select the used serial port, and set Baud rate, data

bit, stop bit and check mode, and select a communication protocol according to the

applicable connection. After setting completes, click OK to display the monitor

screen.

Page 69

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

69

Siemens AG 2014 All rights reserved

Fig. 123: Distribute communication parameters

Fig. 124: Communication monitor interface

Modbus slave address

Modbus initial

address and

length

Type of data accessed by

Modbus, viz. selecting

function code to be used

corresponds

to Q0.0-

Q2.7 in PLC

Page 70

5 MODBUS RTU Protocol communication

CP340/CP341/CP440/CP441 Communication and Programming

Entry-ID: 88867653, V1.0, 02/2014

70

Siemens AG 2014 All rights reserved

Shown in the Fig. below is the corresponding communication monitor screen

when the function code FC04 is used. To read other data, just change the

related access data type. For floating point number display, refer to the read

method for Modbus Slave communication of CP341 as stated above.

Fig. 125: Communication monitor interface

corresponds to

Loading...

Loading...